High-polymer vesicle containing AIE (aggregation-induced emission) molecules as well as preparation method and application of high-polymer vesicle

A technology of aggregation-induced luminescence and polymer vesicles, which is applied in the direction of medical preparations containing active ingredients, luminescent materials, organic active ingredients, etc., can solve the problems of fluorescence quenching, achieve the protection of genetic material, and the preparation process is simple and feasible , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

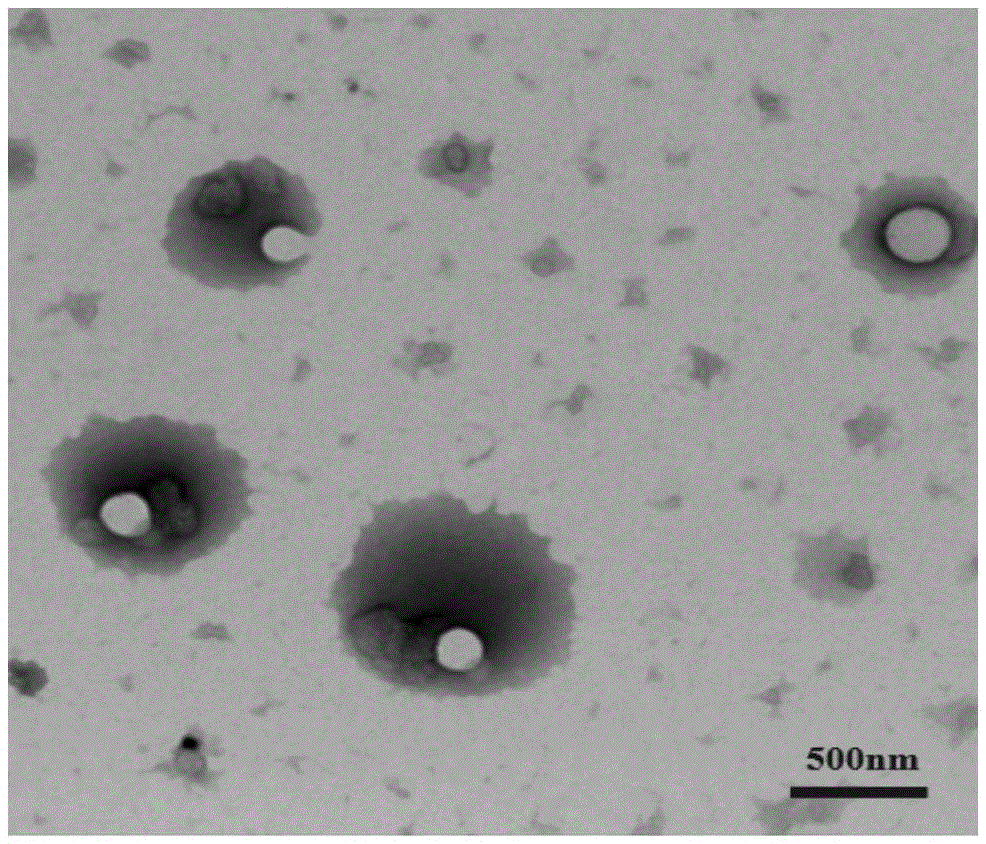

[0046] (1) PEG-4000, caprolactone (the molar ratio of PEG to caprolactone is 1:8) and stannous octoate (the amount of stannous octoate is 0.1% of the mass of caprolactone) are blended into toluene, nitrogen Under protection, stir and react at a constant temperature of 160°C for 8 hours (rotational speed is 800r / min), precipitate and filter with excess glacial ether, and obtain the PCL-PEG-PCL triblock copolymer (i.e., PCL 2000 -mPEG 4000 -PCL 2000 );

[0047] (2) Weigh 0.05g triblock copolymer PCL 2000 -mPEG 4000 -PCL 2000 Join in THF of 2g together with 0.005g hexaphenylsilole, mechanically stir 15min (the rotating speed of stirring is 100r / min), obtain macromolecule solution (the consumption of block copolymer and hexaphenylsilole is organic solvent's 2.75wt%);

[0048] (3) Remove the organic solvent in the polymer solution (dry in vacuum at 35°C for 6 hours to completely volatilize the organic solvent) to prepare a composite film of block copolymer and AIE molecules; ...

Embodiment 2

[0050] (1) PEG-2000, caprolactone (the molar ratio of PEG to caprolactone is 1:4) and stannous octoate (the amount of stannous octoate is 0.1% of the mass of caprolactone) are blended into toluene, nitrogen Under protection, stir and react at a constant temperature of 110°C for 48h (rotation speed: 300r / min), precipitate and filter with excess glacial ether, and obtain a PEG-PCL diblock copolymer (i.e., PCL 2000 -PEG 2000 );

[0051] (2) Weigh 0.05g diblock copolymer PCL 2000 -PEG 2000 and 0.001g tetraphenylethylene were added to 1g of acetone / DMAC (volume ratio 2: 1) composite solvent, mechanically stirred for 50min (the rotating speed of stirring was 100r / min), and a polymer solution (block copolymer and tetraphenyl The consumption of phenylethylene is 5.1wt% of organic solvent);

[0052] (3) Under the condition of stirring (stirring speed is 100r / min), take 10mL of deionized water and slowly add it dropwise into the polymer solution to obtain a W / O composite emulsion; p...

Embodiment 3

[0054] (1) Take PEG-5000, lactide (the molar ratio of PEG to lactide is 1:0.2) and stannous octoate (the amount of stannous octoate is 0.05% of the mass of lactide) is added in toluene solvent, nitrogen atmosphere Stir at a constant temperature of 150°C for 18 hours (350r / min), then precipitate in excess cold ether, and filter with suction to obtain the PEG-PLA block copolymer (PLA 5000 -PEG 5000 );

[0055] (2) Weigh 0.05g diblock copolymer PLA 5000 -PEG 5000 and 0.001g tetraphenyl-1,4-butadiene were added into 1g of THF, mechanically stirred for 5min (the rotating speed of stirring was 700r / min), and a polymer solution (block copolymer and tetraphenyl-1 , 4-butadiene consumption is 5.1wt% of organic solvent);

[0056] (3) Under the condition of stirring (stirring speed is 100r / min), slowly add 10mL of deionized water into the polymer solution dropwise to prepare W / O emulsion, and then continue mechanical stirring for 50h (stirring speed (300r / min) to make the organic so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com