Method for preventing mosaic hollowing and shedding of vitrified tiles

A technology of vitrified tiles and hollowing, which is applied in covering/lining, building, building structure, etc., can solve the problems of hollowing, damage of bonding layer, and rapid water loss, so as to reduce hollowing rate and prevent ceramic tiles. shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

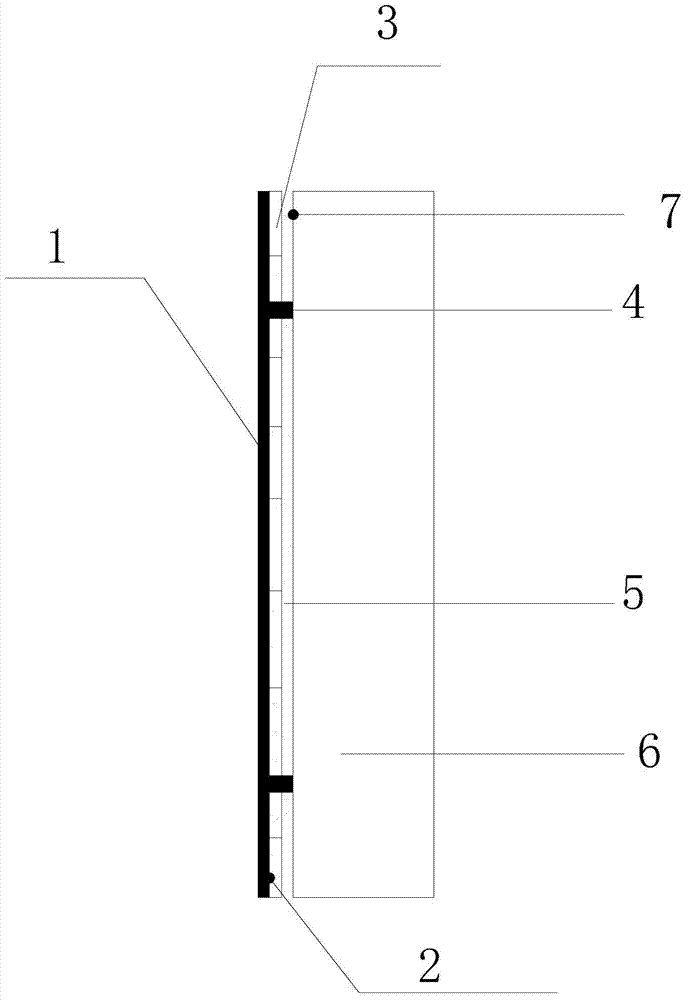

[0020] Paste the same thickness of broken vitrified bricks 3 (50*50mm) on the adhesive surface 2 of the 600*600mm vitrified tile 1 to make it basically covered; and paste it near the four corners of the vitrified tile adhesive surface 2 Four φ8 steel bars 4, the steel bar 4 is perpendicular to the vitrified brick 1, the length of the steel bar 4 is 6mm longer than the thickness of the vitrified brick 1. After pasting, after the broken vitrified brick 3 and the φ8 steel bar 4 are pasted firmly, apply 801 glue Mix it into a grout and evenly cover the surface of broken vitrified bricks 3 to make the surface a roughened state, then dry the fine sand on the surface layer, and use a composite silicate with a strength grade of 32.5 after it has dried out in 24 hours Cement paste construction, mix 20% of the weight of the cement in the composite Portland cement with fine sand, mix it evenly, and carry out the construction. The thickness of the composite Portland cement layer 5 is 6mm; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com