Heat sealer with vacuum pumping device

A vacuum device and heat-sealing technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of easy air intake, reduce the vacuum degree of the packaging bag, and achieve the goal of reducing air intake Possibility, convenient operation, and the effect of ensuring vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

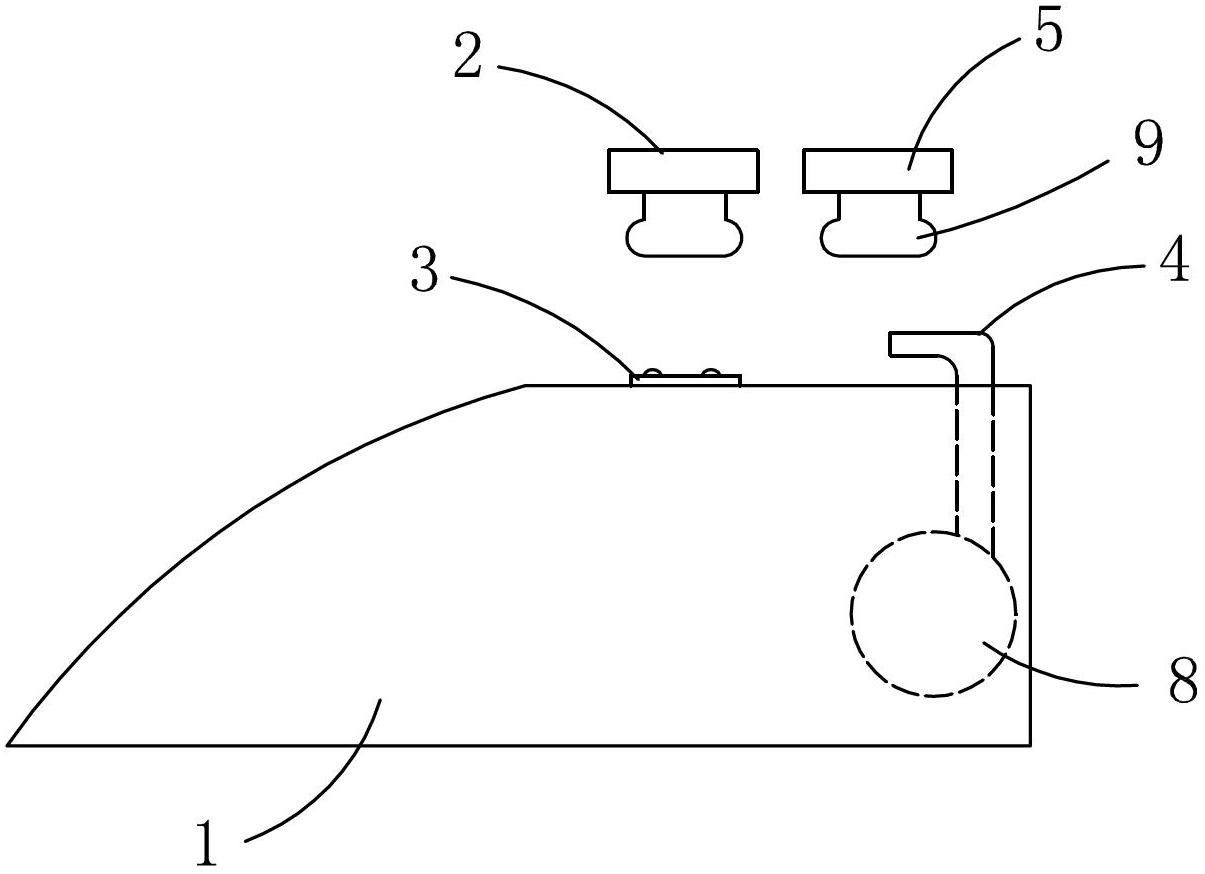

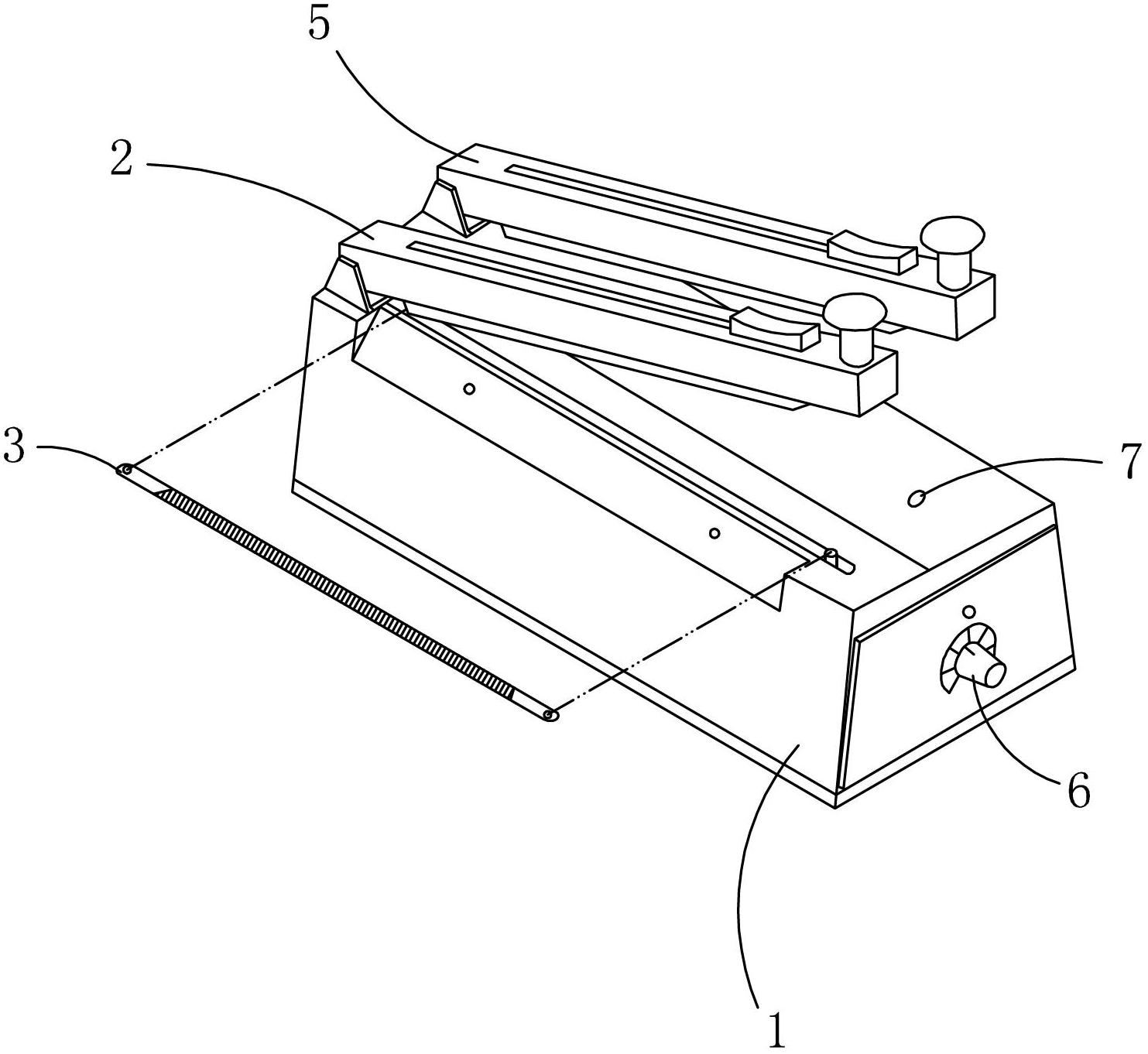

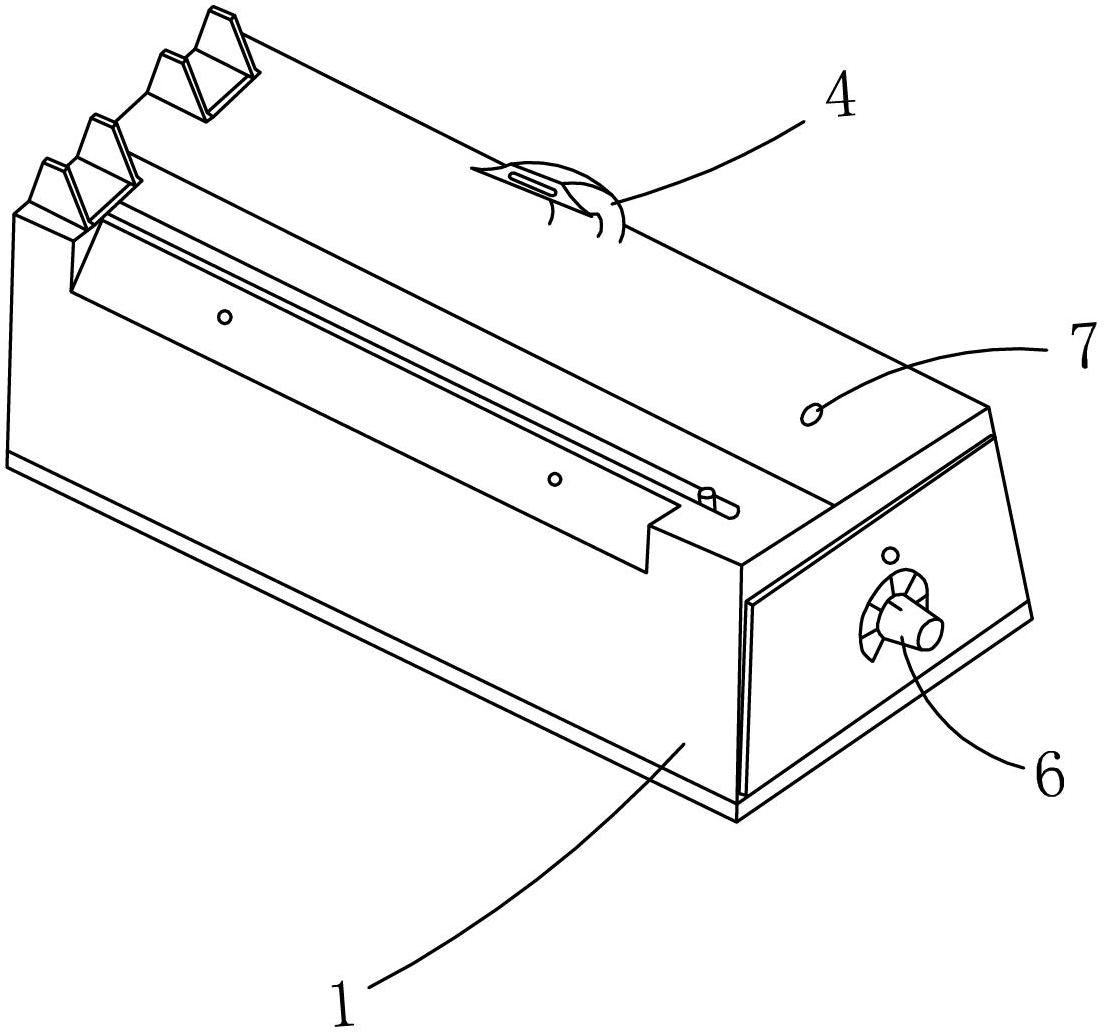

[0016] refer to Figure 1 to Figure 3 , an embodiment of a heat sealing machine with a vacuum device provided by the present invention, a first pressing rod 2 and a second pressing rod 5 are hinged on the base 1, and the first pressing rod 2 and the second pressing rod 5 are parallel to each other Setting, there is a soft silicone 9 under the first pressing rod 2 and the second pressing rod 5, which can be used to better compress the packaging bag without causing damage to the packaging bag. The base 1 and the first pressing rod 2 A heating structure 3 is provided at the pressing position between them, and a vacuum air nozzle 4 is provided below the second pressure rod 5 on the base 1, and the nozzle head of the vacuum air nozzle 4 is arranged between the second pressure rod 5 and the base 1. The pressing position between the vacuum pumping nozzle 4 and the base 1 is about 0.2cm, which is used to let the lower layer of the pocket of the packaging bag extend in so that the pock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com