Cryogenic refrigerator and control method therefor

a refrigerator and cryogenic technology, applied in the field of cryogenic refrigerators, can solve the problems of high cost of working gas, large loss of expensive working gas, and excess pressure resistance of the pressure vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

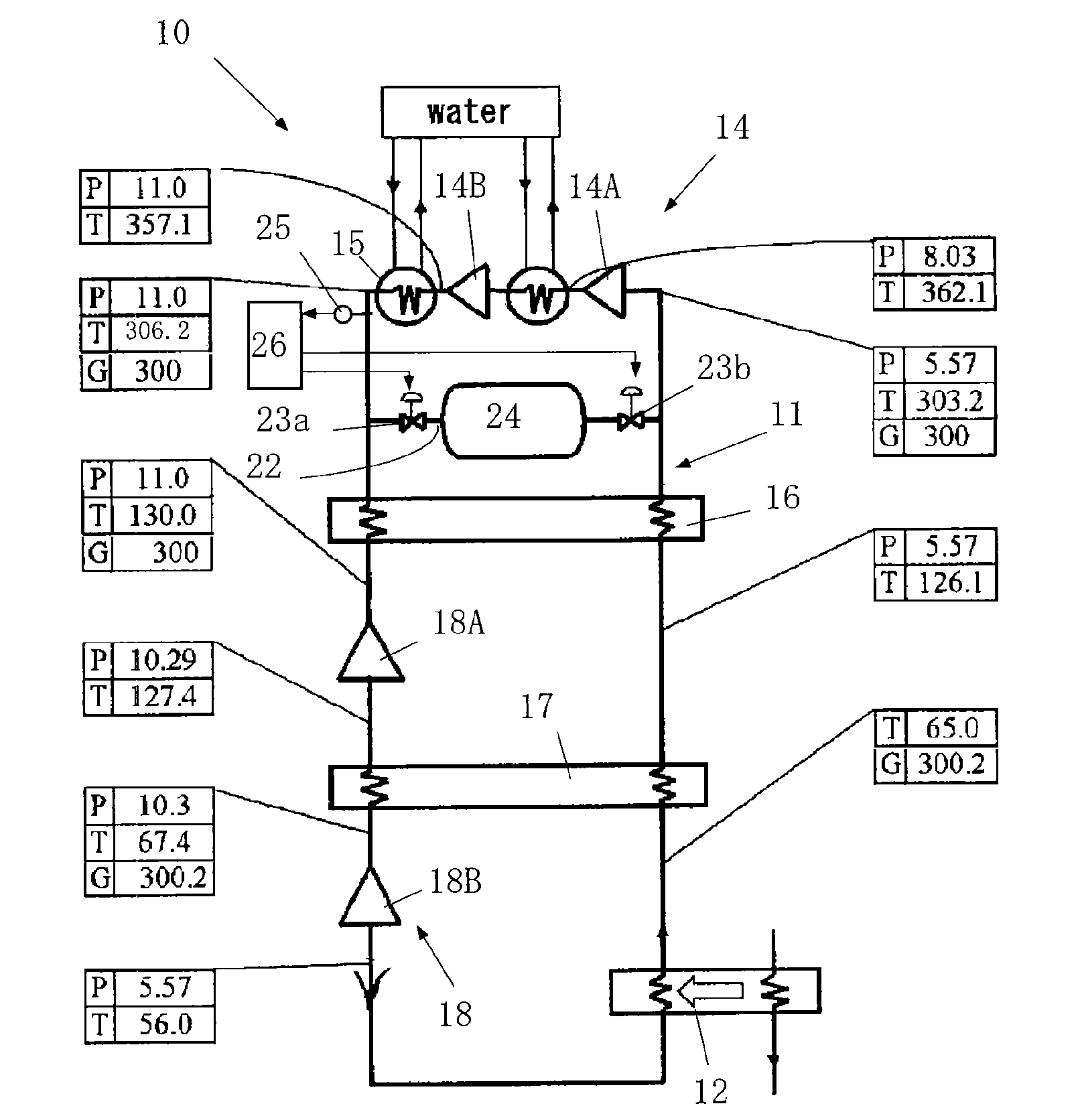

[0068]Referring to FIG. 5, there is shown a diagram illustrating a second embodiment of the cryogenic refrigerator according to the present invention. The outlet temperature of the cryogenic temperature portion is 65 K and the cooling capacity thereof is 3 kW in this example, where P, T and G in this figure represent the pressure (bar), the temperature (K), and the mass flow rate (g / s), respectively.

[0069]In this example, the room-temperature compressor 14 includes a first stage compressor 14A, which compresses a working gas from a predetermined low pressure (5.57 bar) to a first intermediate pressure (8.03 bar) between the low pressure and the high pressure, and a second stage compressor 14B, which compresses the working gas from the first intermediate pressure to a high pressure (11.0 bar). Water-cooled gas coolers 15 are installed on the downstream side (the high-pressure side) of the first stage compressor 14A and the second stage compressor 14B, respectively.

[0070]Moreover, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com