Lemniscate spiral air inlet supercharger

A technology of helical air intake and double kink wire, which is used in machines/engines, components of pumping devices for elastic fluids, non-variable volume pumps, etc., can solve the problem of low efficiency, limited air supply, and limited increase Compressor development and other issues, to achieve the effect of improving emissions, improving supercharger efficiency, reducing intake air flow resistance and flow energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

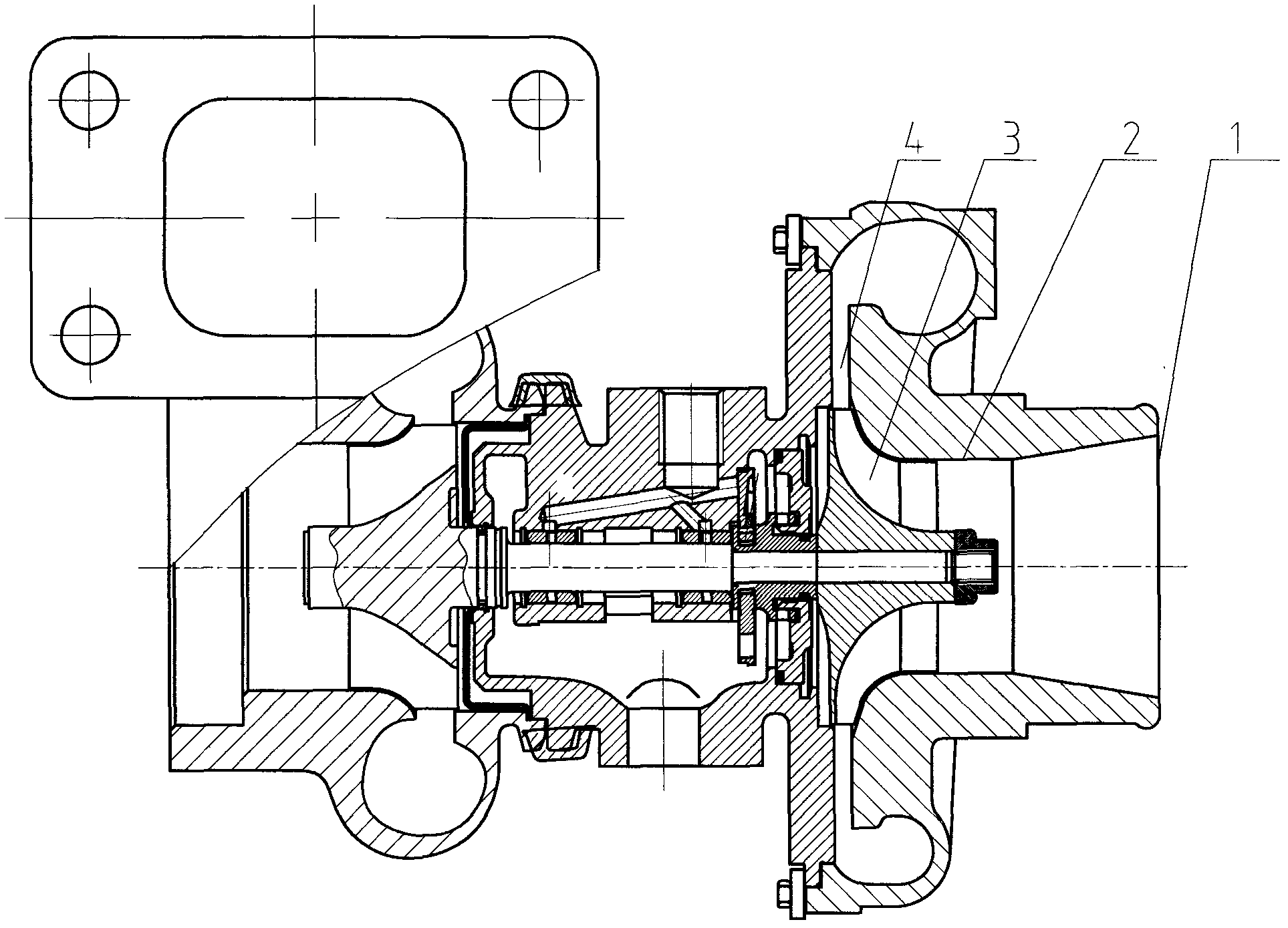

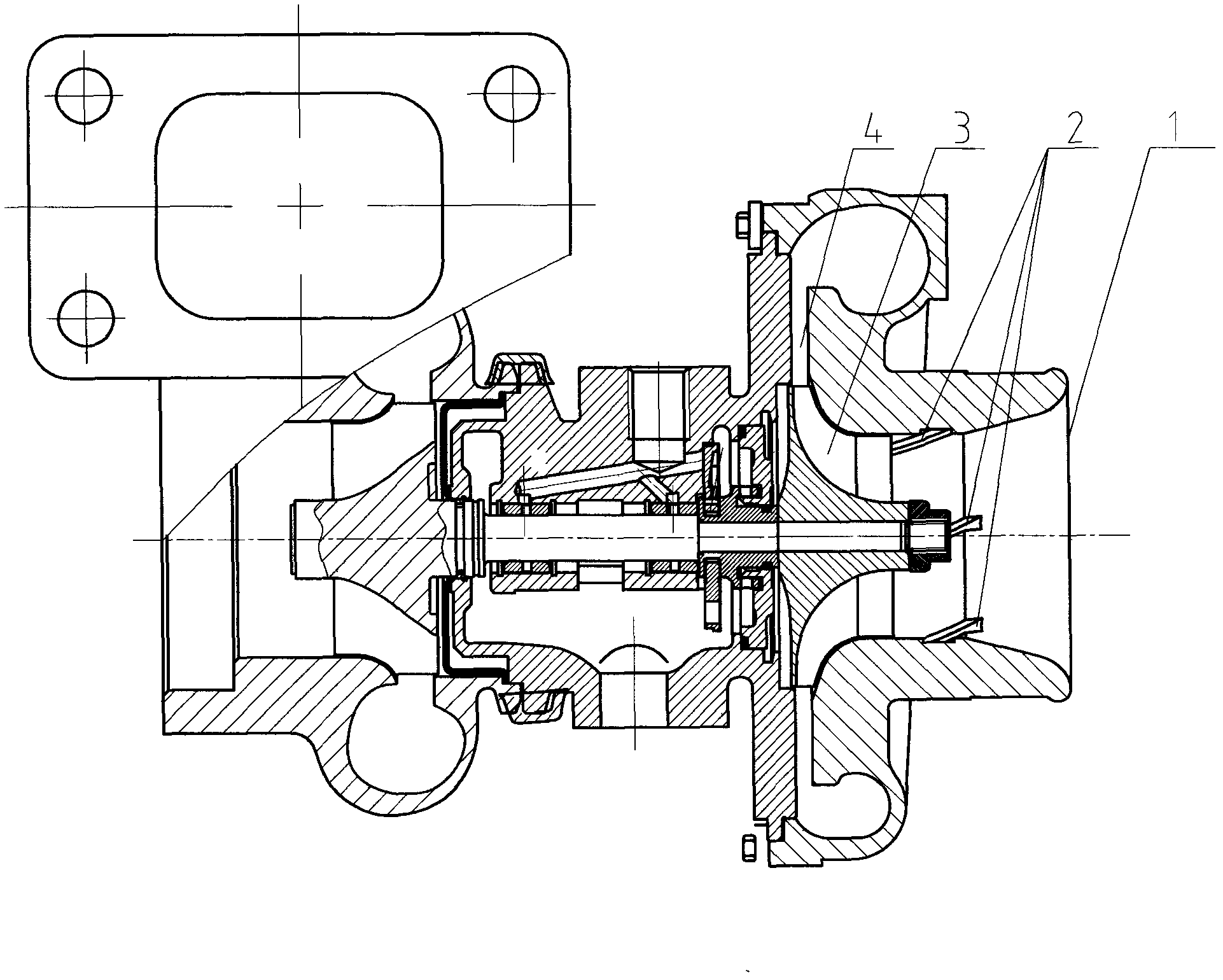

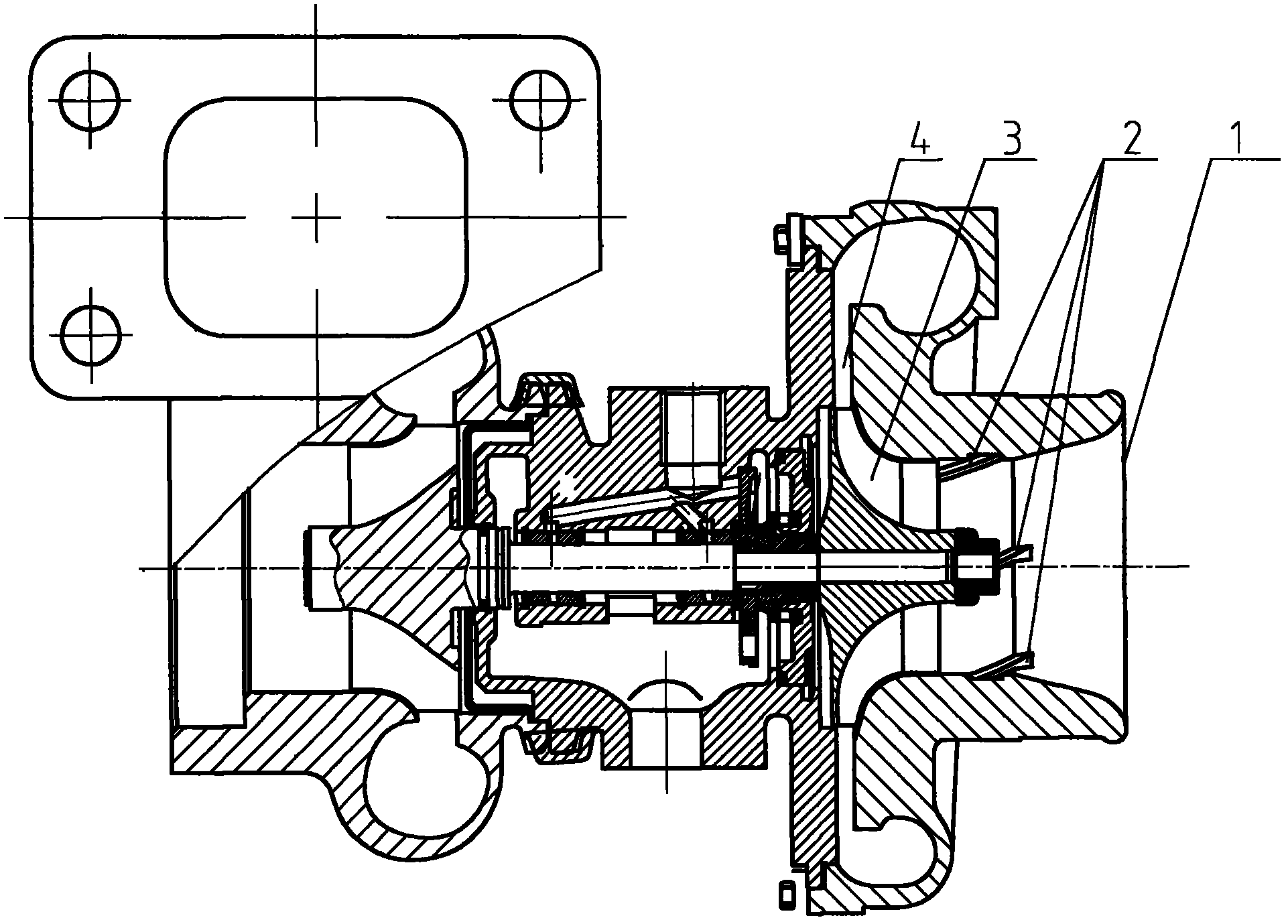

[0011] Such as figure 1 , figure 2 Described a kind of twin wire spiral intake supercharger, comprises compressor air inlet 1, compressor wind deflector front section 2, compressor wind deflector 3, air intake duct 4, intermediate body 6, turbine shell 7 , the compressor inlet 1 adopts the double button line inlet path, such as figure 1 The compressor inlet 1 of the traditional supercharger adopts a right-angle or obtuse-angle linear structure, which hinders the flow of air to this place, generates eddy currents, and increases air flow resistance, thus reducing the pressure of the supercharger. The intake air volume reduces the efficiency of the supercharger. And the present invention is by utilizing the calculation of aerodynamic principle and fluid mechanics principle, and when air enters supercharger compressor air inlet 1, flows along double button line path, and the resistance that suffers is minimum, and flow energy loss is also minimum, therefore can improve booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com