Patents

Literature

256 results about "Petroleum processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

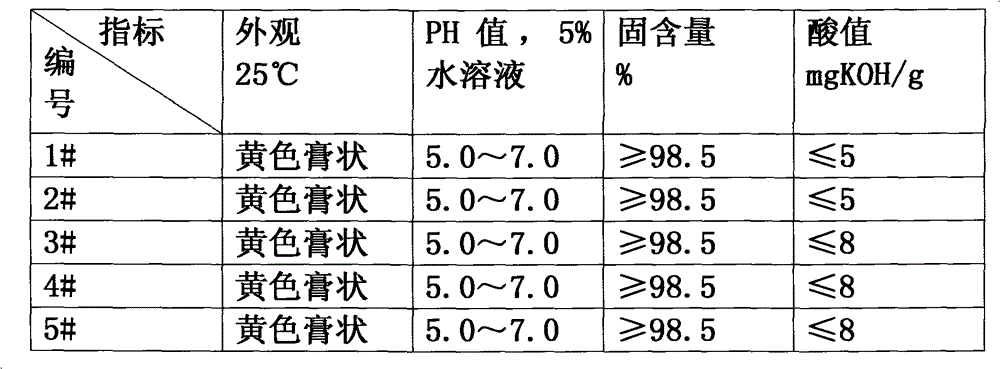

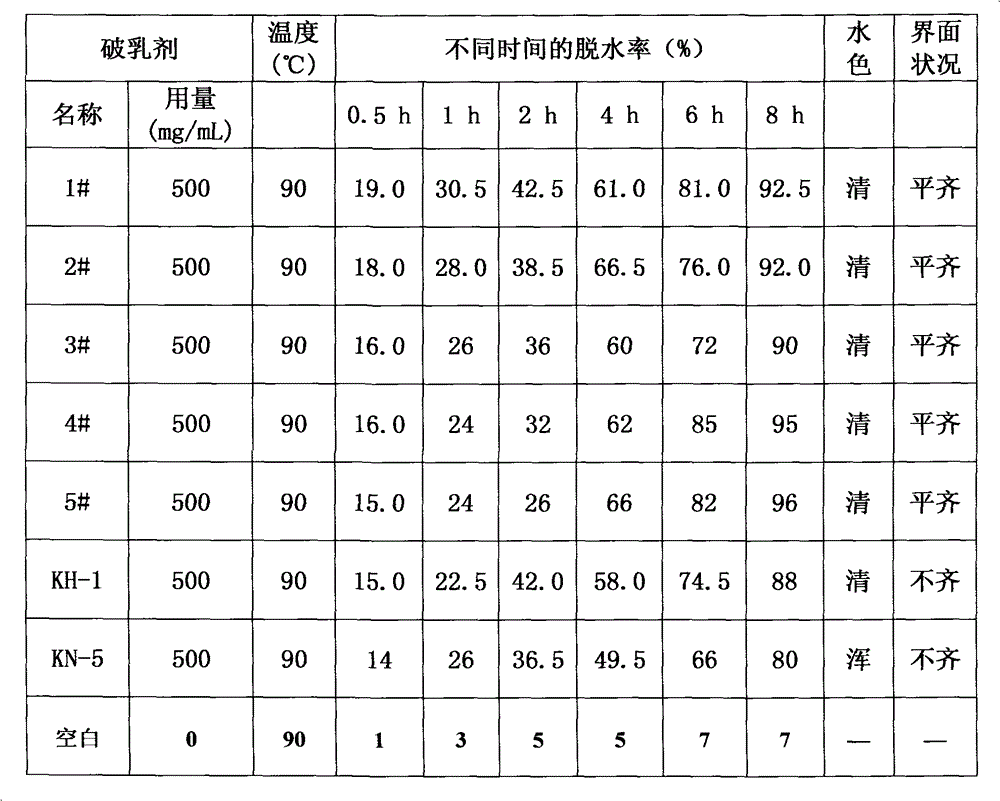

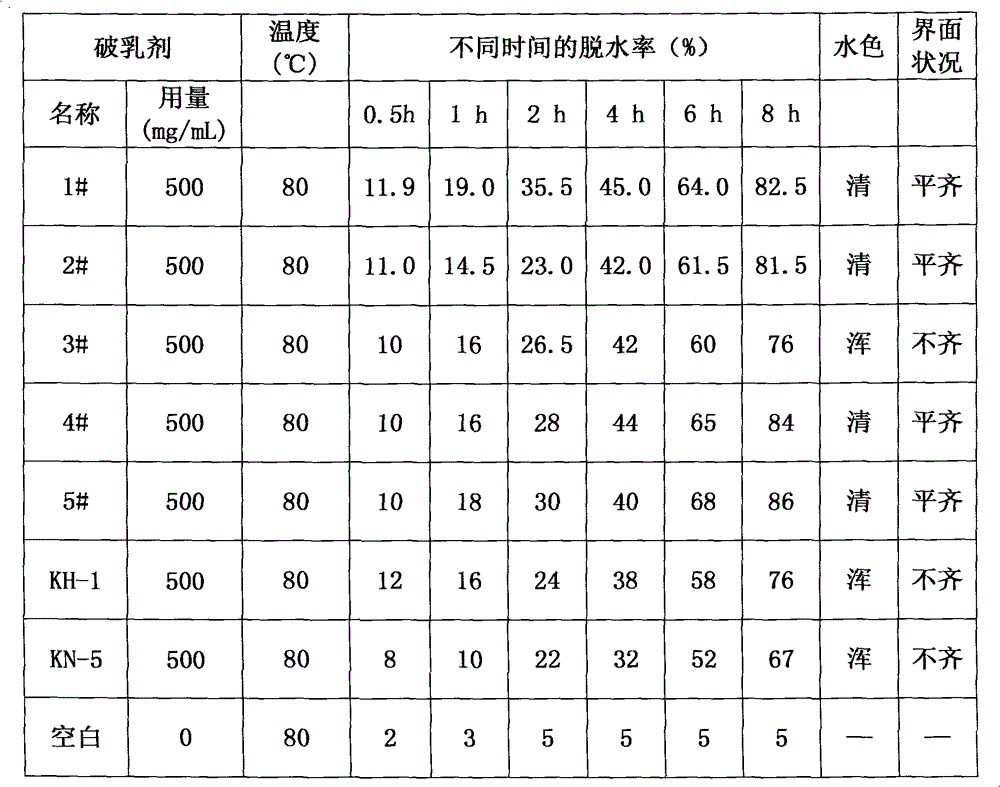

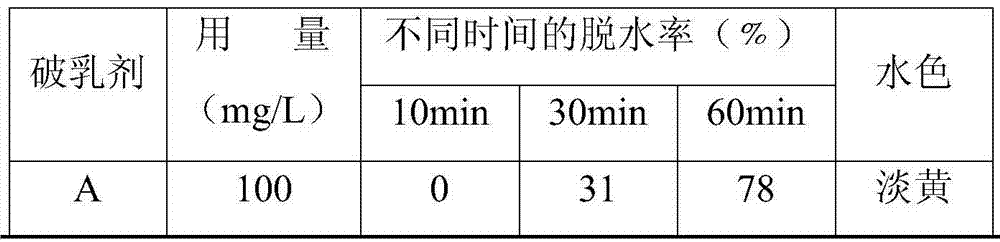

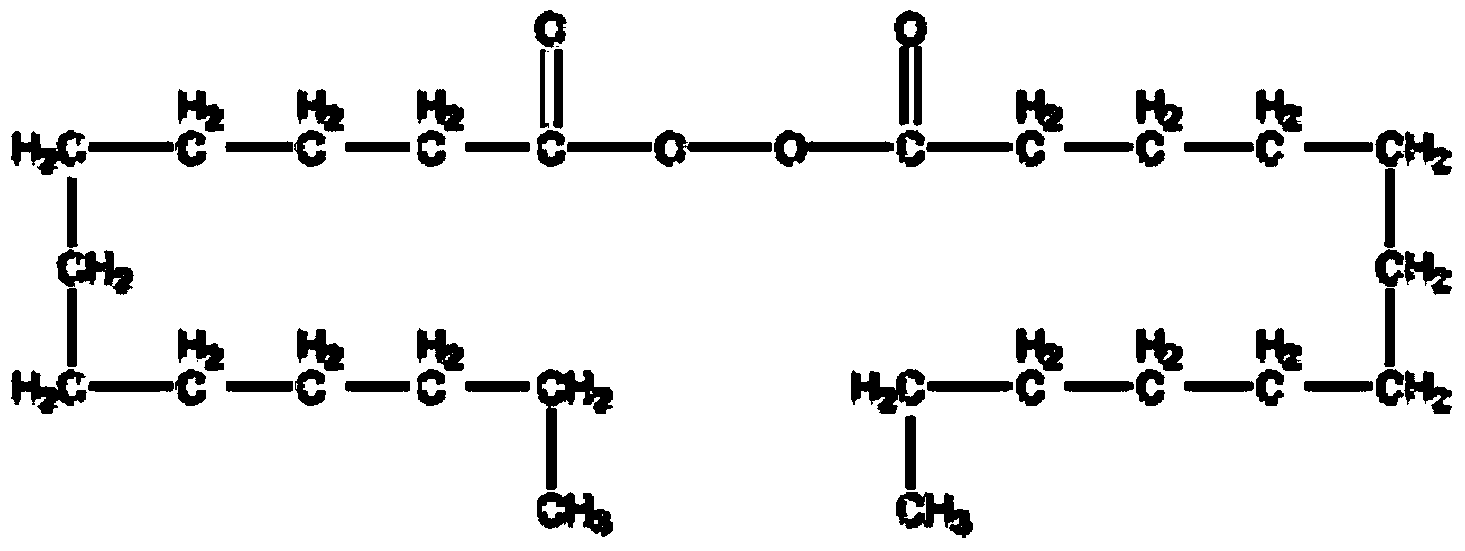

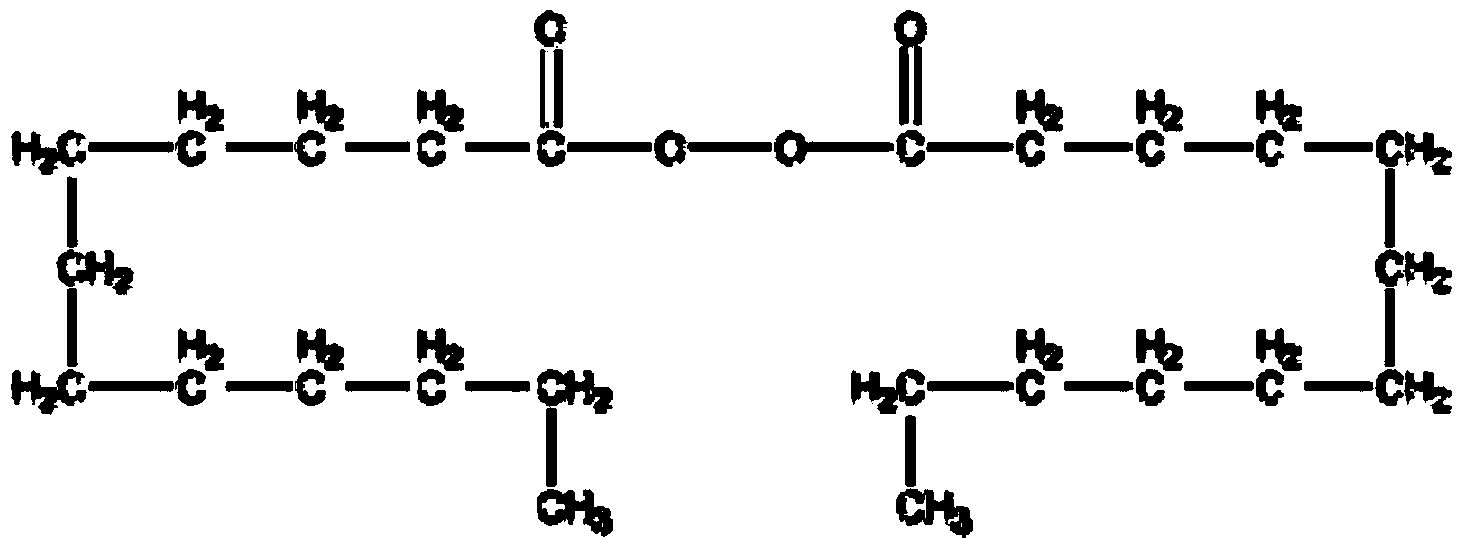

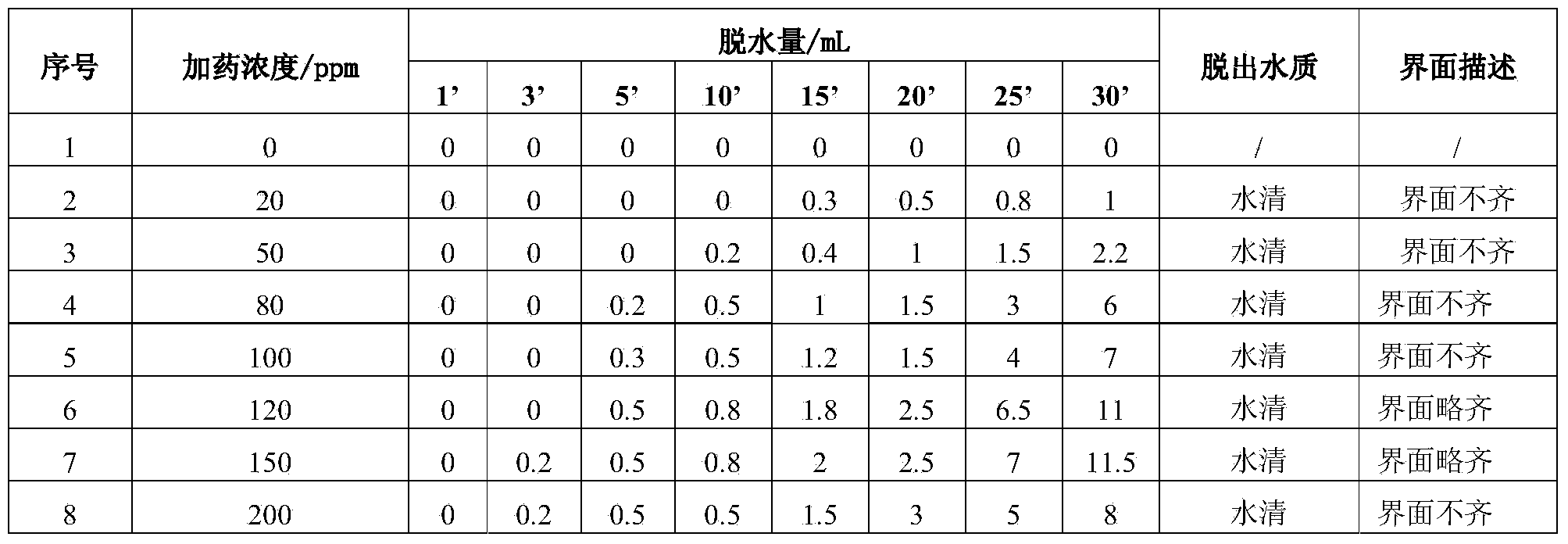

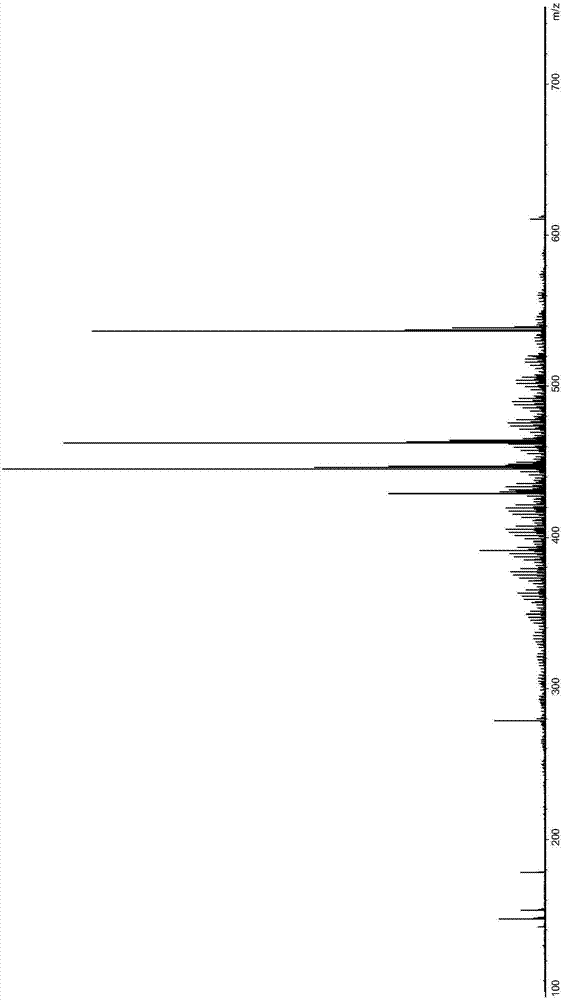

Preparation method of efficient deemulsifier for naphthenic extra heavy oil and product thereof

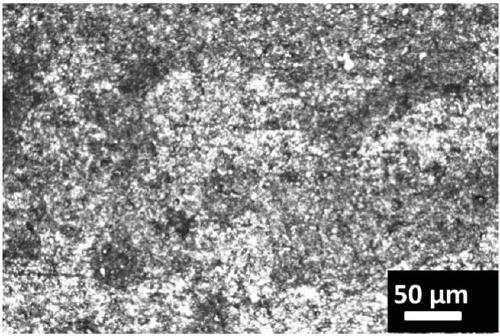

ActiveCN102746470AWeak elasticityReduce viscosityDewatering/demulsification with chemical meansAlkylphenolPhenol

The invention relates to a preparation method of an efficient deemulsifier for naphthenic extra heavy oil and a product thereof, belonging to the technical field of petroleum processing. The efficient deemulsifier is prepared by polymerizing alkylphenol, polyethylene polyamine and formaldehyde to obtain thermoplastic phenol-amine resin as an initiator, polymerizing the initiator with oxirane and epoxypropane to generate polyether blocked copolymer, and then esterifying the polyether blocked copolymer with acrylic acid and other unsaturated acids to generate a modified polyether product by grafting olefine acid. The product prepared by the method has the characteristics of quick dehydration and low dosage. The efficient deemulsifier of the invention is suitable for dehydrating the naphthenic extra heavy oil of Karamay oil fields, meeting the requirements of proper temperature, quick dehydration, high dehydration rate, clear water color, and tidy oil-water interface, and has high efficiency demulsification and dehydration performance.

Owner:克拉玛依市天明化工有限责任公司

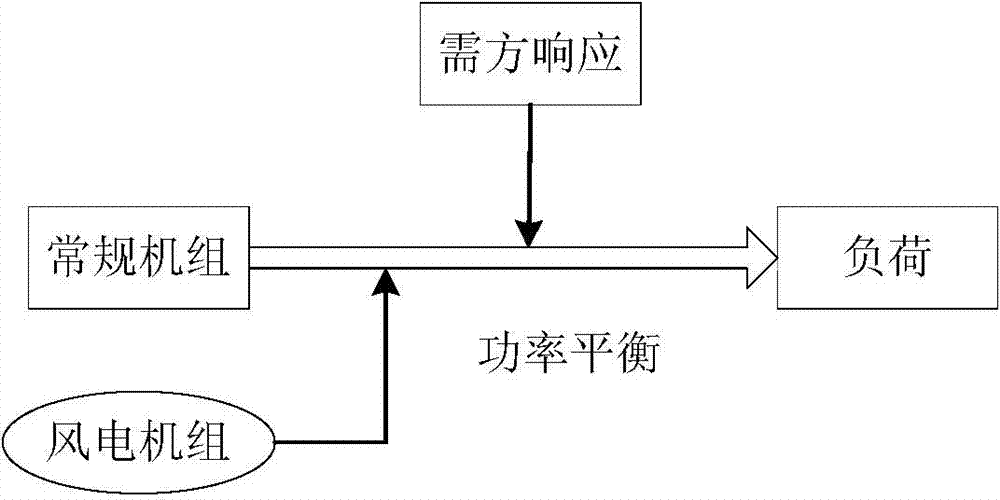

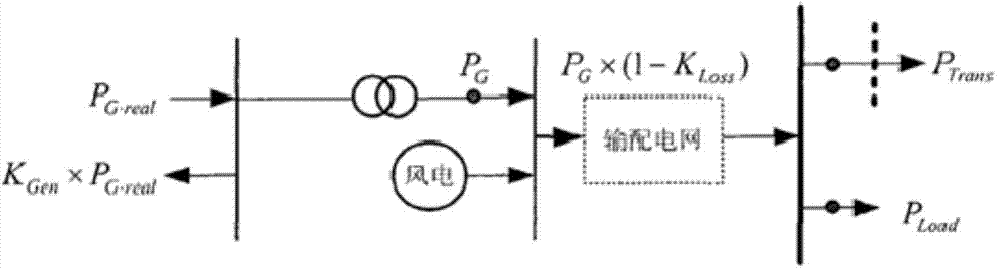

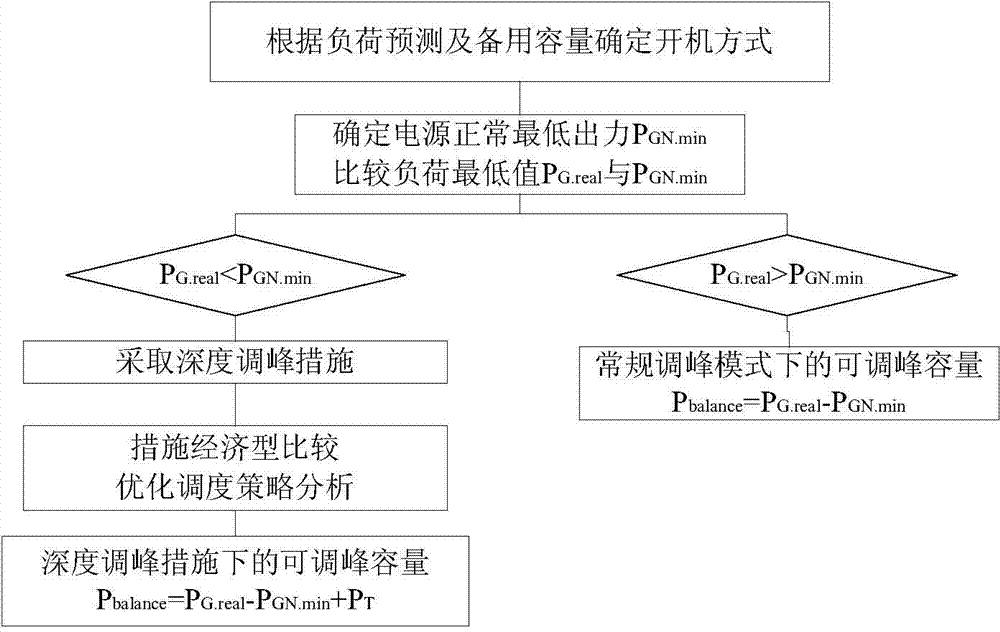

Large-scale grid-connected wind power consumption method based on demander response

ActiveCN103580063ASolve grid-connected consumptionSolve the problem of abandoned windEnergy industrySingle network parallel feeding arrangementsElectricityPower station

The invention relates to the research field that a demander response participates in large-scale grid-connected wind power consumption, in particular to a large-scale grid-connected wind power consumption based on the demander response. The method comprises the steps of establishing high-energy-consumption enterprises of mining, metal smelting, petroleum processing, heating and the like nearby areas with rich wind power, utilizing adjustable and interruptible high-energy-consumption loads for participating in wind power pitch peaks, locally absorbing wind power resources, and avoiding large-scale and remote wind power transmission. Therefore, power grid losses are reduced, the power utilization cost of high-energy-consumption users is saved, output consumption of a wind power plant is increased, and occurrences of the wind abandoning phenomenon are reduced. The method can objectively and comprehensively reflect the output characteristics of large-scale power wind and the user power utilization load characteristics, the sizes of the adjustable and interruptible high-energy-consumption loads are accurately calculated, then the capacity of the newly-increased wind power consumption scale is determined, and the current large-scale wind power grid-connected consumption problem and the wind abandoning problem are solved.

Owner:STATE GRID CORP OF CHINA +1

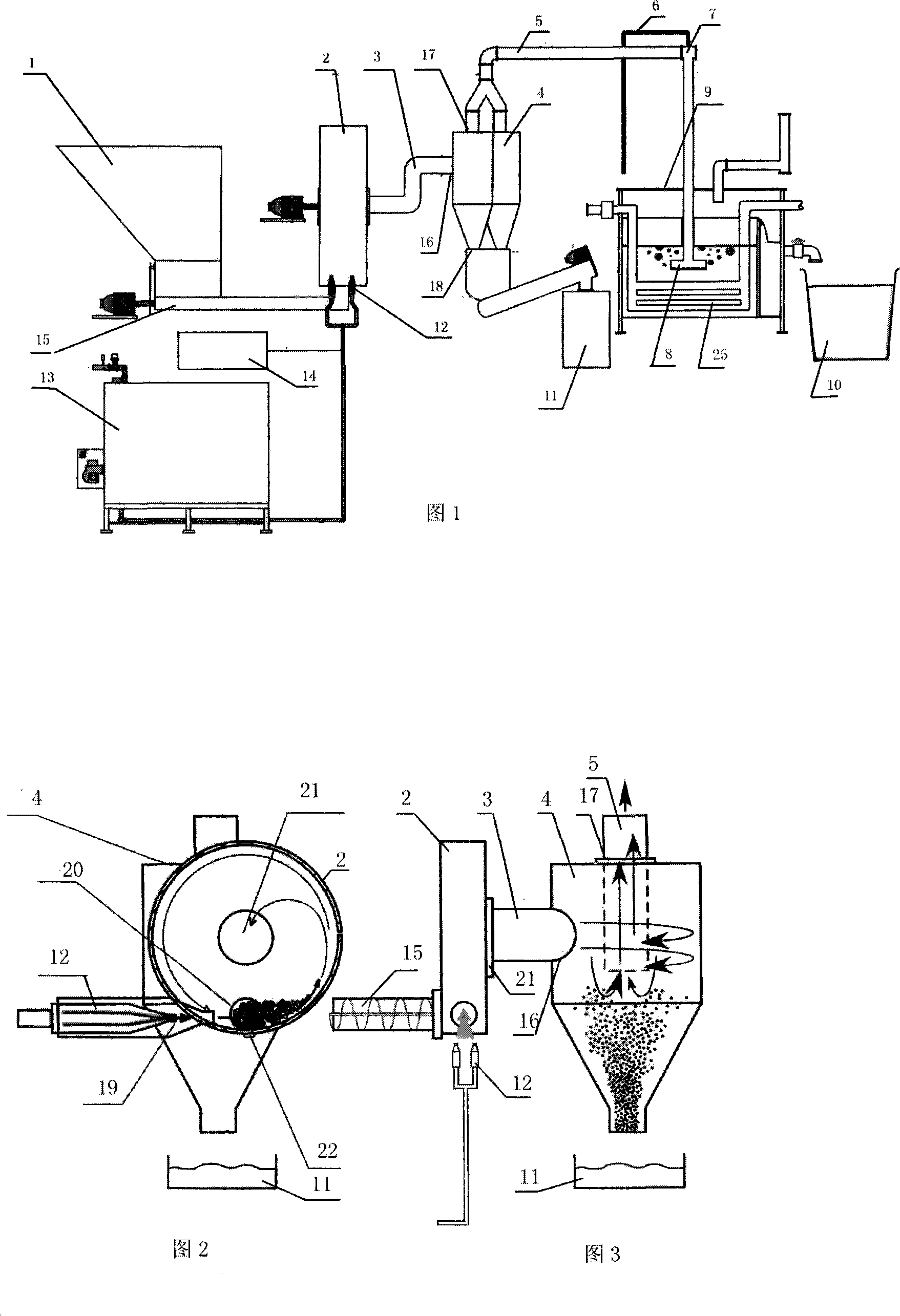

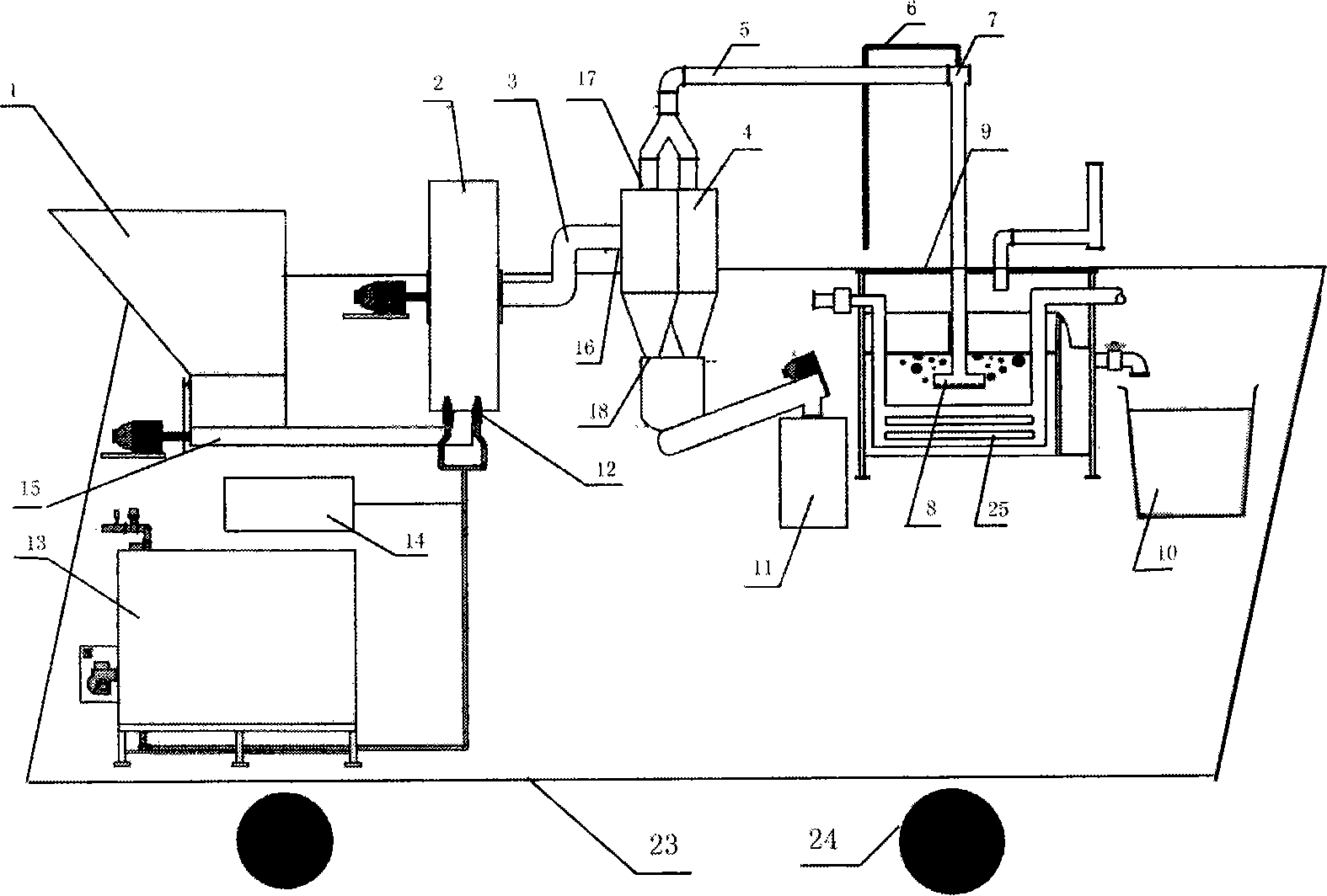

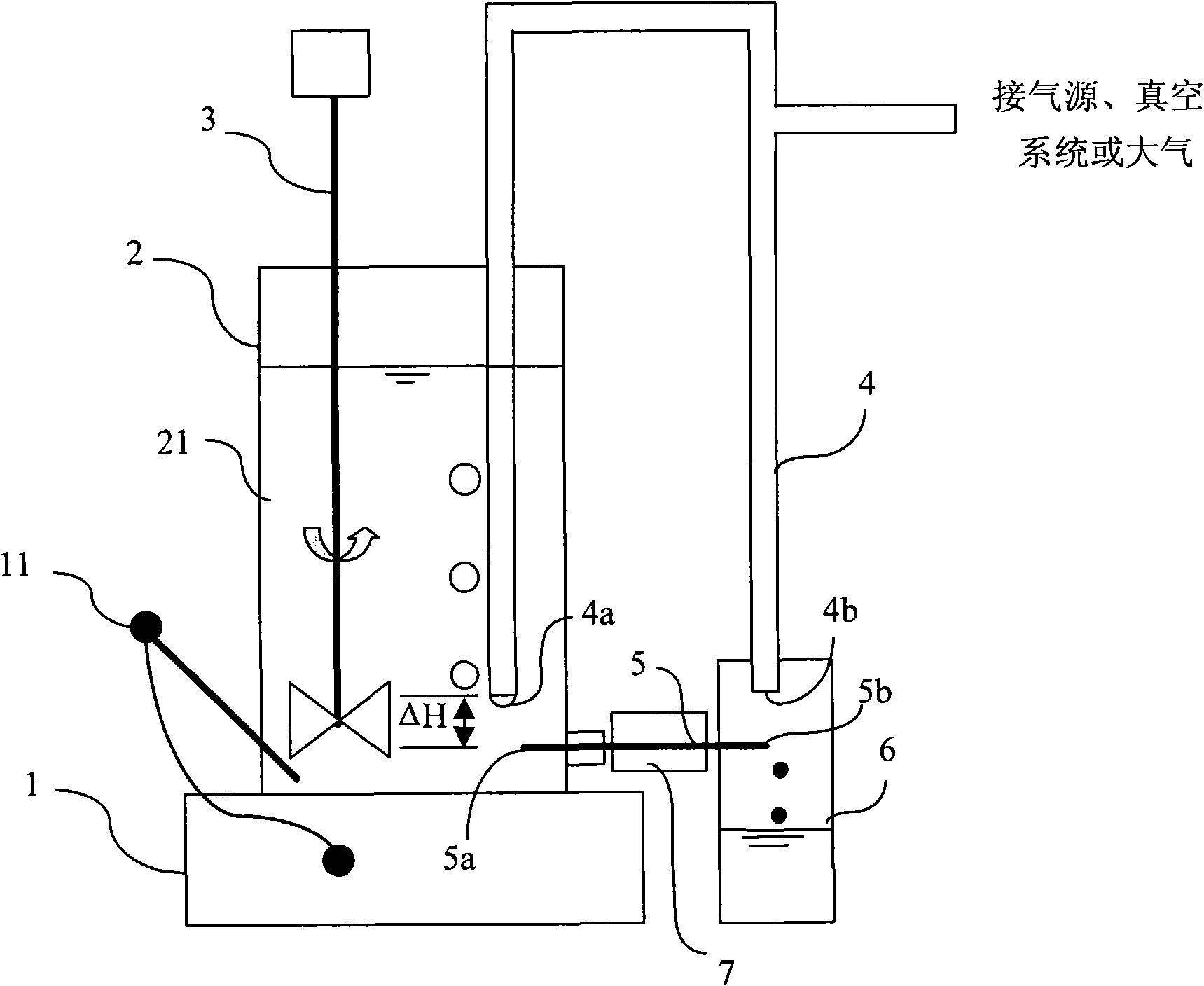

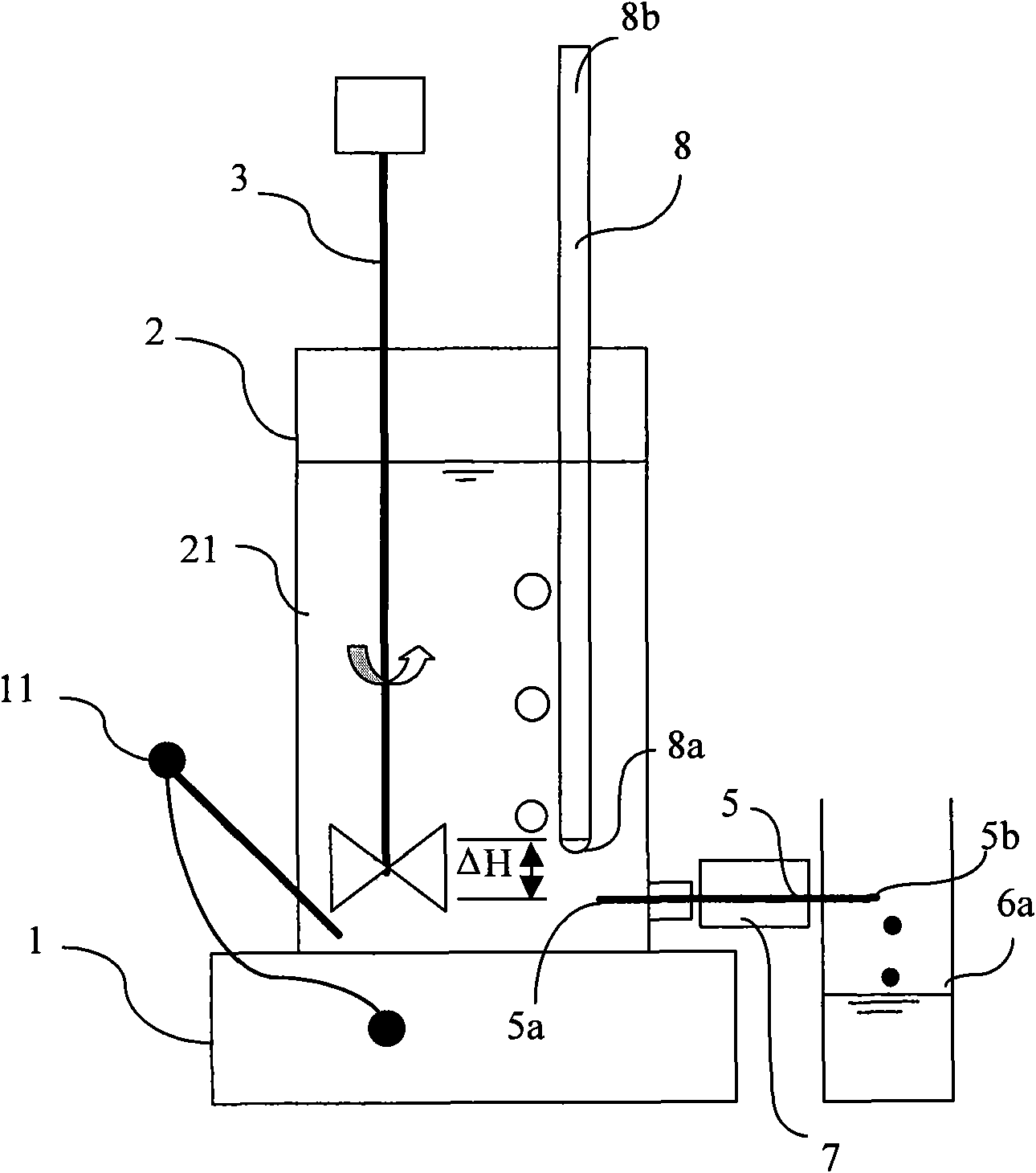

Dirty oil mud separating method and device

InactiveCN101239770ANo secondary pollutionEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWater vaporOil sludge

The present invention relates to a petroleum processing method and equipment, especially to an oil-bearing sludge separating method and equipment, provides a simple, economical, practical, environment-protecting and pollution-free oil-bearing sludge processing method and equipment, and the method comprises the following procedures: heating the water vapor to the superheated steam with temperature above 500 DEG C with a superheated steam boiler; injecting the superheated steam to the oil-bearing sludge with a speed of 2 mach, the oil-bearing sludge is crushed to small particles after instant colliding; separating the water component and the oil component which are evaporated and sublimed instantly with a cyclone separator; dropping the temperature and fluidifying through water spraying; and extracting the oil product up to standard by the separating of the oil-water separating pot, above 95% oil component in the oil-bearing sludge can be recovered and the oil content of the residue is lower than 5%, the petroleum processing method has the advantages of guaranteeing the quality of the recovered oil product, simple operation and maintenance, broad application that can be applied to varies types of oil-bearing sludge and oil-bearing sand, excellent economic benefit and low cost, the equipment is used for processing the oil-bearing sludge that is generated in the crude oil exploration and exploitation, crude oil transportation and the petroleum refinery wastewater treatment.

Owner:张贺新

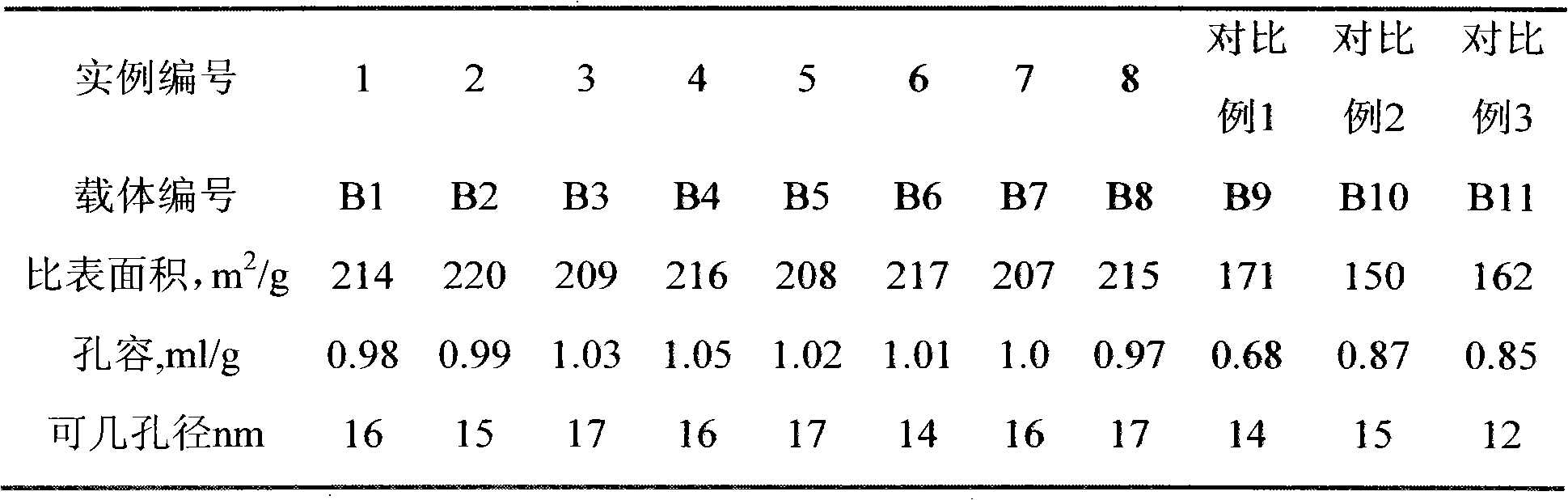

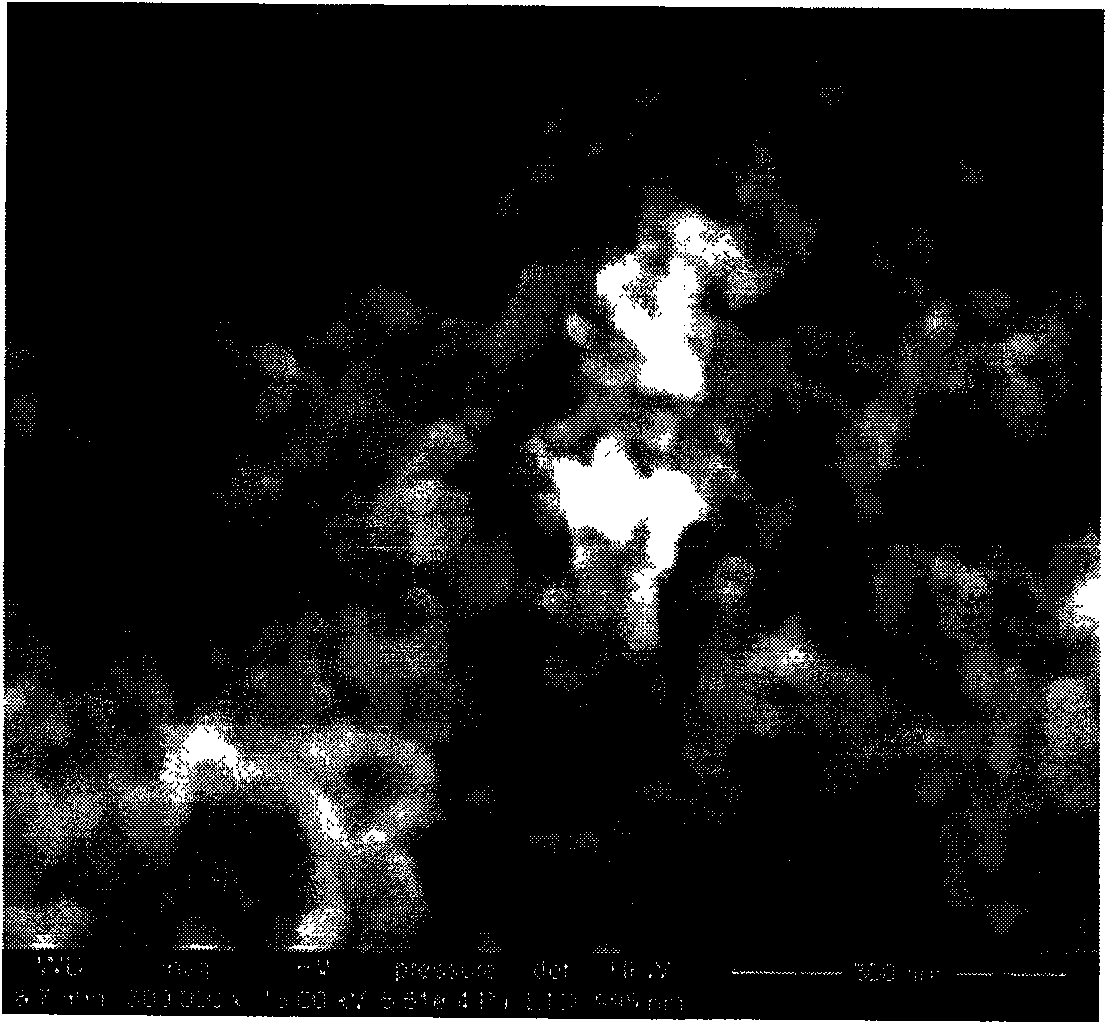

Method for preparing carrier material

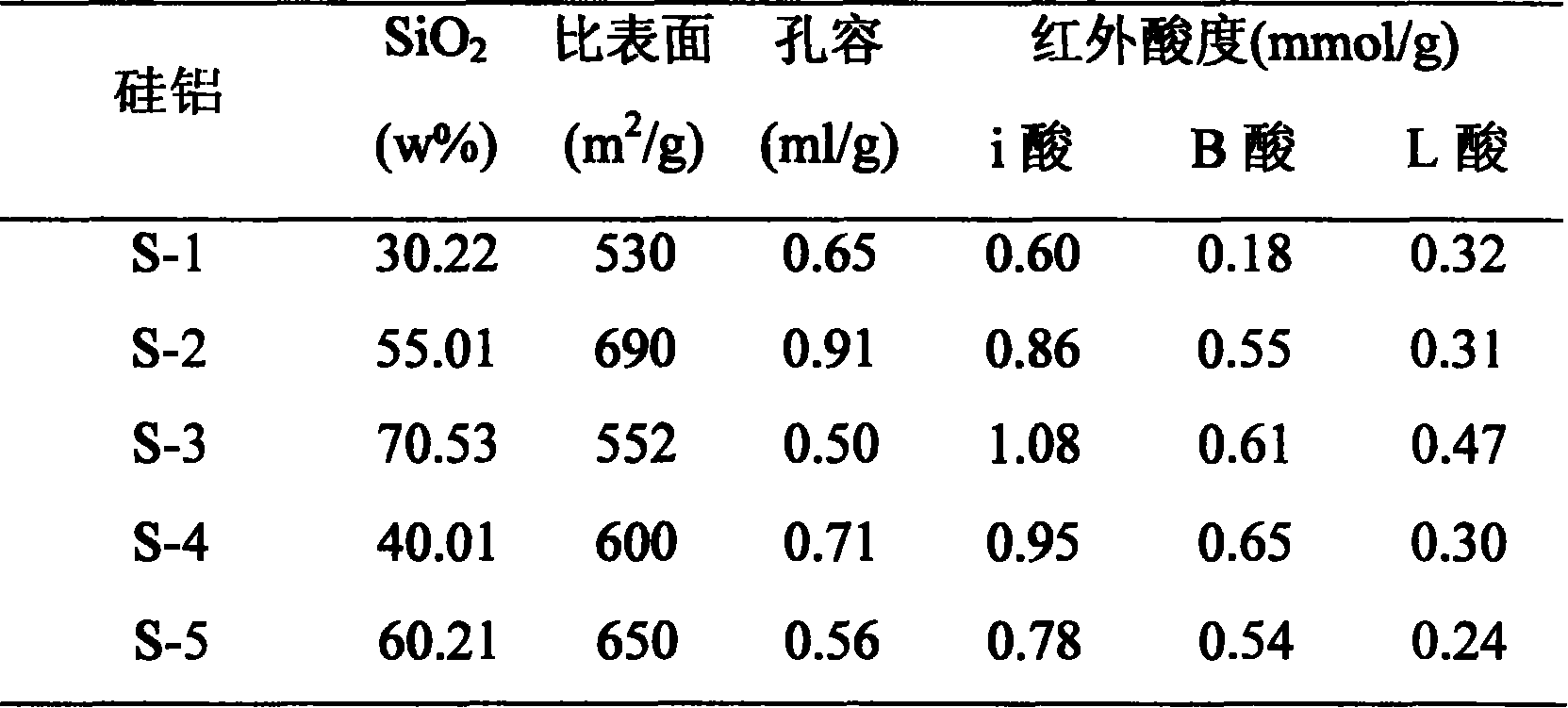

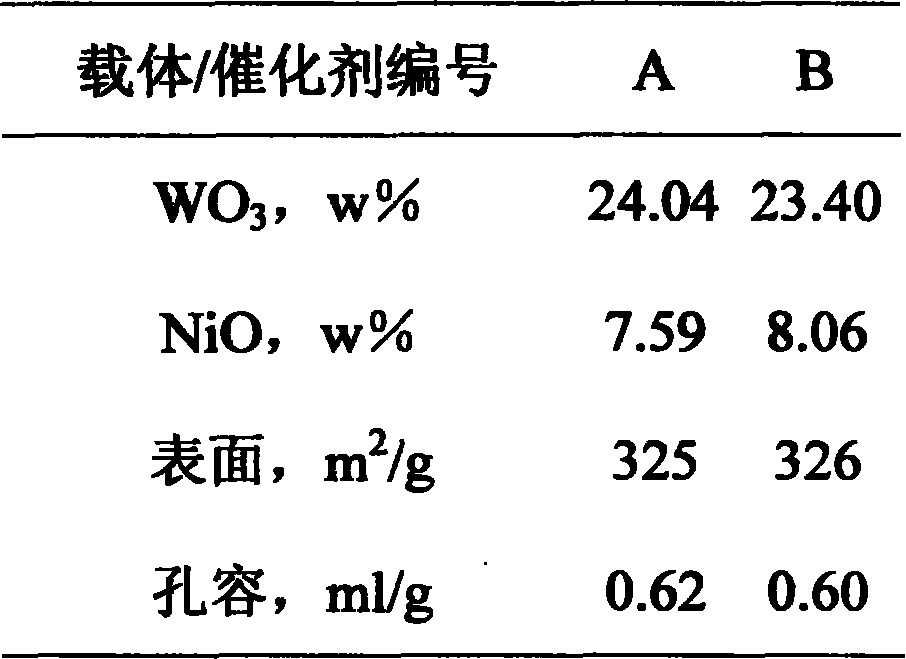

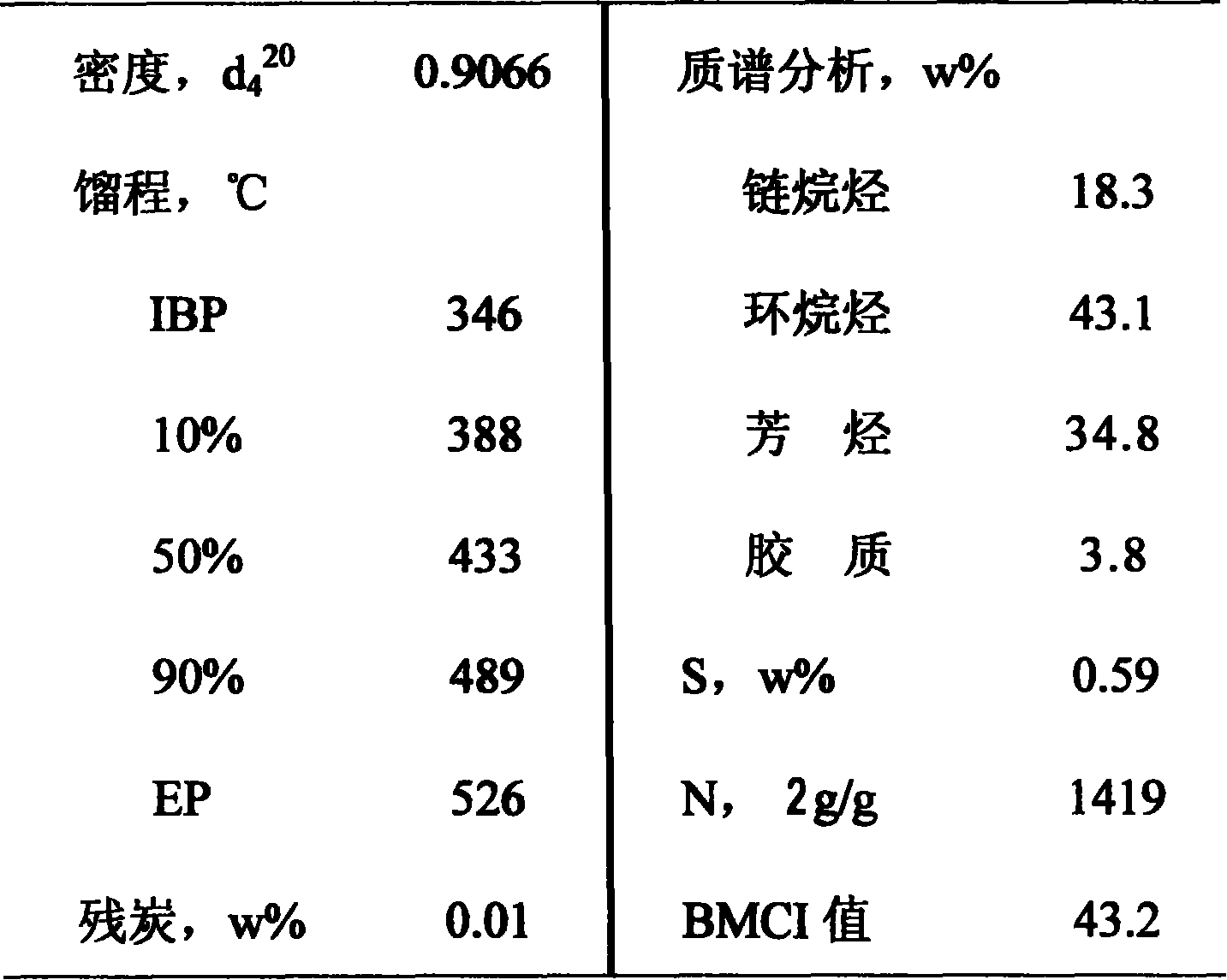

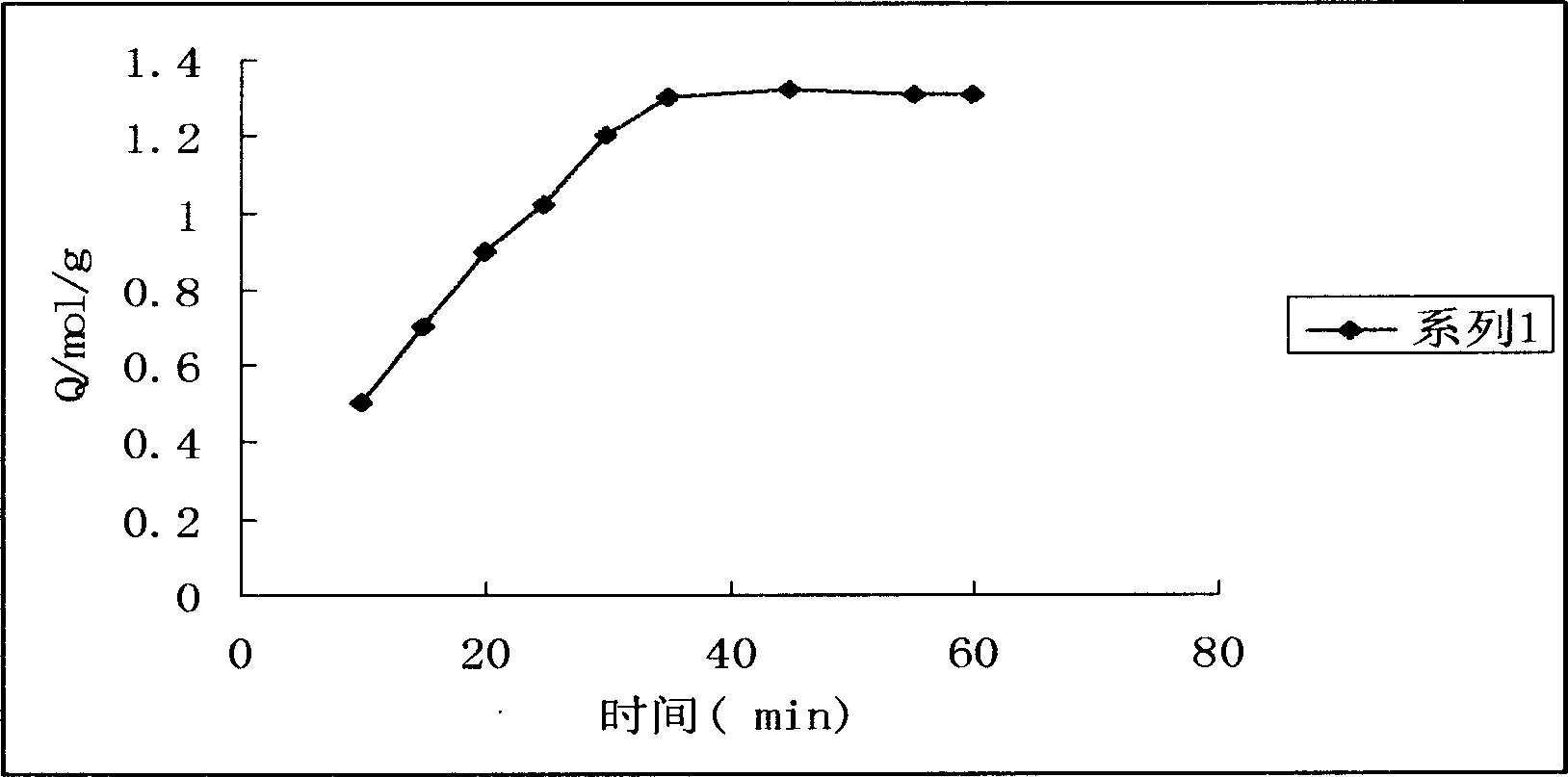

ActiveCN101172259AEvenly dispersedEasy to useCatalyst carriersMolecular sieve catalystsMolecular sieveAmorphous silica-alumina

The invention discloses a preparation method of a carrier material containing molecular sieve and amorphous silicon aluminum. The molecular sieve in the carrier of the present invention is introduced during the process of forming amorphous silica-alumina gel, which greatly improves the specific surface area and acidity of the silica-alumina carrier, and makes the molecular sieve evenly distributed in the silica-alumina carrier, which has a good effect on the dispersion of active metal components in the catalyst. It is beneficial to coordinate with both. The silica-alumina of the invention is suitable as a catalyst material for petroleum processing catalysts, especially as a carrier component for hydrotreating and hydrocracking catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

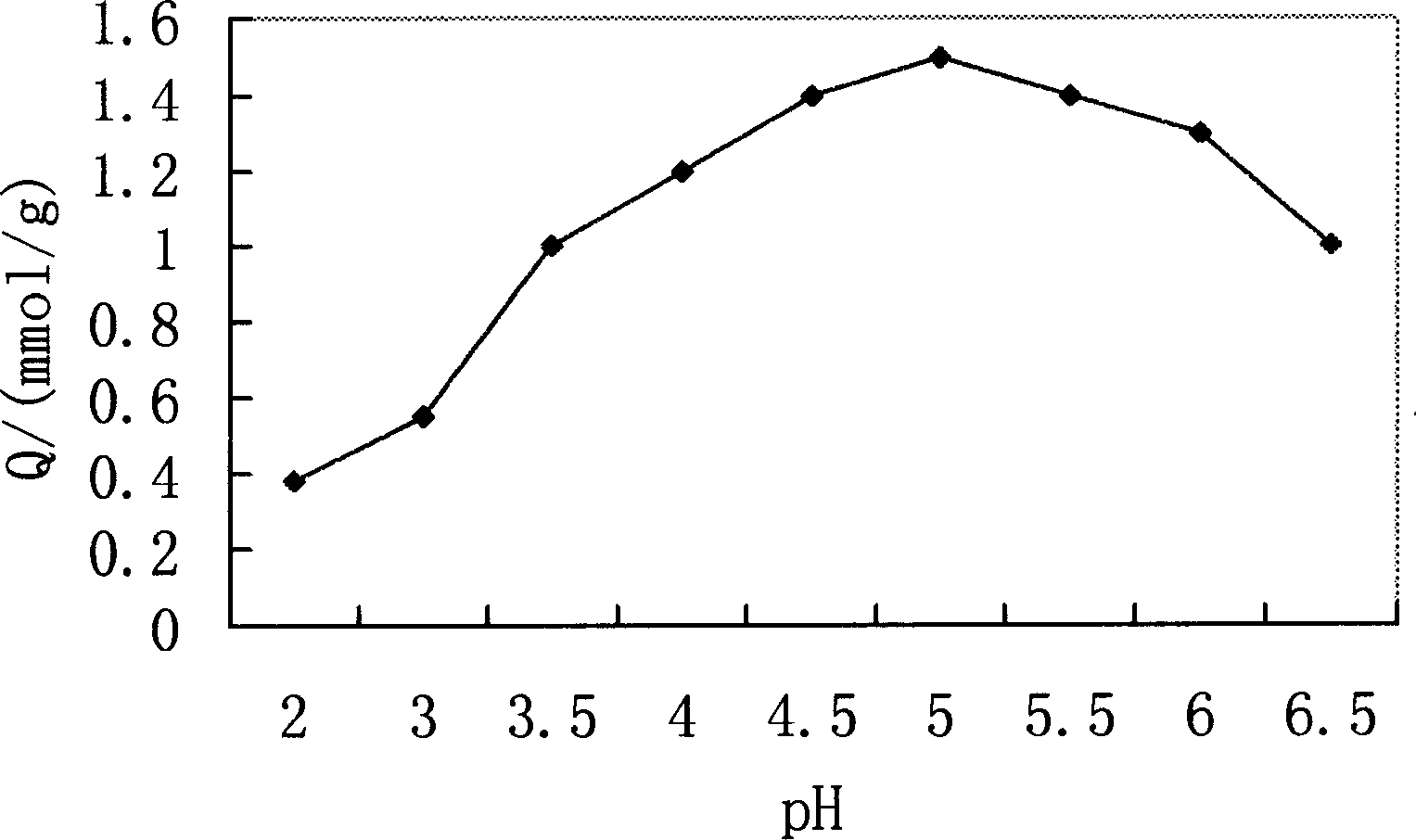

Method for synthesizing dithioamino formic acid and diivinyl triamineethyl polymers

The invention disclosed a synthetic method of the dithiocarbamic acid diethylene ethyl polymer and deals with the composing method of the dithiocarbamic acid polymer. The invention is the single stage process; the water, the sodium hydroxide, the diethylene tren, the carbon bisulfide and 1,2-dichloethane is mixed in turn to the polyreaction, so the adsorbent having the good ability of adsorbing the metallic ion. The invention has some merits of the easy means, the easy operation, the operator saving and the time saving, the water and organic solvent economy, the low cost of the producing, the wild acting condition, the safe produce, the energy saving, easy industrial production, the benefit of extending and applying. The production of the invention can be used for fathering the sullage containing the heavy-metal ion, so it can be applied to some trades such as the plate, the electron, the metallurgy, the petroleum processing and the pulp producing and is favourable to the environmental protection.

Owner:CHONGQING UNIV

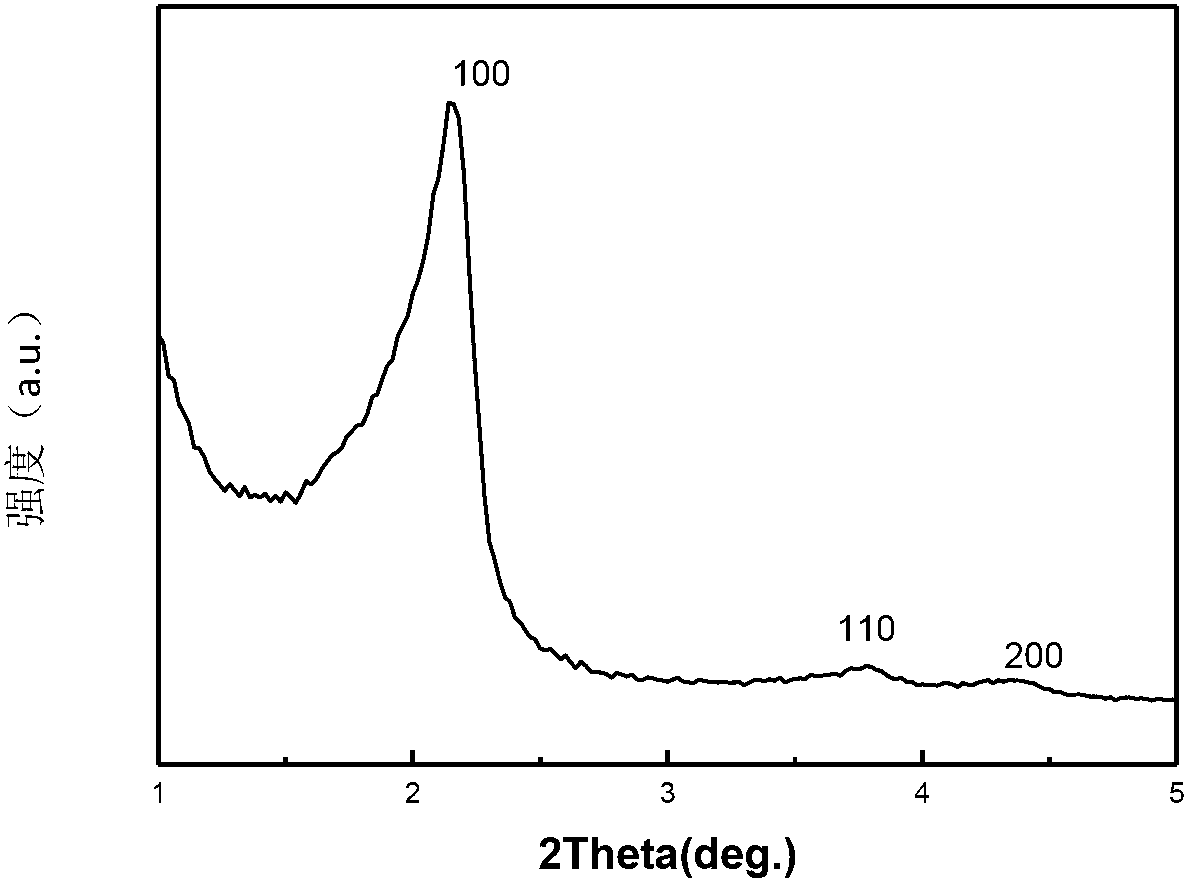

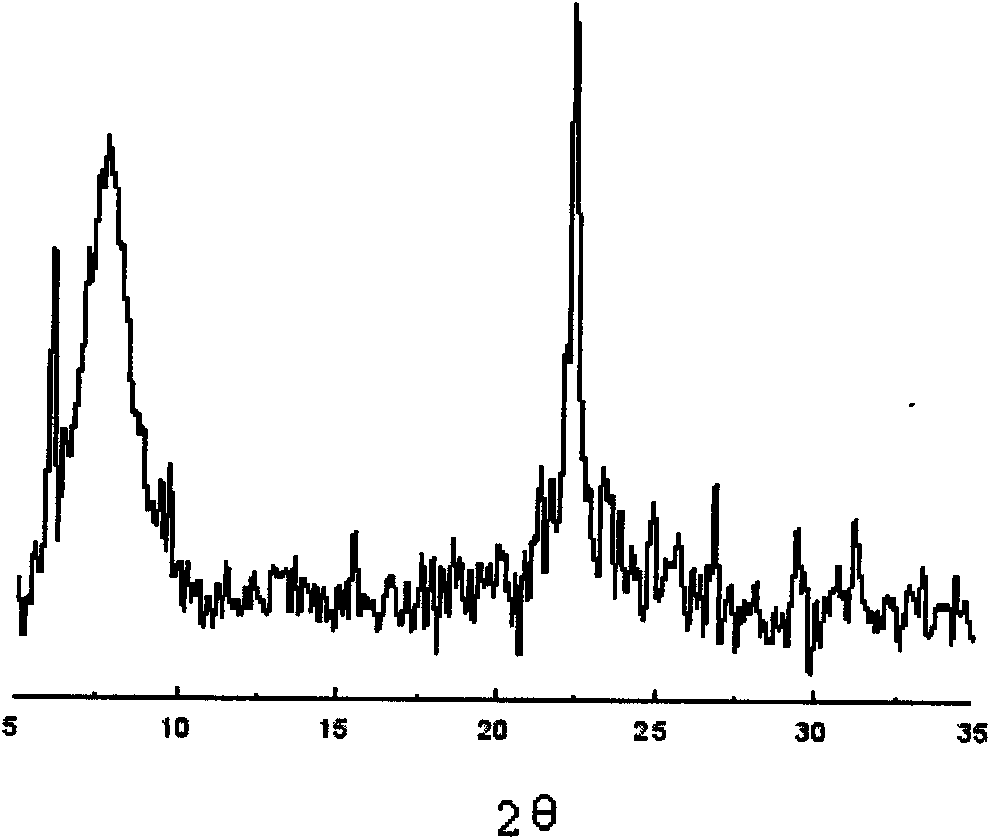

Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

InactiveCN103101930AImprove performanceRemarkable resultsPentasil aluminosilicate zeolitePore diameterPetrochemical

The invention discloses a preparation method of an ordered mesopore ZSM-5 molecular sieve. The preparation method comprises the following steps of: firstly preparing an ordered mesopore silicon oxide molecular sieve serving as a silicon source through an organic template method; and then transforming the ordered mesopore silicon oxide molecular sieve into the ordered mesopore ZSM-5 molecular sieve in situ by adopting a hydrothermal method. The ordered mesopore ZSM-5 molecular sieve disclosed by the invention is provided with ordered micropores with pore diameter being 0.2-2 nanometers and ordered mesopores with pore diameter being 2-50 nanometers and has wide application prospect in the fields of petrochemical industry, petroleum processing, coal chemical industry, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for desulfurization of fuel oil by oxidation process with modified titanium silicalite molecular sieve as catalyst

InactiveCN1844321AEasy to useGood catalytic oxidation performanceHydrocarbon oils refiningOil processingCatalytic oxidation

An oxidation sweetening method for fuel oil selecting modified titanium-silicon molecular screen as accelerating agent belongs to technical sphere of petroleum process. The invention provides an accelerating agent of modified titanium-silicon molecular screen which can be used in oxidation sweetening of fuel oil. The charge number of earth silicon in this invention adopting immersion method is 1.0wt%-3.0wt%. The obtained modified titanium-silicon molecular screen is used for catalytic and oxidation desulfurization of fuel oil. The significance effect of this invention is that it improves the repetitive use of accelerating agent in oxidation sweetening reaction. The method includes selecting modified titanium-silicon molecular screen as accelerating agent and removing sulfidization of fuel oil by hydrocarbonylation, which can reduce the sulfur content of fuel oil to 29.7 mu / g from 226.1 mu / g and reach deep desulfuration, and the accelerating agent can be recovered and the catalytic oxidation susceptibility of the recovered accelerating agent is good. The invention is of mild reaction condition, simple equipment and no consumption of hydrogen gas.

Owner:DALIAN UNIV OF TECH

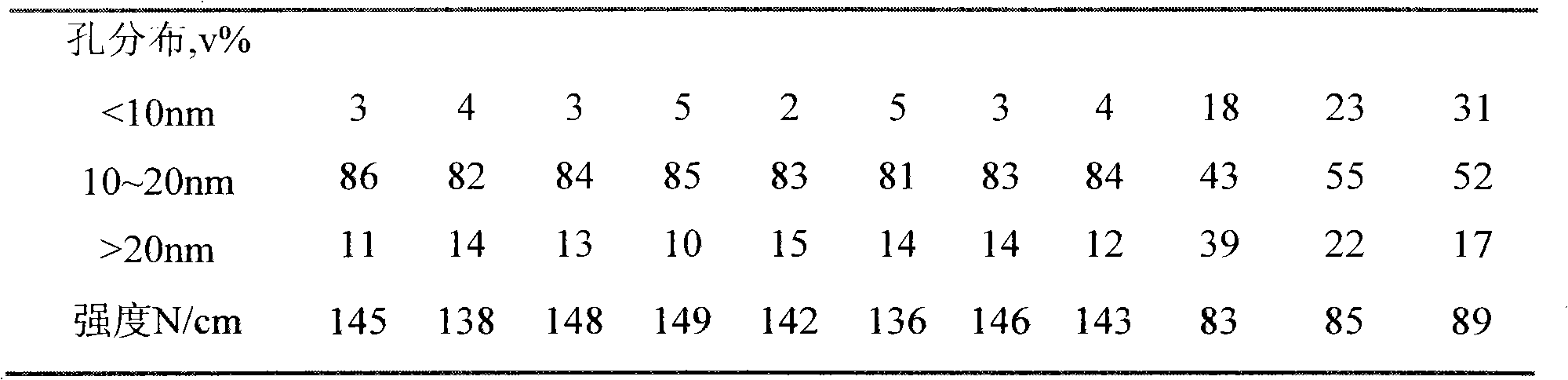

Preparation method for alumina carrier

ActiveCN102310000AReduce dosageExtensive sources of raw materialsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryPore distribution

The invention discloses a preparation method for an alumina carrier. The preparation method comprises the following steps of: (1) performing pressing hydrothermal treatment on pseudo-boehmite dry colloid powder; (2) kneading the pseudo-boehmite dry colloid powder obtained in the step (1) into plastic; and (3) performing forming on the plastic obtained in the step (2), drying and roasting the formed substance, and thus obtaining the final alumina carrier. The alumina (Al2O3) carrier with large aperture, centralized pore distribution and good strength is prepared by the method; and meanwhile, the method is simple in process, low in reaming agent consumption and low in raw material cost. The prepared alumina carrier can be applied in the fields of petroleum processing, chemical industry, environment friendliness and the like, and is particularly suitable for preparing heavy oil and residuum hydro-treating catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

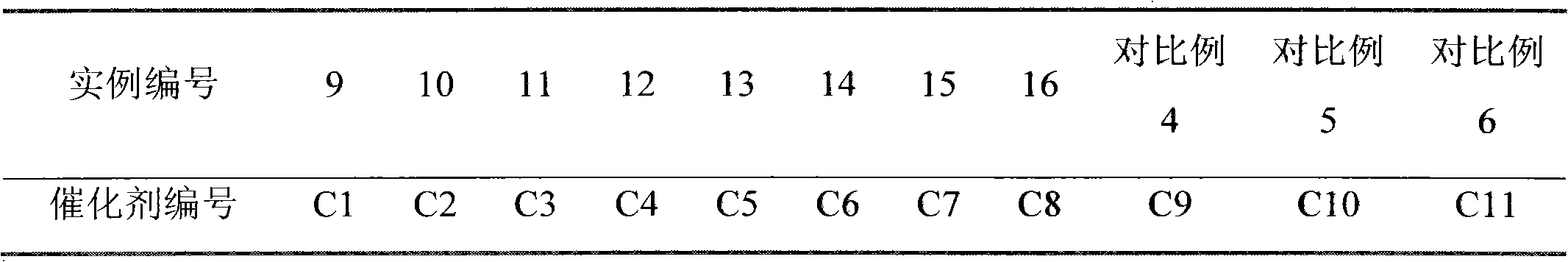

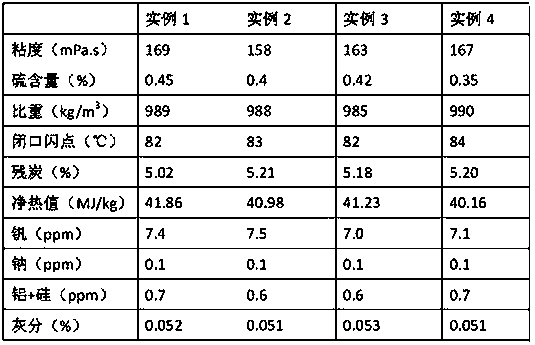

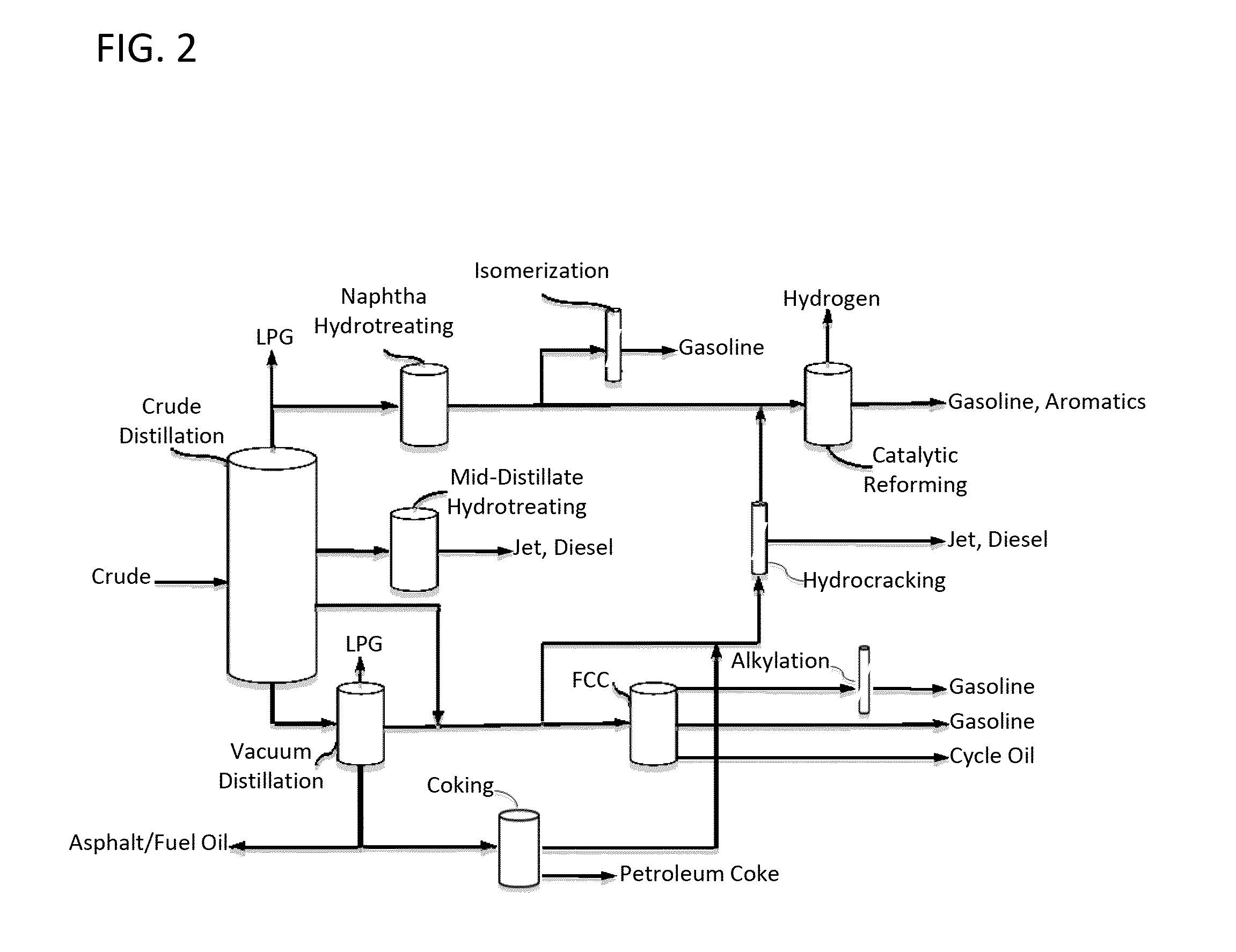

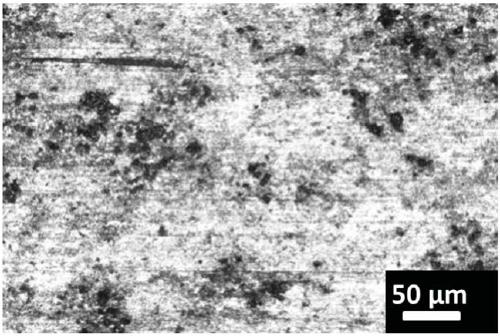

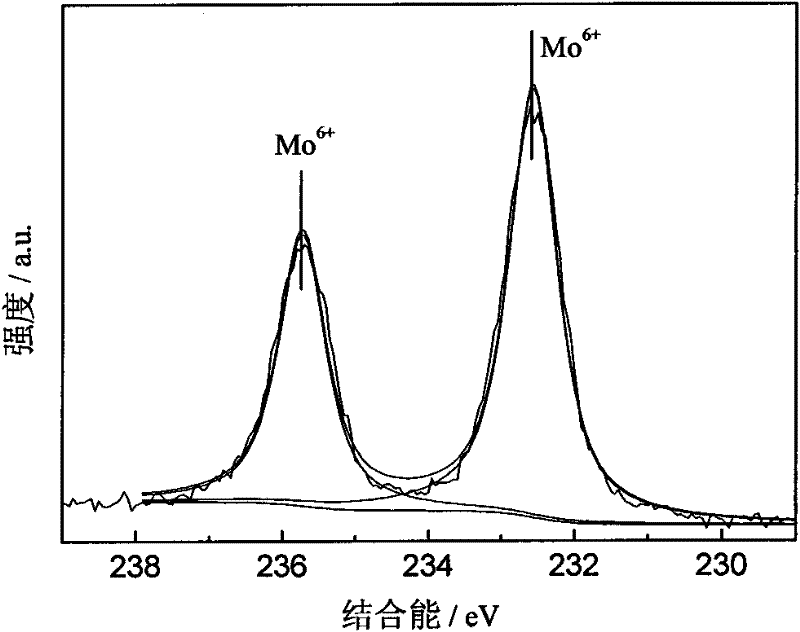

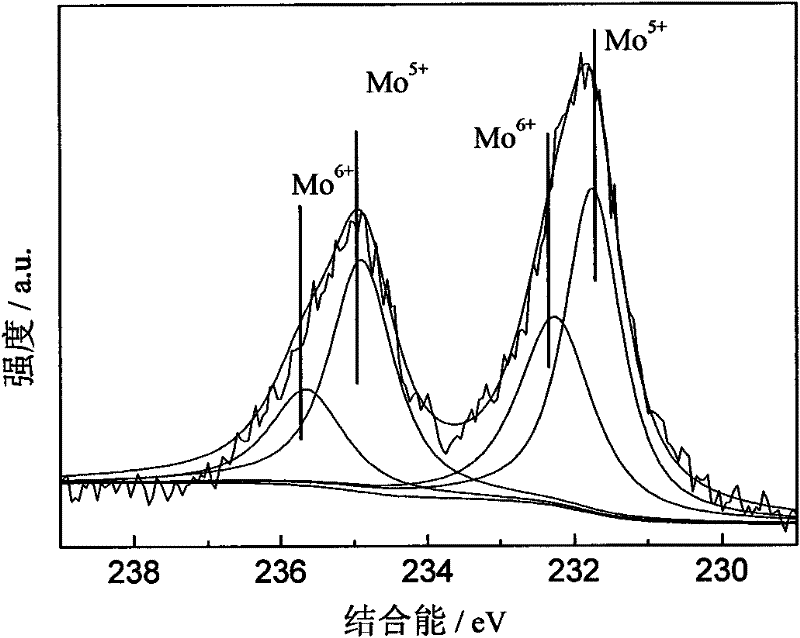

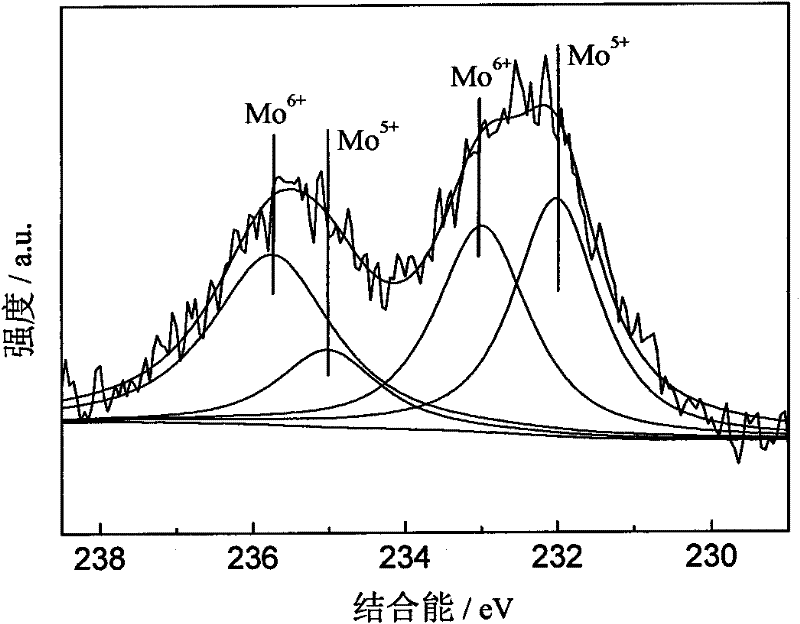

Process method for preparing marine fuel oil on basis of catalytic cracking oil slurry desolidification-hydrogenation

InactiveCN110205160ALow costStay flammableLiquid carbonaceous fuelsTreatment with hydrotreatment processesAdjuvantSlag

The invention relates to a process method for preparing marine fuel oil on the basis of catalytic cracking oil slurry desolidification-hydrogenation and belongs to the technical field of petroleum processing. According to the method, a solvent which is mutually soluble with oil slurry is used as a desolidification adjuvant of the catalytic cracking oil slurry to realize low-temperature desolidification, and the oil slurry which is subjected to desolidification and hydrogenation control is used as a fuel oil component to be compounded with a conventional marine fuel component. The process method for preparing the marine fuel oil on the basis of the catalytic cracking oil slurry desolidification-hydrogenation comprises the steps of oil slurry desolidification, hydrogenation and oil preparation, wherein under the condition of 40-60 DEG C, the catalytic cracking oil slurry is mixed with a diluent, separated, subjected to slag removal and then distilled to obtain desolidified oil slurry; under the action of a catalyst adopting nickel oxide and molybdenum oxide as active components and alumina as a carrier, the desolidified oil slurry is catalytically hydrogenated under the conditions that the space velocity is 0.25-0.5 h<-1>, the temperature is 350-370 DEG C, the pressure reaches 6-10 Mpa, and a hydrogen-oil volume ratio reaches (600-650):1. The method has the advantages that fewerimpurities and charcoal residues are generated, the equipment investment and the process cost are low, and the marine fuel cost is significantly reduced while the combustion performance of oil products is maintained; therefore, the process method is particularly suitable for manufacturing and processing high-performance fuel oil.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

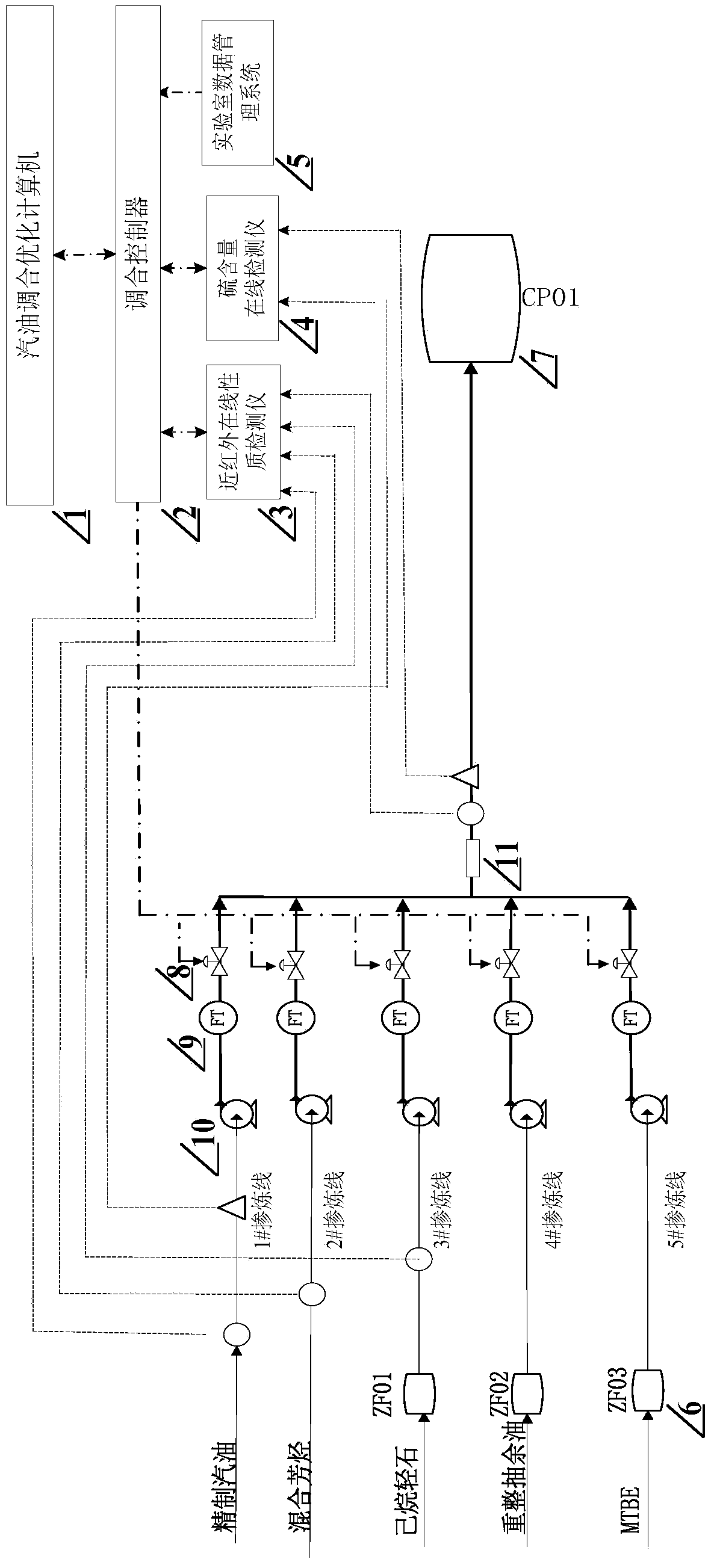

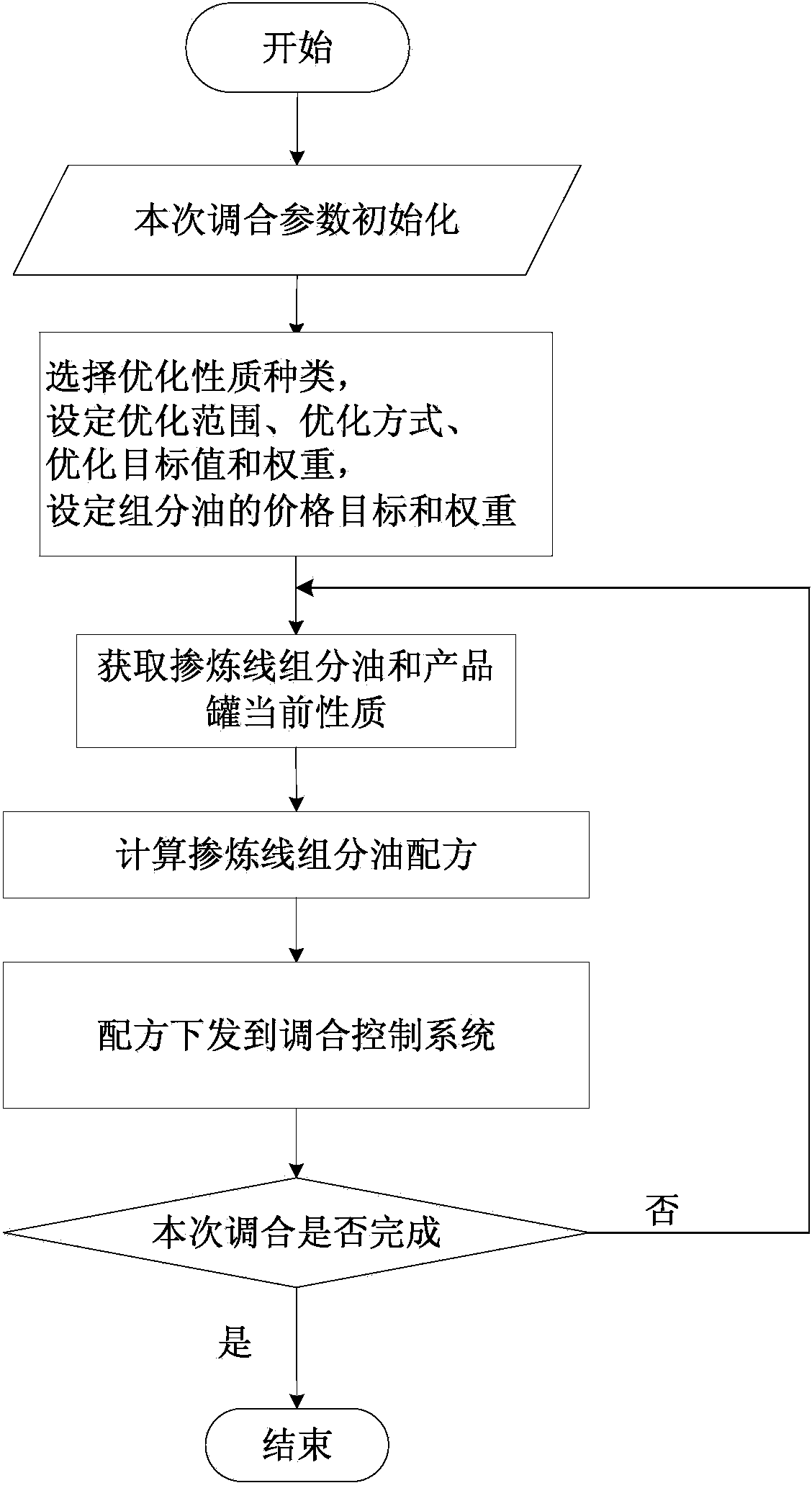

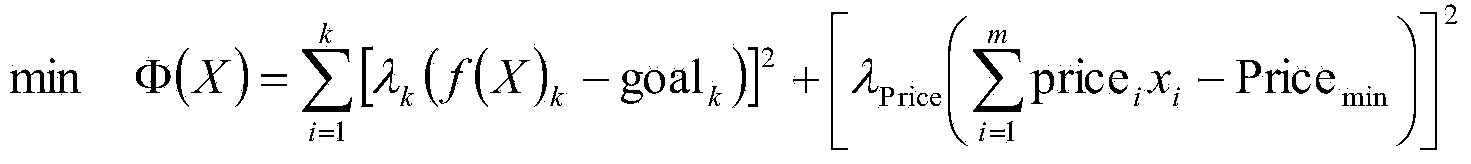

Nonlinear optimization method for high-performance petroleum blending

The invention discloses a nonlinear optimization method for high-performance petroleum blending. The rule combining linear blending and nonlinear blending is adopted to improve the petroleum product blending precision of a petroleum processing enterprise. The nonlinear optimization method supports the comprehensive index combining minimum difference between the blended petroleum nature content and the target and optimal economy, supports the four optimization modes that the petroleum nature content is valued within a range, the petroleum nature content is optimized towards the lower limit, the petroleum nature content is optimized to the upper limit and the petroleum nature content is optimized within the range, and improves the production flexibility. A system automatically generates a petroleum blending formula and issues the petroleum blending formula to a control system to be executed. The nonlinear optimization method can provide petroleum blending formulas meeting the national standard requirements for petroleum blending of refining factories, avoid mass surplus and increase the production efficiency and economical benefits and is particularly suitable for being used for petroleum processing of petroleum refining enterprises.

Owner:南京富岛信息工程有限公司

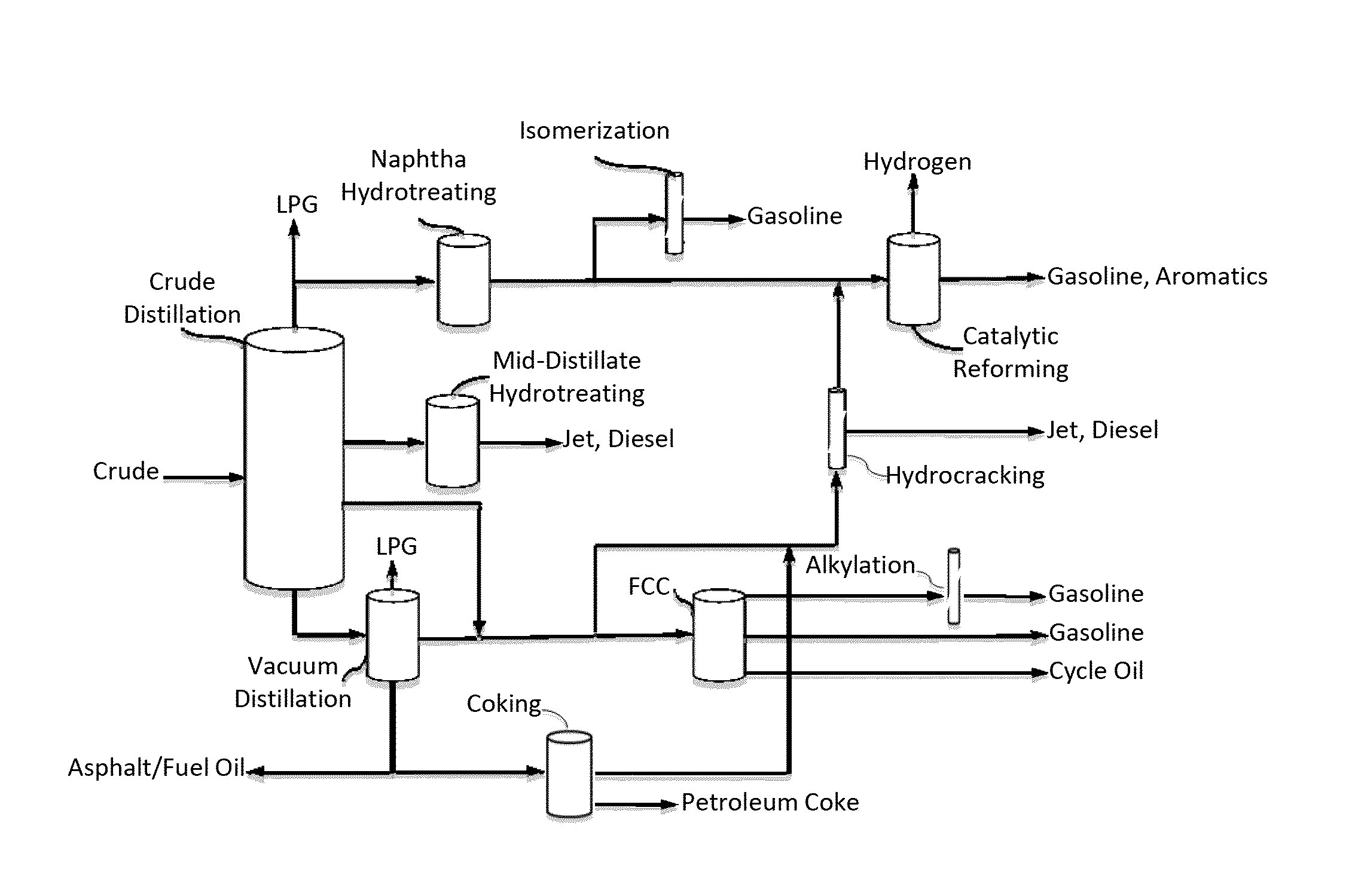

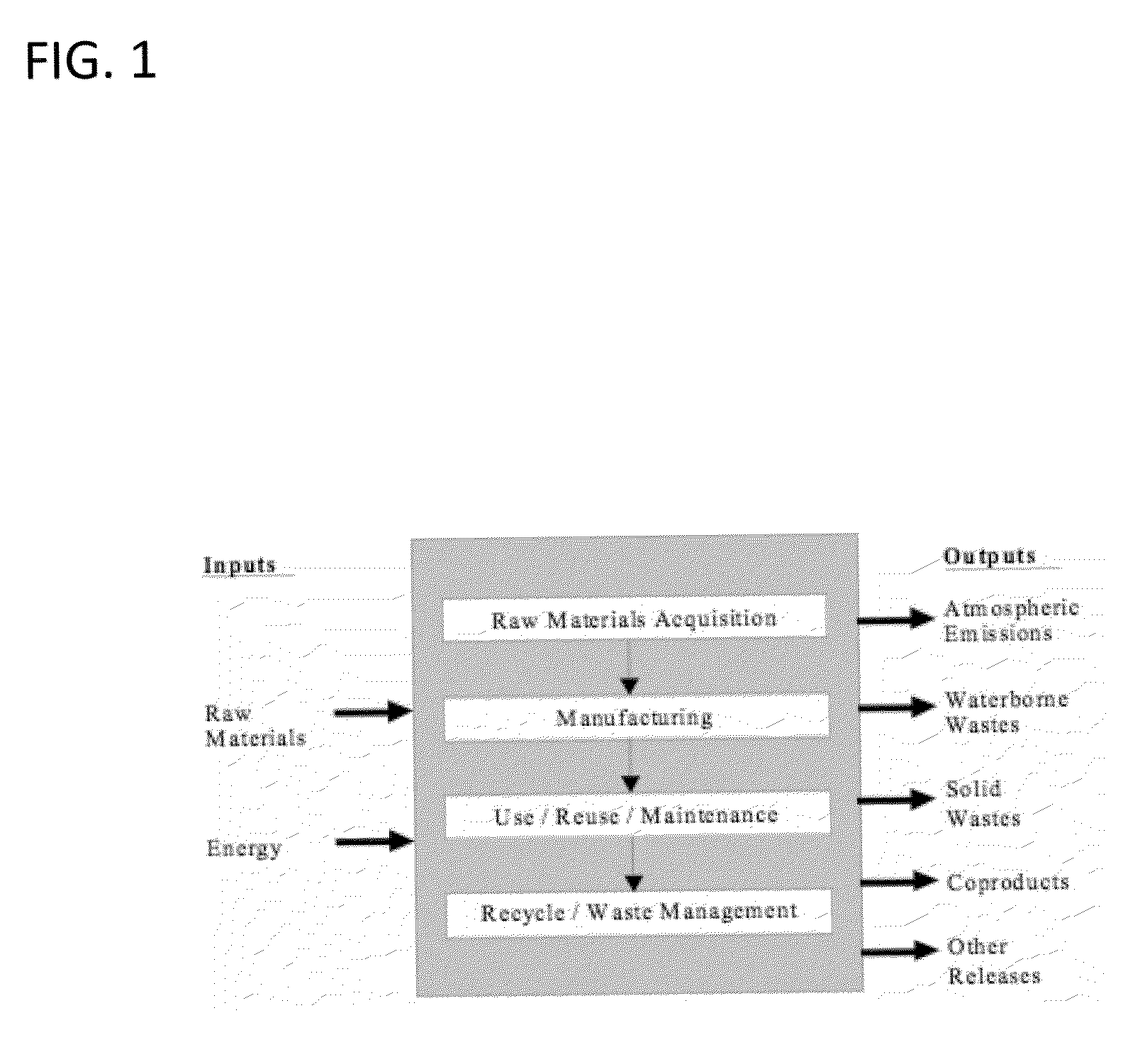

Integrated carbon management system for petroleum refining

InactiveUS8157003B2Increase volumeCombination devicesDrilling rodsSystem integrationPetroleum product

An environmentally and economically more efficient petroleum production / refining / utilization system for managing carbon emissions at all stages of the petroleum lifecycle is provided. The system of the current invention integrates the release of carbon from refined low value, high polluting petroleum products such that those sources of carbon may be utilized in a manner beneficial to the efficiency and environmental footprint of the overall petroleum processing lifecycle.

Owner:STILLWATER ENERGY GROUP

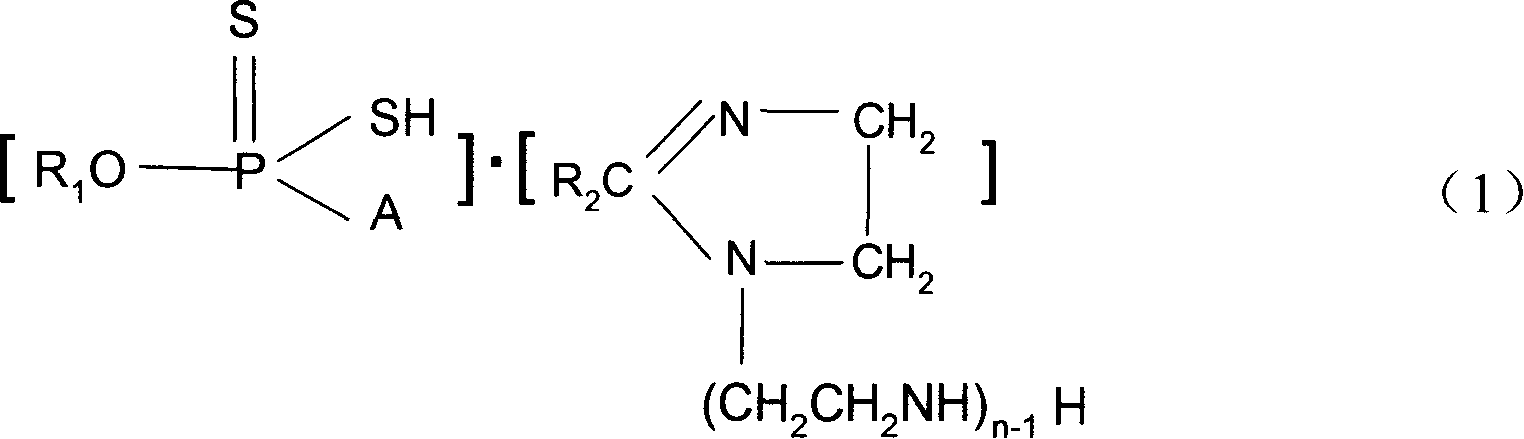

High temp corrosion inhibitor and its preparation method and application

InactiveCN1869287AImprove performanceRaw materials are cheap and easy to getSulfurPetroleum processing

The invention discloses a manufacture method and application for high temperature inhibitor that is the compound has the structure general expression (1), and R1 is C4-C12 alkyl, R2 is C8-C30 alkyl or alkyl derivative, n is 2-5, A is SH or R10. The invention could effectively solve the naphthenic acid corruption and sulfur corruption generated by high temperature section in petroleum processing.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

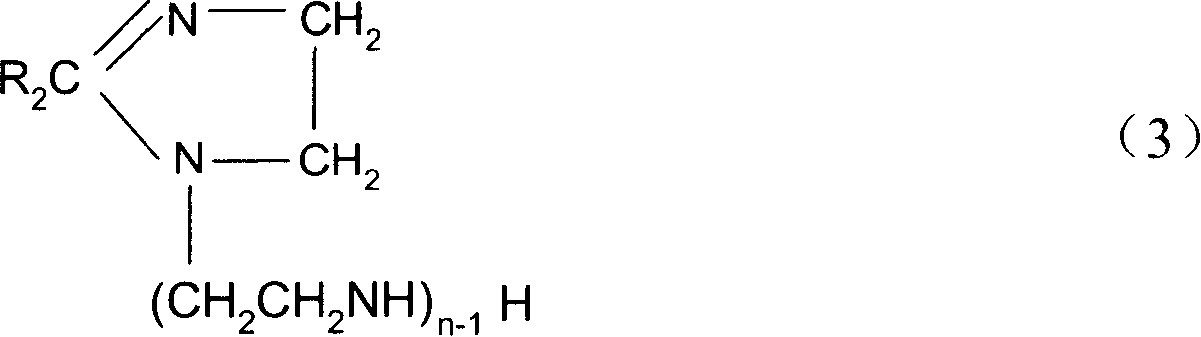

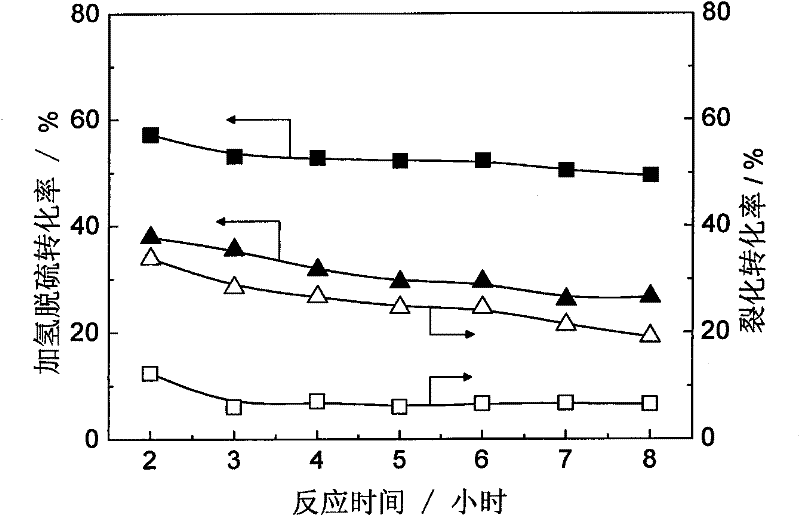

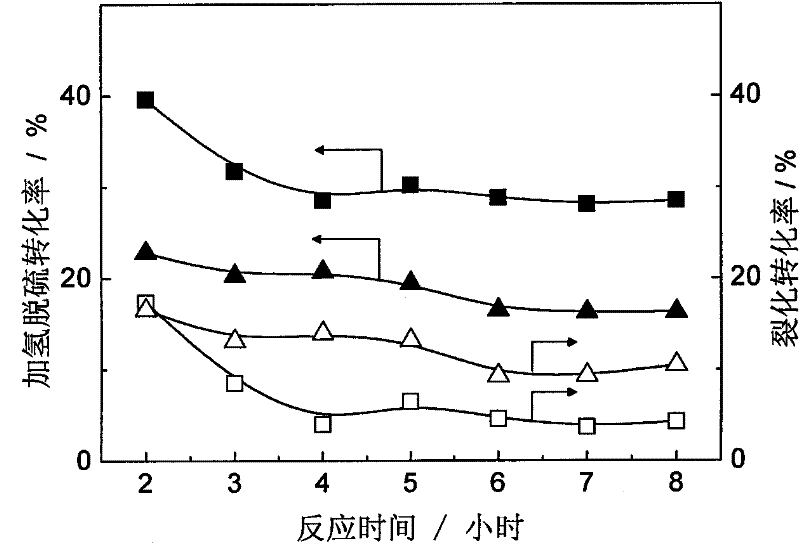

A sulfur-resistant noble metal hydrodesulfurization catalyst

InactiveCN102294269AHigh catalytic activityGood sulfur resistance and stabilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningSilanesHydrogen atmosphere

The invention relates to a sulfur-resistant precious metal hydrodesulfurization catalyst, which belongs to the technical field of petroleum processing and relates to a solid catalyst used in the hydrodesulfurization process of petroleum distillate oil. The feature of the present invention is that the porous silicon-based material modified by silanization is used as a carrier, loaded with noble metal salt or noble metal organic complex, dried and calcined at 350-500°C to obtain the catalyst oxidation state precursor, and then In a hydrogen atmosphere, the temperature is raised to 200-400° C. at a rate of 1-10° C. / min, and the reduction is carried out at this temperature for 0-5 hours to prepare a supported noble metal hydrodesulfurization catalyst. The effects and benefits of the present invention are that the prepared noble metal catalyst has high catalytic activity to aromatic heterocyclic sulfur-containing compounds in petroleum fractions under typical industrial application conditions, and has good sulfur resistance stability and low Cracking activity, can be used for clean fuel oil production.

Owner:DALIAN UNIV OF TECH

C4 mixture hydrating process of preparing butyl alcohol

InactiveCN1506344AHigh catalytic activityImprove catalytic selectivityPreparation by hydroxy group additionChemical recyclingHydration reactionMolecular sieve

The present invention is the process of hydrating C4 fraction in the presence of catalyst with molecular sieve or modified molecular sieve as active component. The reaction is high pressure liquid phase fixed bed process; the material is C4 fraction produced in the petroleum processing process, MTBE processed mixed C4 fraction or some single C4 olefin; and the catalyst has acid molecular sieve or metal salt or oxide modified molecular sieve as active component. The solid acid catalyst with molecular sieve as active component has better catalytic activity and selectivity to the hydration of C4 olefin in corresponding conditions, the material needs no concentration and the catalyst may be regenerated.

Owner:PETROCHINA CO LTD +1

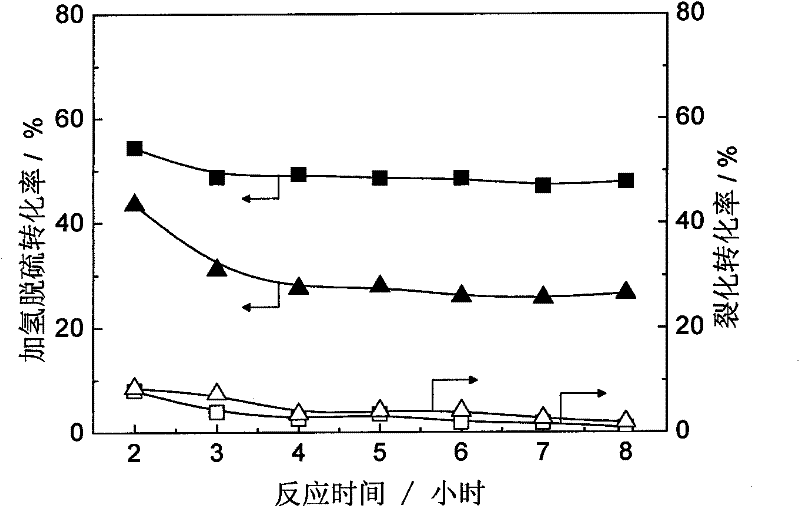

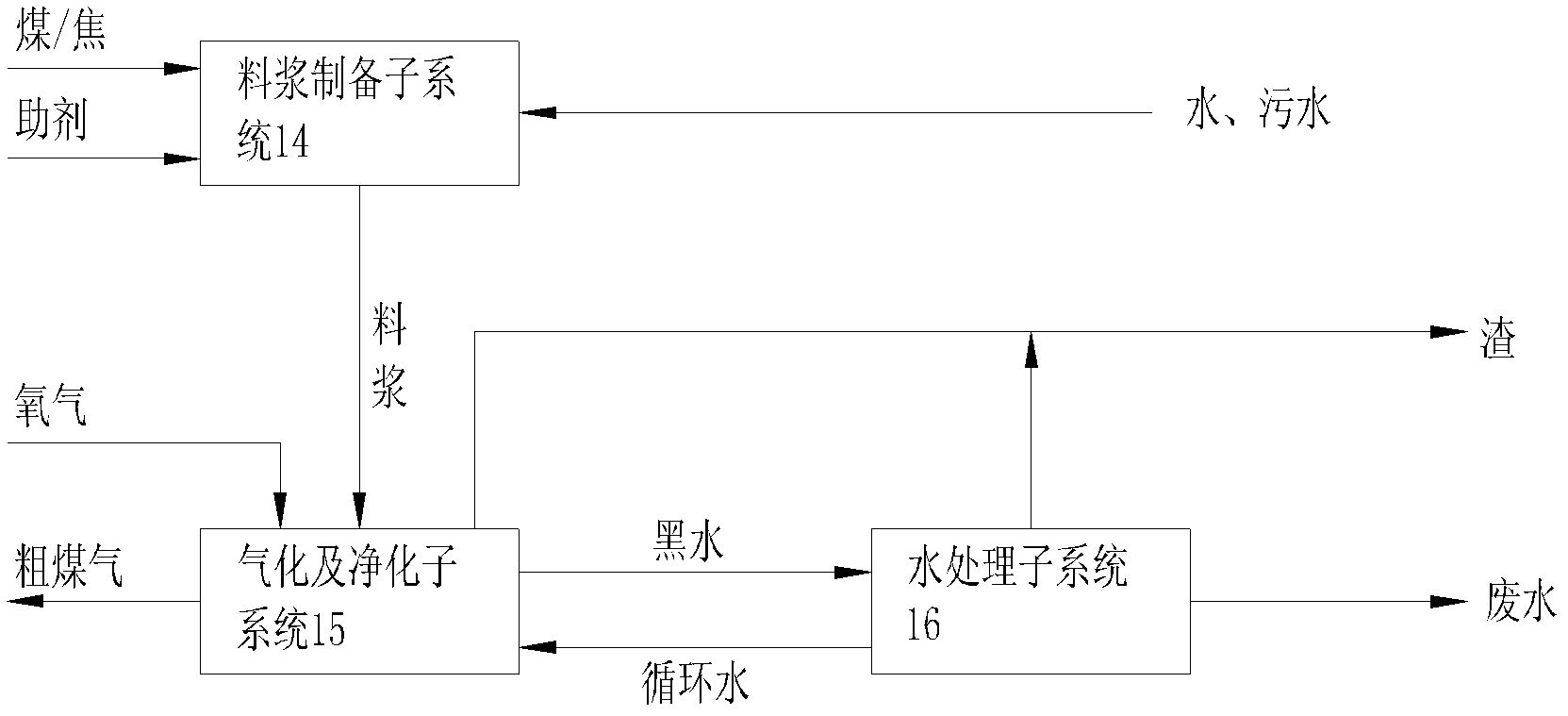

Method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials

ActiveCN102660330ASolve the problem of clean utilizationQuality improvementHydrogenOrganic compound preparationOil processingElectrolysis

The invention relates to a method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials. The method includes the steps of petroleum processing, slurry gasification, natural gas conversion, chemical product synthesis and salt electrolysis conversion. By reasonably using the coal, the petroleum, the natural gas and the salt resources, the energyand chemical overall goals of saving non-renewable resources and relieving environmental pollution can be achieved, and construction basis, solution and technical support are provided for Chinese large and super-huge energy industry base construction.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

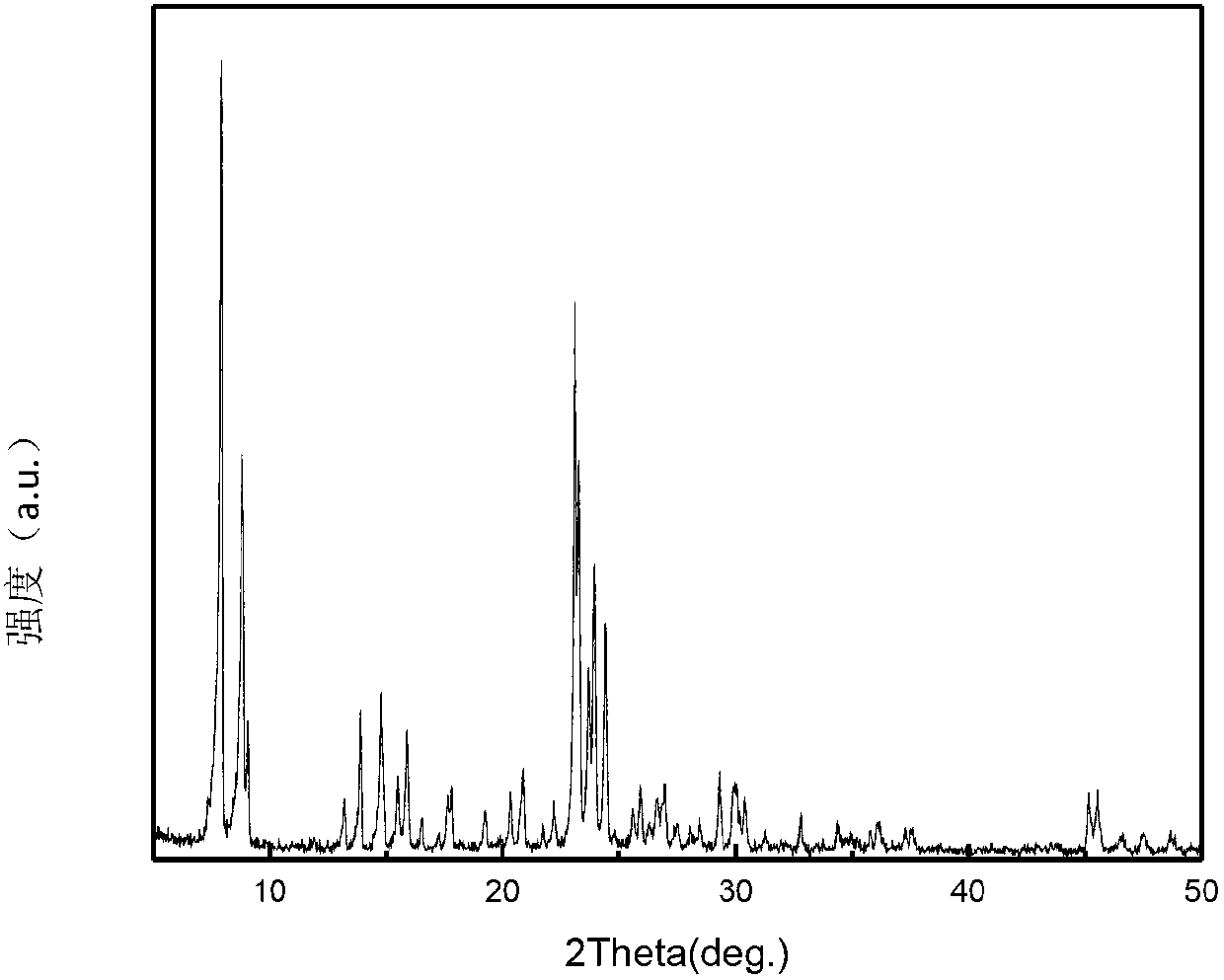

Composite zeolite molecular sieve preparing method containing Y and Beta zeolite structures

A composite zeolite molecular sieve preparing method containing Y and Beta zeolite structures belongs to the inorganic synthetic cellular material field. The invention is characterized by firstly configuring Y type guide agent by sodium aluminate, silicasol and sodium hydroxide; then synthesizing the stabilized colloidal sols containing Y type zeolite structure unit by the guide agent; adding appropriate silicon source and formwork agent in the colloidal sols; after crystallizing 2-12 days under 120 DEG C to 150 DEG C, then filtering, washing, drying and calcining to obtaine the composite zeolite molecular sieve preparing method containing Y and Beta zeolite structures. The molecular sieve not only has the structure and performance of Y type and Beta type zeolite molecular sieve, but also implements the reasonable collocation and the acid gradient allocation of two kinds of molecular sieve pore passage structures, thereby being contribute to implement the cooperating actions between Y type and Beta type zeolite molecular sieves, and the invention has potential application prospects on the fields of fine chemical industry and petroleum processing.

Owner:BEIJING UNIV OF TECH

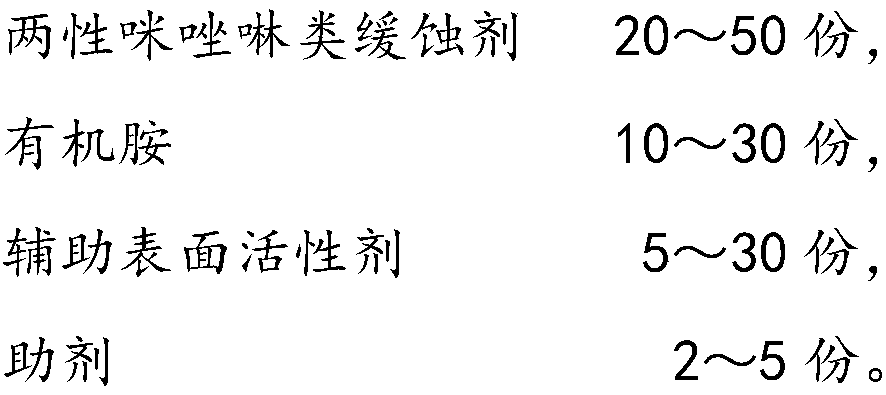

Neutralization corrosion inhibitor and preparation method and application thereof

The invention provides a neutralization corrosion inhibitor and a preparation method and application for the neutralization corrosion inhibitor and belongs to the technical field of chemical engineering. By means of the neutralization corrosion inhibitor and the preparation method and application for the neutralization corrosion inhibitor, the technical problems that existing water-soluble corrosion inhibitors are poor in corrosion inhibition effect and insufficient in protecting effect can be solved. The neutralization corrosion inhibitor comprises the raw material ingredients of, by weight,20-50 parts of an amphoteric imidazoline corrosion inhibitor, 10-30 parts of organic amine, 5-30 parts of cosurfactant and 2-5 parts of adjuvant. The corrosion inhibitor provided by the invention hasgood water solubility, has the advantages of being convenient to use and good in corrosion inhibition performance at the same time, is applied to corrosion prevention of petroleum processing equipment, can well adapt to high-temperature and high-acid working environments and has good protecting effect, and the corrosion inhibitor is simple in production process, low in cost and environmentally friendly and has quite good economic value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing alumina supporter with high specific surface area

The invention discloses a method for preparing an alumina supporter with high specific surface area. The method comprises the following steps of (1) weighing a certain amount of pseudoboehmite dry glue power, a certain amount of physical pore-enlarging agent and a certain amount of extrusion assistant agent to be evenly mixed and then adding an aqueous solution containing a chemical pore-enlarging agent; (2) evenly mixing materials obtained in the step (1) and extruding a mixture into strips; and (3) drying the material obtained the step (2), and calcinating a dried material in the nitrogen atmosphere to calcinate and prepare the alumina supporter in the air atmosphere. The alumina supporter prepared by means of the preparation method is large in pore volume and specific surface area, concentrated in pore distribution and moderate in mechanical strength, can be suitable for the fields of petroleum processing, chemical engineering, environmental protection and the like, and is especially suitable for preparation of heavy oil hydrotreating catalysts and residual oil hydrotreating catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

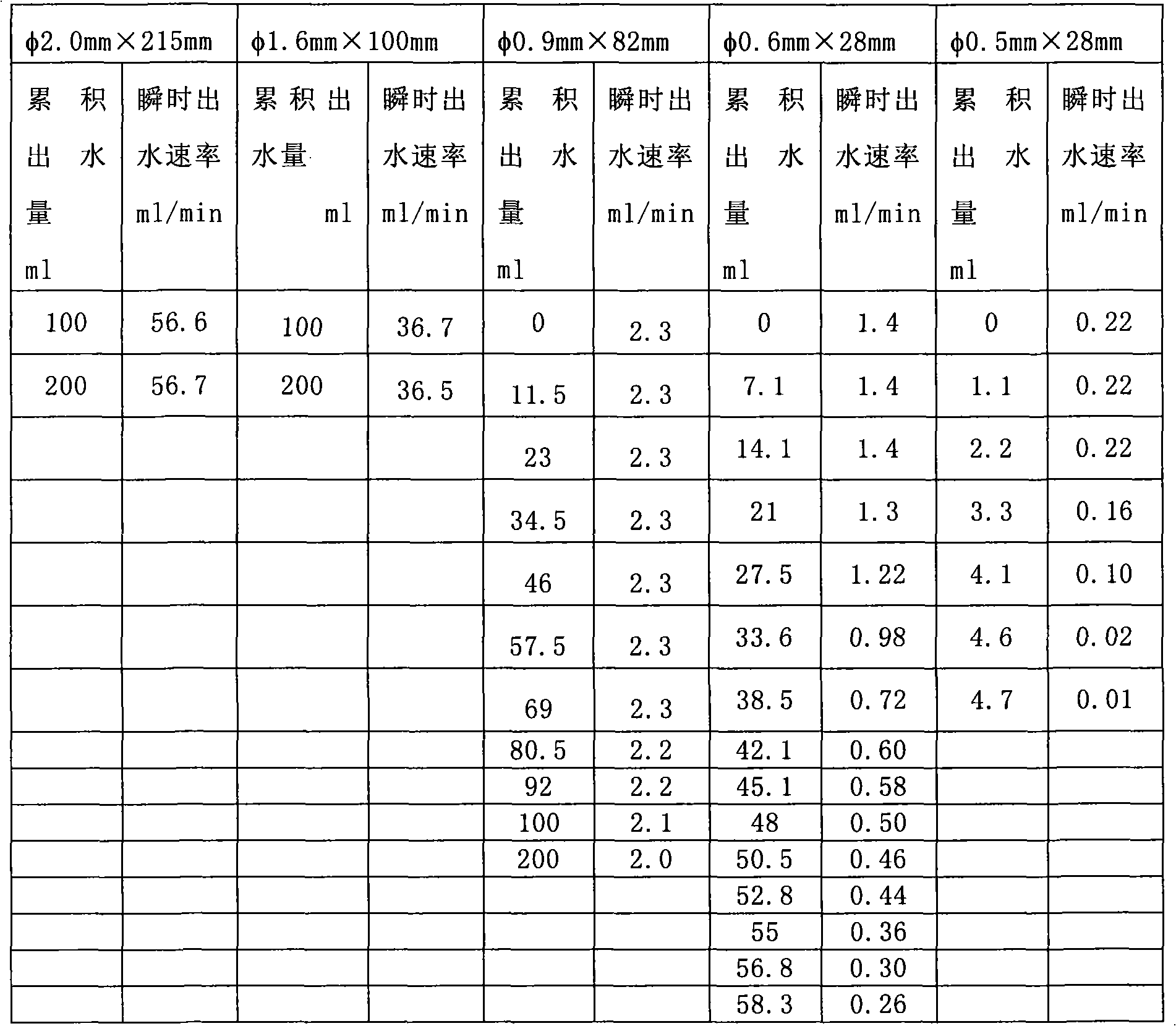

Evaluation device and evaluation method for scale formation trend and scale inhibition effect

InactiveCN101576550APredict fouling trendsPredicting Antiscalant PerformanceMaterial analysisUltrasound attenuationLiquid medium

The invention discloses an evaluation device and an evaluation method for scale formation trend and scale inhibition effect. The principle is as follows: a sample is enabled to flow through a capillary with a constant pressure difference, and the scale formation trend of the sample is represented by the blockage condition of the capillary reflected by monitoring the attenuation of the flow rate of the sample in the capillary; and the scale inhibition performance of a physical measure and medicament is represented by a ratio of the accumulated outflow of a chemical or physical modified sample and the accumulated outflow of a bland sample under the same instantaneous outflow rate attenuating range. The evaluation device and the evaluation method for scale formation trend and scale inhibition effect are suitable for scale formation forecast of various liquid mediums in water treatment, petroleum exploitation, seawater desalination, petroleum processing and chemical production as well as scale inhibition performance evaluation and selection of various physical and chemical scale inhibition measures.

Owner:吴鹏

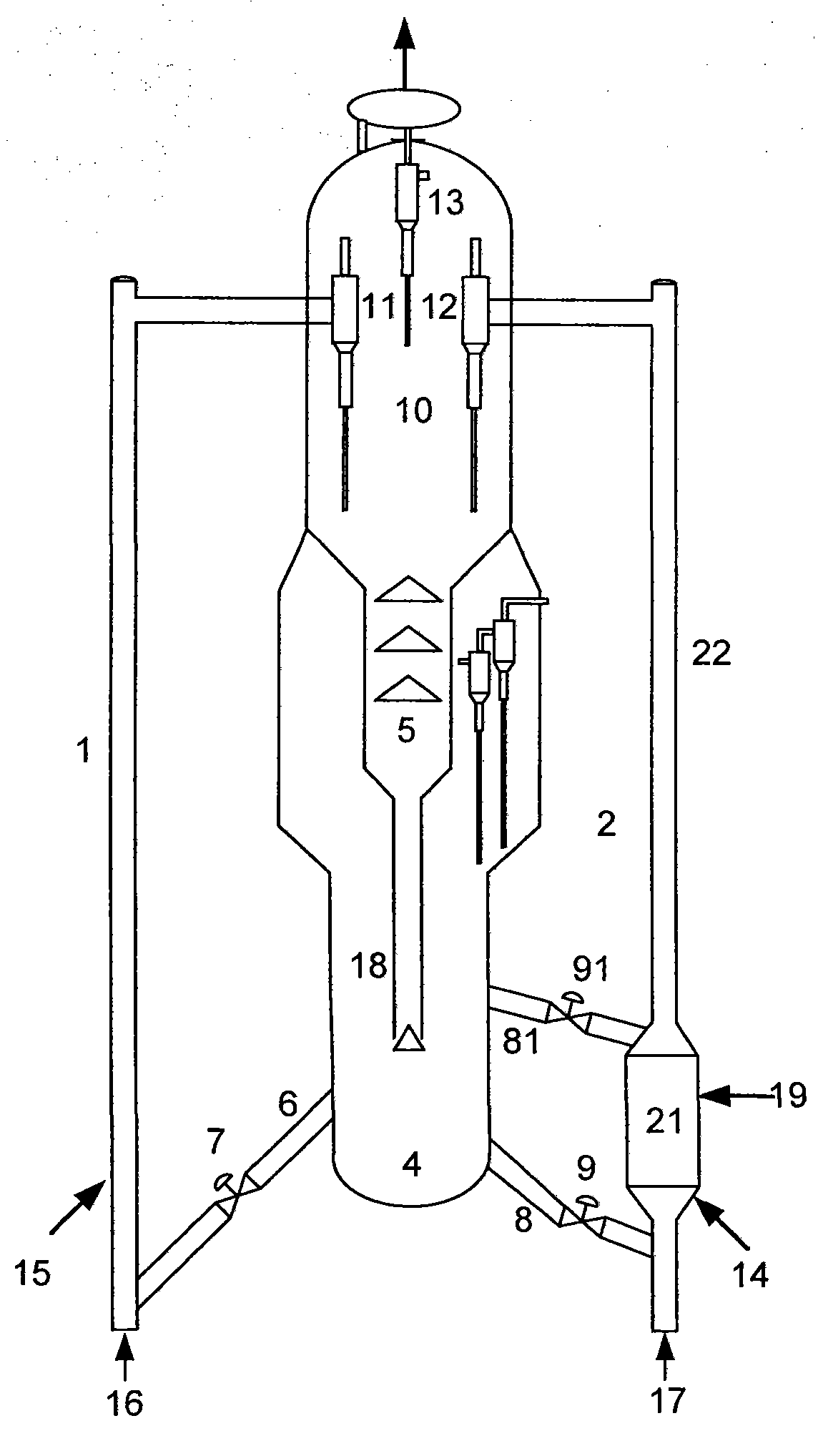

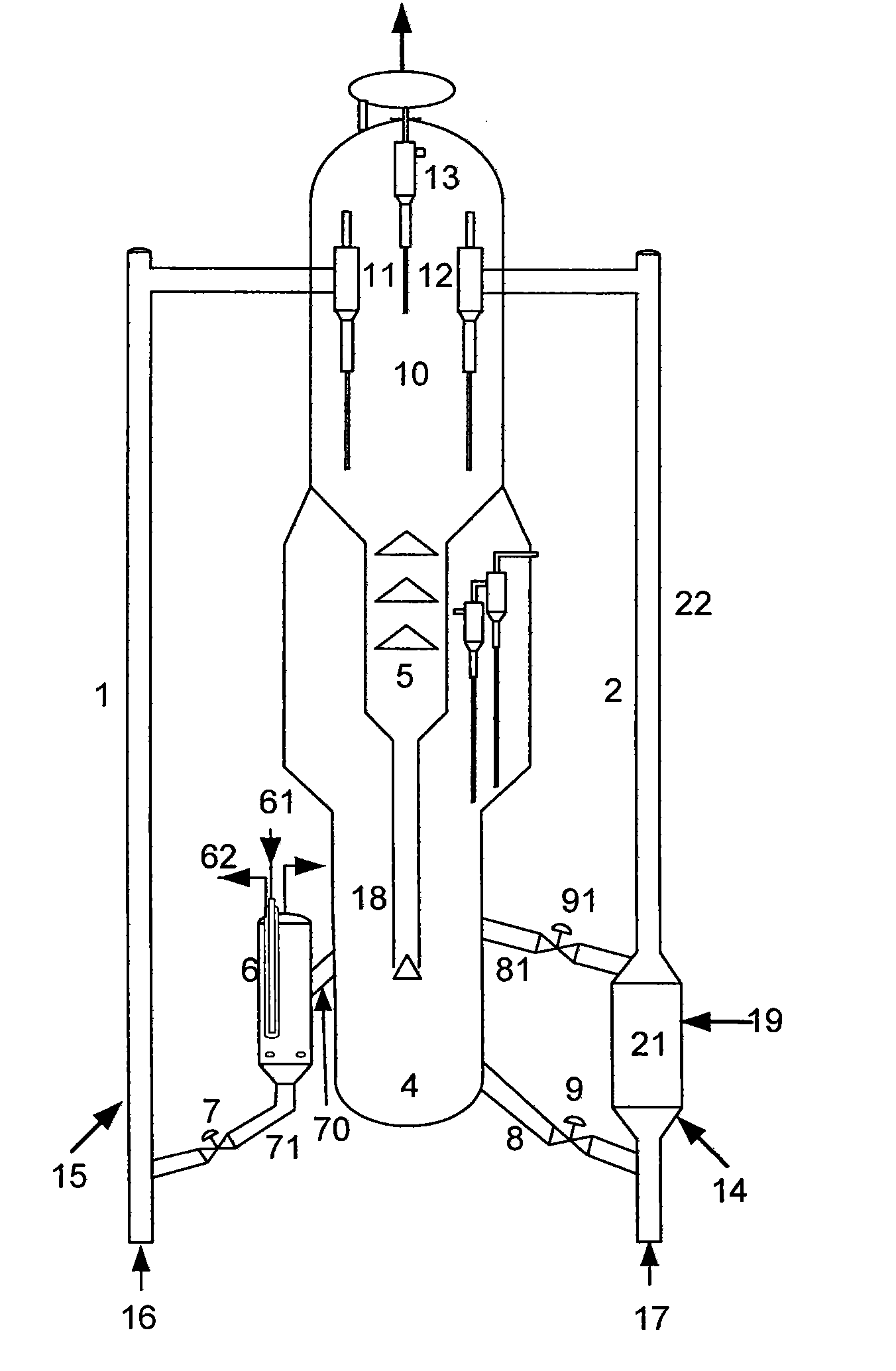

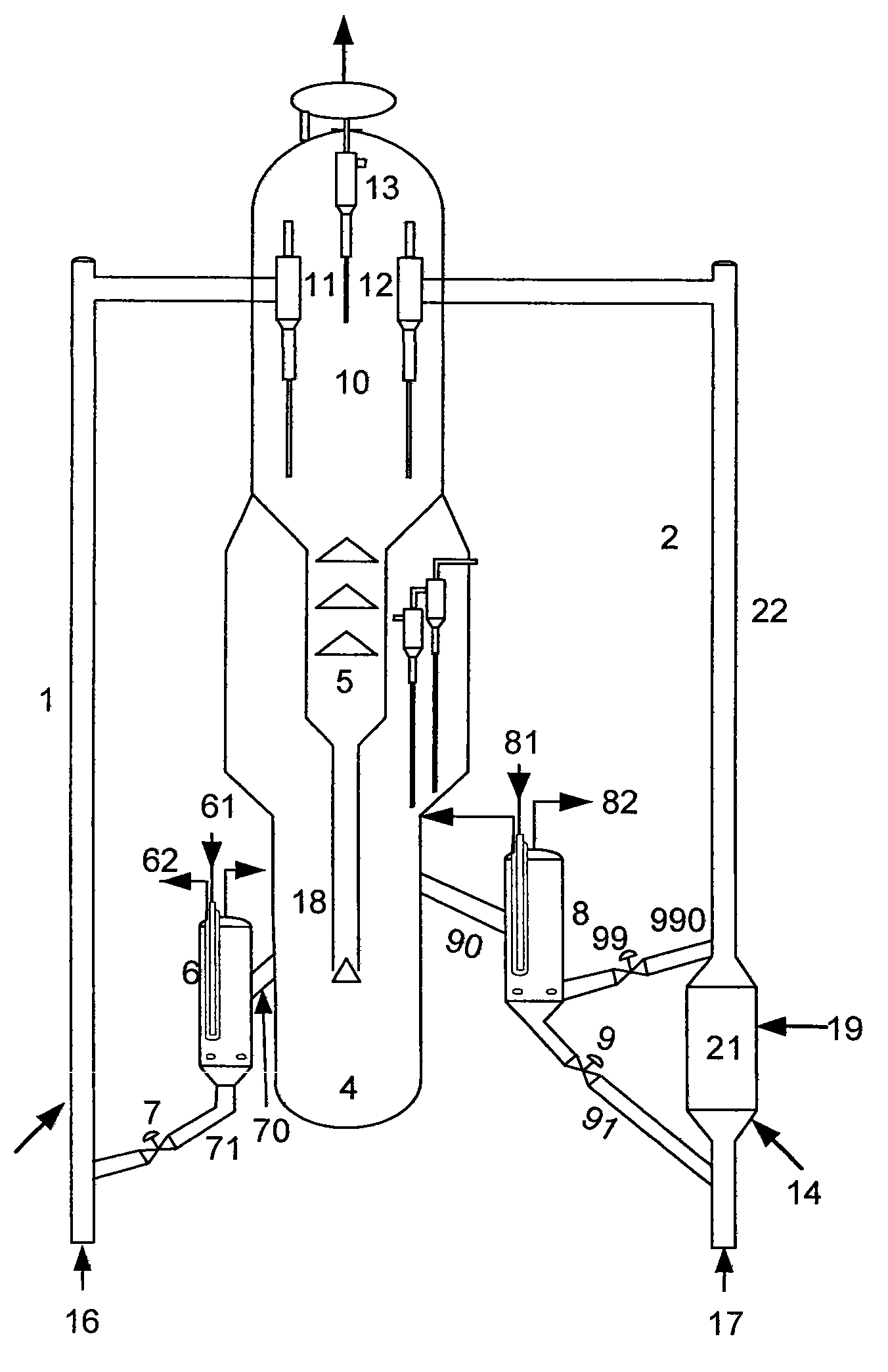

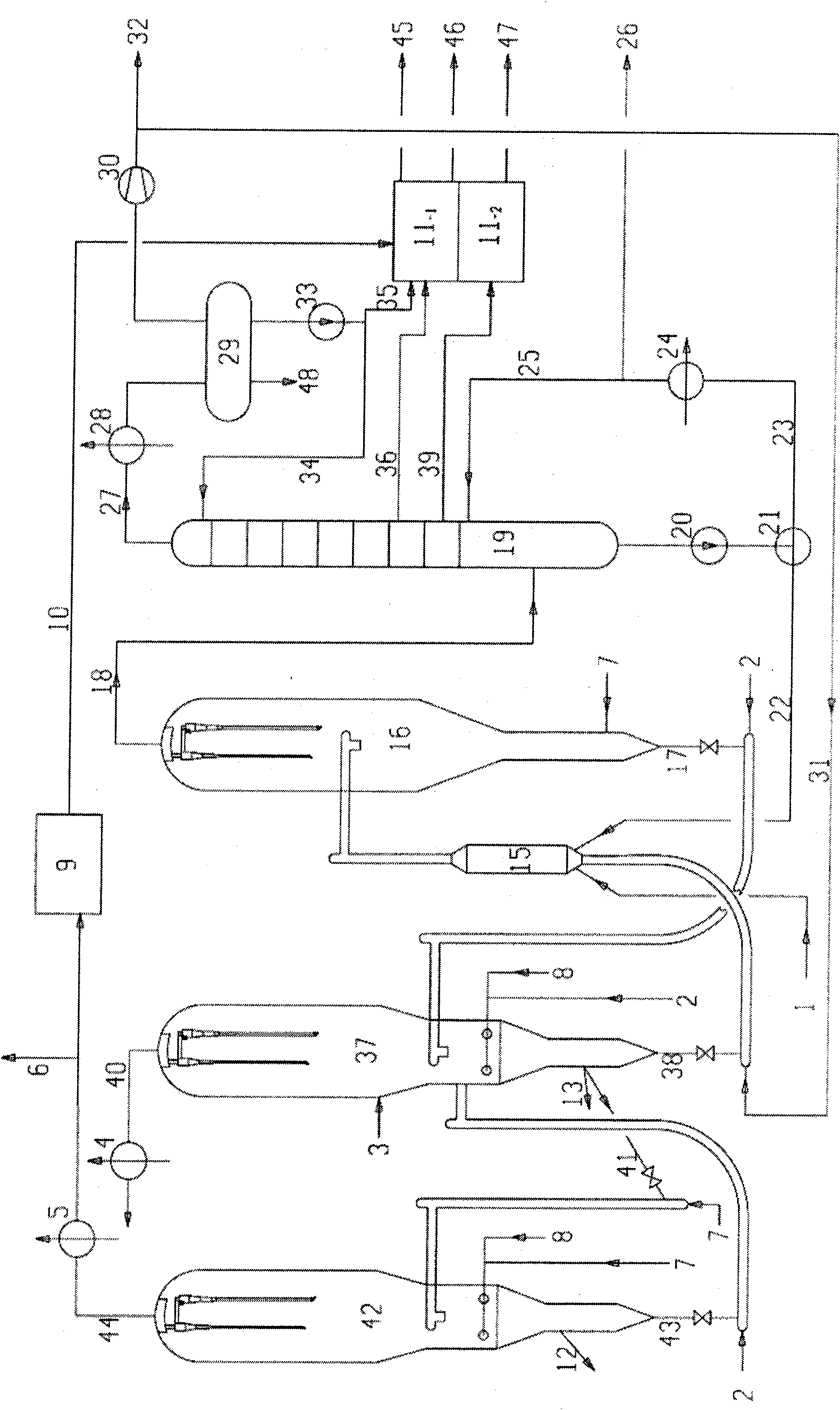

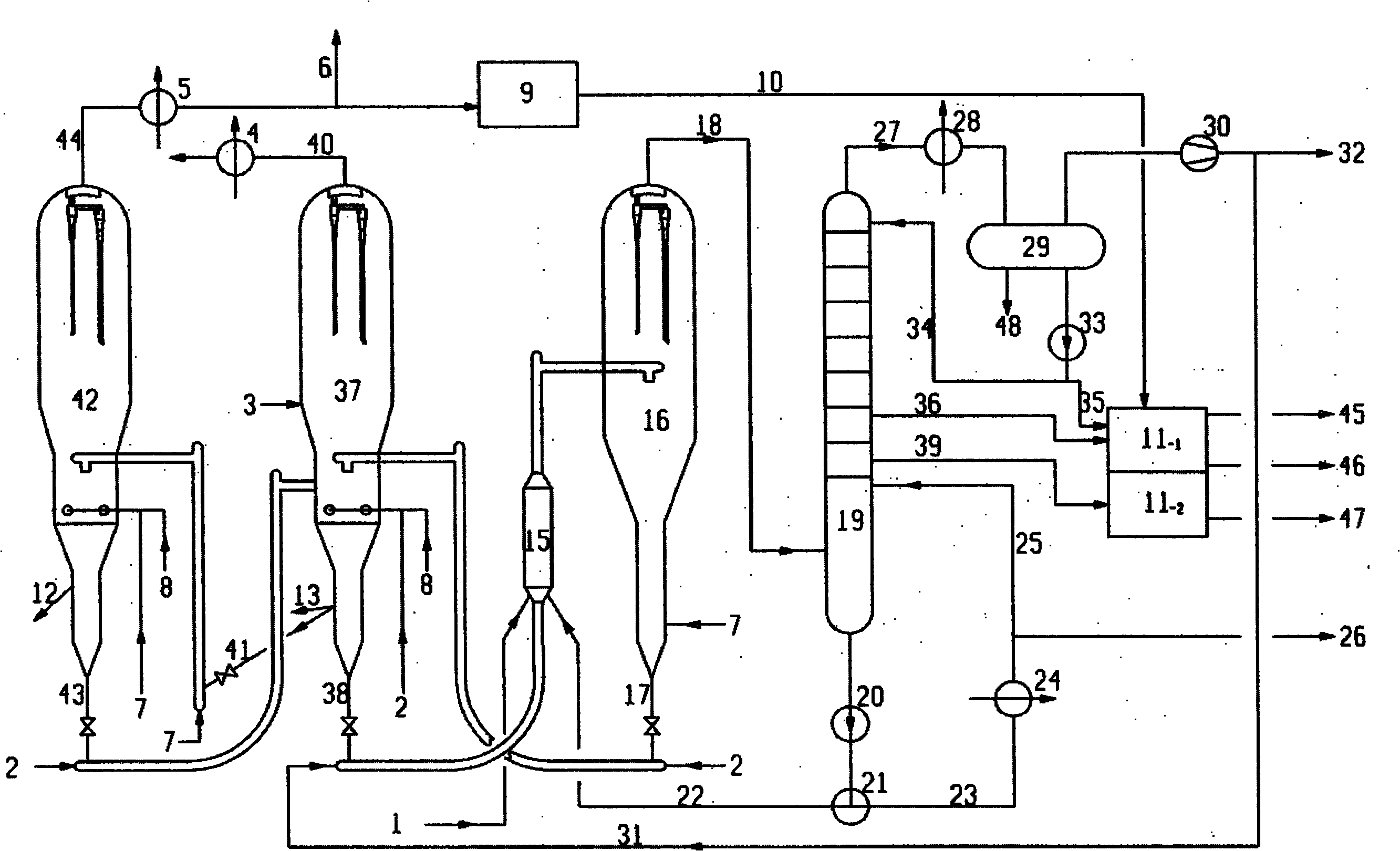

Heavy oil catalytic cracking method and device by double-area coupling and catalyst tandem

InactiveCN102102030AHigh yieldAvoid adsorptionTreatment with plural parallel cracking stages onlyReactive systemFuel oil

The invention provides a method and a device for realizing catalytic cracking of heavy oil by a double-area coupling and catalyst tandem process, and belongs to the technical field of petroleum processing. According to difference of reaction characteristics of heavy oil catalytic cracking materials, the heavy oil catalytic cracking materials are divided into quality catalytic materials and inferior catalytic materials according to carbon residue values; and the quality catalytic materials and the inferior catalytic materials respectively enter different reaction areas in a catalytic cracking reaction system for catalytic cracking reaction. For the quality catalytic materials, a conventional riser reactor is utilized; for the inferior catalytic materials, a turbulent bed or fast bed and transport bed combined reactor is utilized, and the catalyst tandem process is adopted, so that the two parts of materials adopt respectively optimized reaction conditions in respective independent reaction areas provided by different-structure reactors; and the catalyst and oil contact temperature difference is reduced and a large catalyst-oil ratio is achieved by arranging a catalyst cooler, the problem that the catalyst in a reaction area for the inferior materials is severe in coking, quick in deactivation and low in later activity is improved and the light oil yield and the integral liquid yield are obviously improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method of preparing carbon anode active material of lithium-ion battery

ActiveCN101552333ARich sourcesEasy to getElectrode manufacturing processesCarbonizationMicroparticle

The invention relates to a method of preparing carbon anode active material of lithium-ion battery. The prepartion method includes following steps: a materials selection step, selecting heavy products of coal tar processing, heavy products of petroleum processing, heavy products of hydrocarbon polycondensation or, one or multiple of their low-temperature carbonization products as materials; a crushing step, crushing materials obtained from the material selection step into micro-particles with an average grain diameter of 3-80 Mum and granularity distribution range of 0-160 Mum; a thermal chemistry reforming step, in inert atmosphere, the micro-particles obtained by the crushing step is thermal chemistry reformed in moving state; a carbonization or carbonization, graphitization step, products from the thermal chemistry reforming step is proceeded with carbonization or carbonization, graphitization. The lithium-ion battery of carbon anode active material prepared by using the invention is provided with advantages of stable quality, excellent circulation performance, outstanding antidamping ability, high volume electrochemicalspecific capacity.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

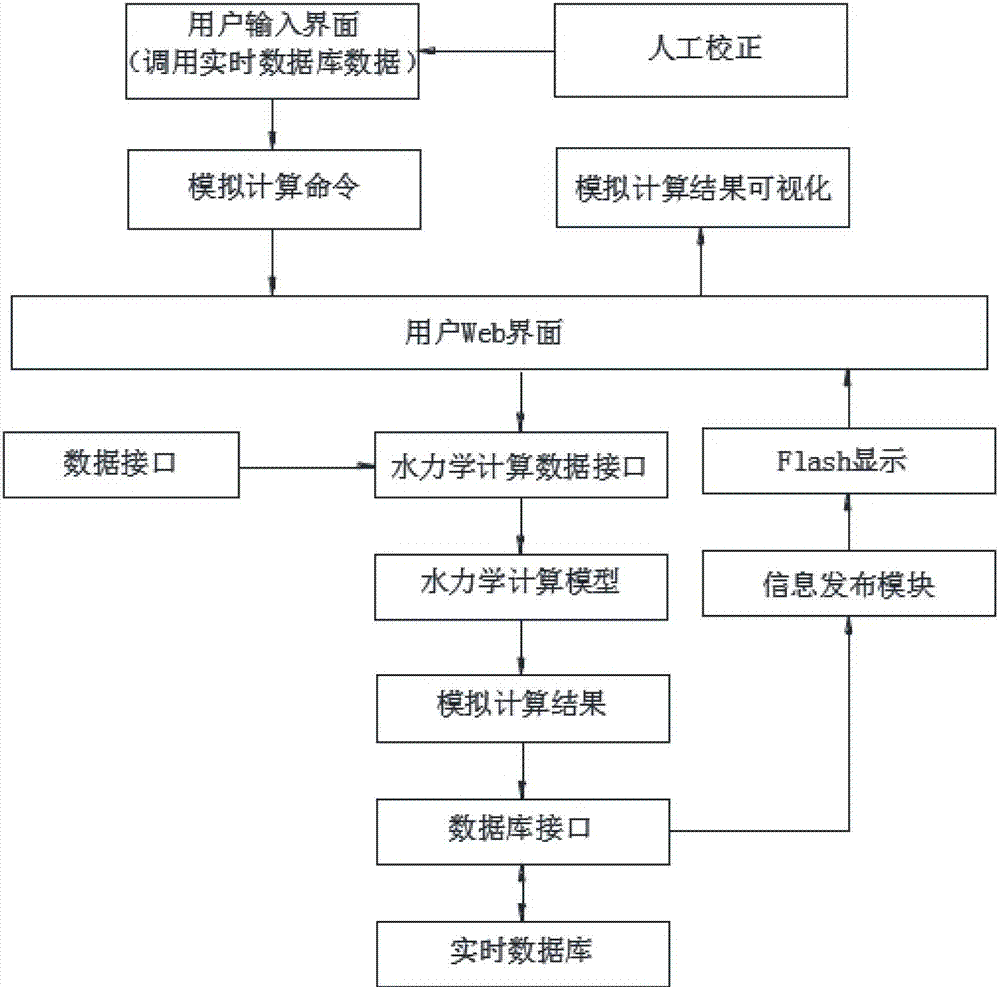

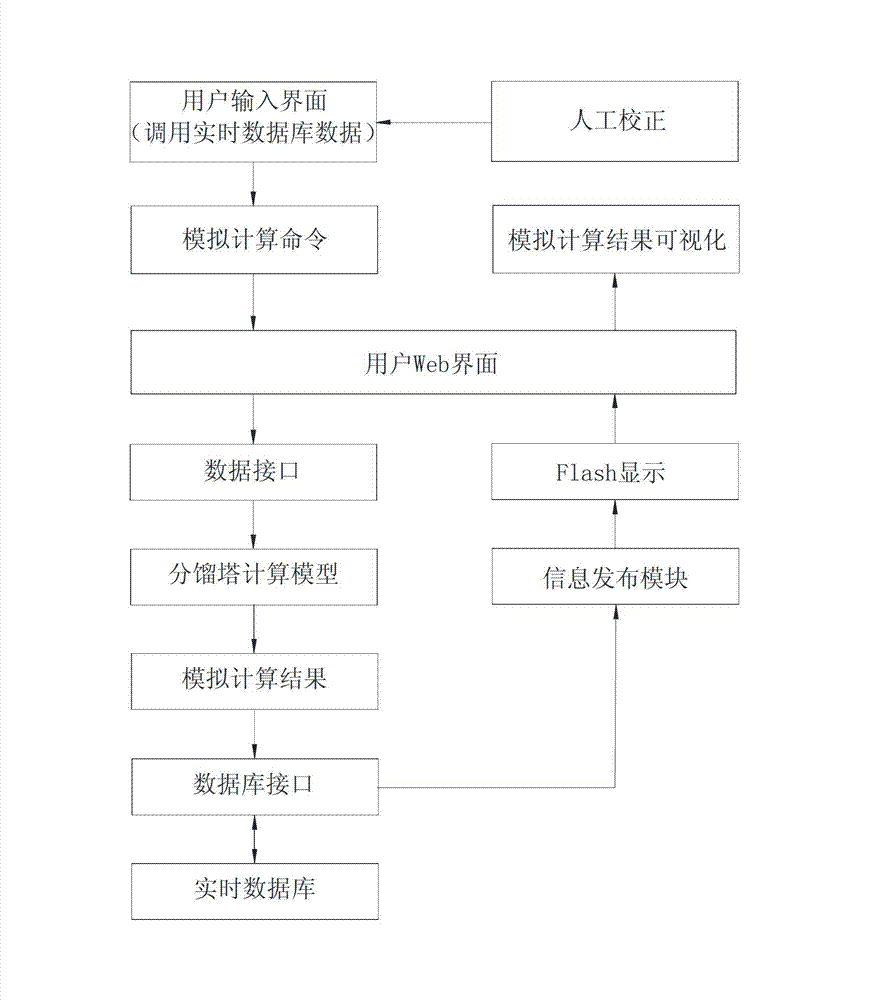

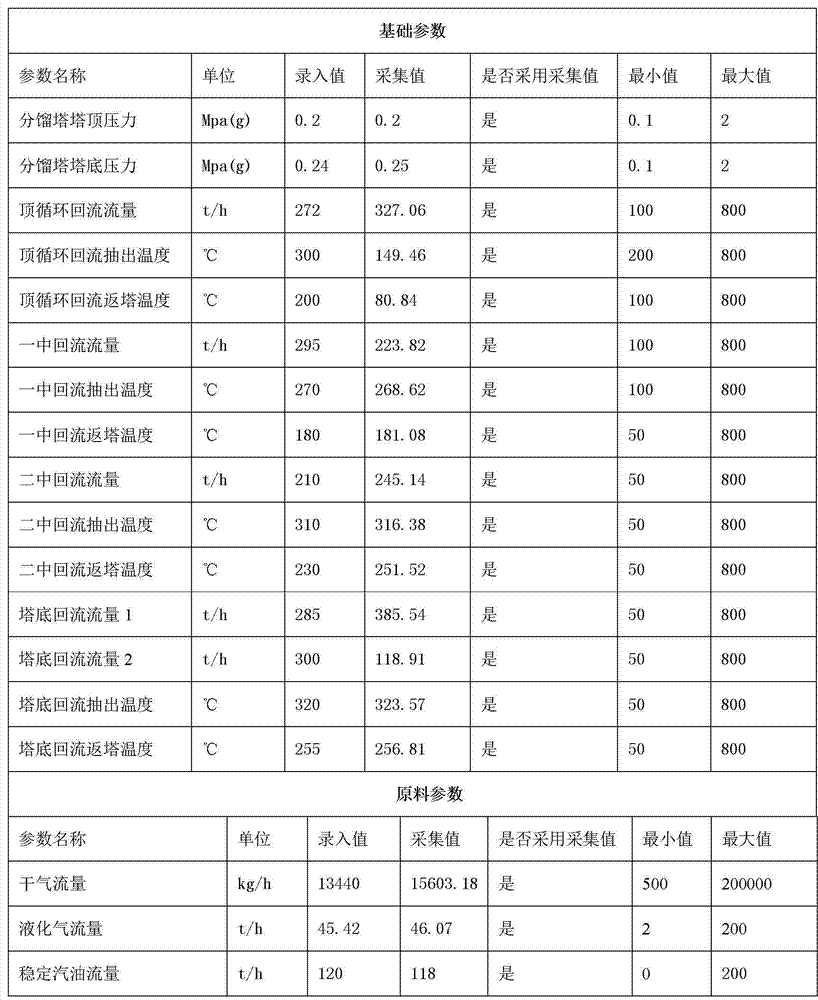

Catalytic cracking transparent fractionating tower simulation calculation system based on process simulation software

InactiveCN103077263ARealize real-time simulationSpecial data processing applicationsTime informationSimulation

The invention belongs to the field of petroleum processing, and particularly relates to a catalytic cracking transparent fractionating tower simulation calculation system based on process simulation software. The catalytic cracking transparent fractionating tower simulation calculation system based on process simulation software comprises a real-time database module, a fractionating tower calculation module, a hydraulics calculation module, a Web user interface and a real-time information release module based on Flash, and is characterized in that a process model is built for the production process of a catalytic cracking transparent fractionating tower system through the process simulation software AspenPlus, so as to carry out simulation calculation. Compared with the prior art, the calculation system is based on a process simulation technology, and the catalytic cracking transparent fractionating tower simulation calculation system based on the process simulation software AspenPlus is established; an independent calculation module solving non-linear model is adopted; and real-time analog simulation is realized. According to a calculation result, real-time operation optimization opinions on a fractionating tower are presented.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

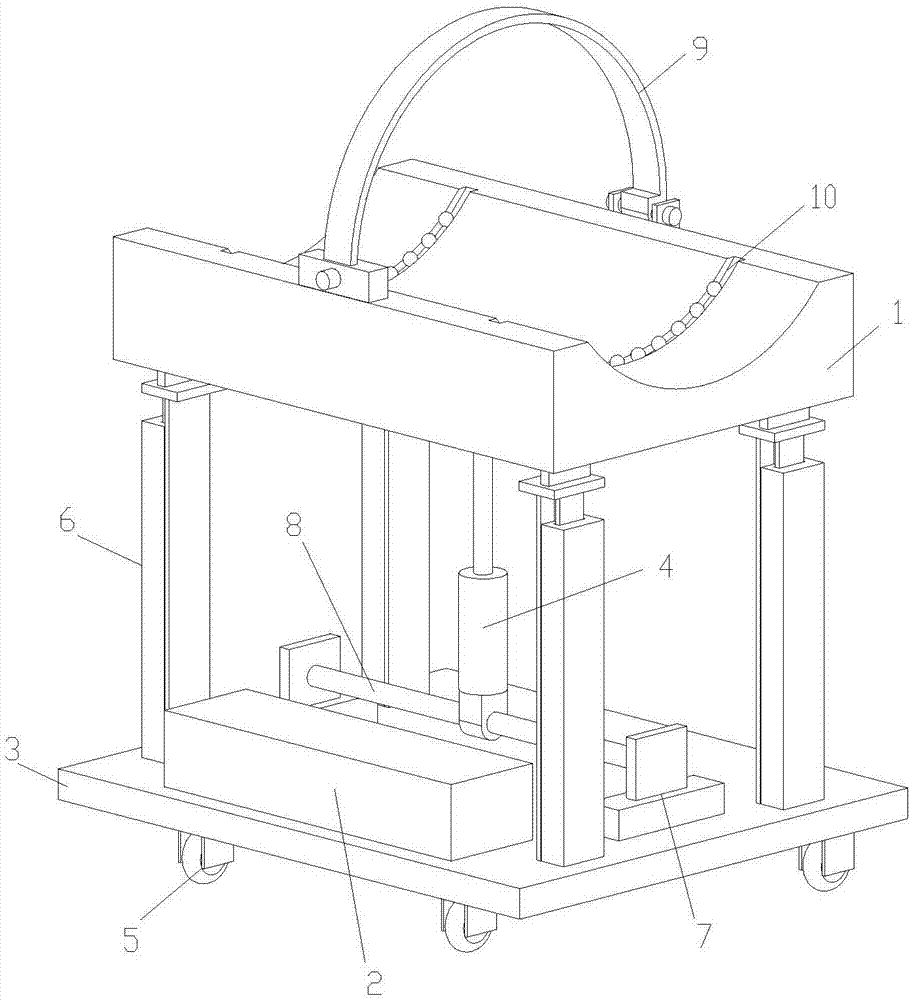

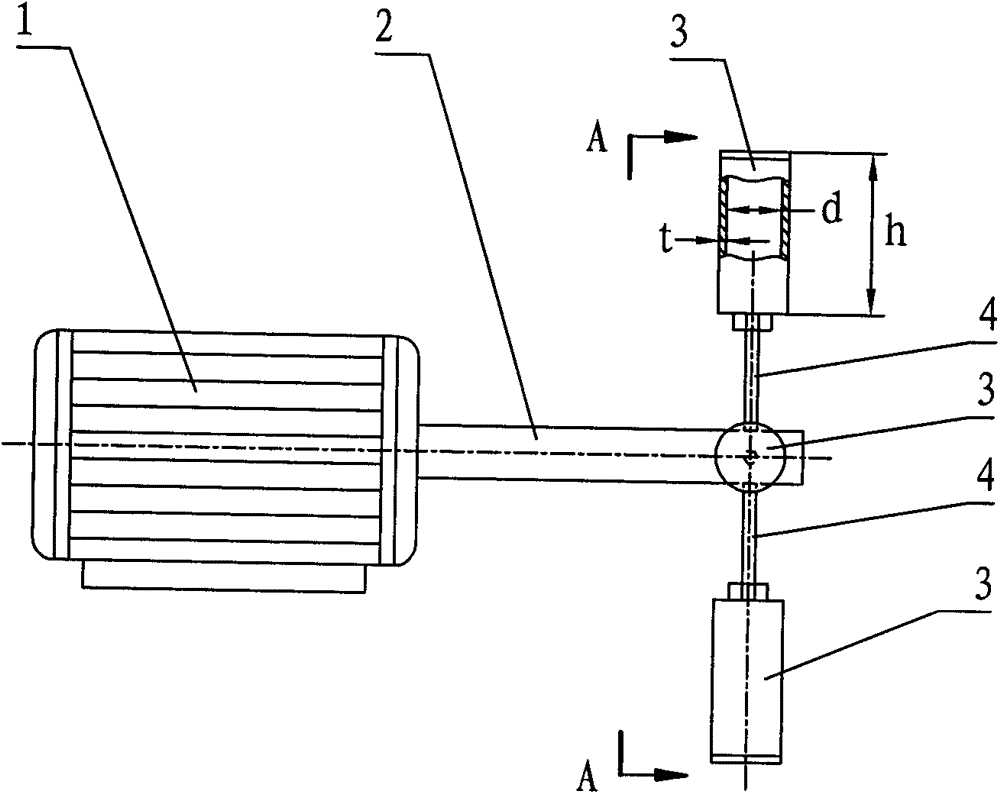

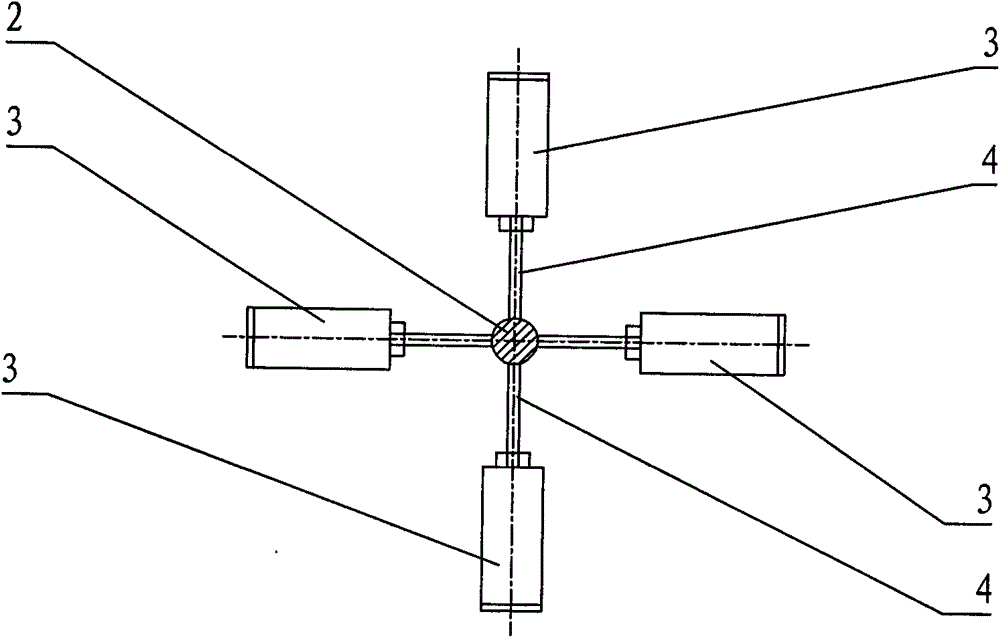

Support frame for petroleum pipe erection

PendingCN107575652AWill not affect subsequent operationsSimple structurePipe supportsPipe supportFriction force

The invention discloses a support frame for petroleum pipe erection, and relates to the field of petroleum processing equipment. The support frame comprises a pipe support base, extension support rods, a baseplate and a cylinder; multiple universal rollers are arranged on the bottom surface of the baseplate; multiple extension support rods are vertically fixed on the front surface of the baseplate; extension ends of the extension support rods are hinged to a connecting block at the bottom of the pipe support base; the pipe support base is provided with a pipe groove for erecting pipes; a cylinder mounting base is arranged on the baseplate; a rotating shaft is mounted on the cylinder mounting base; the cylinder is fixed on the rotating shaft; a piston rod of the cylinder is hinged to the bottom surface of the pipe support base; the pipe support base is provided with a pipe clamping hoop for matching with the pipe groove; one end of the pipe clamping hoop is hinged to the pipe support base, and the other end is locked with the pipe support base through a fastening piece; a ball groove is formed in the pipe groove; multiple balls are arranged in the ball groove; and the balls reduce relative friction force between the pipe groove and the supported pipes.

Owner:苏州诺力达工程技术服务有限公司

Method for measuring catalyst abrasion resisting capability

ActiveCN104865169AGood distinctionGood measurement repeatabilityParticle size analysisInvestigating abrasion/wear resistanceMeasurement deviceGranularity

The invention discloses a method for measuring a catalyst abrasion resisting capability. The method is aimed to solve the problems that repeatability of measurement results is not good, number of catalyst samples abrased for each time is low, structures of measurement devices and measurement operations are complex and the like in the prior art. A catalyst abrasion device used in the method is equipped with a motor, connection rods (4) and more than three abrasion pipes (3). One end of each connection rod is fixed on the output shaft of the motor, and the other end of the connection rod is connected with one end of one abrasion pipe in a detachable manner. Through rotation of the abrasion pipes, a catalyst sample loaded into the cavity of each abrasion pipe is abrased, then the abrasion pipe is dismounted, and the abrased catalyst sample is poured out. Size distribution of the catalyst sample before and after abrasion is measured through a granularity analyzer. The abrasion resisting capability of the catalyst is determined according to the difference between volume percentages of fine catalyst particles in the catalyst sample before and after abrasion. The method is mainly used for measuring the abrasion resisting capability of petroleum processing fluidization catalytic cracking catalysts.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

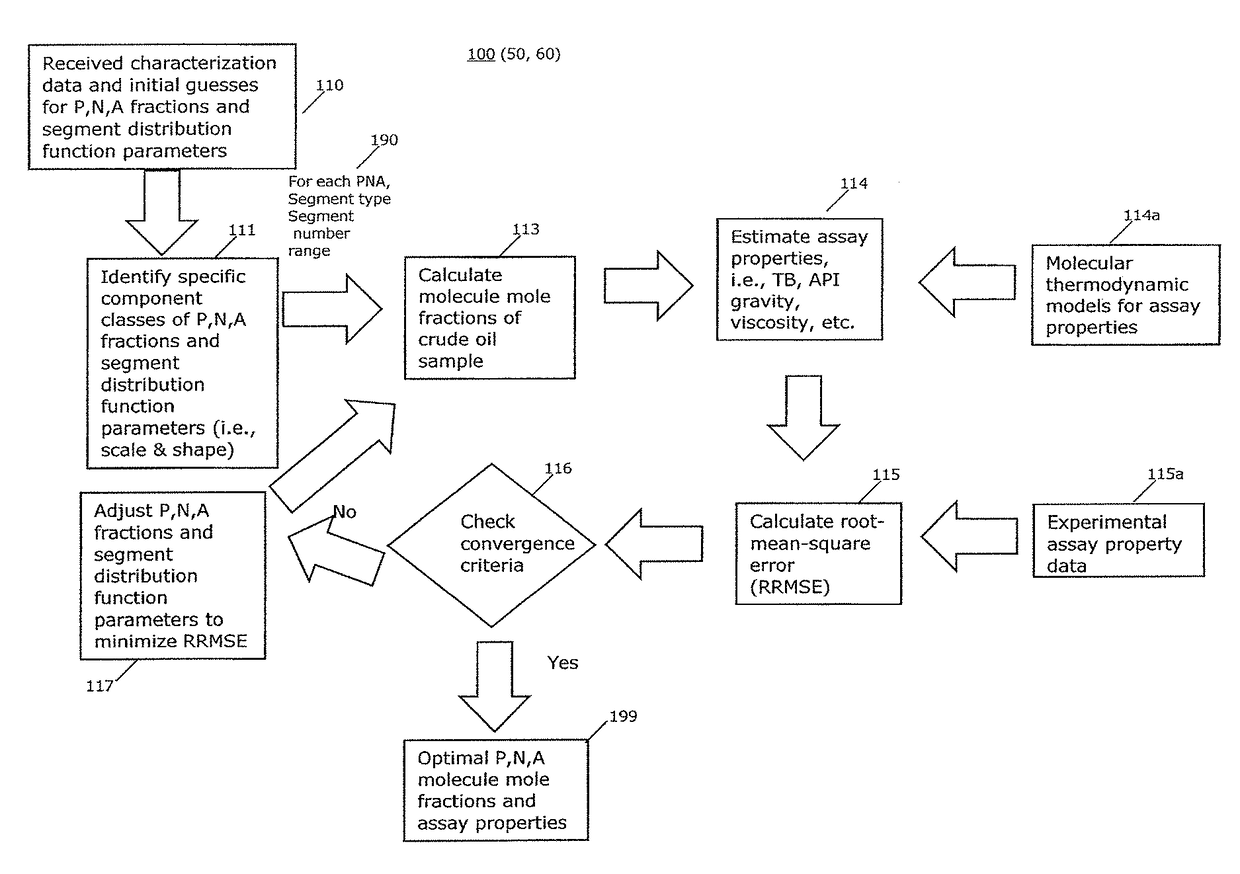

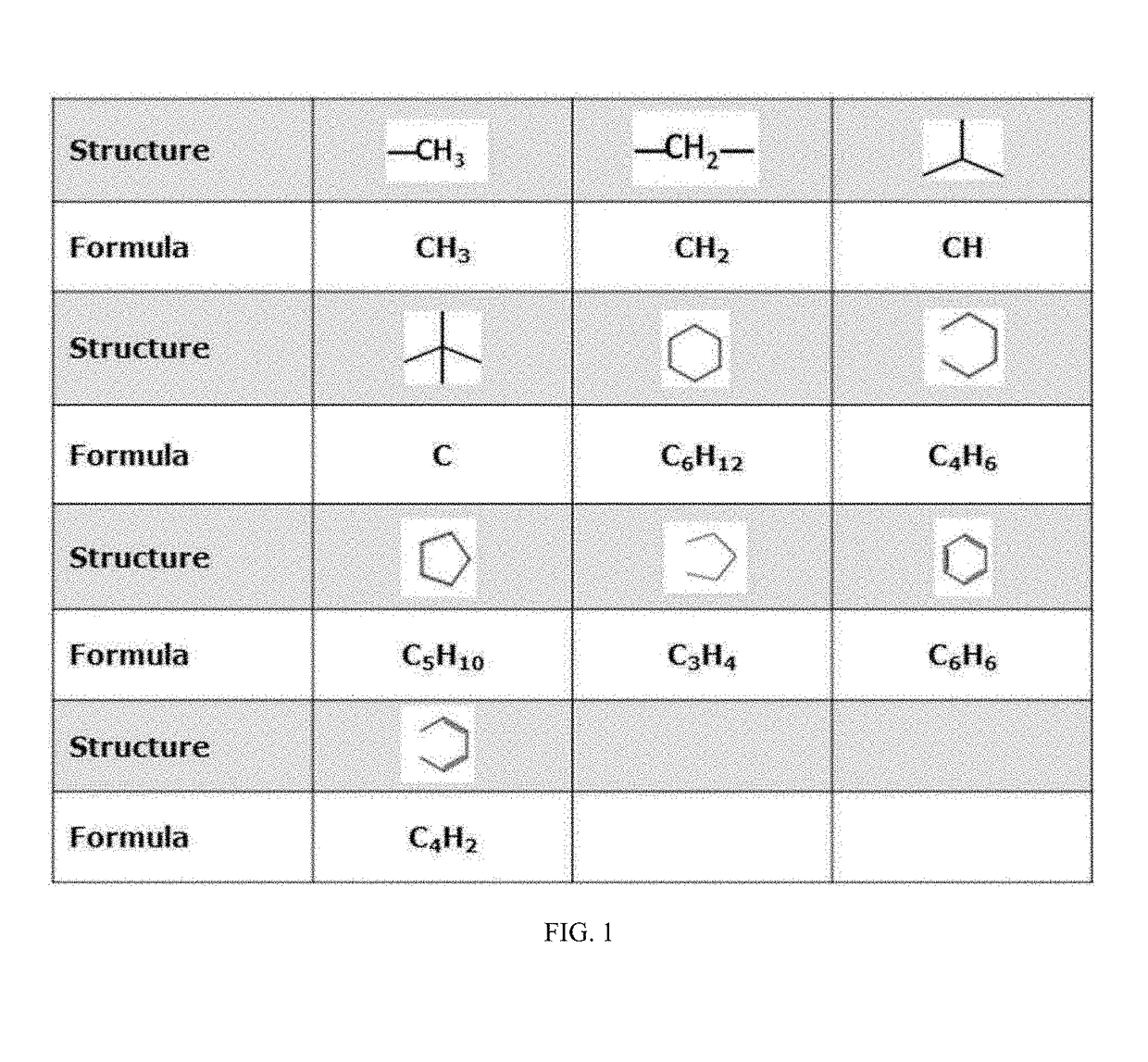

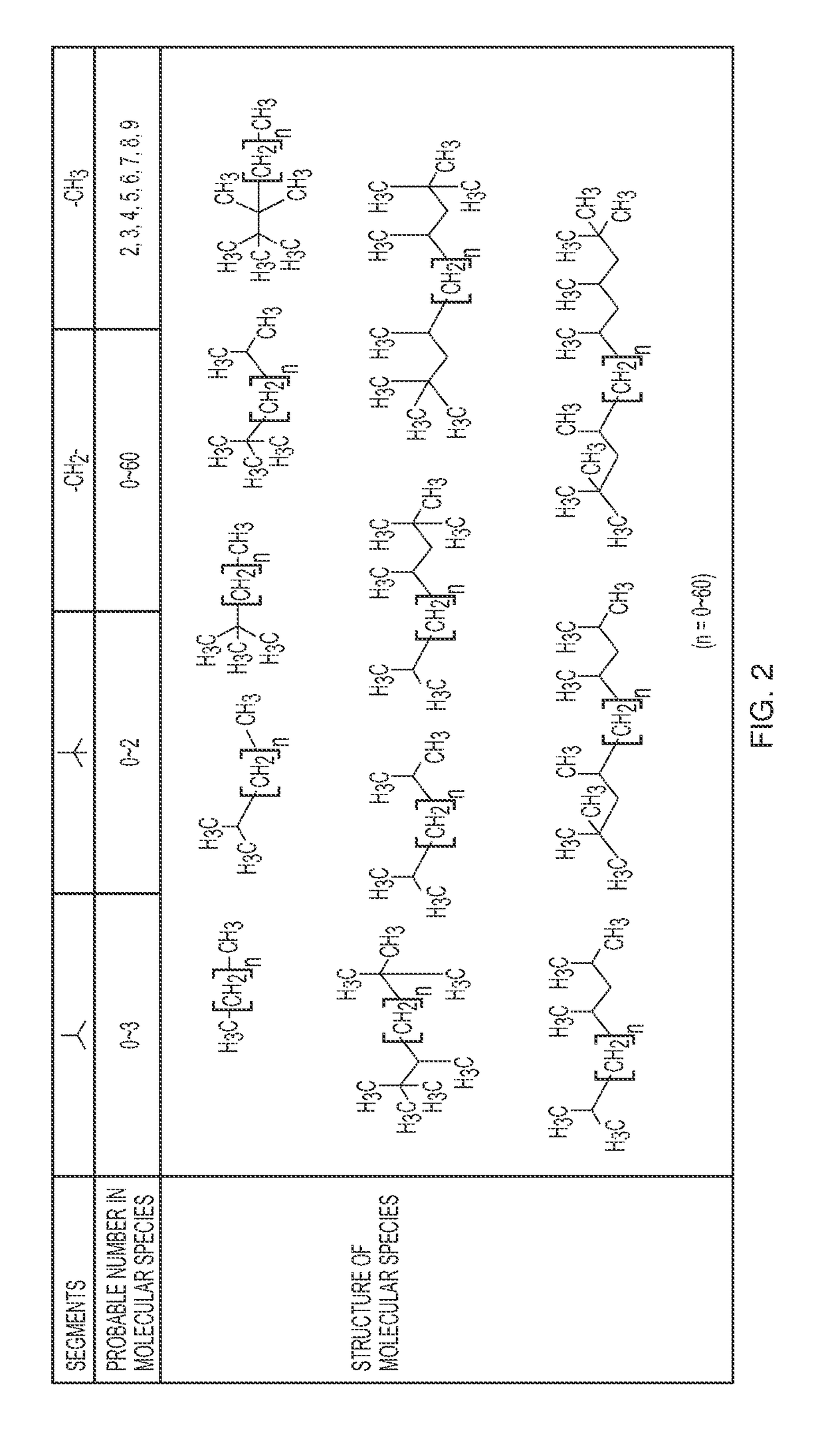

Method of characterizing chemical composition of crude oil for petroleum processing

ActiveUS9934367B2Chemical property predictionData processing applicationsChemical compositionComputer methods

A computer method of characterizing chemical composition of crude oil and crude oil blends, includes determining respective segment type and segment number range of selected classes of hydrocarbon constituent molecules based on physical and chemical property data on each class of hydrocarbon constituent molecules and on crude oil physical and chemical property data. The method determines relative ratio of each class of hydrocarbon constituent molecules that forms a chemical composition representative of the subject crude oil, and therefrom characterizes chemical composition of the subject crude oil. The method / system displays to an end-user, the characterized chemical composition of the subject crude oil. Based on the identified distribution functions and the relative ratio of each class of hydrocarbon constituent molecules, the method estimates chemical composition of the crude oil. Estimates of physical and chemical properties of the crude oil are then based on the estimated chemical composition.

Owner:ASPENTECH CORP

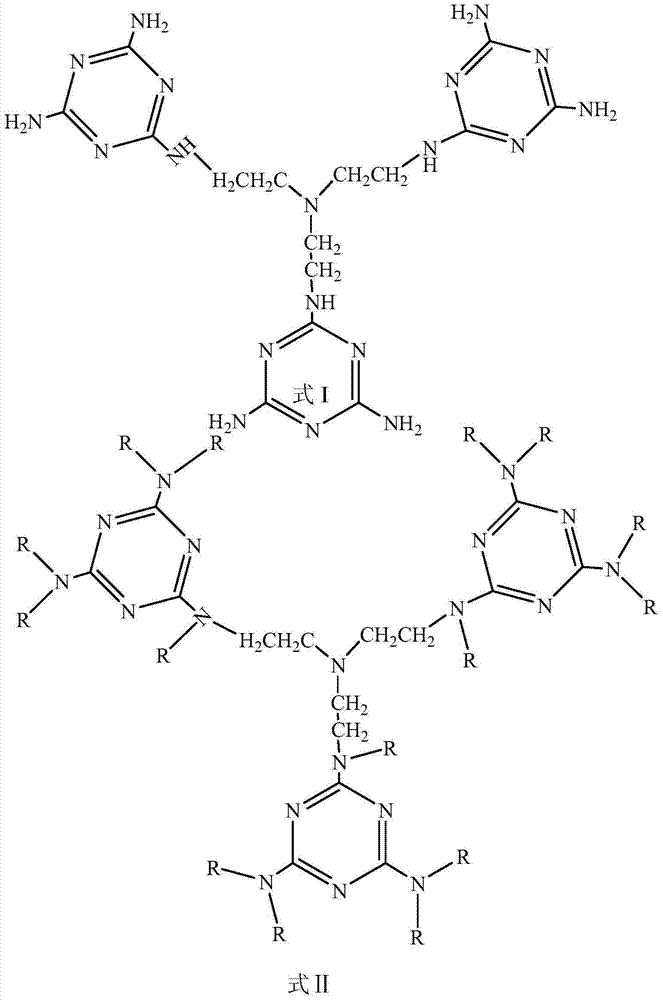

Thick oil demulsifying agent and preparation method thereof

ActiveCN103936961AEasy to spreadDehydration fastDewatering/demulsification with chemical meansEpoxyBenzoyl chloride

The invention relates to a thick oil demulsifying agent and a preparation method thereof, and belongs to the technical field of petroleum processing. The thick oil demulsifying agent is a compound which is obtained in such a way that the N-alkylates of triethanolamine and melamine are taken as initiating agents to successively generate oxyalkylation reaction with epoxy propane and epoxy ethane to generate polyether, are crosslinked through methylbenzene 2,4-diisocyanate to obtain polyurethane and then esterified and blocked through benzoyl chloride. The thick oil demulsifying agent disclosed by the invention has a good dehydration effect on thick oil and can be widely applied to the fields of crude oil exploitation, petroleum refining and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

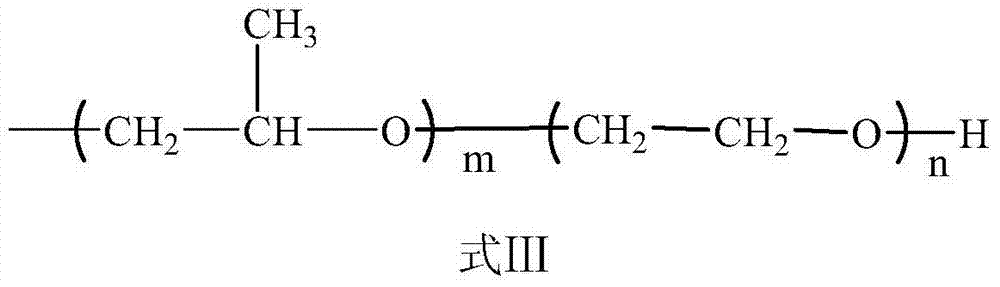

Ageing oil demulsifier and preparation method thereof

ActiveCN103666542AStrong demulsifierImprove dehydration abilityDewatering/demulsification with chemical meansLauroyl peroxideDemulsifier

The invention relates to an ageing oil demulsifier and a preparation method thereof, and belongs to the technical field of petroleum processing. The ageing oil demulsifier comprises mixed acid, a demulsifier monomer and an initiator, wherein the mixed acid consists of acrylic acid and maleic anhydride based on the molar ratio of (1-3): (0.5-1.5); the molar ratio of the mixed acid to the demulsifier monomer, namely, alkyl phenolic resin-polyoxyethylene polyoxypropylene ether, is (0.5-1.7): (0.5-1.5); the initiator, namely, lauroyl peroxide, accounts for 8 to 12% of the mass of the mixed acid. The preparation method comprises the following processes: adding the initiator, namely lauroyl peroxide to mixed acid and demulsifier monomer, namely alkyl phenolic resin-polyoxyethylene polyoxypropylene ether; polymerizing for 1 to 4 hours under a temperature of 70 to 100 DEG C; heating to reach 100 to 150 DEG C; esterifying for 3 to 7 hours to obtain the ageing oil demulsifier. The ageing oil demulsifier has the characteristics of being simple in components, simple in process, convenient, fast and efficient to prepare, low in cost, small in dosage, small in toxic and side effects, wide in application scope, good in demulsifying effect, etc.

Owner:河南鼎源化工科技有限公司

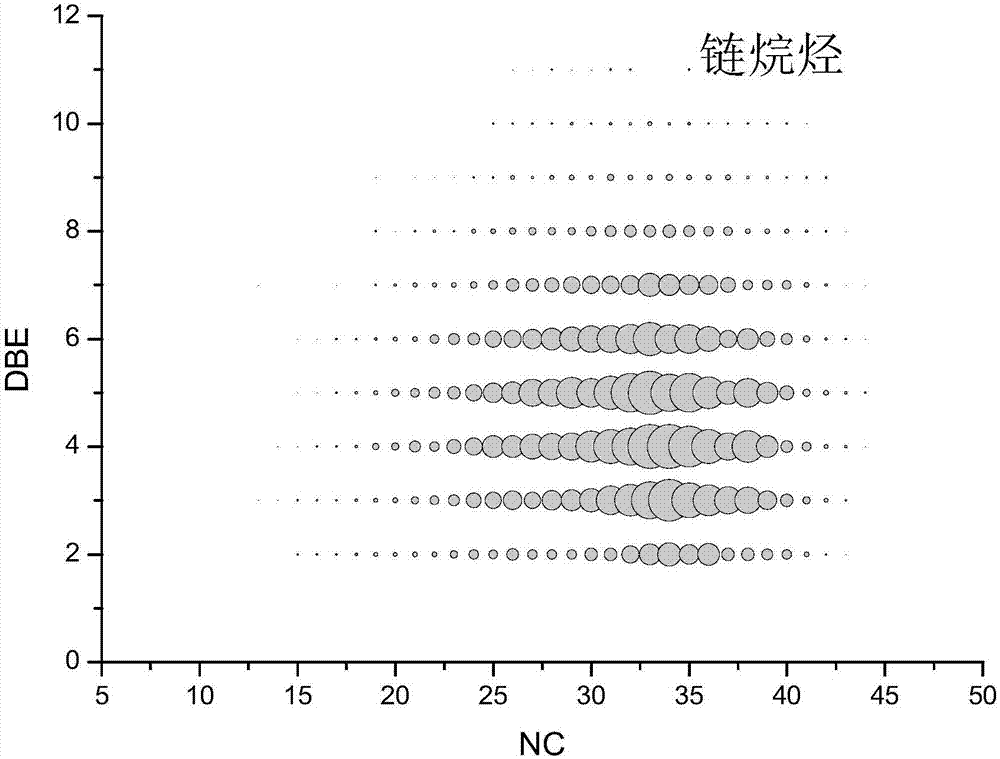

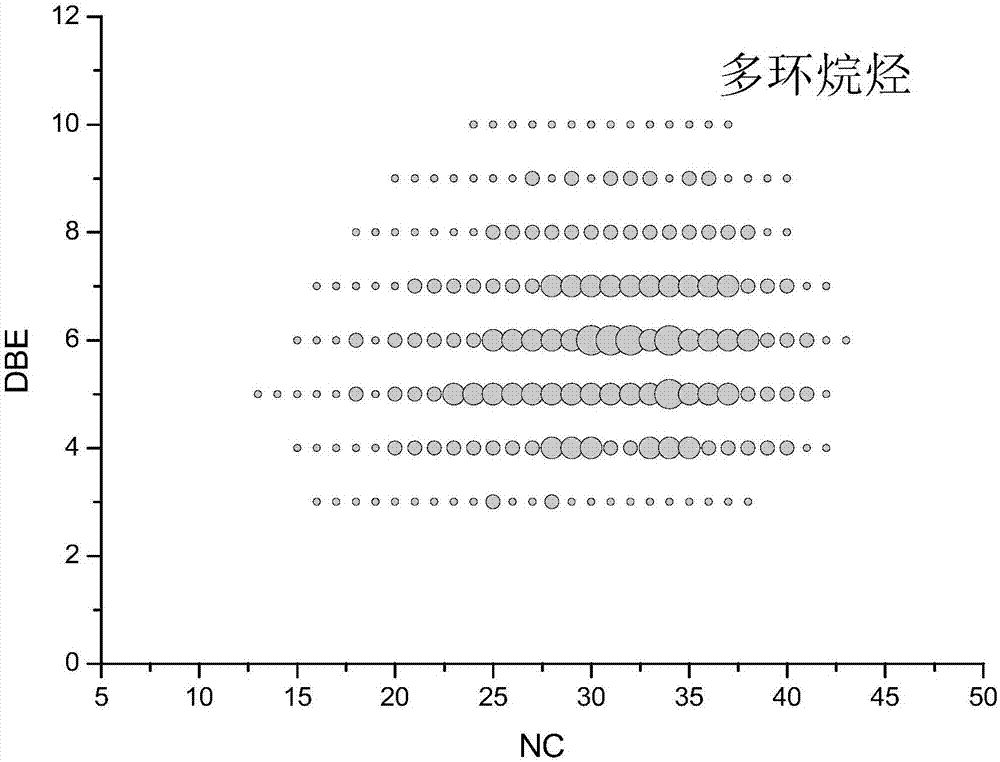

Method for performing soft ionization and direct mass spectrometric analysis on hydrocarbon compounds in petroleum

The invention provides a method for performing soft ionization and direct mass spectrometric analysis on hydrocarbon compounds in petroleum. The method comprises steps as follows: a petroleum sample is subjected to soft ionization by adopting a real-time direct analysis ion source, and then direct mass spectrometric detection is performed; during soft ionization, the real-time direct analysis ion source selects a positive ion mode, carrier gas is argon, and a sampling mode is sample flow assisted sampling; the hydrocarbon compounds in petroleum are classified according to a mass spectrometric detection result, and types of the hydrocarbon compounds comprise alkane, cycloalkane and arene. According to the scheme, molecular composition distribution information of alkane, cycloalkane and arene in petroleum can be provided conveniently and deeply, so that theoretical guidance is provided for petroleum nature judgment and petroleum processing, and the method has broad application prospect in fields of petroleum extraction and processing.

Owner:PETROCHINA CO LTD +1

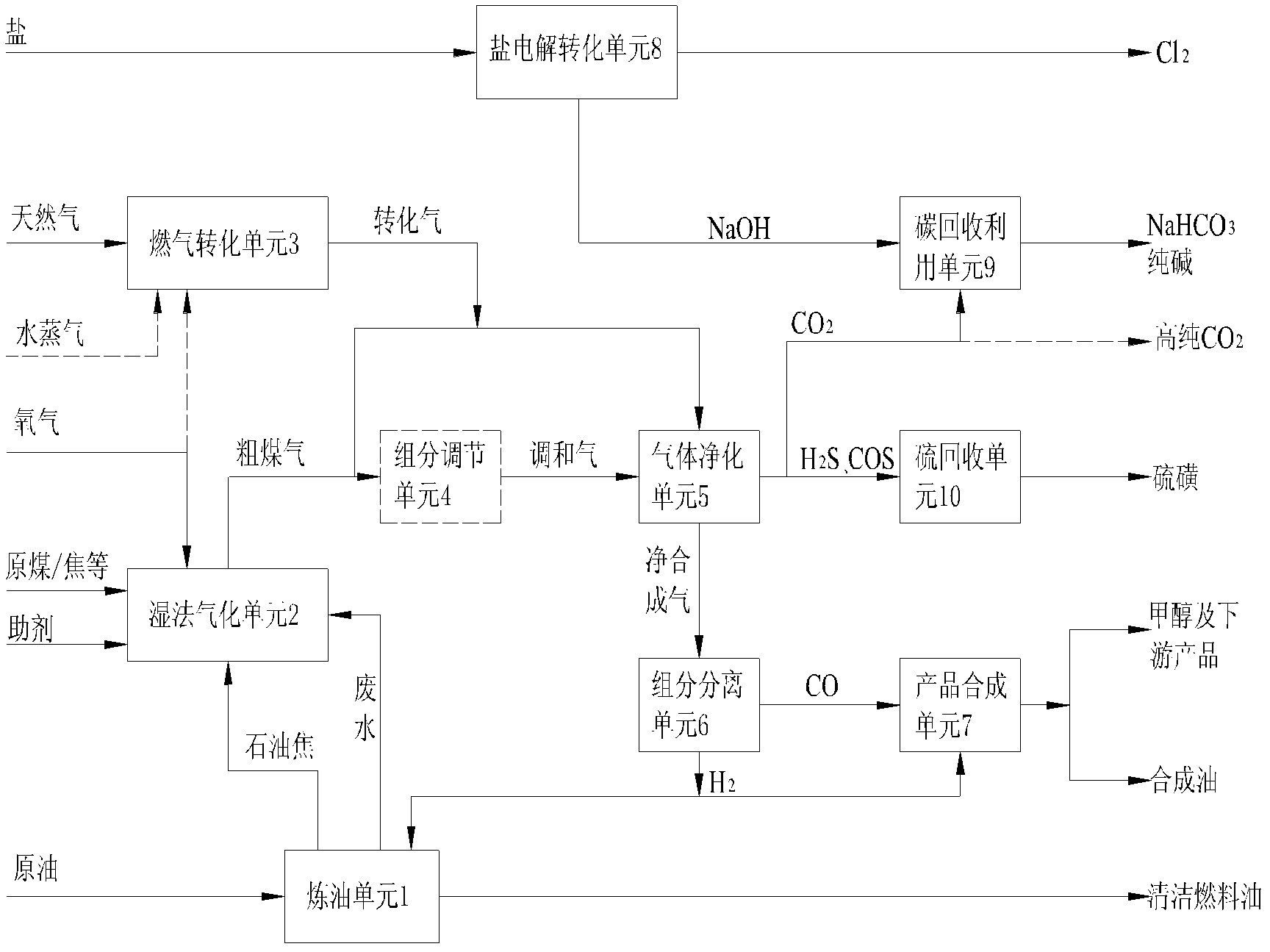

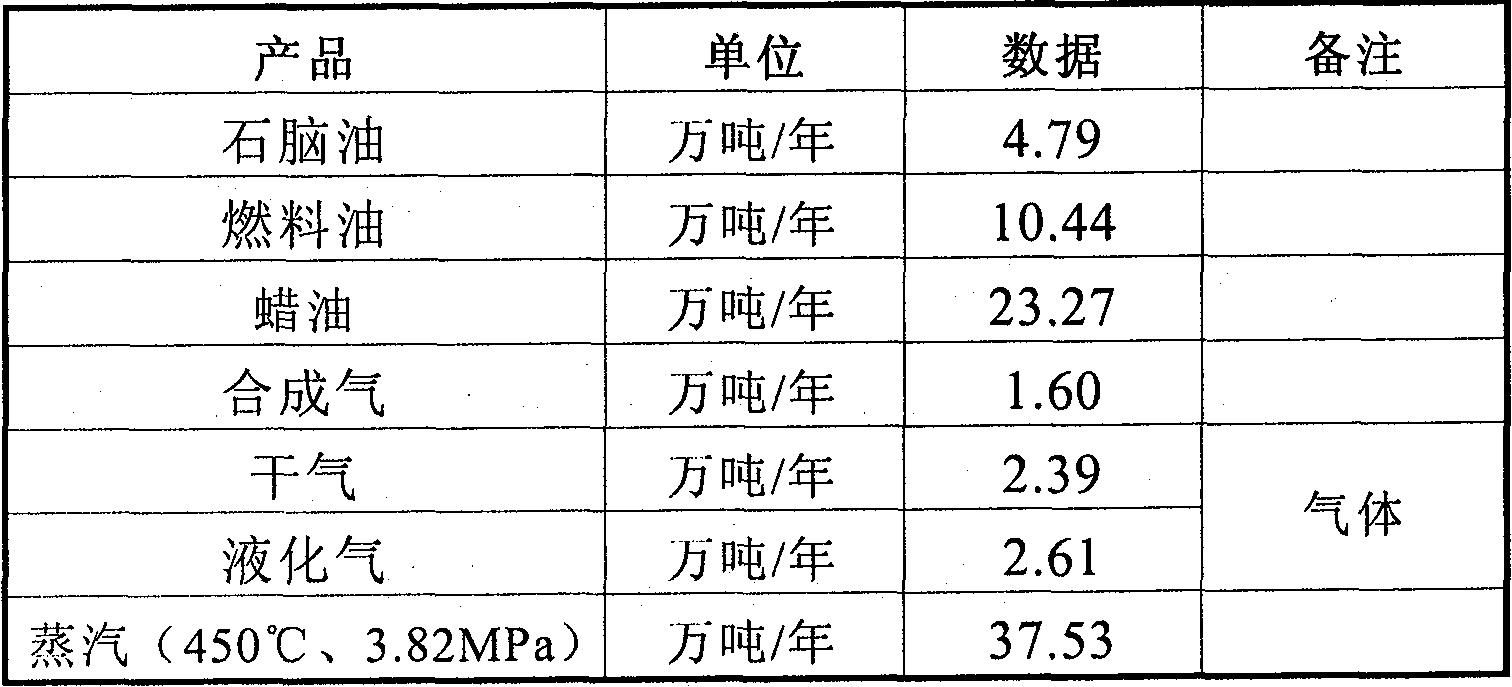

Comprehensive processing and utilizing method for heavy oil

InactiveCN102031135AAchieve rapid lysisImprove light oil yieldThermal non-catalytic crackingHydrogen separationSyngasFuel oil

The invention belongs to the field of petroleum processing and utilization, and relates to a comprehensive processing and utilizing method for heavy oil. By integrating quick cracking of the heavy oil, pre-combustion and gasification of the generated coke, recycling of non-converted heavy oil, hydrogen production by synthetic gas generated through gasification, and a hydrofining process for cracked oil products, light oil can be prepared from the heavy oil to the greatest degree, the light oil is hydrogenated to form high-quality clean oil products, and also can generate the synthetic gas through gasification, and the synthetic gas can serve as a hydrogen production raw material to provide a cheap hydrogen source for oil product hydrofining, and also can serve as fuel gas to provide clean fuel for a refinery. The invention provides a low-cost comprehensive processing and utilizing method for converting the heavy oil into clean light oil products to the greatest degree.

Owner:WISON ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com