Varnish for repairing vehicles

A technology for varnishes and vehicles, applied in the field of coatings, can solve the problems of repairing varnishes such as poor flexibility, loss of gloss, large manpower, material resources and time, and achieve excellent gloss and aging resistance, good anti-graffiti performance, and good anti-staining performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

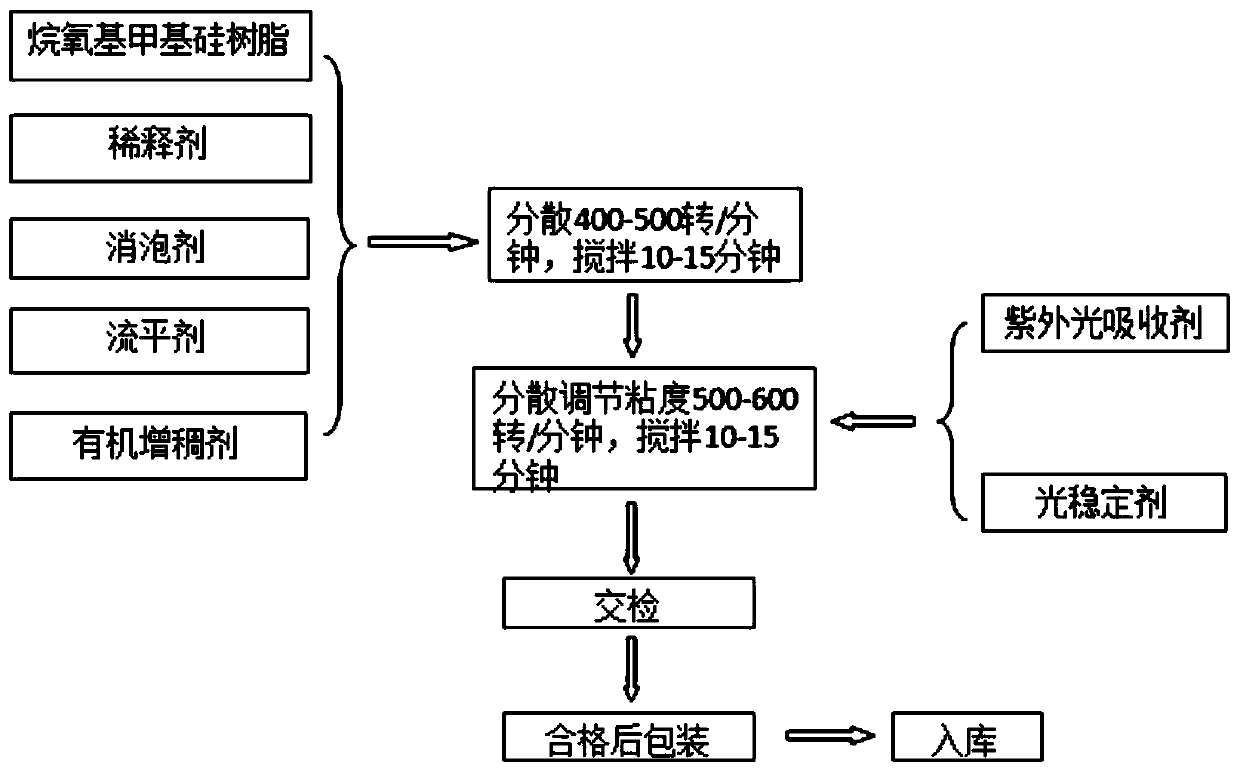

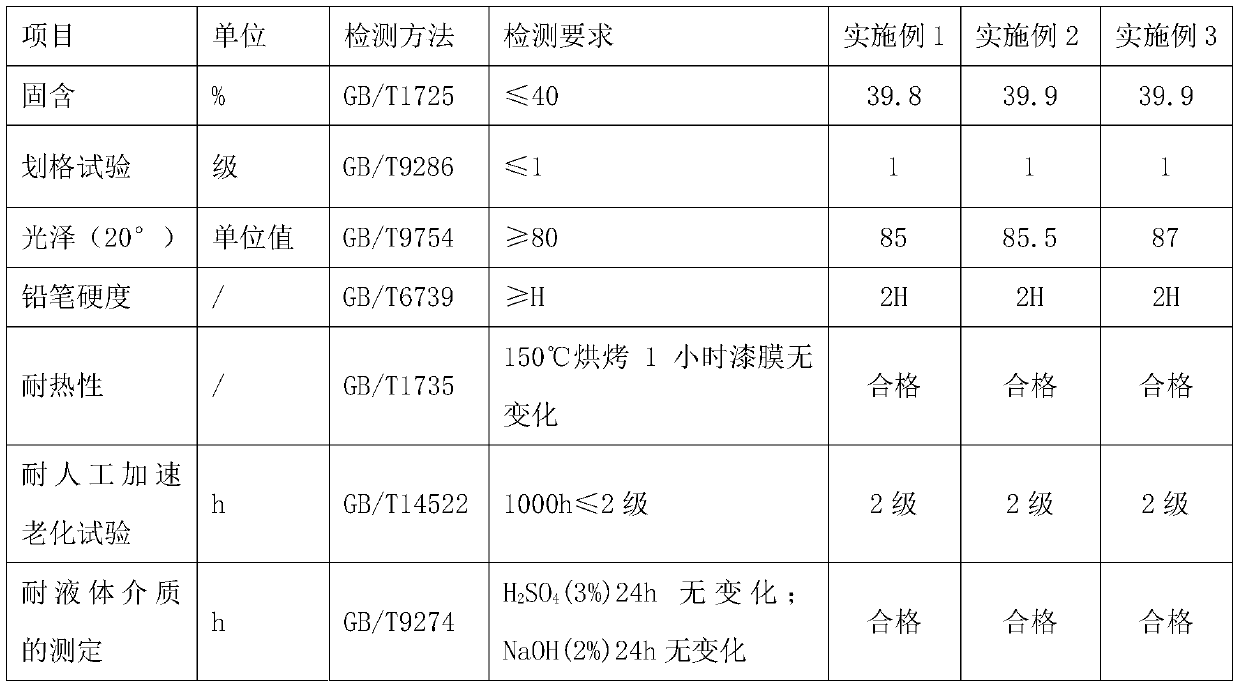

[0031] 1. Preparation of paint: Weigh each raw material by weight: 55 parts of alkoxymethyl silicone resin, 0.2 parts of polysiloxane defoamer, 1.5 parts of ultraviolet light absorber, 1.5 parts of light stabilizer, fluorine modified 0.5 parts of leveling agent, 1.0 parts of organic thickener, 40.3 parts of thinner. The solvent is a mixed solvent of xylene:butyl acetate=40:60 weight ratio. First pour the alkoxymethyl silicone resin into the container tank, and put the container tank under the disperser for dispersion, adjust the speed to 400-500 rpm, then add the solvent, defoamer, Leveling agent, thickener, UV absorber, light stabilizer. After feeding, adjust the speed of the disperser to 500-600 rpm, and stir for 10-15 minutes to obtain the varnish product; filter with a 120-mesh filter to remove mechanical impurities, and pack it in an iron bucket to prevent the paint from absorbing moisture And metamorphic;

[0032] 2. Preparation of the catalyst: by weight, 25 parts of...

Embodiment 2

[0035] .Preparation of paint: Weigh each raw material by weight: 58 parts of alkoxymethyl silicone resin, 0.2 parts of polysiloxane defoamer, 1.2 parts of ultraviolet light absorber, 1.8 parts of light stabilizer, fluorine modified fluid 0.4 parts of leveling agent, 0.8 parts of organic thickener, and 37.6 parts of diluent. The solvent is a mixed solvent of xylene:butyl acetate=45:55 weight ratio. First pour the alkoxymethyl silicone resin into the container tank, and put the container tank under the disperser for dispersion, adjust the speed to 400-500 rpm, then add the solvent, defoamer, Leveling agent, thickener, UV absorber, light stabilizer. After feeding, adjust the speed of the disperser to 500-600 rpm, and stir for 10-15 minutes to obtain the varnish product; filter with a 120-mesh filter to remove mechanical impurities, and pack it in an iron bucket to prevent the paint from absorbing moisture And metamorphic;

[0036] 2. Preparation of the catalyst: by weight, 27 ...

Embodiment 3

[0039]Preparation of paint: Weigh each raw material by weight: 60 parts of alkoxymethyl silicone resin, 0.3 parts of polysiloxane defoamer, 1.0 part of ultraviolet light absorber, 2.0 parts of light stabilizer, fluorine modified leveling agent 0.3 parts of agent, 0.5 parts of organic thickener, 35.9 parts of diluent. The solvent is a mixed solvent of xylene:butyl acetate=1:1 weight ratio. First pour the alkoxymethyl silicone resin into the container tank, and put the container tank under the disperser for dispersion, adjust the speed to 400-500 rpm, then add the solvent, defoamer, Leveling agent, thickener, UV absorber, light stabilizer. After feeding, adjust the speed of the disperser to 500-600 rpm, and stir for 10-15 minutes to obtain the varnish product; filter with a 120-mesh filter to remove mechanical impurities, and pack it in an iron bucket to prevent the paint from absorbing moisture And metamorphic;

[0040] 2. Preparation of the catalyst: by weight, 30 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com