Heat-insulation and decorative integral plate and manufacturing method thereof

A thermal insulation and decorative layer technology, applied to the surface coating liquid device, special surface, covering/lining, etc., can solve the problems of its own property limit, unsafe hidden danger, high energy consumption, etc., and achieve thermal insulation The effect of overcoming performance, easy large-scale production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

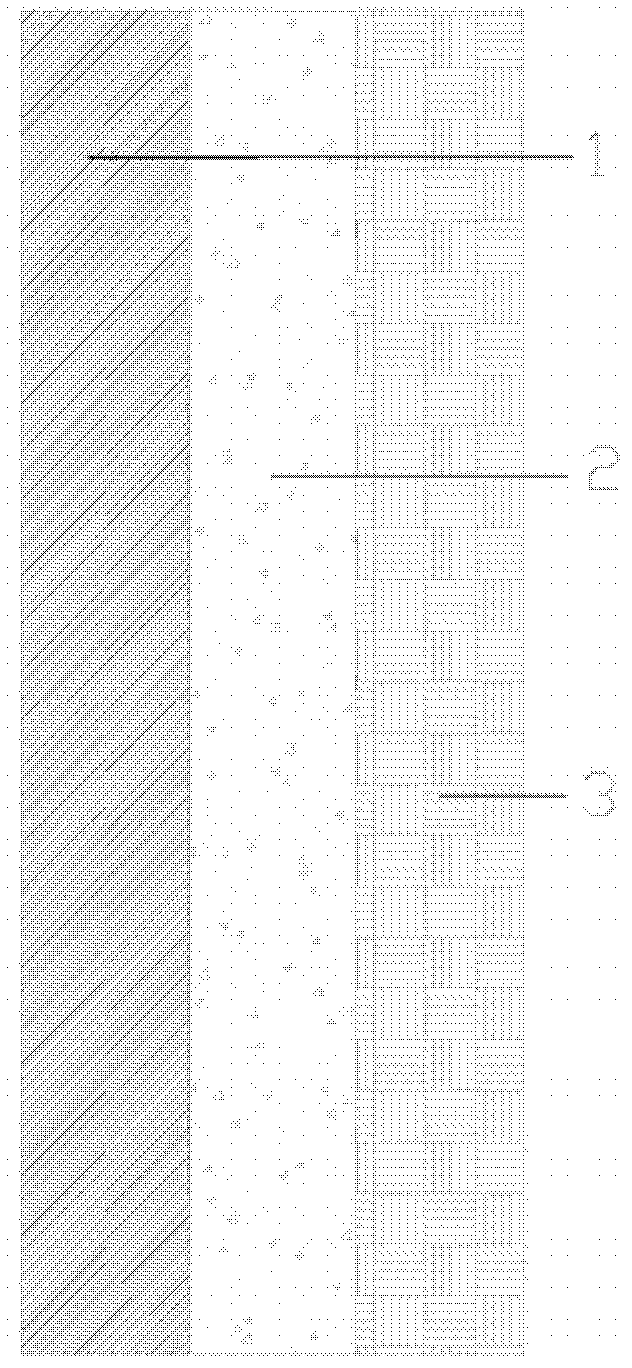

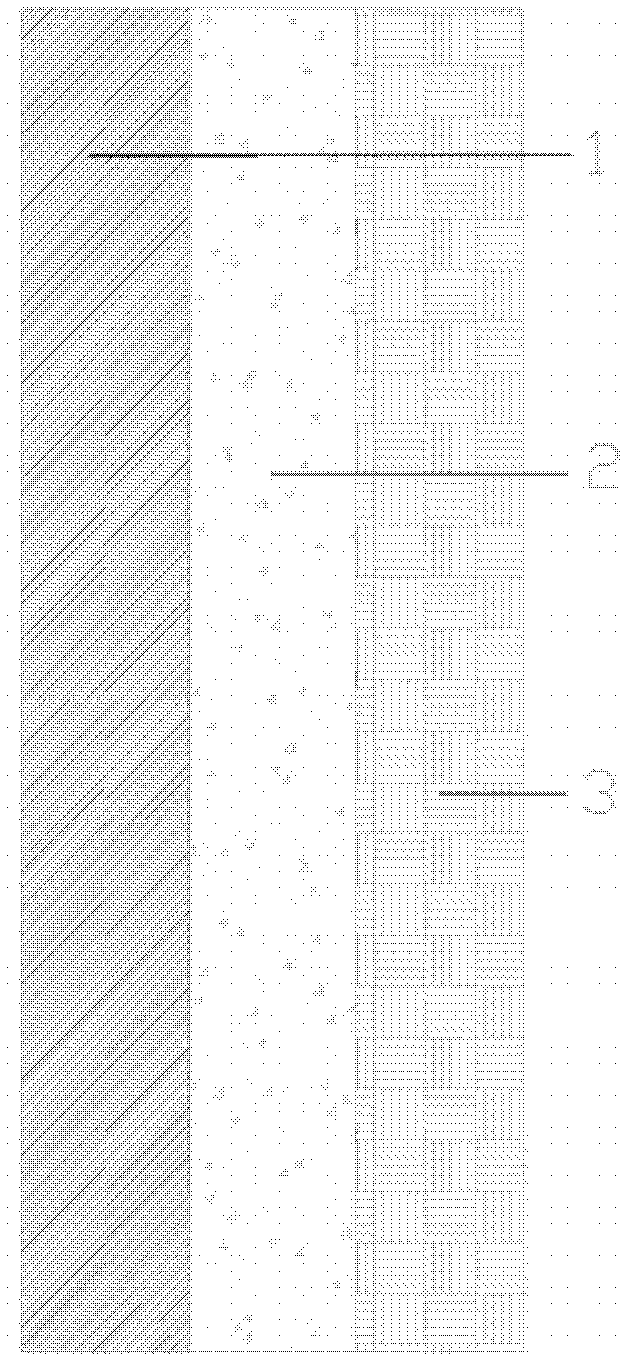

[0029] Such as figure 1 As shown, this embodiment provides an integrated thermal insulation and decoration board, the board is composed of thermal insulation layer 1, intermediate protective layer 2 and decorative layer 3 from the base wall to the outside. The nano-airgel felt in this example is produced by Nano Hi-Tech Co., Ltd., the crack-resistant plastering mortar and the special interface mortar are produced by Shanghai Polymeric Materials Co., Ltd., and the imitation stone paint is purchased in the market.

[0030] The insulation layer is surface-treated nano-airgel felt; the middle protective layer is crack-resistant plastering mortar; the decorative layer is imitation stone paint finish.

[0031] In this embodiment, the thermal conductivity of the surface-treated nano-airgel felt is 0.020w / m.k, the thickness is 20mm, and the density is 200kg / m 3 .

[0032] In this embodiment, the surface treatment process of the surface-treated nano-airgel felt is a special interface...

Embodiment 2

[0036] Such as figure 1 As shown, this embodiment provides an integrated thermal insulation and decoration board, the board is composed of thermal insulation layer 1, intermediate protective layer 2 and decorative layer 3 from the base wall to the outside. The nano-airgel sheet described in this example is produced by Nano Hi-Tech Co., Ltd., the crack-resistant plastering mortar and special interface agent are produced by Shanghai Polymeric Materials Co., Ltd., and the granite stone is purchased from the market.

[0037] The insulation layer is surface-treated nano-airgel sheet; the middle protective layer is crack-resistant plaster mortar; the decorative layer is granite stone veneer.

[0038] In this embodiment, the thermal conductivity of the surface-treated nano-airgel sheet is 0.020w / m.k, the thickness is 20mm, and the density is 200kg / m 3 .

[0039] In this embodiment, the surface treatment process of the surface-treated nano-airgel felt is double-sided spraying of a s...

Embodiment 3

[0043] The preparation method of the thermal insulation and decoration integrated board described in Example 1 provided includes the following steps:

[0044] 1) Cut the nano-airgel mat into 1000*1000mm specifications, flatten it, stand it upright, and reserve; special interface mortar, reserve;

[0045] 2) Spray the special interface mortar on one side of the nano-airgel felt to a thickness of 1.0mm, and then spray the special interface mortar on the other side to a thickness of 1.0mm after finalizing the shape, and dry it until the coating layer develops strength for later use;

[0046] 3) Batch-coat the anti-crack plastering mortar on the surface of the nano-airgel felt that has been sprayed with special interface mortar, and dry it until strength is generated;

[0047] 4) On the anti-crack plastering mortar layer, paint primer, middle coat and top coat in sequence to make a finishing layer.

[0048] The insulation board is installed on the wall by bonding and anchoring. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com