Variable air inflow structure of engine

An intake structure and variable technology, applied in the direction of combustion air/combustion-air treatment, engine components, machines/engines, etc., can solve the problems of not being able to meet the requirements of intake efficiency and performance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make it easier to understand the structure of the present invention and the effect that can be achieved, it is described as follows in conjunction with the drawings:

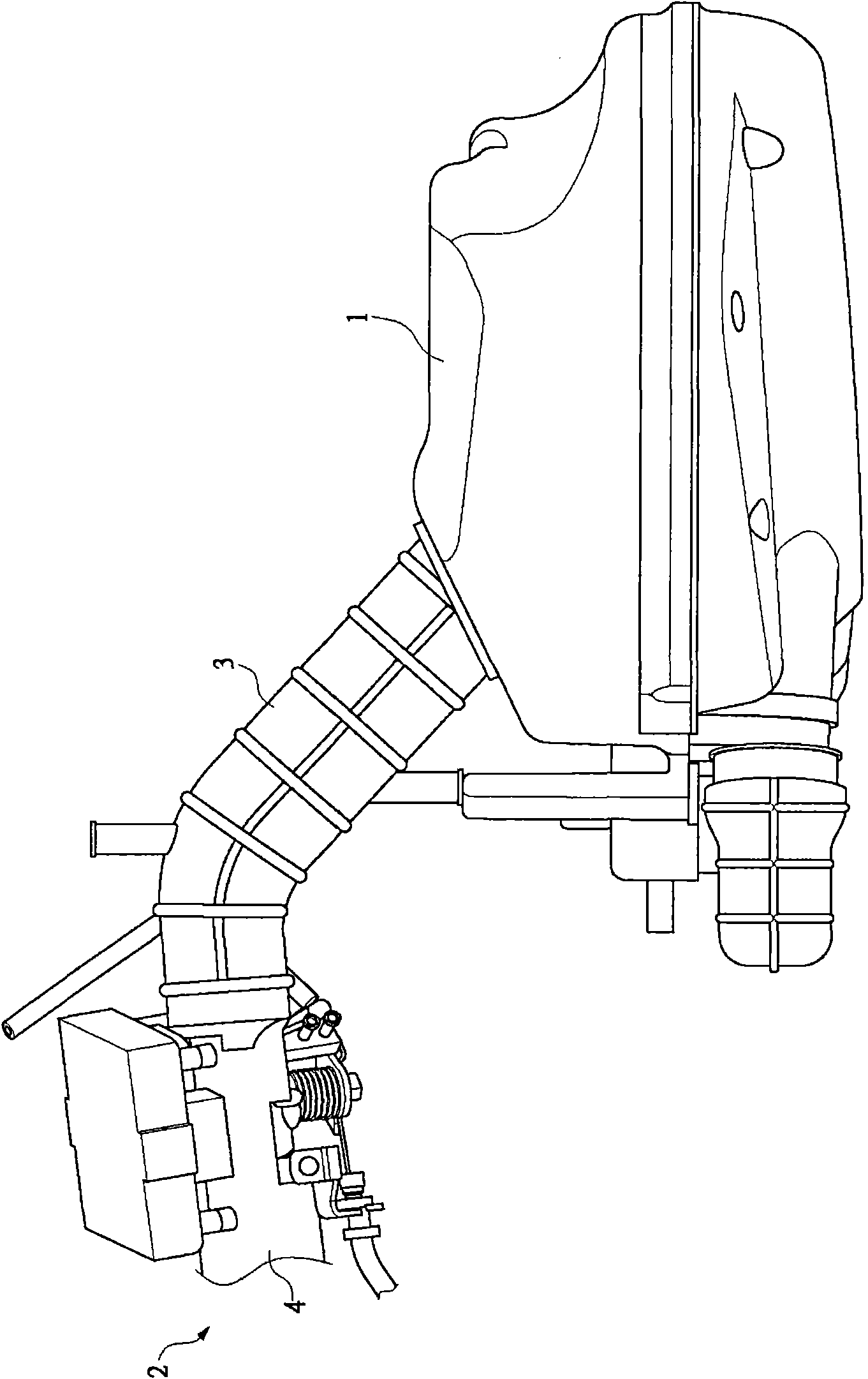

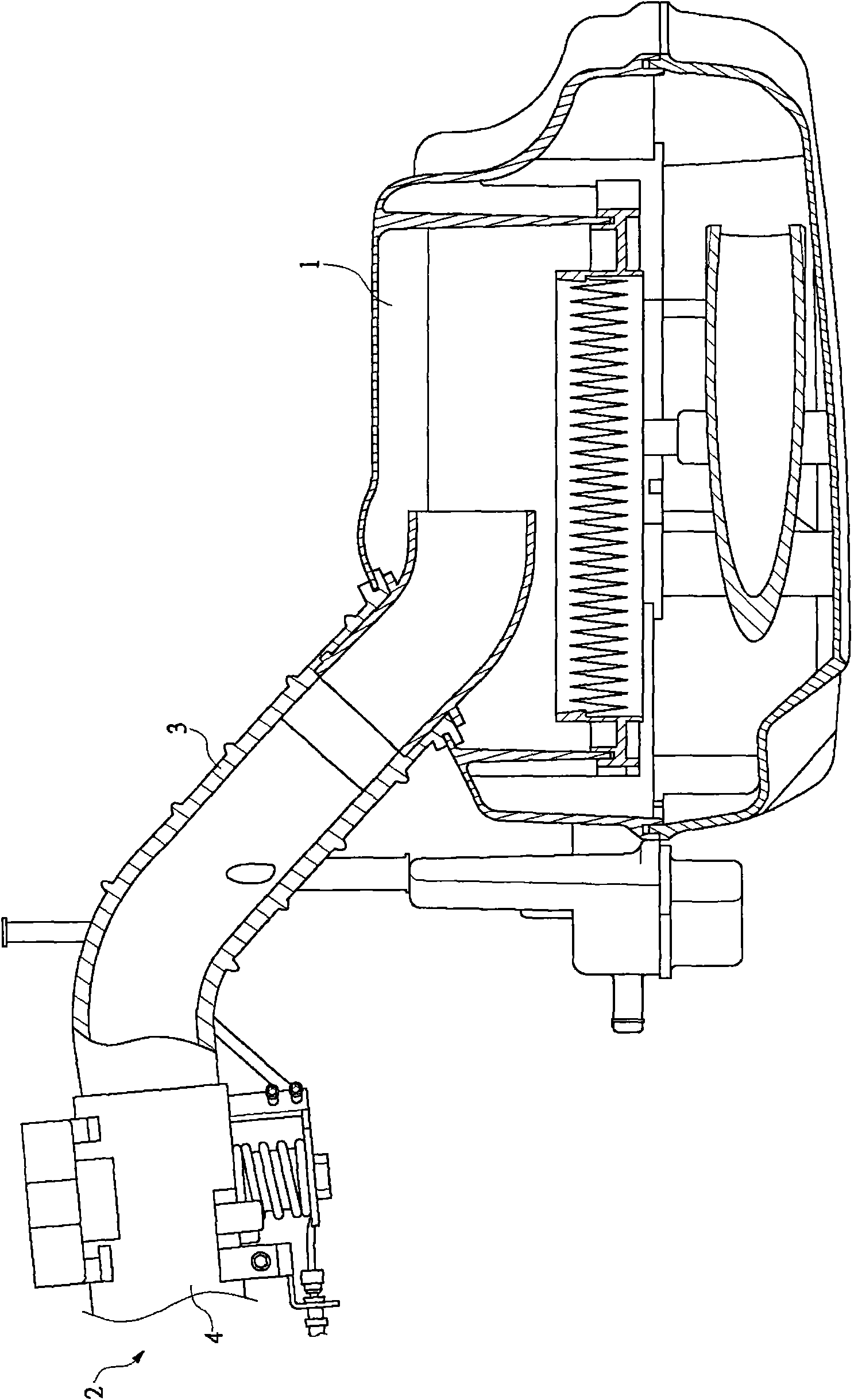

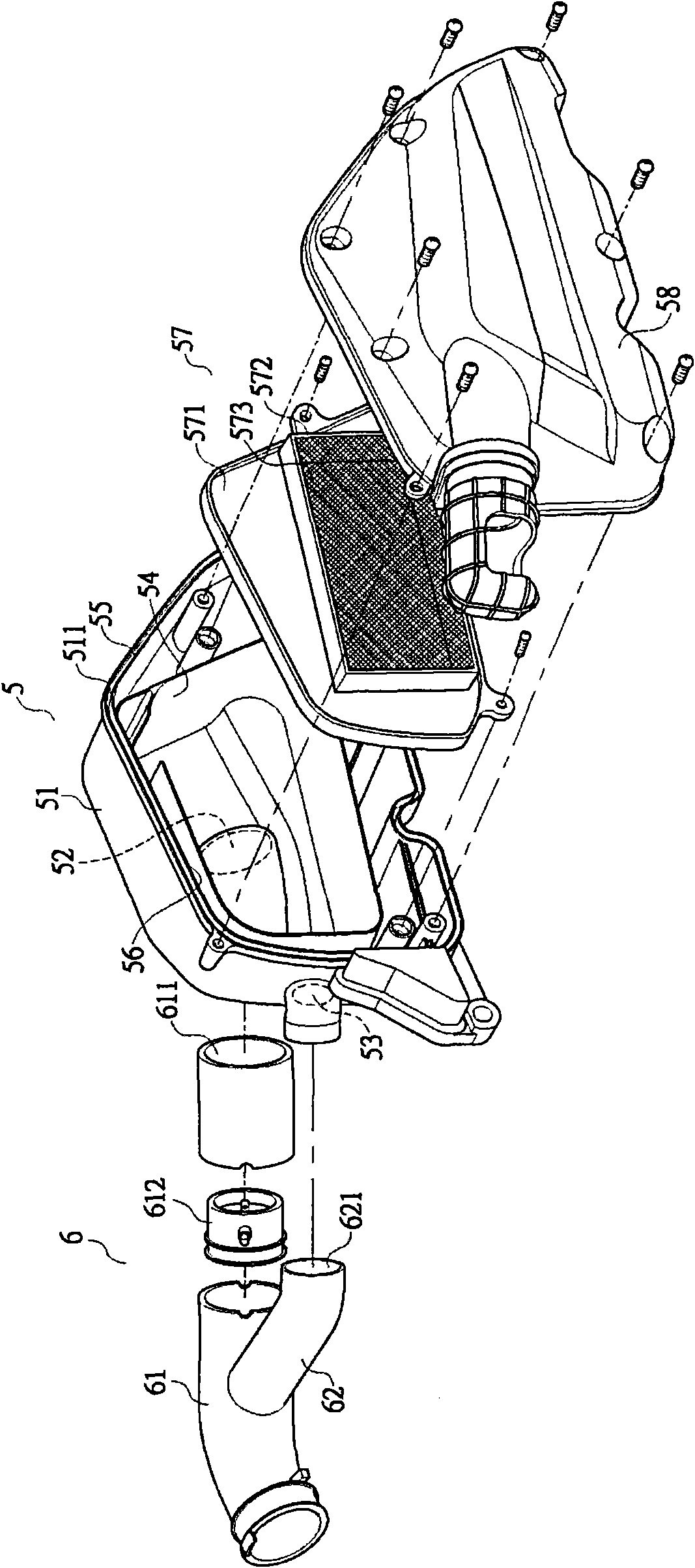

[0036] First, see image 3 , 4 As shown, the engine variable intake structure of the present invention at least includes an air filter 5, an intake manifold 6, an intake variable member (which can be a carburetor or a throttle body) 7 (hereinafter only Take the throttle body as the implementation description of this case).

[0037] The air filter 5 has a box body 51, a first air inlet 52 and a second air inlet 53 are arranged at its front end, and an intake manifold 6 is connected to the front end of the first air inlet 52, and an air intake manifold 6 is arranged at the front end of the first air inlet 52. The inside of the box body 51 is provided with a partition plate 54 that surrounds the box body 51. The partition plate 54 and the ring wall 55 of the box body 51 can just form an air pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com