External wall heat-insulation low-carbon energy-saving paint

A technology for energy-saving coatings and exterior walls, applied in the direction of reflection/signal coatings, anti-fouling/underwater coatings, coatings, etc., can solve the unfavorable appearance and use of exterior wall surfaces, hollow glass beads are easy to fly, and affect human health, etc. Problems, to achieve excellent thermal insulation effect, excellent color development, excellent elongation at break of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

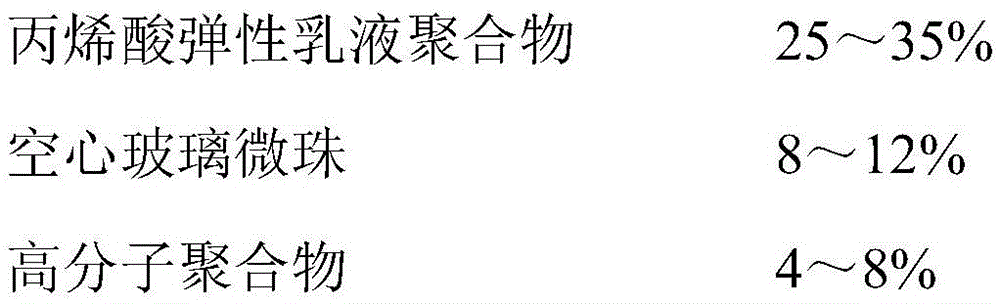

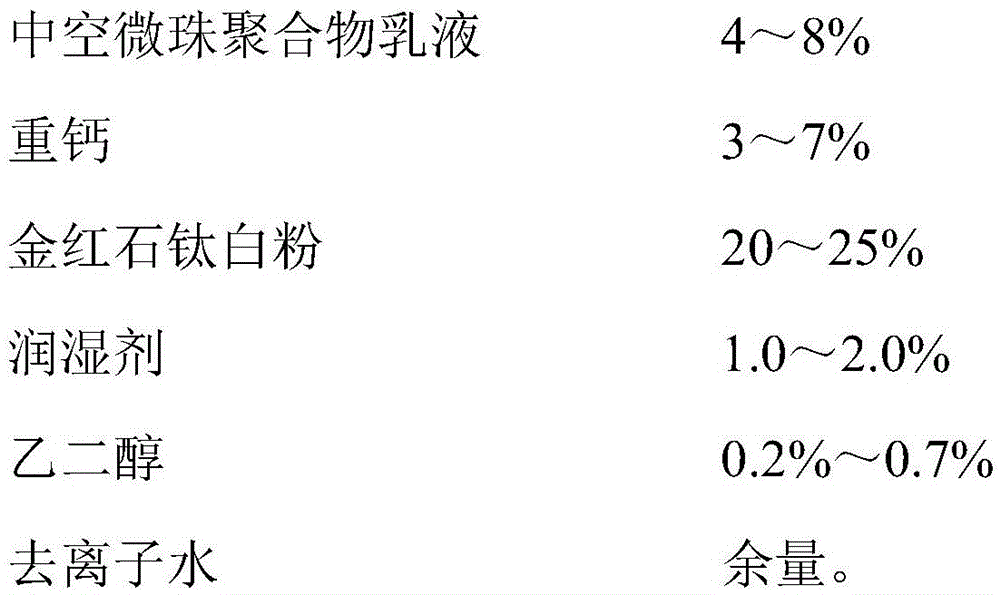

Method used

Image

Examples

Embodiment 1-5

[0032] The preparation methods of Examples 1-5 are as follows:

[0033] First dilute the high molecular polymer with ethylene glycol, film-forming aids and a small amount of water for later use. Mix the acrylic elastic emulsion polymer, hollow microbead polymer emulsion, heavy calcium, rutile titanium dioxide, wetting agent and the balance of water. Evenly, slowly add the polymer diluent, stir evenly, adjust the rotation speed to 0r / min, put in the hollow glass beads, wait until the hollow glass beads are completely dissolved in the liquid, and then disperse evenly at a low speed of 300r / min, then continue to add others Mix the components evenly. The paint film performance test after coating of Examples 1-5 is shown in Table 3:

[0034] table 3:

[0035]

[0036] It can be seen from Table 1 and Table 3 that the paint film of the paint of the present invention has better anti-cracking performance, but still has good reflection performance in thin coating. The present invention also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com