Elastic thin layer thermal insulation coat

A thermal insulation and thin-layer technology, applied in the direction of coating, thermal insulation, fireproof coatings, etc., to achieve the effects of good stain resistance, prolonging decay time, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides 15 examples, which are listed in Table 1-Table 3, Example 1-Example 5 is the embodiment of the middle layer, Example 6-Example 15 is the embodiment of the surface layer. Table 4 and Table 5 are test examples of heat insulation effect.

[0031] The bottom layer of the present invention is epoxy zinc-rich paint with respect to metal substrate, as the product inorganic epoxy zinc-rich primer CHG-FT-1 of Jiangsu Chenguang Paint Co., Ltd., is water-based sealing paint with respect to building exterior wall substrate, such as Jiangsu The anti-alkali sealing primer CHG-120T of Chenguang Paint Co., Ltd.; the protective layer is a transparent anti-staining and anti-aging liquid, such as the product CHG-1500 of Jiangsu Chenguang Paint Co., Ltd.

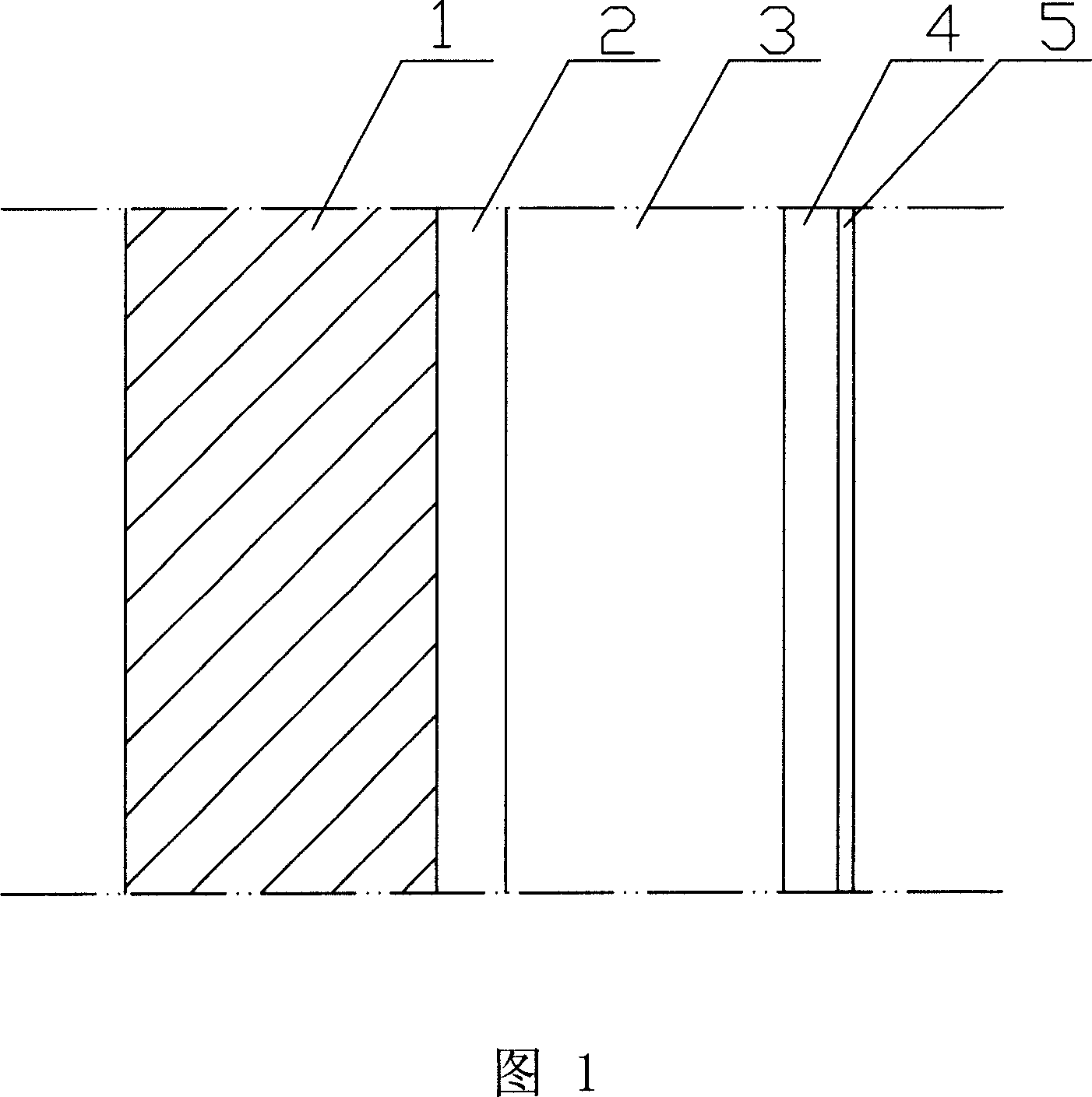

[0032] The thickness ratio of each layer of the coating of the present invention is bottom layer: middle layer: surface layer: protective layer = 1: 4: 0.8: 0.2, and the total thickness of the four-layer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com