Patents

Literature

550 results about "Cryogenic temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cryogenic temperature range has been defined as from −150 °C (−238 °F) to absolute zero (−273 °C or −460 °F), the temperature at which molecular motion comes as close as theoretically possible to ceasing completely.

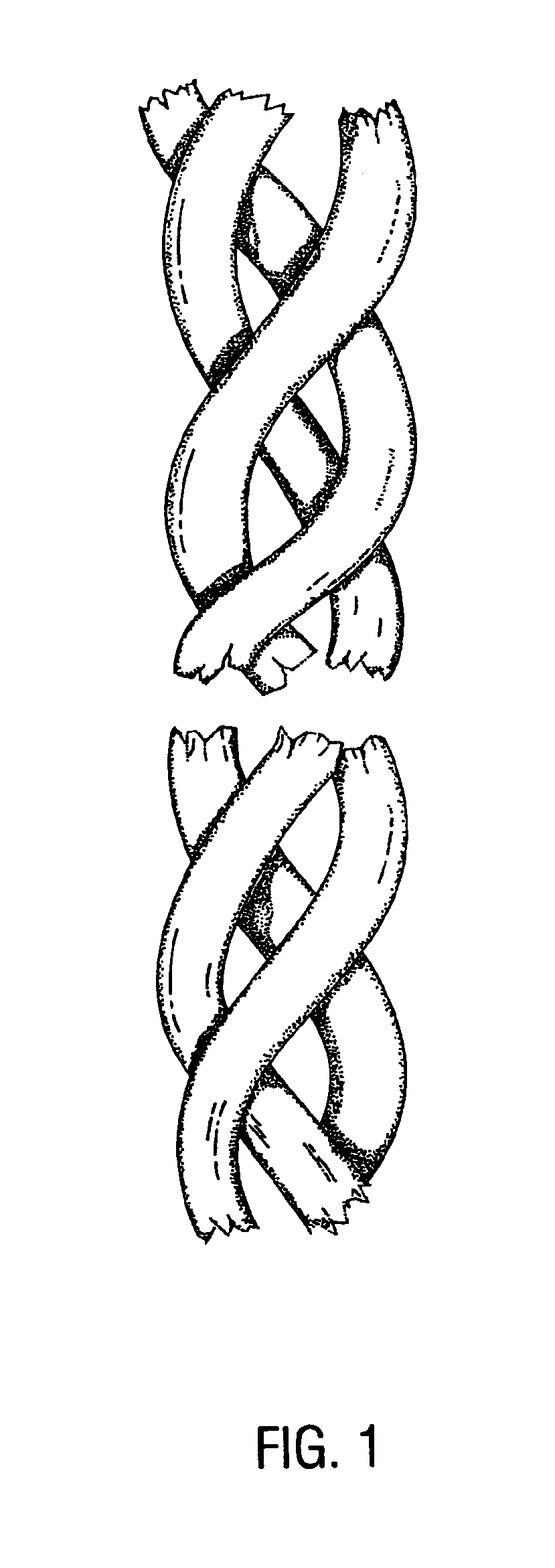

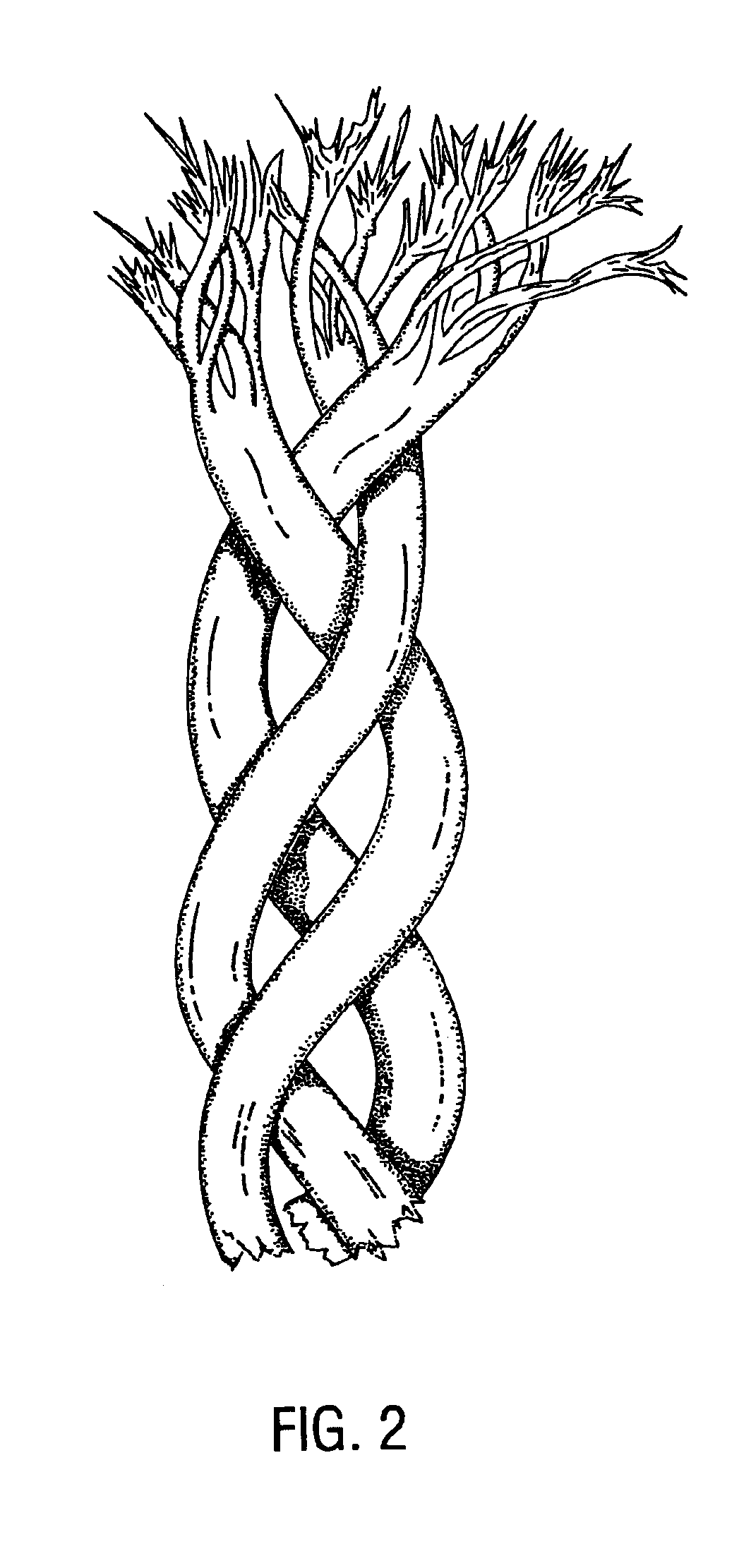

Particulate acellular tissue matrix

A method of processing an acellular tissue matrix to give a particulate acellular tissue matrix includes: cutting sheets of dry acellular tissue matrix into strips; cryofracturing the dry acellular tissue matrix strips at cryogenic temperatures; separating the resulting particles by size at cryogenic temperatures; and freeze drying the fraction of particles desired size to remove any moisture that may have been absorbed to give a dry particulate acellular tissue matrix. Rehydration of the dry particulate acellular tissue matrix may take place just prior to use. The particulate acellular tissue may be applied to a recipient site, by way of injection, spraying, layering, packing, in-casing or combinations thereof. The particulate acellular tissue may further include growth and stimulating agents selected from epidermal growth factor, fibroblast growth factor, nerve growth factor, keratinocyte growth factor, platelet derived growth factor, vasoactive intestinal peptide, stem cell factor, bone morphogetic proteins, chondrocyte growth factor and combinations thereof. Other pharmaceutically active compounds may be combined with the rehydrated particulate material including: analgesic drugs; hemostatic drugs; antibiotic drugs; local anesthetics and the like to enhance the acceptance of the implanted particulate material. The particulate material product may also be combined with stem cells selected from mesenchymal stem cells, epidermal stem cells, cartilage stem cells, hematopoietic stem cells and combinations thereof.

Owner:LIFECELL

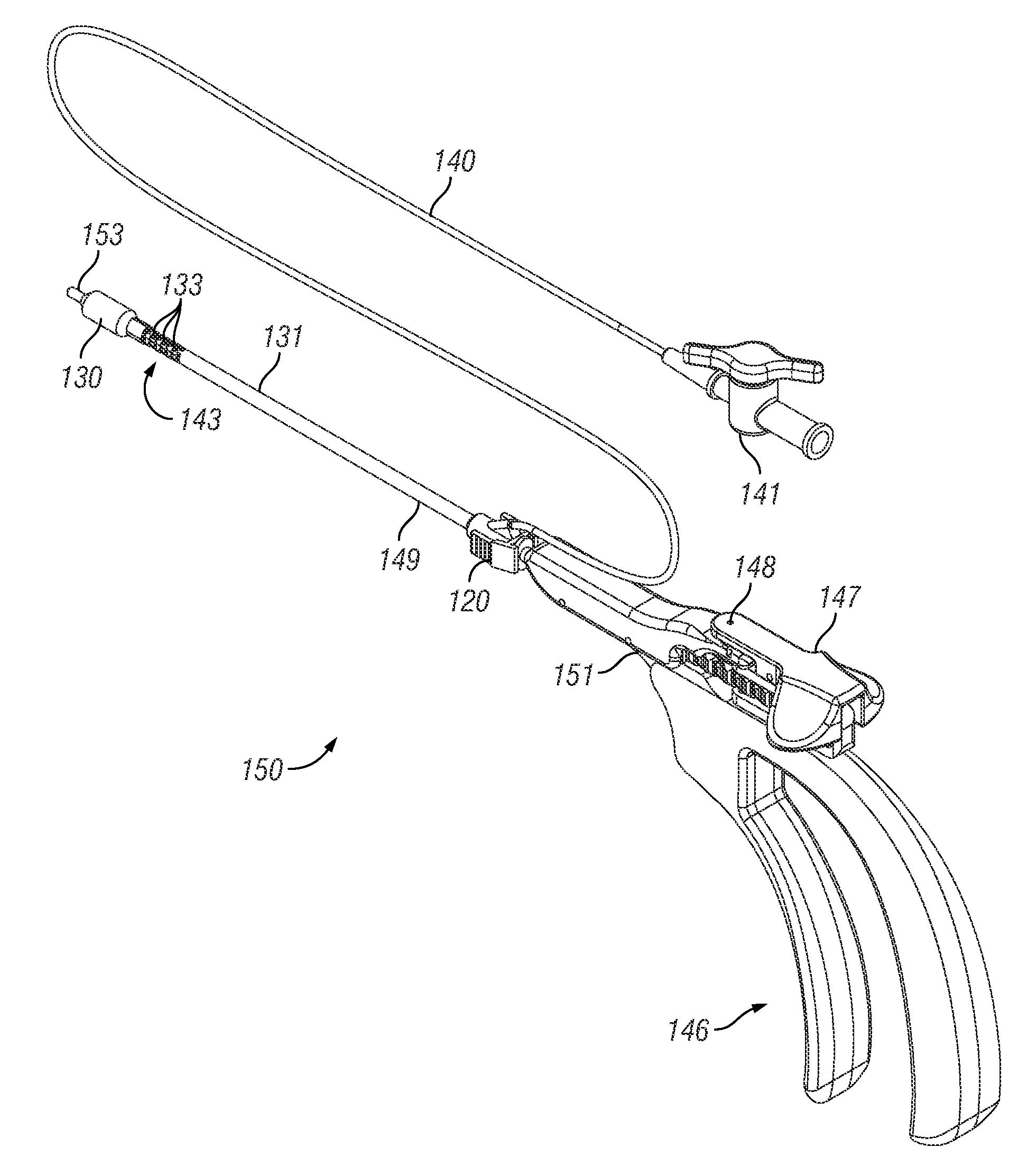

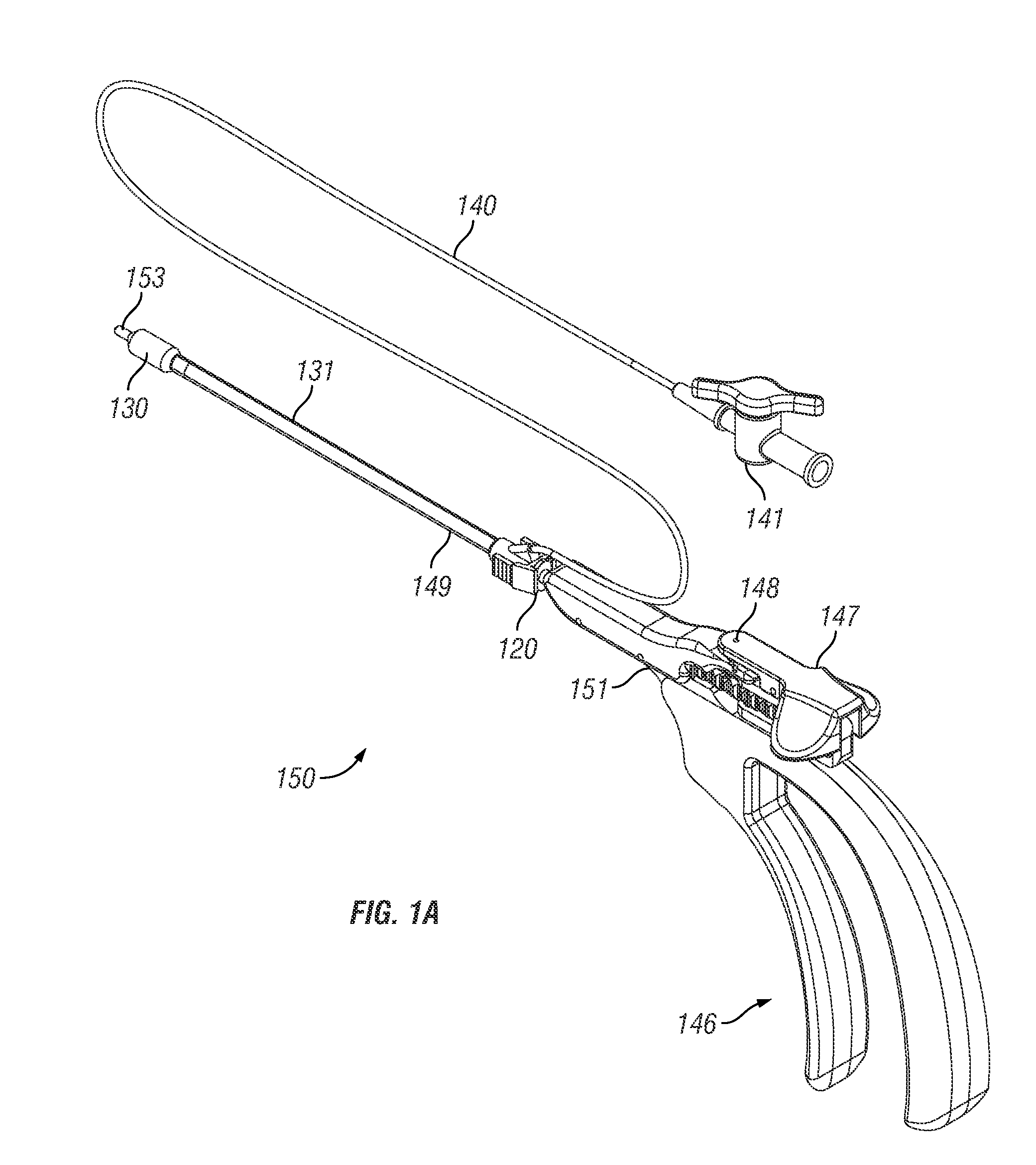

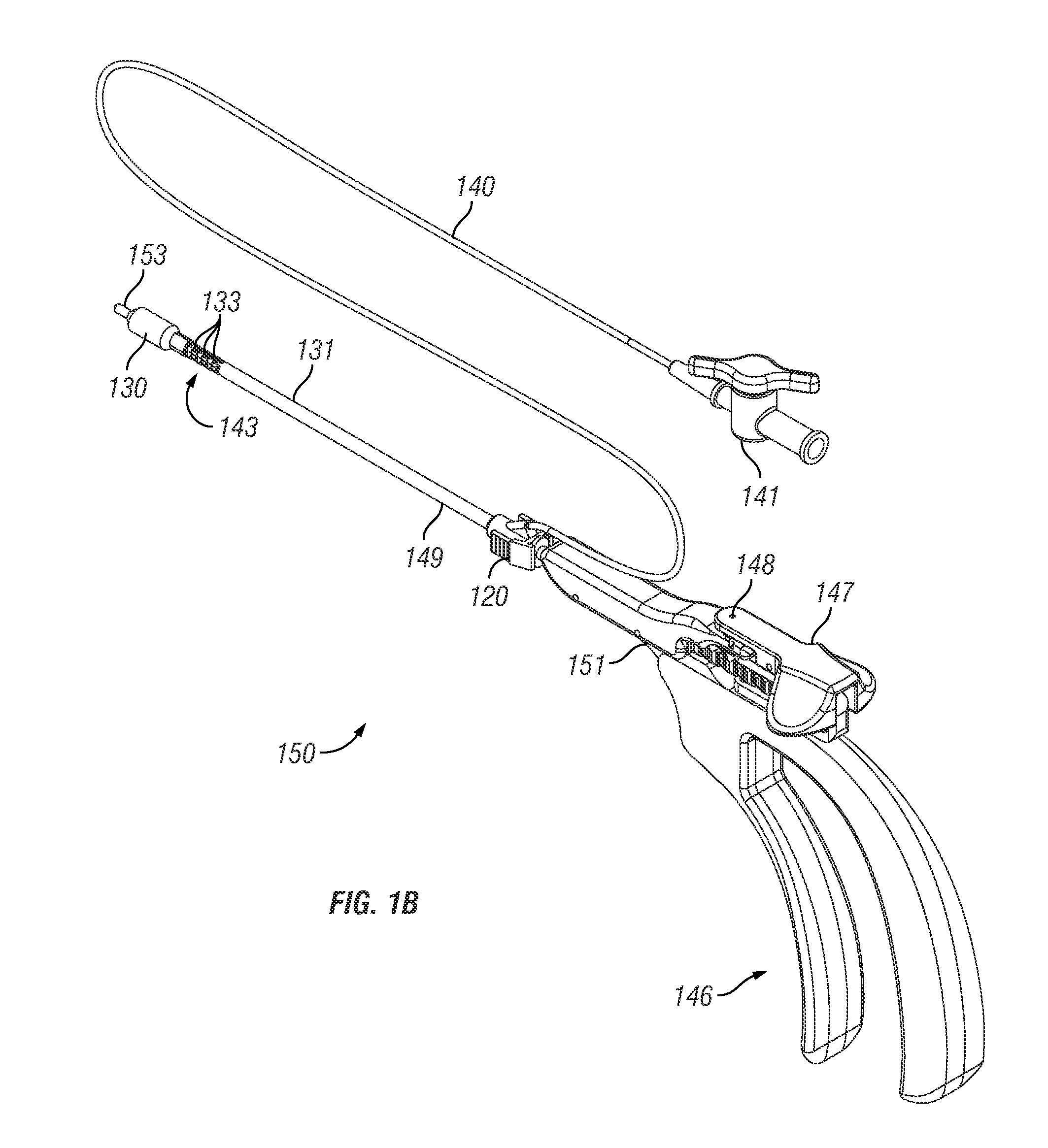

Systems, devices and methods for providing therapy to an anatomical structure using high frequency pressure waves and/or cryogenic temperatures

ActiveUS20120078377A1Reduce in quantityLow costElectrotherapyDiagnosticsAnatomical structuresBiomedical engineering

A system, device and method for dilating an anatomical structure. Systems, devices and methods may comprise a therapeutic component configured to treat a paranasal sinus. Specific embodiments may use high frequency pressure waves and / or cryogenic temperatures.

Owner:ARTHROCARE

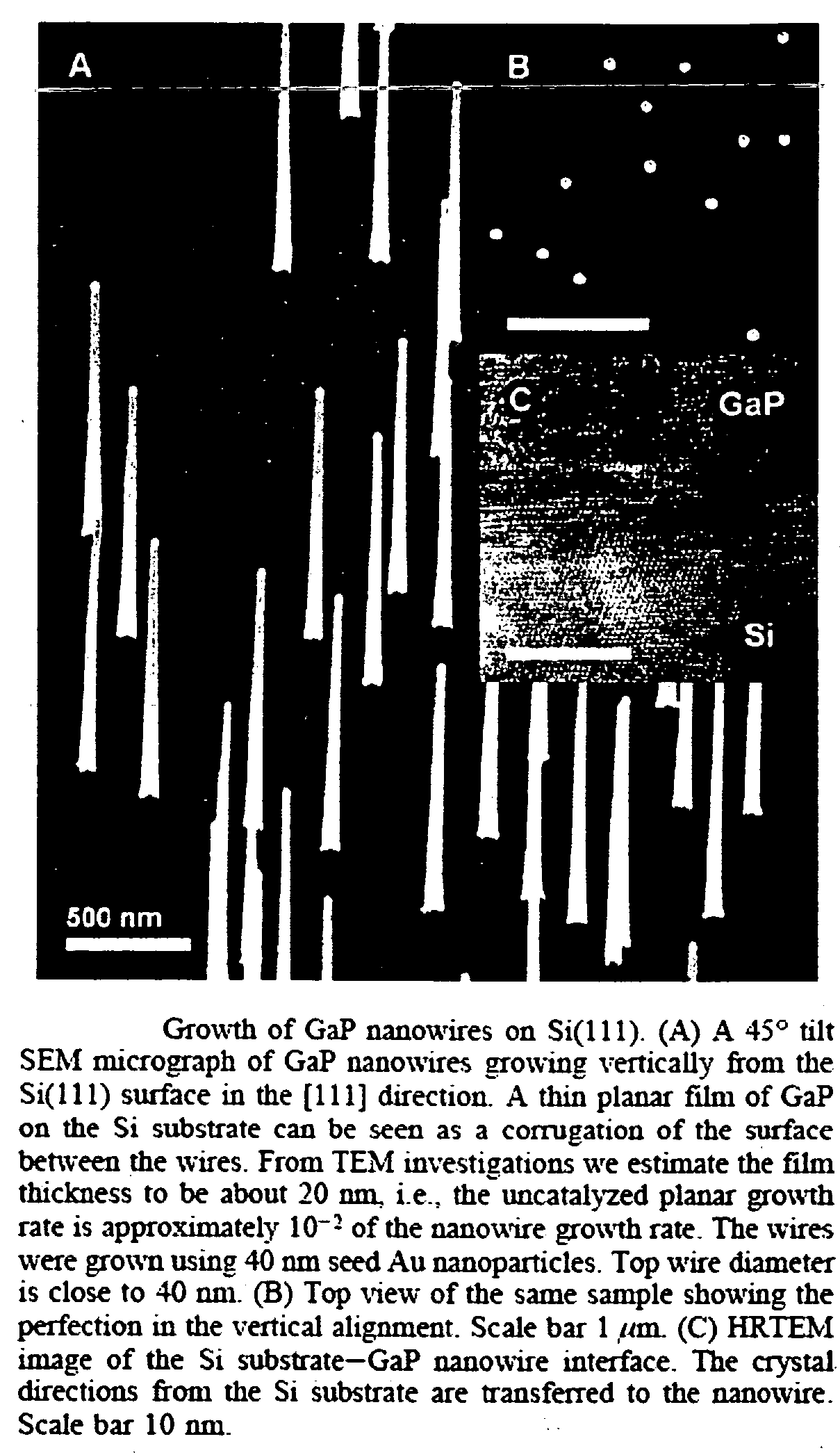

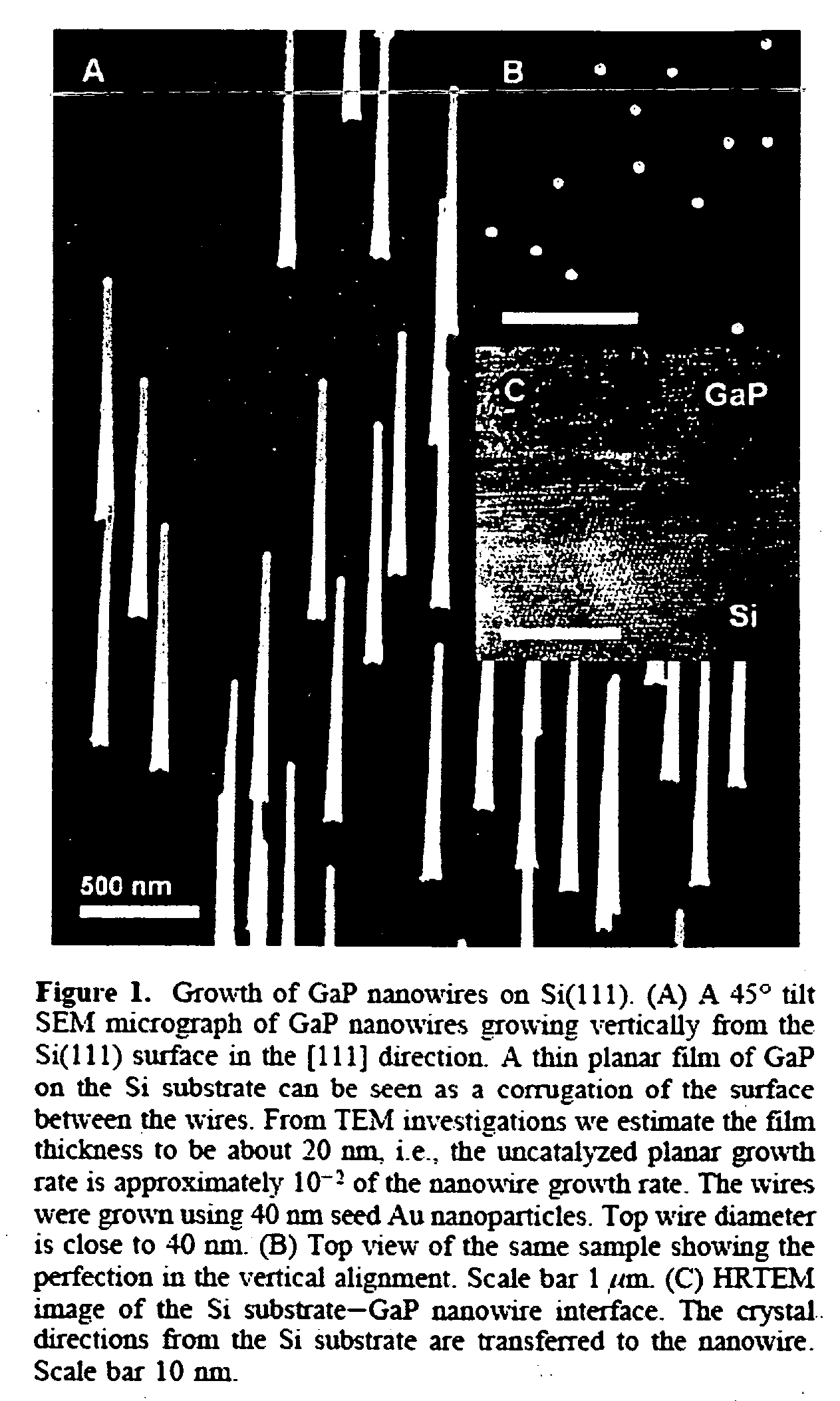

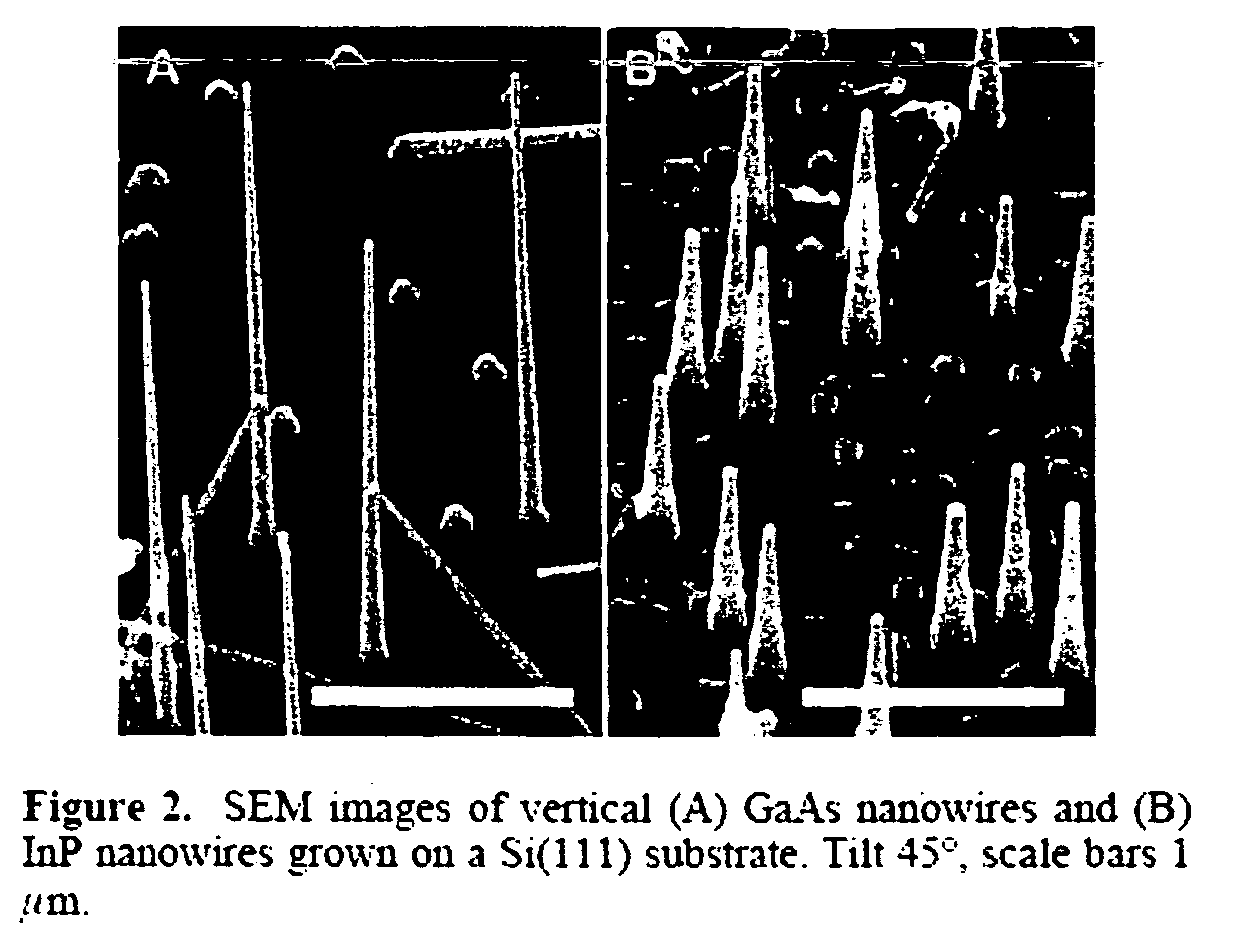

Formation of nanowhiskers on a substrate of dissimilar material

InactiveUS20060125056A1Improve reliabilityEfficient implementationMaterial nanotechnologyPolycrystalline material growthHeterojunctionThermal energy

A method for forming a nanowhisker of, e.g., a III-V semiconductor material on a silicon substrate, comprises: preparing a surface of the silicon substrate with measures including passivating the substrate surface by HF etching, so that the substrate surface is essentially atomically flat. Catalytic particles on the substrate surface are deposited from an aerosol; the substrate is annealed; and gases for a MOVPE process are introduced into the atmosphere surrounding the substrate, so that nanowhiskers are grown by the VLS mechanism. In the grown nanowhisker, the crystal directions of the substrate are transferred to the epitaxial crystal planes at the base of the nanowhisker and adjacent the substrate surface. A segment of an optically active material may be formed within the nanowhisker and bounded by heterojunctions so as to create a quantum well wherein the height of the quantum well is much greater than the thermal energy at room temperature, whereby the luminescence properties of the segment remain constant without quenching from cryogenic temperatures up to room temperature.

Owner:QUNANO

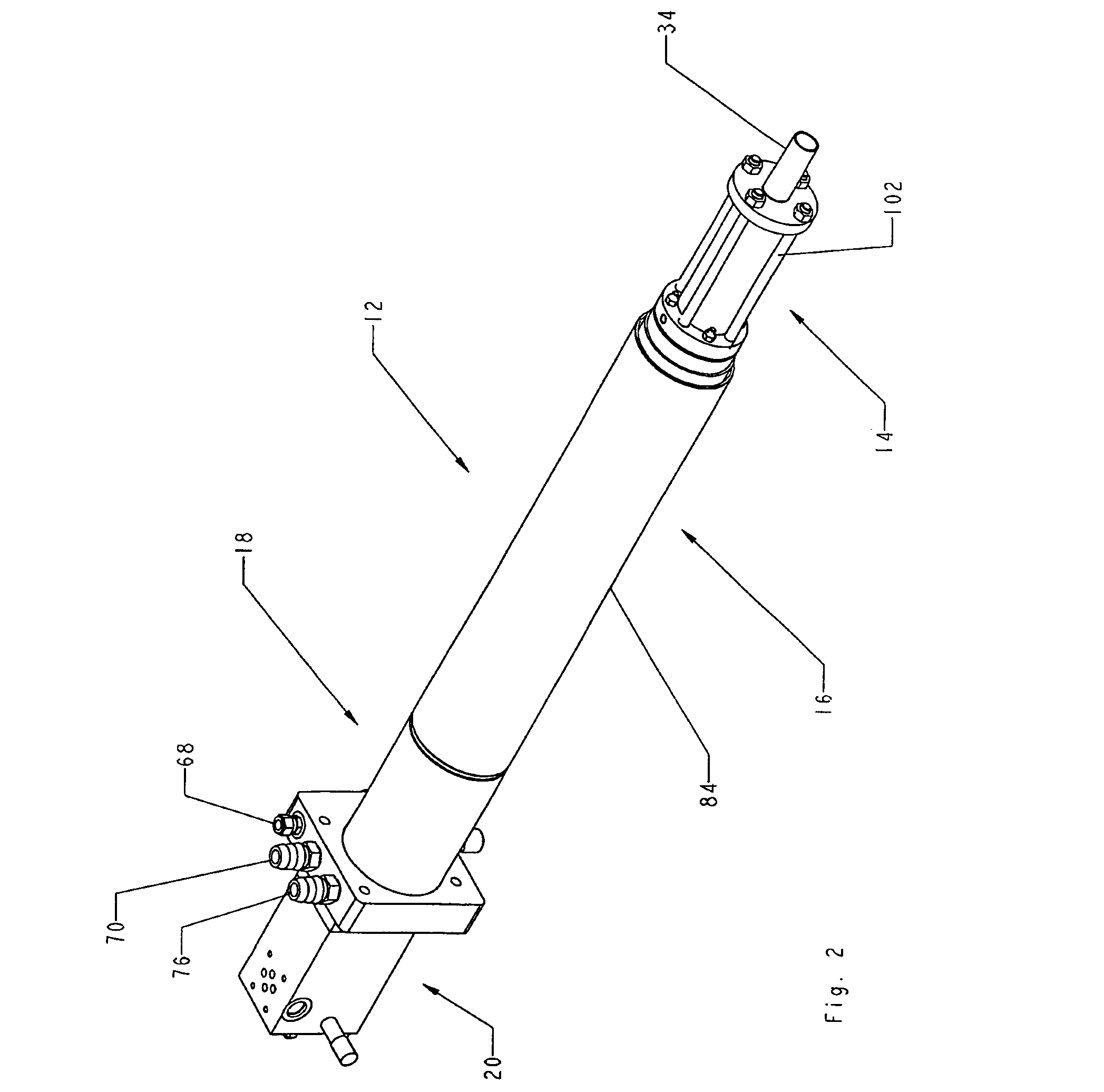

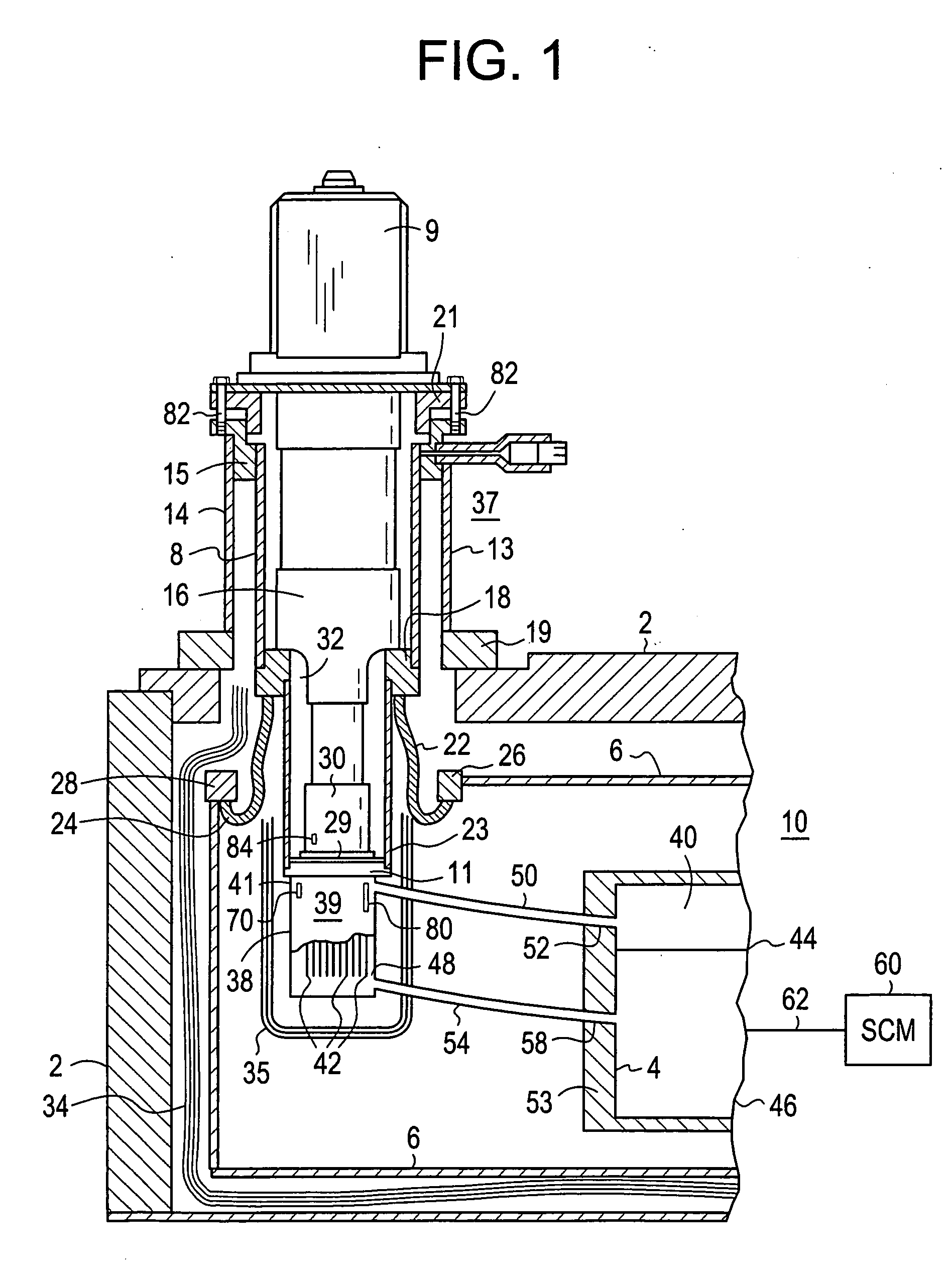

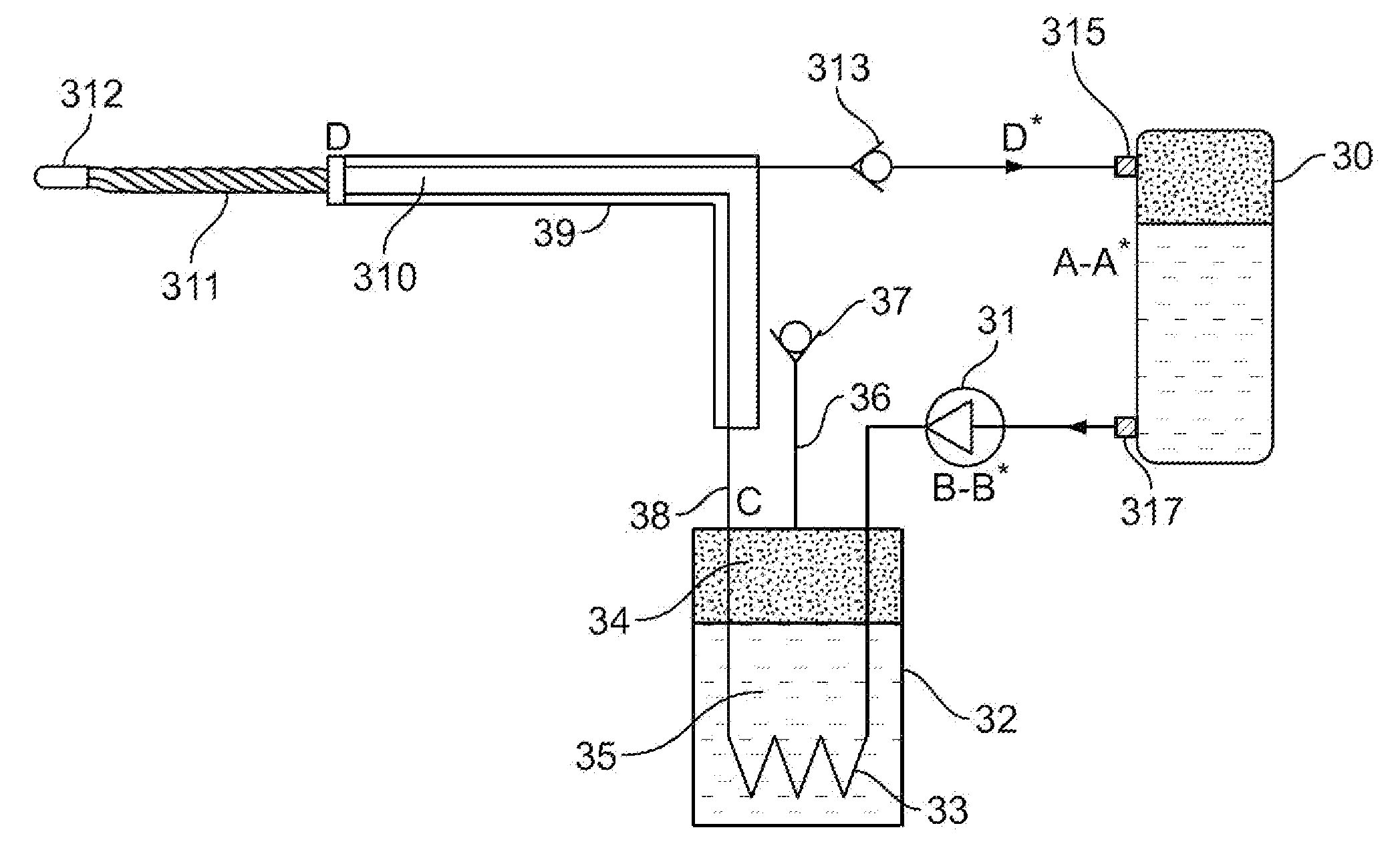

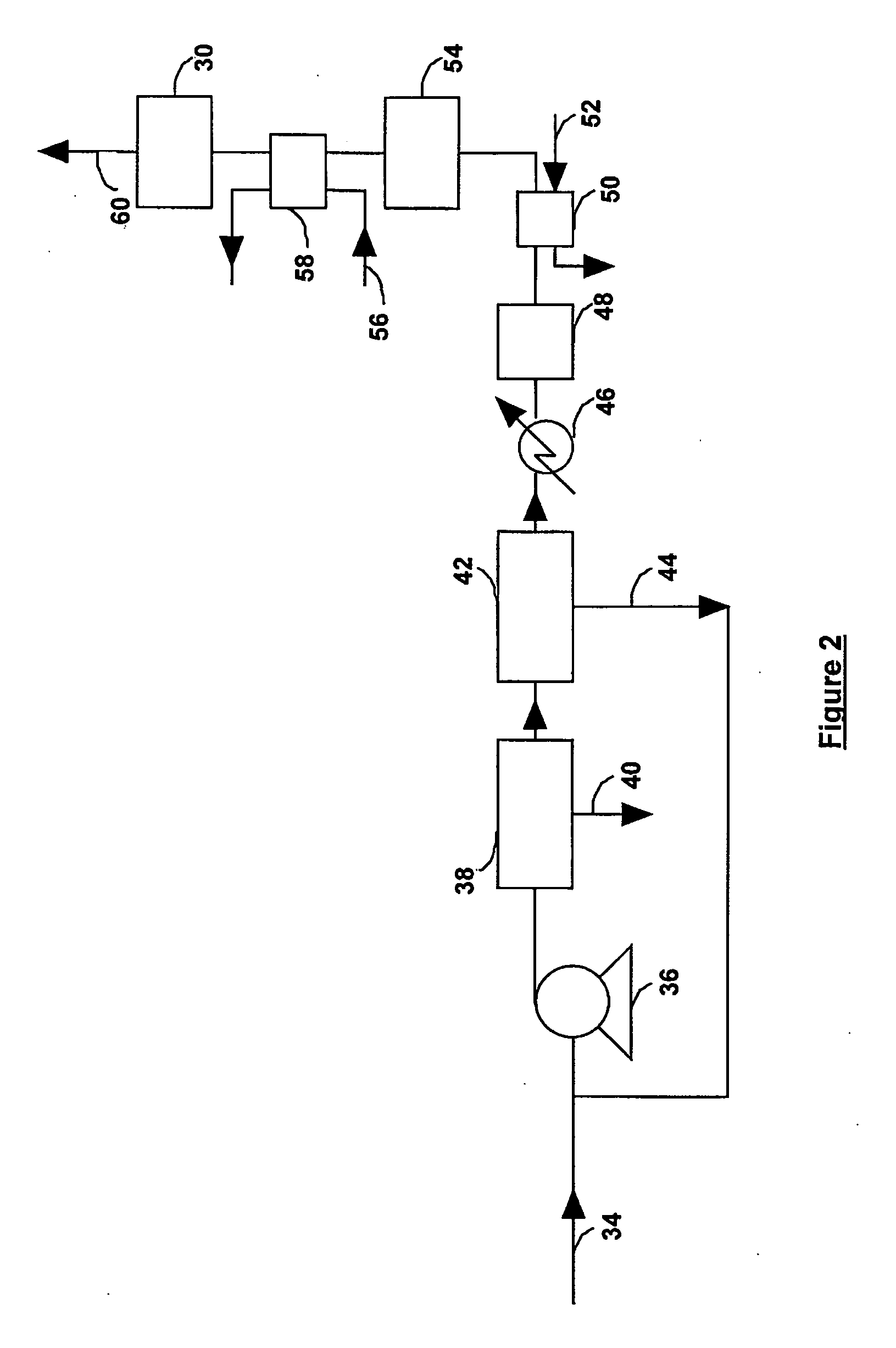

Method and apparatus for delivering a high pressure gas from a cryogenic storage tank

InactiveUS7293418B2Reduce heat transferPoint of failureInternal combustion piston enginesFuel supply apparatusProcess engineeringEngineering

A cryogenic tank assembly has a pump which discharges into an accumulator which is located in the cryogenic storage area. This reduces the space required for the device as well as the functioning of the device. The high pressure fluid in the accumulator remains at a cryogenic temperature. The system may also include a heater to deliver high pressure gas form the liquid storage volume.

Owner:WESTPORT FUEL SYST CANADA INC +1

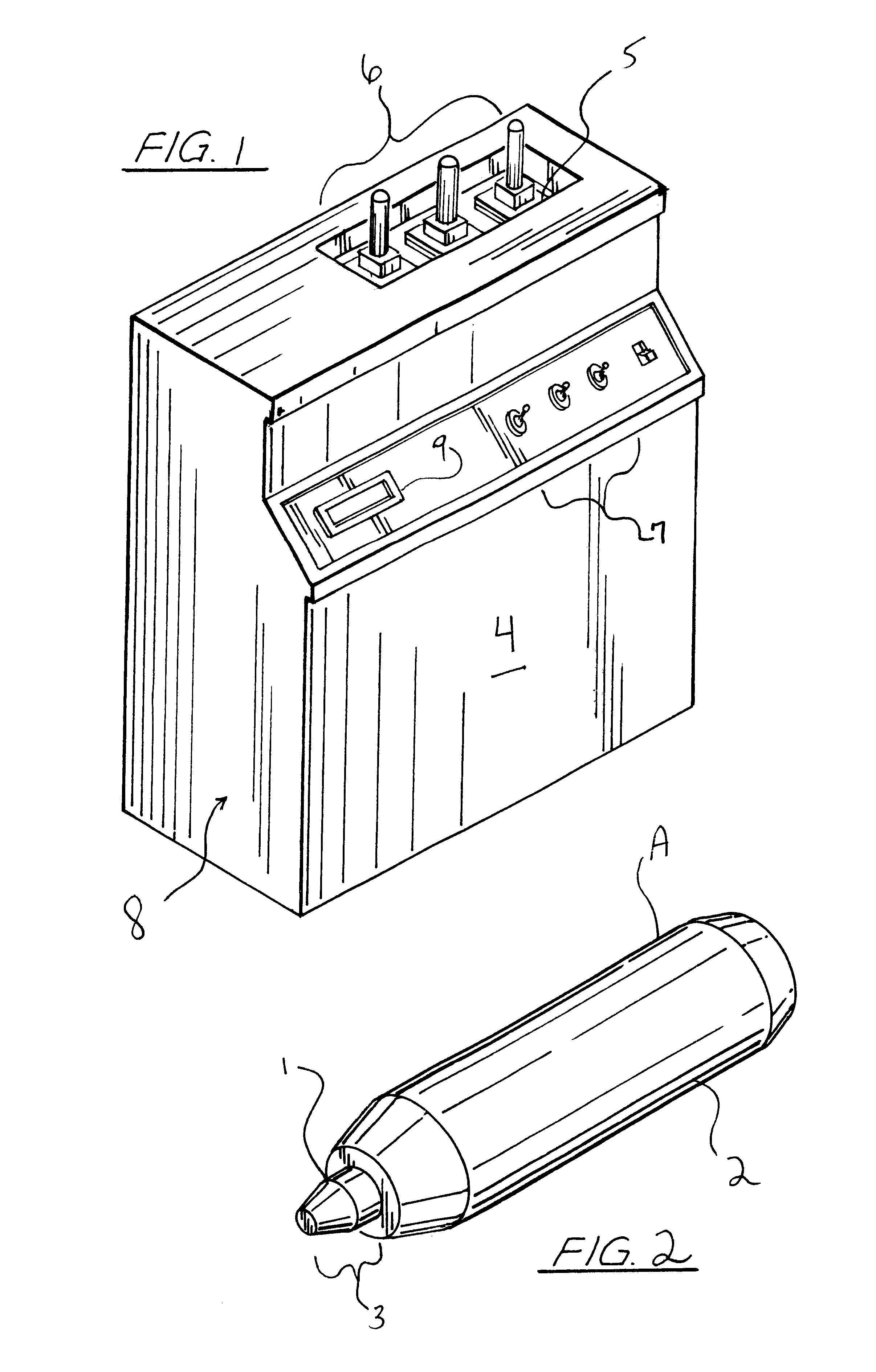

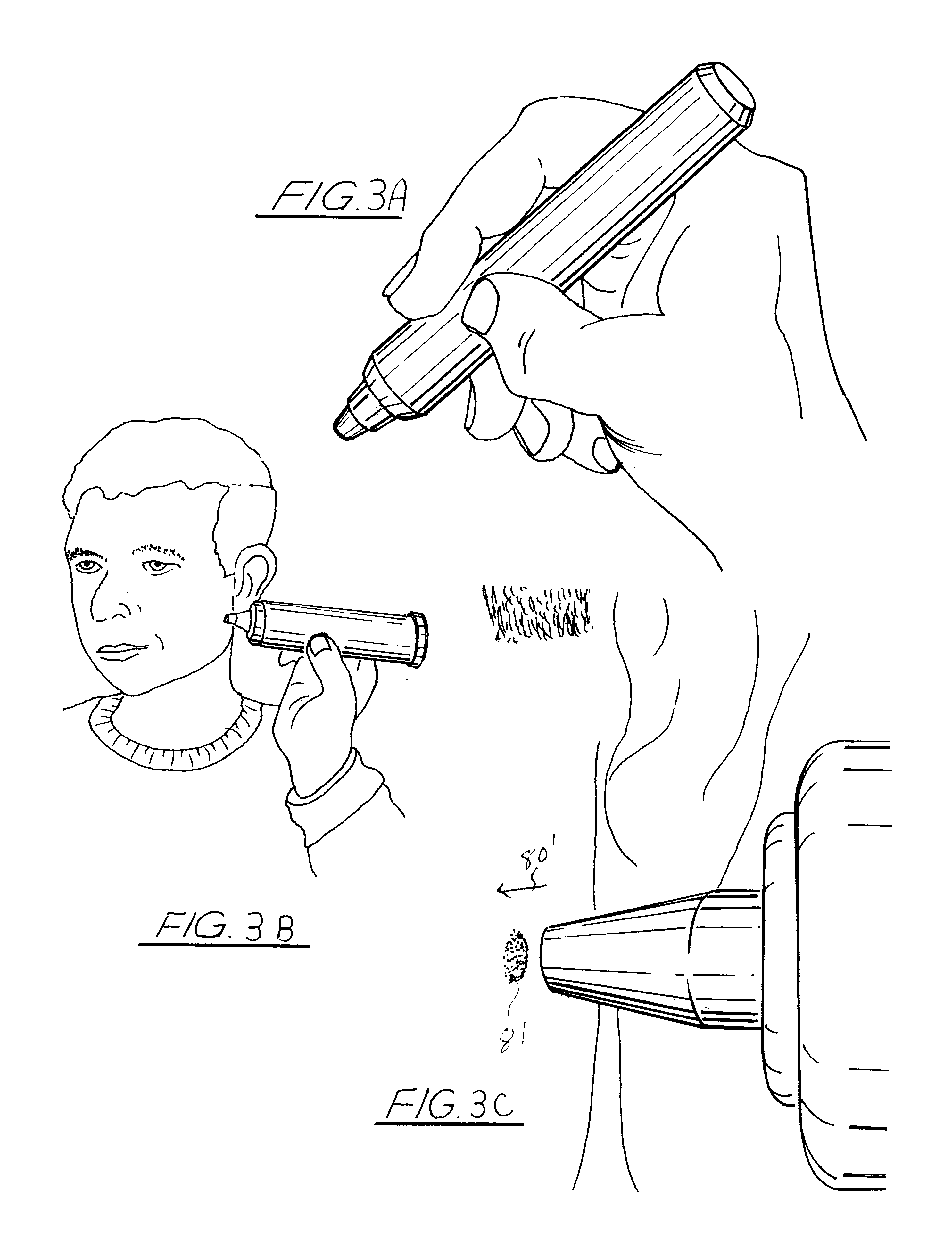

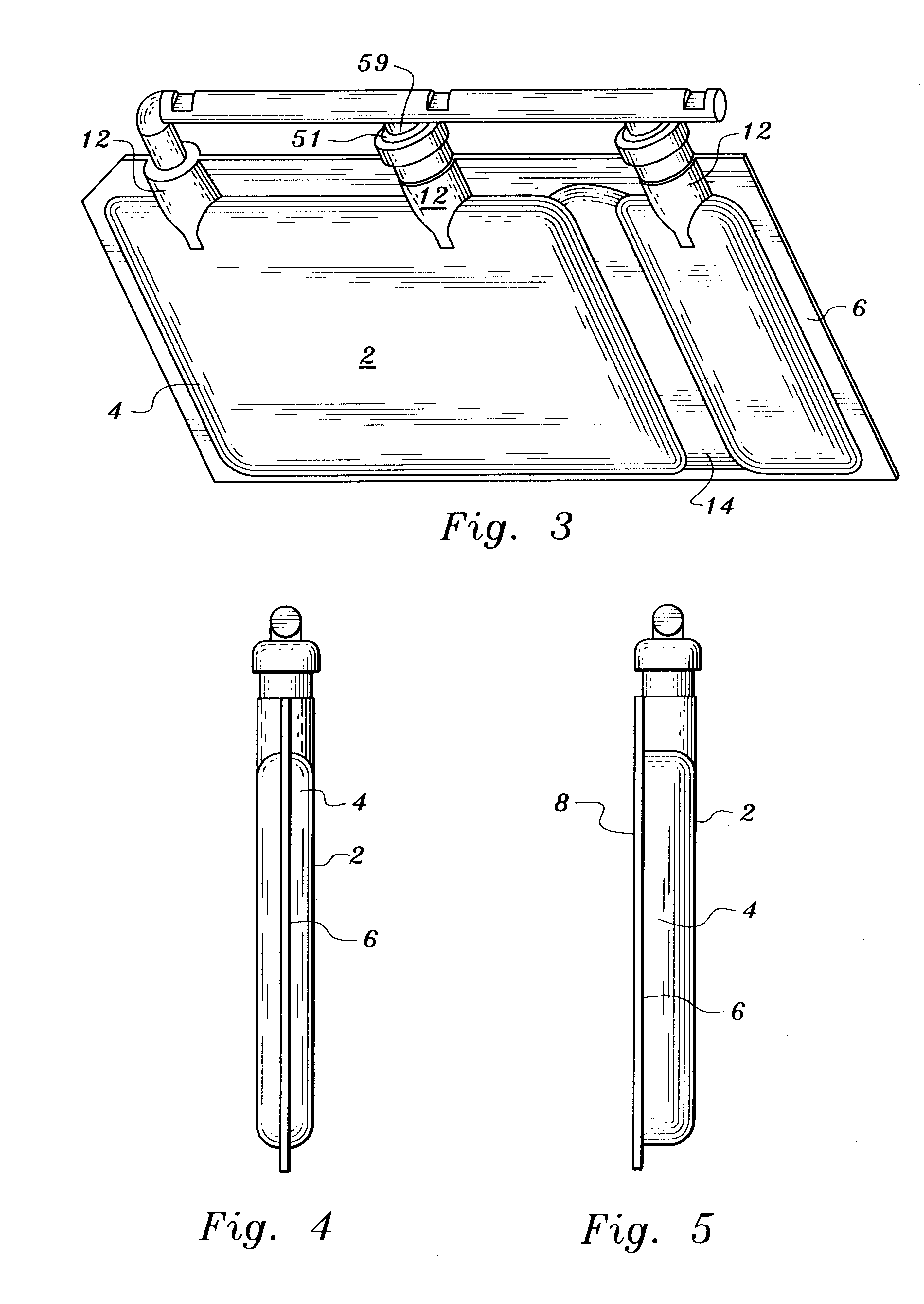

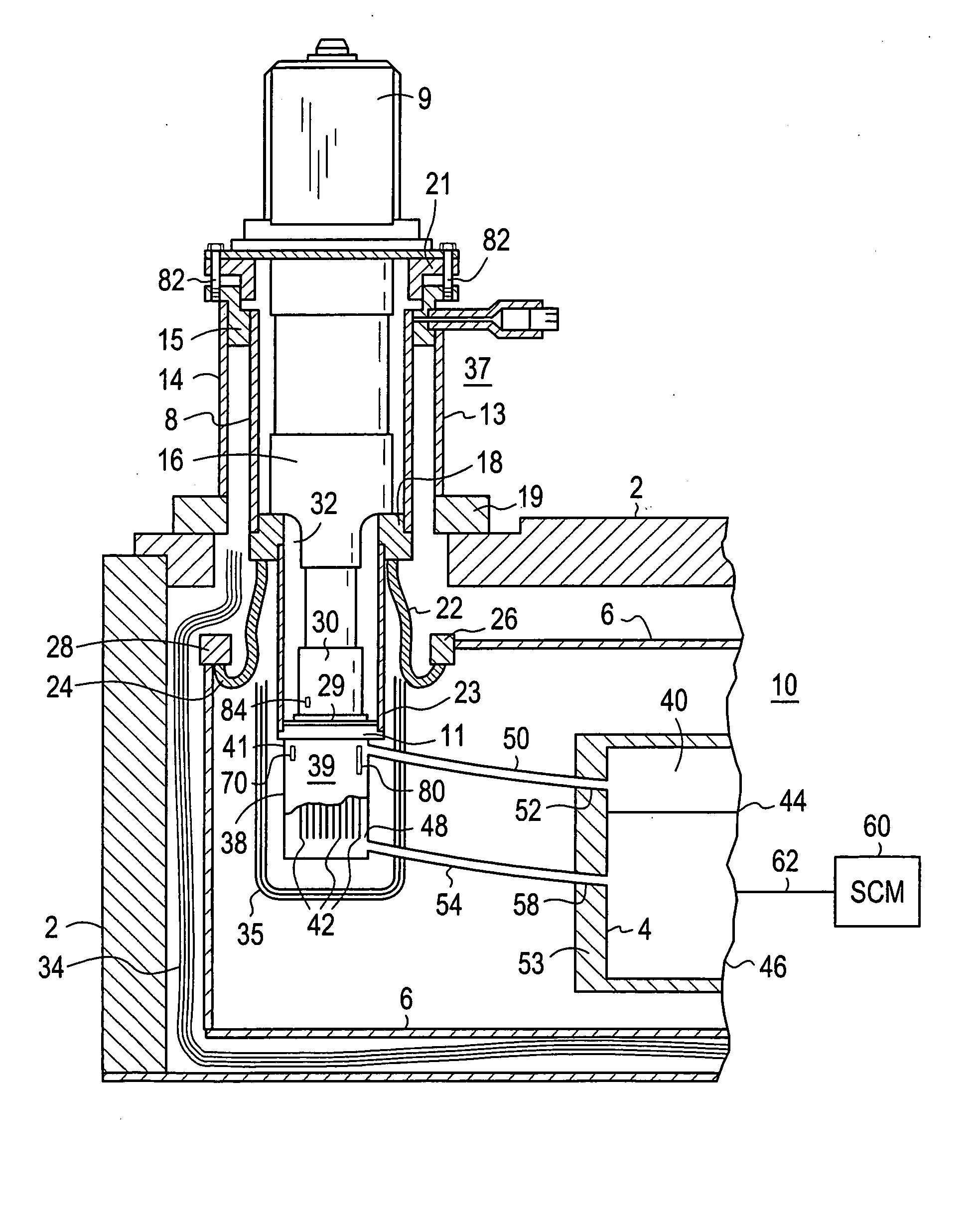

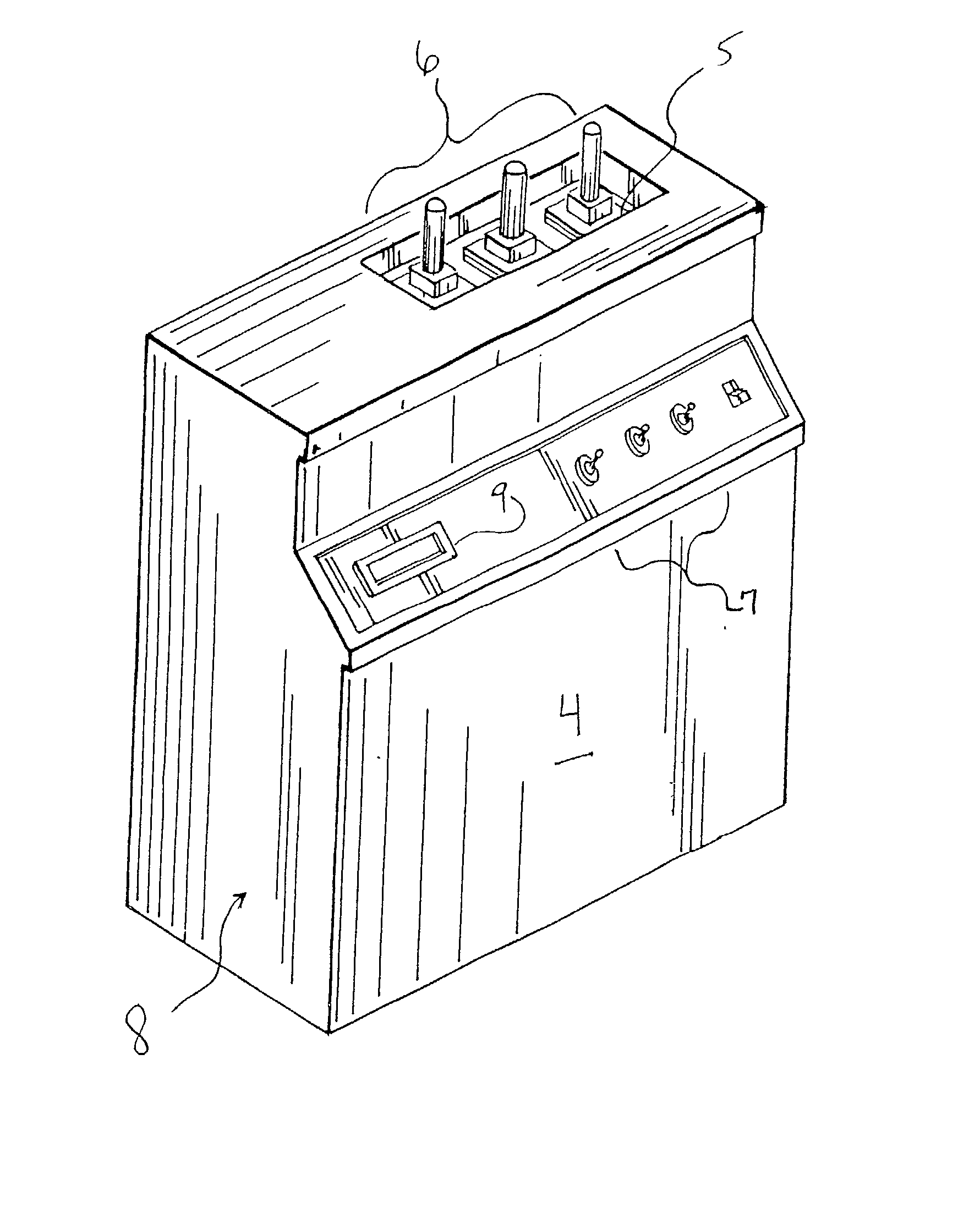

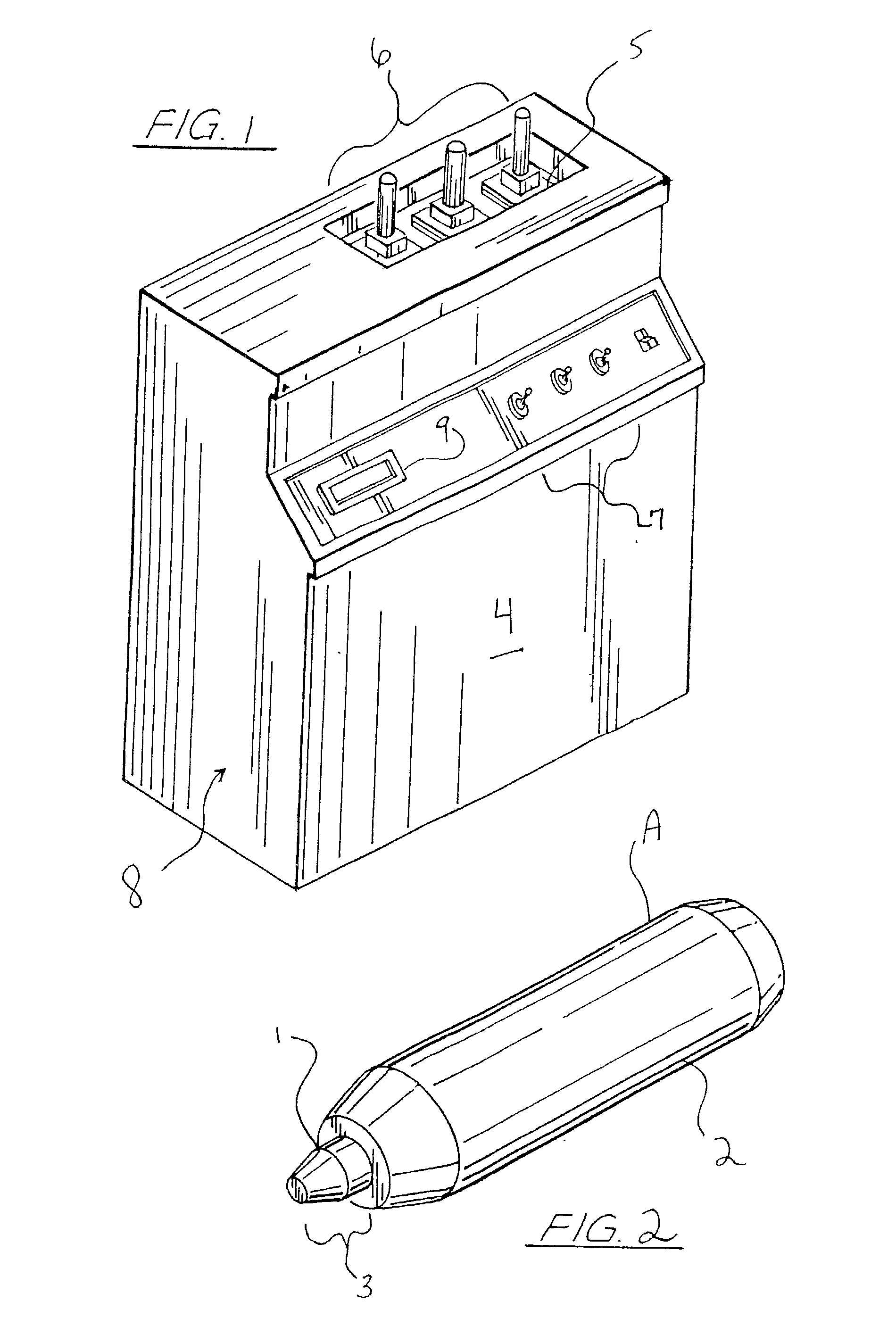

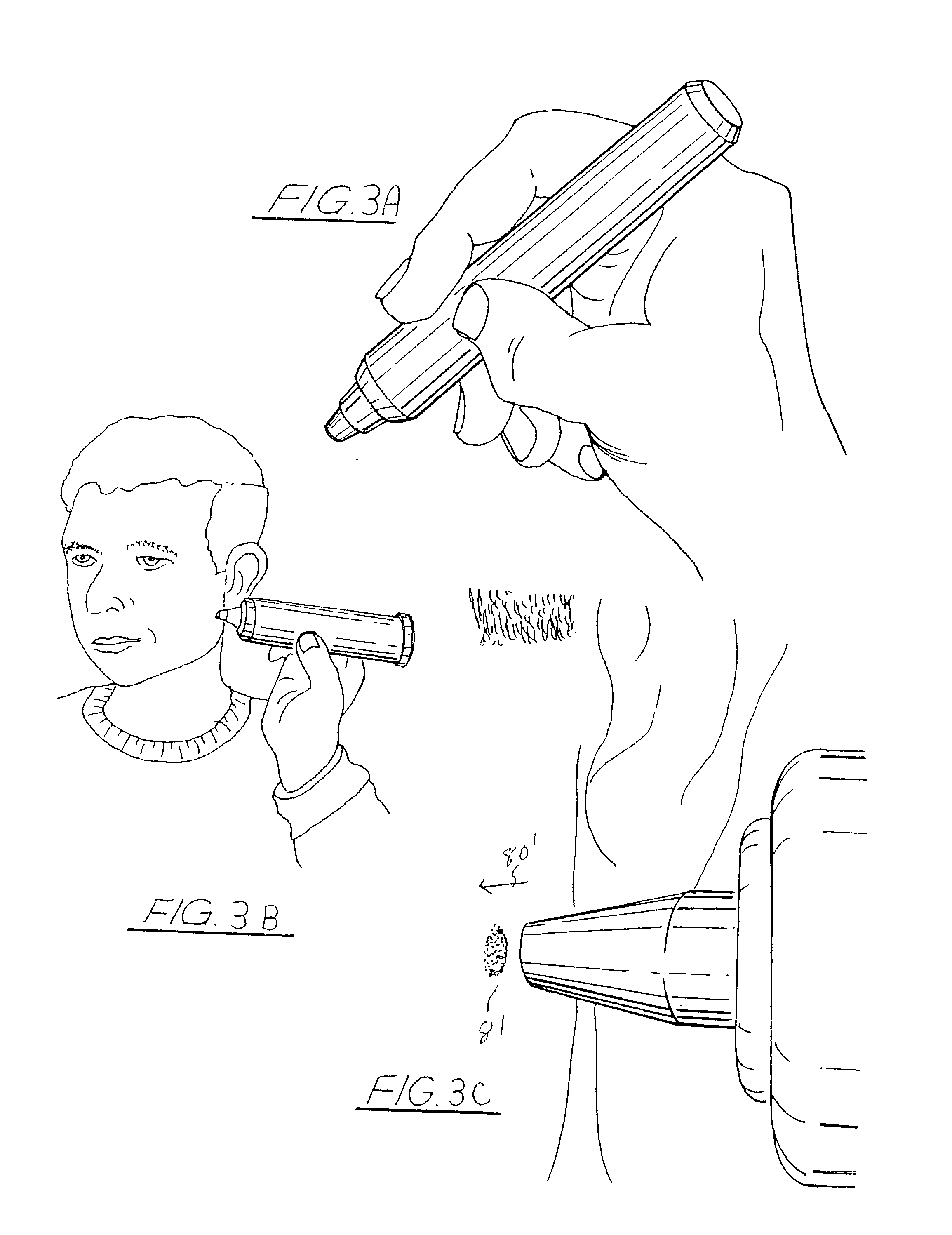

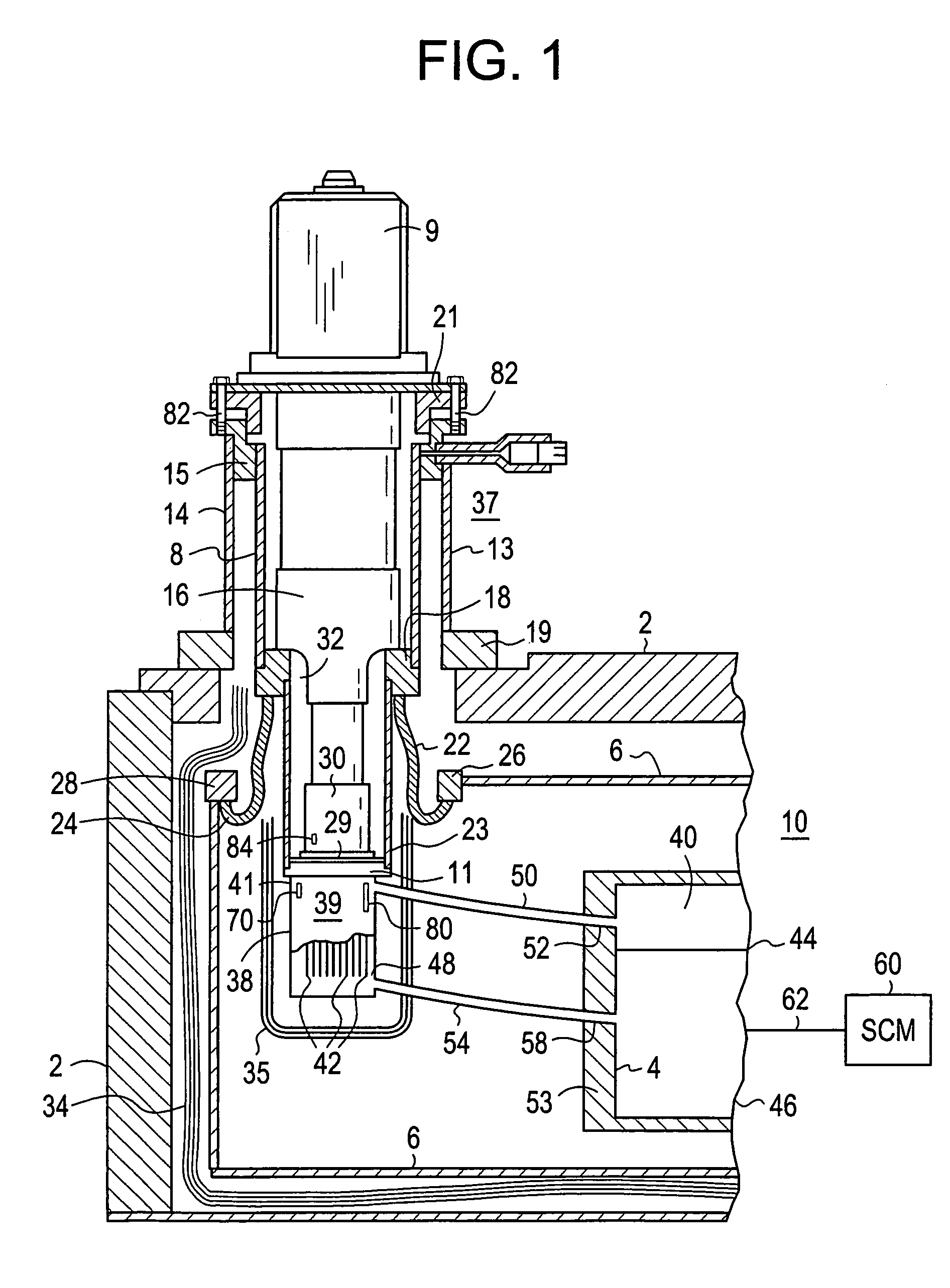

Hand-held, heat sink cryoprobe, system for heat extraction thereof, and method therefore

InactiveUS6430956B1Easy to useGuaranteed uptimeCompression machinesMachines using electric/magnetic effectsOff the shelfHand held

A cryoprobe system utilizing a monolithic, insulated, hand-held thermal mass having an exposed tip for cryosurgical applications and the like, as well as a heat extraction base configured to interface with the thermal mass to quickly and efficiently reduce the heat of the thermal mass to cryogenic temperatures. The heat extraction base of the preferred embodiment of the present invention is configured to interface with the tip of the thermal mass, such that the tip plugs in securely to the base, to permit an efficient thermal transfer of heat from the thermal mass through the base via a heat exchange system communicating with the base which employs a low temperature cryo-refrigeration unit. The cryo-refrigeration unit may comprise a single low temperature cooling unit to reduce the temperature of the base to around minus one hundred degrees Centigrade utilizing off-the-shelf cryogenic refrigeration methods, or may utilize a series of more conventional refrigeration units in a primary and secondary heat extraction arrangement, which method may further utilize thermocouple or Peltier effect device assist to further reduce the temperature of the heat extraction base to the required temperature. Also claimed is the method of cryosurgery employing the device(s) of the present invention.

Owner:CRYOPEN

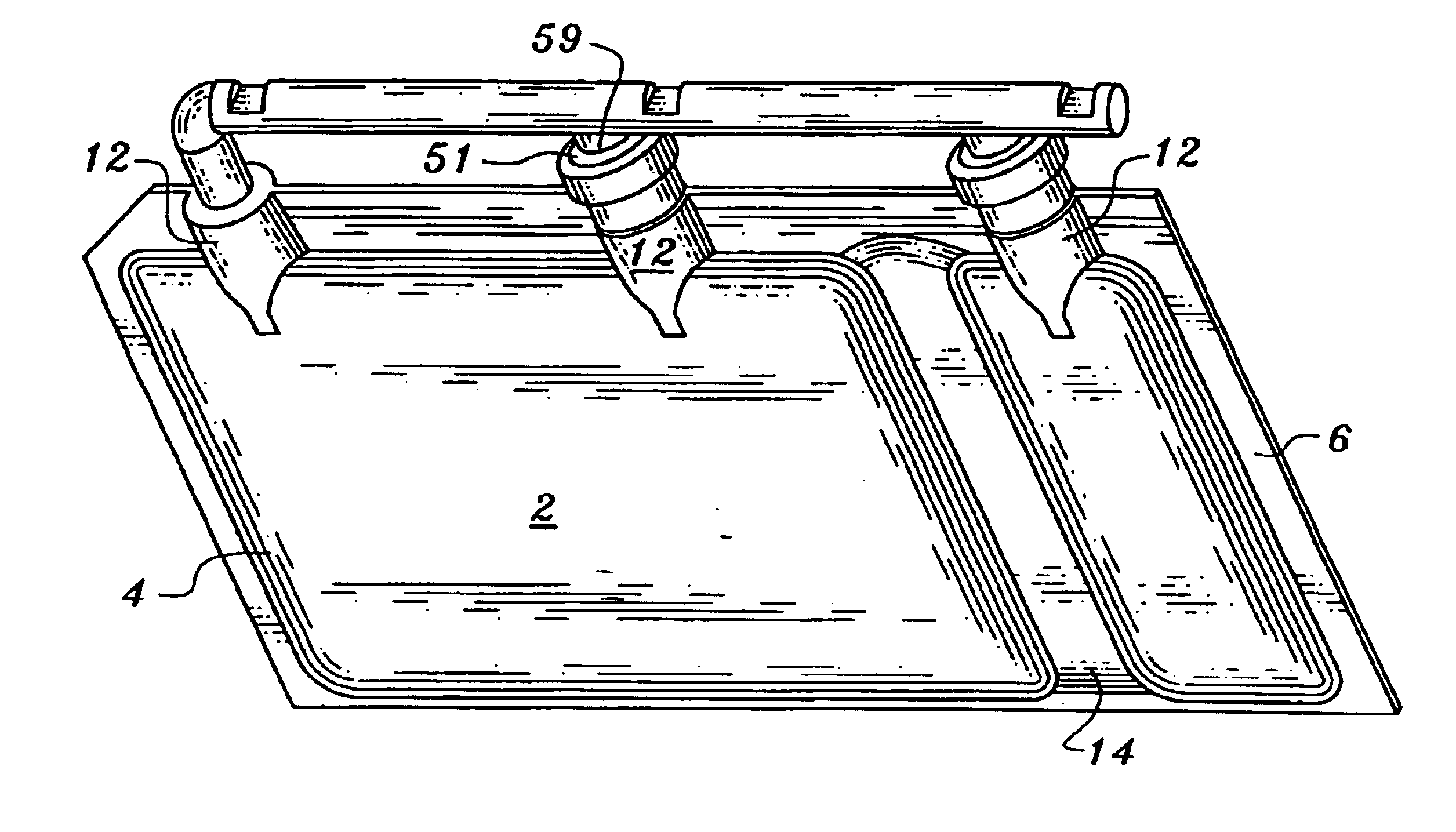

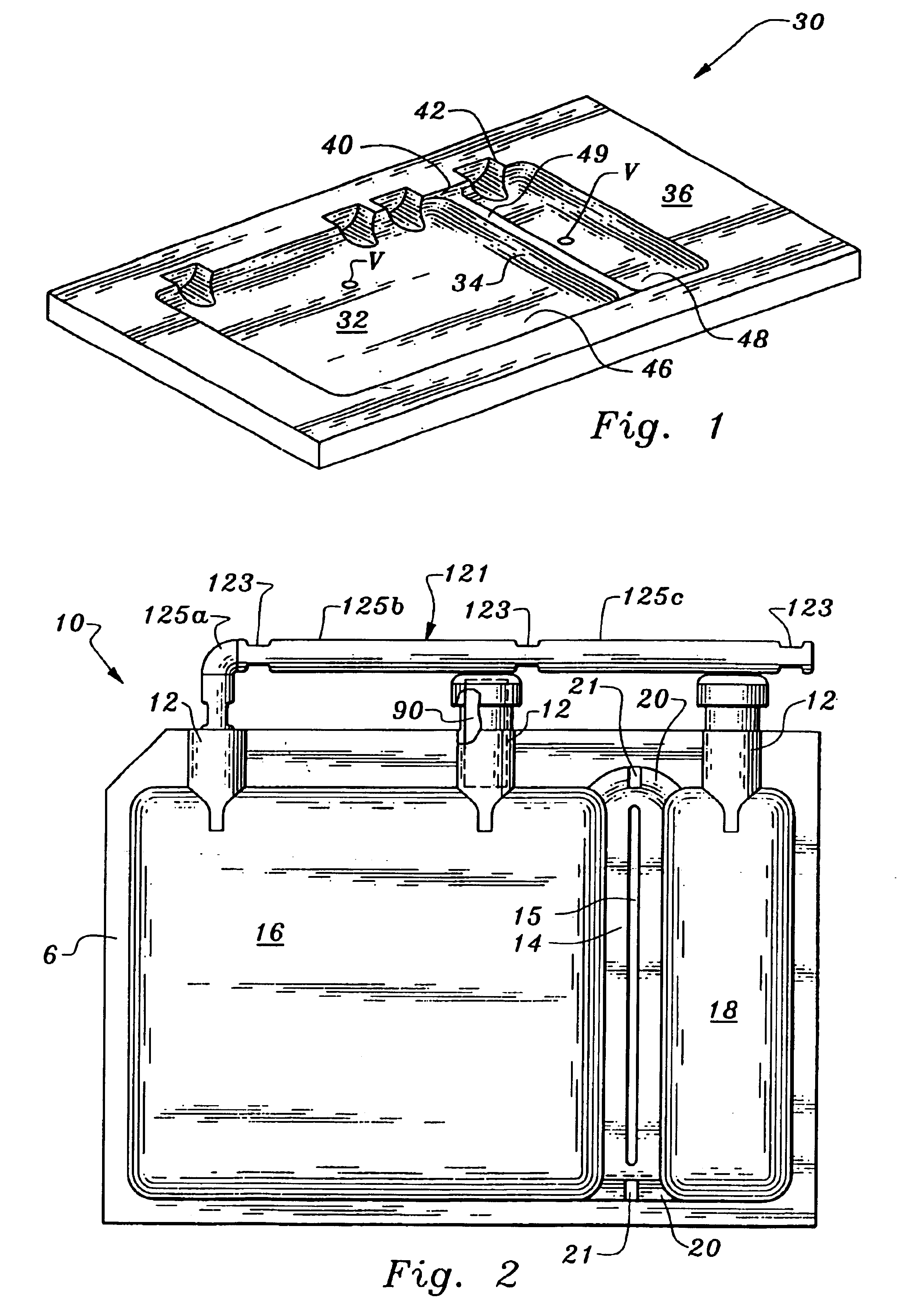

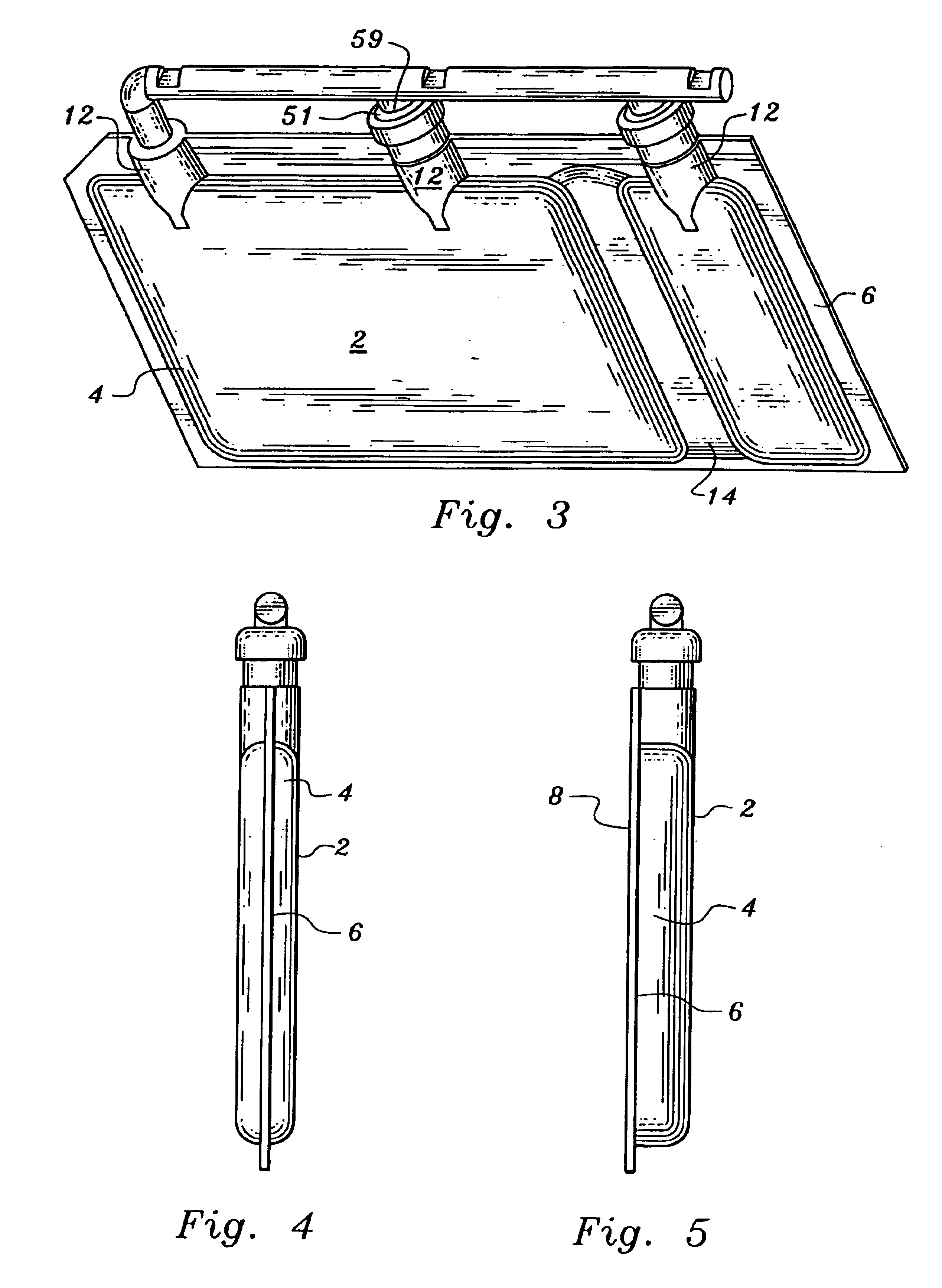

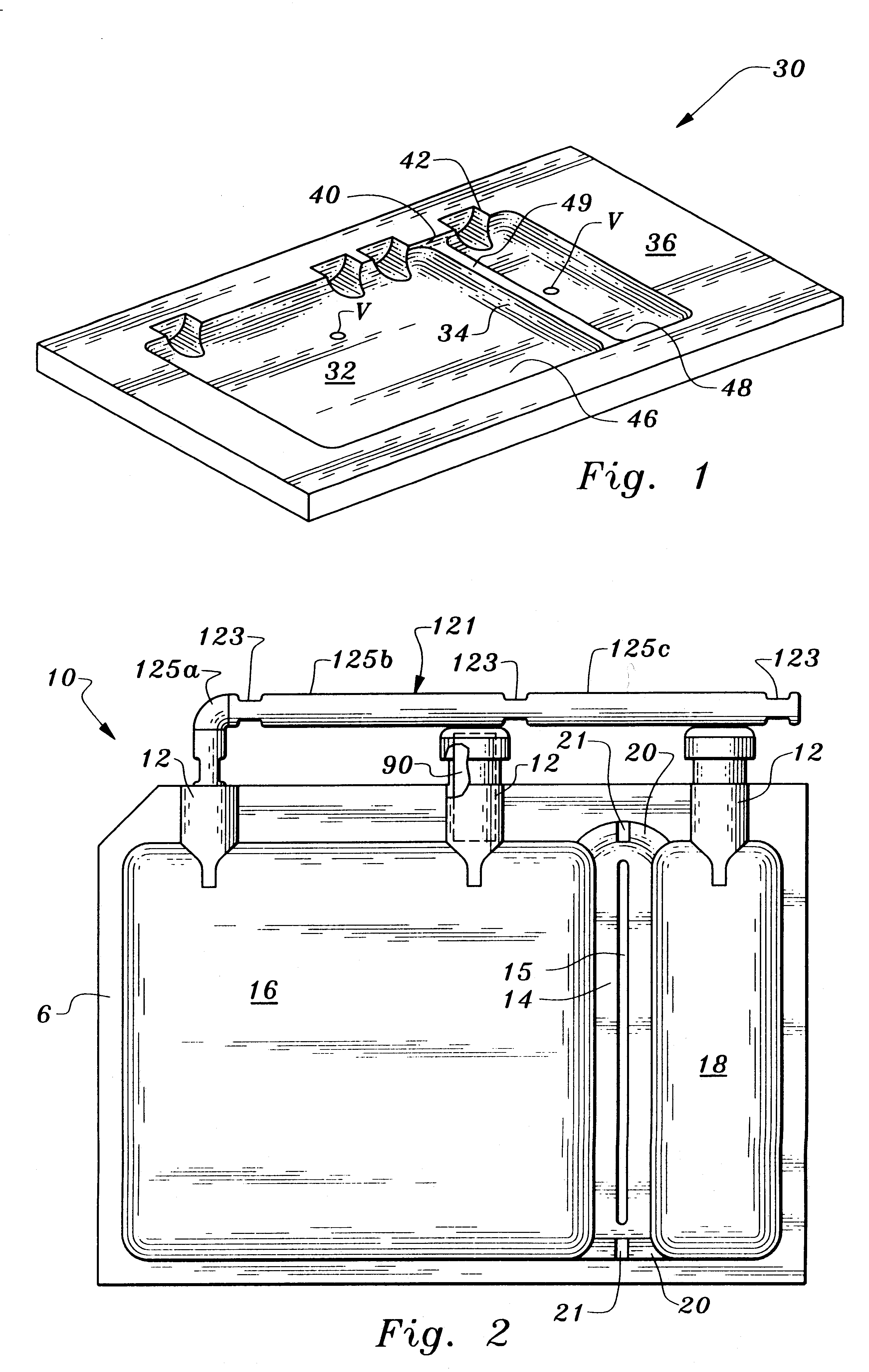

Freezing and thawing bag, mold, apparatus and method

InactiveUS6808675B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed with their larger planar surfaces in contact with each other.

Owner:CESCA THERAPEUTICS

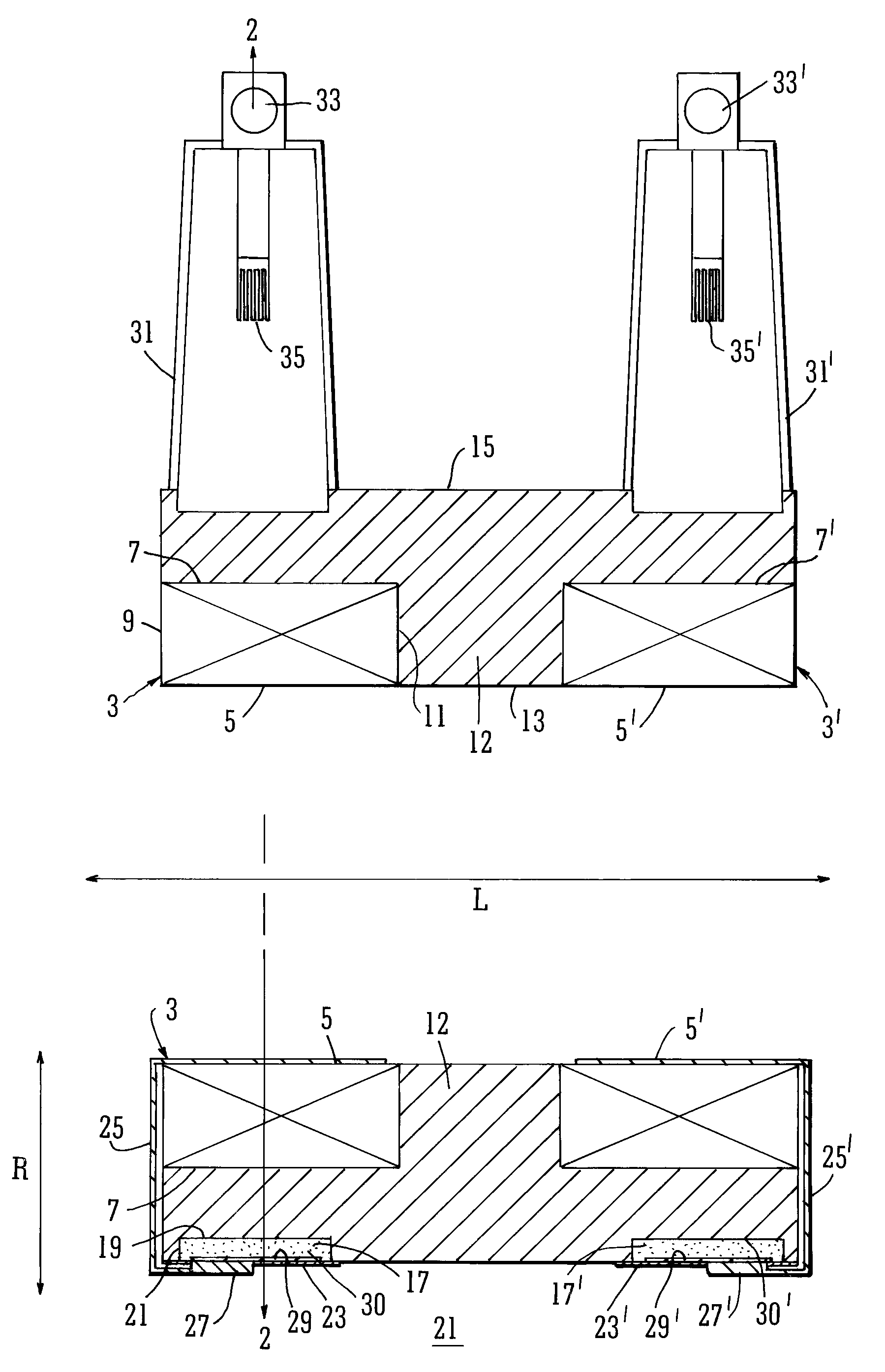

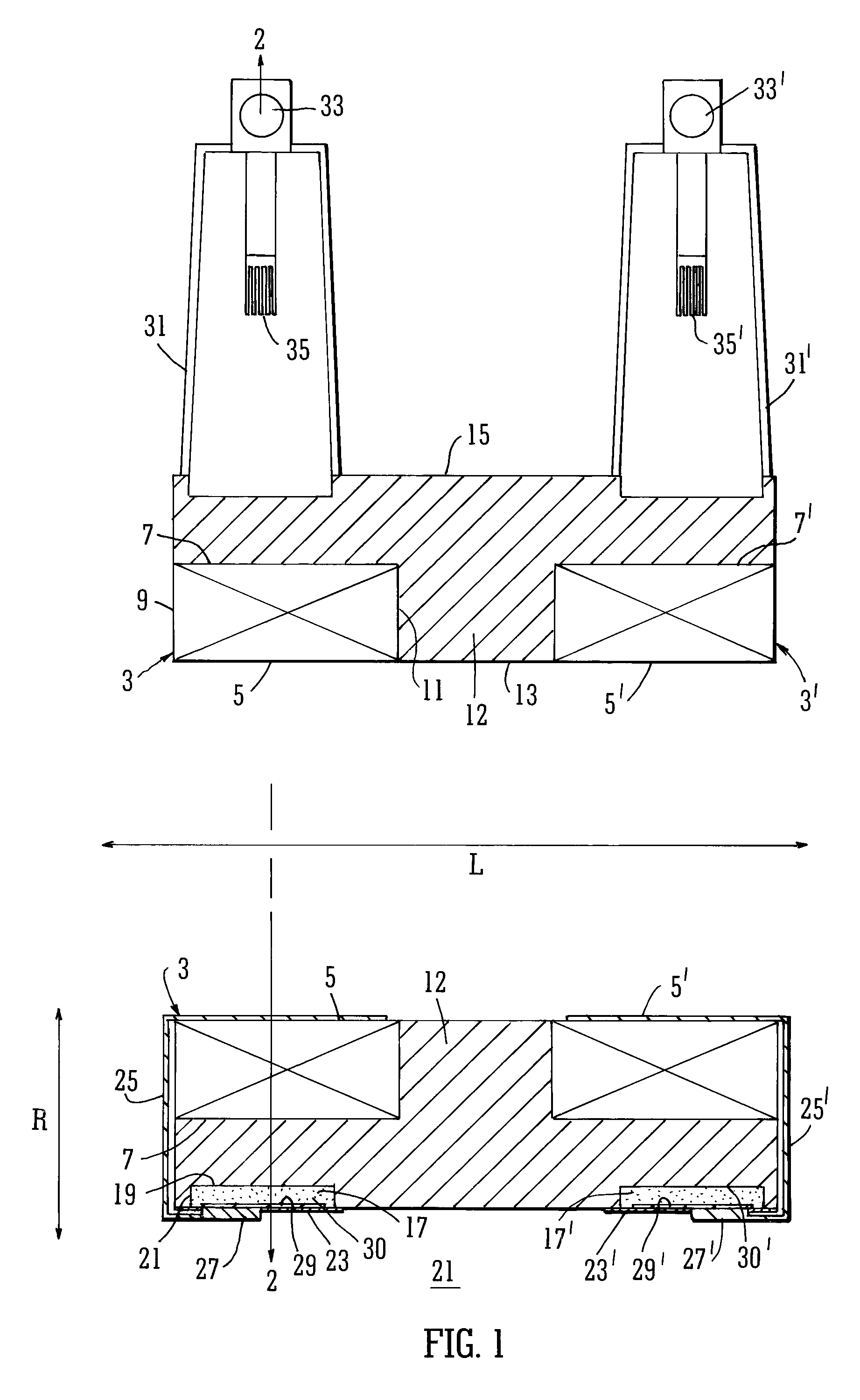

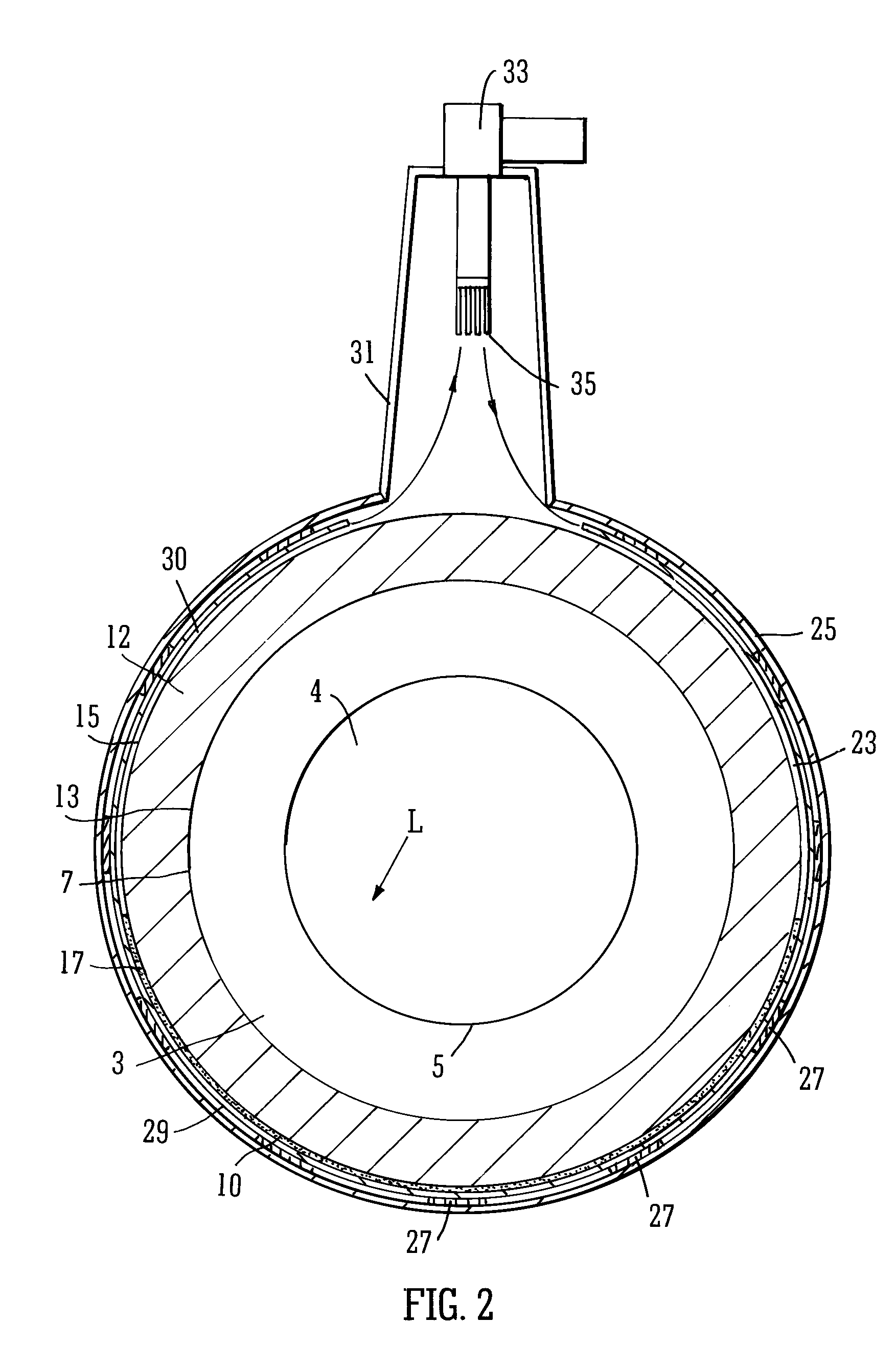

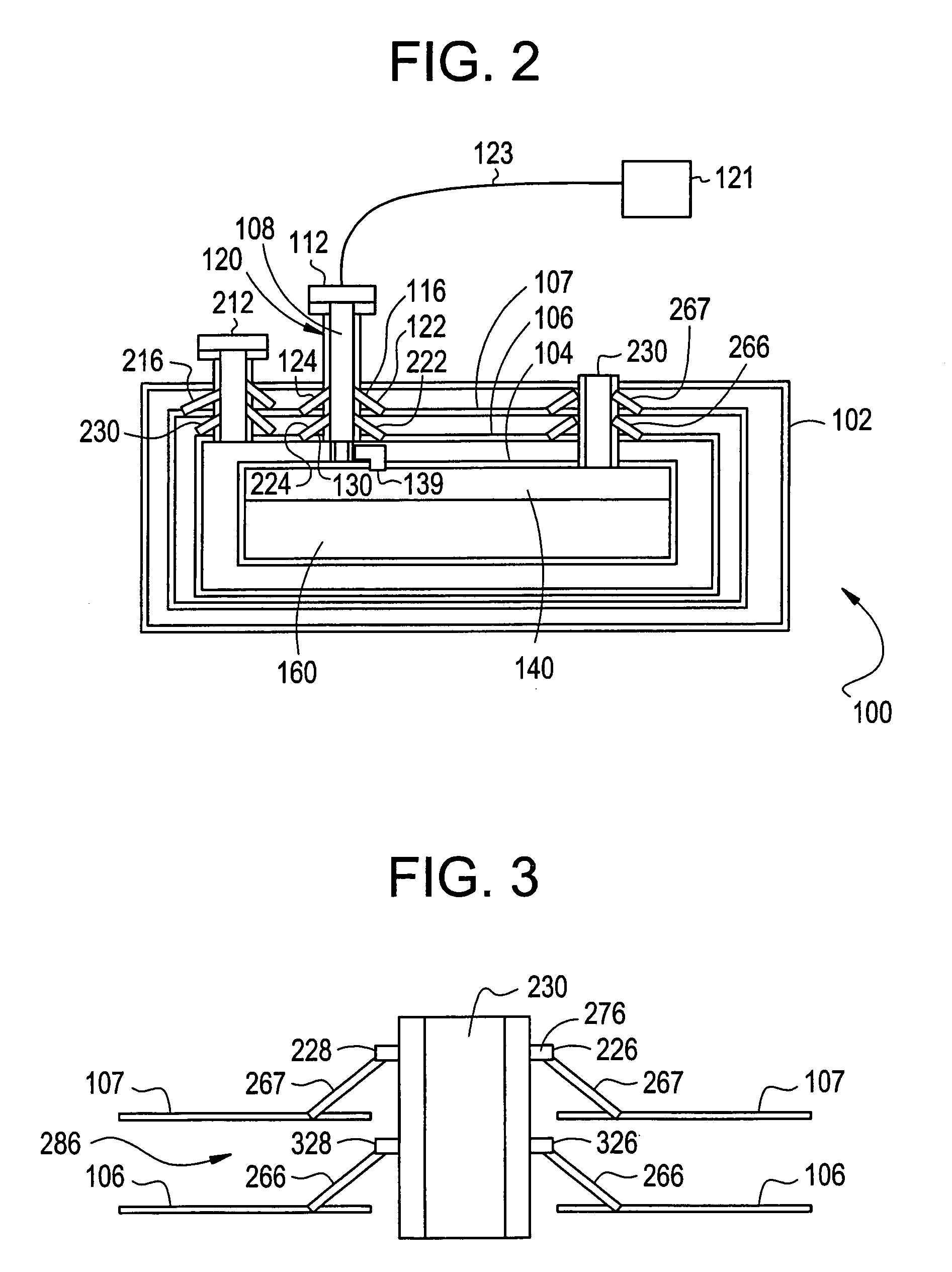

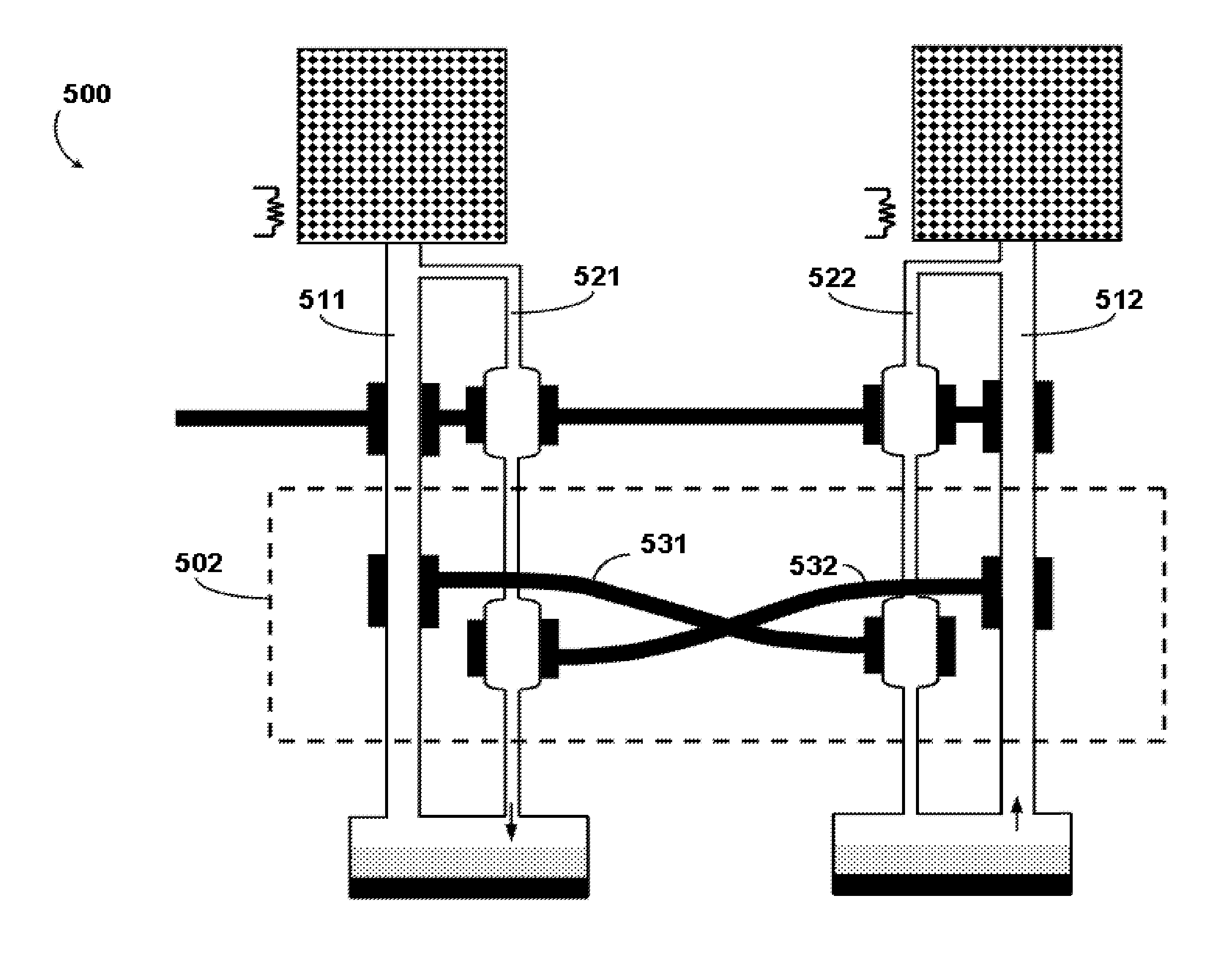

Cooling methods

InactiveUS20090038318A1Improve heat transfer performanceRemove heatTransformers/inductances coolingMagnetic measurementsSuperconducting CoilsEngineering

A superconducting system comprises a superconducting coil (3) mounted in a support (12). The coil is surrounded by a cryogen chamber (17) which is located radially outwardly from the coil (3) on the other side of the support (12). The cryogen chamber is in fluid communication with a cryogen recondensing unit (33) whereby vaporized cryogen may flow from the cryogen chamber (17) to the cryogen recondensing unit (33) to be recondensed in use before returning to the cryogen chamber. Thermally conductive means (25) is arranged to facilitate heat transfer from the superconducting coil (3) to the cryogen chamber (17) to vaporize cryogen contained therein in use and thereby remove heat from the coil. The thermally conductive means (25) is highly thermally conductive at cryogenic temperatures. In use, the highly thermally conductive means (25) facilitates transfer of heat from the coil (3) to the interior of the cryogen chamber (17) to vaporize cryogen located therein. A thermal conduction path is therefore used to transfer heat from the coil to the cryogen in the cryogen chamber. Cryogen vaporized in the cryogen chamber then flows to the cryogen recondensing unit (33) to be recondensed before returning to the chamber, while the vaporized cryogen acts as the heat transfer medium over the longer distance between the cryogen chamber and the recondensing unit.

Owner:TESLA ENG

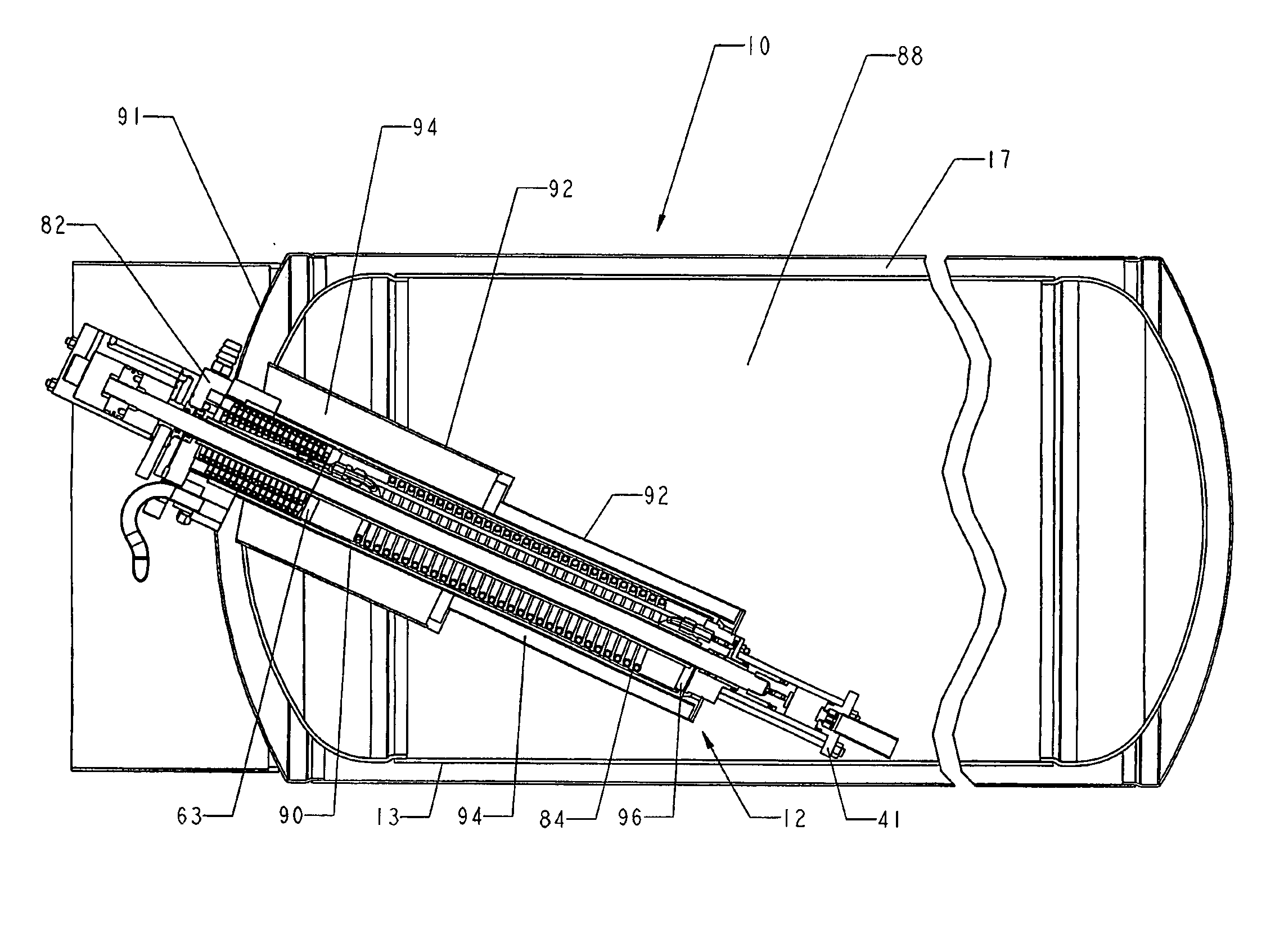

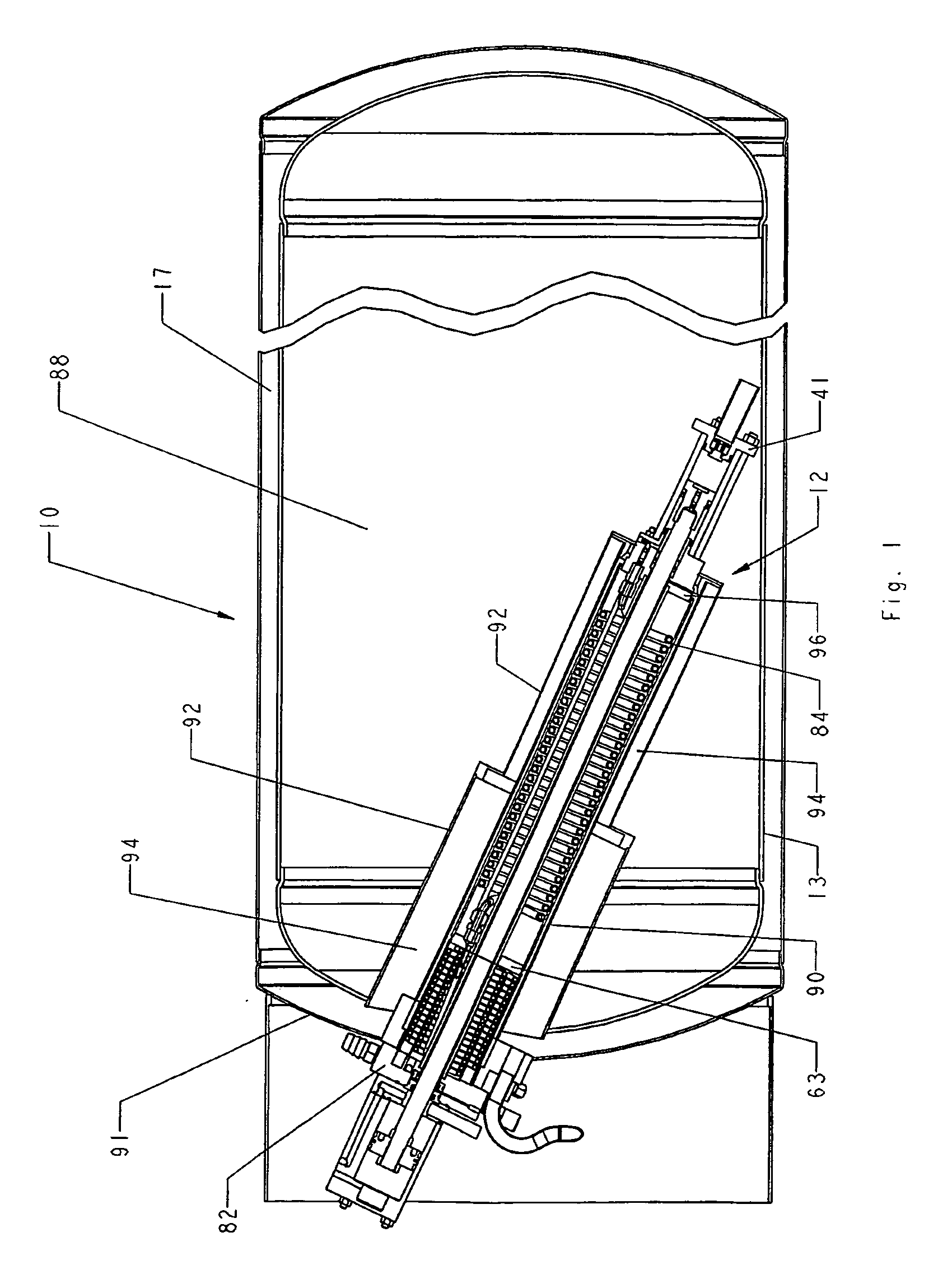

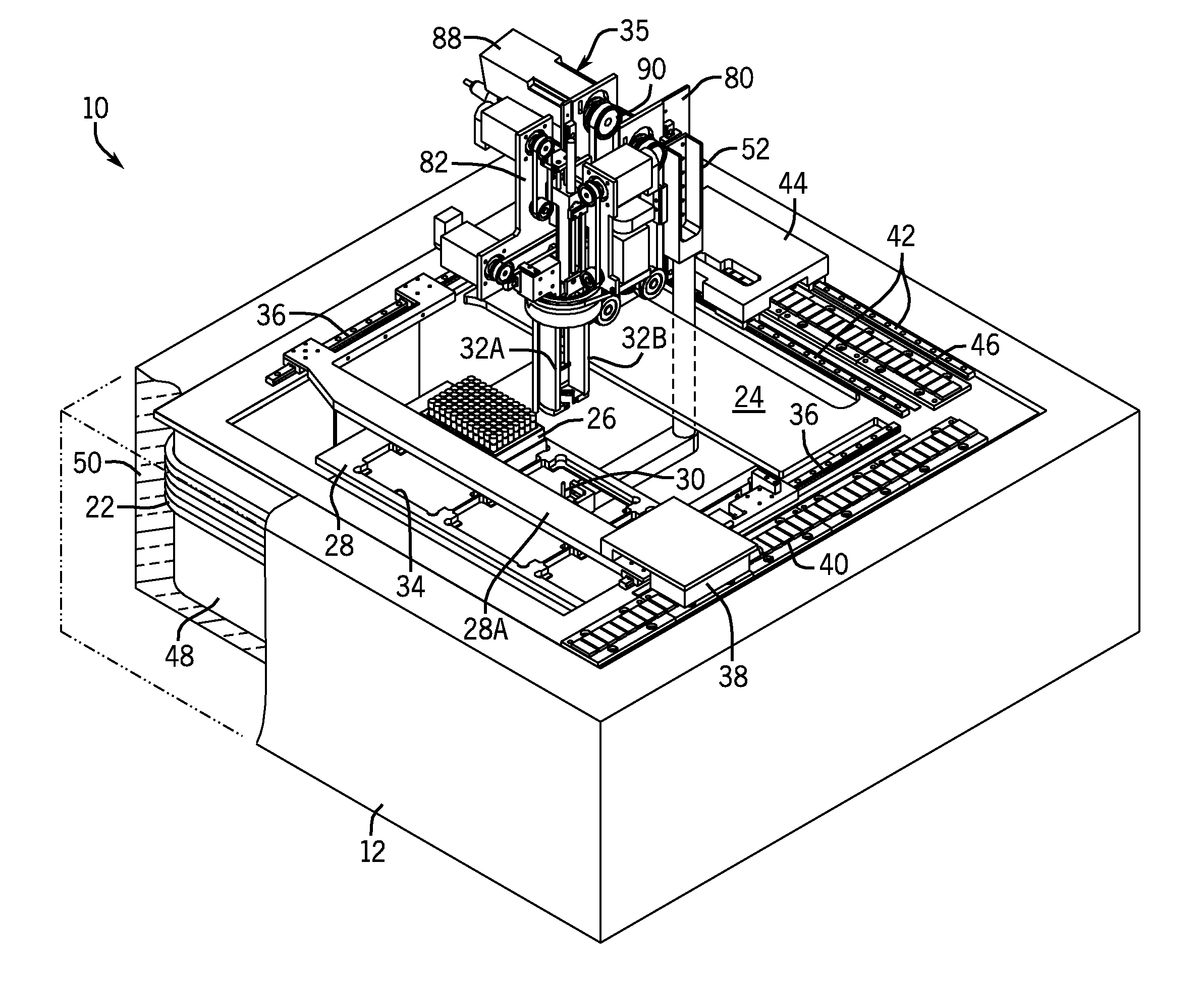

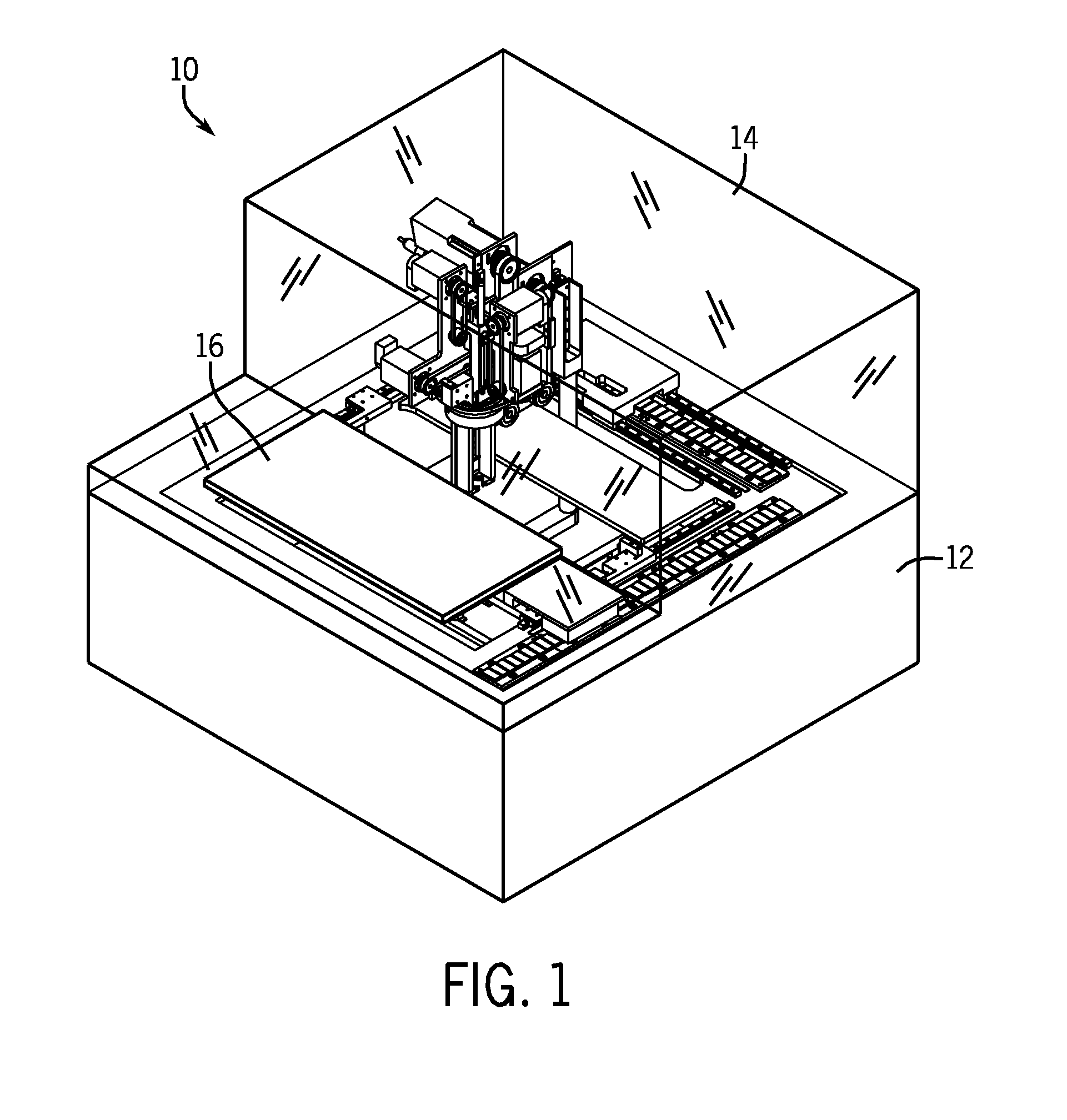

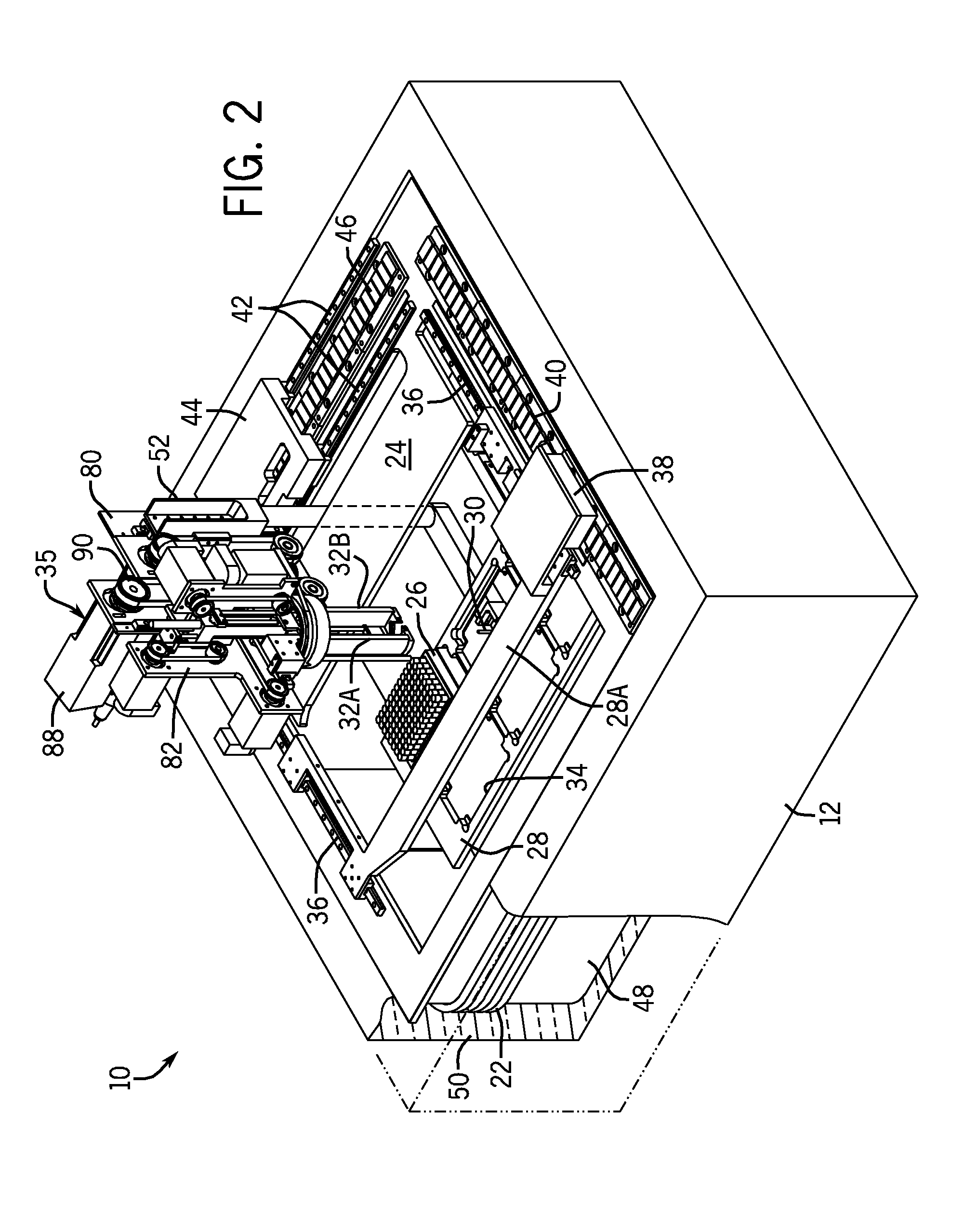

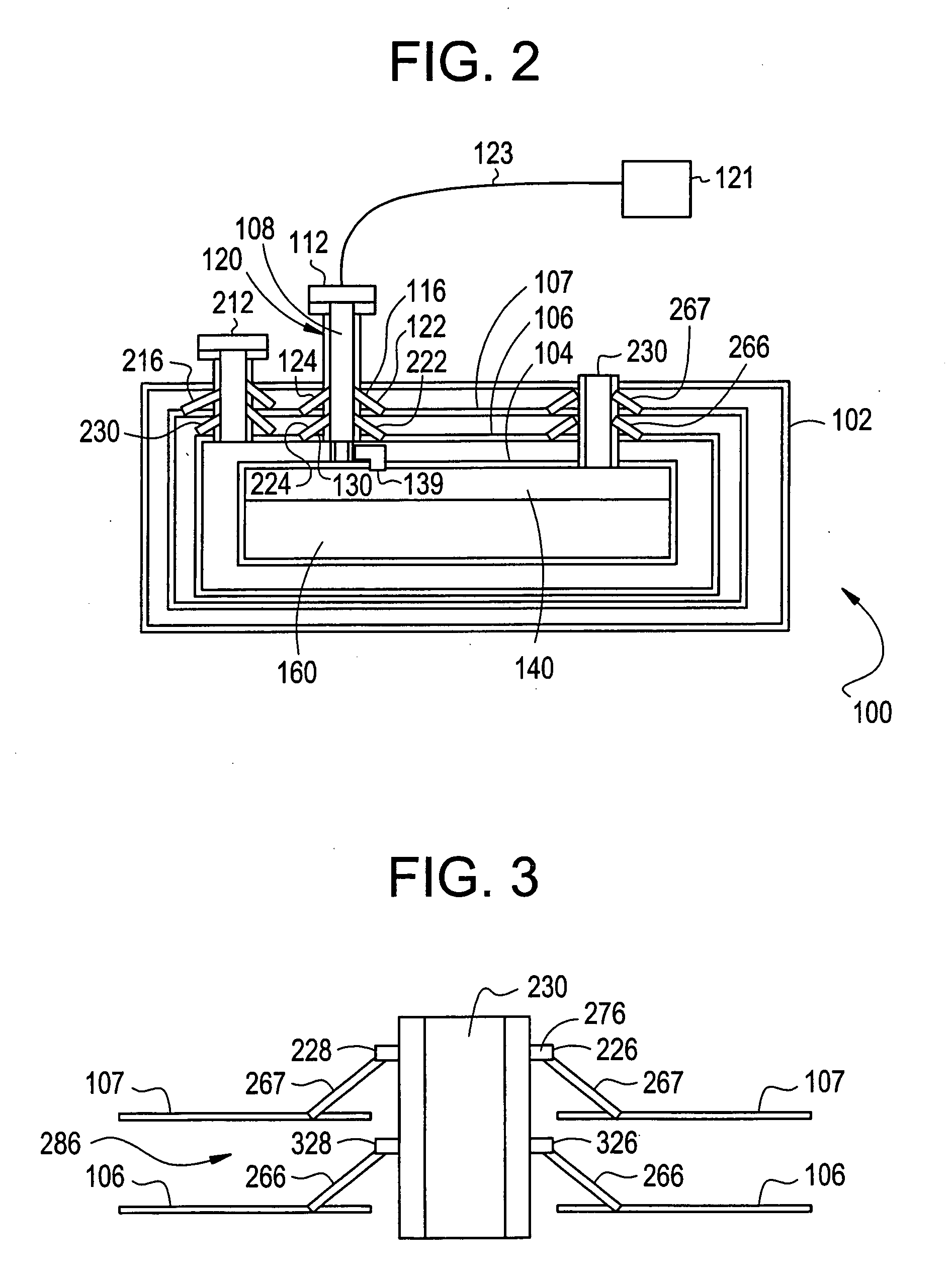

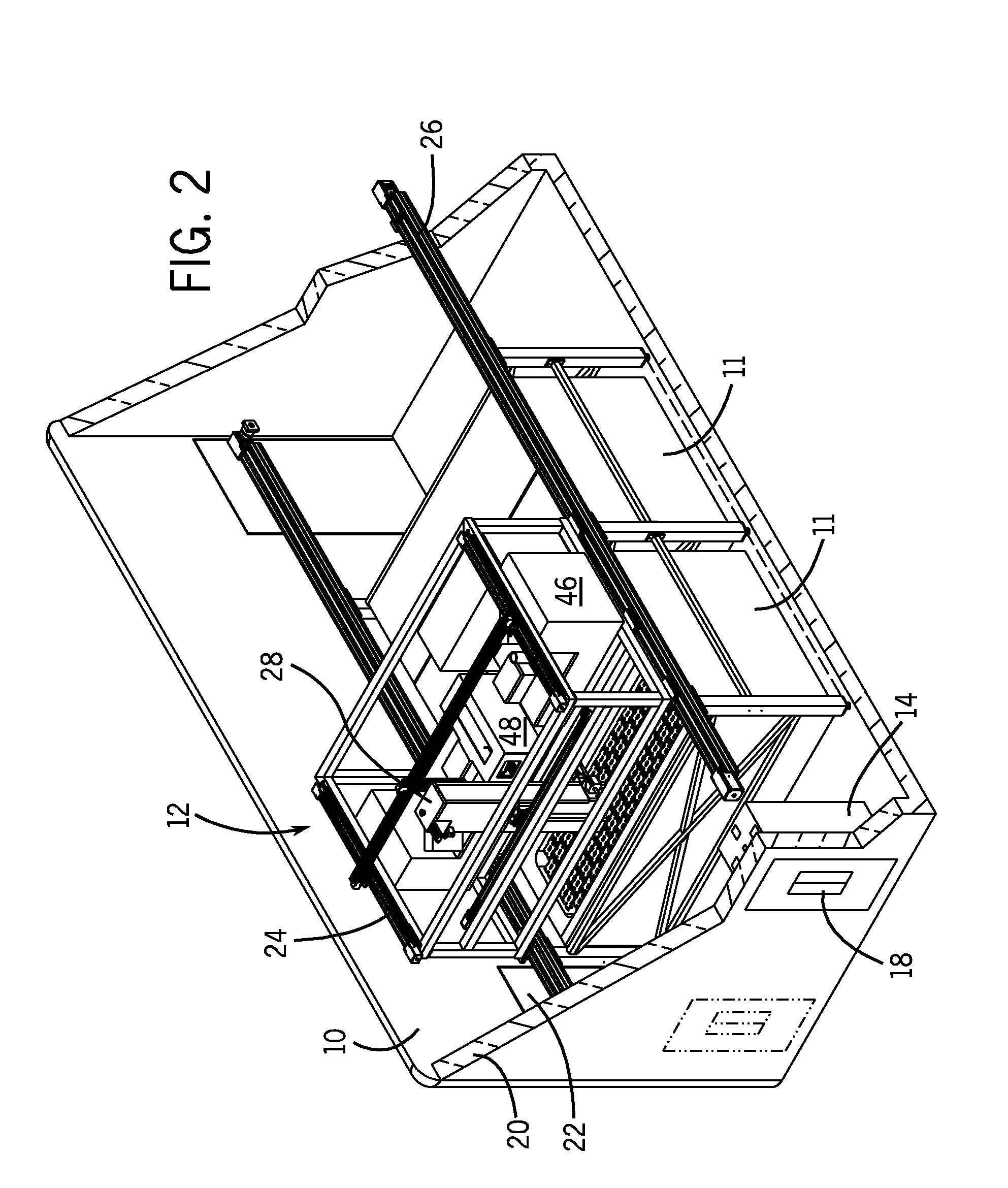

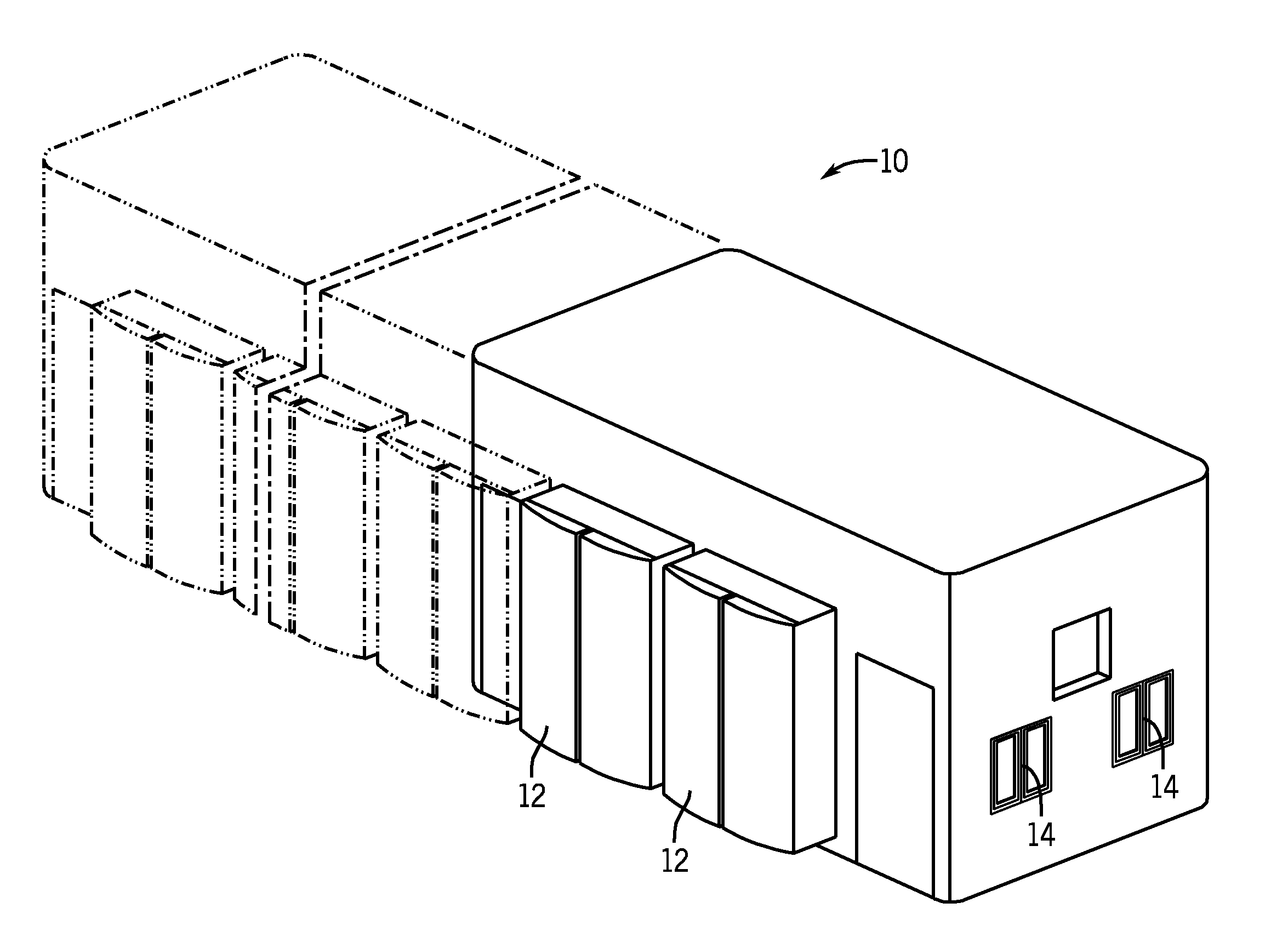

Tube Picking Mechanisms with an Ultra-Low Temperature or Cryogenic Picking Compartment

ActiveUS20120060514A1Low thermal conductivityPromote sportsPreparing sample for investigationCompression machinesMechanical componentsProcess engineering

A tube picking mechanism is designed for use in an automated, ultra-low temperature (e.g. −80° C. or −135° C.) or cryogenic (e.g., about −140° C. to −196° C.) storage and retrieval system that stores biological or chemical samples. The samples are contained in storage tubes held in SBS footprint storage racks that are normally stored within an ultra-low temperature or cryogenic freezer compartment. The tube picking mechanism includes a tube picking chamber that is maintained at about −80° C., about −135° C. or at cryogenic temperatures in cryogenic applications. Active electrical and mechanical components are maintained in a compartment above and separate from the refrigerated, ultra-low temperature or cryogenic compartment. Thermal stratification inhibits heat transfer into the lower, ultra-low temperature or cryogenic compartment in which tube picking occurs from the upper compartment in which active electrical and mechanical components are located, and also inhibits heat transfer into the lower, ultra-low temperature or cryogenic compartment via an access door for tube storage racks.

Owner:HAMILTON STORAGE TECH

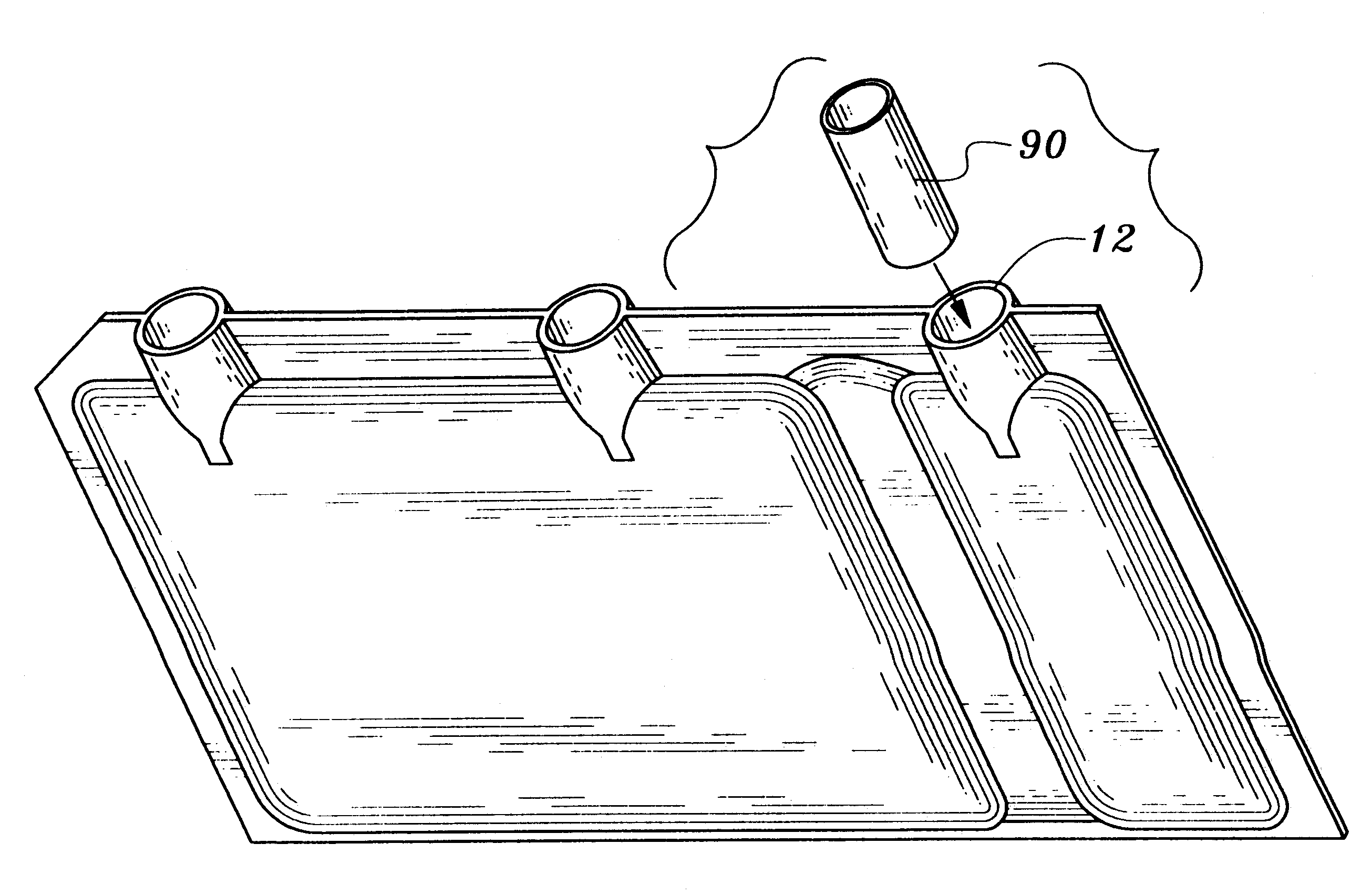

Freezing and thawing bag, mold, apparatus and method

InactiveUS6232115B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed, with their larger planar surfaces, in contact with each other.

Owner:NEW YORK BLOOD CENT

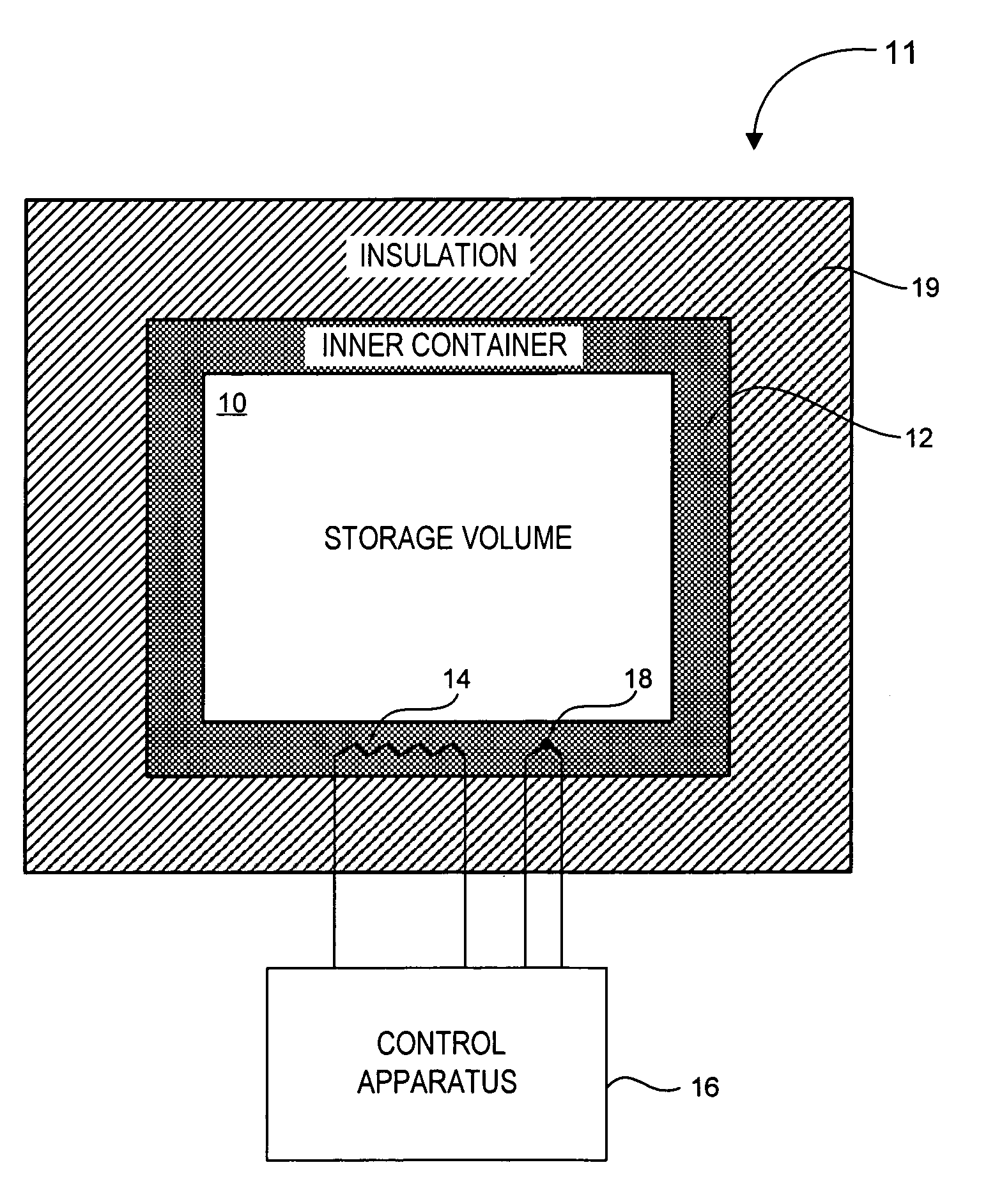

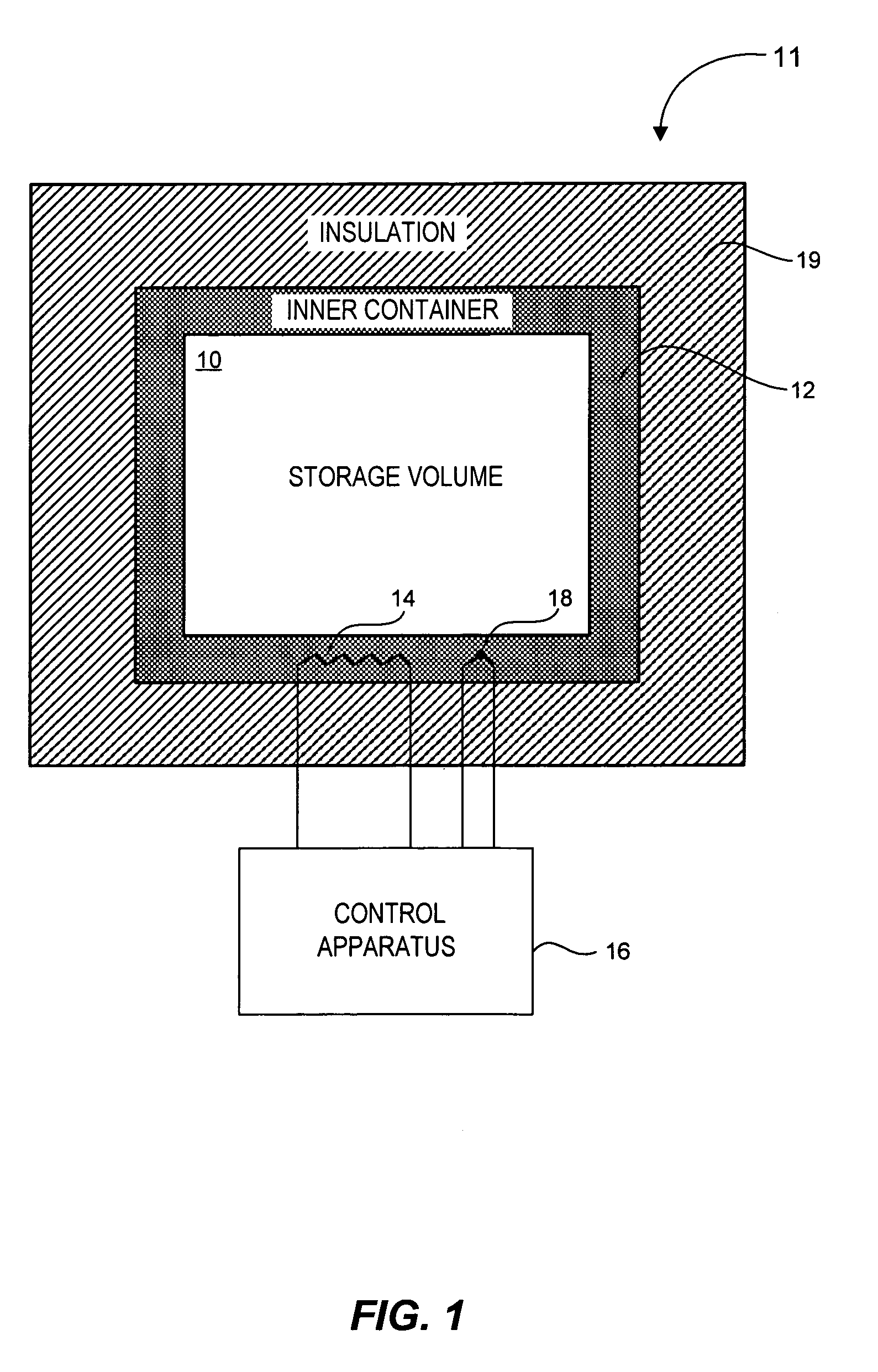

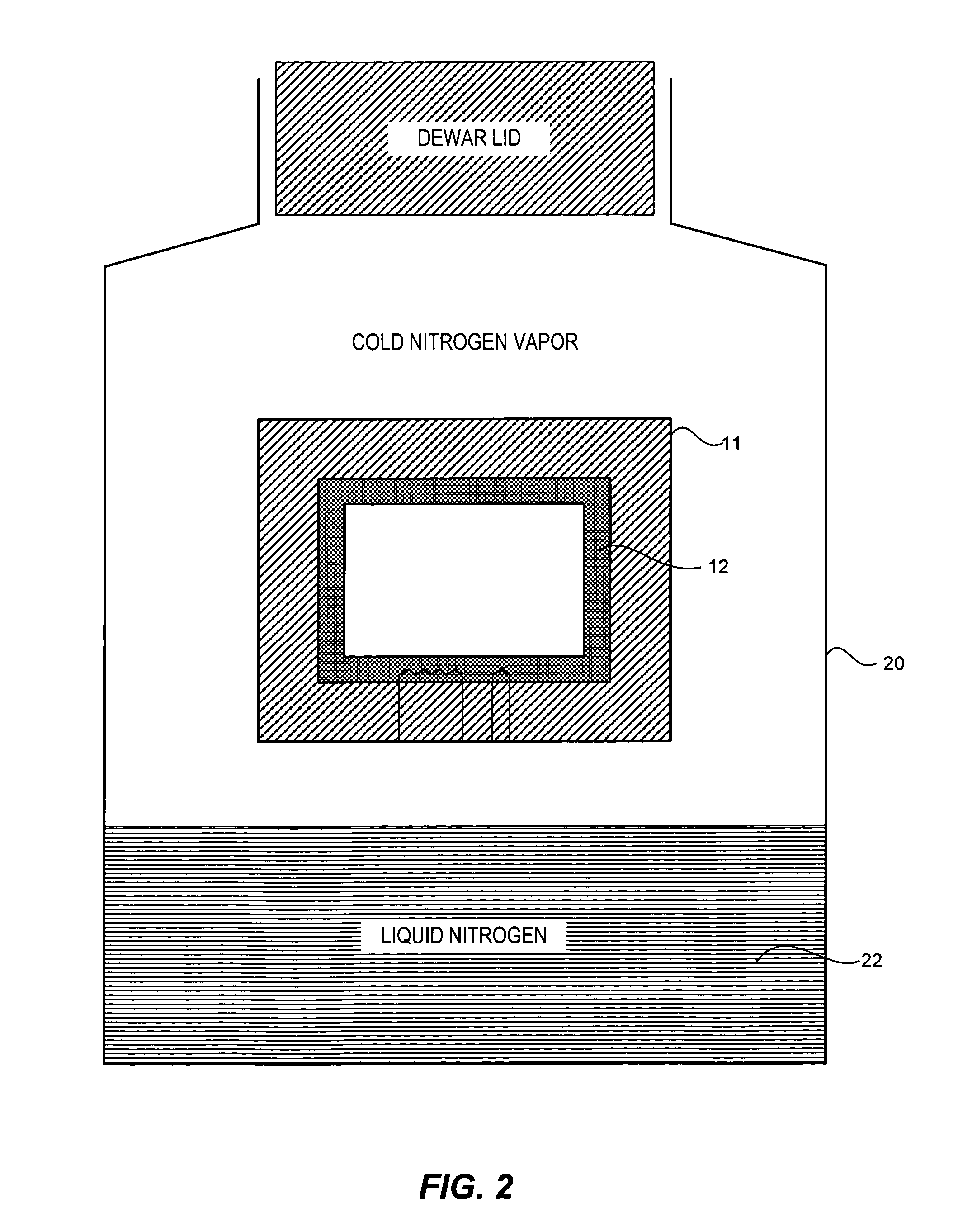

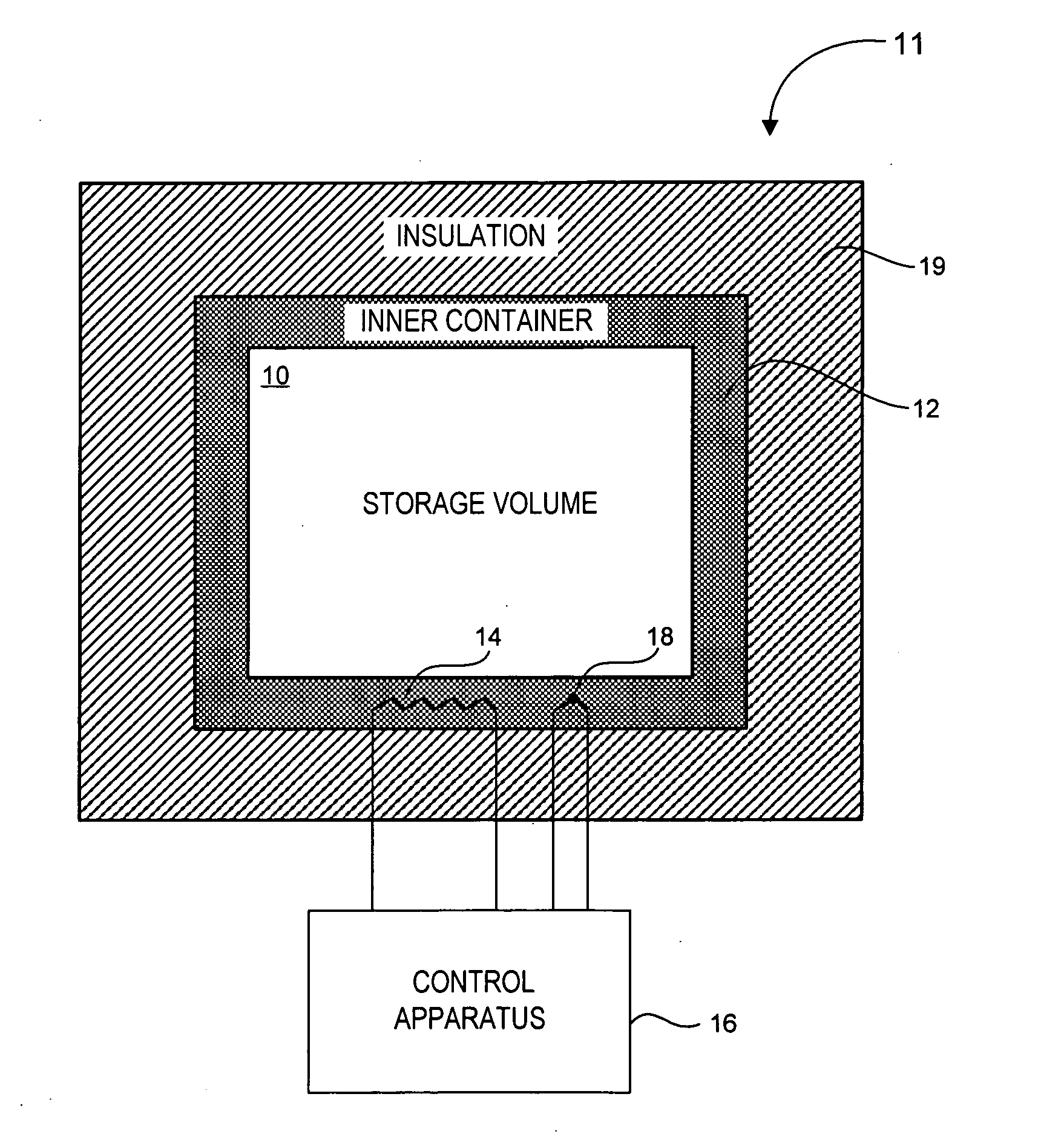

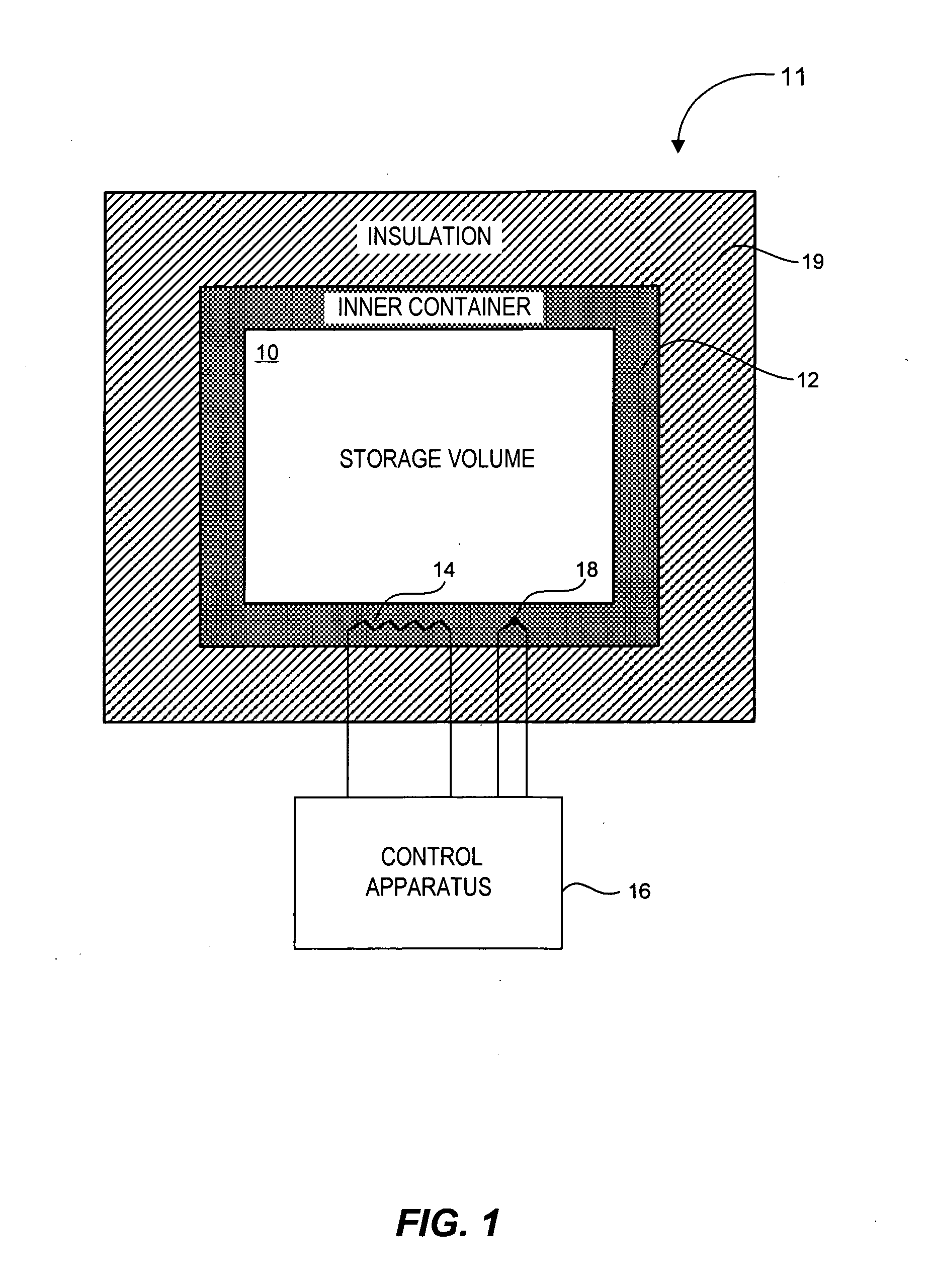

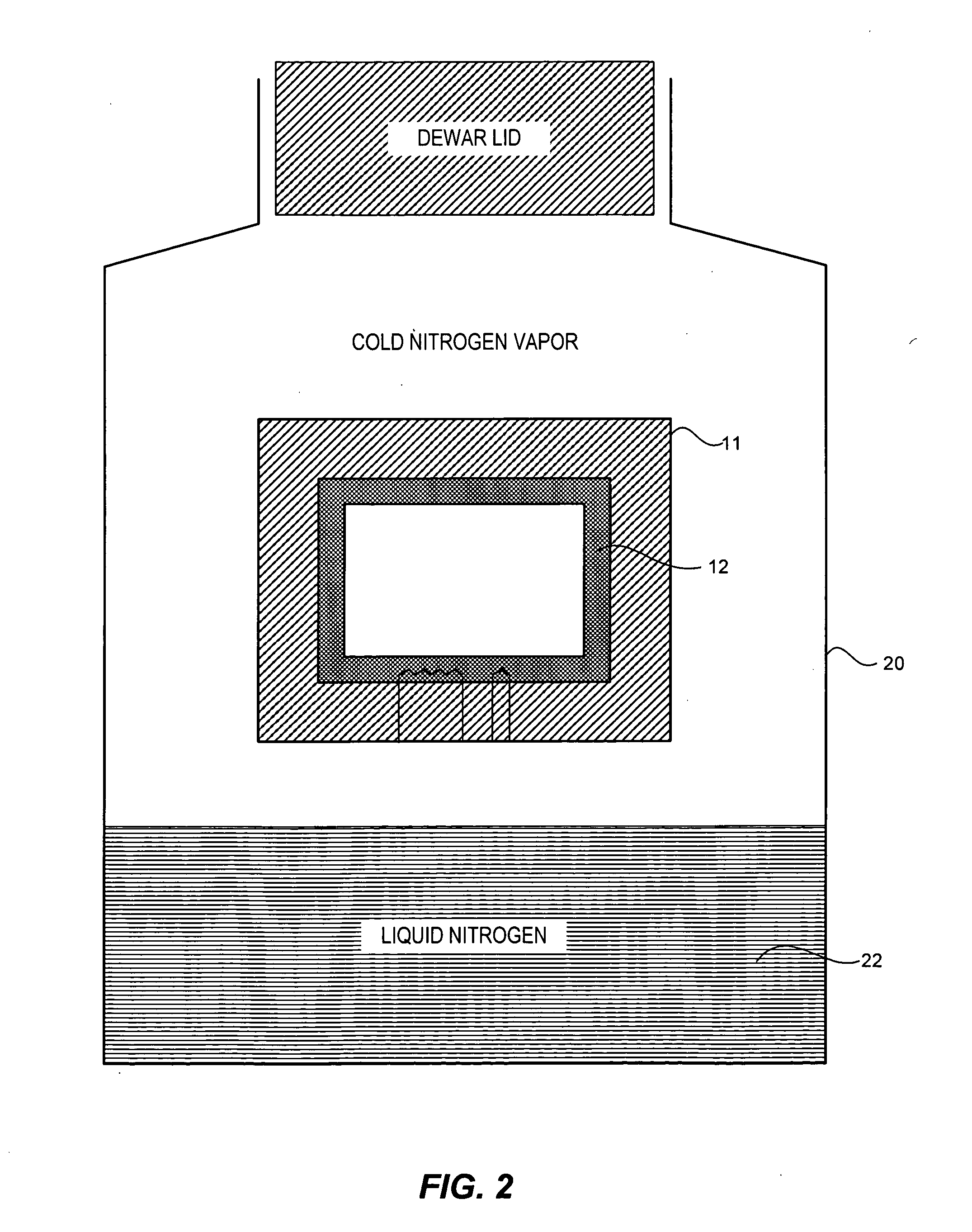

Cryogenic storage system

ActiveUS7278278B2Improve temperature stabilityNon-uniform temperatureVessel mounting detailsDomestic cooling apparatusThermal insulationEngineering

Owner:21ST CENTURY MEDICINE

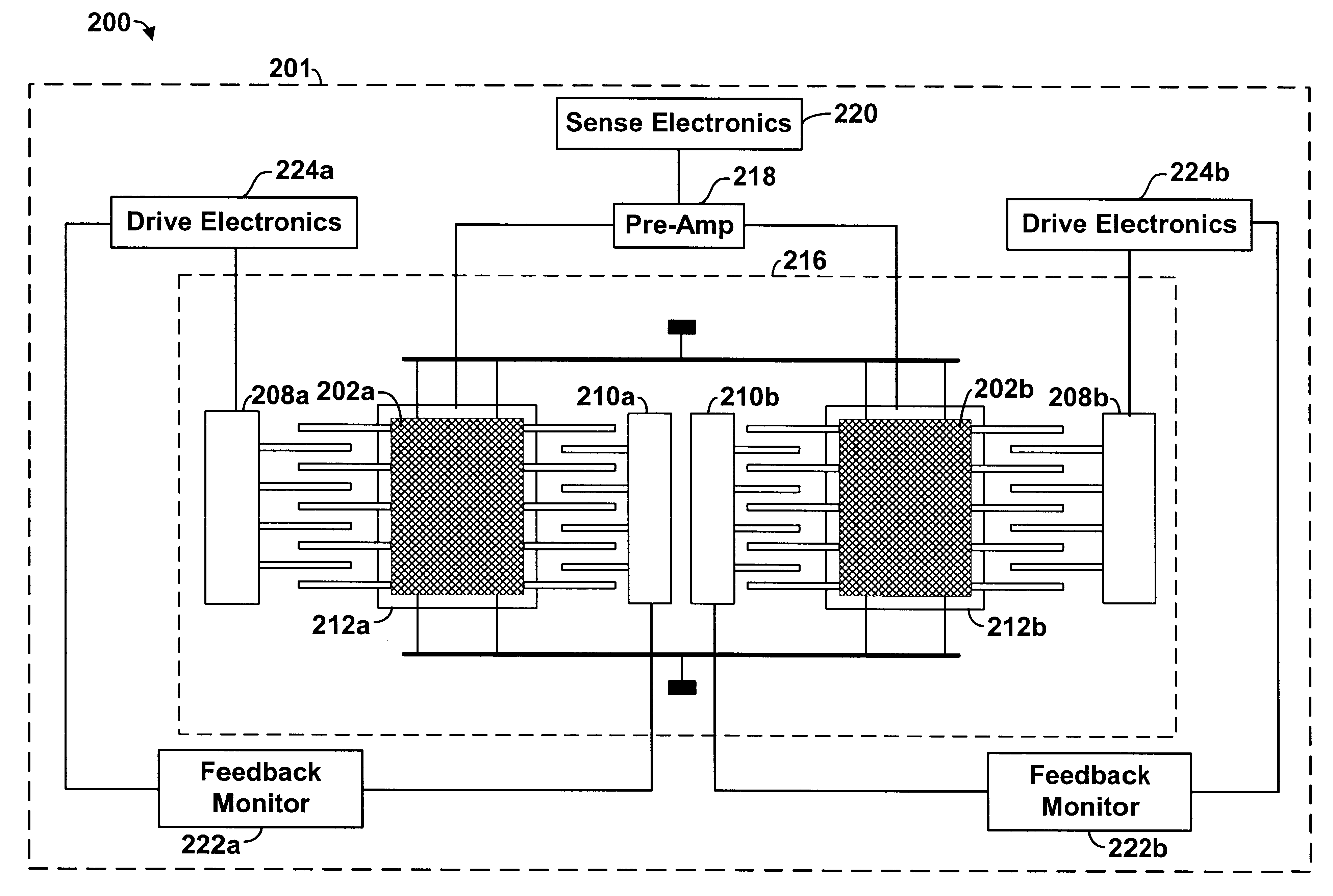

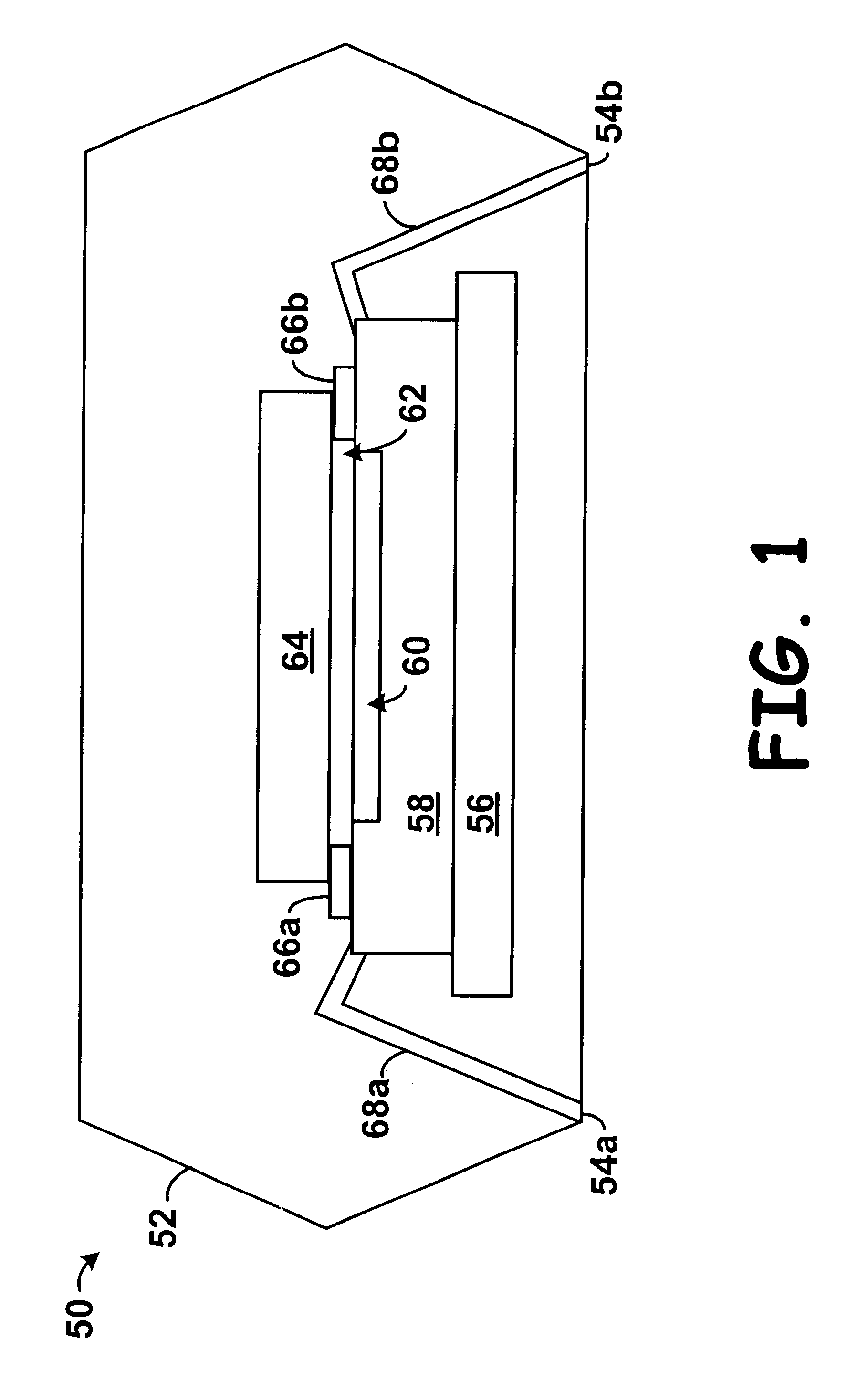

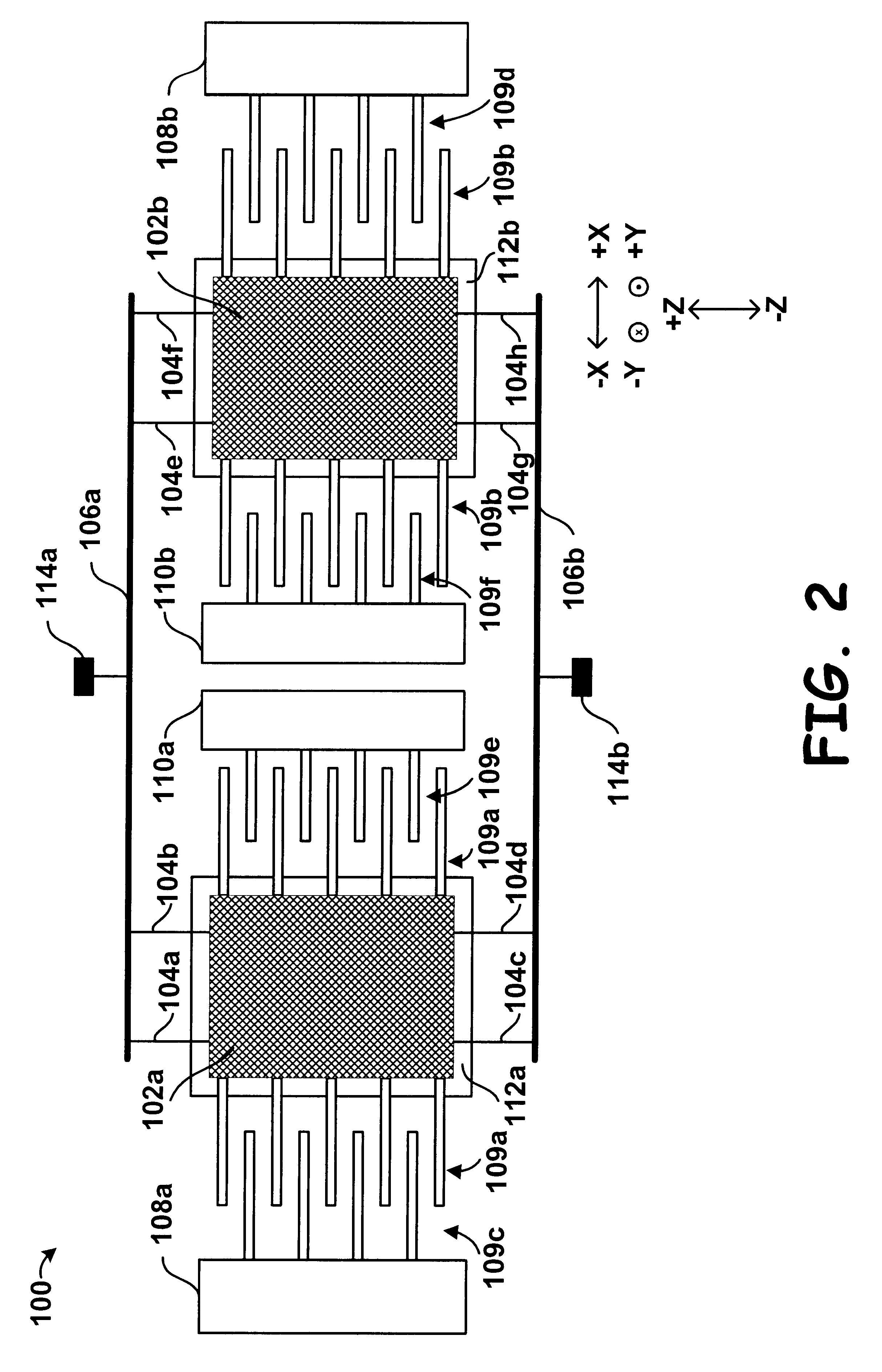

Cyrogenic inertial micro-electro-mechanical system (MEMS) device

InactiveUS6487864B1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeAudio power amplifier

A cryogenic inertial Micro-Electro-Mechanical System (MEMS) device is provided. The device may include a vibratory gyroscope operable to sense a rotational acceleration. The device may also include a pre-amplifier co-located in a close proximity to the vibratory gyroscope. The device may be operated at substantially low temperatures, such as cryogenic temperatures, to reduce electrical noise and improve stability of outputs of the system.

Owner:HONEYWELL INT INC

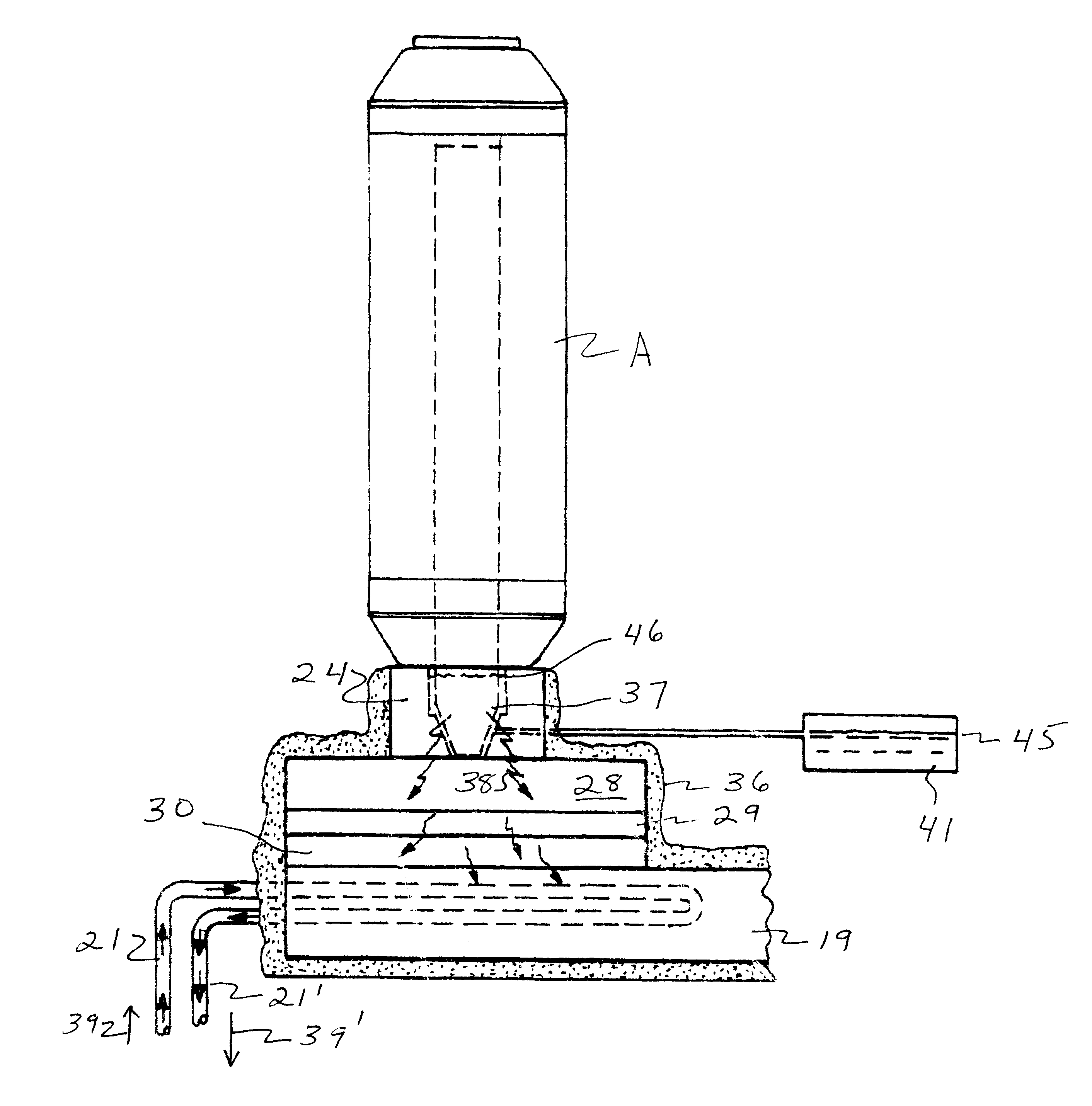

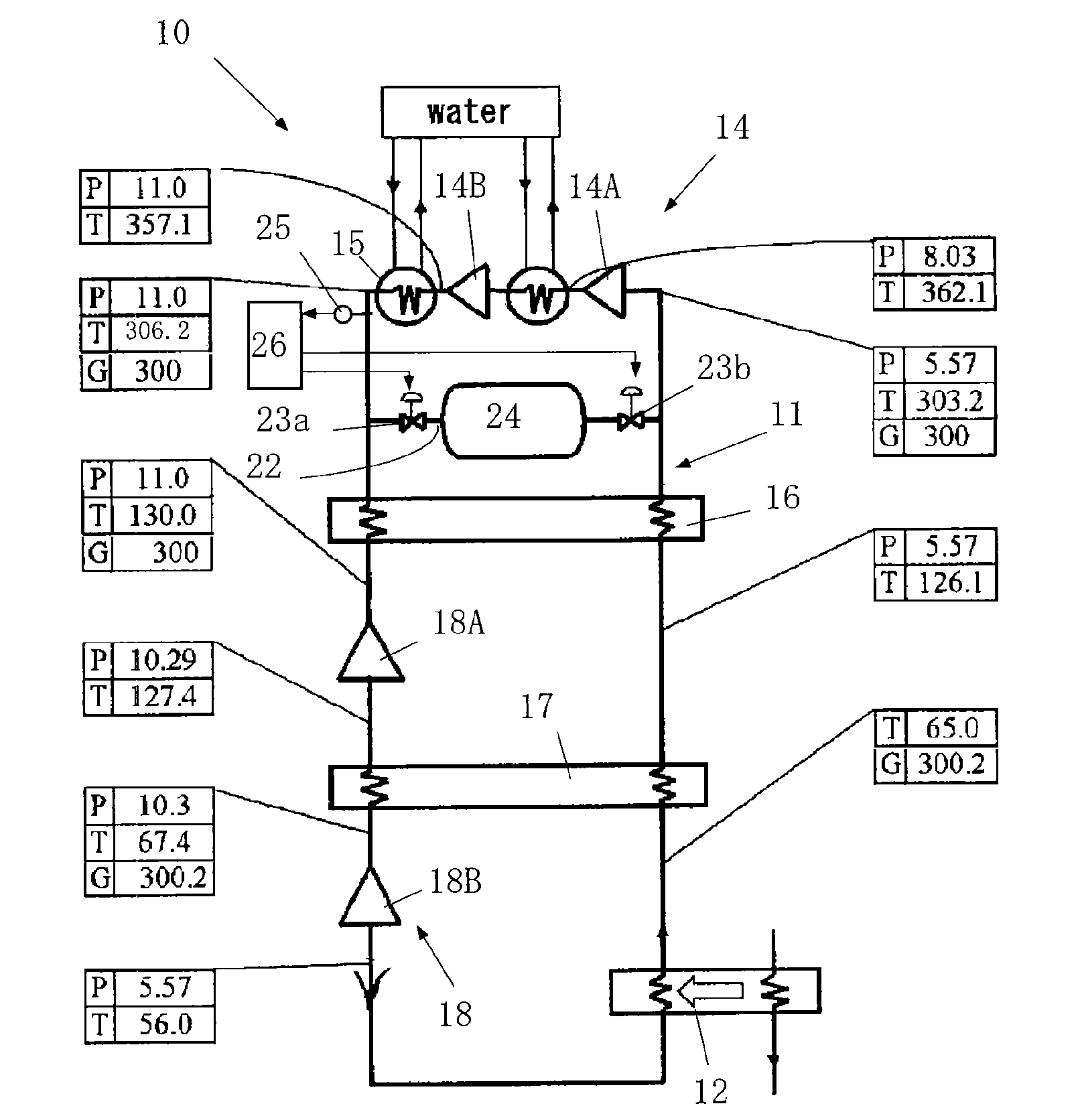

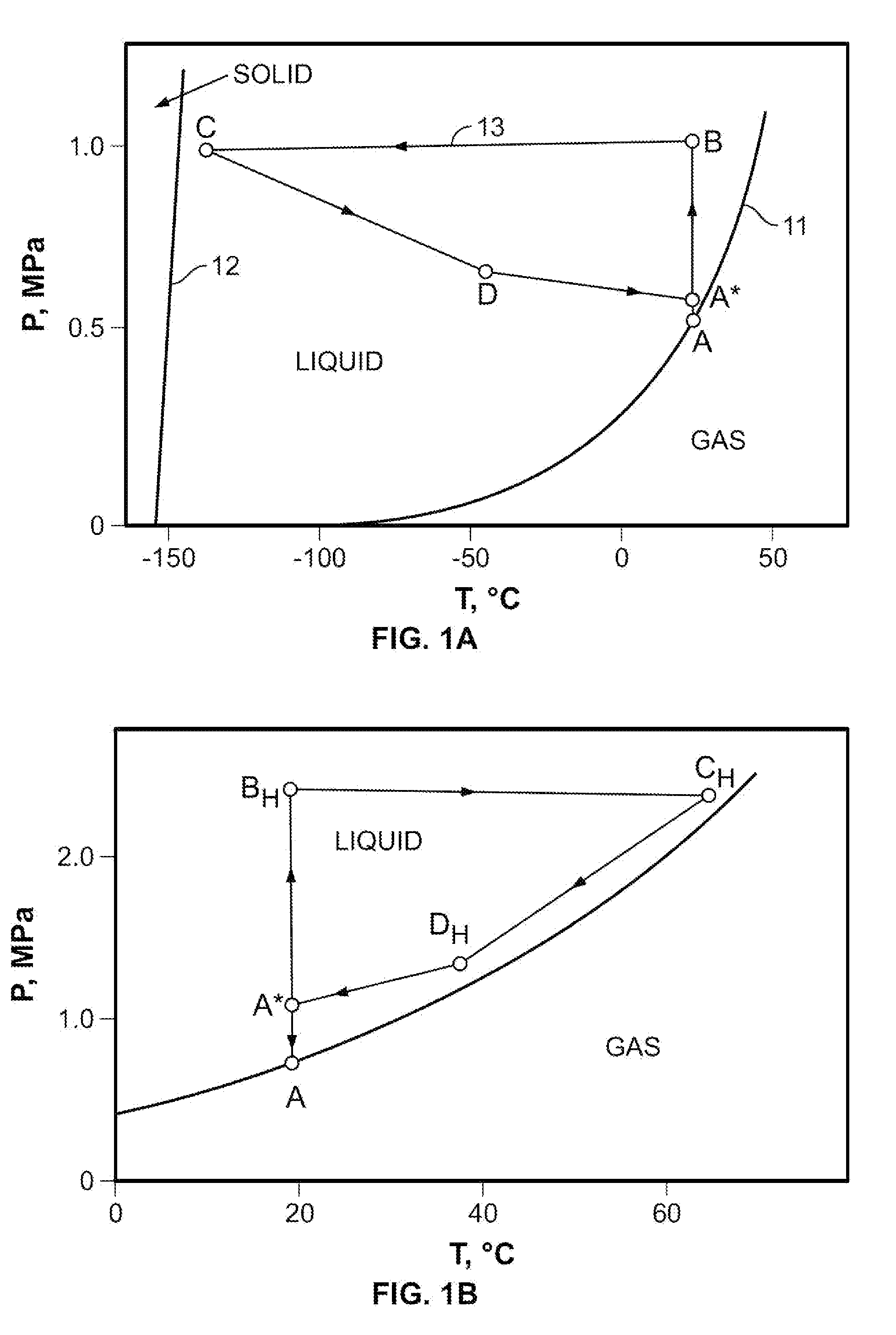

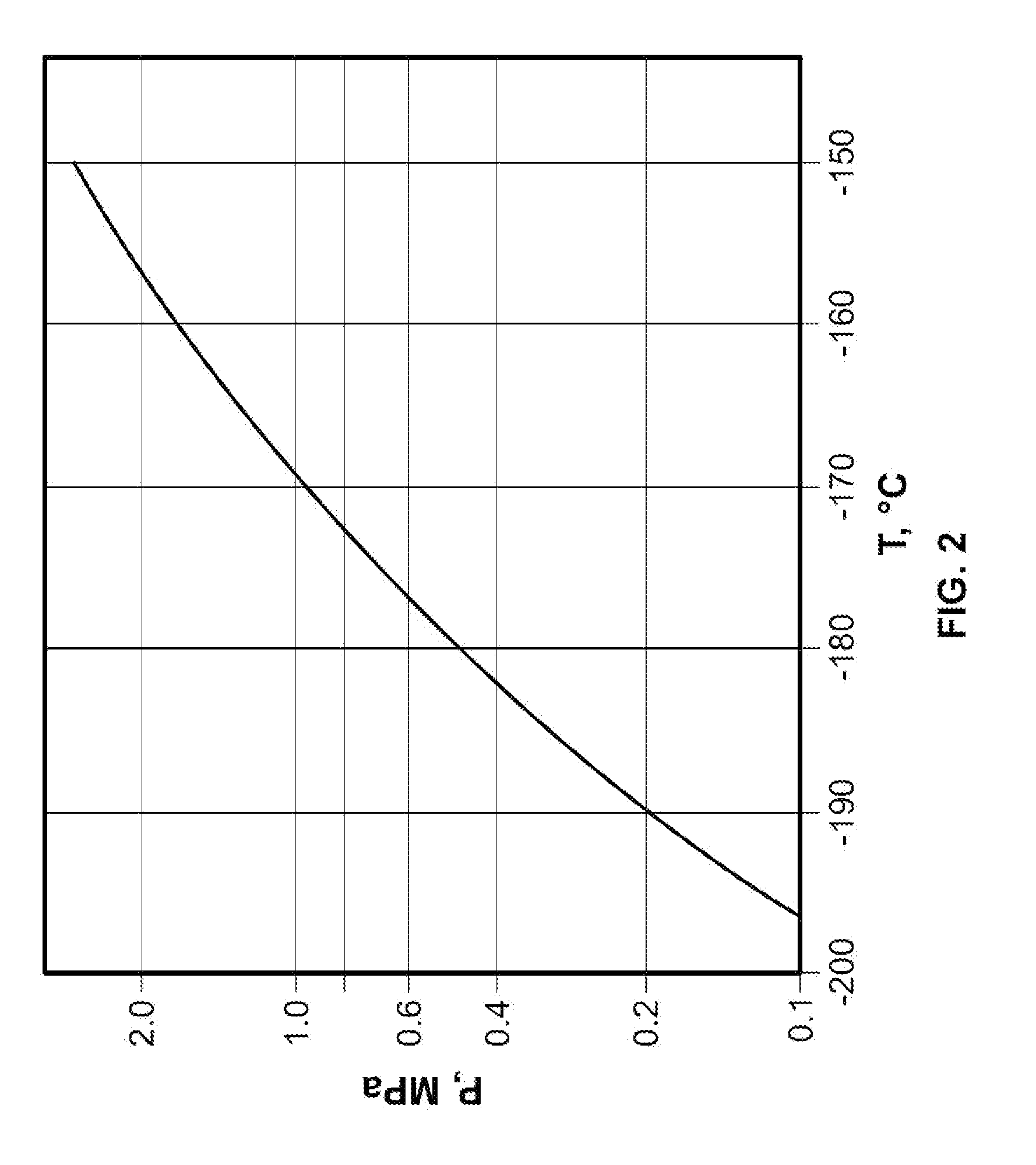

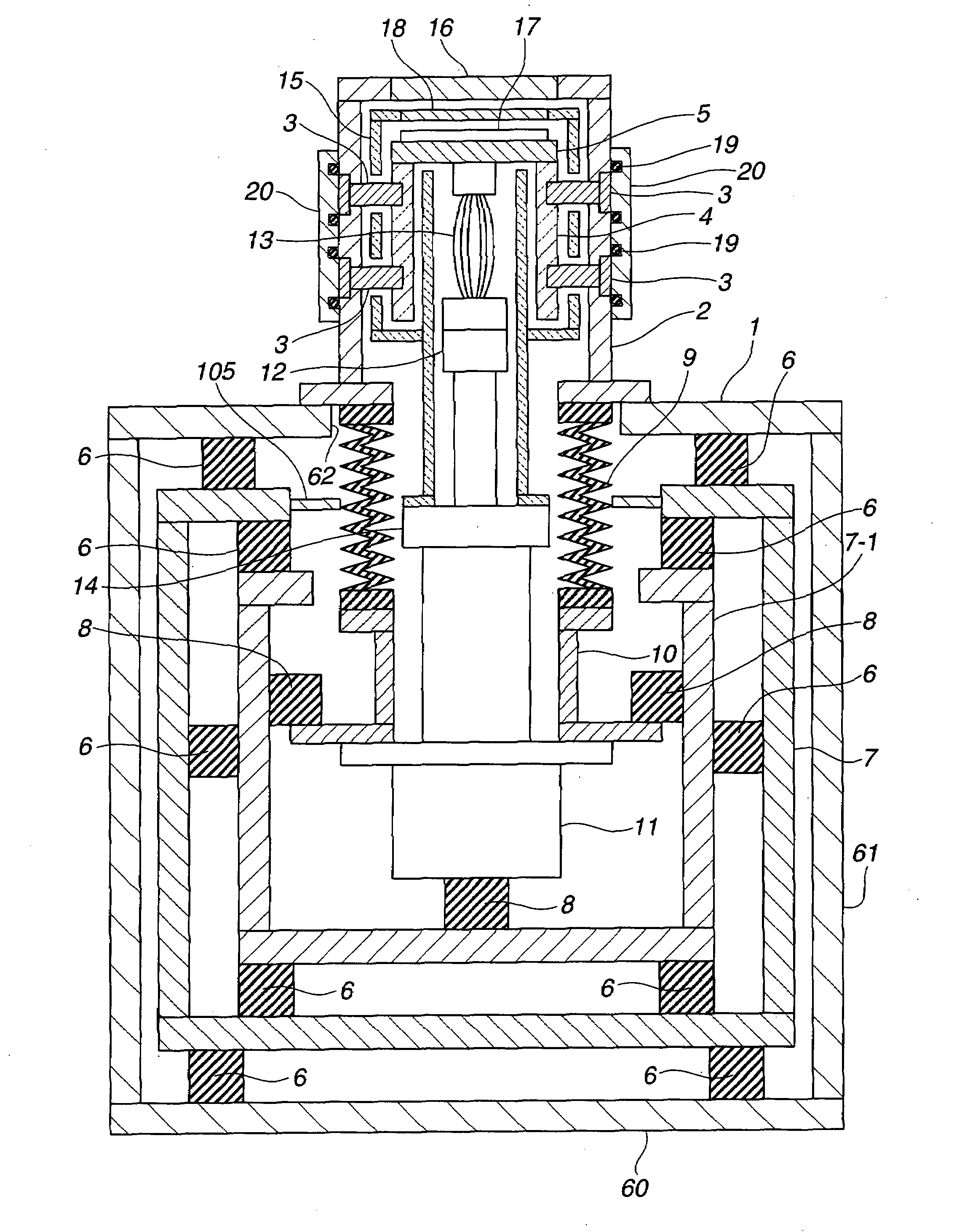

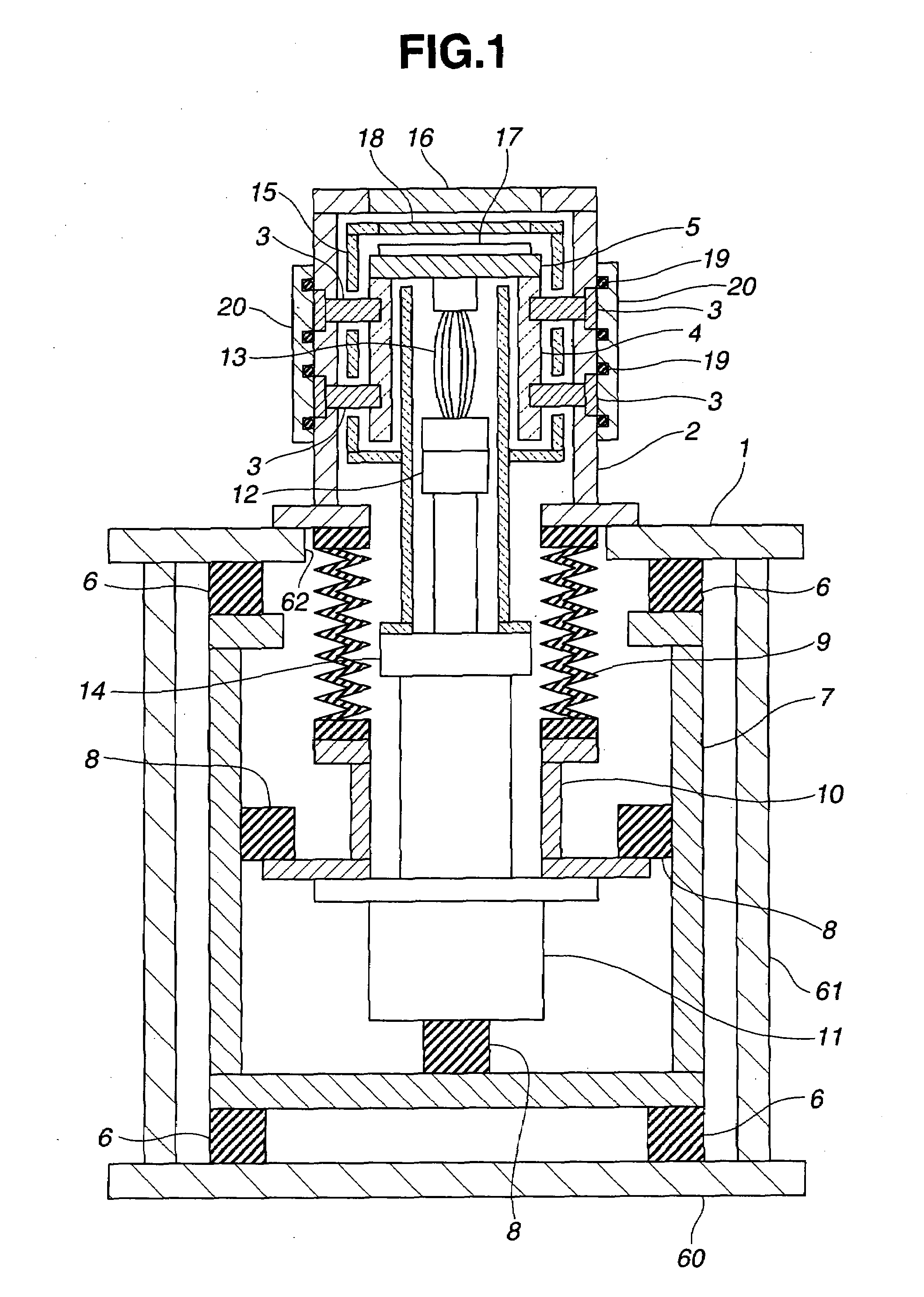

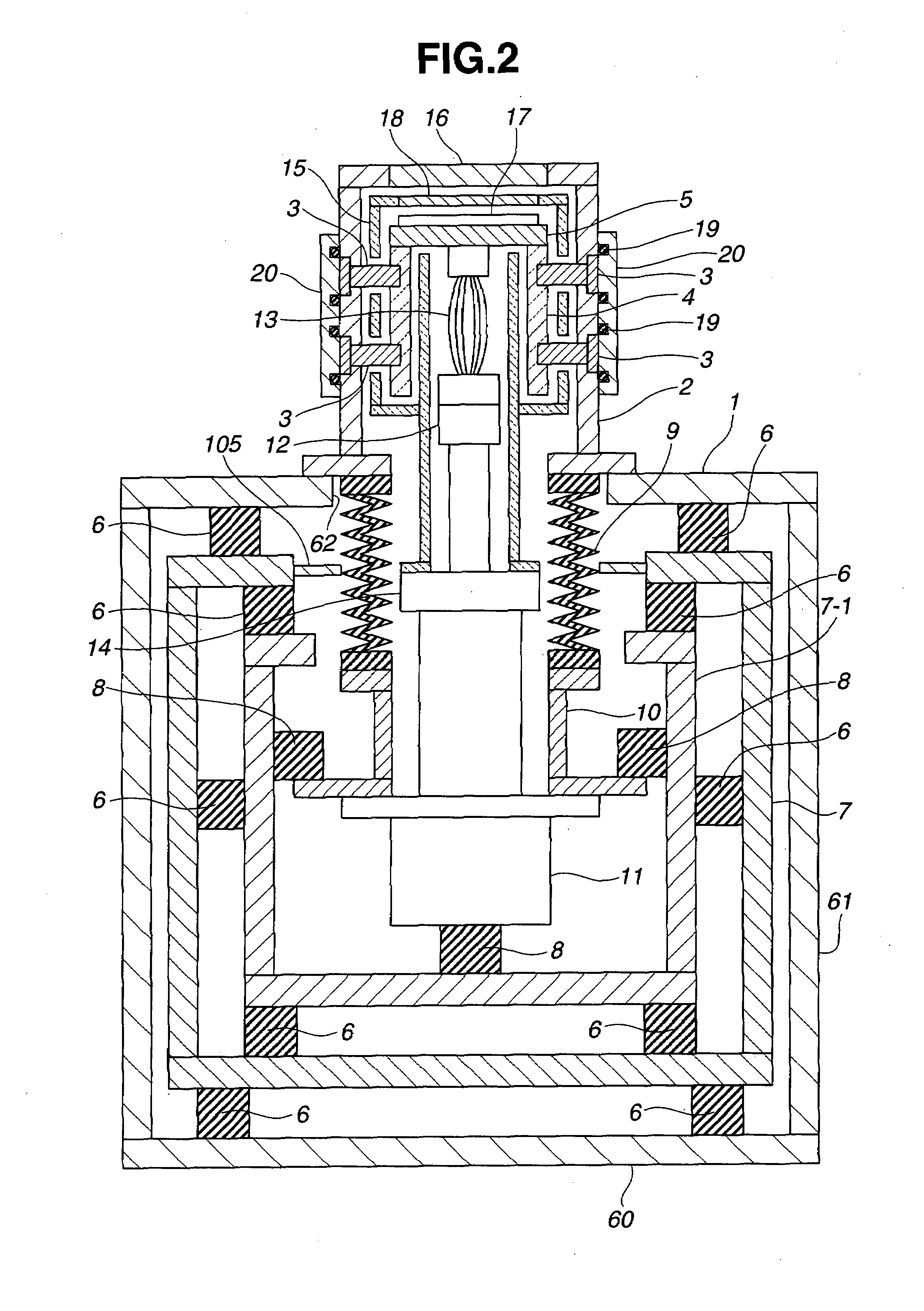

Cryogenic refrigerator and control method therefor

InactiveUS20100275616A1Smooth rotationPrevent reversalSolidificationLiquefactionClosed loopRoom temperature

A cryogenic refrigerator (10) which generates a cryogenic temperature by compressing and expanding a working gas in a closed loop (11). The cryogenic refrigerator comprises a bypass line (22) allowing a high-pressure portion and a low-pressure portion to communicate with each other, a gas storage tank (24) located midway in the bypass line and having pressure regulation valves (23a, 23b) on the high-pressure side and the low-pressure side, respectively, and a pressure control unit (26) controlling the pressure regulation valves. The pressure control unit (26) controls the pressure regulation valves (23a, 23b) so that the pressure in the gas storage tank (24) is equal to the pressure in the closed loop at room temperature and in a stopped state and so that the pressure in the gas storage tank (24) is between the pressures in the high-pressure portion and in the low-pressure portion and is close to the pressure in the low-pressure portion in an operating state.

Owner:IHI CORP

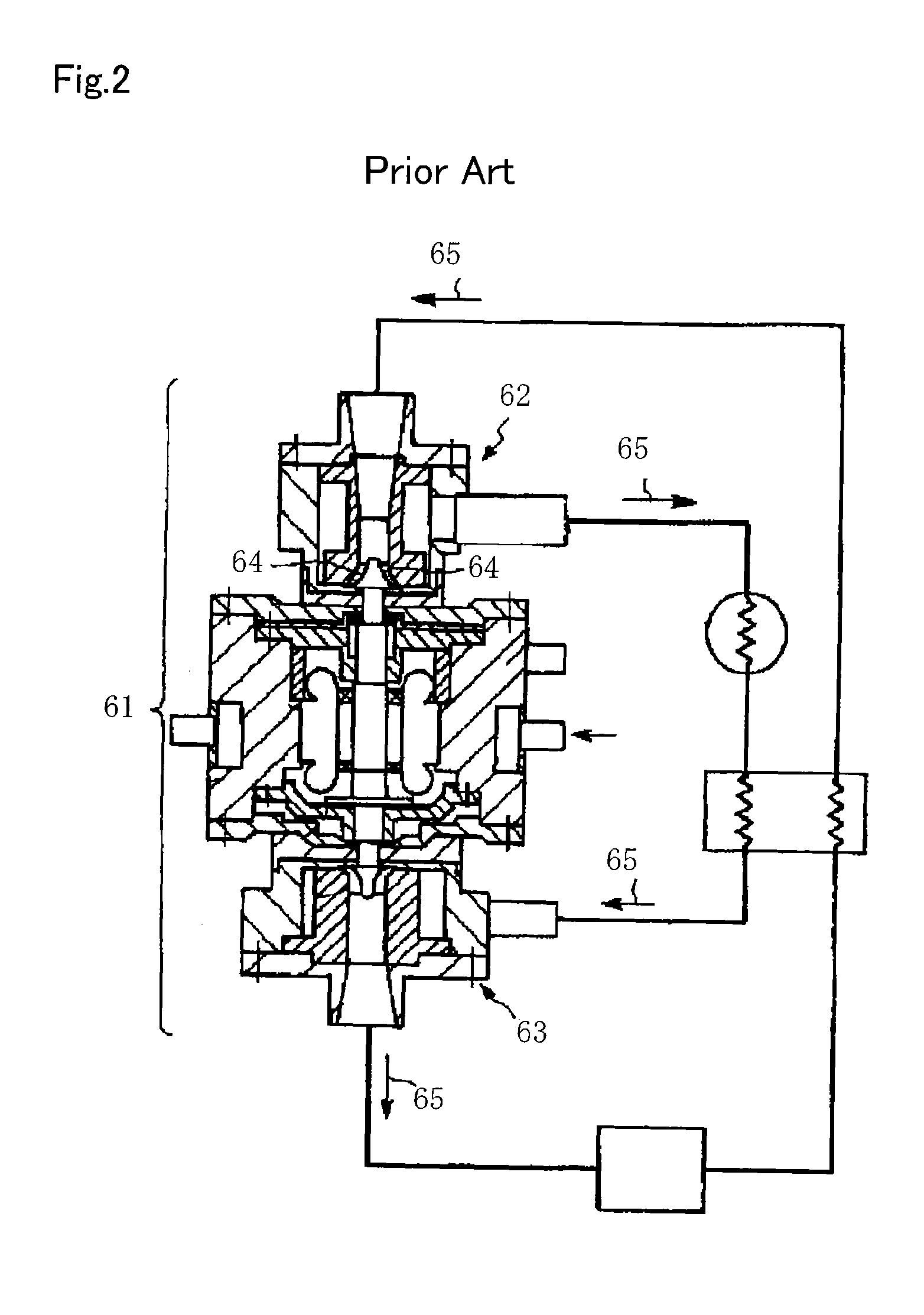

Superconductive magnet including a cryocooler coldhead

ActiveUS20060022779A1Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

A zero boiloff cryogen cooled recondensing superconducting magnet assembly including superconducting magnet coils suitable for magnetic resonance imaging including a cryogen pressure vessel to contain a liquid cryogen reservoir to provide cryogenic temperatures to the magnet coils for superconducting operation; a vacuum vessel surrounding the pressure vessel and spaced therefrom; a first thermal shield surrounding and spaced from the pressure vessel; a second thermal shield surrounding and spaced from the first thermal shield and intermediate the vacuum vessel and the first shield; a cryocooler thermally connected by a first and a second thermal interface to the first and second thermal shields, respectively; a recondenser positioned in the space between the pressure vessel and the first thermal shield and thermally connected by a thermal interface to the cryocooler to recondense, back to liquid, cryogen gas provided from the pressure vessel; and means for returning the recondensed liquid cryogen the pressure vessel; wherein the second thermal shield surrounding the first thermal shield reduces a radiation heat load from the first thermal shield to the pressure vessel lowering boiloff of cryogen gas under conditions of failure or power off of the cryocooler.

Owner:GENERAL ELECTRIC CO

Cryogenic storage system

ActiveUS20050016198A1Improve temperature stabilityNon-uniform temperatureVessel mounting detailsDomestic cooling apparatusThermal insulationEngineering

The present invention provides devices and methods for the cryogenic storage of biological material. Devices of the invention are useful for storing material at a cryogenic temperature. The devices include a temperature chamber defined by a thermally-conductive container and at least one layer of thermal insulation surrounding the thermally-conductive container. Some embodiments utilize one or more heat sources thermally connected to the thermally conductive container. Other embodiments are arranged so that no net flow of heat occurs from the temperature chamber when the temperature chamber is at a set target temperature. Also provided are methods of using the devices.

Owner:21ST CENTURY MEDICINE

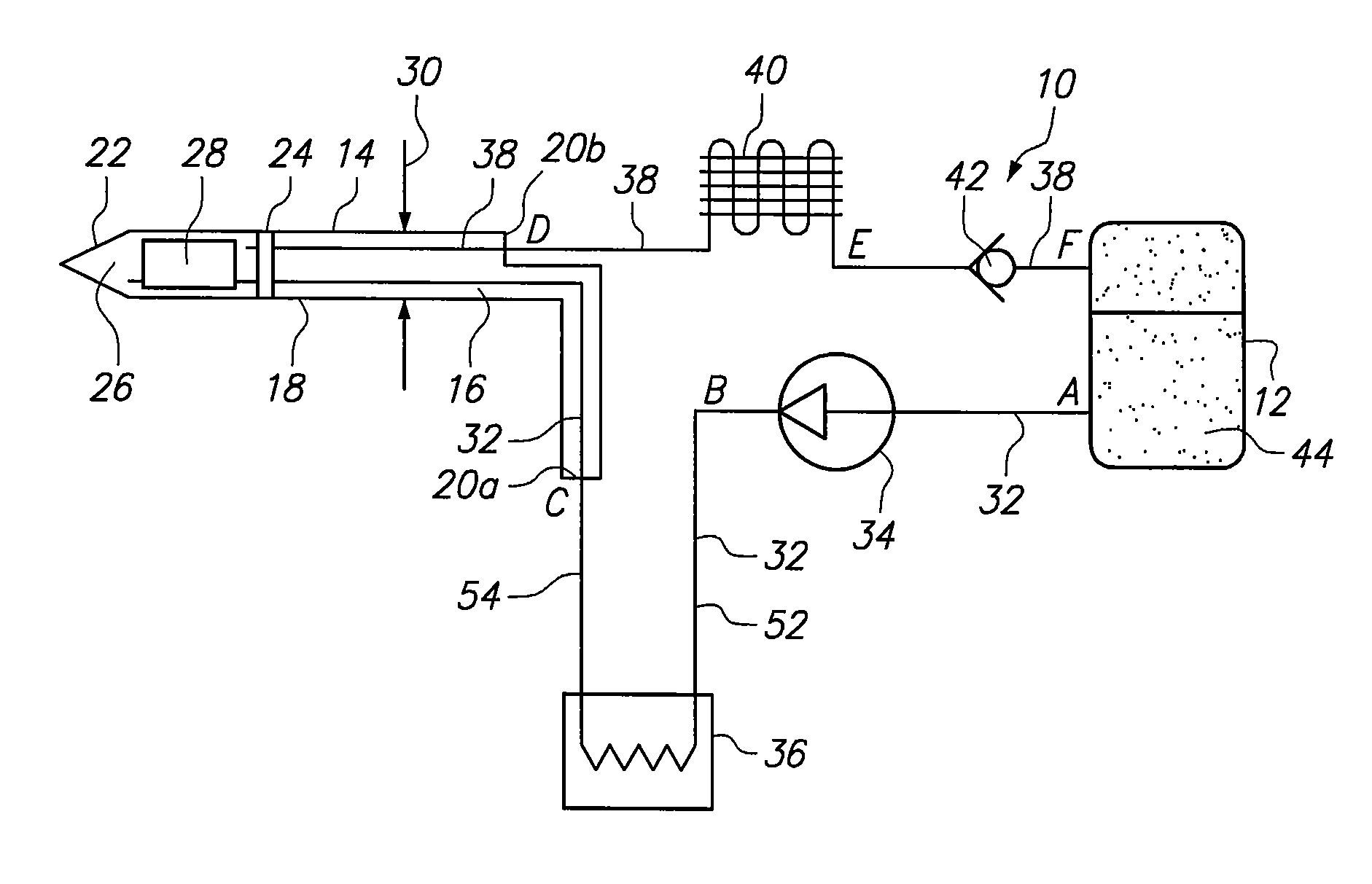

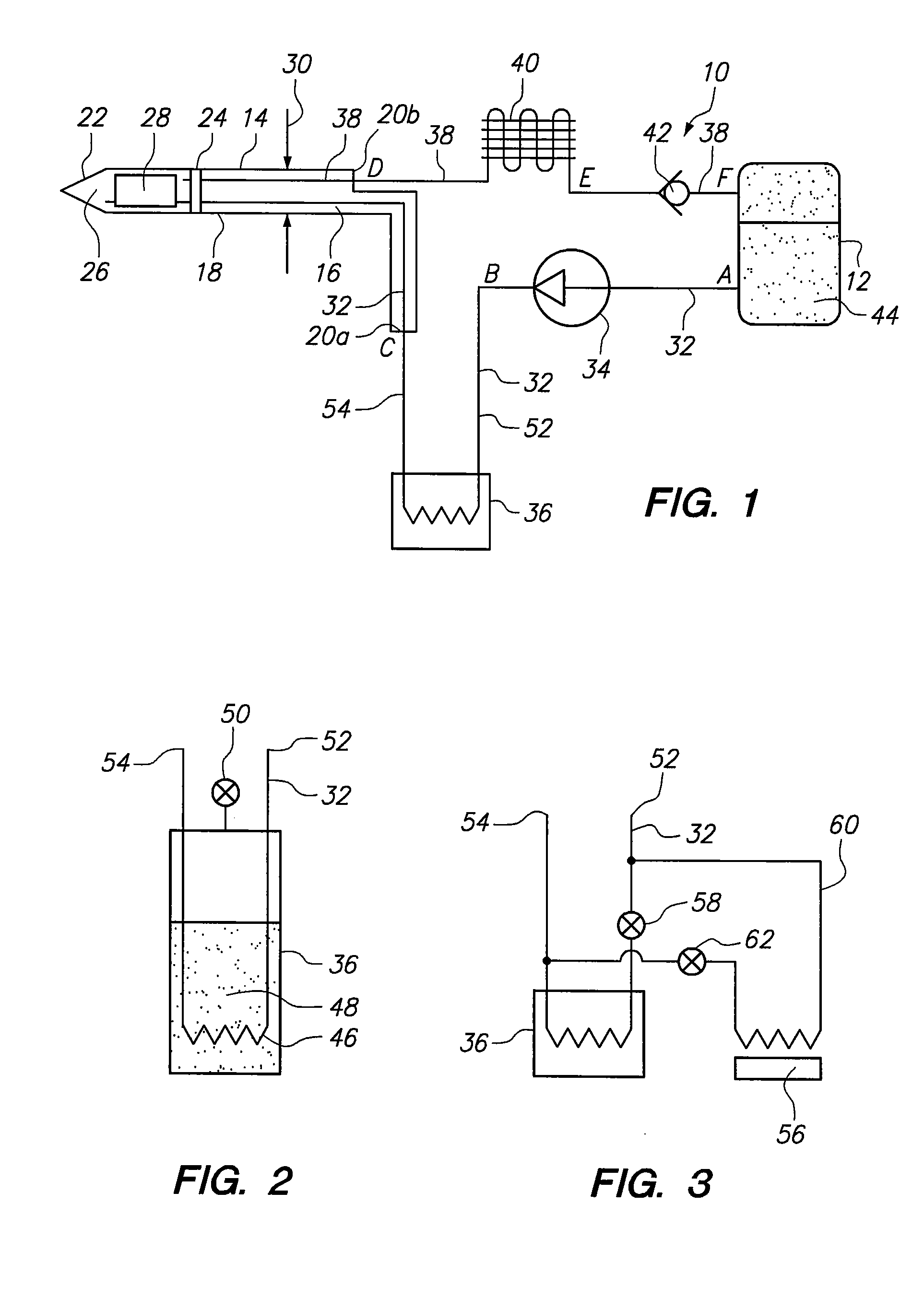

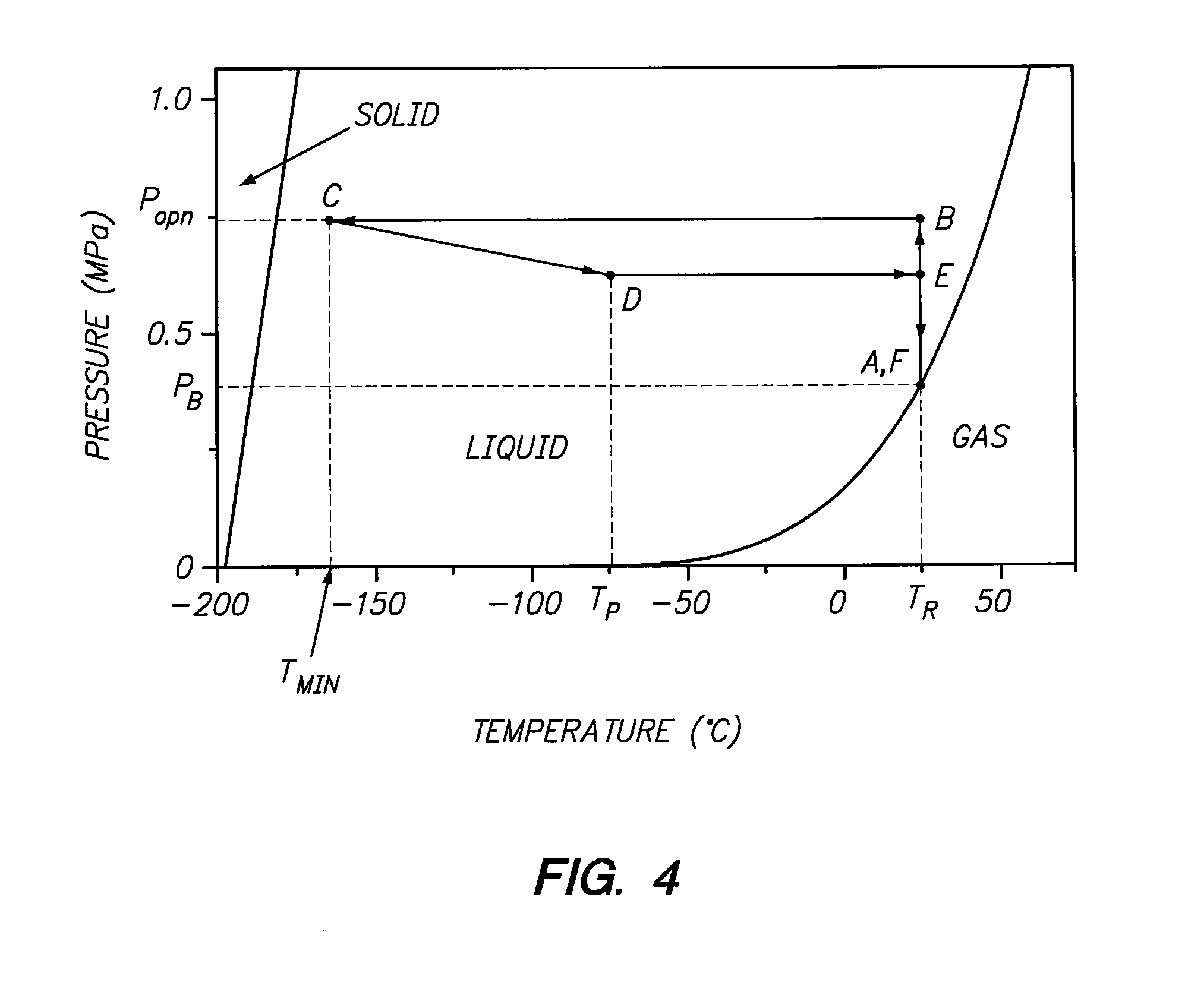

Method and System for Cryoablation Treatment

A system and a method for its use are provided to cool a cryotip at the distal end of a probe for a cryosurgical procedure. In particular, the cryotip is cooled by a liquid refrigerant to cryogenic temperatures in order to perform a cryosurgical procedure on biological tissue. The system is closed-loop, and during transit of the liquid refrigerant through the entire system, the liquid refrigerant always remains in a liquid state at a relatively low pressure.

Owner:CRYOMEDIX

Single phase liquid refrigerant cryoablation system with multitubular distal section and related method

InactiveUS20100256621A1Reduce pressureReduce stressCatheterSurgical instruments for coolingEvaporationRefrigerant

Single phase liquid refrigerant cryoablation systems and methods are described herein. The cryoablation systems drive liquid cryogen or refrigerant along a closed fluid pathway without evaporation of the liquid cryogen. A cryoprobe includes a distal energy delivery section to transfer energy to the tissue. A plurality of cooling microtubes positioned in a distal section of the cryoprobe transfer cryogenic energy to the tissue. The plurality of microtubes in the distal section are made of materials which exhibit flexibility at cryogenic temperature ranges, enabling the distal section of the cryoprobe to bend and conform to variously shaped target tissues.

Owner:CRYOMEDIX

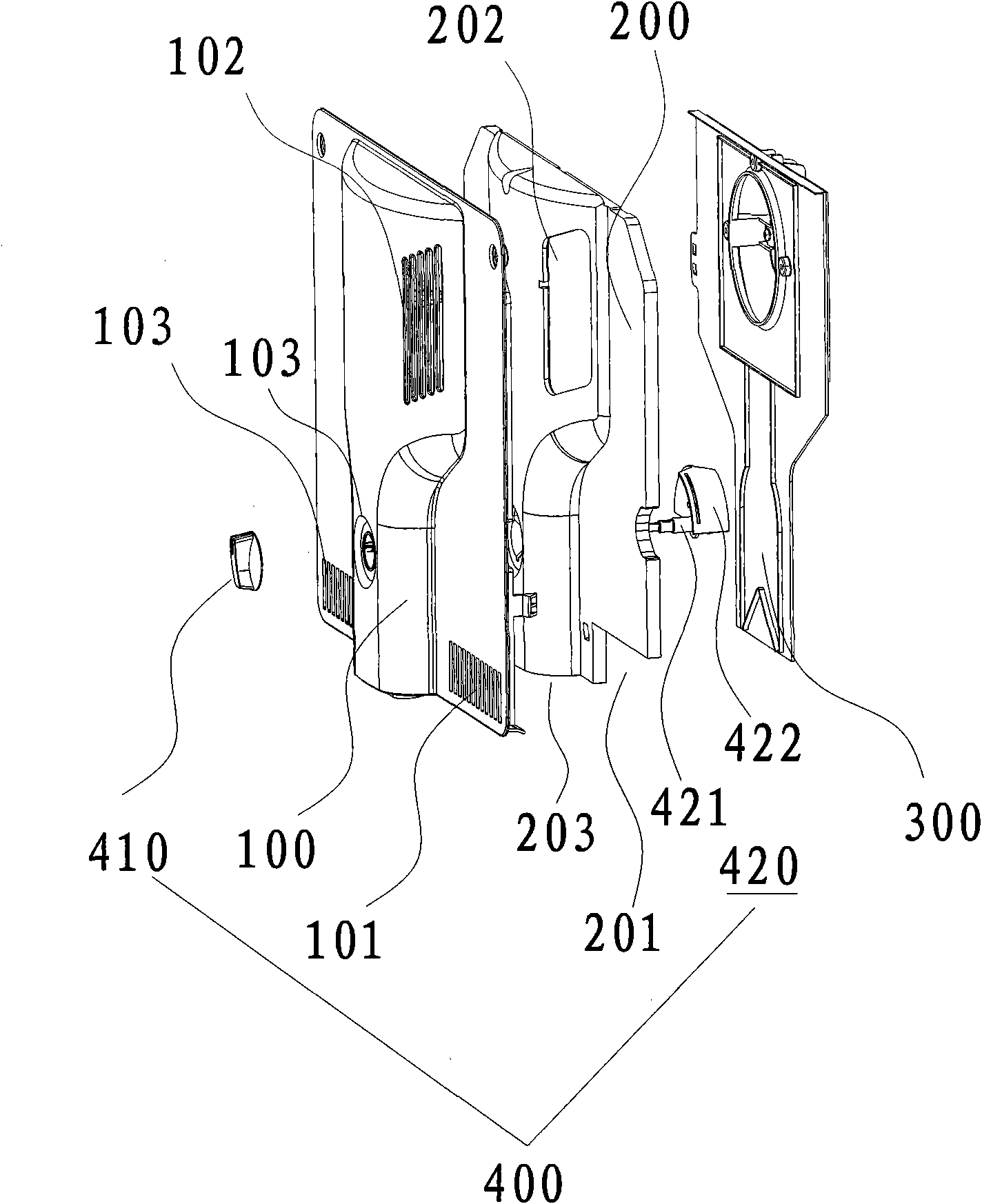

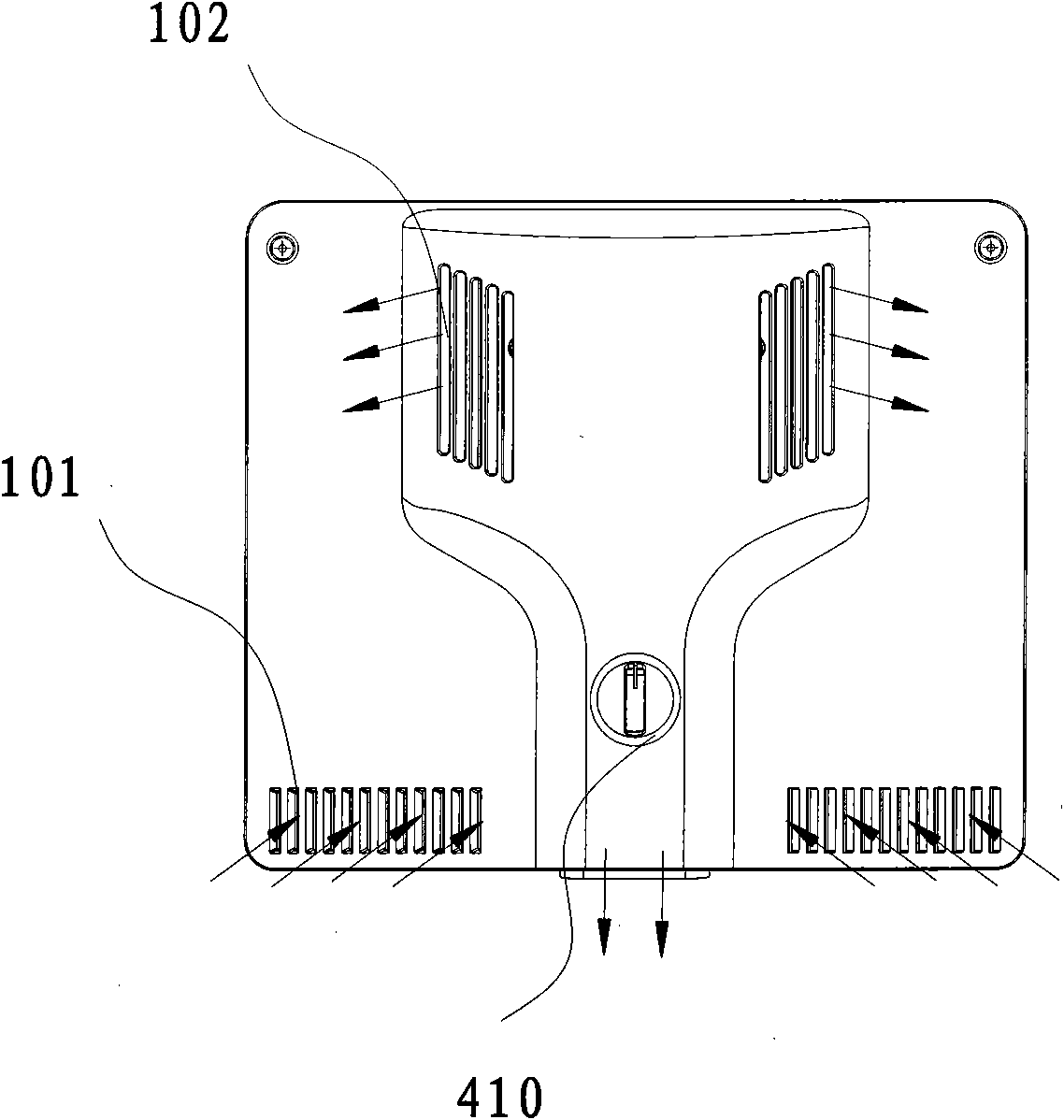

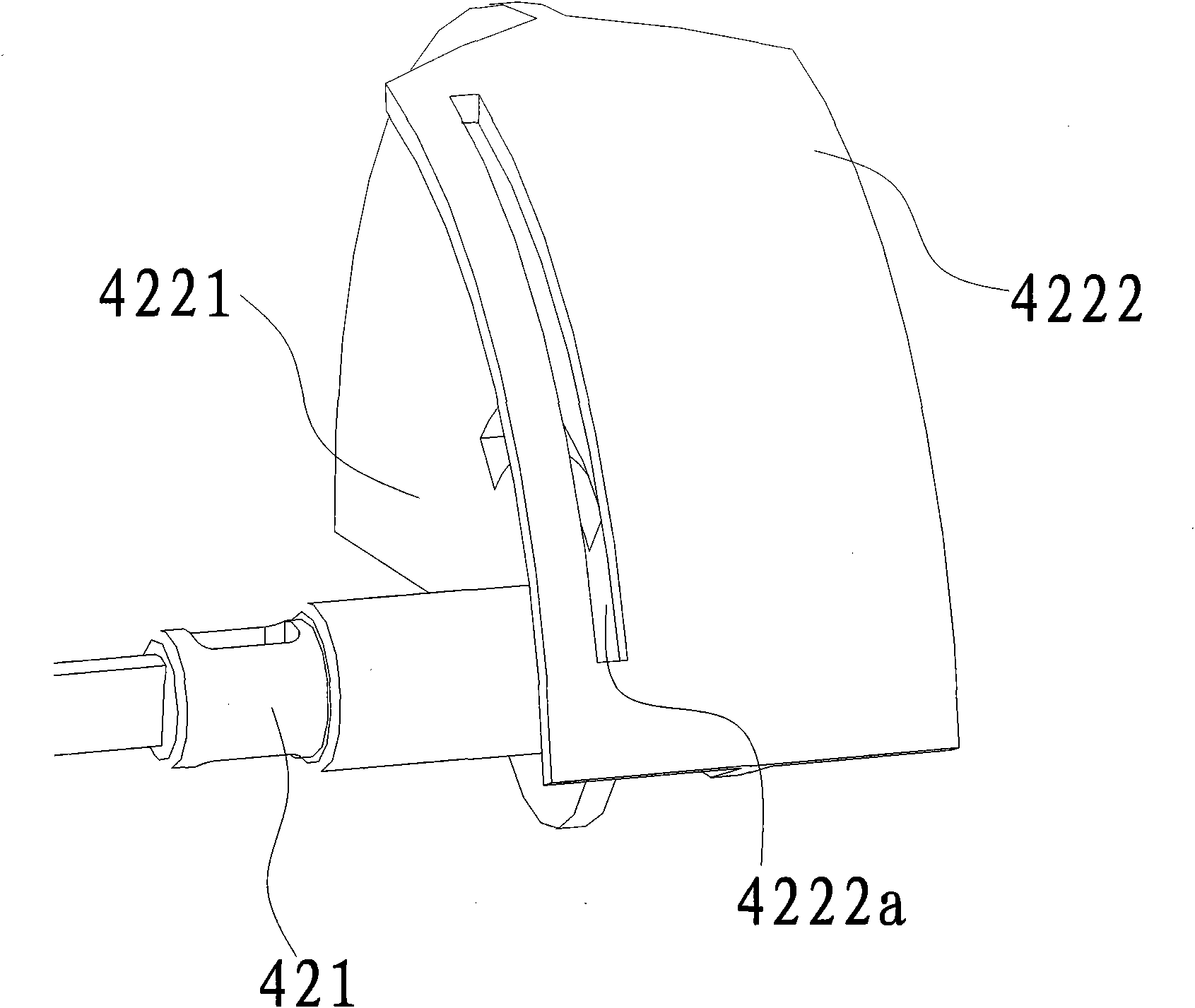

Air flue device and refrigerator with same

ActiveCN101975497ARealize regulationImprove heat exchange efficiencyLighting and heating apparatusDomestic refrigeratorsAir volumeGrating

The invention provides an air flue device, which comprises an air flue rear cover plate, an air flue foam piece, an air flue front cover plate and an air quantity adjusting mechanism, wherein the air flue foam piece is matched with the air flue rear cover plate to define an air outlet flue therebetween, an air inlet is formed on the lower part of the air flue foam piece, a first air outlet is formed on the upper part of the air flue foam piece, the upper end of the air flue is closed, and a second air outlet is formed at the lower end of the air flue; the air flue front cover plate is matchedon the outer surface of the air flue foam piece and provided with an air outlet grating and an air inlet grating corresponding to the first air outlet and the air inlet respectively; and at least onepart of the air quantity adjusting mechanism is rotationally arranged in the air flue and positioned between the first air outlet and the second air outlet, and the air quantity adjusting mechanism is used for adjusting the air outlet quantity of the second air outlet. According to the air flue device, the air volume at the air outlet can be controlled more easily, and the cryogenic temperature can be regulated.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Method for preparing high-strength heat-resistant and cold-resistant modified polypropylene pipe

ActiveCN102966801AImprove toughnessGood strength performanceRigid pipesMasterbatchEngineering plastic

The invention discloses a method for preparing a high-strength heat-resistant and cold-resistant modified polypropylene pipe. The pipe is formed by the following steps of: extruding an outer layer, a middle transition layer and an inner wall layer onto the same one mold through three extruders, fusing and compounding. The outer layer of the pipe consists of modified polypropylene, an impact-resistant modifying agent, an antibacterial agent, a light stabilizer, an antioxygen, a compatibilizer, nanometer materials, a tackifier and a color masterbatch in parts by weight; the middle transition layer of the pipe consists of engineering plastics, the modified polypropylene, the compatibilizer, the a tackifier and the color masterbatch in parts by weight; and the inner wall layer of the pipe consists of the engineering plastics, the modified polypropylene, the compatibilizer, a fortifier, a filler, the nanometer materials and the color masterbatch in parts by weight. Compared with traditional similar pipes, the operating temperature of the pipe prepared by the method disclosed by the invention is improved by 30-70 DEG C; the cold-resistant temperature is lowered by minus 15-minus 30 DEG C; the pressure-resistant property is improved by 30-50 percent; the creep resistance is improved by 100-200 percent; the service life is prolonged by 10-20 years; and the wall thickness of the pipe is reduced by 20-50 percent.

Owner:HONGYUE PLASTIC GROUP

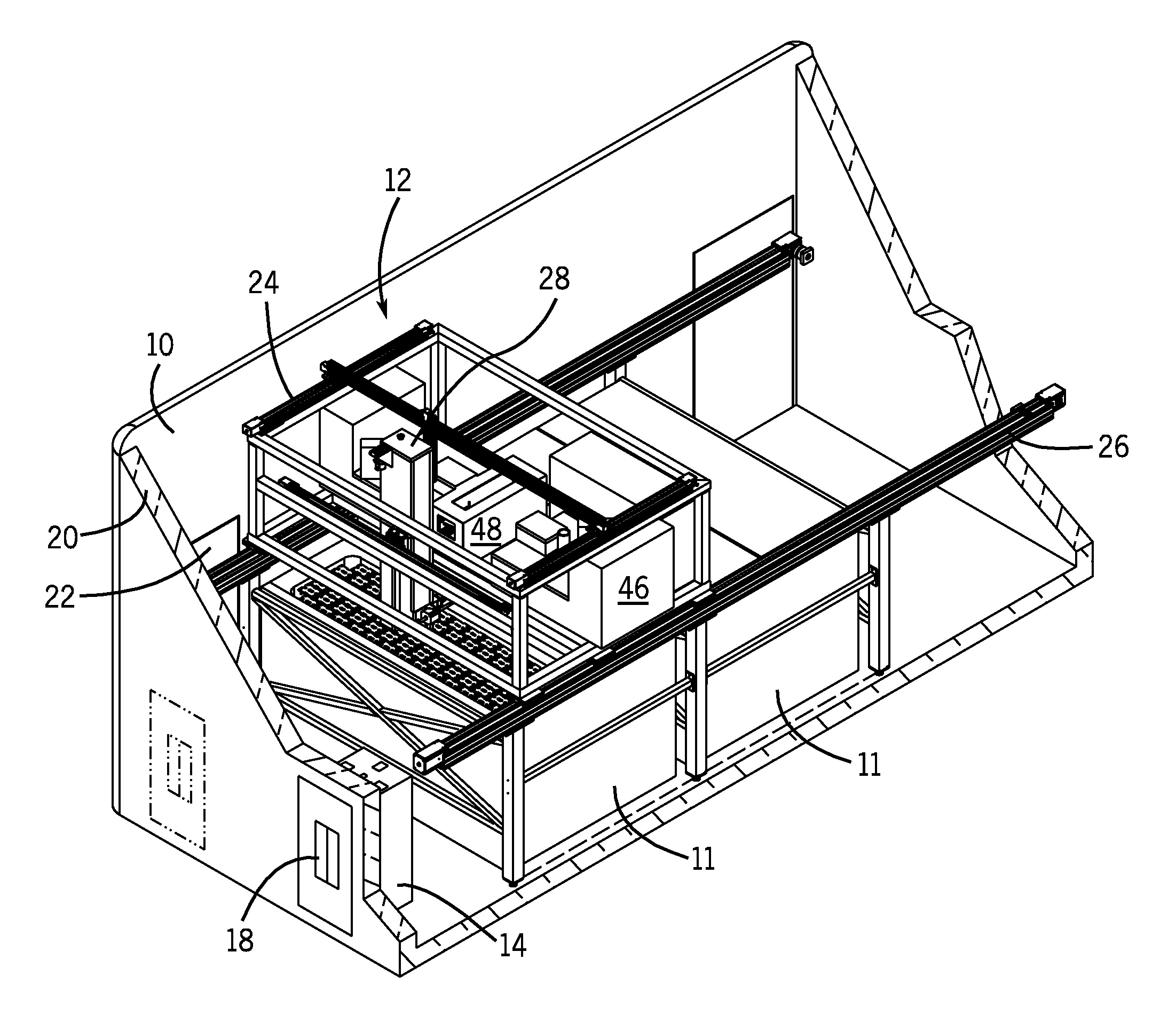

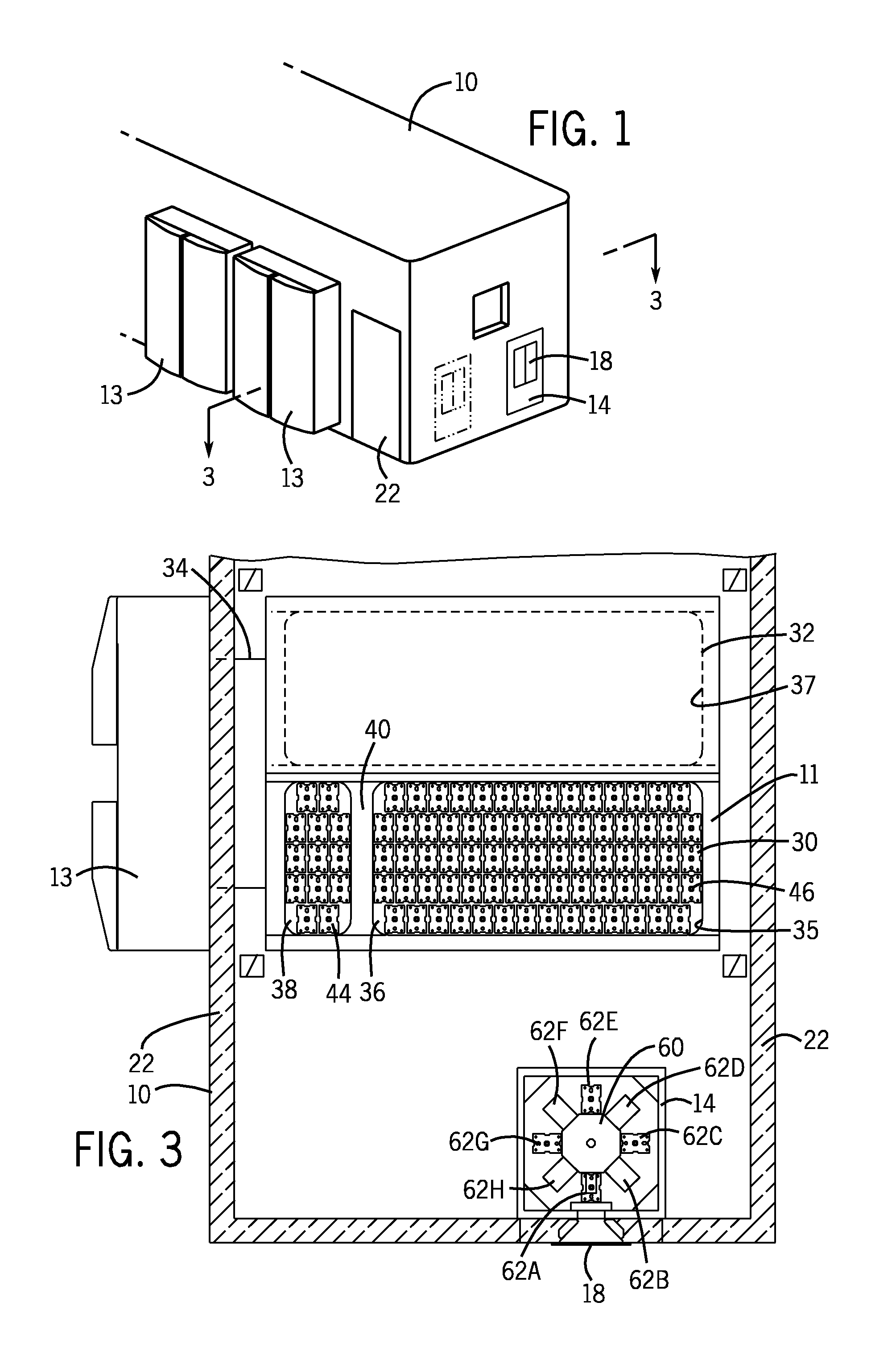

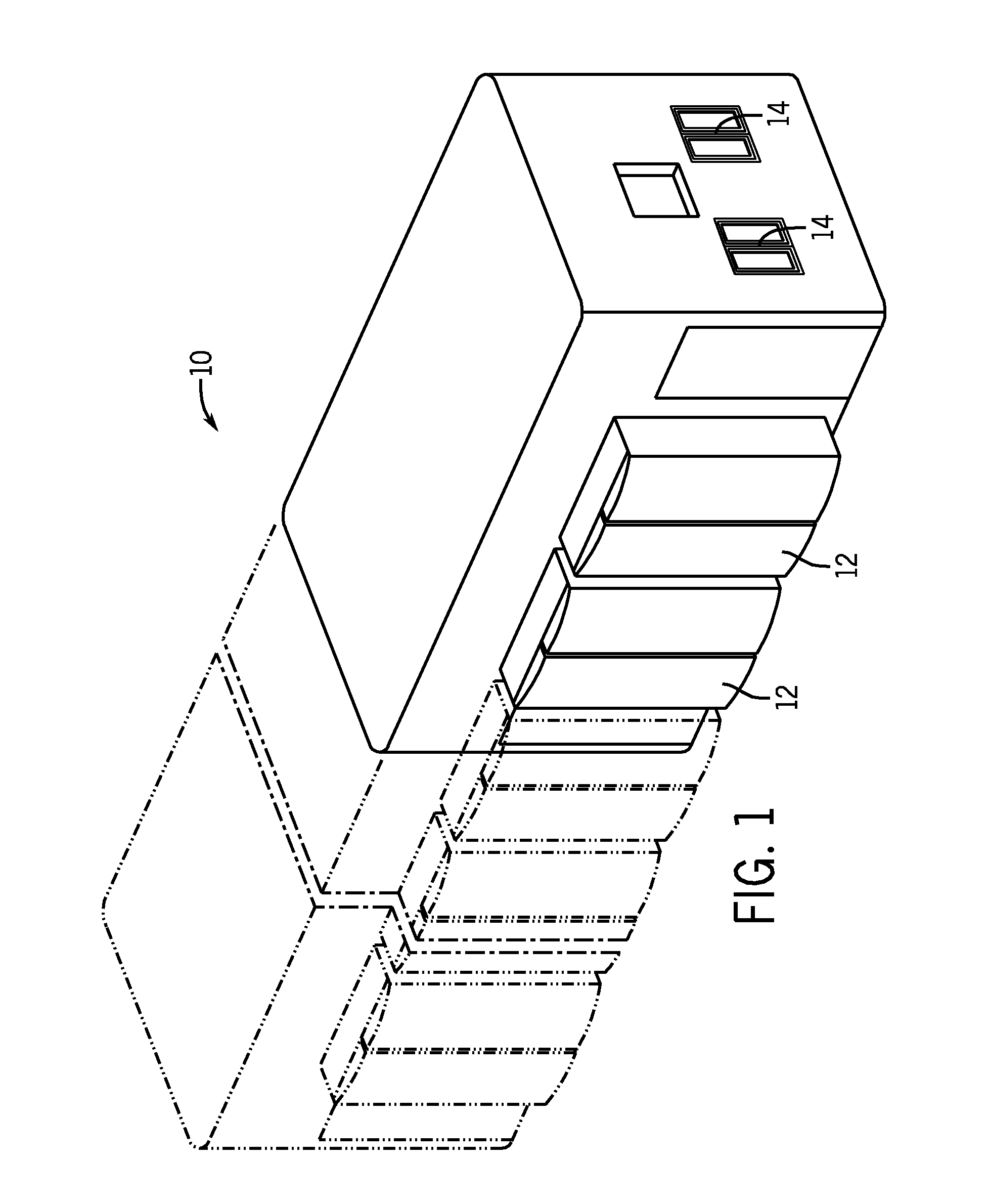

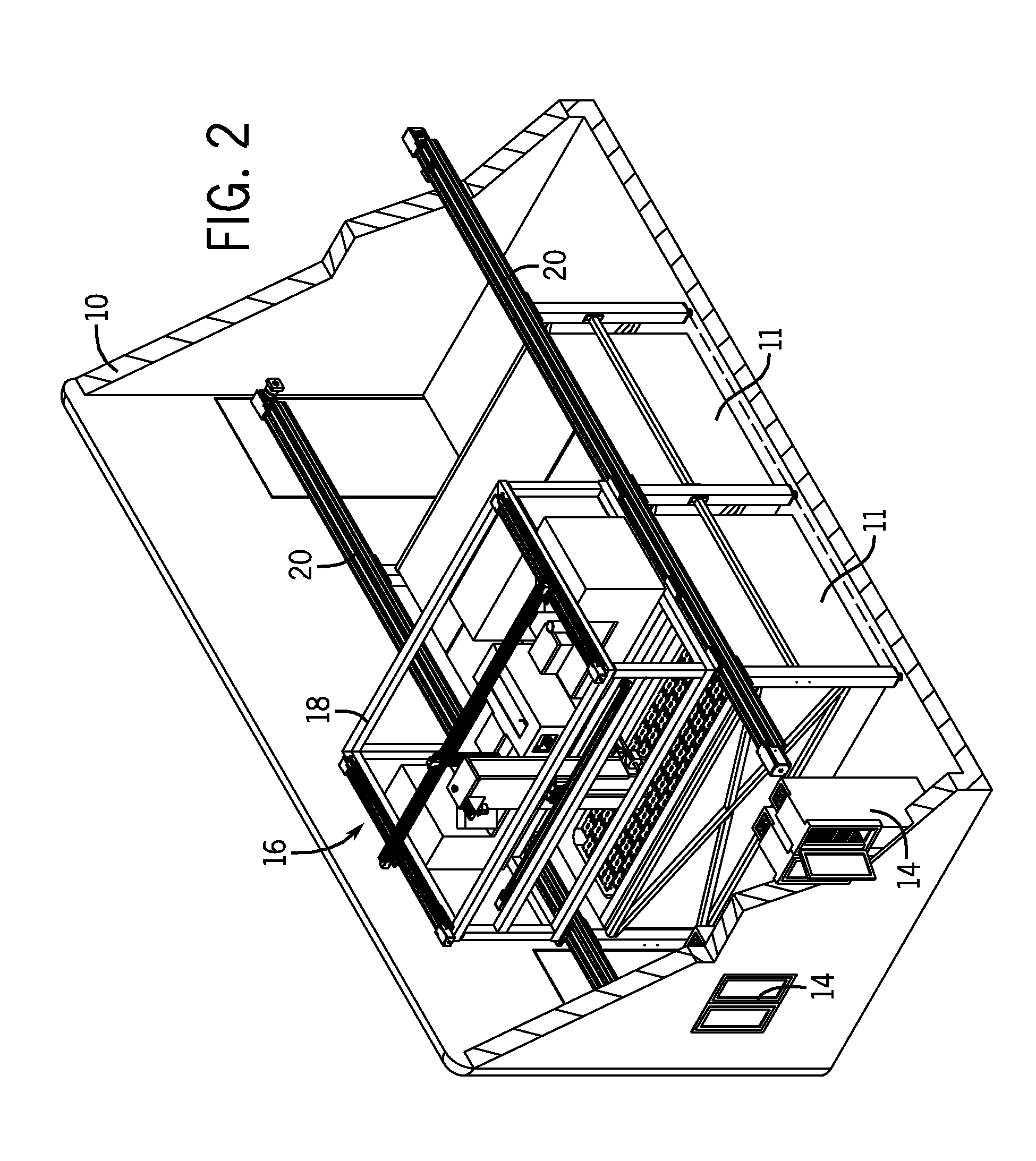

Input/Output Module and Overall Temperature Control of Samples

InactiveUS20120060520A1Easy transferLighting and heating apparatusPreparing sample for investigationTemperature controlComputer module

An automated storage and retrieval system for storing chemical and biological samples includes freezer chests maintained at an ultra-low temperature (e.g. −80° C.) or a cryogenic temperature. The freezer chests are located within a refrigerated (e.g. −20° C.) enclosure. Samples are loaded through a wall of the enclosure and are then transferred to an input / output buffer section in an ultra-low temperature or cryogenic freezer chest that is thermally segregated from a long-term storage section in the same freezer. Specialized input / output cassettes are used for transferring the samples through an input / output module into the system.

Owner:HAMILTON STORAGE TECH

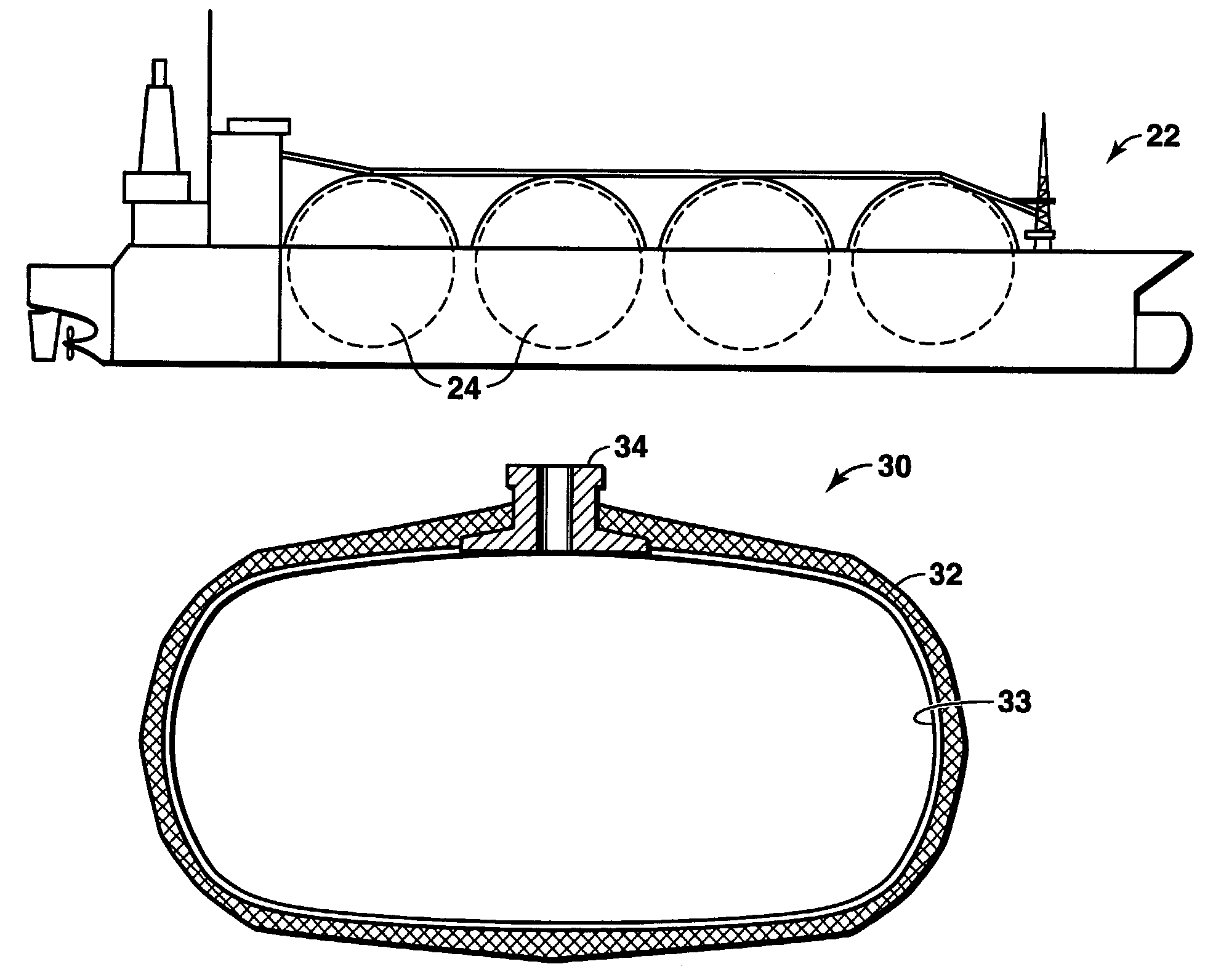

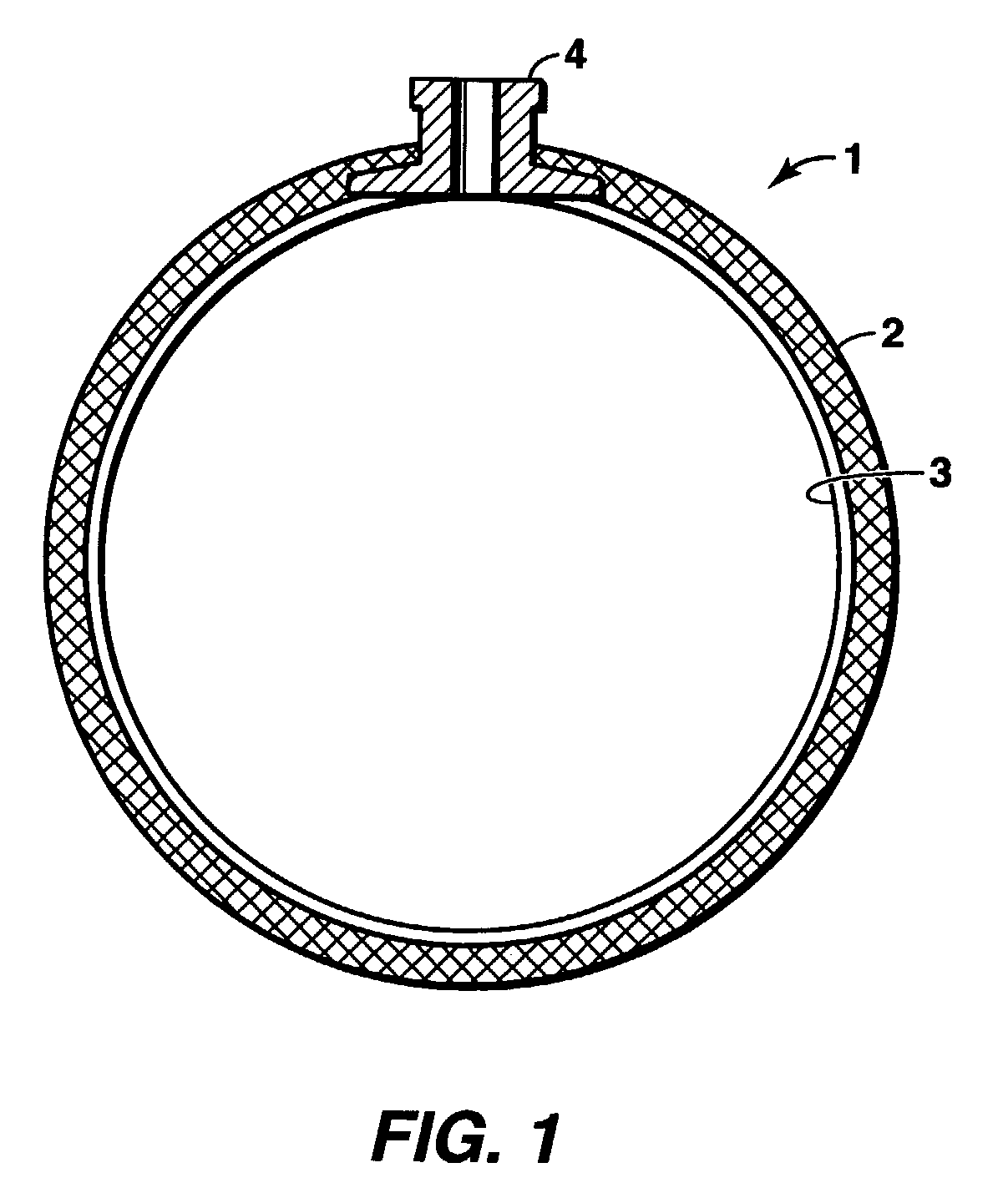

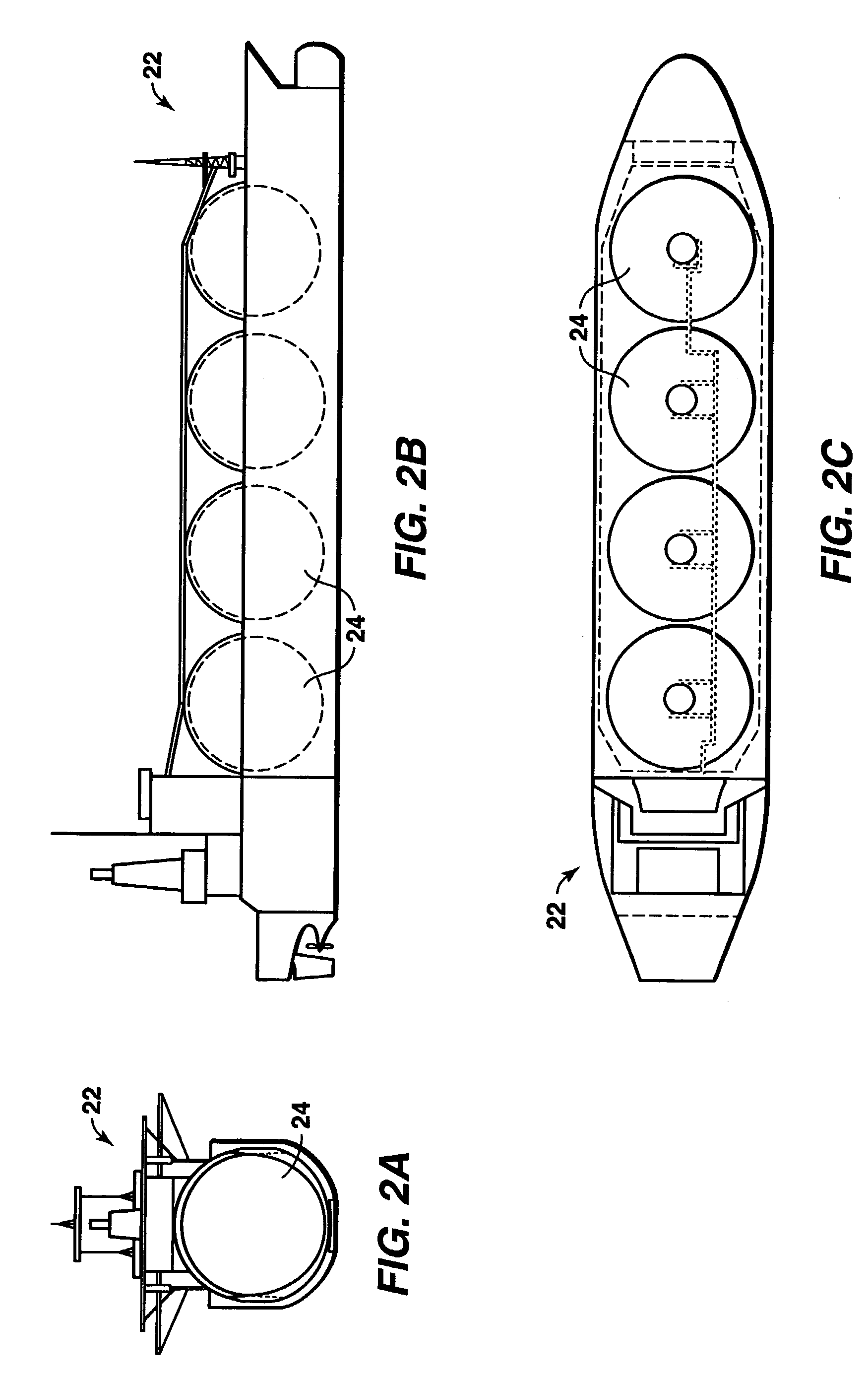

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

Process for homogenizing polyolefin drag reducing agents

ActiveUS6894088B2Accelerated dissipationImprove solubilityOther chemical processesRefining by heating/coolingPolyolefinKetone

A process for producing polymer drag reducing agent (DRA) slurries without cryogenic temperatures or conventional grinding is described. The homogenizing or size reduction of polymer, such as poly(alpha-olefins), may be achieved by the use of granulated polymer and at least one liquid, non-solvent for the polymer DRA. In one non-limiting embodiment of the invention, the homogenizing is conducted at ambient temperature. Examples of suitable non-solvents include water and non-aqueous non-solvents including, but not necessarily limited to, alcohols, glycols, glycol ethers, ketones, and esters; having from 2-6 carbon atoms, and combinations thereof. The polymeric DRA may be homogenized to an average particle size of about 600 microns or less.

Owner:BAKER HUGHES INC

Hand-held, heat sink cryoprobe, system for heat extraction thereof, and method therefore

InactiveUS20030024250A1Easy to useGuaranteed uptimeCompression machinesMachines using electric/magnetic effectsOff the shelfHand held

A cryoprobe system utilizing a monolithic, insulated, hand-held thermal mass having an exposed tip for cryosurgical applications and the like, as well as a heat extraction base configured to interface with the thermal mass to quickly and efficiently reduce the heat of the thermal mass to cryogenic temperatures. The heat extraction base of the preferred embodiment of the present invention is configured to interface with the tip of the thermal mass, such that the tip plugs in securely to the base, to permit an efficient thermal transfer of heat from the thermal mass through the base via a heat exchange system communicating with the base which employs a low temperature cryo-refrigeration unit. The cryo-refrigeration unit may comprise a single low temperature cooling unit to reduce the temperature of the base to around minus one hundred degrees Centigrade utilizing off-the-shelf cryogenic refrigeration methods, or may utilize a series of more conventional refrigeration units in a primary and secondary heat extraction arrangement, which method may further utilize thermocouple or Peltier effect device assist to further reduce the temperature of the heat extraction base to the required temperature. Also claimed is the method of cryosurgery employing the device(s) of the present invention, and a heat pipe appliance to engage a remote treatment area.

Owner:CRYOPEN

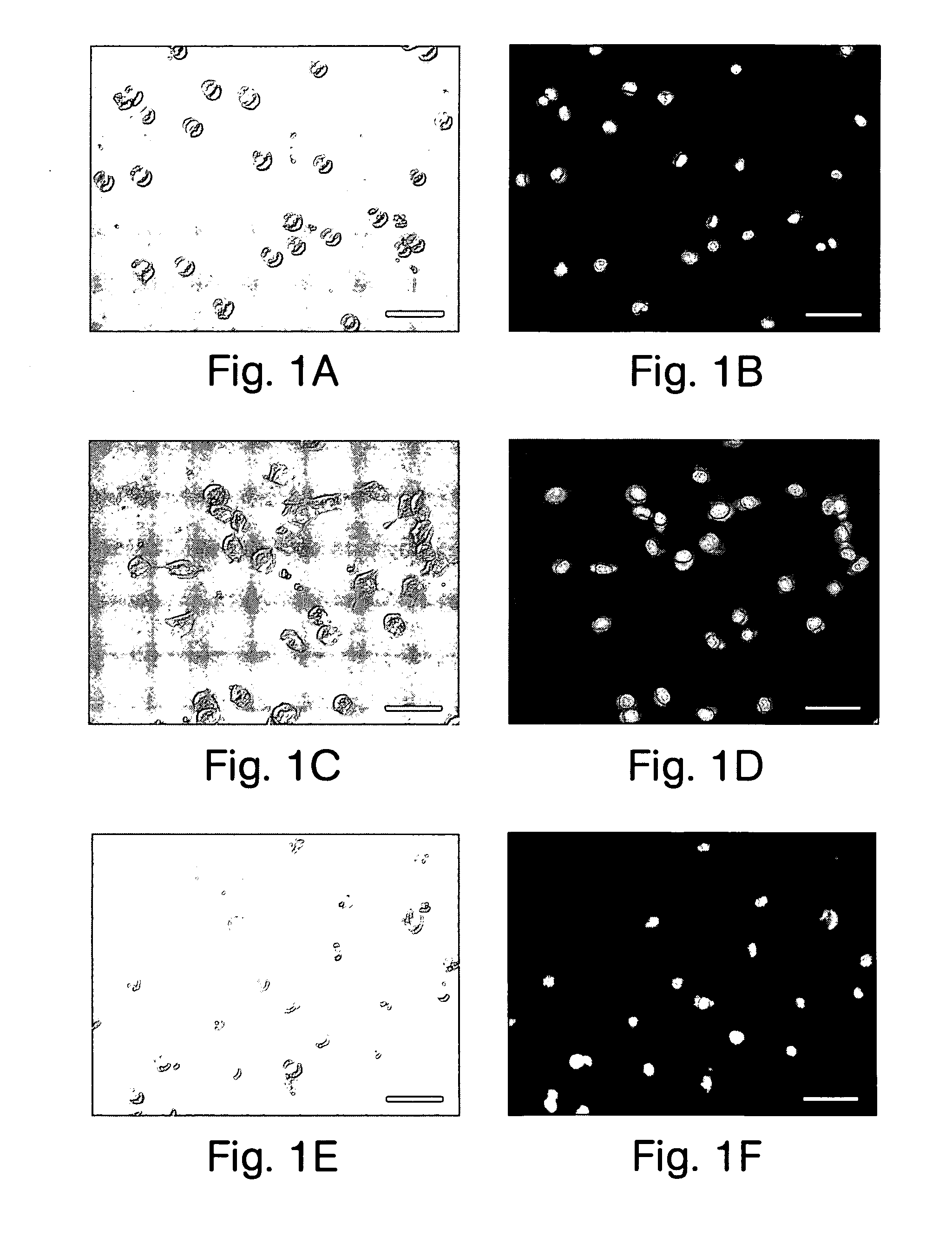

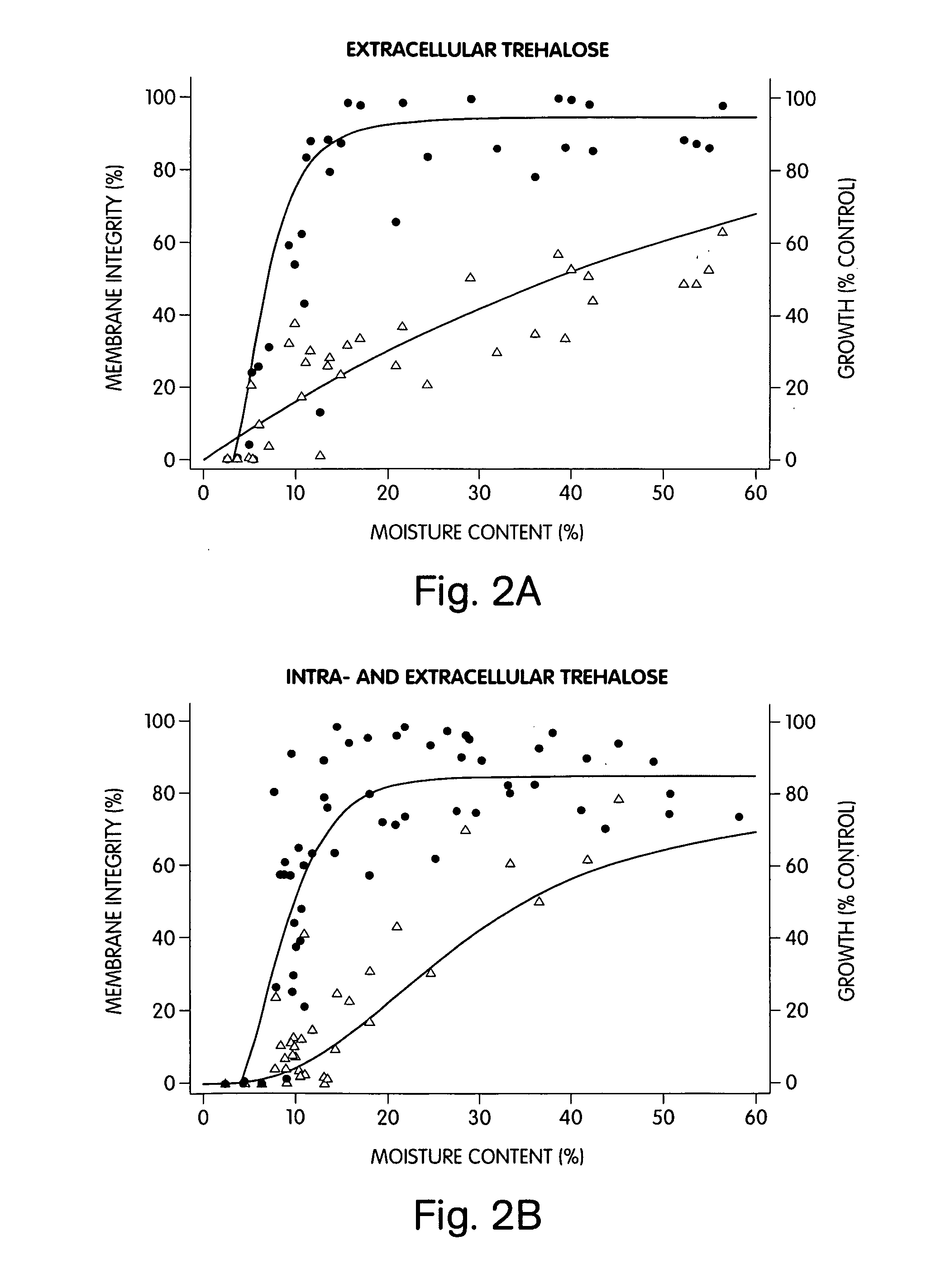

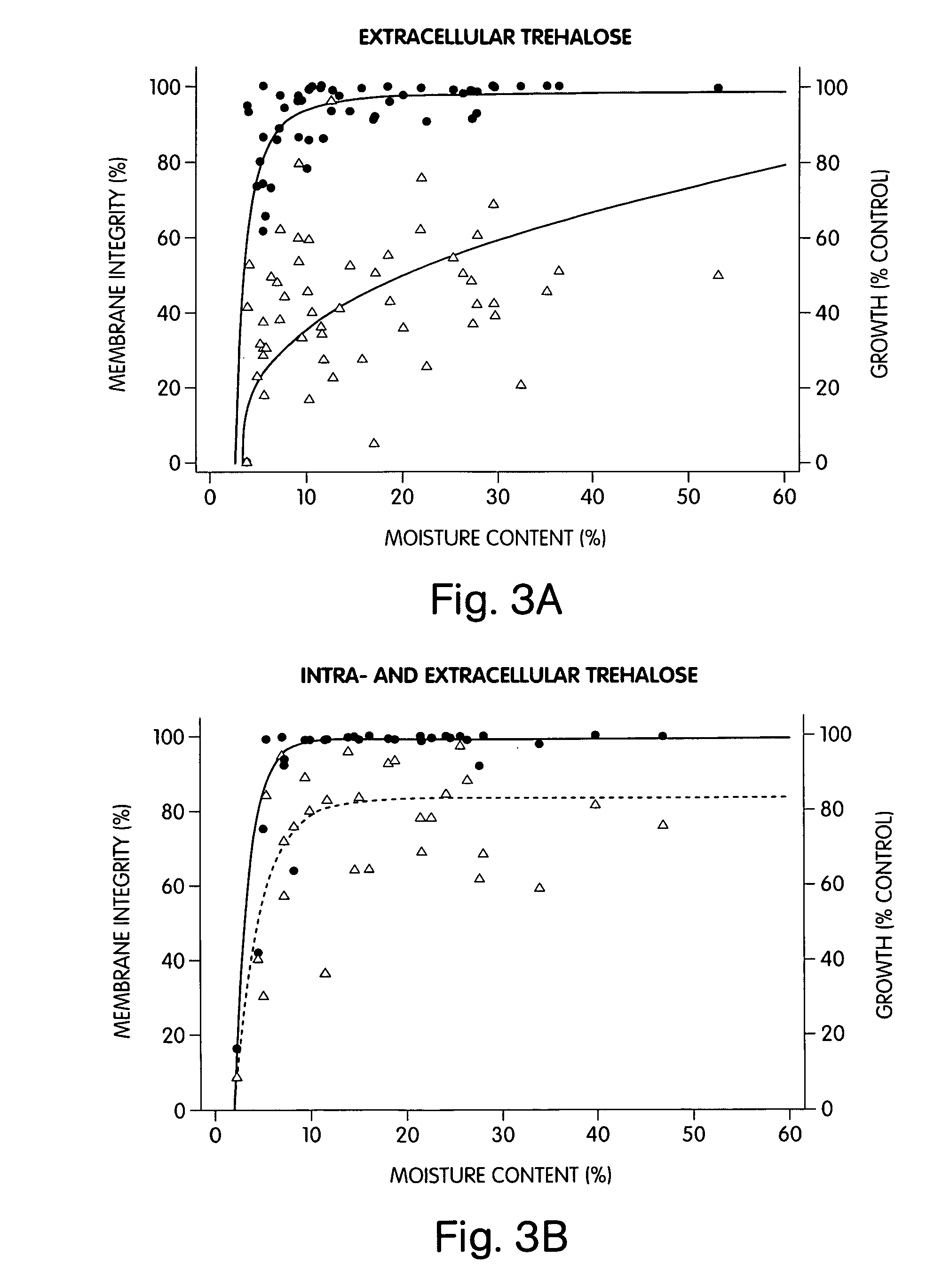

Systems and methods for cell preservation

The present invention generally relates to devices and methods for the preservation of cells using drying, freezing, and other related techniques. In one set of embodiments, the invention allows for the preservation of cells in a dried state. In another set of embodiments, the invention allows for the preservation of cells within a glass or other non-viscous, non-frozen media. In some embodiments, the invention allows for the preservation of cells at temperatures below the freezing point of water, and in some cases at cryogenic temperatures, without inducing ice formation. The cells, in certain embodiments, may be preserved in the presence of intracellular and / or extracellular carbohydrates (which may be the same or different), for example, trehalose and sucrose. Carbohydrates may be transported intracellularly by any suitable technique, for example, using microinjection, or through non-microinjected methods such as through pore-forming proteins, electroporation, heat shock, etc. In certain instances, the glass transition temperature of the cells may be raised, e.g., by transporting a carbohydrate intracellularly. In some cases, the cells may be dried and / or stored, for example, in a substantially moisture-saturated environment or a desiccating environment. The cells may also be stored in a vacuum or a partial vacuum. The cells may be protected from oxygen, moisture, and / or light during storage. In certain cases, an inhibitor, such as a cell death inhibitor, a protease inhibitor, an apoptosis inhibitor, and / or an oxidative stress inhibitor may be used during preservation of the cells. The cells may be stored for any length of time, then recovered to a viable state, e.g., through rehydration, for further use.

Owner:THE GENERAL HOSPITAL CORP

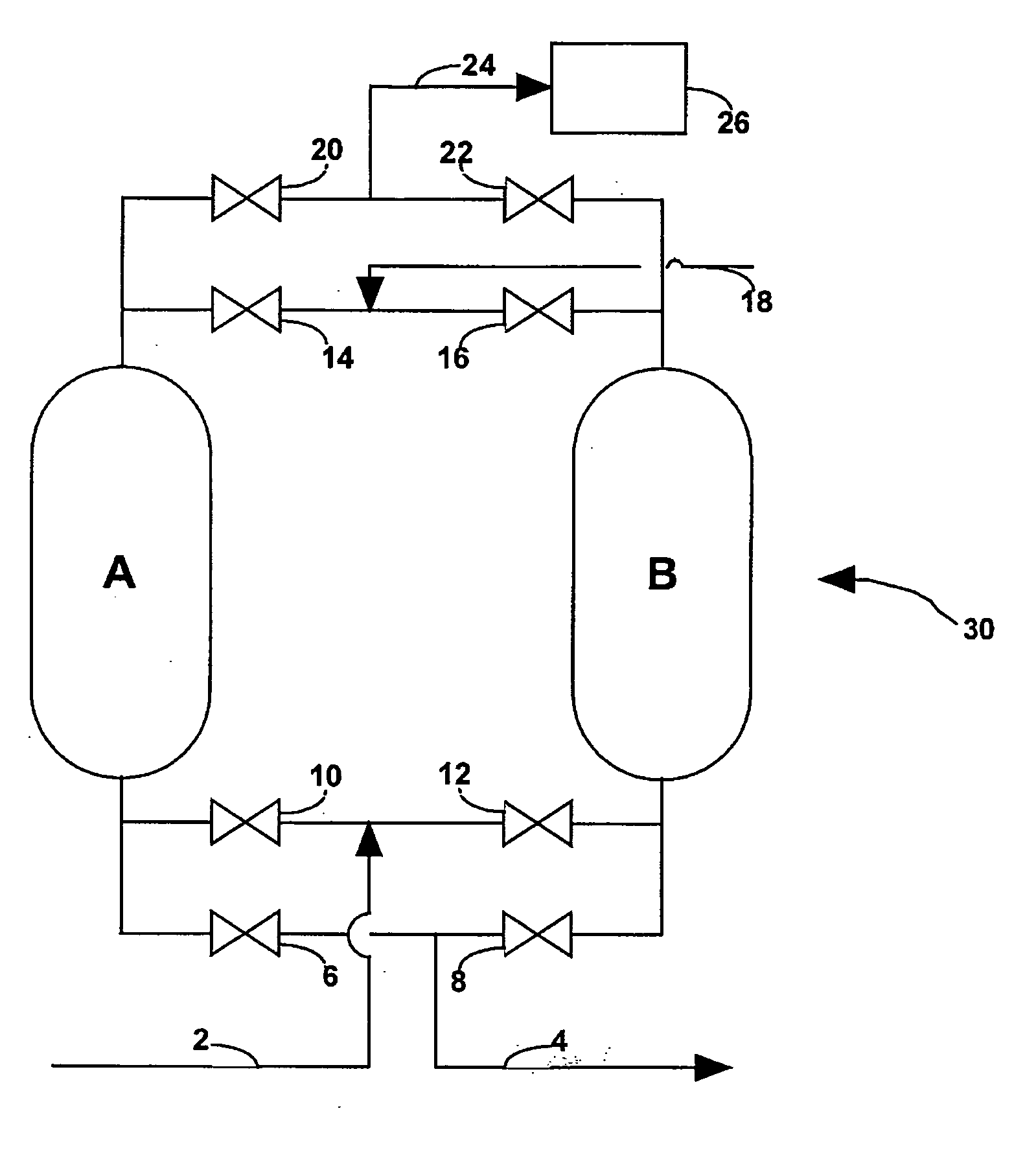

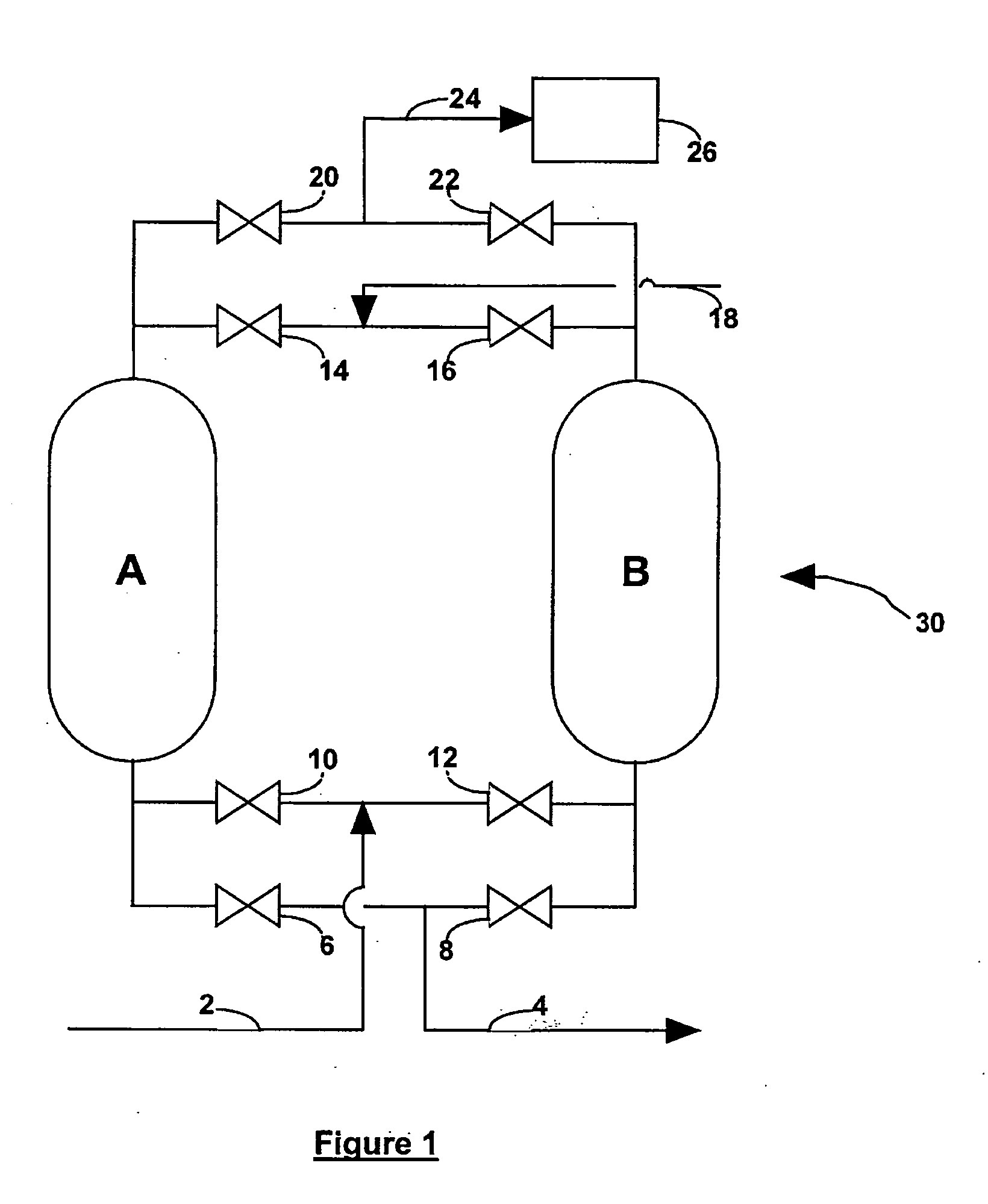

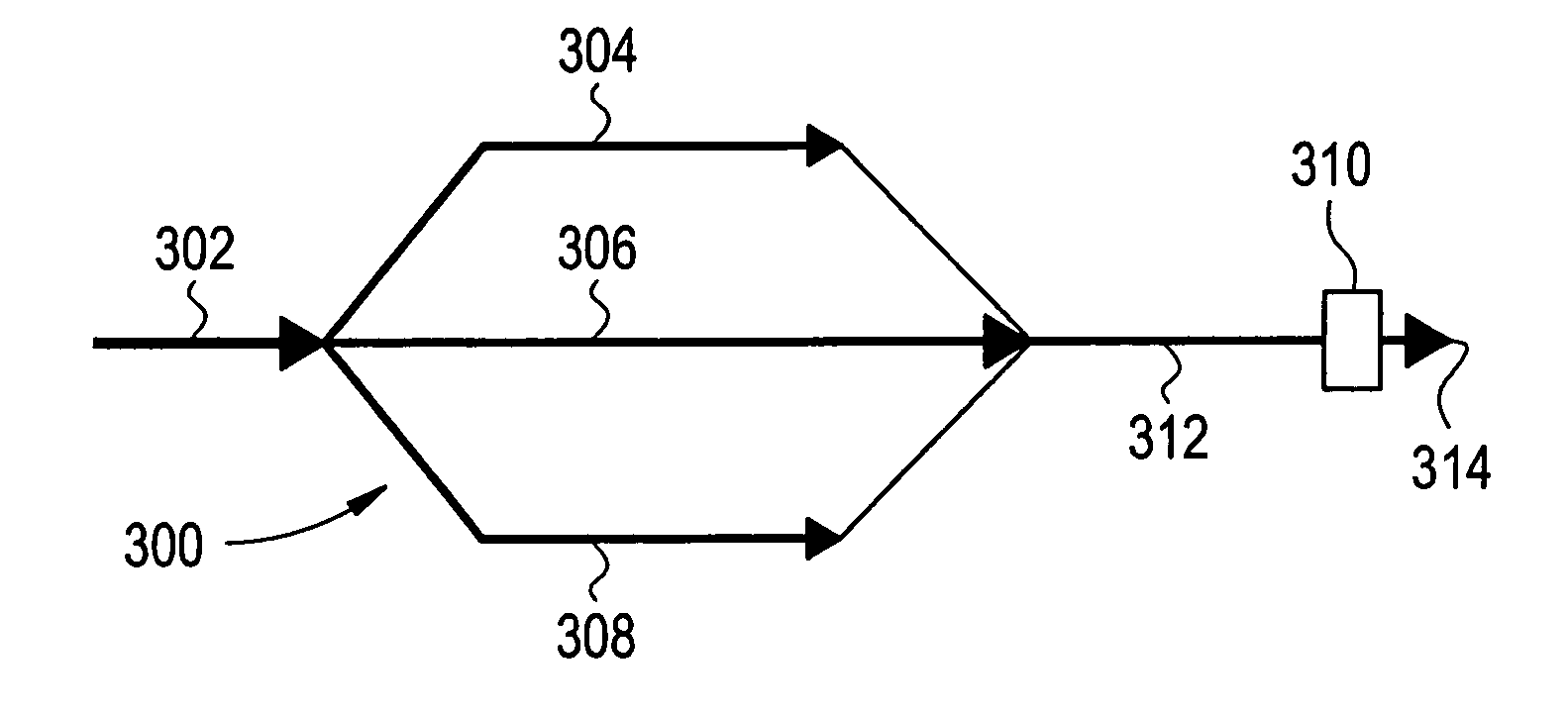

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:BOC GRP INC

Superconductive magnet including a cryocooler coldhead

ActiveUS7170377B2Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

Owner:GENERAL ELECTRIC CO

Cassette Puller

InactiveUS20120060539A1Minimize temperature riseReduce convective heat transferLighting and heating apparatusPreparing sample for investigationEngineeringInput/output

A cassette puller for an automated storage and retrieval system that stores biological or chemical samples in freezers maintained at ultra-low temperature (e.g., −80° C.) or cryogenic temperatures includes a vertical sleeve into which the selected cassette is lifted. The cassette puller is mounted to a traveling gantry and transports cassettes from one freezer location to another and to the system input / output module, and also includes an ejection mechanism that inserts and retrieves tube storage racks or plates from a selected shelf on the cassette. Other components such as a rack robot, a tube picking mechanism, a sample identification station, etc. are mounted on the traveling gantry as well.

Owner:HAMILTON STORAGE TECH

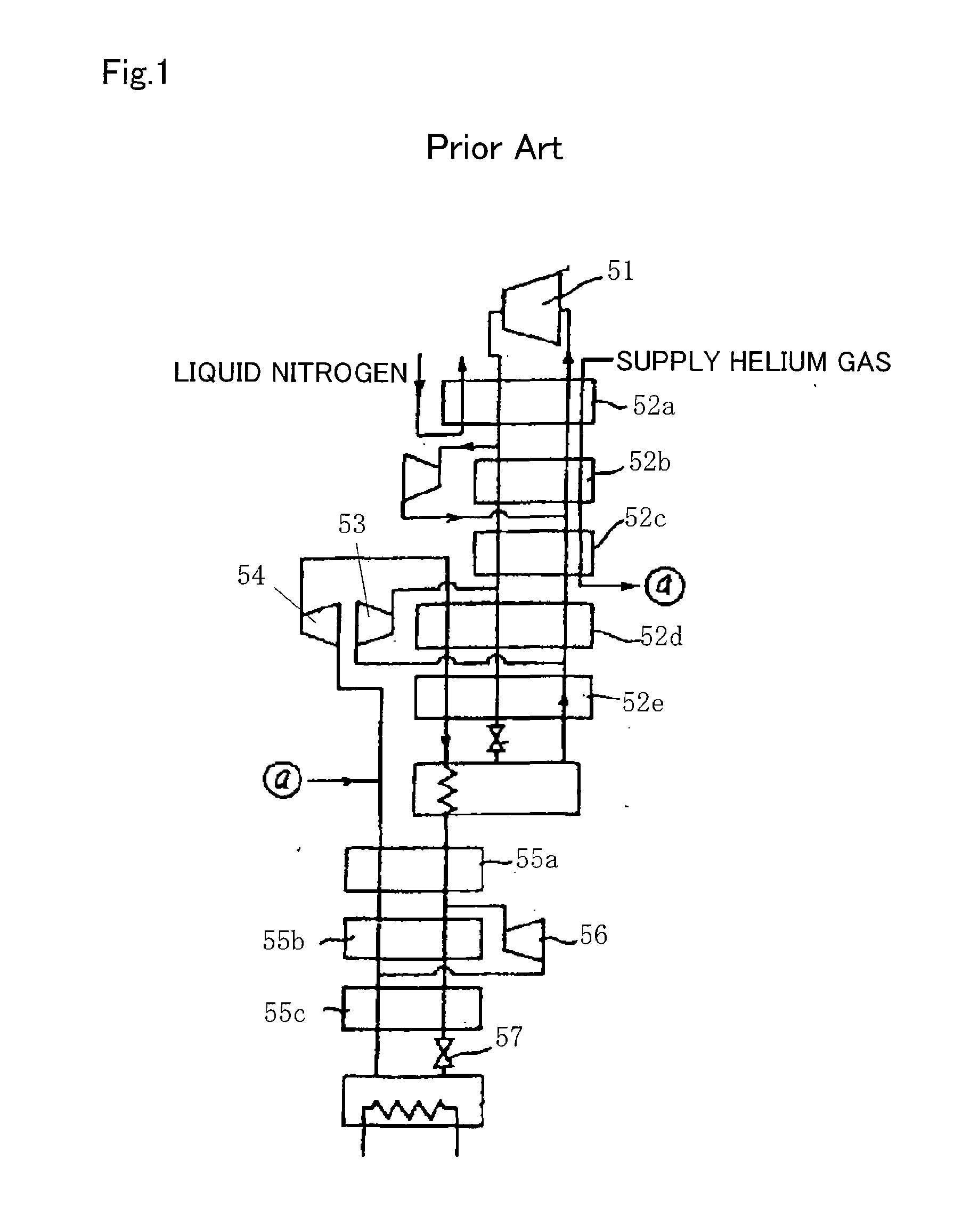

Systems, methods, and apparatus for cryogenic refrigeration

ActiveUS20100281885A1Efficient evacuationDigital data processing detailsCompression machinesDilution refrigeratorEvaporation

Cryogenic refrigeration employs a pulse tube cryo-cooler and a dilution refrigerator to provide very low temperature cooling, for example, to cool superconducting processors. Continuous cryogenic cycle refrigeration may be achieved using multiple adsorption pumps. Various improvements may include multiple distinct thermal-linking points, evaporation pots with cooling structures, and / or one or more gas-gap heat switches which may be integral to an adsorption pump. A reservoir volume may provide pressure relief when the system is warmed above cryogenic temperature, reducing the mass of the system. Additional heat exchangers and / or separate paths for condensation and evaporation may be provided. Multi-channel connectors may be used, and / or connectors formed of a regenerative material with a high specific heat capacity at cryogenic temperature. Flexible PCBs may provide thermal links to components that embody temperature gradients. Various components may be pre-cooled, for example via a switchable thermalization system.

Owner:D WAVE SYSTEMS INC

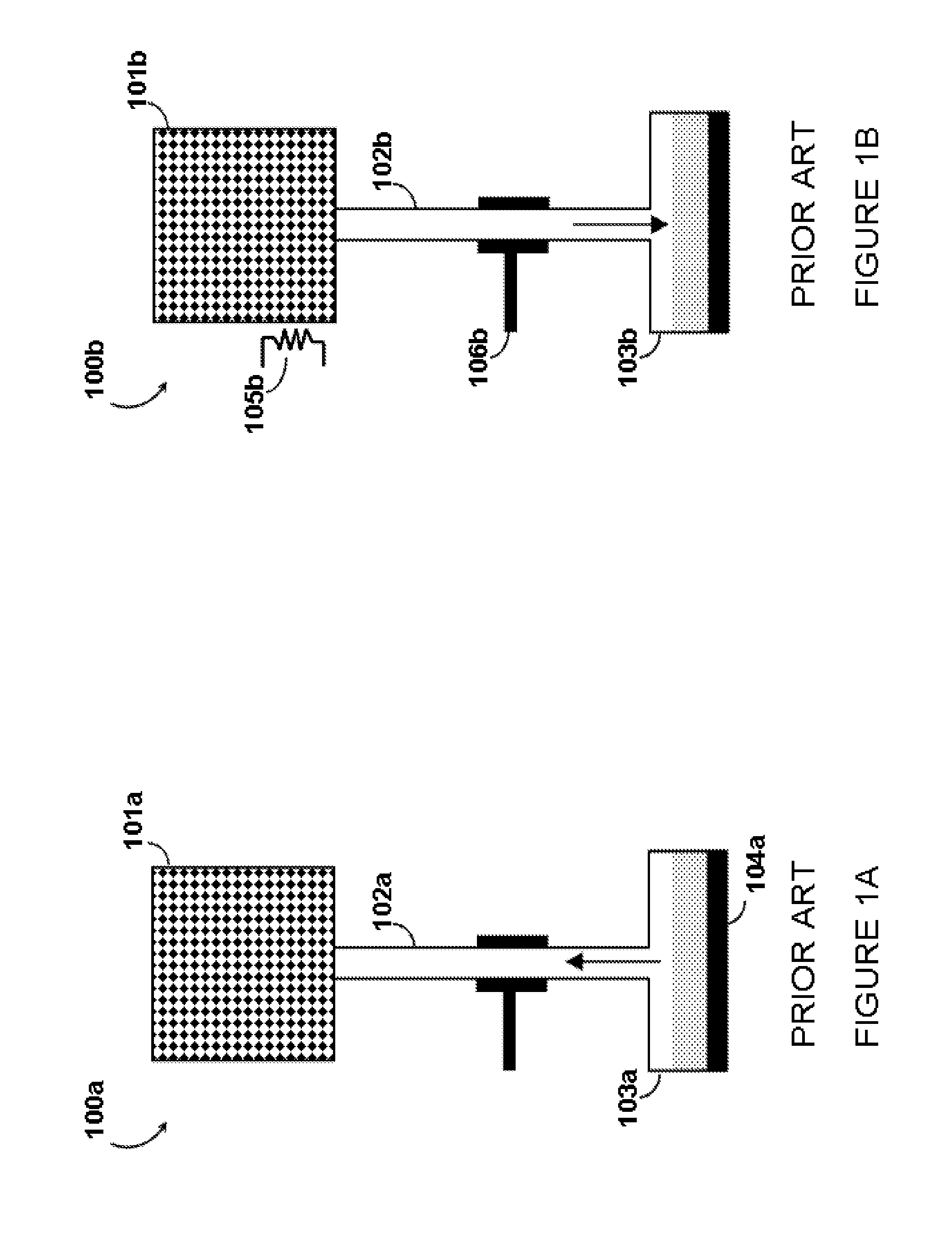

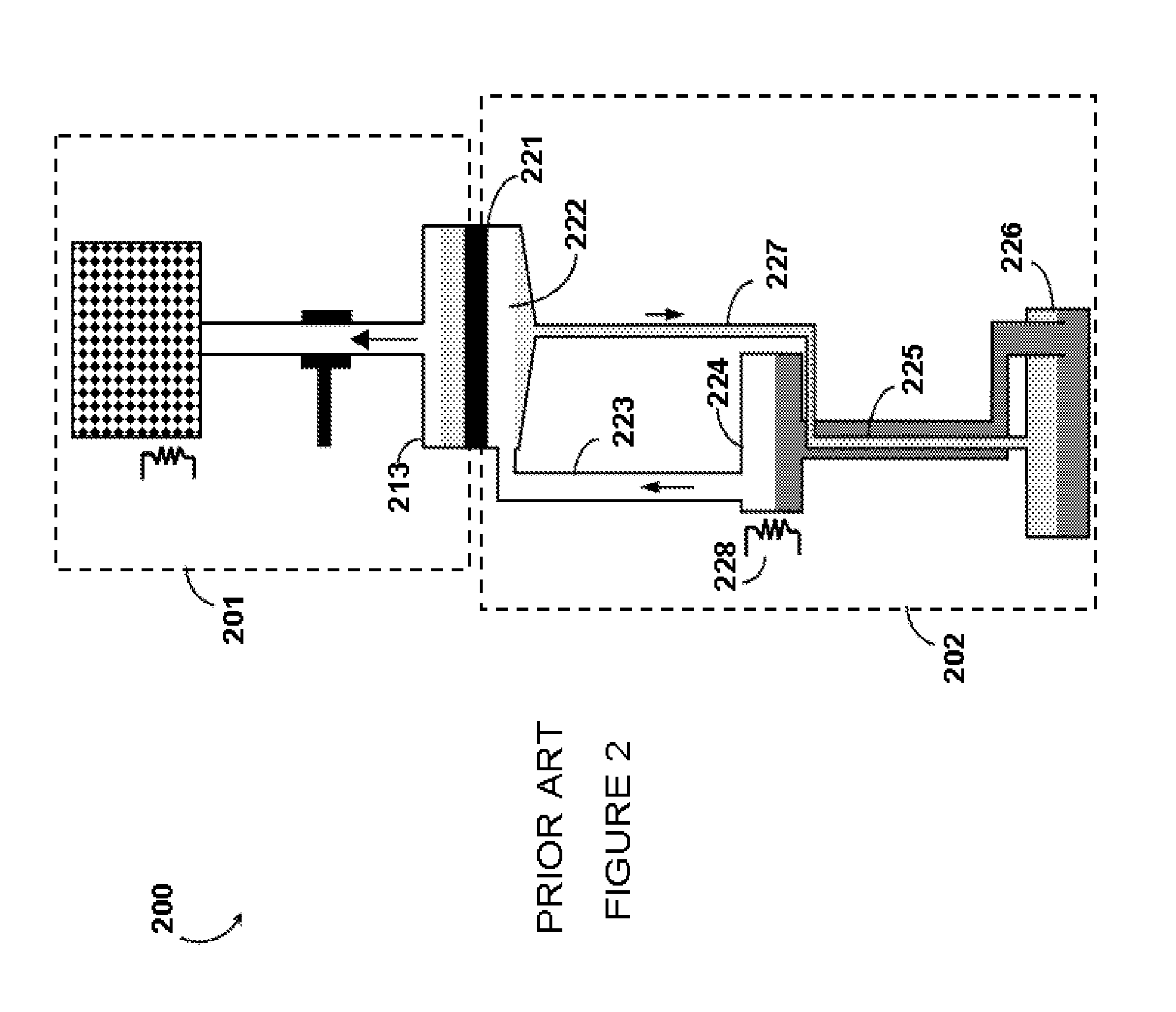

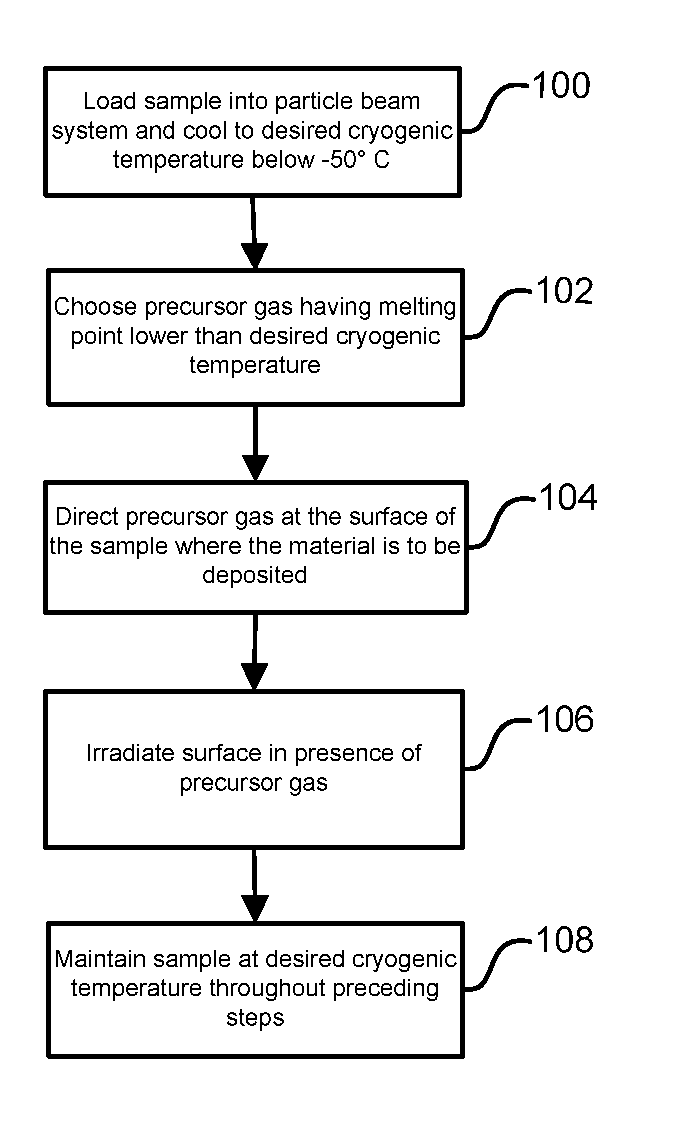

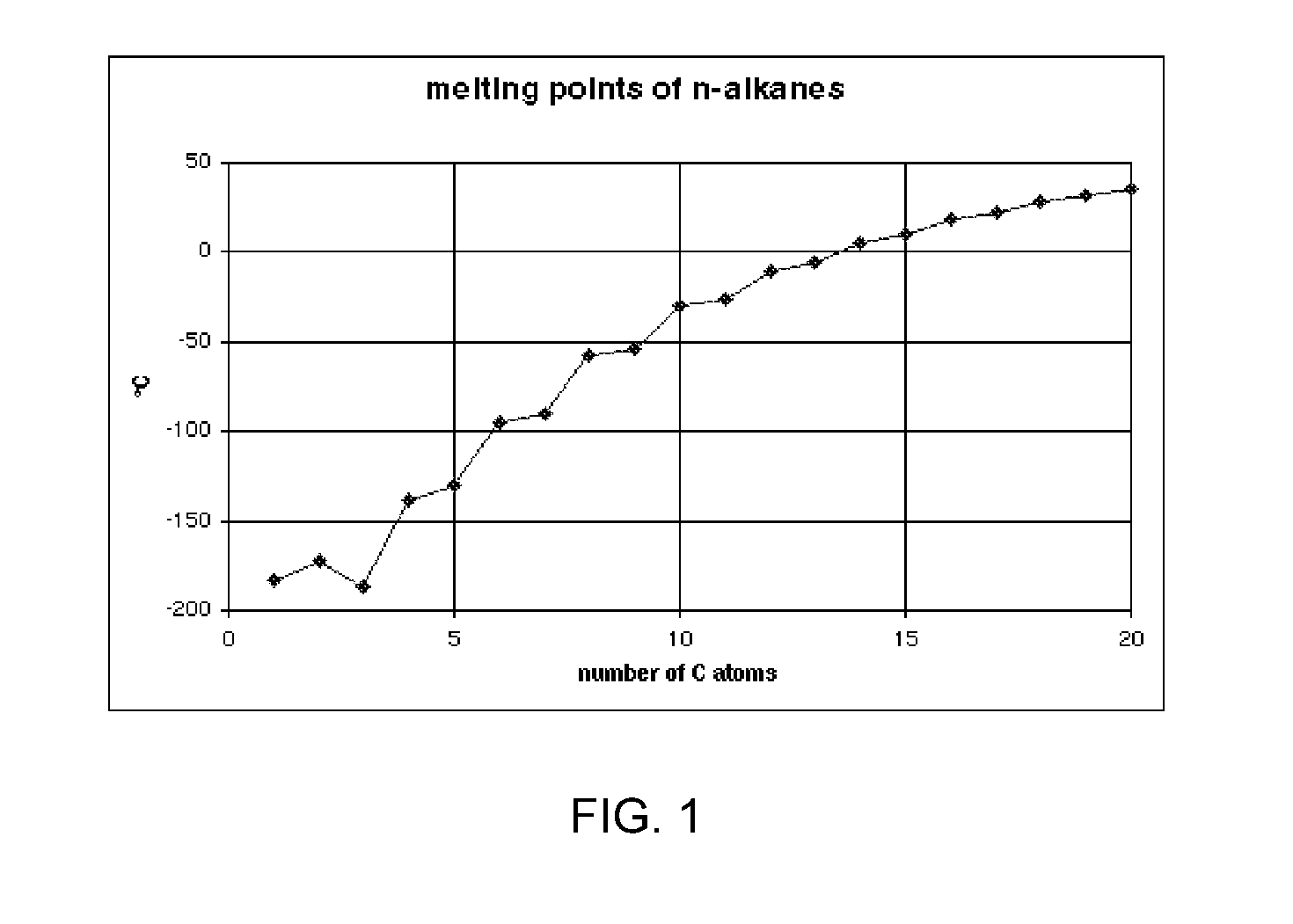

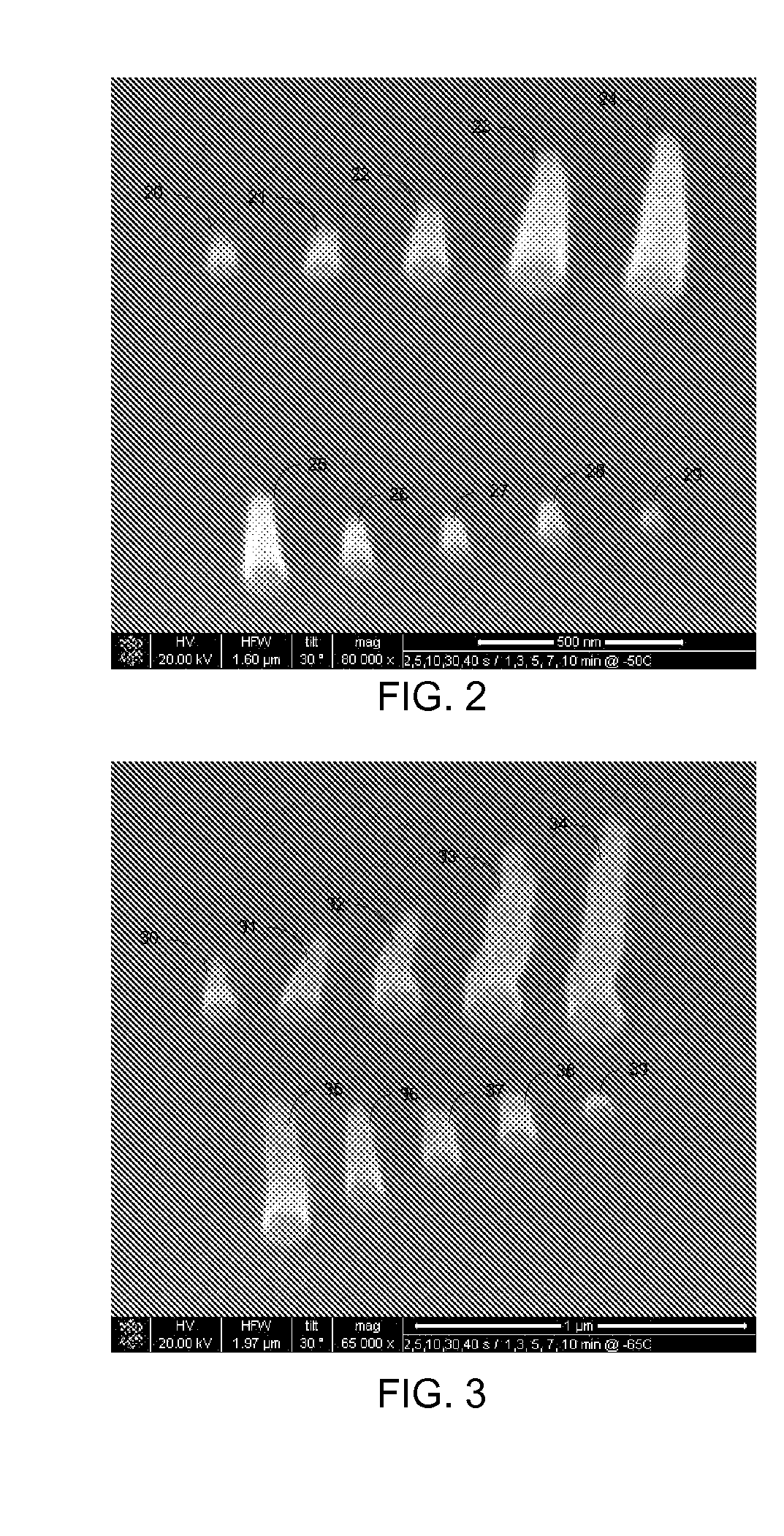

Beam-Induced Deposition at Cryogenic Temperatures

ActiveUS20120003394A1Easy to usePretreated surfacesChemical vapor deposition coatingAlkaneAlkyne formation

A method of depositing material onto a substrate at cryogenic temperatures using beam-induced deposition. A precursor gas is chosen from a group of compounds having a melting point that is lower than the cryogenic temperature of the substrate. Preferably the precursor gas is chosen from a group of compounds having a sticking coefficient that is between 0.5 and 0.8 at the desired cryogenic temperature. This will result in the precursor gas reaching equilibrium between precursor molecules adsorbed onto the substrate surface and precursor gas molecules desorbing from the substrate surface at the desired cryogenic temperature. Suitable precursor gases can comprise alkanes, alkenes, or alkynes. At a cryogenic temperature of between −50° C. and −85° C., hexane can be used as a precursor gas to deposit material; at a cryogenic temperature of between −50° C. and −180° C., propane can be used as a precursor gas.

Owner:FEI CO

Sample cooling apparatus

InactiveUS20070234751A1Eliminate driftEliminate vibrationCompression machinesRefrigeration devicesEngineeringMechanical engineering

A sample cooling apparatus capable of cooling and holding samples or wafers at a cryogenic temperature with no vibration or drift with respect to a measurement reference surface is disclosed. In the sample cooling apparatus, a sample holder is arranged in a vacuum vessel mounted on a housing having a table for forming a measurement reference surface to be supported by a thermal insulator. A frame is disposed within the housing to be supported by a first buffer. A refrigerating machine is disposed in the frame to be supported by a second buffer and has a head directed to the vacuum vessel. The cooling head of the refrigerating machine is connected to the sample holder by way of a flexible thermal conduction member.

Owner:NAT INST OF ADVANCED IND SCI & TECH

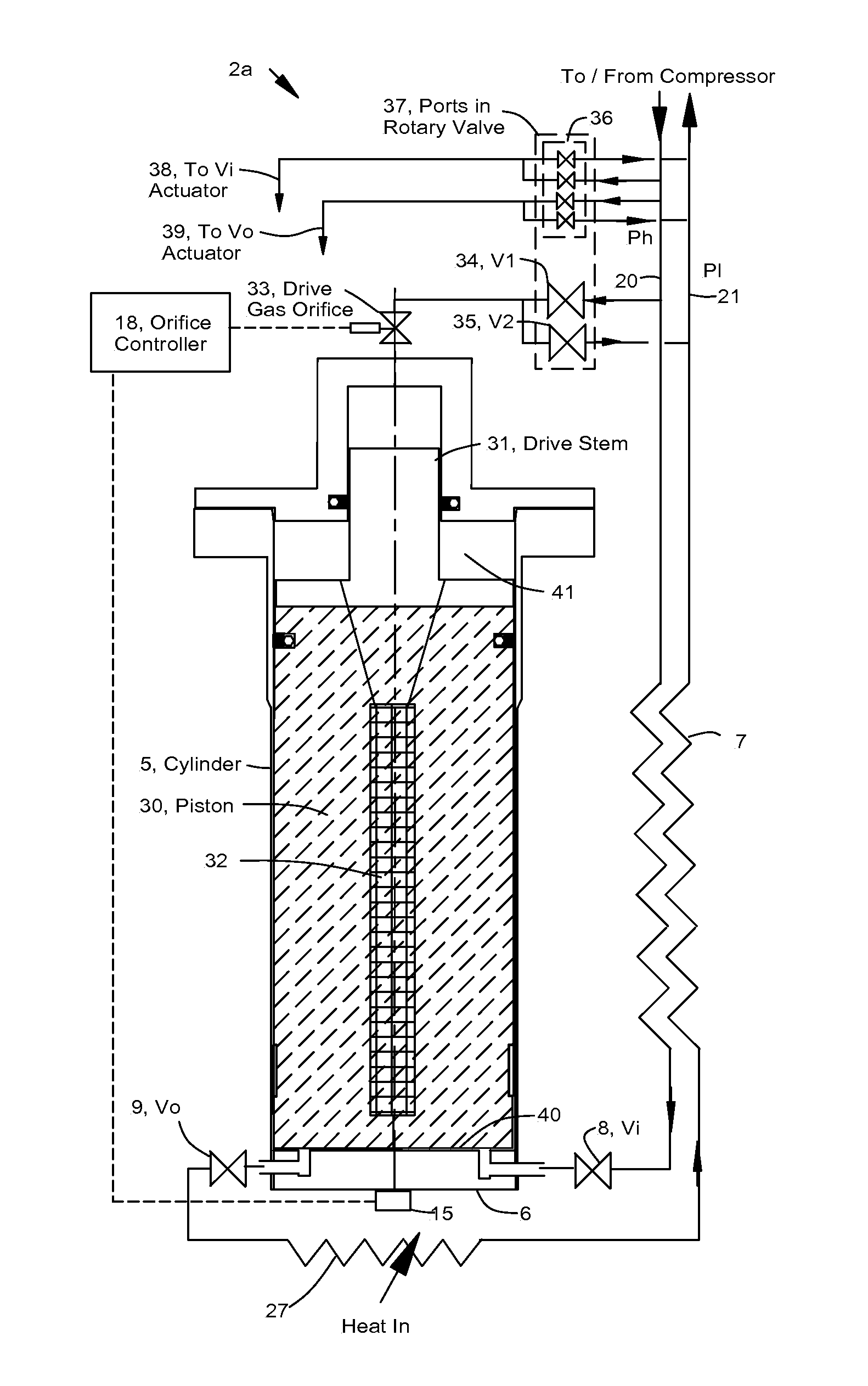

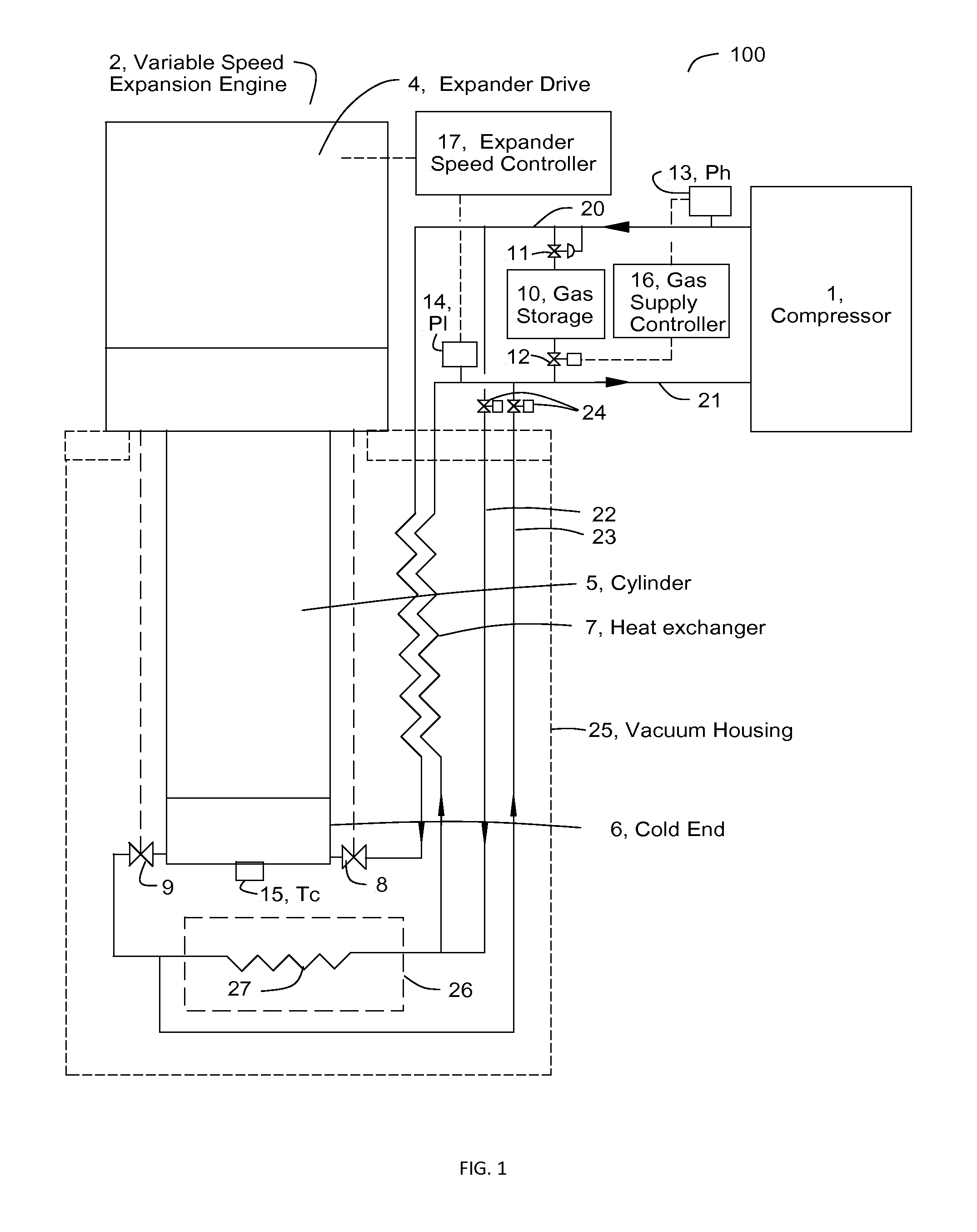

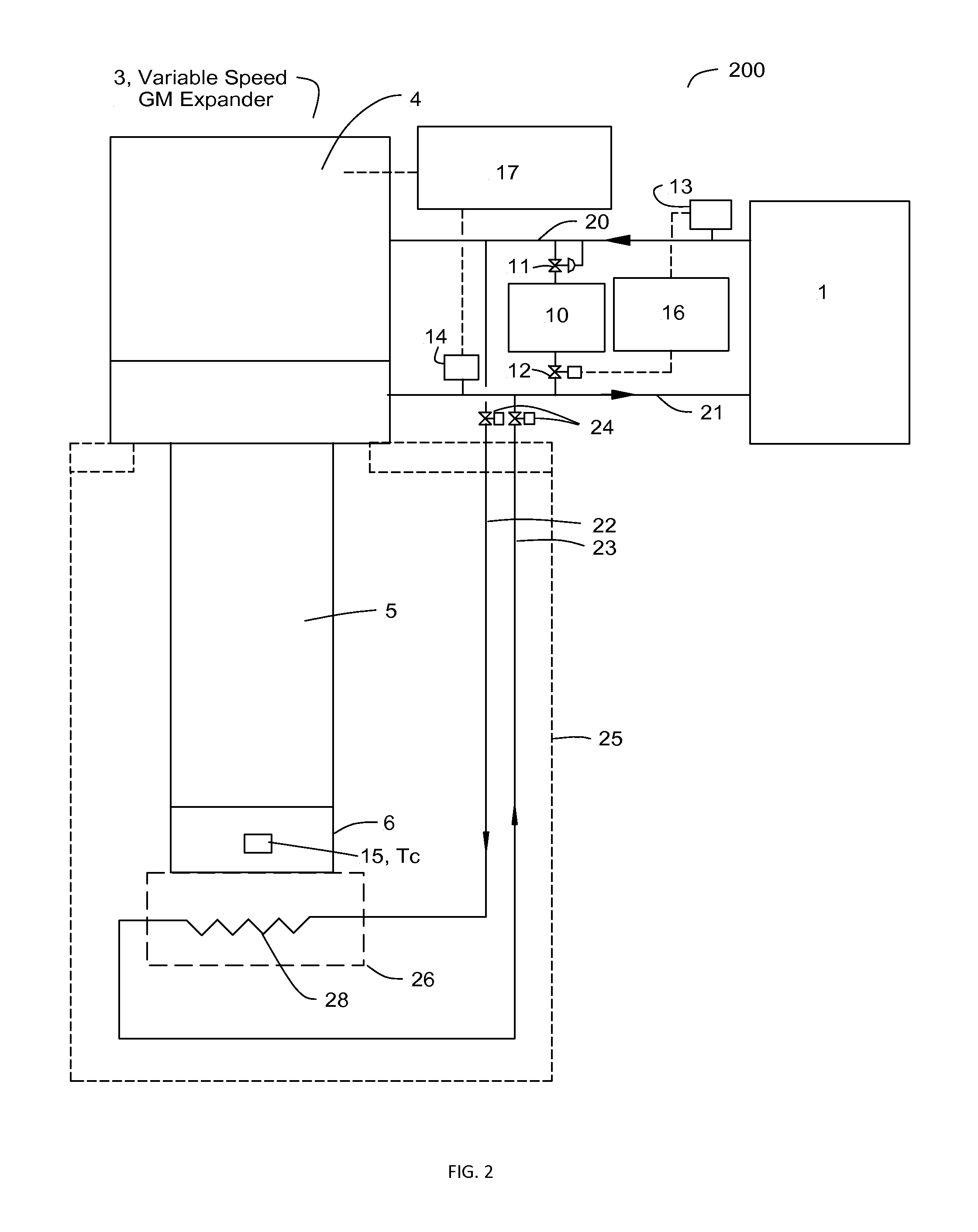

Fast Cool Down Cryogenic Refrigerator

ActiveUS20120085121A1Maximize refrigeration rateConstant supply pressureDomestic cooling apparatusCompression machinesLine tubingControl system

A refrigeration system for minimizing the cool down time of a mass to cryogenic temperatures including a compressor, an expander, a gas storage tank, interconnecting gas lines, and a control system. The compressor output is maintained near its maximum capability by maintaining near constant high and low pressures during cool down, gas being added or removed from the storage tank to maintain a near constant high pressure, and the speed of said expander being adjusted to maintain a near constant low pressure, no gas by-passing between high and low pressures.

Owner:SUMITOMO SHI CRYOGENICS OF AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com