Patents

Literature

554results about How to "The preparation process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

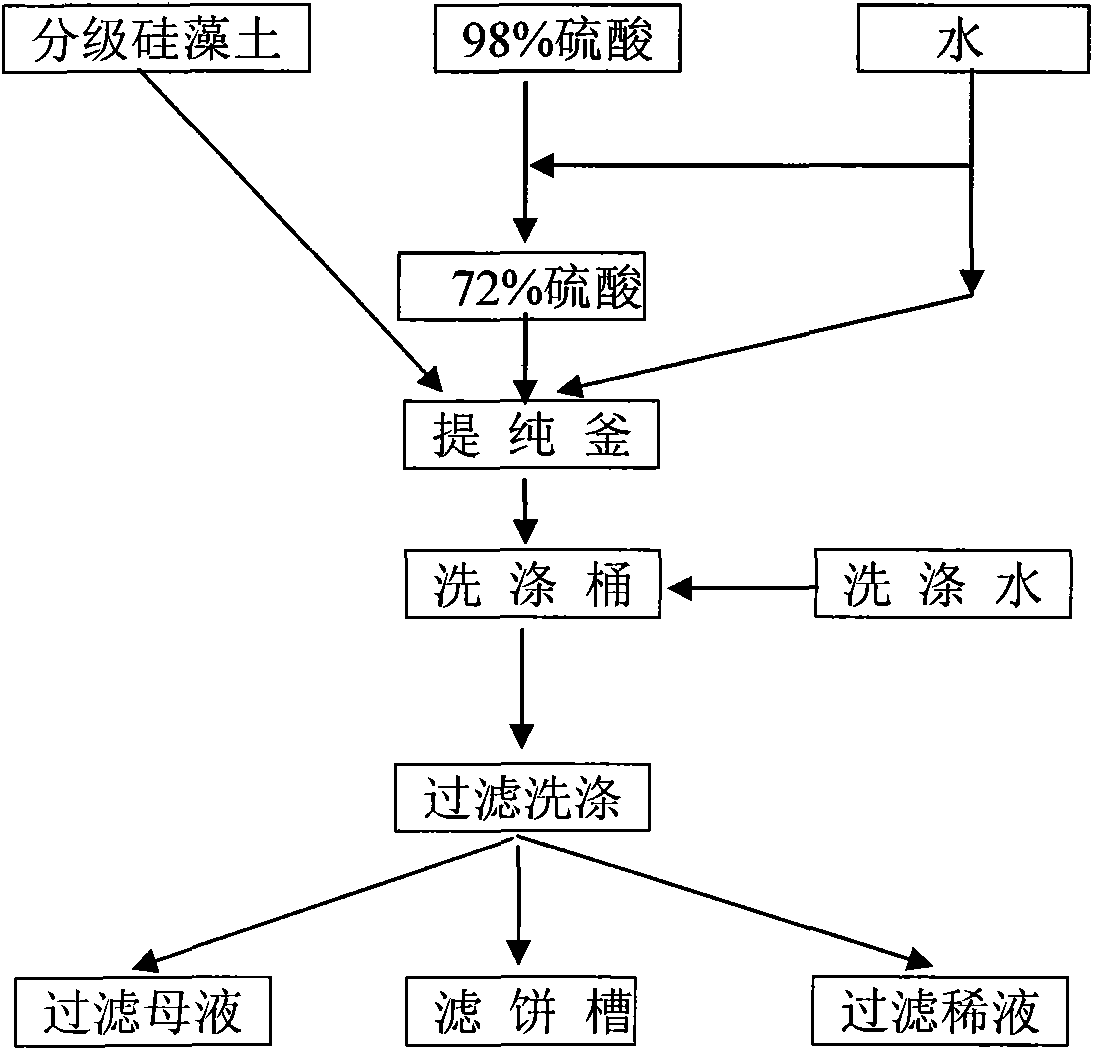

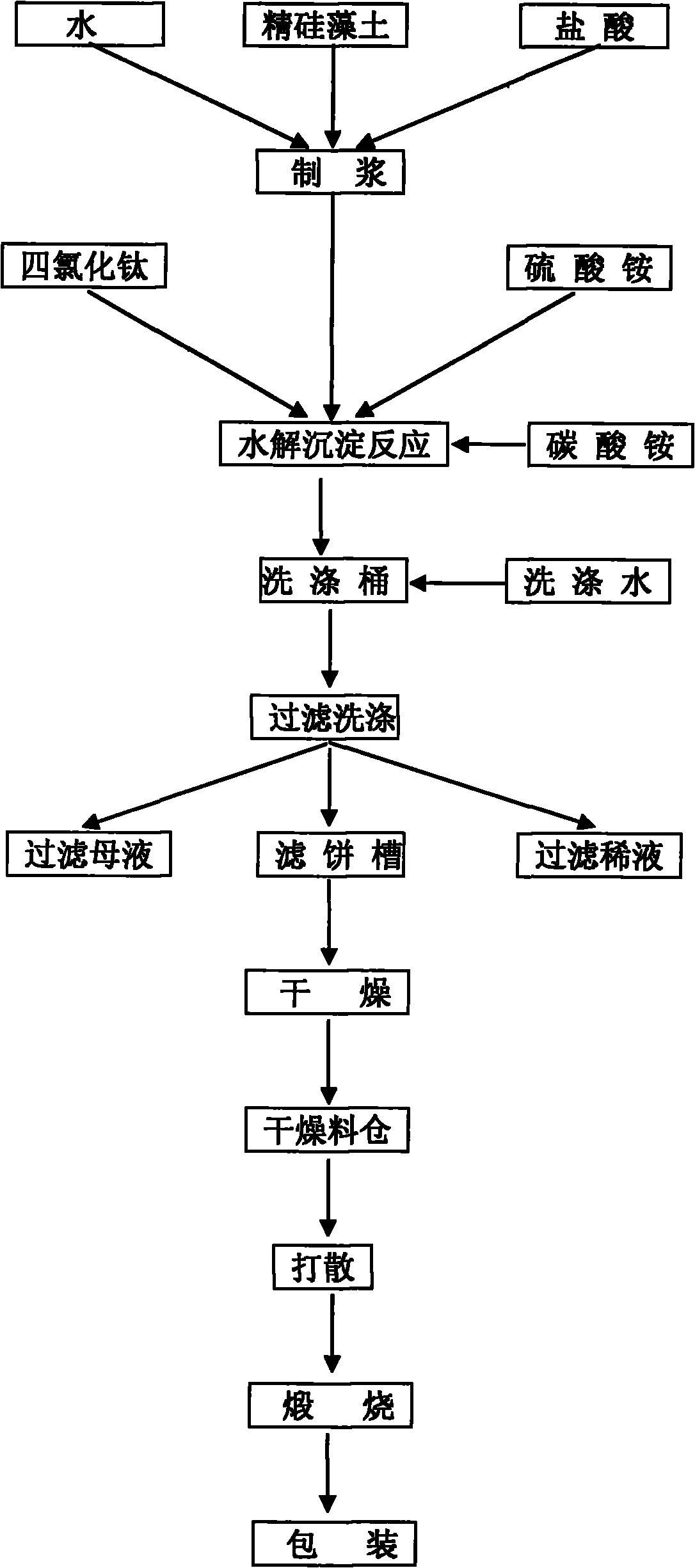

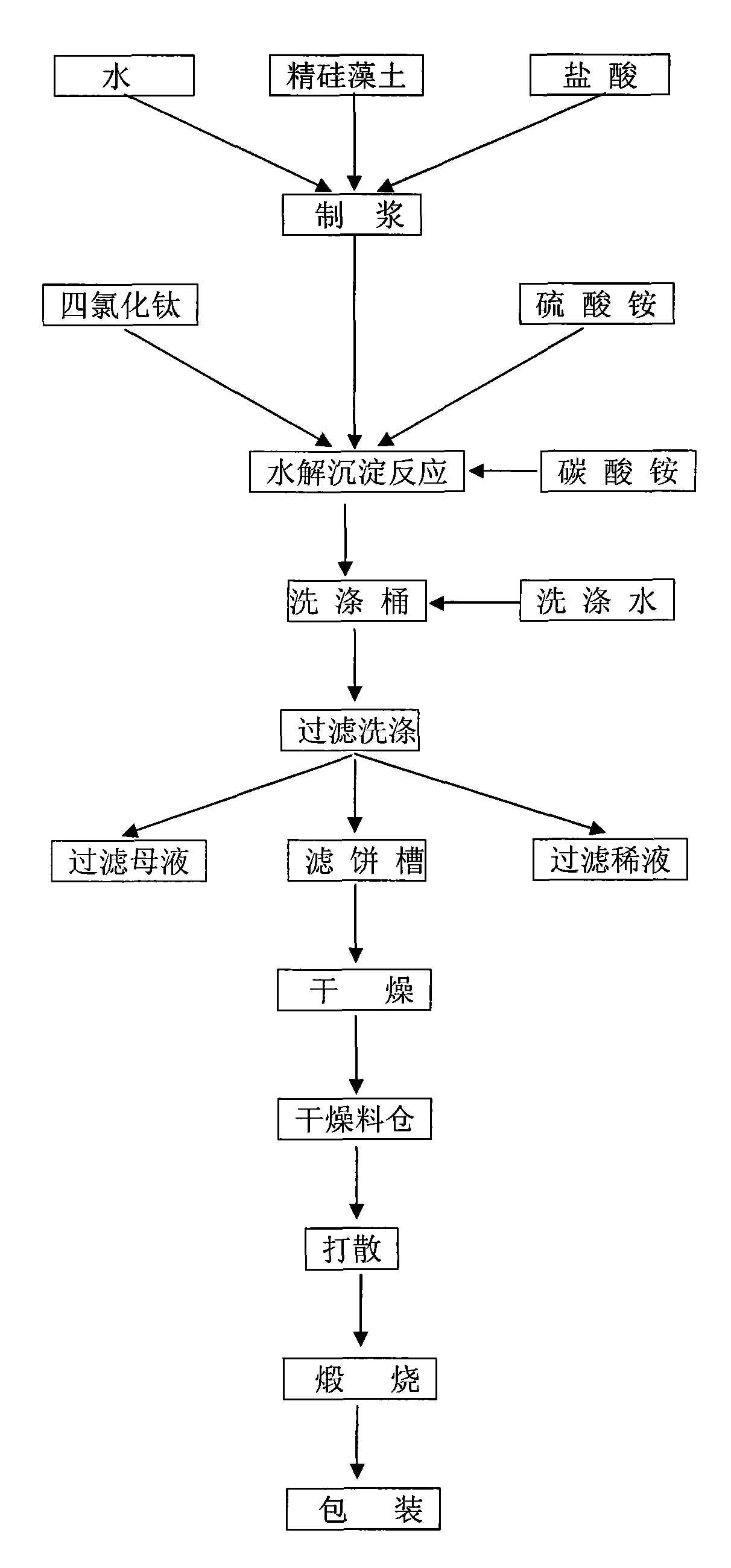

Process for producing nano titanium dioxide/diatomite composite photocatalytic material

ActiveCN101804338AThe preparation process is simpleGood effectOther chemical processesCatalyst activation/preparationAmmonium sulfateTitanium tetrachloride

The invention relates to a process for producing a nano titanium dioxide / diatomite composite photocatalytic material. The process comprises the following steps: purifying a diatomite raw material by using grading and acid-washing processes; synthesizing nano titanium dioxide / diatomite composite particles by adopting a hydrolysis-precipitation method through the purified diatomite serving as a carrier, titanium tetrachloride serving as a precursor and hydrochloric acid, ammonium sulfate and ammonium carbonate serving as aids; and filtering, washing, drying and burning the composite particles to form a finished product. The process can thoroughly remove harmful substances, has quite ideal effect on deep treatment of waste gas, lowers the cost and improves the photocatalytic performance.

Owner:临江市宝健纳米复合材料科技有限公司

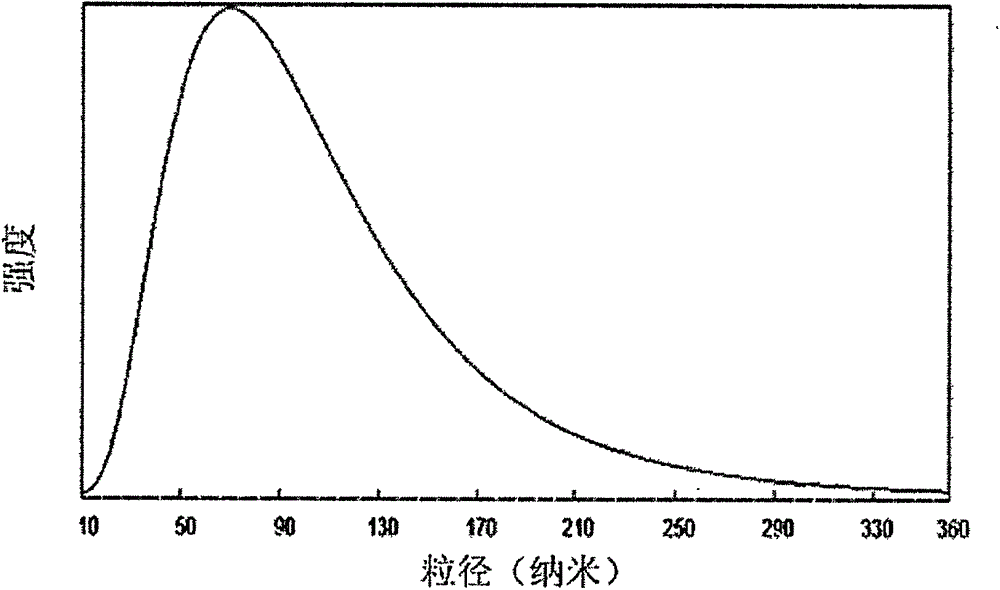

Nano-paste, self-cleaning coating liquid and thermal insulating coating liquid as well as transparent substrates and preparation methods thereof

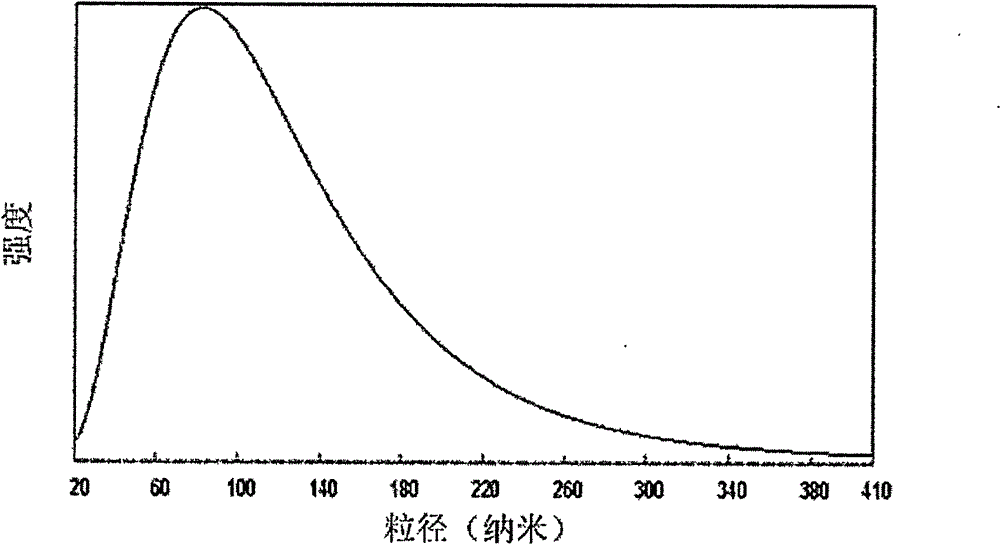

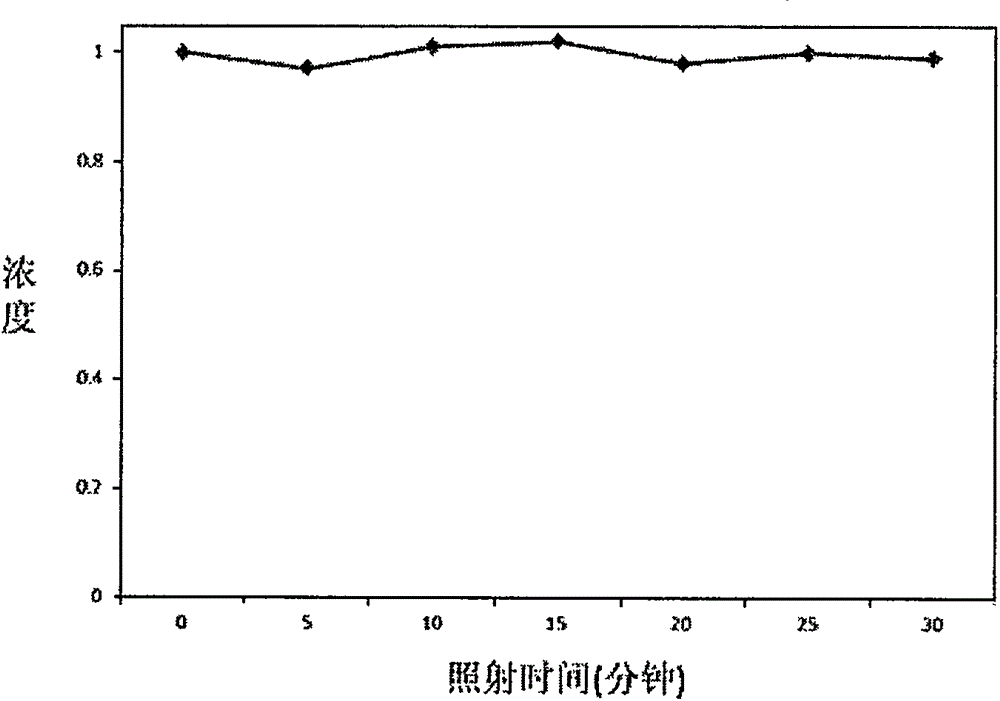

ActiveCN104059420AThe preparation process is simpleWide range of applicationsPolyurea/polyurethane coatingsThermal insulationParticle-size distribution

The invention discloses a nano-paste, a self-cleaning coating liquid and a thermal insulating coating liquid as well as transparent substrates and preparation methods thereof. The formula of the nano-paste comprises the following components in parts by weight: 5-25 parts of nano-powder, 1-25 parts of wetting agent, 1-25 parts of active dispersant and 10-200 parts of dispersion medium, wherein the nano-powder is a photocatalyst powder or a thermal insulating powder; the solid content of the nano-powder is 5-50wt%; the particle size distribution of particles in the nano-paste is 10-200 nanometers. The self-cleaning coating liquid and the thermal insulating coating liquid are obtained by firstly preparing stable nano-photocatalyst paste and nano-thermal insulating paste and then compounding the stable nano-photocatalyst paste and nano-thermal insulating paste with film forming matters such as inorganic sol and organic resin. The coating liquids can be applied to the surfaces of different transparent substrates by use of a plurality of different construction methods, so that transparent materials having double functions of self-cleaning and thermal insulation can be obtained; as a result, large-scale preparation of multifunctional transparent coated materials, such as multifunctional coated glass, is realized.

Owner:张扬 +2

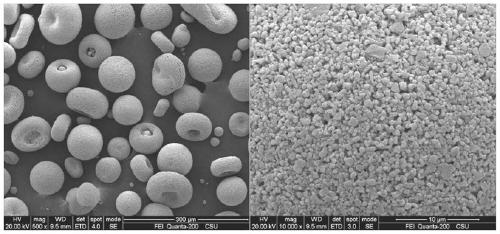

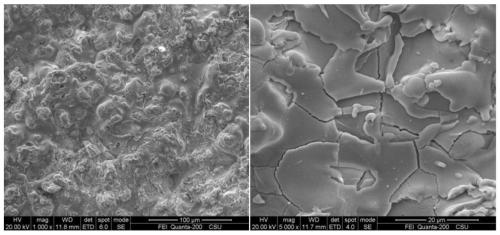

Process for preparing tungsten-copper composite material with fine grain

The invention relates to the field of powder metallurgy technology characterized in that, forming the powder with 200 MPa-500 MPa and feeding into sintering furnace, elevating the temperature to 400-700 deg. C. at the speed of 5-20 deg. C per minutes, heat preserving for 15-120 mins, elevating the temperature to sintering temperature of 1150-1350 deg. C. at the speed of 20-60 deg. C per minutes, heat preserving for 30-120 mins.

Owner:CENT SOUTH UNIV

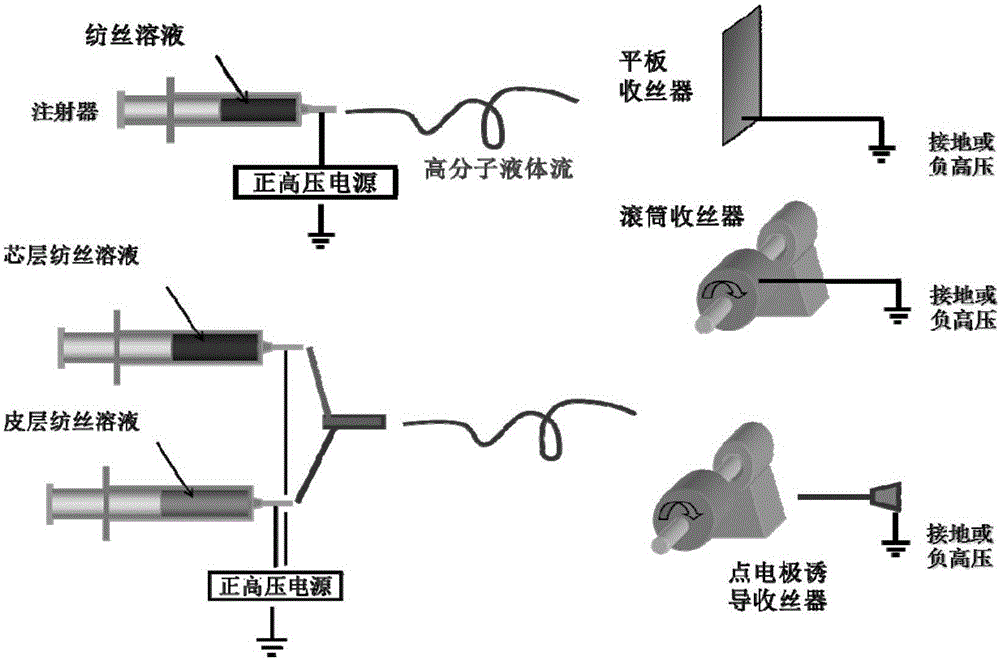

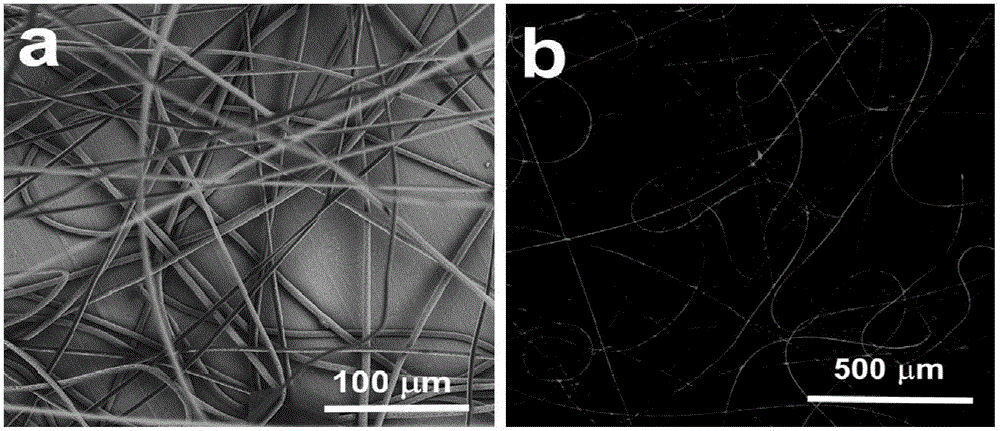

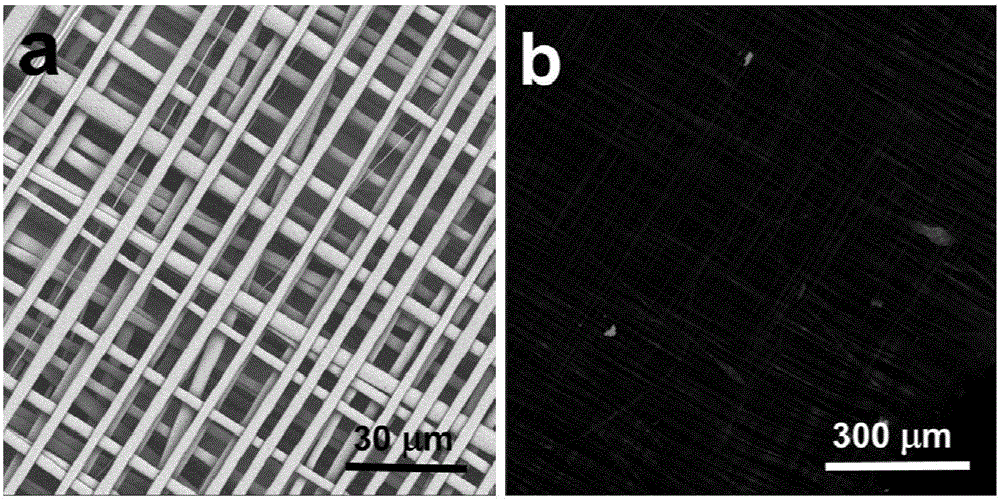

Composite fiber containing aggregation-induced luminescent molecules, preparation method thereof and application thereof

InactiveCN106381555AOvercoming the disadvantages of aggregation-induced fluorescence quenchingEasy for long-term observationOrganic non-active ingredientsElectro-spinningFiberFluorescent staining

The invention belongs to the field of high polymer materials, and discloses a composite fiber containing aggregation-induced luminescent molecules, a preparation method thereof and an application thereof. The preparation method of the composite fiber comprises the steps of adding aggregation-induced luminescent molecules into a high polymer material solution or a solution of a high polymer material and a carrier, uniformly mixing the solution, and preparing the composite fiber through the electrostatic spinning process. The composite fiber containing aggregation-induced luminescent molecules has multiple types of AIE, and is strong in fluorescence intensity. Therefore, the composite fiber can meet the requirements of different fluorescent staining operations. The preparation method provided by the invention is simple, high in production efficiency, and good in repeatability. The composite fiber containing aggregation-induced luminescent molecules can be applied in the fields of cell positioning and imaging, fiber microstructure observation, fiber drug loading and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-strength high-swelling nanocellulose and polyving akohol composite hydrogel

The invention discloses a preparation method of high-strength high-swelling nanocellulose and polyving akohol composite hydrogel. The method comprises the following steps that nanocellulose suspension is added in dimethyl sulfoxide solvent, and magnetic stirring is conducted to prepare mixed dispersion liquid; polyving akohol is added, and magnetic stirring is conducted for 3 h on the condition that the temperature is 95 DEG C; standing is conducted for 30 min at the constant temperature of 60 DEG C, the dispersion liquid is placed at the constant temperature after being frozen at low temperature, and freezing and thawing circulation is conducted for 5-8 times; obtained hydrogel is put in deionized water to swap out the dimethyl sulfoxide solvent in the gel, and the nanocellulose and polyving akohol composite gel is obtained. According to the preparation method of the high-strength high-swelling nanocellulose and polyving akohol composite hydrogel, reactions are physical reactions, and pollution to the environment in the preparation process is extremely low; by means of a mixed solvent system of dimethyl sulfoxide and water, formation of a uniform network structure of the nanocellulose and polyving akohol gel can be effectively facilitated, the formed three-dimensional interpenetrating network structure can effectively improve the strength and the swelling degree of the gel, the dimethyl sulfoxide can be directly swapped out from the gel after the reaction is completed, and the obtained biomass gel is free of toxicity and pollution.

Owner:NANJING FORESTRY UNIV

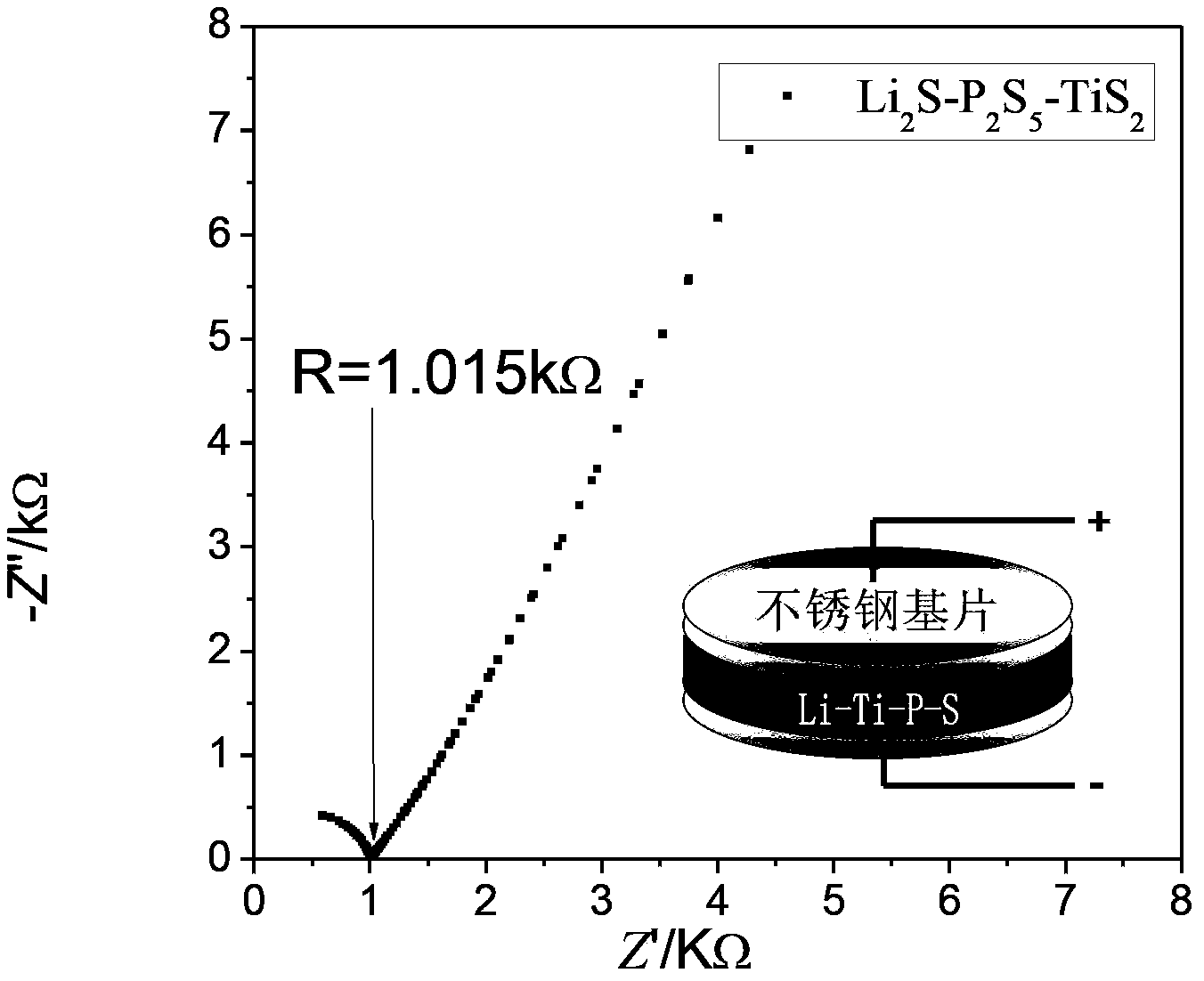

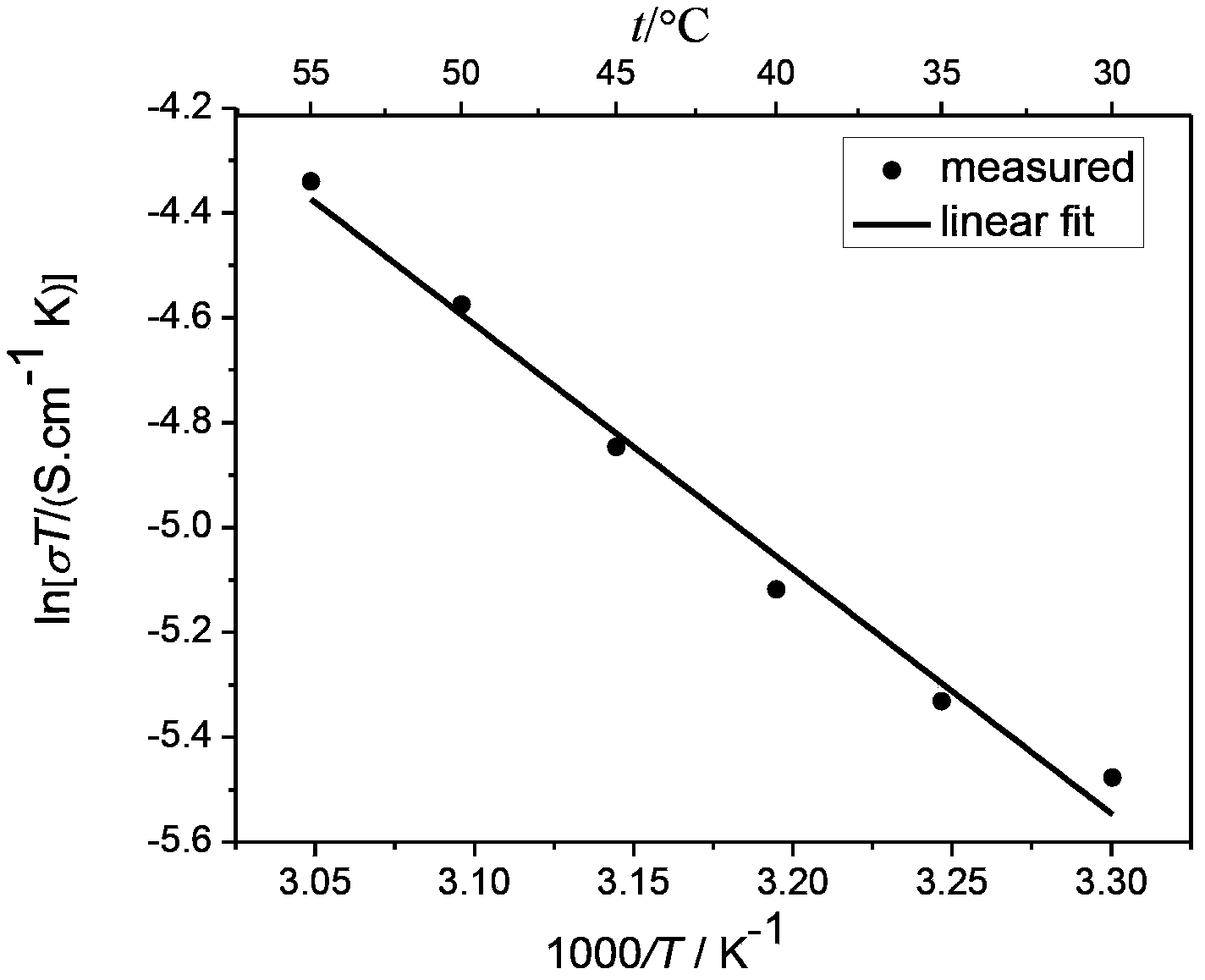

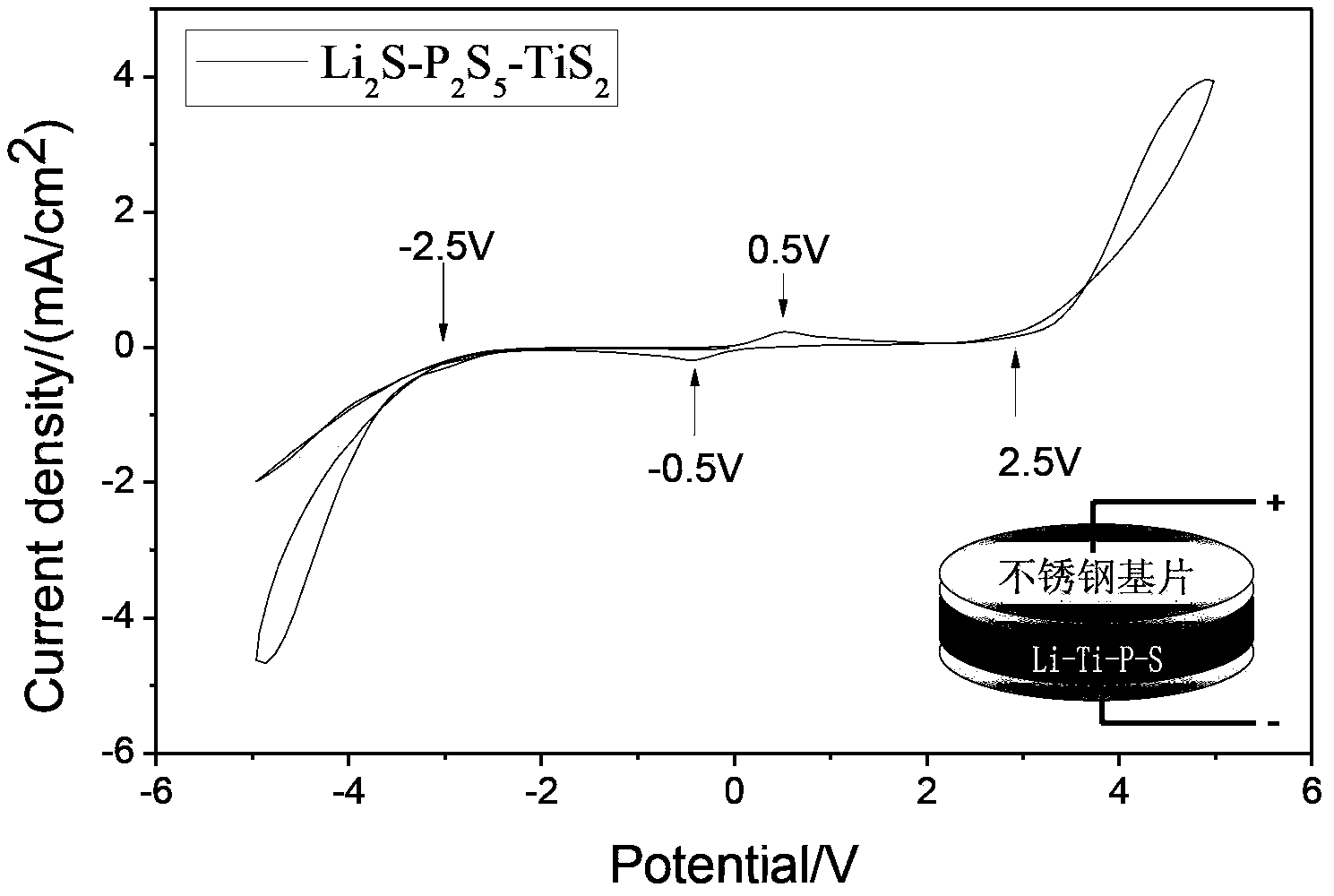

Li2S-P2S5-TiS2 amorphous electrolyte material

ActiveCN103401017AHigh room temperature ionic conductivityThe preparation process is simpleSecondary cellsIonTube furnace

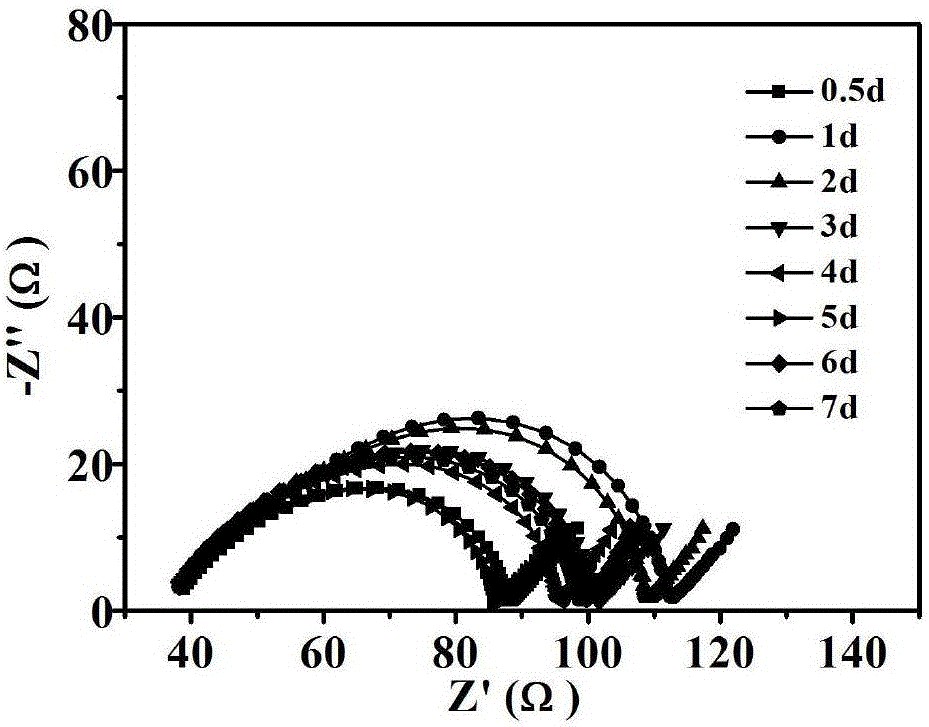

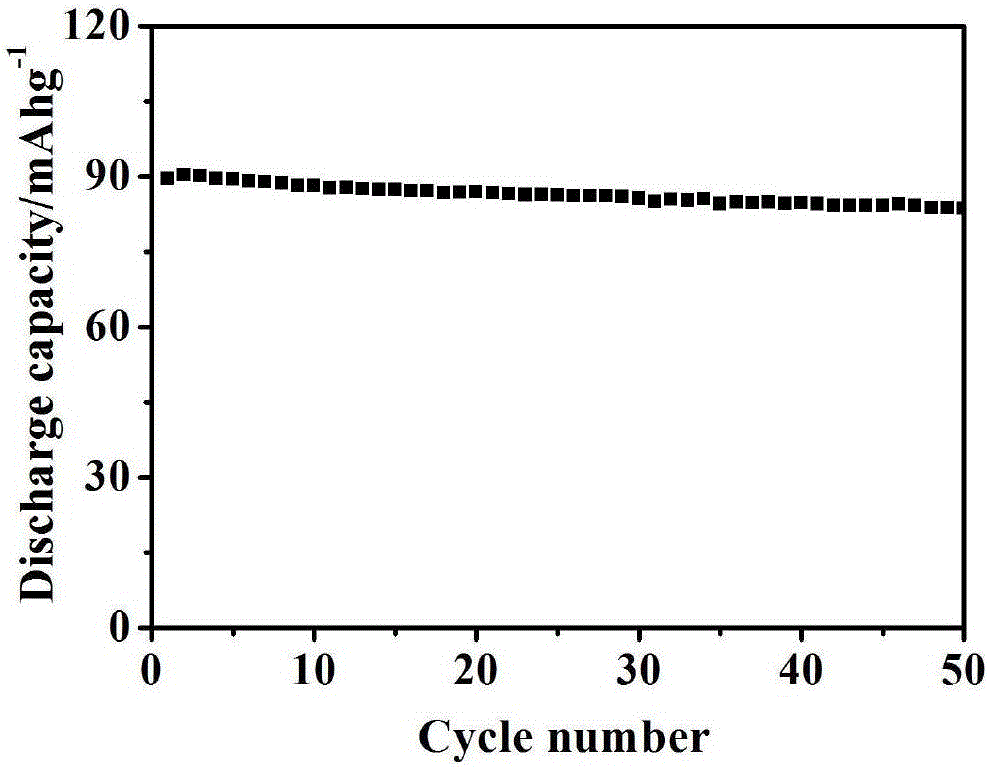

The invention relates to a Li2S-P2S5-TiS2 amorphous electrolyte material with high room-temperature ironic conductivity, and belongs to the field of preparation of lithium ion battery related materials. The Li2S-P2S5-TiS2 amorphous electrolyte material is prepared by application of high-energy ball milling and low-temperature solid-phase reaction, and a preparation method of the Li2S-P2S5-TiS2 amorphous electrolyte material comprises following steps: in a glove box with argon protective atmosphere, three raw materials Li2S, P2S5 and TiS2 are mixed uniformly at a mole ratio of 34:15:1; agate balls are placed in a ball milling tank, and the mixture of the three raw materials is sealed in argon protective atmosphere, and is subjected to high-energy ball milling treatment; samples after ball milling treatment are added into a tube furnace, and is sintered at 300 DEG C for 3h in argon atmosphere so as to obtain the Li2S-P2S5-TiS2 amorphous electrolyte material. The Li2S-P2S5-TiS2 amorphous electrolyte material is prepared by combining high-energy ball milling and low-temperature solid-phase reaction, so that the Li2S-P2S5-TiS2 amorphous electrolyte material possesses relatively high room-temperature ironic conductivity, preparation technologies are simple, and reaction conditions are mild.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

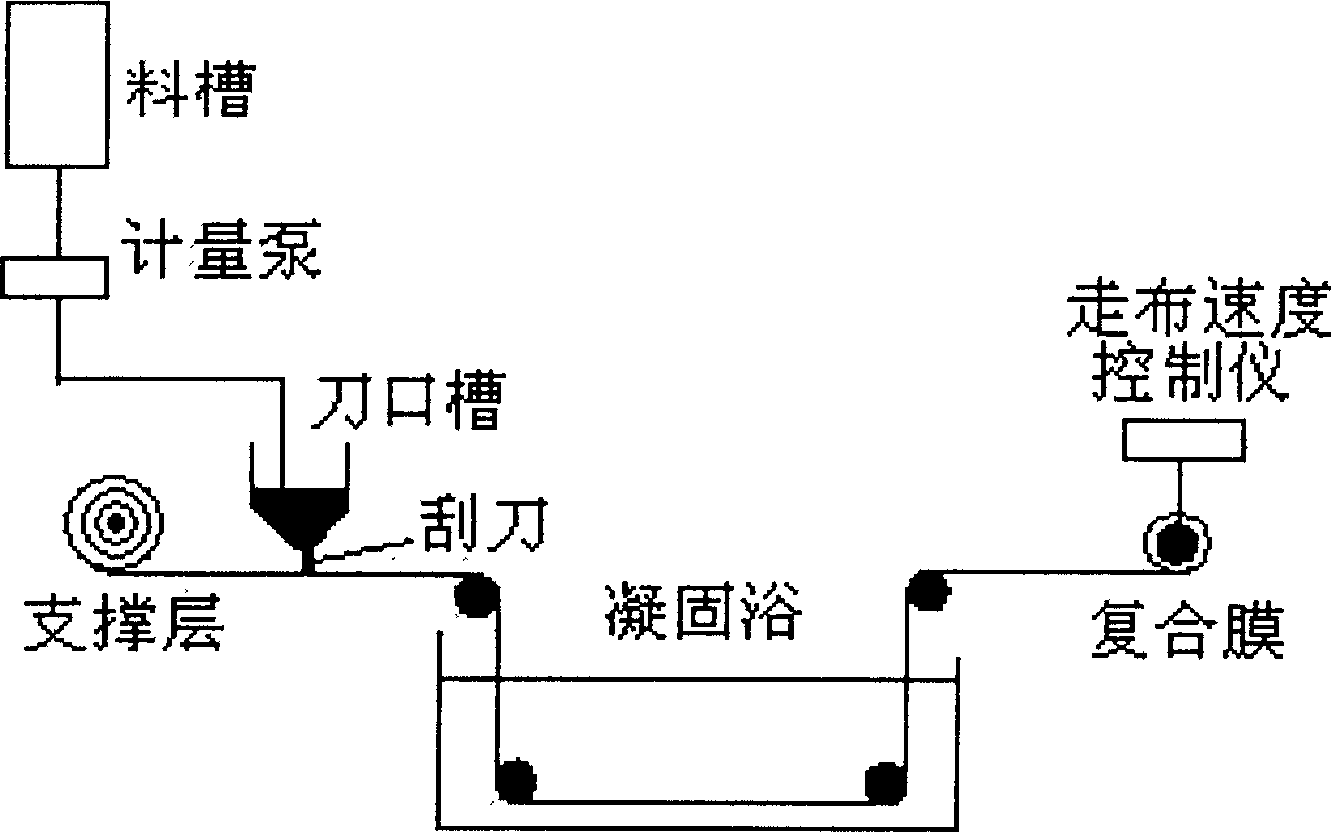

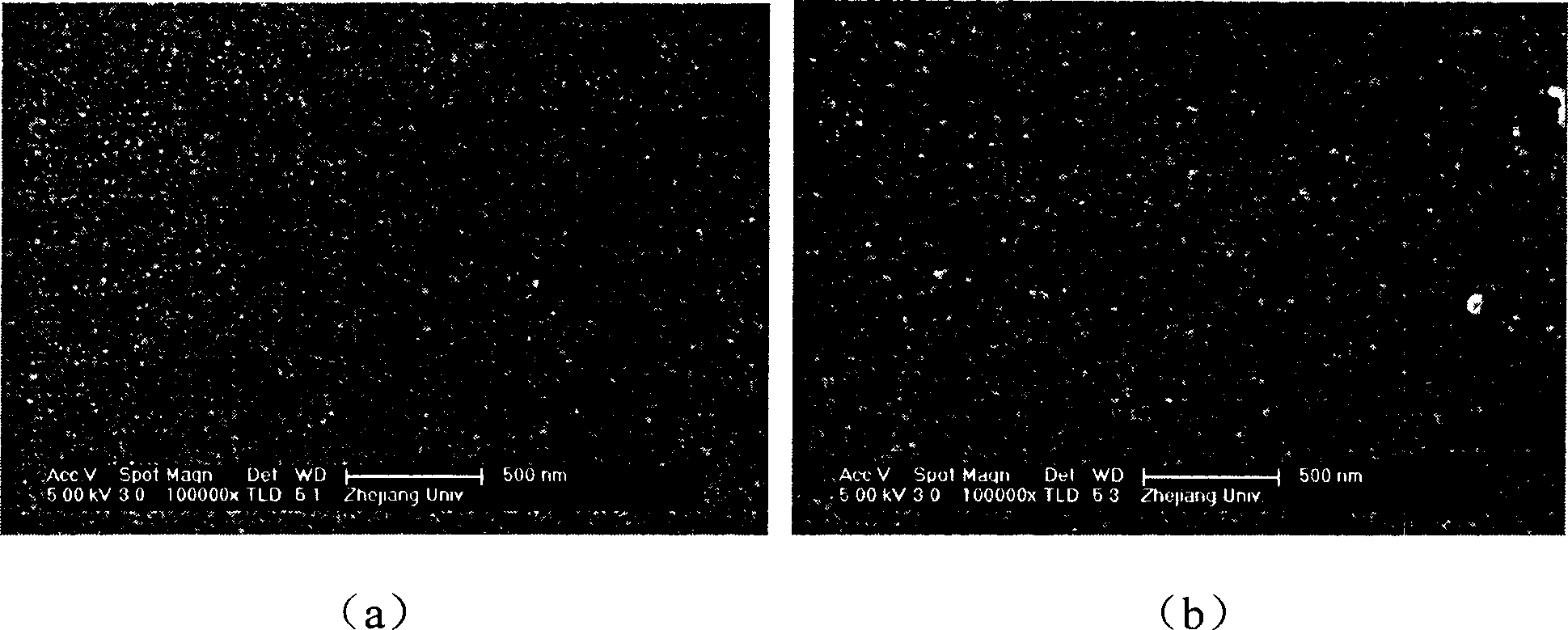

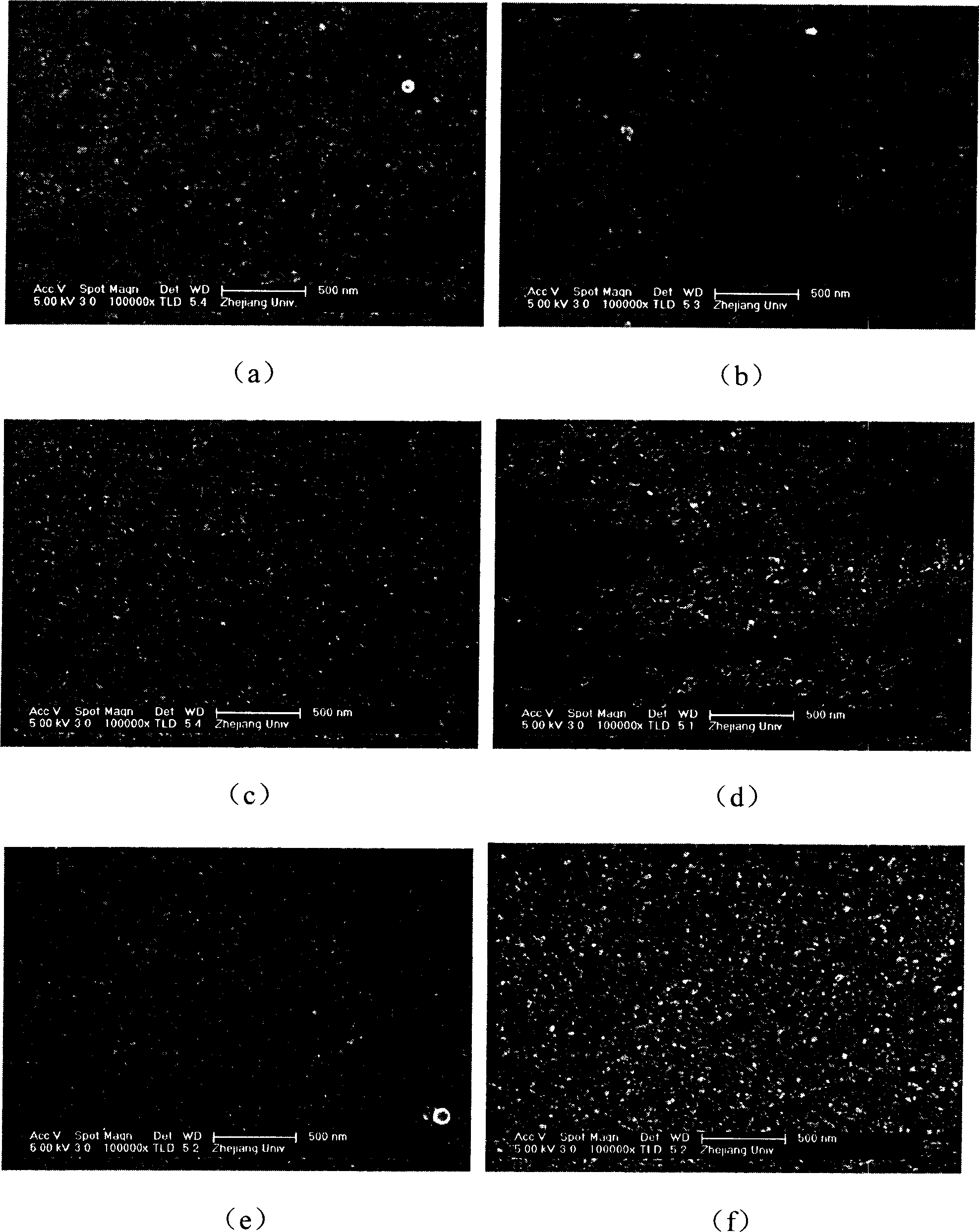

Process for preparing co-mixed polyethersulfone platform complex film

InactiveCN1730141AThe preparation process is simpleGood repeatabilitySemi-permeable membranesFilm-forming agentHigh intensity

The invention discloses a method for preparing slab-shaped complex film made by blending polyethersulfone. Various film-forming agents according to certain proportion are made by blending polymer (polyethersulfone and sulfonated polyethersulfone), additive, non-solvent and organic solvent. Complex film is prepared on traditional shearing machine via pouring film-forming agents into loading chute, entering knife-edge groove, covering solution on supporting layer and dipping it into coagulating bath. The invention is characterized in that mainly via adjusting composition of film-forming agents, it prepares slab-shaped complex film with high intensity, high water flux and good hydrophilicity.

Owner:ZHEJIANG UNIV

Composite solid-state polymer electrolyte and all-solid-state lithium battery

ActiveCN106654363AImprove electrochemical stabilityExcellent charge and discharge characteristicsSolid electrolytesSecondary cellsMicro nanoAll solid state

The invention discloses a composite solid-state polymer electrolyte and an all-solid-state lithium battery. The composite solid-state polymer electrolyte comprises organic micro-nano porous granules, a polymer having lithium ion conducting capability and a lithium salt; the composite solid-state polymer electrolyte takes the organic micro-nano porous granules as filler; and natural compatibility exists between the organic filler and the polymer matrix. The composite solid-state polymer electrolyte disclosed by the invention has high electrochemical window (4.2-5V), excellent interface stability with a lithium-based negative electrode material, and low interface impedance. The all-solid-state lithium battery, assembled by the composite solid-state polymer electrolyte disclosed by the invention, is high in cycling performance and rate capability.

Owner:UNIV OF SCI & TECH BEIJING

Regular structure adsorbent and application thereof

ActiveCN106669636AThe preparation process is simpleLow cost of preparationOther chemical processesDispersed particle separationSolventChemistry

The invention discloses a regular structure adsorbent and a preparation method to greatly improve the diffusion efficiency of the adsorbent. The regular structure adsorbent is prepared from a support, an adsorbent material, a binder and other additives. The fibrous support, the powdery adsorbent material, the binder and other additives are mixed and dispersed in a solvent, a catalyst precursor is prepared firstly and then dried and activated to form the adsorbent. The regular structure adsorbent is applicable to purification separation processes of multiple gases, such as air separation, hydrogen separation, carbon dioxide separation, methane separation and the like, and the synthesis method is simple, good in repeatability and prone to industrialization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

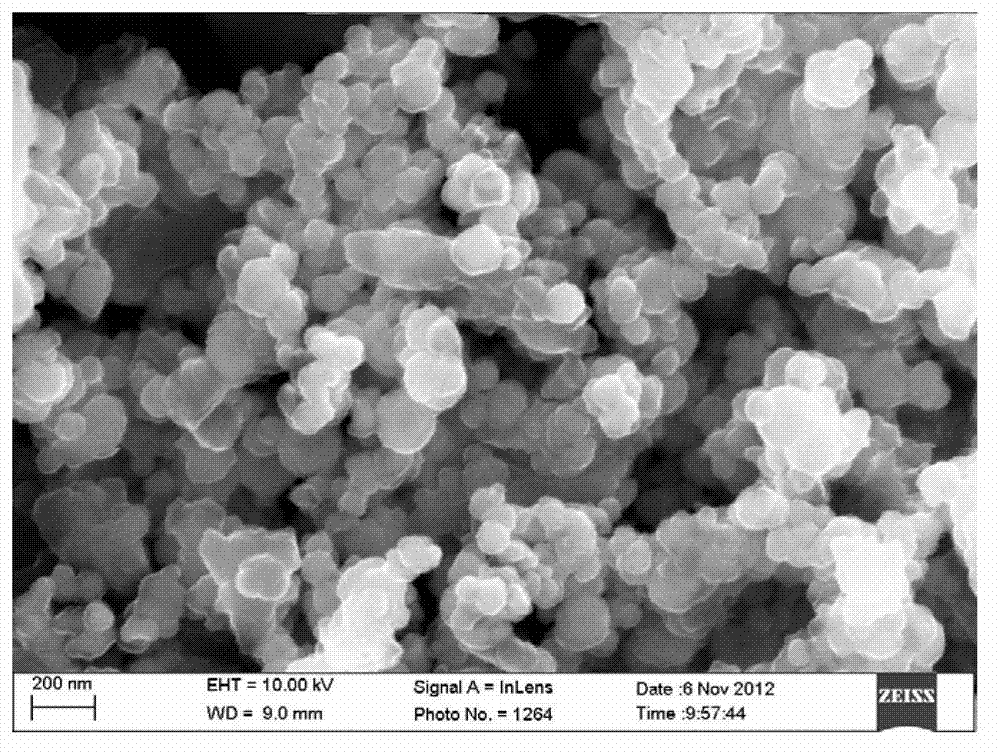

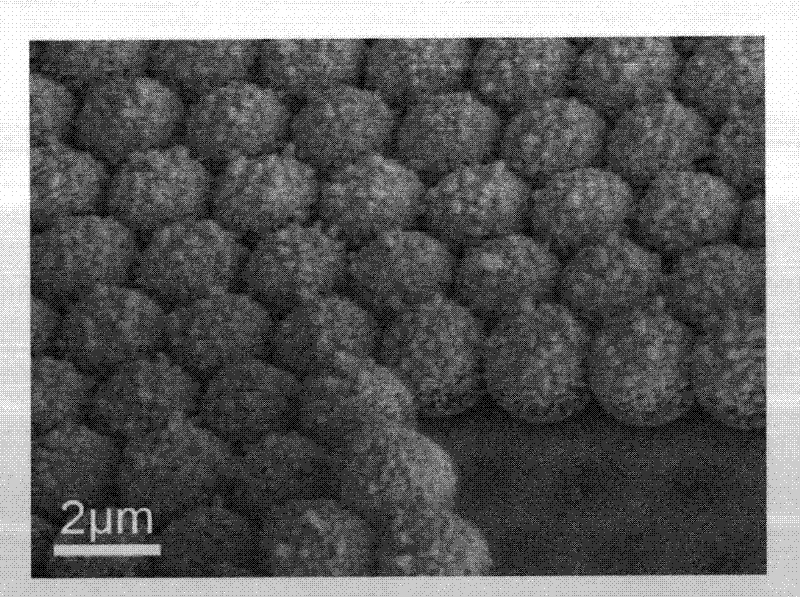

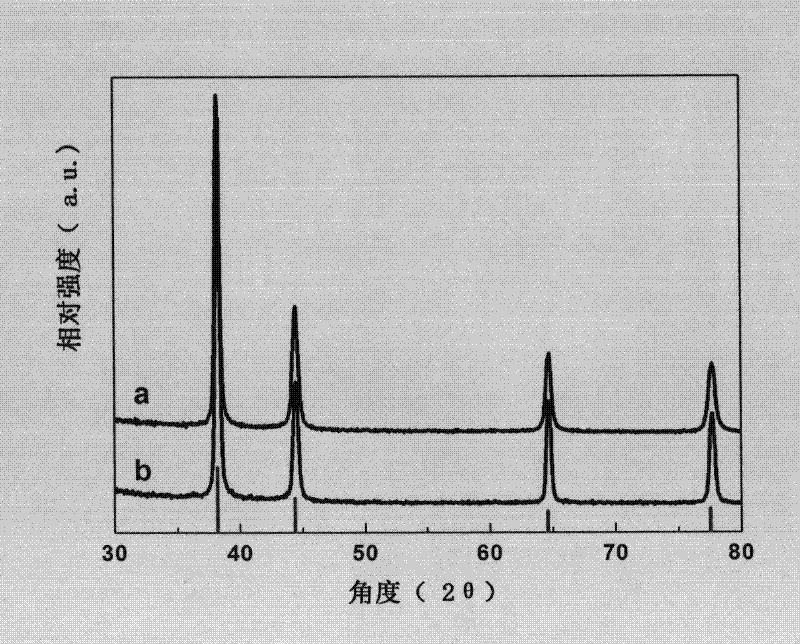

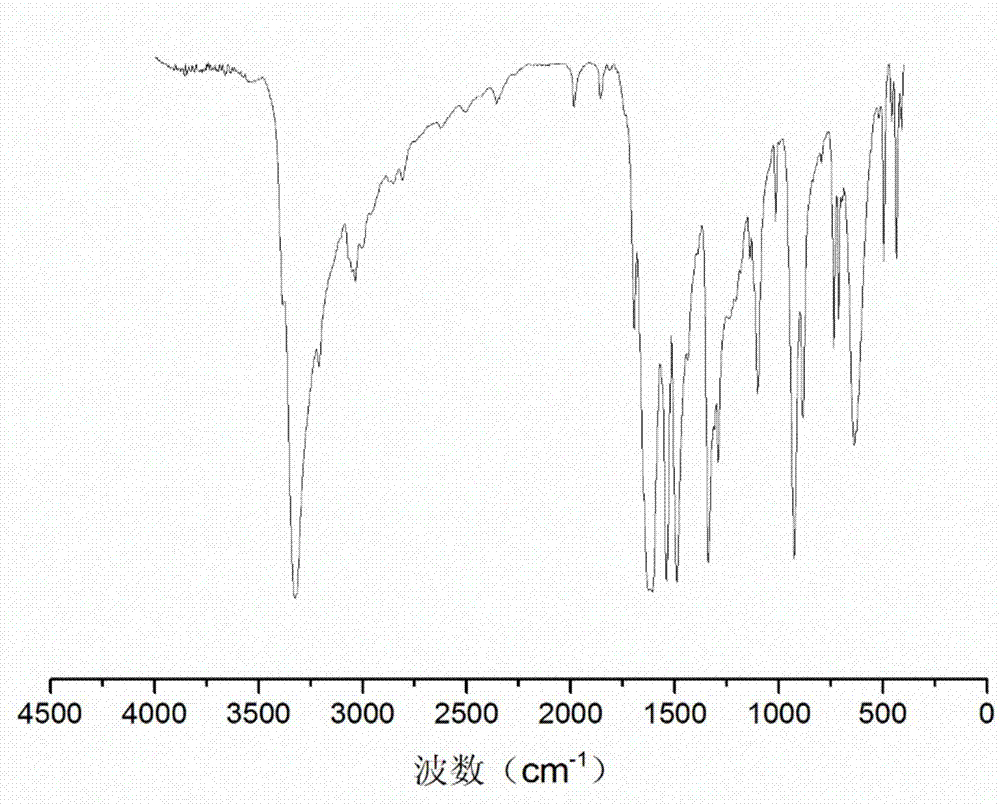

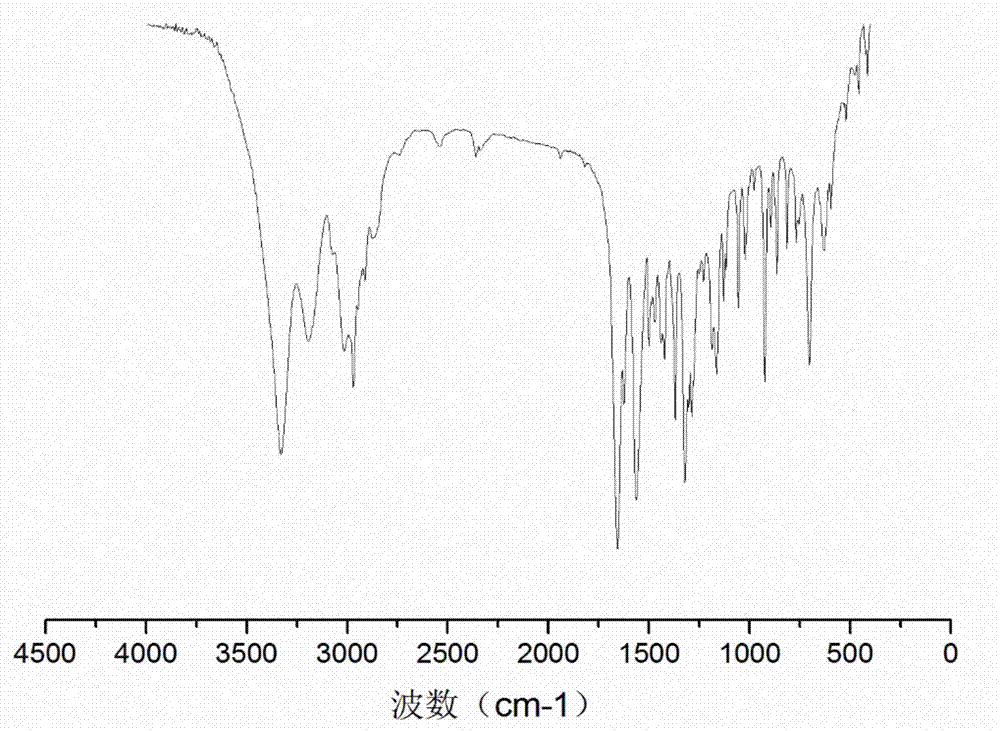

Preparation method of ferroferric-oxide-based high-performance negative electrode material for lithium ion battery

ActiveCN103208625AThe preparation process is simpleMild reaction conditionsCell electrodesFerriferrous OxideLithium electrode

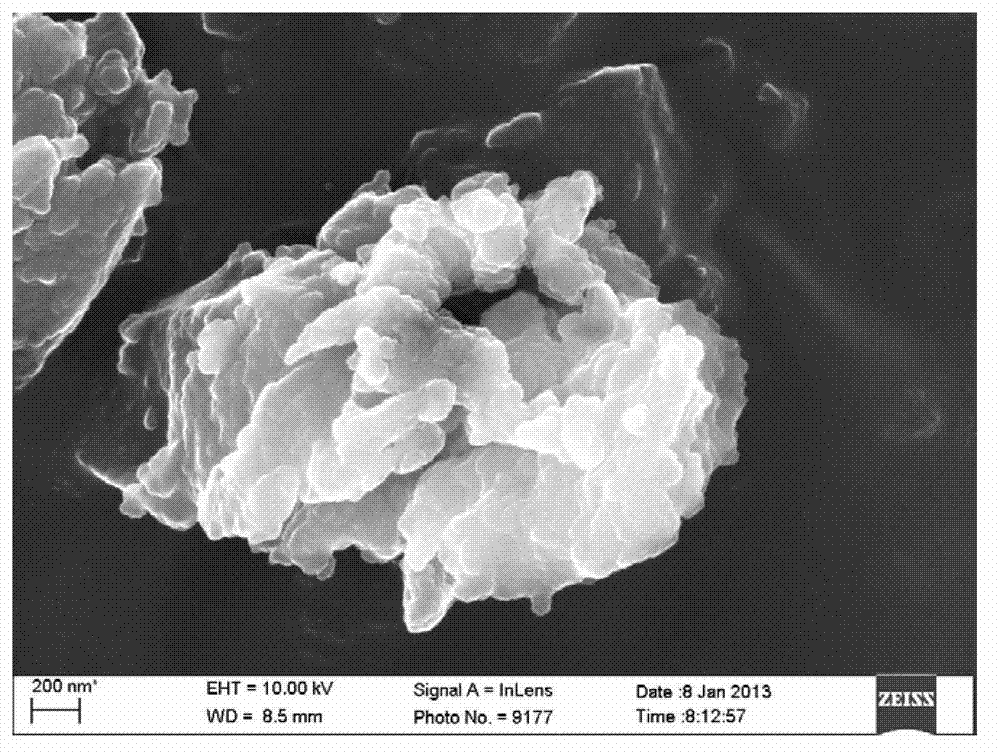

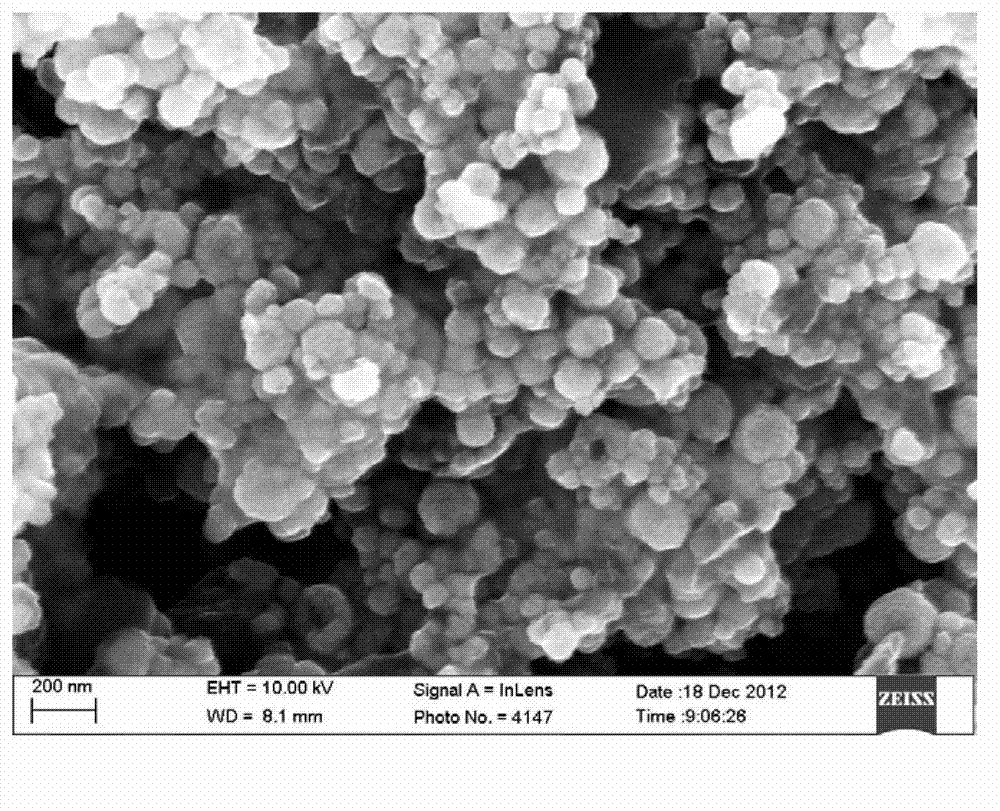

The invention discloses a preparation method of ferroferric oxide / carbon composite negative electrode material for a lithium ion battery, and belongs to the field of new energy resources and electrochemistry. According to the invention, a Fe3O4 / C composite negative electrode material with a nano porous structure is prepared by taking inorganic iron salt as an iron source, taking a carbon matrix as a carrier, and adopting a solvothermal method. The carbon matrix is directly introduced into reaction liquid, transformation of the spherical structure of carbon particles occurs in the solvothermal process, and active substances of nano iron oxide are absorbed on the surfaces of the porous carbon particles so as to form the Fe3O4 / C composite negative electrode material with an embedding structure; the carbon matrix is used for fixing the nano iron oxide particles to improve the structural stability of the electrode on one hand, and forms a conducting network to be beneficial to fast transmission of electrons on the other hand, so that the polarization of the electrode is reduced and the rate capability of the electrode is improved. The ferroferric oxide / carbon composite negative electrode material synthesized according to the invention has the advantages that the particle powder is fine and is distributed uniformly, the preparation process is simple, the condition is mild, the cost is low and the electrochemical performance is excellent.

Owner:加道材料科技嘉兴有限公司

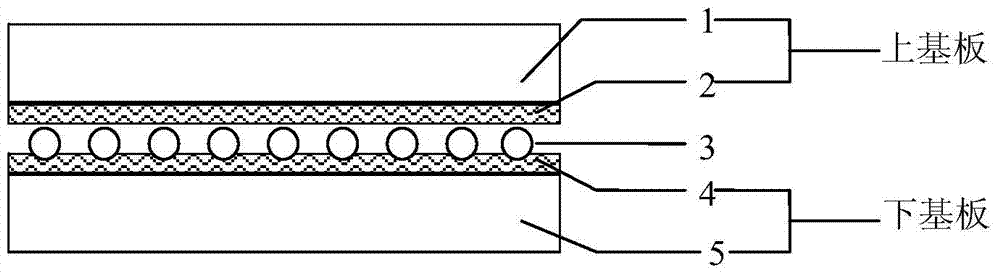

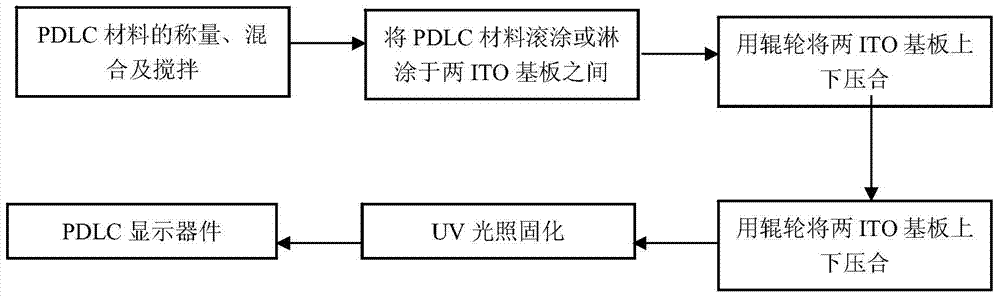

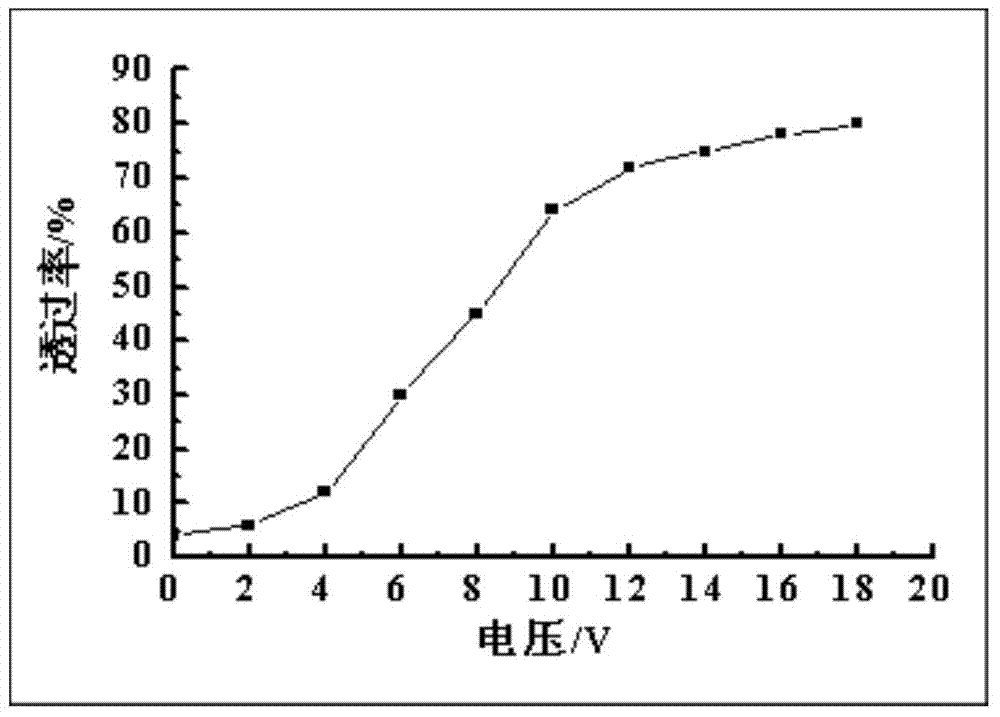

Polymer dispersed liquid crystal material, display apparatus containing same and preparation method thereof

ActiveCN103614146AExtensive sources of raw materialsThe preparation process is simpleLiquid crystal compositionsNon-linear opticsPhotoinitiatorOperating temperature range

The invention relates to a polymer dispersed liquid crystal (PDLC) material which is low in voltage and wide in temperature mode, wherein the material consists of a liquid crystal material, an aliphatic polyurethane acrylate oligomer, an acrylate monomer, a photoinitiator and interstitials. The invention further provides a polymer dispersed liquid crystal display apparatus prepared by using the polymer dispersed liquid crystal material and a preparation method thereof. The polymer dispersed liquid crystal material provided by the invention has the advantages of wide raw material source and simple and convenient preparation process. The PDLC display apparatus prepared from the PDLC material has the advantages of low driving voltage, wide range of working temperature, no shrinkage and deformation and good adhesive force. The preparation method of the PDLC display apparatus is simple and convenient, the thickness of the display apparatus can be adjusted according to size of the interstitials added, and the display apparatus obtained is good in adhesive force and not easy to shrink and deform, so that the PDLC display apparatus with a large area can be probably prepared.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

High-temperature-resistant radar and infrared compatible stealth coating and preparation method thereof

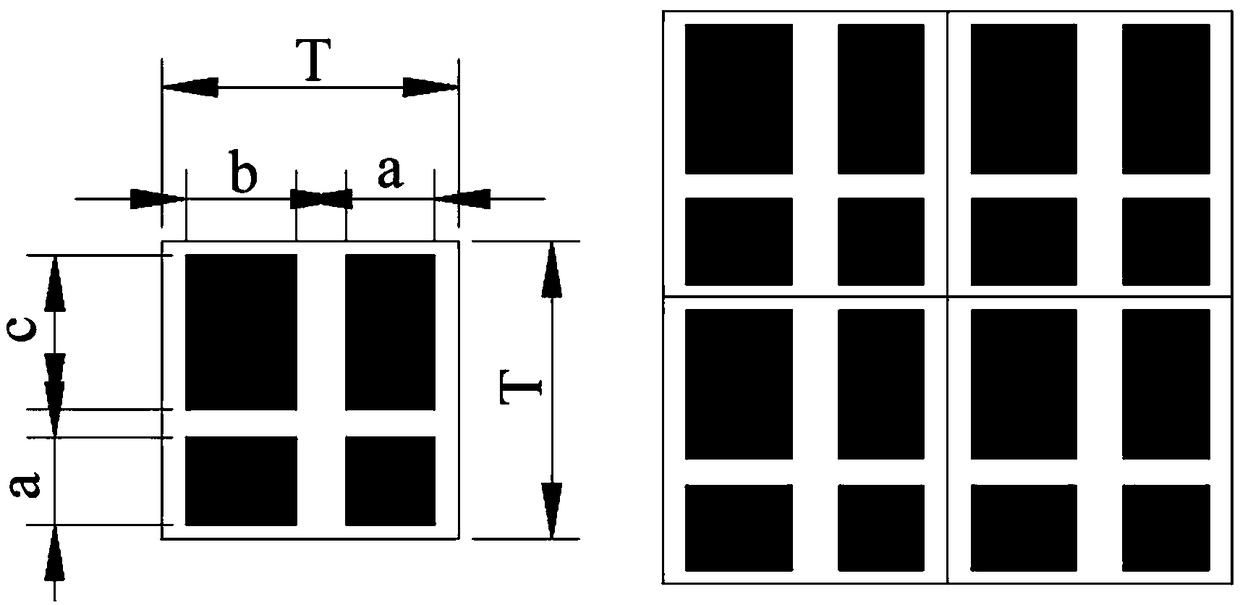

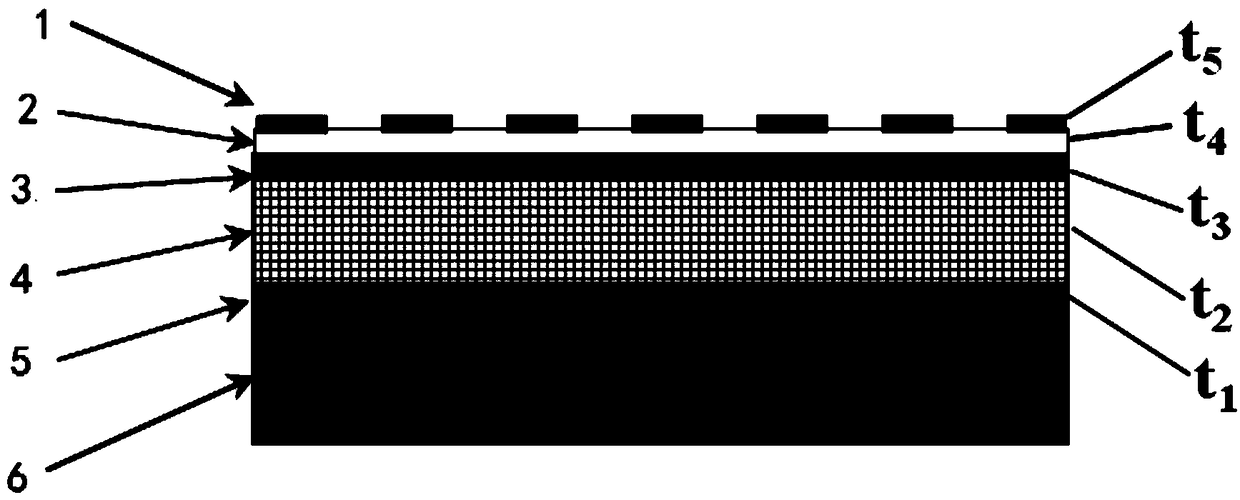

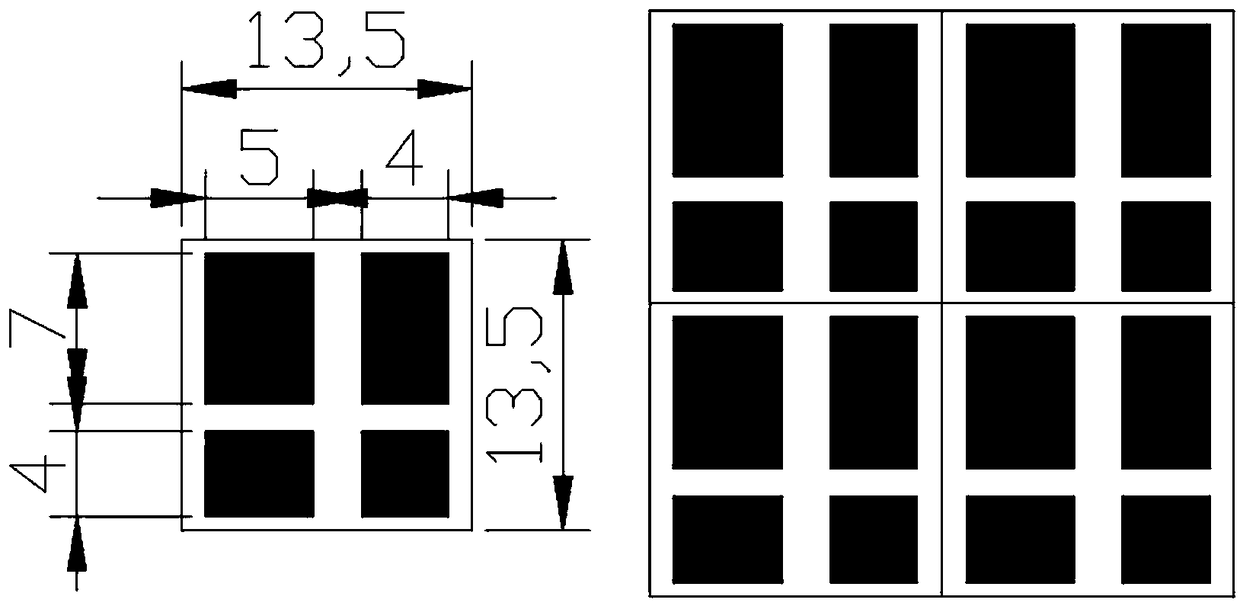

ActiveCN108212722ARealize integrationThe overall thickness is thinPretreated surfacesCoatingsLayered structureTemperature resistance

The invention relates to a high-temperature-resistant radar and infrared compatible stealth coating and a preparation method thereof. The high-temperature-resistant radar and infrared compatible stealth coating is of a layered structure, and sequentially comprises a metal bonding layer, a ceramic wave absorbing layer, a chip resistance type high-temperature periodic structure layer, a ceramic isolation layer and an infrared low-emissivity frequency selective surface layer from inside to outside; and the chip resistance type high-temperature periodic structure layer is a high-temperature resistance coating which is arranged in a periodic characteristic mode, and the infrared low-emissivity frequency selective surface layer is a high-temperature conductor coating which is arranged in a periodic characteristic mode. According to the radar and infrared compatible stealth coating, integration of the radar stealth function and the infrared stealth function is effectively achieved, the coating has both the radar stealth effect and the infrared stealth effect, and the defects that a traditional radar stealth coating cannot be compatible with the infrared stealth function, and the wave absorbing performance is not ideal are overcome; and the preparation method is simple and relatively mature, and is easy for large-scale production and application.

Owner:NAT UNIV OF DEFENSE TECH

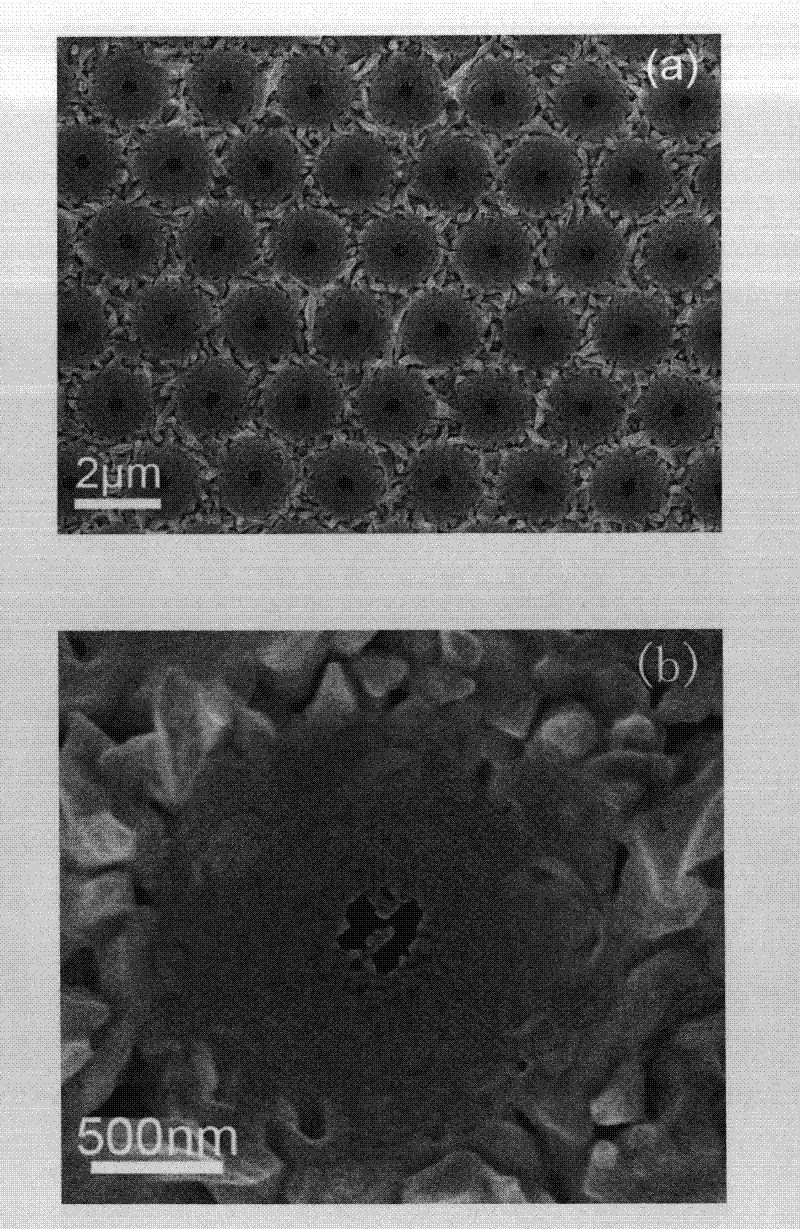

Gold micro-nano composite structure array and preparation method thereof

InactiveCN102674236AEliminate interfering peaksThe preparation process is simpleDecorative surface effectsCoupling light guidesGold filmMicrometer

The invention discloses a gold micro-nano composite structure array and a preparation method thereof. The array is a gold bowl array or a gold hollow sphere array disposed above a gold film covered on a substrate, wherein the diameter of a gold bow opening is from 500 nanometers to 10 micrometers, a bowl wall is composed of gold rods, the lengths of the gold rods are 100-1000 nanometers, the diameters of the gold rods are 50-400 nanometers, the inner diameter of a gold hollow sphere is from 500 nanometers to 10 micrometers, a sphere casing is composed of gold particles with diameters of 50-600 nanometers, and the thickness of the gold film is 5-25 nanometers. The preparation method includes sputtering a layer of the gold film on the substrate, placing a single layer colloidal crystal template which is composed of polystyrene colloidal spheres with diameters from 500 nanometers to 10 micrometers on the substrate which is covered with the gold film, then placing the substrate covered with the gold film and the colloidal crystal template into a chloroauric acid solution with concentration of 0.3-0.7g / L, using the solution with the substrate as a working electrode, subjecting the mixture to electro-deposition for 2-8 hours under the deposition electric current density of 0.03-0.05mA / cm<2> or 0.15-0.45mA / cm<2> to obtain a complex array, and placing the complex array in a dichloromethane solution for to removing the polystyrene colloidal spheres to obtain target products. The gold micro-nano composite structure array can be used as a surface enhanced raman scattering active substrate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

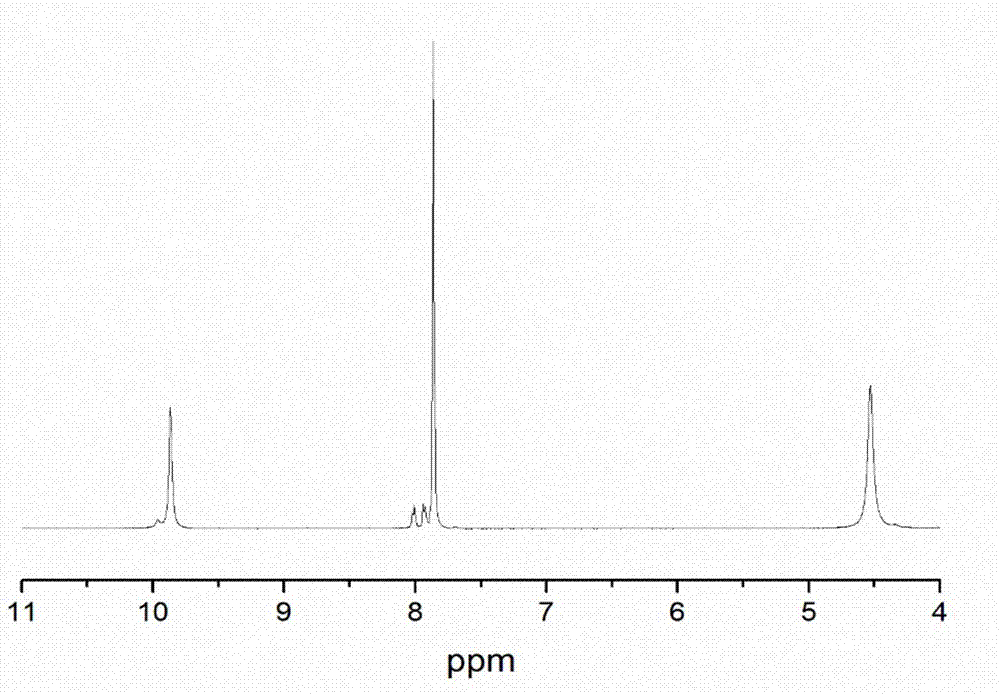

Aromatic terminal hydroxyl chain extender containing acylhydrazone bond, self-repairing polyurethane and preparation method thereof

ActiveCN107236106AEasy to prepareStrong performance controllabilityHydrazone preparationAlcoholRoom temperature

On the basis of the current situation of self-repairing polyurethane materials, the invention provides an aromatic terminal hydroxyl chain extender containing an acylhydrazone bond, self-repairing polyurethane prepared by using the aromatic terminal hydroxyl chain extender and a preparation method of the self-repairing polyurethane. Compared with dihydric alcohol containing an acylhydrazone bond, the aromatic terminal hydroxyl chain extender containing the acylhydrazone bond has the advantages that the molecular structure of the aromatic terminal hydroxyl chain extender has the large pi bond of a hydrazide benzene ring and the pi-pi conjugative effect of the pi bond of carbon-oxygen double bonds, and accordingly the chain extender is stable in structure. The prepared self-repairing polyurethane has the advantages that the molecular chain of the polyurethane contains the reversible acylhydrazone bond, can achieve self-repairing under room temperature, and is high in repairing efficiency and good in mechanical performance. The preparation of the self-repairing polyurethane has the advantages that the method is simple, raw materials are products which are commercially produced, and the prepared polyurethane is high in performance controllability and promising in application prospect.

Owner:QINGDAO UNIV OF SCI & TECH +1

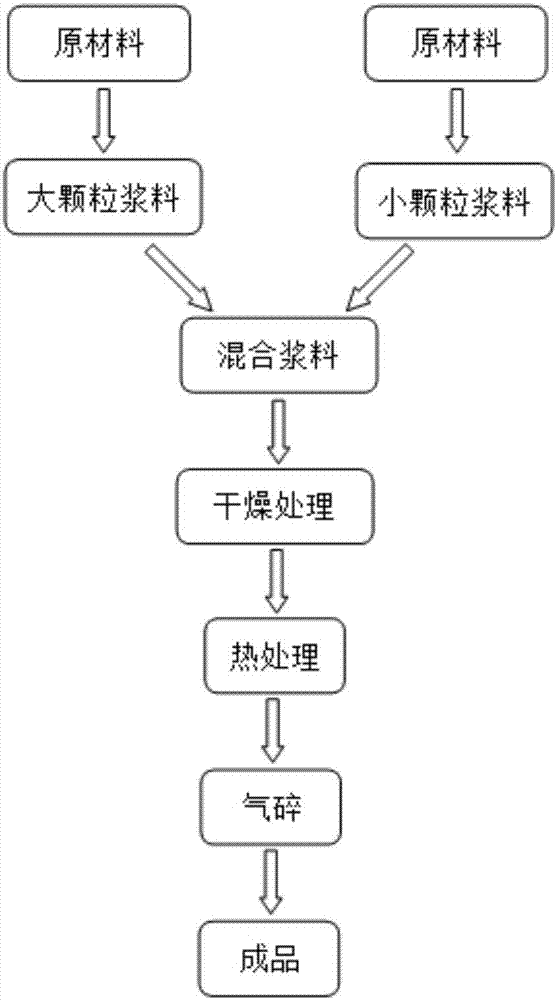

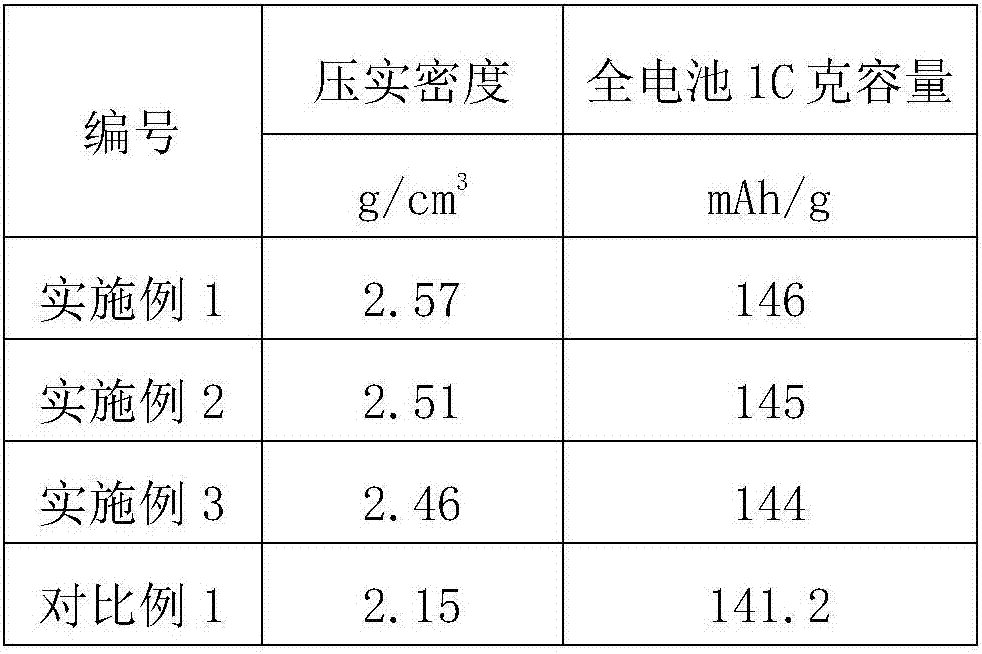

High-compaction-density lithium iron phosphate anode material and preparation method thereof

InactiveCN108011104AHigh densityThe preparation process is simpleCell electrodesSecondary cellsAutomatic controlSizing

The invention discloses a high-compaction-density lithium iron phosphate anode material and a preparation method thereof. Sizing agents of two different particles are selected, the large-particle sizing agent and the small-particle sizing agent are mixed according to a certain ratio in the grinding stage, then, drying treatment and thermal treatment are performed to obtain high-compaction-densitylithium iron phosphate, the obtained lithium iron phosphate is large in density, the preparation technological process is simple, the cost is low, the material can be applied to industrial mass production, automatic control is achieved, the finished lithium iron phosphate is good in performance, resources are saved, and the production efficiency is improved.

Owner:桑顿新能源科技(长沙)有限公司

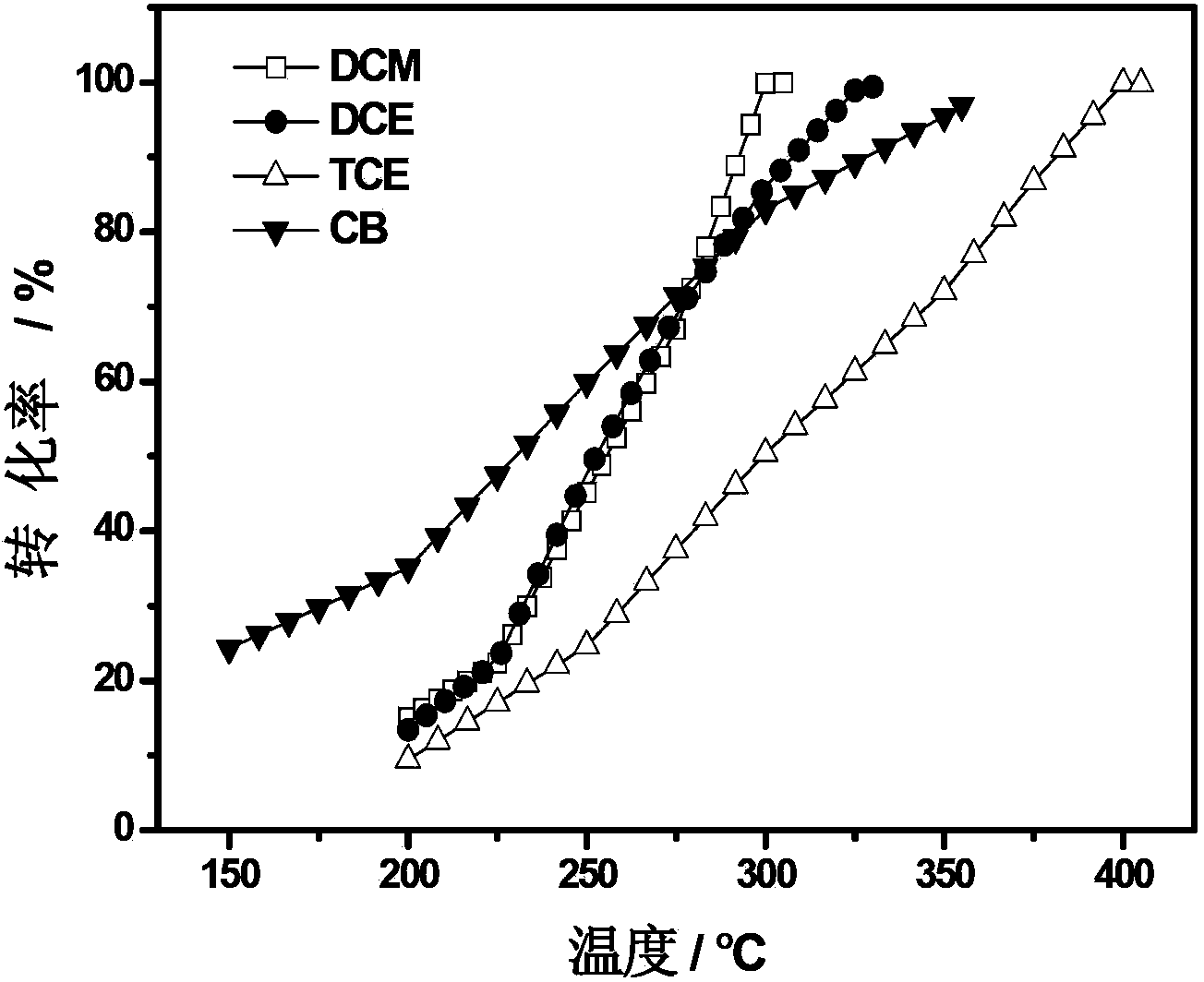

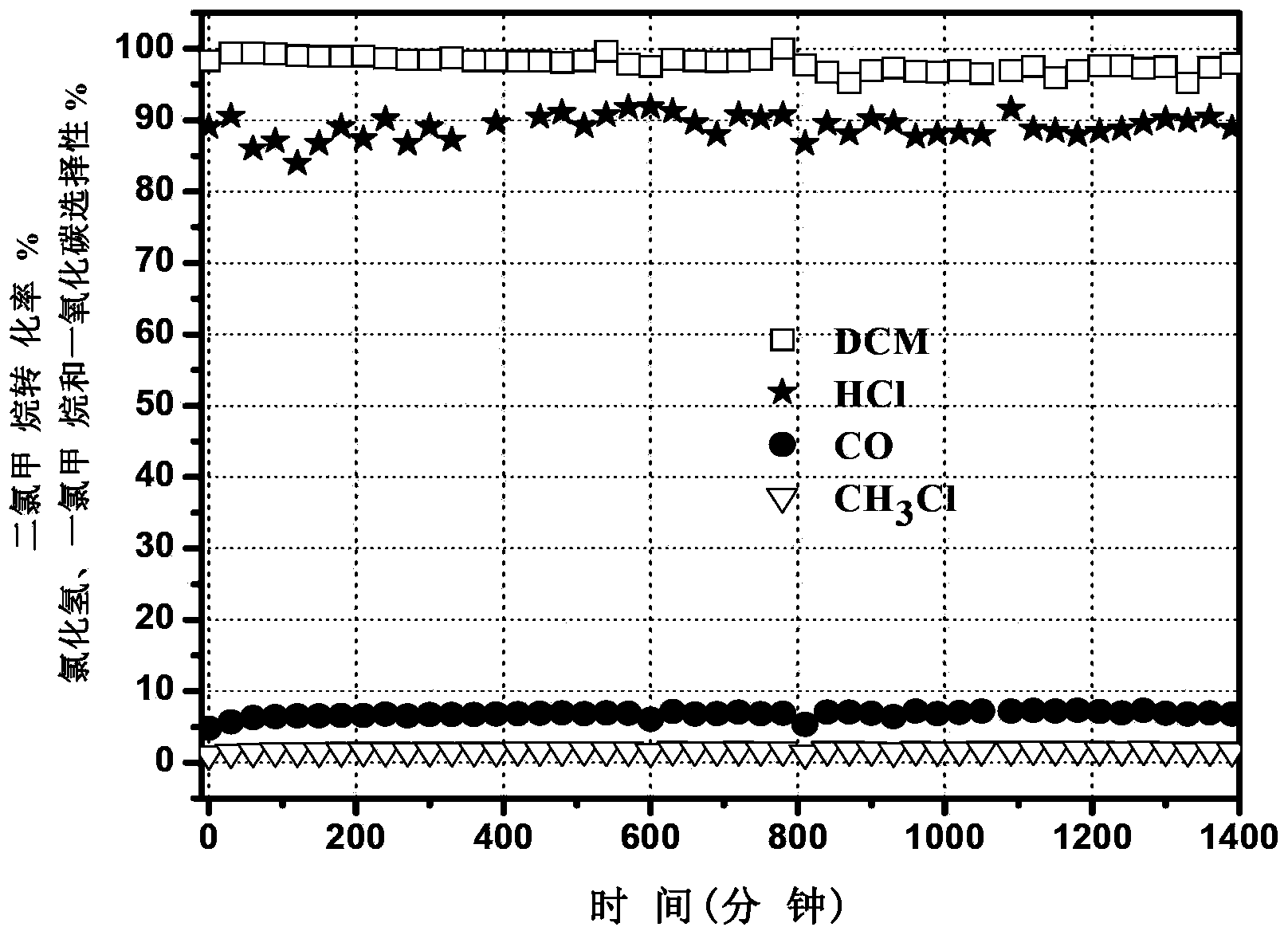

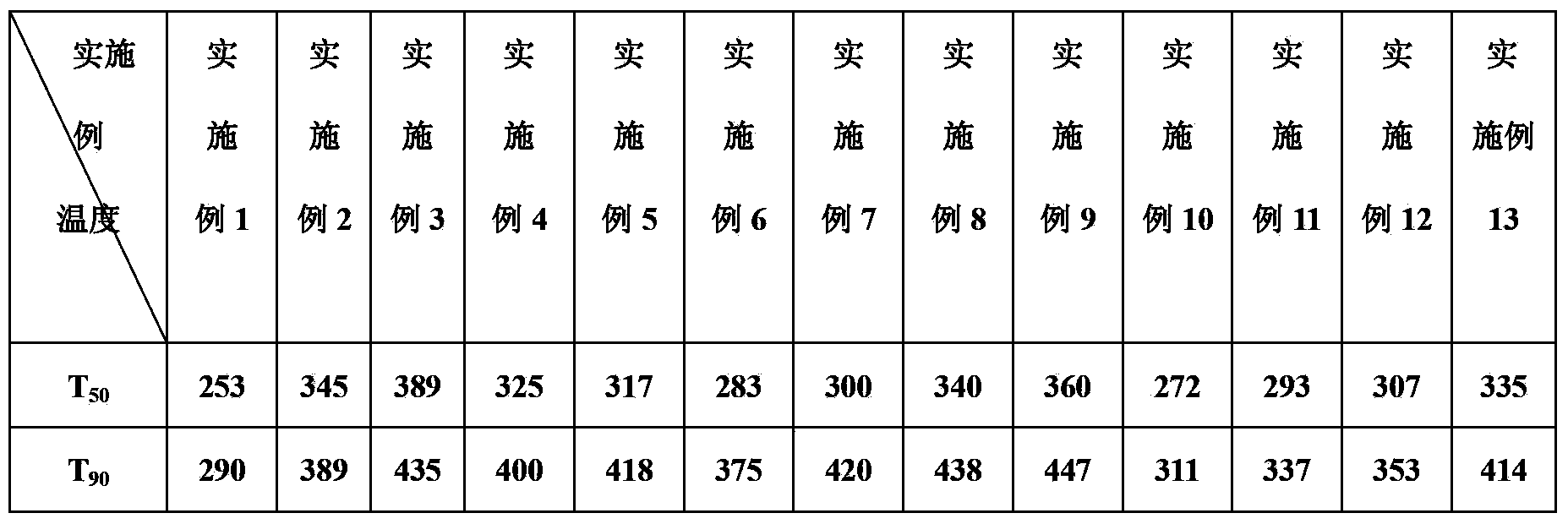

Catalyst for catalytic combustion of chlorine-containing organic waste gas

ActiveCN103357415ALow costThe preparation process is simpleIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsNickel oxidesOxide

The invention discloses a catalyst for catalytic combustion of chlorine-containing organic waste gas. The catalyst consists of a carrier and an active ingredient loaded on the carrier, wherein the carrier is TiO2, Al2O3, ZrO2 or SiO2, and the active ingredient is composed of nickel oxide and an active auxiliary; the active auxiliary is oxide of one or more then one element of copper, manganese, cerium, iron, chrome and vanadium; the mass of all metallic elements in the active ingredient is 5-40 wt% of the mass of the carrier, preferably 10%, and the mass ratio of the total metallic elements in the active auxiliary to Ni is 1.0: (1.0-5.0). Furthermore, the invention discloses a preparation method of the catalyst. The elements of the active ingredient of the catalyst provided by the invention are transition metal and rare-earth metal oxides, and the catalyst is free of noble metal and low in cost; and the catalyst has the advantages of high activity, high selectivity, high stability and the like.

Owner:杭州润信科技有限公司

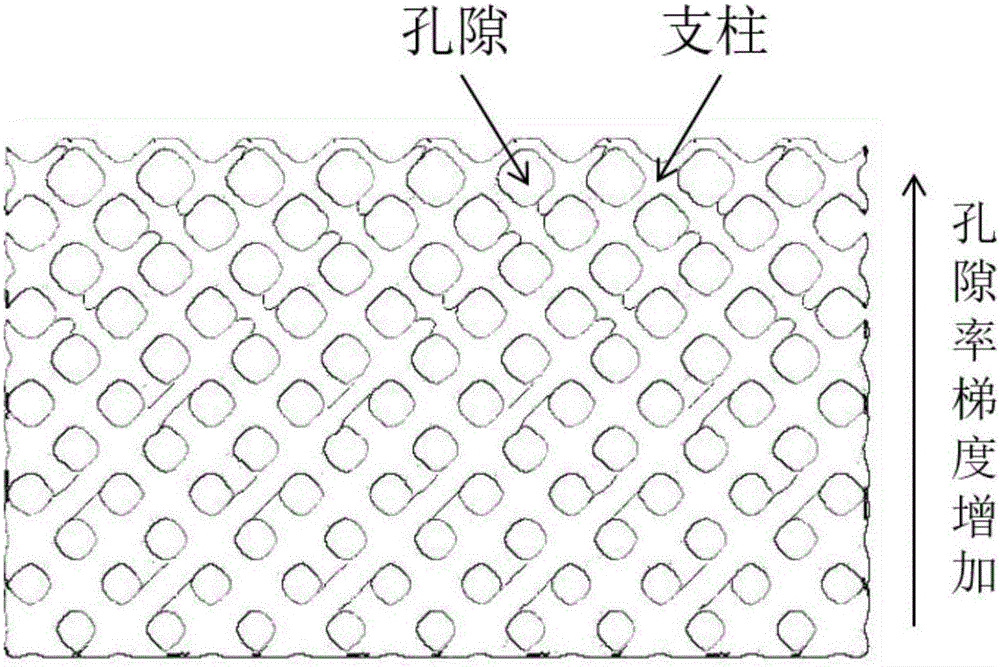

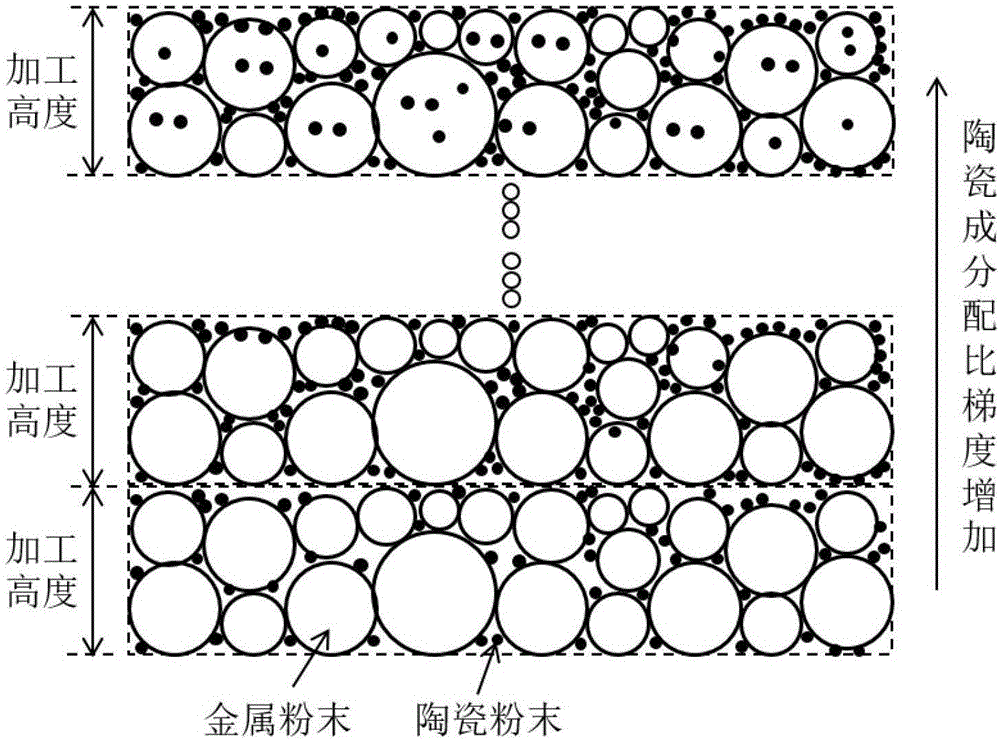

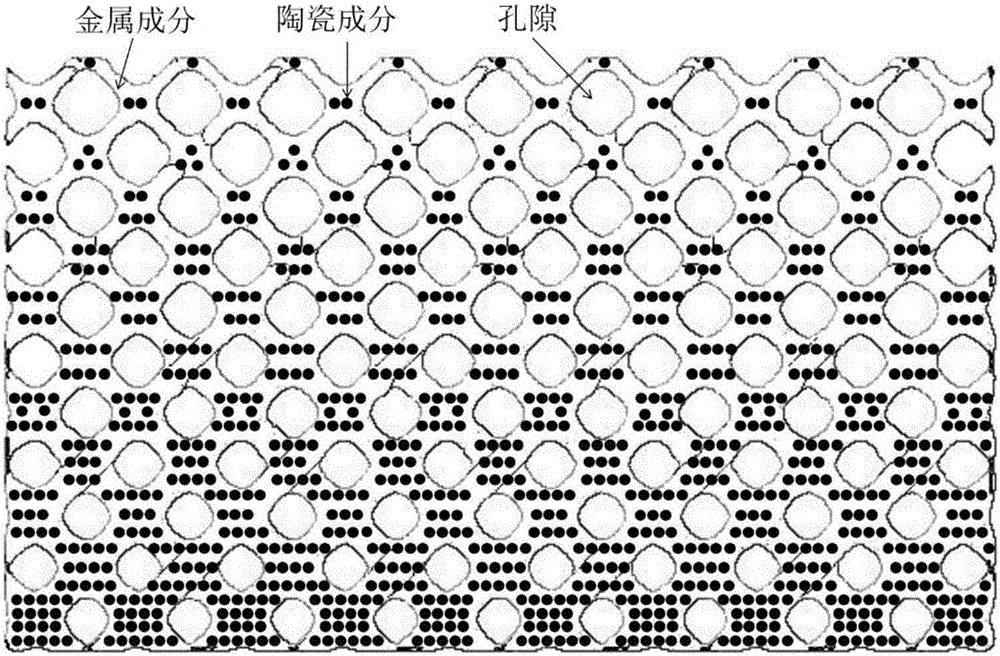

Preparation method for reticulate structural part provided with component and pore double gradient transition layers

ActiveCN106270517AUniform mechanical propertiesImprove osseointegration performanceAdditive manufacturing apparatusLaser scanningTransition layer

The invention discloses a preparation method for a reticulate structural part provided with component and pore double gradient transition layers. The method comprises the following steps that (1) a three-dimensional model of a reticulate structure with bionic unit topology and gap dimension gradient changes is design, the three-dimensional model is subjected to slicing treatment and then converted into an STL document, and the STL document is input into SLM forming equipment; (2) various powders are evenly mixed according to a preset ratio, and a mixed powder is fed and laid; (3) a current slice layer of the reticulate structural part is subjected to laser scanning forming and is descended by the thickness of a laid power layer after forming is finished, and then the mixed powder in the current ratio is adopted for forming the next slice layer; (4) the step (3) is repeated until forming of the layers with the set height is completed through the powder in the current ratio, mixing of powder in another ratio is completed, and powder feeding and laying are conducted; and (5) the step (3) and (4) are repeated until forming of the whole reticulate structure with various components being in gradient transition is completed. The preparation method has the advantages of being high in preparation efficiency, simple in preparation technological process, low in cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Compound concrete admixture with early strength and water reduction functions, and preparation method and application thereof

ActiveCN104030595AExcellent early strength performance and water reducing effectThe preparation process is simpleMother liquorCement Material

The invention discloses a compound concrete admixture with early strength and water reduction functions. The compound concrete admixture is mainly prepared by 10-20 parts by mass of a polycarboxylate water-reducer, 1-5 parts by mass of a surfactant, 5-40 parts by mass of an early strength agent, 2 or less parts by mass of an air entraining agent, and 20-100 parts by mass of water. The preparation method of the compound concrete admixture comprises the following steps: processing a polycarboxylate water-reducer mother liquor to prepare a solution, mixing the polycarboxylate water-reducer solution with the early strength agent, the surfactant, the air entraining agent and water according in proportion, and uniformly stirring. The application of the concrete admixture is realized through the following steps: stirring the concrete admixture and standard sand; taking cement and water, and carrying out low-speed uniform mixing; mixing the above two materials, carrying out low-speed stirring, then carrying out high-speed stirring, intermediately stopping, and then continuously carrying out high-speed stirring; and adding the finally obtained mixture into a mold, and maintaining, wherein the addition of the polycarboxylate water-reducer is not greater than 1% of the amount of a cement mortar. The compound concrete admixture has the advantages of simple preparation method, fast effectiveness, wide application range, low cost and good effect.

Owner:重庆市宝霸石材有限公司

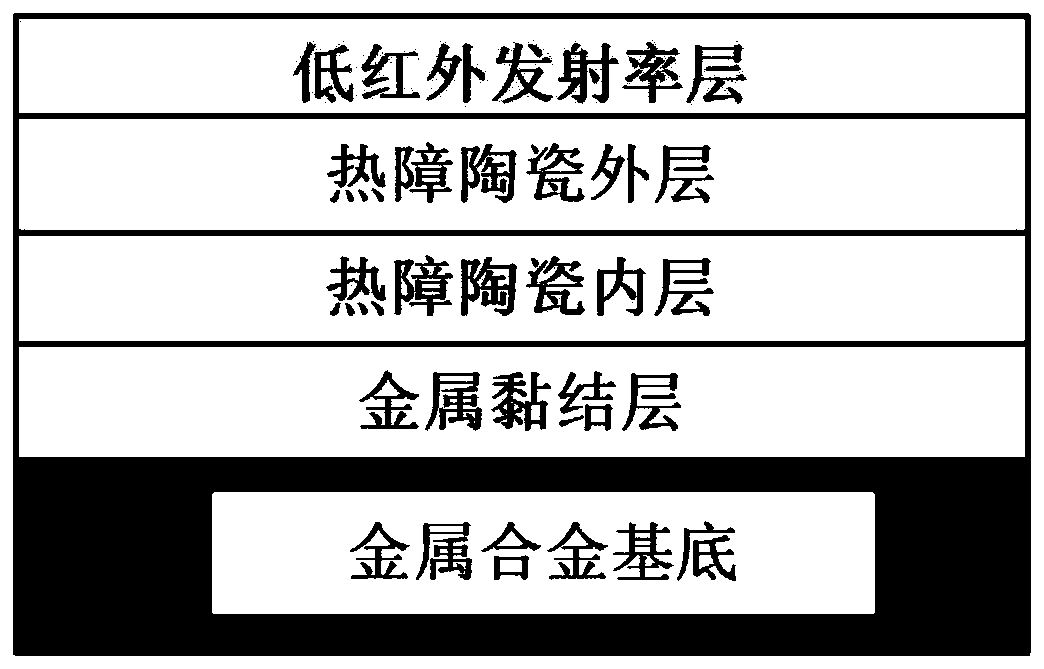

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

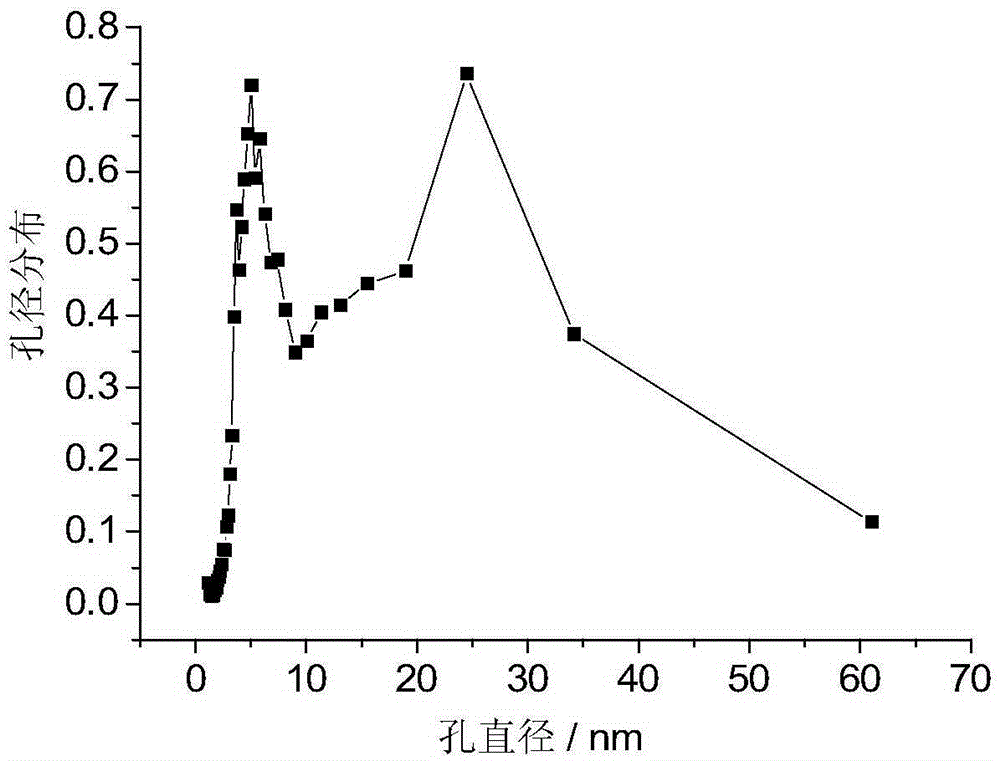

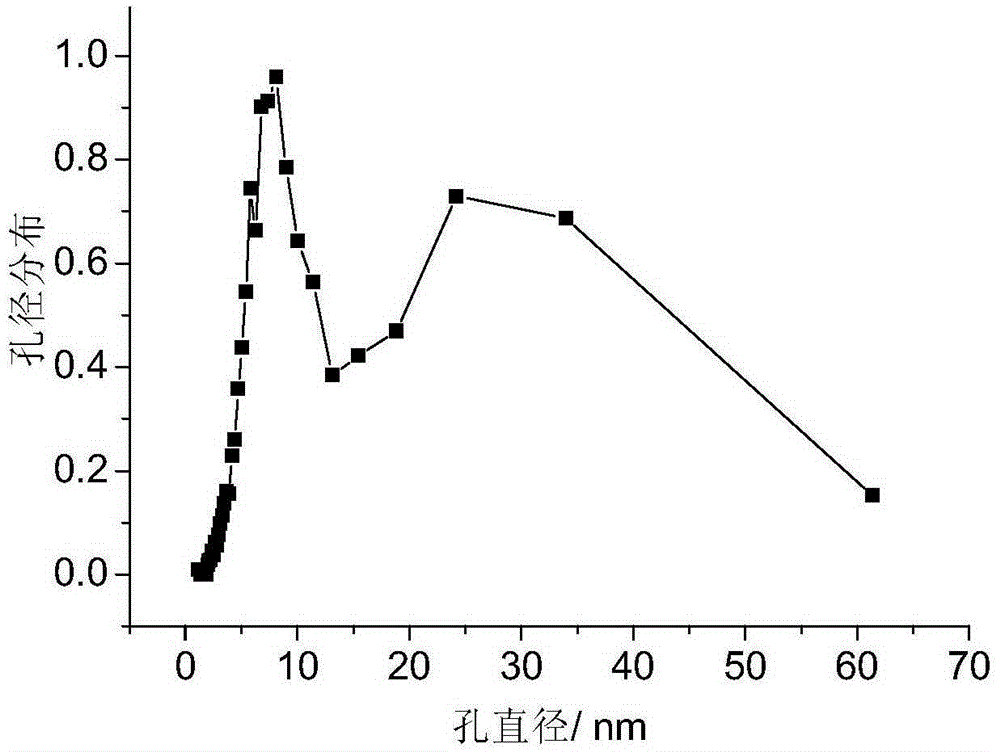

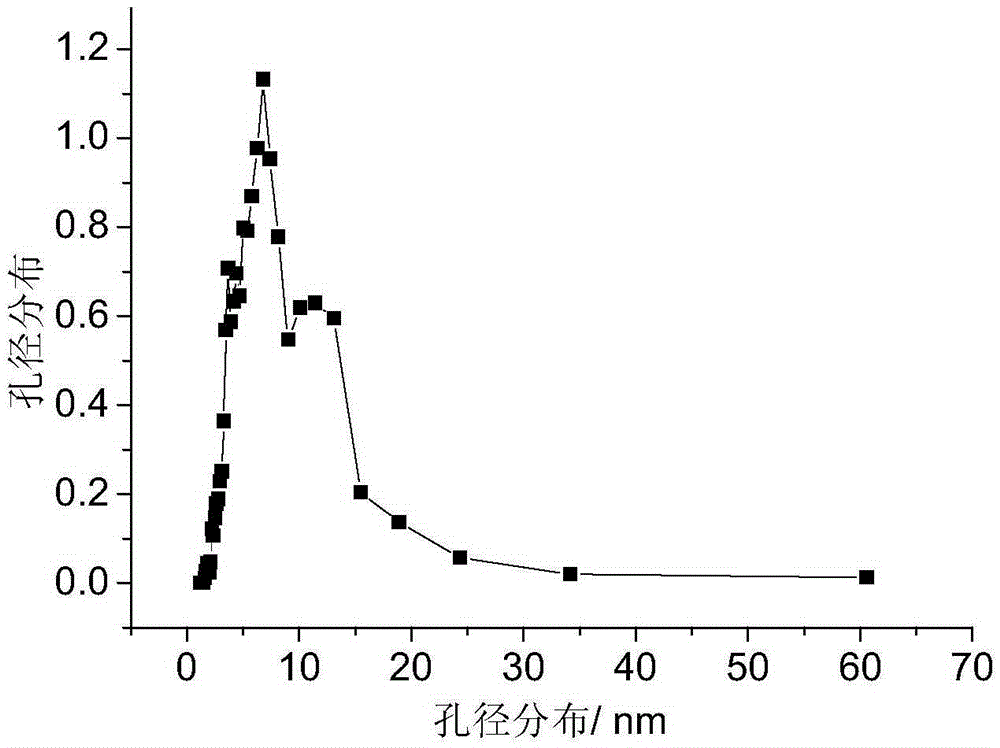

Carbon-coated aluminum oxide carrier with bimodal pore structure, and preparation method thereof

ActiveCN106582515AThe preparation process is simpleSimple equipmentCatalyst carriersOther chemical processesCarbon coatedSorbent

The invention discloses a carbon-coated aluminum oxide carrier with bimodal pore structure, and a preparation method thereof. The preparation method comprises: (1) mixing hydrated alumina and ammonium aluminum carbonate, mixing with a carbon precursor, kneading into a plasticized body, and obtaining a molded material by using a physical molding method, wherein a weight ratio of the hydrated alumina to the ammonium aluminum carbonate is 1:9-9:1, and the sum of the weight of the hydrated alumina and the ammonium aluminum carbonate to the carbon precursor is 7:3-19:1; and (2) drying the molded material obtained in the step (1) at a temperature of 50-100 DEG C, and carrying out heat treatment in an oxygen-free atmosphere to obtain the carbon-coated aluminum oxide carrier with the bimodal pore structure. According to the present invention, the process of the preparation method is simple, the bimodal pore structure covers on the surface of the prepared carbon-coated aluminum oxide carrier, and the carbon-coated aluminum oxide carrier can be used as the adsorbent and the catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acid carboxymethyl guargum fracturing fluid and preparation method thereof

InactiveCN102391851AThe preparation process is simpleEasy to operateDrilling compositionBacteriocidesDemulsifier

The invention relates to the technical field of the fracturing of an oil field, and particular relates to an acid carboxymethyl guargum fracturing fluid and a preparation method of the fluid. The acid carboxymethyl guargum fracturing fluid comprises the following raw materials: carboxymethyl guargum power, discharge aiding agent, swelling-resistant agent, bactericide, demulsifier, acid cross-linking agent, cross-linking time delay action activator, gel breaker and water. The preparation method of the fluid comprises the following steps of: firstly preparing base liquid; secondly preparing cross-linking; and thirdly preparing the acid carboxymethyl guargum fracturing fluid. The invention has the beneficial effects of acidic crosslinking environment, simple technology, convenience of in-field operation, and good combination property; and the acid carboxymethyl guargum fracturing fluid has the advantages of being good in compatibility performance, delayed in crosslinking characteristic, good in fluid loss characteristic, good in swelling-resistant effect, low in residue, and thorough in gel breaking, and can meet the fracturing construction of a reservoir stratum under the temperature from 30 DEG C to 100 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing high heat conducting foam carbon material

ActiveCN101164875AAccelerate the graphitization processImprove thermal conductivityArgon atmospherePolyvinyl alcohol

This invention relates to a method for preparing high-thermal conductivity foamy carbon material. In this invention, polyoxyethylene, polyvinyl alcohol or polymethylcellulose and distilled water are mixed to obtain the dispersing agent; asphaltum, as the intermediate phase, is added with adulterant particle Ti and mixed; the mixture is then added into said dispersing agent, after ball-milling, drying to obtain doped intermediate phase asphaltum. After that, the same is heated, in protective nitrogen atmosphere, at 450-500deg.C for 2-3hrs, after cooling to obtain asphaltum foam. Then it is heated, under nitrogen protective atmosphere, to 800-1000deg.C, for 1-2hrs, after cooled to room temperature to obtain foamy carbon. Finally, the same is heated to 2500-2800deg.C, under argon atmosphere, for 10-20min, cooled to room temperature to obtain graphite foamy carbon. The advantages of this invention are: simple process, low cost, and high-thermal conductivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Light-and-temperature-induced color change masterbatch and preparation process thereof

ActiveCN102888006AReasonable structural designThe preparation process is simpleLight sensitiveChange color

The invention relates to a light-and-temperature-induced color change masterbatch and a preparation process thereof, and belongs to the technical field of color masterbatch and preparation processes thereof. The light-and-temperature-induced color change masterbatch comprises a carrier, wherein the carrier is covered with a photosensitive layer made of photochromic material; and the rest part of the carrier is covered with a thermosensitive layer made of thermochromic paint. The preparation process comprises the following steps of: 1, grinding; 2, mixing; 3, internal mixing; 4, stripping, palletizing; and 5, drying. The color masterbatch disclosed by the invention has a reasonably designed structure; the photochromic material and thermochromic paint added into the raw materials allow the color masterbatch prepared to change color with temperature and light intensity; the masterbatch meets industrial requirements; the preparation process of the light-and-temperature-induced color change masterbatch is easy; the preparation cost is low; and thus, the masterbatch has a bright application prospect.

Owner:江苏博云塑业股份有限公司

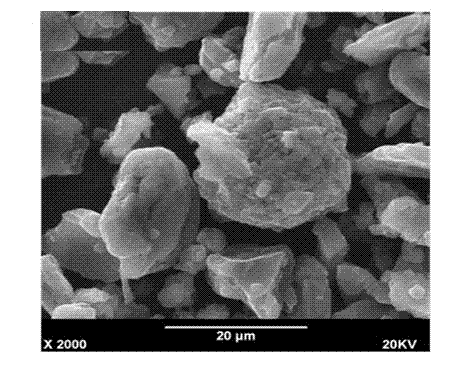

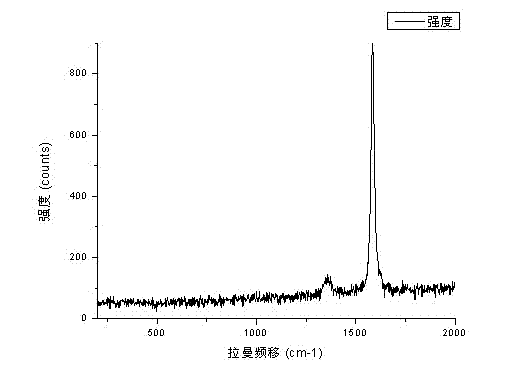

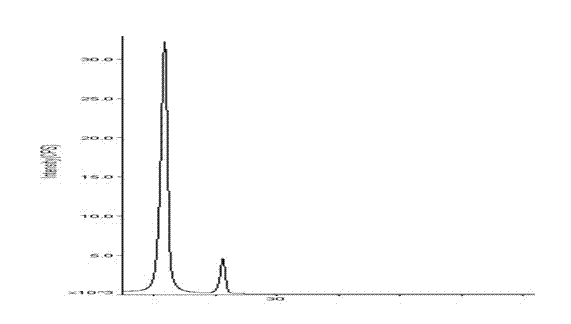

Composite graphite cathode material for high-capacity lithium ion battery, and its preparation method

ActiveCN103078089ALow costThe preparation process is simpleCell electrodesChemistryElectrical battery

The invention relates to a composite graphite cathode material for a lithium ion battery, and its preparation method, mainly relates to a composite graphite cathode material for a high-capacity lithium ion battery, and its preparation method, and belongs to the field of cathode materials for the lithium ion battery. The composite graphite cathode material for the high-capacity lithium ion battery is formed by blocky powder and spheroidic powder, and is characterized in that the specific surface area is 1.5-3.5m<2> / g, the average particle size is 7-30mum, the Raman ratio R is 0.1-0.3, and the interlamellar spacing of a crystal face (002) is 0.335-0.337nm. The composite graphite cathode material for the lithium ion battery has the advantages of excellent compact density, excellent gram specific capacity and excellent cycle stability, so the energy density per unit volume of the lithium ion battery is improved, and the electrical performances of the cathode material in the lithium ion battery are comprehensively improved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

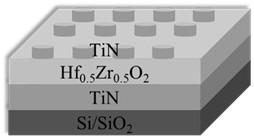

Method for preparing Hf0.5Zr0.5O2 ferroelectric film by ALD for ferroelectric memory applications

PendingCN110165053AThe preparation process is simpleShort manufacturing timeSolid-state devicesCapacitorsFerroelectric thin filmsHafnium

The invention discloses a method for preparing a Hf0.5Zr0.5O2 ferroelectric film by ALD for ferroelectric memory applications, characterized by preparing the ferroelectric film by using atomic layer deposition, using a hafnium source and a zirconium source as reaction precursors, using ozone or water as an oxygen source, using a cavity temperature of 250 to 280 degrees centigrade, and using a reaction precursor heating temperature of 75 to 80 degrees centigrade. Compared with a ferroelectric film having a perovskite structure obtained by a conventional process, the ferroelectric film preparedby the method is more liable to be compatible with a standard semiconductor manufacturing process, has higher integration, a lower annealing temperature, a higher annealing rate, shorter annealing time, and a lower ferroelectric layer thickness. The film obtained by a high annealing rate heat treatment process has high remanent polarization, a large dielectric constant, and low leakage current. The preparation method of the invention has high repeatability and can obtain uniform ferroelectric film, and contributes to realizing the wide application prospect of the ferroelectric film in the fields of information storage and integrated circuits.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

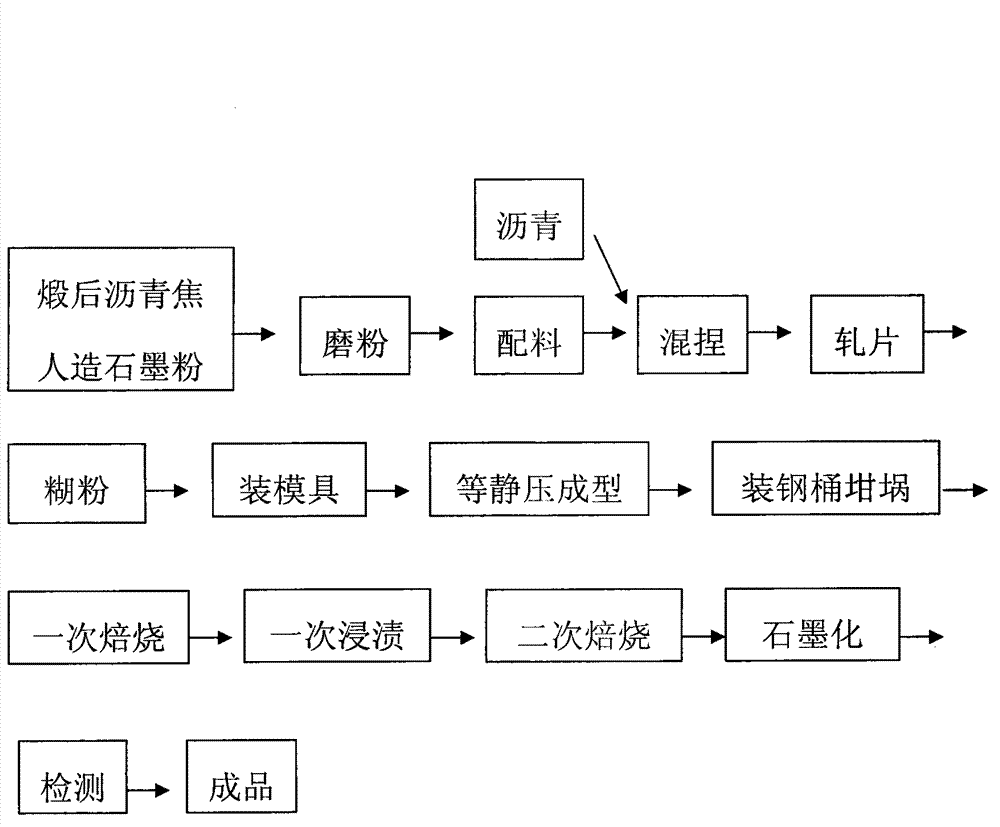

Preparation method for die graphite material used for electrical discharge machining

The invention relates to a preparation method for a die graphite material used for electrical discharge machining. The preparation method comprises the following steps: crushing calcined pitch coke and artificial graphite powder; carrying out batching and adding 20 to 35% of molten asphalt; then carrying out kneading, rolling and isostatic compaction; roasting a green compact at a temperature of 850 to 1000 DEG C for 600 and 800 h; carrying out high pressure dipping with 10 to 25% of molten special dipping asphalt; then carrying out roasting at a temperature of 800 to 900 DEG C for 300 and 400 h; and finally carrying out graphitization at a temperature of 2400 to 2800 DEG C for 150 and 230 h. The preparation method provided by the invention has the advantages of simple operation, high yield, full utilization of resources, conservation of cost, capacity of allowing high volume density and mechanical strength to be maintained and strong practicality.

Owner:唐山金湾特碳石墨有限公司

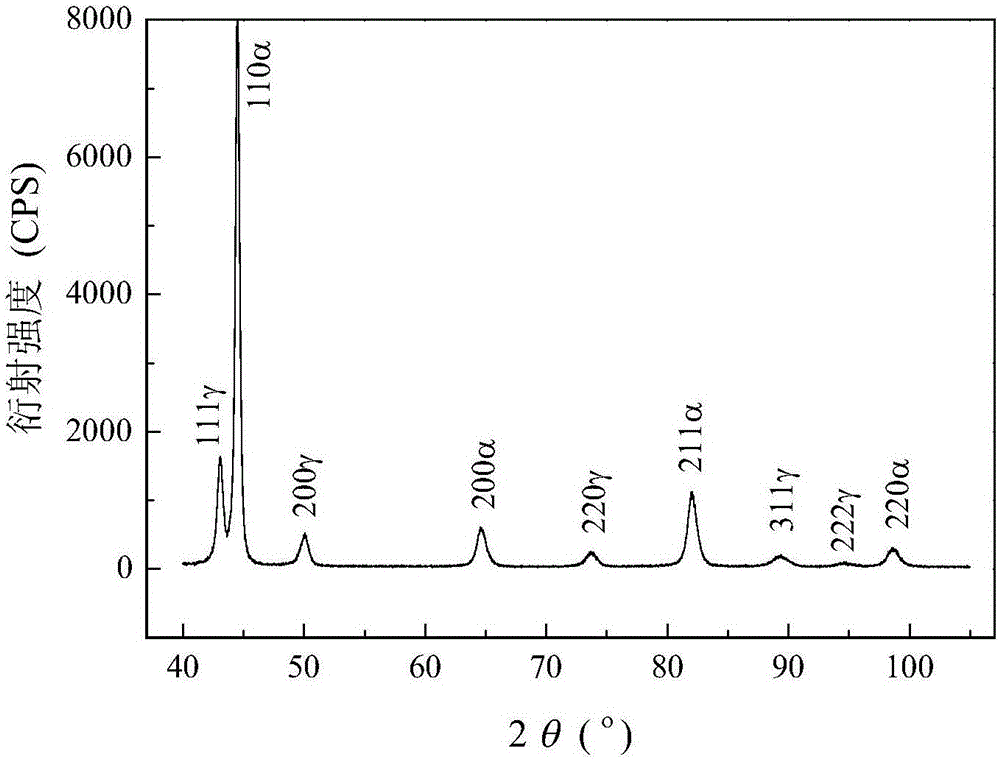

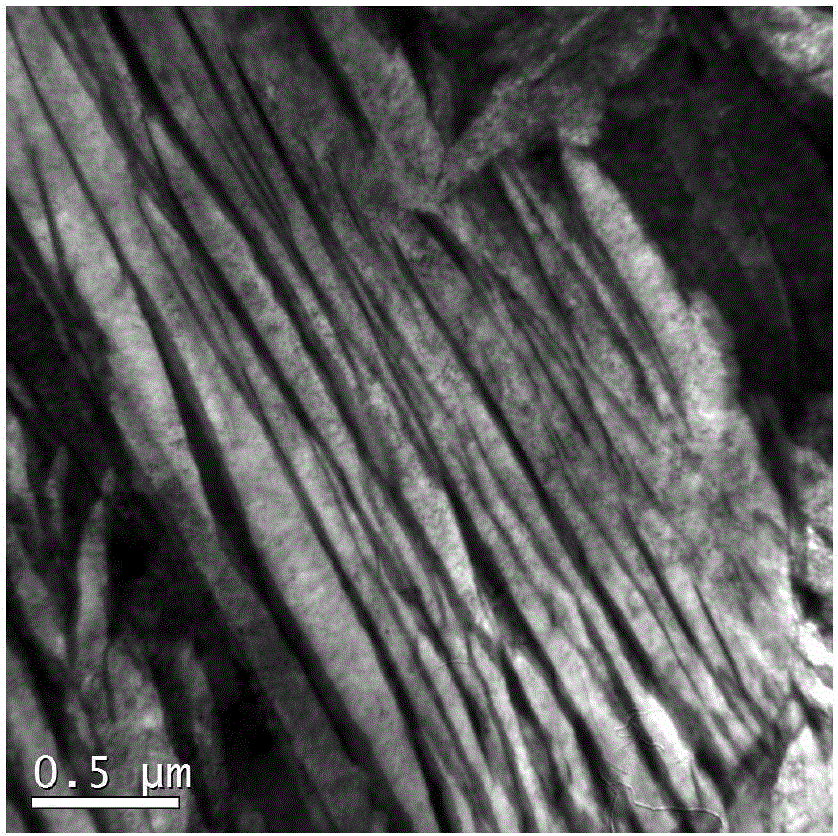

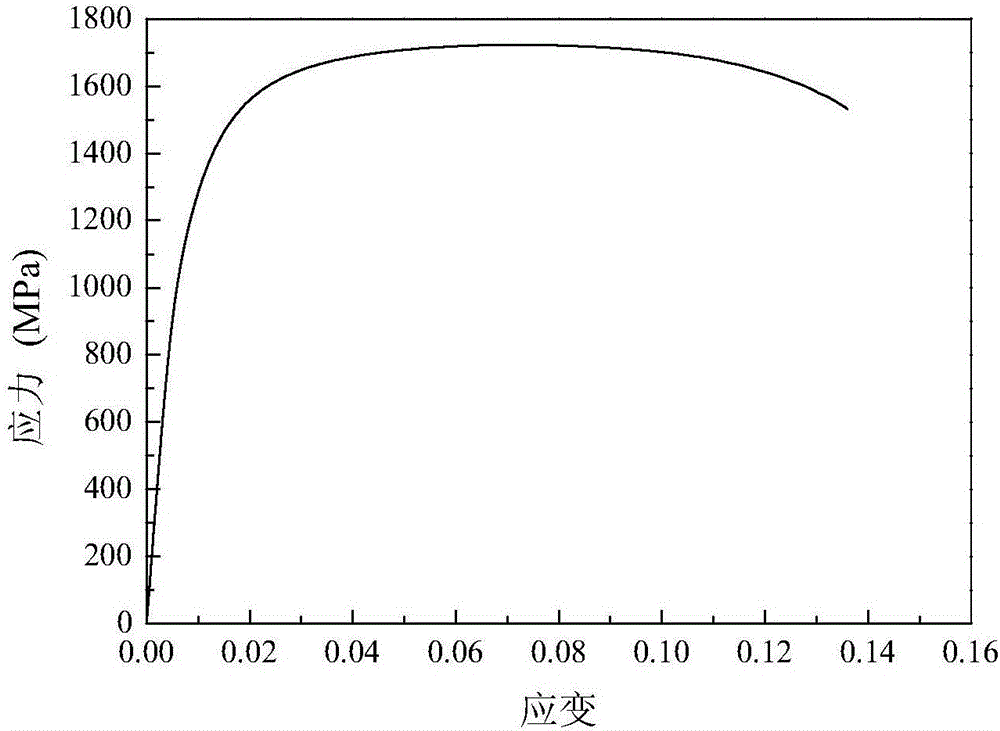

Nanometer bainite spring steel and preparation method thereof

The invention relates to a nanometer bainite spring steel and a preparation method thereof. The spring steel is prepared from, by weight percentage, 0.62%-0.67% of C, 1.6%-2.0% of Si, 0.8%-1.1% of Mn, 0.8%-1.1% of Cr, 0.5%-0.8% of Ni, 0.8%-1.2% of Al, 0.7%-1.0% of W, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance Fe and inevitable impurities. The metallographic structure of the spring steel is nanometer bainite; the tensile strength is not less than 1700 MPa; the yield strength is not less than 1200 MPa; the elongation is not less than 10%; and the U-shaped notch impact energy is not less than 49 J. The preparation method comprises the steps of steelmaking, annealing, hot rolling, heat treatment and the like. By means of the nanometer bainite spring steel and the preparation method thereof, the nanometer bainite structure composed of nanoscale lath bainite ferrite and retained austenite can be obtained; no carbide is contained; no quenching stress or quenching crack is generated; strength, plasticity and toughness are high; and good anti-over-loading fracture performance is achieved.

Owner:YANSHAN UNIV

Inorganic fiber reinforced composite material and preparation method thereof

InactiveCN102180644AReduce material costsThe preparation process is simpleSolid waste managementBatch productionCorrosion

The invention relates to an inorganic fiber reinforced composite material which is characterized in that the composite material is prepared by magnesium oxide, phosphate, a retarder, short fibers, fillers and water according to a certain weight ratio; the composite material can be used to produce various products by mold pouring or pressure molding, and the operation is simple and convenient; the composite material has the advantages and effects of good mechanical properties, good density, acid and base corrosion resistance, nontoxicity, environmental protection, low cost and wide applications; and the inorganic fiber reinforced composite material has low cost, high strength, and good toughness, is applicable to industrial batch production, is suitable for producing pipes, tanks, decoration materials, handicrafts, fireproof doors and windows and the like with various shape specifications, and can substitute wood, metal, and plastics in many aspects.

Owner:顺平县普惠农丰新能源科技有限公司

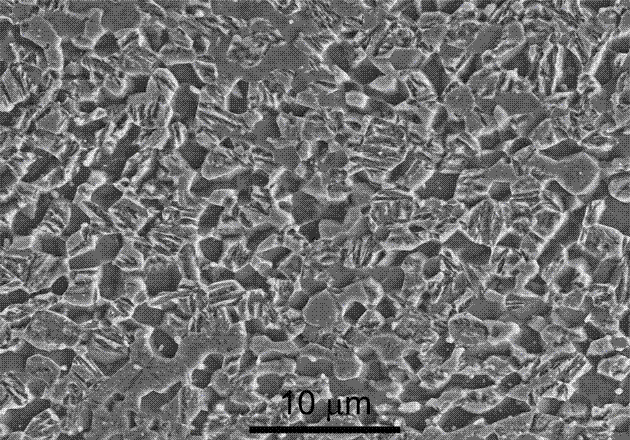

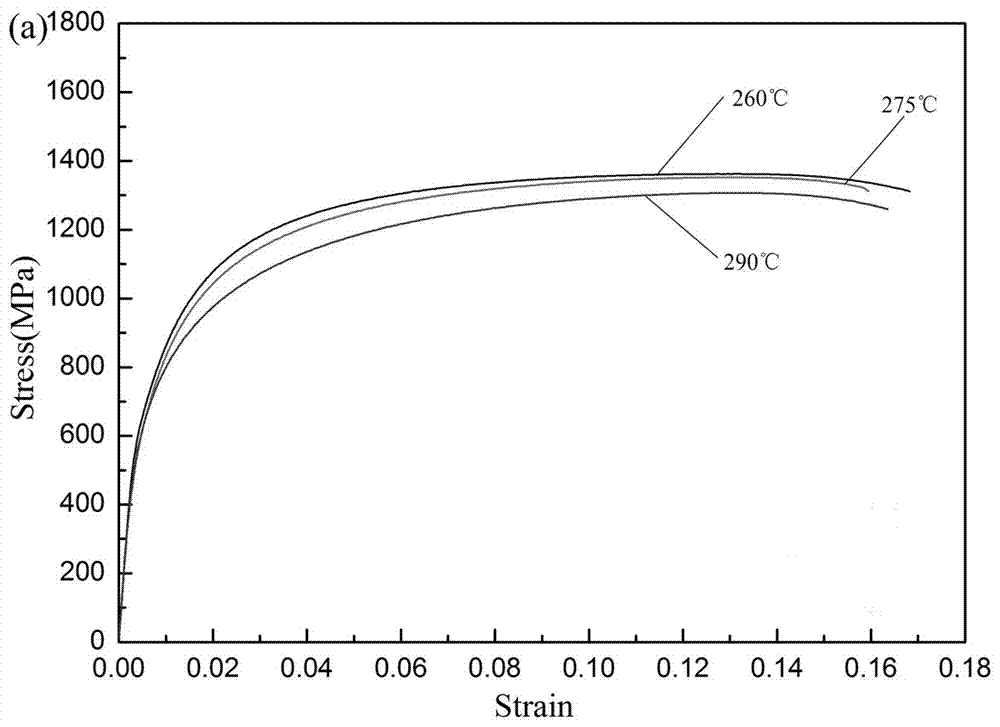

Ultra-fine grain ferrite/low-temperature bainite dual-phase steel and preparation method thereof

The invention discloses ultra-fine grain ferrite / low-temperature bainite dual-phase steel and a preparation method thereof and belongs to the field of steel and iron material engineering. The grain size of ultra-fine grain ferrite is 0.5-3 microns, and the batten size of low-temperature bainite is 75-300 nm; and the volume content of ultra-fine grain ferrite is 15-75%. According to the dual-phase steel, steel of a tempered troostitic structure is rolled to deform, and then heated and recrystallized to form ultra-fine grain ferrite and fine grain austenite, and the fine grain austenite is manufactured by transforming low-temperature bainite; the ultra-fine grain ferrite / low-temperature bainite dual-phase steel has the advantages of high strength, high plasticity, low yield ratio, high strength and ductility and excellent comprehensive mechanical property; and the preparation technology is simple and feasible in process and easy to control and facilitates industrial production.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com