Composite graphite cathode material for high-capacity lithium ion battery, and its preparation method

A lithium-ion battery, composite graphite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low capacity, high cost, difficult industrialization, etc., achieve high capacity retention rate, improve liquid absorption performance, and improve surface condition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

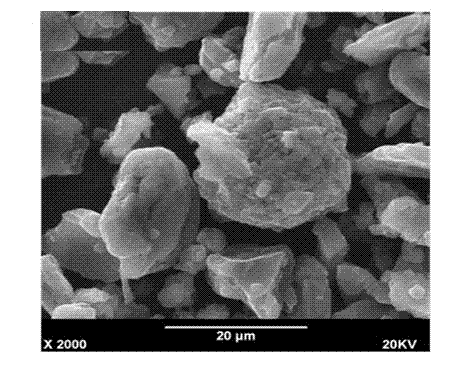

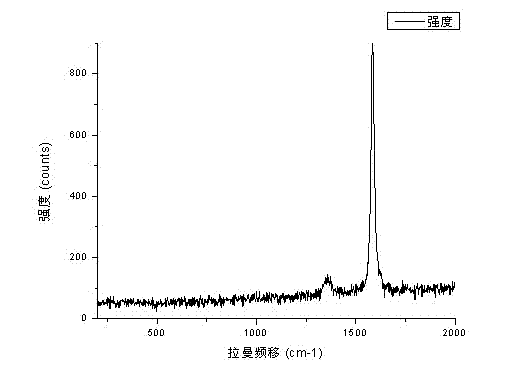

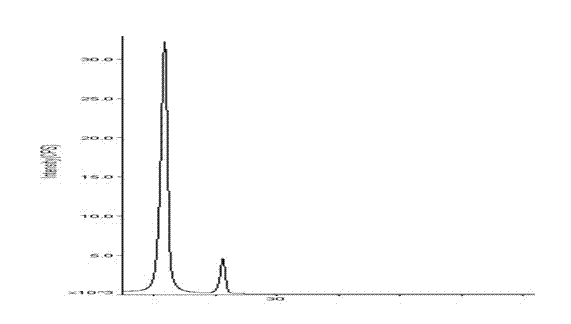

Image

Examples

Embodiment 1

[0036] In a 50L small reaction kettle, first add carbon raw materials, that is, sequentially add spherical flake natural graphite with an average particle size of 5 μm, a fixed carbon content greater than 85%, and an average particle size of 3 μm. % average particle diameter is 3 μm coal tar processing heavy product, the weight ratio of described natural graphite material and described petroleum processing heavy product is 1:0.1; The described natural graphite material and described coal tar processing heavy product The weight ratio is 1:10; then add the catalytic modification additive silicon dioxide with a weight ratio of 1:0.02 to the carbon raw material; then raise the temperature of the reactor from room temperature to 350 °C according to the heating rate of 0.5 °C / min °C, during the whole heating process, by controlling the steam pressure to keep it at -0.1MPa, under the final temperature condition, keep it for 4 hours, then cool the material and take it out. During the ...

Embodiment 2

[0039] In a 50L small reactor, first add carbon raw materials, that is, sequentially add spherical flake natural graphite with an average particle size of 17 μm, a fixed carbon content greater than 85%, and an average particle size of 15 μm. % average particle diameter is 15 μm coal tar processing heavy product, the weight ratio of described natural graphite material and described petroleum processing heavy product is 1:9; The described natural graphite material and described coal tar processing heavy product The weight ratio is 1:0.001; then add catalytic modification additives tetramethoxysilane and silicon carbide with a weight ratio of 1:0.2 to the carbon raw material; The room temperature was raised to 450°C. During the entire temperature rise process, the steam pressure was controlled to keep it at 6.0 MPa. Under the final temperature condition, it was kept for 20 hours, and then the material was cooled and taken out. During the whole production process, the equipment is...

Embodiment 3

[0042] In a 50L small reaction kettle, first add carbon raw materials, that is, sequentially add spherical flake natural graphite with an average particle size of 10 μm, a fixed carbon content greater than 85%, and an average particle size of 15 μm. % average particle diameter is 30 μm coal tar processing heavy product, the weight ratio of described natural graphite material and described petroleum processing heavy product is 1:20; The described natural graphite material and described coal tar processing heavy product The weight ratio is 1:0.001; then add the catalytic modification additive iron oxide and zinc chloride with the weight ratio of 1:0.1 to the carbon raw material; Rising to 800°C, during the entire heating process, by controlling the steam pressure, keep it at 4.0 MPa, and keep it at the final temperature for 20 hours, then cool the material and take it out. During the whole production process, the equipment is in a stirring state, so that the whole material maint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com