Vacuum valve with vacuum gauge function

A vacuum valve and vacuum gauge technology, which is applied to packaging, kitchen utensils, household utensils and other directions under vacuum/special atmosphere, can solve the problems of rising manufacturing cost, increased assembly time, and increased number of parts, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

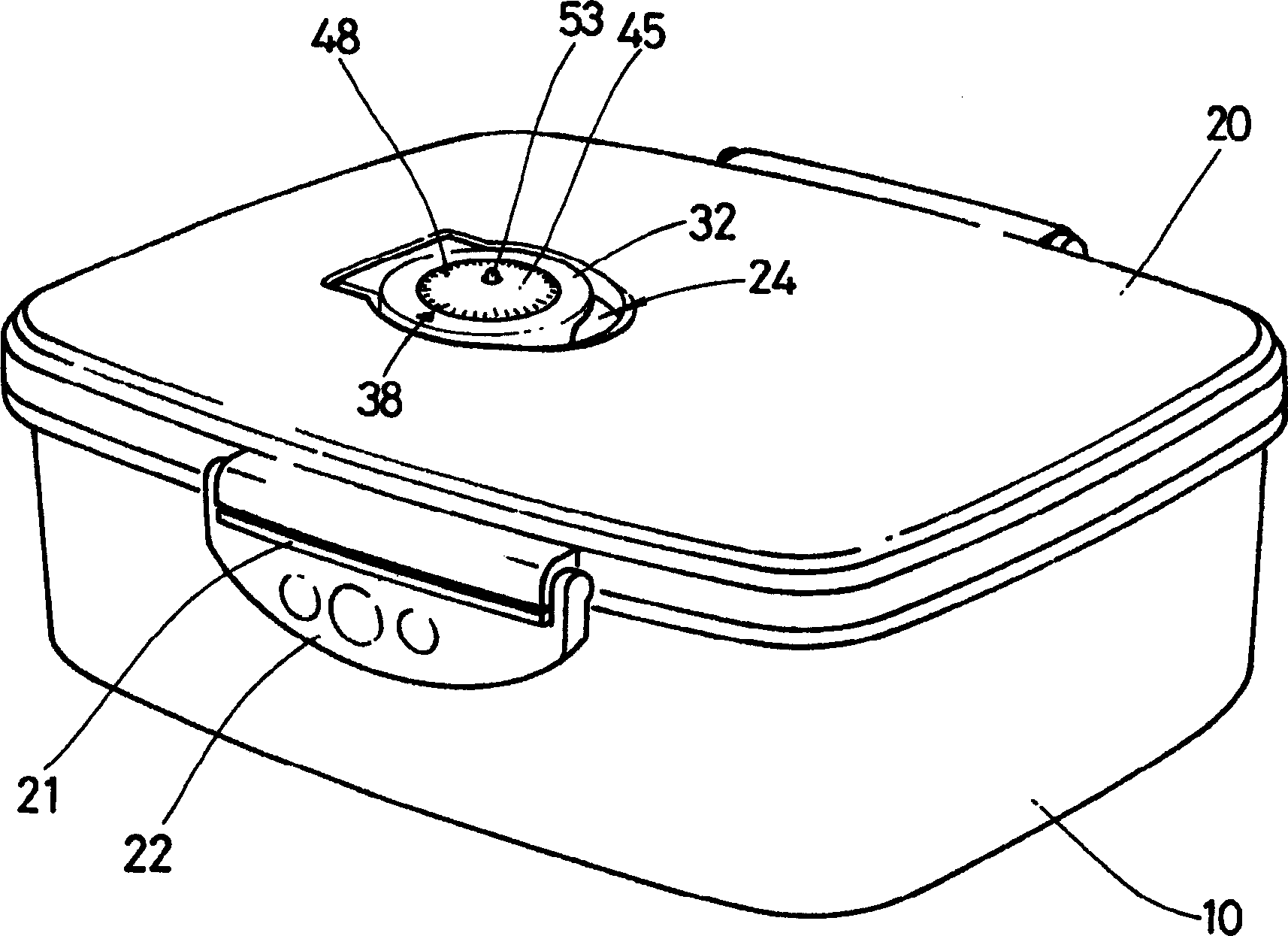

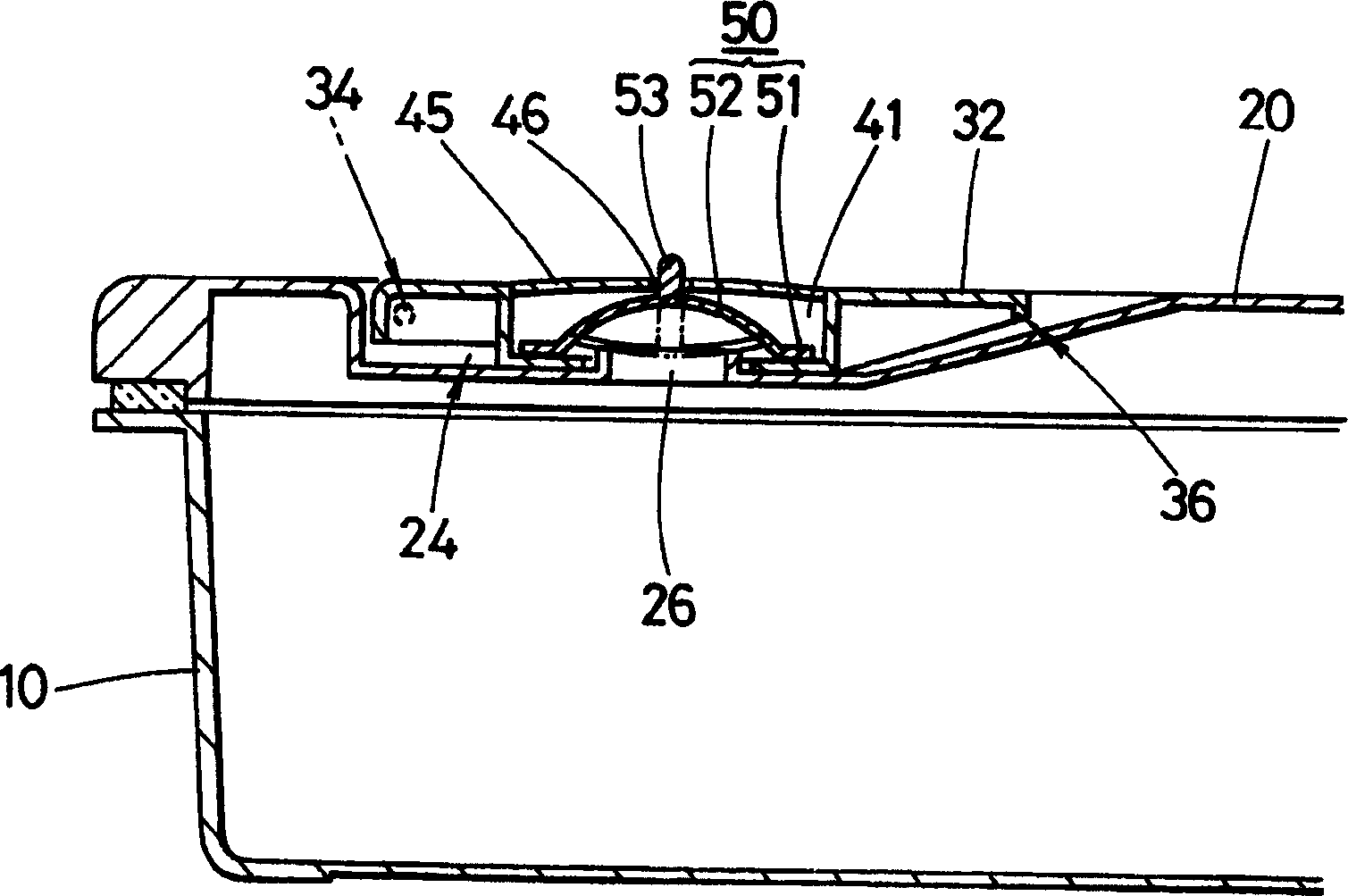

[0027] First, refer to figure 1 The structure of the vacuum storage container equipped with the vacuum valve of this embodiment is demonstrated. and figure 1 It is a perspective view of the vacuum storage container provided with the vacuum valve of the first embodiment of this embodiment.

[0028] First, if figure 1 Shown, the container body (10) that accommodates ordered food has an opening, and the vacuum valve of the present embodiment form is located on the container cover (20) of the input opening of the opening and closing container body (10).

[0029] The container body (10) is generally in the shape of a cuboid, and is used for storing various foods such as meat and vegetables in a vacuum state, and can maintain the freshness and preservation state of the various foods accommodated for a long time. In addition, although in this embodiment form, the container body (10) that is generally rectangular is used as an example for illustration, but as the type and shape ...

Embodiment 2

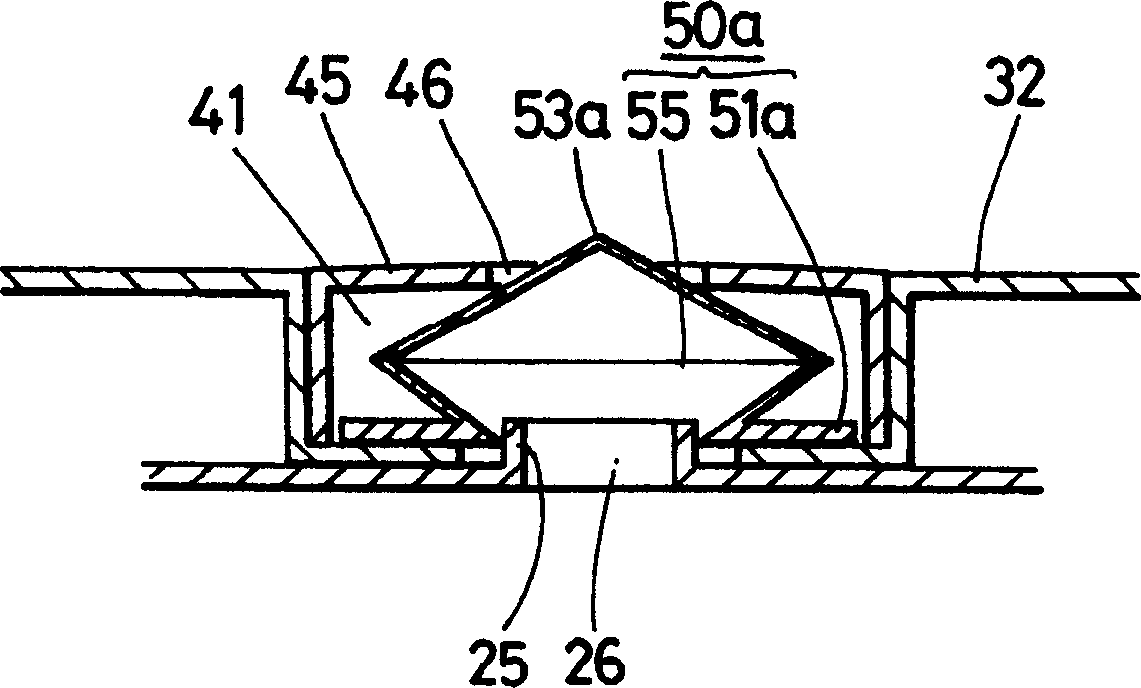

[0043] Below, refer to image 3 The structure of the vacuum valve according to the second embodiment will be described. image 3 It is a sectional view showing the structure of the vacuum valve according to the second embodiment.

[0044] First, if image 3 As shown, the vacuum holding member (50a) of this embodiment form is different from the form of the first embodiment in that it has a sealing flange portion (51a) larger than the opening diameter of the raised portion (25), and a folded portion ( 55). With this vacuum holding member (50a), the air communication port (26) can be brought into contact with the periphery of the formed protrusion (25) to keep hermetically sealed.

[0045] The vacuum holding member (50a) expands in diameter at a set height from the inside of the sealing flange portion (51a), has an upward folded portion (55), and then shrinks in diameter toward the center to form a cone. The tip (53a) of the cone moves up and down from the through hole (46) o...

Embodiment 3

[0048] Below, refer to Figure 4 The structure of the vacuum valve according to the third embodiment will be described. Figure 4 It is a sectional view showing the structure of the vacuum valve according to the third embodiment.

[0049] In this embodiment, the upper part of the protruding portion (25) is detachably connected to the hollow sealing member (30). The sealing member (30) can be formed of, for example, elastic soft silicone resin for blocking air. The sealing member (30) can simultaneously maintain the vacuum inside the vacuum holding member (50b) and the container body (10) when the rotating cover (32) described later is actuated by being embedded in the upper portion of the protrusion (25).

[0050] Sealing parts (30), such as Figure 5 As shown, it has a hollow housing part (35), and film-like protruding flange parts (31, 33) protruding radially from the upper and lower ends of the housing part (35). Hereinafter, for convenience of explanation, the protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com