Input/Output Module and Overall Temperature Control of Samples

a sample and module technology, applied in the field of automatic storage and retrieval systems, can solve problems such as the temperature rise among other samples stored in the system, and achieve the effect of facilitating the transfer of storage cassettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

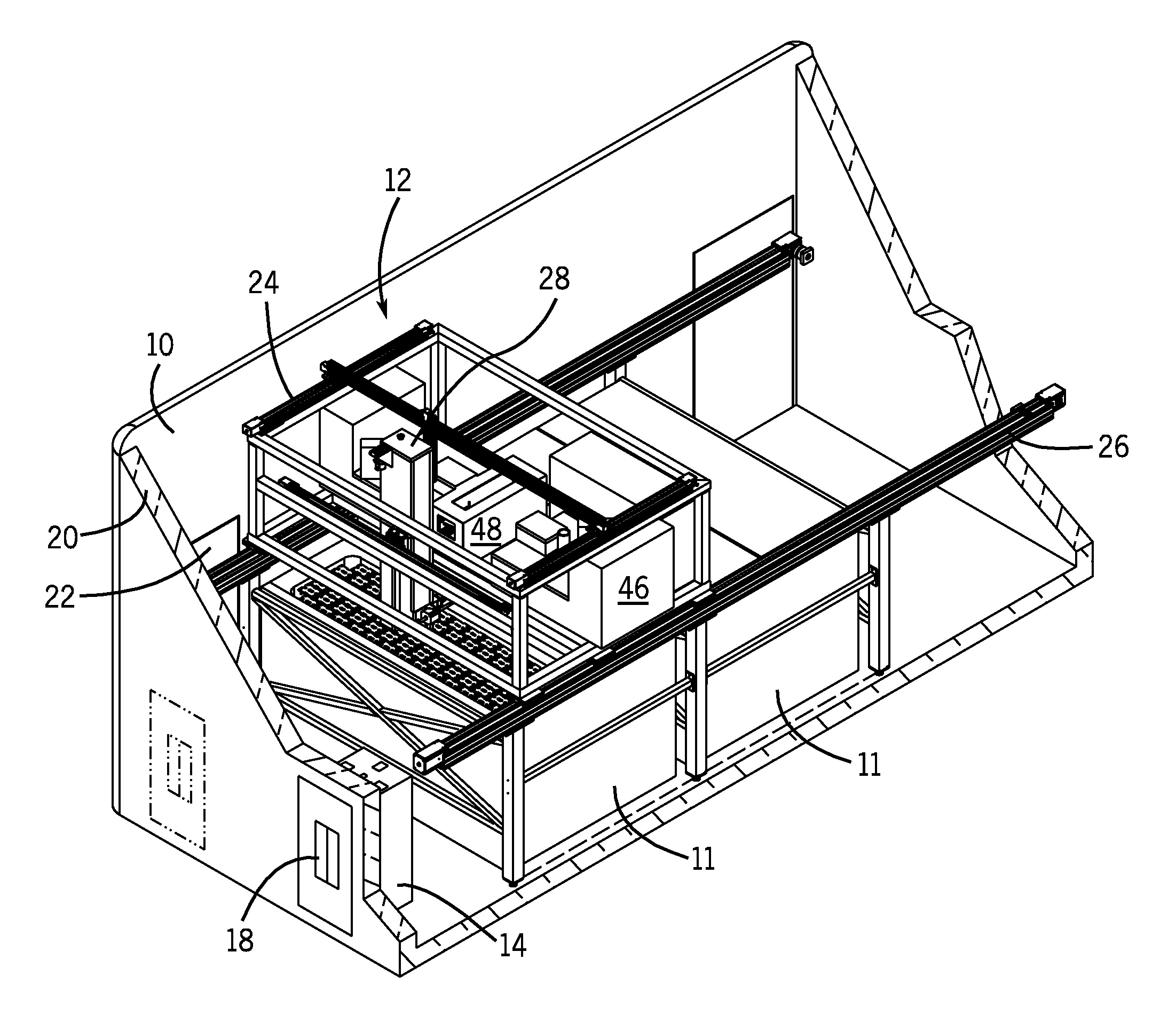

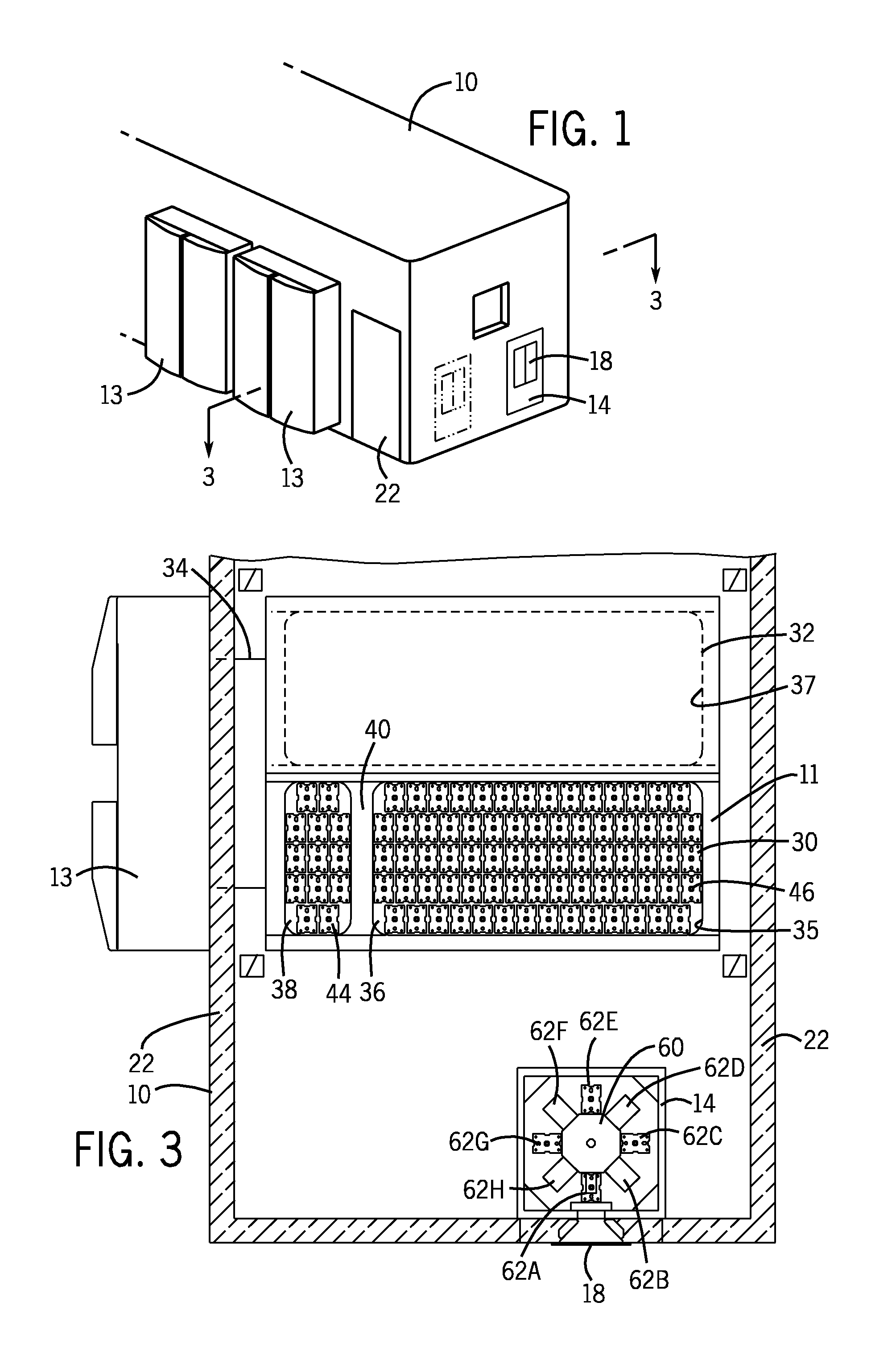

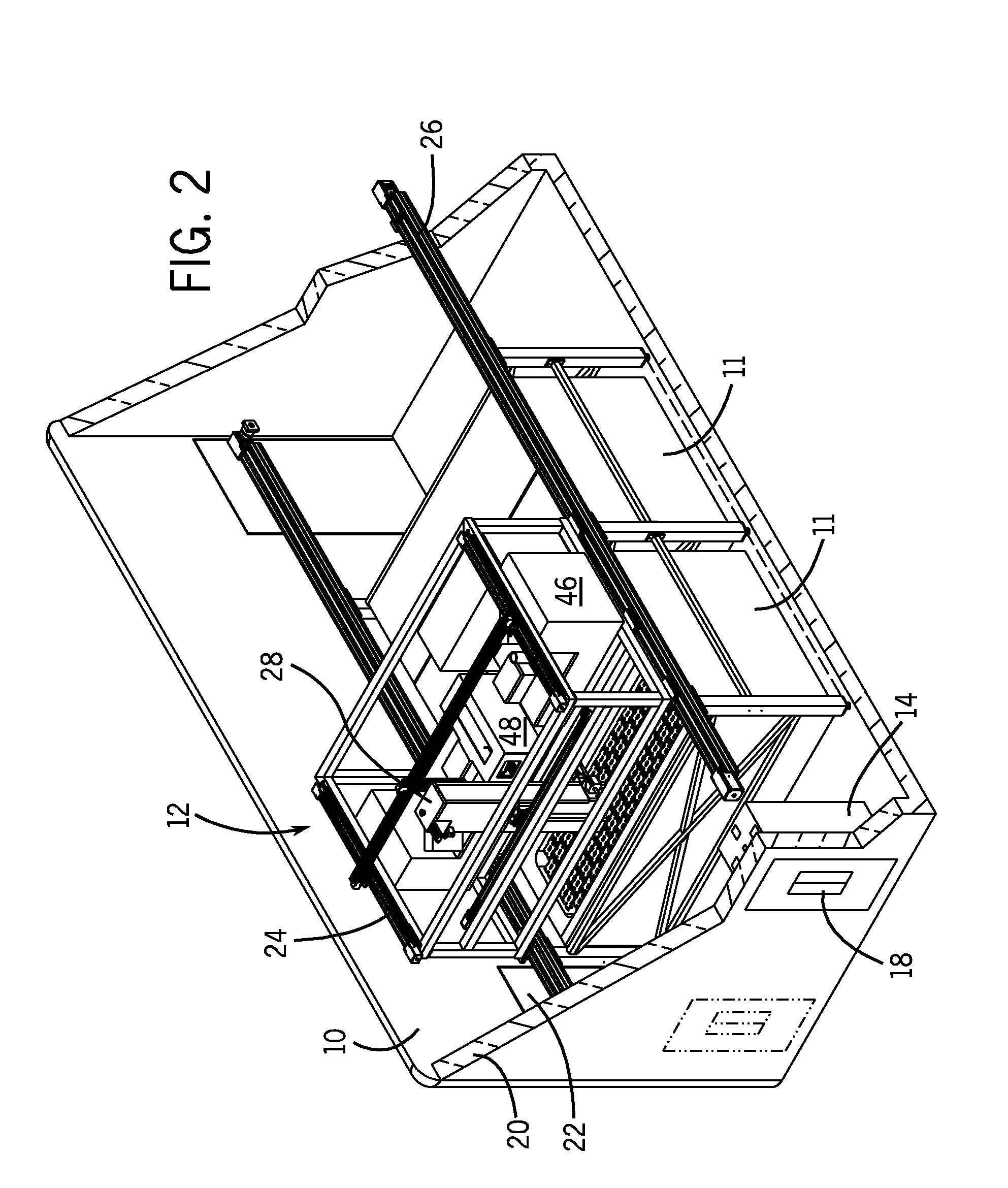

[0027]FIG. 1 illustrates the outside of a refrigerated enclosure 10 maintained at a temperature of approximately −15° C. to −30° C., preferably about −20° C. FIG. 2 shows an automated storage and retrieval system 12 for storing sample tube racks or plates at an ultra-low or cryogenic temperature located within the refrigerated enclosure 10. A sample input / output module 14 is located inside the refrigerated enclosure 10 along its front wall adjacent an opening 16 (FIG. 3) covered by a door 18 or a set of doors. FIGS. 1 and 2 illustrate in phantom that it may desirable for the system to include a second input / output module. In FIGS. 1 and 2, the input / output modules are located along a front wall 20 of the refrigerated enclosure 10, however depending on the application it may desirable to locate the input / output module 14 along a sidewall 22 of the refrigerated enclosure 10, for example in the location of the full length door shown in FIGS. 1 and 2. Multiple horizontal freezer chests ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com