Composite fiber containing aggregation-induced luminescent molecules, preparation method thereof and application thereof

A technology of aggregation-induced luminescence and composite fibers, which can be used in medical preparations with non-active ingredients, fiber processing, organic non-active ingredients, etc., can solve problems such as fluorescence quenching, achieve good repeatability, a wide variety, and facilitate long-term observation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

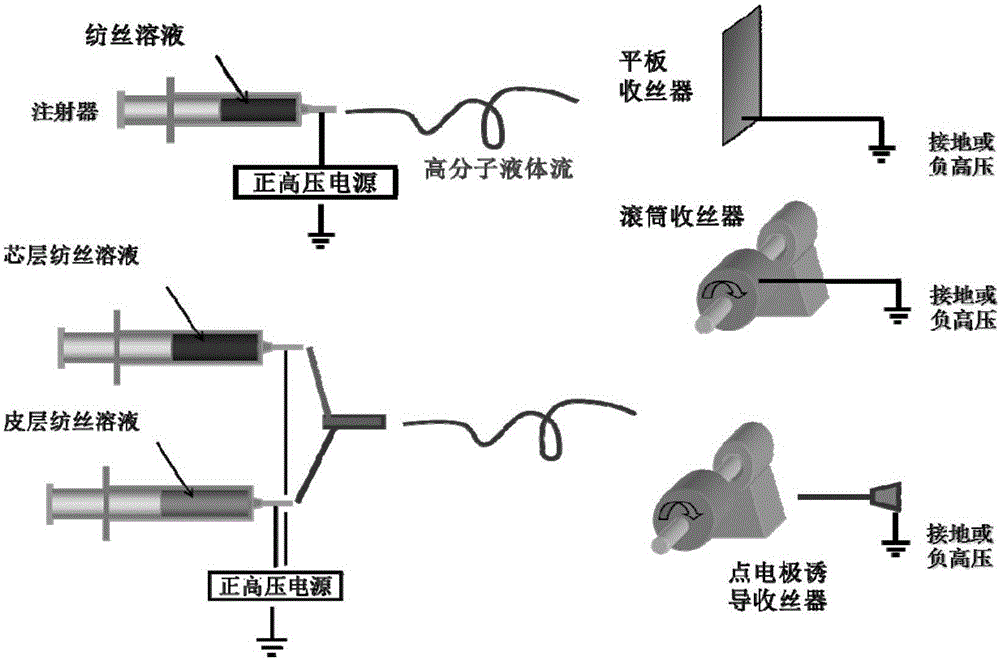

Method used

Image

Examples

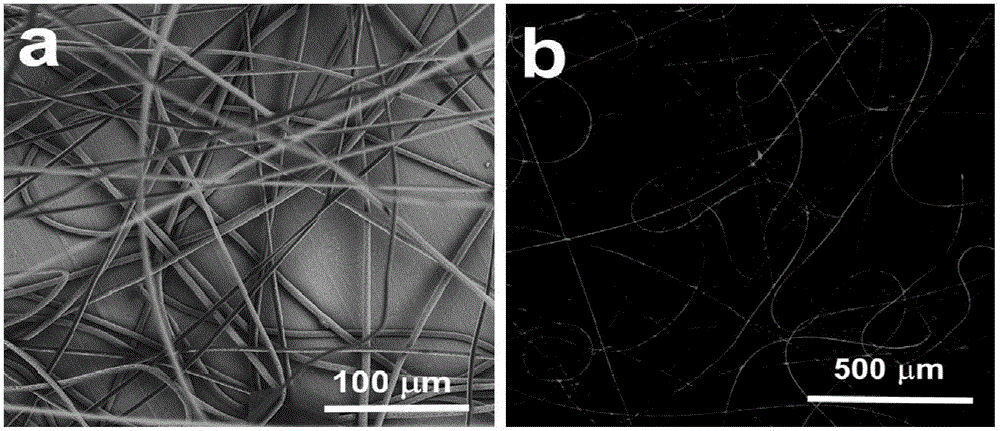

Embodiment 1

[0052] Mix polylactic acid (PLA) and dichloromethane (DCM) in a mass ratio (1:8) (PLA molecular weight 500,000), and then add AIE molecule hexaphenylsilole (HPS) (mass ratio PLA / HPS=5:1 ), at a speed of 100r / min, stirred for 48h, mixed evenly, to obtain a spinning solution; put the spinning solution into an injection device, electrospun, collected by a collection device, dried (naturally dried at 25°C for 24h), and obtained a solution containing Composite fibers of AIE (composite fibers containing aggregation-induced luminescent molecules); the conditions of electrospinning are: the spinning ambient temperature is 15°C, the relative humidity is 15%, the injection flow rate of the spinning solution is 0.5mL / h, and the spinning is normal. The voltage is 40kV, and the glass sheet is attached to the flat plate for grounding. The distance between the needle in the injection device and the collecting plate is 15cm. In addition, a grounding needle (point electrode) is set 2cm behind t...

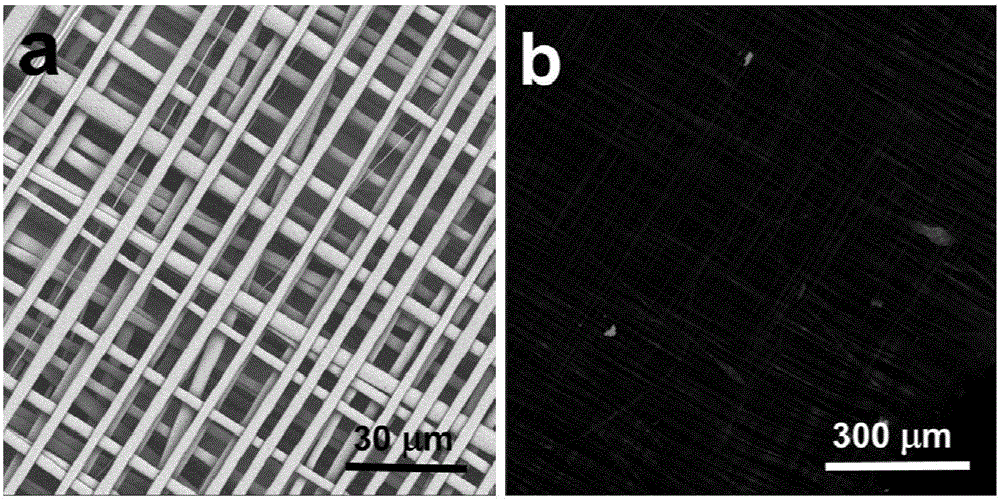

Embodiment 2

[0055] Add polyurethane (PU) to a mixed solvent of tetrahydrofuran (THF) and N,N-dimethylformamide (DMF) (mass ratio THF / DMF=1:1) to prepare a polymer with a mass fraction of polyurethane of 15%. solution, then add AIE hexaphenylsilole (HPS) (mass ratio PU / HPS=10:1), mechanically stir for 6h (stirring speed is 900r / min), fully mix to obtain spinning solution; The solution was loaded into an injection device, electrospun, collected by a collection device, and dried (drying in a vacuum oven at 70°C for 4 hours) to obtain a composite fiber containing AIE (composite fiber containing aggregation-induced luminescent molecules); the conditions of electrospinning It is: the spinning voltage is 20kV, the ambient temperature is 50°C, the relative humidity is 99%, nitrogen is used as the protective gas, the spinning solution injection flow rate is 10mL / h, and aluminum foil is attached to a drum with a diameter of 20cm as the spinning device (Drum rotation speed 3000r / min), the drum is co...

Embodiment 3

[0057] Preparation of coaxial electrospinning solution: take polylactic acid (PLA) and polyvinylpyrrolidone (PVP) (mass ratio = 9:1), and use dichloromethane (DCM) as a solvent to prepare a high concentration of solute with a total mass concentration of 6%. Molecular mixing solution, add tetraphenylethylene (TPE) (mass ratio: macromolecule / TPE=20:1); mechanically stir for 12h (stirring speed is 300r / min) to obtain shell spinning solution; take polylactic acid (PLA) and polyethylene glycol (PEG) (PLA: PEG mass ratio = 5: 1), using tetrahydrofuran (THF) as a solvent to prepare a polymer solution with a total solute mass concentration of 15%, adding 2,3-dicyano- 5,6-bis(4'-diphenyl-biphenyl-4-tertiary amino)pyrazine (CAPP) (mixed polymer / CAPP=20:1); mechanical stirring for 12h (stirring speed: 300r / min) to obtain Core layer spinning solution; respectively put the shell layer spinning solution and the core layer spinning solution into the injection device of the coaxial electrospi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com