Gas shielded arc welding device

A technology of gas protection and arc welding, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

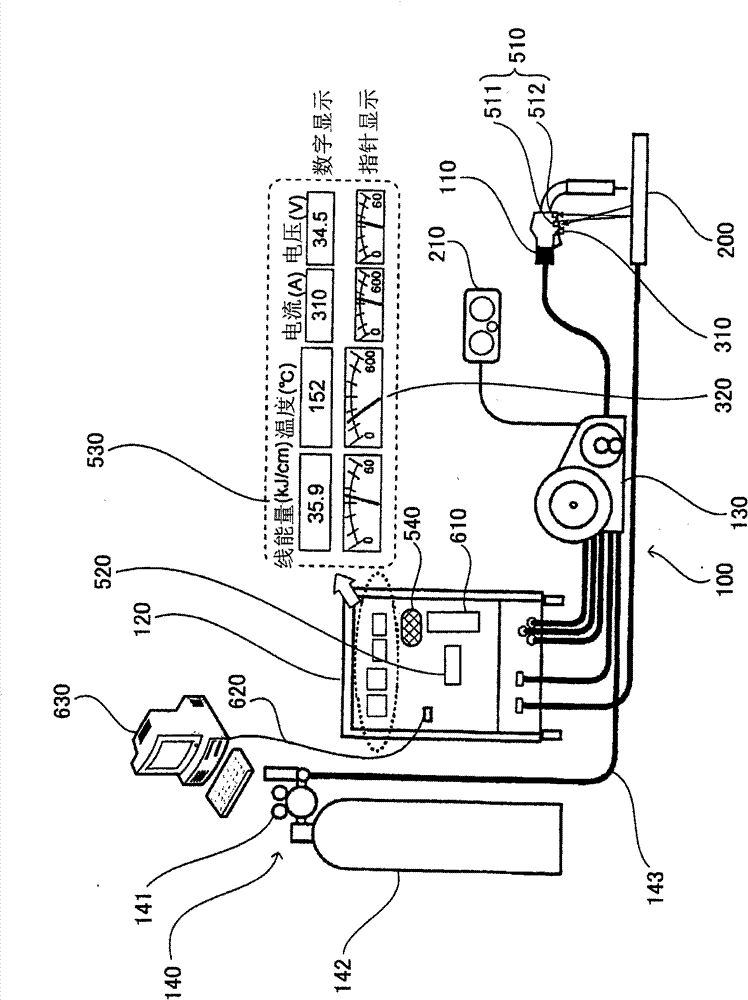

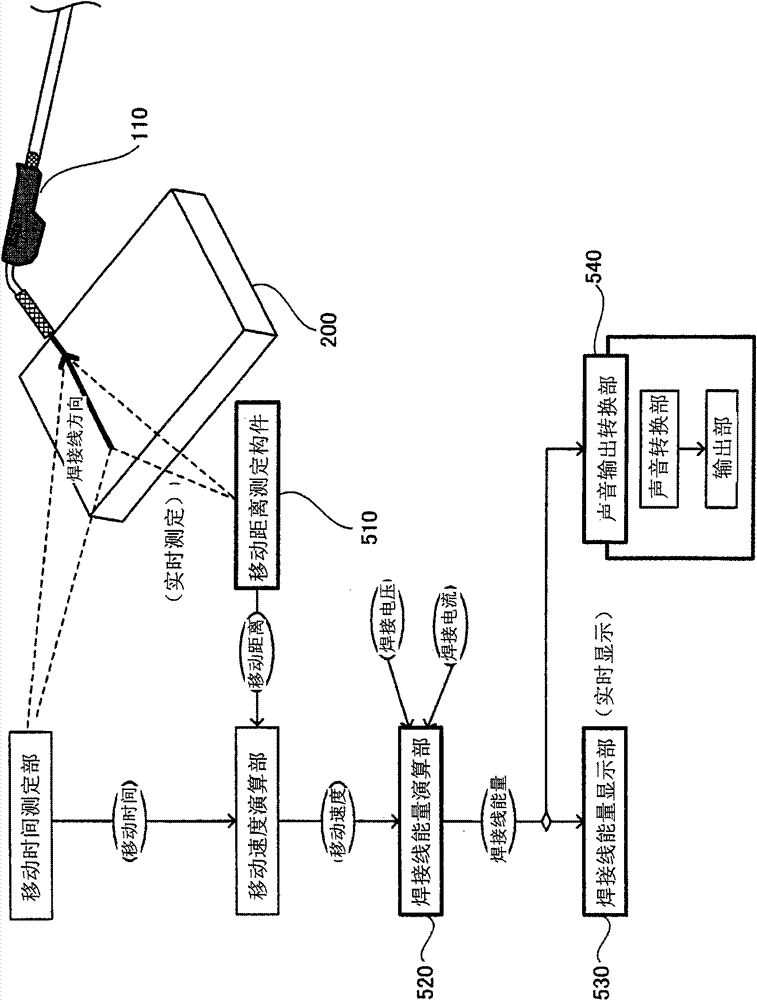

[0023] The gas shielded arc welding device 100 of the present embodiment, such as figure 1 As shown, it has: welding torch 110; welding power supply 120; welding wire supply part 130; shielding gas supply part 140; moving distance measuring member 510; welding heat energy calculation part 520; welding heat energy display part 530; sound output conversion part 540.

[0024] The welding power source 120 supplies electric power between the welding torch 110 and the steel plate 200 as a part to be welded. The welding wire supply unit 130 continuously supplies welding wire to the welding torch 110 . The supply amount of welding wire is adjusted from the outside by the remote control device 210 .

[0025] The shielding gas supply unit 140 is composed of: a tank body 142 ; a gas flow regulating valve 141 ; and a gas pipe 143 , and supplies the shielding gas jetted from the welding torch 110 . Protective gas such as CO 2 monomer gas or CO 2 Mixed gas with Ar gas.

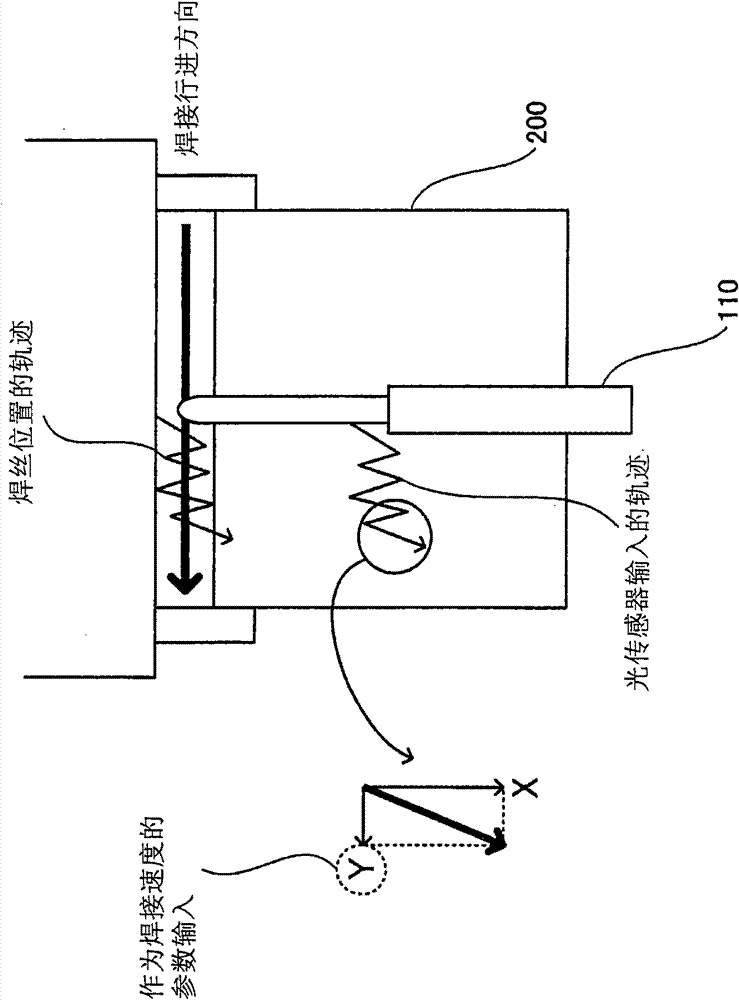

[0026] The mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com