Patents

Literature

419 results about "Brayton cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

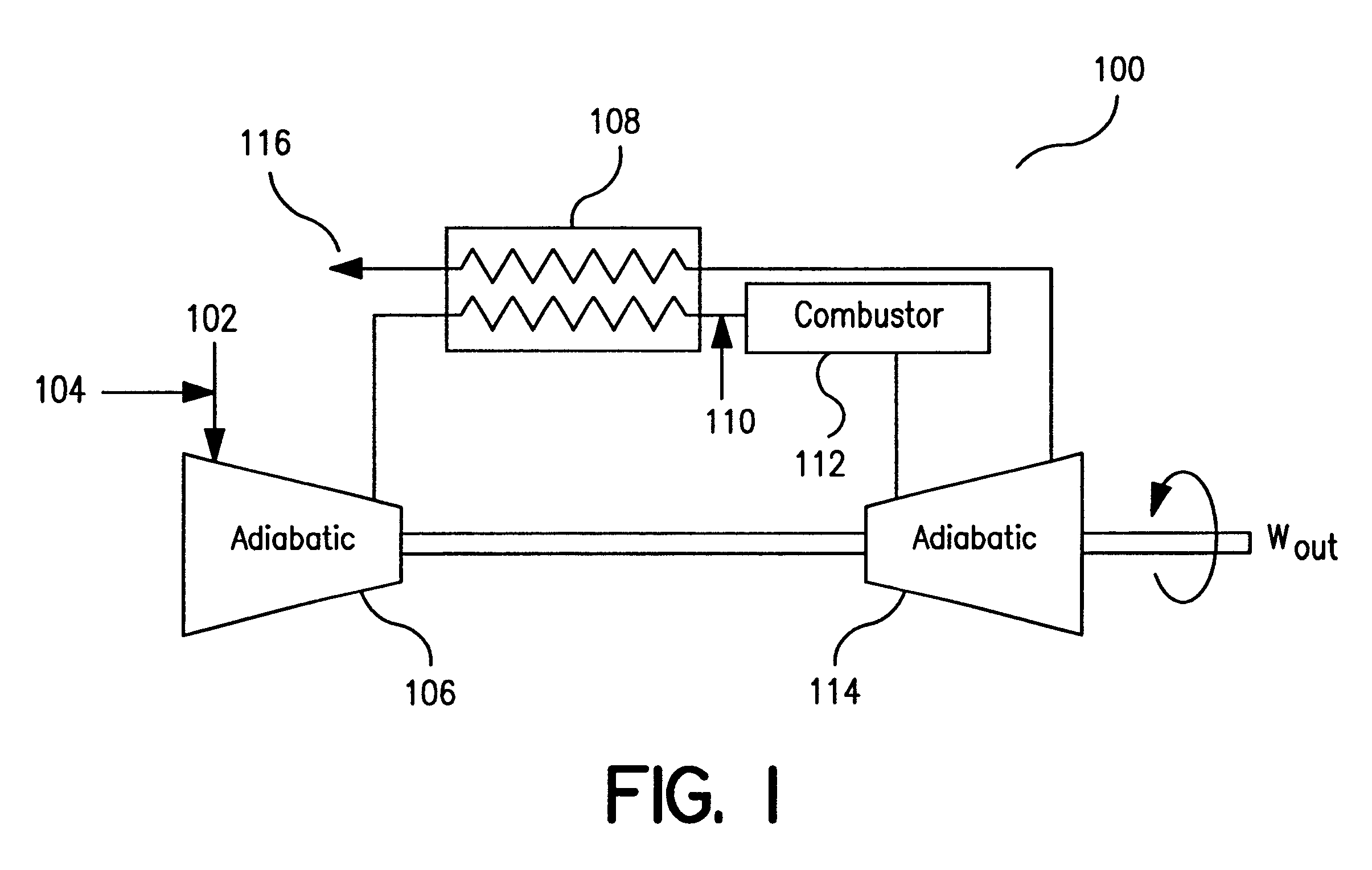

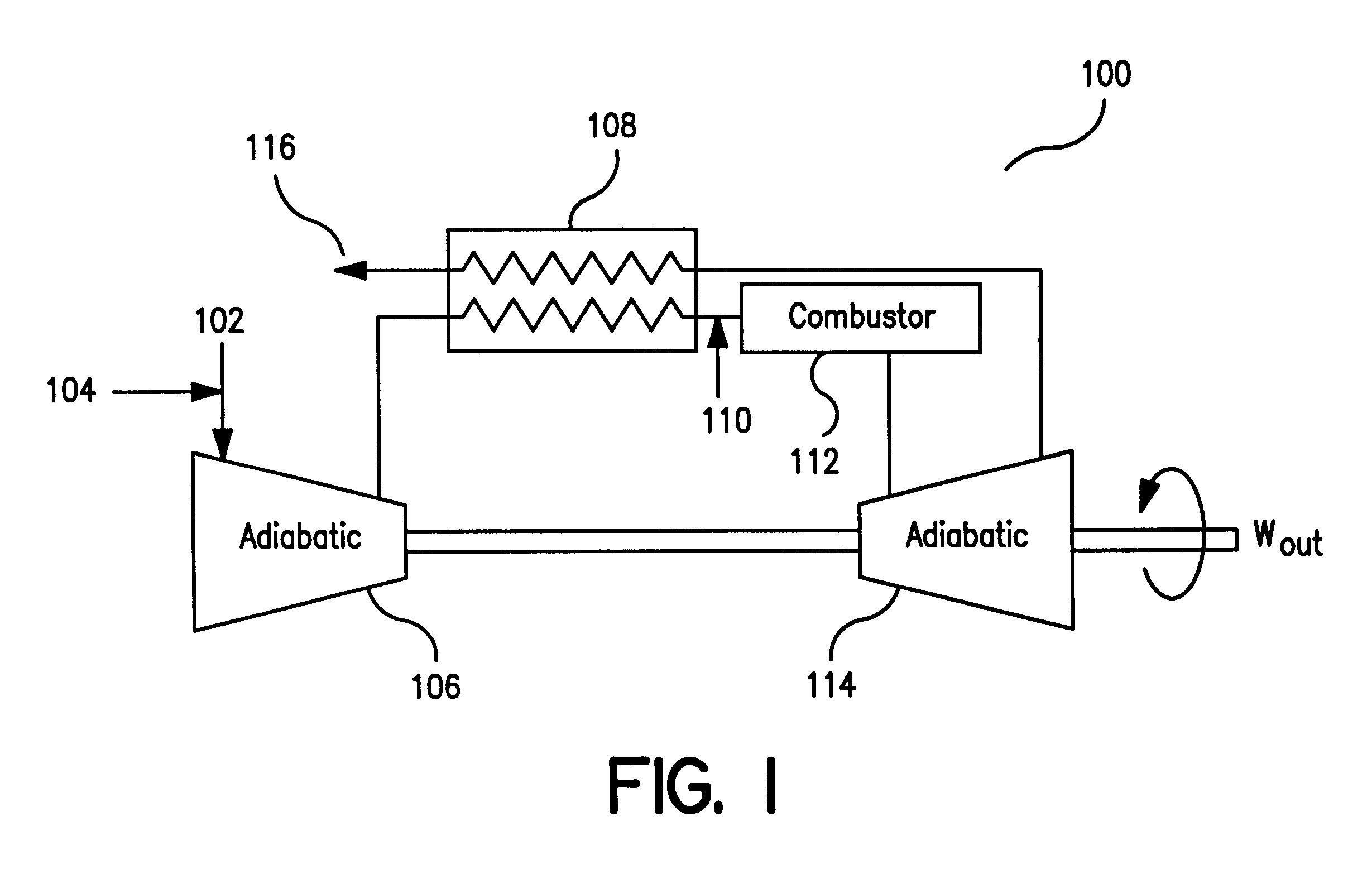

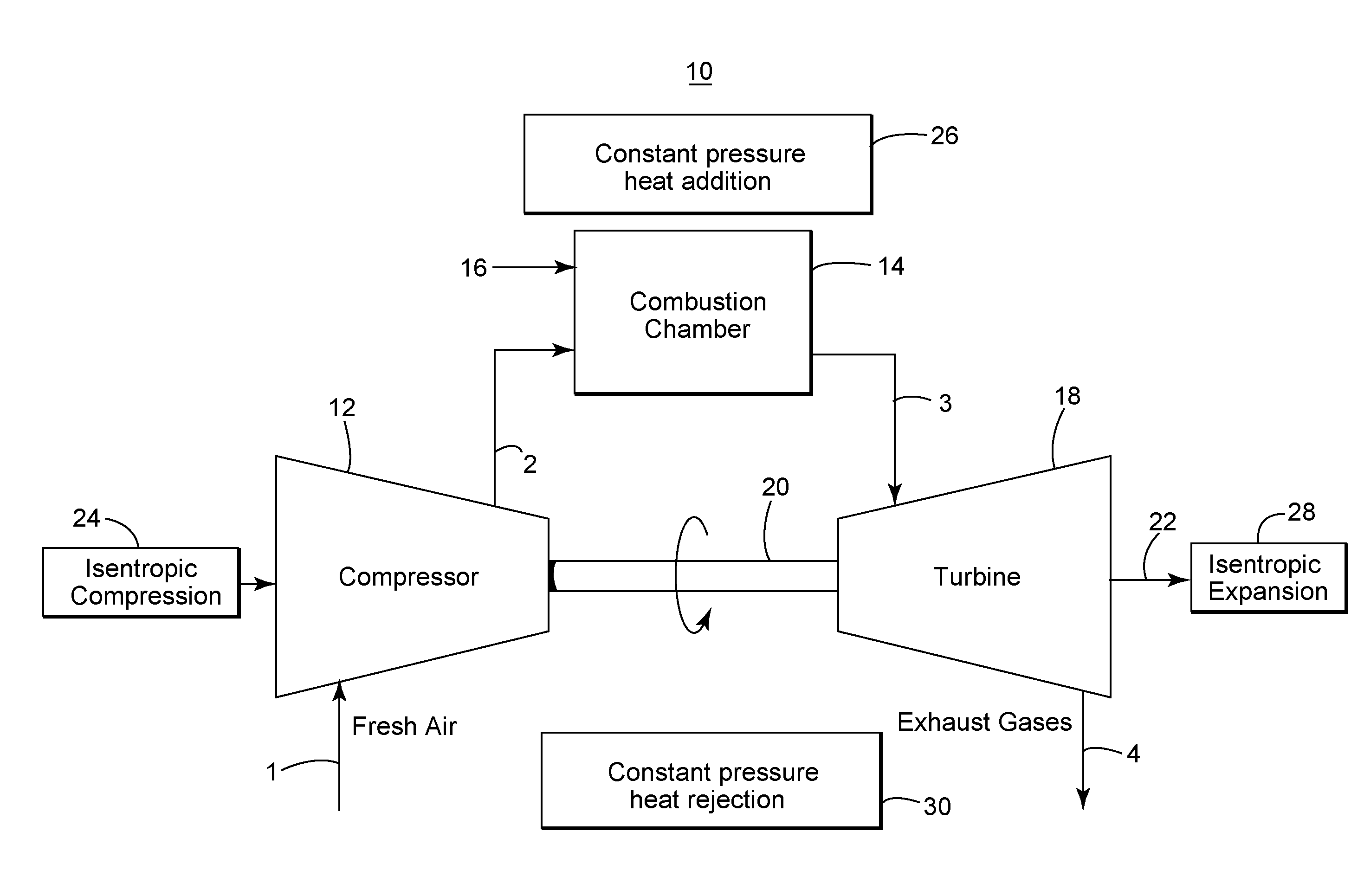

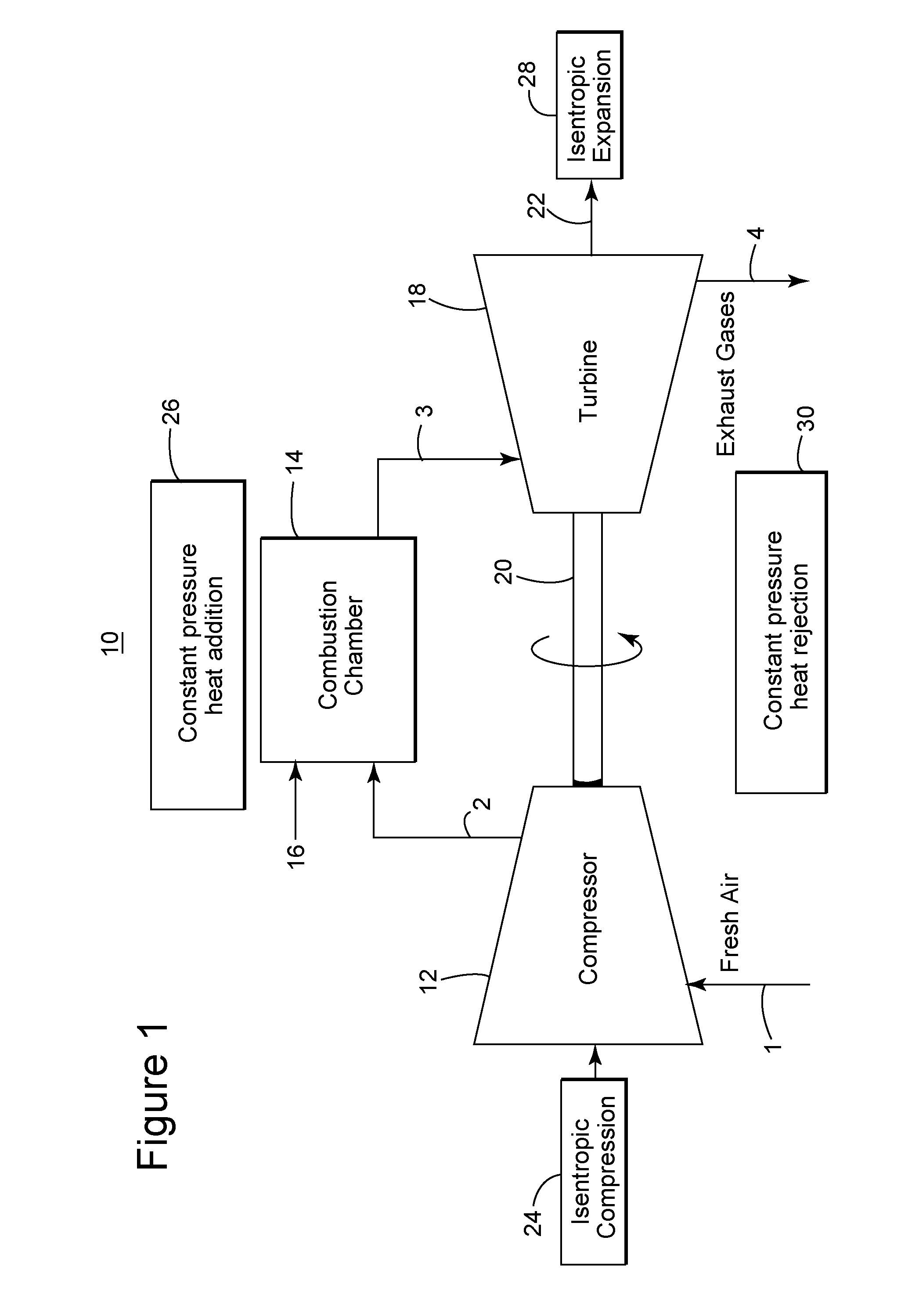

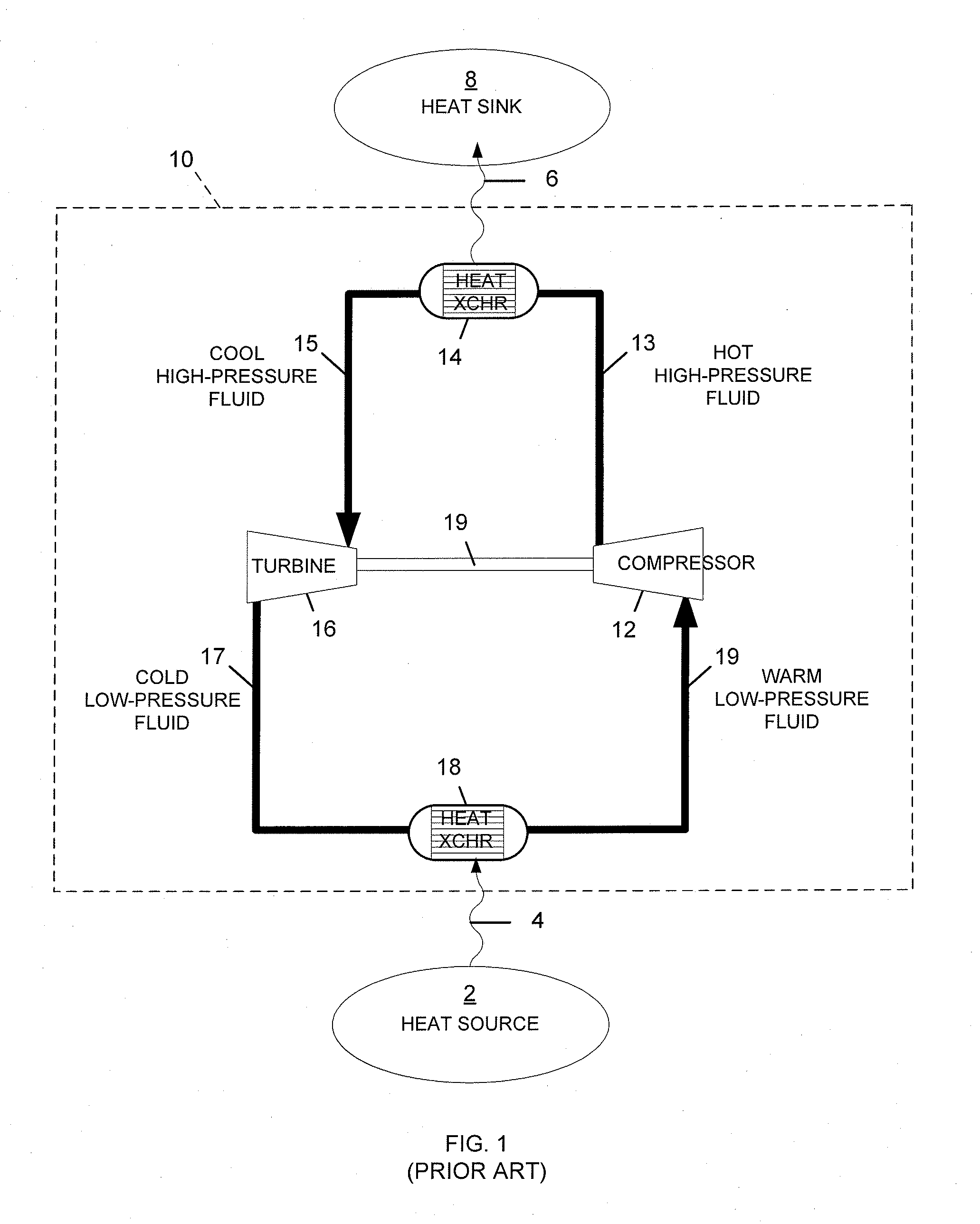

The Brayton cycle is a thermodynamic cycle named after George Brayton that describes the workings of a constant-pressure heat engine. The original Brayton engines used a piston compressor and piston expander, but more modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle. Although the cycle is usually run as an open system (and indeed must be run as such if internal combustion is used), it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system.

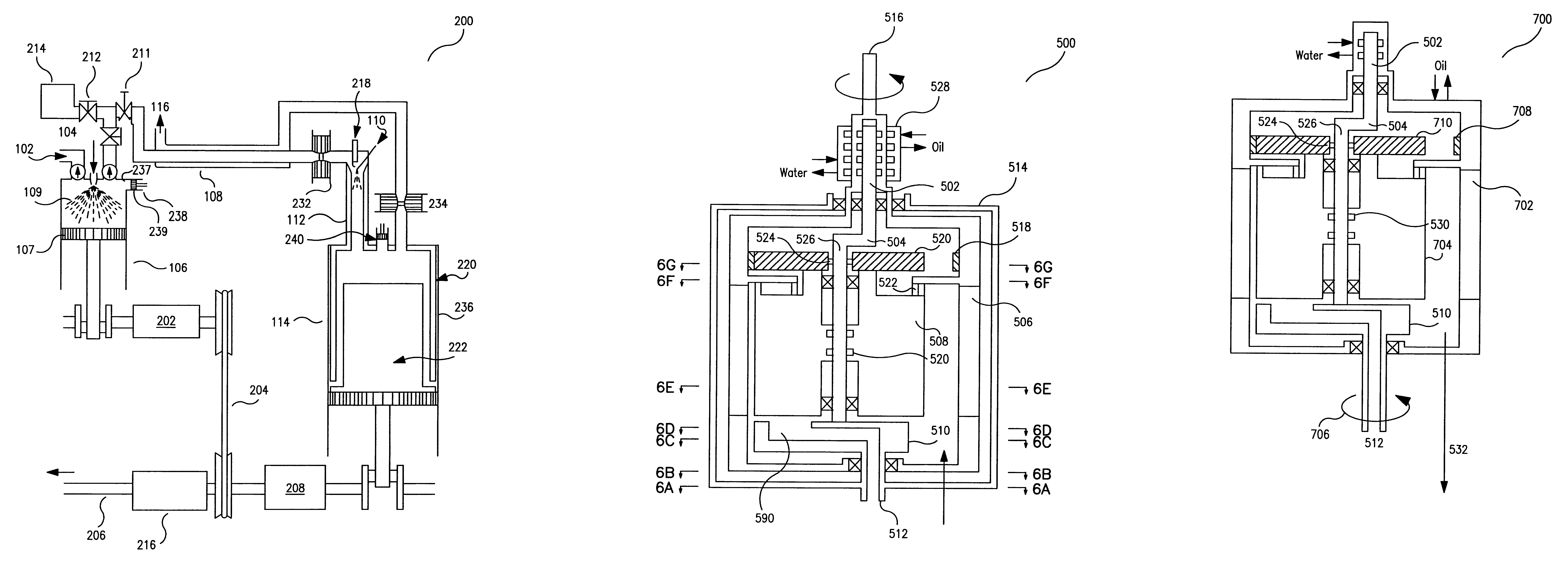

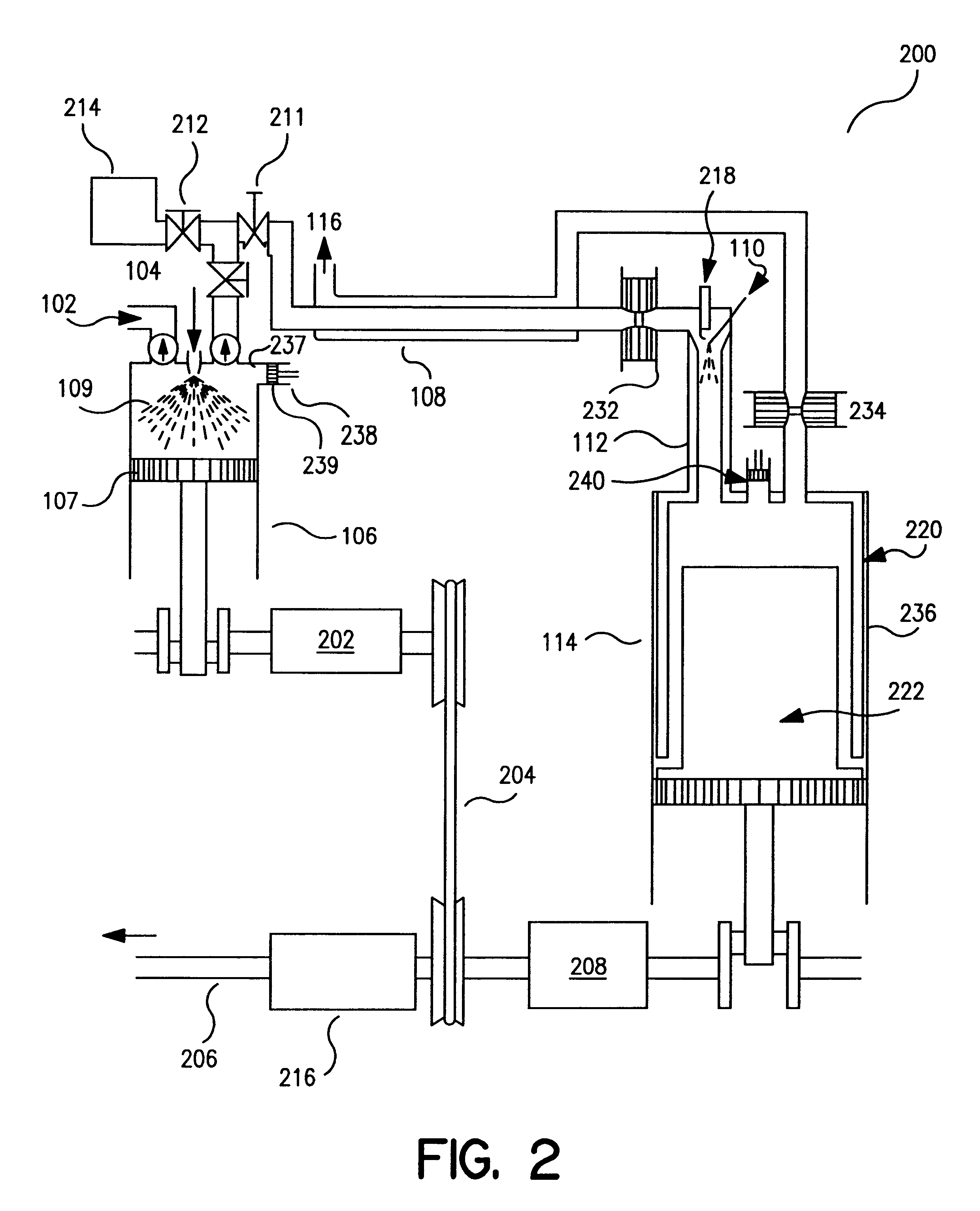

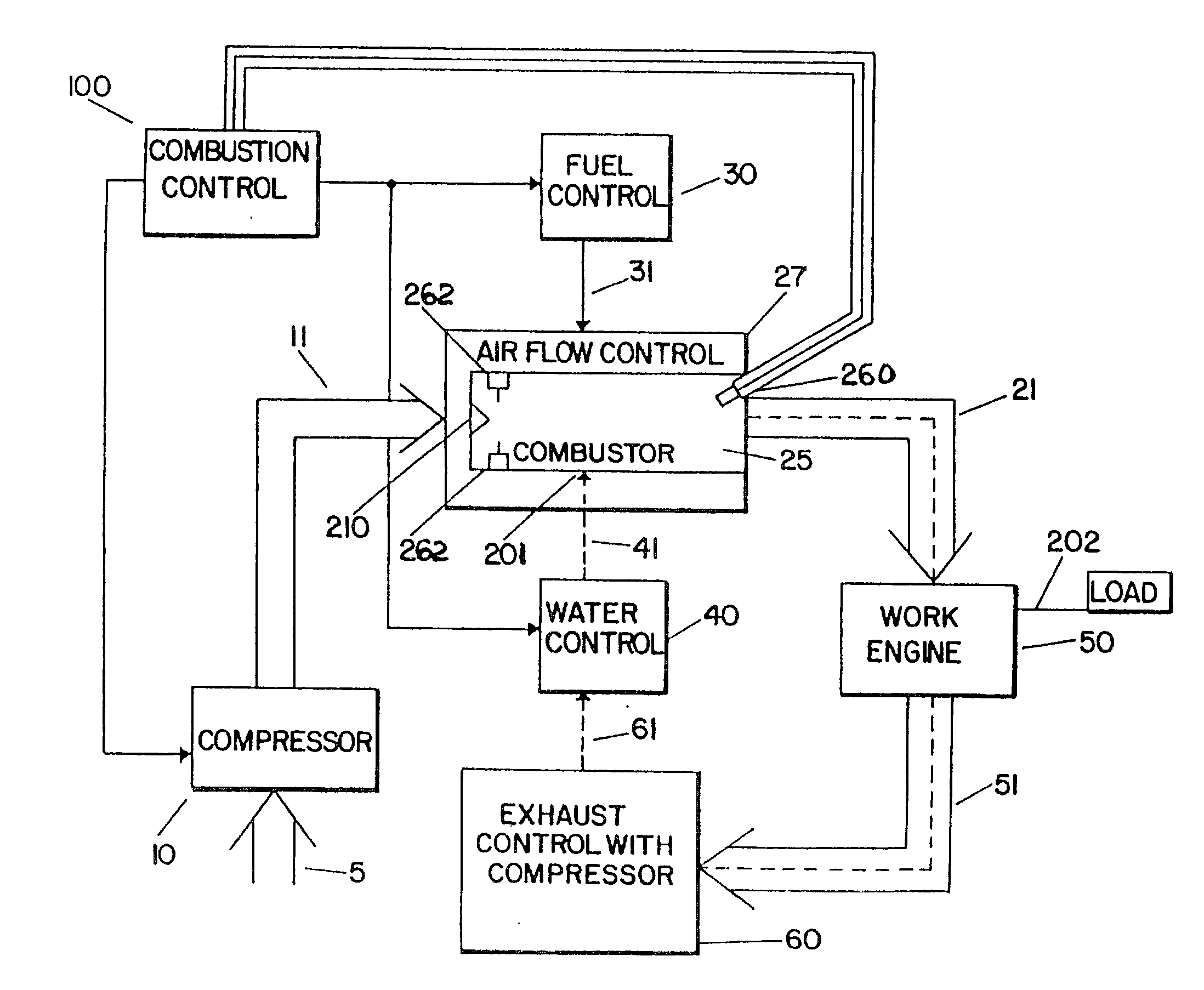

Partial load combustion cycles

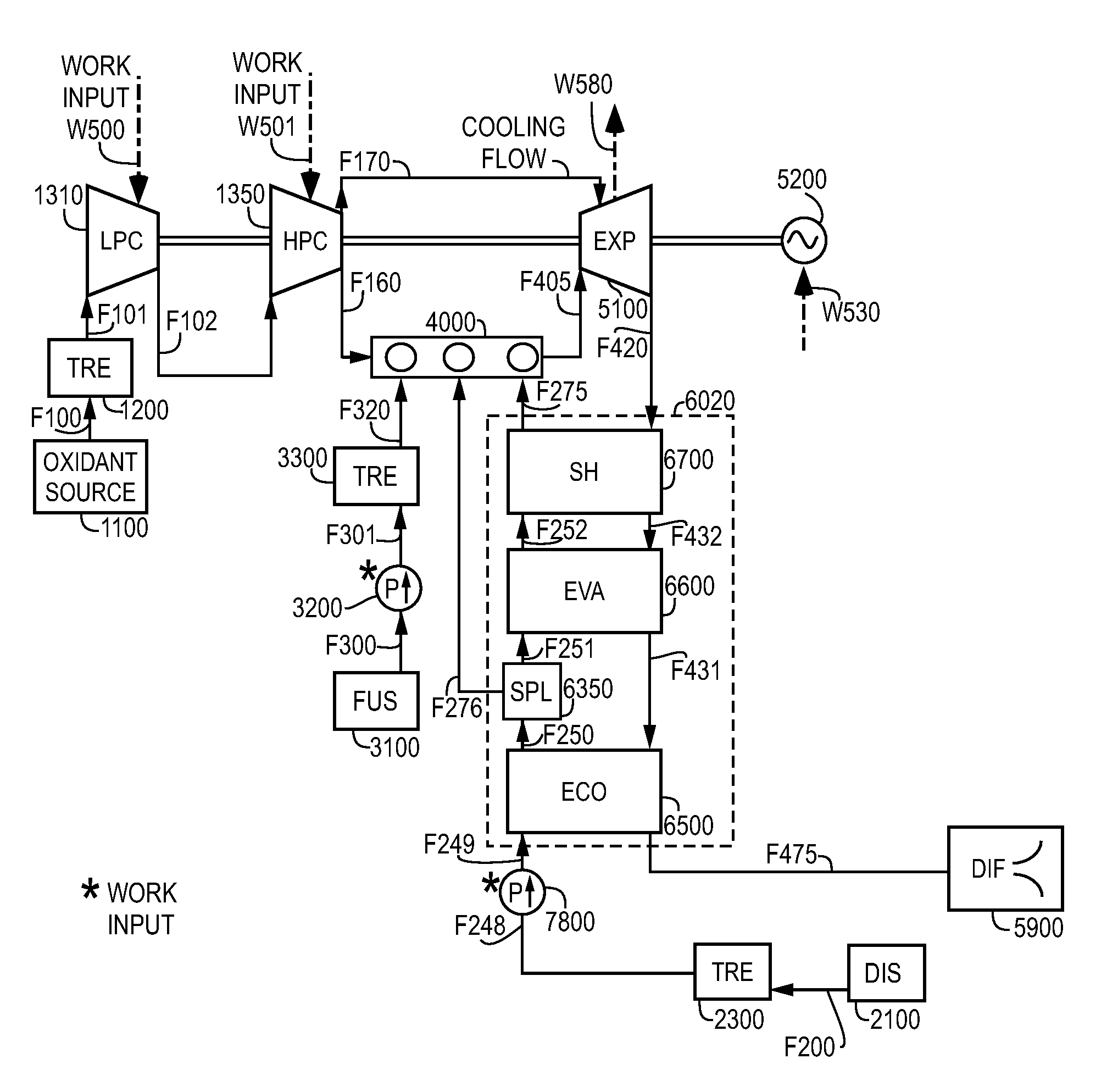

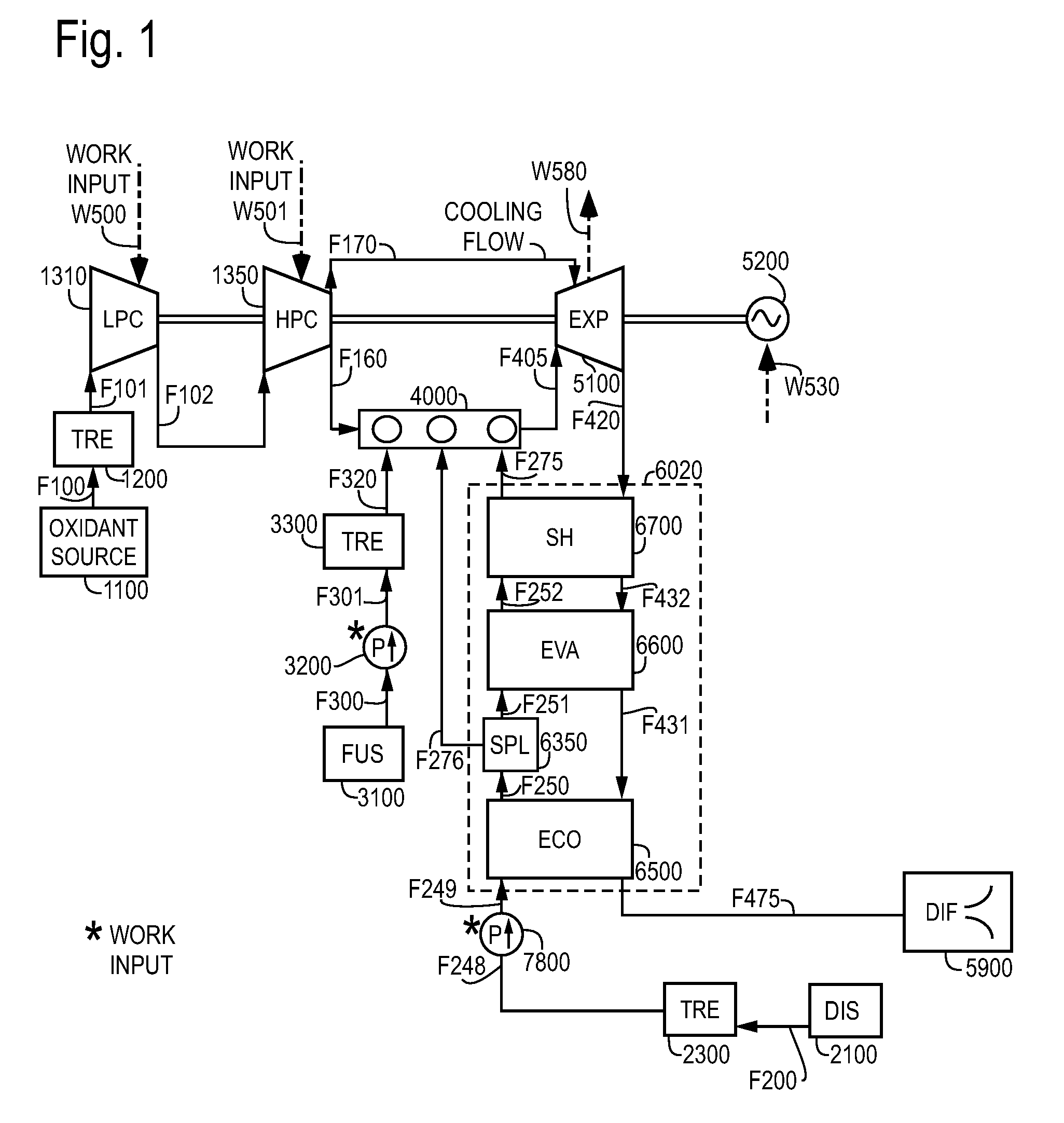

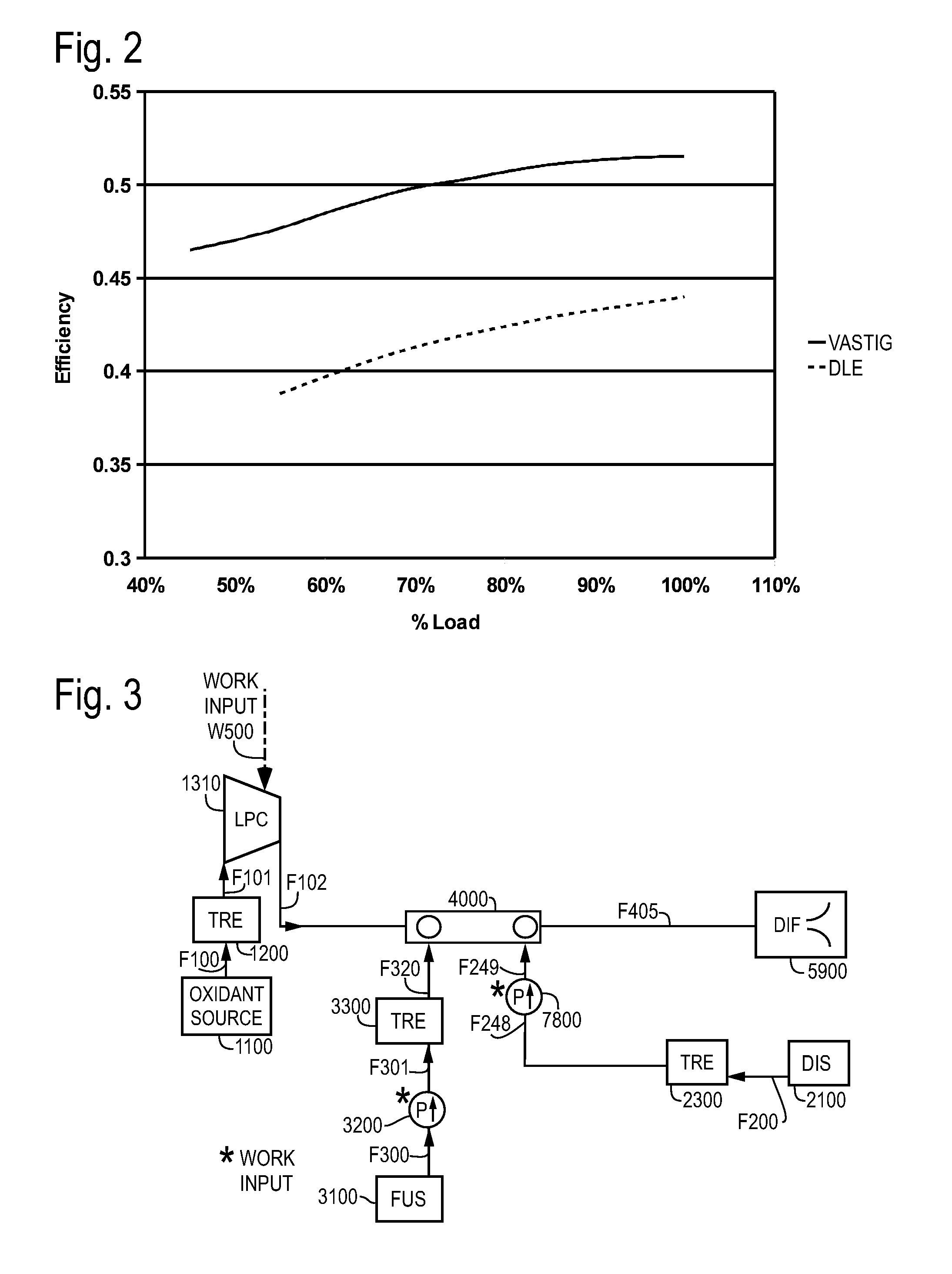

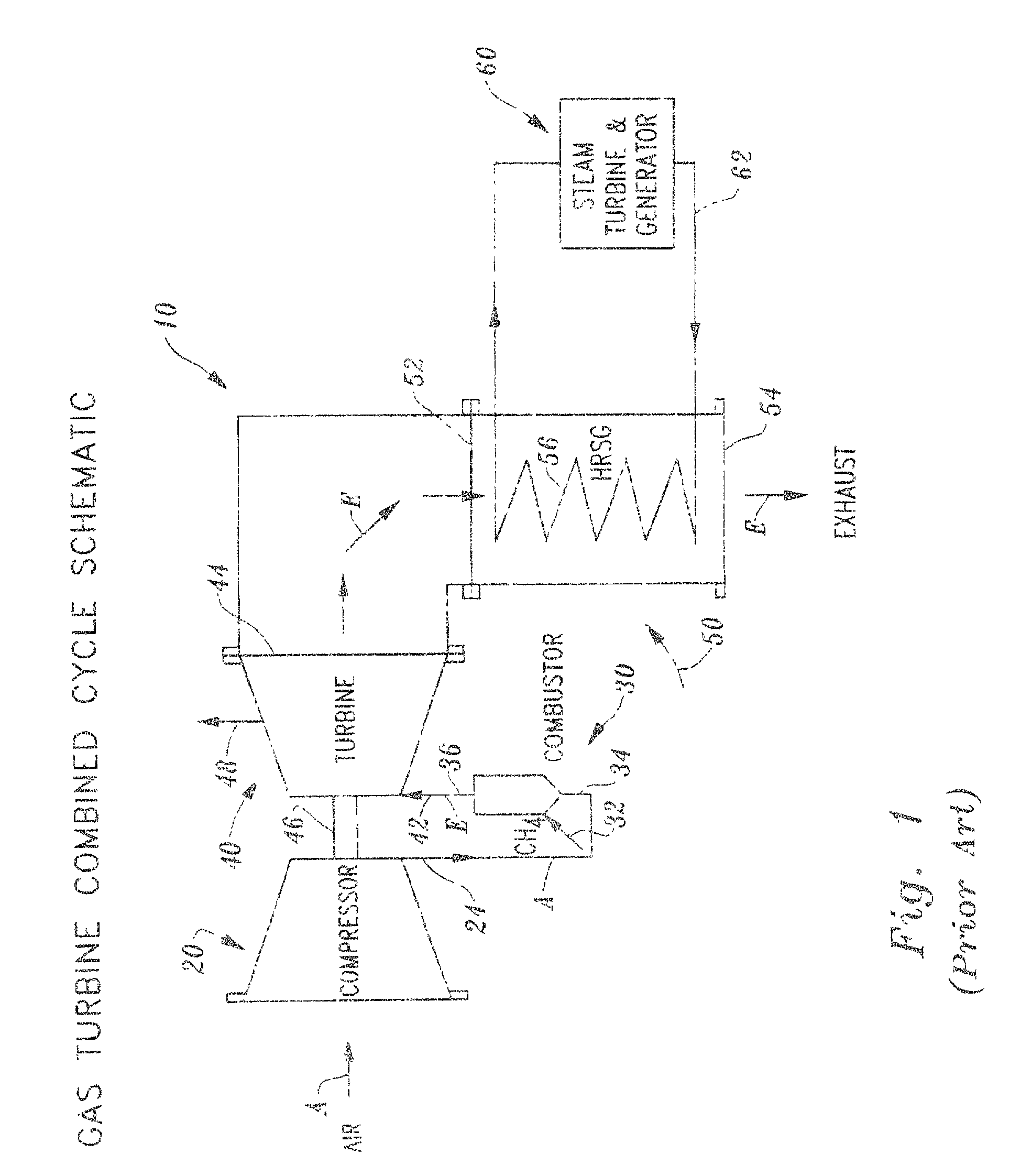

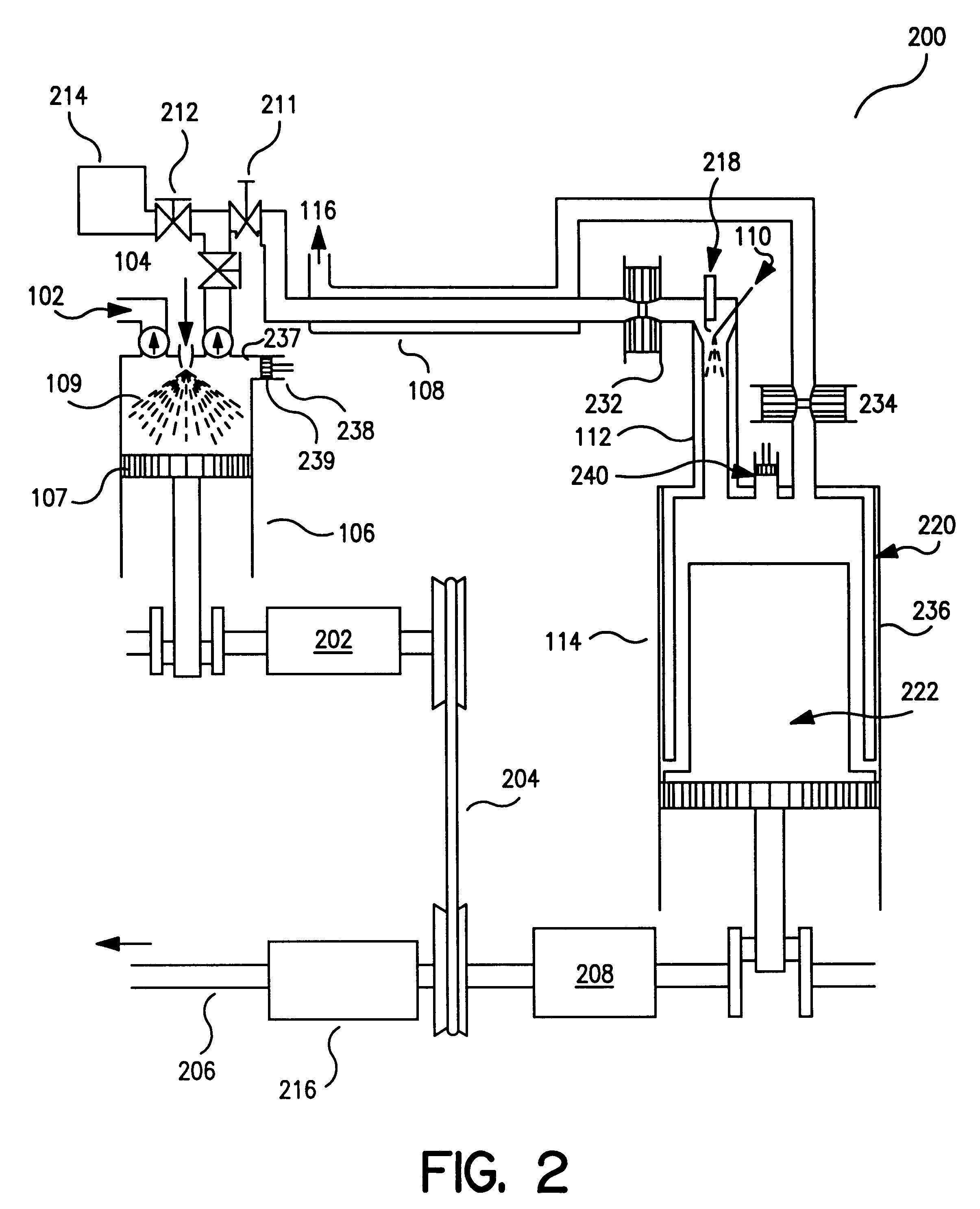

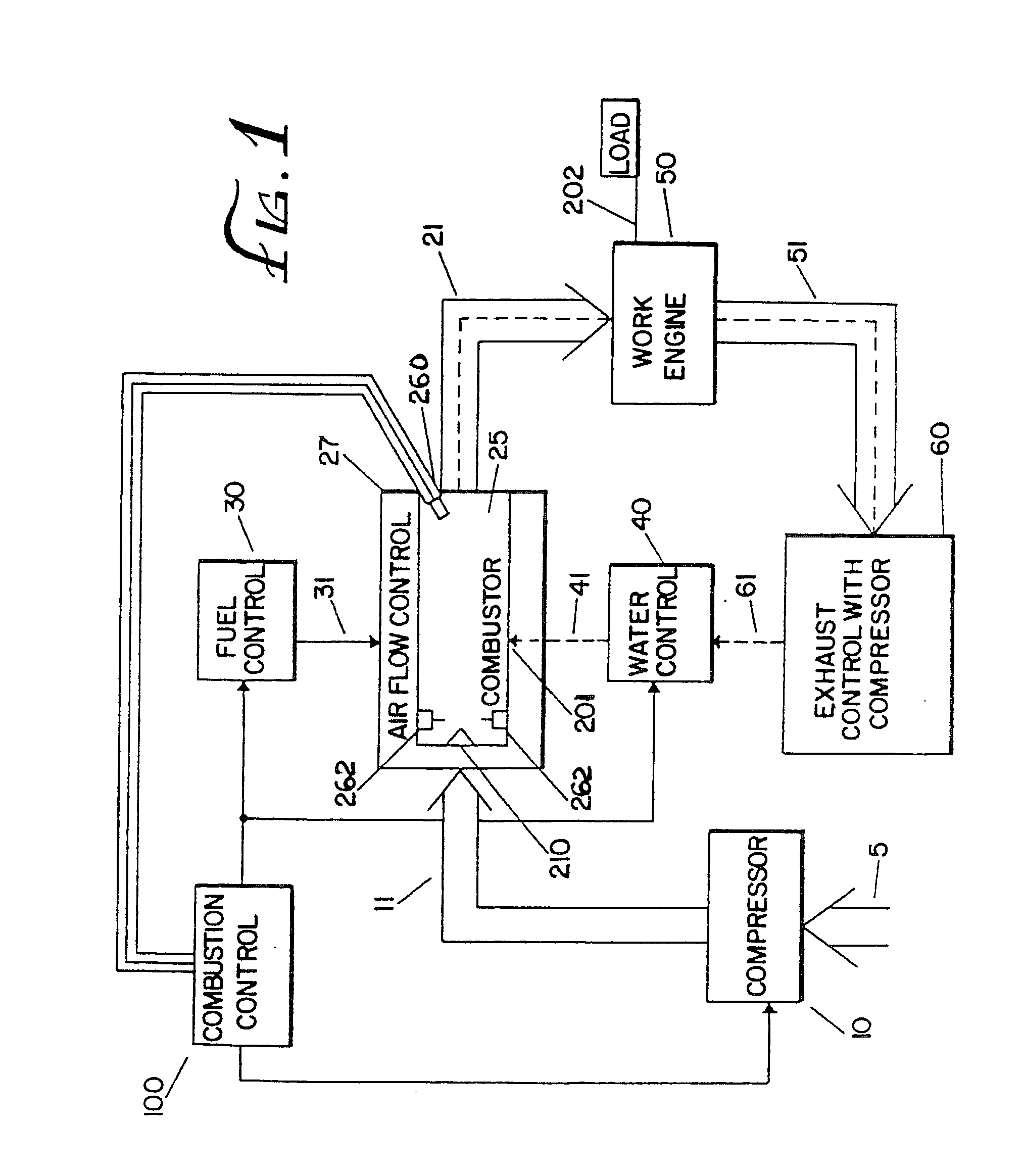

ActiveUS20090064653A1Improve efficiencyReduced Power RequirementsGas turbine plantsVehicle heating/cooling devicesBrayton cycleCombustion

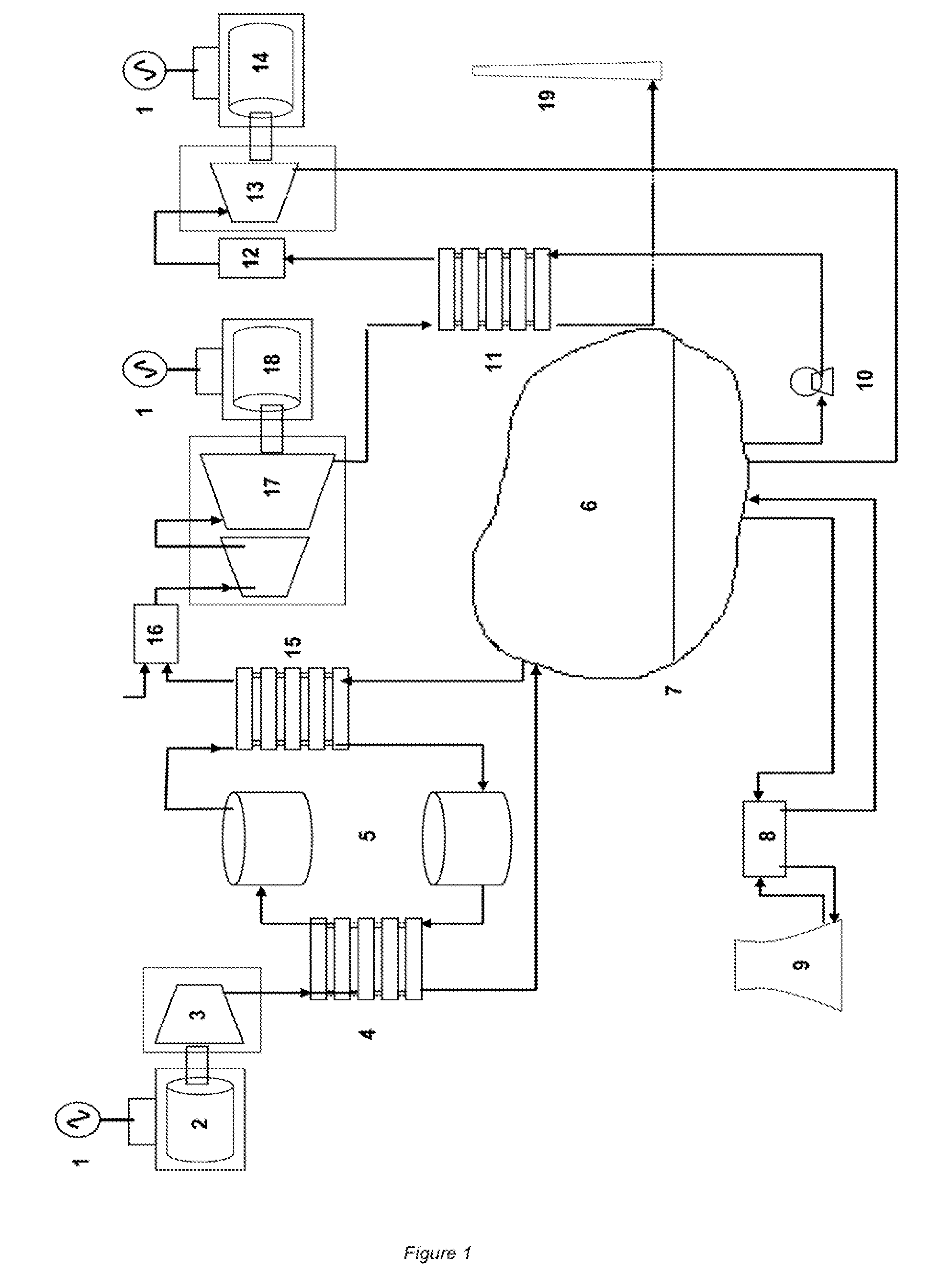

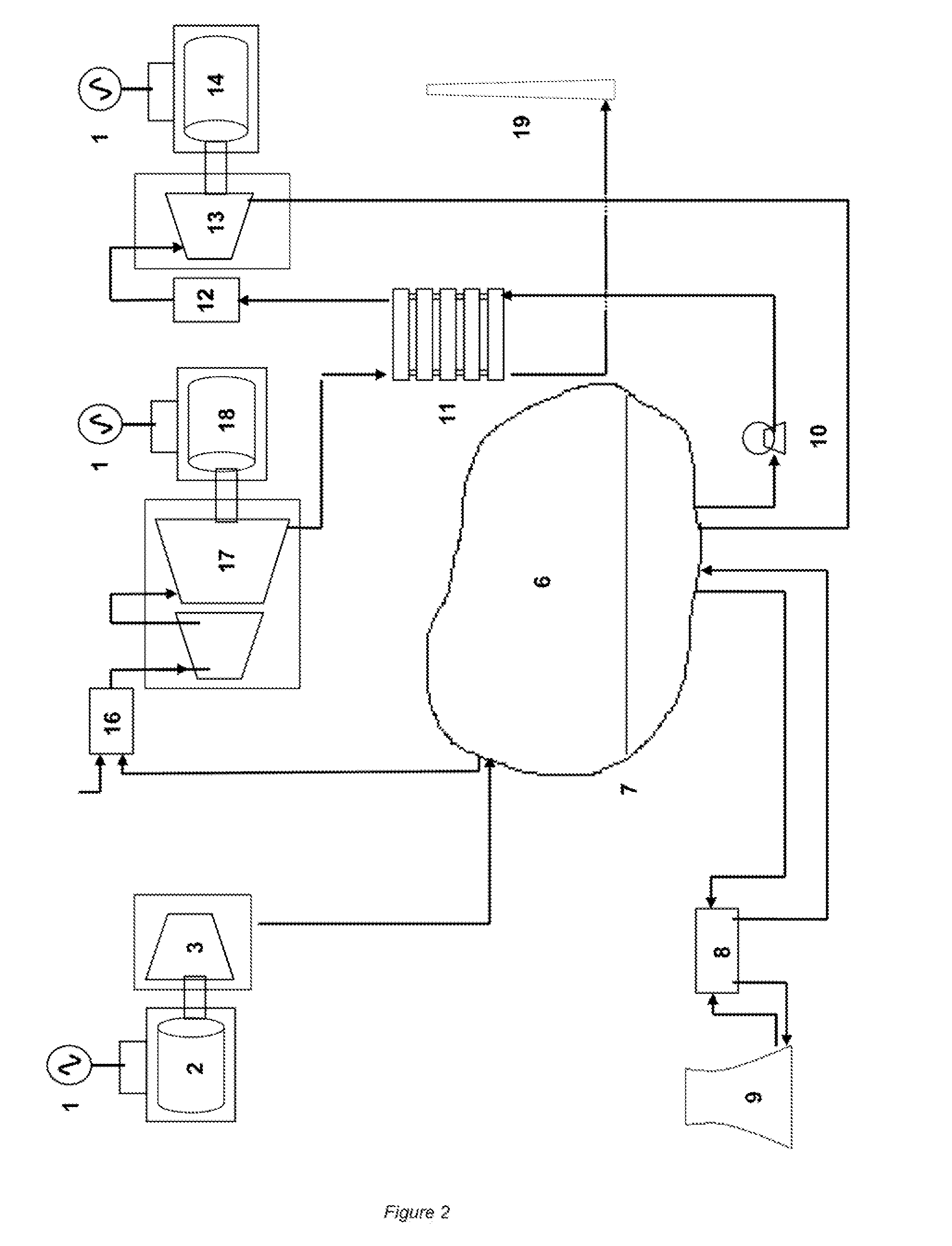

The part load method controls delivery of diluent fluid, fuel fluid, and oxidant fluid in thermodynamic cycles using diluent, to increase the Turbine Inlet Temperature (TIT) and thermal efficiency in part load operation above that obtained by relevant art part load operation of Brayton cycles, fogged Brayton cycles, or cycles operating with some steam delivery, or with maximum steam delivery. The part load method may control the TIT at the design level by controlling one or both of liquid and / or gaseous fluid water over a range from full load to less than 45% load. This extends operation to lower operating loads while providing higher efficiencies and lower operating costs using water, steam and / or CO2 as diluents, than in simple cycle operation.

Owner:VAST HLDG LLC

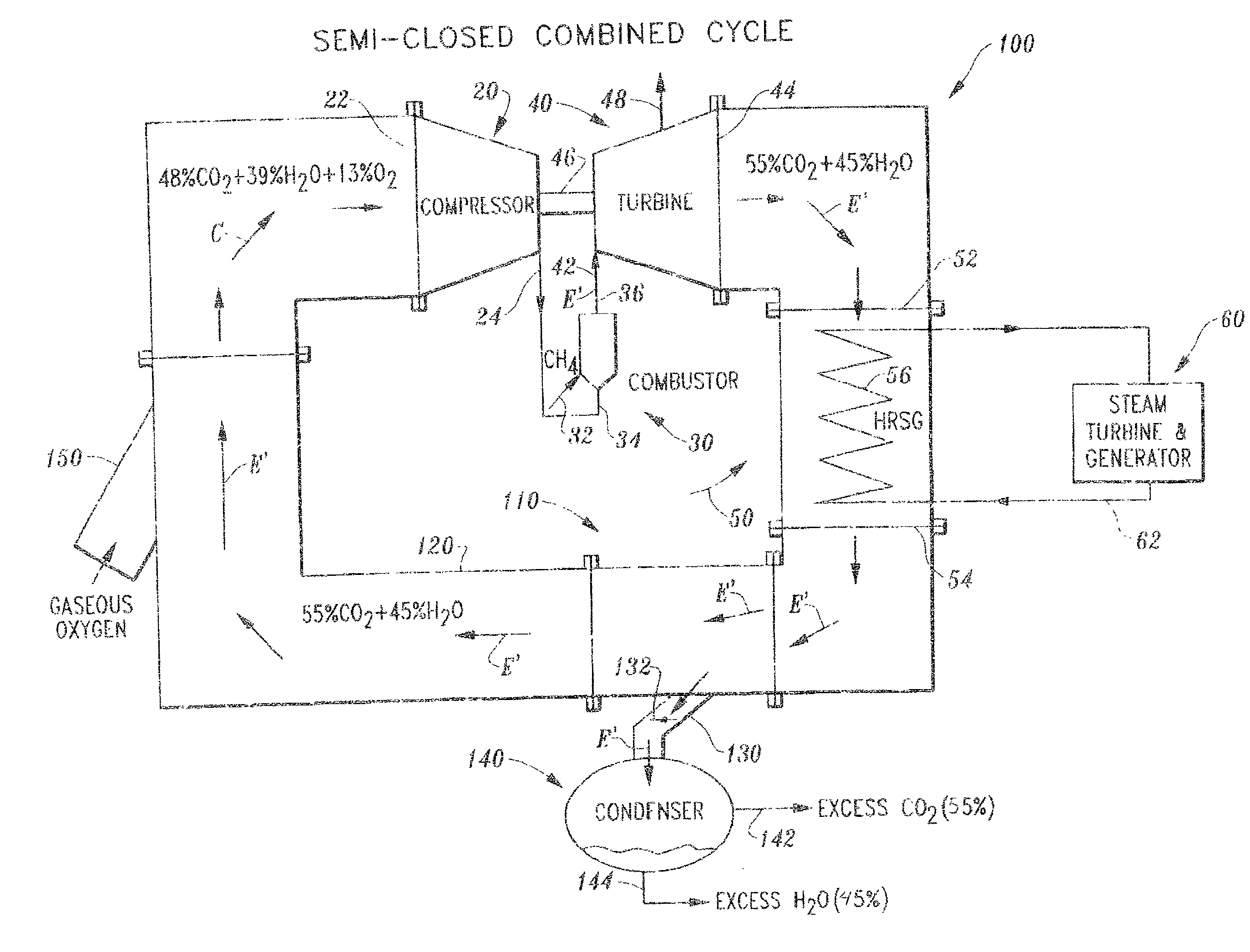

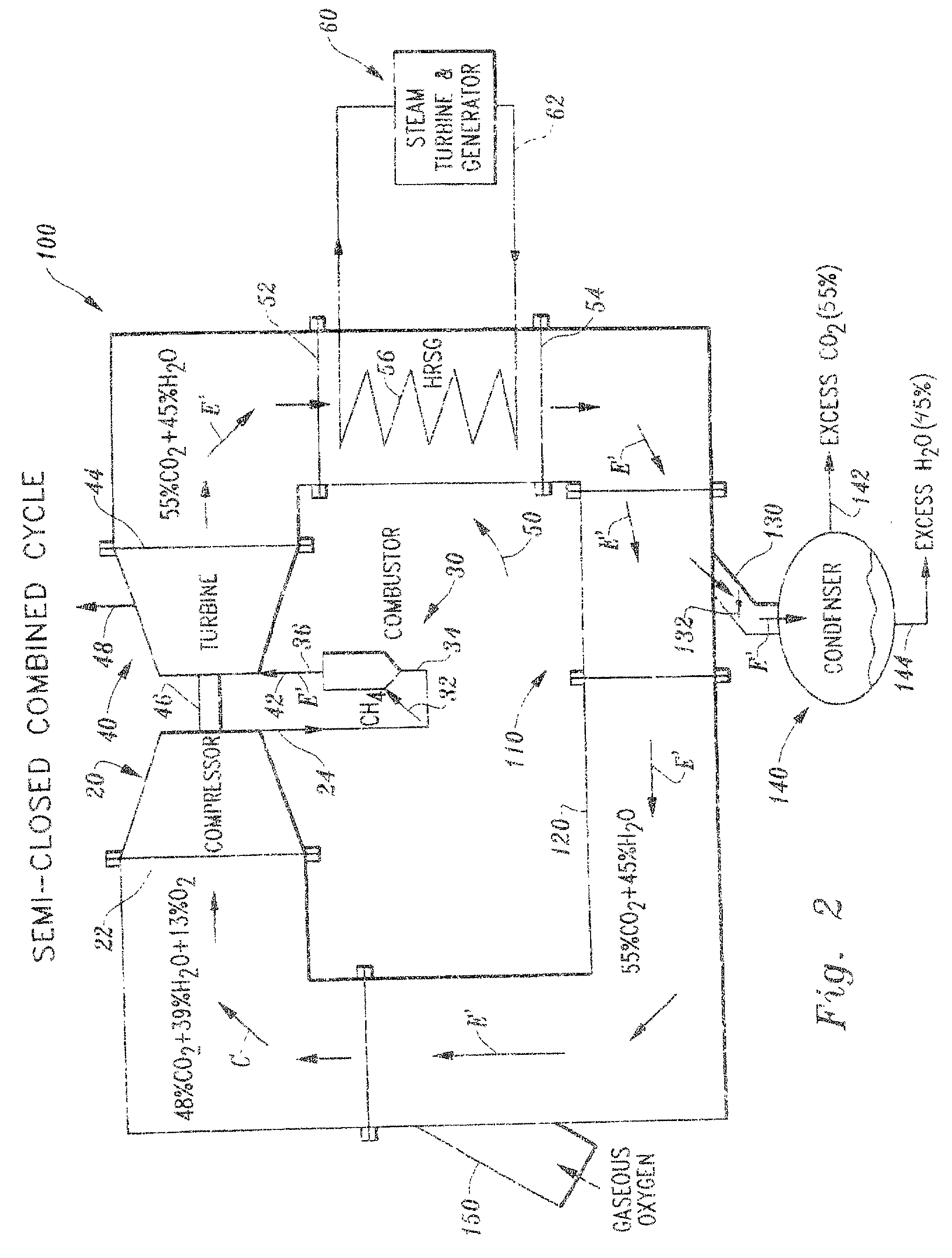

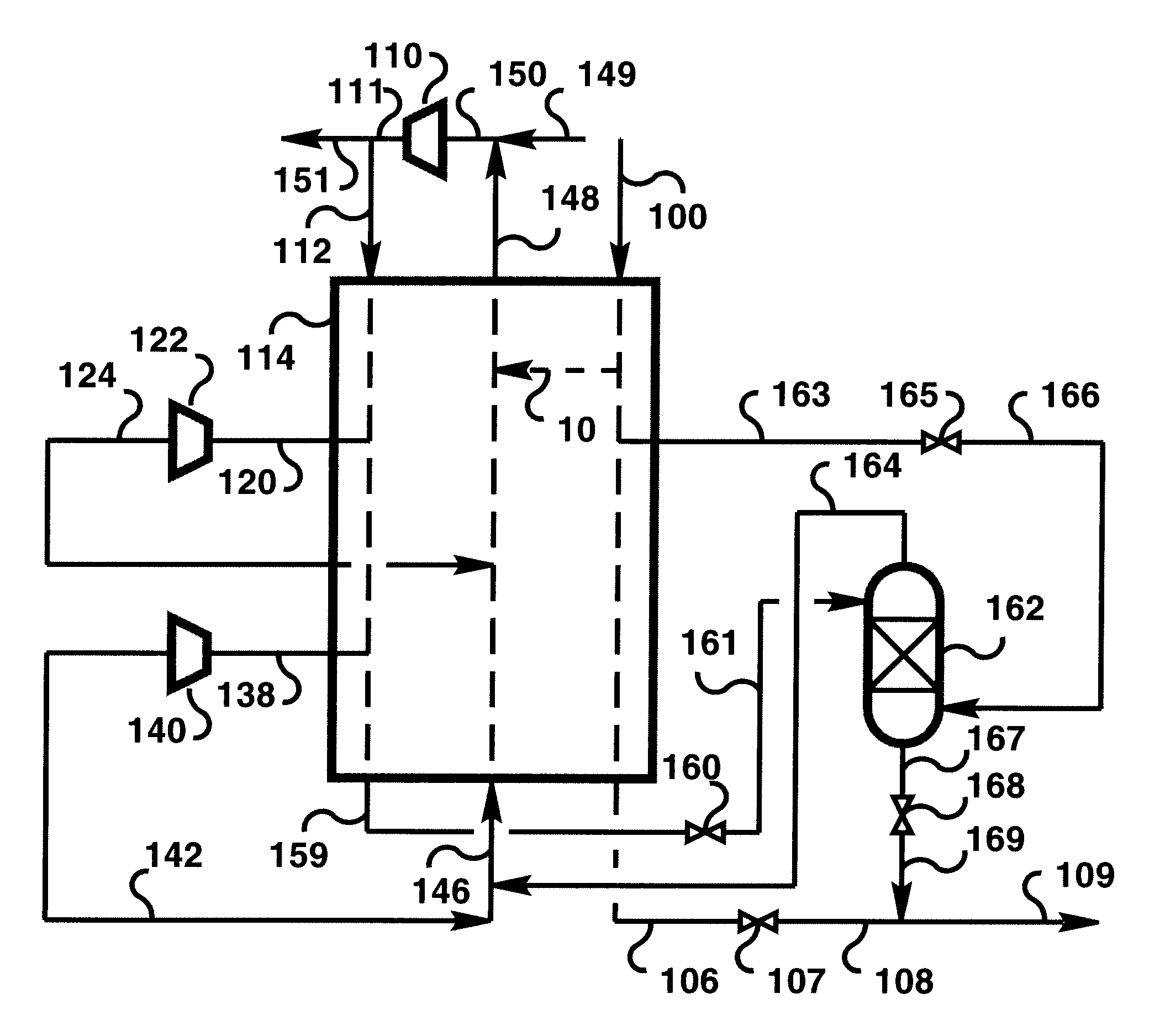

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

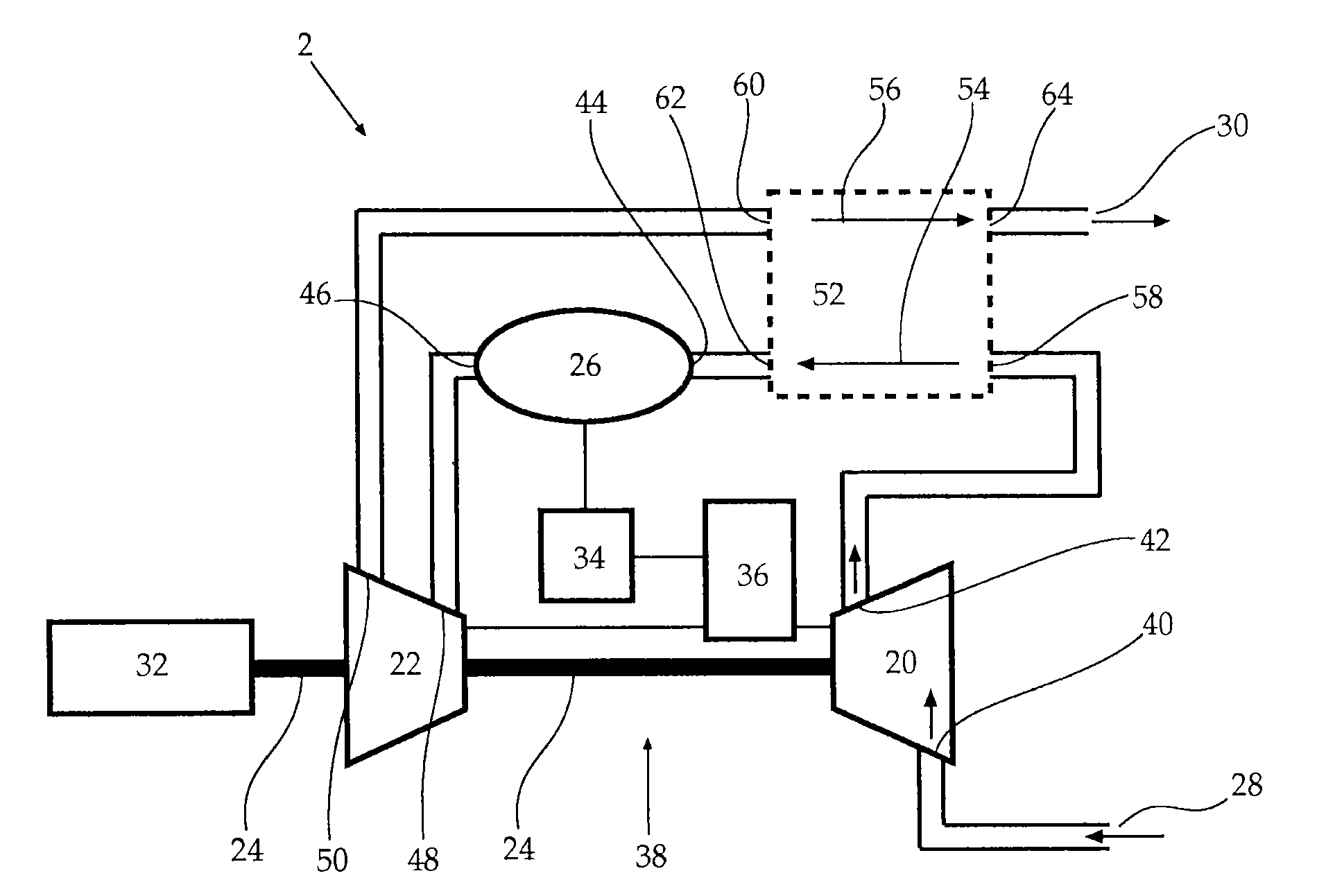

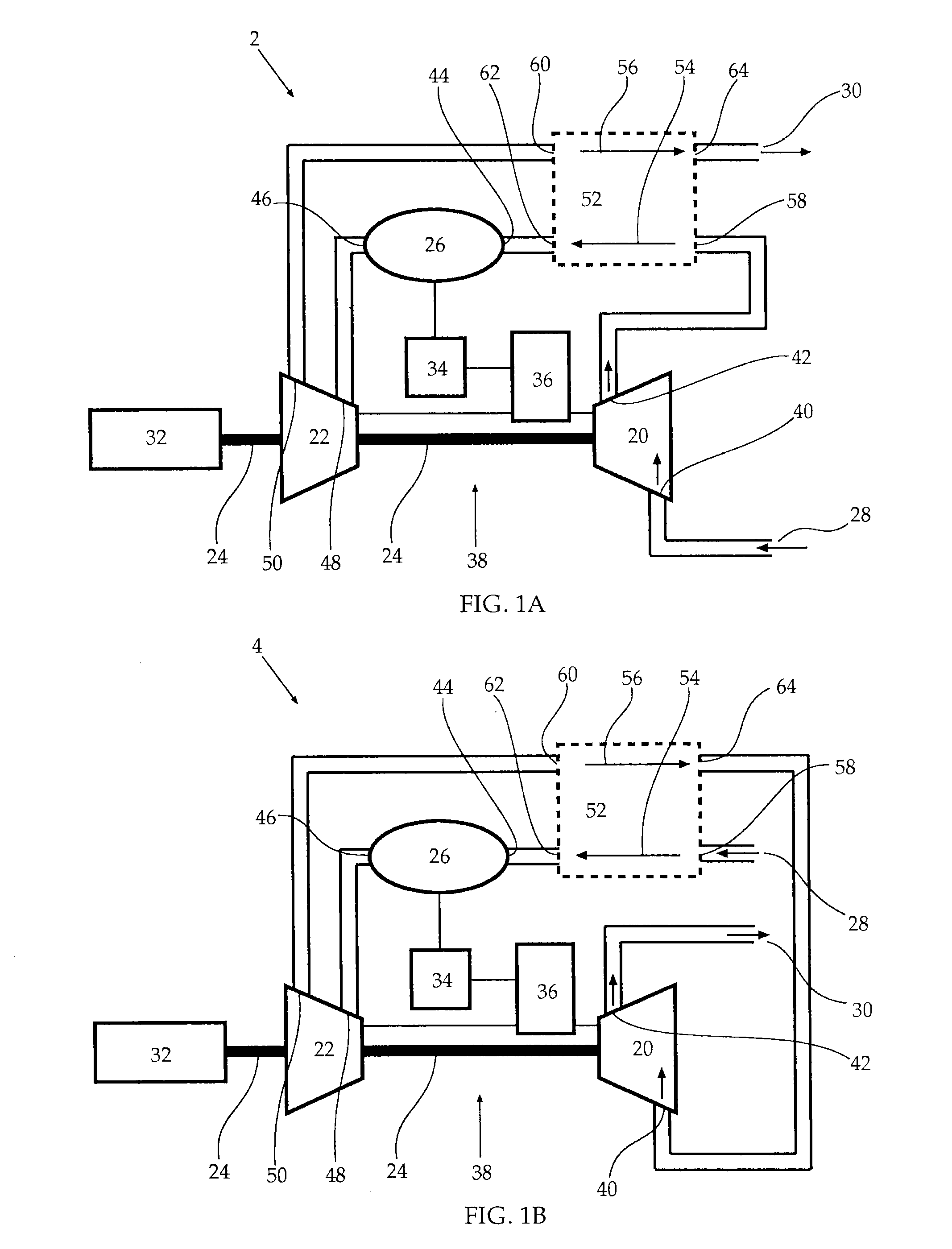

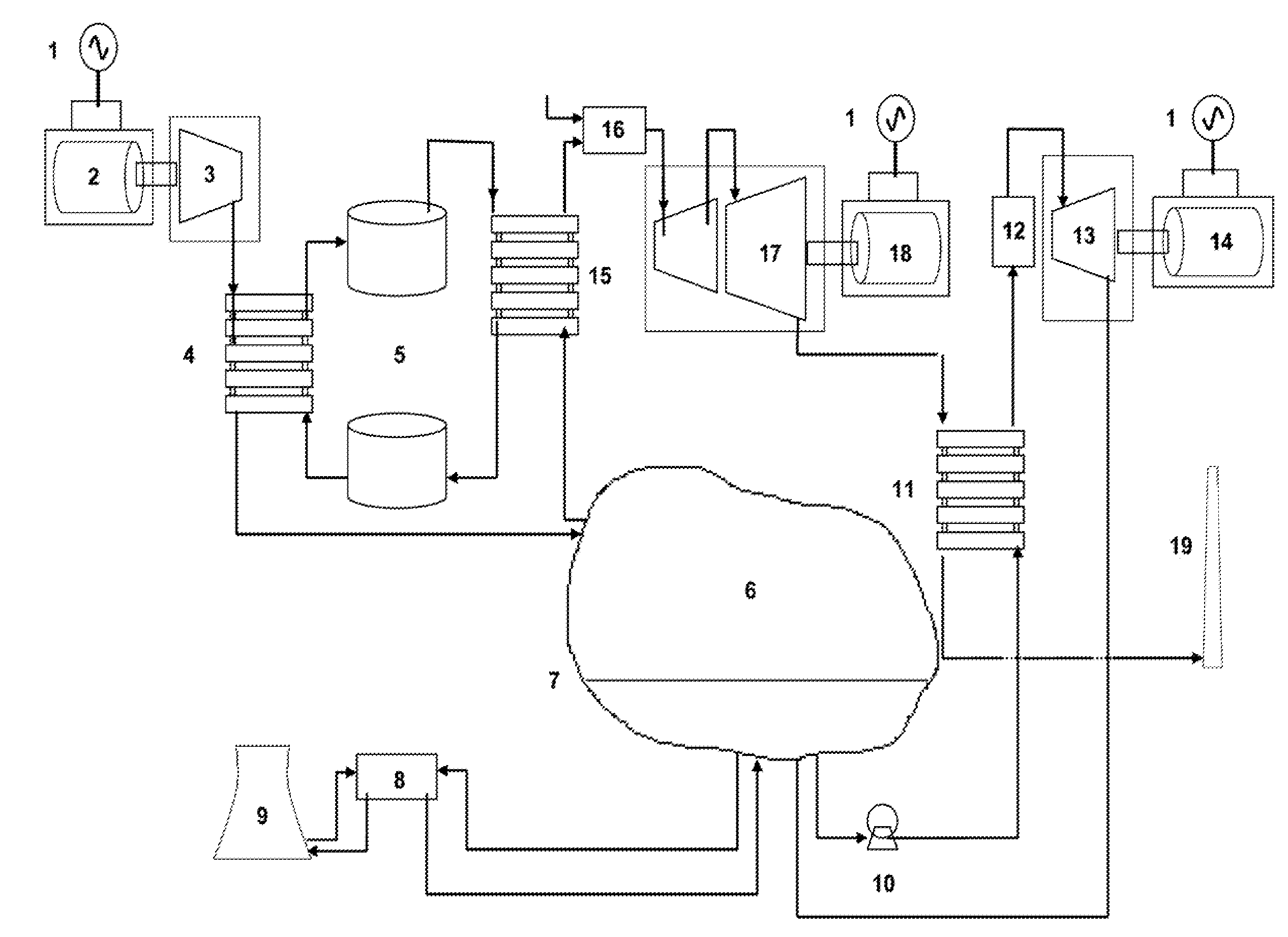

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

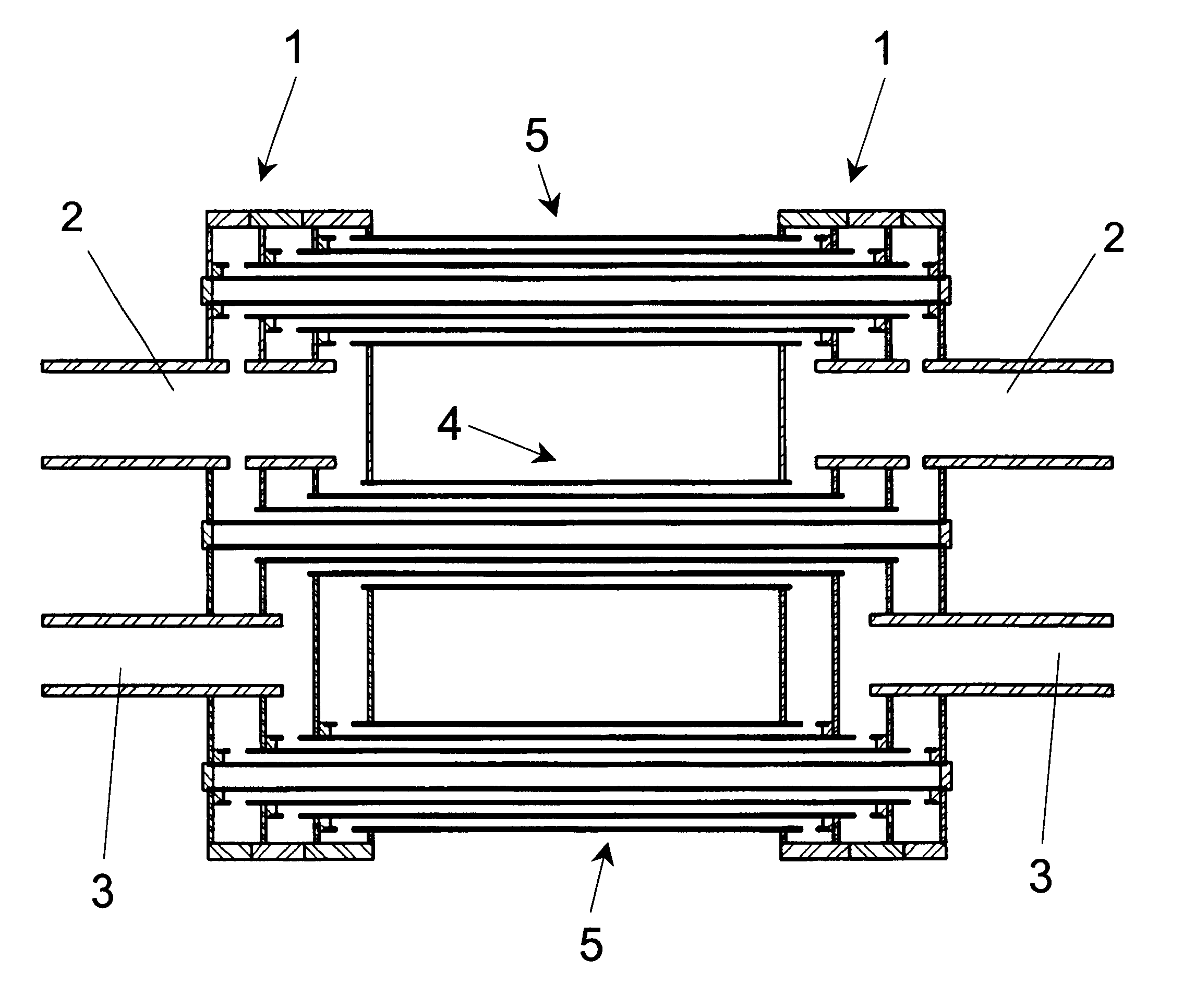

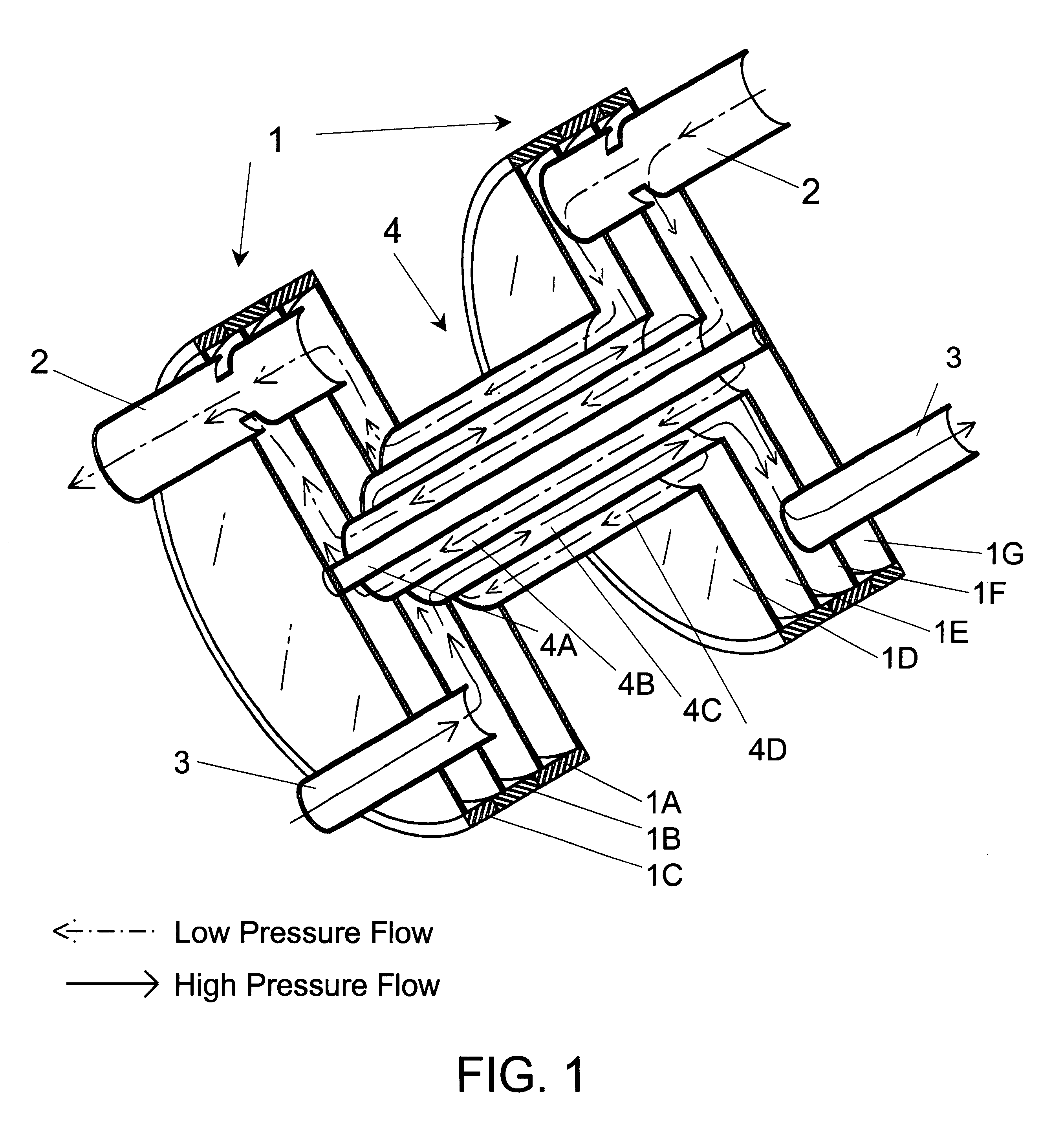

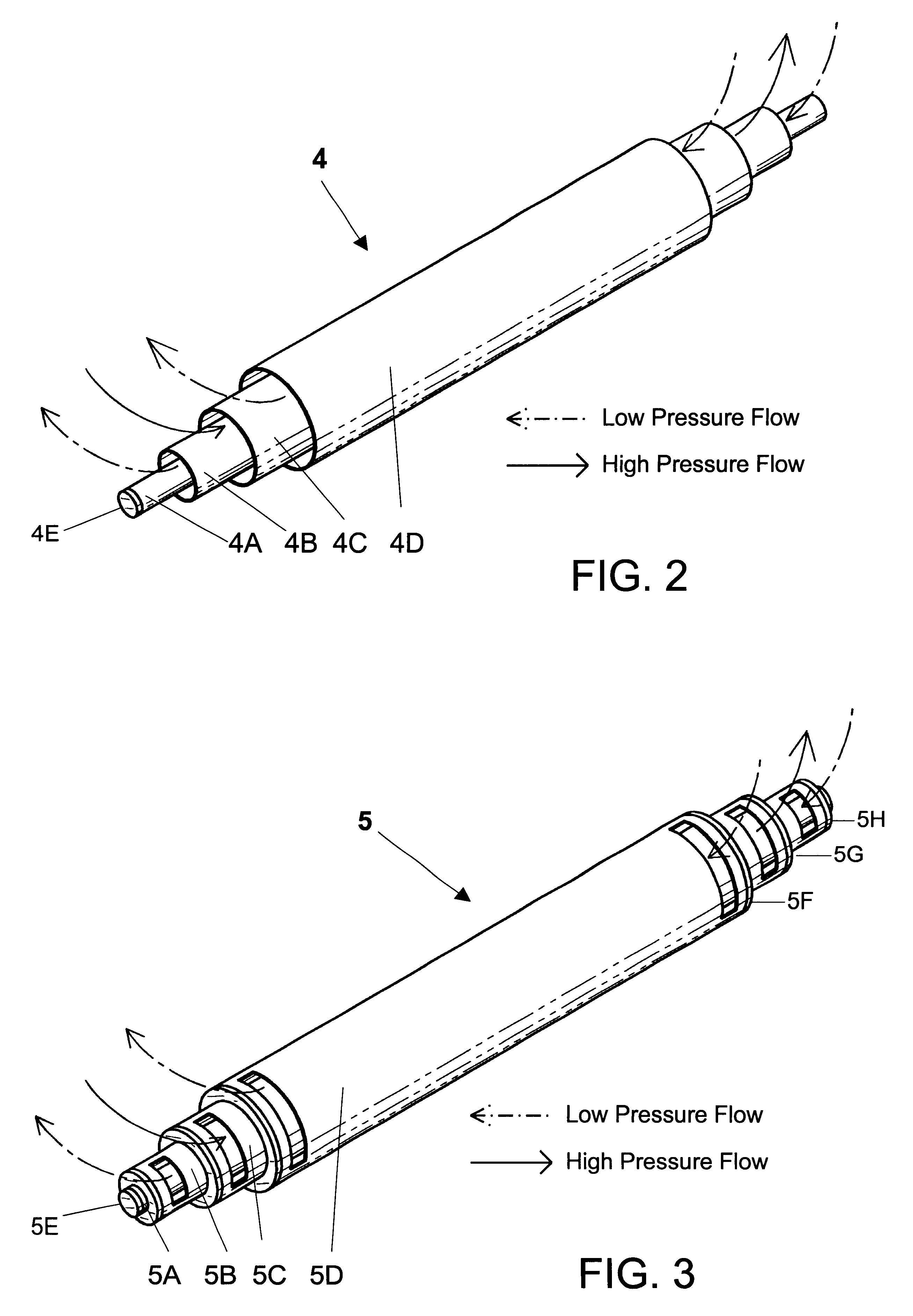

Annular flow concentric tube recuperator

InactiveUS6390185B1Minimal effectivenessNegligible reduction in effectivenessRecuperative heat exchangersStationary tubular conduit assembliesCounter flowVolumetric Mass Density

An annular flow concentric tube heat exchanger for heating two counter flowing fluid streams has been devised. Although capable of heating gases or liquids, the primary purpose of the invention is to function as an improved recuperator for recovering exhaust heat from a Brayton Cycle gas turbine engine, Ericsson Cycle engine or similar recuperated engine. The basic element of the recuperator is a concentric tube assembly that, in the preferred embodiment, is comprised of four concentric tubes that enclose three concentric annular flow passages. The low pressure exhaust flows through the inner and outer annular passages while the high pressure compressor exit air flows through the annular passage that is between the two low pressure passages. The high and low pressure flows are in opposite directions to achieve the high effectiveness that is only available with a counterflow heat exchanger. Heat is transferred from the exhaust gas to the compressor air though the tube walls on each side of the high pressure passage. Two low pressure passages are provided for each high pressure air passage to compensate for the lower pressure (and therefore lower density) of the exhaust gas. Multiple concentric tube assemblies are used to make a recuperator. The tube assemblies terminate in header assemblies located at each end of the concentric tube assemblies. The headers are made of simple plates and rings that serve the dual function of structurally locating the concentric tube assemblies and directing the flow to the proper passage in the concentric tube assemblies. High and low pressure flow tubes provide flow passages connecting the recuperator to the engine compressor air and exhaust tubing respectively. The annular flow concentric tube recuperator can be easily made from commercial tubing with minimal special tooling and is capable of very high effectiveness with very low pressure drop.

Owner:PROE POWER SYST

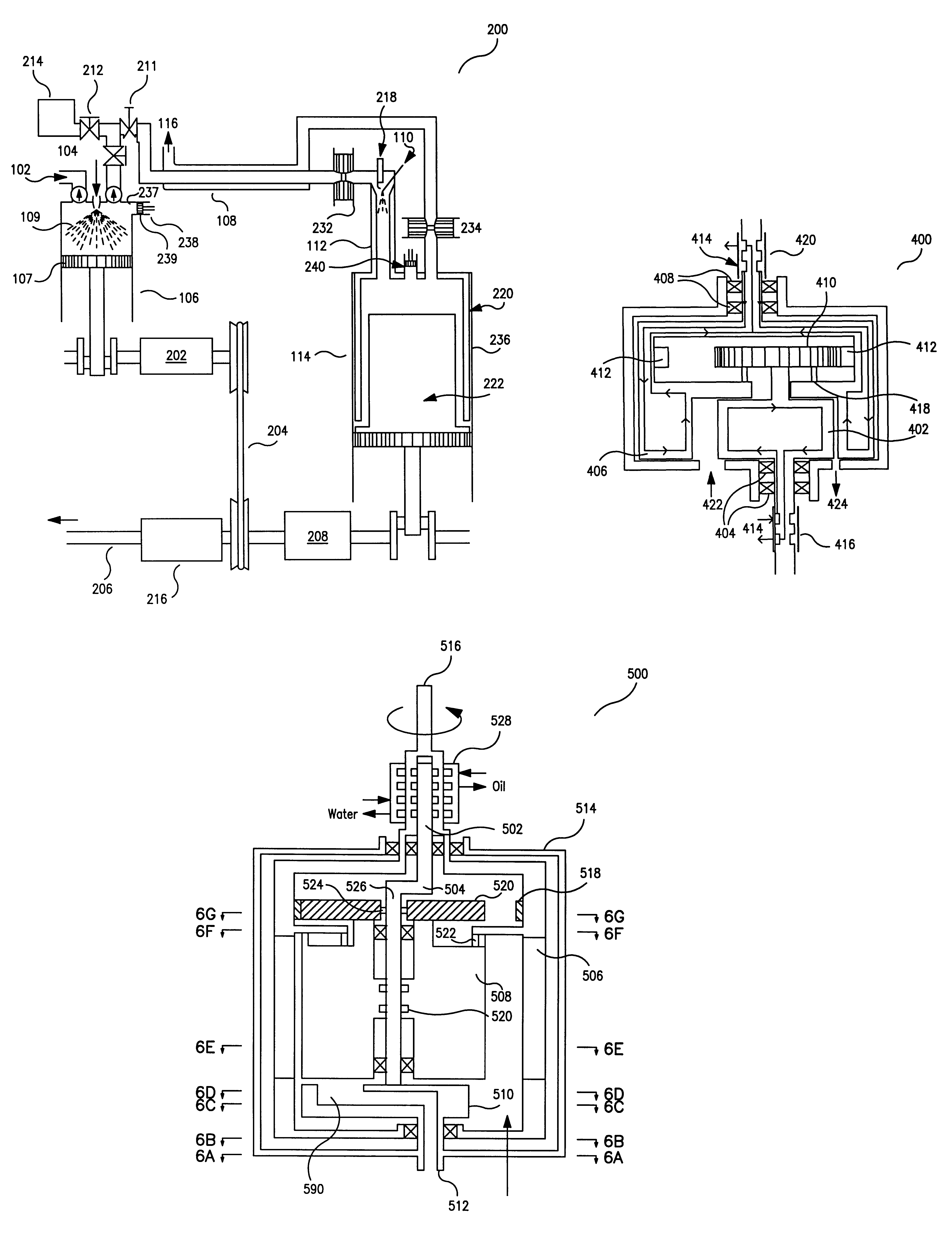

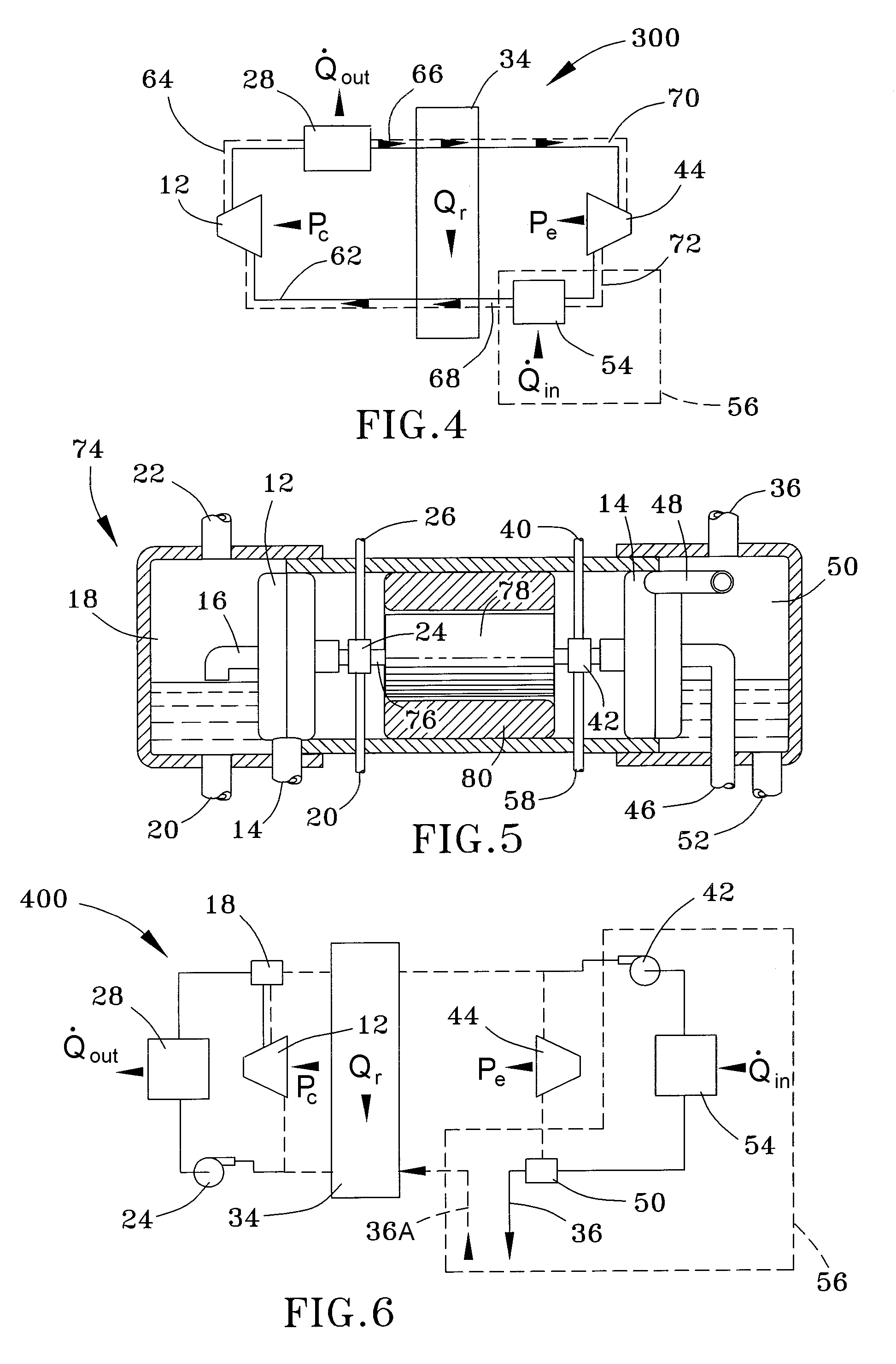

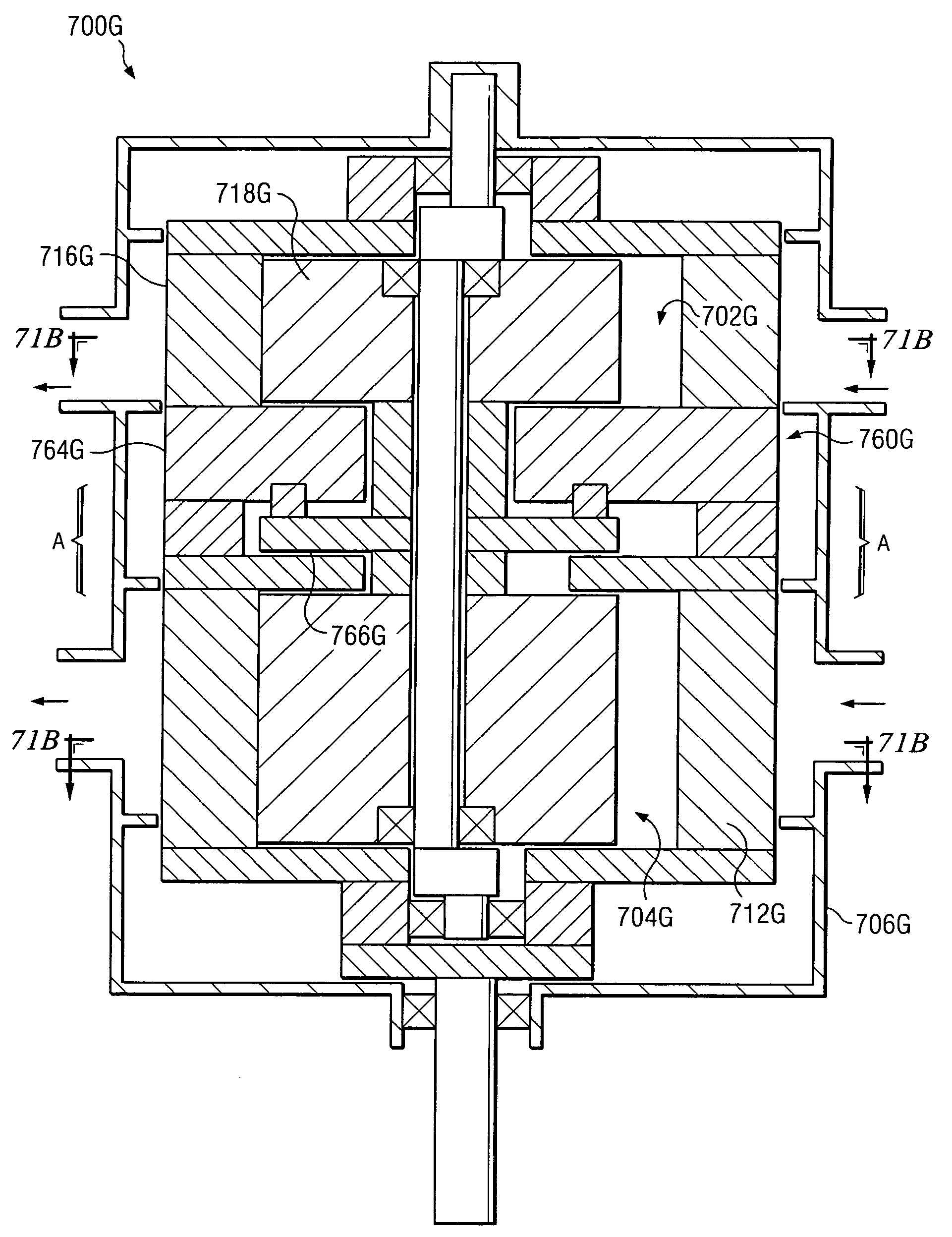

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

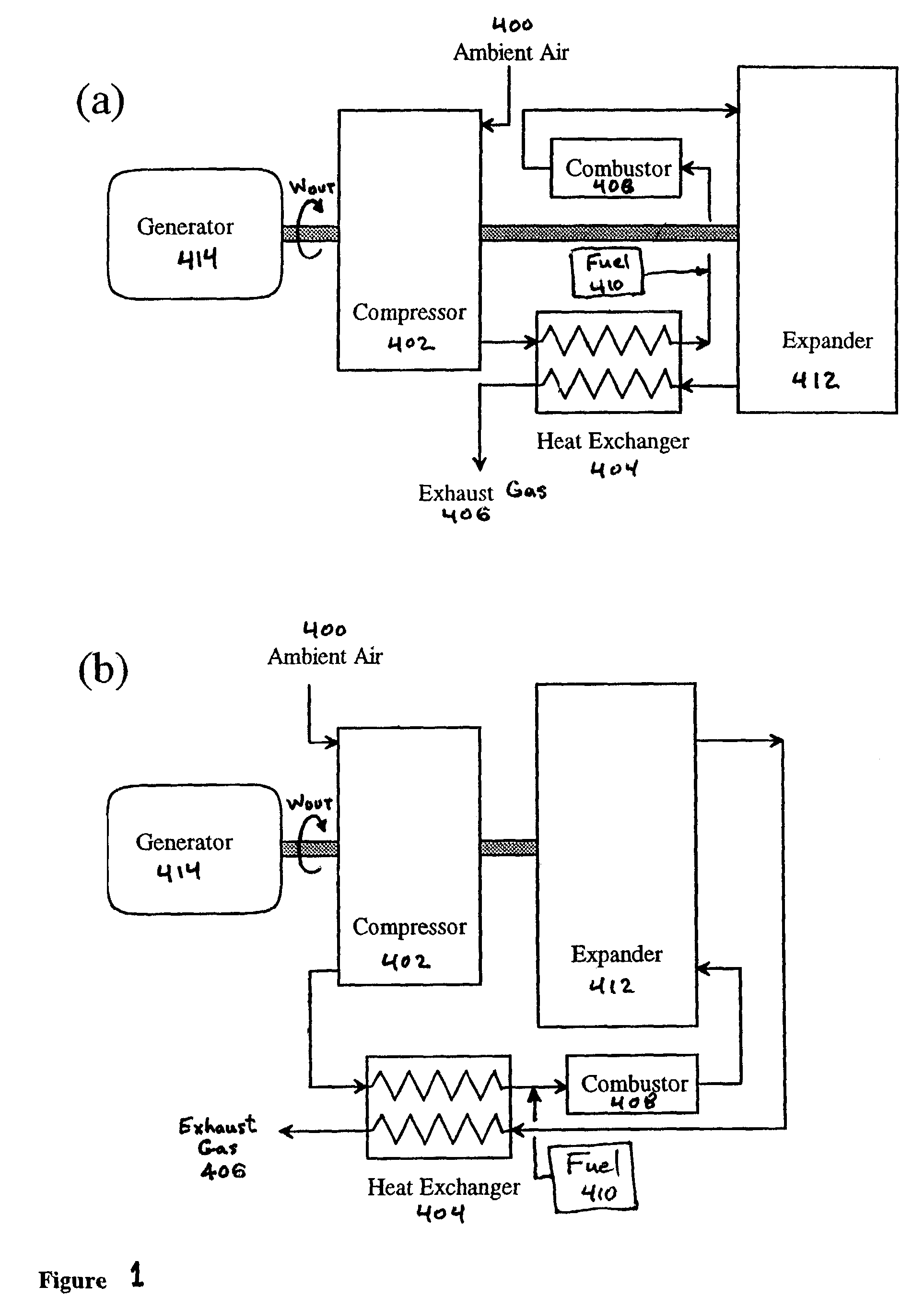

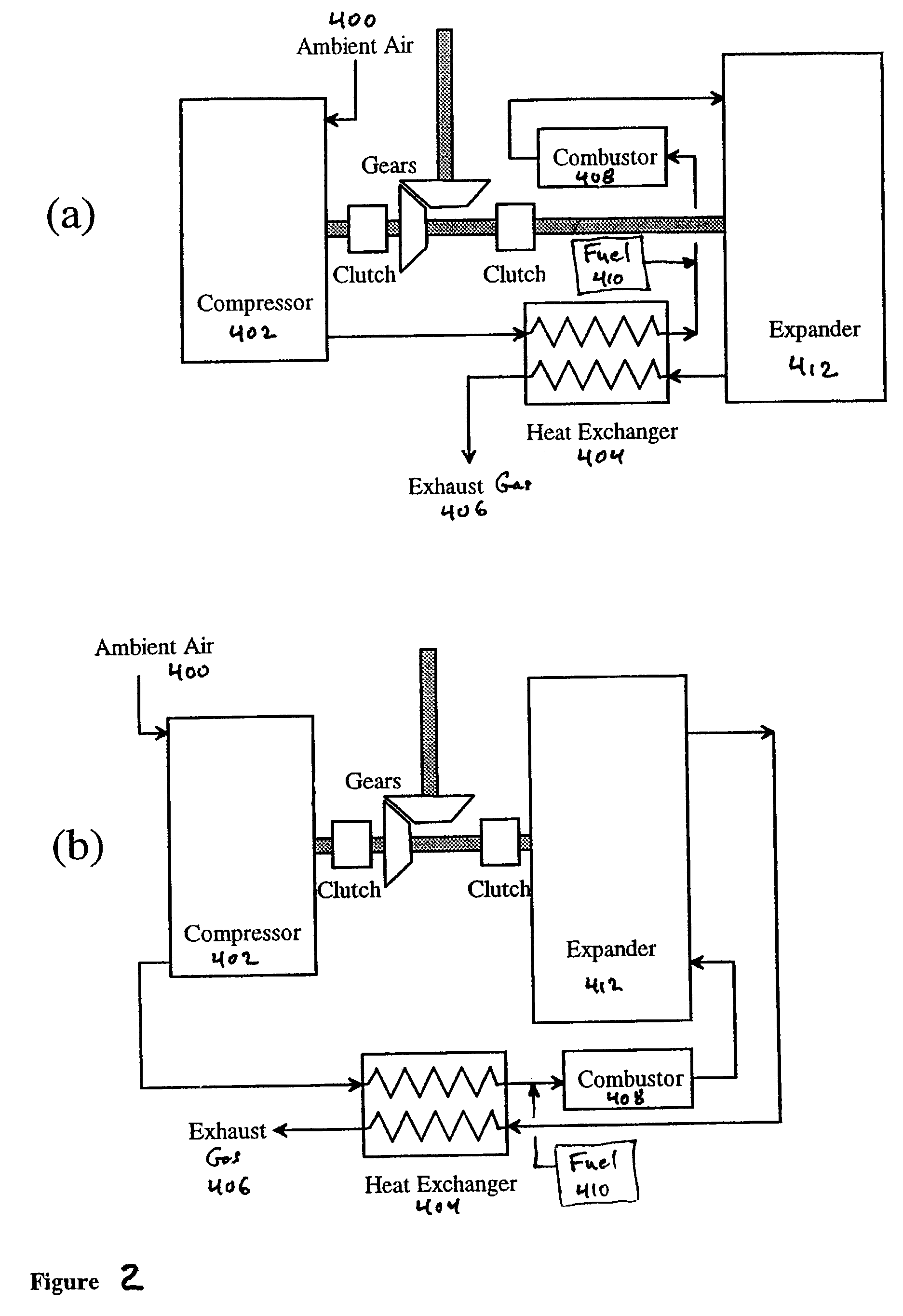

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

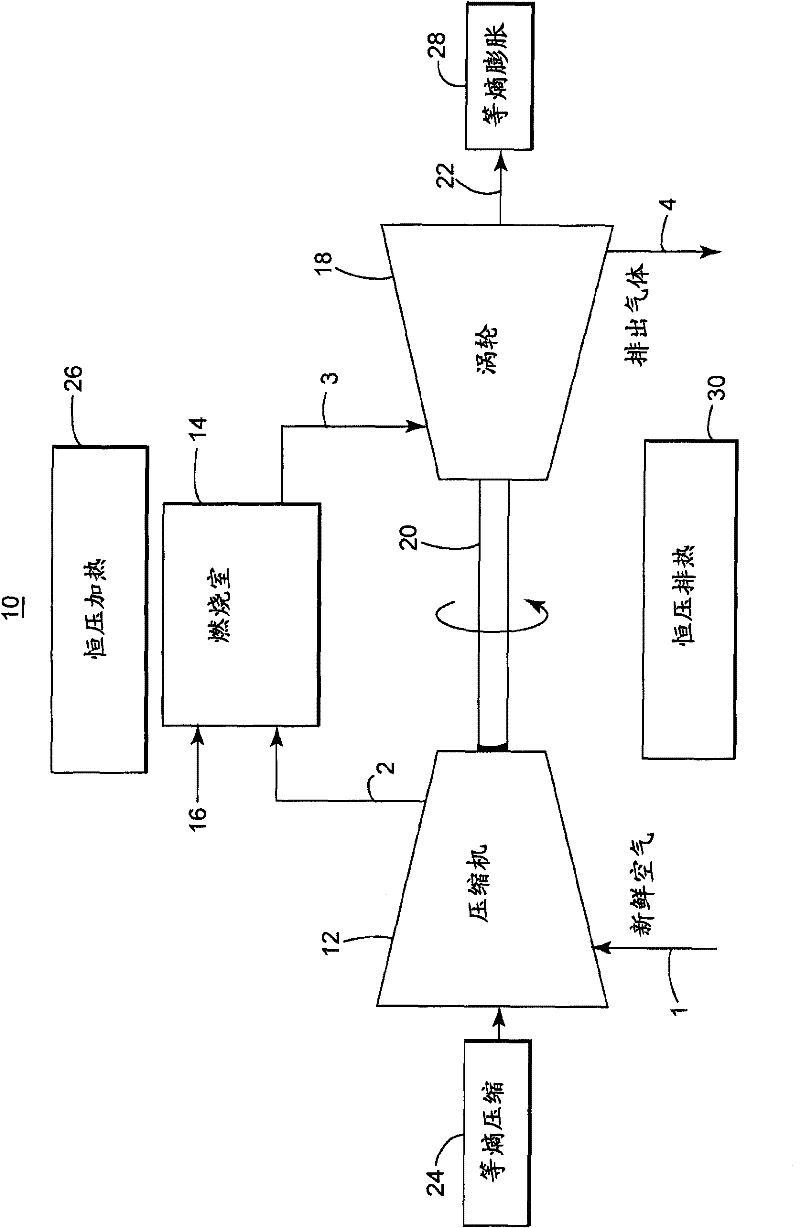

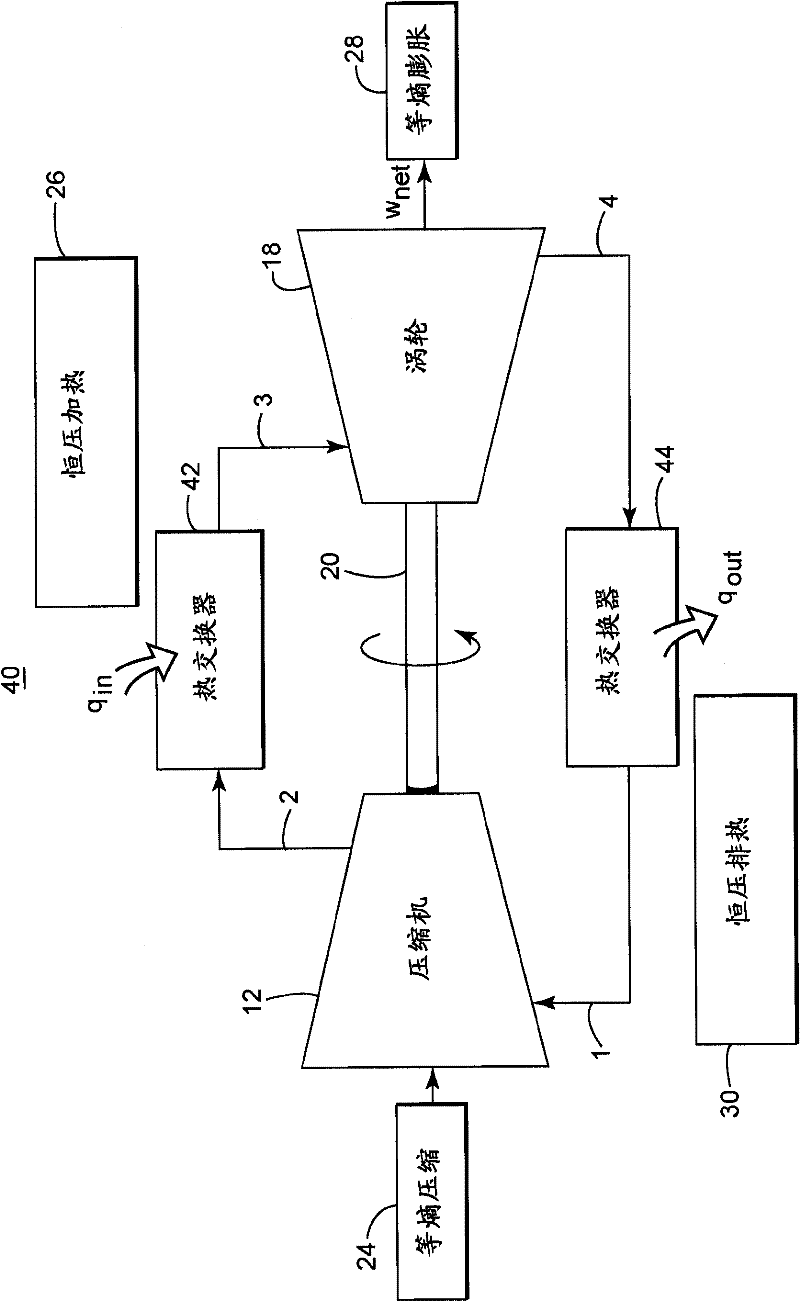

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

Hydrocarbon gas conversion system and process for producing a synthetic hydrocarbon liquid

InactiveUS6130259AEliminates high capital costCost effectiveCombustion enginesGas turbine plantsLiquid productCombustion chamber

A system and process are provided for converting a light hydrocarbon gas to a synthetic heavier hydrocarbon liquid. The system includes an autothermal reformer, a Fischer-Tropsch reactor and a Brayton cycle that are structurally and functionally integrated. In the practice of the process, a mixture of a hydrocarbon feed gas, a compressed air feed and process steam is fed to the autothermal reformer to produce a synthesis gas. The synthesis gas is fed to the Fischer-Tropsch reactor where it is catalytically reacted to produce heavy hydrocarbons. The outlet from the Fischer-Tropsch reactor is separated into water, a low heating value tail gas, and the desired hydrocarbon liquid product. The water is pressurized and heated to generate process steam. The tail gas is heated and fed with compressed air and steam to the Brayton cycle having a combustor and a series of power turbines and compressors. The tail gas and air feed are burned in the combustor to produce a combustion gas that is used to drive a power turbine linked by a shaft to an air compressor, thereby driving the air compressor. The system further includes a plurality of heat exchangers that enable heat to be recovered from the outlet of the autothermal reformer. The recovered heat is used to make the process steam as well as to preheat the hydrocarbon feed gas before it is fed to the autothermal reformer, preheat the synthesis gas before it is fed to the Fischer-Tropsch reactor and preheat the tail gas before it is fed to the combustor.

Owner:REG SYNTHETIC FUELS LLC +1

Refrigerant Composition Control

ActiveUS20110036121A1Reduces efficiency of systemLow efficiencySolidificationLiquefactionBrayton cycleReflux

A system and method for removal of a contaminant comprising removing a liquefied portion of a refrigerant stream comprising nitrogen from a reverse Brayton cycle refrigerant system, introducing the liquefied refrigerant stream into a contaminant removal column as a reflux stream removing a contaminant stream from the bottom of the contaminant removal column, removing a vapor stream enriched in nitrogen from the top of the contaminant removal column, and introducing the vapor stream enriched in nitrogen back into the reverse Brayton cycle refrigerant system.

Owner:AIR PROD & CHEM INC

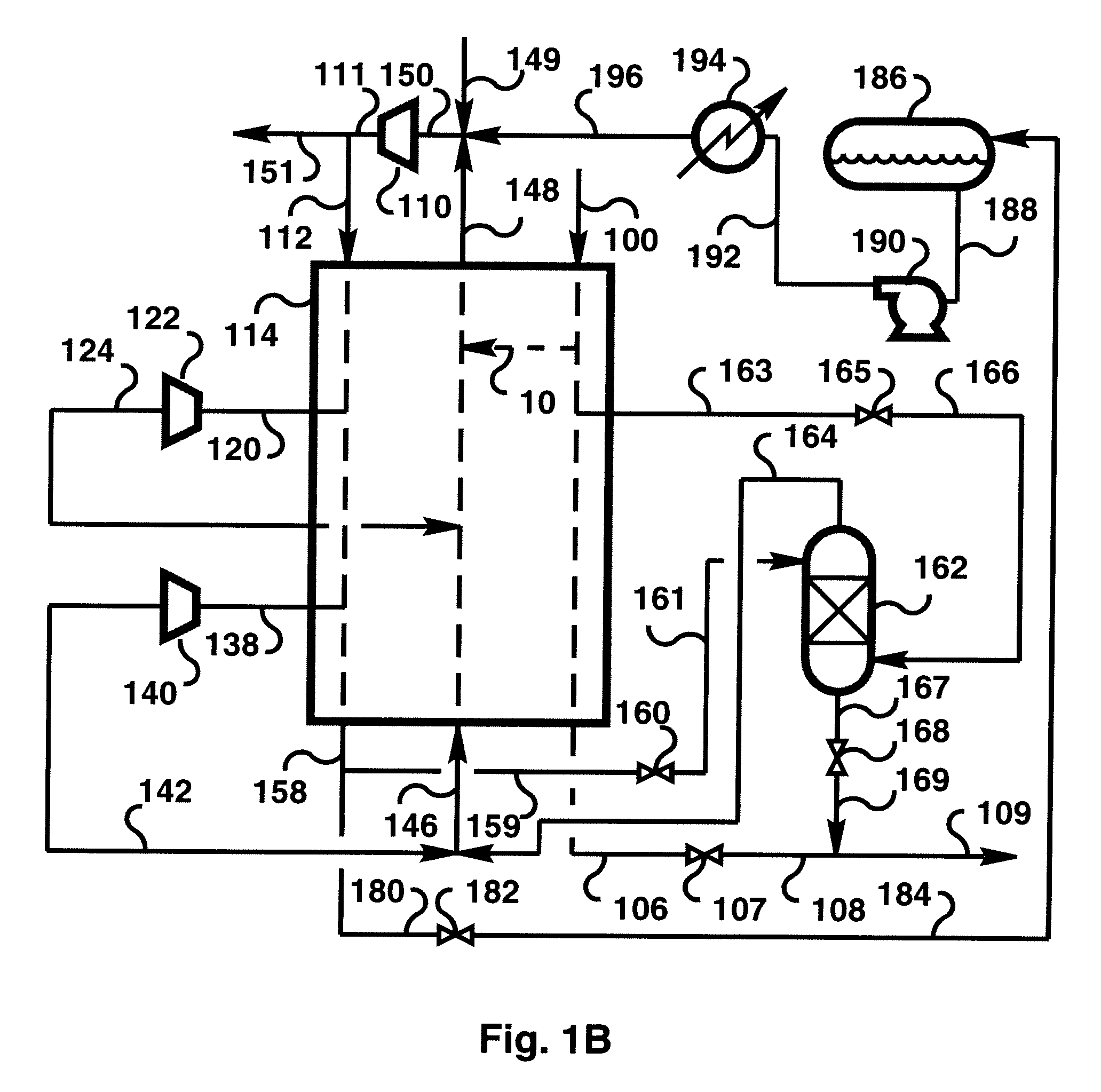

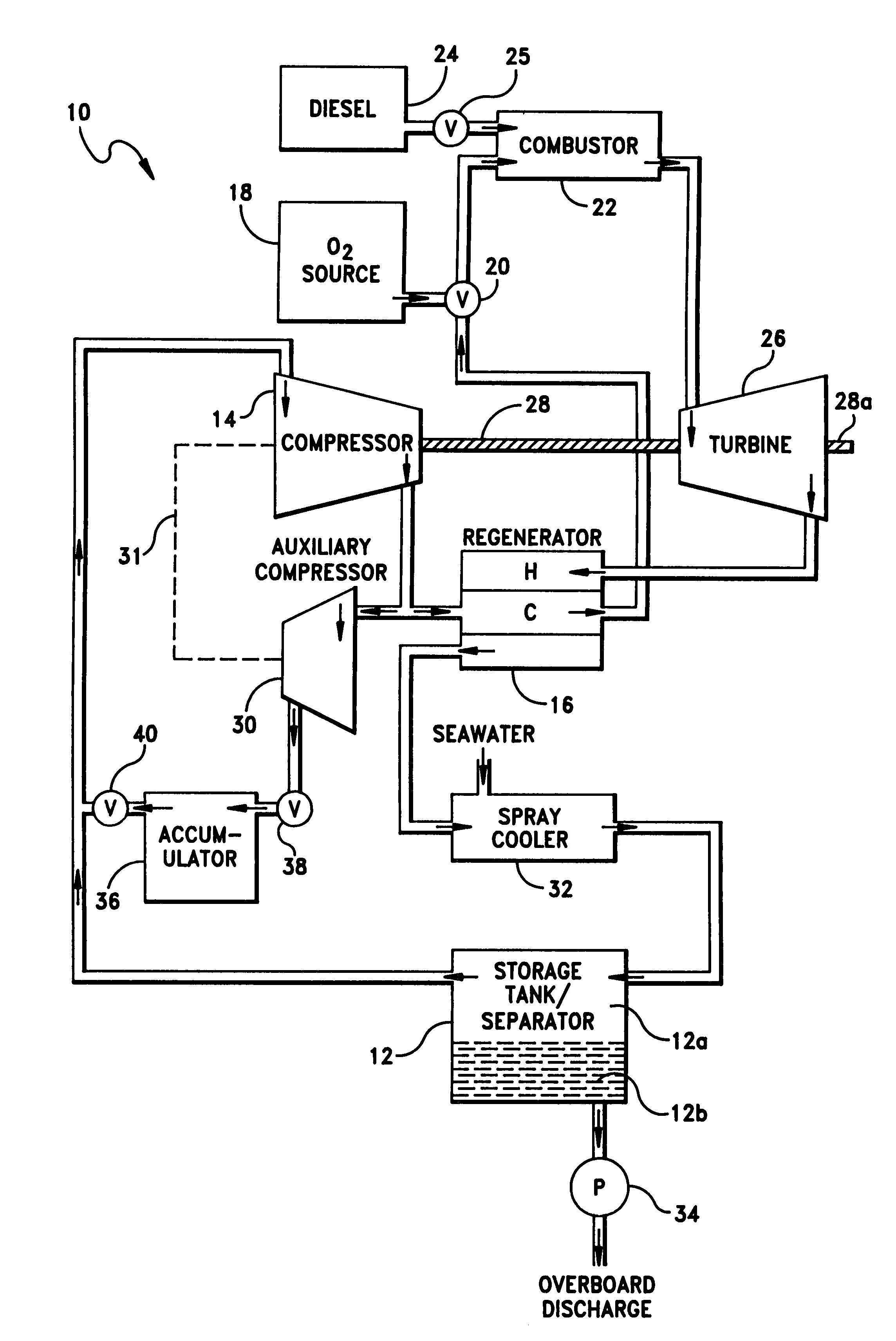

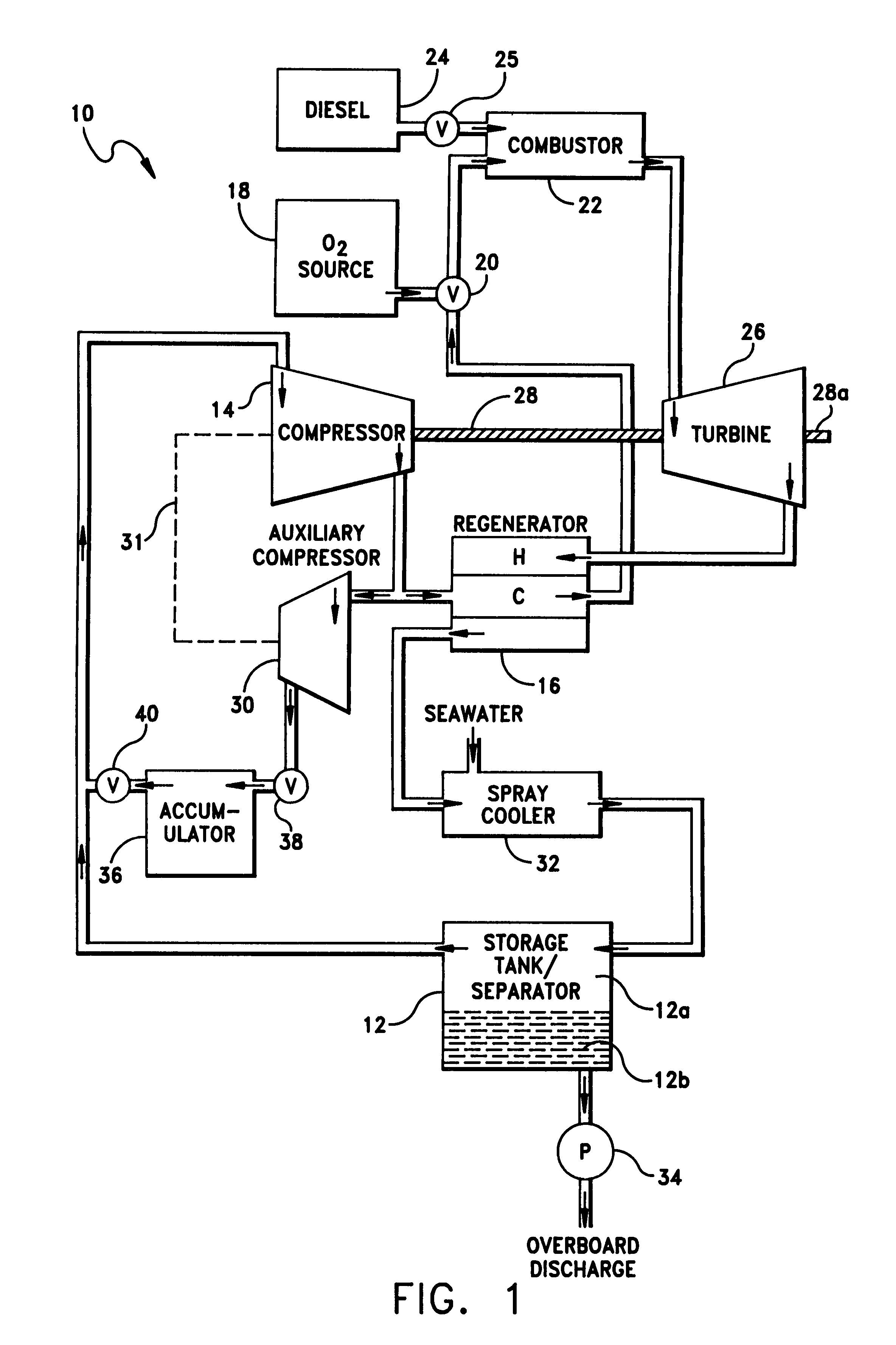

Semiclosed Brayton cycle power system with direct heat transfer

A semiclosed power system utilizing a Brayton cycle with combustion occurring between diesel fuel and O2 in direct contact with an inert gas. The inert gas and products of combustion form a heated working fluid which is expanded in a turbine to provide power. The expanded working fluid is then used in a regenerator to heat the cooler, compressed inert gas before the inert gas is transferred to the combustor. The expanded working fluid is cooled by direct contact with seawater causing the steam within the expanded working fluid to condense to water and CO2 in the working fluid to be dissolved in the water and seawater. The inert gas is separated from the fluids and recycled within the system. The fluids are pumped overboard.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

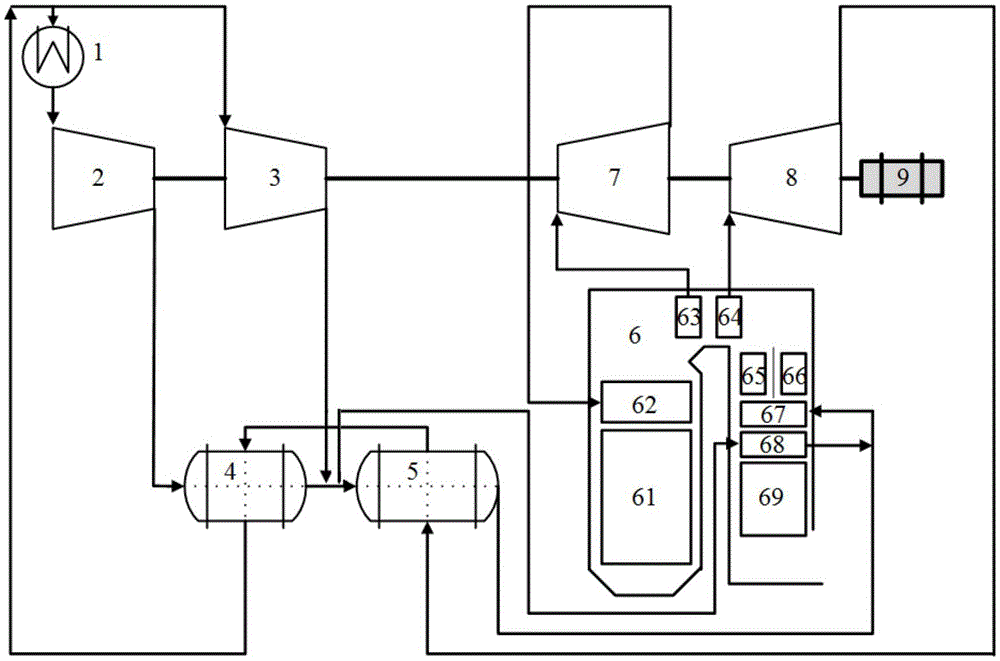

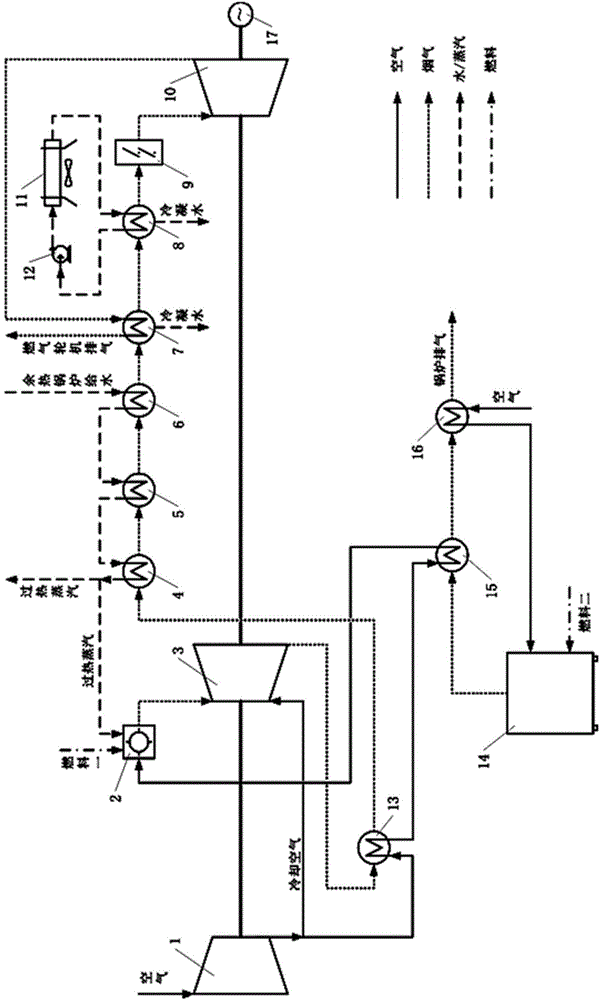

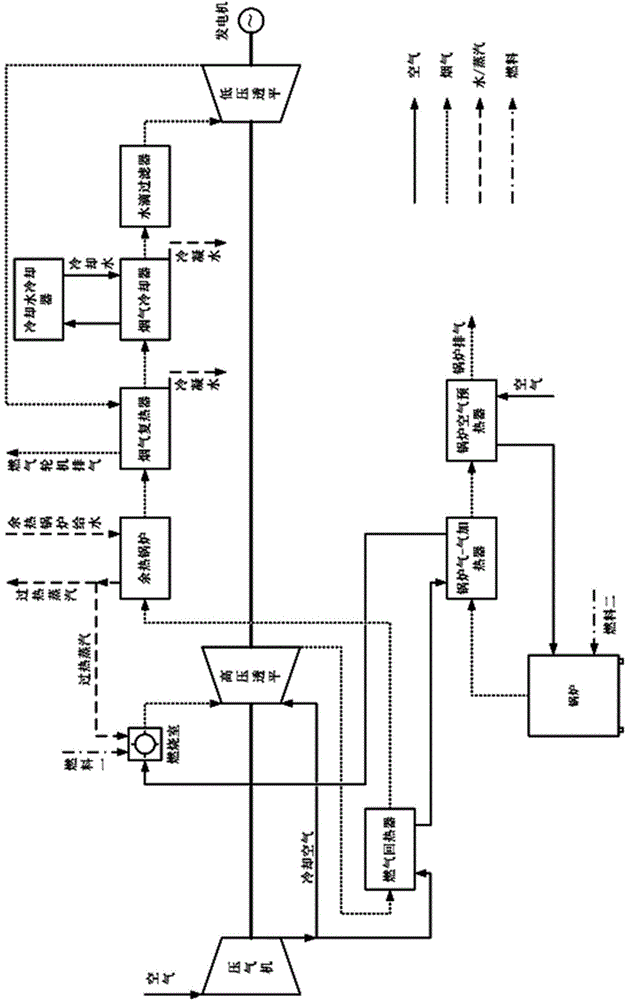

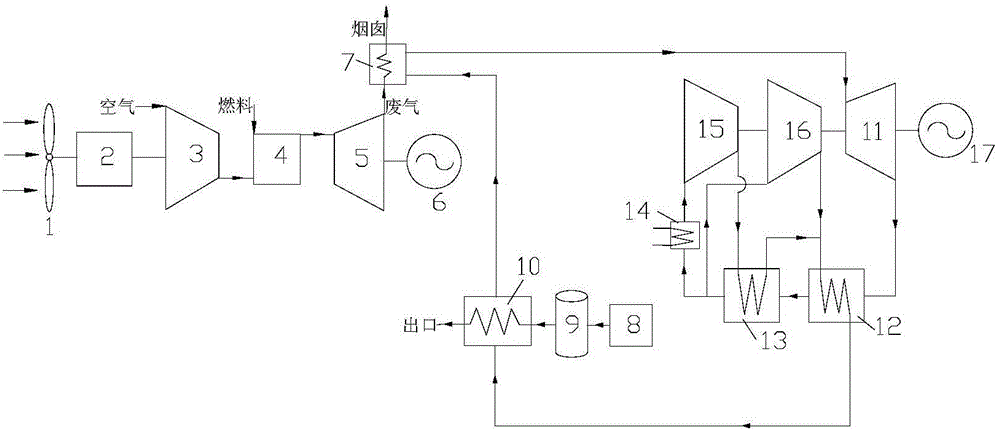

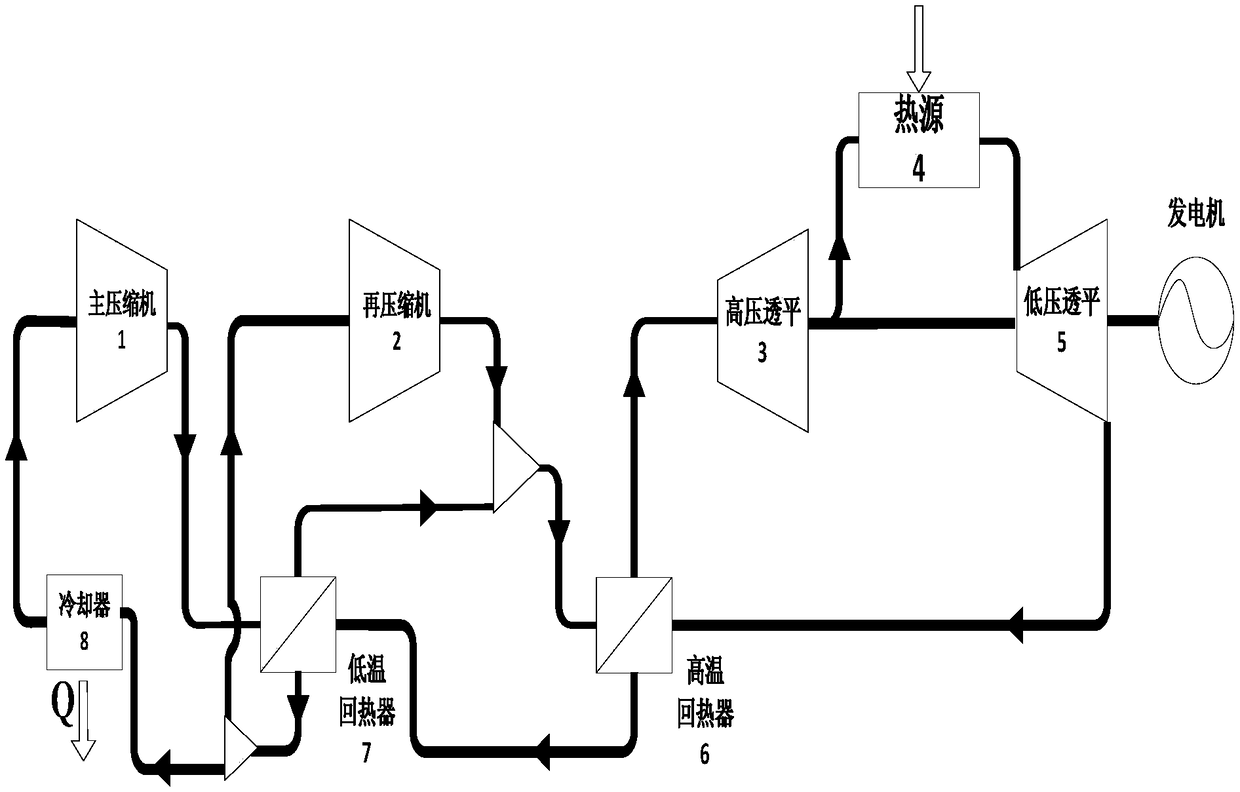

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

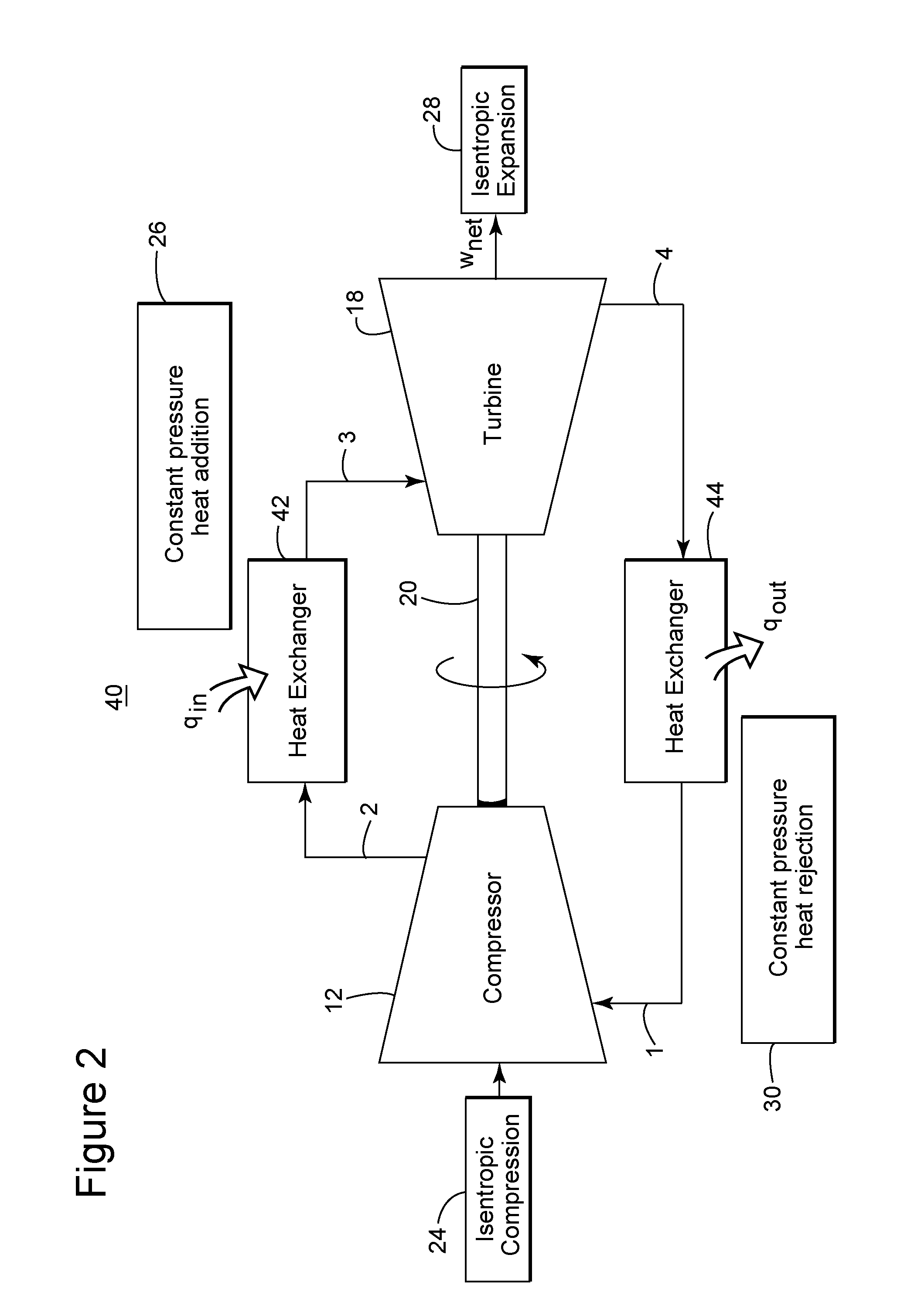

Closed Cycle Brayton Cycle System and Method

Method and unit for generating energy with improved efficiency. A Brayton cycle unit includes a multistage compressor configured to compress a flowing medium; a first heat exchanger fluidly connected to the multistage compressor and configured to transfer heat from a working medium passing the first heat exchanger to the compressed flowing medium; an expander fluidly connected to the first heat exchanger and configured to expand the heated compressed flowing medium for producing a rotation of a shaft of the expander; and a second heat exchanger fluidly connected between the expander and the compressor and configured to remove heat from the expanded flowing medium. A path of the flowing medium through the unit is closed. At least one inter-cooler mechanism between first and second stages of the multistage compressor is configured to cool the flowing medium to a predetermined temperature.

Owner:NUOVO PIGNONE SPA

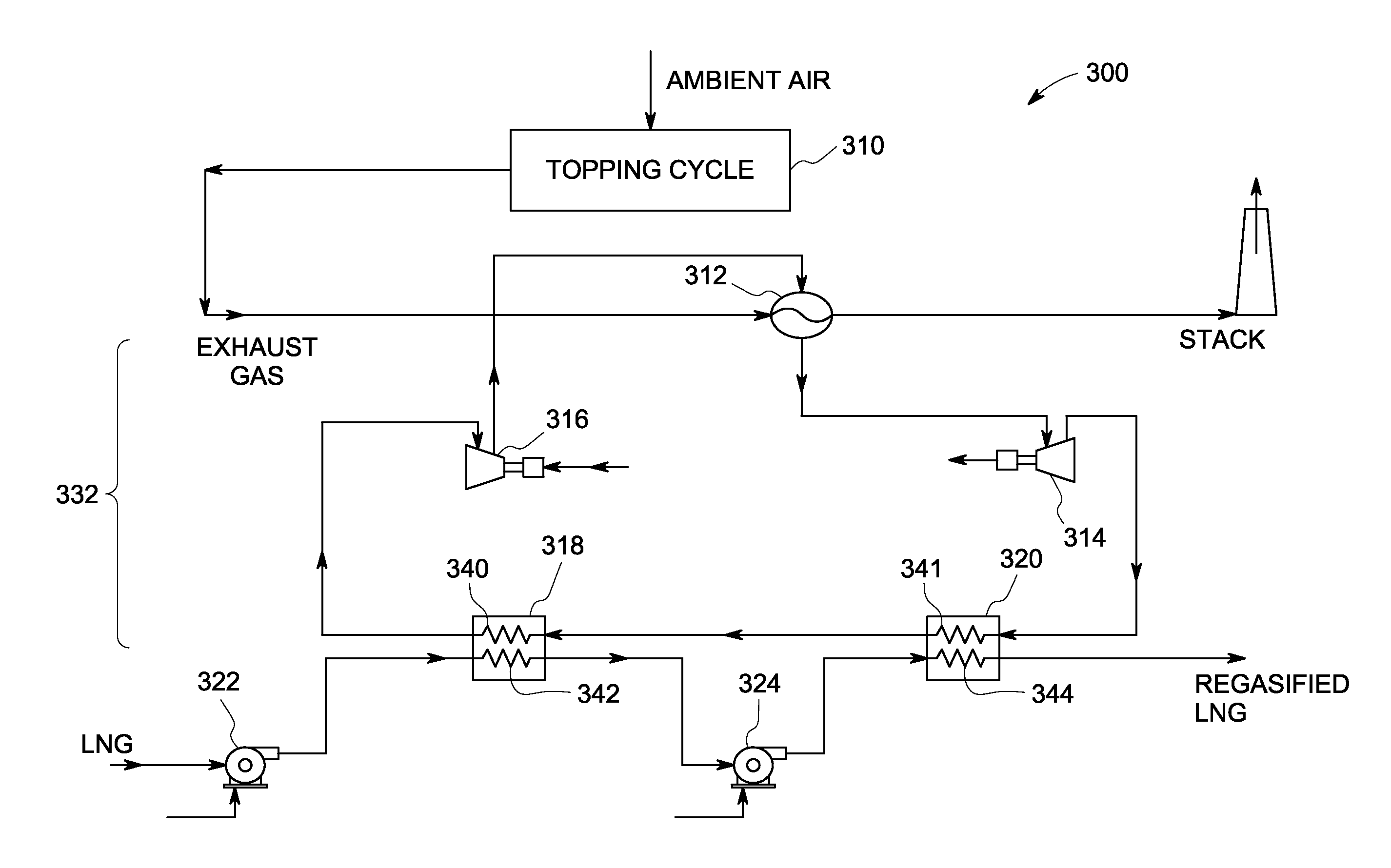

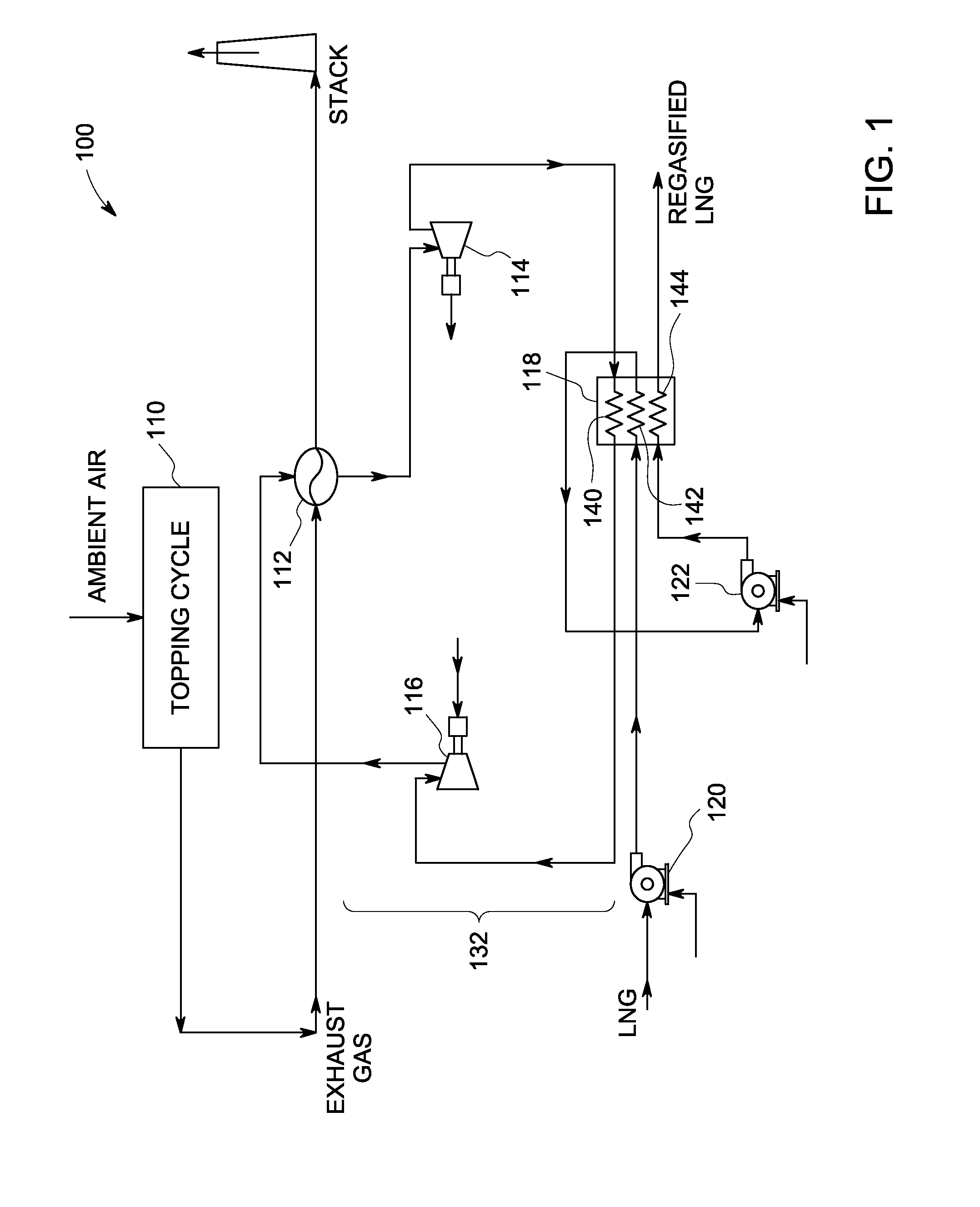

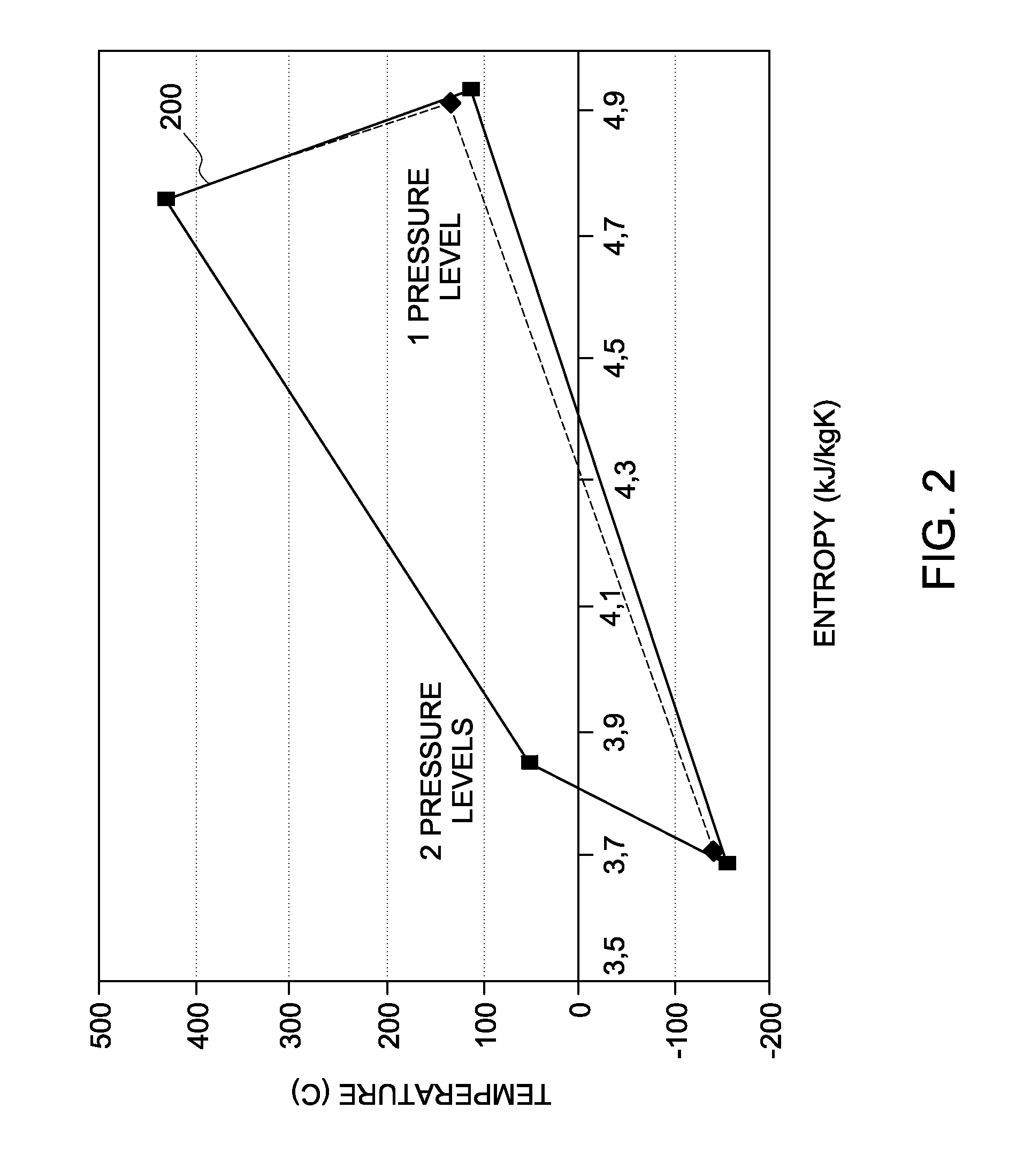

Brayton cycle regasification of liquiefied natural gas

A power plant including an apparatus for regasification of liquefied natural gas (LNG) is provided. The apparatus includes a compressor configured to pressurize a working fluid and a heat recovery system configured to provide heat to a working fluid. A turbine is configured to generate work utilizing the heated working fluid. One or more heat exchangers are configured to transfer heat from the working fluid to a first stage liquefied natural gas at a first pressure and at least one of a second stage liquefied natural gas at a second pressure, and a compressed working fluid.

Owner:GENERAL ELECTRIC CO

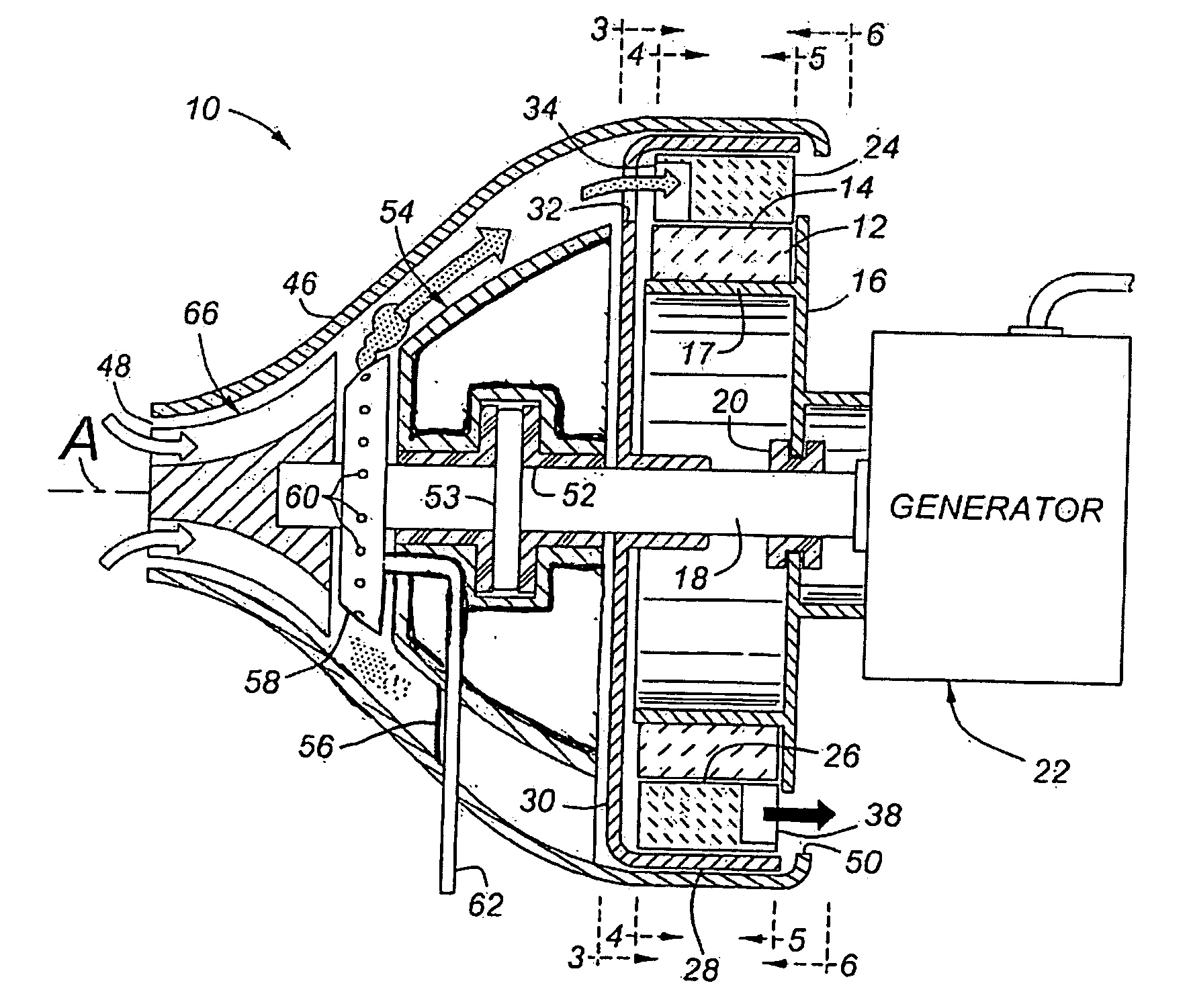

Rotary ramjet turbo-generator

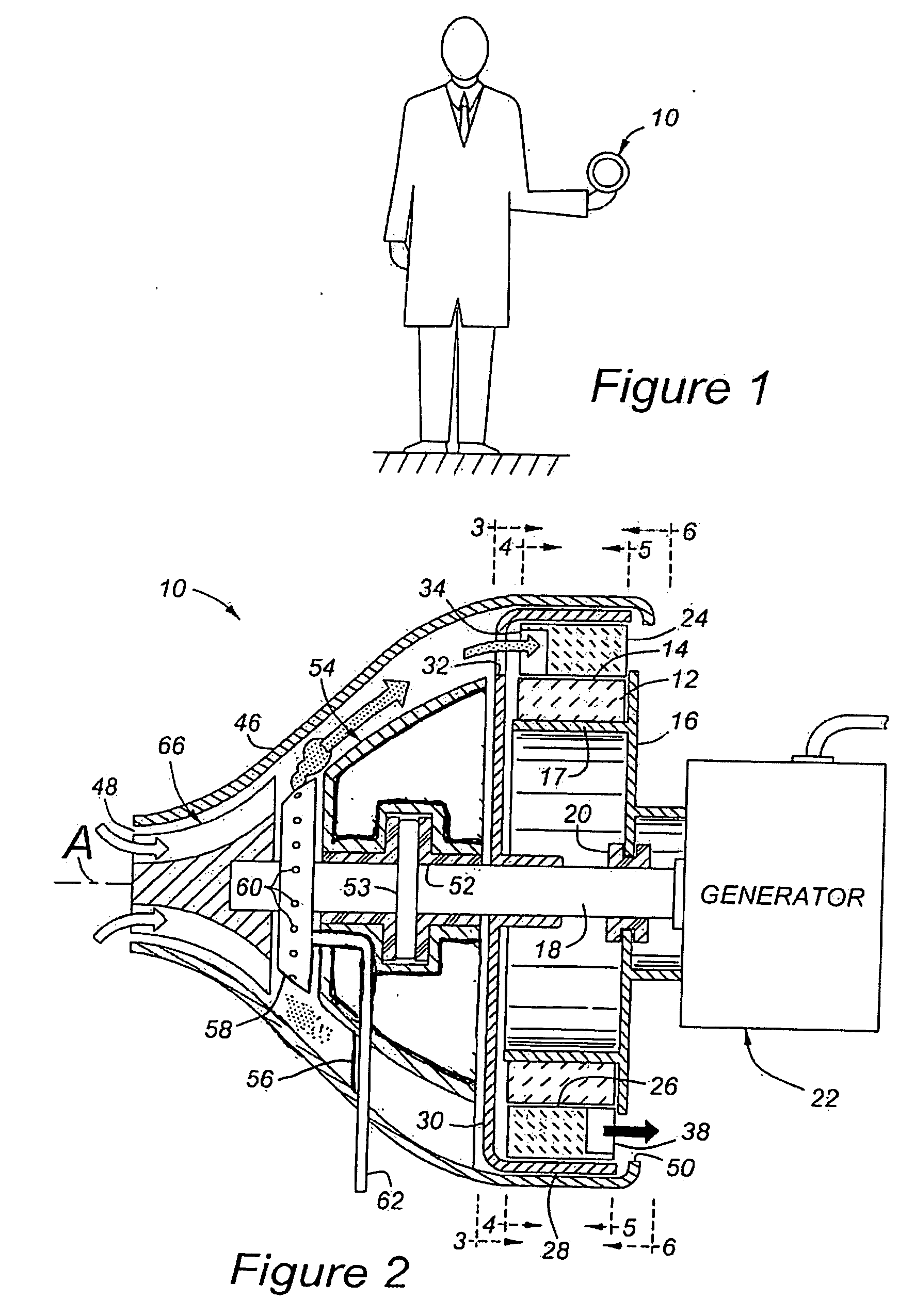

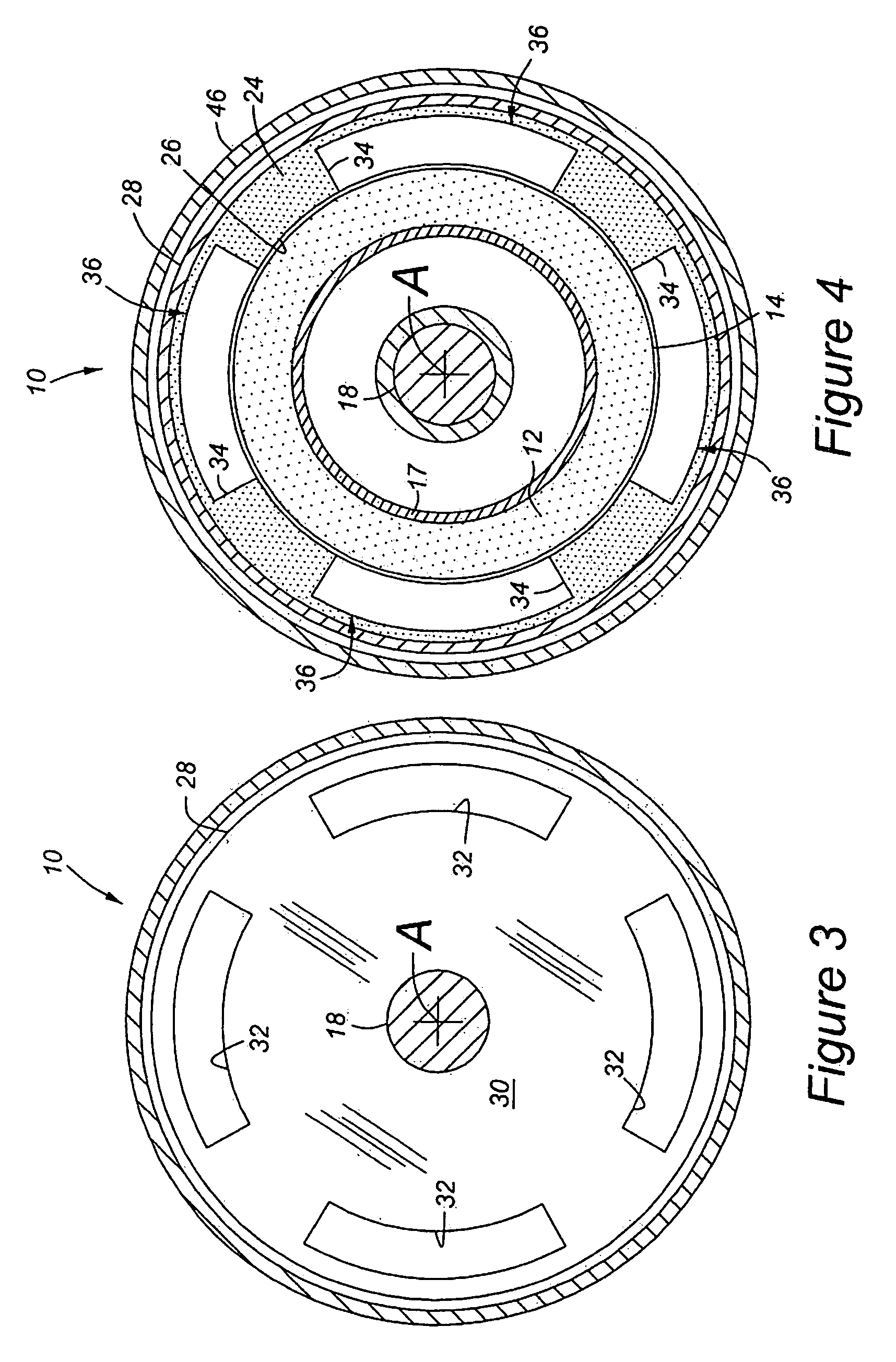

ActiveUS20070056290A1MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

Valves for gas-turbines and multipressure gas-turbines, and gas-turbines therewith

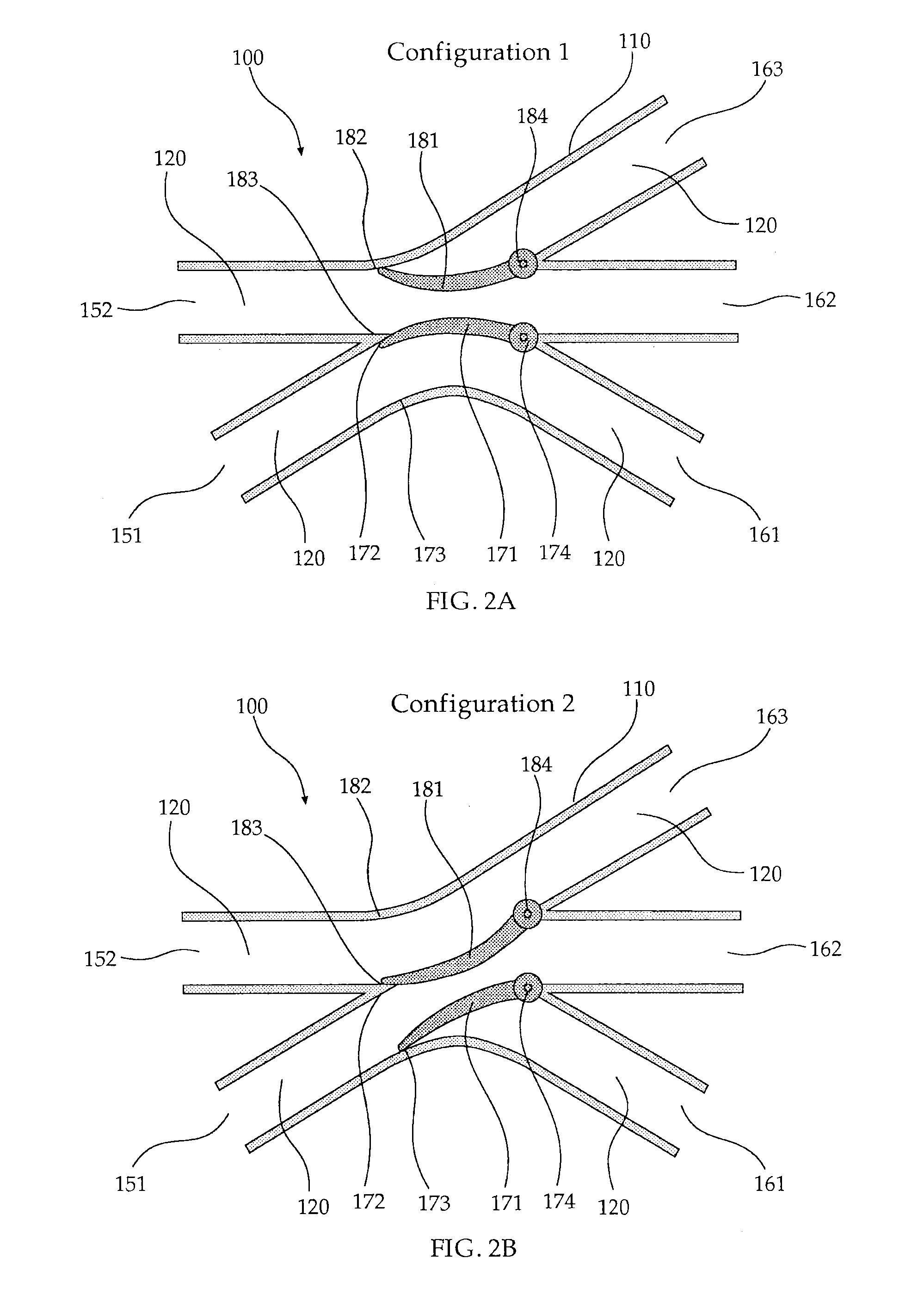

InactiveUS20110262269A1Low oxygenReduce the amount requiredPump componentsBlade accessoriesBrayton cycleOperation mode

A multiport valve suitable for use with a gas-turbine allowing switching of a mode of gas-turbine operation between a Brayton cycle and an inverse Brayton cycle, and a gas-turbine configured to switch between a high-pressure operation mode according to a Brayton cycle and a low-pressure operation mode according to an inverse Brayton cycle employing the valve are provided. Also provided are a method and apparatus for operating a gas-turbine according to an inverse Brayton cycle.

Owner:ETV ENERGY LTD

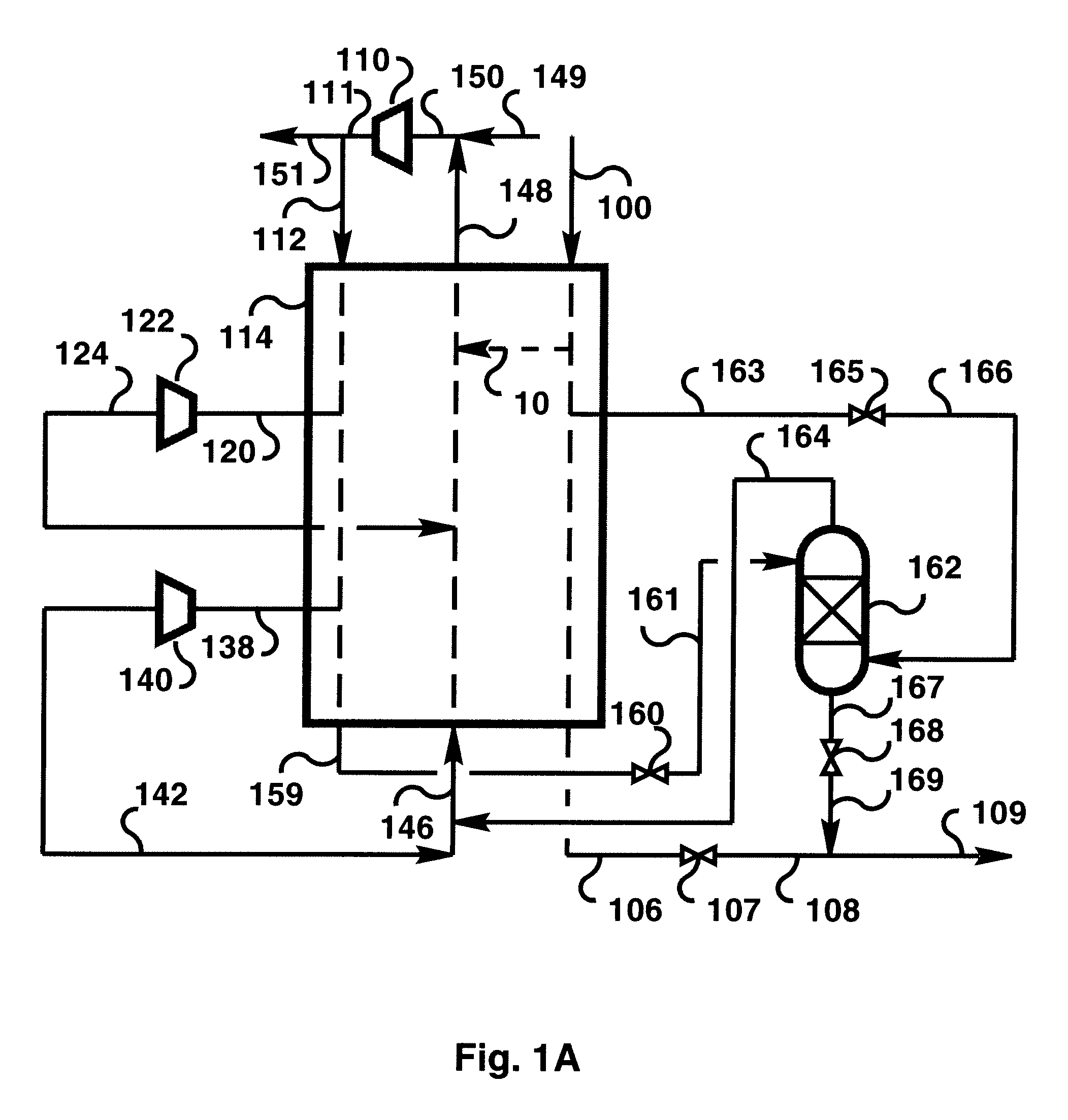

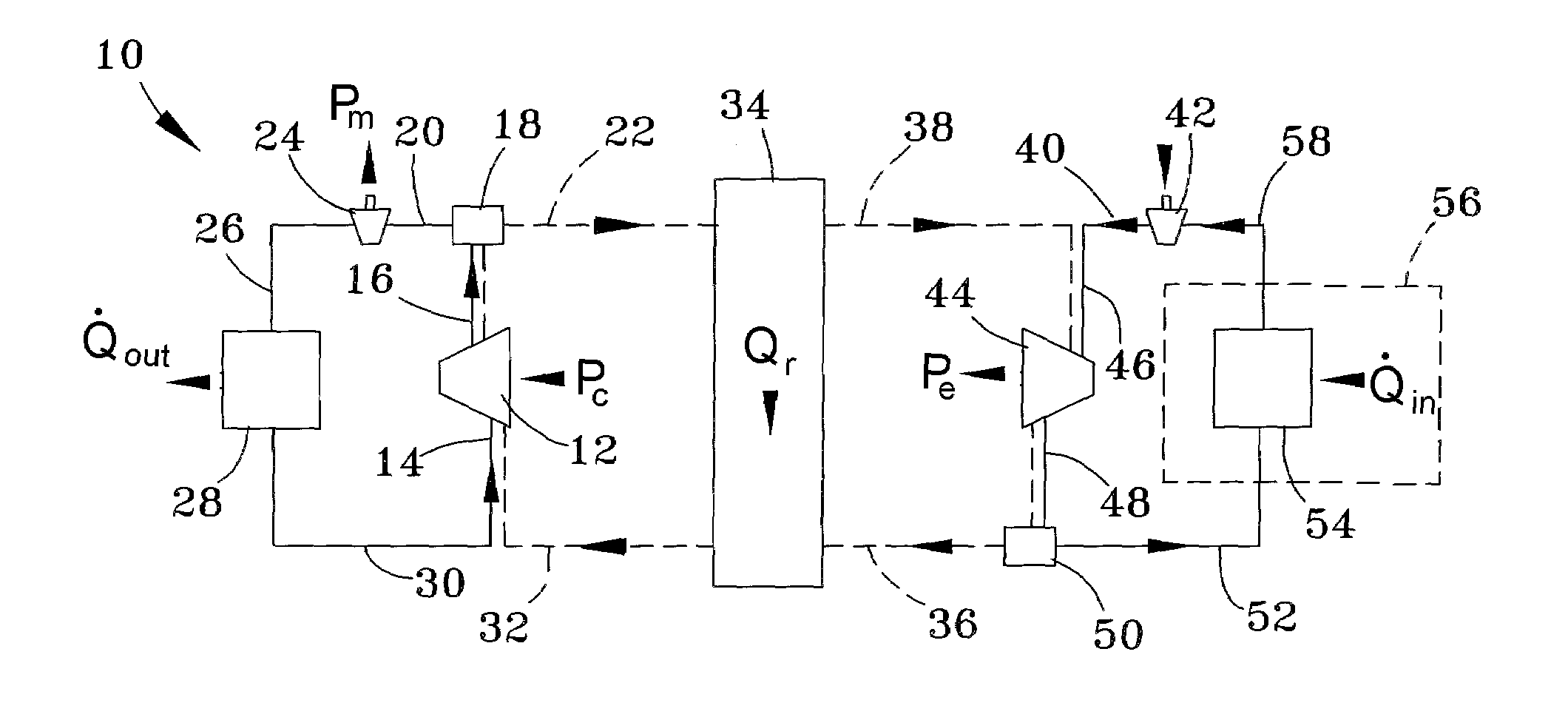

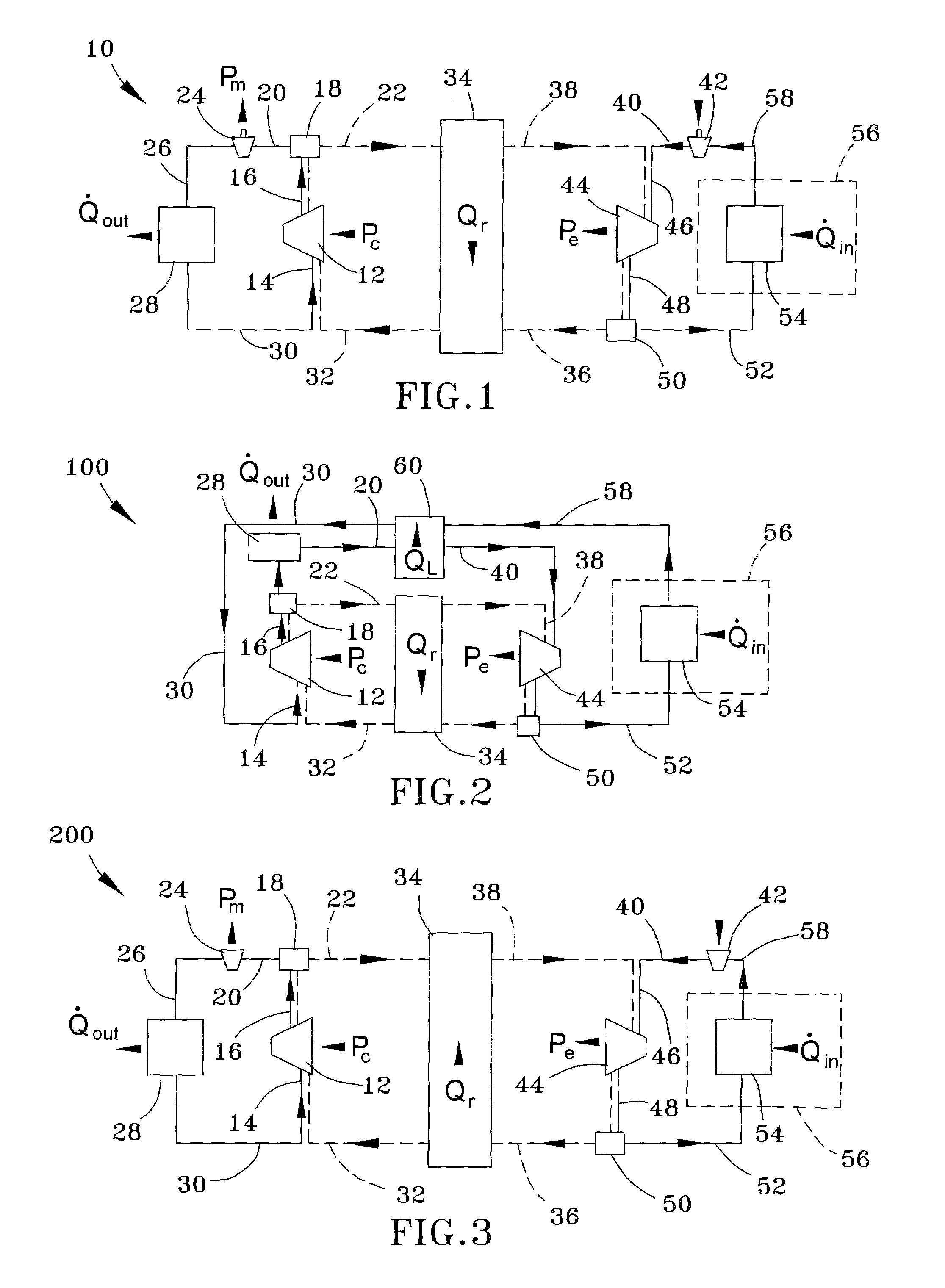

Thermodynamic systems operating with near-isothermal compression and expansion cycles

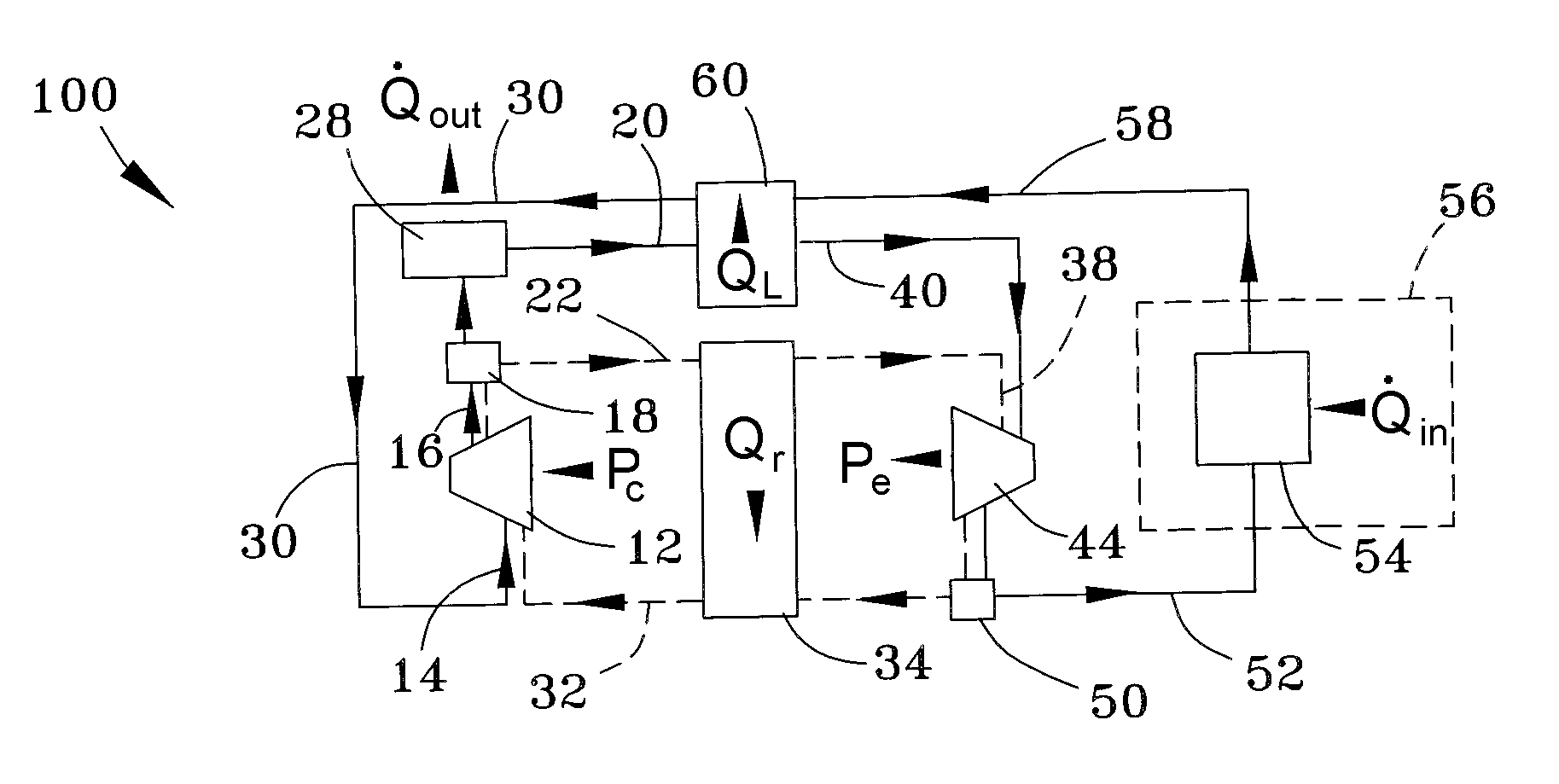

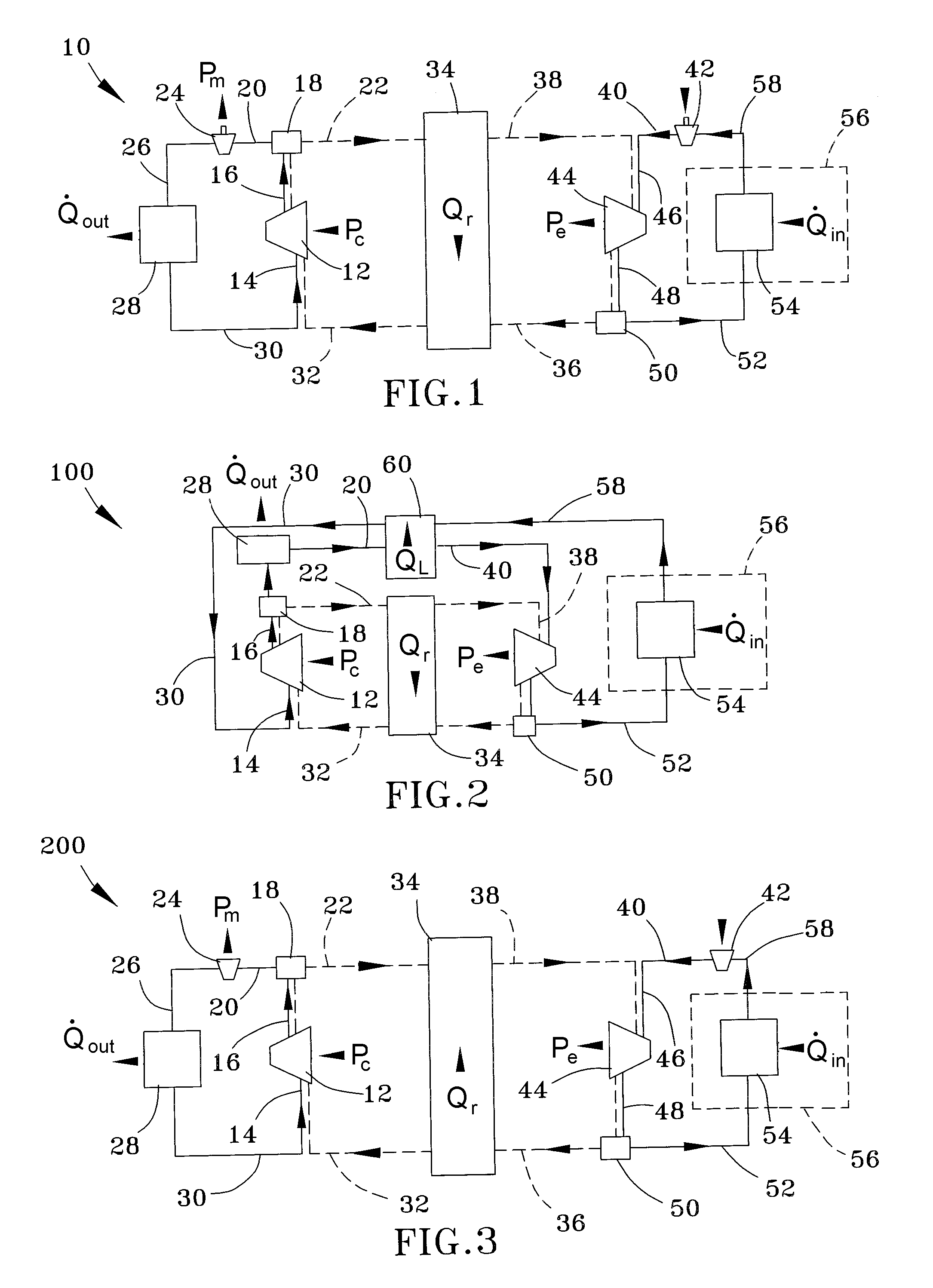

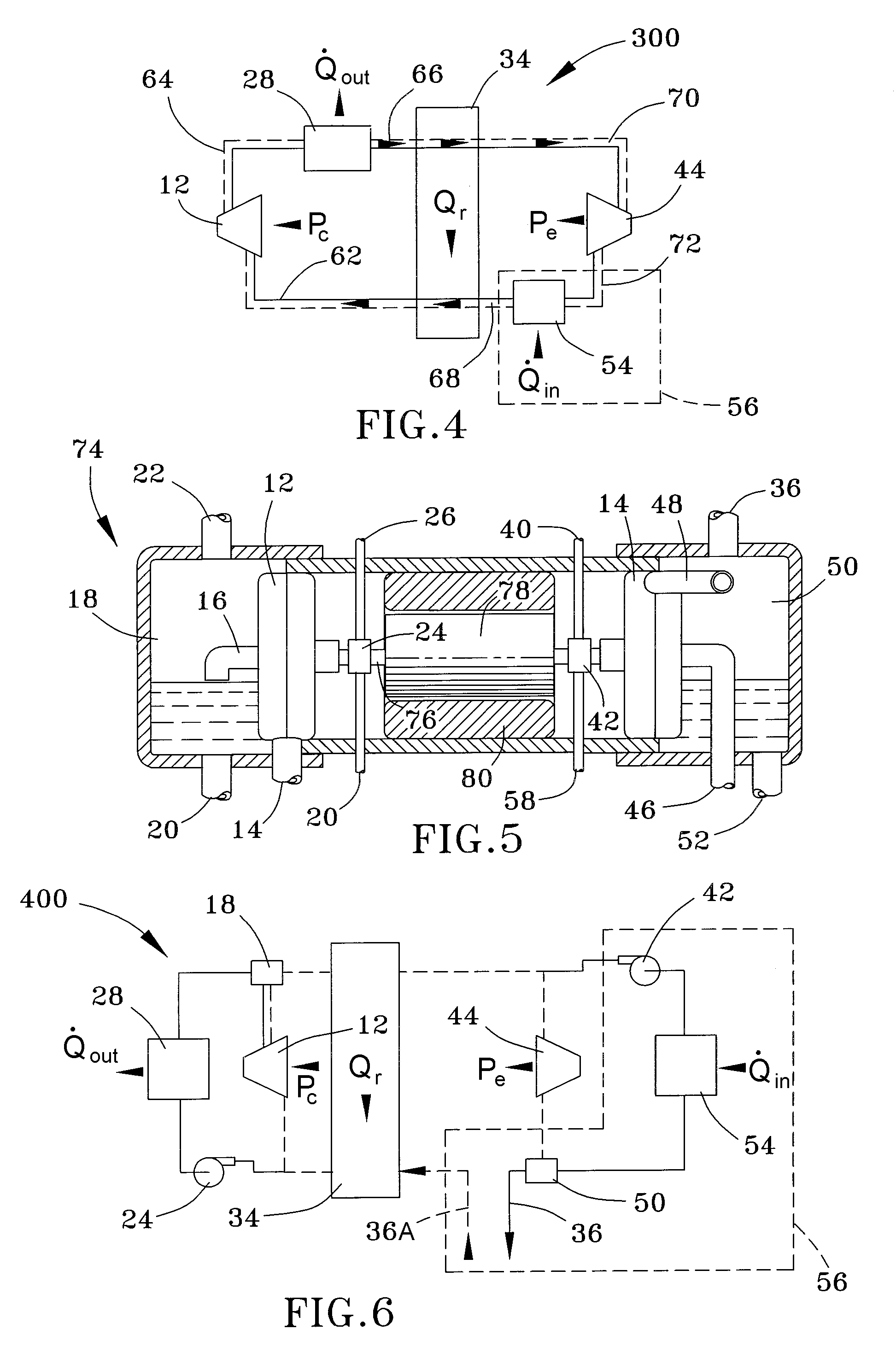

InactiveUS20070074533A1Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleEngineering

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

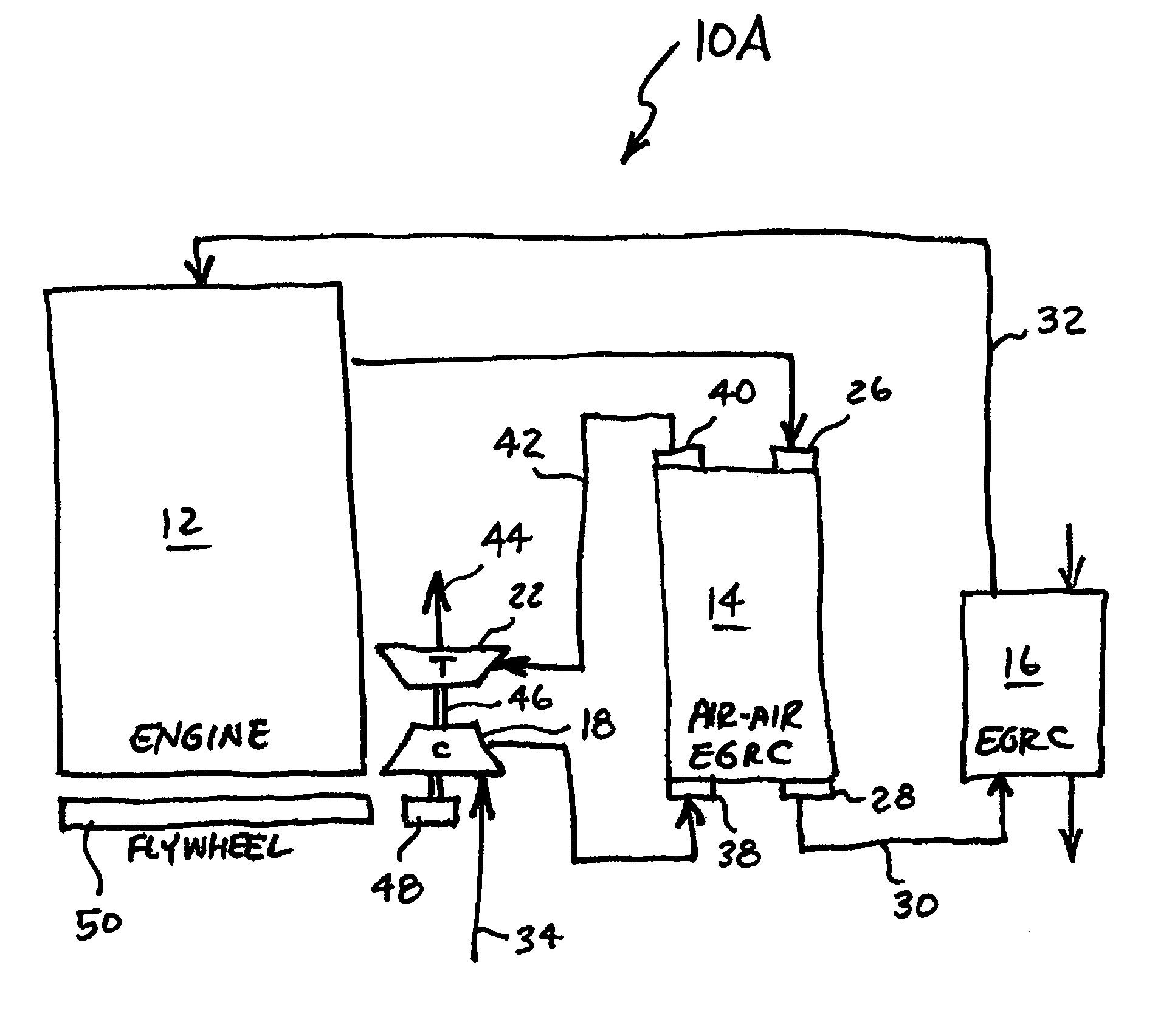

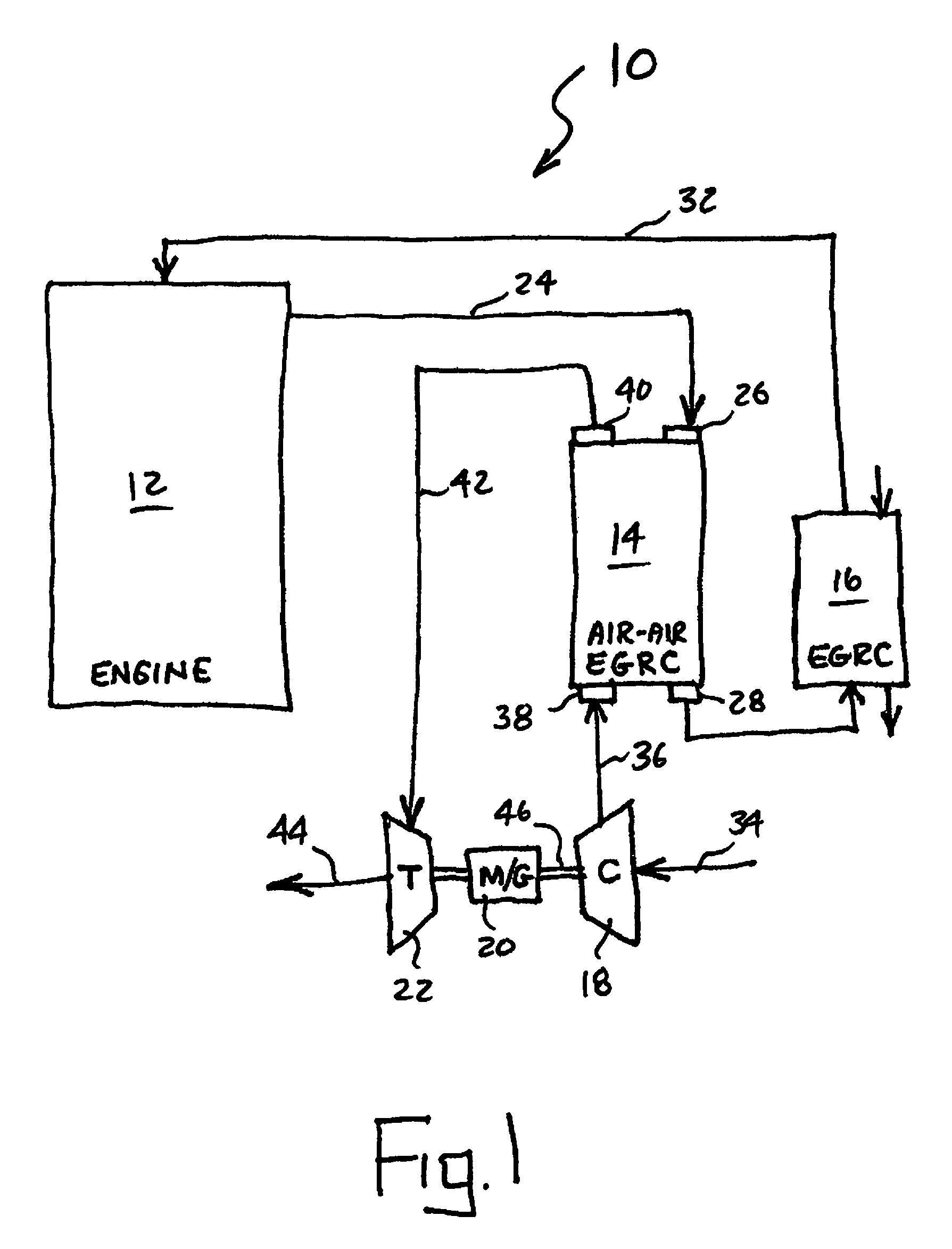

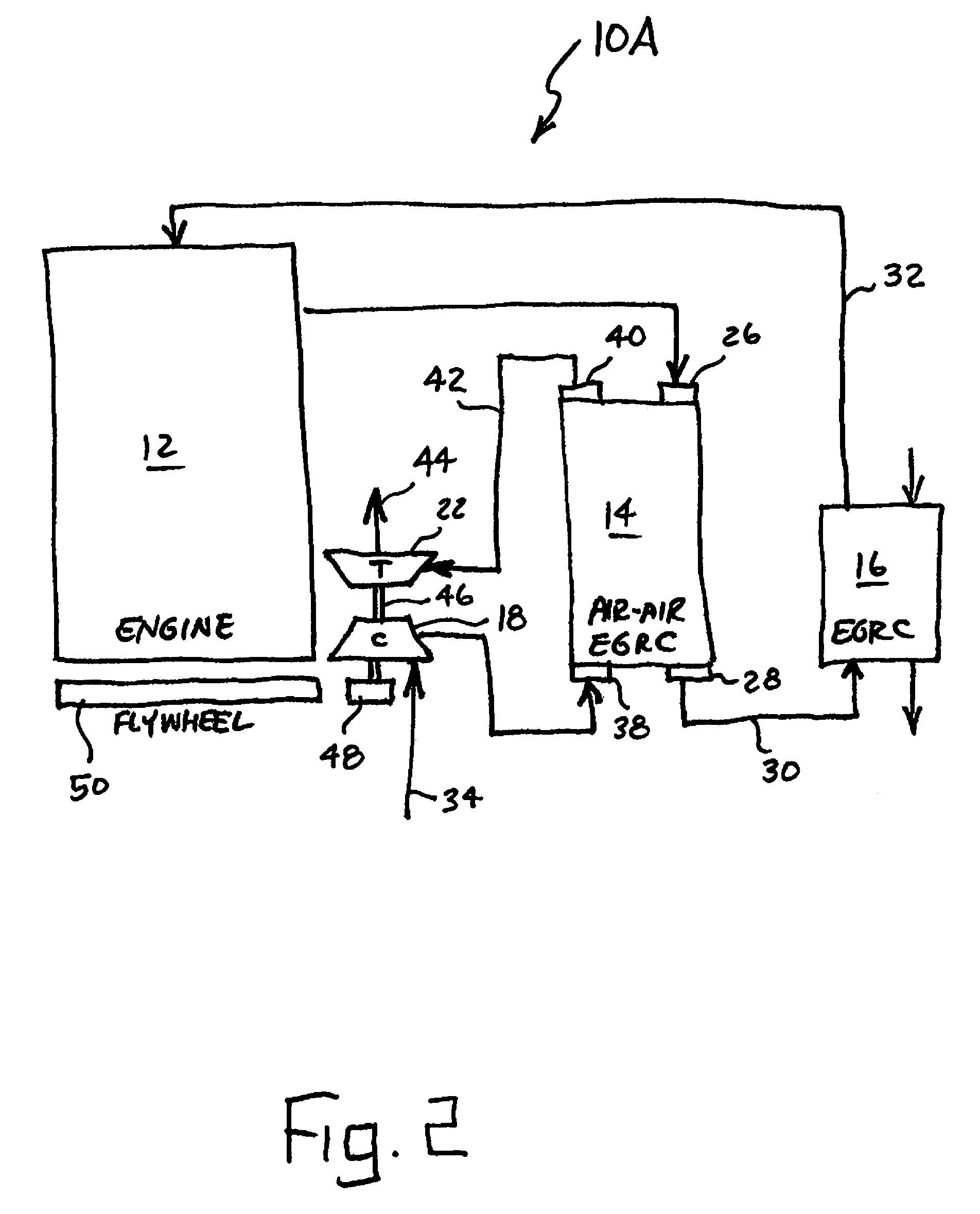

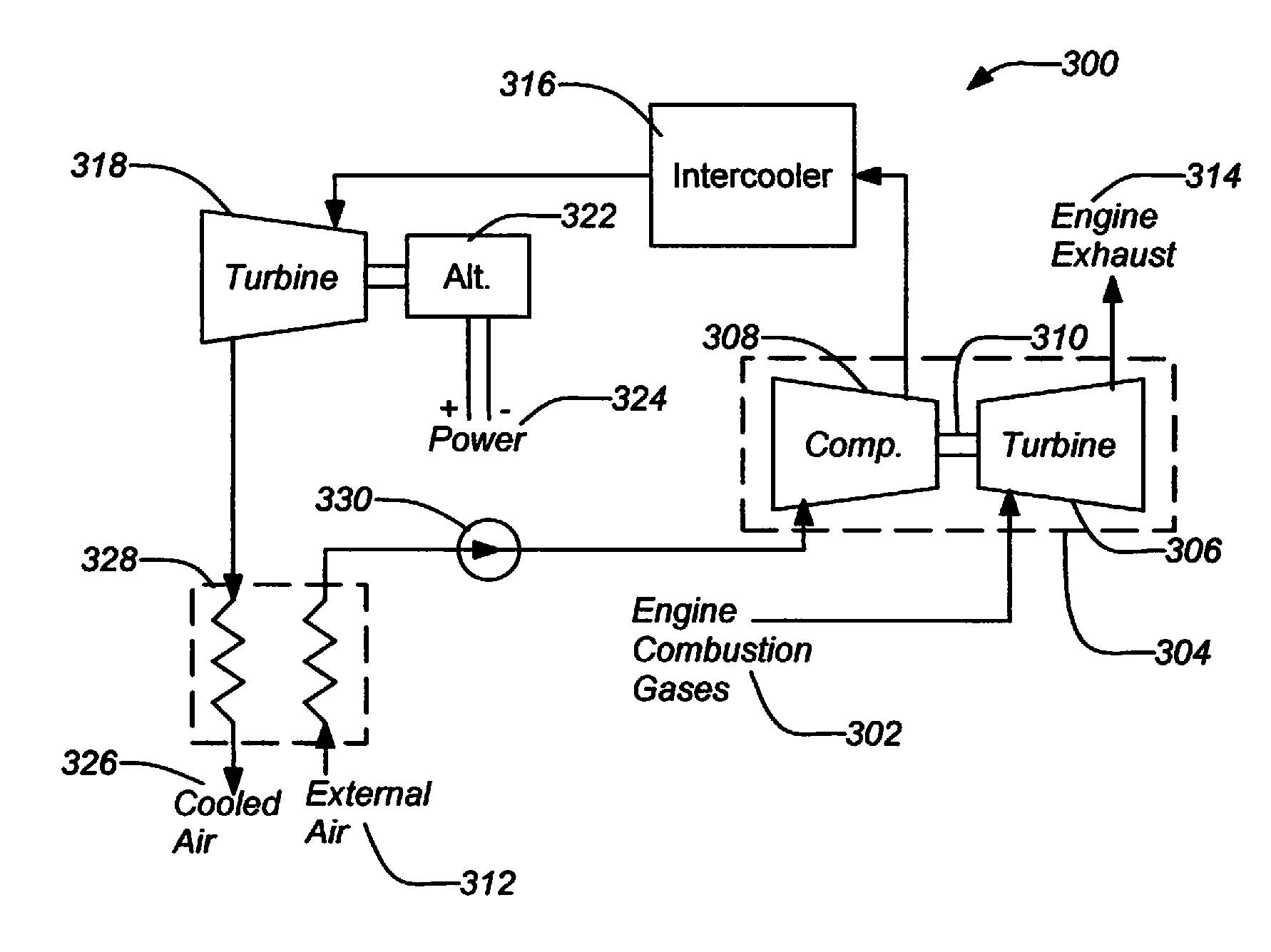

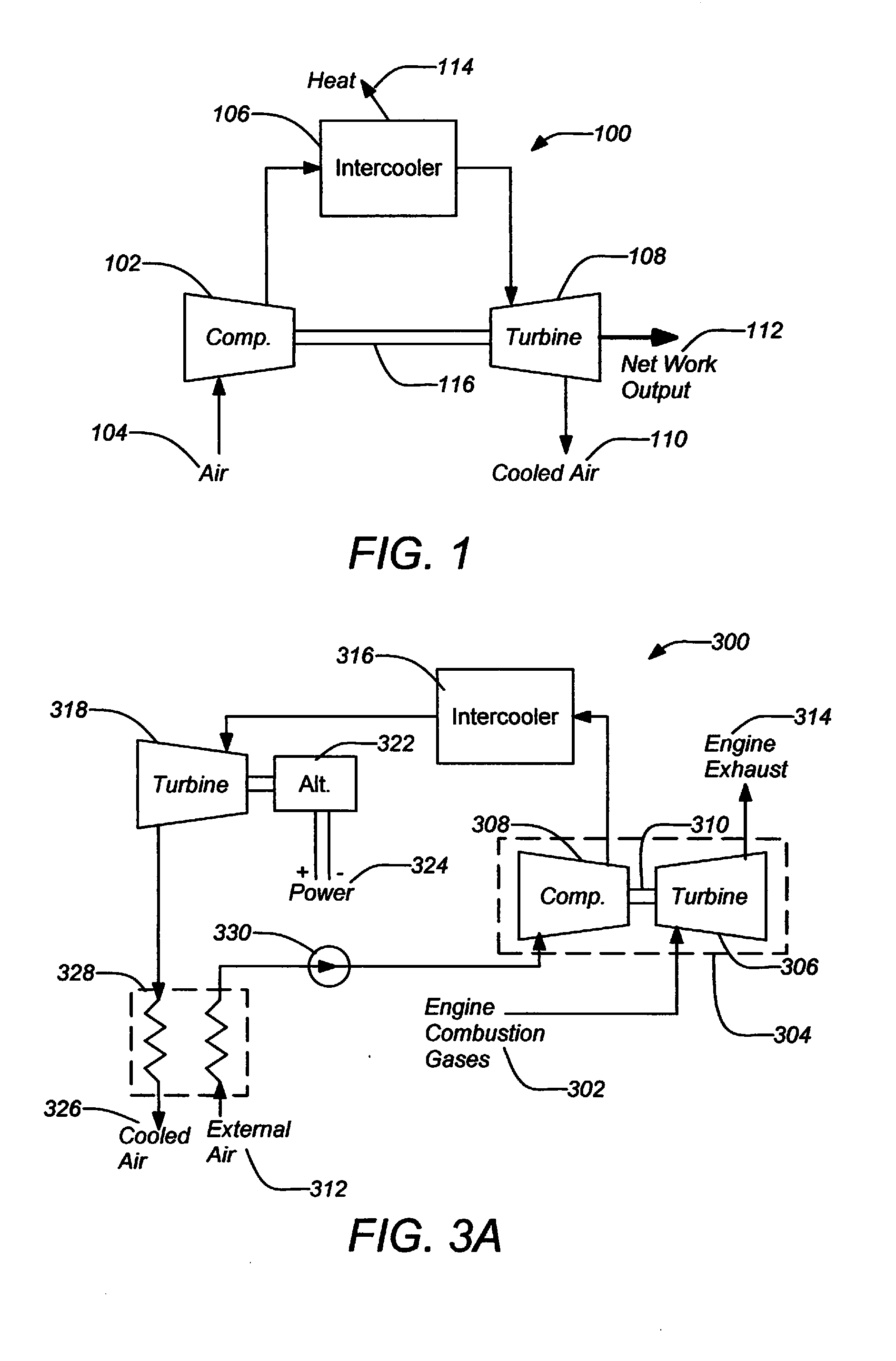

Open loop Brayton cycle for EGR cooling

ActiveUS7958873B2Lower exhaust gas temperatureReduce heat dissipationInternal combustion piston enginesNon-fuel substance addition to fuelBrayton cycleTurbine

A system for reducing the temperature of waste heat from a waste heat source of a vehicle engine, including an open loop Brayton cycle having a cooler, a compressor, a turbine, and a shaft coupling the compressor to the turbine. Waste heat and compressed air from the compressor flow through the cooler, thereby transferring heat from the waste heat to the compressed air and lowering the temperature of the waste heat. The heated and compressed air is expanded across the turbine, to cause rotation of the shaft, thereby powering rotation of the compressor. Excess power beyond that necessary to drive the compressor may be drawn off through a generator which has its rotor mounted on the same shaft as the compressor and turbine.

Owner:CUMMINS INC

Combined Cycle CAES Technology (CCC)

InactiveUS20150000248A1Size reduction requirementsImprove efficiencySteam accumulatorsGas turbine plantsBrayton cycleAir compression

This is a system that stores energy by compressing atmospheric air and confining it in tanks or caverns, combining the thermodynamic cycle followed by the atmospheric air (Brayton cycle) with another thermodynamic cycle followed by an auxiliary fluid, that is confined in the same cavern within a membrane, following two sections of a Rankine cycle, one during the air compression and entry into the cavern process and the other during the air outlet and turbininig process, using heat from the exhaust gases from the turbine as a heat source for an additional Rankine cycle, and being able to use the tanks or caverns for making an extra constant volume heating of compressed air and I or of the auxiliary fluid

Owner:PREXTOR SYST

Closed cycle brayton cycle system and method

The invention relates to a closed cycle brayton cycle system and a method. Specifically, the invention provides a method and a unit for generating energy with improved efficiency. A Brayton cycle unit includes a multistage compressor configured to compress a flowing medium; a first heat exchanger fluidly connected to the multistage compressor and configured to transfer heat from a working medium passing the first heat exchanger to the compressed flowing medium; an expander fluidly connected to the first heat exchanger and configured to expand the heated compressed flowing medium for producing a rotation of a shaft of the expander; and a second heat exchanger fluidly connected between the expander and the compressor and configured to remove heat from the expanded flowing medium. A path of the flowing medium through the unit is closed. At least one inter-cooler mechanism between first and second stages of the multistage compressor is configured to cool the flowing medium to a predetermined temperature.

Owner:NUOVO PIGNONE SPA

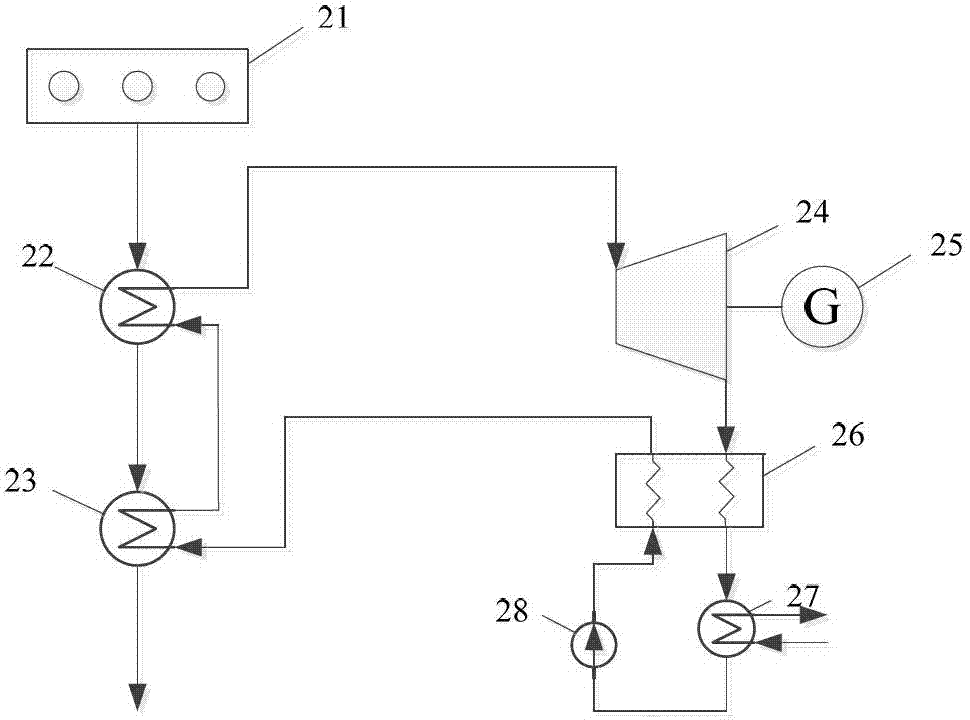

Combined power generating system based on waste-heat utilization of combustion motor

InactiveCN103161607ARealize cascade utilizationImprove waste heat utilization efficiencyInternal combustion piston enginesFuel supply apparatusGas compressorOrganic Rankine cycle

The invention discloses a combined power generating system based on waste-heat utilization of a combustion motor. The combined power generating system based on waste-heat utilization of the combustion motor is composed through combination of Bretton cycle and organic Rankine cycle. The combined power generating system based on waste-heat utilization of the combustion motor mainly comprises a gas turbine, a heat exchanger, a gas compressor, a turbine, a condenser, a booster pump and a circulating pump. Waste gas of the combustion motor firstly passes through a heater and transfers heat to carbon dioxide of Bretton cycle, carbon dioxide steam at the high temperature and the high pressure is formed to drive the gas turbine to generate power. The waste gas of the combustion motor still has high heat after passing through the heater, then the heat is transferred to an organic working medium in Rankine cycle through an evaporator, and organic working medium steam at the high temperature and the high pressure is formed. Carbon dioxide discharged from the gas turbine passes through a cooler, and heat of the carbon dioxide is transferred to the organic working medium in the Rankine cycle too, and organic working medium steam at the high temperature and the high pressure is formed. The turbine with the organic working medium is driven to generate power by two blasts of organic working medium steam at the high temperature and the high pressure.

Owner:XI AN JIAOTONG UNIV

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS7401475B2Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleProduct gas

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

Dual-fuel steam injection direct-inverse gas turbine combined cycle

ActiveCN104533621ACombined Cycle Efficiency ImprovementEmission reductionTurbine/propulsion engine coolingGas turbine plantsSystem integrationBrayton cycle

The invention relates to a clean fuel and biomass fuel dual-fuel steam injection direct-inverse gas turbine combined cycle. A backheating type steam injection-inverse gas turbine combined cycle form is adopted for a gas turbine, and clean fuel is adopted for the gas turbine; flue gas produced when biomass fuel burns in a boiler indirectly heats the air entering a combustion chamber of the gas turbine first and then preheats the air entering the boiler, wherein the steam cyclically produced by the gas turbine can be used for supplying heat to the outside. According to the dual-fuel steam injection direct-inverse gas turbine combined cycle, the gradient utilization principle of energy is utilized, an external combustion method and the advanced steam injection direct-inverse Brayton cycle are organically combined through system integration, the energy utilization efficiency of the biomass fuel can be substantially improved, the proportion of the biomass fuel to the clean fuel is adjustable, and self-balance of water consumption and water recovery for steam injection can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

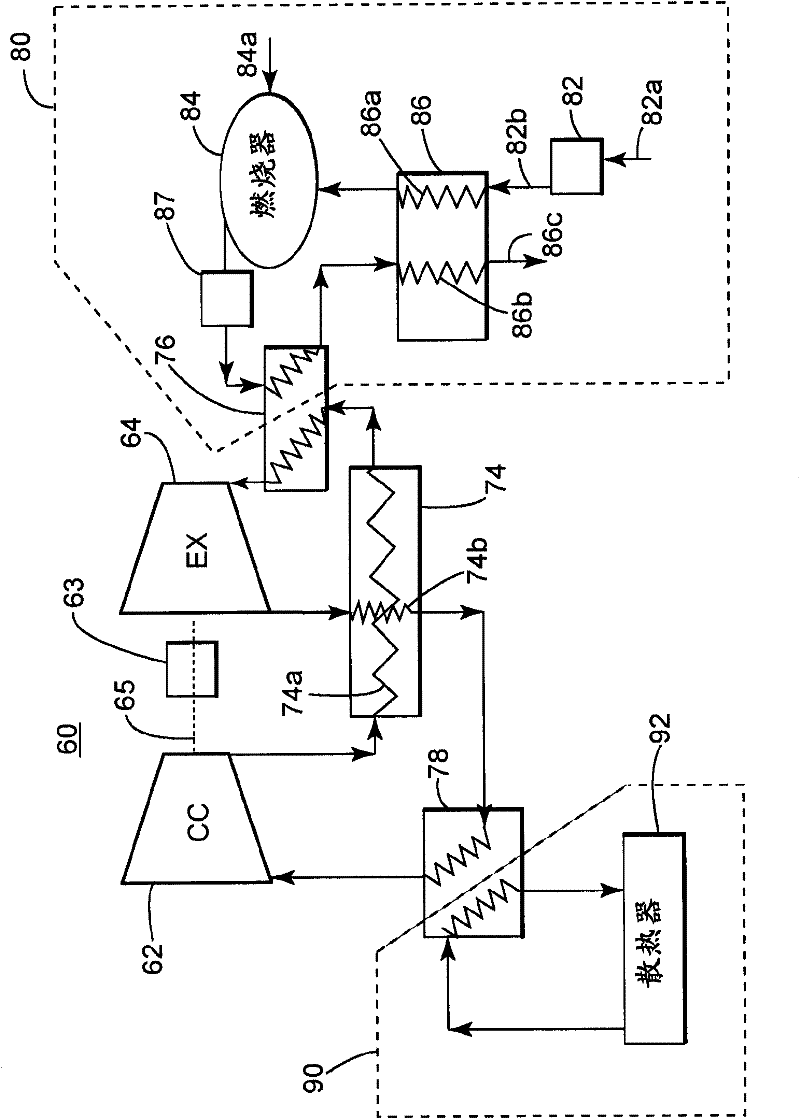

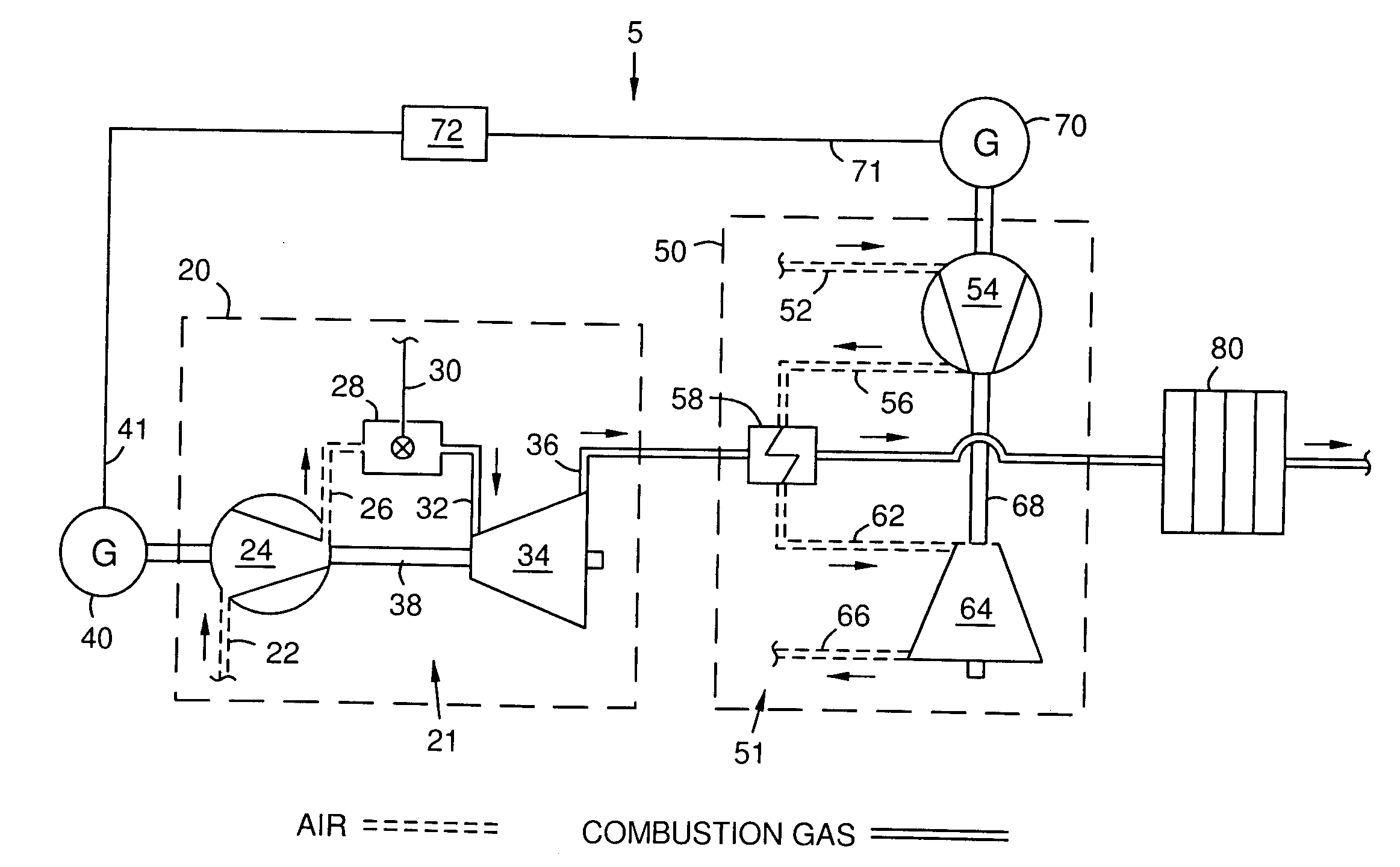

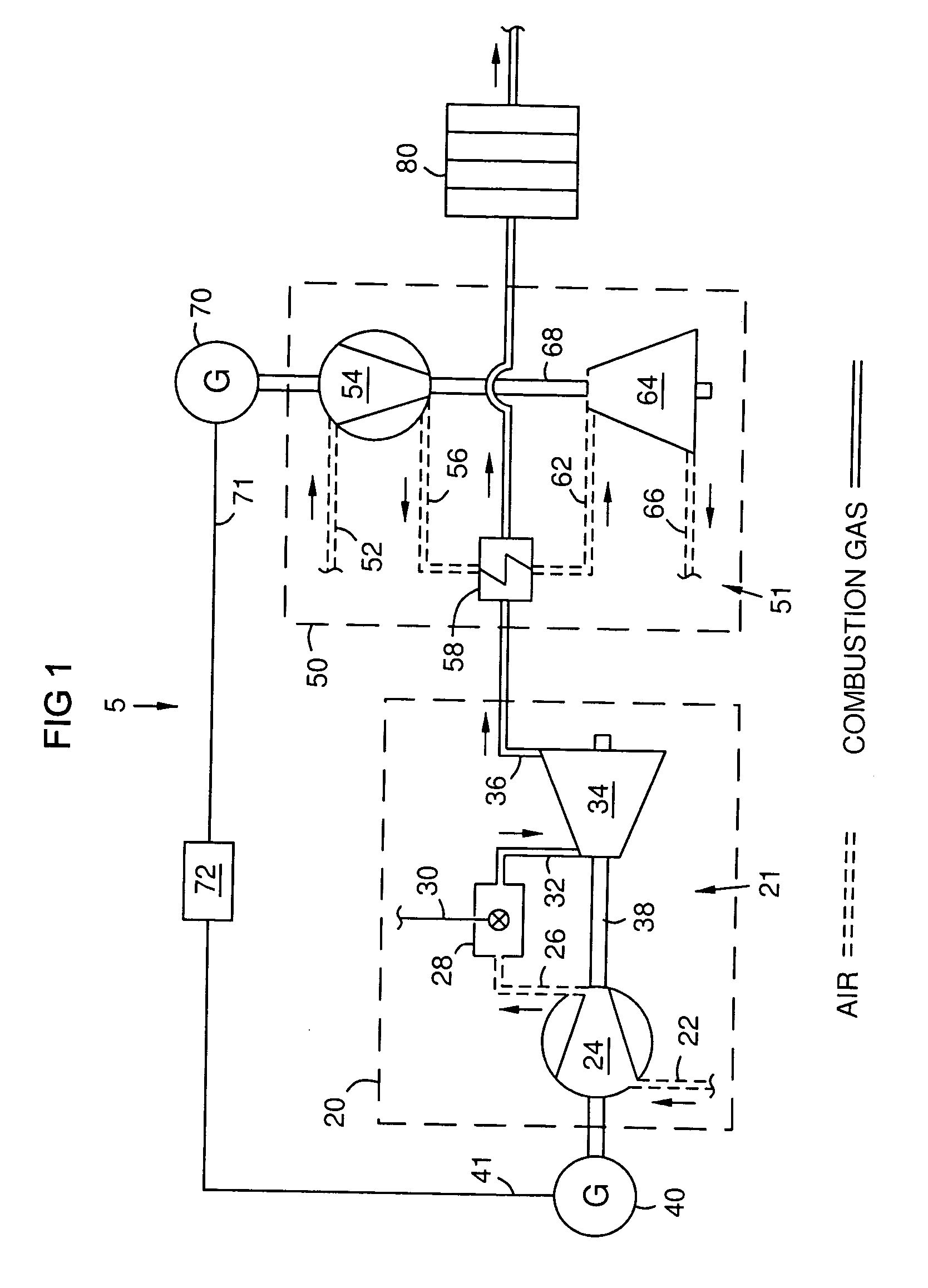

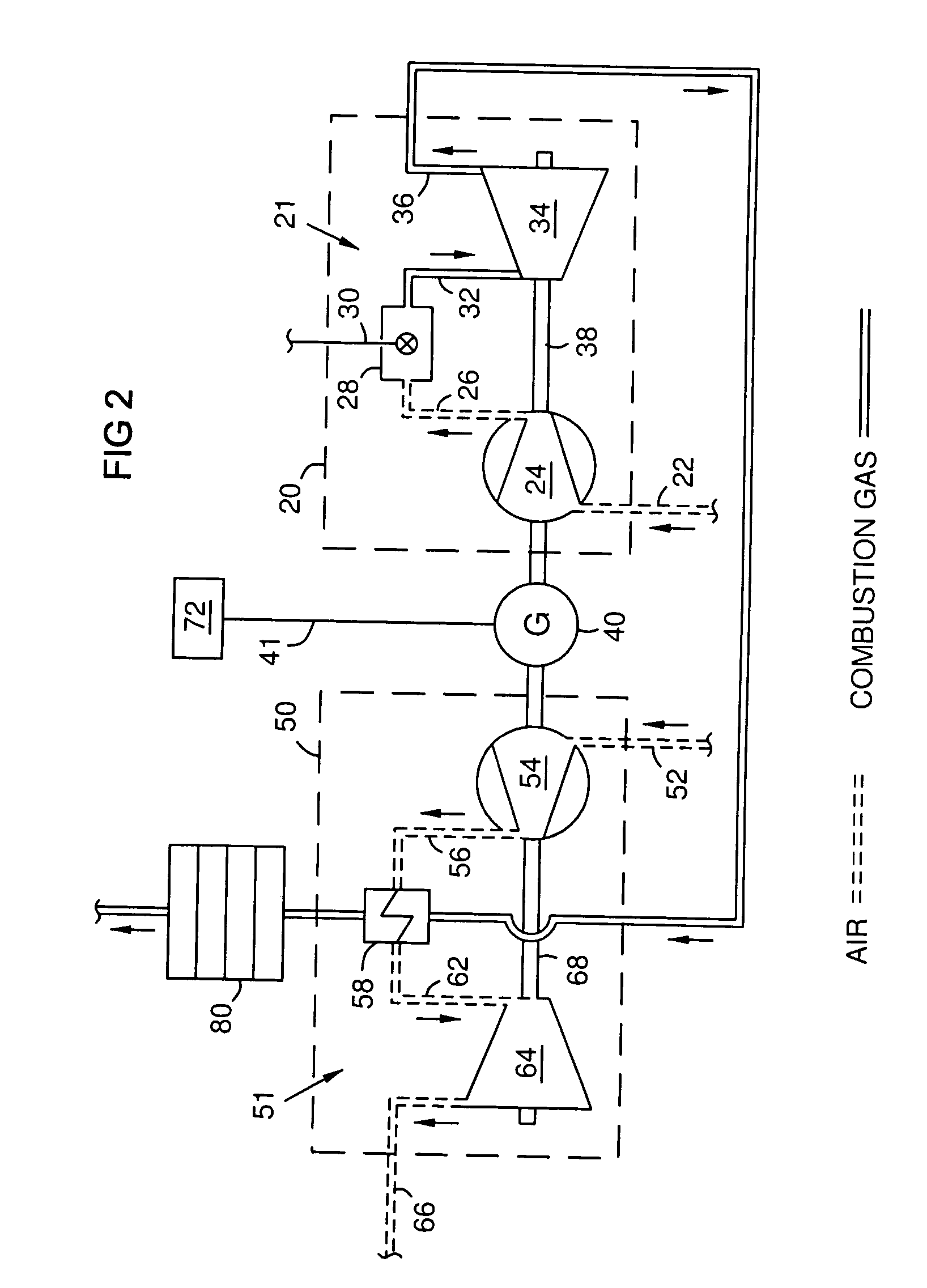

Heat recovery gas turbine in combined brayton cycle power generation

A combined Brayton cycle power plant (5). A combustion gas turbine engine (21) in the power plant uses a first Brayton cycle (20), and produces waste heat in an exhaust combustion gas (36). A heat exchanger (58) transfers the waste heat to a compressed working airflow (56) for a second Brayton cycle (50) in a heat recovery gas turbine engine (51). The heat transfer lowers the temperature of the combustion exhaust gas (36) to within an operating range of a conventional selective catalytic reduction unit (80), for efficient reduction of nitrogen oxide emissions to meet environmental regulations.

Owner:SIEMENS ENERGY INC

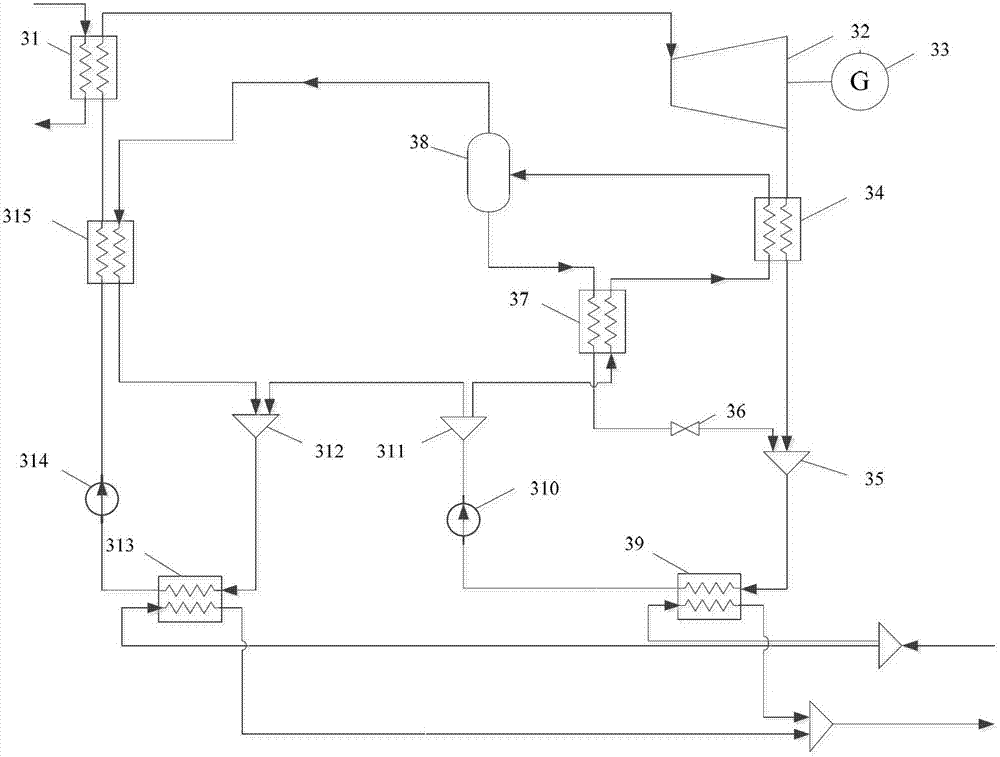

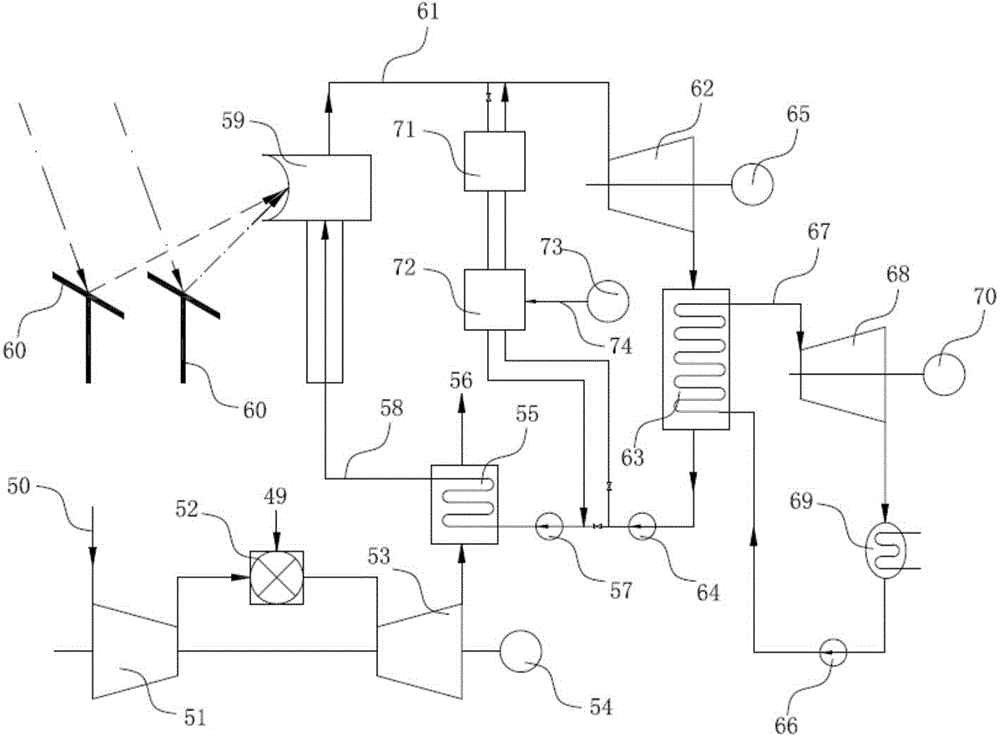

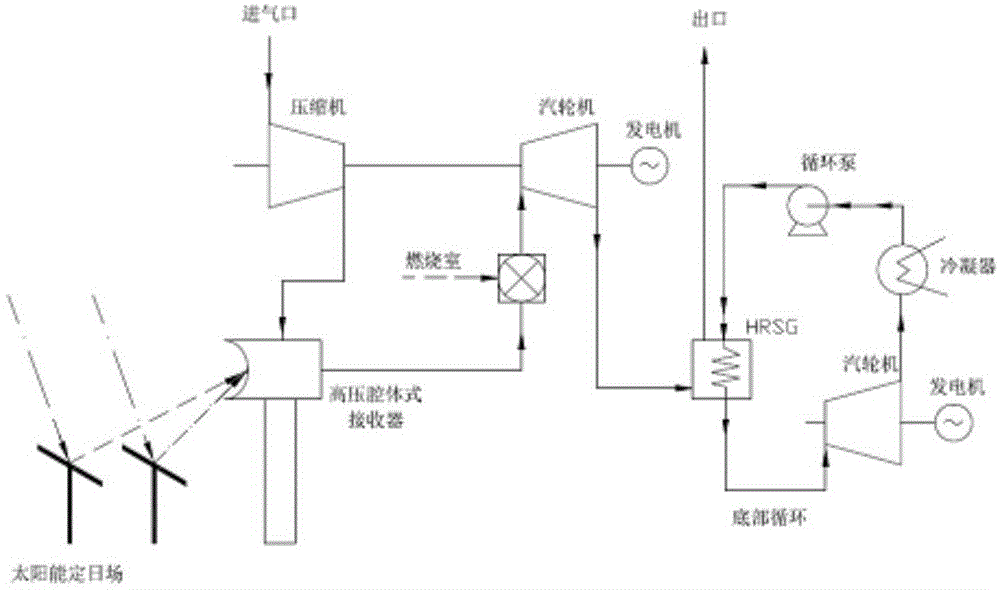

Combined power generation system for gradient utilization of wind energy, fuel gas and supercritical carbon dioxide energy

InactiveCN105840258AReduce consumptionReduce the temperatureGas turbine plantsWind motor combinationsPower cycleSupercritical carbon dioxide

The invention discloses a combined power generation system for gradient utilization of wind energy, fuel gas and supercritical carbon dioxide energy, and the combined power generation system is used for wind energy utilization and application of the supercritical carbon dioxide recompression Bretton power cycle. The system comprises a wind energy collecting system, a fuel gas turbine power generation system, an intermediate-low-temperature waste heat utilization system and a supercritical carbon dioxide recompression Bretton power cycle power generation system. During system work, wind energy is utilized for driving an air compression device, the compressed air is used for the fuel gas turbine system, waste gas and intermediate-low-temperature waste heat exhausted by a fuel gas turbine are recycled to serve as a heat source of a heat exchanger, and gradient utilization of energy is achieved. Carbon dioxide serves as a working medium of the supercritical carbon dioxide recompression Bretton cycle, the power mechanical structure of the supercritical carbon dioxide recompression Bretton cycle is compact, and economic performance is good. The stable combined power generation is achieved through the fuel gas turbine power generation system and the supercritical carbon dioxide recompression Bretton cycle system, and generated power energy is finally input into a power grid.

Owner:XI AN JIAOTONG UNIV

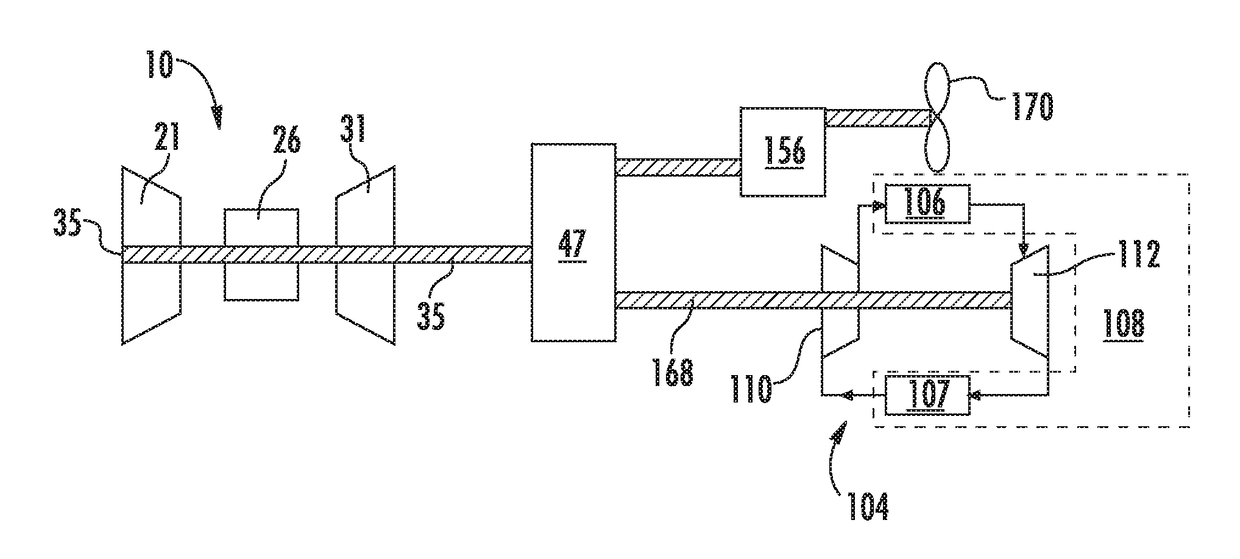

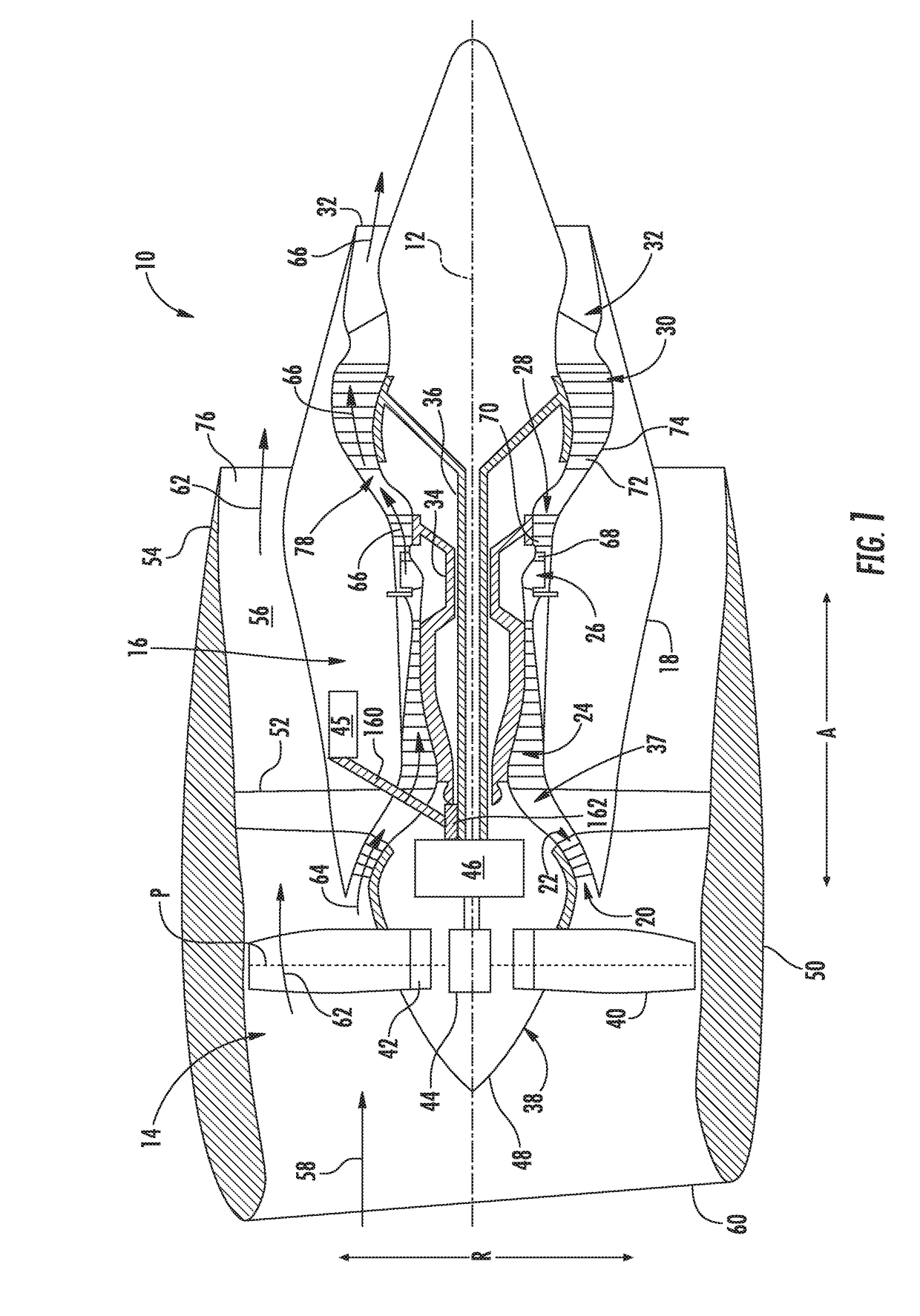

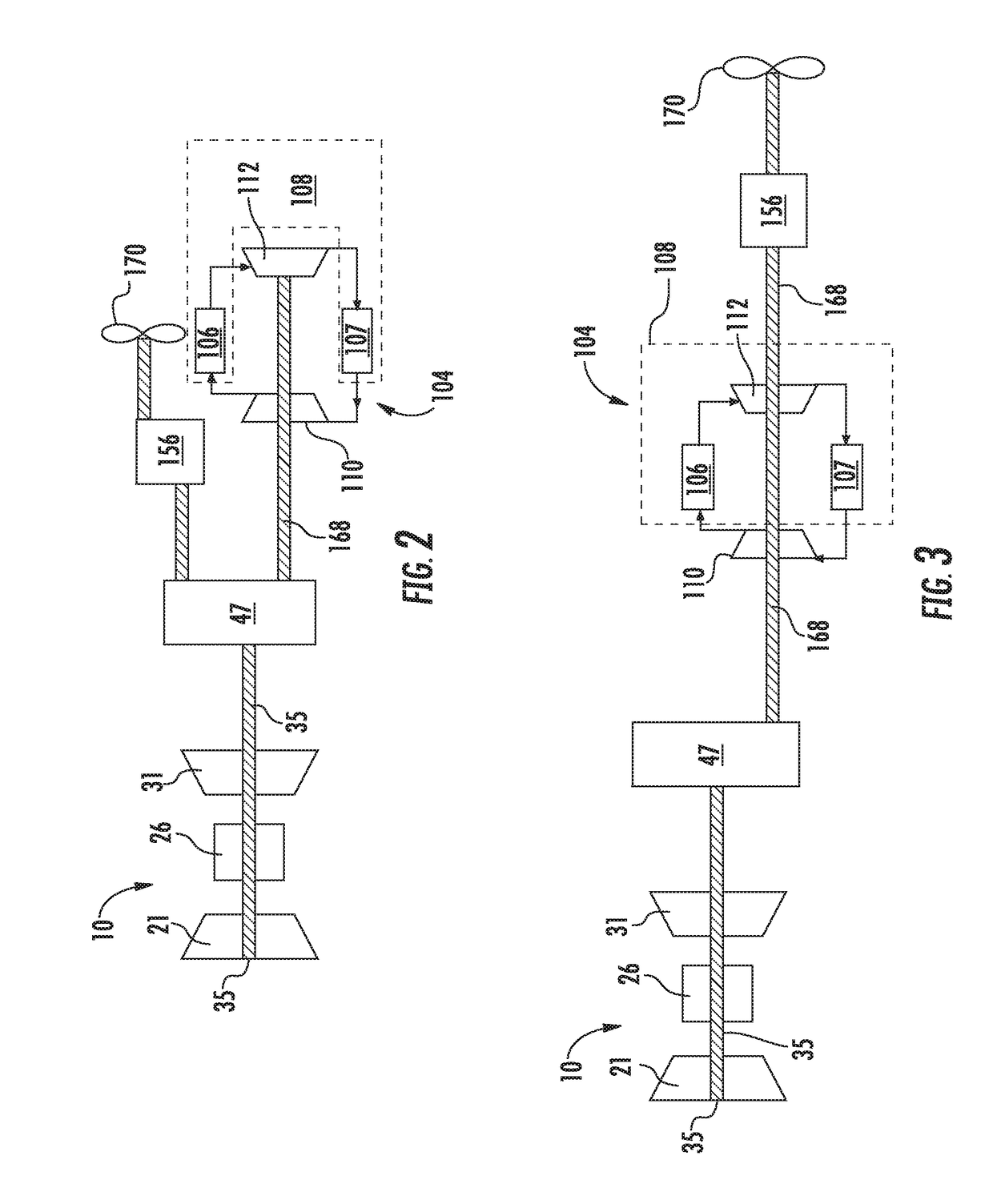

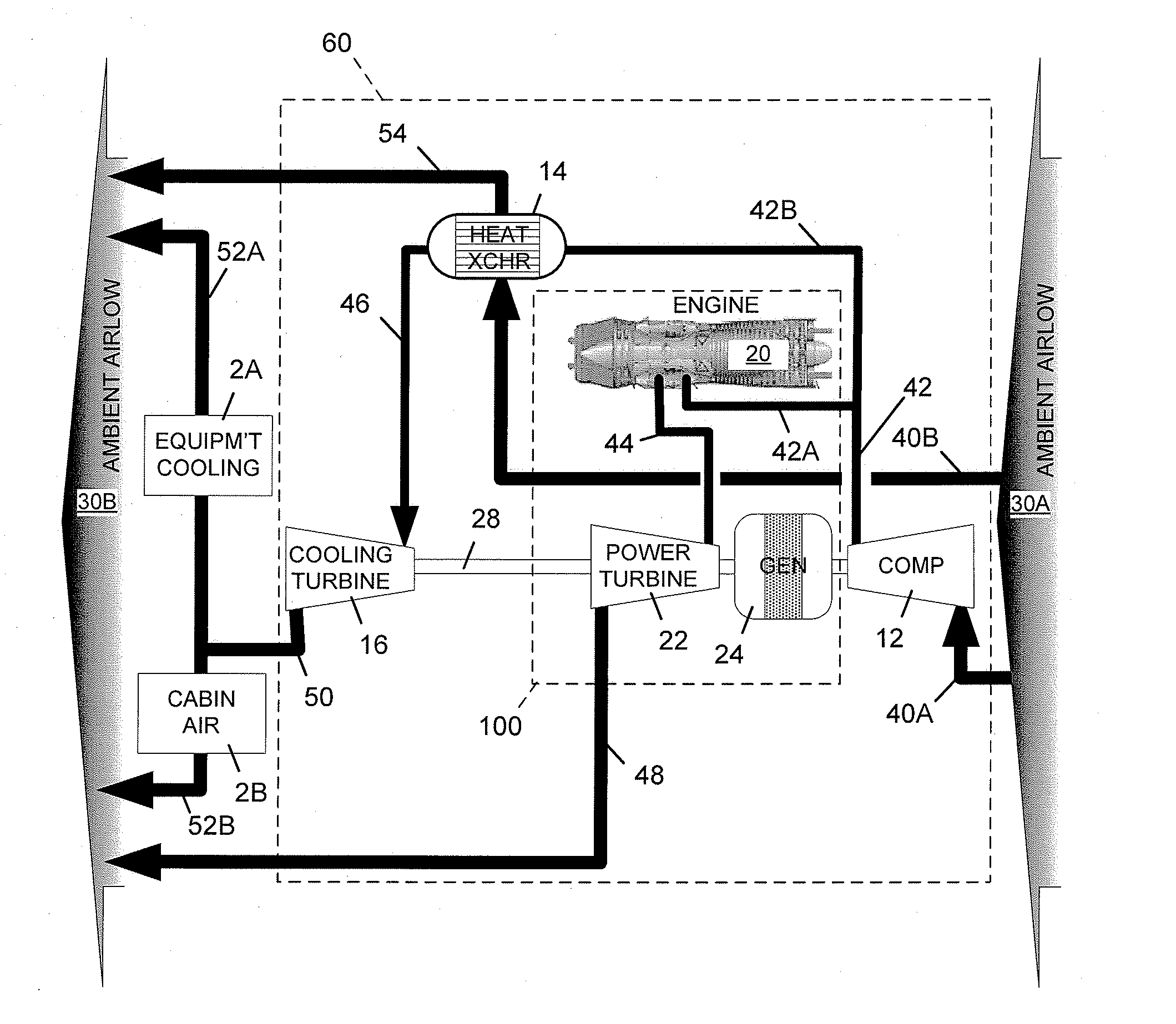

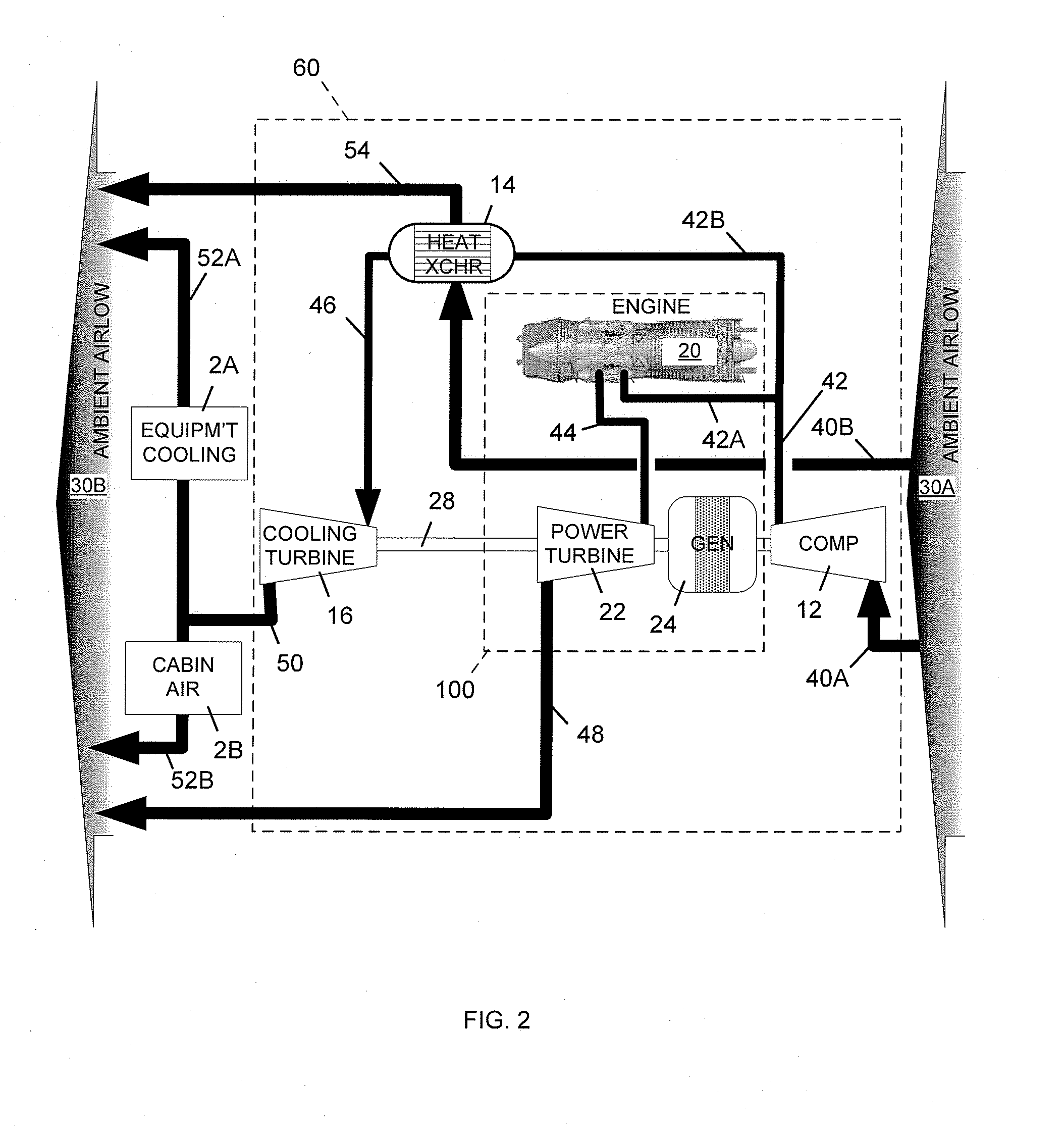

Mechanically driven air vehicle thermal management device

The present disclosure is directed to an aircraft power generation system including a reverse Brayton cycle system, a gas turbine engine, and a gearbox. The gas turbine engine includes a compressor section, a turbine section, and an engine shaft. The compressor section is arranged in serial flow arrangement with the turbine section. The engine shaft is rotatable with at least a portion of the compressor section and with at least a portion of the turbine section. The reverse Brayton cycle system includes a compressor, a driveshaft, a turbine, and a first exchanger. The driveshaft is rotatable with the compressor or the turbine, and the compressor, the first heat exchanger, and the turbine are in serial flow arrangement. The gearbox is configured to receive mechanical energy from the engine shaft and transmit mechanical energy to the reverse Brayton cycle system through the driveshaft.

Owner:GENERAL ELECTRIC CO

Integrated air-cycle refrigeration and power generation system

ActiveUS20130086927A1Low sizeReduce weightDomestic cooling apparatusAir-treatment apparatus arrangementsBrayton cycleAir cycle

An integrated power and refrigeration system is disclosed that includes a first subsystem configured to provide cooling air using a reverse-Brayton cycle using compressed air and a second subsystem configured to provide power by accepting a first portion of the compressed air from the first subsystem, heating the accepted first portion of the compressed air to form hot compressed air, and using the hot compressed air to drive a turbine that is coupled to a power generator.

Owner:LOCKHEED MARTIN CORP

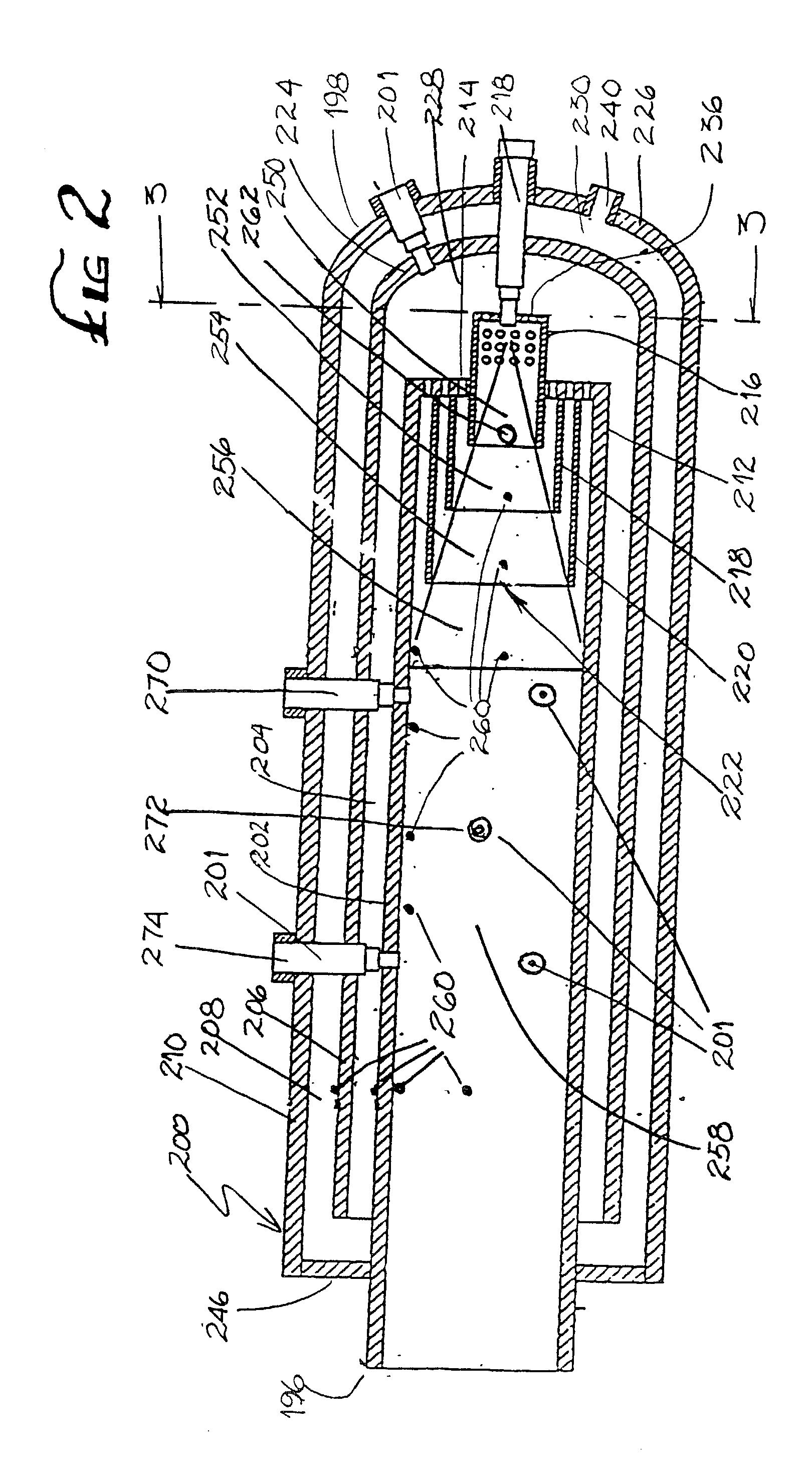

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20030014959A1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsEfficient propulsion technologiesHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NO.sub.x. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL

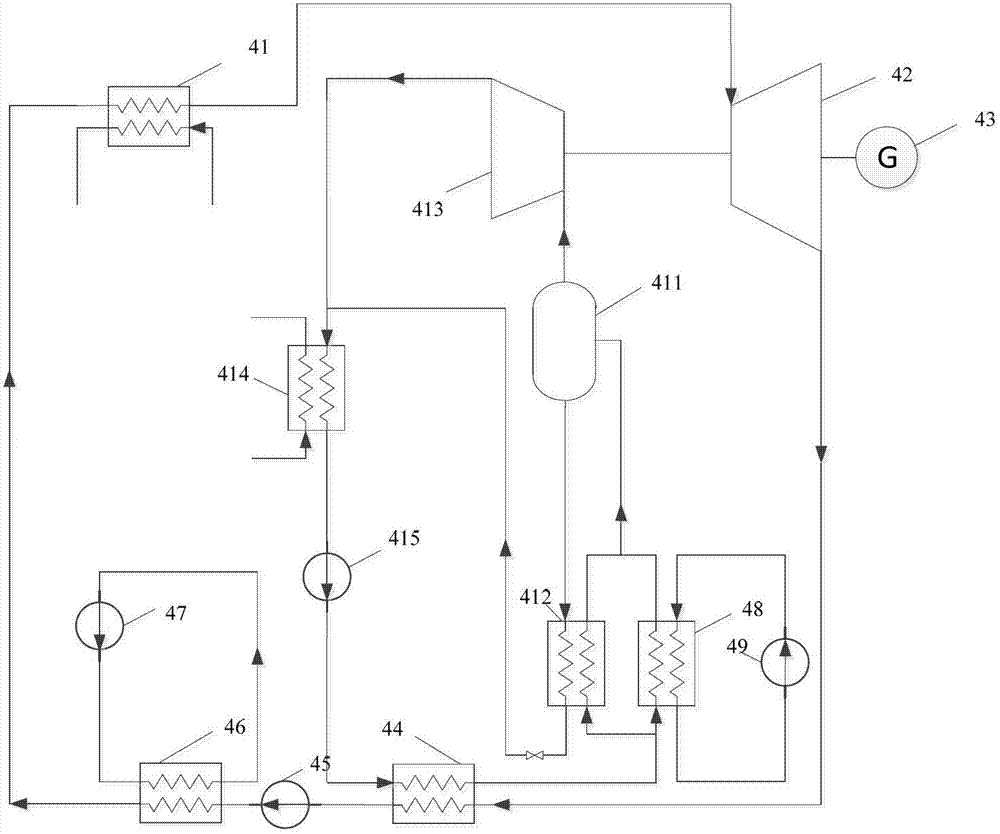

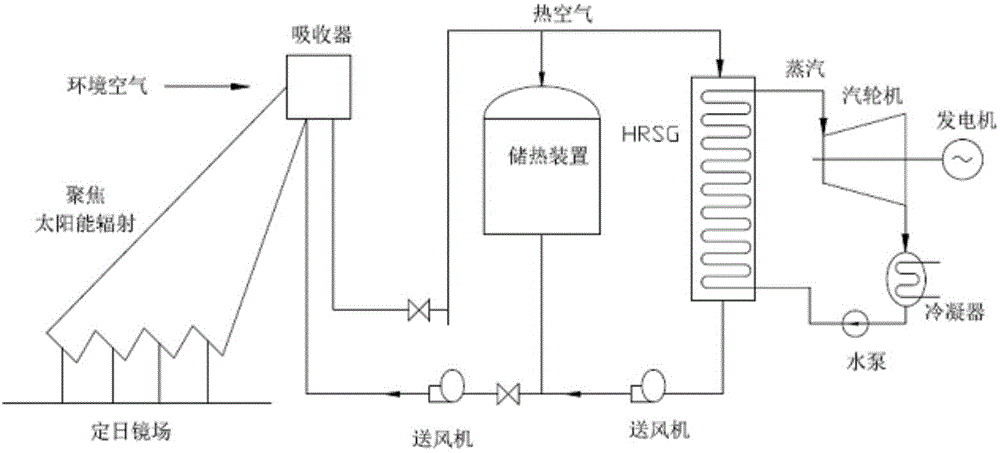

Tower solar thermal power generation method and system using closed Brayton cycle

InactiveCN104653420AImprove formation efficiencyImprove economyFrom solar energySolar heat devicesBrayton cycleWater vapor

The invention relates to a tower solar thermal power generation method and system using a closed Brayton cycle. The method and the system reserve the advantages of liquid pressurization and closed Brayton cycle of a supercritical carbon dioxide tower solar thermal power generation system, eliminate the disadvantages of excessively high system pressure and excessively low critical temperature, use extracted steam in an open Brayton cycle as the heat source of the closed Brayton cycle and water vapor as the heat absorbing working medium of the tower solar thermal power generation system, greatly reduce power consumption in working medium pressurization in a solar Brayton cycle by using the uncompressible fluid property and very good heat transfer performance of liquid water, and use a bottom Rankine cycle for absorbing heat released in the closed Brayton cycle, thereby forming an open Brayton-closed Brayton-Rankine combined cycle solar thermal power generation system which has the advantages of higher efficiency and better economic performance.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

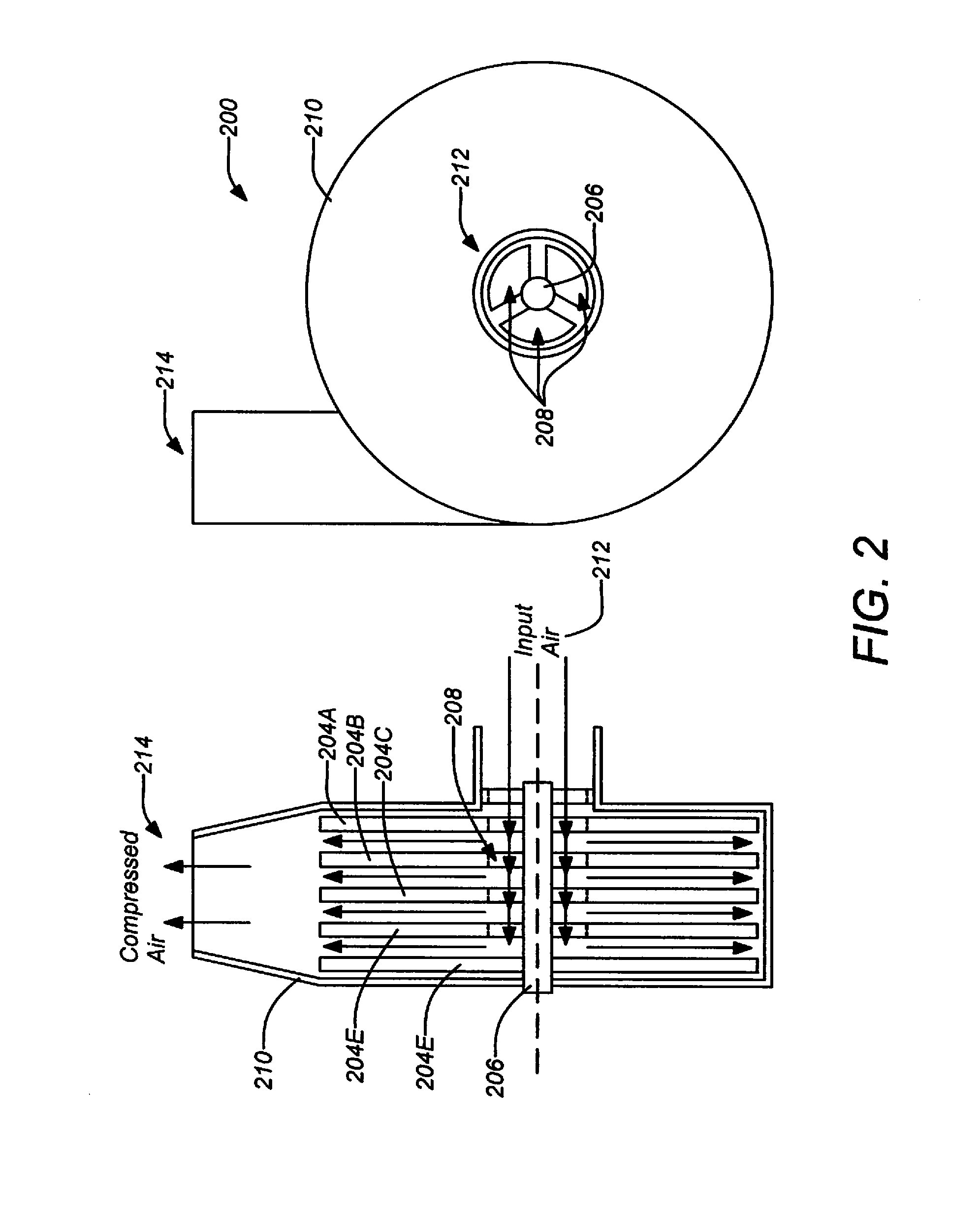

Reverse brayton cycle with bladeless turbo compressor for automotive environmental cooling

InactiveUS20130294890A1Reduce moisture contentIncrease air temperaturePump componentsCompression machinesBrayton cycleAlternator

An automotive cabin cooling system uses a bladeless turbocompressor driven by automobile engine exhaust to compress incoming ambient air. The compressed air is directed to an intercooler where it is cooled and then to another bladeless turbine used as an expander where the air cools as it expands and is directed to the cabin interior. Excess energy may be captured by an alternator couple to the expander turbine. The system employs no chemical refrigerant and may be further modified to include another intercooler on the output of the expander turbine to isolate the cooled cabin environment.

Owner:CALIFORNIA INST OF TECH

Supercritical carbon dioxide Brayton cycle power generation system

PendingCN108612573AGuaranteed cycle power generation efficiencyRelieve pressureSteam engine plantsBrayton cycleEngineering

The invention belongs to the technical field of power generation and discloses a supercritical carbon dioxide Brayton cycle power generation system. According to the supercritical carbon dioxide Brayton cycle power generation system, an inlet of a main compressor is connected with a cooler, an outlet of the main compressor is connected with the low-temperature heat regenerator, an inlet of a recompressor is connected with the low-temperature heat regenerator, an outlet of the recompressor is connected with a high-temperature heat regenerator, the high-temperature heat regenerator is connectedwith an inlet of a high-pressure turbine, an inlet of a heat source is connected with the high-pressure turbine, an outlet of the heat source is connected with a low-pressure turbine, an outlet of thelow-temperature turbine is connected with the high-temperature heat regenerator, the compressors and the turbines are not coaxial, and the heat source is arranged between the high-pressure turbine and the low-pressure turbine. The supercritical carbon dioxide Brayton cycle power generation system can guarantee that the supercritical carbon dioxide Brayton cycle power generation efficiency is 40%or over and can effectively reduce the pressure of the heat source by 25%; and in this way, the supercritical carbon dioxide power generation system can adopt multiple kinds of heat sources to efficiently generate power.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Gerotor apparatus for a quasi-isothermal brayton cycle engine

InactiveUS7008200B2Simpler gas flow pathLess loadRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesBrayton cycleEngineering

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:STARROTOR CORPORATION +1

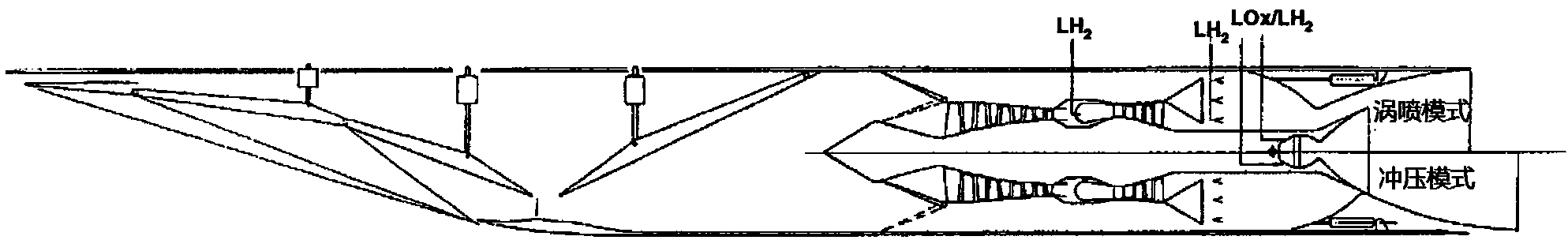

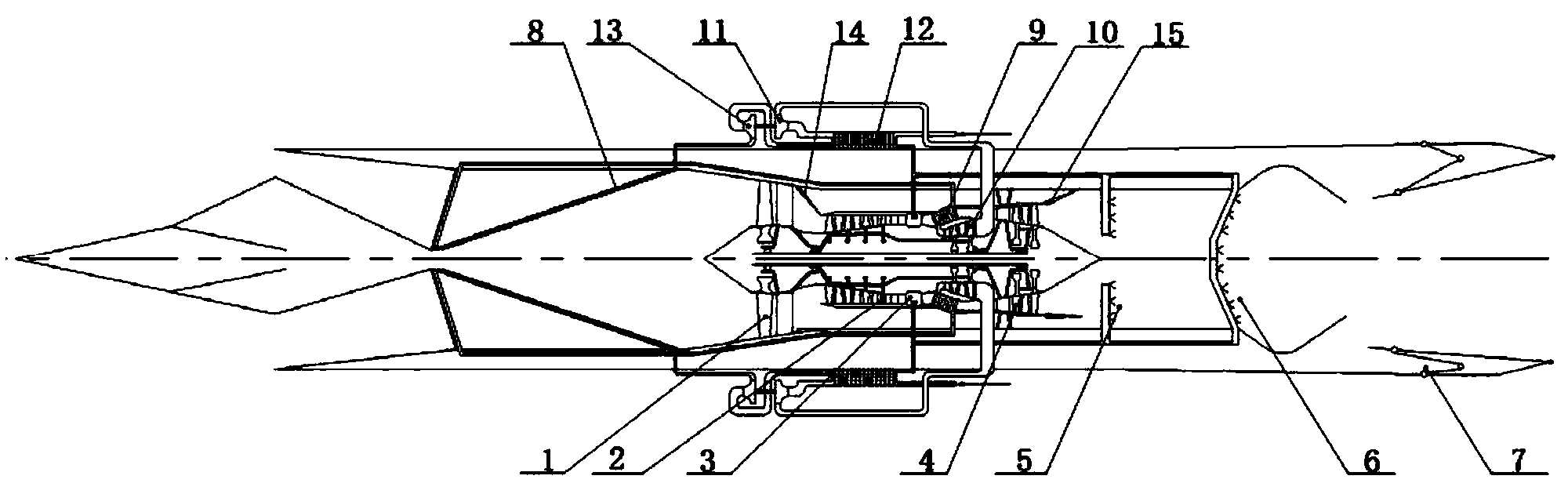

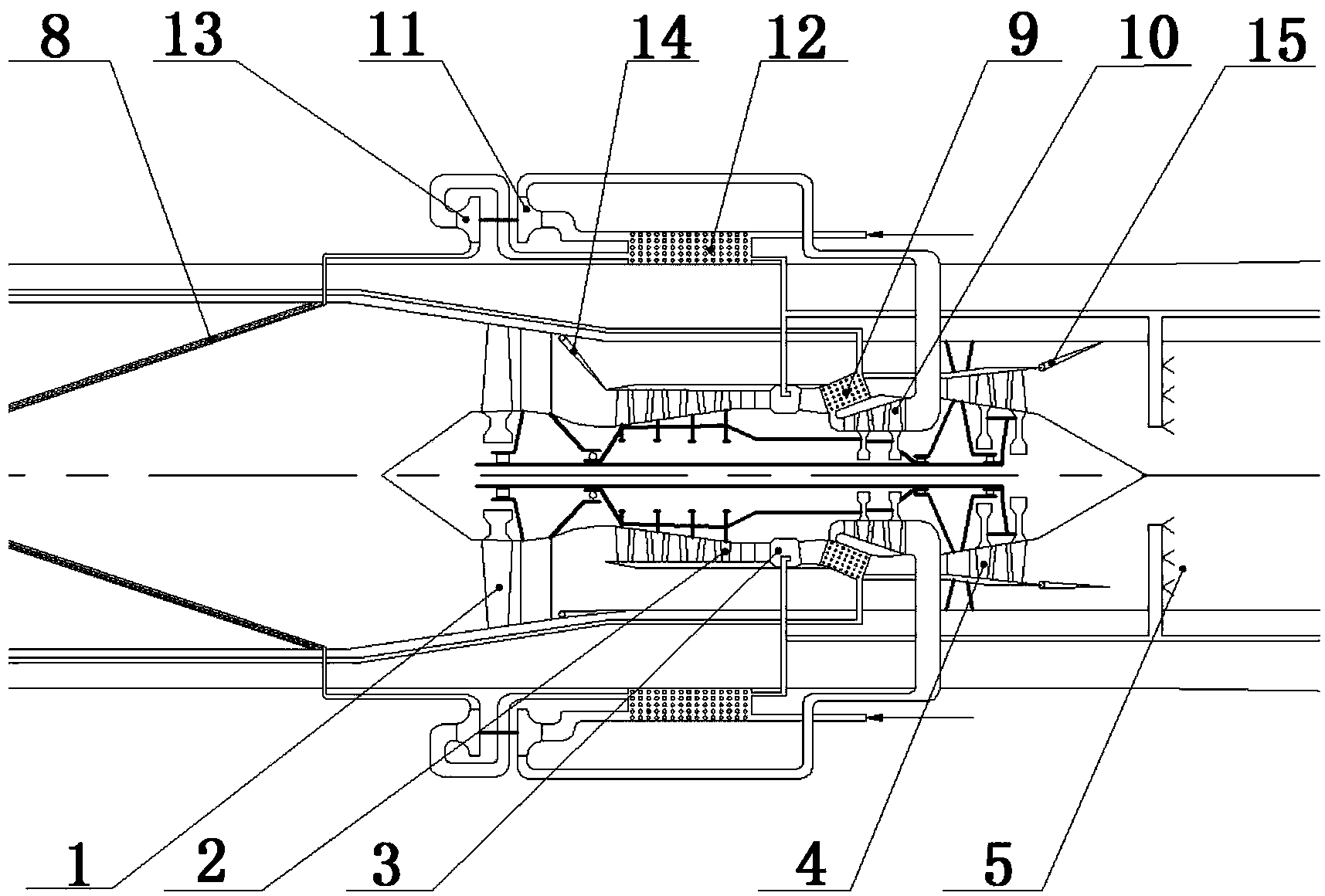

New concept high-speed aerocraft propulsion system layout method

ActiveCN104110326AEfficient cruiseLarge heat capacityRam jet enginesComposite engine plantsSpacecraft propulsionBrayton cycle

The invention provides a new concept high-speed aerocraft propulsion system layout method. Two cycles are built in a propulsion system, namely a Brayton cycle with the air as the working medium and a closed cycle with supercritical state fluid as the working medium. The two cycles are coupled through a supercritical microscopic scale heat exchange technology, a supercritical state fluid turbine and compressor power balance. By adjusting related valves, the propulsion system can be in a turbofan engine model when taking off or flying at a low speed and in a turbine rocket engine model when flying at a high Mach number, so that it is guaranteed that the aerocraft can effectively cruise for a long time in both a subsonic state and a supersonic state. Through the supercritical microscopic scale heat exchange technology, the gas flow temperature at an inlet of a compressor can be effectively reduced when the propulsion system is flying at a high speed, and when the supercritical microscopic scale heat exchange technology is applied in combination with a closed cycle technology, optical distribution of energy of the propulsion system can be achieved. By means of the method, the defects of the propulsion system of an existing high-speed aerocraft are overcome, and working performance of the high-speed aerocraft propulsion system is remarkably improved when Ma ranges from 0 to 5.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com