Patents

Literature

109results about How to "Increase horsepower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

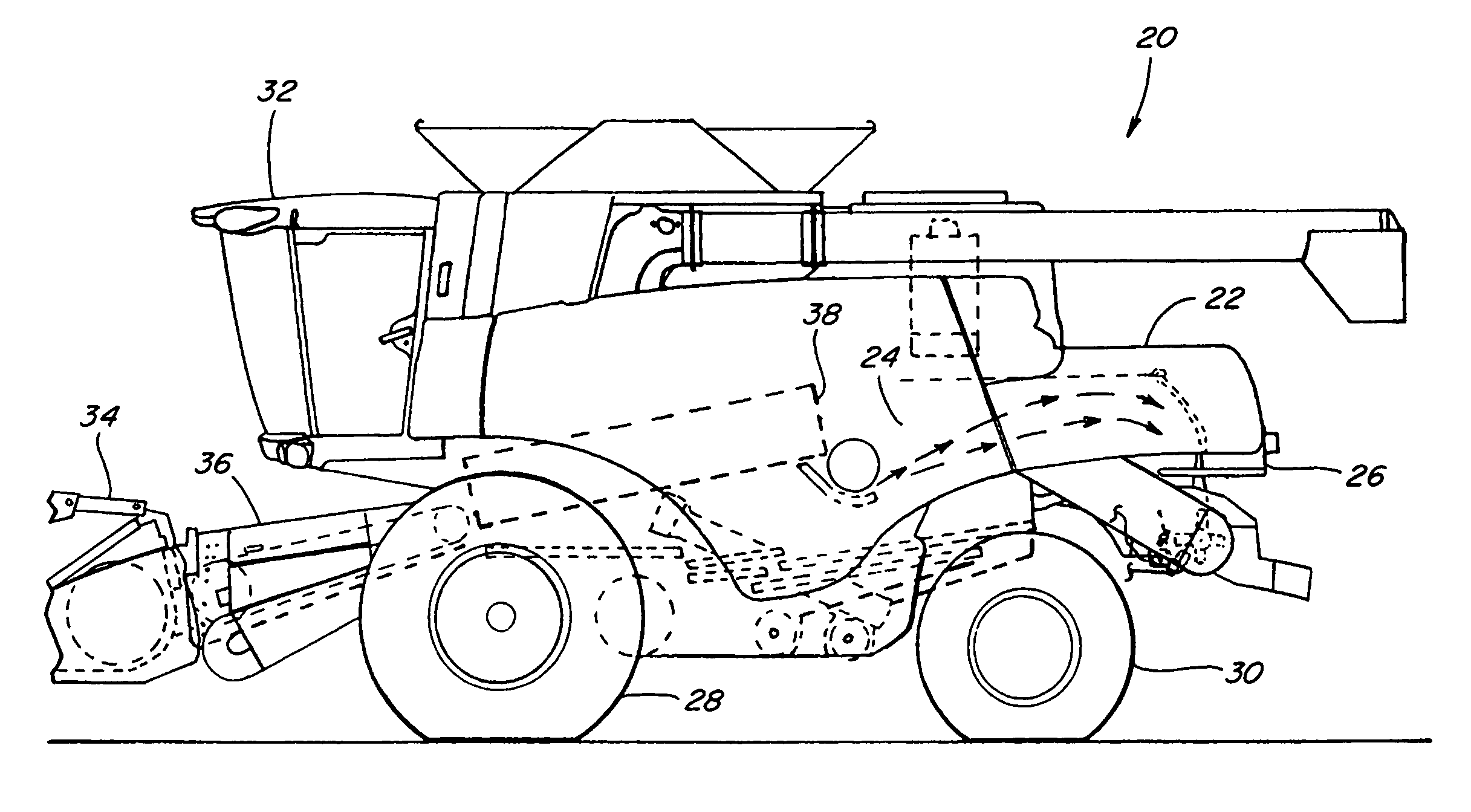

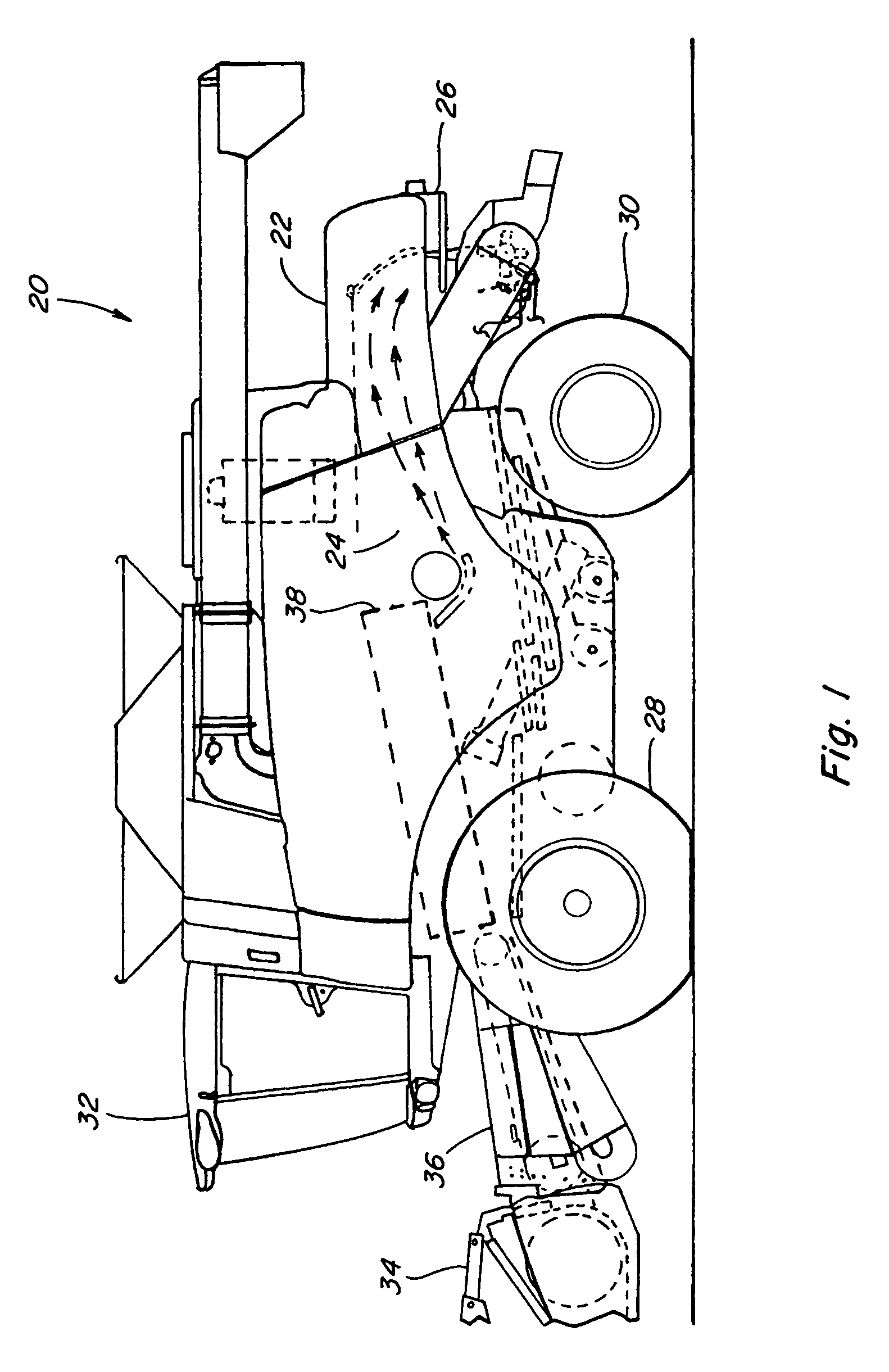

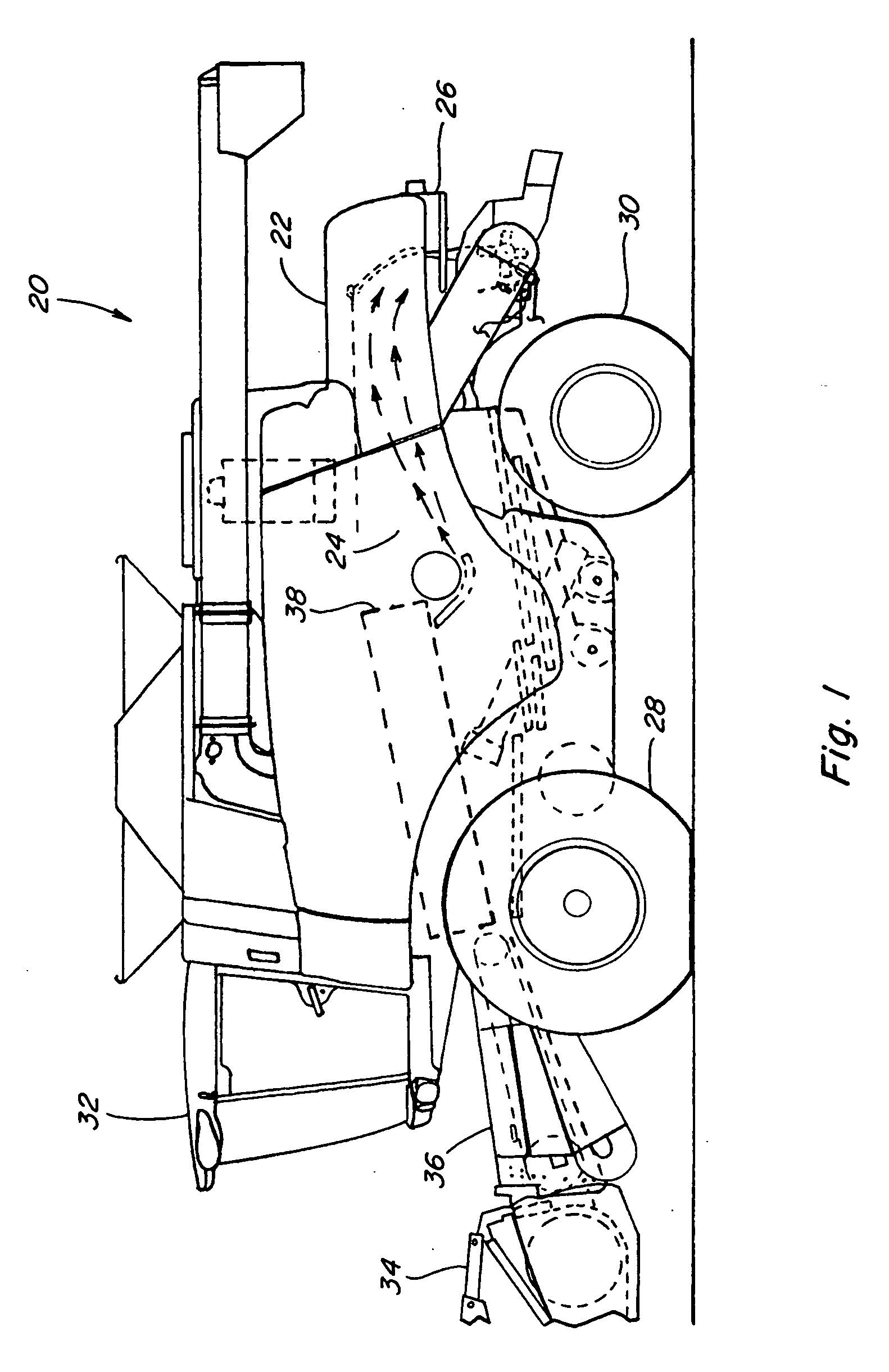

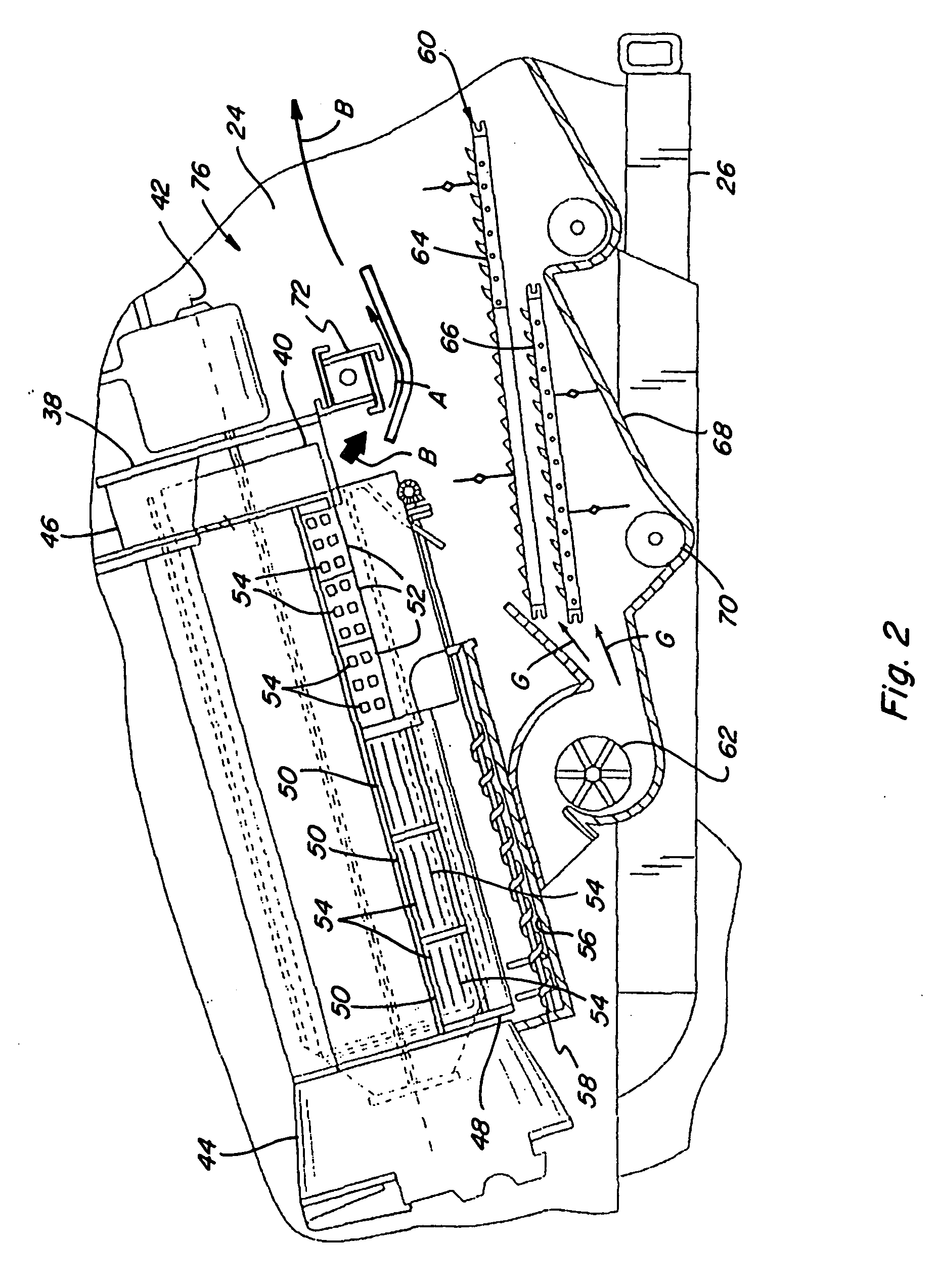

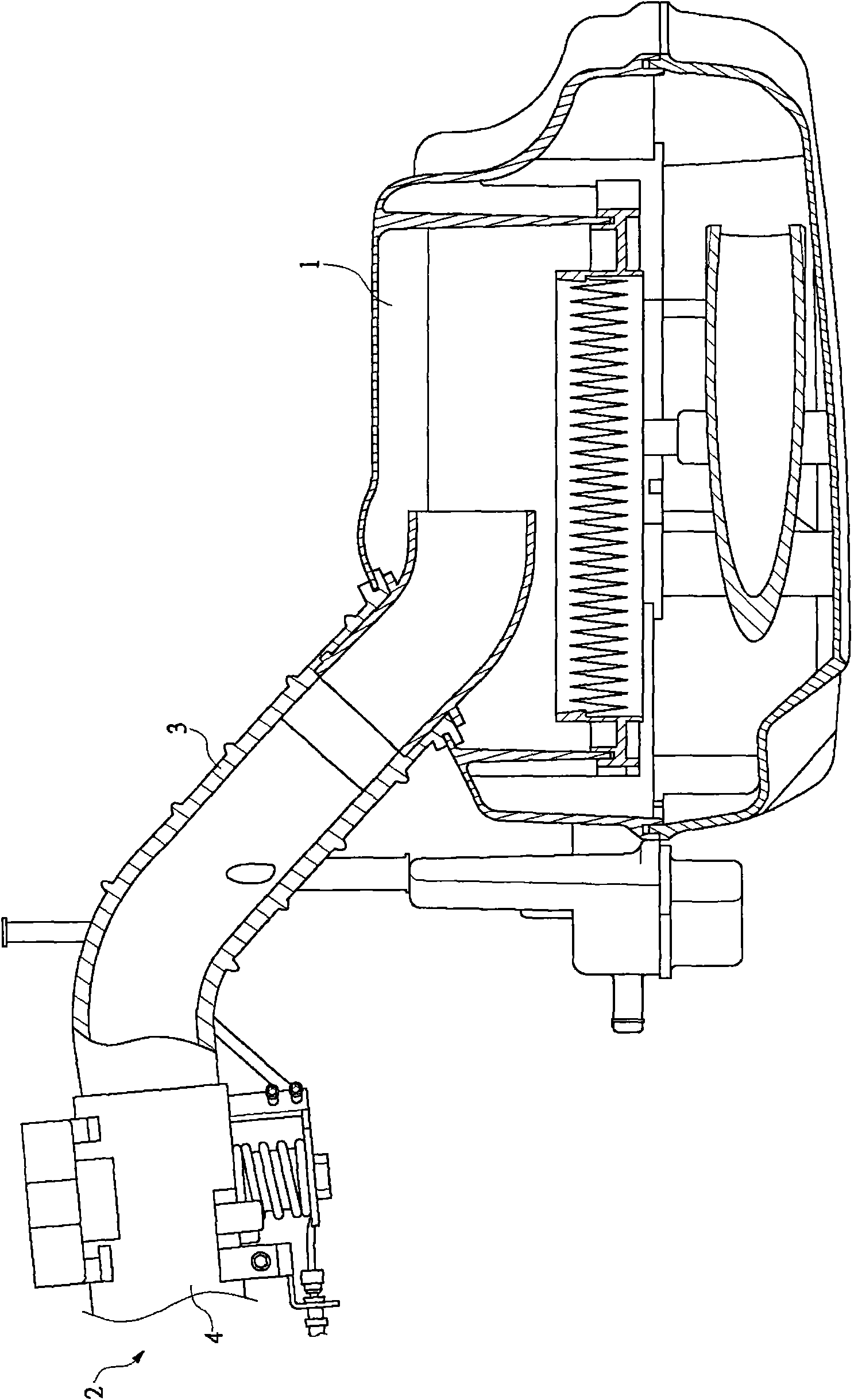

Combine harvester power management control

ActiveUS7648413B2Reduce total powerNeed for powerAnalogue computers for trafficMowersEngineeringCrop residue

A system and method of controlling maximum available engine power of a combine harvester wherein the engine drives the harvester and additionally powers a threshing mechanism for separating harvested crop into grain and crop residue and at least one further crop processing subsystem that may be selectively configured and disengaged, including a straw chopper engageable for chopping the crop residue and propelling the chopped residue from the harvester, structure configurable for directing the crop residue into the chopper or to bypass the chopper, utilizing a controller for automatically reducing the maximum available engine power as a function of the status of the engagement of the subsystems, particularly the chopper and the configuration of the associated structure.

Owner:BLUE LEAF I P INC

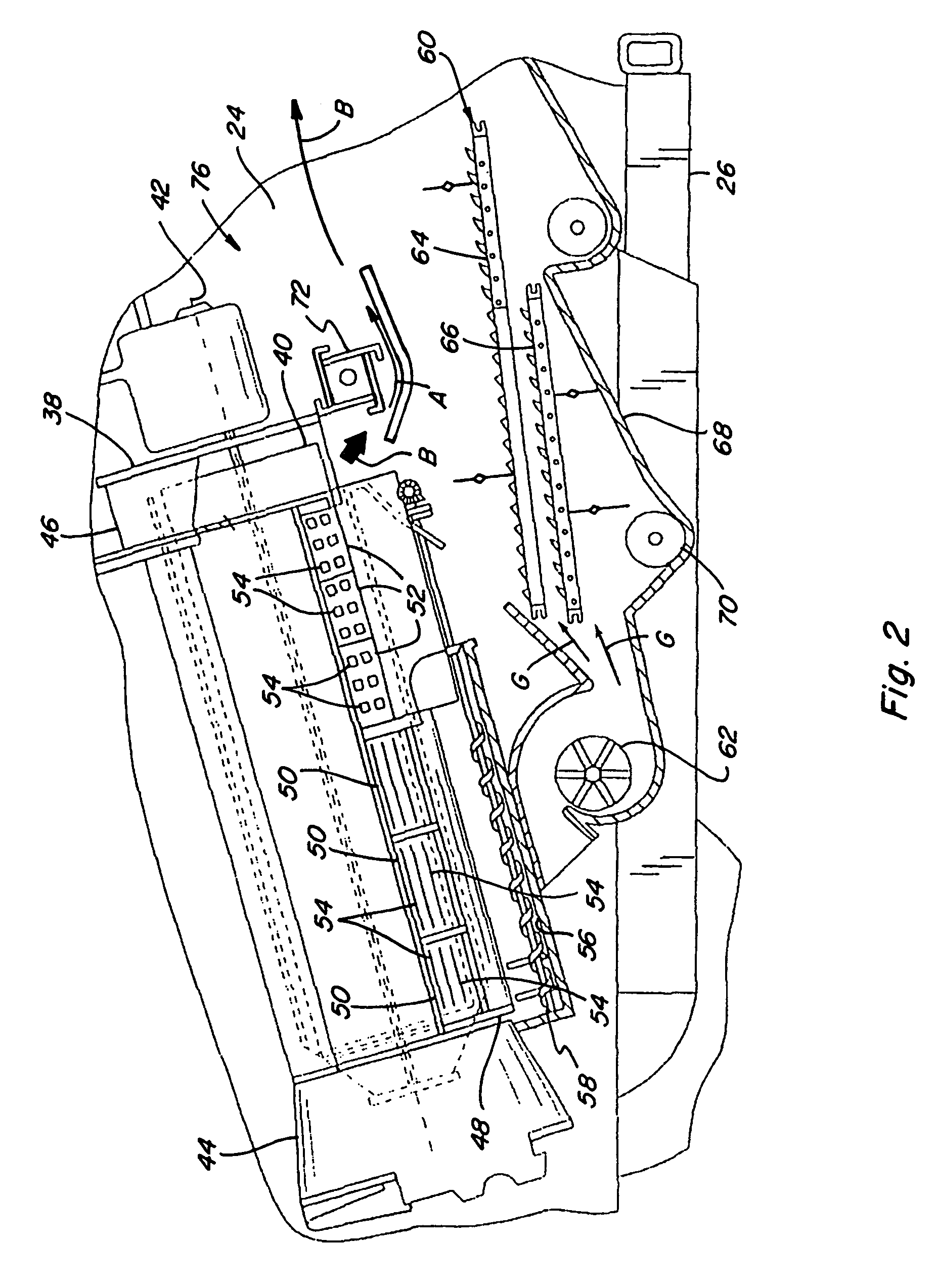

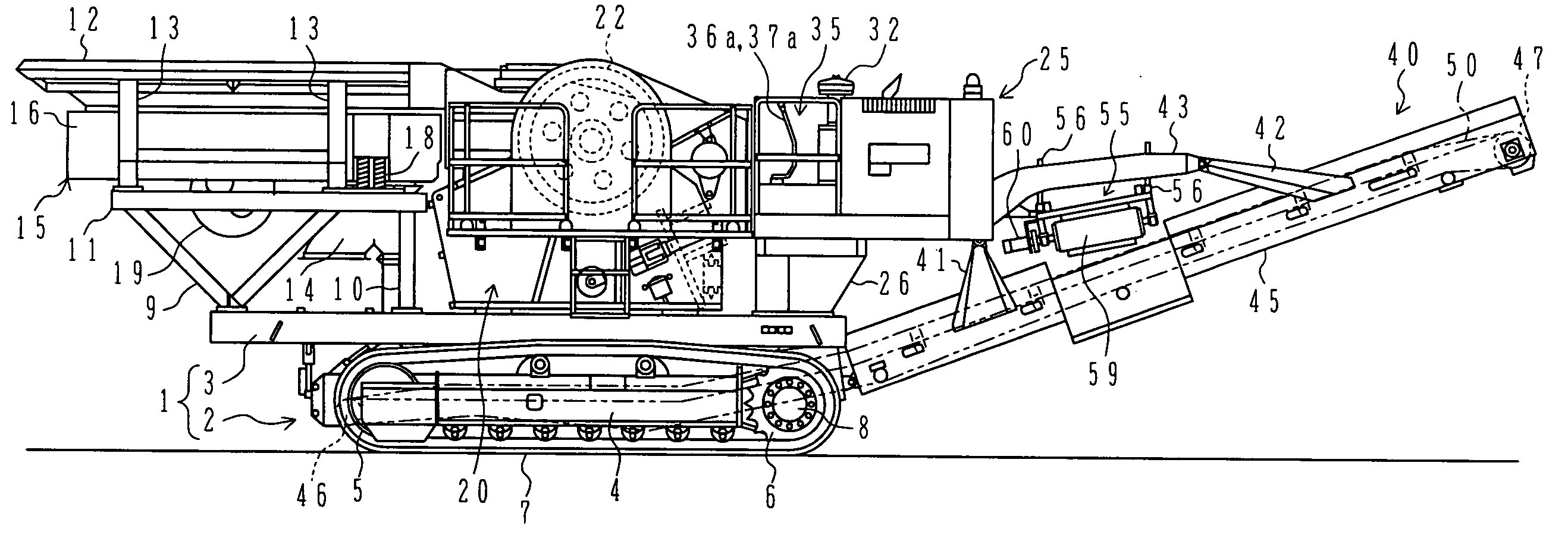

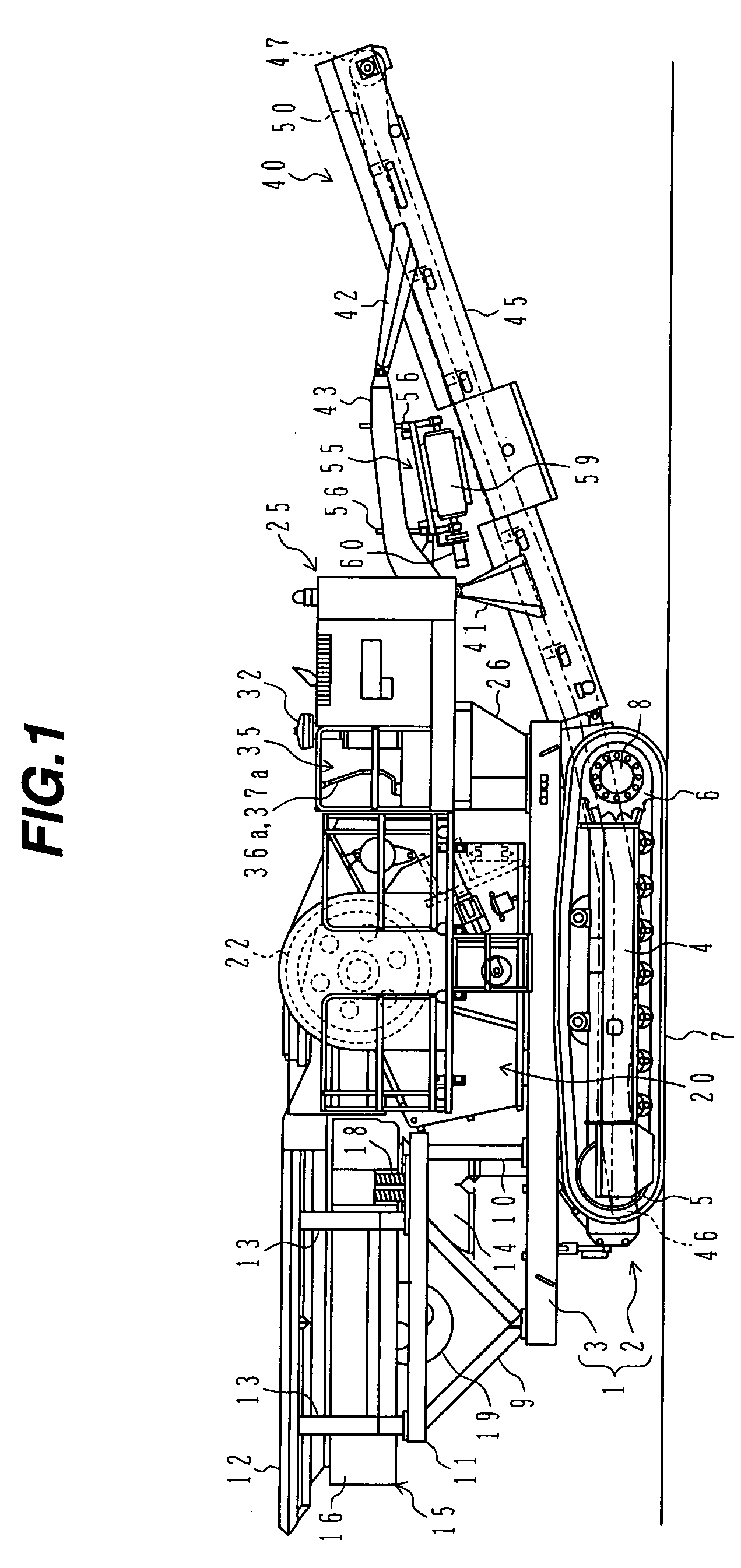

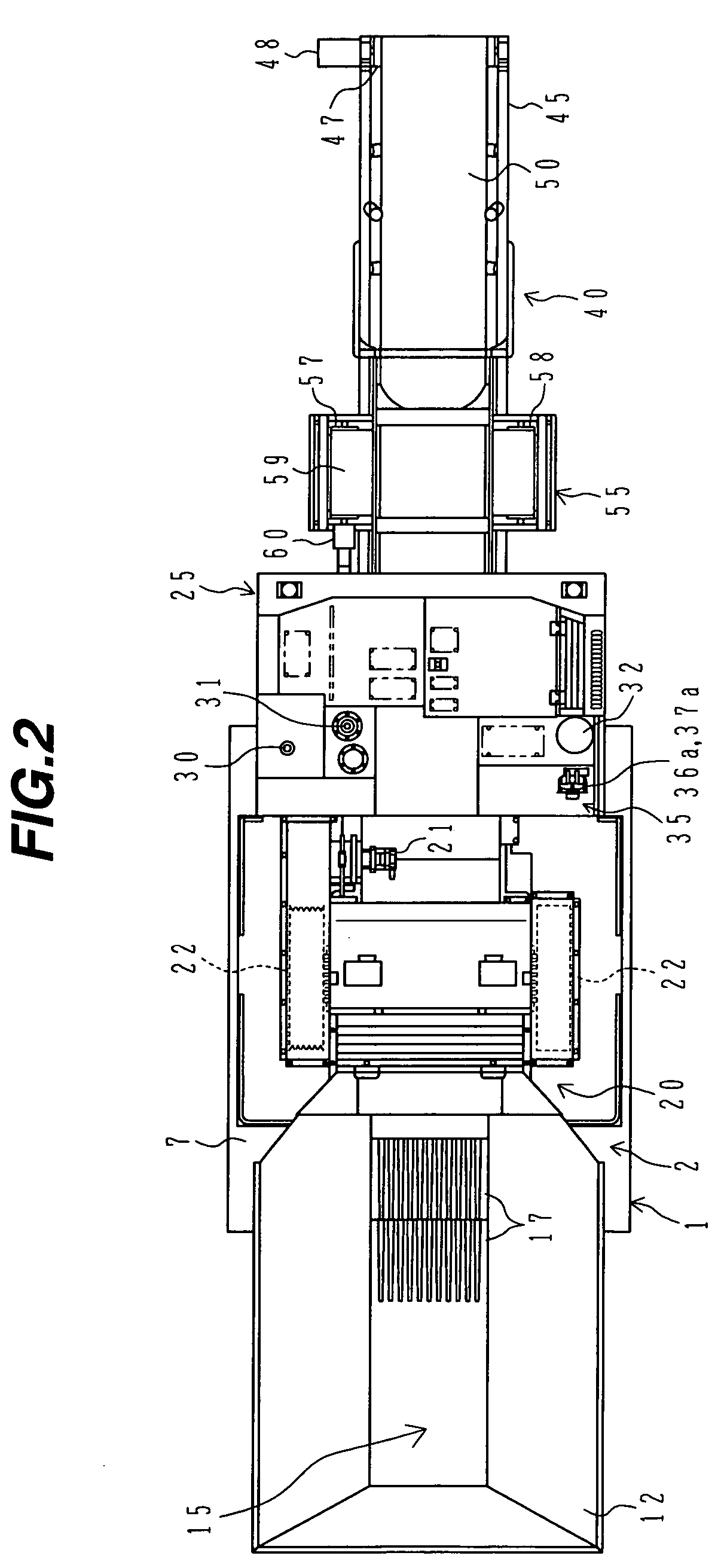

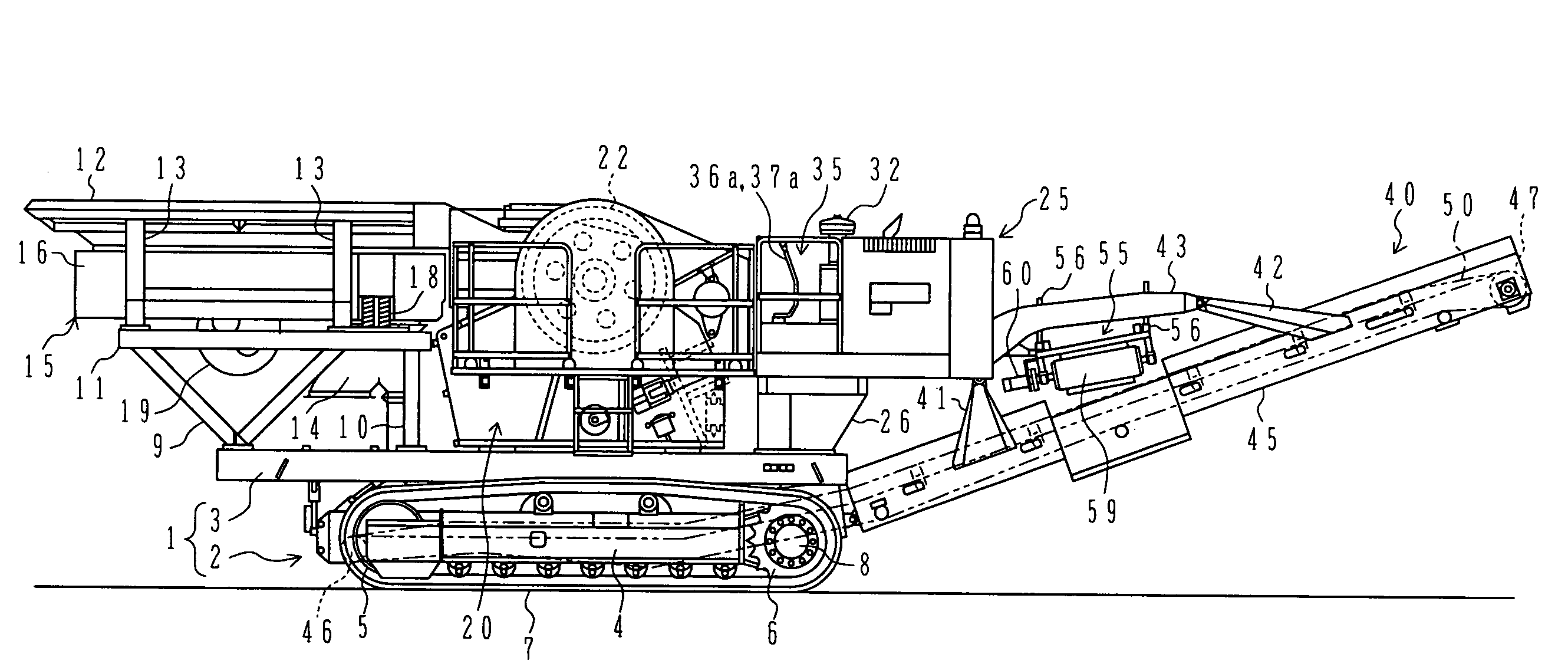

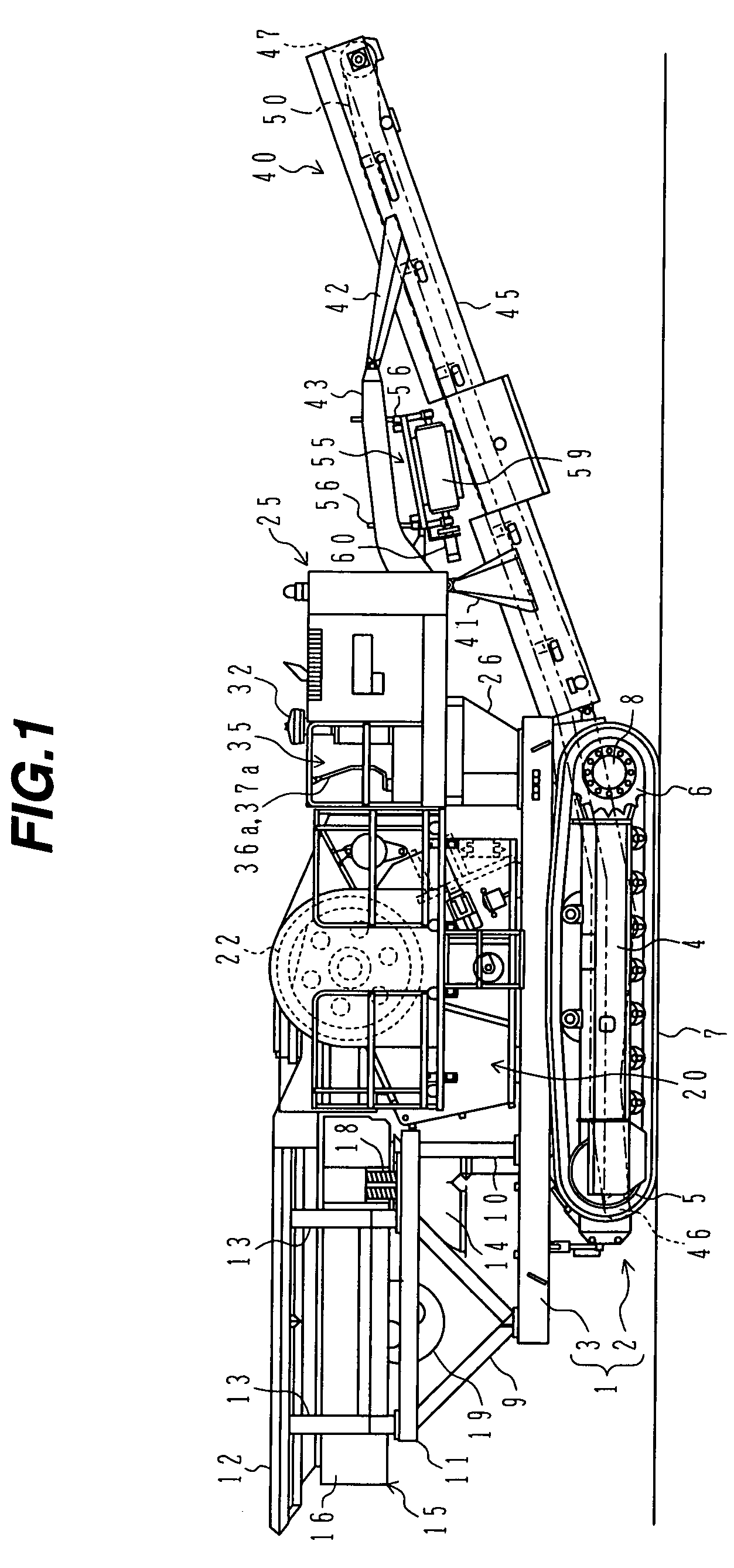

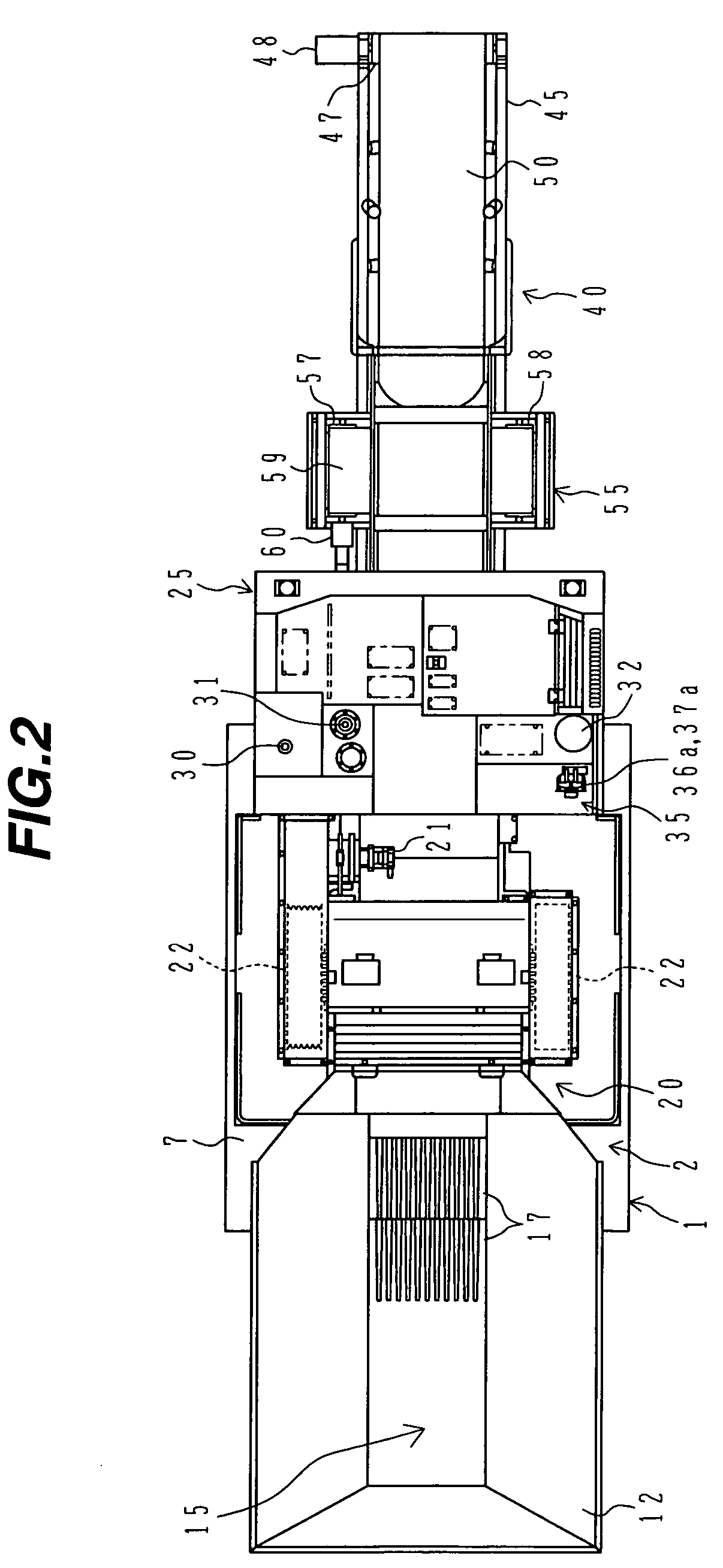

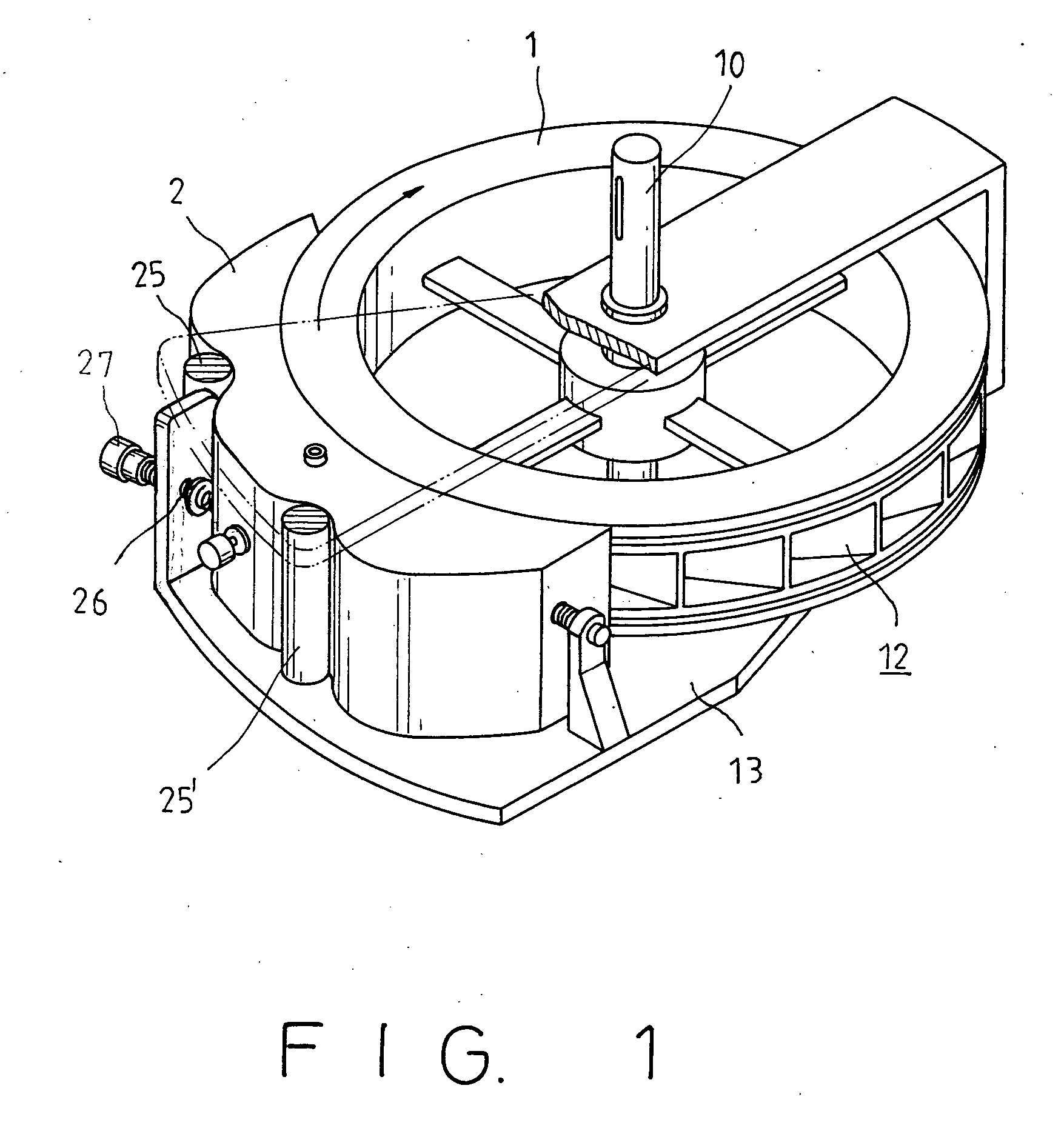

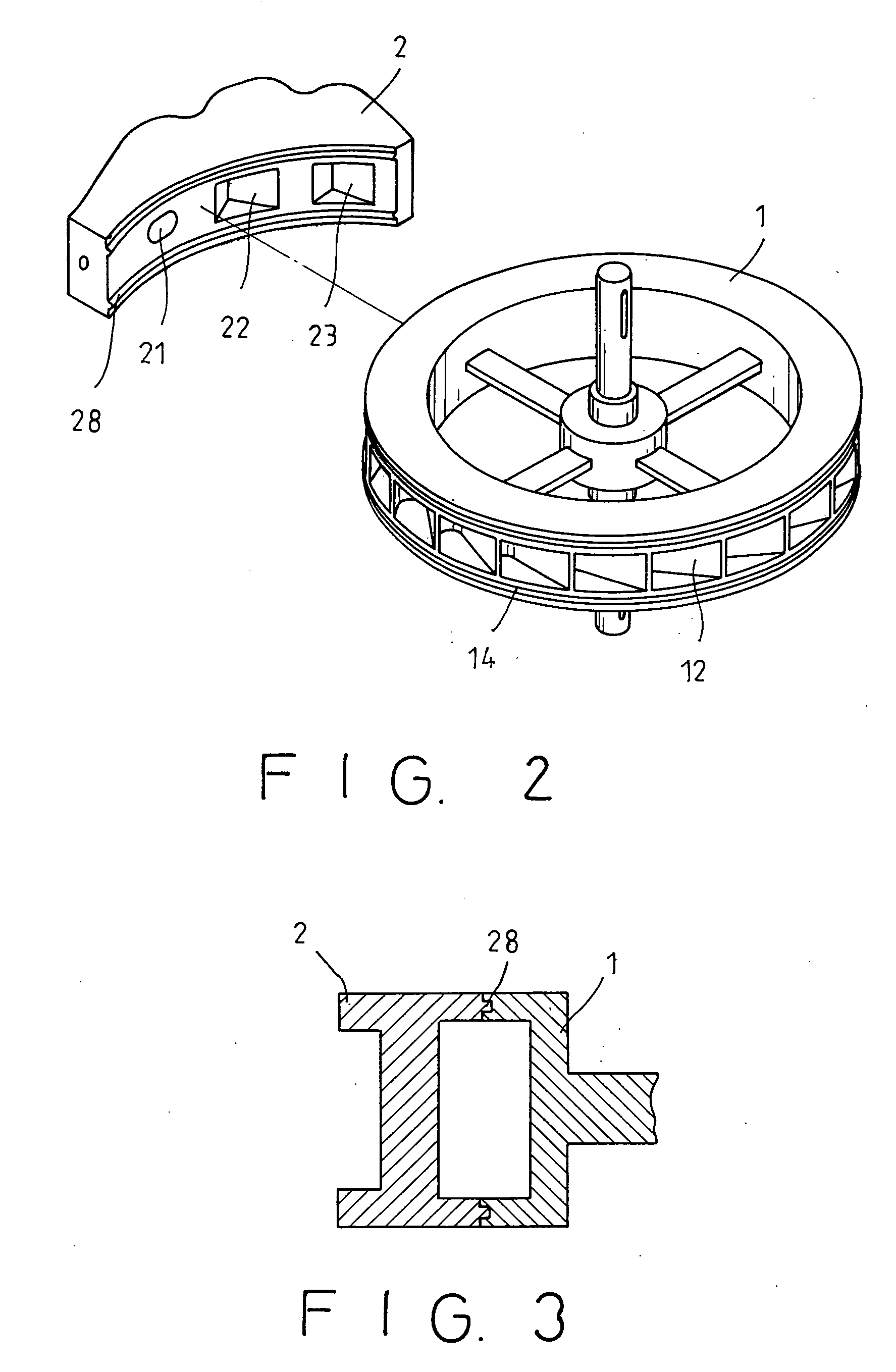

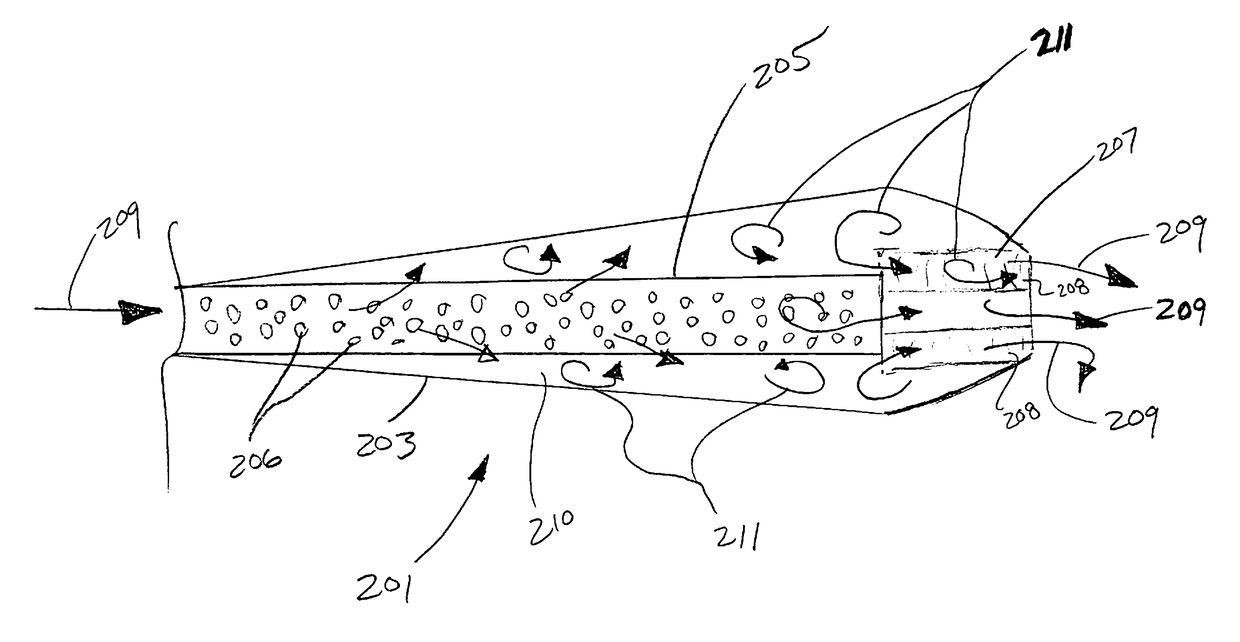

Self-propelling crusher

InactiveUS20050173570A1Reduce crushing efficiencyIncrease speedMowersMulti-purpose machinesEngineeringHydraulic pump

A self-propelled crushing machine comprises a crushing device 20; a hydraulic drive system including a crushing device hydraulic motor 21 for driving the crushing device 20, a first hydraulic pump 62 for driving the crushing device hydraulic motor 21, and an engine 61 for driving the first hydraulic pump 62; a pressure sensor 151 for detecting a load condition of the crushing device 20; and a controller 84″ for executing control to increase a revolution speed of the engine61 in accordance with a detected signal from the pressure sensor 151. Accordingly, even when a heavy load is imposed on the crushing device, a reduction of crushing efficiency can be prevented.

Owner:HITACHI CONSTR MASCH CO LTD

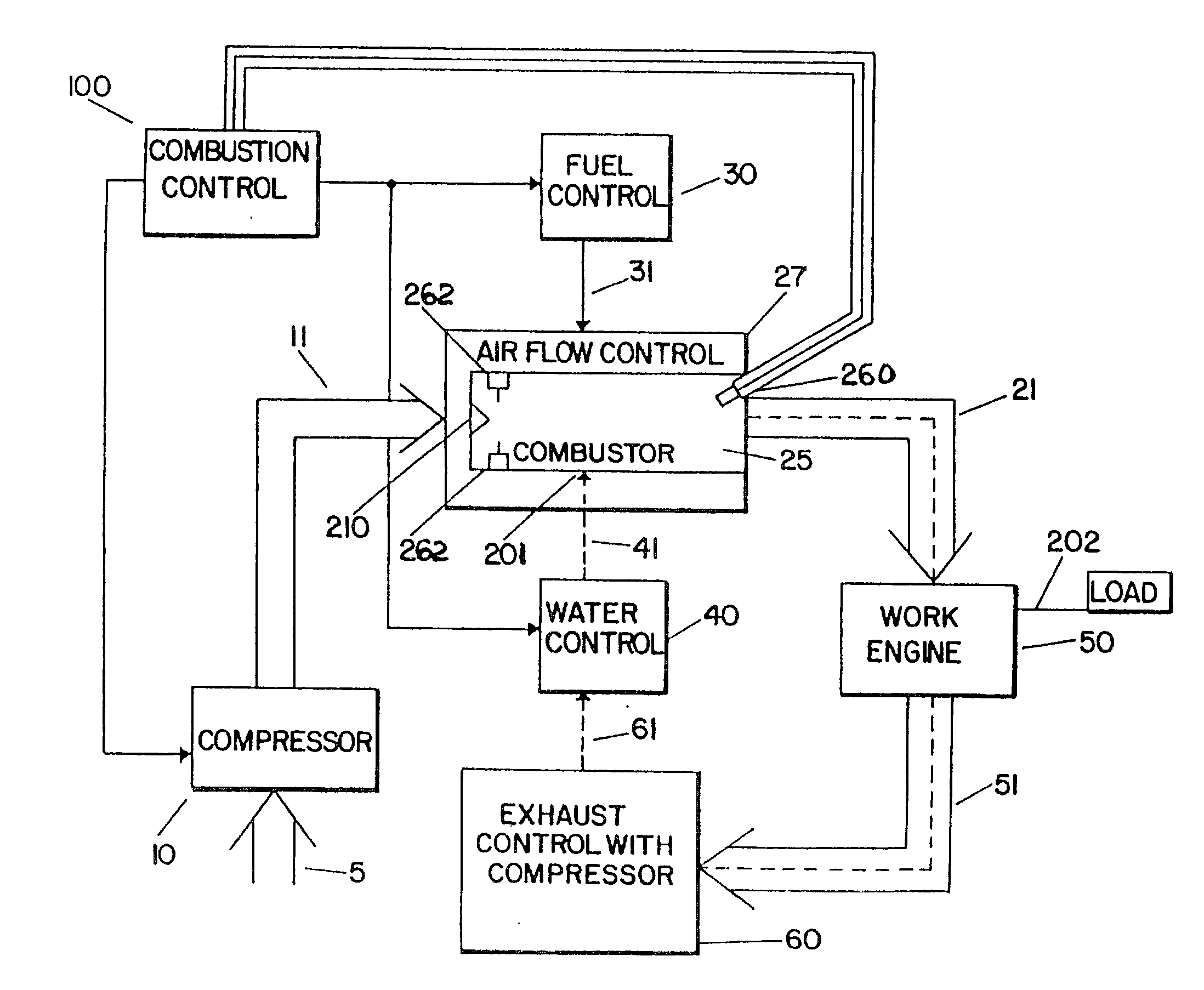

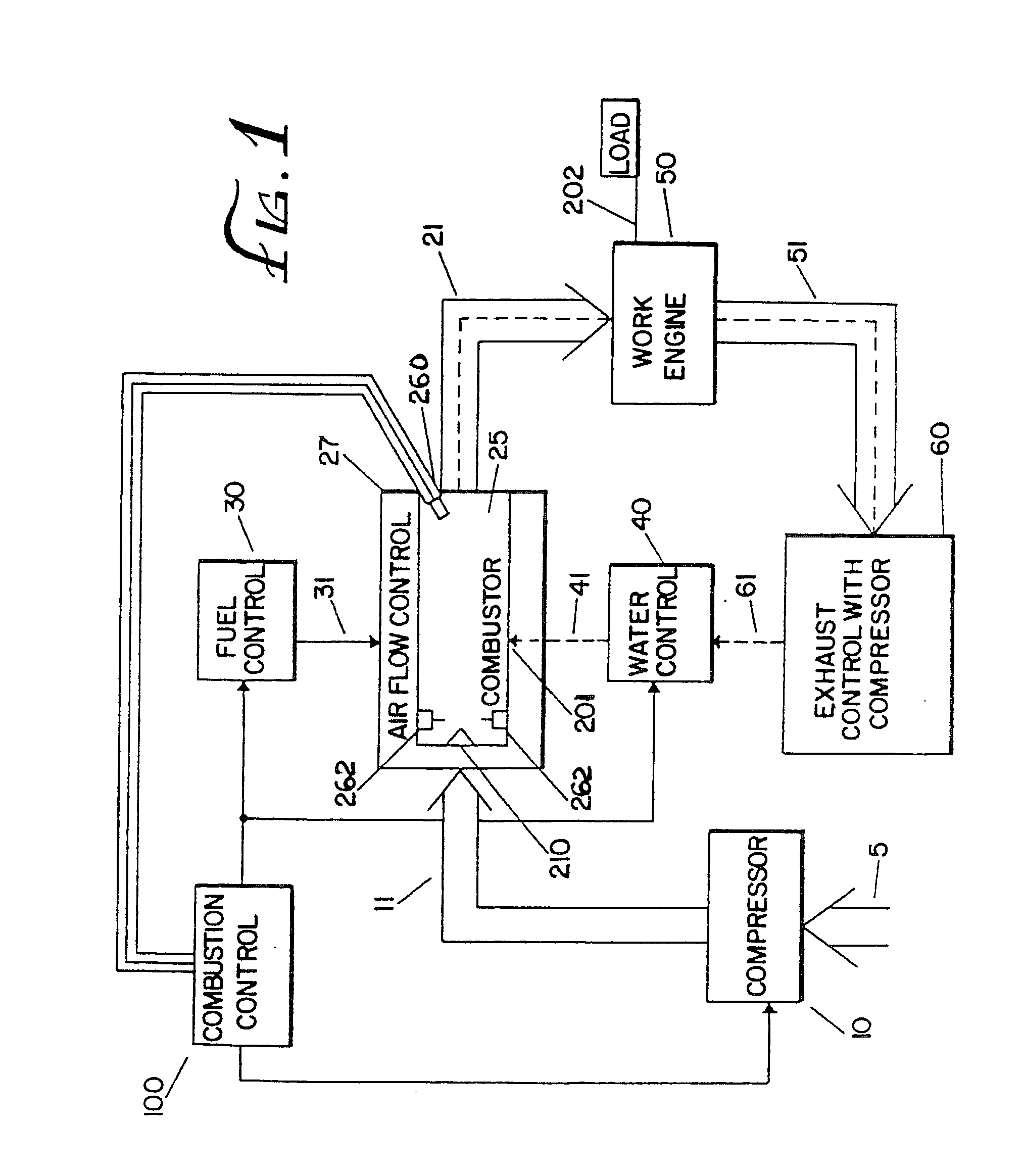

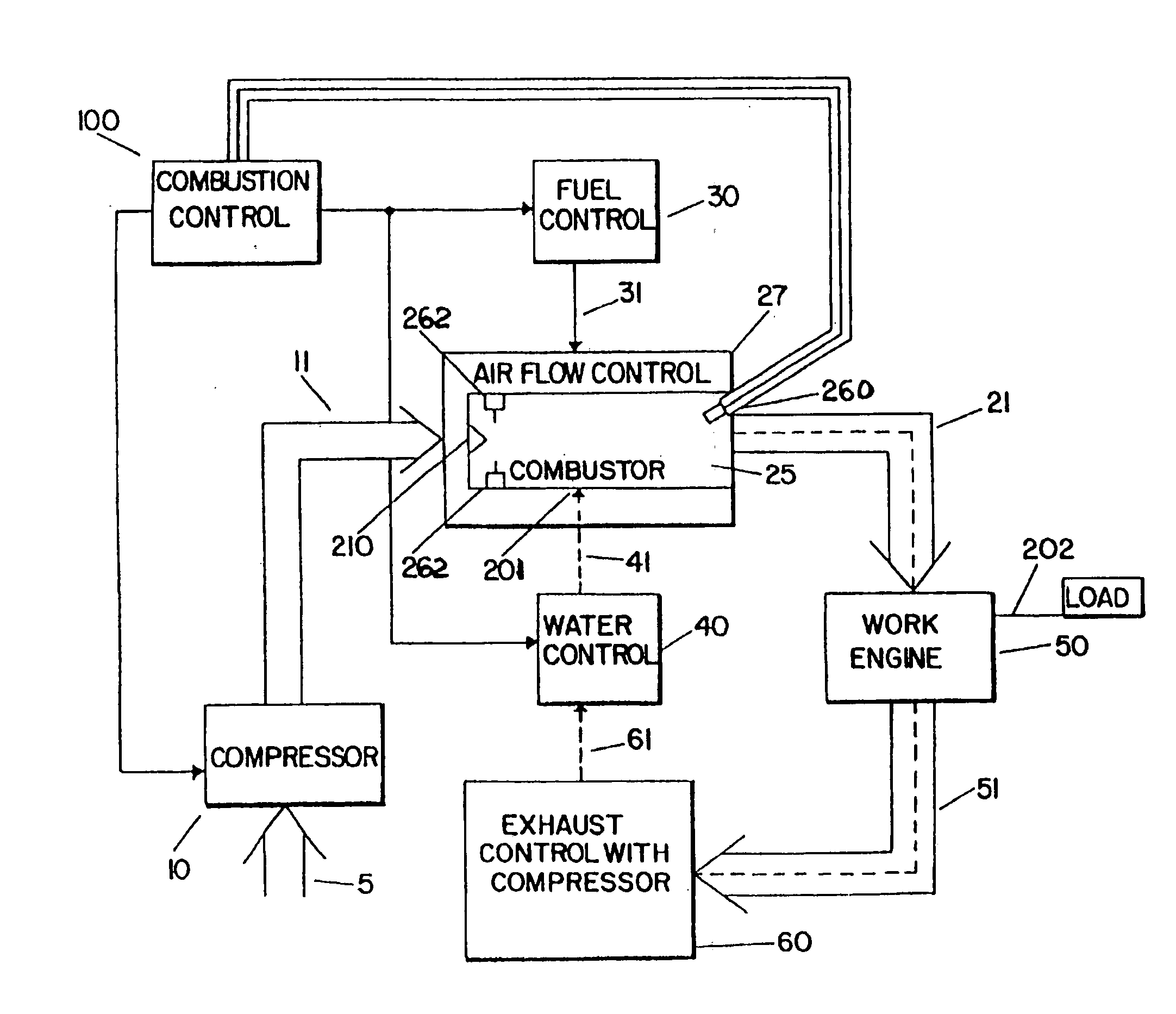

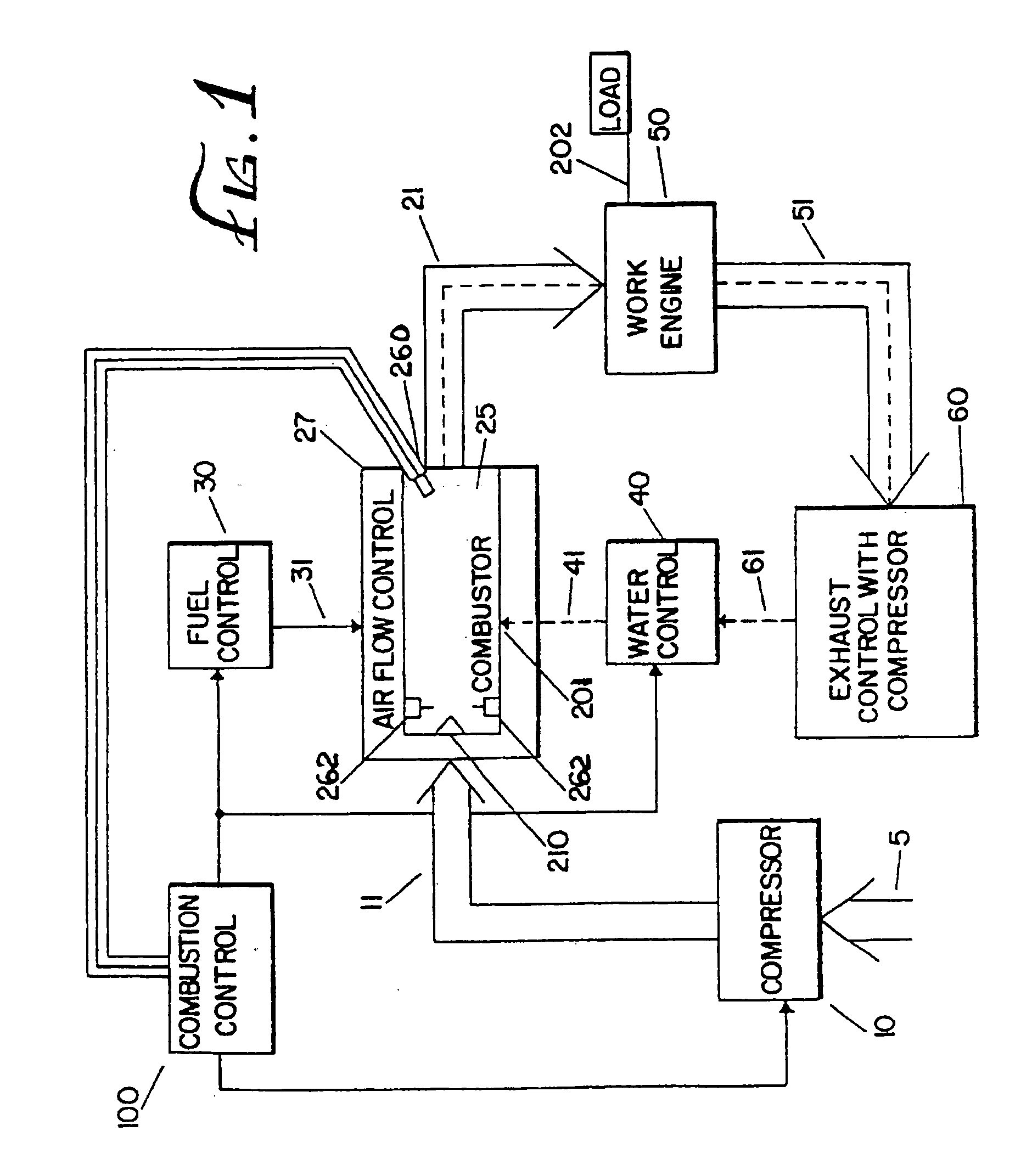

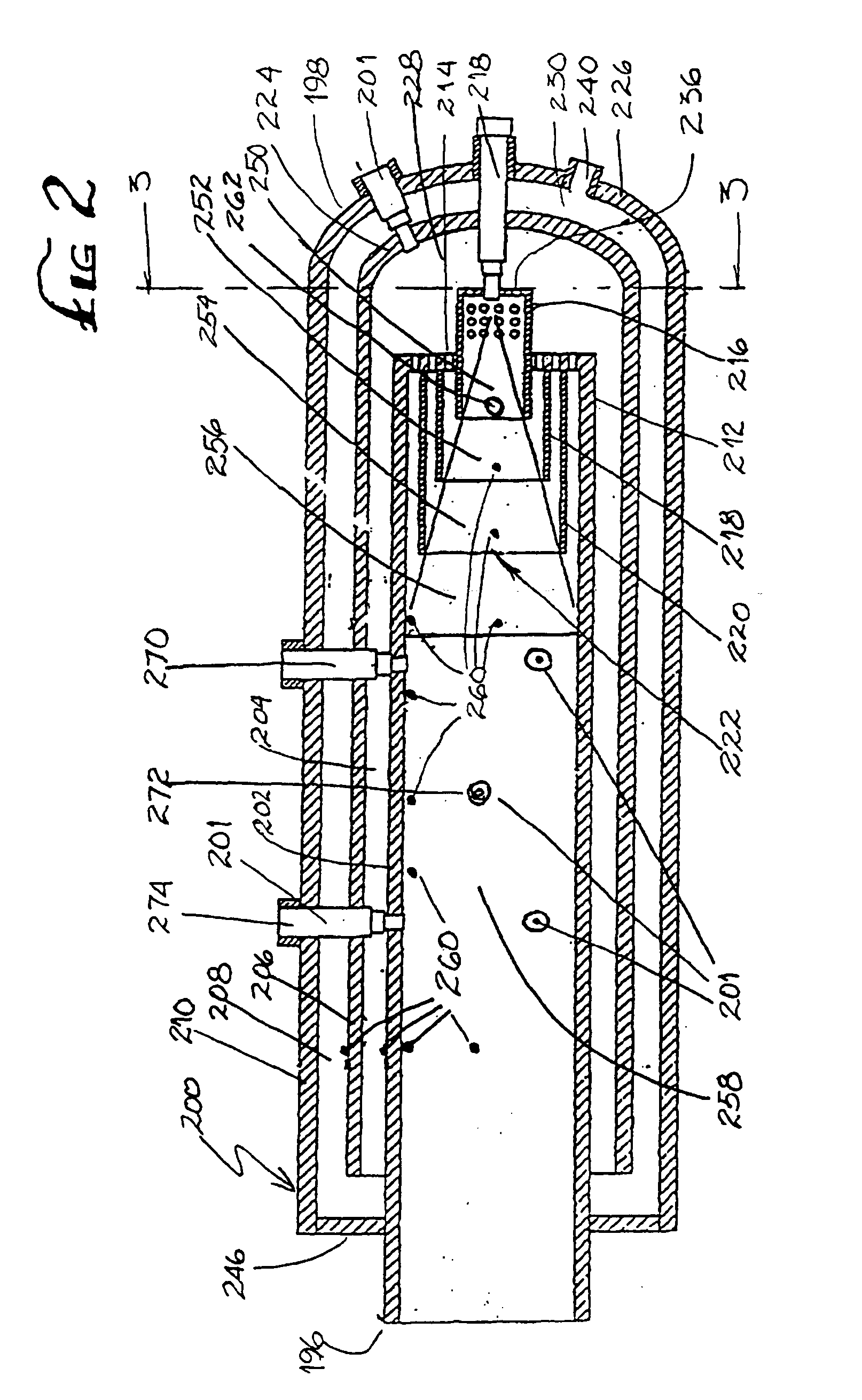

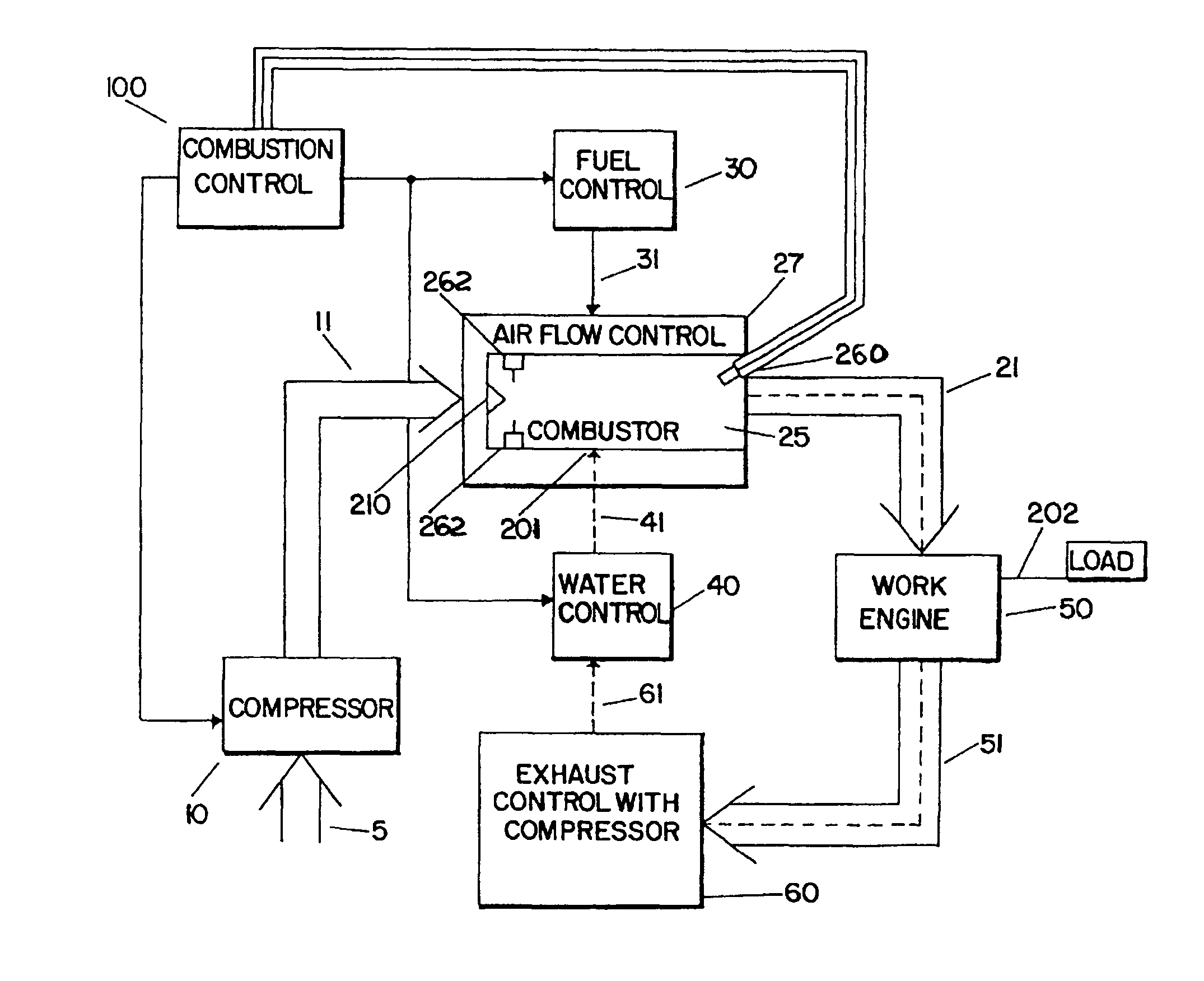

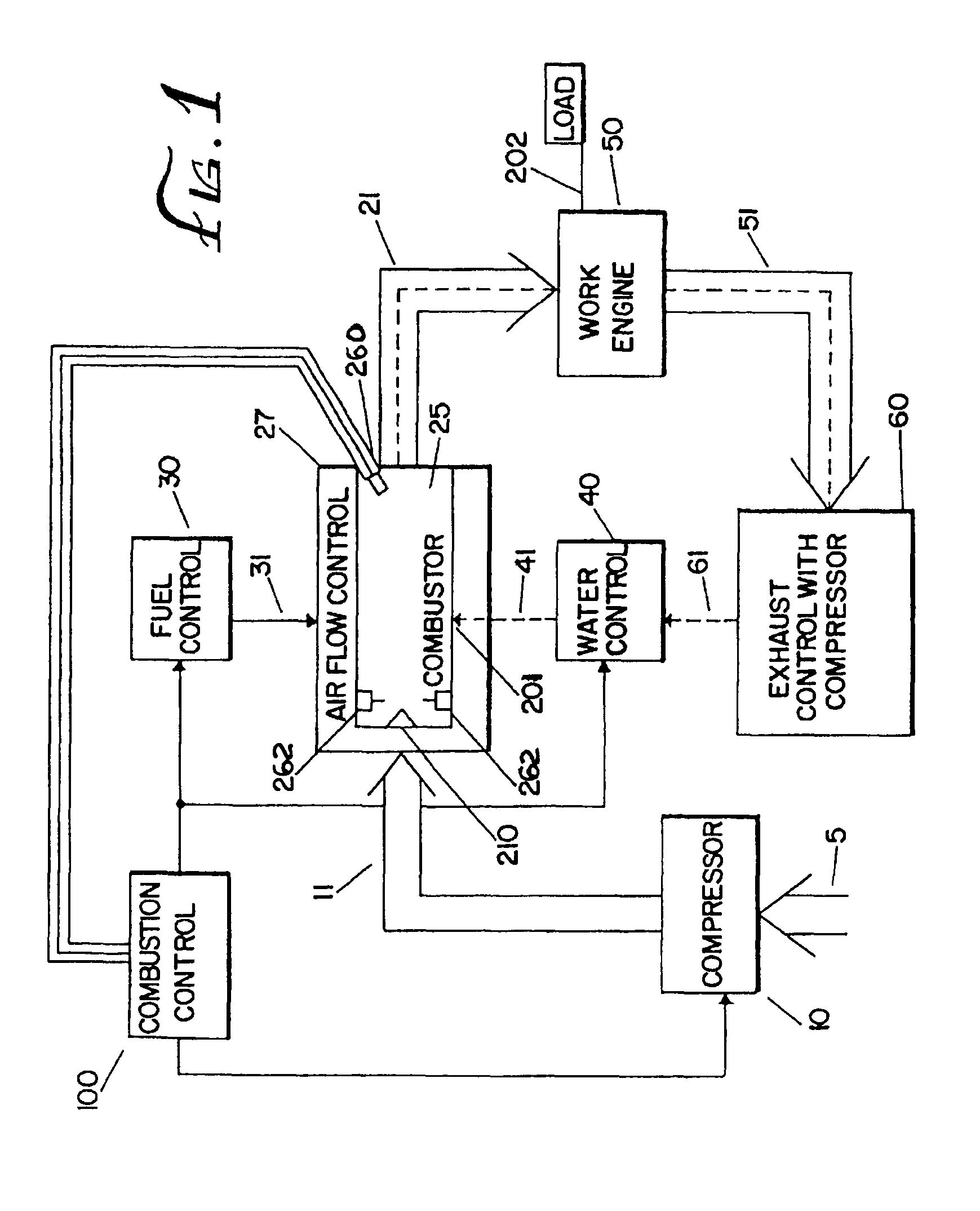

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20030014959A1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsEfficient propulsion technologiesHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NO.sub.x. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL

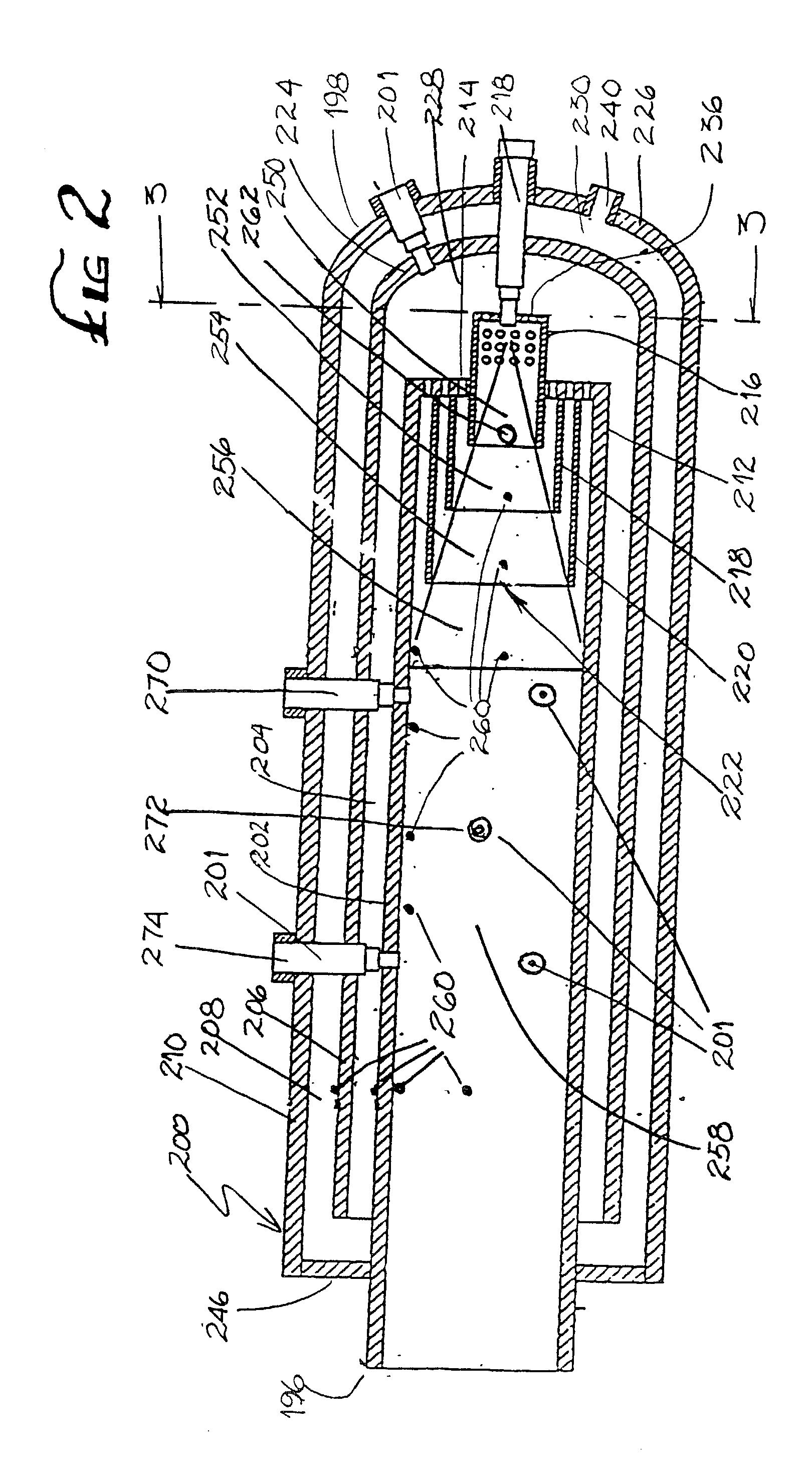

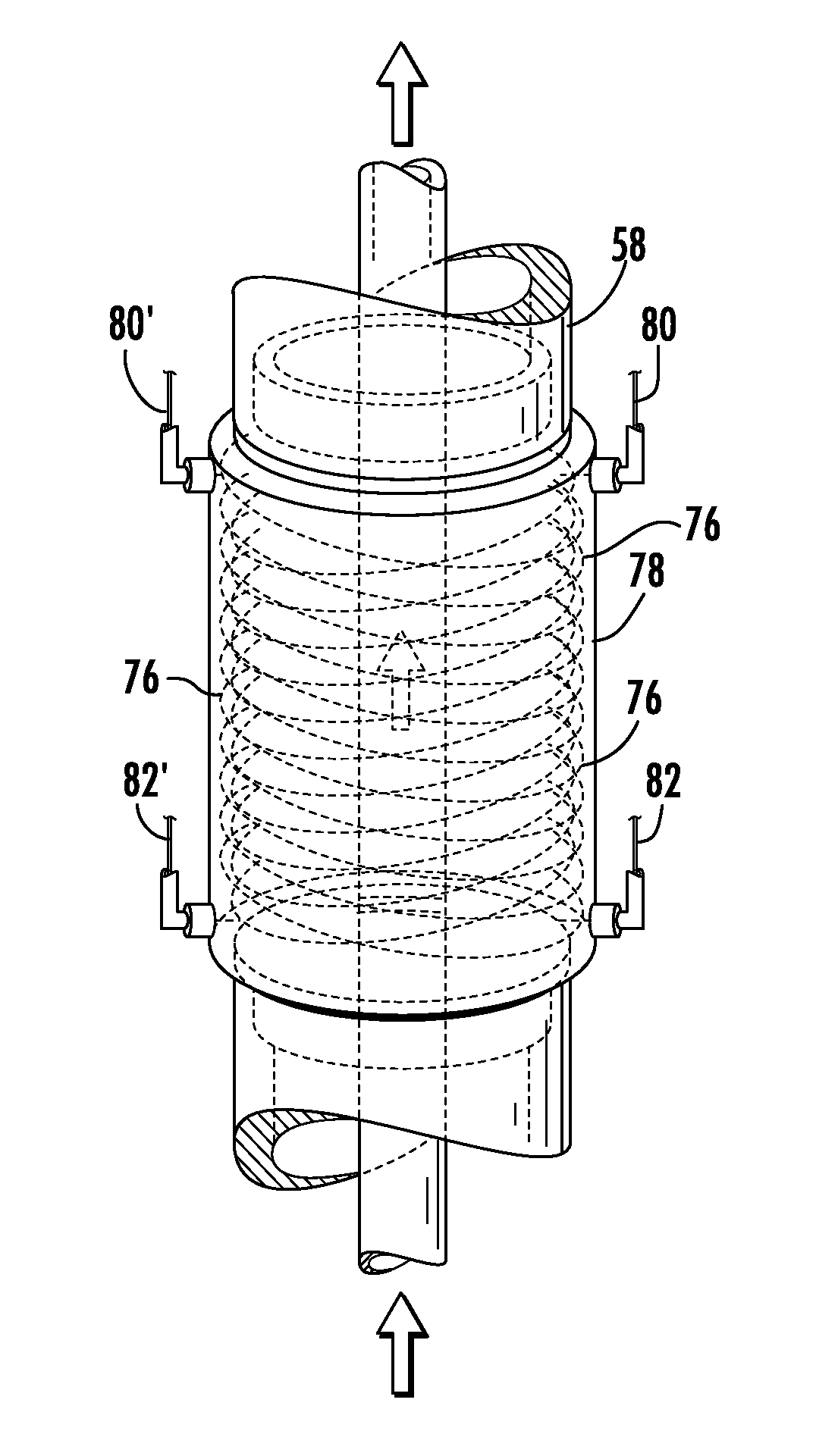

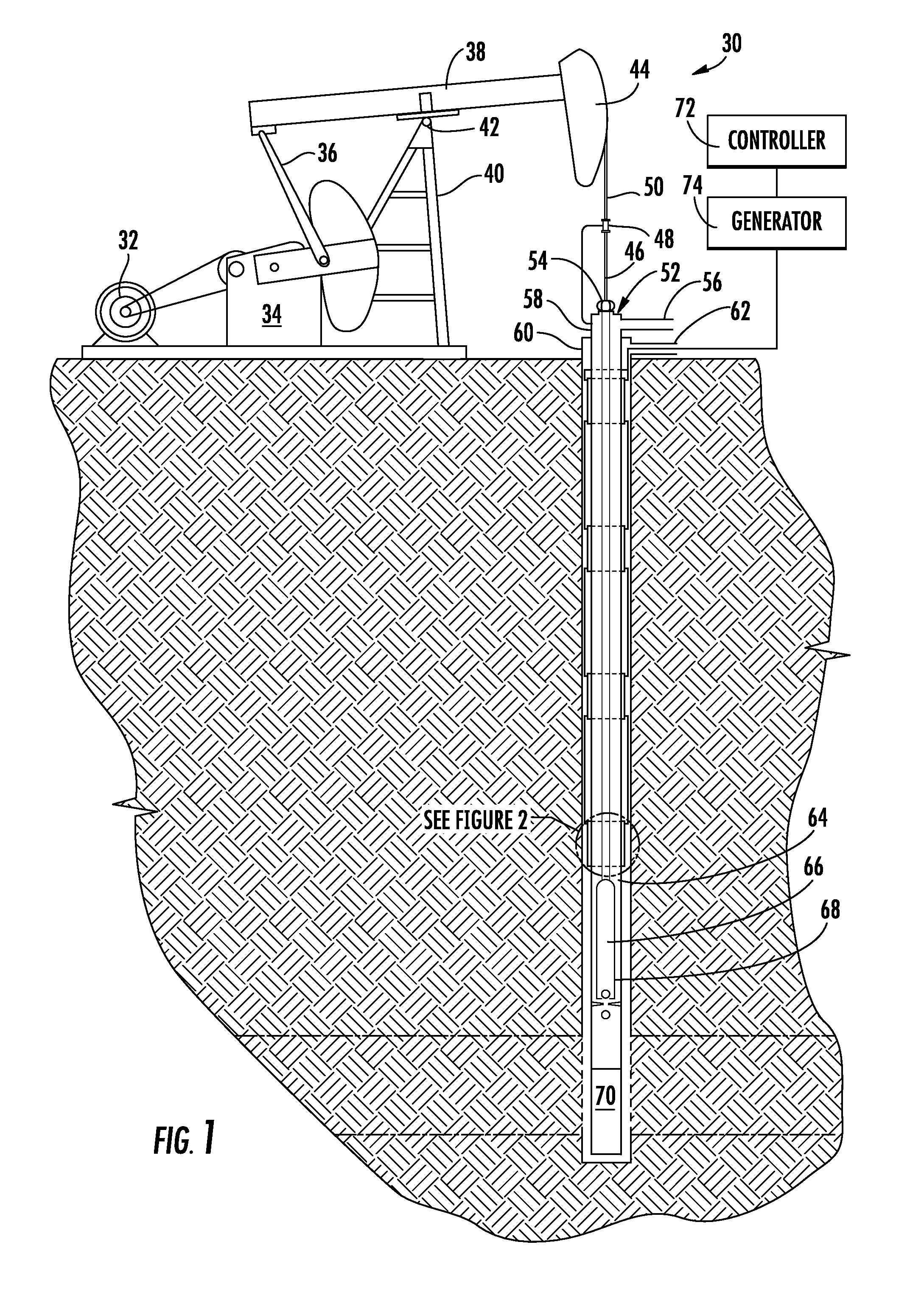

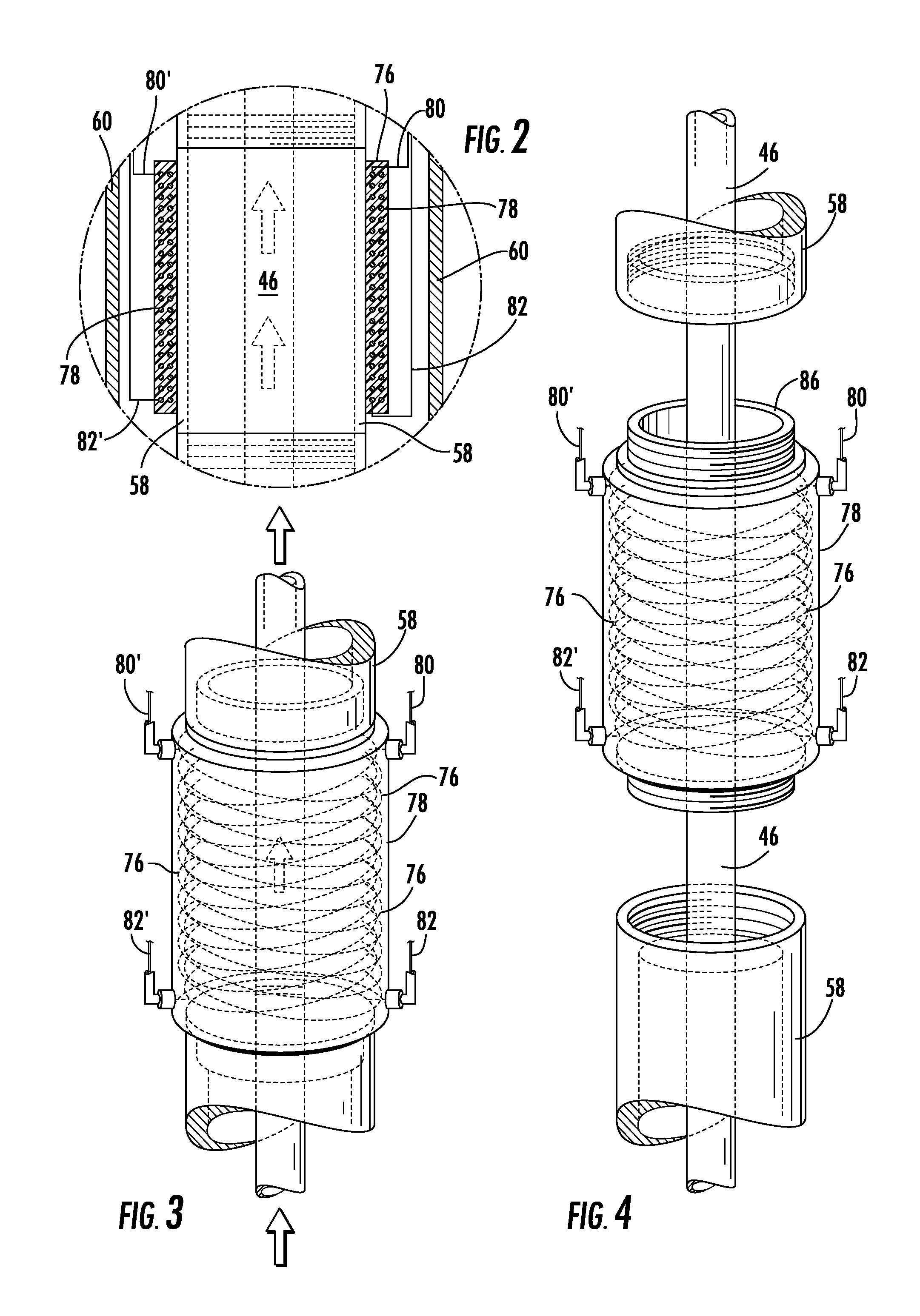

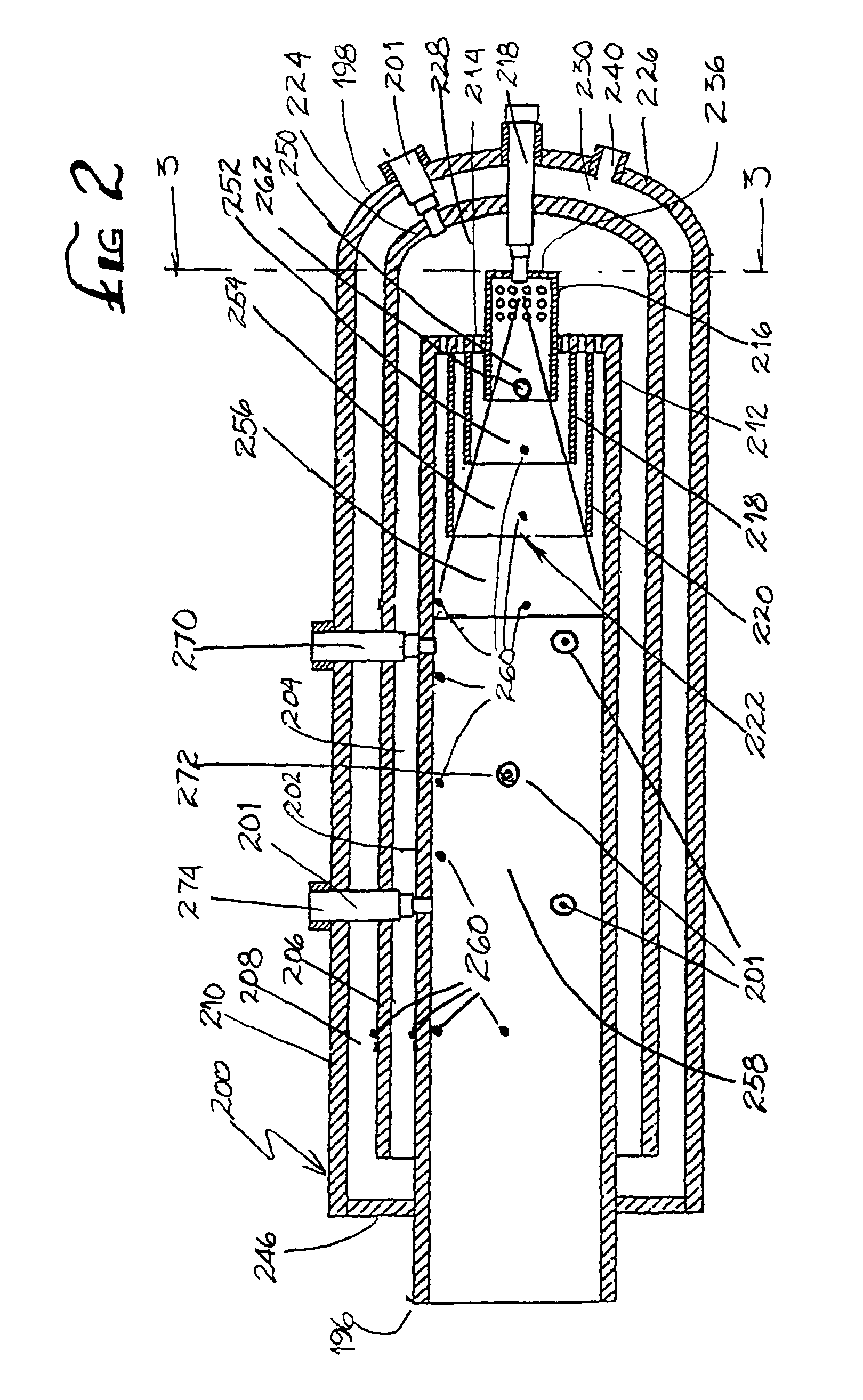

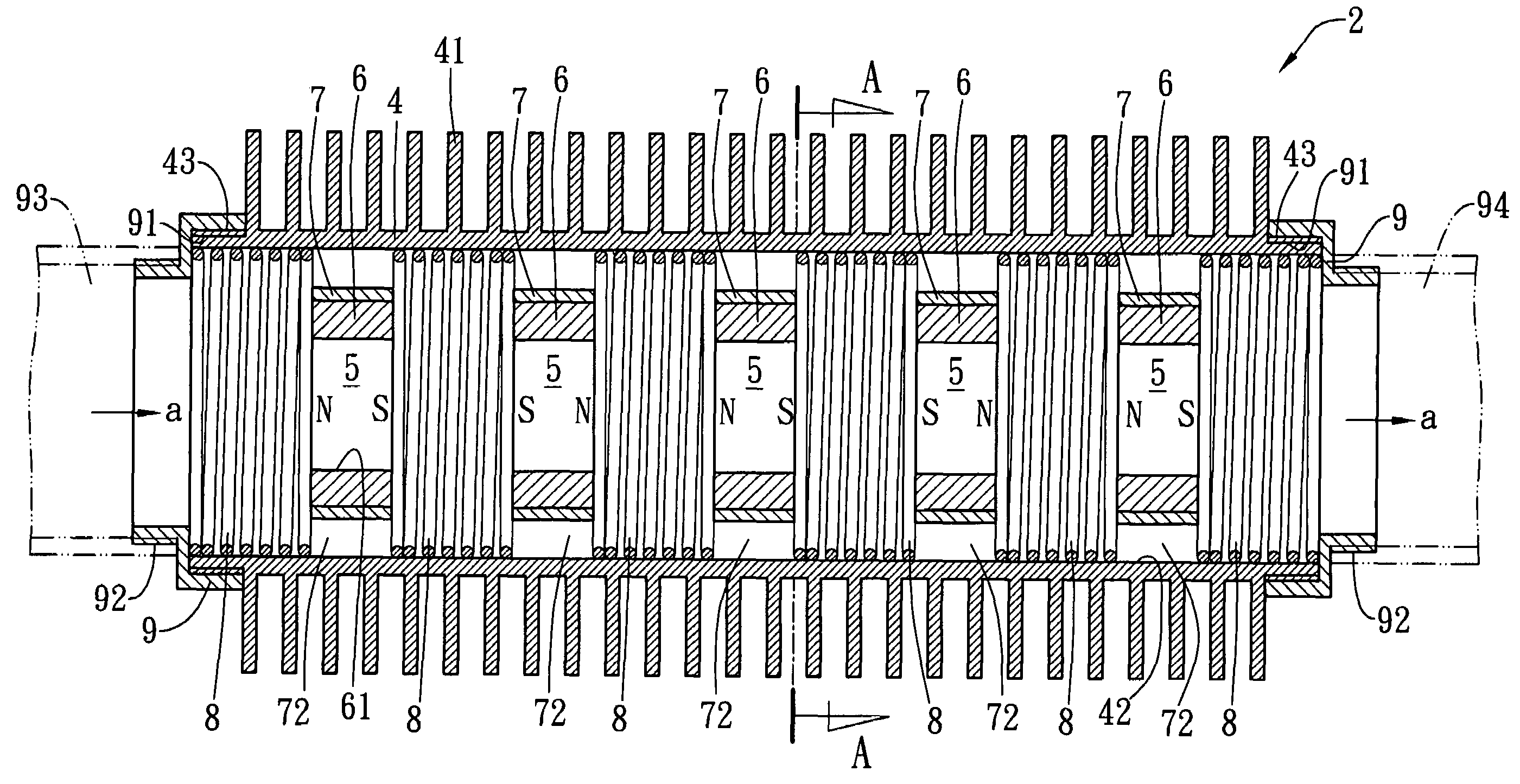

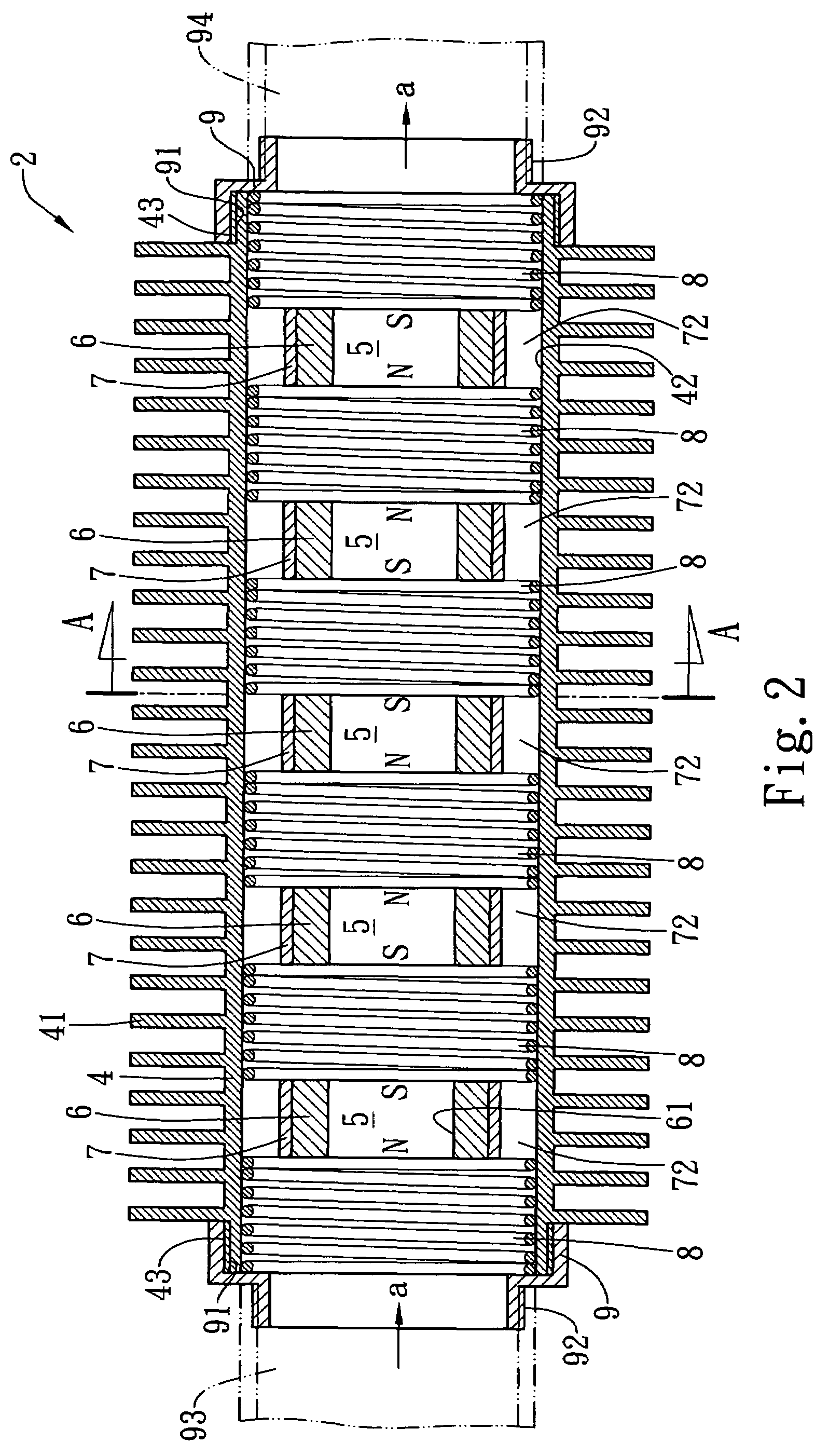

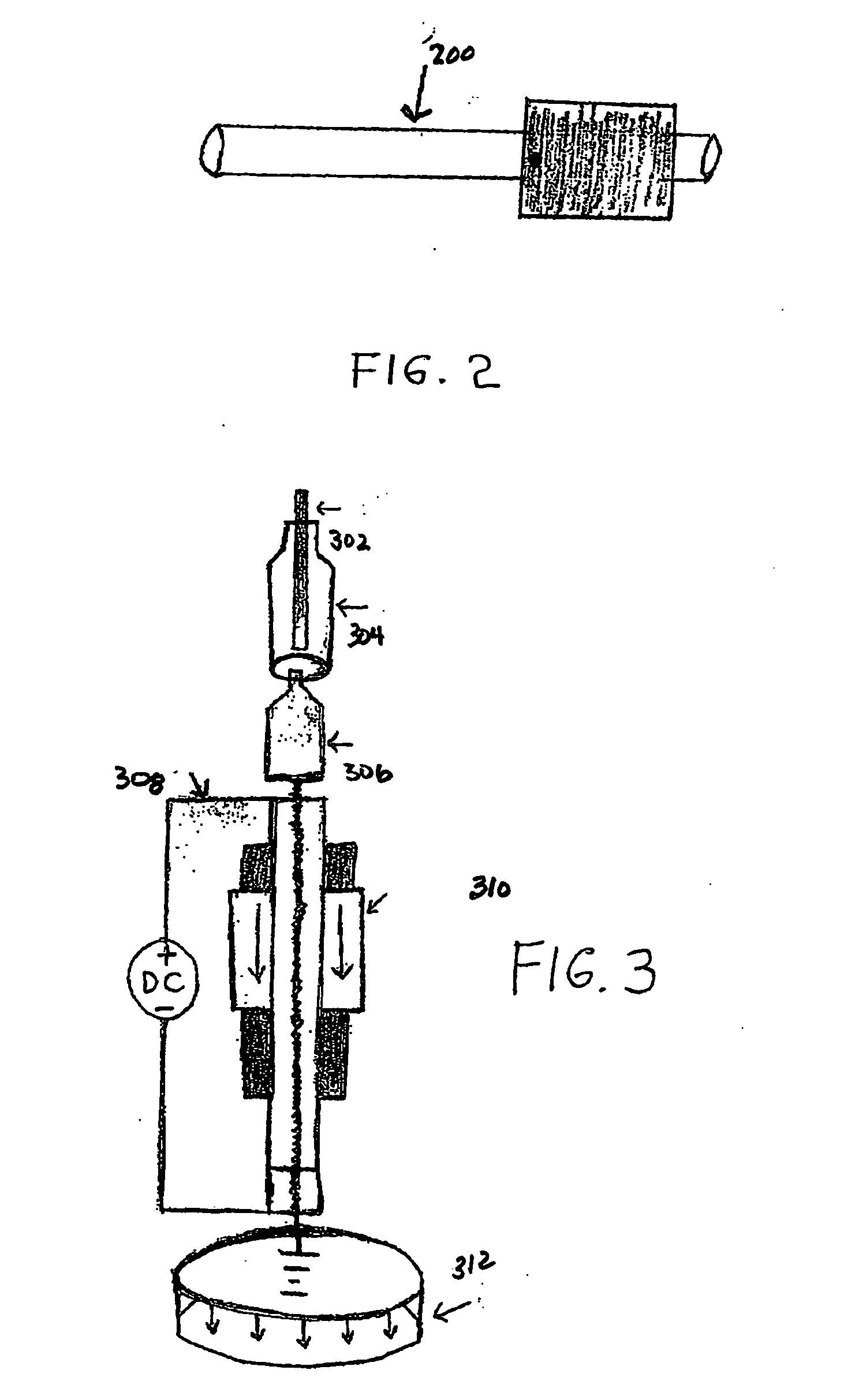

Apparatus and method for magnetically conditioning fluids

InactiveUS20130192682A1Increase oil extractionAvoid corrosionWater treatment parameter controlSpecific water treatment objectivesElectrical conductorEngineering

Methods and apparatus for fluid conditioning to reduce scaling, inactivate microbes, reduce surface tension, maintain fluid composition, and improve pumping are provided for use in treating crude petroleum, industrial water, agricultural water, municipal water supplies, or any fluid flow system and comprise electromagnets of variable control that can be powered or in which a current can be induced by a permanent magnet. Magnetic field direction and intensity can be selected depending on the nature of the fluid and in some embodiments, the field can be varied during operation, including pulsing and variably selecting one or more field directions and intensities, or combinations thereof, during operation. A non-magnetic fluid transfer conduit section has at least one conductor assembly mounted about the section. In one embodiment, the conductor assembly comprises a concentric, tilted double helix coil or multipole coil. If desired, one or more rotating or reciprocating permanent magnets may be located in magnetic field contact with one or more multipole conductor assemblies and rotated or reciprocated to induce a current in the multipole conductor assembly, thereby to induce a magnetic field in the conductor assembly.

Owner:ENVIRONMENTAL TECH INT

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20060064986A1Increase horsepowerFast accelerationEfficient propulsion technologiesGas turbine plantsHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NOx. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL +1

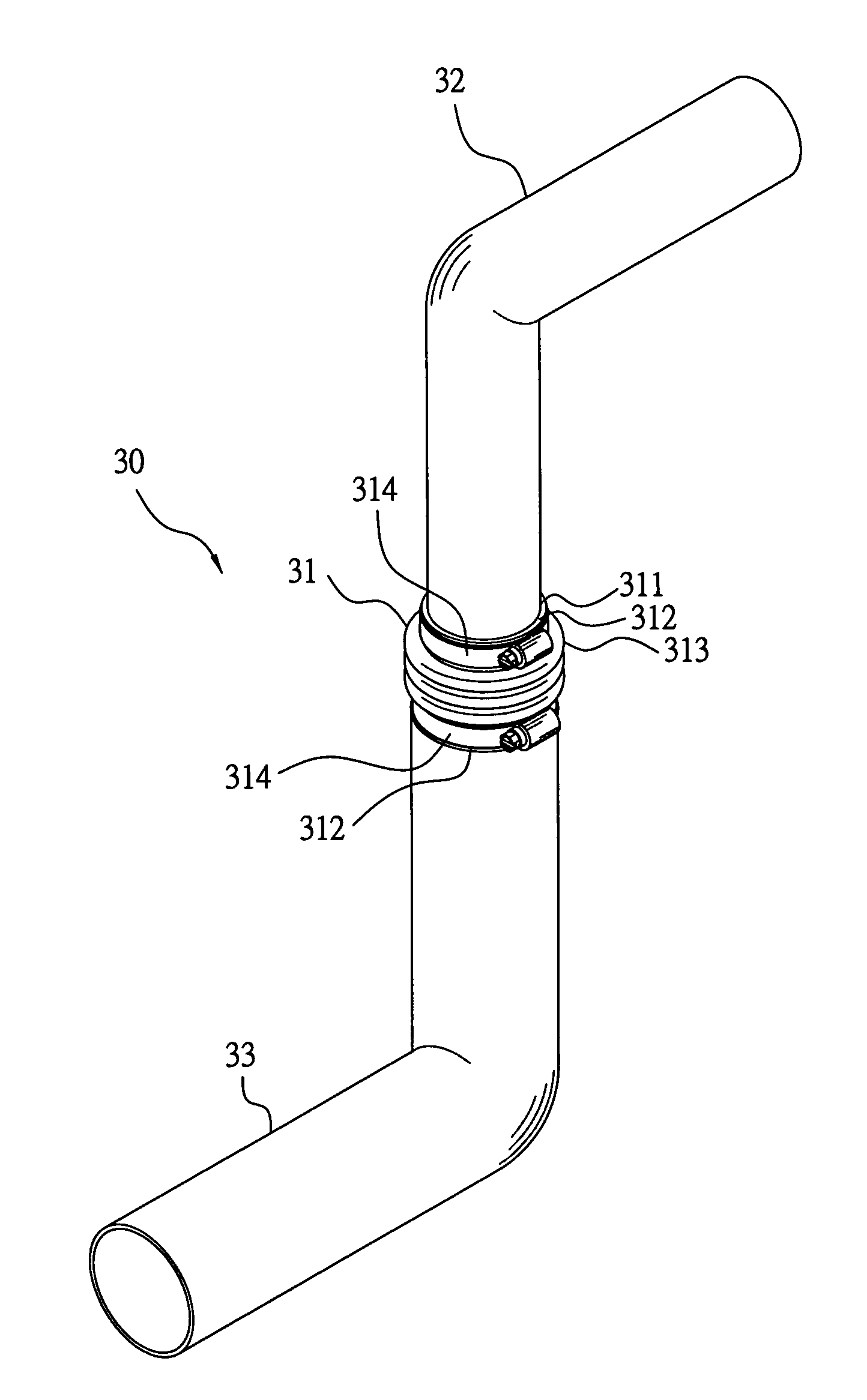

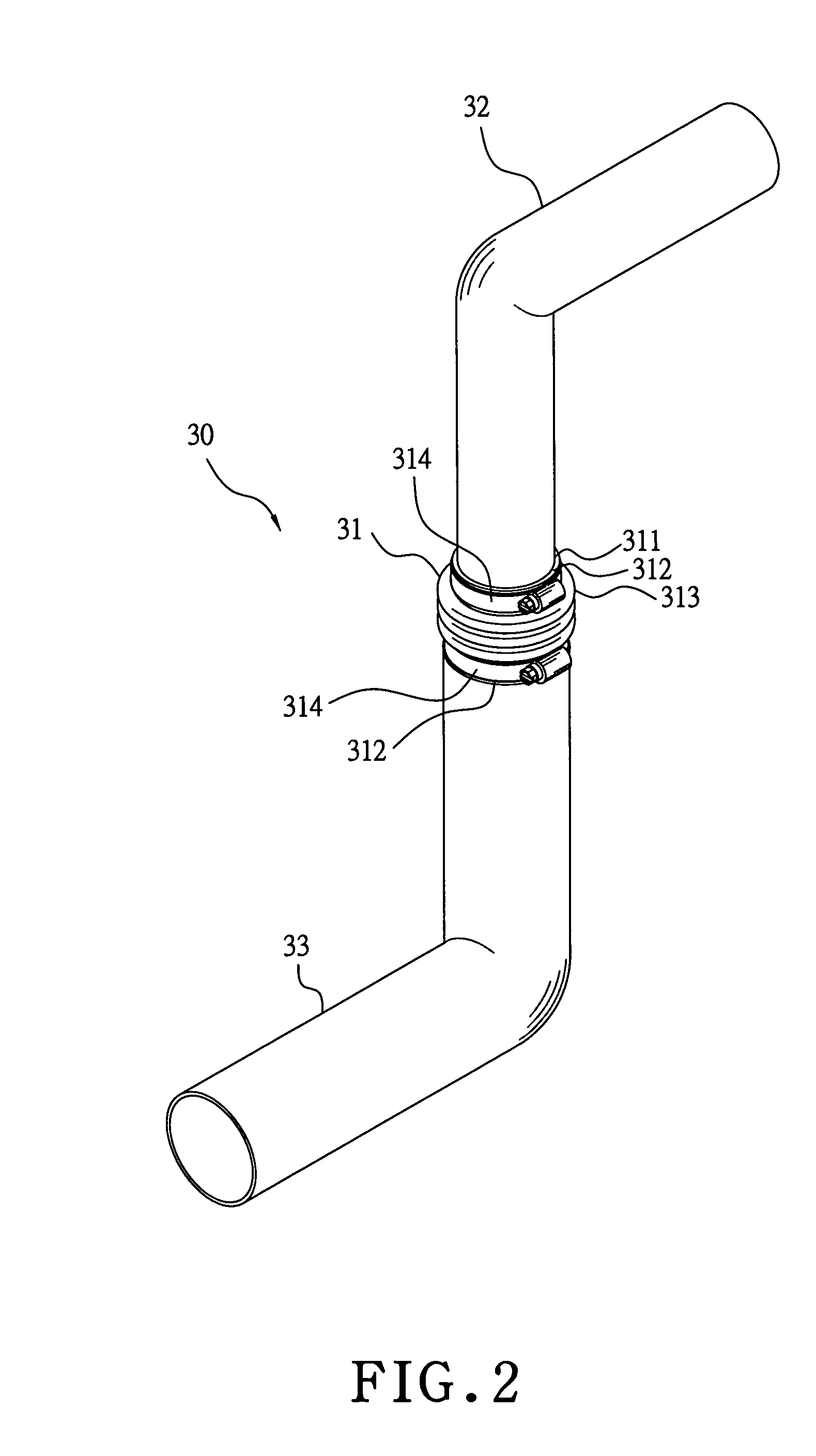

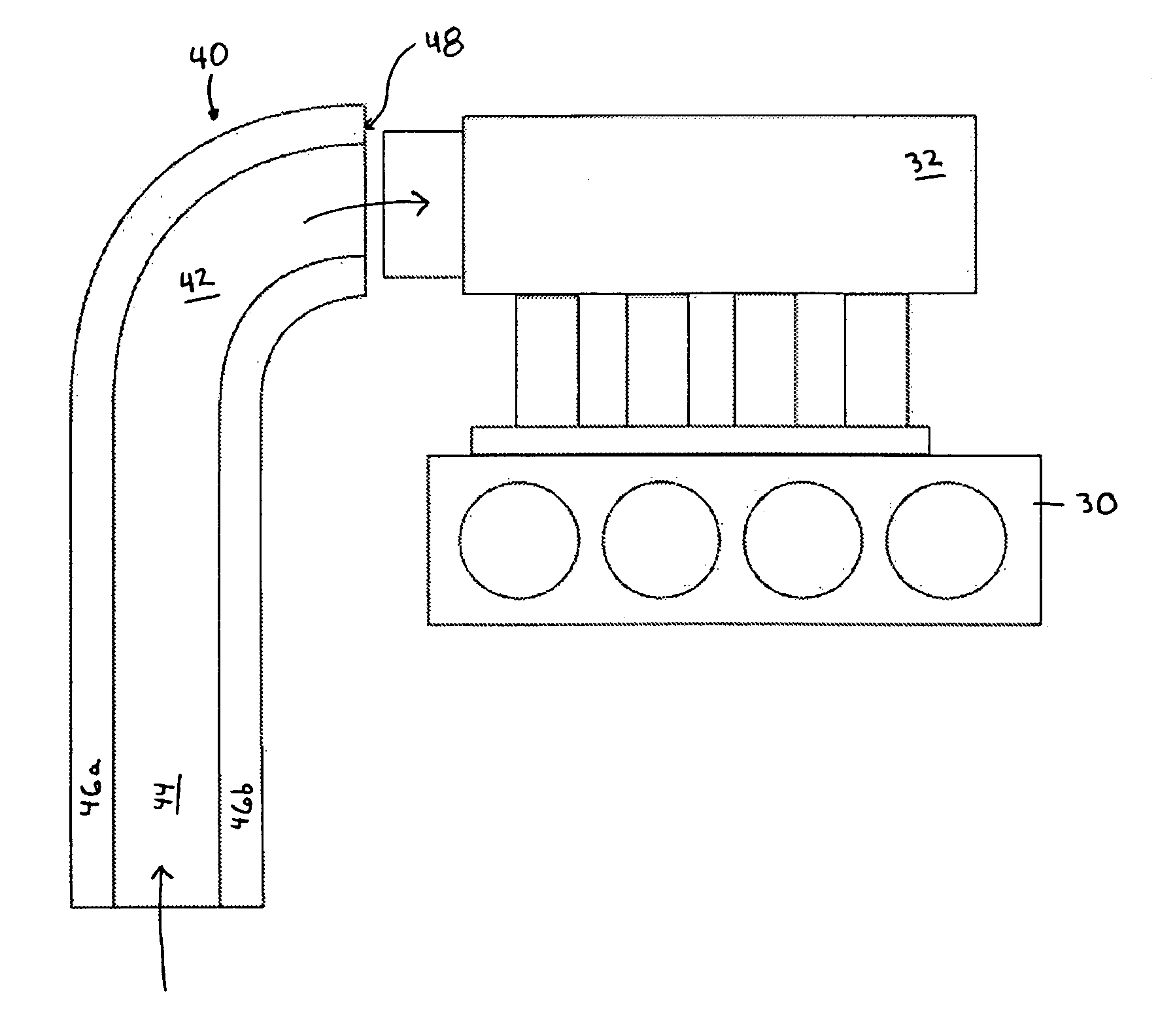

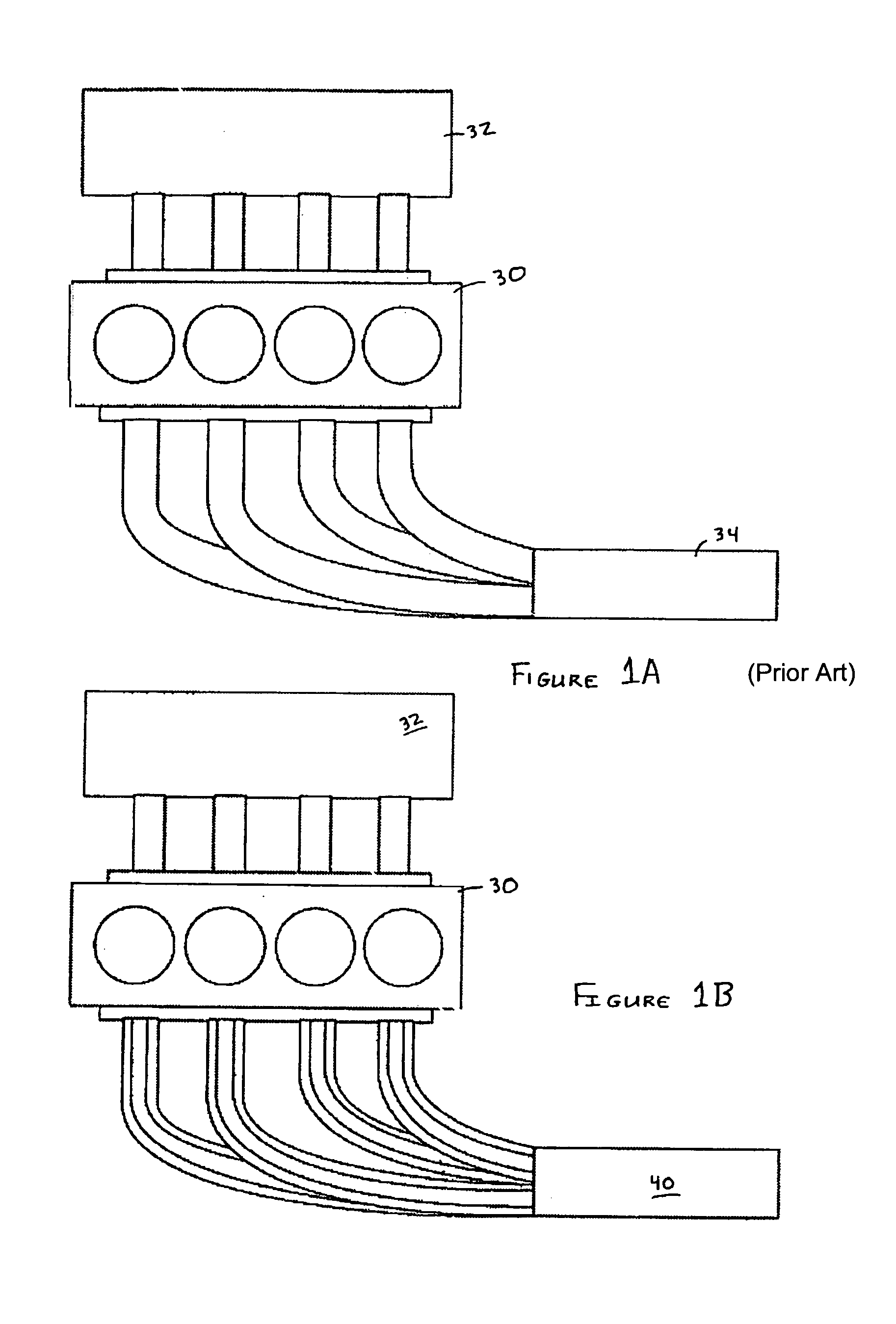

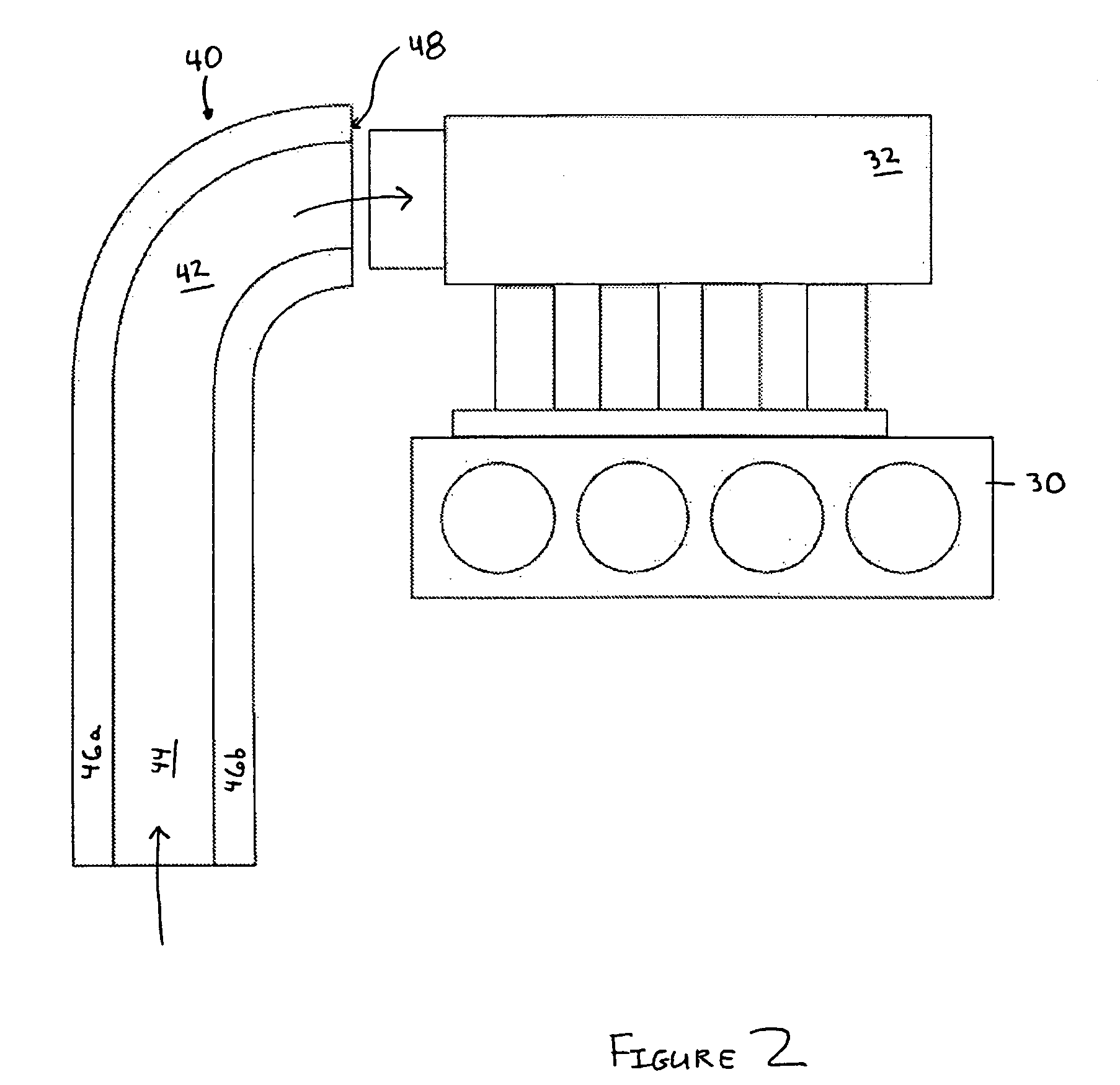

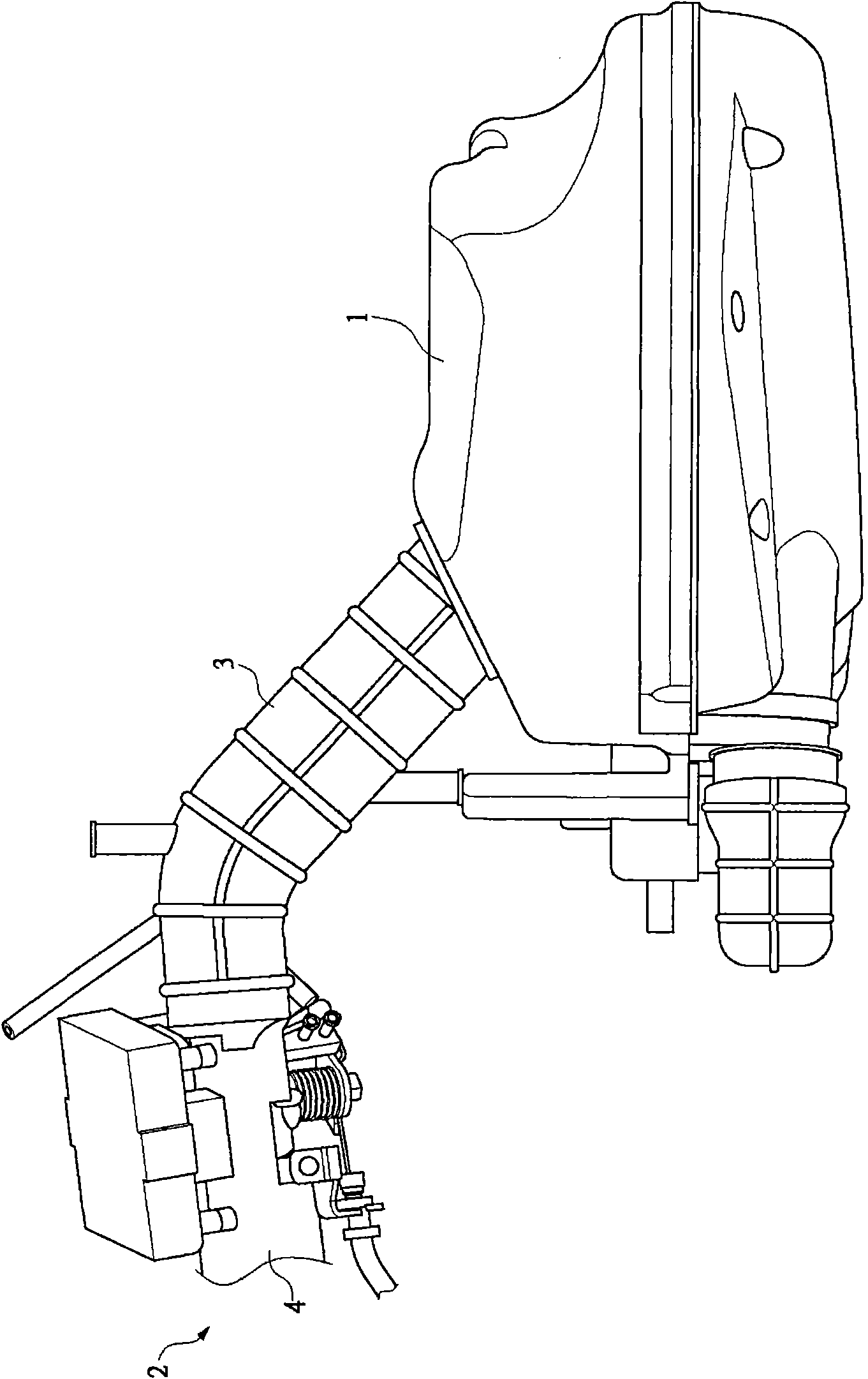

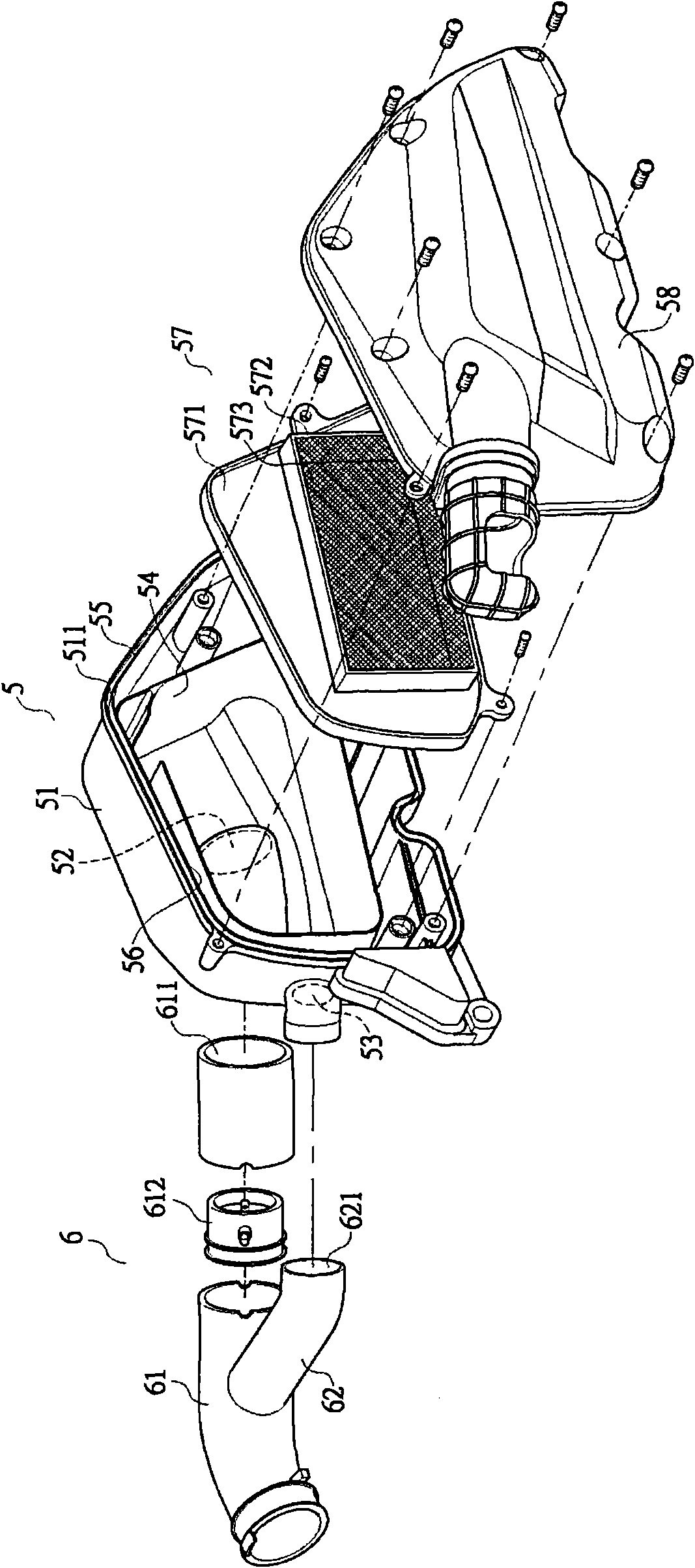

Air intake pipe able to increase intake of air and bendable freely for assembly

InactiveUS6966292B2Increase intakeWide applicabilityFuel injection apparatusPipe elementsAir filterEngineering

An air intake pipe able to increase intake of air and bendable freely for assembly includes an accelerating inner pipe, an air intake outer pipe and a flexible fit pipe. The accelerating inner pipe has one end connected with the air intake end of an engine, and the air intake outer pipe has one end connected with an air filter. The accelerating inner pipe and the air intake outer pipe respectively have the other end movably fitted with the flexible fit pipe. The diameter between the air intake outer pipe and the accelerating inner pipe is shrunk to increase the intake and pressure of air. The rotatable fit structure between the flexible fit pipe and the accelerating inner pipe and the air intake out pipe, and the flexibility of the flexible fit pipe enable the air intake pipe to be installed in various engine rooms of different automobiles.

Owner:HUANG RUEY FA

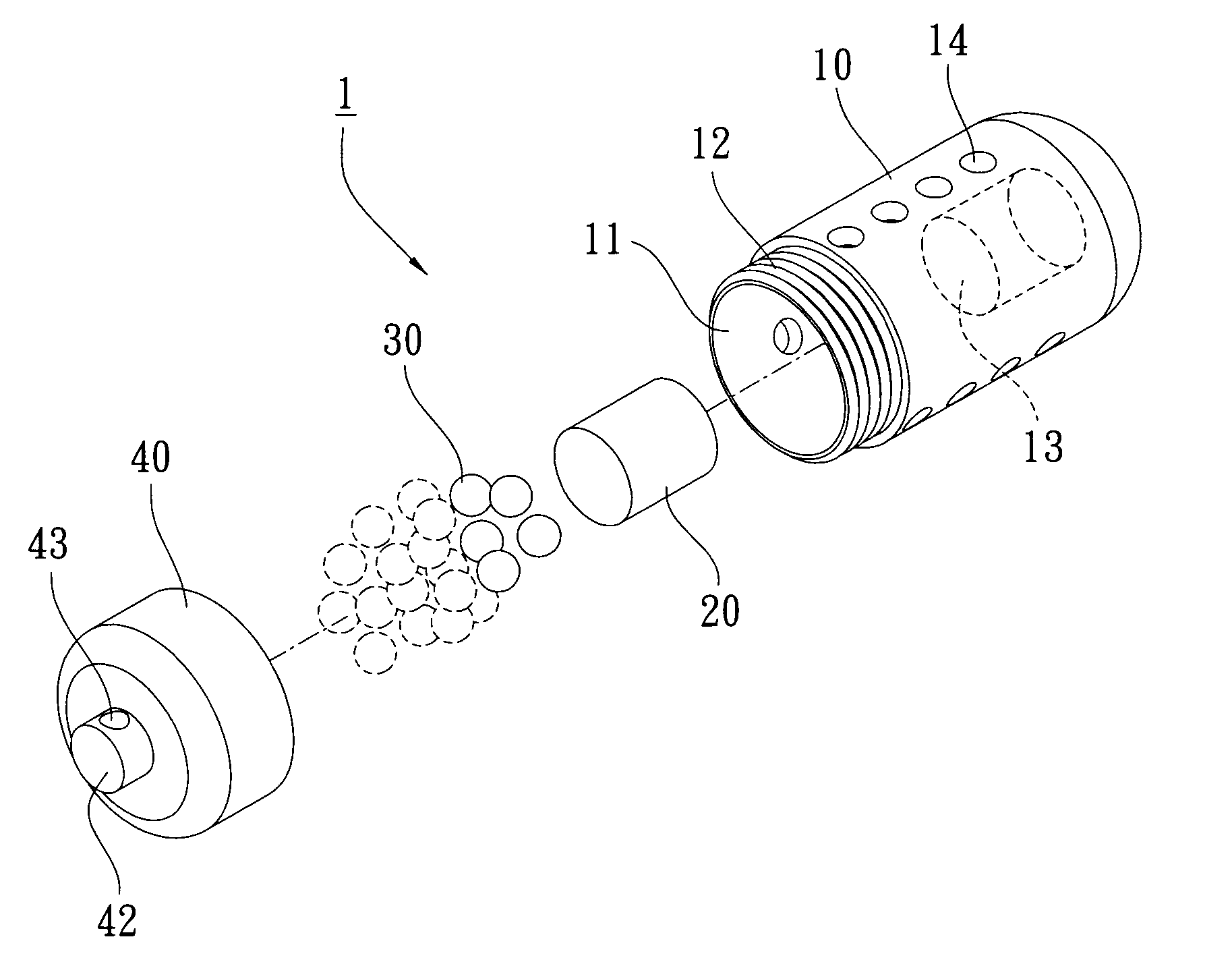

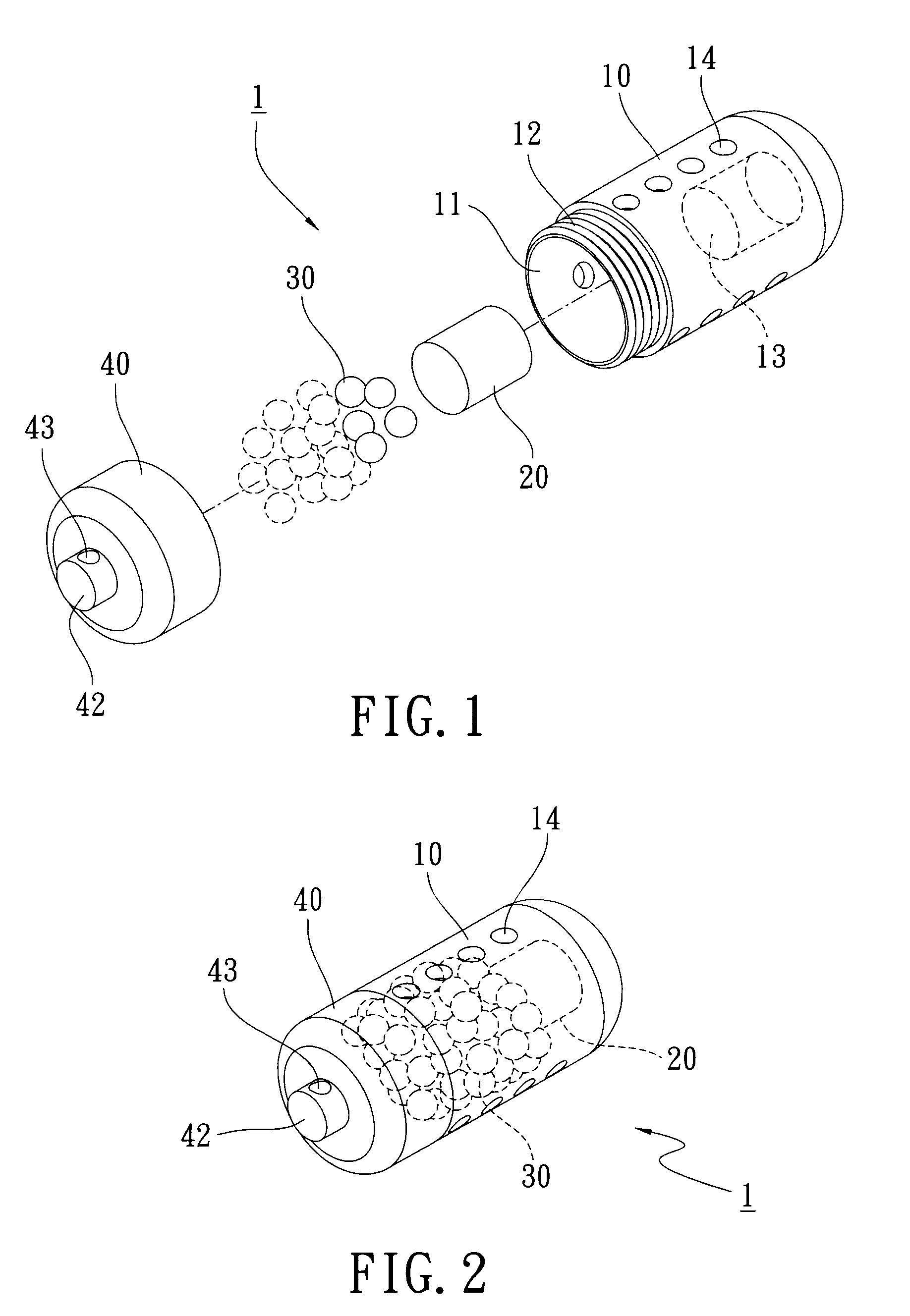

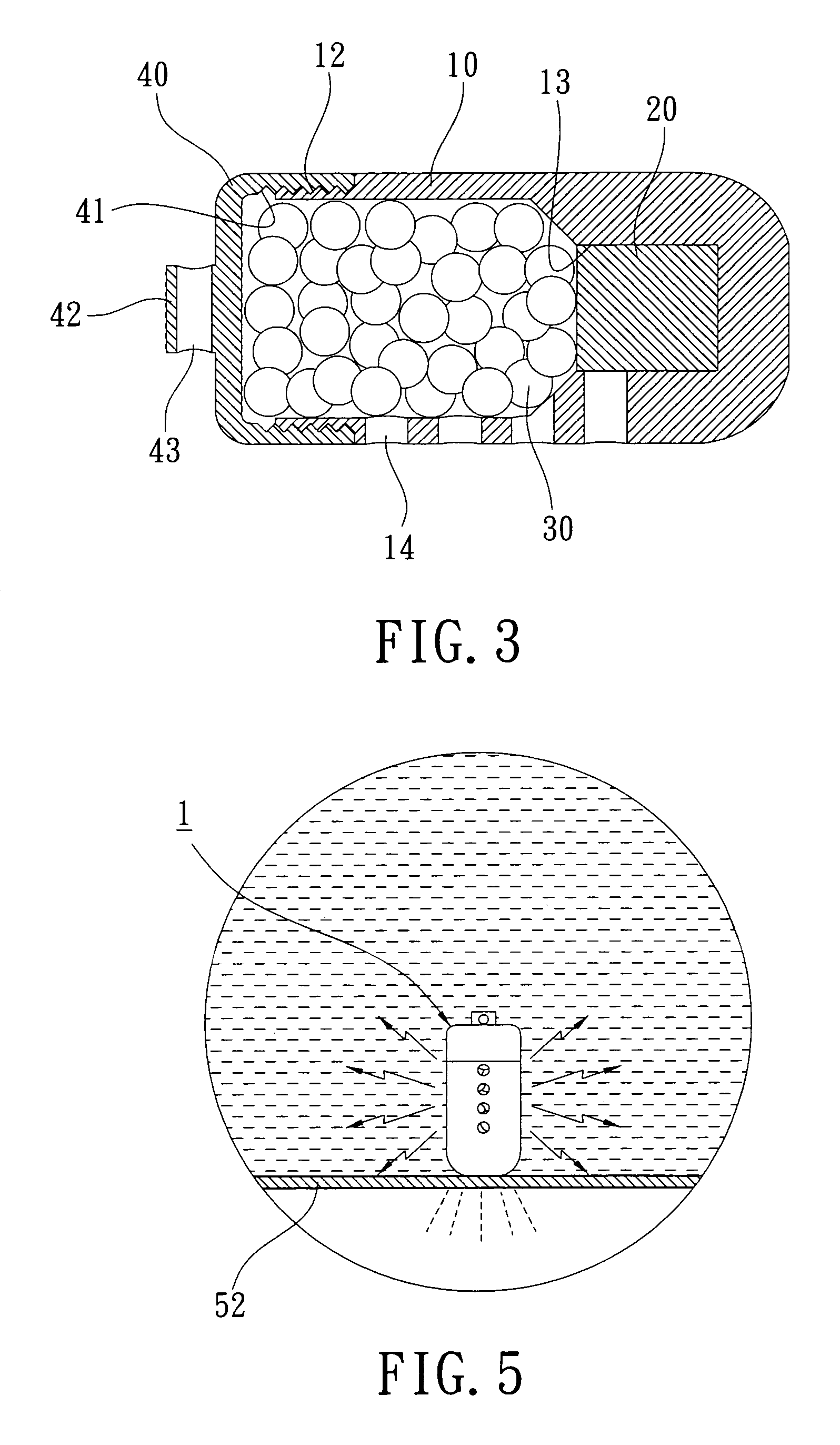

Automobile fuel saver

ActiveUS7377269B1Firmly attachedMaximum effectivenessCombustion-air/fuel-air treatmentMachines/enginesFuel tankEngineering

An automobile fuel saver is composed of a container, a magnetic block, a plurality of nano far-infrared pellets and a cover, wherein the container is configured with an opening that enables a magnetic block and a plurality of the nano far-infrared pellets to be disposed into the container therethrough, and the cover is used to cover and seal the opening. Such a configuration enables a user to use connecting rods to respectively screw into screw holes defined in the cover to juxtapose and assemble a plurality of the fuel savers. The assembled composite structure of the fuel savers is disposed into a fuel tank to effectively improve automobile performance, decrease fuel consumption, and reduce exhaust discharge while simultaneously increasing horsepower and torsion.

Owner:KUO WEI LING

High efficiency low pollution hybrid Brayton cycle combustor

InactiveUSRE43252E1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsTurbine/propulsion fuel controlCombustion chamberWorking fluid

A power generating system is described which operates at high pressure and utilizes a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid exiting the power generating system is substantially free of NOx and CO.Working fluid is provided at constant pressure and temperature. Combustion air is supplied by one or more stages of compression. Fuel is injected at pressure as needed. At least about 40% of the oxygen in the compressed air is consumed when the fuel is burned. Inert liquid is injected at high pressure to produce working an inert mass of high specific heat diluent vapor for use for internal cooling of the combustion chamber.The use of non-flammable liquid injection inhibits the formation of pollutants, increases the efficiency and available horsepower from the system, and reduces specific fuel consumption. Control systems allow the independent control of the quantity, temperature and pressure of the air, fuel and non-flammable liquid introduced in the combustion chamber allowing control of the maximum temperature and average temperature within the combustion temperature as well as the temperature of the exhaust from the combustion chamber.

Owner:VAST POWER PORTFOLIO

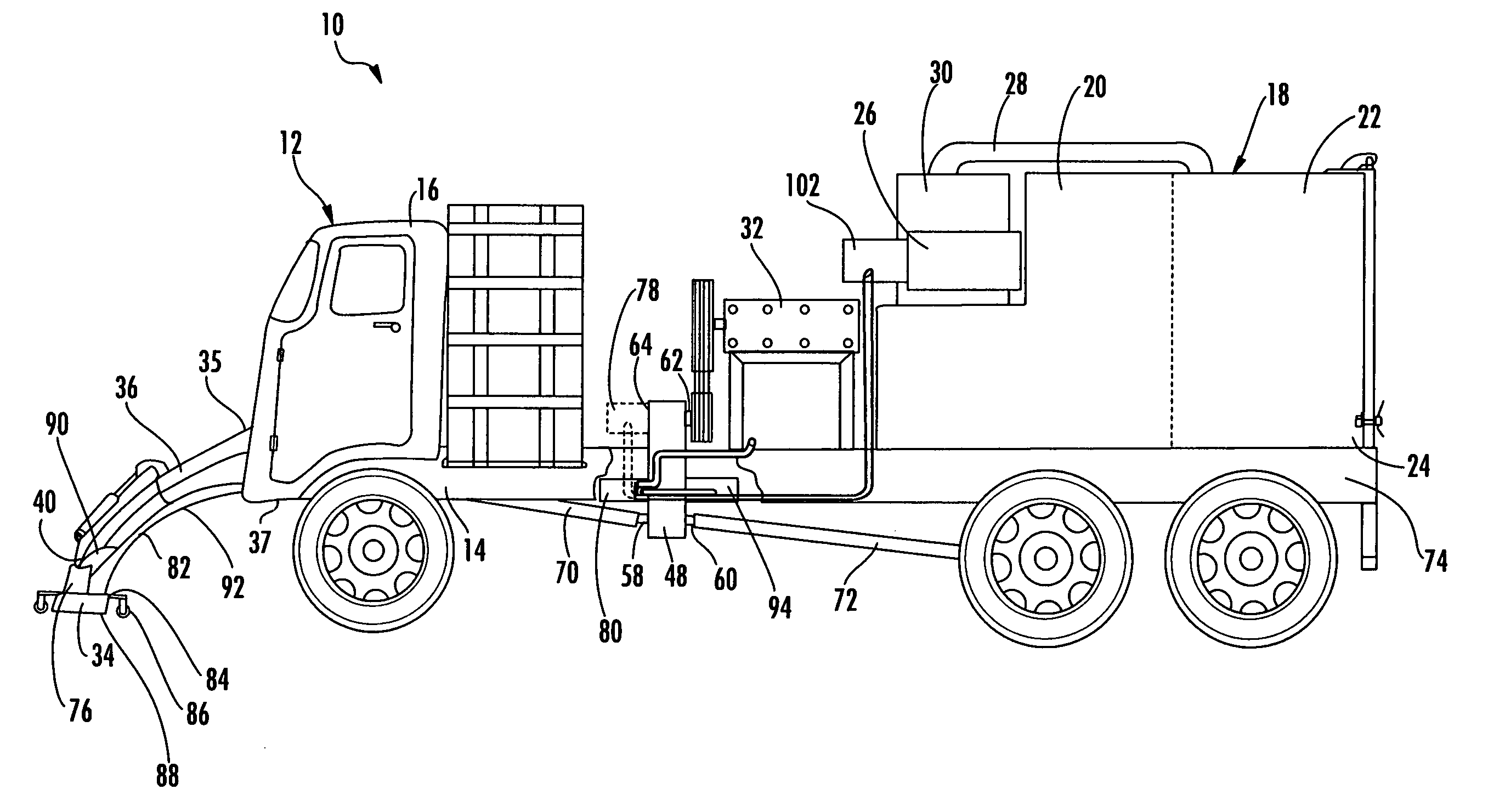

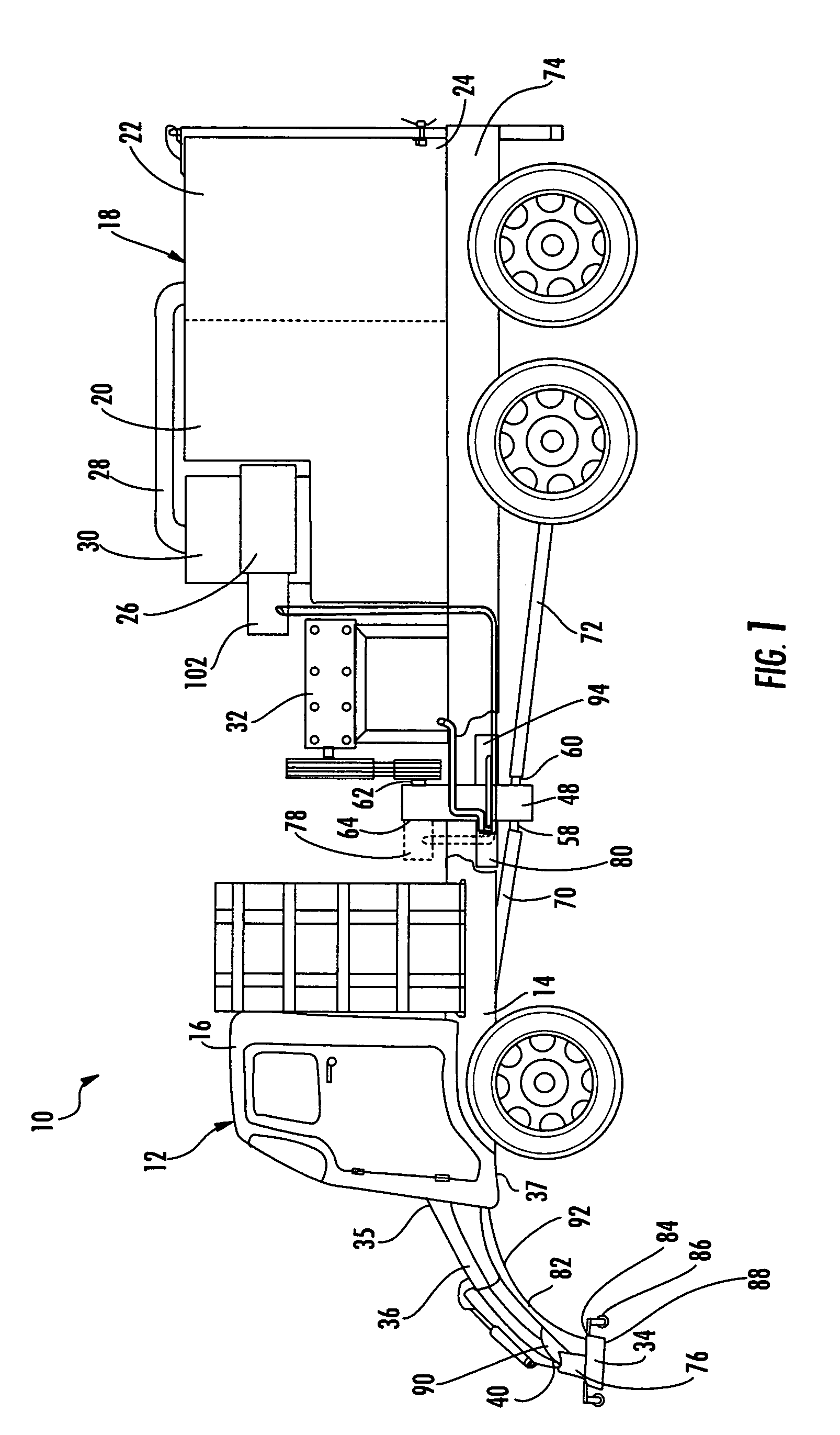

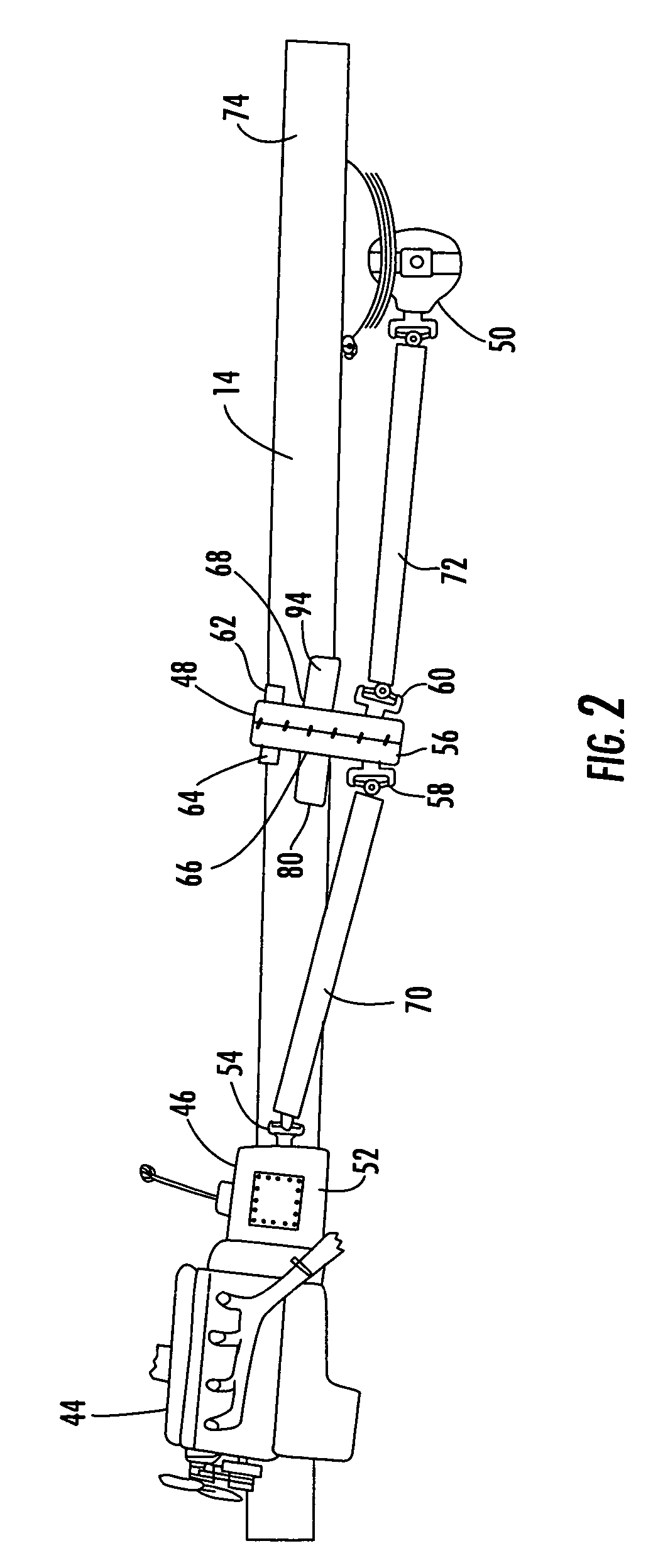

Mobile mark removal system

ActiveUS7798158B2Increase horsepowerHigh removal rateAuxillary drivesElectrostatic cleaningUltra high pressureHigh pressure

Owner:WATERBLASTING

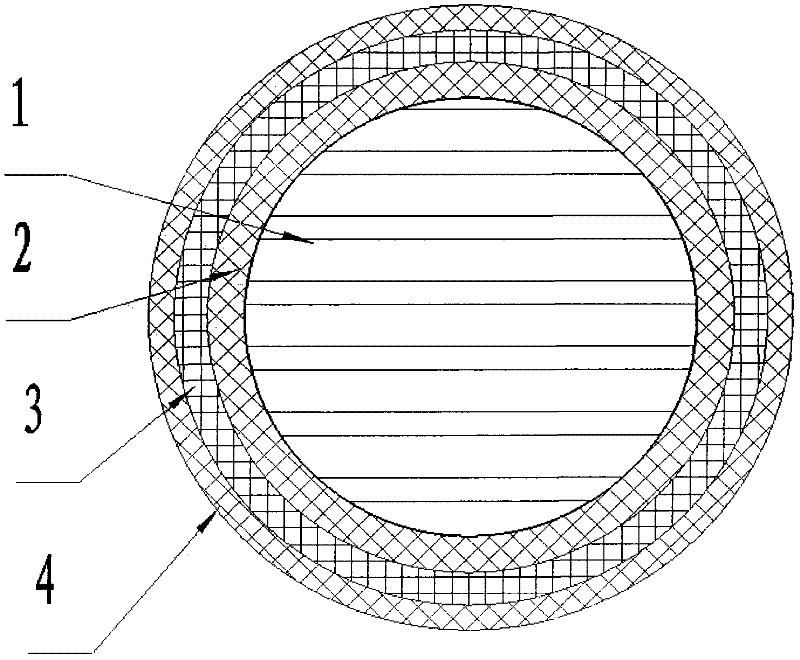

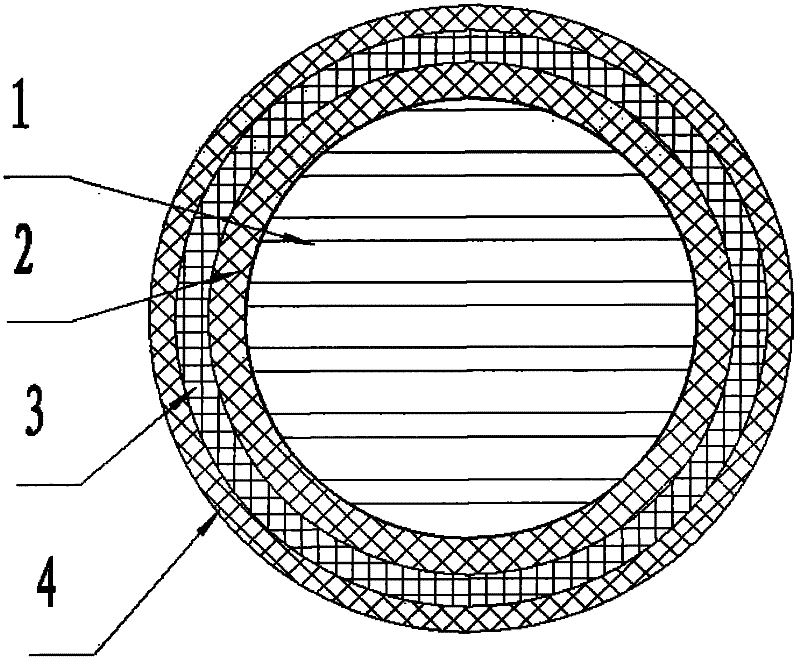

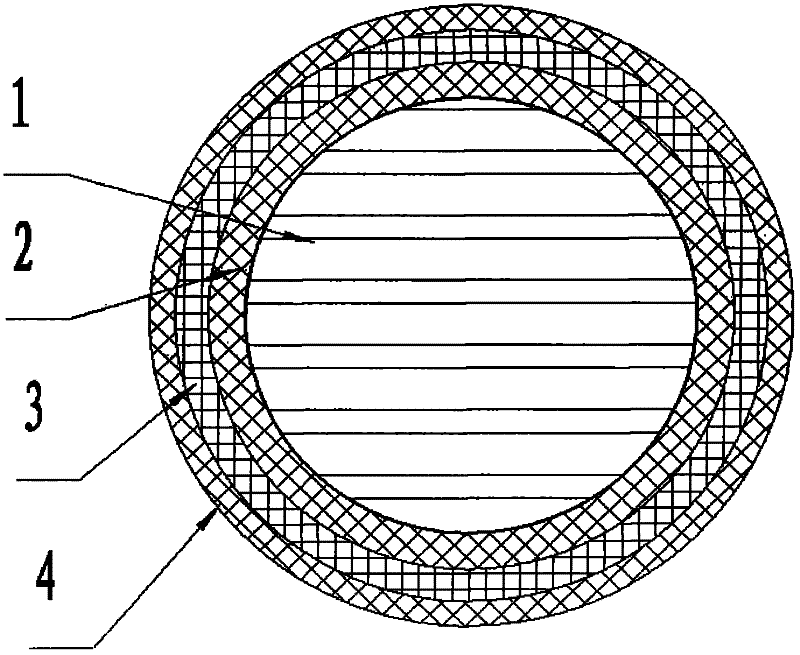

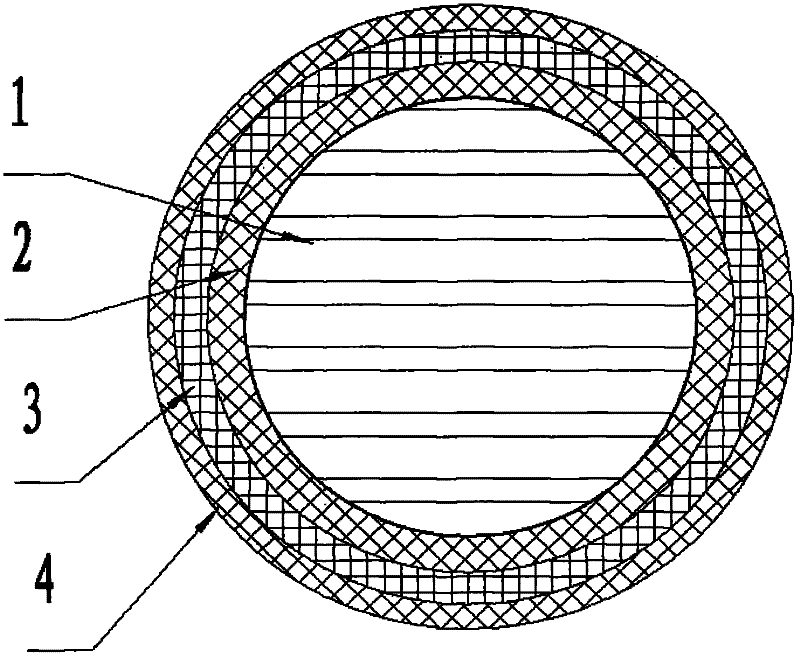

Silicon rubber extrusion rubber tube utilizing carbon fiber as reinforcement layer and manufacturing technique thereof

ActiveCN102514169AIncrease horsepowerIncrease powerFlexible pipesTemperature resistanceSurface finishing

The invention discloses a manufacturing technique of a silicon rubber extrusion rubber tube utilizing a carbon fiber as a reinforcement layer, which comprises the following steps of: extruding an inner rubber layer on a mould core with required dimension; performing surface treatment on the carbon fiber cloth to improve the content of a surface polar group thereof; weaving or winding the carbon fiber cloth with treated surface on the inner rubber layer as the reinforcement layer; extruding an outer rubber layer on the carbon fiber cloth to wrap the surface of the carbon fiber cloth; vulcanizing the obtained rubber tube after the forming procedure to obtain a finished product, wherein the inner rubber layer and the outer rubber layer comprise silicon rubber. According to the invention, the carbon fiber cloth is used as the reinforcement layer to manufacture the silicon rubber coated rubber tube, thereby not only solving the problems of low strength and bad pressure resistance of the current silicon rubber tube, but also improving the temperature resistance of the silicon rubber tube and playing the temperature and pressure resistance of the silicon rubber to the utmost. The rubber tube produced in the invention can be applied in such fields with high pressure and temperature resistance demands as high power diesel engines and generators, etc.

Owner:XIAMEN CHUANGXINYUAN RUBBER PROD

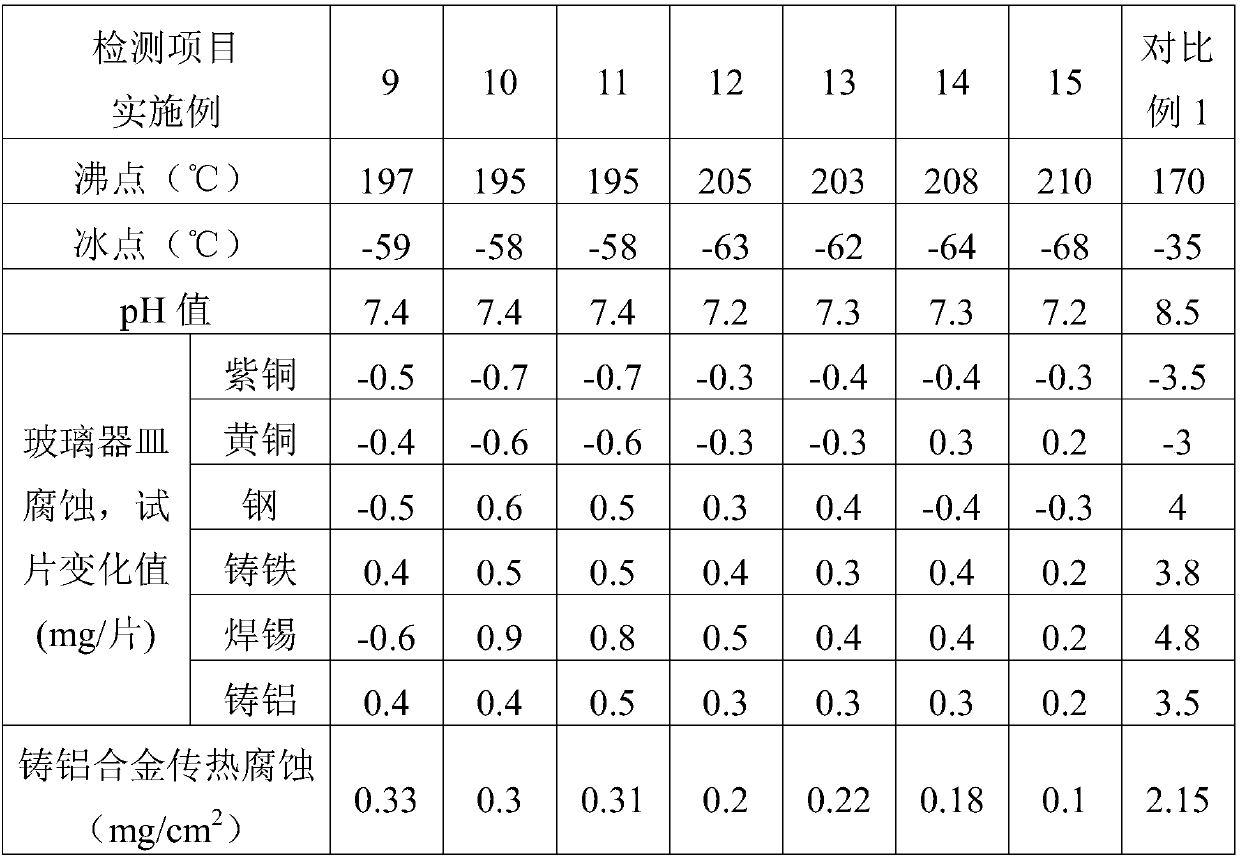

Engine anhydrous cooling liquid and preparation method thereof

ActiveCN107629765AGood conditionPowerfulHeat-exchange elementsBulk chemical productionNausea sicknessCavitation

The invention discloses an engine anhydrous cooling liquid and a preparation method thereof, wherein the engine anhydrous cooling liquid comprises the following raw materials by the weight percentage:60-70% of propylene glycol, 25-30% of ethylene glycol, 3-4% of 1,2-aminoazophenylene, 1-2% of sodium nitrate, 2-3% of glycerol, 1-2% of triethanolamine, 0.5-1.5% of sodium hydroxide, and 0.1-1% of apigment. The anhydrous cooling liquid has the freezing point lower than -52 DEG C and the boiling point more than 190 DEG C and has a large thermal safe space, so with the use of the product, the anhydrous cooling liquid can maintain a good state for operation, adequate power is maintained, noise is reduced, a water tank does not produce 'boiling', and cylinder score is not generated. With use ofthe anhydrous cooling liquid, zero corrosion can be achieved, no water rust is generated, cleaning and repair are not needed forever, and boiling, cylinder score, water tank blocking, water rust, water scale, corrosion and cavitation corrosion, engine fatigue, nausea, explosive vibration, precombustion, large noise, unstable idle speed, cylinder pressure reduction, insufficient power, oil consumption increase and large exhaust gas emission smoke and other phenomena are thoroughly eliminated.

Owner:四川路恒达机械科技有限公司

Self-propelling crusher

InactiveUS7318463B2Reduce crushing efficiencyIncrease speedMowersMulti-purpose machinesHydraulic pumpEngineering

A self-propelled crushing machine comprises a crushing device 20; a hydraulic drive system including a crushing device hydraulic motor 21 for driving the crushing device 20, a first hydraulic pump 62 for driving the crushing device hydraulic motor 21, and an engine 61 for driving the first hydraulic pump 62; a pressure sensor 151 for detecting a load condition of the crushing device 20; and a controller 84″ for executing control to increase a revolution speed of the engine 61 in accordance with a detected signal from the pressure sensor 151. Accordingly, even when a heavy load is imposed on the crushing device, a reduction of crushing efficiency can be prevented.

Owner:NIHON KENKI CO LTD

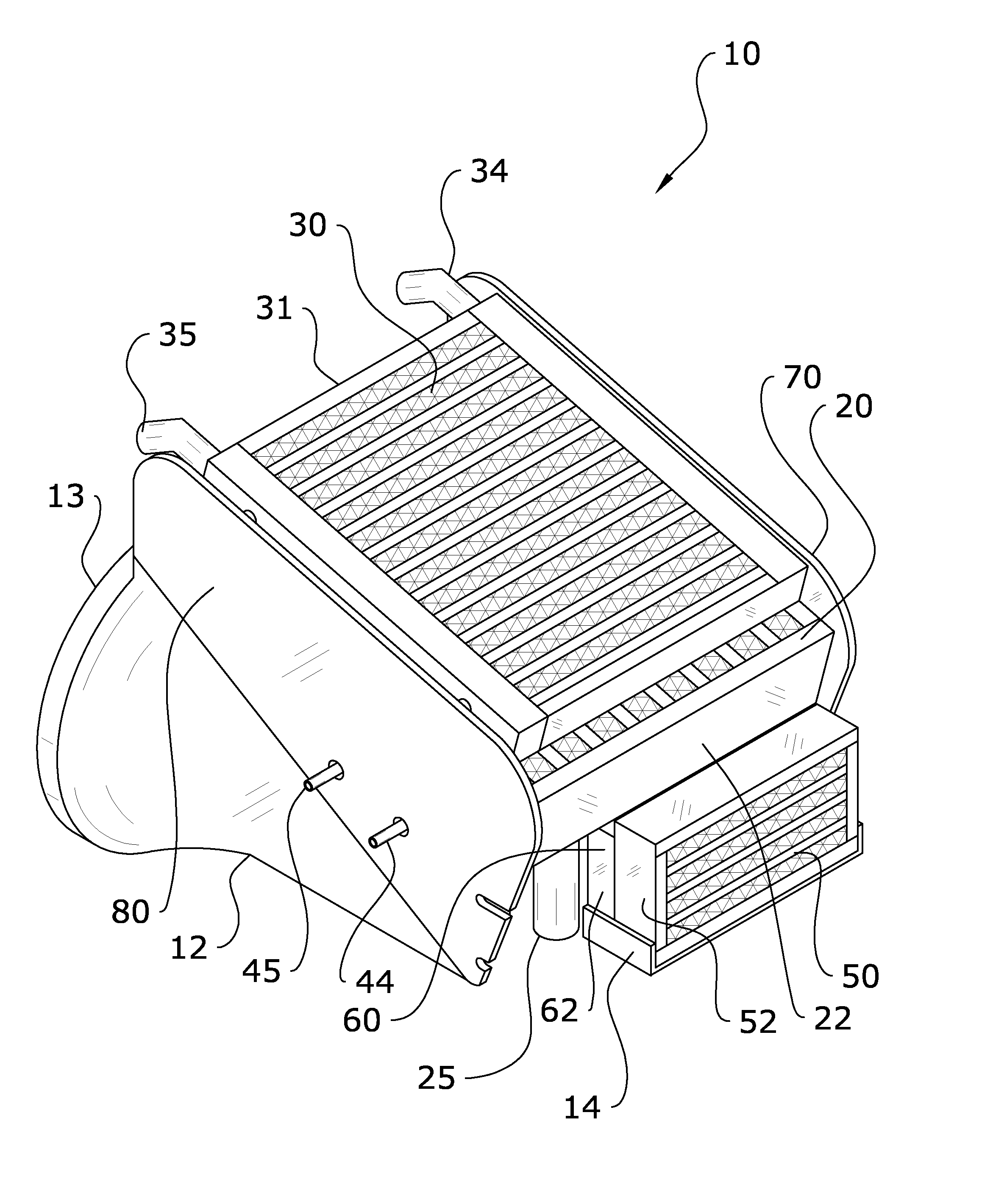

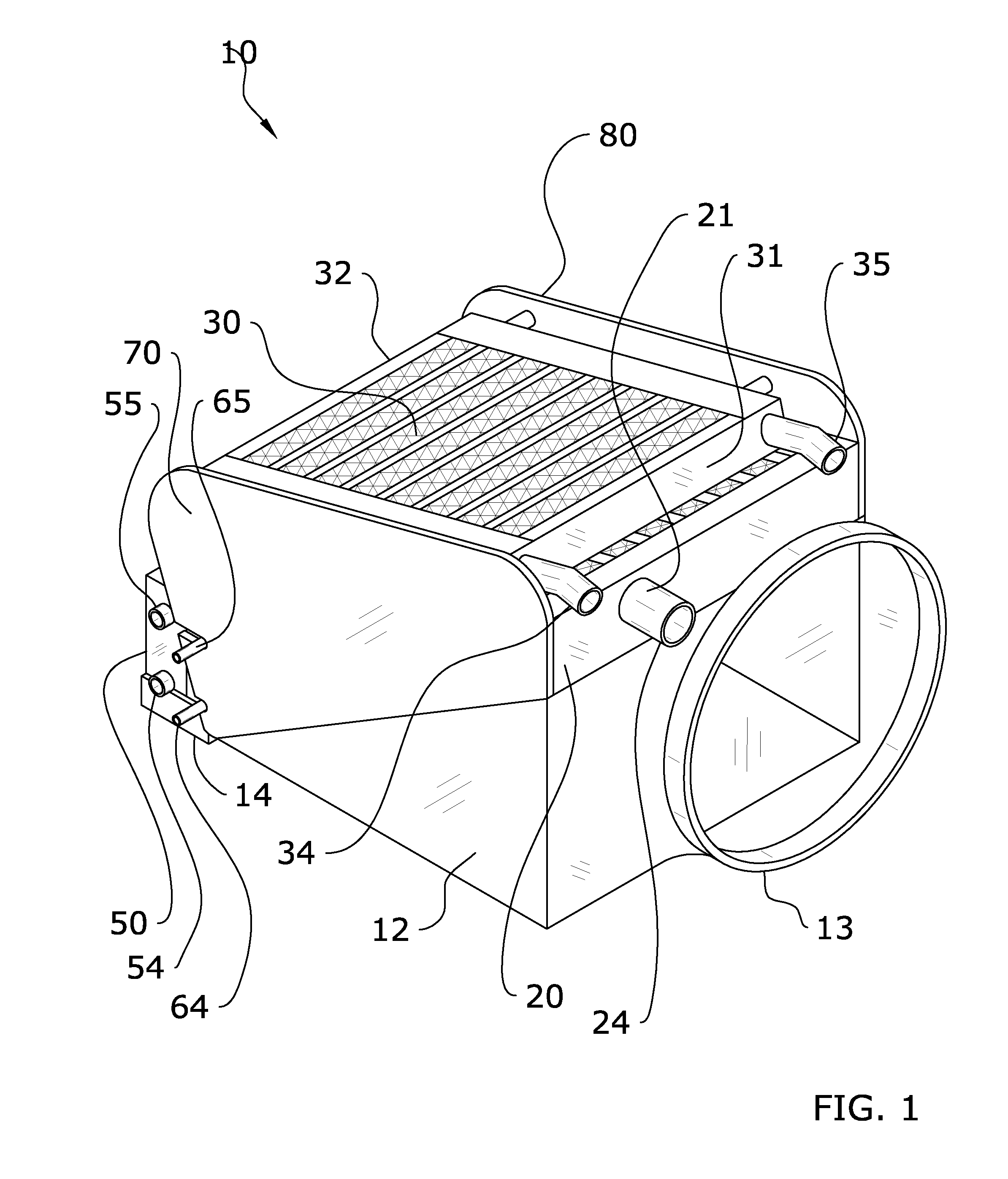

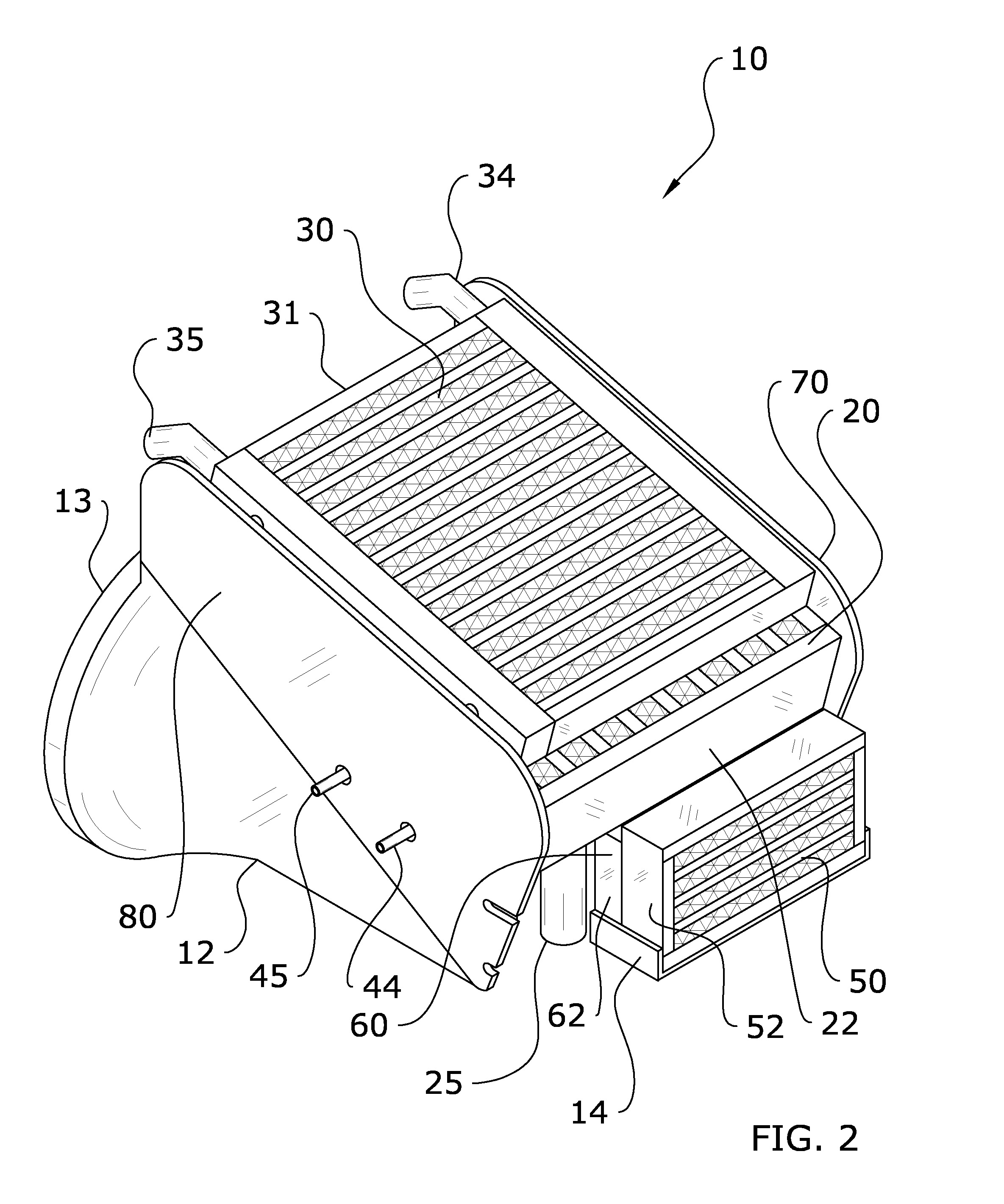

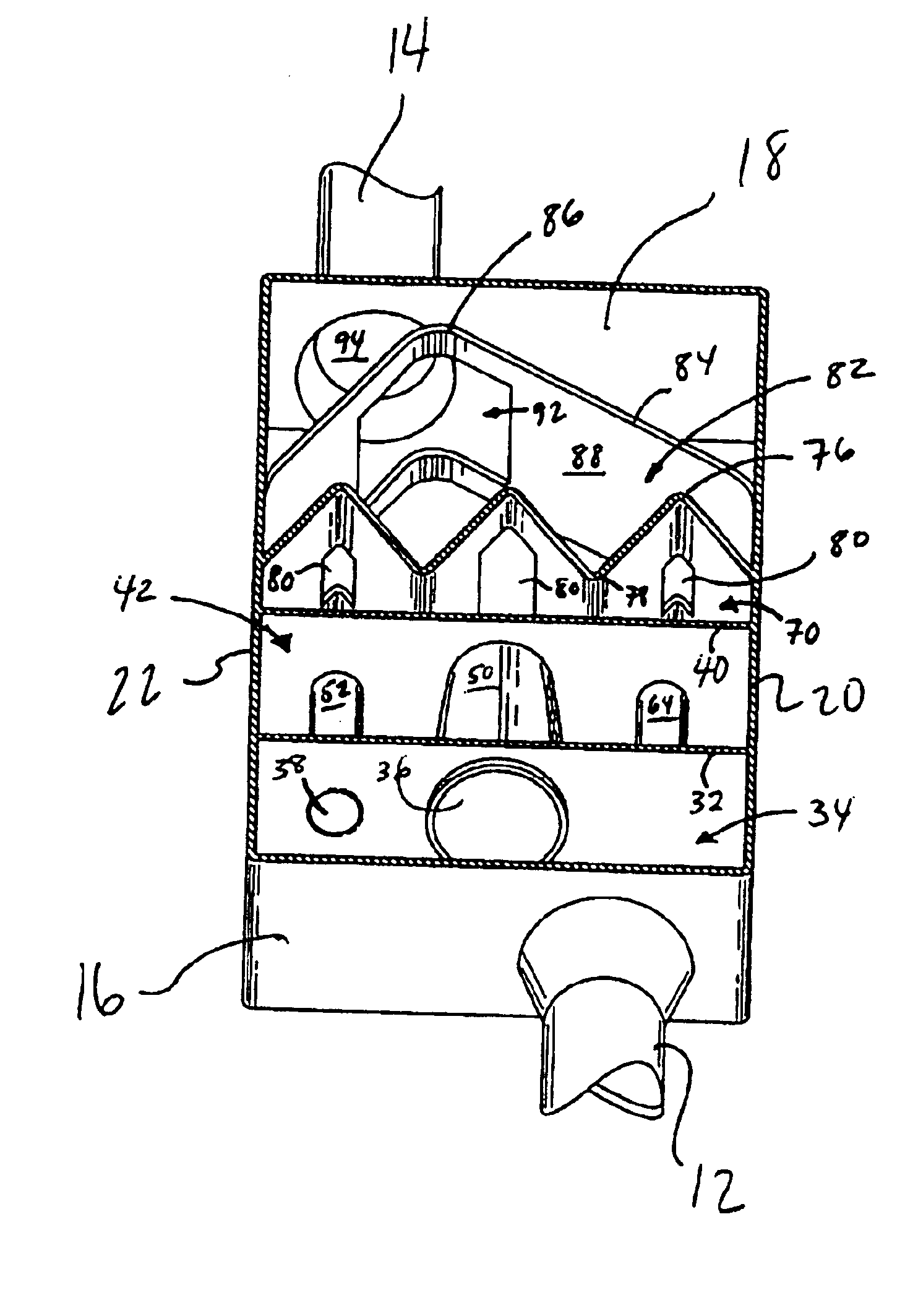

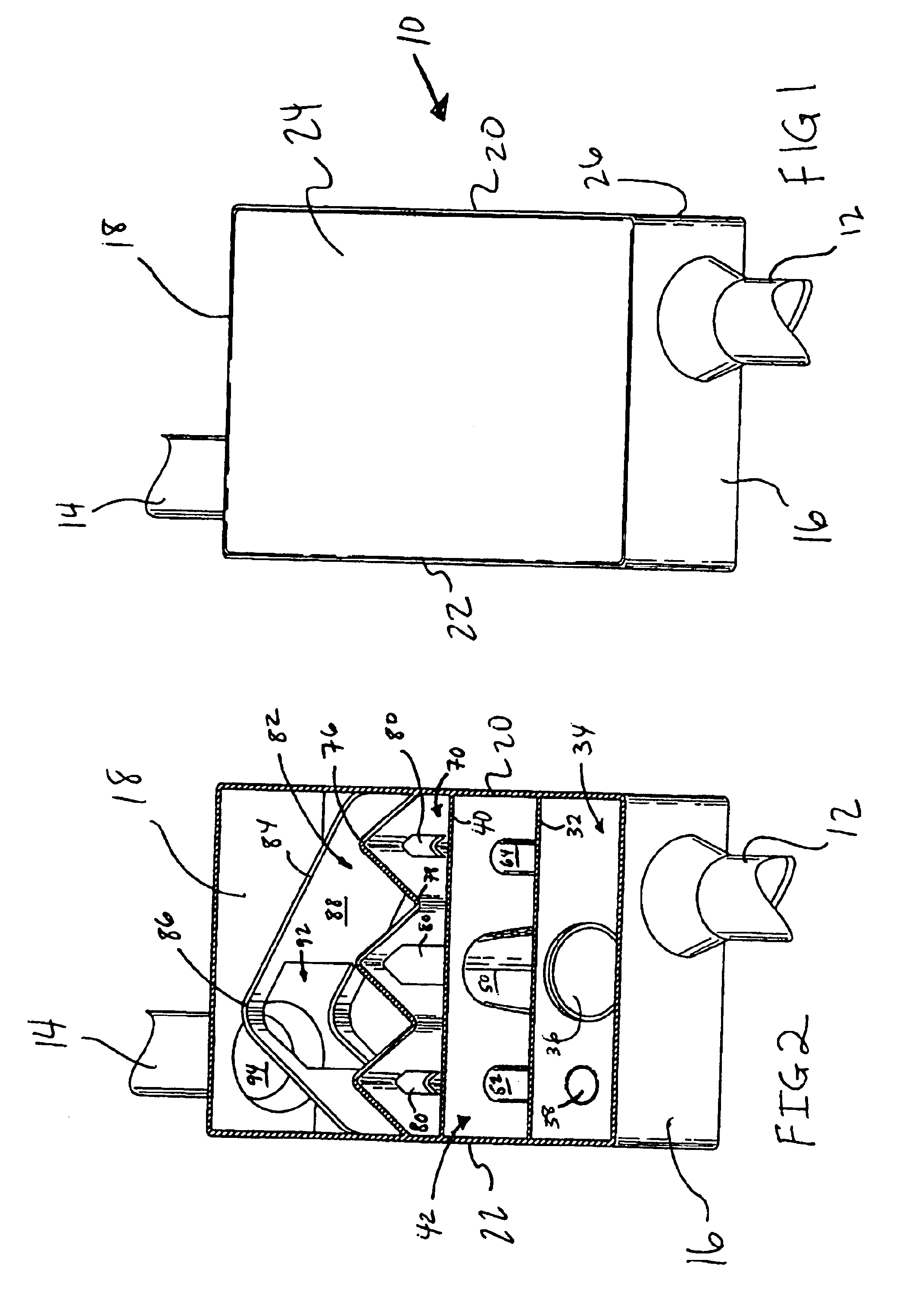

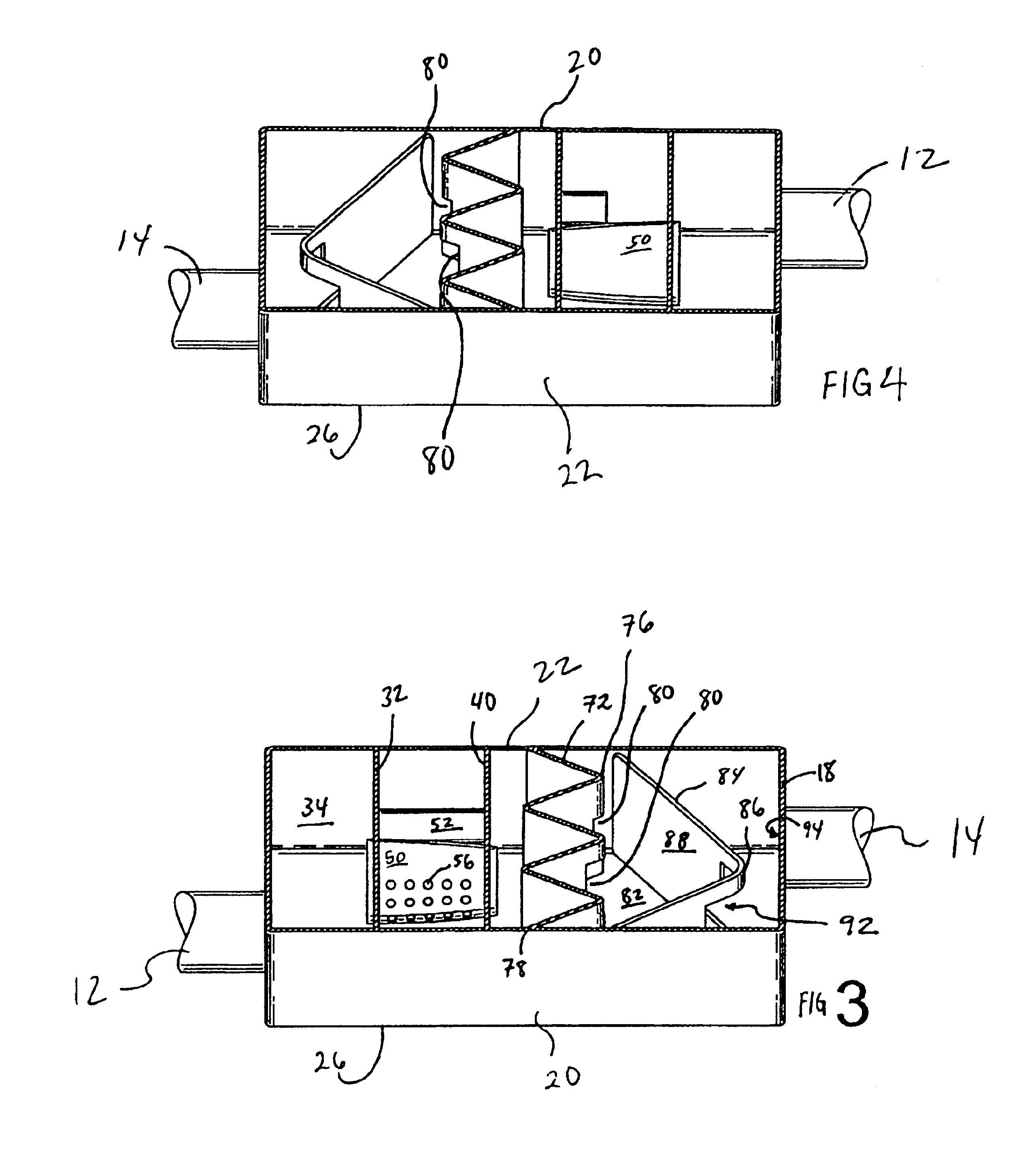

Compact multi-unit vehicle cooling system

A compact multi-unit vehicle cooling system for reducing heat toward the engine of a vehicle. The compact multi-unit vehicle cooling system generally includes a radiator, an air charge cooler, a transmission oil cooler, an engine oil cooler and a power steering oil cooler. Each of the components of the present invention is secured in a compact package for installation in a vehicle such as a HUMMER or the like. By utilizing a modulated, compact design, the present invention may more easily be installed and serviced while significantly reducing heat towards the vehicle's engine and thus increasing horsepower.

Owner:COHEN ASAF

Fuel economizer

ActiveUS20070256672A1Reducing waste gas producedIncrease temperatureCombustion-air/fuel-air treatmentMachines/enginesEngineeringEconomizer

A fuel economizer comprises a pipeline with thermal conducting elements and having a chamber contained therein, a plurality of magnetic elements each of which having a through hole formed therein and wrapped within a metal element that is formed with a plurality of spacings and disposed within the chamber of the pipeline, and a plurality of elastic elements disposed within the chamber of the pipeline and located at two opposite sides of the magnetic elements, respectively.

Owner:WANG JIN LANG

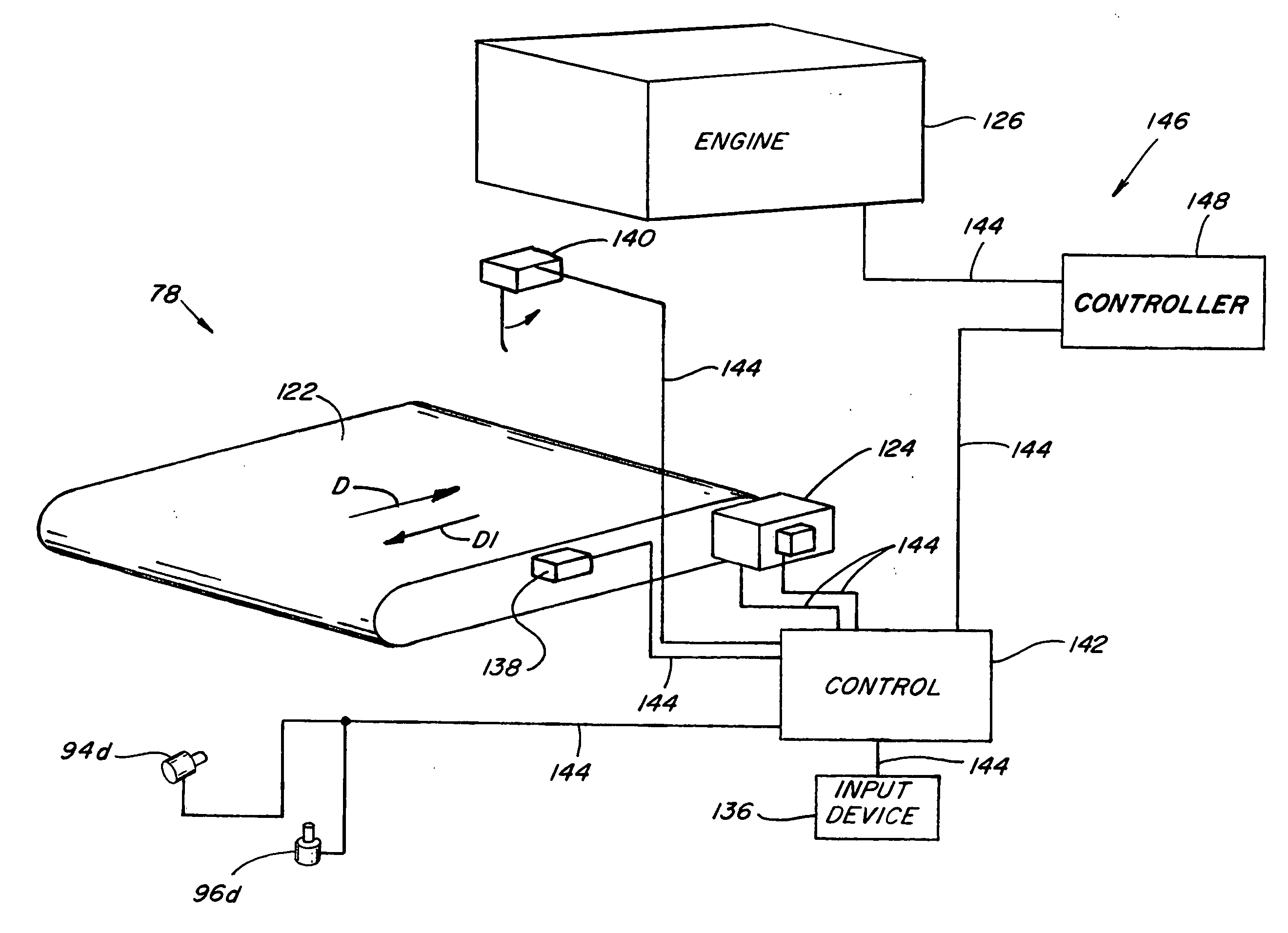

Combine harvester power management control

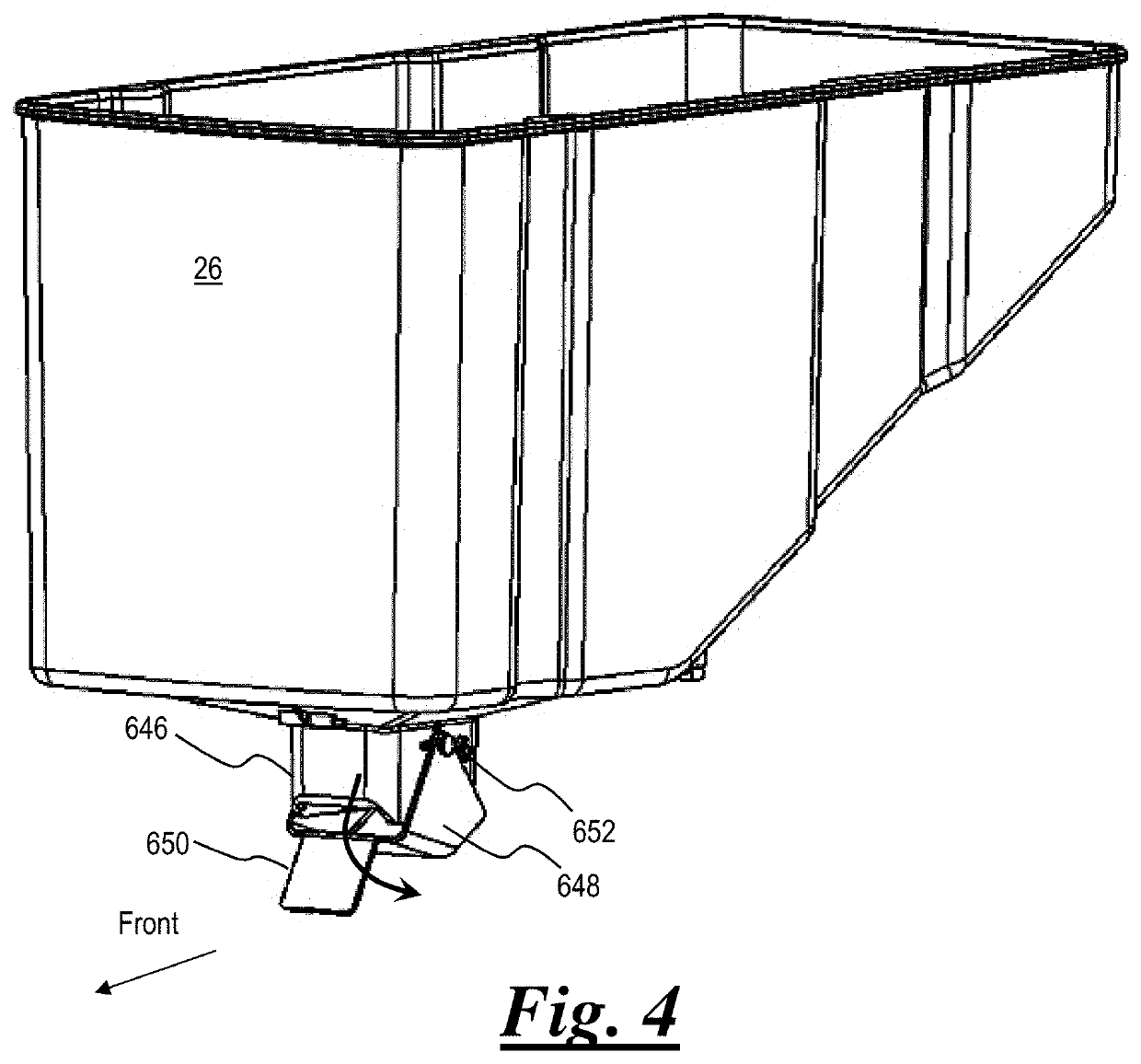

ActiveUS20080209878A1Reduce lengthReduce total powerAnalogue computers for trafficMowersEngineeringPower management

A system and method of controlling maximum available engine power of a combine harvester wherein the engine drives the harvester and additionally powers a threshing mechanism for separating harvested crop into grain and crop residue and at least one further crop processing subsystem that may be selectively configured and disengaged, including a straw chopper engageable for chopping the crop residue and propelling the chopped residue from the harvester, structure configurable for directing the crop residue into the chopper or to bypass the chopper, utilizing a controller for automatically reducing the maximum available engine power as a function of the status of the engagement of the subsystems, particularly the chopper and the configuration of the associated structure.

Owner:BLUE LEAF I P

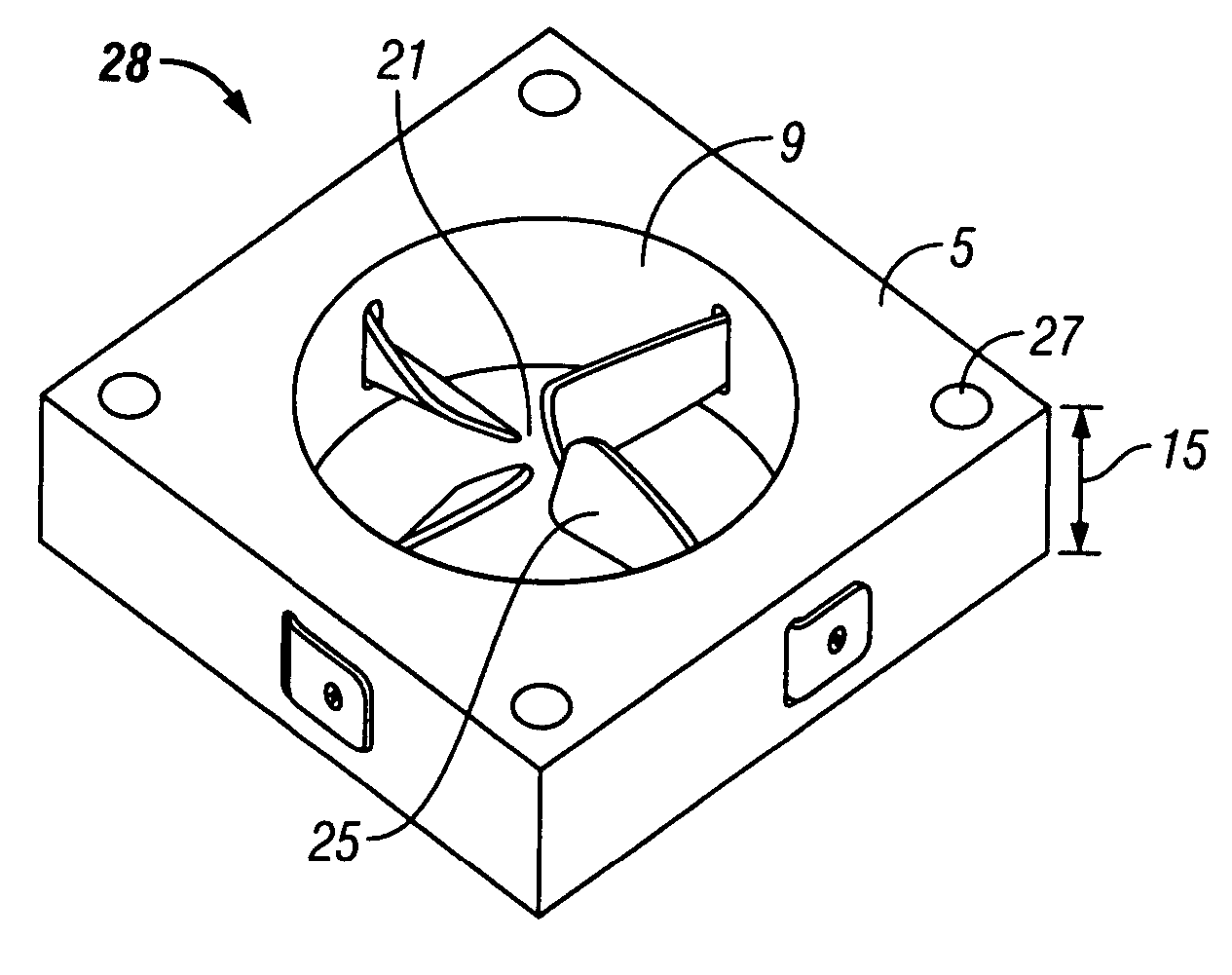

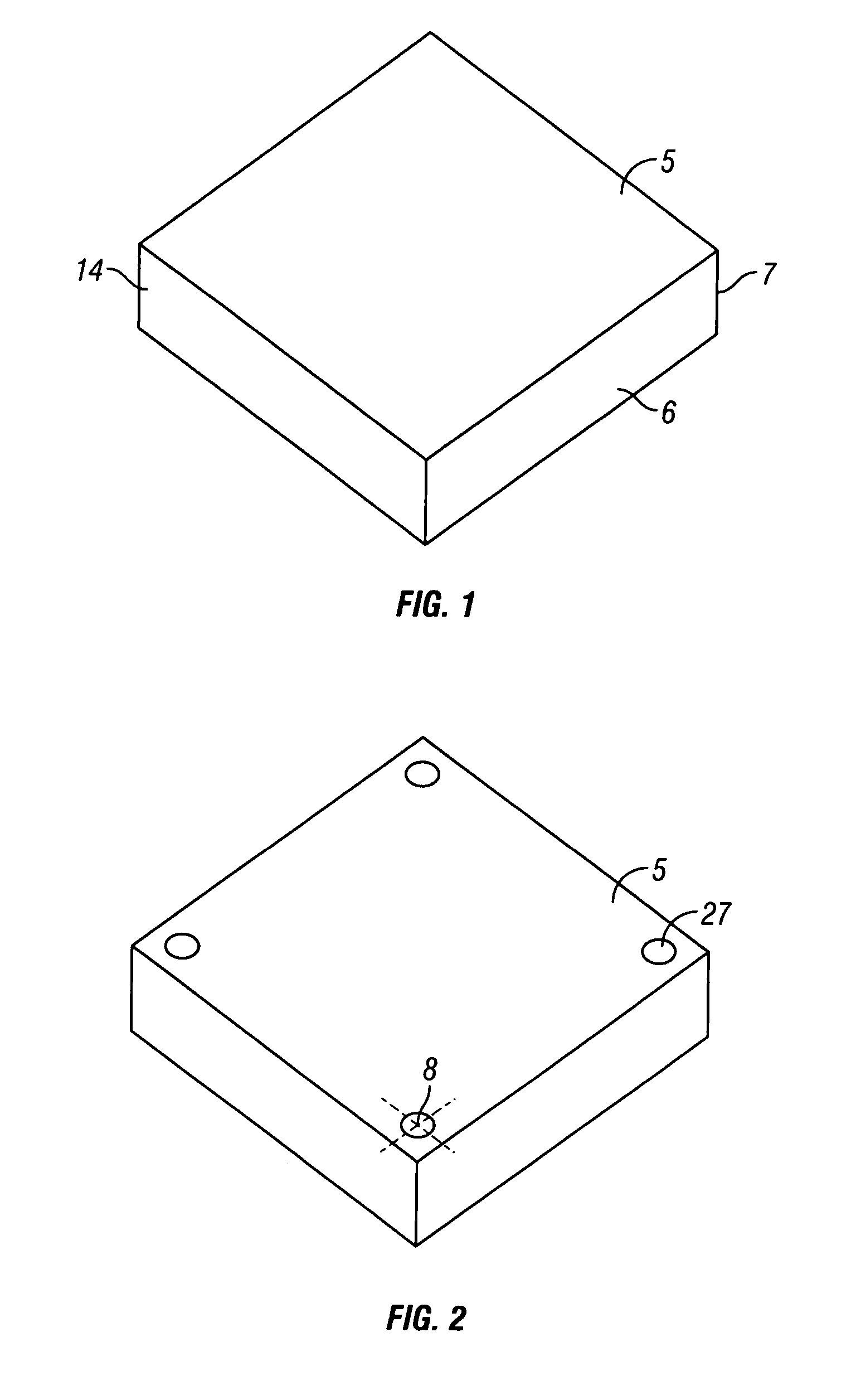

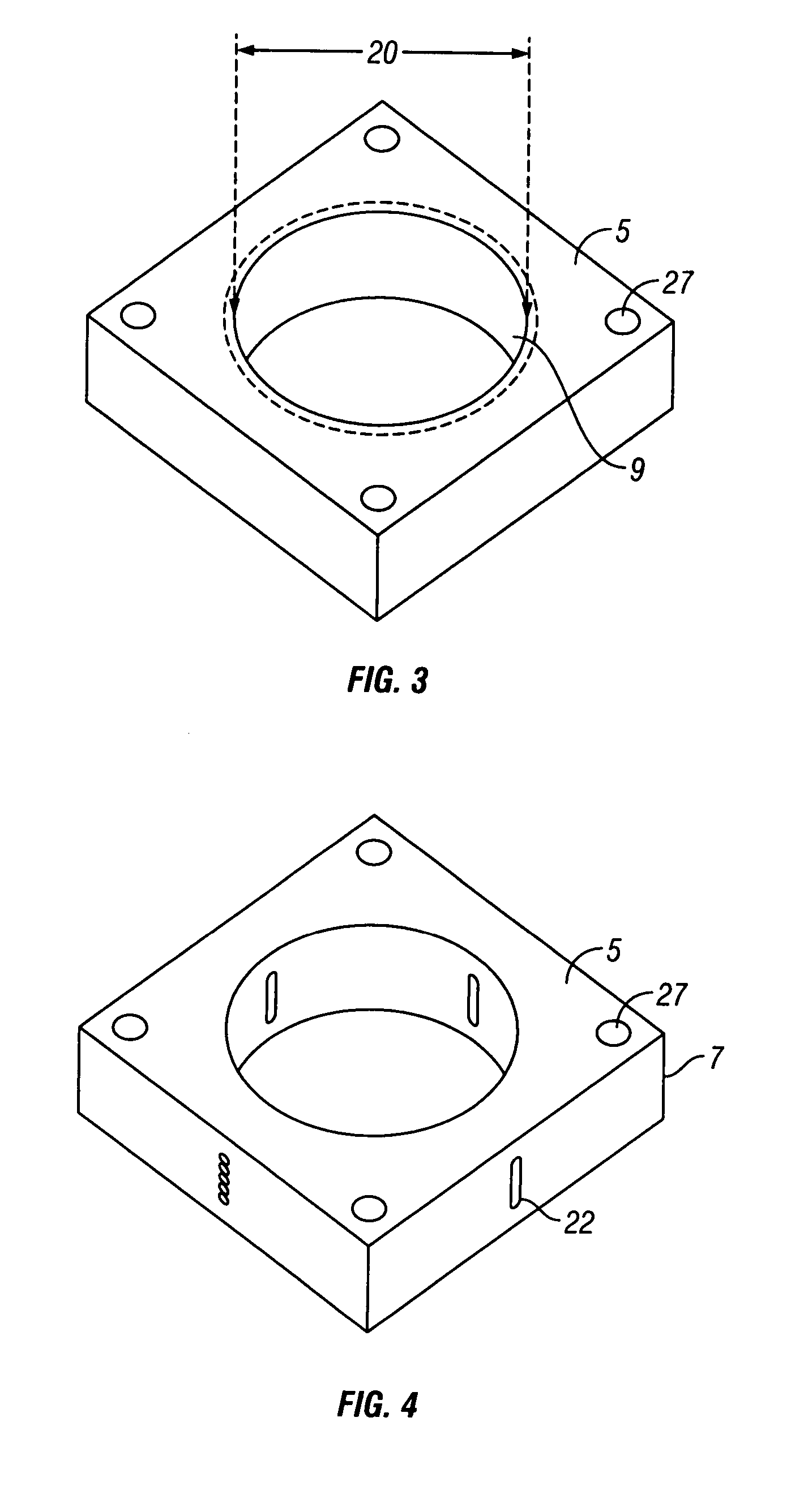

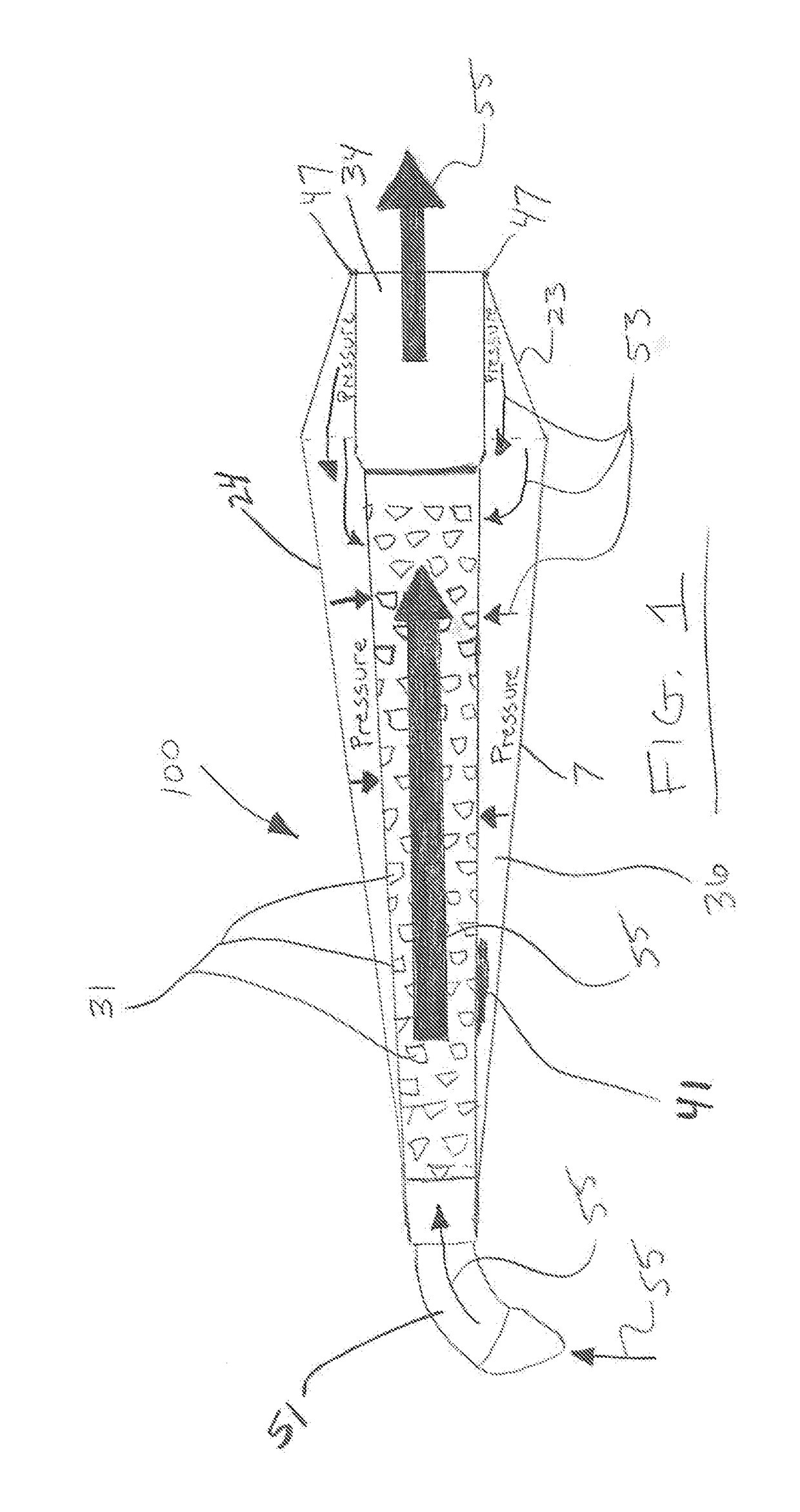

Throttle body spacer for use with internal combustion engines

InactiveUS7690349B2Improve efficiencyIncreases velocity and forceInternal combustion piston enginesFuel re-atomisation/homogenisationCombustionEngineering

A throttle body spacer for improving engine performance is provided. It comprises a spacer block with a smooth bore hole, a plurality of air fins, each air fin being connected at one end to the spacer block and the distal end extending to about the center of the bore hole, and a means for mounting the throttle spacer body to hold it in place. In one embodiment the spacer block forming the throttle spacer body is square with a single bore hole in the center. There are four air fins, one mounted from about the middle of each side of the spacer body, that extend to about the center of the hole. The air fins can be made from aluminum and are bent at a forty-five degree angle. In order to accomplish the goal of absorbing less heat, the spacer block forming the throttle body spacer is comprised of thermoset resin. The throttle body spacer has holes located near each corner where fastening elements can be inserted to hold the apparatus in place.

Owner:GSP POWERSPACER

Silicon rubber wrapped rubber tube using carbon fiber as reinforcing layer and manufacture process thereof

InactiveCN102514197AIncreased horsepower and powerLight weightFlexible pipesLower intensityPressure resistance

The invention relates to a manufacture process of a silicon rubber wrapped rubber tube using carbon fiber as a reinforcing layer. The manufacture process comprises the following steps that: surface treatment is carried out on carbon fiber cloth, and the surface polar group content of the carbon fiber cloth is improved; an inner rubber layer is wound on a mold core in the required dimension; the carbon fiber cloth subjected to the surface treatment is used as the reinforcing layer to be wrapped on the inner rubber layer; an outer rubber layer is wrapped and wound on the surface of the carbon fiber cloth, and a rubber tube is formed; the rubber tube is vulcanized, and finished products are obtained, wherein the inner rubber layer and the outer rubber layer comprise silicon rubber. The carbon fiber cloth is used as the reinforcing layer for manufacturing the silicon rubber wrapped rubber tube, the problems of low intensity and poor pressure resistance capability of the existing rubber tube are solved, in addition, the problem of low temperature resistance performance of the silicon rubber tube using traditional materials such as polyester fiber or glass fiber and the like as the rubber reinforcing layer is solved, and the temperature resistance and pressure resistance performance of the silicon rubber is exerted to the maximum degree. The rubber tube produced by the manufacture process can be applied to the fields of high-power diesel engines, generators and the like with high pressure resistance and temperature resistance requirements.

Owner:XIAMEN CHUANGXINYUAN RUBBER PROD

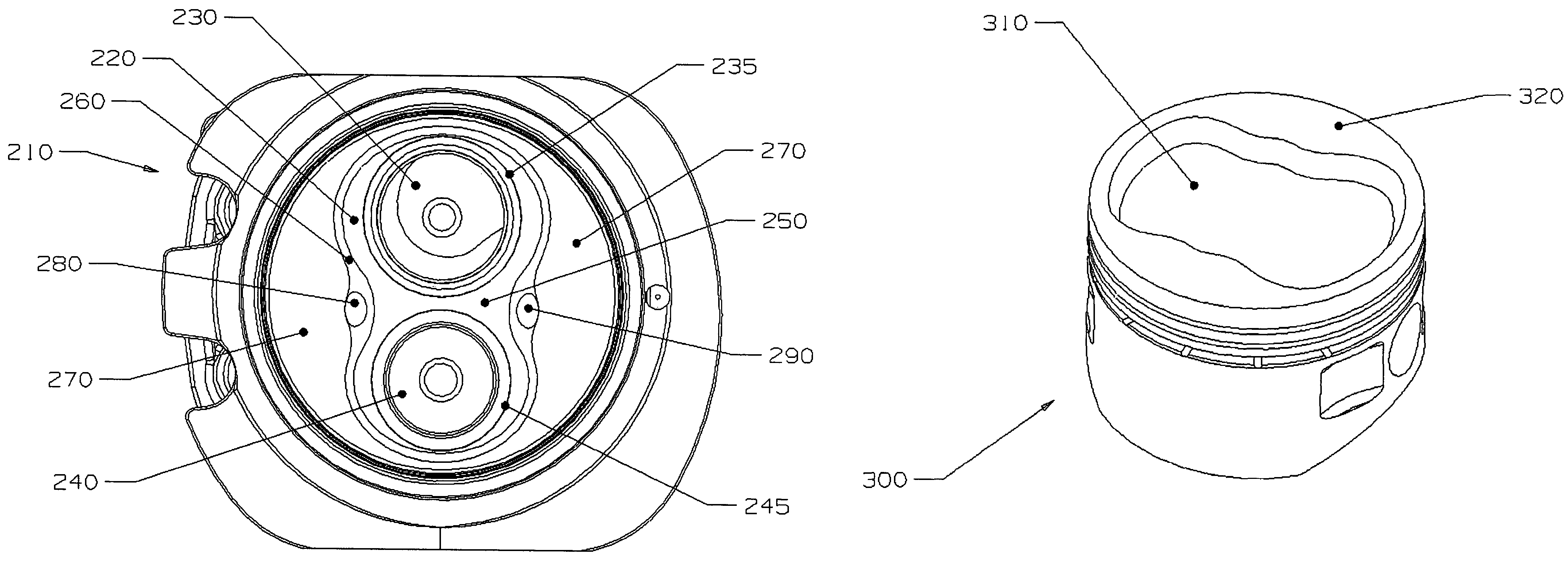

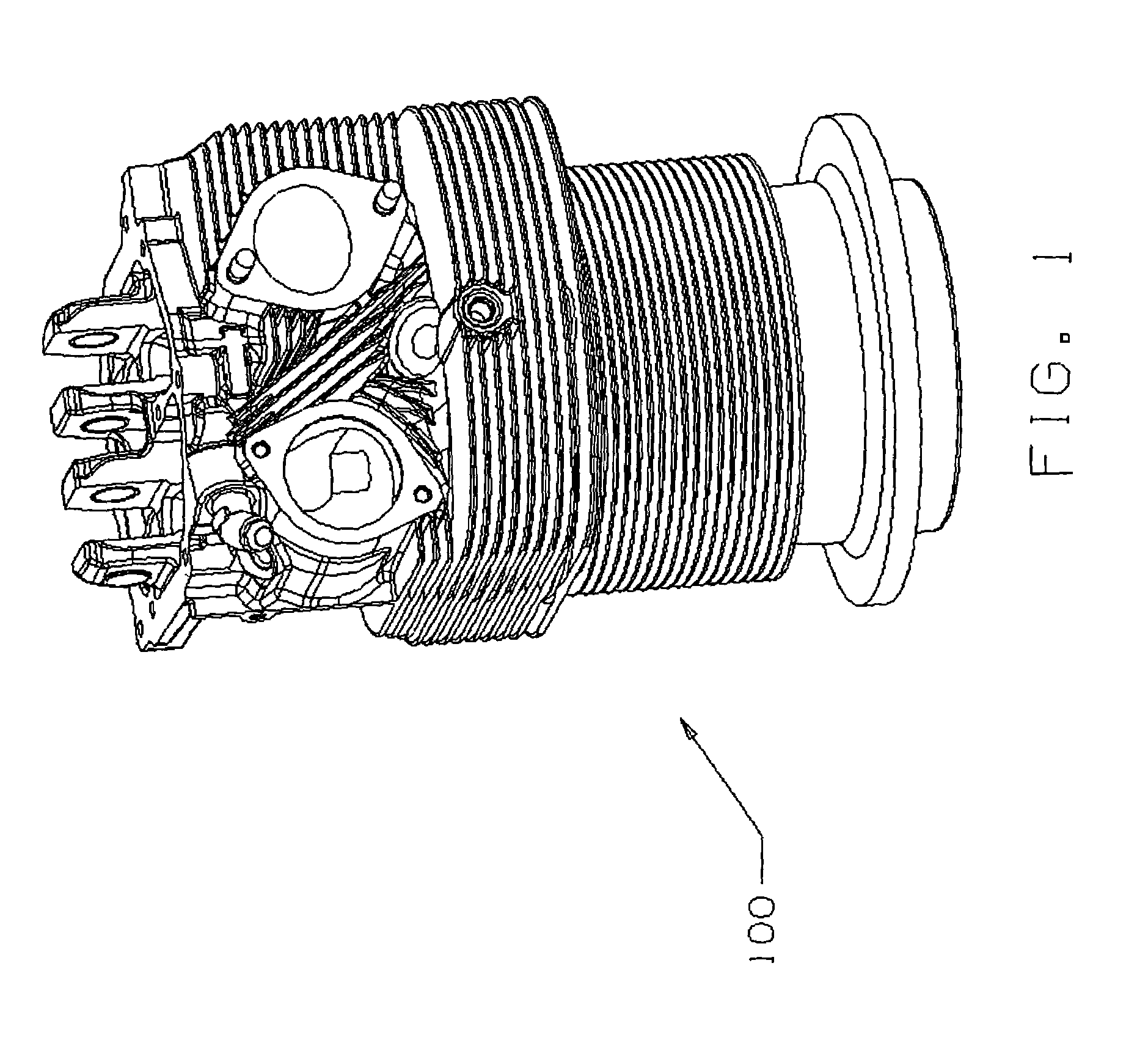

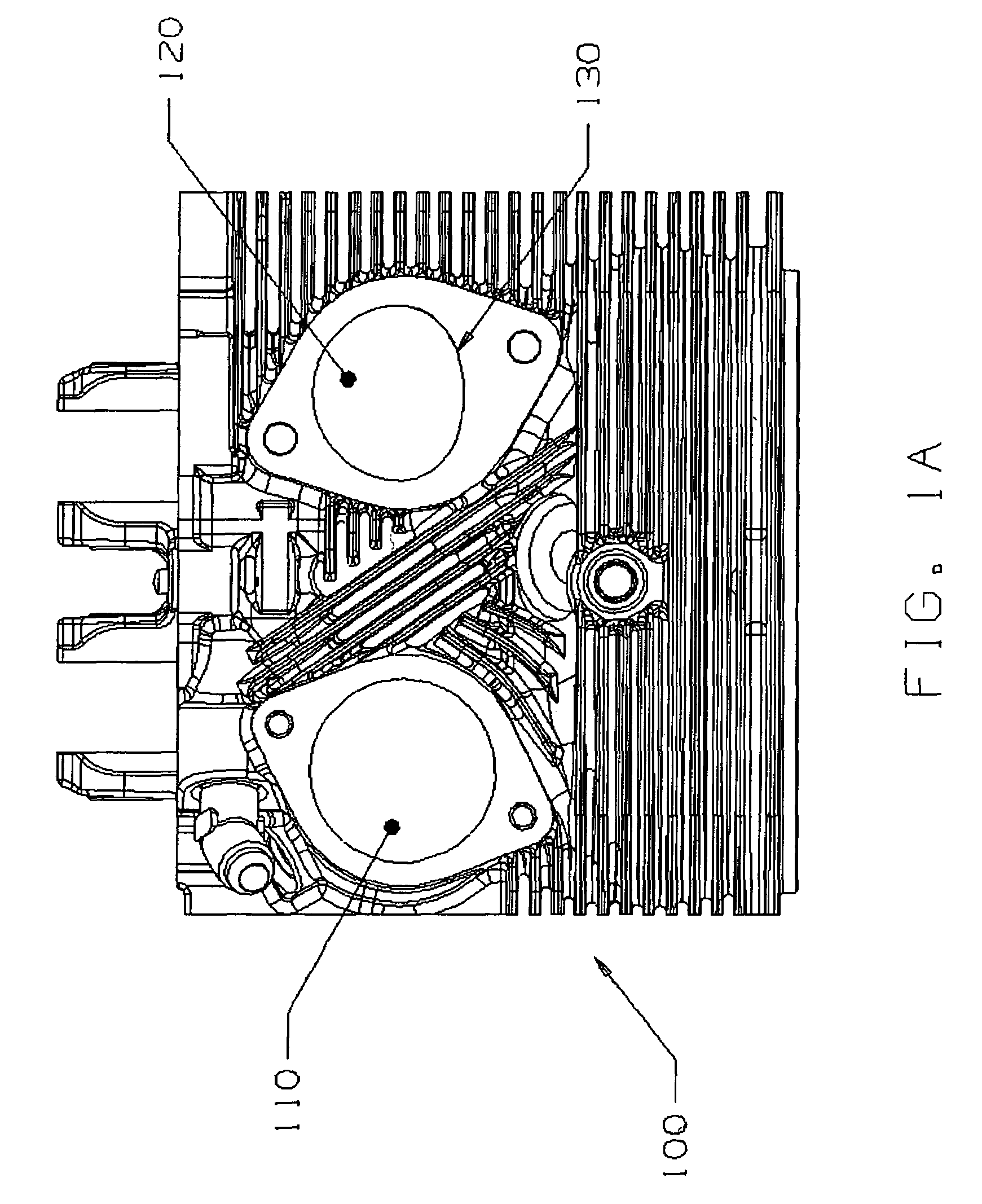

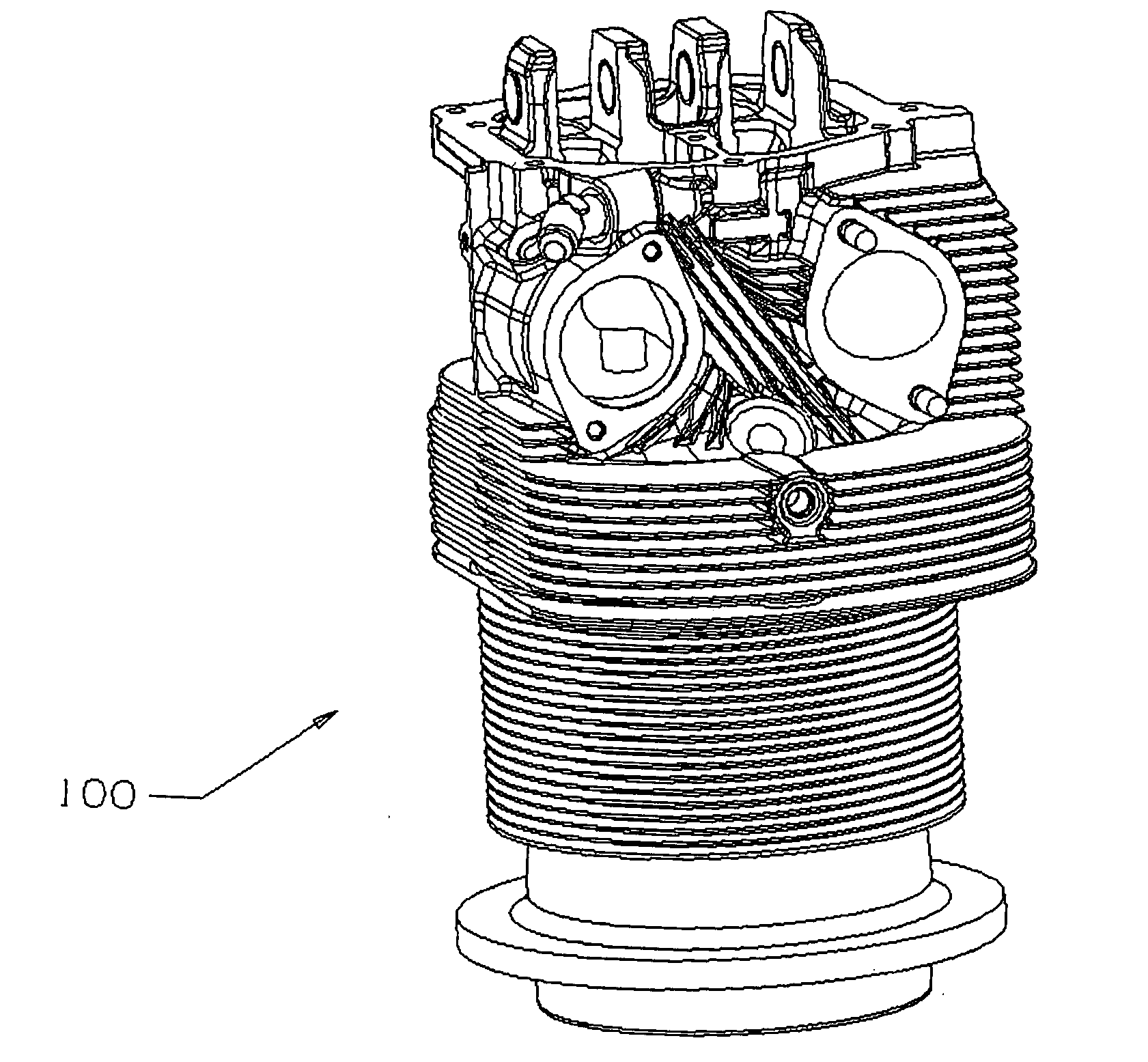

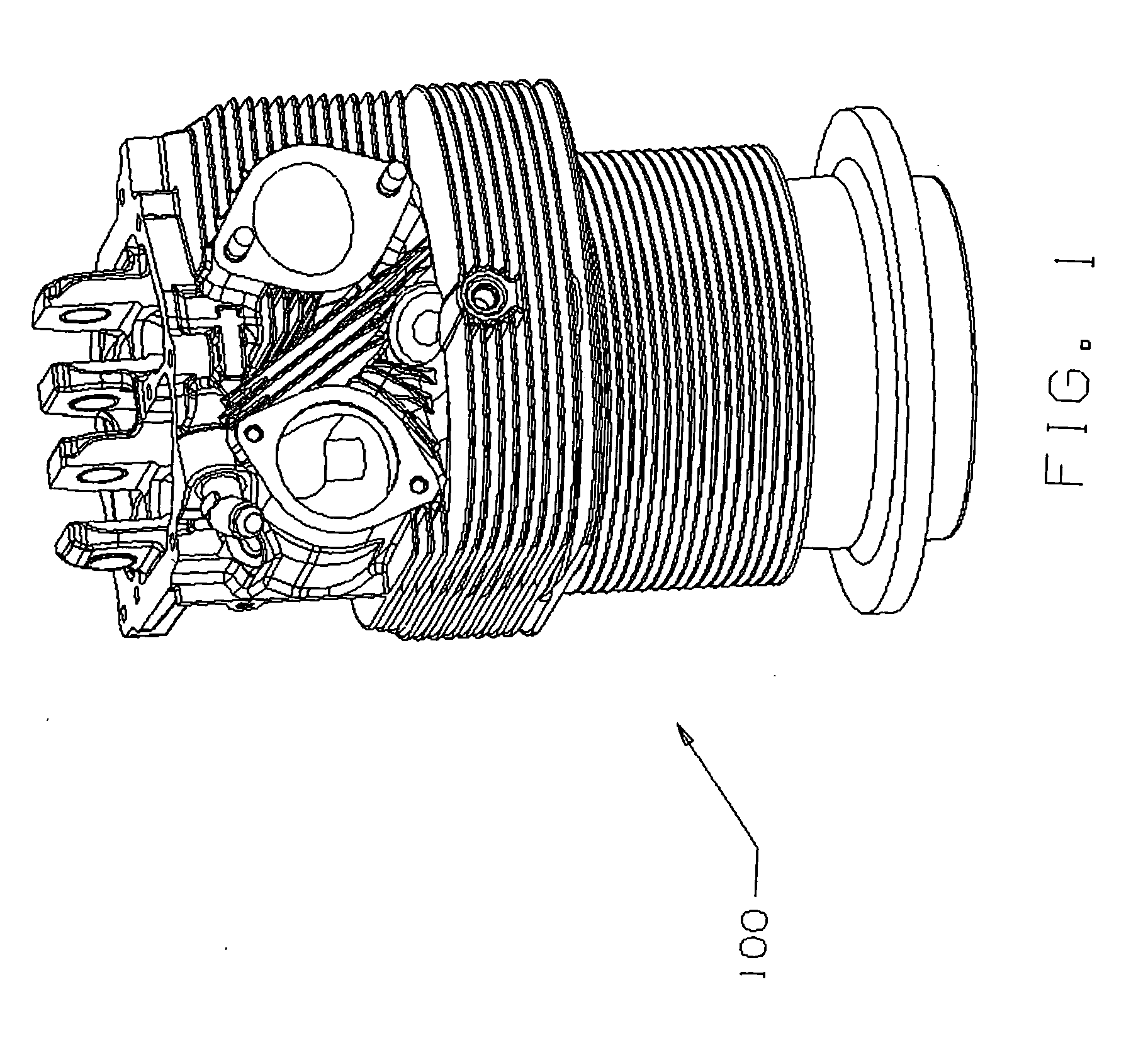

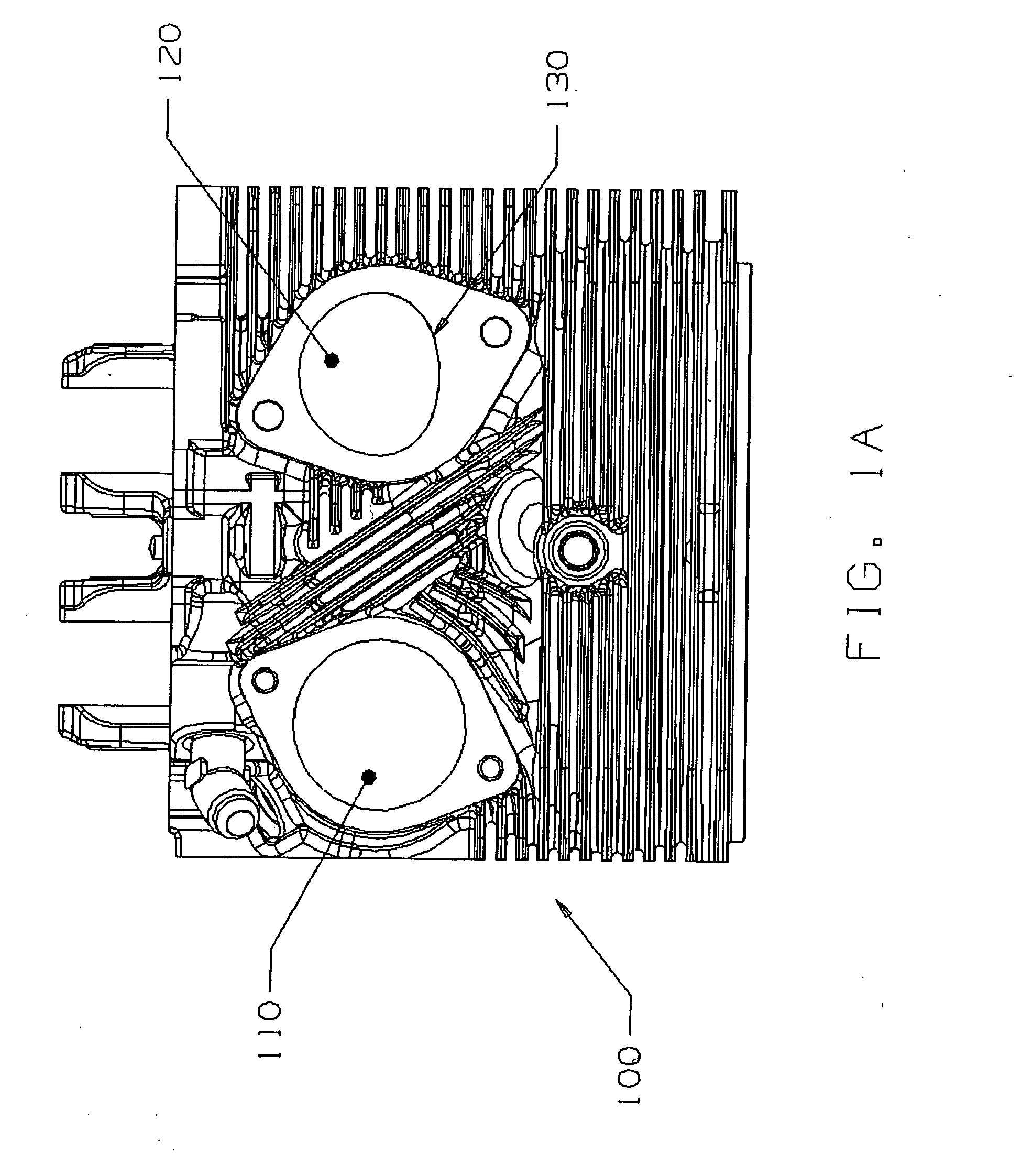

Cylinder head assemblies

ActiveUS7284524B2Increase horsepowerMaintain securityInternal combustion piston enginesCylinder headsExhaust valveCylinder head

Cylinder head assemblies including a cylinder head and a piston are disclosed. The cylinder head includes: a recessed valve region including a first and second bulbous portion connected by a waist, the first bulbous portion accommodating an intake valve and the second bulbous portion accommodating an exhaust valve; an intake port passageway having a gradually contoured flowpath between an intake port and the intake valve in the valve region; and an exhaust port passageway having a gradually contoured flowpath between an exhaust port and the exhaust valve in the valve region. The piston includes a recessed region that substantially conforms to the recessed valve region of the cylinder head. Related overhaul kits and methods of making improved cylinder head assemblies are further disclosed.

Owner:LYCOMING ENGINES A DIV OF AVCO

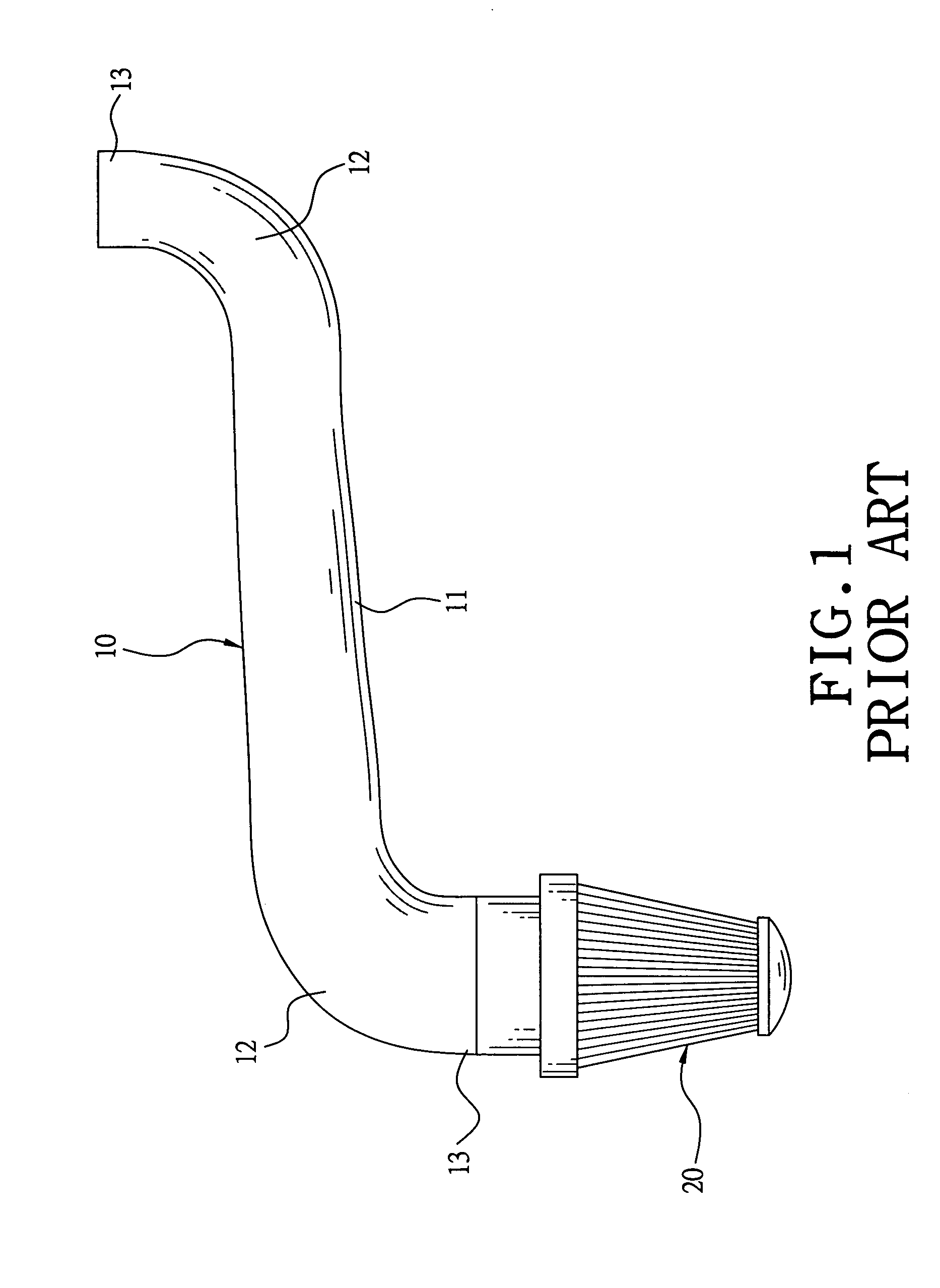

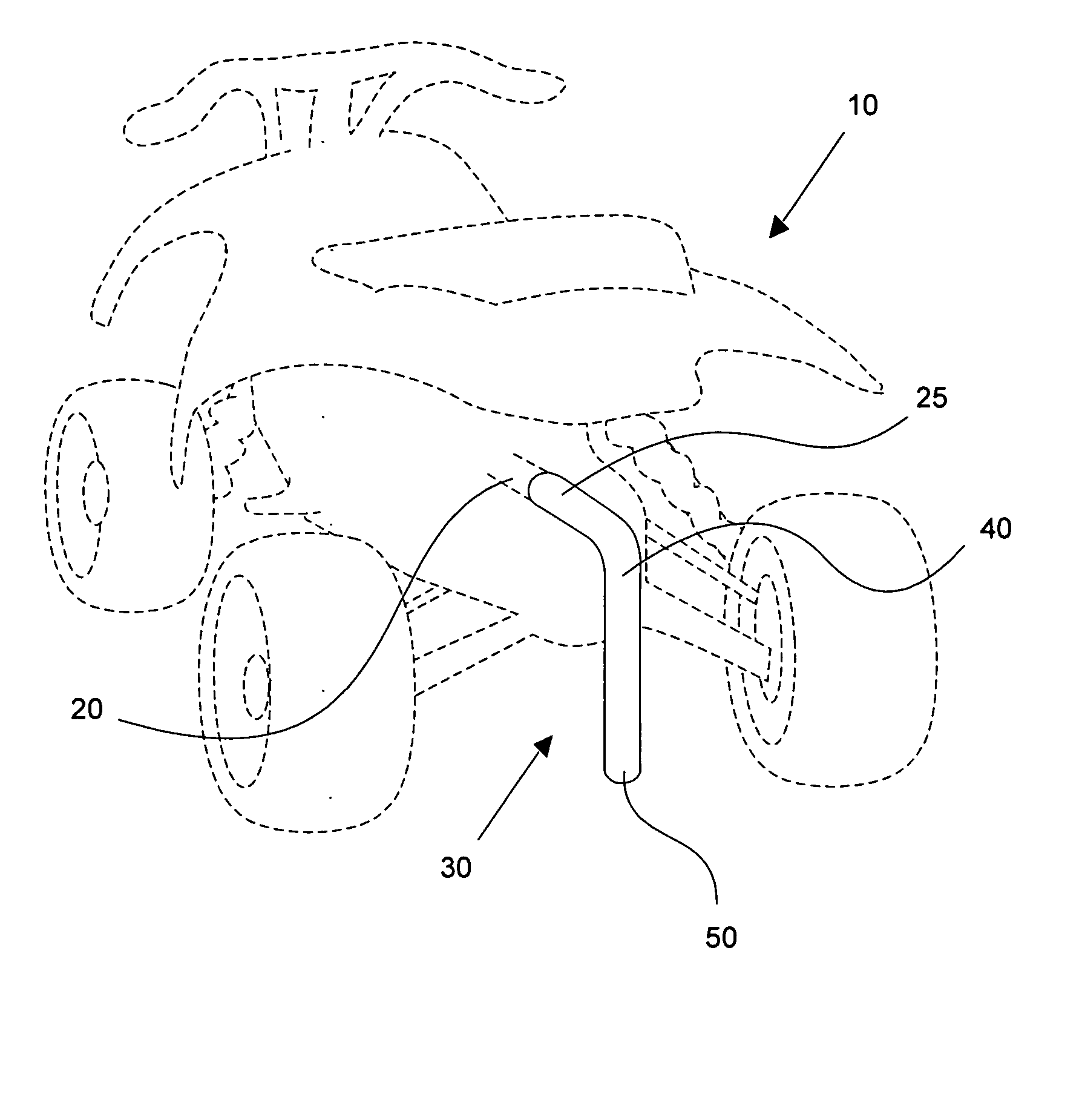

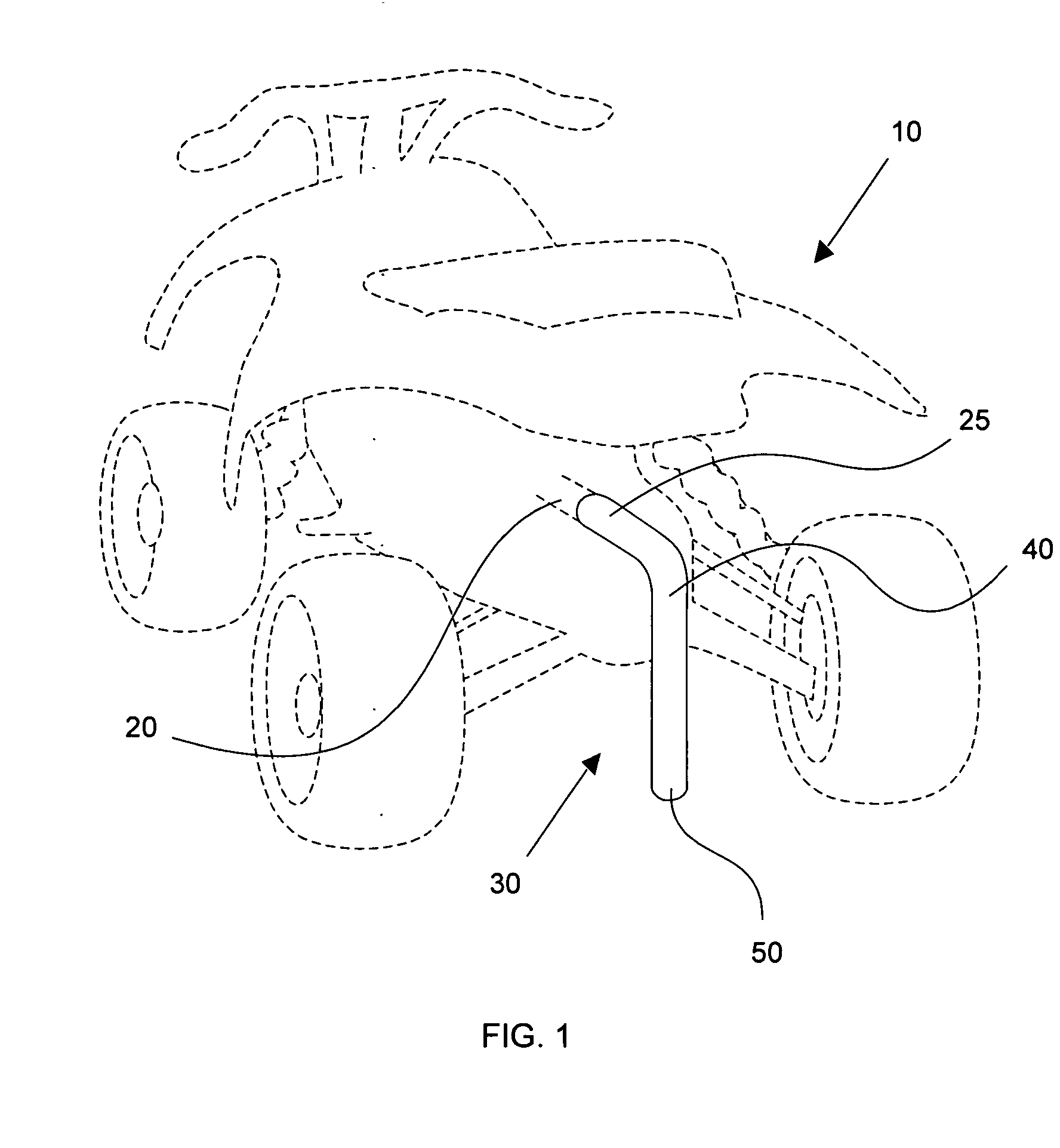

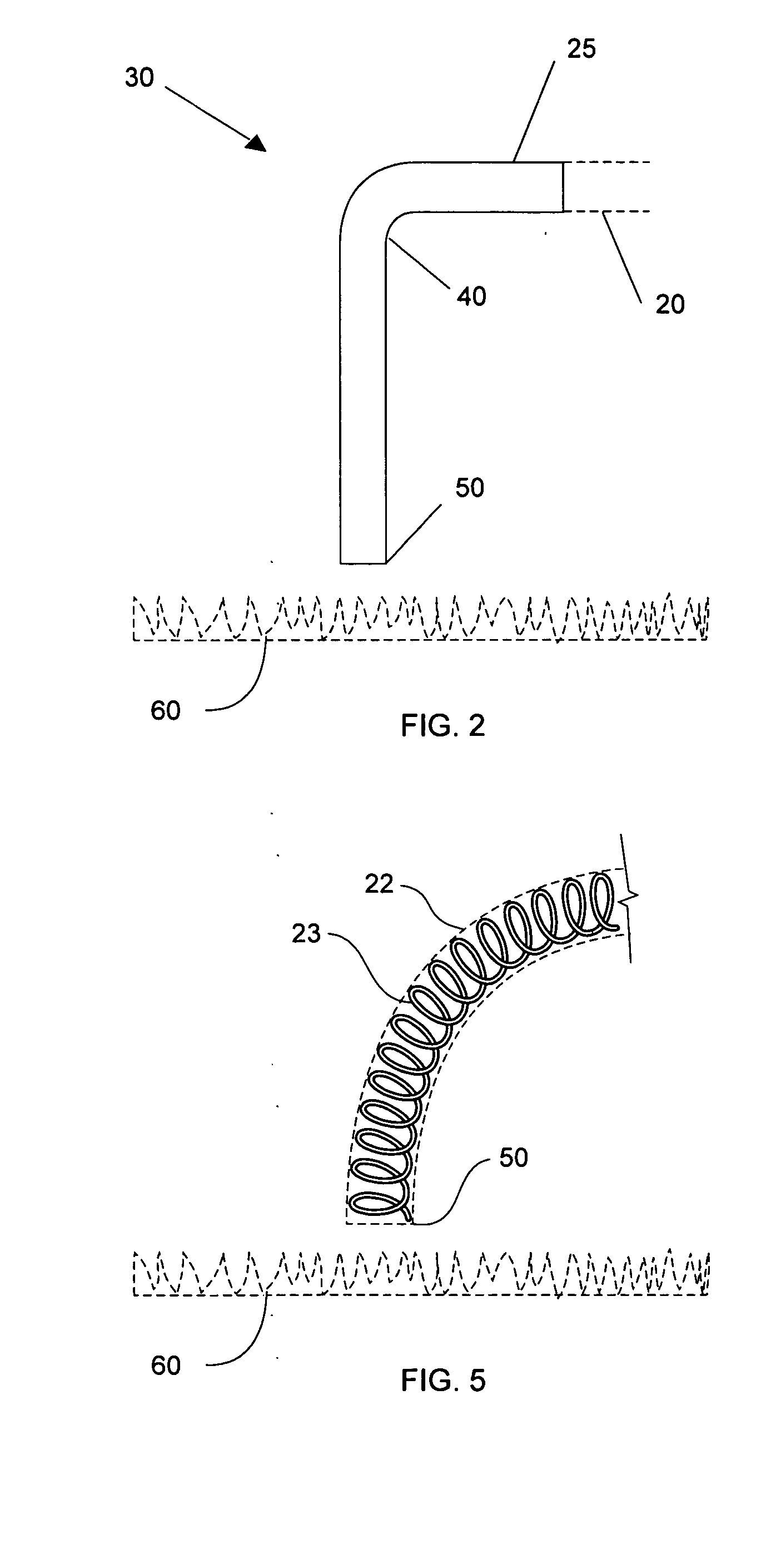

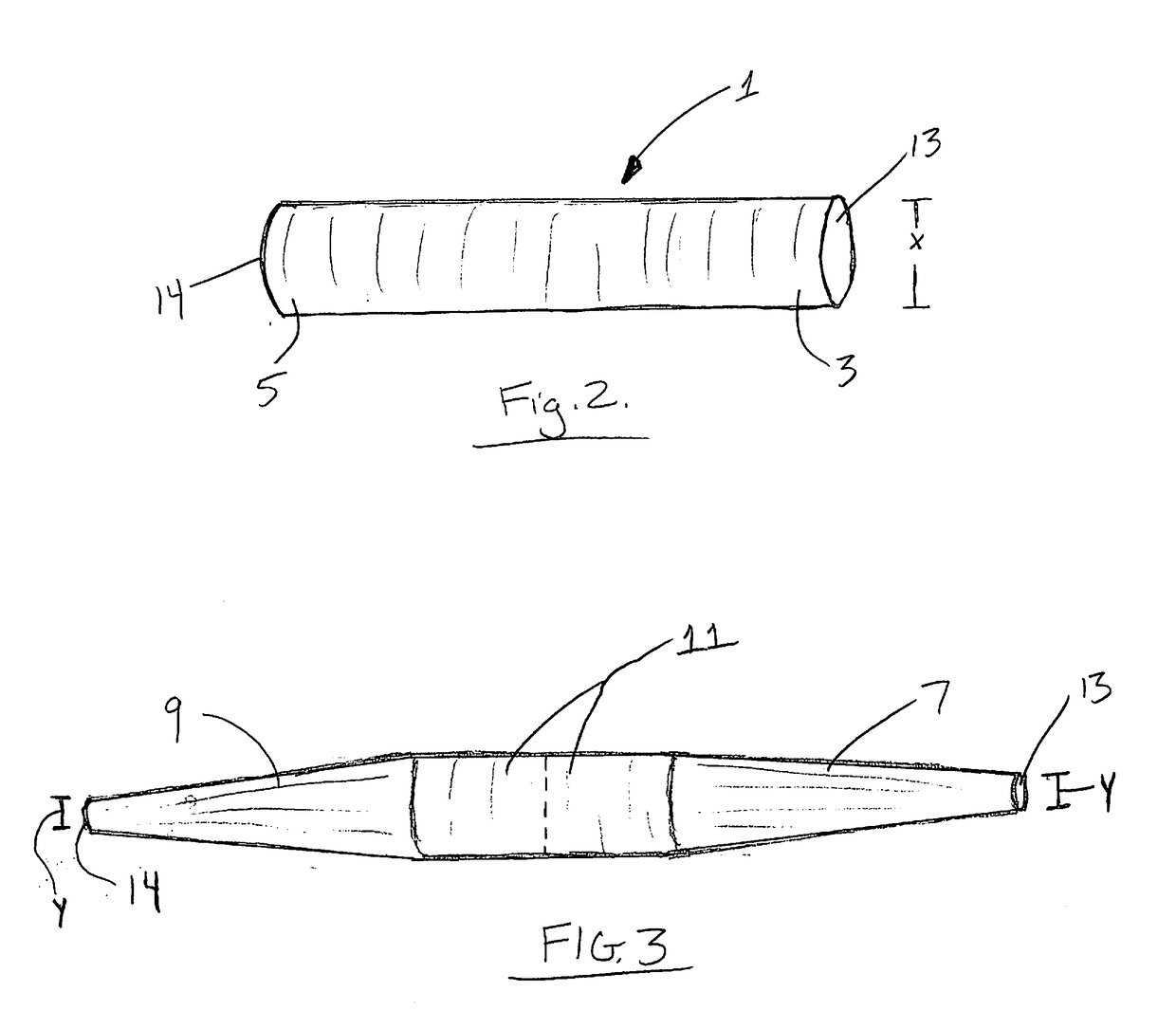

Muffling device and method for internal combustion engine

InactiveUS20050061578A1Reduce exhaust noiseAvoid less flexibilitySilencing apparatusMachines/enginesEngineeringInternal combustion engine

A device and method for muffling the sound from an internal combustion engine is described, wherein the device is a tube made of a suitable material such as rubber and is attached to the exhaust outlet of the vehicle. Further described is a method of muffling the sound of an internal combustion engine that is comprised of taking a length of tubing having a spring disposed therein, and attaching one end of the tubing to the outlet of the exhaust of an internal combustion engine, and directing the other end of the tubing toward the ground surface, by forming an approximate ninety degree bend, such that the second end of the tubing is in close proximity with the ground surface, with the result that the sound level of the exhaust from the engine is substantially reduced.

Owner:SCHULTE FRANCIS

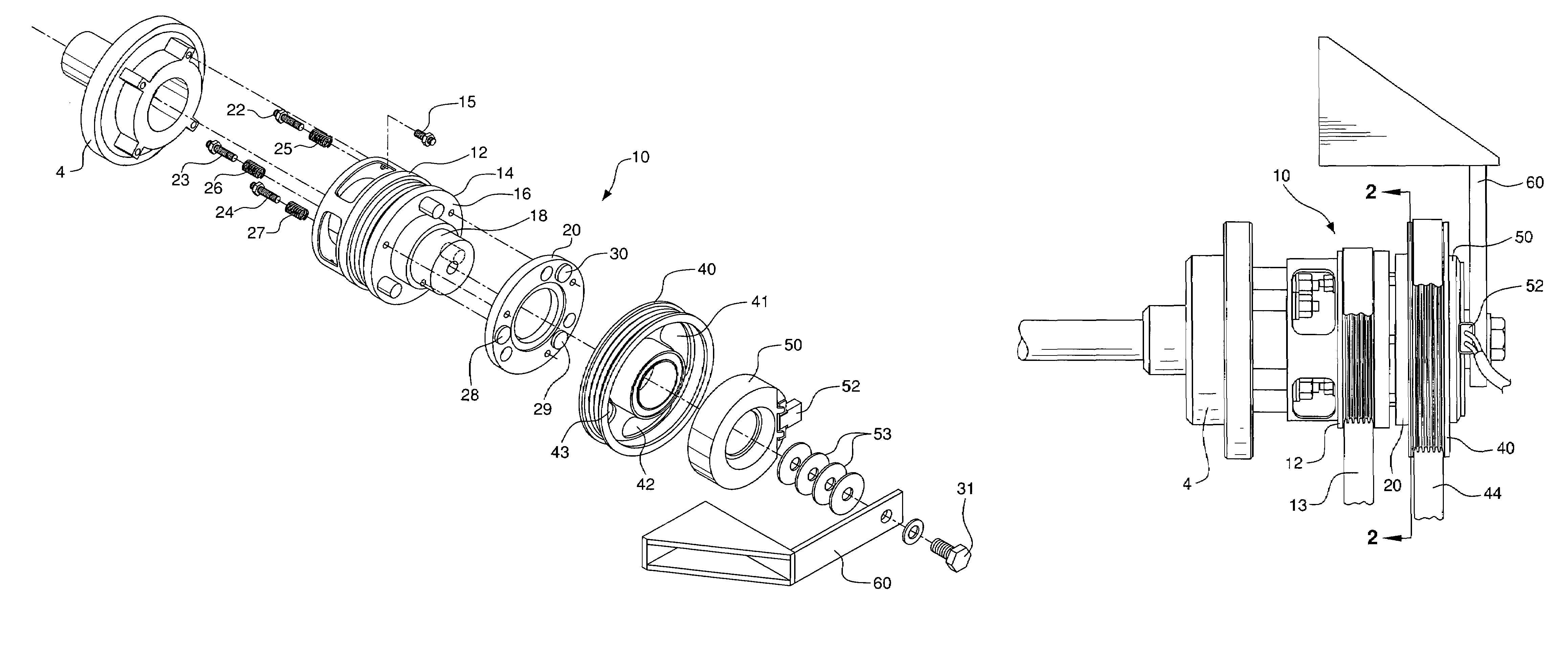

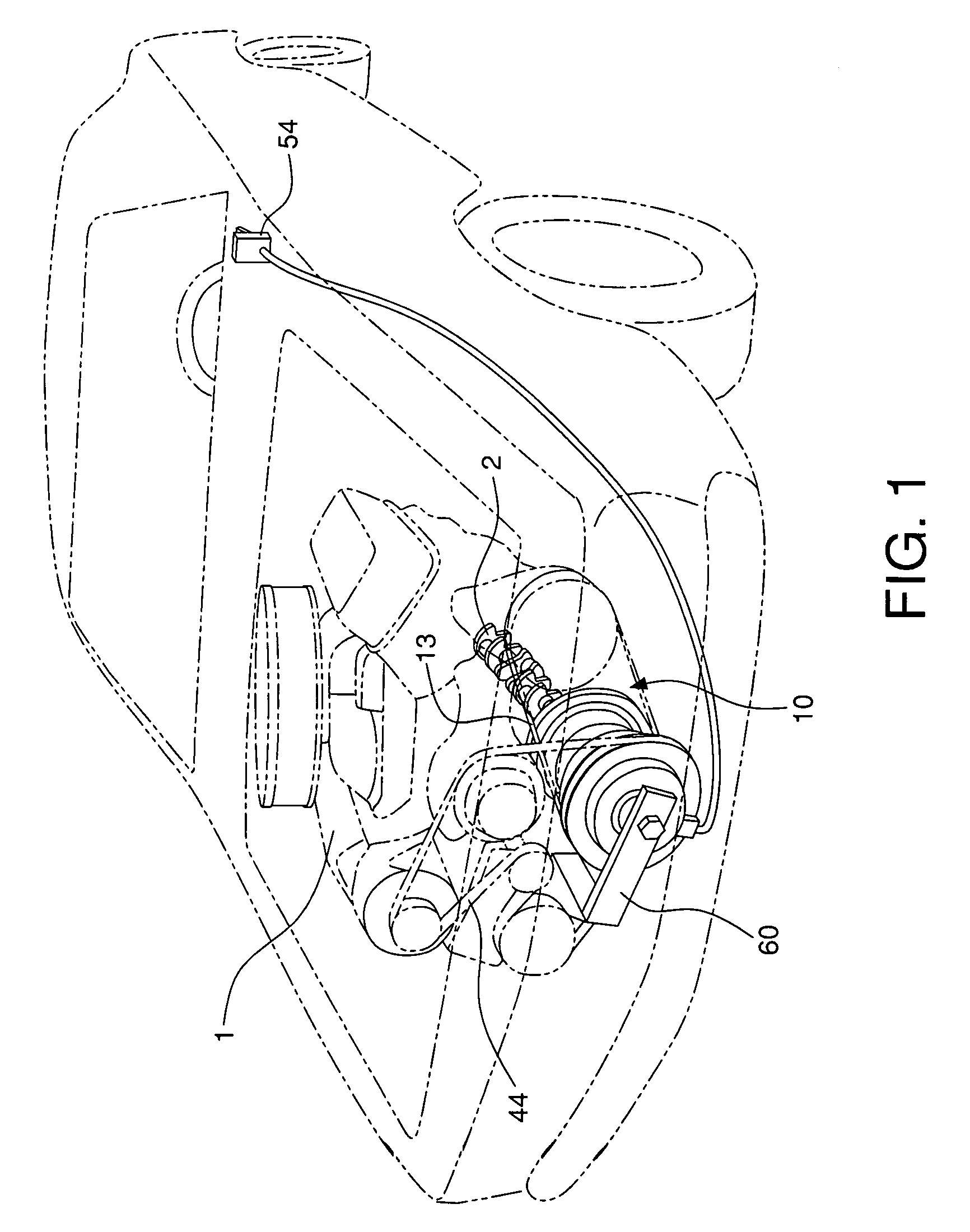

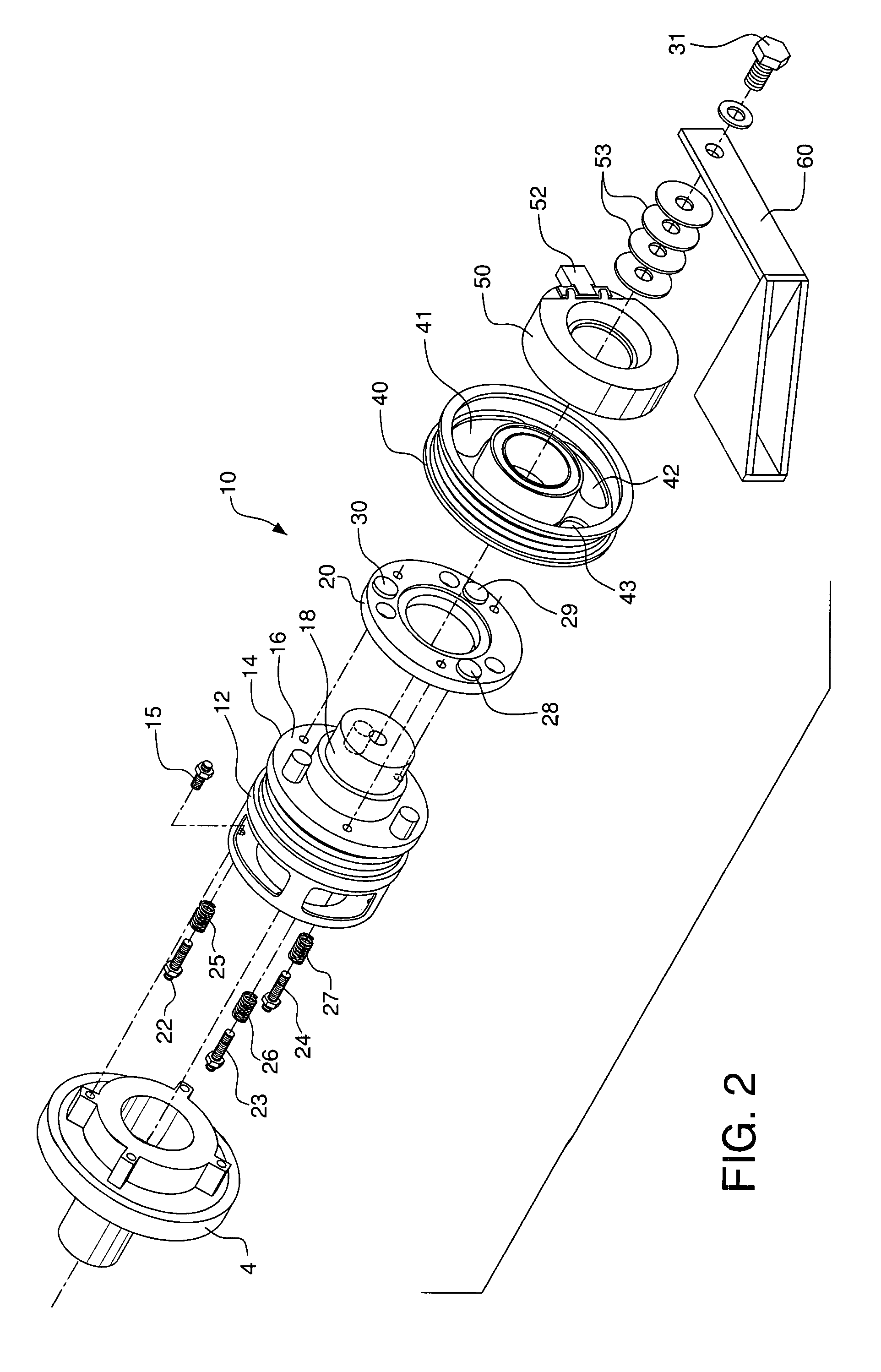

Supercharger control system

A supercharger control system is installed at the bottom front end of the engine, directly onto the crankshaft. An accessory drive belt around the accessory belt pulley rotates continuously to keep vehicle accessories operating. A second belt around a larger pulley drives the supercharger blower. When the dashboard mounted switch is turned on, electricity from the engine energizes an electromagnet, which compels engagement of the rotating accessory pulley with the supercharger pulley by means of a slide plate. The belt around the supercharger pulley then rotates, operating the supercharger. If the driver does not require extra power and performance delivered by the supercharger, the switch is turned off, stopping the flow of electricity. This shuts down the magnetic field, causing the pulleys to be disengaged and disconnecting the supercharger, while still allowing the crankshaft to operate the accessories.

Owner:MACHNER BILLY

Muffler device

InactiveUS6915877B2Decreasing capacityAvoid accumulationSilencing apparatusMachines/enginesUltrasound attenuationBarrier function

A muffler device, in one preferred embodiment, having four barriers therein. Each barrier functions to form an within which the exhaust stream can be partitioned and redirected. Eventually, the exhaust streams are once again recombined and expelled from the muffler. The partitioning and reassembly of the exhaust streams provides sound attenuation while increasing the horsepower of the engine and without resulting in any build up of unignited fuel.

Owner:KHAYALIAN GARABED

Cylinder head assemblies

ActiveUS20060191507A1Increase horsepowerMaintain securityInternal combustion piston enginesCylinder headsExhaust valveCylinder head

Cylinder head assemblies including a cylinder head and a piston are disclosed. The cylinder head includes: a recessed valve region including a first and second bulbous portion connected by a waist, the first bulbous portion accommodating an intake valve and the second bulbous portion accommodating an exhaust valve; an intake port passageway having a gradually contoured flowpath between an intake port and the intake valve in the valve region; and an exhaust port passageway having a gradually contoured flowpath between an exhaust port and the exhaust valve in the valve region. The piston includes a recessed region that substantially conforms to the recessed valve region of the cylinder head. Related overhaul kits and methods of making improved cylinder head assemblies are further disclosed.

Owner:LYCOMING ENGINES A DIV OF AVCO

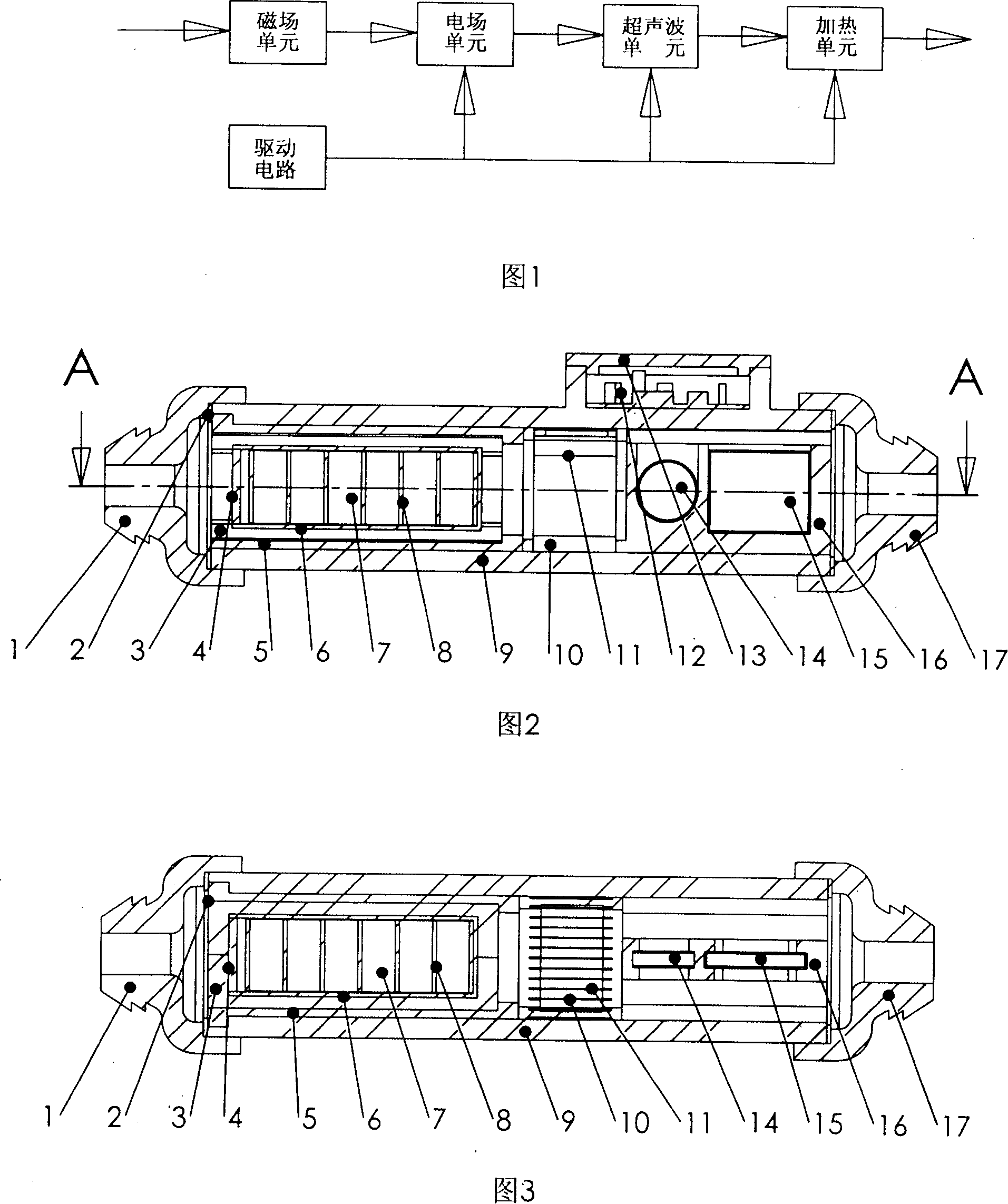

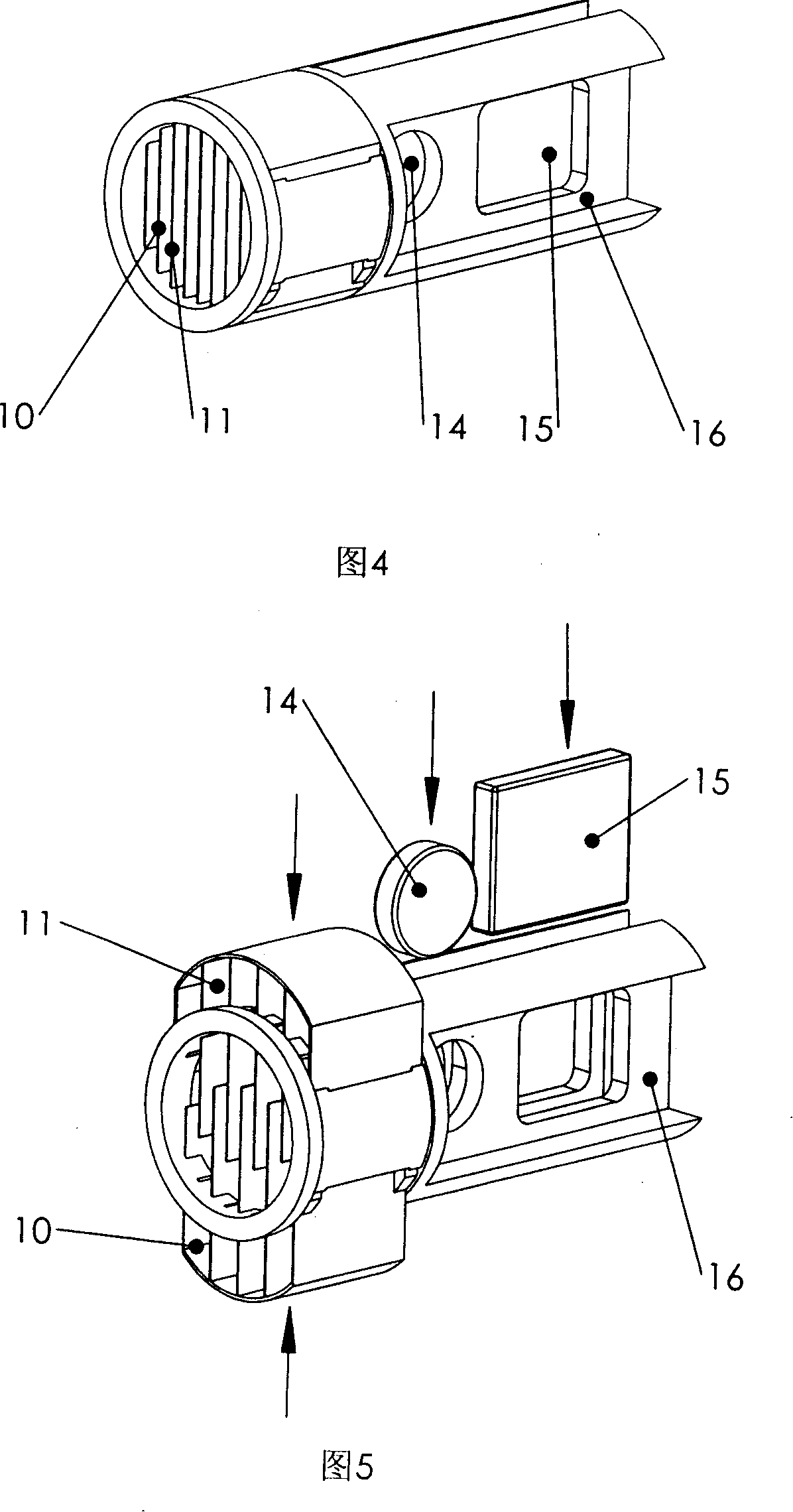

Fluent fuel energy-saving and pollution-reducing purifier

InactiveCN101153715ALow viscosityImprove liquidityLiquid fuel feeder/distributionInternal combustion piston enginesElectricityCombustion

The invention relates to a fuel processing device, in particular relating to a fluid fuel energy saving and pollution reducing purifier, comprising a magnetic field unit, an electric field unit, an ultrasonic wave unit and a heating unit, wherein, the magnetic field unit, the electric field unit, the ultrasonic wave unit and the heating unit are orderly arranged inside a casing which has two ends respectively provided with an inlet and an outlet; the electric field unit, the ultrasonic wave unit and the heating unit are also arranged on an axial direction supporting rack; in addition, the fuel processing device also comprises a drive circuit; the magnetic field unit consists of a shield, a squirrel cage type supporting rack, a sealed cylindraceous magnetic pole sleeve, high energy magnetic sheets and guide magnetic sheets; the electric field unit consists of a cathode and a anode; the ultrasonic wave unit consists of piezoelectric ceramic plates; the heating unit consists of PCT elements. Before the fluid fuel is fired, the invention processes the fuel, causing macro-molecular groups of the fuel to fully fission and be thinned; as a result, the'long chain'of the molecules of the fuel is changed into the 'short chain',the activity of the molecules is fully activated; the invention can greatly improve the combustion efficiency of the fluid fuel, increase power, reduce pollution, protect environment and cut down expenditures.

Owner:张文豪 +1

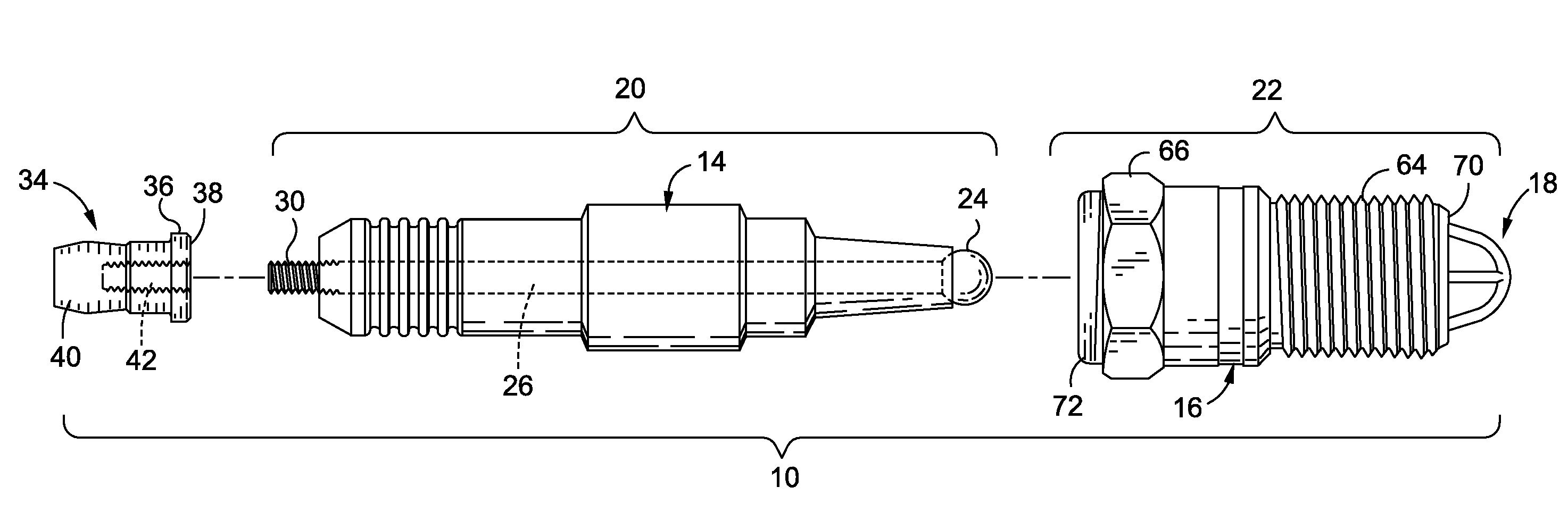

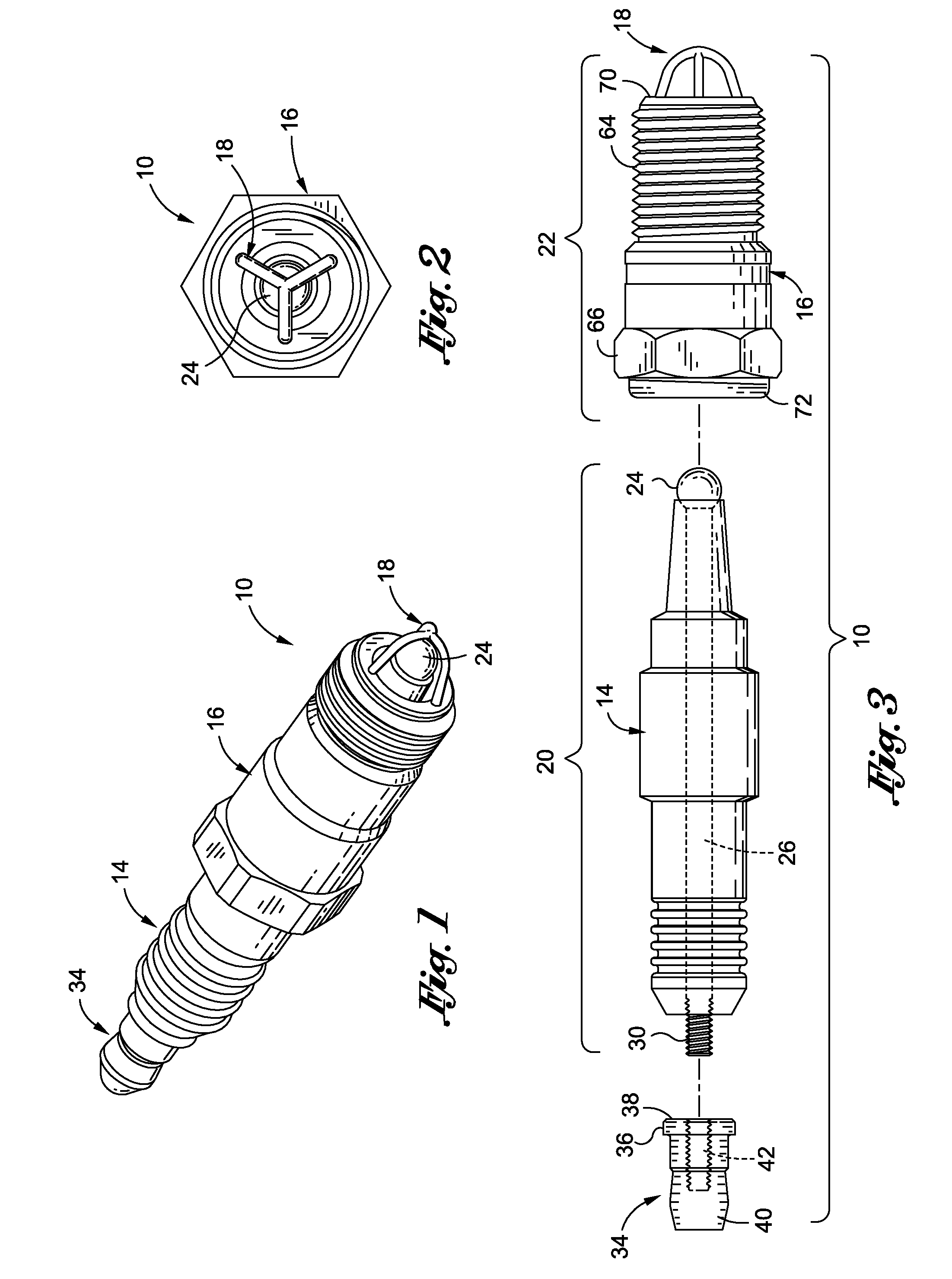

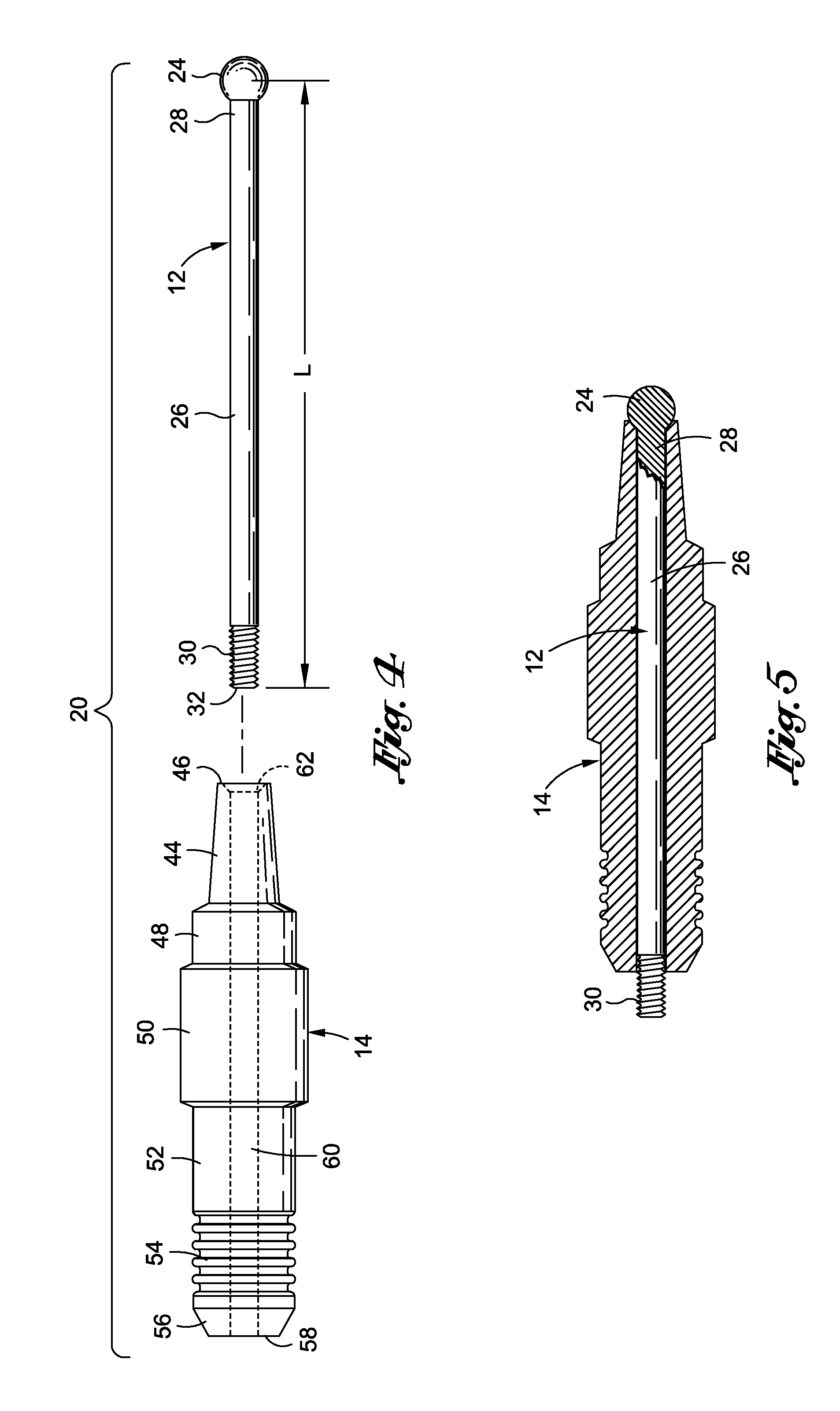

Method of manufacturing a spark plug

InactiveUS20120062098A1Reduce misfireImproves gas mileageSpark gapsSparking plugs manufactureGasolinePeak value

Provided is a manufacturing method for manufacturing a spark plug which produces a spark plug which mitigates misfire and improves gas mileage, peak engine performance, horsepower, and increases the RPM range of the host vehicle. The improved performance of the spark plug is, at least in part, attributable to the spacing between an electrode body and an electrode cage. In particular, the electrode cage extends over the electrode body such that the arcuate members of the electrode cage are equidistantly spaced from the bulbous or spherical electrode body. The manufacturing method described herein results in a spark plug having the above-described configuration, while being formed and assembled at an economical cost.

Owner:HKA INVESTMENTS

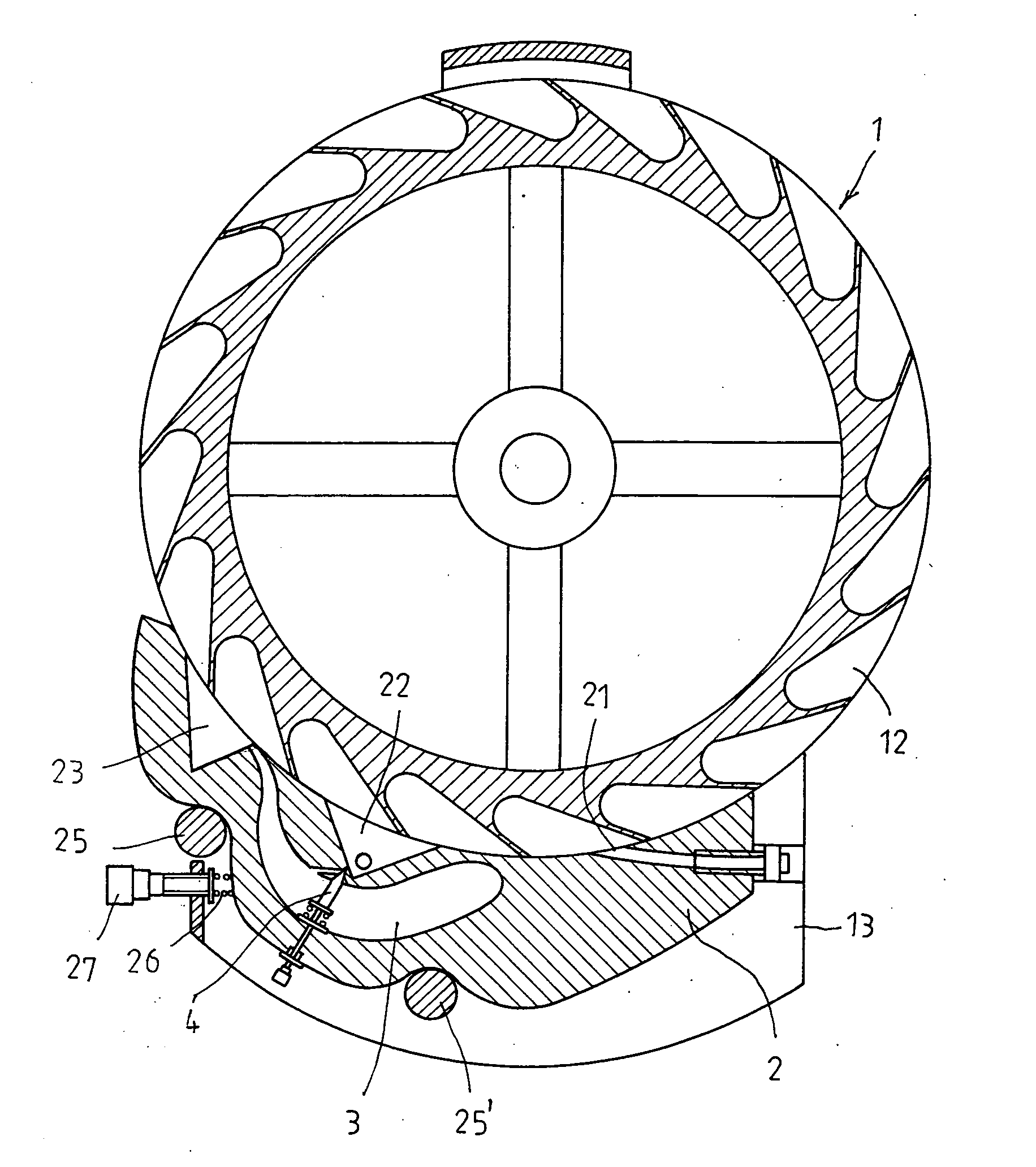

Rotary engine

InactiveUS20050188675A1Improve efficiencyLittle strengthInternal combustion piston enginesGas turbine plantsCombustion chamberRotary engine

A rotary engine includes a round wheel, which has a shaft pivoted on a frame to provide kinetic force during rotating, wherein the round wheel is provided with a plurality of pockets. At least one block is located at a lateral side or round surface of the wheel, which keeps stable contact with the round surface of the wheel by use of elastic force provided by a spring mounted on a screw and provides a suitable oblique angle between the block and the wheel. The block has an aperture, a combustion chamber, and a power room, which are opposite to pockets of the wheel to form quasi cylinders. A roller is fixed on the frame to support and maintain the block in stable. Acting force, which can be produced when mixture fuel is input into the pocket, when the fuel is ignited and exploded in the combustion chamber, and when expansion gas is exhausted into the power room, pushes the wheel to rotate continuously for outputting efficient kinetic force for utilization.

Owner:CHOU JUNG KUANG

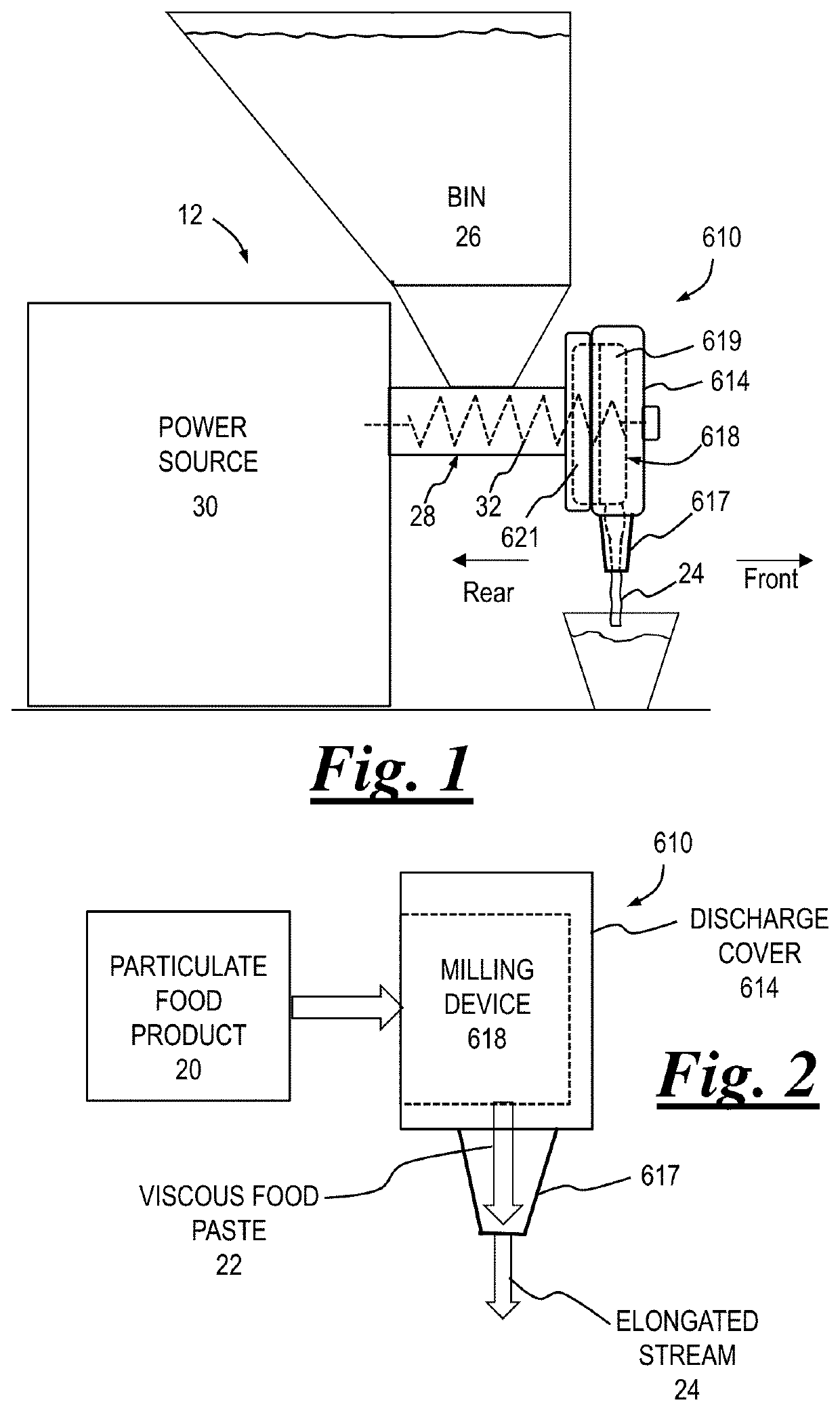

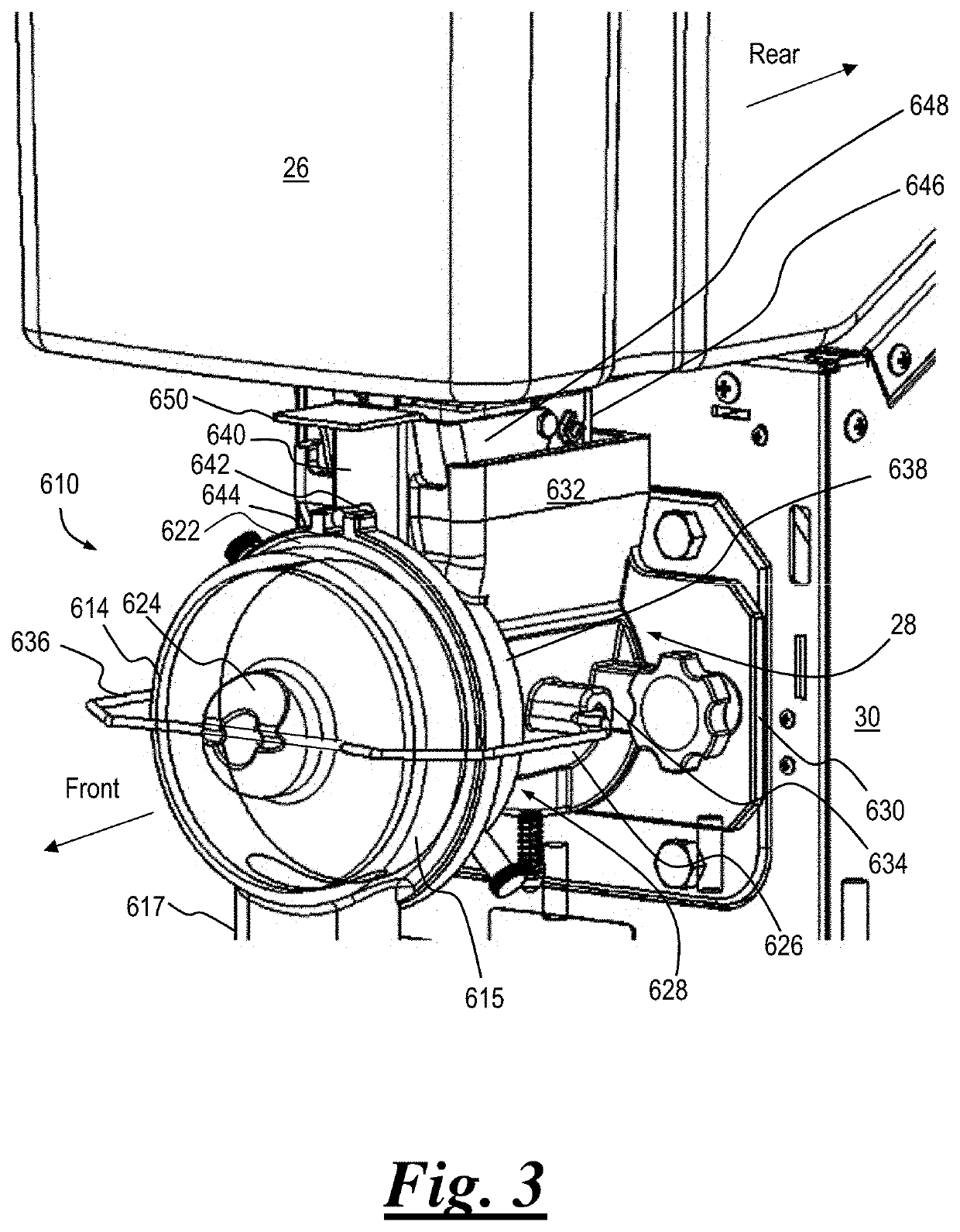

Viscous food product grinding and dispensing system

ActiveUS20200290054A1Increase distanceIncrease the gapCoffee millsSpice millsIngested foodFood products

A viscous food dispensing system includes a chute inlet configured to funnel particulate food product into a sleeve and a transport device having an over-center cutout. The transport device is configured to rotate within the sleeve to convey the particulate food product. A processing surface extends downward from the chute inlet towards a curved base of the sleeve along a portion of the transport device. The processing surface is spaced laterally apart from the transport device to define a processing zone between the processing surface and the transport device. The particulate food product is processed as the particulate food product is captured between a leading edge of the over-center cutout and the processing surface while the transport device is rotating.

Owner:TRADE FIXTURES

Gas directing system and method

InactiveUS7263961B2Increase horsepowerPromote combustionInternal combustion piston enginesExhaust apparatusFirst pathwayEngineering

An gas directing / exhaust system and method are provided. The gas directing system has an gas directing mechanism. The gas directing mechanism has different embodiments. In some embodiments, the gas directing mechanism has a first pathway and a second pathway. In other embodiments, the gas directing mechanism has a second pathway and one or more first pathways located inside of the second pathway. In other embodiments, the gas directing mechanism has the first and second pathways and a third pathway inside of the second pathway.

Owner:NOW LEO

Muffler and/or exhaust apparatus and method of manufacture

InactiveUS20170314435A1Improve engine performanceImprove flow characteristicsSilencing apparatusMachines/enginesPulp and paper industryMuffler

Mufflers with unique configurations which, in certain (but not all) embodiments, improve engine performance. In other embodiments, improved manufacturing processes and methods for making mufflers. In particularly preferred embodiments, methods for making motorcycle mufflers with swaging techniques. In still other preferred embodiments, swaged motorcycle mufflers with improved exhaust flow. In still other embodiments, aftermarket mufflers which can be assembled to a variety of engine exhaust systems utilizing a universal coupler.

Owner:TORQUE RES & DEV INC

Variable air inflow structure of engine

InactiveCN102094735AReduce air intakeHigh torqueCombustion-air/fuel-air treatmentMachines/enginesLow speedMiniaturization

The invention discloses a variable air inflow structure of an engine. The variable air inflow structure is mainly characterized in that an air inflow manifold is arranged between an air cleaner and a variable air inflow structural member of a motorcycle; the air inflow manifold comprises a high-speed manifold and a low-speed manifold; the front end of the high-speed manifold is provided with the variable air inflow structural member, and the other end of the high-speed manifold is connected with the air cleaner through a first inlet, wherein the high-speed manifold is provided with a rotary valve; the low-speed manifold is arranged between the rotary valve of the high-speed manifold and the variable air inflow structural member in an extending manner; the other end of the low-speed manifold is connected with the air cleaner through a second inlet, and forms an air duct with an annular wall by means of a baffle plate in the air cleaner; and the flow duct of the low-speed manifold can be prolonged in a limited space, so that the performance of high and low speed of the engine is considered simultaneously, and the efficacy of miniaturization of the low-speed manifold can be achieved.

Owner:KYMCO

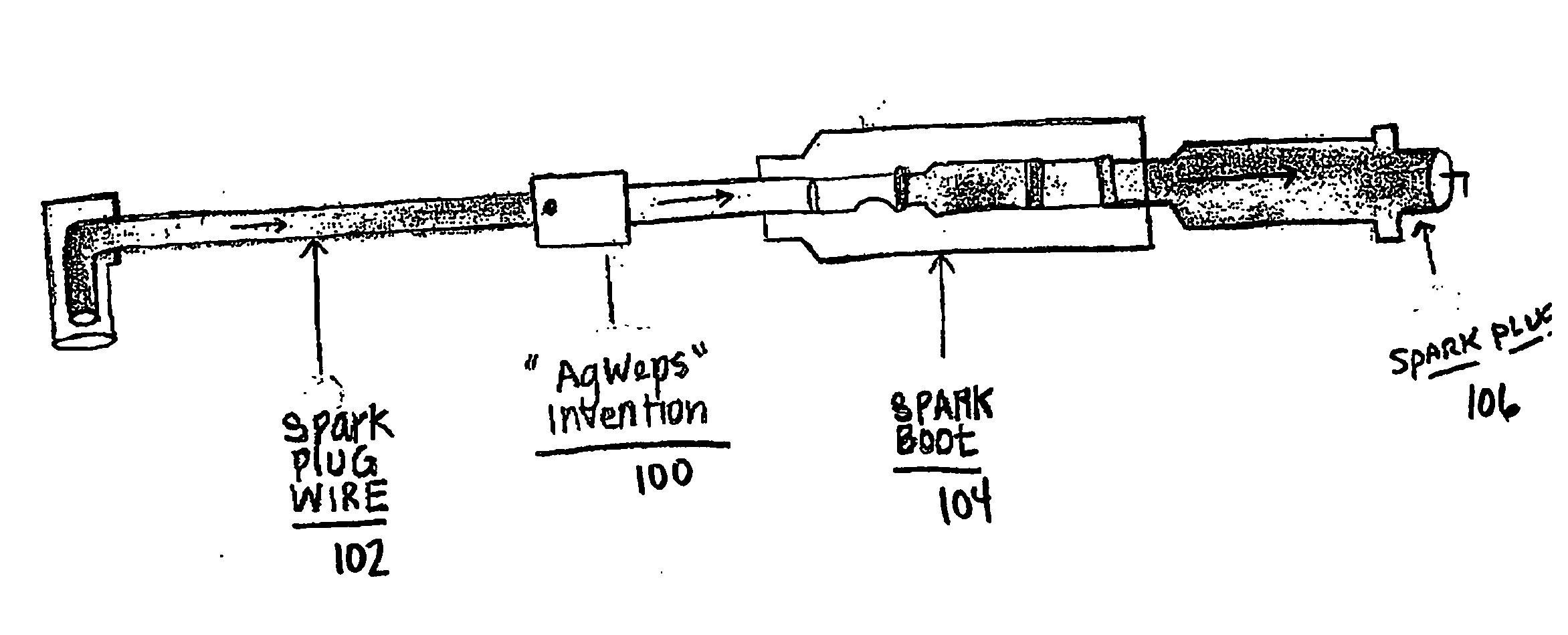

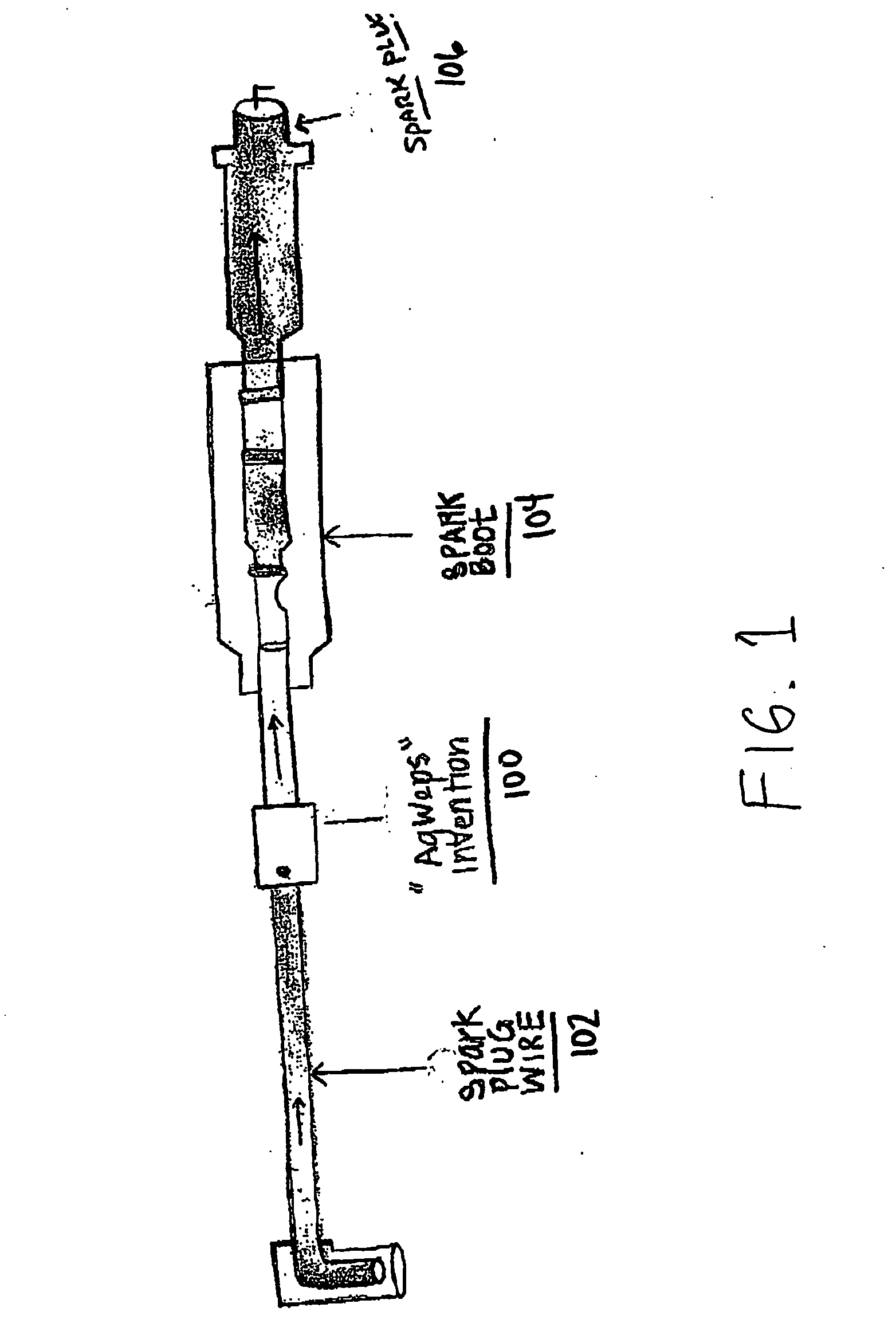

Anti global warming energy power system and method

InactiveUS20080271723A1Increase powerClean burningNon-insulated conductorsInsulated cablesElectricityCombustion chamber

A piezo-ceramic device is attached to the power wire of an engine to facilitate cleaner burning of fuel and improve to improve fuel consumption. In the presence of an electrical field around the power wire, the device directs acoustical energy of a subsonic frequency towards the combustion chamber which acts to ionize the fuel and impart a thrust on the piston.

Owner:COWDEN RALPH A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com