Patents

Literature

146 results about "Vitrified tile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vitrified tile is a ceramic tile with very low porosity. It is an alternative to marble and granite flooring. Vitrified tiles are often used outdoors due to their water and frost resistance. There are four types of Vitrified tiles - Soluble salt, Double charge, Full Body, Glazed.

Lightweight ceramic tile and production method

The invention discloses a light-weight ceramic brick, which is a light-weight ceramic brick fired at high temperature and has a honeycomb-like internal structure of closed pores. The invention also discloses a preparation method of the above-mentioned lightweight ceramic tiles, which is formed by dry pressing after wet ball milling, sieving, iron removal, spraying drying tower and powder spraying on the vitrified brick polishing waste produced in large quantities in the ceramic industry at present. Method forming, or kneading using wet extrusion molding, and then firing products in continuous or batch kilns. Manufacture a kind of lighter quality ceramic tiles, aiming at the insufficient use of waste materials in the past, more effectively utilize industrial waste residues in large quantities, and because of its light structure, it can be used in the decoration of high-rise building walls, It has good properties such as light weight, high strength, heat preservation, and sound absorption, and it can significantly reduce the weight of the wall structure. At the same time, it also has the characteristics of easy transportation, easy construction, and fast speed. It has great advantages in saving energy and reducing the weight of buildings. The outstanding advantage is that it is an environment-friendly building ceramic decoration material.

Owner:FOSHAN OCEANO CERAMICS

Preparation method for super white ceramic vitrified tile produced by using magnesium aluminum silicate as raw material

The invention provides a preparation method for a super white ceramic vitrified tile produced by using magnesium aluminum silicate as a raw material. The super white ceramic vitrified tile comprises components of potassium feldspar, albite, calcined talc, black clay, a water reducing agent, a lithium feldspar, diopside, an intensifier, washed mud and quartz. The ultralow temperature fast firing vitrified tile belongs to a special ultralow temperature, high-strength, high-hardness, high abrasion-resistance, strong antifouling, low-radiation, environment-friendly, healthy and novel vitrified tile material and product. The technology can reduce firing temperature and shorten a firing period greatly and is favorable for energy conservation and emission reduction of ceramic industry, green manufacturing and low carbon production.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

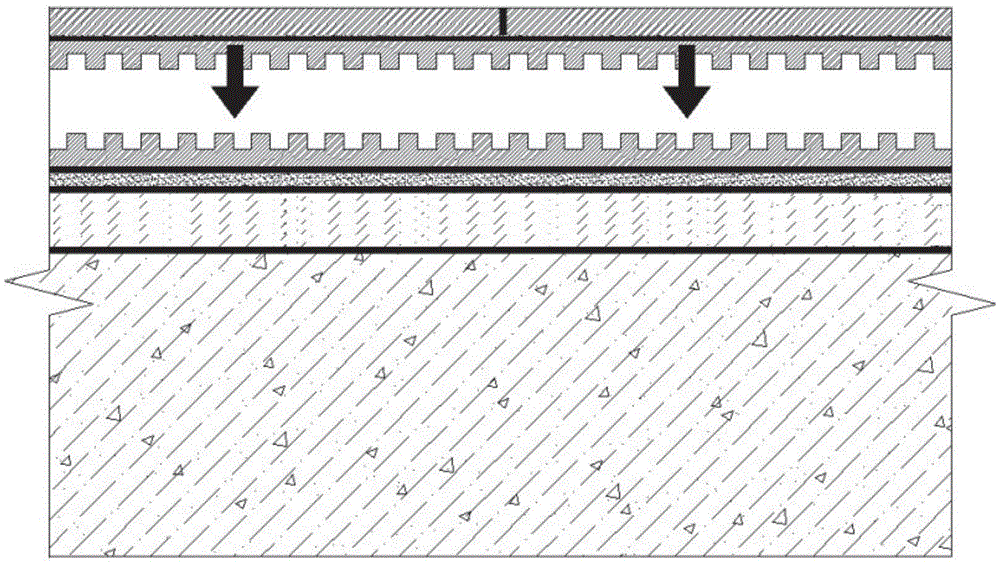

Heat-insulation and decorative integral plate and manufacturing method thereof

InactiveCN102535787AImprove thermal insulationOvercome fire resistanceCovering/liningsSpecial surfacesInsulation layerGranolithic

The invention discloses a heat-insulation and decorative integral plate and a manufacturing method thereof. The heat-insulation and decorative integral plate comprises a heat-insulation layer, a middle protecting layer and a decorating layer; the heat-insulation layer is made of a nano aerogel felt material with treated surfaces or a nano aerogel plate material with treated surfaces; the middle protecting layer is made of anti-crack plastering mortar; and the decorating layer is made of coatings or finish or vetrified tiles for curtain walls or granite materials for curtain walls or non-granite materials. The manufacturing method is simple, the heat-insulation and decorative integral plate is mounted on a wall surface in an adhesion or anchoring combination mode, and a total system meets A-level incombustible standards, is safe and reliable, is convenient and fast in construction, and realizes integration of decoration and heat insulation.

Owner:上海英硕聚合材料股份有限公司

Vitrified brick gum

The invention discloses a vitrified brick gum which consists of a liquid component and a powder component according to the weight ratio of 1:(1-5), wherein the liquid component comprises 25-70 percent of high polymer, 29-74.8 percent of water, 0.2-0.5 percent of preservative and 0-0.5 percent of cellulose; and the powder component comprises 30-65 percent of cement, 35-70 percent of silica sand and 0-0.5 percent of cellulose. The vitrified brick gum can be directly smeared to the back face of a vitrified brick and adhered with a cement base material, and excellent shear strength and tensile strength can be achieved after the vitrified brick gum is dried up, therefore, the problem that the vitrified brick is unstable to adhere after the cement base material is adopted is solved.

Owner:余春冠

Production method for ultra low temperature rapid firing vitrification ceramic brick

The present invention provides a production method for an ultra low temperature rapid firing vitrification ceramic brick. In a blank entering ball mill step, low temperature ceramic mineral raw materials are mixed and poured into a ball mill to carry out wet grinding, wherein the low temperature ceramic mineral raw materials comprise a calcination material, lithium sand, black mud, a water reducing agent, a reinforcing agent and an auxiliary agent. The present invention relates to a production method for producing the ultra low temperature rapid firing vitrification brick by using the calcium magnesium silicate material and the tantalum-niobium tailings. The ultra low temperature rapid firing vitrification ceramic brick belongs to a special and novel vitrification brick material and a product, wherein the special and novel vitrification brick material has characteristics of ultra low temperature, high strength, high hardness, high wear resistance, strong pollution prevention, no radiation, environmental protection, and health. With the technology of the present invention, the firing temperature can be substantially reduced, the firing period can be substantially shortened, and the method provides good benefits for energy-saving emission reduction, green manufacturing and low carbon production of the ceramic industry.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

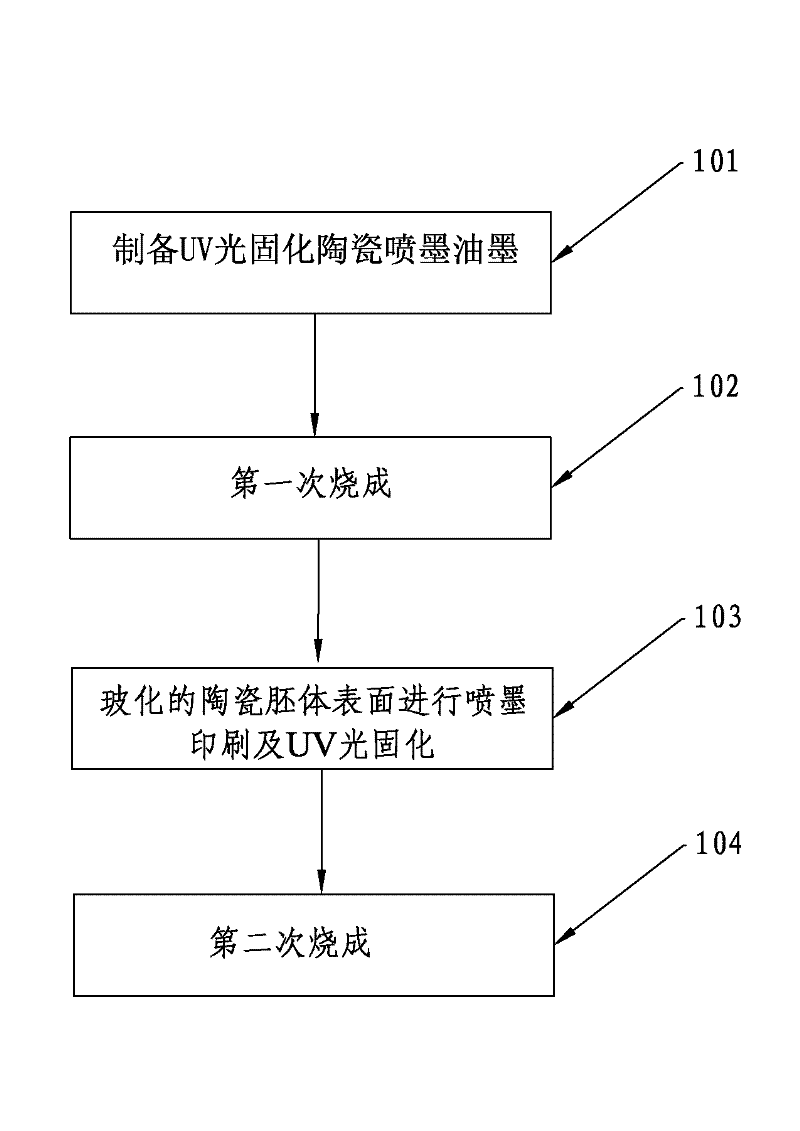

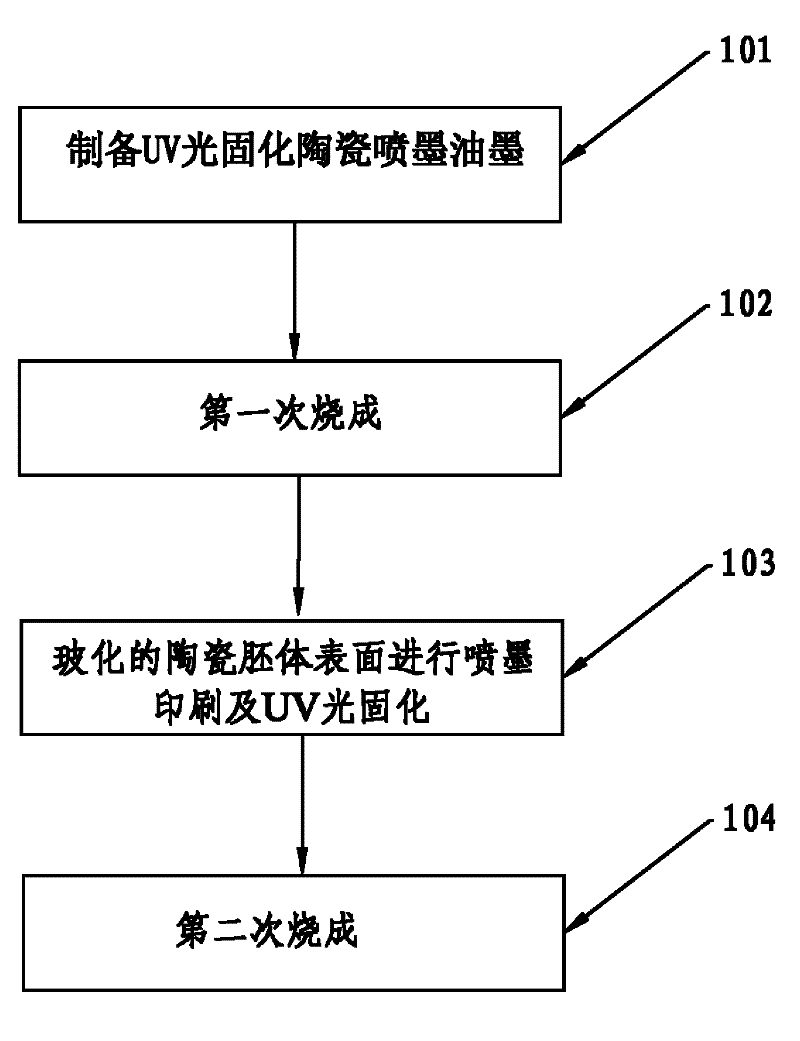

UV (ultraviolet) photo-cured ceramic inkjet ink and method for using same on ceramic surface for printing

ActiveCN102477234AFast curingExcellent color developmentInksTypewritersVitrified tileComposite material

The invention relates to the technical field of ceramic inkjet, in particular to UV (ultraviolet) photo-cured ceramic inkjet ink and a method for using the UV photo-cured ceramic inkjet ink on ceramic surface for printing. The method comprises the following steps of: 1) preparing the UV photo-cured ceramic inkjet ink according to formula proportions; 2) putting a moulded ceramic blank into a furnace and baking the moulded ceramic blank for the first time so as to obtain a vitrified ceramic blank; 3) spraying the UV photo-cured ceramic inkjet ink on the surface of the vitrified ceramic blank by a ceramic ink jet machine, and performing UV photo-curing shaping at the same time; and 4) feeding the ceramic blank subjected to the UV photo-curing shaping into the furnace, and baking the ceramicblank for the second time so as to obtain a ceramic finished product. The ceramic inkjet ink provided by the invention is applied to ceramic production, ceramic ink spraying and the UV photo-curing shaping are simultaneously performed on the surface of the ceramic blank which is baked two times, the defect that the ordinary ceramic inkjet ink cannot be sprayed on a baked vitrified tile is overcome, and the UV photo-cured ceramic inkjet ink has a better color development performance compared with the ordinary ceramic inkjet ink, and better keeps high resolution and high accuracy of ceramic inkjet.

Owner:佛山市明朝科技开发有限公司 +1

In-situ synthesized mullite whisker reinforced high-temperature ceramic roller

InactiveCN102249722AIn situ generation of composite enhancementsImprove thermal shock resistanceRefractoryWhiskers

The invention relates to an in-situ synthesized mullite whisker reinforced high-temperature ceramic roller which is prepared from natural raw mineral materials and industrial raw chemical materials. The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller comprises the following compositions in percentage by weight: 15-25% of kaolin, 5-15% of refractory clay, 15-25% of alpha-Al2O3 micro-powder, 3-10% of zirconium silicate, 10-20% of zirconium-titanium mineralizer containing andalusite and 30-40% of refractory corundum; and the ceramic roller is prepared through the following steps: ball-milling, stirring, molding, drying, roasting at a temperature of 1500-1600 DEG C, carrying out heat preservation for 5-10 hours, and naturally cooling, thus obtaining a ceramic roller product (the rupture strength of the product is greater than 57.40 Mpa at a temperature of 1350 DEG C). The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller provided by the invention has a wide application prospect in roasting roller kilns for products such as high-temperature and high-load domestic ceramics, building sanitary ceramics, high-grade large-sized vitrified tiles, technical ceramics and magnetic materials and the like.

Owner:JINGDEZHEN NUONAI TECH CERAMICS

Gum for vetrified bricks, preparation method for gum and construction method

The invention discloses gum for vetrified bricks, a preparation method for the gum and a construction method. The gum for the vetrified bricks comprises liquid components and powder components. A weight ratio of the liquid components to the powder components is 1:2-2.5; the liquid components comprise, by weight, 35-45% of butylbenzene emulsion, 30-40% of benzene acrylic emulsion, 20-30% of water, 1.5-2.5% of reinforcing agents, 0.5-1% of mould inhibitors, 0.5-1% of defoaming agents and 0.5-1% of water repellents; the powder components comprise, by weight, 40-50% of silicate cement, 45-55% of river sand, 0.5-1% of cellulose ether, 0.5-1% of water reducing agents, 1-1.5% of organic silicon powder and 1-1.5% of nanometer silicon oxide. The gum for the vetrified bricks, the preparation method and the construction method have the advantages that the vetrified bricks and bonding layers are excellent in compatibility and high in bonding power, the gum is excellent in compatibility, and excellent adhesion effects can be realized; the gun is high in permeability and adhesive power.

Owner:GOLD MANTIS CONSTR DECORATION

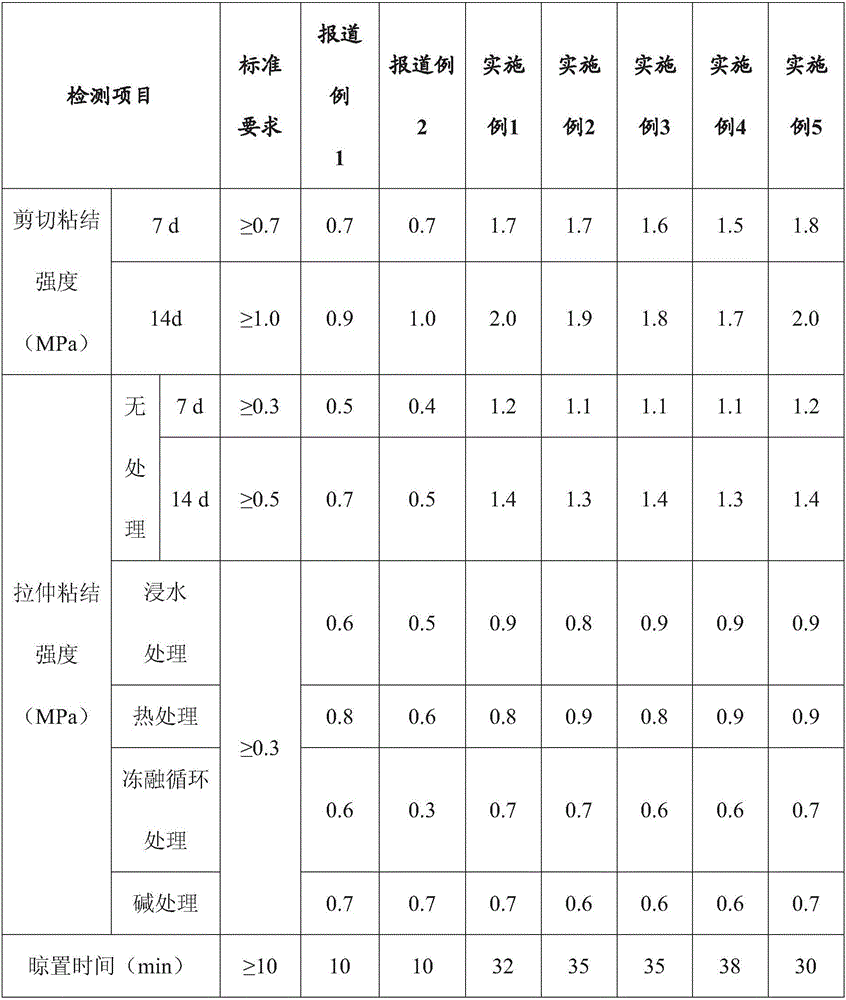

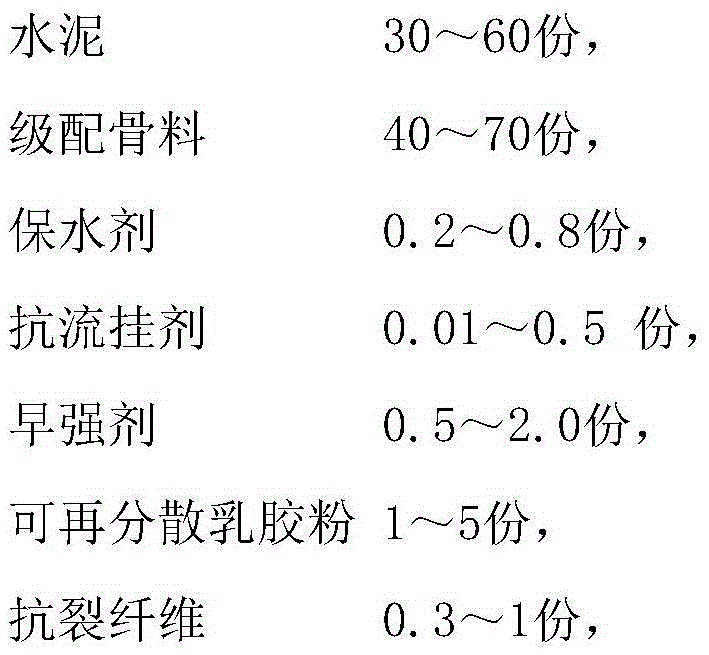

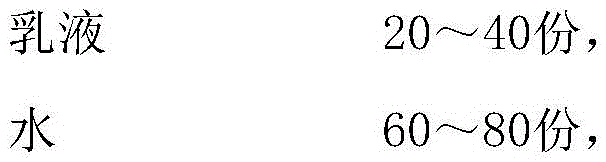

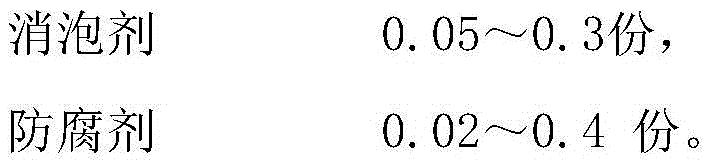

Vitrified brick gum adhesive

The invention discloses a vitrified brick gum adhesive, which is prepared from the following powder and liquid in parts by weight, wherein the powder is prepared from: 30-60 parts of cement, 40-70 parts of grading aggregate, 0.2-0.8 part of water-retaining agent, 0.01-0.5 part of anti-sagging agent, 0.5-2.0 parts of early strength agent, 1-5 parts of redispersible powder, 0.3-1 part of anti-cracking fiber and the liquid is prepared from: 20-40 parts of emulsion, 60-80 parts of water, 0.05-0.3 part of defoaming agent and 0.02-0.4 part of corrosion remover. By using organic combining of the ordinary Portland cement, high molecular redispersible powder and emulsion, the adhering strength of a large-sized vitrified brick is improved, the large-sized vitrified brick can be repasted to different base materials; construction performance is improved under the effect of the anti-sagging agent and operation is more convenient.

Owner:上海亚瓦新型建筑材料有限公司

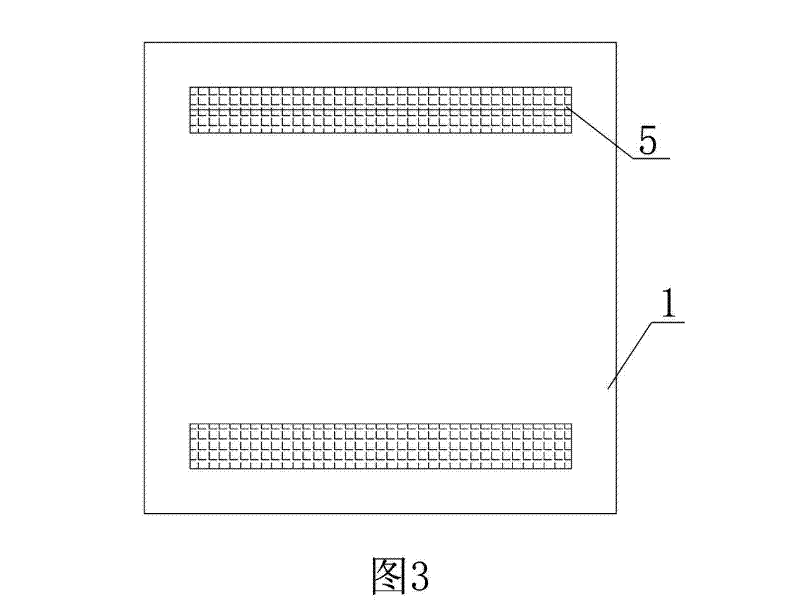

Wet combining process for vitrified porcelain tiles

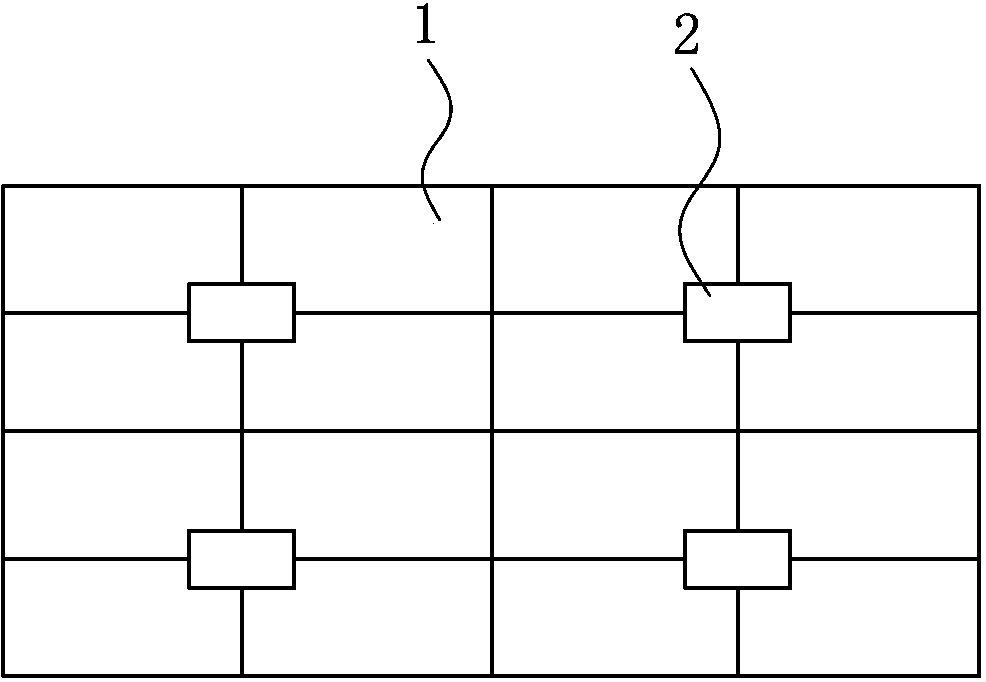

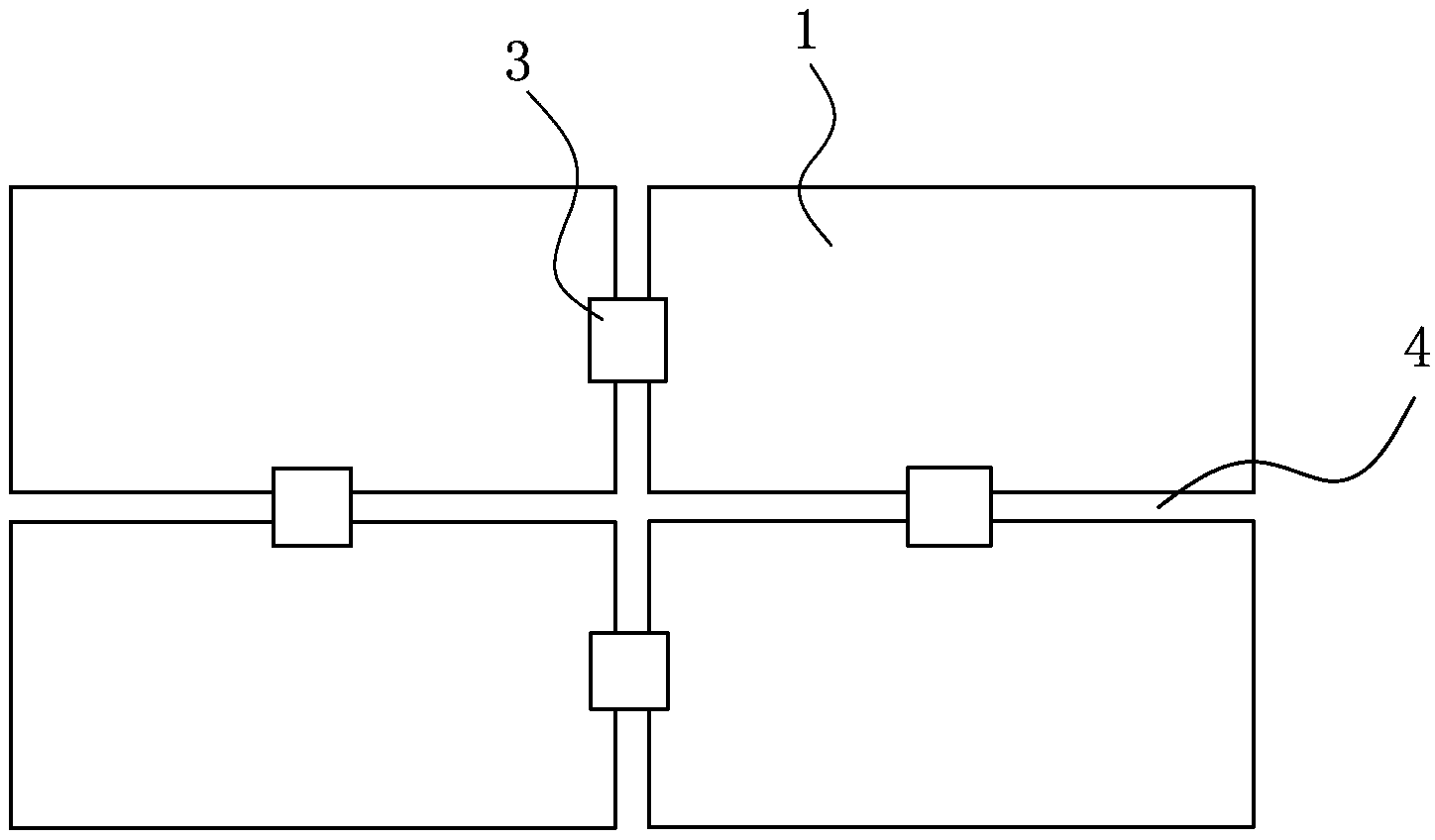

ActiveCN103410331AImprove bindingReduce hollowingCovering/liningsBuilding material handlingBrickVitrified tile

The invention discloses a wet combining process for vitrified porcelain tiles, which is characterized in that firstly cleaning is performed, a plurality of small reinforcing bricks are uniformly pasted onto the reverse side of each vitrified porcelain tile, and after being dried, the reverse side of each vitrified porcelain tile is uniformly coated with concrete interfacial agents; after the hollowing of the wall surface is shoveled, the wall surface is whitewashed, and building glue is brushed on the whitewashing layer; after a bonding layer is brushed from bottom to top according to a construction facade mesh division figure, the paving operation is performed layer by layer; a gap with the width of 0.8-1.5 mm is required to be reserved between the adjacent vitrified porcelain tiles; then a small temporary vitrified porcelain tile is pasted at each gap to connect the vitrified porcelain tiles on the two sides; rubbish in the gap between the adjacent vitrified porcelain tiles is cleared; joint mixture is adopted for pointing joint; after the joint mixture is dried, the small temporary vitrified porcelain tiles are removed, and the surfaces of the vitrified porcelain tiles are cleaned, so that the processes are completed. According to the wet combining process, the bonding force of the bonding layer and each brick is improved through enhancing the arrangement of the small bricks, the problem about falling of the hollowing is reduced, and bridging abutted seam operation is performed by virtue of small vitrified porcelain tiles, so that the co-contraction of the adjacent bricks is realized, the flatness of the surfaces is ensured, and the paving quality is improved.

Owner:苏州苏明装饰股份有限公司

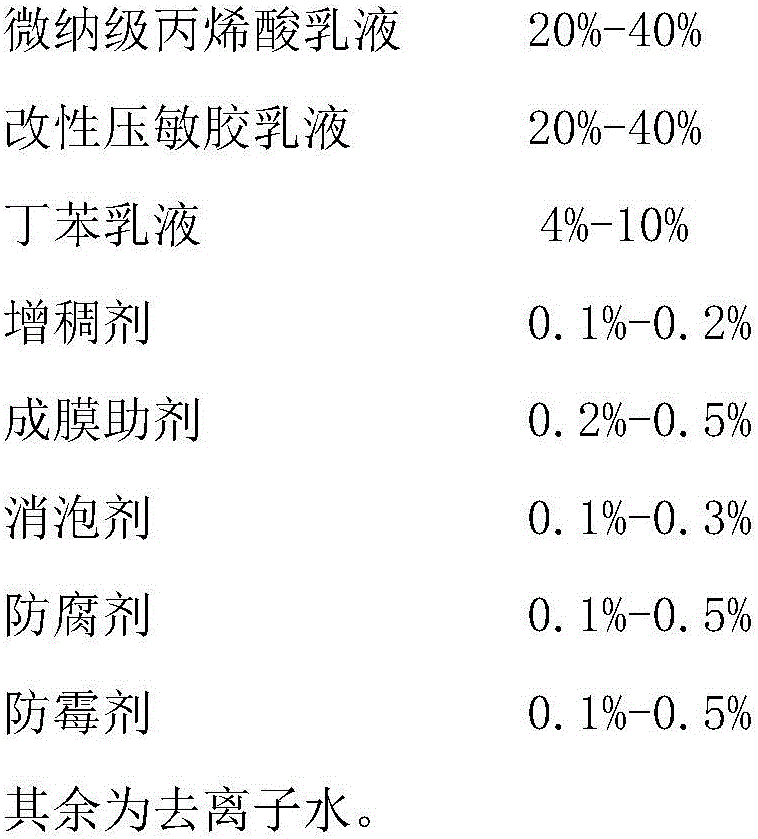

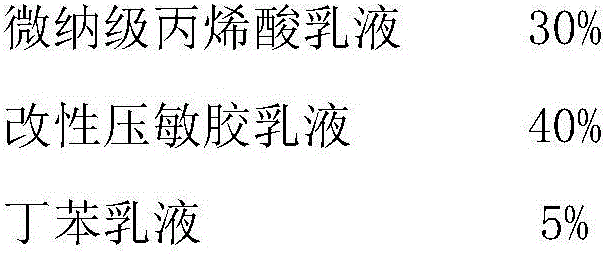

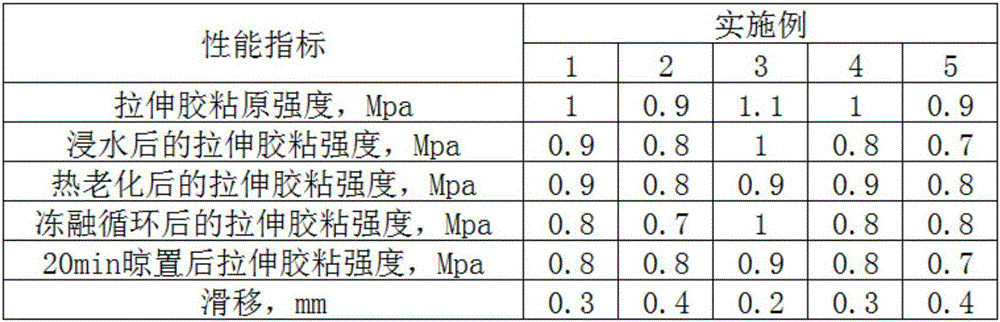

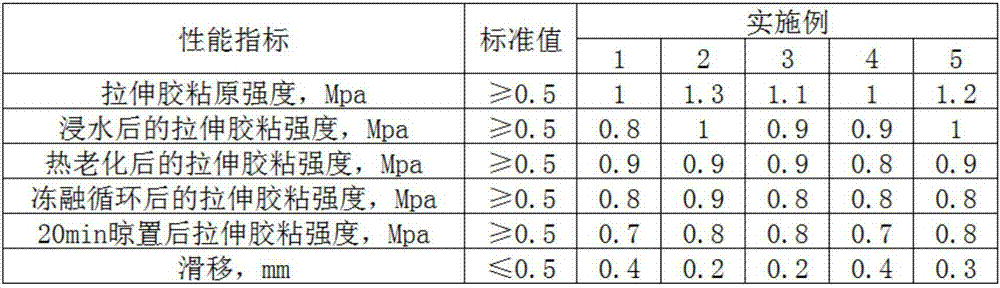

Eco-friendlyceramic tilegum for vitrified tiles

InactiveCN105969308AStrong crack resistance and elongation abilityHigh bonding strengthConjugated diene hydrocarbon adhesivesFreeze thawingRough surface

The invention provides an eco-friendlyceramic tilegum for a vitrified tile. The eco-friendlyceramic tilegum for the vitrified tile is prepared from the following components: 20 percent to 40 percent of micro-nanoacrylic emulsion, 20 percent to 40 percent of modified pressure-sensitive adhesiveemulsion,4 percent to 10 percent of butylbenzeneemulsion,0.1 percent to 0.2 percent of thickening agent,0.2 percent to 0.5 percent of coalescing agent,0.1 percent to 0.3 percent of defoamer,0.1 percent to 0.5 percent of preservative,0.1 percent to 0.5 percent of mildew preventive, and the balance deionized water. The gum provided by the invention is high in bonding strength, and a new rough surface can be formed on a bonding surface of the vitrified tile, so that the bonding capacity between the gum and a bonding material is enhanced; the gum is good in flexibility, small in hardening shrinkage, strong in compatibility with the cement-based bonding material, and firm in bonding; the gum has a certain anti-seepage performance; the gum is resistant to freeze thawing, long in service life due to long-time care, strong in anti-cracking and extending capacities, and excellent in acid and alkali resistance and antiseptic property; the gum is convenient to construct and low in cost, can ensure zero breakage in the vitrified tile, and time and labor saving.

Owner:浙江共创建材科技有限公司

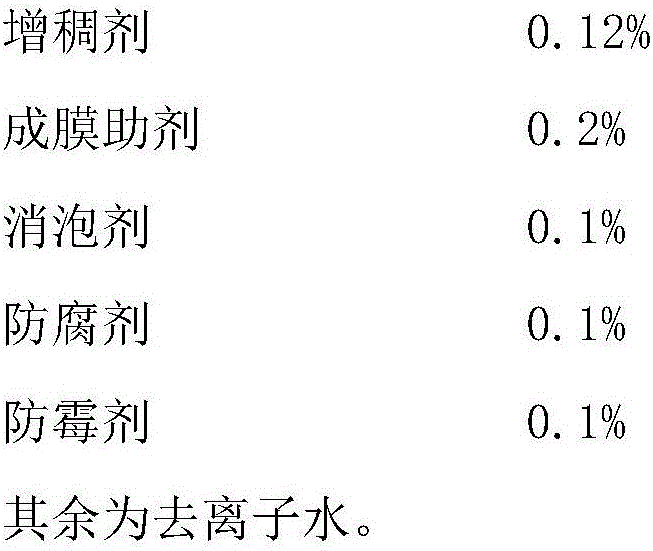

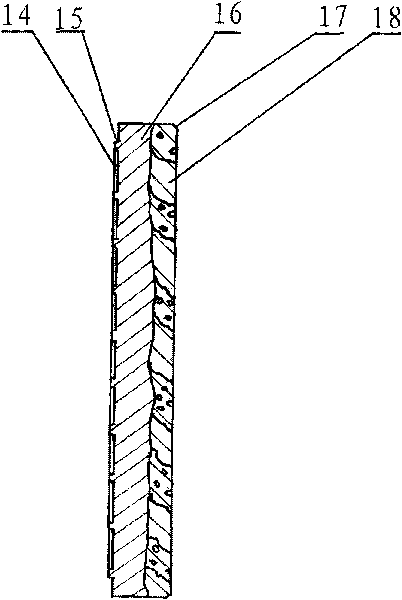

Process and device for manufacturing vitrified tiles with triple cloths and imitation jade textures

ActiveCN103042594ARealistic effectNatural and smooth texture linesFeeding arrangmentsControllabilityNatural stone

The invention relates to a process and a device for manufacturing vitrified tiles with triple cloths and imitation jade textures. The device comprises cloth delivery, line delivery, tabletting granulation and separation area combined cloth stacking. The device comprises a blanking delivery unit, a stacking integral delivery unit, a micro powder combined blanking unit and a powder smashing micro powder manufacturing unit. The blanking delivery unit is arranged above the stacking integral delivery unit, the micro powder combined blanking unit is arranged above the blanking delivery unit, and the powder smashing micro powder manufacturing unit is arranged at the top of the whole device system. Compared with the prior art, the vitrified tiles manufactured by the process and the device have the advantages of presenting polycrystalline elements in natural stones, and being natural and smooth in texture and line, few in artificial trace and high in controllability, and the like.

Owner:JIANGXI CIMIC CERAMICS +1

Method of preparing infrared ceramics vitrified brick

InactiveCN101058500AHigh emissivityEffective protectionCeramic shaping apparatusCeramic materials productionBrickSlag

The invention discloses a making method of infrared ceramic glassing brick, which comprises the following steps: adopting normal natural mineral such as feldspar, caoline and so on as raw material; adding at least one of chromite slag and copper waste; grinding; balling; sieving; drying; graining; moulding; sintering; polishing; obtaining the product with 8-14um infrared band irradiating rate at 0. 86-0. 94 under normal temperature. The invention saves cost greatly with new hygienic and antibiotic function, which possesses high-effective waste utility and environment-protective meaning.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing water permeable brick with vitrified tile waste and product obtained

InactiveCN101525241AReduce consumptionHigh strengthSidewalk pavingsCeramic shaping apparatusBrickToxic industrial waste

The invention relates to a method for preparing a water permeable brick with vitrified tile waste and a product obtained. The method comprises the followings steps: taking industrial waste (the vitrified tile waste) as an aggregate; adding a small amount of following mineral raw materials and chemical raw materials in weight percentages: 73-78% of the vitrified tile waste, 3-4% of clay, 9-13% of feldspar, 10% of water glass, 0-5% of calcium carbonate and 0-5% of aluminum hydroxide; blending, mixing, forming at the forming pressure of 20MPa, drying in the air for 1-2 days, firing at the firing temperature of 800-1100 DEG C for 2 hours and keeping for 0.5h heat preservation to obtain the product. The water permeable brick has the advantages of simple preparation process, easy control, low firing temperature, low production cost and excellent product performance, and can be widely applied to ground laying of public places such as walkways, parking areas, squares and the like which require rain penetration.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Tablet line flower fabric technology for vitrified tiles

InactiveCN102773912ANatural and smooth texture linesRealistic imitation marble effectShaping conveyorsFree fallingControllability

The invention relates to a tablet line flower fabric technology for vitrified tiles. The technology comprises the steps of fabric conveying, line fabric conveying, tablet pelletizing and fabric combining and stacking in areas. The fabric conveying includes that micro powder fabric is placed into a fabric hopper, and subjected to blanking in a rotary mode into a fabric storage hopper through a fabric roller, free falling and stack on a plane plate; the line fabric conveying includes that the line fabric is blanked onto a baffle and a shaking screen by the rotation of a line blanking roller and evenly scattered below the baffle and the shaking screen, and covers the fabric; the tablet pelletizing includes that powder fabric is ground into micro powders and pressed into tablet pellets, the pellets are added into the fabric storage hopper and fall on the fabric and the line fabric in a suspension mode; and the tablet pelletizing and fabric combining and stacking in areas includes that the fabric, the line fabric and the sheet pellets are stacked successively in a circulation running board mode, fillers are filled to perform flattening, and the mixtures are conveyed to a press machine cavity through a fidelity grille to complete the pressing. The tablet line flower fabric technology for vitrified tiles has the advantages of showing polycrystalline elements in natural stones, being natural and smooth in grains and lines, few in human traces, high in controllability and the like.

Owner:JIANGXI CIMIC CERAMICS +1

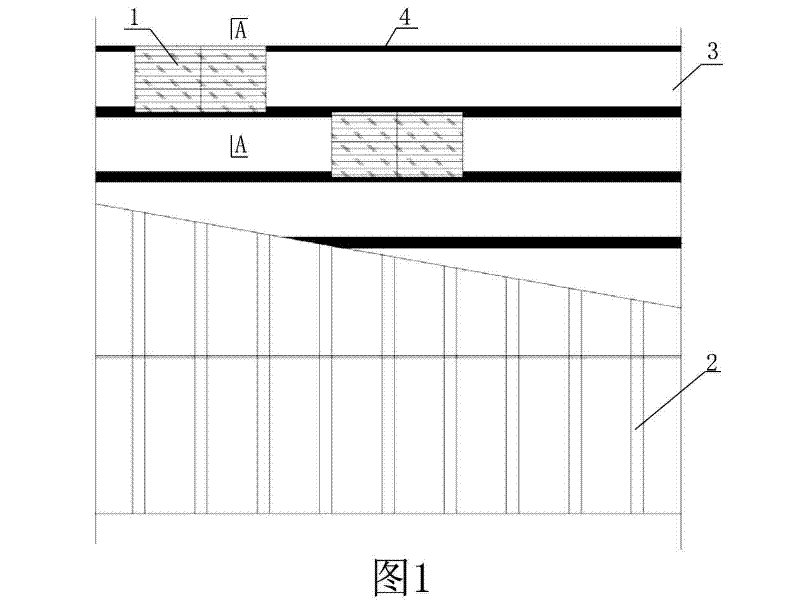

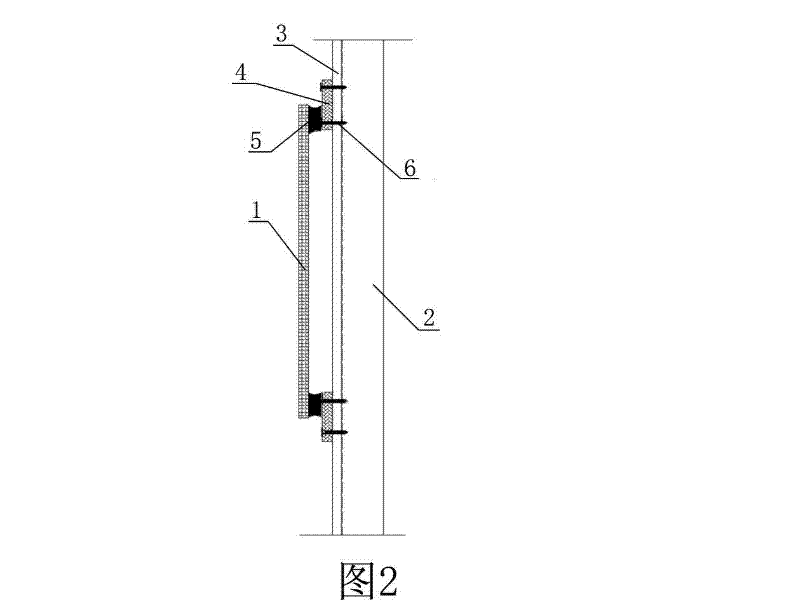

Light steel keel and plasterboard vitrified tile decoration wall and method for constructing same

The invention relates to a light steel keel and plasterboard vitrified tile decoration wall and a method for constructing the same. The light steel keel and plasterboard vitrified tile decoration wall comprises a base layer and a veneer; the base layer is formed by adhering plasterboards to at least one side of a light steel keel; level-up battens are transversely arranged on the outer surfaces of the plasterboards at intervals; the level-up battens are fixed on the light steel keel by self-tapping screws to form into a whole body with the light steel keel; and the veneer is a vitrified tile which is adhered to adjacent two level-up battens by AB adhesive which is applied to the back surface of the vitrified tile. The level-up battens arranged at intervals play a role of further leveling up and reinforcing the base surface and dispersing the influence of the wall deformation stress to the wall tiles. The adhering force of the basal body and the wall tiles is improved through the AB adhesive. The light steel keel and plasterboard vitrified tile decoration wall can be easily, conveniently and rapidly constructed. The traditional wet process work for the adhesion of the wall tiles is changed into the dry process work, thus the material is greatly saved, the high work efficiency is ensured, the labor cost efficiency is reduced, the energy is saved, and the environment can not be polluted.

Owner:CHINA STATE DECORATION GRP

Novel environmentally-friendly ceramic permeable brick and preparation method thereof

InactiveCN102372468AGuaranteed to be environmentally friendlySolid waste managementClimate change adaptationBrickSlag

The invention discloses a technology of a novel environmentally-friendly ceramic permeable brick. In the method, ceramic slag is taken as the raw material which is sintered at 800 DEG C and the method comprises the following steps: adding cement as the binder, and vibrating and pressurizing to prepare and mould the finished product. In the method, ceramic slag is used as the raw material, wherein the fragments and slag of the vitrified tile are sintered at 1100-1250 DEG C, the Moth's hardness is no less than 7 and is more than the hardness of granite; and the compressive strength of the permeable brick prepared from the raw material is more than 30MPa, the flexural strength is more than 3MPa and the water permeability is more than or equal to 3*10<-2>cm / s. Sand blasting treatment is performed on the surface of the product to ensure that the natural color of ceramic is outstanding, the color of the product can be more gorgeous and long-lasting, and the high water permeability and skid resistance can be maintained. By adopting the new environmentally-friendly ceramic permeable brick, environmental pollutions and resource wastes can be reduced, cyclic utilization can be realized and the product has high compressive strength, flexural strength and permeability effect, thus rain and snow water can fast penetrate the underground to supplement the groundwater, the urban heat island effect can be reduced, the municipal drainage load can be lowered, ecological balance can be maintained and the ground settlements and noises can be reduced. The product has rich color and good landscape effect.

Owner:丘华彪

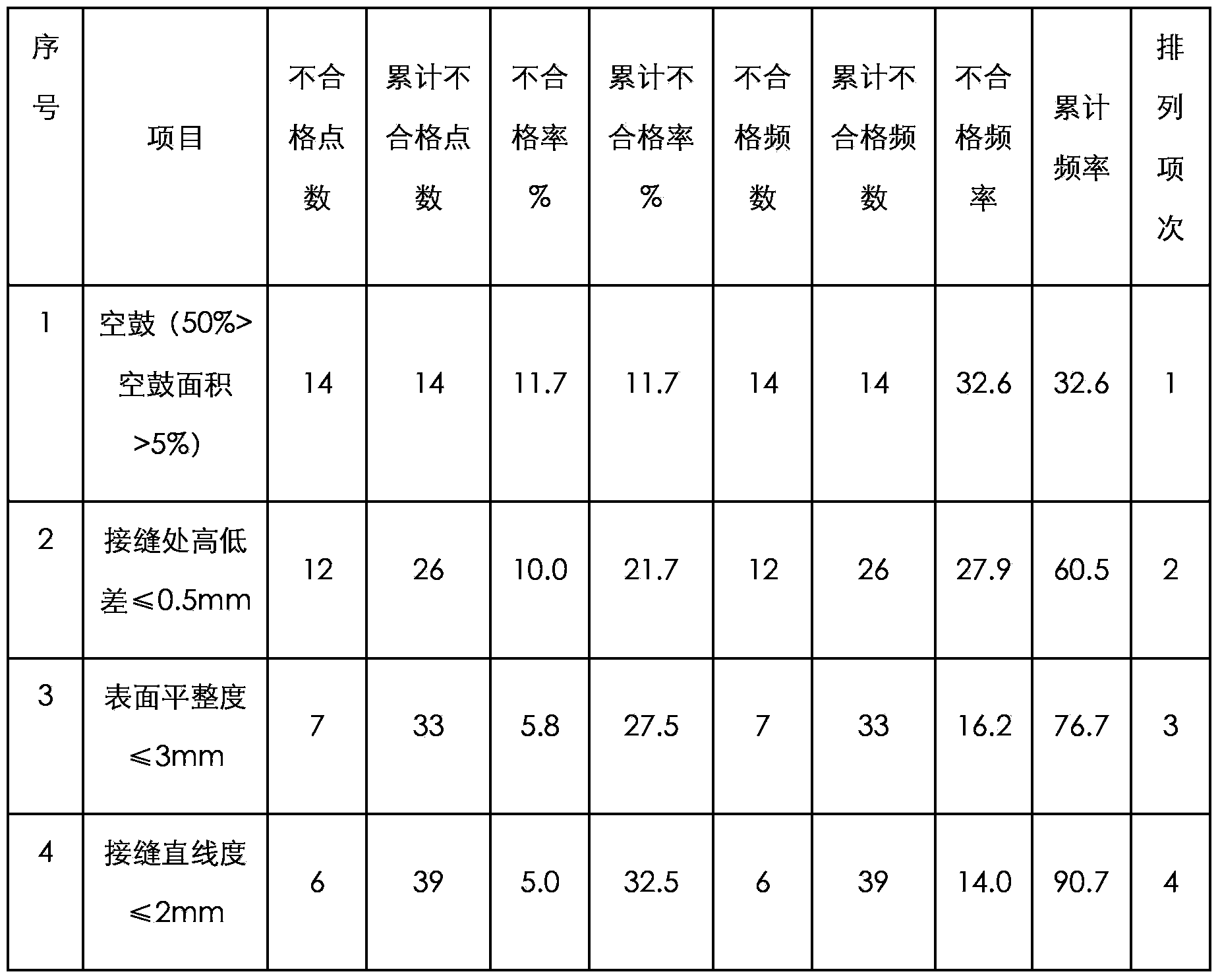

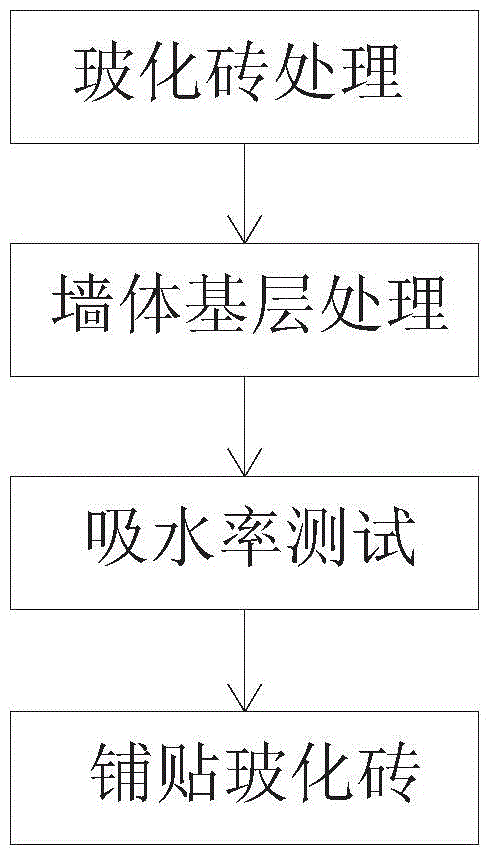

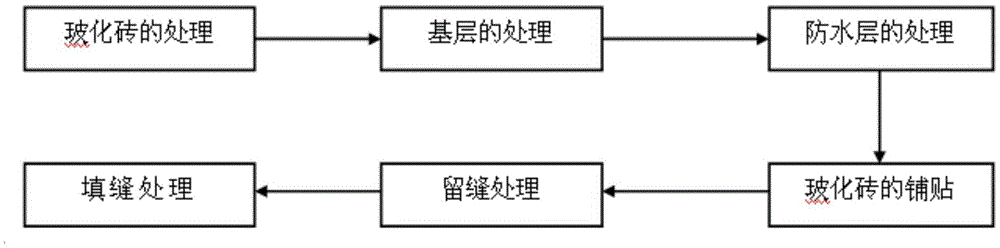

Anti-hollowing paving process of vitrified tiles

The invention discloses an anti-hollowing paving process of vitrified tiles. The process includes the steps of 1, treating the vitrified tiles, to be specific, cleaning the back of each vitrified tile, soaking the vitrified tiles to move dust and other impurities, brushing off industrial wax from the back of the vitrified tiles, and air-drying the vitrified tiles; 2, treating a base layer of a wall, to be specific, cleaning a bonding face of the wall with a cleaning tool before painting so as to keep the bonding face of the wall clean, spraying water to the wall for moisturizing, drying the surface of the wall in shade to make sure the surface has no evident water stain, and applying bonding agent to the bonding face of the wall with the thickness of the bonding agent ranging from 0.6 mm to 1.2 mm; 3, testing water absorption of the vitrified tiles, and selecting proper binder; 4, paving the vitrified tiles, to be specific, by means of double-side bonding, scrape-coating the base layer of the wall with a layer of binder, scrape-coating the back of each vitrified tile with a layer of binder, smearing the periphery of each vitrified tile into a beveled edge, and performing paving. By the use of the anti-hollowing paving process, the vitrified tiles and the base layer of the wall can be fully contacted and bonded, and hollowing or shedding rarely occurs.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Method for preventing mosaic hollowing and shedding of vitrified tiles

The invention relates to a method for preventing mosaic hollowing and shedding of vitrified tiles. The method includes firstly, sticking fragmentary vitrified tiles with same thickness on the sticking faces of the vitrified tiles to enable the fragmentary vitrified tiles to be basically overspread; sticking a plurality of rebars on the sticking faces of the vitrified tiles, wherein the rebars are perpendicular to the vitrified tiles and the length of each rebar is 6-8mm larger than the thickness of each vitrified tile; after the fragmentary vitrified tiles and the rebars are firmly bound, mixing a cement adhesion agent into grout, evenly coating the grout on the surfaces of the fragmentary vitrified tiles to enable the surfaces to be textured, and plastering a composite portland cement layer on the textured fragmentary vitrified tiles after the grout is thoroughly dried, wherein the thickness of the composite portland cement layer ranges from 5mm to 8mm; painting a wall plastering base face between a shear wall and the composite portland cement layer after painting with the adhesion agent in advance. A construction process in which bonding and dry hanging of the vitrified tiles and mortar are combined is adopted, so that hollowing rate is reduced, and tile shedding caused by hollowing of the bonding layers of the vitrified tiles is prevented.

Owner:中建八局装饰工程有限公司

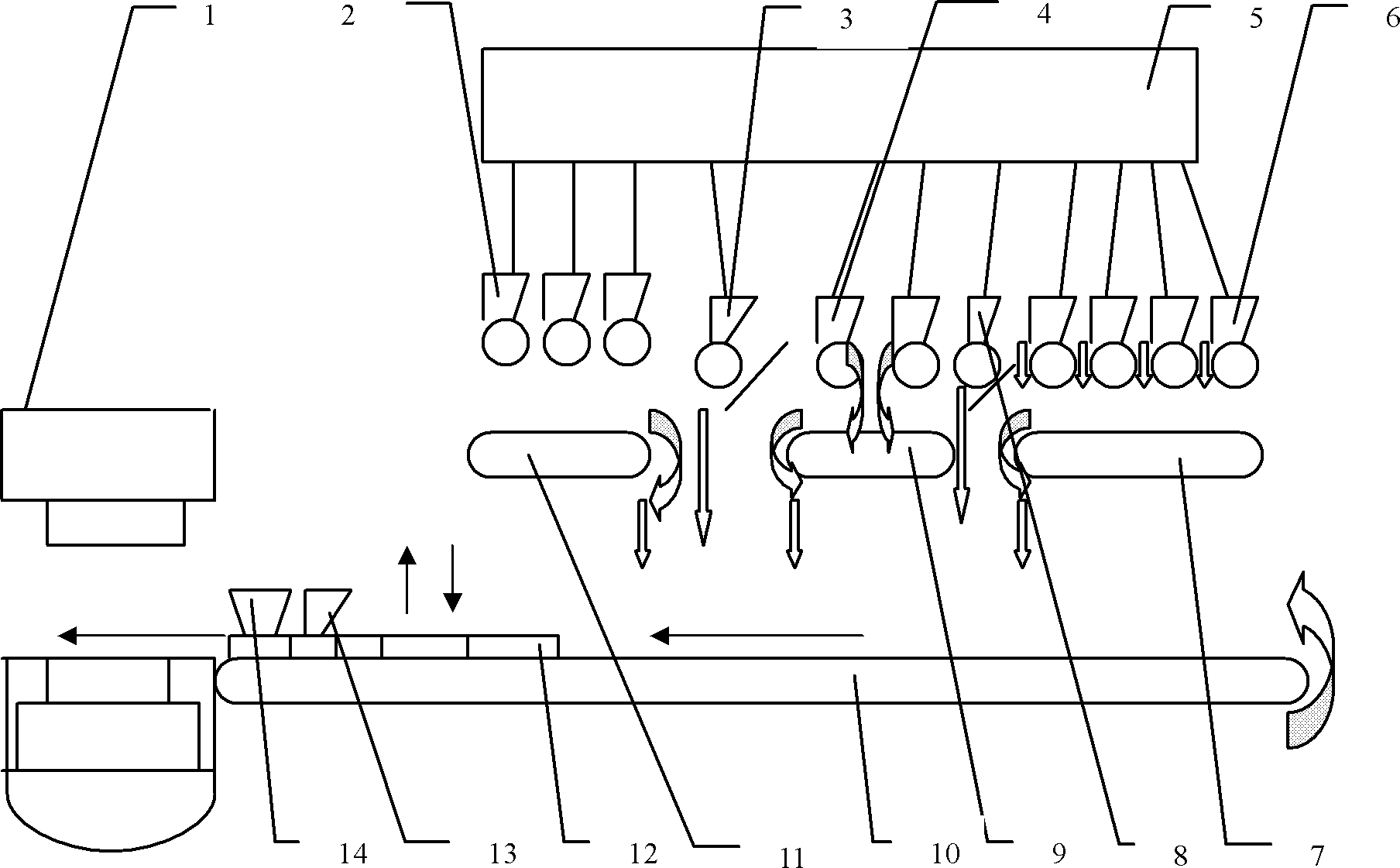

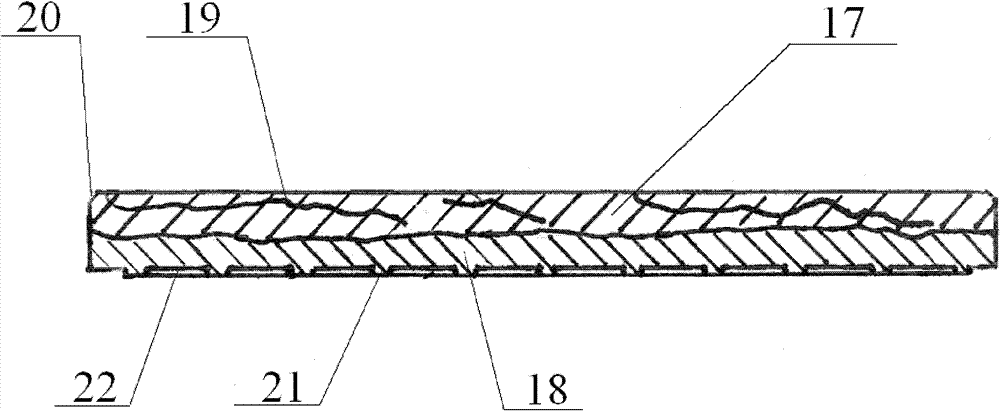

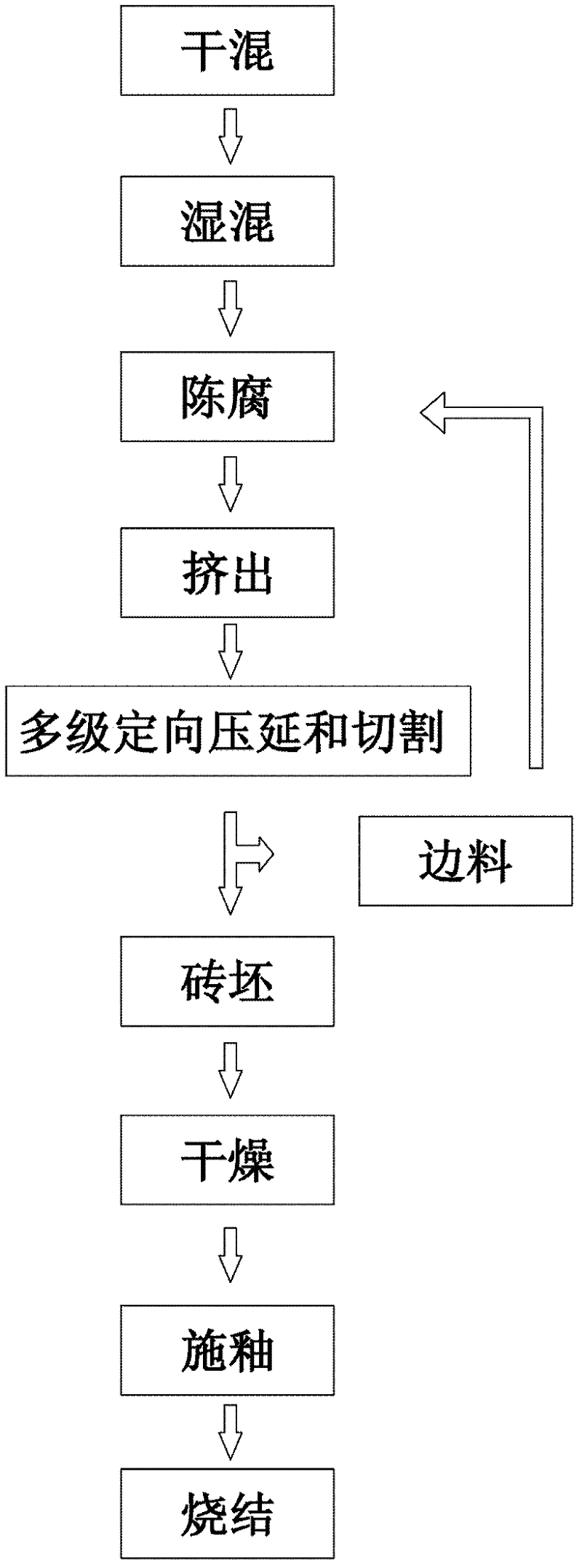

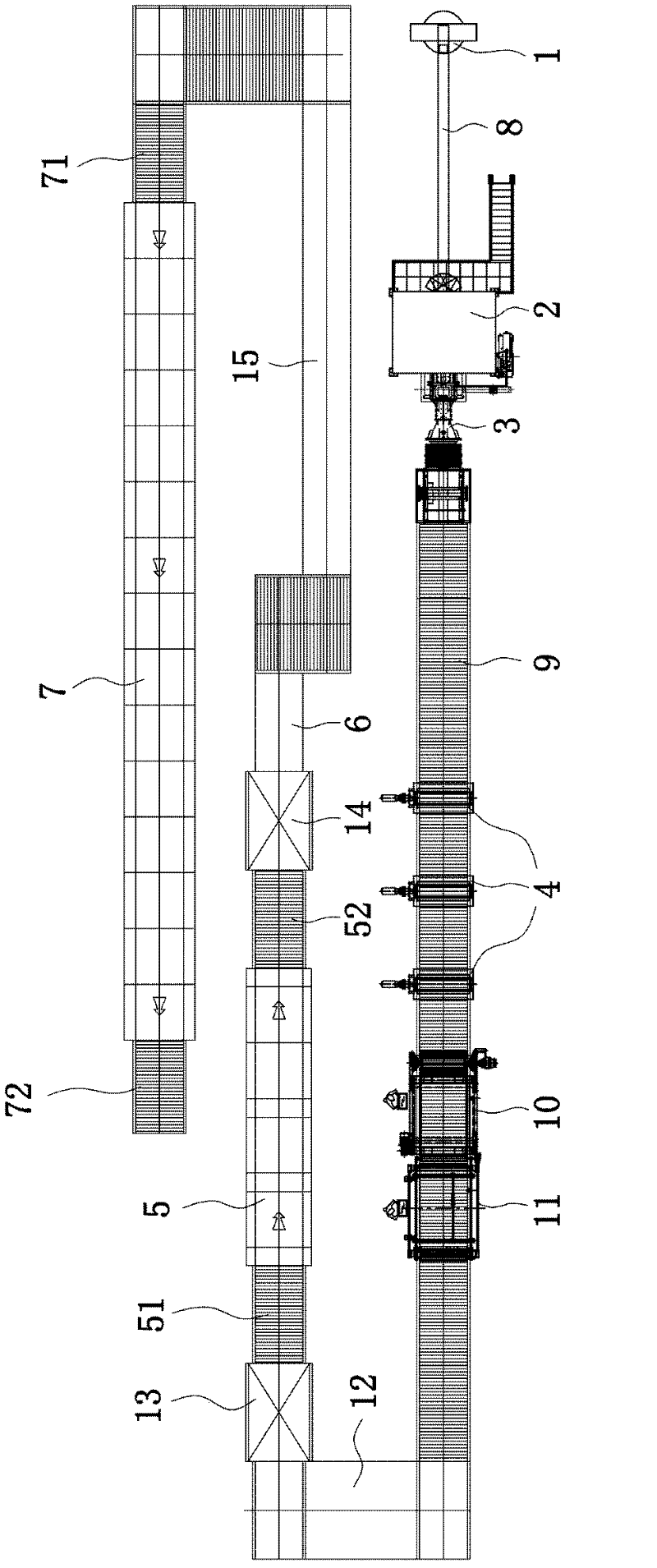

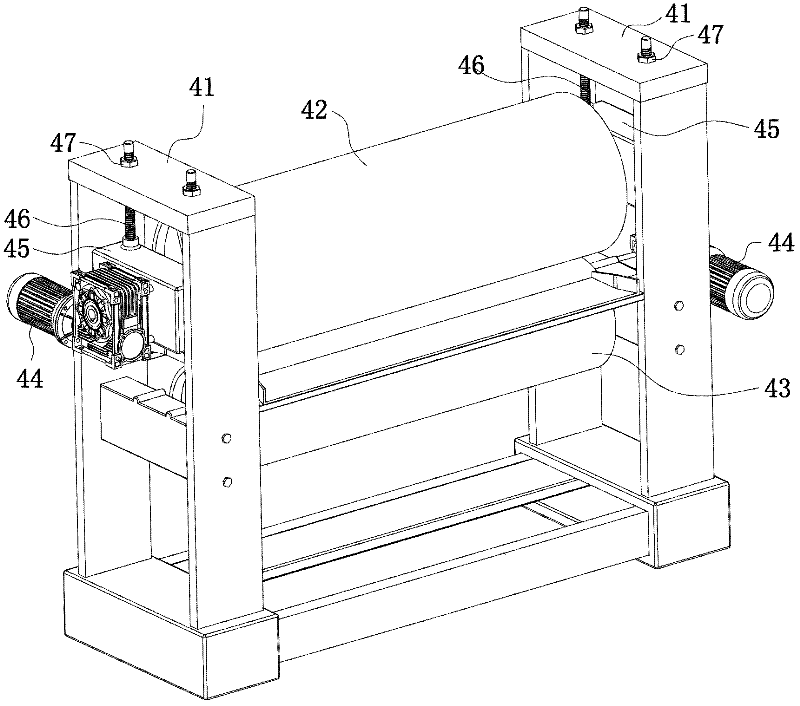

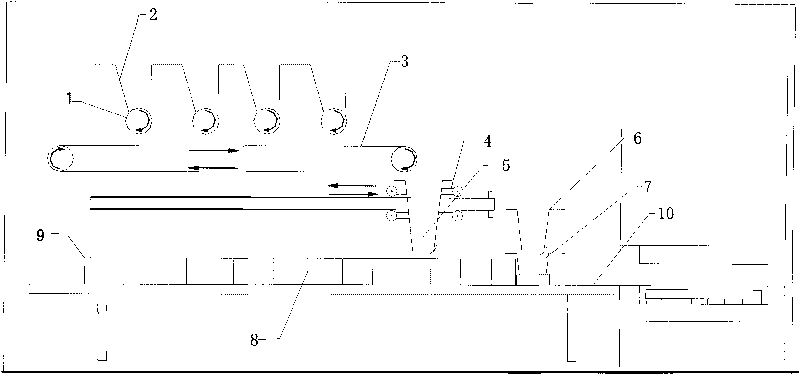

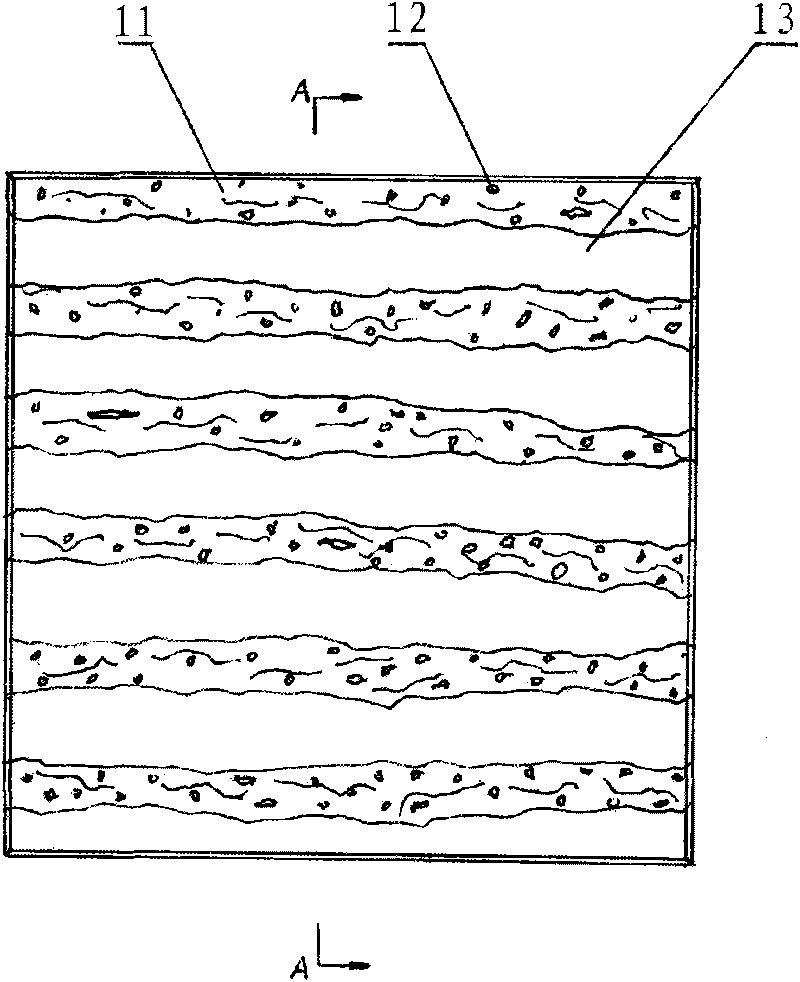

Process and device for producing ultrathin vitrified tile

The invention discloses a process for producing an ultrathin vitrified tile, which comprises the following steps of: 1, dry-mixing raw materials, and then adding water for carrying out wet mixing; 2, sending to an ageing tower for ageing after the wet mixing is finished; extruding the aged raw materials and a pigment through an extruding machine; 4, carrying out multiple times of step rolling on the extruded blank materials by using a multi-stage rolling manner to ensure that the blank materials reach the required thickness; 5, cutting the rolled blank materials to prepare a brick blank; 6, sending the brick blank to a drying kiln for drying; and 7, glazing and sintering the brick blank after drying. The invention has the advantages of being capable of realizing batch production of ultrathin brick blanks with very high strength and flatness by adopting an extruding-rolling manufacture method, laying the foundation of subsequent drying and sintering, avoiding generating defects of cracked and rugged bricks during drying and sintering, and improving the yield rate and the production efficiency of the ultrathin vitrified tile.

Owner:MODENA TECH LTD

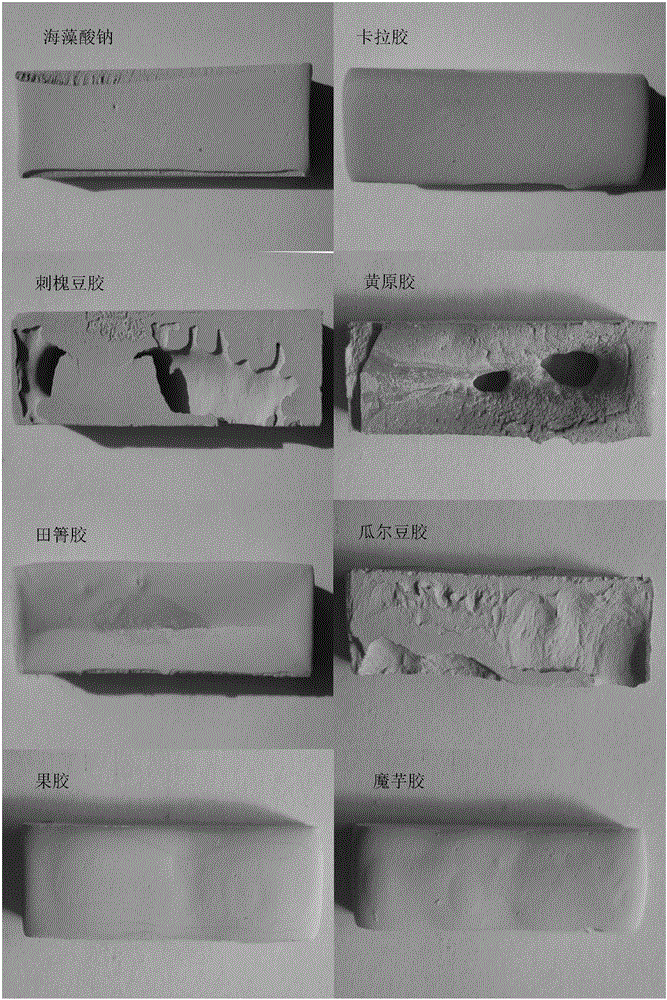

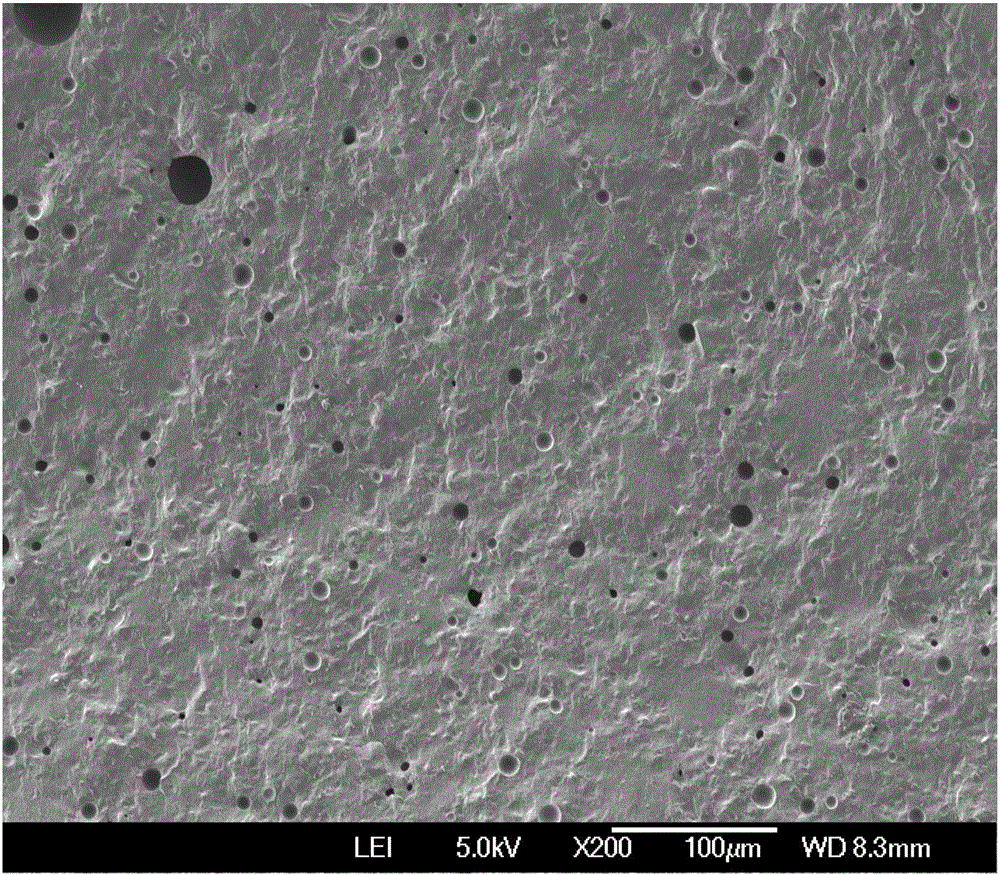

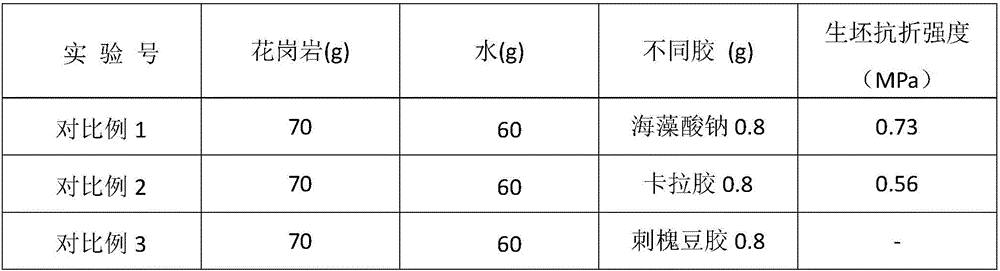

Building ceramic prepared from granite waste through wet process forming and preparation method of building ceramic

InactiveCN106187090ASimple moldingImprovement ingredientsDischarging arrangementFeeding arrangmentsLocust bean gumGranolithic

The invention relates to a building ceramic prepared from granite waste through wet process forming. The building ceramic is characterized in that slurry used for wet process forming is prepared from raw materials in parts by weight as follows: 50-70 parts of granite powder, 30-50 parts of water, 1 part of locust bean gum and sodium alginate and 0.5-2 parts of sodium humate and sodium hexametaphosphate. The invention further relates to a preparation method of the ceramic. The building ceramic is prepared from full-non-plastic granite, the increasing shortage problem of conventional ceramic raw materials such as clay and the like is solved, the building ceramic is lower in price while compared with the same kind of building ceramics, higher economic benefits can be brought, and replacement raw materials which have huge reserves and are cheap and easy to obtain are developed for the industry of building ceramics. The preparation method can be used for preparing the building ceramics for vitrified tiles, polished tiles, archaized tiles and the like.

Owner:曹晓宏

Process for producing natural travertine-imitated vitrified brick

ActiveCN101747019AStrong ornamentalNon-uniformPolishing machinesFeeding arrangmentsBrickMixed materials

The invention relates to a process for producing a natural travertine-imitated vitrified brick. The process comprises the following steps: feeding a base material and travertine in a material blanking roller through a roller hopper respectively, wherein the travertine is positioned on the middle material blanking roller; controlling the blanking proportion of the base material and the travertine by adjusting the rotating speed of the material blanking roller; rotating the base material and the travertine to a feeding belt through the rotation of the material blanking roller; conveying a laminated material consisting of the base material and the travertine to a movable storage hopper through the rotation of the feeding belt; moving a gate of the storage hopper; conveying the mixed materialto a straight grain shaping grille for shaping along with the movement of the movable storage hopper; conveying the mixed material to a press die cavity for pressing and shaping through the straight grain shaping grille; conveying the shaped product to a kiln and burning a burnt brick by controlling the temperature of the kiln; and polishing the burnt brick to obtain the natural travertine-imitated vitrified brick. Compared with the prior art, the natural travertine-imitated vitrified brick has the advantages of controllable distribution of textures and holes, strong appreciation, wide application range and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

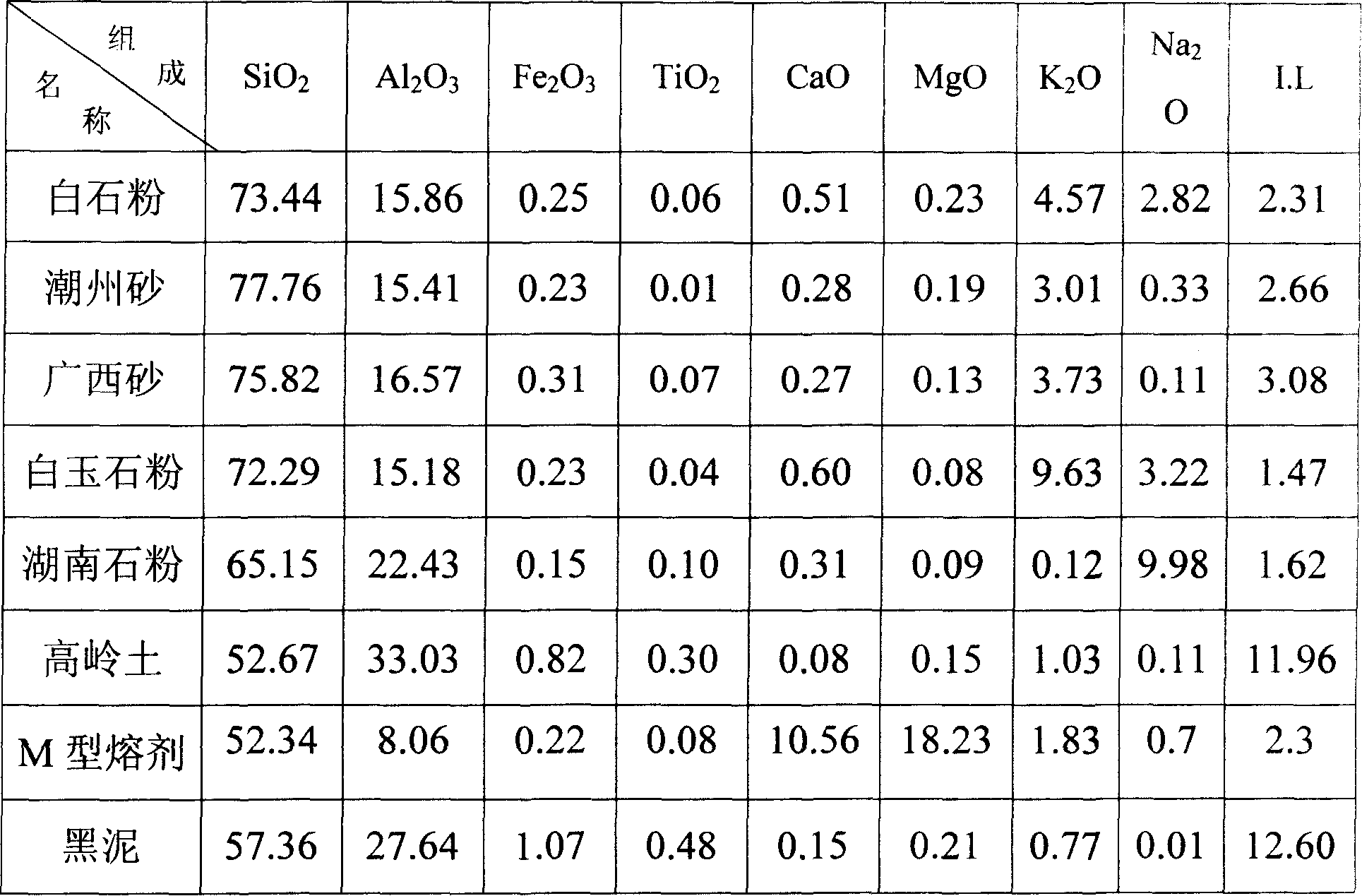

High-white transparent material formulation and manufacture method of crystal full transparency polishing brick

The present invention relates to one kind of decorating transparent vitrified ceramic tile and its material recipe and production process. The material for the decorating transparent vitrified ceramic tile consists of white stone powder 10-25 wt%, Chaozhou sand 15-30 wt%, Guangxi sand 15-30 wt%, white jade powder 5-25 wt%, Hunan stone powder 15-30 wt%, kaolin 10-20 wt%, black mud 1-10 wt% and M-type flux 0-10 wt%. The production process includes the steps of compounding material, ball milling, color mixing, spray drying, forming, drying, sintering and polishing. The produced ceramic tile is transparent, high white and high bright, and has no radioactivity, relatively high heat expanding coefficient and other advantages.

Owner:关润启

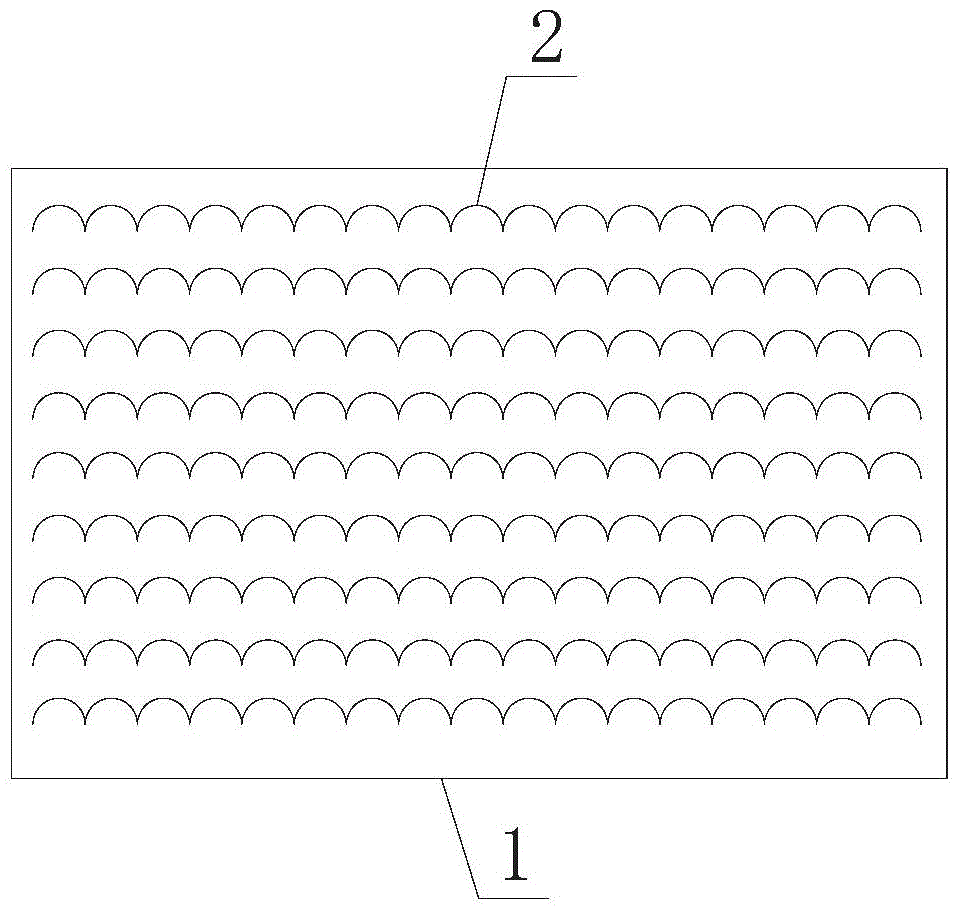

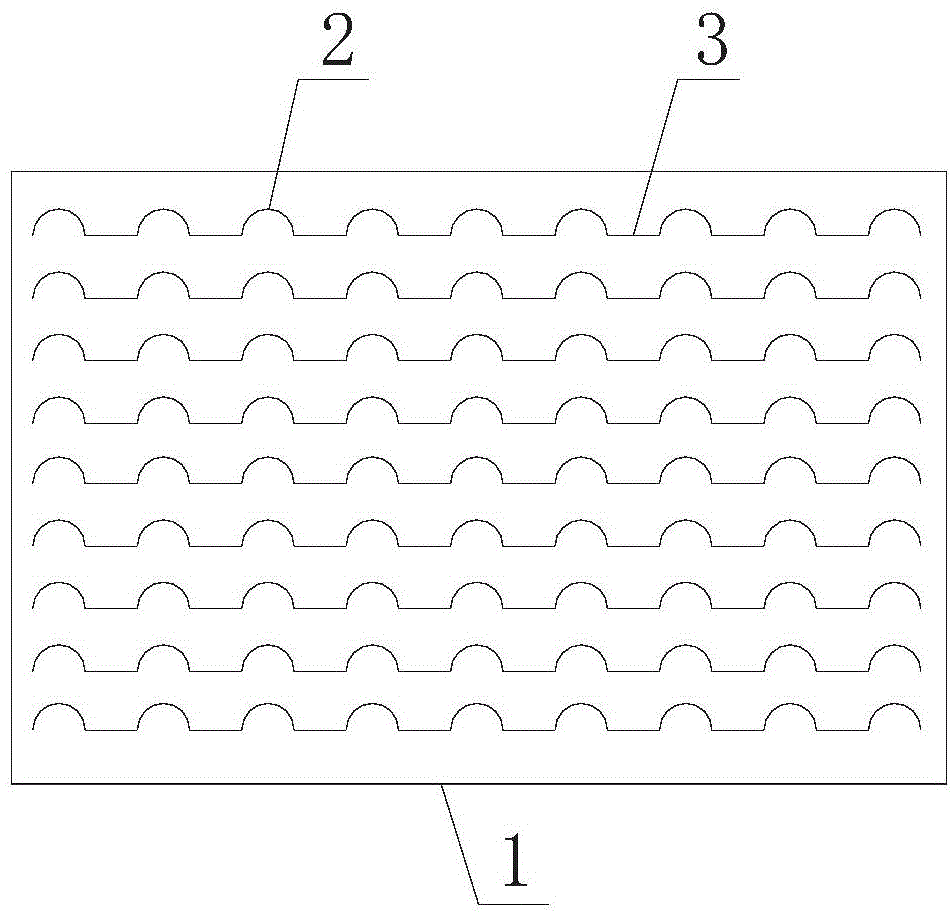

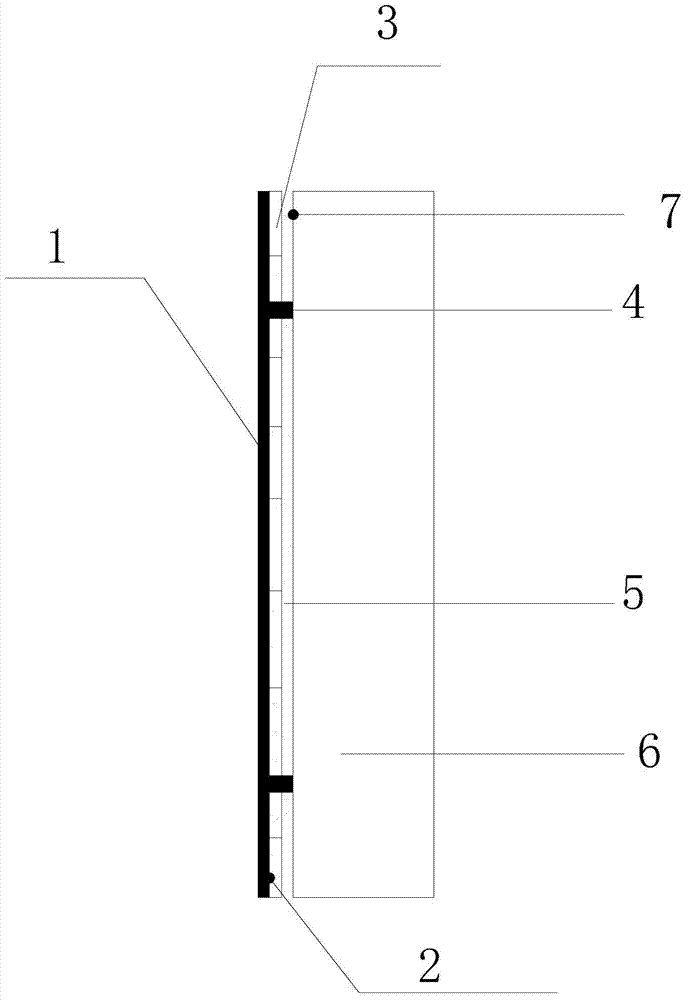

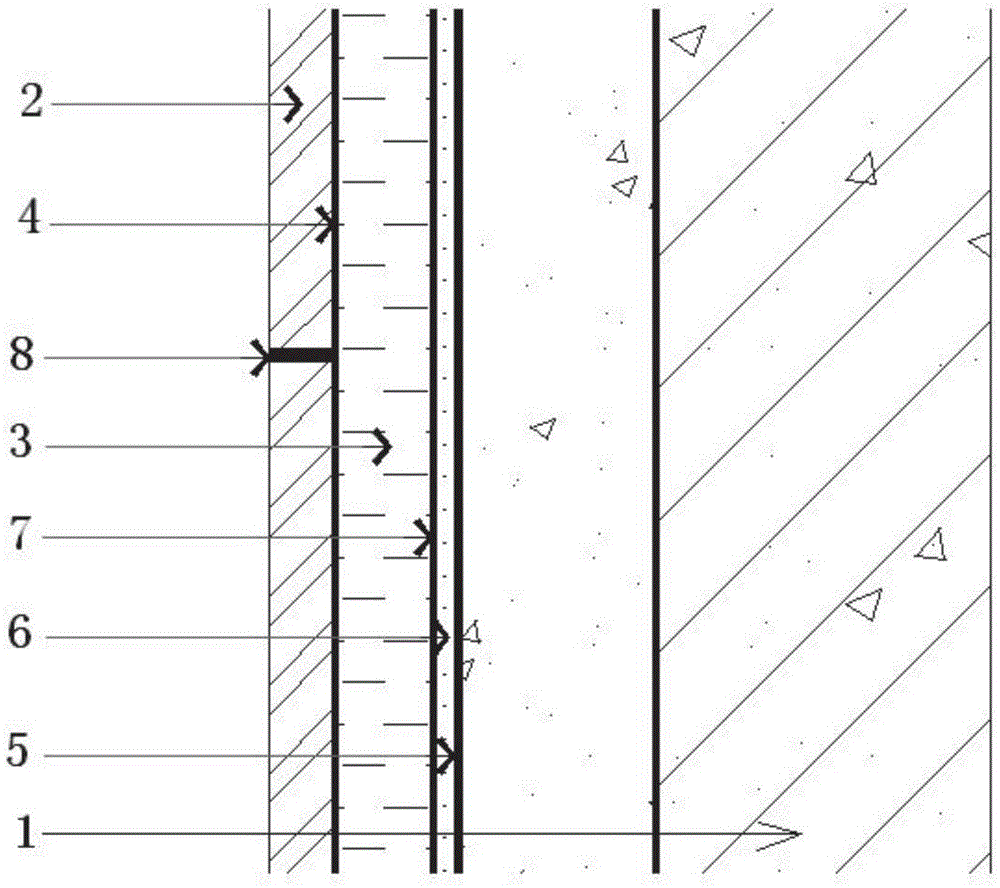

Vitrified tile paving structure and paving method thereof

ActiveCN105625669AReduce material costsSolve prone to surface chalkingCovering/liningsBuilding material handlingUltimate tensile strengthVitrified tile

The invention discloses a vitrified tile paving structure and a paving method thereof.The vitrified tile paving structure comprises a base layer, a vitrified tile layer is arranged on the base layer and formed by paving multiple vitrified tiles, the vitrified tile layer is arranged on the base layer through a bonding layer, a back gum layer is arranged between the vitrified tile layer and the bonding layer, the bonding layer is connected with the base layer through a wall curing processing agent layer, and a waterproof layer is arranged between the bonding layer and the wall curing processing agent layer.The paving method comprises the steps of vitrified tile processing, base layer processing and vitrified tile paving.According to the vitrified tile paving structure and the paving method thereof, by additionally arranging the back gum layer on the bonding layer, firm bonding can be formed between the vitrified tile layer and the bonding layer, the bonding strength is increased by 80% or above, and the cost of a bonding layer material can be saved by 50%; through the wall curing processing agent layer, the advantages of being little in using quantity per unit area, high in sealing and curing speed and permeability, good in closing property, high in strength and the like.

Owner:GOLD MANTIS CONSTR DECORATION

Repairing method for bulging and falling of finish material

InactiveCN106285037APatching is simple, fast and safeImprove repair effectBuilding repairsAdhesiveVitrified tile

The invention provides a repairing method for bulging and falling of a finish material. The method comprises the steps that (1) the finish material at the bulging portion is taken out, and the surface of an adhesion layer and the adhesion surface of the finish material are cleaned; (2) bulging and falling repairing adhesives are painted to the surface of the adhesion layer and the adhesion surface of the finish material, and the thickness of the adhesives is controlled to range from 0.1 mm to 0.2 mm; (3) the finish material is placed back to the bulging portion, a joint is arranged between the finish material and finish materials around, the finish material is leveled and compacted, and the bulging and falling repairing adhesives squeezed out of the joint are completely removed, specifically, the amount of the bulging and falling repairing adhesives per square meter is 0.3-0.4 kg; and (4) 2-3 days after natural maintenance, the joint is cleaned, the joint is filled with a flexible joint mixture so that the joint can be leveled up, the joint filling depth is not smaller than 3 mm, and natural maintenance is carried out to cure the flexible joint mixture. The repairing method is simple, rapid and safe, the repairing effect is good, design is ingenious, the original decoration effect of stone and vitreous tiles can be maintained, the maintenance cost can be greatly reduced, and the repairing method is suitable for being widely applied and popularized.

Owner:余春冠

Manufacture technology of vitrified tiles embedded with lines

InactiveCN105500513ANatural and smooth texture linesRealistic imitation marble effectFeeding arrangmentsManufacturing technologyBrick

The invention relates to a manufacture technology of vitrified tiles embedded with lines. The manufacture technology comprises: (1), conveying a surface material, to be specific, placing the micro-powder surface material in surface material tanks, discharging the material into a main surface material storage tank through surface material rotating rollers below surface material hoppers, and conveying the material to a line gathering material guide plate through a material storage and surface material conveying integral belt; (2), conveying a line material, to be specific, placing the micro-powder line material in line material tanks, discharging the micro-powder line material to a line material vibrating sieve through the rotating of line material discharging rotating rollers, evenly dispersing the line material on a surface material conveying oblique belt rotating below, and conveying the material to the line gathering material guide plate by the surface material conveying oblique belt; and (3), stacking the materials, to be specific, mixing the micro-powder surface material and the line material at the part of the line gathering material guide plate, enabling the mixed material to drop on a material gathering flat plate below the line gathering material guide plate in a mutual extrusion manner, driving the material gathering flat plate forwards by a driving belt, and conveying the mixed material to a press die cavity through an anti-counterfeiting grille so as to finish brick pressing, namely,obtaining the vitrified tiles embedded with lines. Compared with the prior art, the products manufactured by the technology have the advantages that the texture lines are natural and smooth, are as vivid as true granite, are strong in controllability and the like.

Owner:JIANGXI CIMIC CERAMICS +1

Environmental-friendly single-component vitrified brick gum and preparation method thereof

ActiveCN106497473ASolve empty drumSolve crackingNon-macromolecular adhesive additivesStarch adhesivesWater basedEpoxy

The invention provides environmental-friendly single-component vitrified brick gum and a preparation method thereof. The vitrified brick gum comprises the following components in percentage by weight: 60 to 80 percent of emulsion, 10 to 20.5 percent of a waterproof agent, 7 to 13 percent of a bonding agent, 0.2 to 0.7 percent of a dispersing agent, 0.2 to 0.6 percent of an antifoaming agent, 0.3 to 0.6 percent of an anticorrosion agent, and 1.5 to 5 percent of a modifying agent. The environmental-friendly single-component vitrified brick gum can completely meet the bonding requirements of vitrified bricks, effectively solves the problems of hollowing, peeling, falling off and the like of vitrified bricks during bonding, and has the advantages of simplicity in construction, environment protection, low cost and the like. By mixing the emulsion formed by mixing water-based epoxy resin emulsion and carboxy styrene-butadiene latex, with the solid content being 50 percent or higher, with other components, the solid content of the gum reaches 50 to 55 percent, so that the increasingly strict VOC limitations are met, and the gum shows extremely high bonding powder.

Owner:湖北碱克新材料有限公司

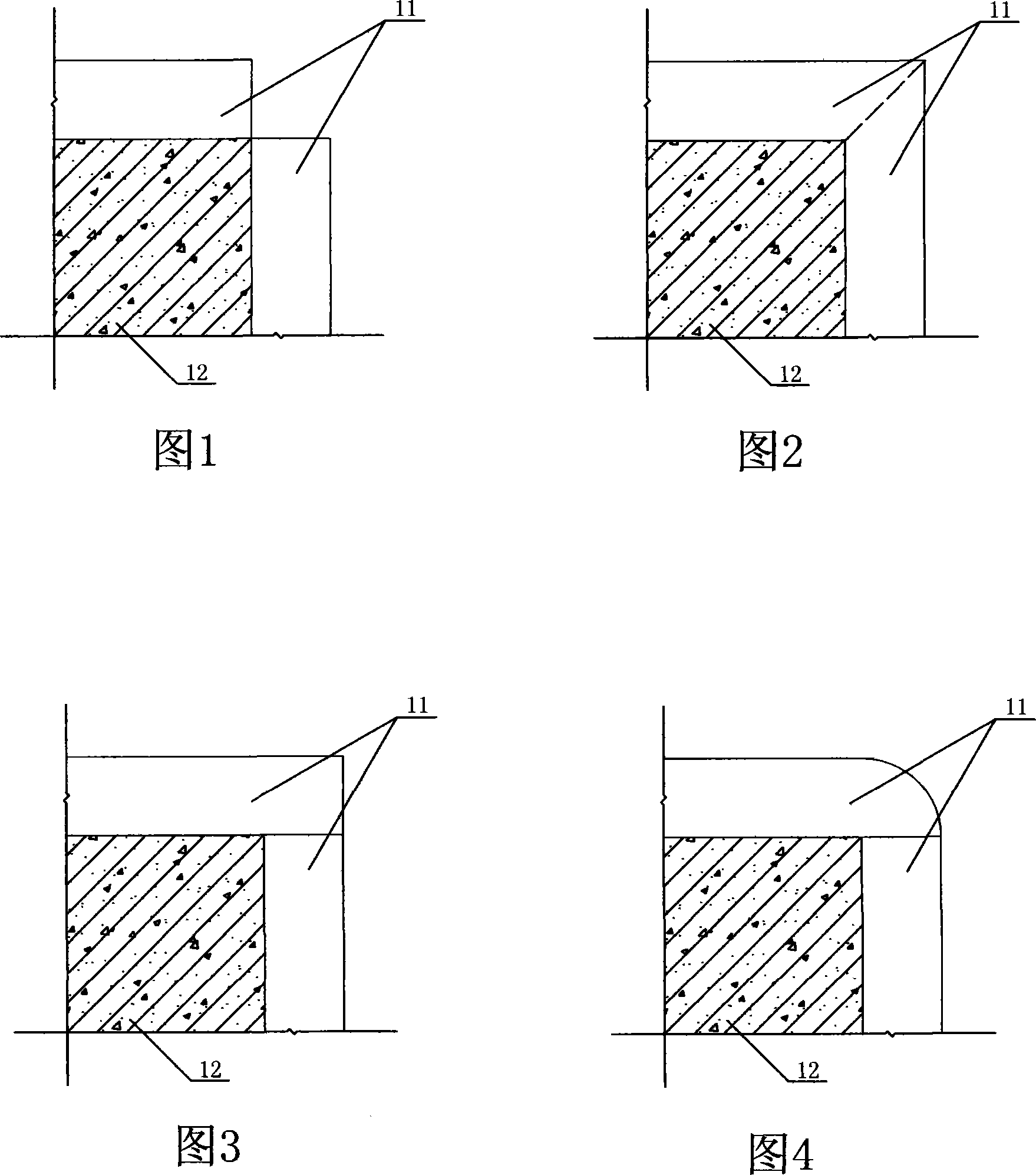

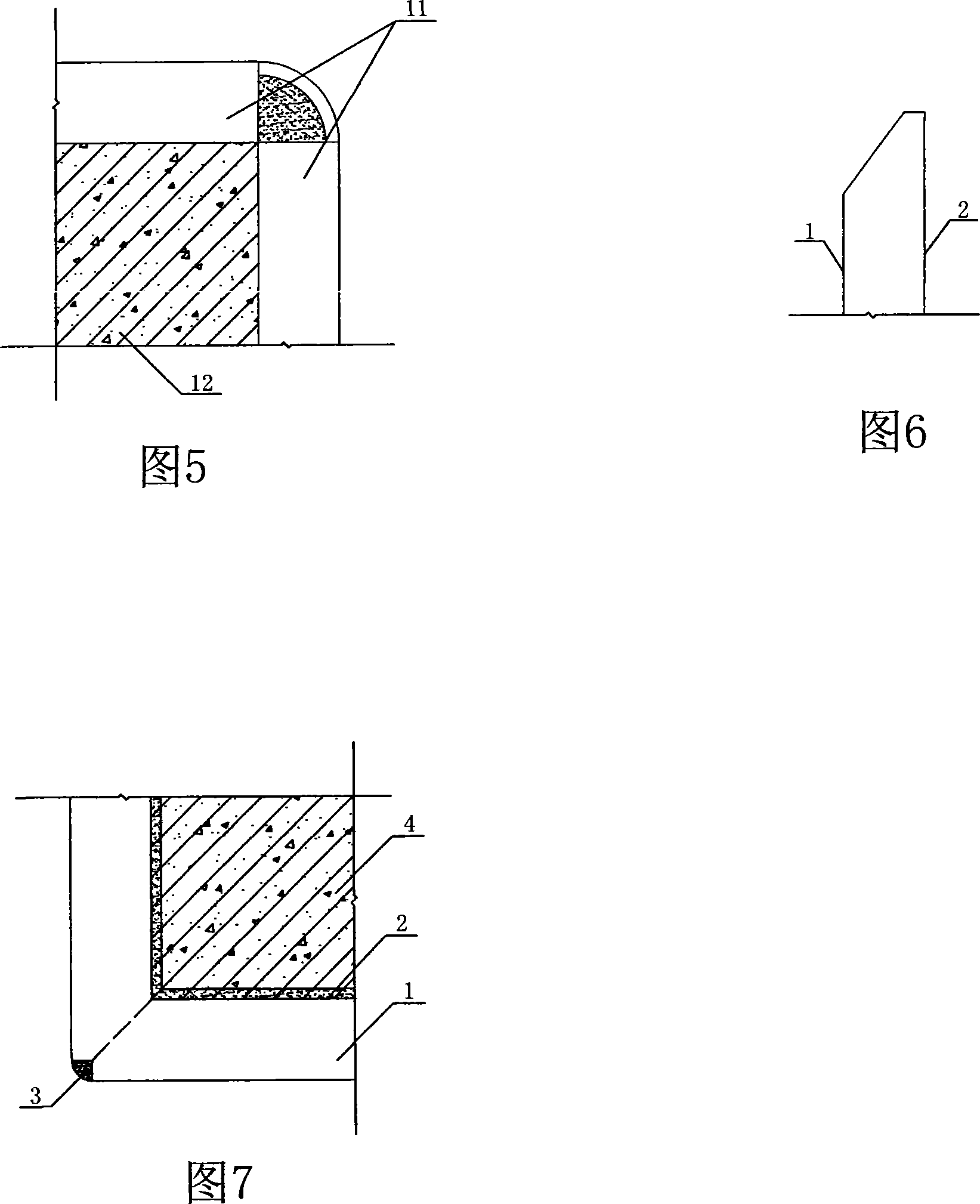

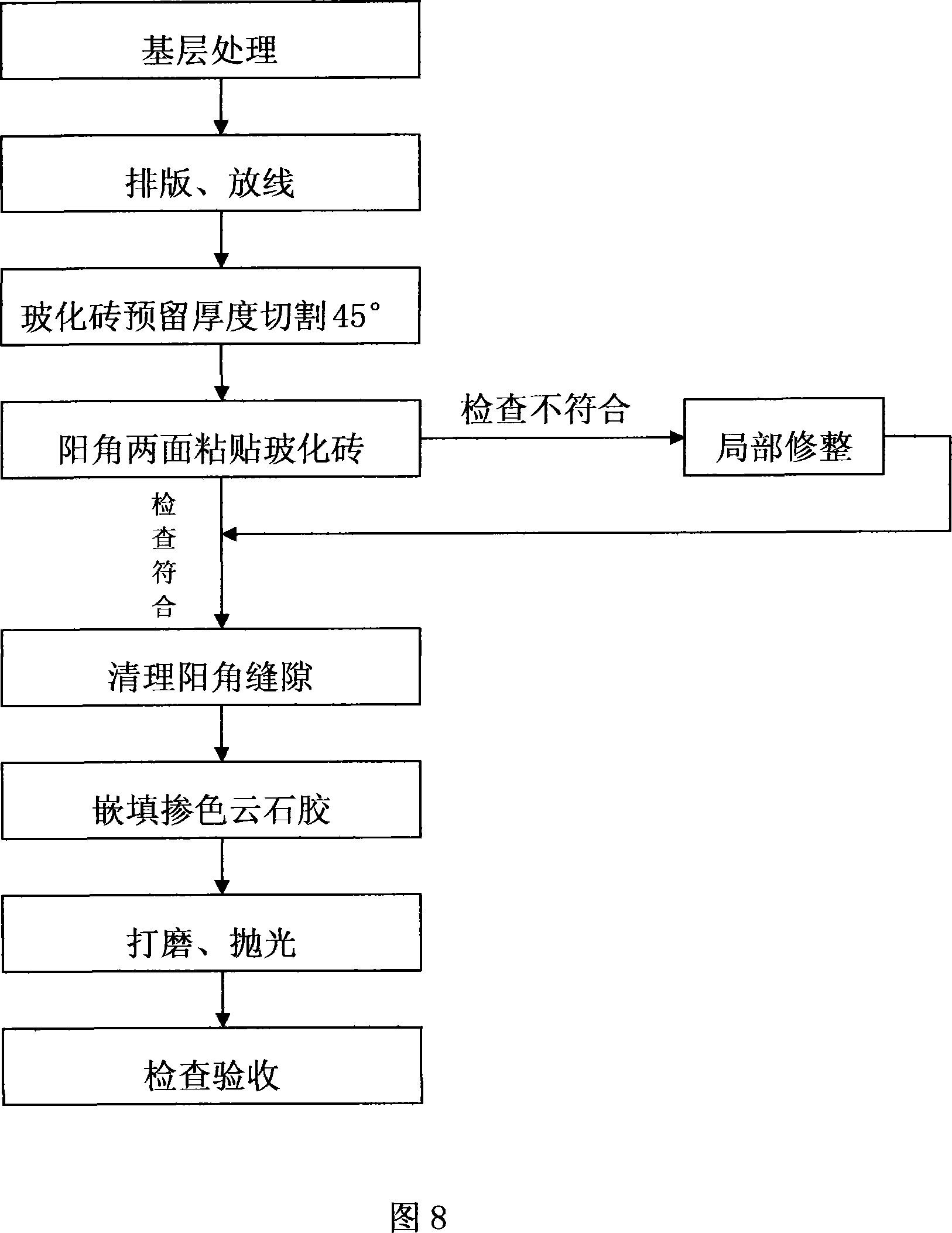

Construction technique for plastering vitrified brick at positive angle

This invention discloses a technology of pasting outside angles of glass bricks including the following steps: treating base players, typesetting, setting out, cutting and pasting, in which the cutting technology includes that a 45deg. angle is cut at the place at a 2-4mm distance of preserved thickness to the plain surface of the glass brick between the plain surface and a rough surface and the paste technology refers to pasting the cut glass brick and the base layer with cement mortar and a gap small angle formed at the outside angle of two glass bricks is filled with marble glue.

Owner:浙江中联建设集团有限公司

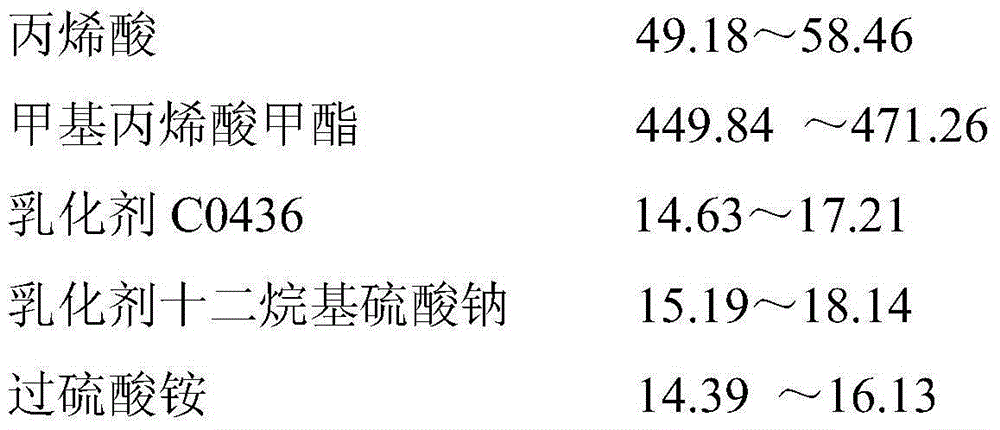

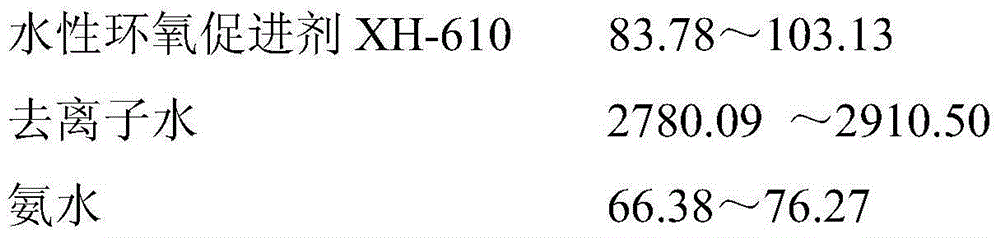

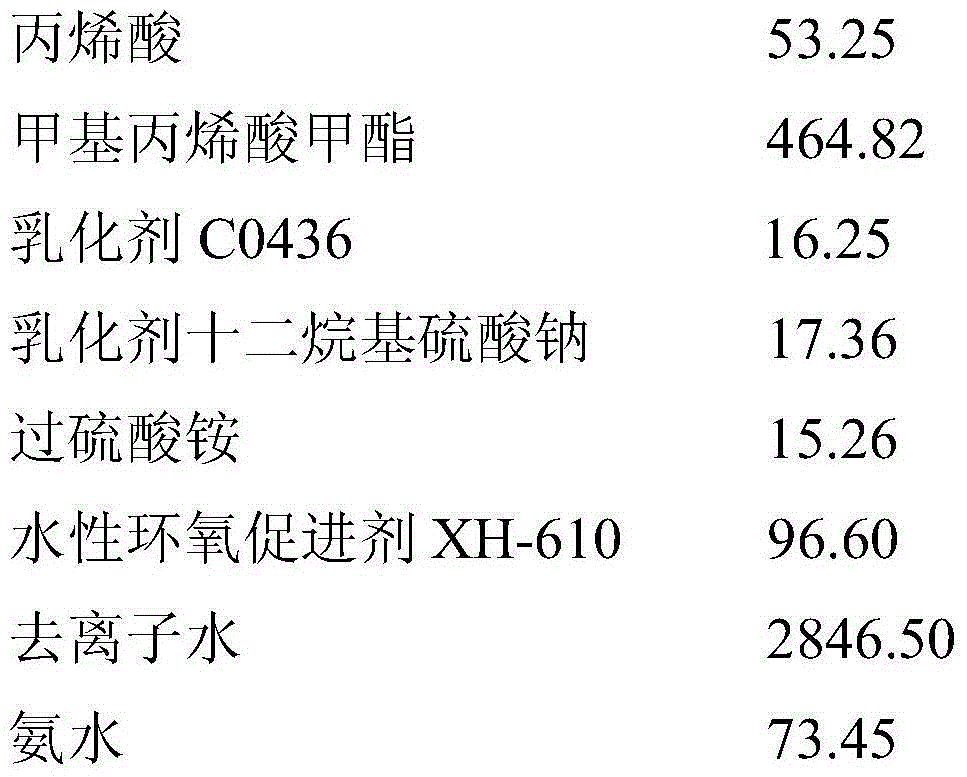

Novel one-component water-based adhesive and production technology thereof

The invention discloses novel one-component water-based adhesive and a production technology thereof. The novel one-component water-based adhesive comprises the following components: acrylic acid, methyl methacrylate, an emulsifying agent C0436, sodium dodecyl sulphate, ammonium persulphate, a water-based epoxy accelerator XH-610, deionized water and ammonia water. The production technology of the novel one-component water-based adhesive comprises the following steps: adding the emulsifying agent C0436 and the emulsifying agent sodium dodecyl sulphate into deionized water so as to be dissolved and emulsified, then adding mixed monomers of acrylic acid and methyl methacrylate, fully stirring for 5 hours, dropwise adding an initiating agent ammonium persulphate in 2 hours, then adding the water-based epoxy accelerator XH-610, finally dropwise adding ammonia water for regulating the pH value, carrying out heat preservation at the temperature of 85 DEG C, and placing for 3 hours, thereby obtaining one-component water-based adhesive in white emulsion. The novel one-component water-based adhesive can be used for not only effectively preventing empty drums and falling-off of ceramic tiles such as vitrified tiles and polished tiles as well as marble, and but also greatly lowering the material cost for architectural decoration.

Owner:唐一平

Single component vitrified brick back glue

ActiveCN106916554AGood flexibilityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyBrick

The invention discloses a single component vitrified brick back glue, which comprises the following components in parts by weight: 20 to 50 parts of emulsion, 5 to 25 parts of aqueous epoxy resin, 0.5 to 3 parts of sodium silicate, 0.5 to 2 parts of auxiliary agent, 0.5 to 2 parts of modifier, 50 to 70 parts of slag micro powder, 0.1 to 0.8 part of antiseptic, and 0.1 to 1 part of dispersant, wherein the emulsion comprises 15 to 35 parts of acrylic acid emulsion and 5 to 15 parts of VAE emulsion, the auxiliary agent is fumed silica, and the modifier is a silane coupling agent. The provided single component vitrified brick back glue has the advantages of good flexibility, high bonding strength, and good weatherability, the compatibility between the back glue and a cement based adhesive material is good, and the bonding requirements of vitrified bricks can be met completely. Aqueous epoxy resin has the characteristics of good adhesive force, excellent operability, good anticorrosion performance, and acid / alkali resistance. Through the back glue, vitrified bricks can be adhered on different base materials, the construction is simple, and the problems such as hollowing, bubbling, falling, and the like, in vitrified brick pasting are solved.

Owner:湖北碱克新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com