Patents

Literature

400results about How to "Remarkable results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

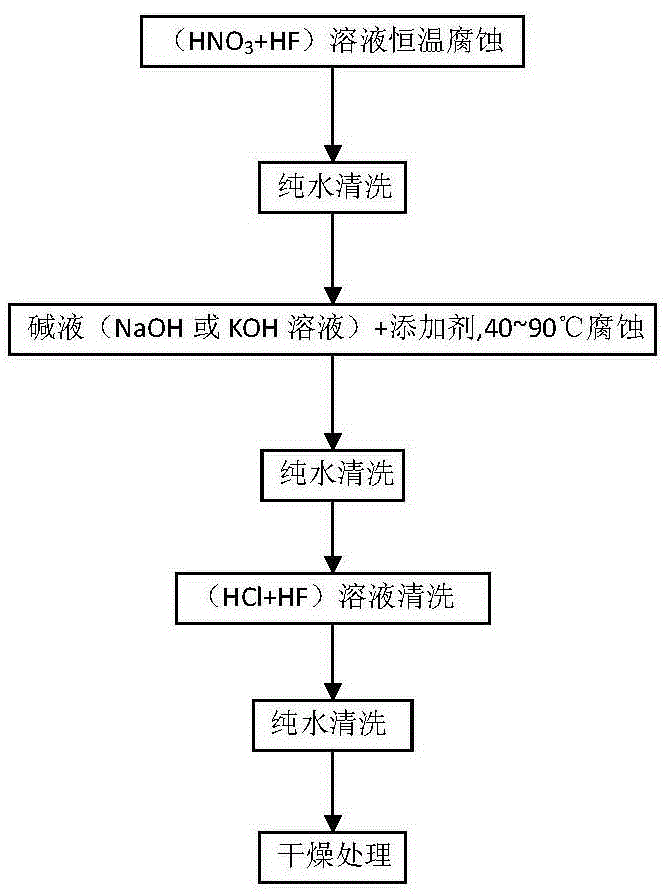

Texturing and cleaning process method of polysilicon wafer

ActiveCN103151423AImproving the effect of wool cleaningEasy to cleanAfter-treatment detailsFinal product manufactureHydrogen fluorideHydrogen Nitrate

The invention discloses a texturing and cleaning process method of a polysilicon wafer. The method comprises the following steps of 1, firstly, putting the polysilicon wafer in a mixing solution of HF (hydrogen fluoride) and HNO3 (hydrogen nitrate), and soaking; 2, putting the polysilicon wafer corroded by acid into pure water, and cleaning; 3, putting the polysilicon wafer in an alkaline solution, carrying out alkaline corrosion treatment, adding a texturing additive into the alkaline solution, and carrying out secondary texturing on the polysilicon wafer; 4, putting the polysilicon wafer corroded by alkali into the pure water, and cleaning; 5, putting the polysilicon wafer in a mixing solution of HCl (hydrogen chloride) and HF, and soaking; 6, putting the polysilicon wafer corroded by the acid into the pure water, and cleaning; and 7, drying the treated polysilicon wafer. The process method has the advantages that on the premise of not changing other processes, the final converting efficiency of the polysilicon wafer is improved by 0.2% to 0.3%, and the purpose of final efficiency stacking of a battery sheet is realized.

Owner:CHANGZHOU S C EXACT EQUIP

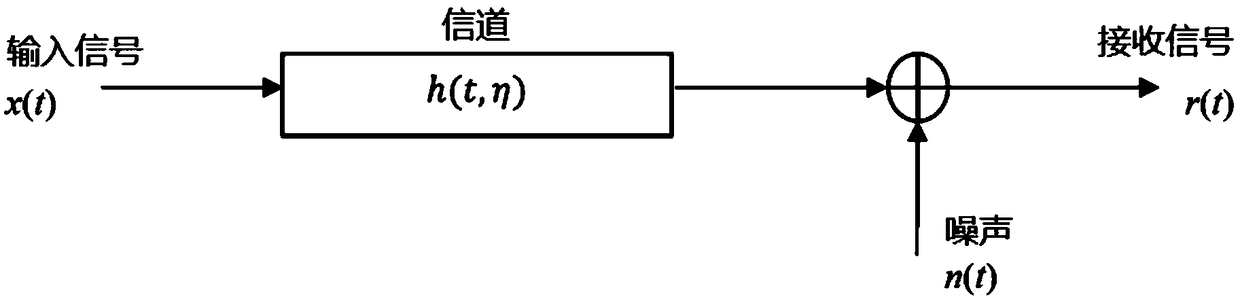

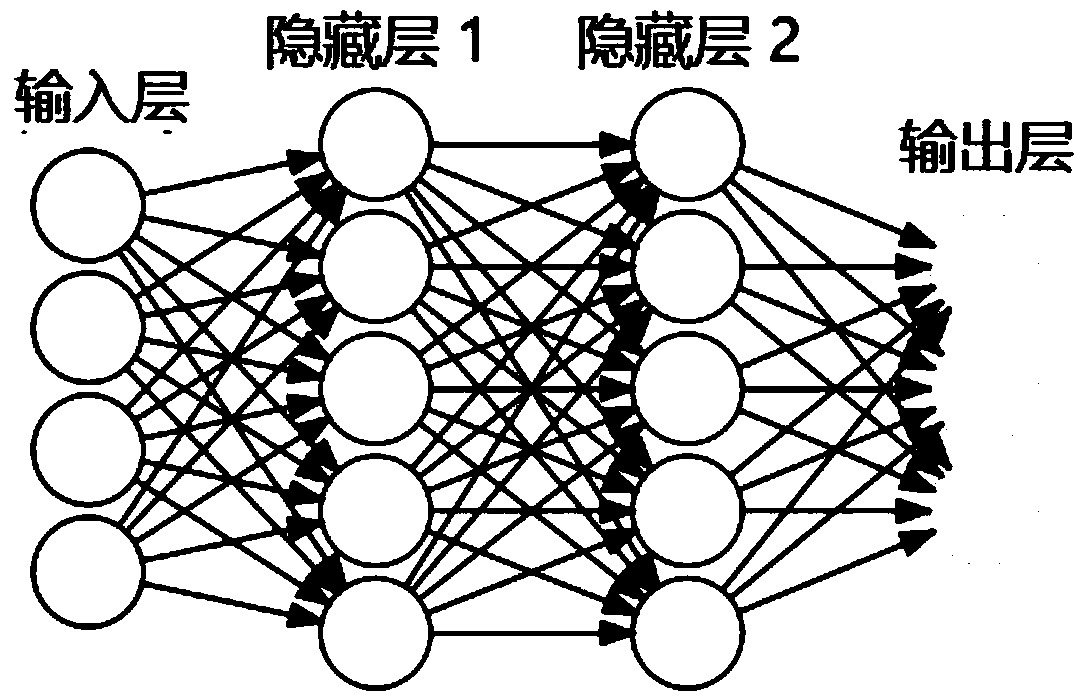

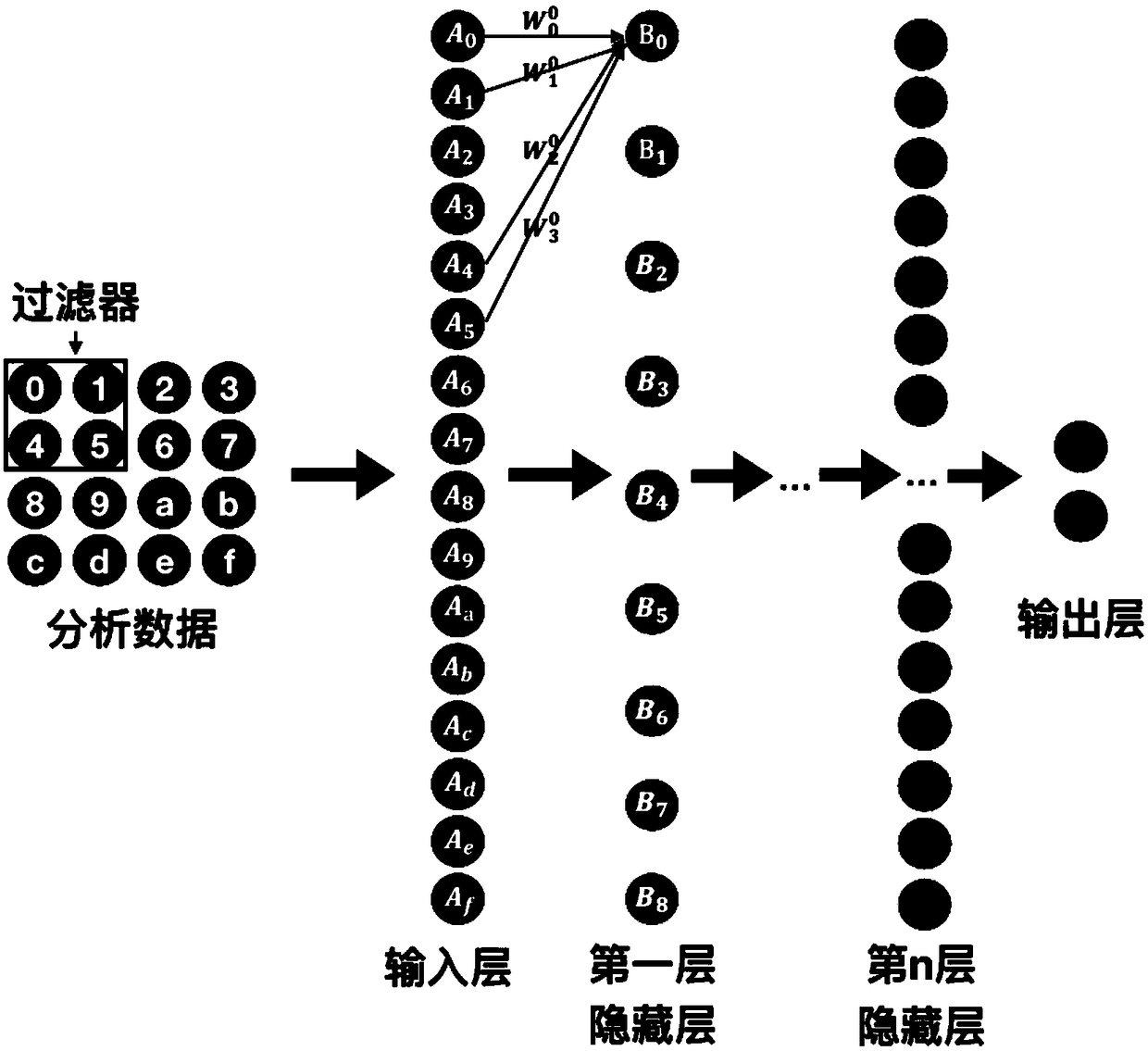

Depth neural network system and method based on modulation mode recognition of underwater acoustic communication

InactiveCN109299697AImprove the accuracy of judgmentRemarkable resultsCharacter and pattern recognitionNeural architecturesFeature setNeural network system

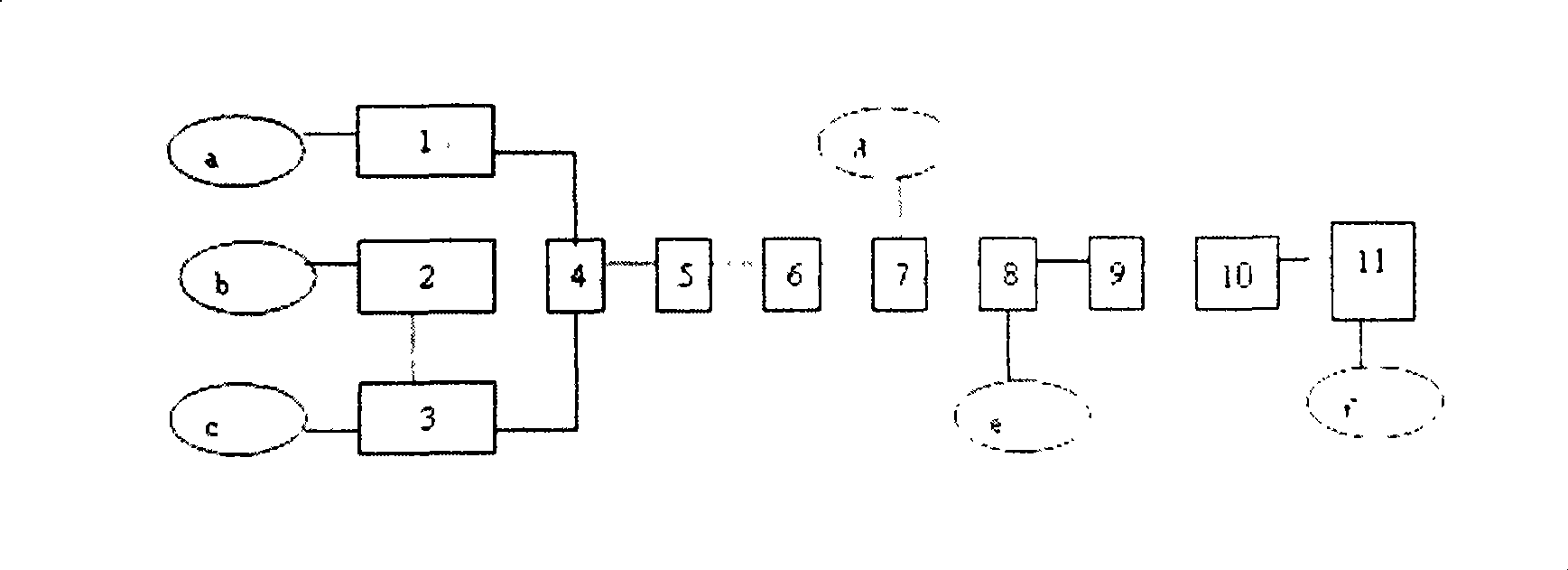

The invention provides a depth neural network system and a method based on modulation mode identification of underwater acoustic communication. The system comprises: a data preprocessing part for preprocessing data of a plurality of modulation modes transmitted through underwater acoustic communication; A first layer neural network generates a feature extraction set of the first layer according toa plurality of modulation mode data transmitted from the pretreated underwater acoustic communication; The second layer neural network generates the second layer high-level feature set; The third layer neural network generates higher level feature set, the fourth layer neural network classifies and identifies the initial data by the feature set extracted in front; The fifth layer is the neural network layer, which generates the final modulation mode judgment and outputs the identified modulation mode. The depth neural network system and method based on the modulation mode recognition of underwater acoustic communication can simulate the actual use situation, improve the use effect in the actual underwater acoustic communication, more conveniently and efficiently complete the modulation recognition of underwater acoustic communication, and improve the accuracy of recognition and judgment.

Owner:TAISHAN UNIV

Tooth bleaching compositions and methods of bleaching discolored tooth

InactiveUS6843981B1Efficient use ofImprove securityCosmetic preparationsGum massageLight irradiationDiscolored tooth

The bleaching compositions of discolored teeth comprise titanium dioxide initiating photocatalyst action with light irradiation, chemical compounds generating hydrogen peroxide in an aqueous solution and thickening agents. Further the bleaching methods of discolored teeth comprising applying the bleaching composition onto the surface area of the teeth and then initiating photocatalyst action by irradiating the applied surfaces area with light. Therefore, the present invention shows remarkable bleaching results due to easy application of the compositions onto discolored teeth and keeping the original activity of the photocatalyst without its deterioration.

Owner:MITSUBISHI GAS CHEM CO INC

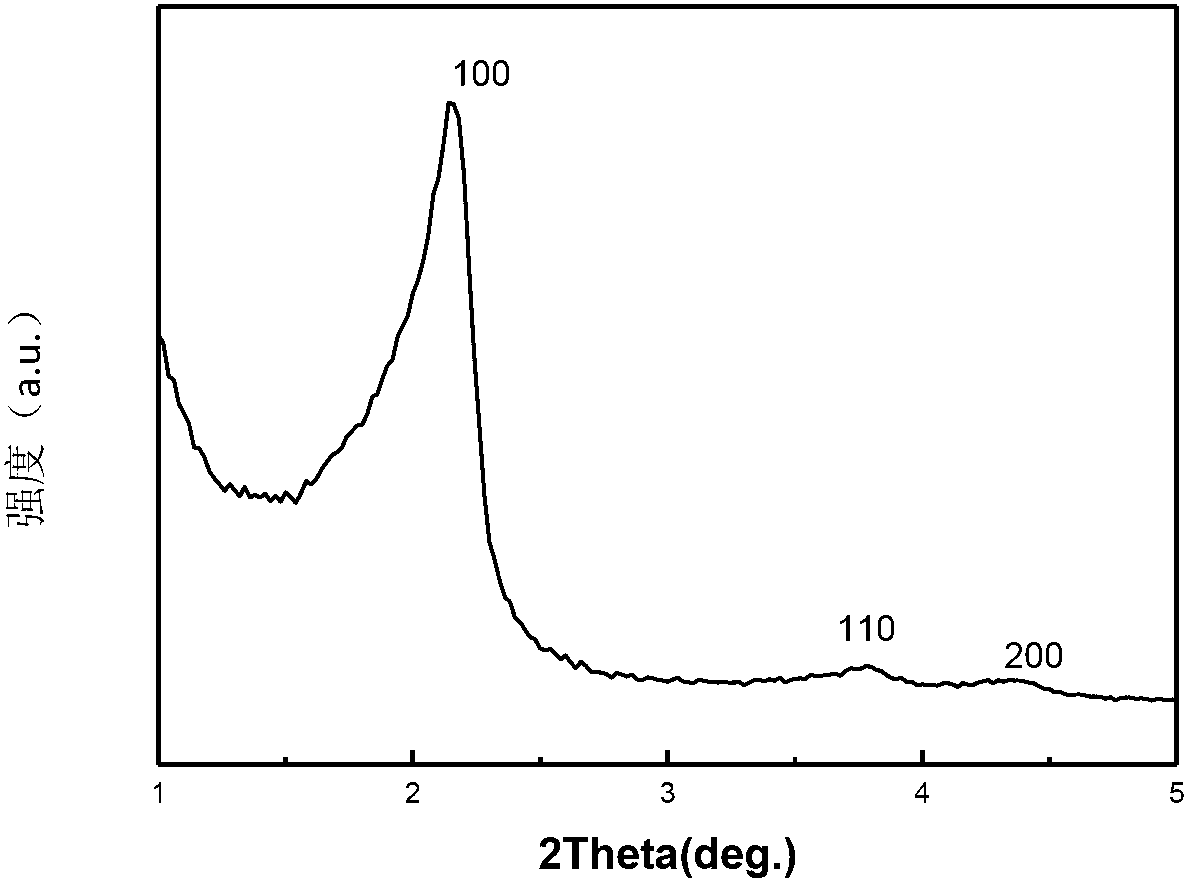

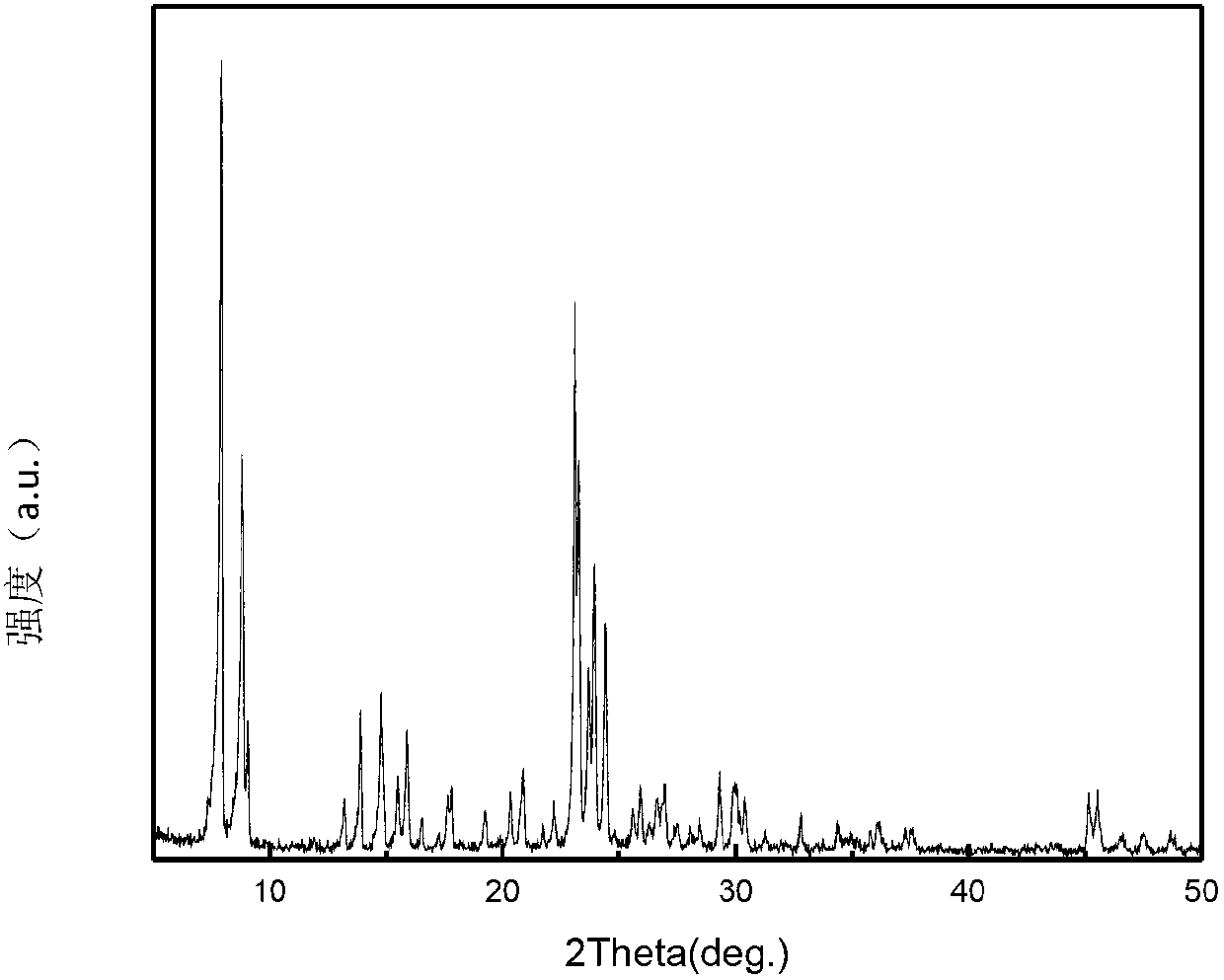

Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

InactiveCN103101930AImprove performanceRemarkable resultsPentasil aluminosilicate zeolitePore diameterPetrochemical

The invention discloses a preparation method of an ordered mesopore ZSM-5 molecular sieve. The preparation method comprises the following steps of: firstly preparing an ordered mesopore silicon oxide molecular sieve serving as a silicon source through an organic template method; and then transforming the ordered mesopore silicon oxide molecular sieve into the ordered mesopore ZSM-5 molecular sieve in situ by adopting a hydrothermal method. The ordered mesopore ZSM-5 molecular sieve disclosed by the invention is provided with ordered micropores with pore diameter being 0.2-2 nanometers and ordered mesopores with pore diameter being 2-50 nanometers and has wide application prospect in the fields of petrochemical industry, petroleum processing, coal chemical industry, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

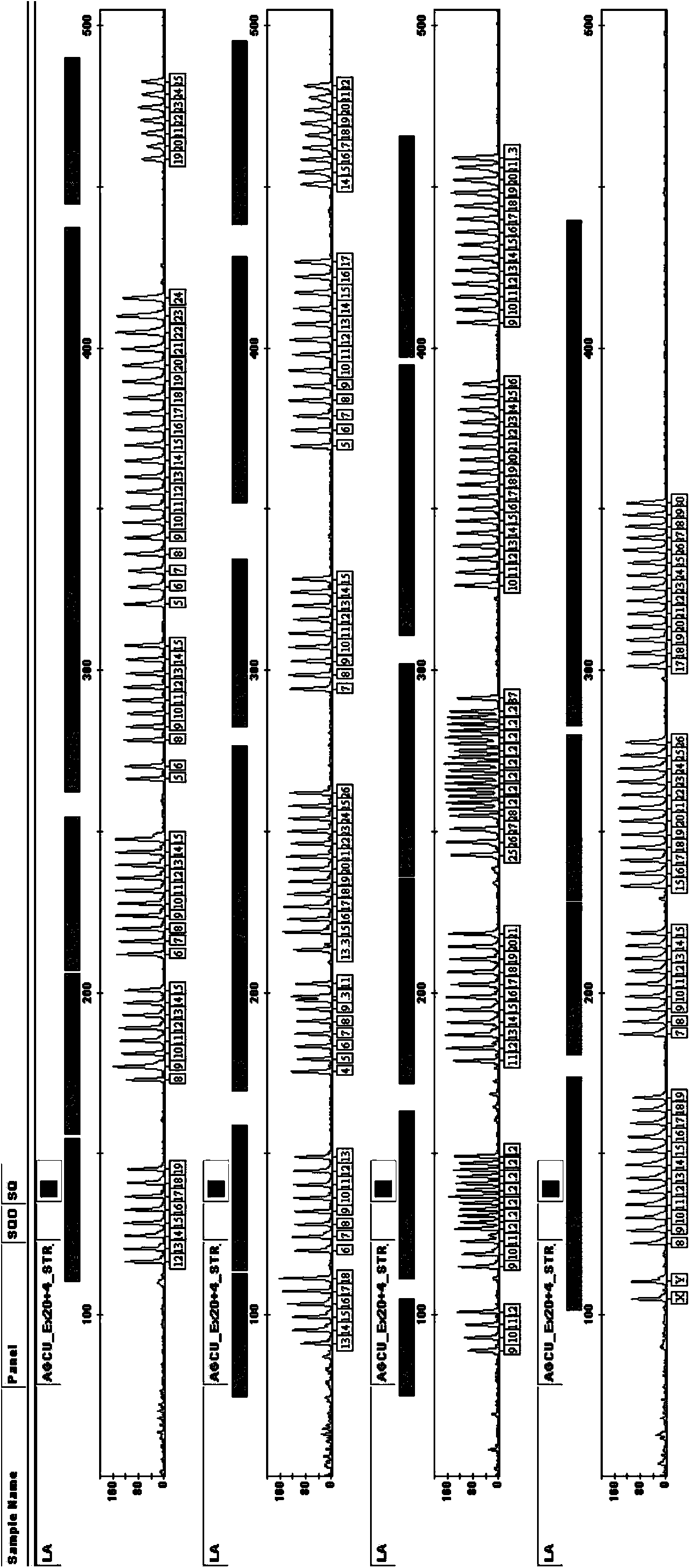

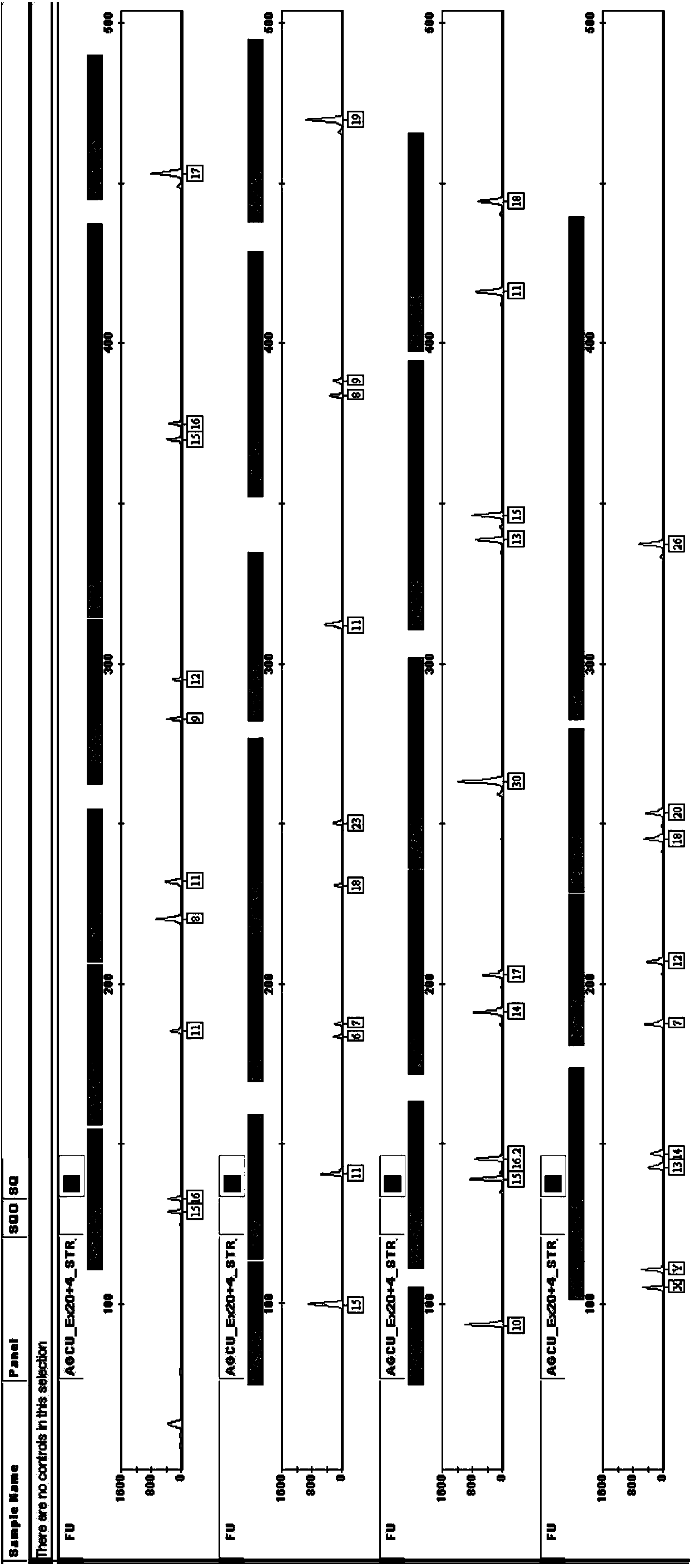

Kit for multiplex amplification of 24 loci of human genome DNA

ActiveCN103614361AQuick checkImprove detection efficiencyMicrobiological testing/measurementDNA preparationHuman DNA sequencingBlood filter paper

The invention relates to a five-color fluorescence labeling multiplex amplification system for analysis of 24 loci of human genome DNA at the same time. 19 autosome loci, 4 Y chromosome loci and 1 sex determination locus are detected at the same time. The system divides the 24 loci into 4 groups, and relates to fluorescence labeling of 5 colors. The fluorescence labeling multiplex amplification system has high sensitivity, under condition that the DNA template amount is 0.12ng, all the 24 loci can be detected, and the system is suitable for direct amplification of blood filter paper and FTA card collecting samples.

Owner:AGCU SCIENTECH +1

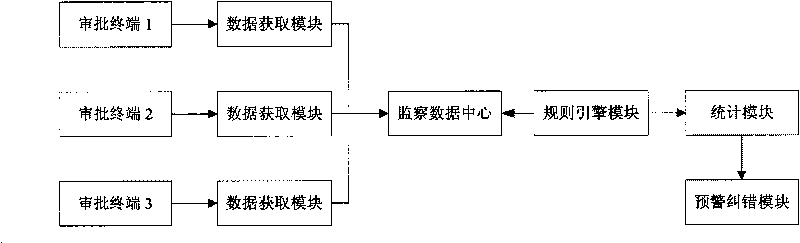

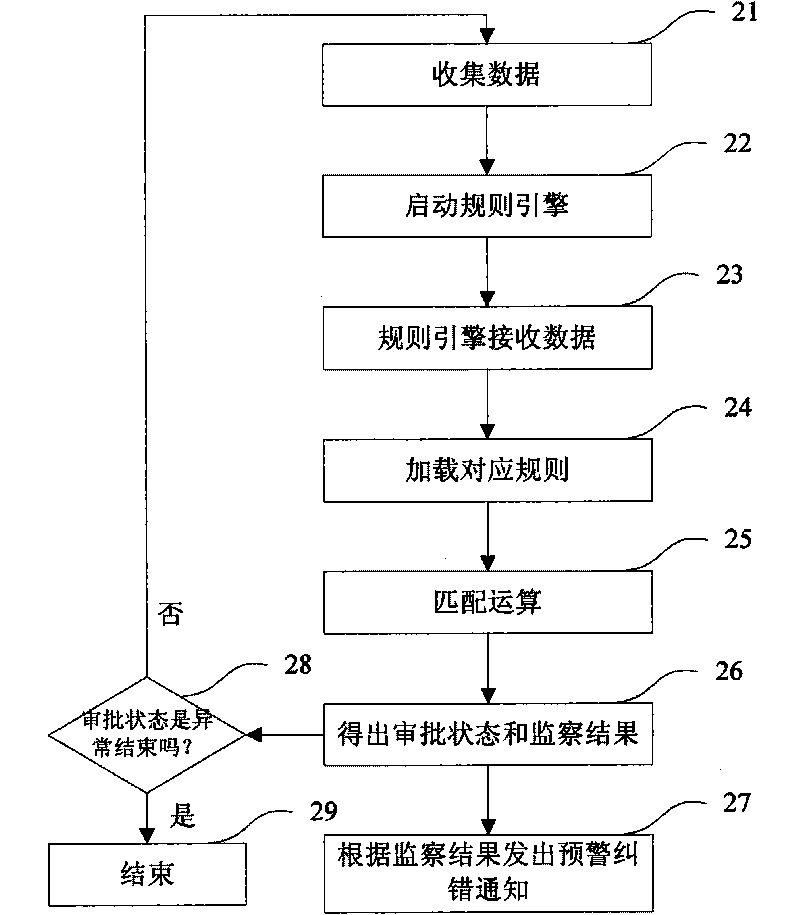

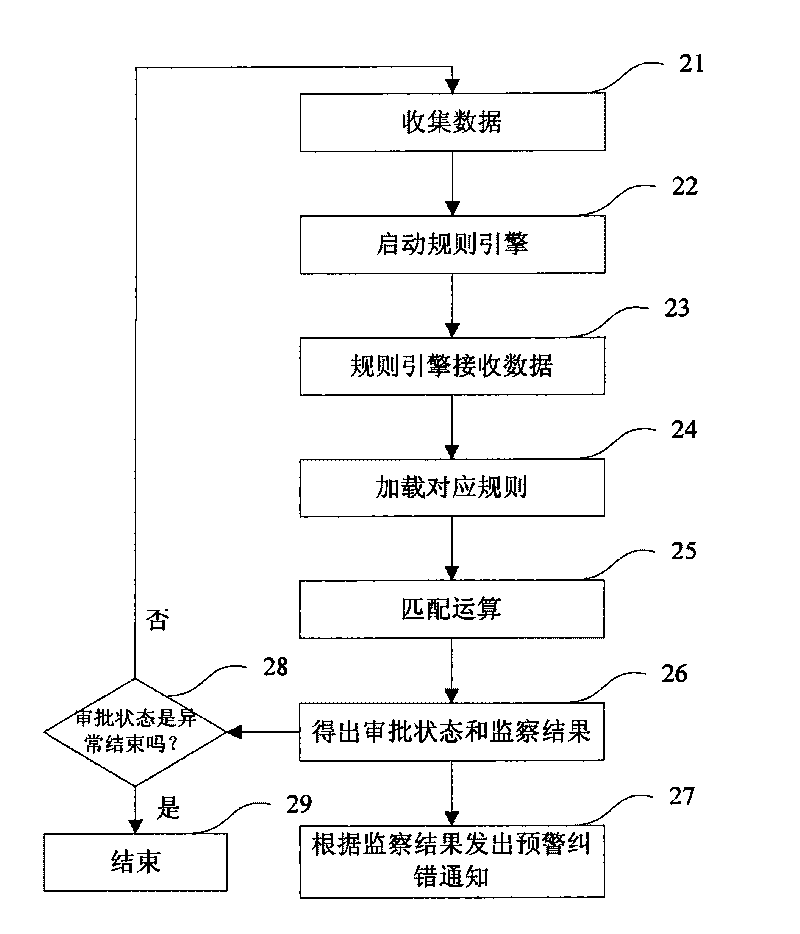

Method and system for electronic supervising of administrative examination and approval

InactiveCN101706889ASolve problems that are difficult to superviseStrong supervisory effectResourcesData centerData harvesting

The invention discloses a method and a system for electronic supervising of administrative examination and approval, comprising the following steps: A. collecting data from all examination and approval terminals and sending the collected data to a supervising data center; B. matching and operating the collected data according to a prearranged rule; C. obtaining the state of the examination and approval and the supervising result of all items according to the matching and operating results; and D. generating a corresponding early-warning correction notice according to the supervising result. The method and the system have strong supervising efficacy, solve the problem that the traditional supervising mode is difficult to be realized, convert the existing soft constraint into a rigid constraint, and have obvious effect.

Owner:深圳市监察局

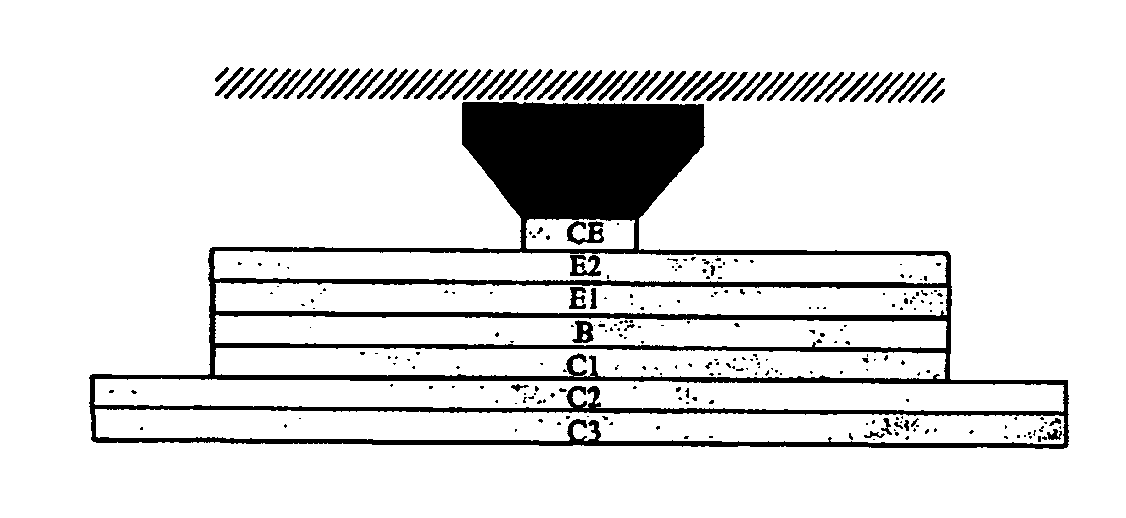

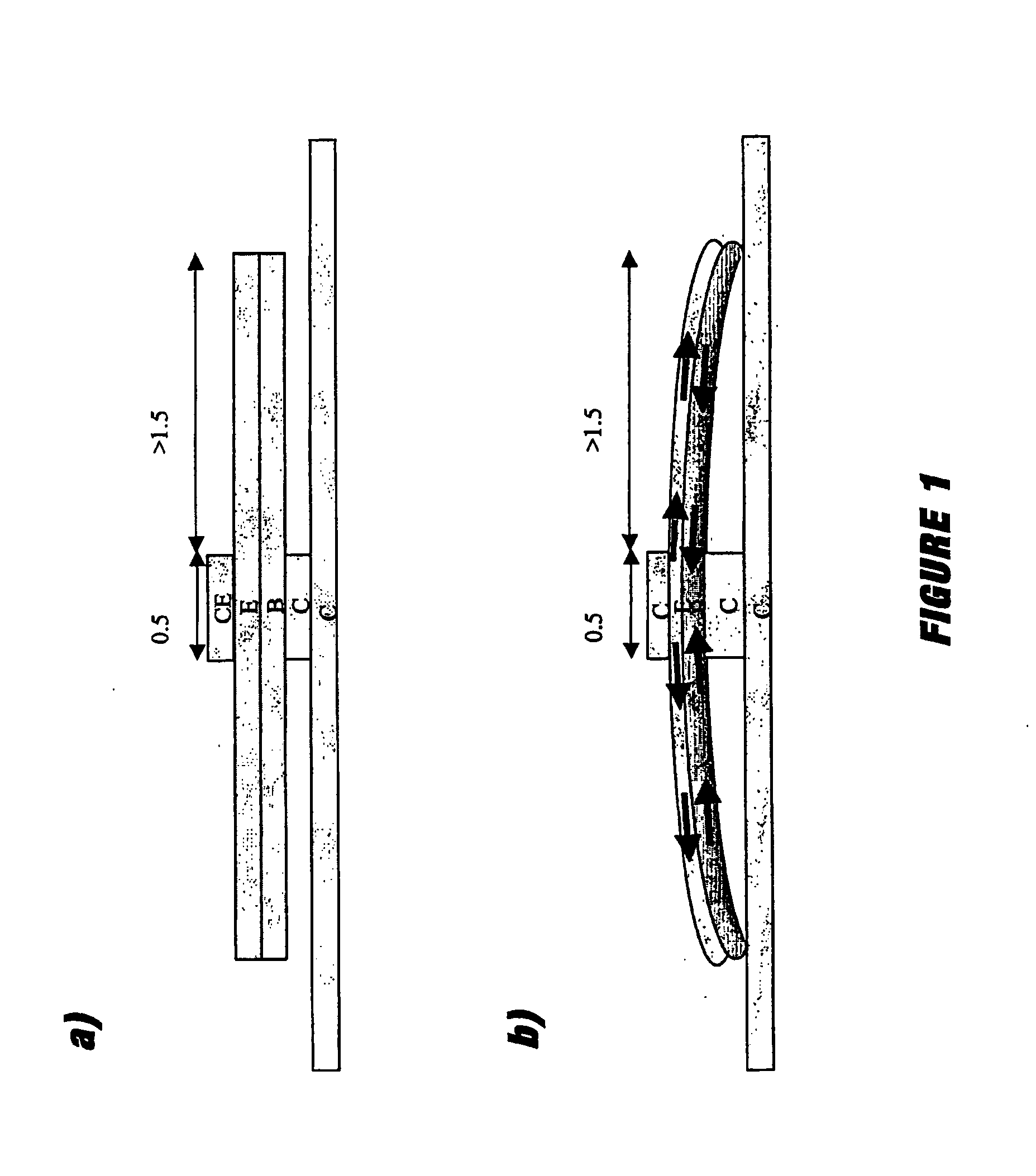

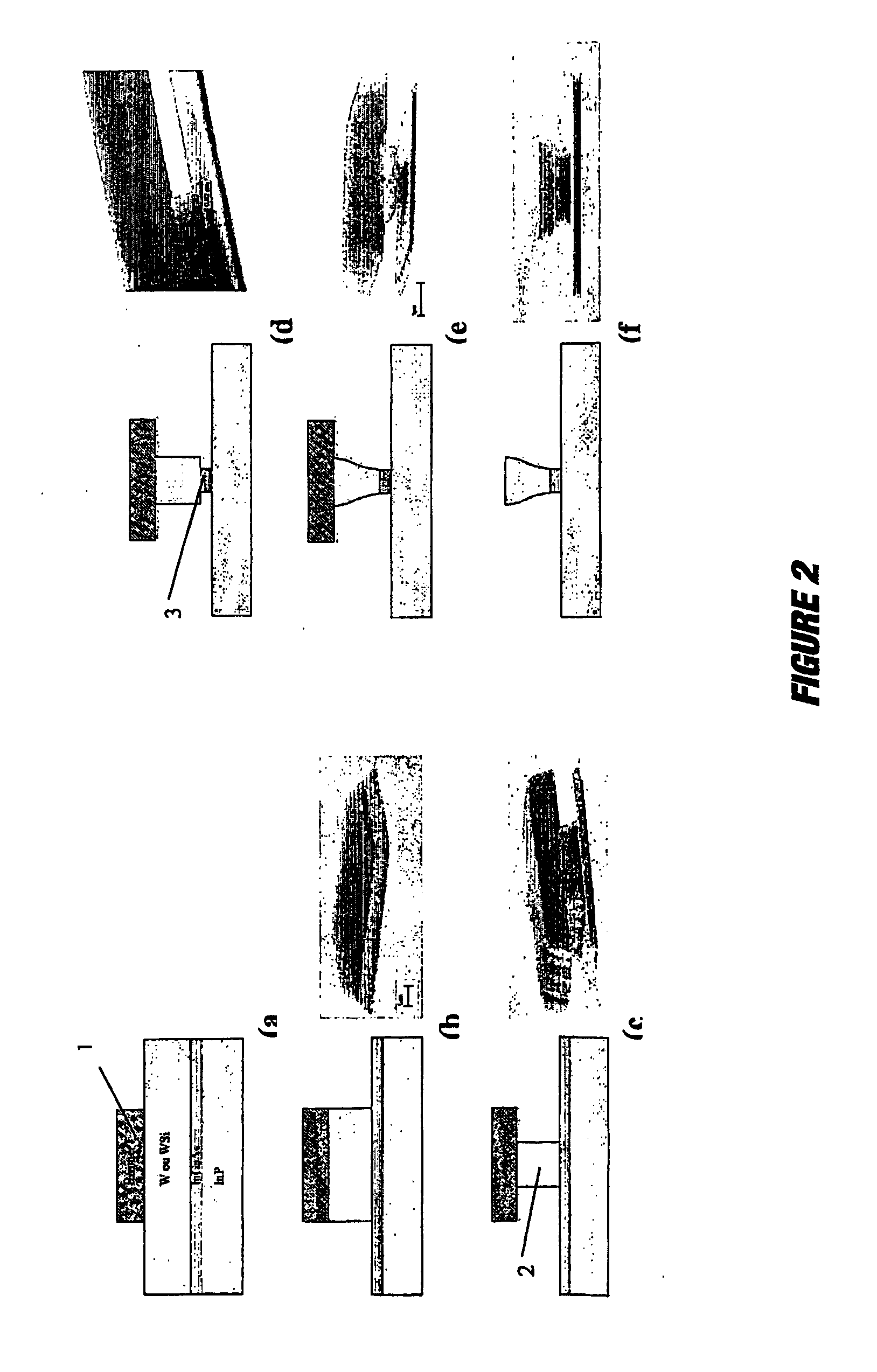

Method for Making a Heterojunction Bipolar Transistor

ActiveUS20100001319A1Reduce distortionGuaranteed CompatibilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringHeterojunction bipolar transistor

The invention concerns a heterojunction bipolar transistor comprising a support, and epitaxially grown from said support, at least: one collecting, respectively emitting, layer; at least one base layer; and at least one emitting, respectively collecting, layer. The collecting, respectively emitting, layer comprises: at least one first undercoat contacted with said base layer, substantially of similar composition as said emitting, respectively collecting, layer; and at least one second undercoat on the side opposite said base layer relative to said first undercoat.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Method for breeding southern Anhui local chickens

The invention discloses a method for breeding southern Anhui local chickens. The breeding method is a green ecological breeding method and has the advantages of being easy to implement and popularize, low in cost, high in practicability and the like. According to the method, implementation is convenient, time and labor are saved, management is convenient, notable results are brought, and convenience is brought to expanding the breeding scale of the southern Anhui local chickens and increasing market promotion of the southern Anhui local chickens. The southern Anhui local chickens are bred in an outside-cage mode, the outside-cage breeding site environment is elegant and fresh in air, and egg products and meat products are natural, green, nutrient, healthy, delicious in taste and unique in relish.

Owner:安徽逻根农业科技有限公司

Instant spice powder preparation method

InactiveCN108030053APreserve the active flavor componentsWith standardized productionFood scienceWater solubleEmbedding Agent

The invention relates to a seasoning preparation method, and especially relates to an instant spice powder preparation method. The method comprises the following steps: raw material preparation, dispersion, pre-emulsification, embedding, blending, and packaging; an oil dispersant, an emulsifier, an embedding agent, a carrier are added, resin essential oil of whole spice can be fully dispersed, andis processed to water-soluble oil powder. The preparation method has the advantages of simple technology and low cost, realizes instant dissolution of the spice in water, and cannot influence original taste of the spice.

Owner:洛阳味之泉调味技术有限公司

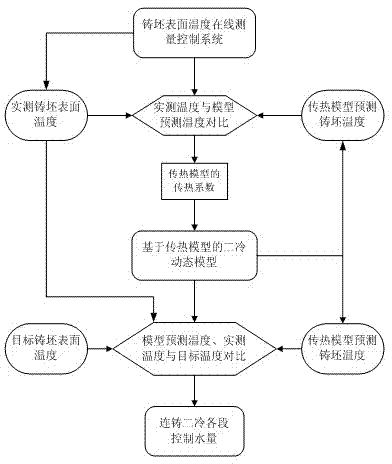

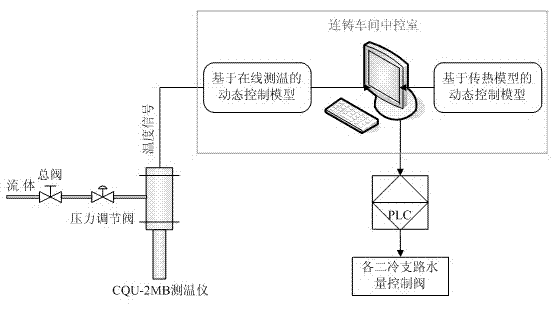

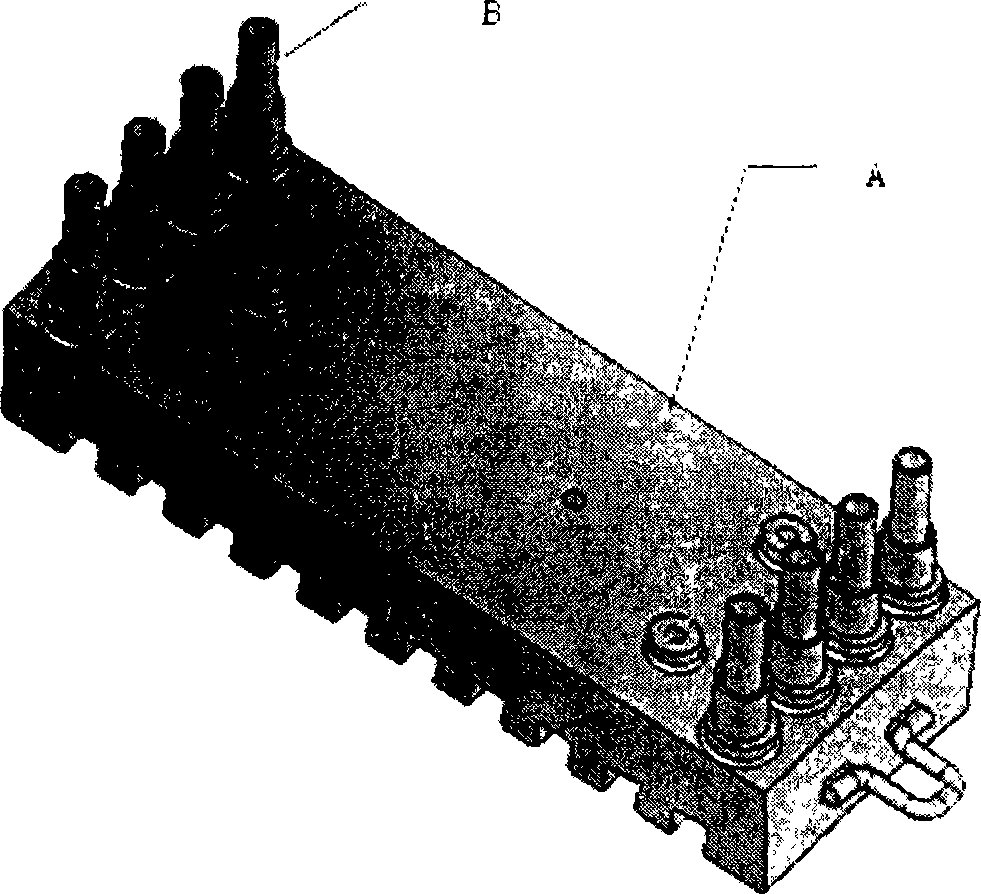

Continuous casting secondary cooling dynamic control method based on online temperature measuring and heat transferring model

The invention provides a continuous casting secondary cooling dynamic control method based on an online temperature measuring and heat transferring model. The continuous casting secondary cooling dynamic control method includes constructing a new continuous casting secondary cooling dynamic model, planting the new continuous casting secondary cooling dynamic model into a computer system, embedding the new continuous casting secondary cooling dynamic model into a water distribution system of a continuous casting machine and enabling the new continuous casting secondary cooling dynamic model to be in communication connection with a PLC (programmable logic controller); mounting a non-contact type temperature measuring instrument CQU-2MB in a continuous casting straightening area and enabling the non-contact type temperature measuring instrument CQU-2MB to be in communication connection with the PLC and to form a feedback circuit with the new continuous casting secondary cooling dynamic model; acquiring various technological operation parameters by the new continuous casting secondary cooling dynamic model in an online manner during continuous casting; carrying out simulation computation of parameters in real time; measuring the temperature of the surface of a casting blank in the continuous casting straightening area in an online manner; and controlling and adjusting the quantity of water for continuous casting secondary cooling by comparison and computation for the temperature measured in real time in the online manner, the temperature which is predicted by a heat transferring model and is corrected in real time and the temperature of the surface of a target casting blank. By the continuous casting secondary cooling dynamic control method, accuracy and reliability of continuous casting secondary cooling dynamic control and stability of running of continuous casting secondary cooling are greatly improved, and the method is simple and feasible in implementation and obvious in effect.

Owner:CHONGQING UNIV

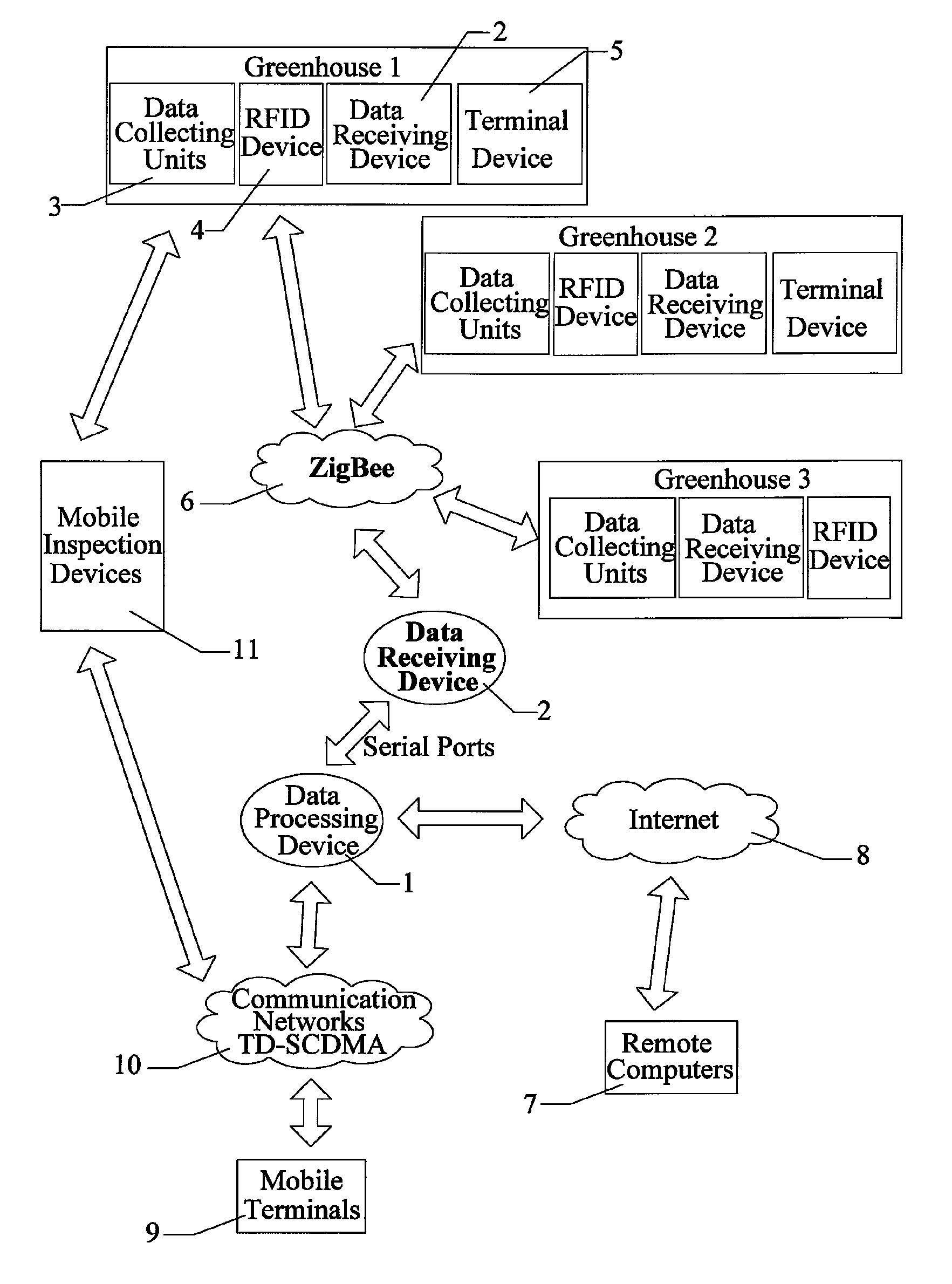

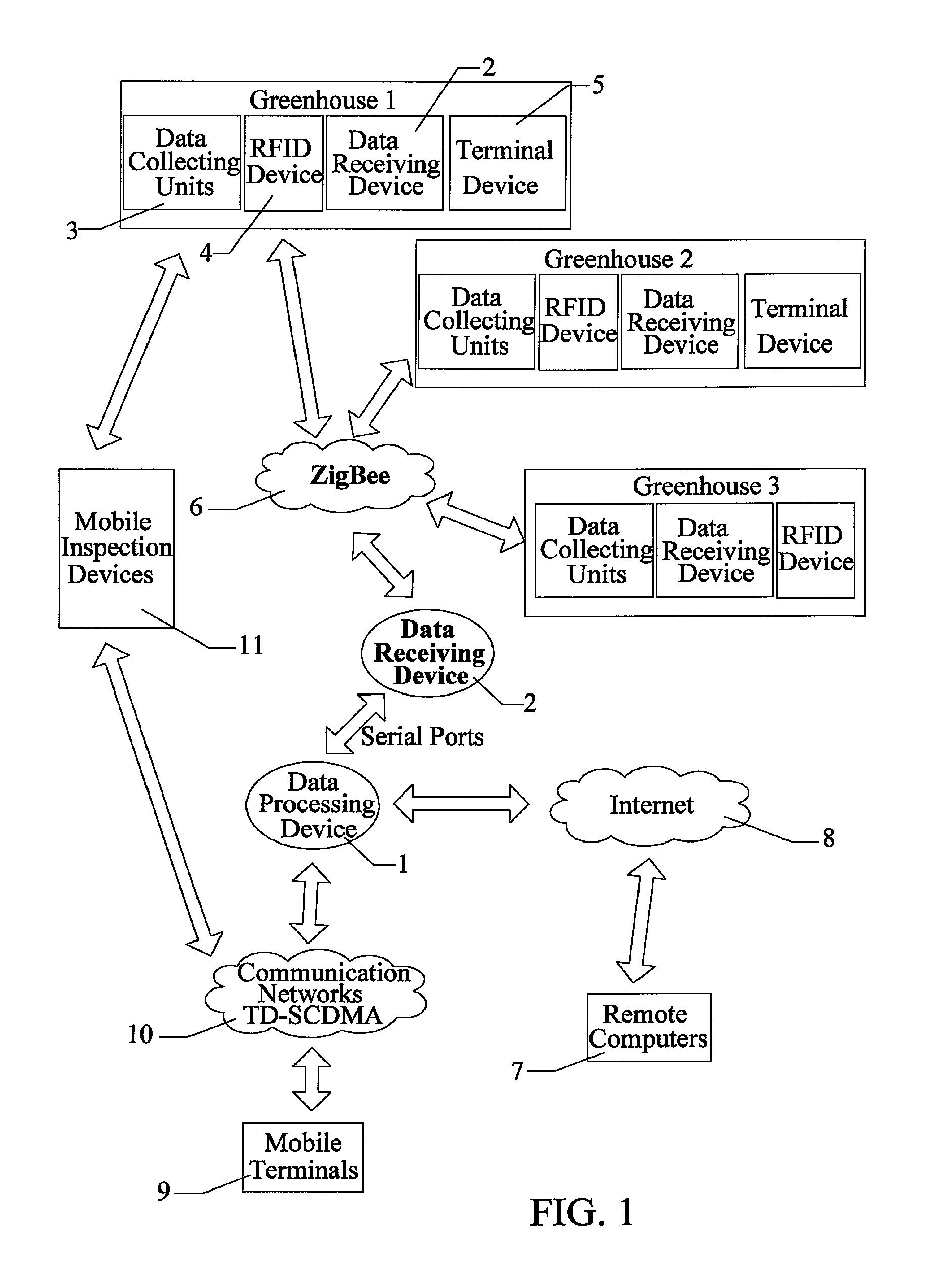

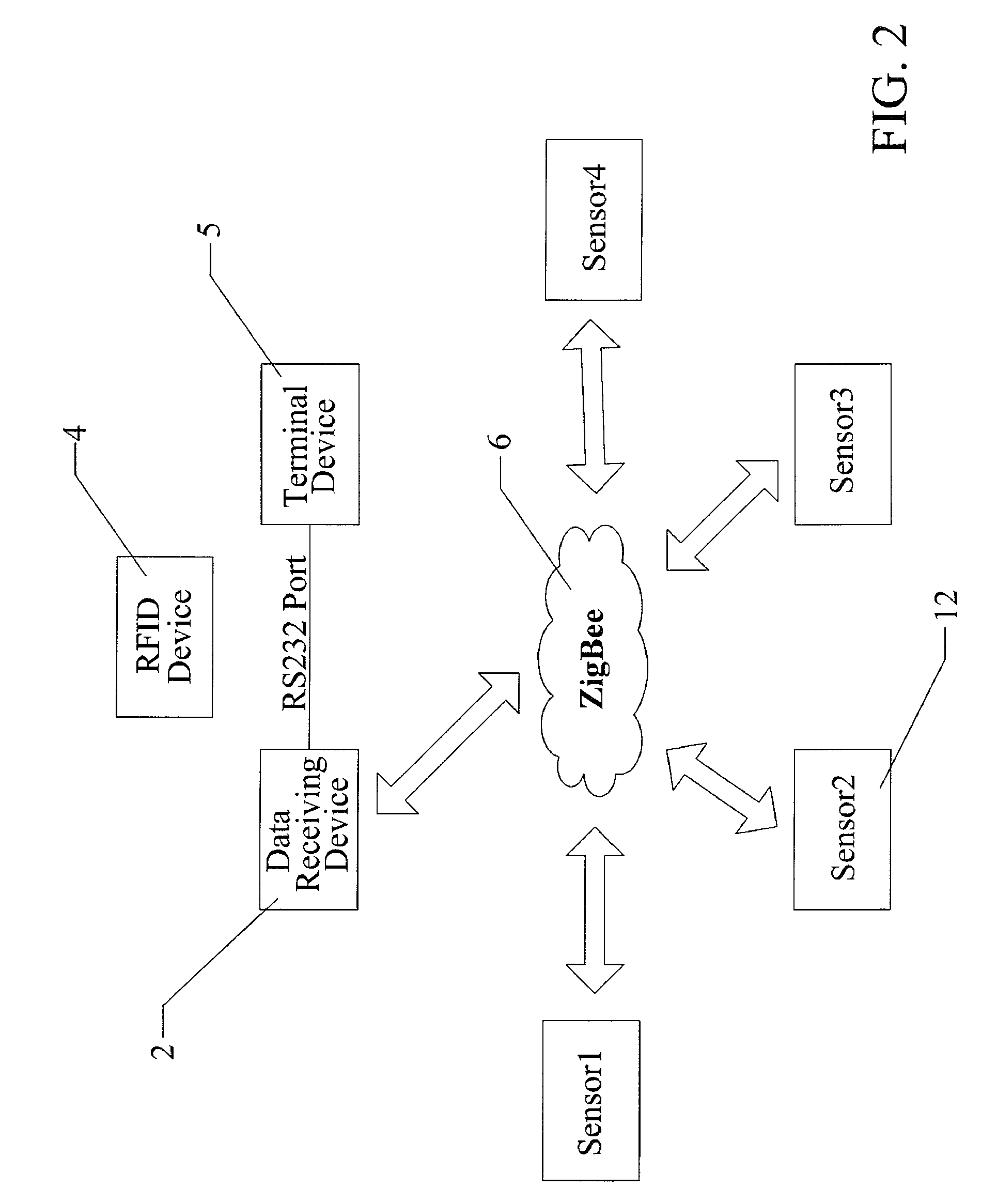

Internet of things based farm greenhouse monitor and alarm management system

ActiveUS8643495B2Easy to operateDeployment flexibilityElectric signal transmission systemsClimate change adaptationThe InternetData acquisition

A farm greenhouse monitor and alarm management system based on the Internet of things with real-time monitoring environmental parameters, which is aimed at monitoring and managing the growth of crops in the farm greenhouse, includes mobile inspection devices, data acquisition units, data receiving devices, REID devices and data storage servers. The system can automatically collect greenhouse environmental parameters such as air temperature, air humidity, illumination, soil temperature and soil moisture, etc. and also can automatically judge the critical value of every parameter and alarm. It utilizes ZigBee chip integrated wireless sensors and data collecting modules. This system provides inspection devices, which lowers the requirements for practitioners and reduces the cost of automatic management of the farm greenhouse.

Owner:LAN ZEHUA

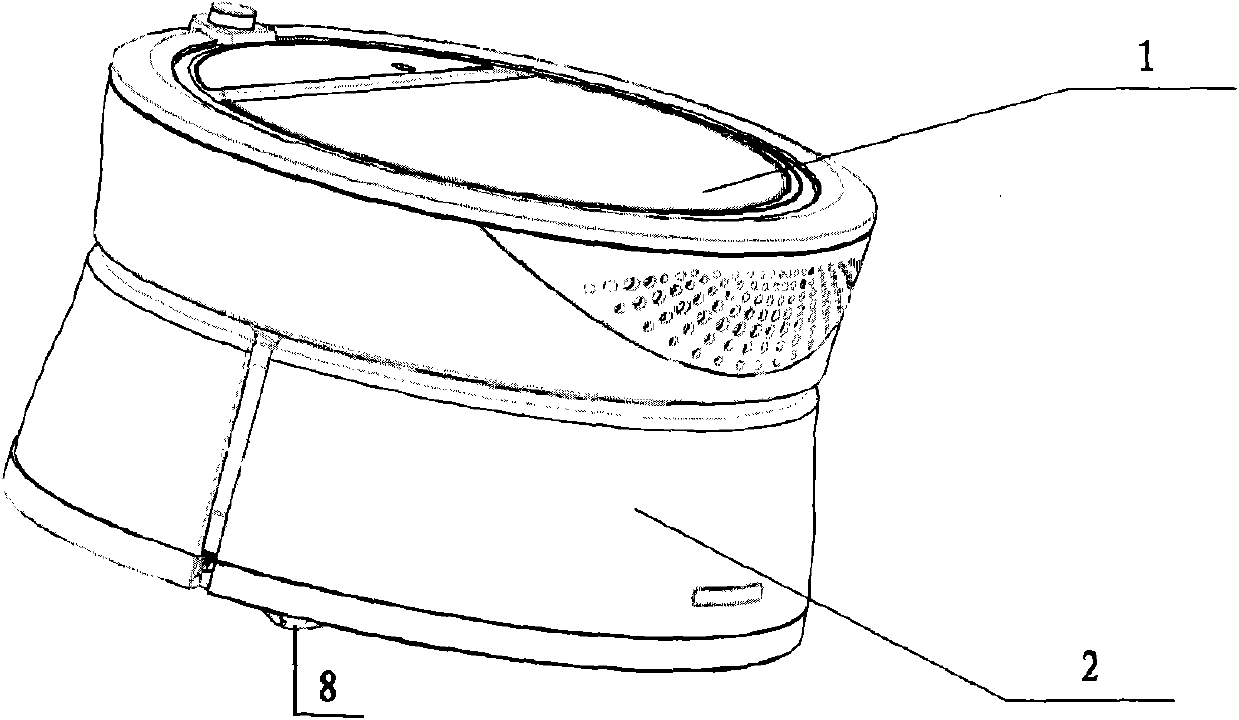

Air purifier and air treatment method thereof

ActiveCN102221252ASave time at workRemarkable resultsMechanical apparatusSpace heating and ventilation safety systemsDrive wheelAir purifiers

The invention relates to an air purifier and an air treatment method thereof. The air purifier comprises an upper main body and a lower main body and is characterized in that an air treatment unit arranged in the upper main body is used for treating the air in the area to be treated; a moving unit arranged in the lower main body comprises a driving unit and a driving wheel; a control unit is used for respectively controlling the air treatment unit and the moving unit to work; an air quality sensor is used for detecting the information value of air pollution; the signal of the air quality sensor is transferred to the control unit; an information storage subunit in the control unit is used for storing the information value detected by the air quality sensor, of air pollution in the starting and finishing positions from and to which the air purifier goes straight in two different directions; and an information treatment subunit in the control unit is used for treating the information value stored in the information storage subunit, of air pollution and judging the direction of the pollution source. The air purifier and the air treatment method have the following beneficial effects: the air purifier purifies the pollution source from the source by actively seeking the pollution source, thus shortening the working time and achieving an obvious effect.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

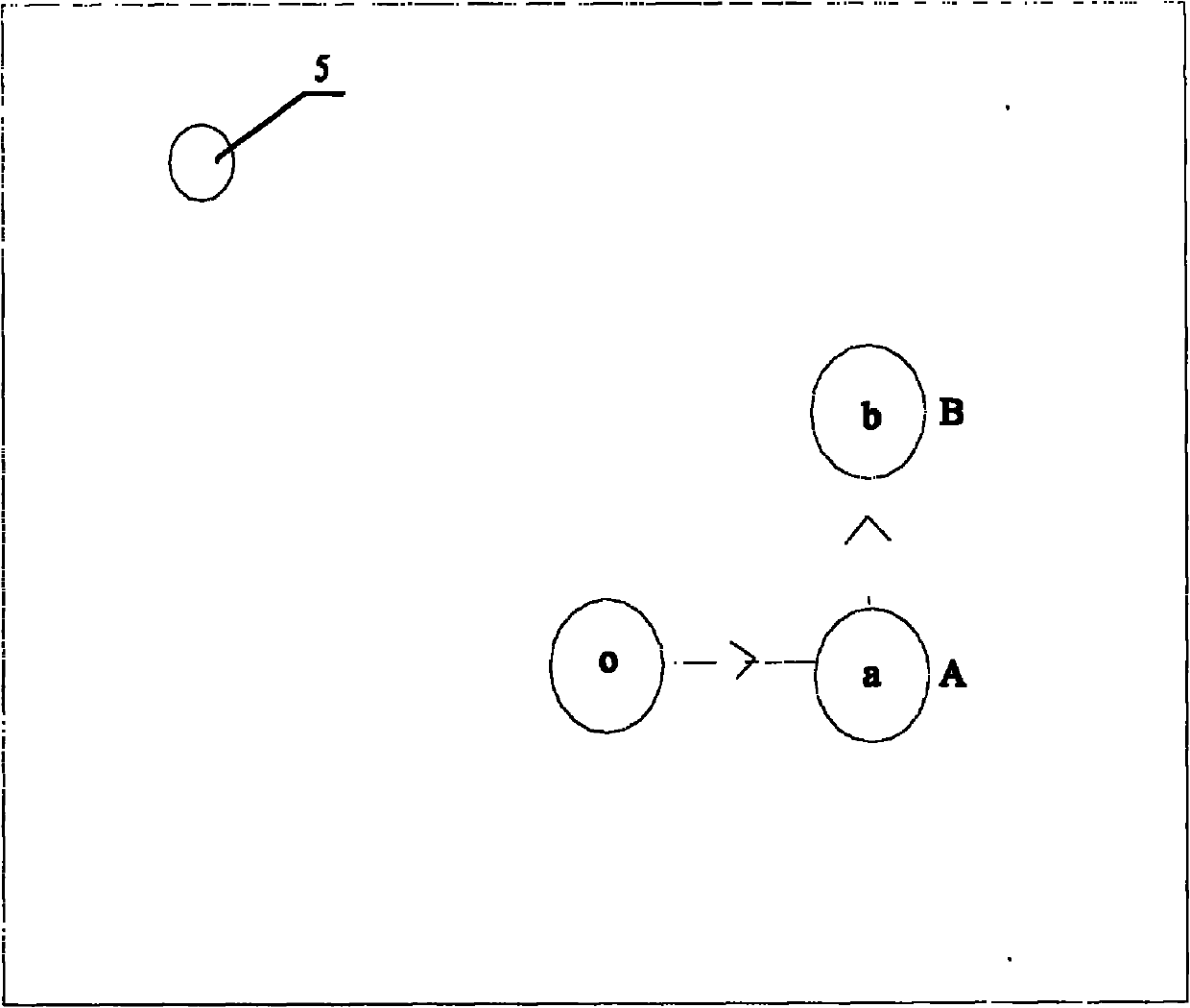

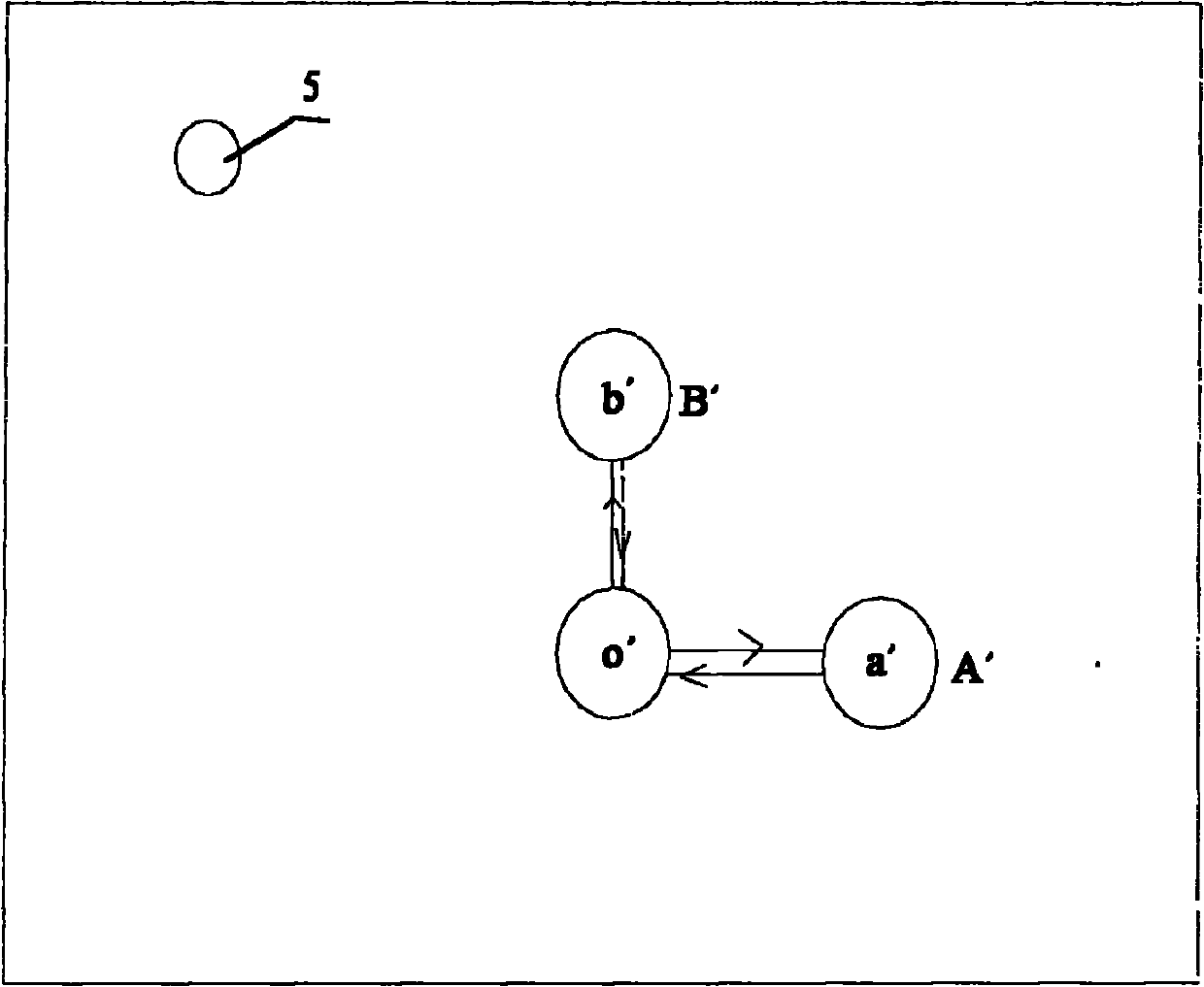

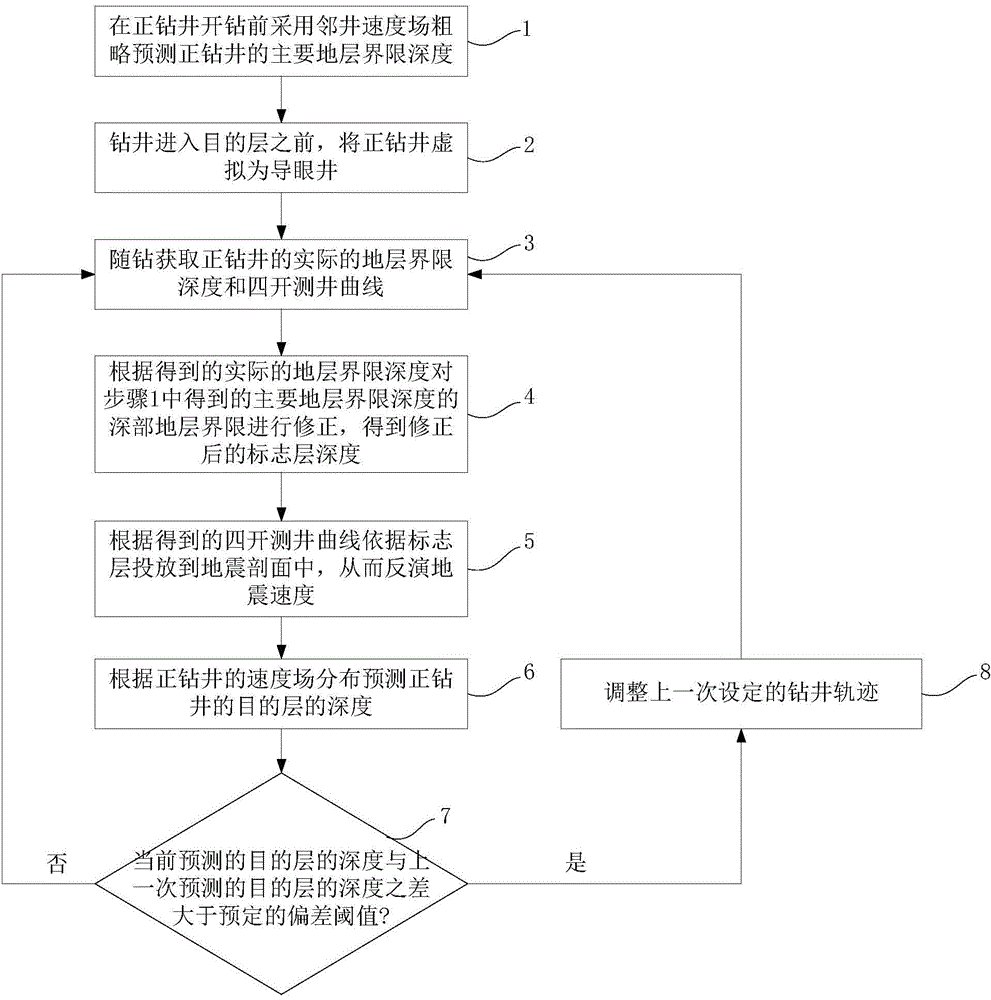

Deep horizontal well drilling track regulating method

ActiveCN104975808ARemarkable resultsGood economic and social benefitsSurveyDirectional drillingSection planeEnvironmental geology

The invention discloses a deep horizontal well drilling track regulating method, which comprises the following steps of: before the drilling of a drilling well, using an adjacent well speed field for predicting the main formation limit depth of the drilling well; before the drilling to a target layer, virtualizing the drilling well into a pilot well; obtaining the actual formation limit depth of the drilling well and a quarto well logging curve while drilling; correcting the deep formation limit at the main formation depth obtained before the drilling according to the obtained actual formation limit depth, and obtaining a corrected marking layer depth; performing the putting into a seismic profile according to the obtained quarto well logging curve in accordance with the marking layer so as to reverse the speed field of the drilling well; predicting the depth of the target layer of the drilling well according to the speed field of the drilling well; and regulating the drilling track set in the last time if the difference of the current predicted depth of the target layer and the depth of the target layer predicted in the last time is greater than the preset deviation threshold. The method has the advantages that the Yuanba horizontal well track optimization and regulation are effectively guided, and the effective reservoir drilling ratio is improved.

Owner:CHINA PETROCHEMICAL CORP +4

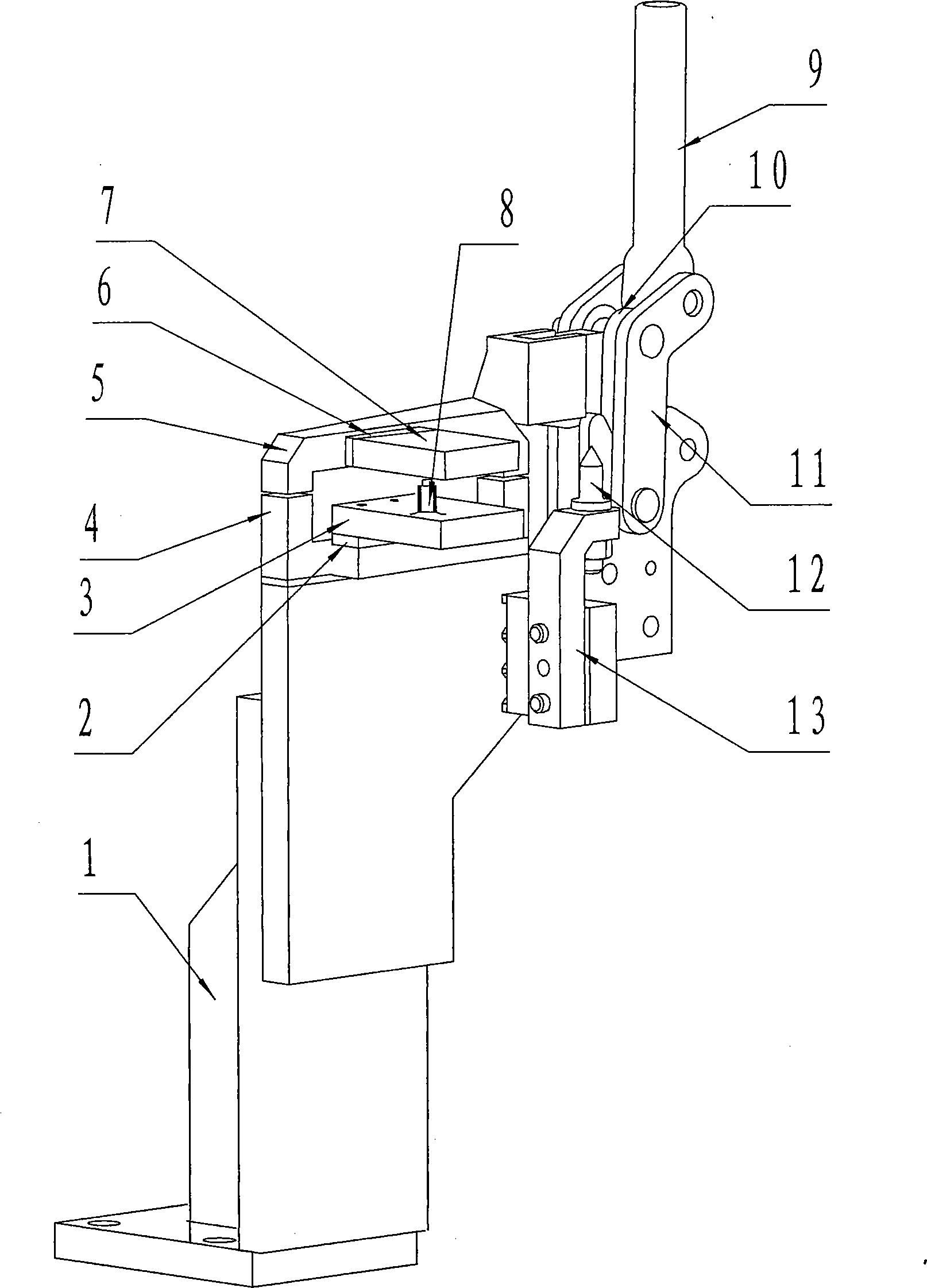

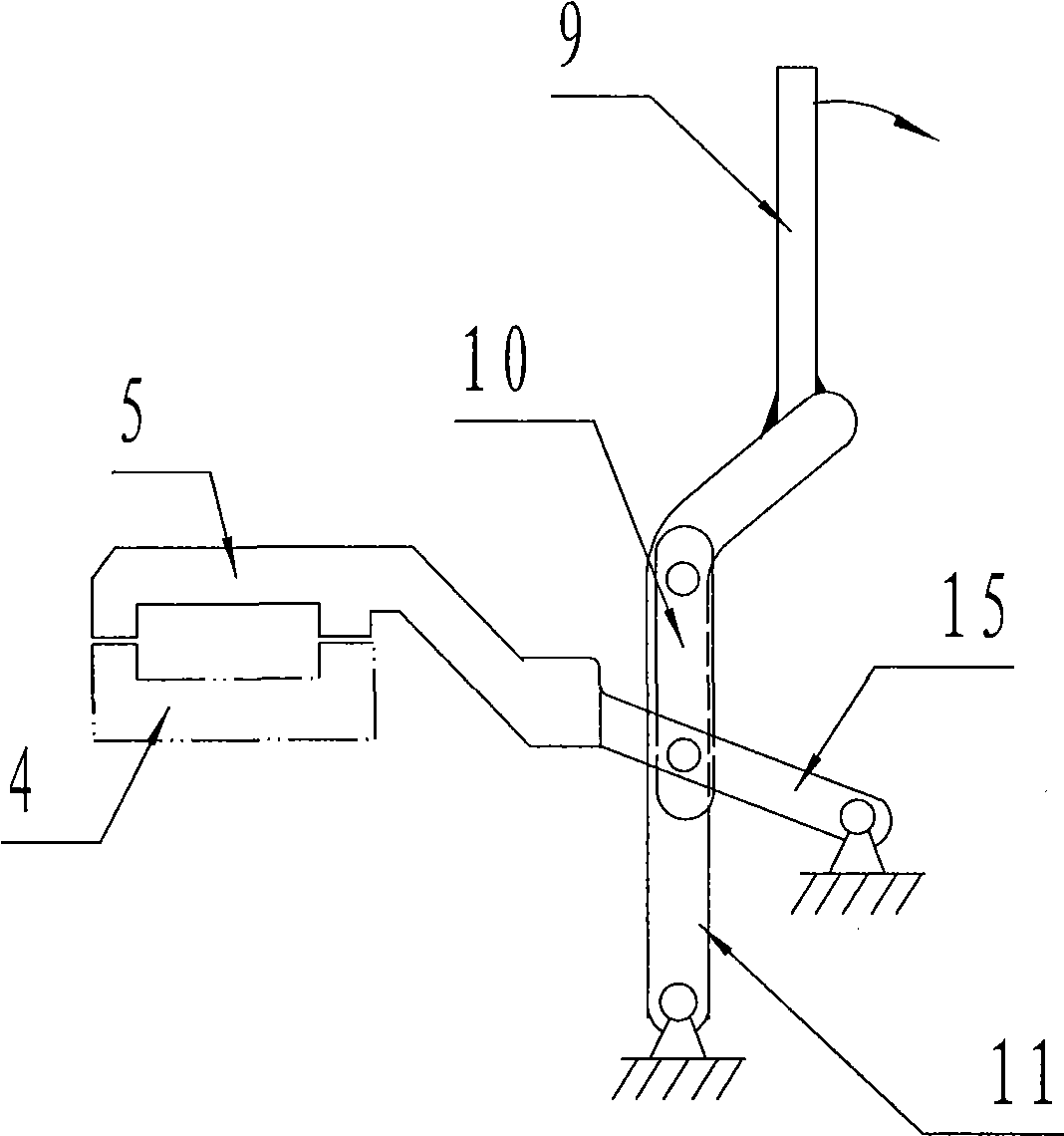

Projection welding nut welding clamp

InactiveCN101480771ASimple processReduce intermediate transportation linksWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a welding clamp for projection welding nuts, which is used for solving the welding problem of a sheet metal component. The welding clamp comprises a clamp seat, a clamping mechanism, an upper clamping piece, a lower clamping piece, an upper press block and a lower press block, wherein the position of the upper press block corresponds to the position of the lower press block from top to bottom, the lower clamping piece is fixed on the clamp seat, the lower press block is fixedly connected with the lower clamping piece, and the lower press block is provided with a nut positioning pin coated with an insulating layer; the upper clamping piece is connected with the clamping mechanism and fixedly connected with the upper press block, an insulation sheet is arranged between the upper press block and the upper clamping piece, and a lower insulation sheet is arranged between the lower press block and the lower clamping piece. The welding clamp can position and clamp a projection welding nut and a sheet metal component and directly weld the projection welding nut on the sheet metal component on a positioned work station by utilizing a suspension spot welder. Due to the adoption of the clamp, the technique process is simplified, a middle transportation link is saved, and the clamp plays an obvious role in enhancing the work efficiency and saving the carrying space.

Owner:GREAT WALL MOTOR CO LTD

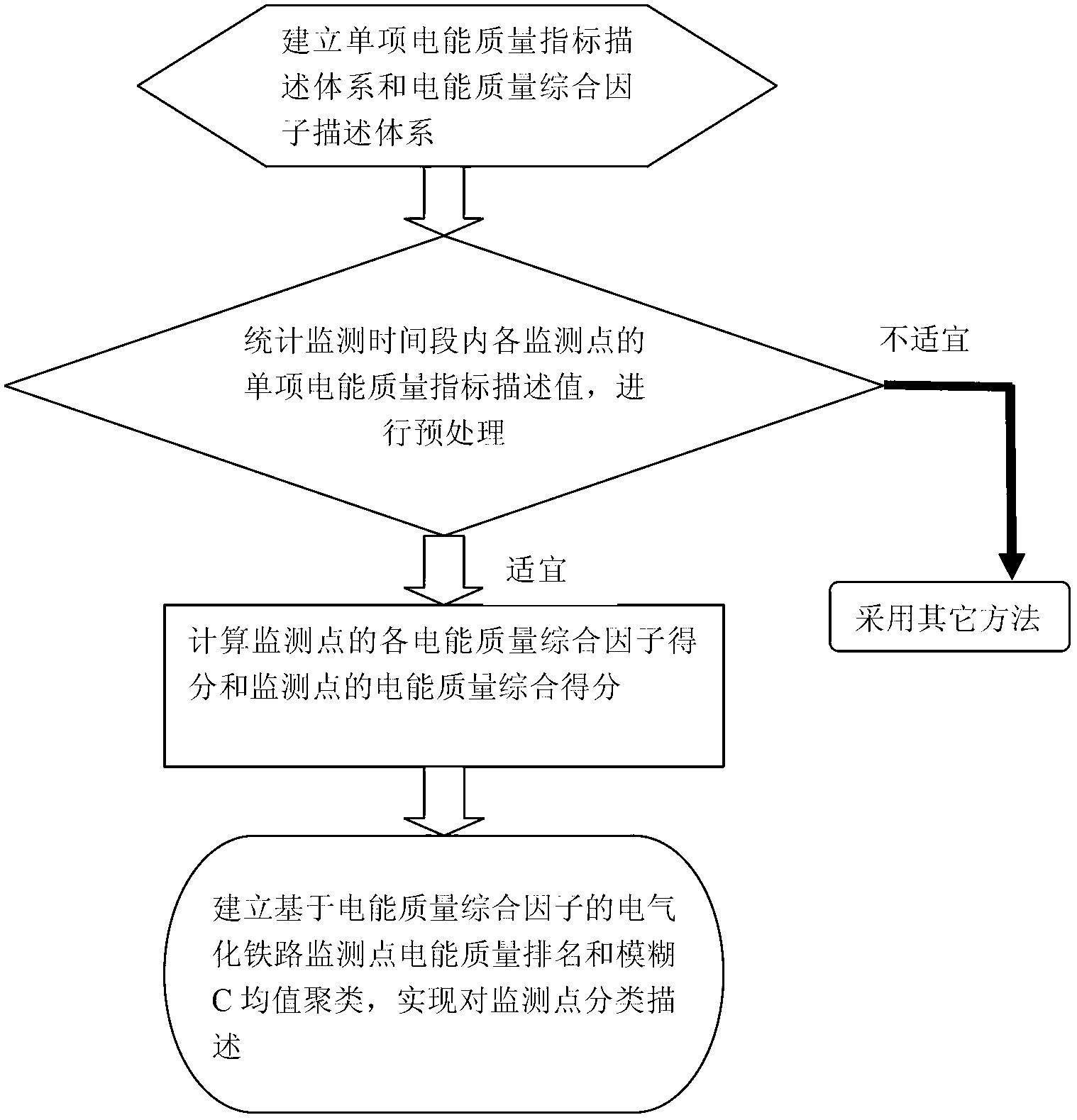

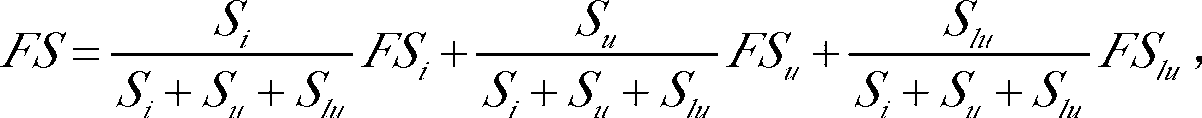

Comprehensive evaluation method based on multi-stress for electric energy quality of monitoring points of electrified railway

ActiveCN103023023AAchieve rankingRemarkable resultsHarmonic reduction arrangementAc network to reduce harmonics/ripplesPower qualitySimulation

The invention discloses a comprehensive evaluation method based on multi-stress for the electric energy quality of monitoring points of an electrified railway. The comprehensive evaluation method is characterized by comprising the following steps of: firstly establishing a single electric energy quality index description system and an electric energy quality multi-stress description system; and then calculating the score of electric energy quality multi-stress of each monitoring point, sorting the electric energy quality of each monitoring point according to the size of the synthesis score of the electric energy quality of each monitoring point by taking a variance contribution rate of each electric energy quality multi-stress as a weight for calculating a synthesis score of the electric energy quality of the monitoring points, simultaneously, classifying all the monitoring points by adopting a fuzzy C mean value clustering method according to the need of sorting management, and carrying out category classification on the monitoring points. According to the comprehensive evaluation method, the overall sorting and clustering of the electric energy quality condition of the monitoring points of the electrified railway are realized, and references and basis are provided for the unified management and deep planning management of electric energy quality.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER

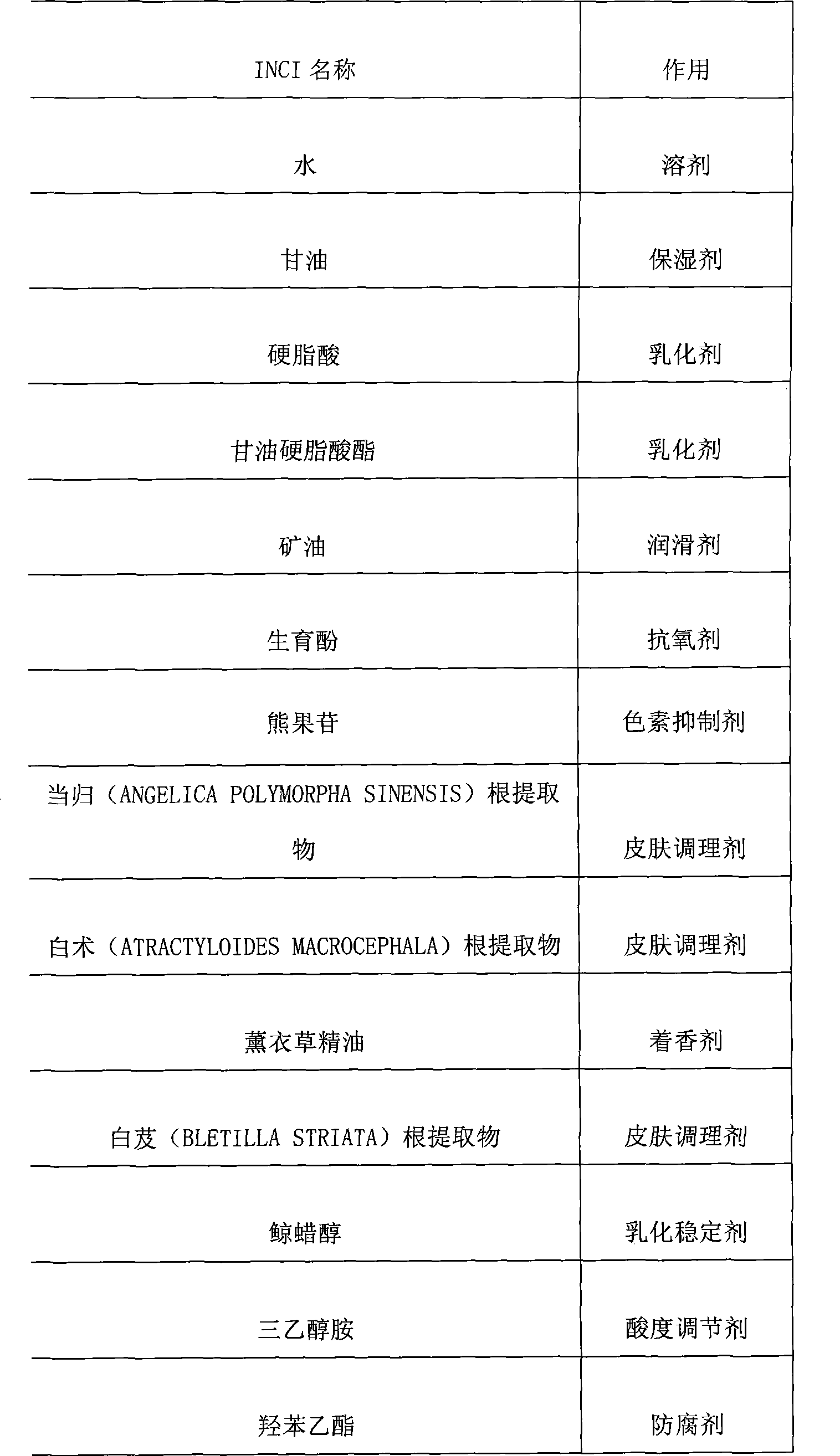

Spot-eliminating skin care product and preparation method thereof

InactiveCN101502481AEnhance metabolic functionNo side effectsCosmetic preparationsToilet preparationsRhizomeMineral oil

The invention relates to a spot-removing skin care product and a preparation method thereof. The spot-removing skin care product comprises the following raw materials: glycerin, stearic acid, glyceryl stearate, mineral oil, tocopherol, arbutin, angelica, atractylodes rhizome and bletilla striata root extract, lavender essential oil, spermol, trolamine and a preservative. The method comprises the following steps: the raw materials are melted in a melting tank, insulated and blended evenly in a vacuum homogeneous emulsion tank, cooled and stirred to obtain the semi-finished products; the semi-finished products are inspected, discharged and filled to prepare the finished products. The spot-removing skin care product of the invention contains diverse active ingredients having the functions of whitening, spot-removing and healing and effectively inhibits tyrosinase activity, thereby comprehensively inhibiting formation of melanin, accelerating metabolism, healing damaged skin, comprehensively caring skin, improving the metabolism function of skin cell and ensuring fast spot-removing effect, good effect and no toxic side effects on human bodies.

Owner:赵超涛 +1

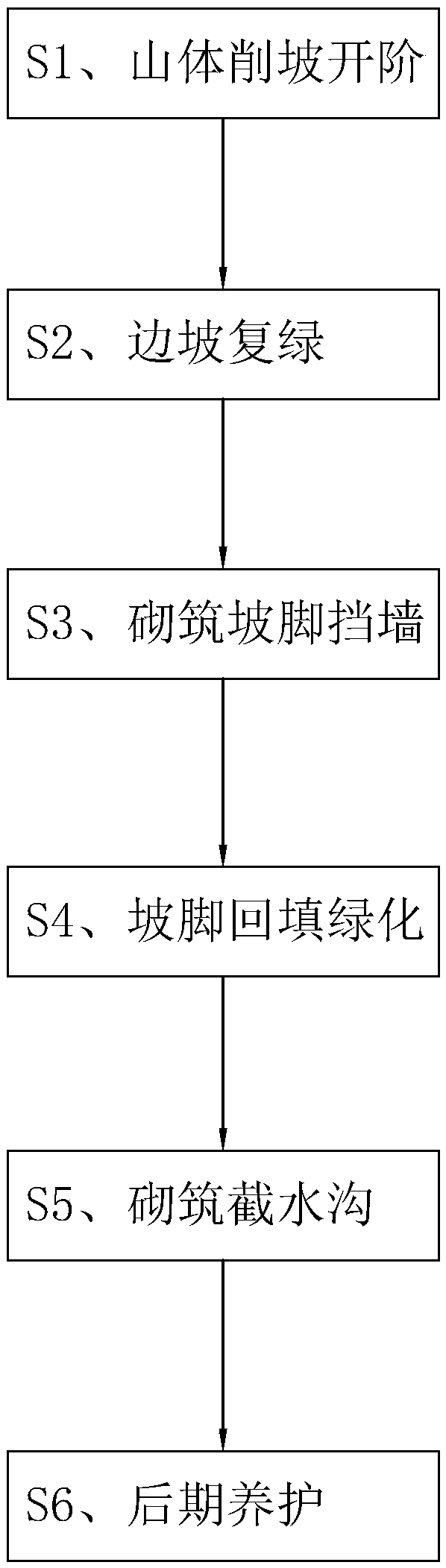

Repair treatment method of mine

The invention discloses a repair treatment method of a mine. The method comprises following steps of mountain slope cutting and side-benching; slope green retrieving; slope toe retaining wall construction; slope toe backfill greening; intercepting ditch construction; and later maintenance. During mountain slope cutting and side-benching, the mountain gradient is larger than or equal to 60 degrees,during slope green retrieving, according to whether the slope is a slope cutting area, the slope is divided into a spray sowing treatment area and a fish-scale pit planting area; a backfilling area is arranged on the side, close to the mountain, of a constructed slope toe retaining wall, and the backfilling material is stone generated by mountain slope cutting and side-benching; through the abovescheme, mountain slope cutting and side-benching can adapt to the mountain with the larger gradient, the stability of vegetation retrieving is improved, the constructed slope toe retaining wall can improve the stability of the mountain, disasters of landslide and the like are reduced, meanwhile, stone generated by slope cutting and side-benching is adopted in backfilling of the slope toe retaining wall, and can be well used, and pollution and transport cost is reduced.

Owner:湖北安达泰建设工程有限公司

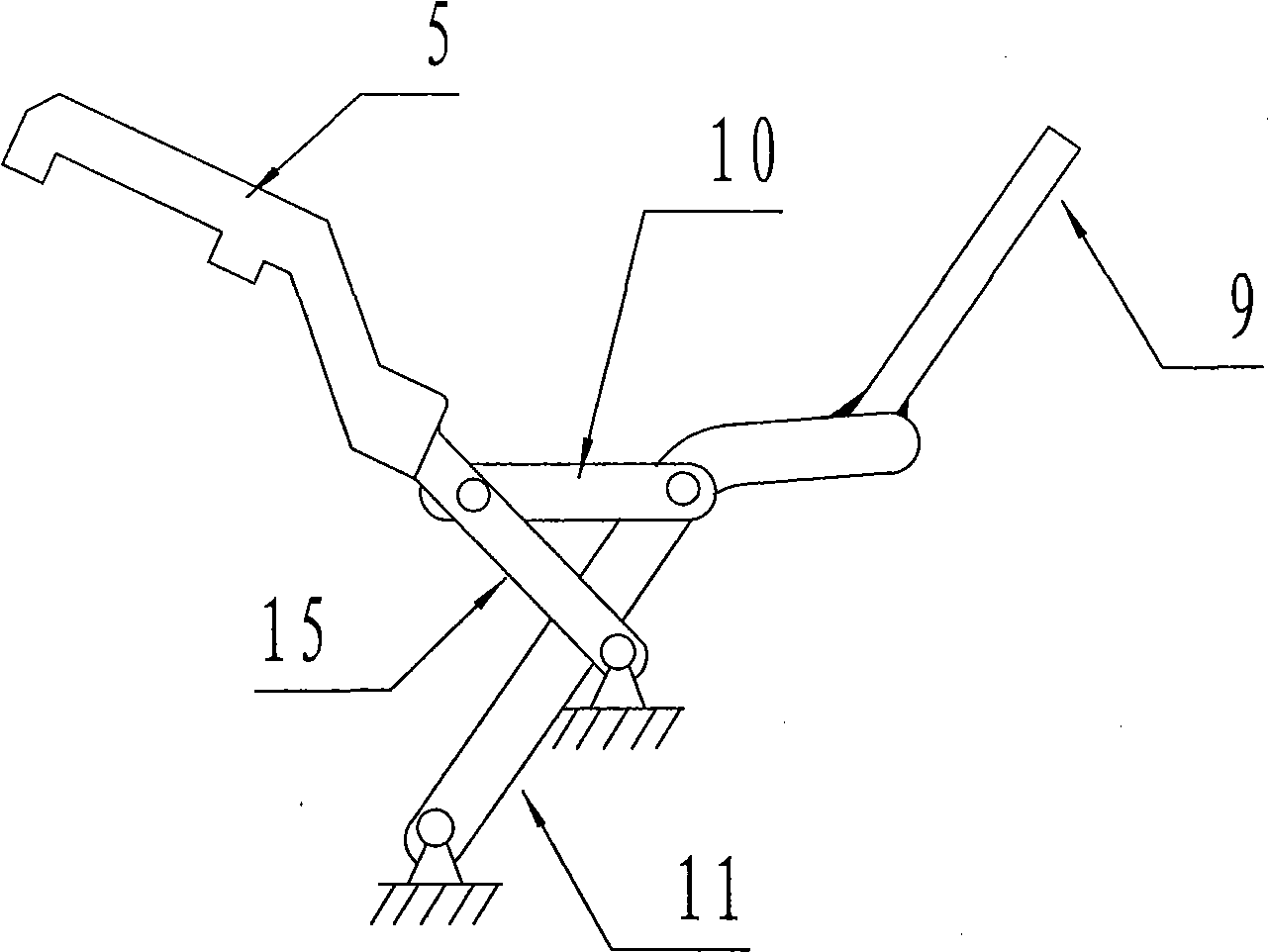

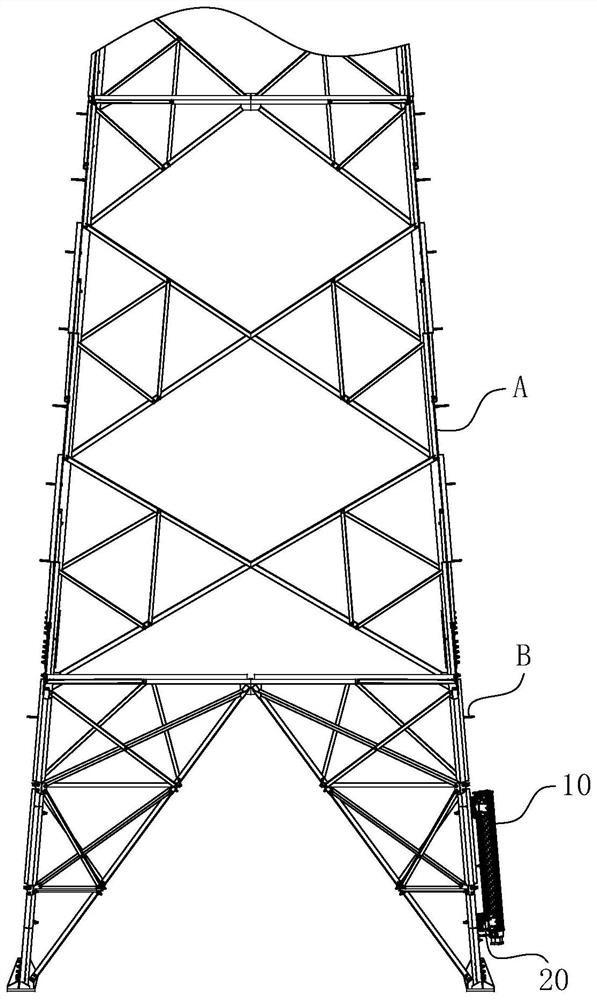

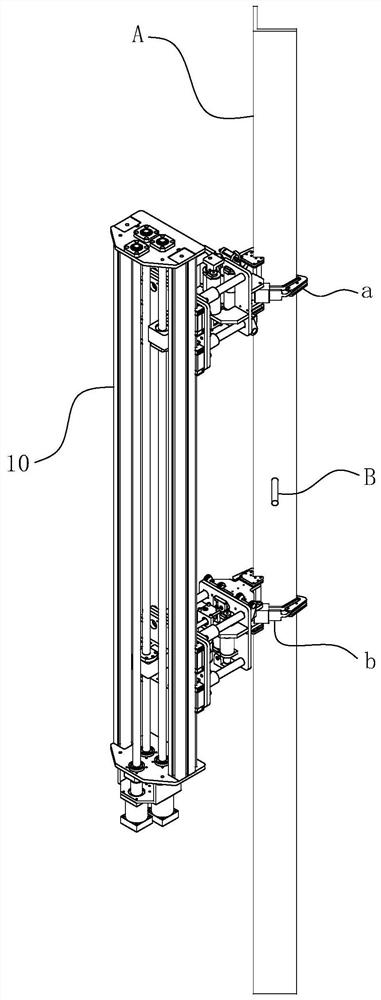

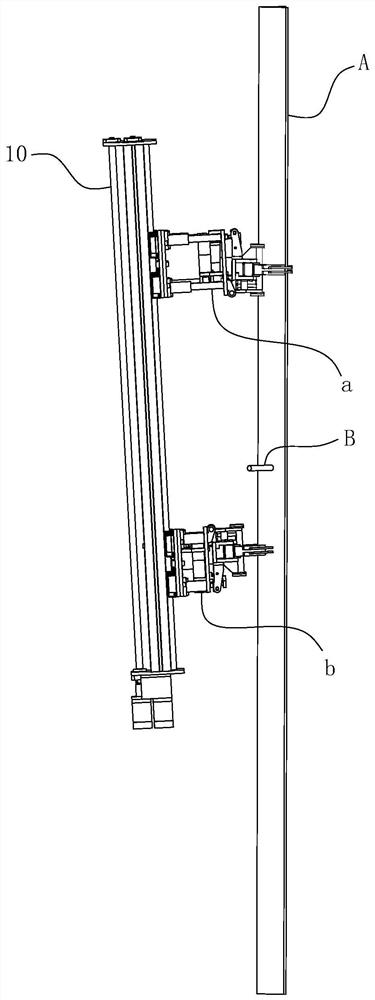

Climbing robot for angle steel tower

ActiveCN112356940AGuaranteed efficient obstacle clearanceGuaranteed clamping effectManipulatorVehiclesControl engineeringMachine

The invention belongs to the technical field of climbing robots for electric power operation, and particularly relates to a climbing robot for an angle steel tower. The robot comprises a main machineand clamping assemblies, the clamping assemblies comprise the upper clamping assembly and the lower clamping assembly, and at least one set of clamping assemblies can do reciprocating displacement motion parallel to the advancing path of the main machine relative to the main machine; each clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is installed on the clamping jaw and can enable the main machine to generate pitching angle adjustment relative to the angle steel, and the lifting assembly can enable the clamping jaw to generate approaching and departing actions relative to the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicular to the length directionof the angle steel. The robot has high obstacle crossing capability and high climbing efficiency, and can synchronously guarantee the action stability and action reliability of climbing operation, sothat the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and the safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

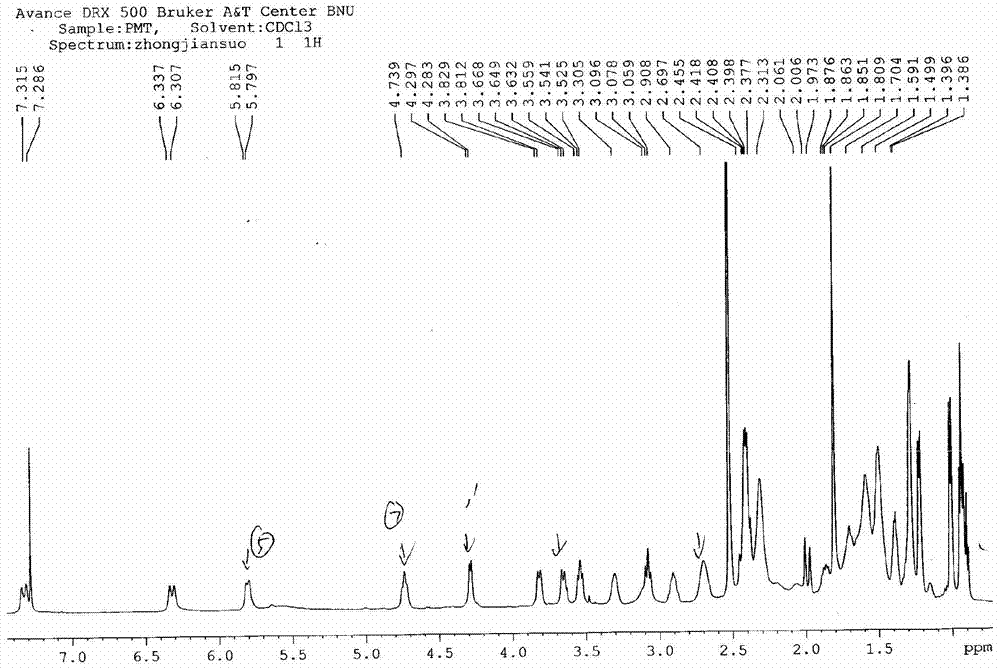

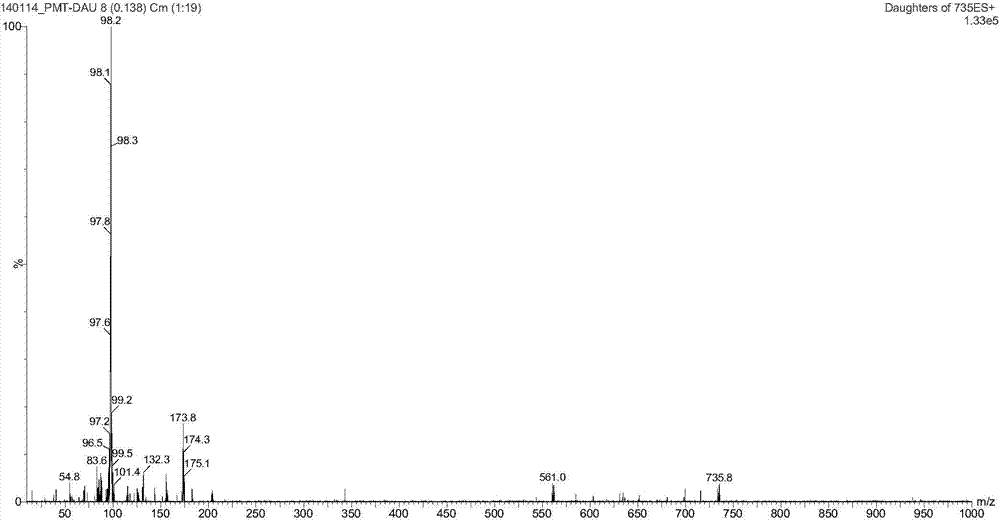

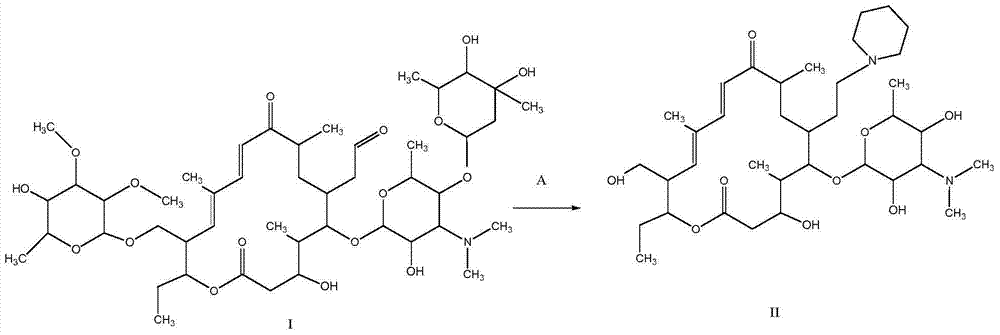

Synthetic method for Tildipirosin

ActiveCN104497082AEfficient hydrolysis reactionEasy to optimizeSugar derivativesSugar derivatives preparationChemistryColumn chromatography

The invention relates to a synthetic method for Tildipirosin. The method comprises the synthetic steps of 23-hydroxy-20-piperidyl-5-O-mycaminoseyl-tylolactones, and 23-sulphonate-20-piperidyl-5-O-mycaminoseyl-tylolactones. The reaction yield of the method is high, and the conversion rate of each step of the reaction is up to more than 80%; and the purity of the product is high, and is up to more than 98.2%. The main raw material of the method is tylosin, the reaction reagent is the normal reagent which is easily obtained in the market and is cheap, and does not need to be stored in the ultralow temperature. The method is simple and safe in operation, does not need the devices in high temperature and high pressure, and has no risk. The method is capable of effectively solving the completeness of the reactant conversion, avoiding the column chromatography isolation for the intermediate product and the environment pollution, recovering the triphenylphosphine oxide of the byproduct, shortening the reaction period, improving the yield of the product, and reducing the production cost, and has the industrialized application value.

Owner:CHINA INST OF VETERINARY DRUG CONTROL

Desulfurization recovery method of slag iron of blowing-process desulfurizing slag

ActiveCN104561428AImprove responseReduce contentRecycling and recovery technologiesProcess efficiency improvementRecovery methodSlag

The invention discloses a desulfurization recovery method of slag iron of blowing-process desulfurizing slag, which comprises the following steps: 1) transporting slag iron obtained from blowing-process desulfurizing slag by magnetic separation to a converter slag field; 2) adding the slag iron to the middle of a slag ladle of the converter for use, wherein 20kg of slag iron is added to every ton of liquid converter steel slag, the size is less than 0.5*0.5m (length*width), the thickness is less than 0.2m, the slag iron is kept dry, and the maximal amount is not greater than 500kg for each ladle; 3) suspending the converter slag ladle with the blowing-process desulfurizing slag slag iron to a converter slag vehicle, and receiving the converter turndown slag by a converter slag pit; 4) pouring the turndown slag into the slag ladle by the converter according to the conventional slag discharge technique; 5) transporting the slag ladle filled with the converter turndown slag to the converter slag field, and standing for 20-40 minutes; 6) treating according to a hot application or hot braising conventional treatment technique for converter carbon steel slag; and 7) after the hot application or hot braising technique is finished, carrying out magnetic separation to recover the slag iron in the steel slag, which is directly used for steel making.

Owner:北京璞域环保科技有限公司

Lactobacillus, paracasei subsp. paracasei strain, bacteriostatic composition and applications thereof

ActiveCN101768559AGrowth inhibitionGood antibacterial effectAntibacterial agentsBacteriaFood additiveEscherichia coli

The invention discloses a Lactobacillus, paracasei subsp. paracasei strain, a bacteriostatic composition and applications thereof. The preservation number of the SG96 strain microorganism is CGMCC2697. The strain can inhibit the growth of pathogenic bacteria of Escherichia coli, Salmonella typhimurium and the like, and has bacteria killing effect. The invention also discloses a bacteriostatic composition containing the Lactobacillus, paracasei subsp. paracasei strain SG96. The composition can be prepared into animal water-feeding additives, animal fodder additives, animal and human medical compositions, food additives, beverage additives, foods, beverages, health foods, and the like.

Owner:SYNGEN BIOTECH

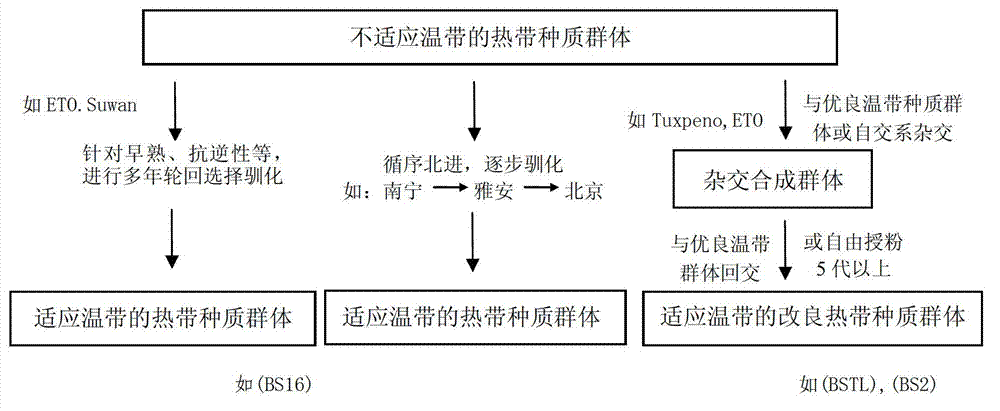

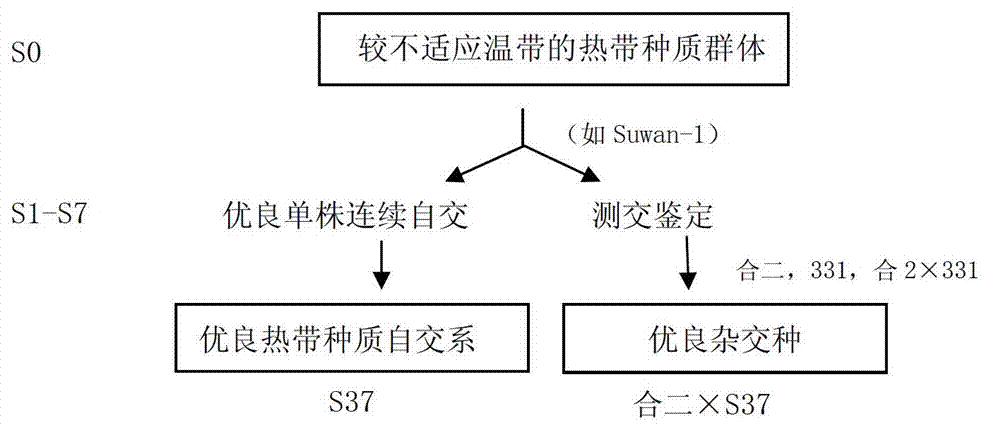

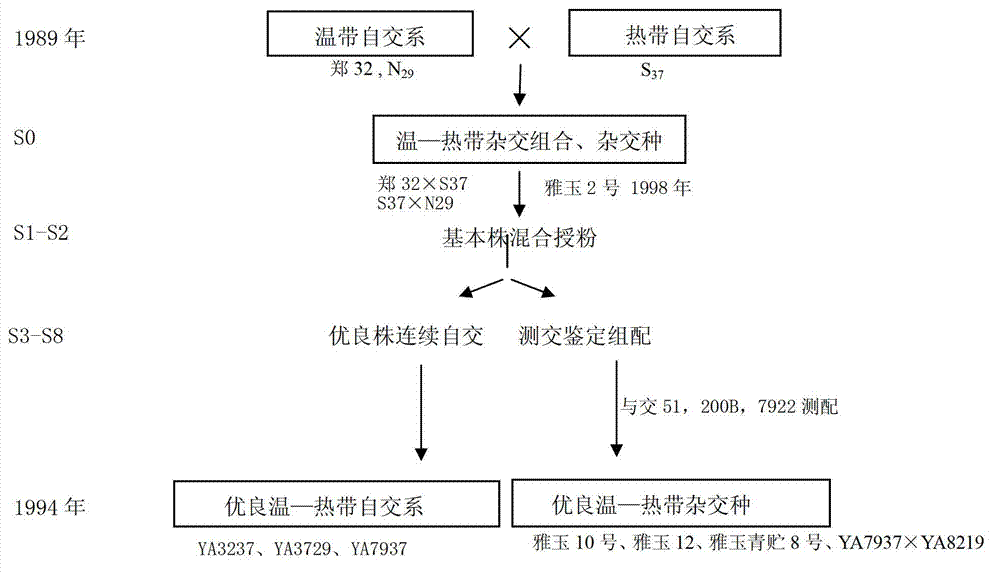

Breeding method for temperate corn employing tropical germplasm

InactiveCN103026963ARich genetic diversityWide range of usesPlant genotype modificationTemperate forestAgricultural science

The invention provides a breeding method for a temperate corn employing tropical germplasm. The method comprises the steps that a temperate-tropical germplasm hybridized combination A*B or B*A crossed by a temperate germplasm selfing line A and a tropical germplasm selfing line B, a temperate-tropical germplasm hybrid C, a tropical germplasm hybridized combination D*E, or a tropical germplasm hybrid F serves as a breeding material; 1-2 generations are bred with a mixed pollination method or a method of mixed pollination after backcrossing; a single plant is selected for continuous selfing; a temperate-tropical germplasm selfing line X or a tropical germplasm selfing line Y having the characteristics of temperate germplasm and tropical germplasm is breeded through multi-generation pedigree selection; and then a temperate-tropical germplasm hybrid Z having the characteristics of the temperate germplasm and tropical germplasm is crossed. The breeding method has the benefits that the breeding time is short, the cost is low, the efficiency is high, and multiple tropical germplasm colonies not adapting to a temperate zone can be fully used.

Owner:SICHUAN YAYU TECH DEV CO LTD

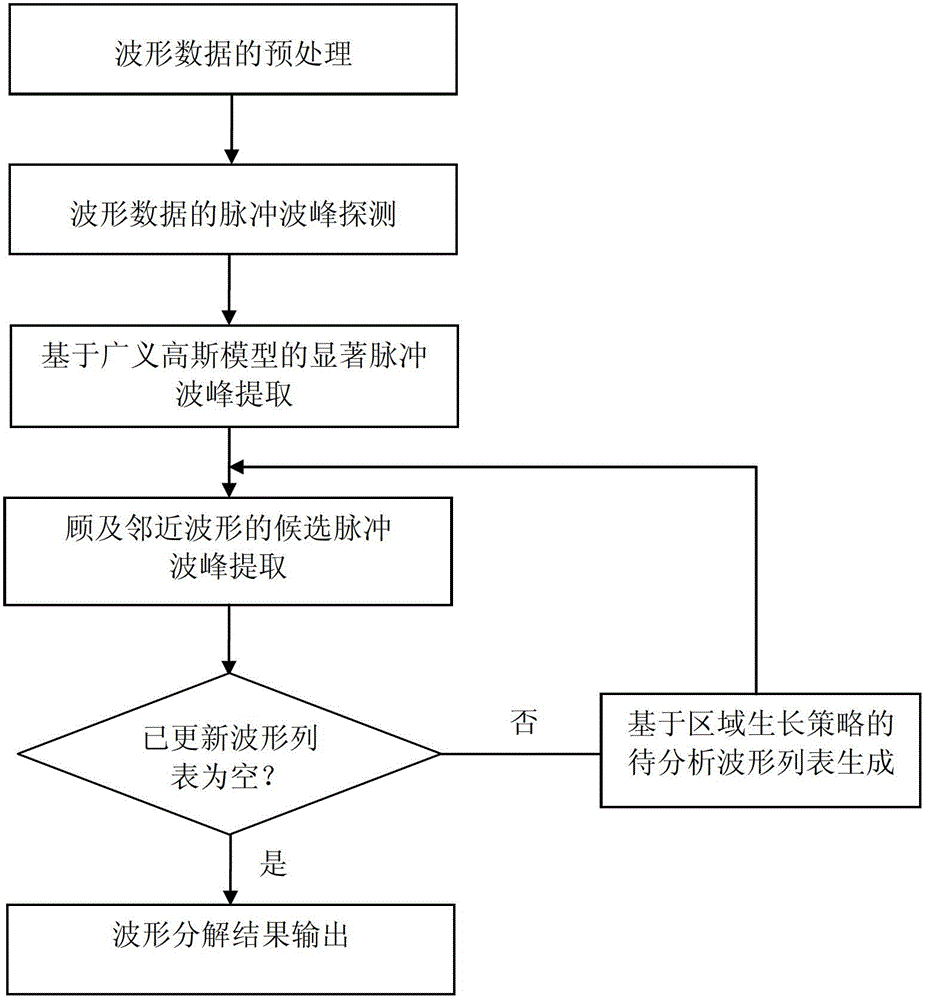

Airborne laser waveform data decomposition algorithm considering adjacent waveform information

ActiveCN102722640AOvercoming the defects that are difficult to choose properlyRobust extractionSpecial data processing applicationsPoint cloudDecomposition

The invention discloses an airborne laser waveform data decomposition method considering adjacent waveform information. The method comprises the following steps of: (A), preprocessing waveform data; (B), detecting the pulse wave crest of the waveform data; (C), extracting a significant pulse crest based on a generalized Gaussian model; (D) extracting a candidate pulse crest considering an adjacent waveform; (E) generating a list of the waveforms to be analyzed based on a regional growth strategy; and (F) outputting a waveform decomposition result. According to the method, a high threshold value and a low threshold value are adopted, so that the defect that a single threshold value is difficult to select properly can be overcome, and weak pulse signals in the waveform data can be considered effectively; during waveform decomposition, the candidate pulse crests of the waveforms to be analyzed are analyzed by continuously utilizing the reliable information provided by the significant pulse crests of the adjacent waveforms in a regional growth way, so the robust extraction of the weak pulse crest information can be realized; and therefore, complete point cloud information is acquired.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

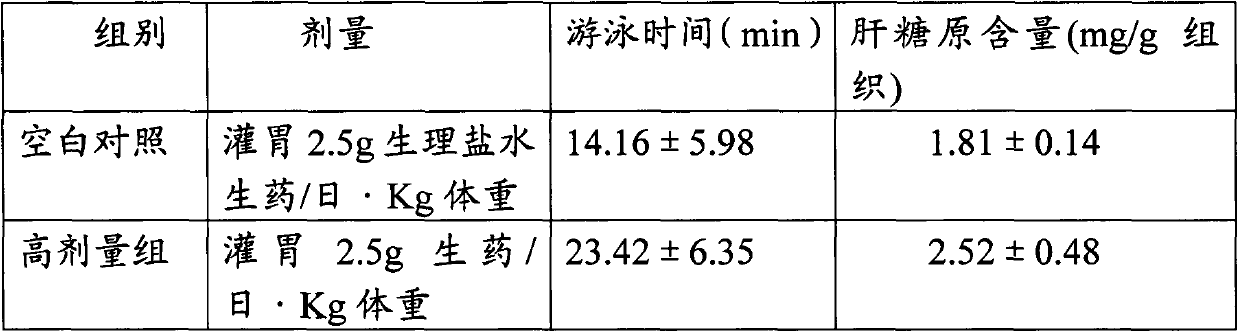

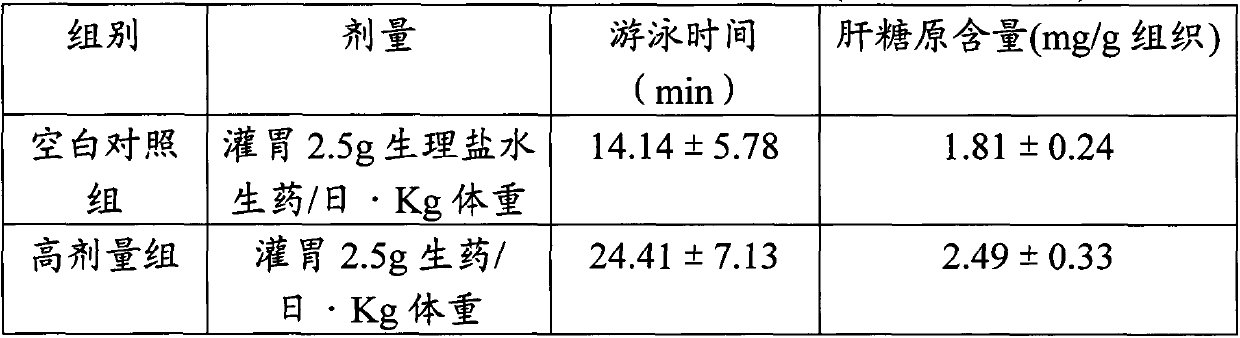

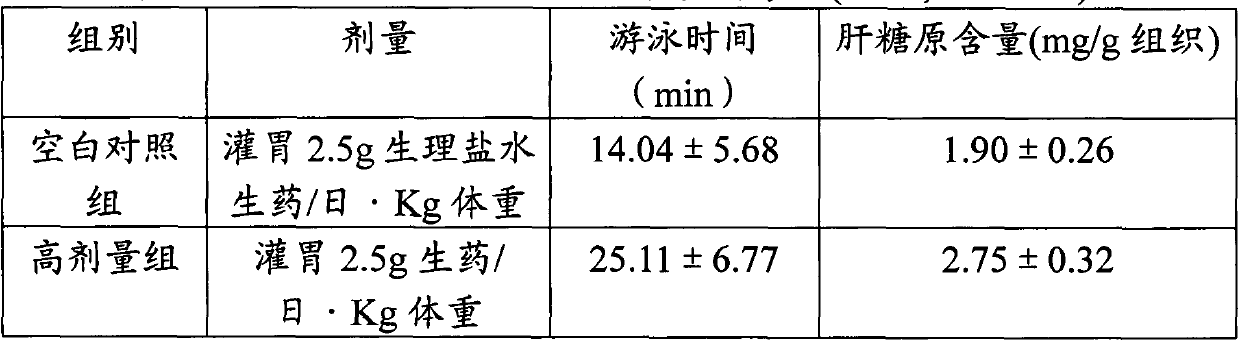

Chinese herbal medicine compound for resisting fatigue of human body, nourishing kidneys and tonifying yang

InactiveCN103340957ARemarkable resultsEasy to takeAntinoxious agentsUrinary disorderTolypocladiumTherapeutic effect

The invention discloses a Chinese herbal medicine compound for resisting the fatigue of a human body, tonifying the kidneys and tonifying yang. The Chinese herbal medicine compound is prepared from the following raw materials in parts by weight: 15 to 50 parts of mair conditioning unita, 15 to 50 parts of tolypocladium sinensis mycelia, 10 to 30 parts of cistanche, 15 to 50 parts of the seed of Chinese dodder, 10 to 30 parts of morinda officinalis and 10 to 30 parts of herba epimedii. The Chinese herbal medicine compound has obvious treatment effects of resisting the fatigue, nourishing the kidneys and tonifying yang and is convenient to take.

Owner:苏州菩芸生物科技有限公司

Treatment of skin conditions

This present invention provides methods of and apparatus for, treating skin conditions such as acne, psoriasis and dermatitis. The methods employ a combination of two anti-phased electromagnetic radiation wavebands having a first peak wavelength of between 1050 to 1085 nm and a second peak wavelength of between 405 to 425 nm, the two specified wavelengths act synergistically to provide improved treatments for chronic and acute skin conditions.

Owner:DOUGAL GORDON REX PATERSON

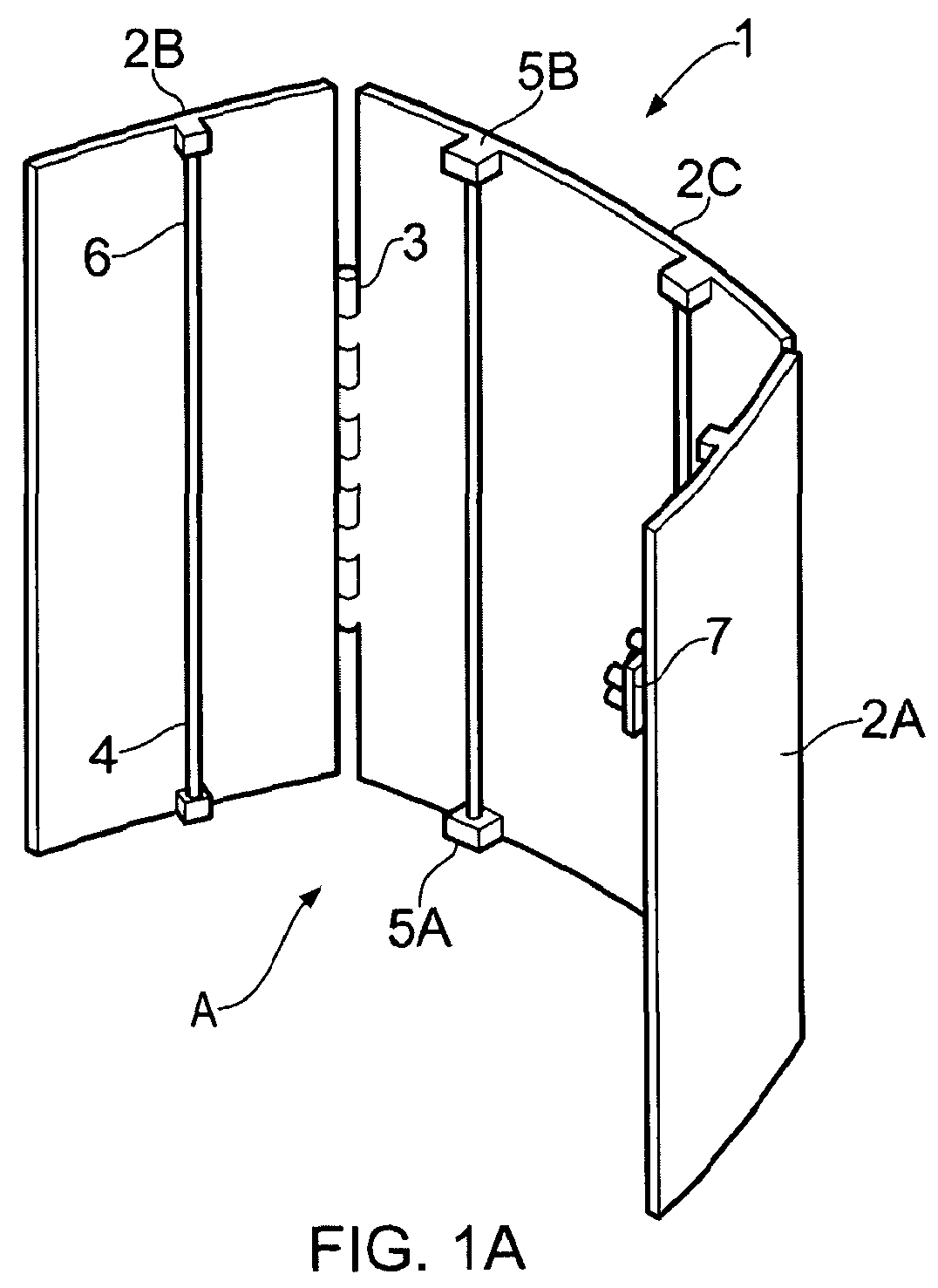

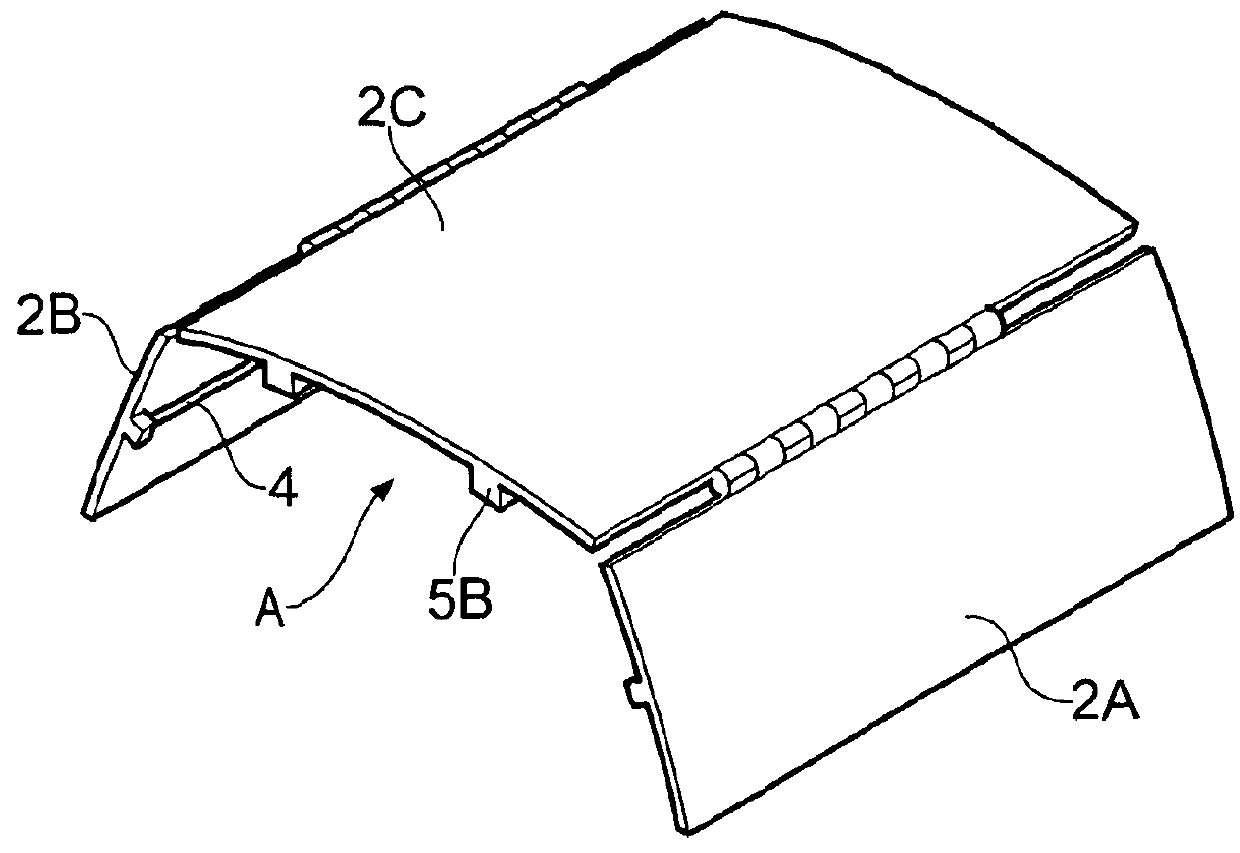

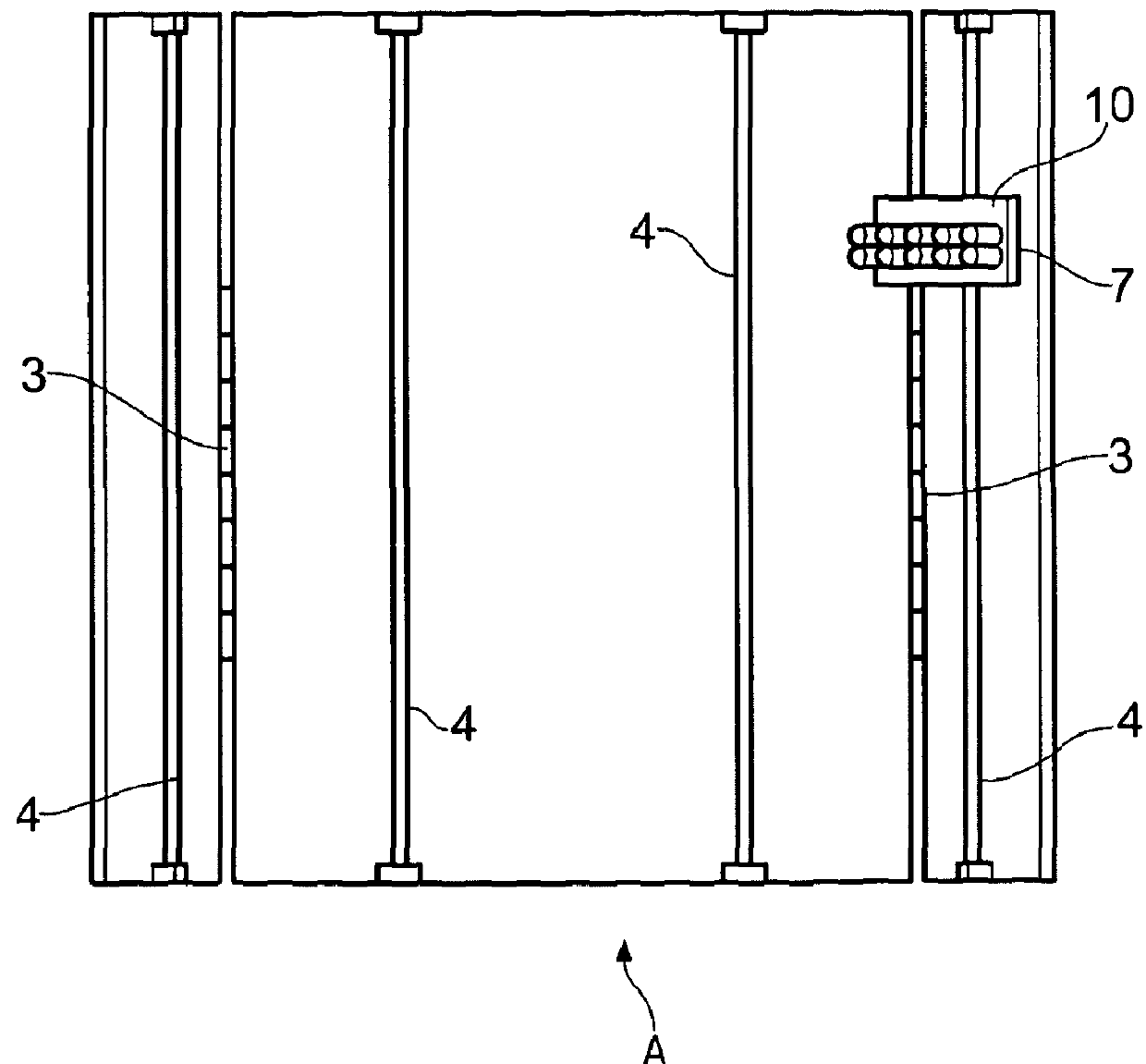

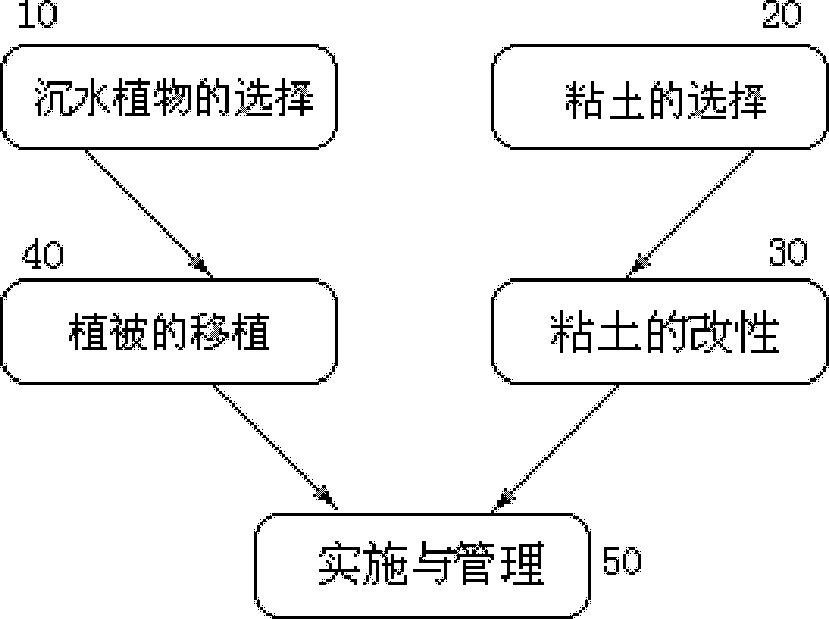

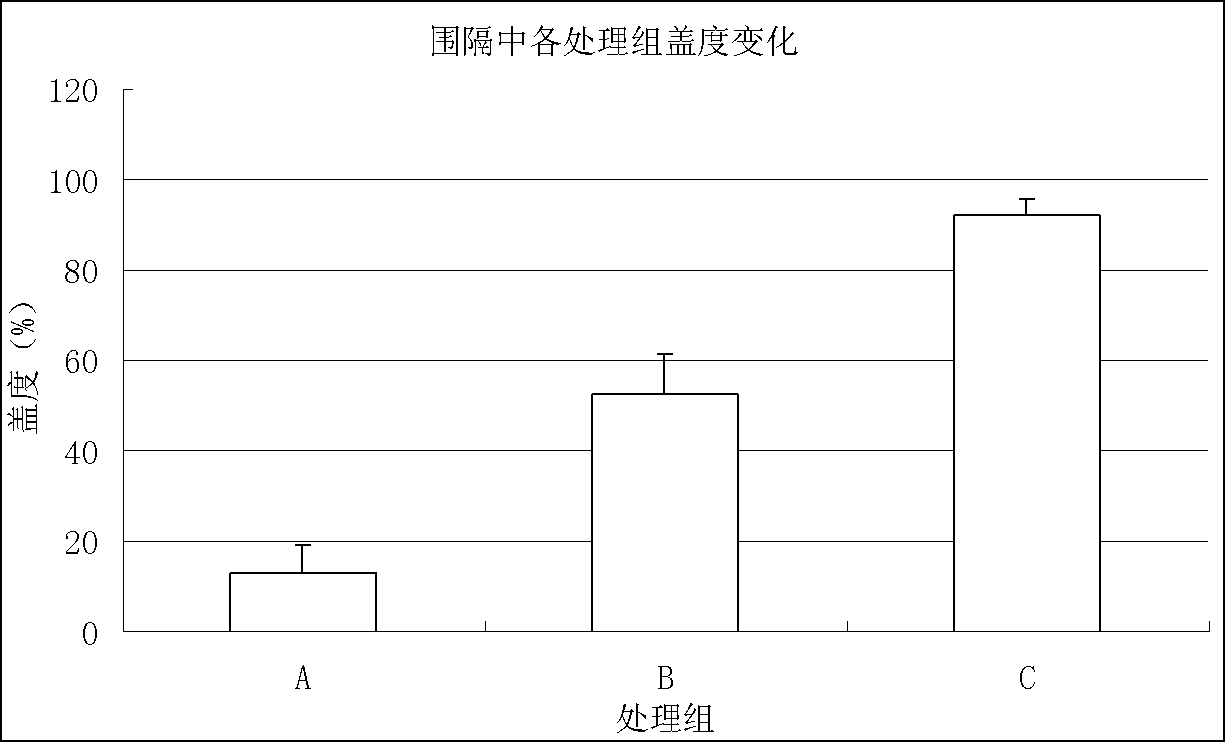

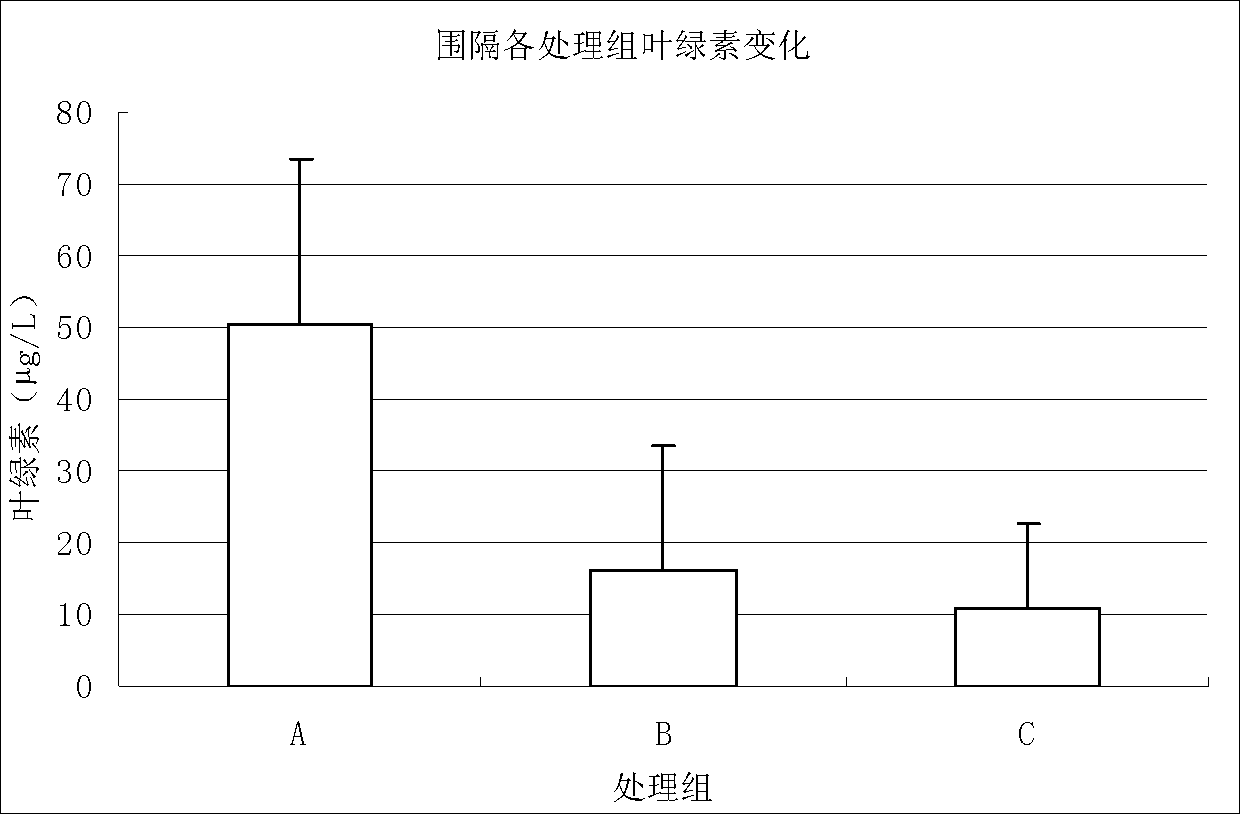

Method for restoring algal-inhibition submerged vegetation in eutrophic water

InactiveCN102502969ASimple methodLow costSustainable biological treatmentBiological water/sewage treatmentWater transparencyShallow lake

The invention discloses a method for restoring algal-inhibition submerged vegetation in the eutrophic water, and relates to a technology for large-area and large-scale water environment biological control. The invention comprises the following steps: 1, selection of submerged vegetation (10); 2, selection of clay (20); 3 modification of clay (30); 4, transplantation of vegetable (40); and 5, implementation and management (50). The invention has the advantages of simple method, low cost, convenience in material selection and construction and remarkable effect, can effectively improve water quality and water transparency, remarkably decreases nutrient salt, maintains the stability of water in the oligotrophic state, can quickly restore submerged vegetation in eutrophic shallow lakes, and issuitable for restoration works for lake aquatic vegetation and diversified lakes water plants or lake aquatic ecological system ecological reconstruction works.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Blast furnace water wall production method using vanishing-die forging technique

PendingCN101417329AExcellent performance indexReduce operational technical difficultyFoundry mouldsFoundry coresSocial benefitsWorking environment

The invention relates to a method for producing a blast furnace water-cooling wall by using lost foam casting technique. Foam plastics is utilized to make the model of the lost foam of the blast furnace water-cooling wall, meanwhile, after a supporting pillar is welded on a simmered cooling water pipe of the blast furnace water-cooling wall and masking paste is brushed, the cooling water pipe is fixedly installed in the model of the lost foam of the blast furnace water-cooling wall, is treated with joint sealing, finishing, the painting of masking refractory coating, drying and ram-jolt by being arranged in a molding box, and is poured with molten metal with qualified smelting under a negative pressure state; and after cooling, box-opening, trimming and processing are carried out, the blast furnace water-cooling wall product produced by the lost foam casting technique is obtained. The method can be used for the production of the blast furnace water-cooling walls with the materials of gray cast iron, ductile cast iron, low carbon steel, micro-alloying low carbon steel, pure copper and the like, all the performances of the blast furnace water-cooling wall are better than those of the blast furnace water-cooling walls with the same material and casted by san mold, the use amount of the moulding sand can be reduced by 90 to 95 percent, the procedure is simplified, the labor productivity is improved, the working environment of the workers is improved, the labor intensity and operation technical difficulty of the workers are reduced, and the method has good economic and social benefits.

Owner:周传录

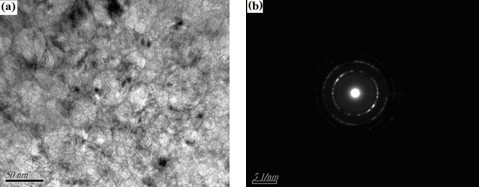

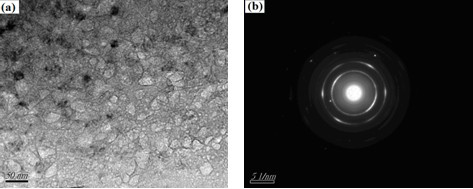

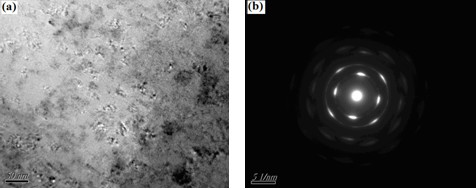

A kind of preparation method of nanocrystalline polycrystalline magnesium material

The invention relates to a high-performance magnesium alloy or magnesium-based composite material. The grain size of the prepared material matrix is in nano scale. The material has the characteristics of high strength and high toughness and belongs to the field of preparation of new materials. A cast state or deformation state magnesium alloy or magnesium-based composite material is subjected to cryogenic-low heat circulation treatment by controlling important parameters such as cryogenic temperature, cold treatment time, cold heat circulation times, low-heat temperature, heat treatment time and the like; the magnesium material after treatment has a nanocrystal microstructure and corresponds to the mechanical properties of high strength and high toughness. A preparation method of the high-performance magnesium material has the advantages of 'high performance, high efficiency, low cost and low pollution'.

Owner:JIANGSU UNIV

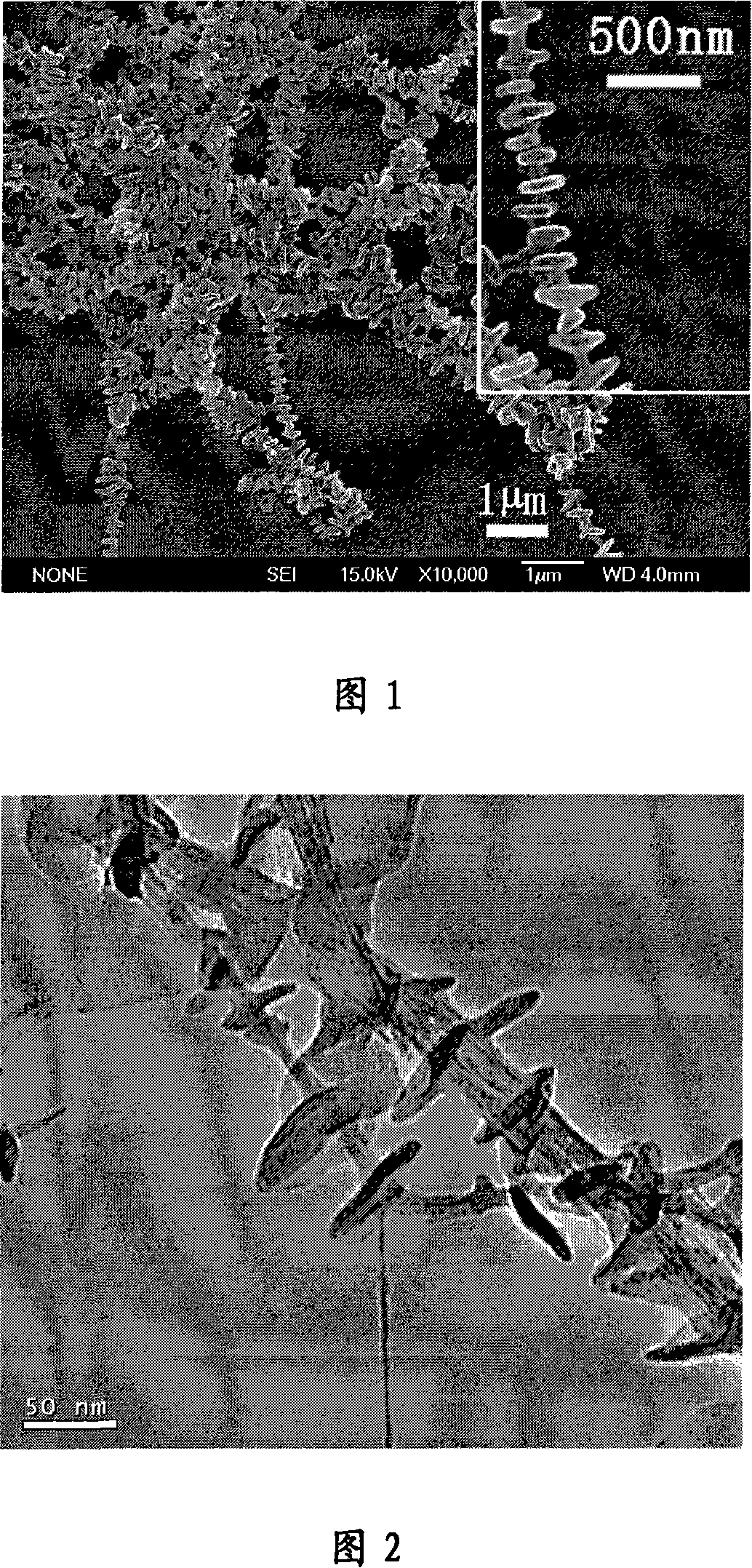

Method for realizing modification of carbon nano-tube by using polymer crystallization

InactiveCN101112982AImprove mechanical propertiesSolve the problem of weak forceMaterial nanotechnologyNanostructure manufactureAnti solventOrganic solvent

The invention relates to a method for realizing decoration of a carbon nano tube through polymer crystallization, in particular to induce polymer crystallization by using supercritical or compressive carbon dioxide as anti-solvent so as to achieve decoration. The method is carried as follows: the polymer prepared under constant temperature is dissolved in organic solvent solution 1; the carbon nano tube is evenly dispersed in the organic solvent under a temperature condition that is higher than the room temperature, so as to obtain a system 2; the ultimate density of the polymer and the carbon nano tube in the organic solvent after mixture is 0.003 to 0.1wt percent and 0.002 to 0.02 wt percent respectively for the mixture solution 1 and the system 2, thereby, a system 3 is obtained upon balance; then the system 3 is moved into a closed reactor and carbon dioxide is added into the reactor till the pressure in the reactor is 5 to 25MPa and be kept for 0.5 to 7 hours, finally the carbon nano tube decorated with the polymer crystallization is obtained after the pressure is reduced to a normal level. The method has simple technique, easy operation, notable effect and being environment protective, therefore, the performance of the carbon nano tube decorated with the polymer crystallization is good.

Owner:ZHENGZHOU UNIV

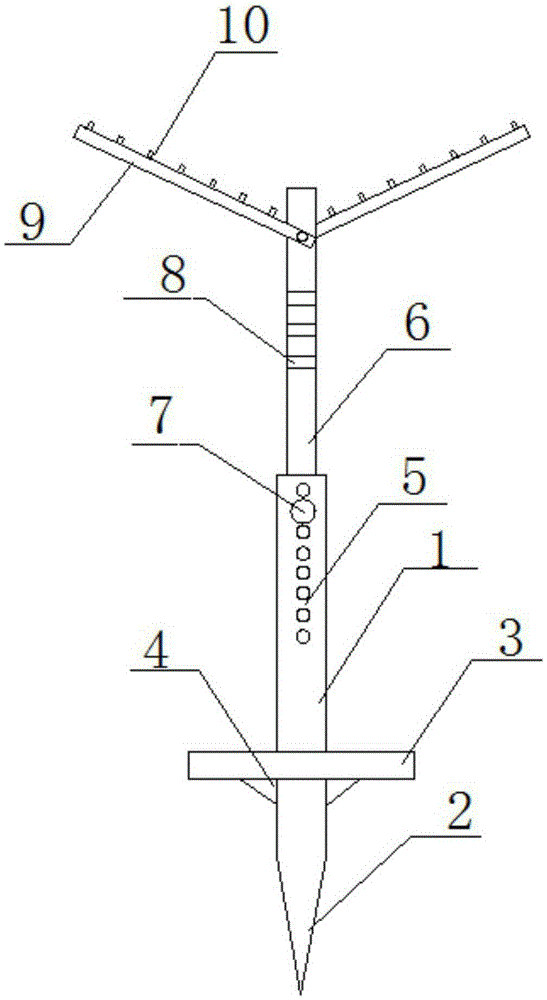

Auxiliary frame for shaping peach trees

The invention discloses an auxiliary frame for shaping peach trees. The auxiliary frame comprises a loop bar and a supporting rod, wherein a pointed cone part is arranged at the lower end of the loop bar, a limiting plate is arranged above the pointed cone part, reinforcing ribs are arranged on the lower side of the limiting plate, a cavity which is opened at the upper end is formed inside the loop bar, the lower end of the supporting rod is arranged on the inner side the cavity, a plurality of adjusting holes are formed in the loop bar, a through hole is formed at the lower end of the supporting rod, the supporting rod and the loop bar are fixed through a bolt, a warning tape is arranged on the outer side of the middle part of the supporting rod, two side rods are arranged at the upper end of the supporting rod, and a plurality of stop hooks are arranged on each of the side rods. The auxiliary frame for shaping peach trees disclosed by the invention is simple in structure, convenient to use, suitable for all peach tree cultivation modes, time-saving and labor-saving and high in safety.

Owner:徐州市贾汪区滨农农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com