Patents

Literature

66 results about "Cost competitiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meaning of cost-competitive in English. cost-competitive. › a product or service that is cost competitive is cheap compared to other similar products, or services:

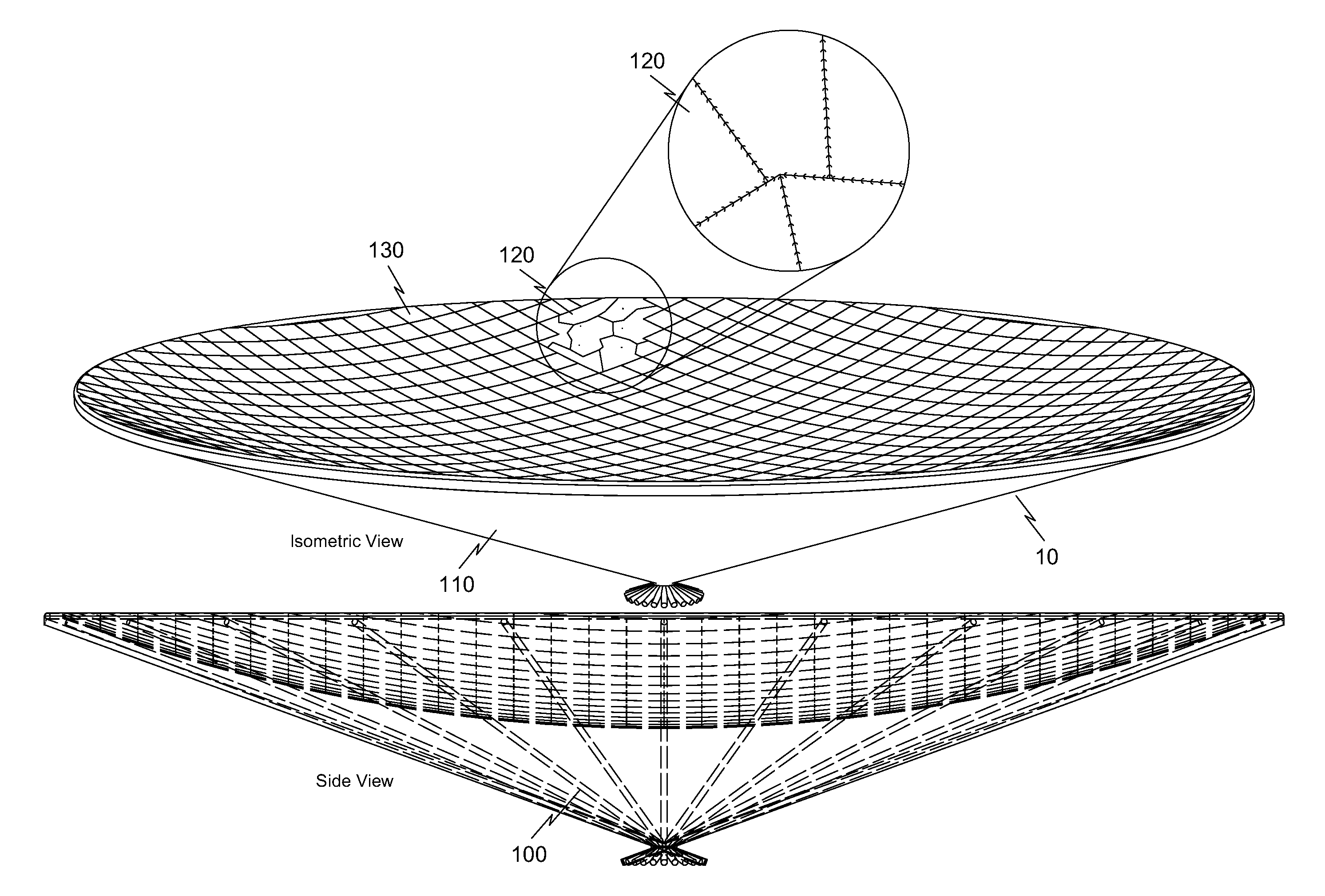

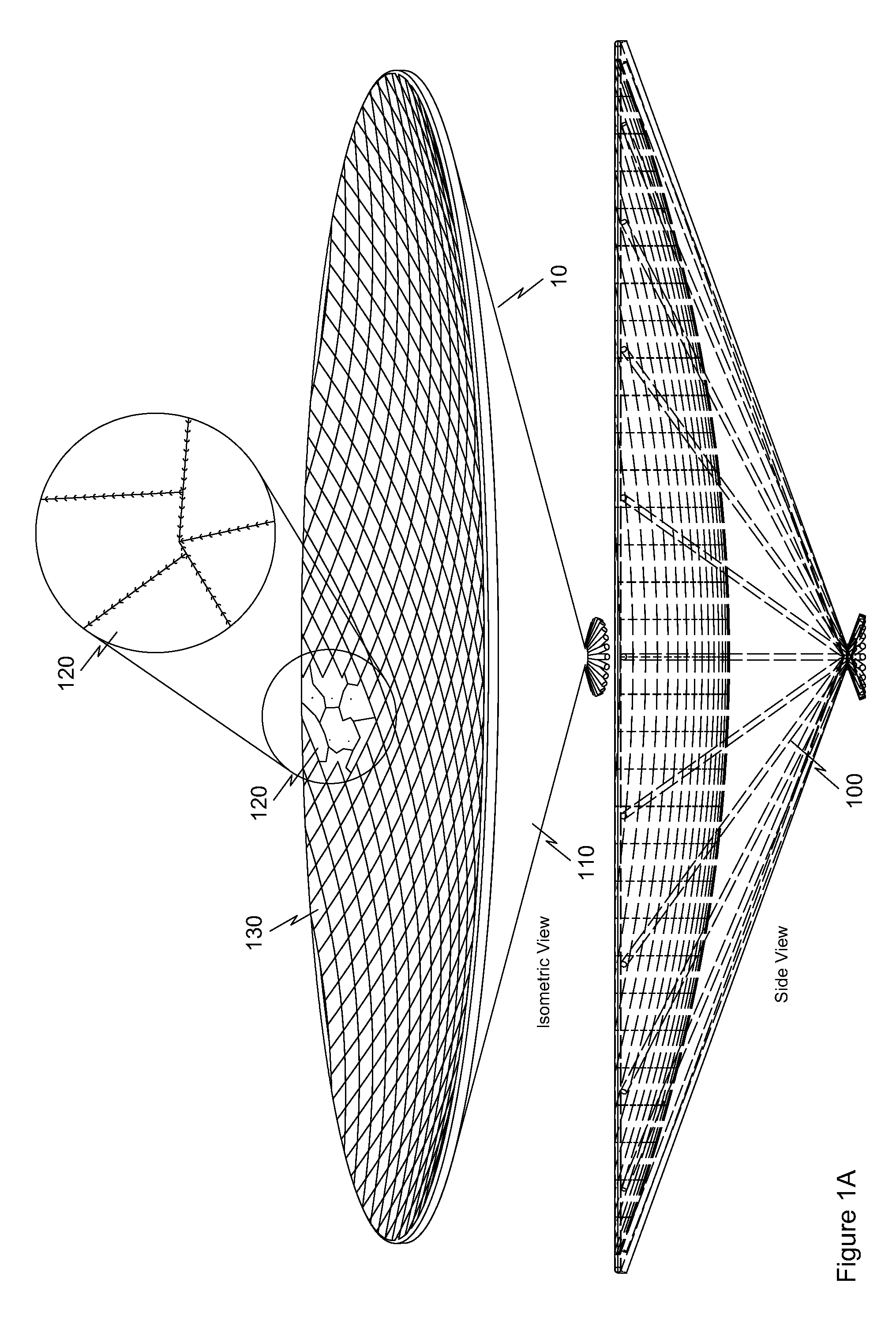

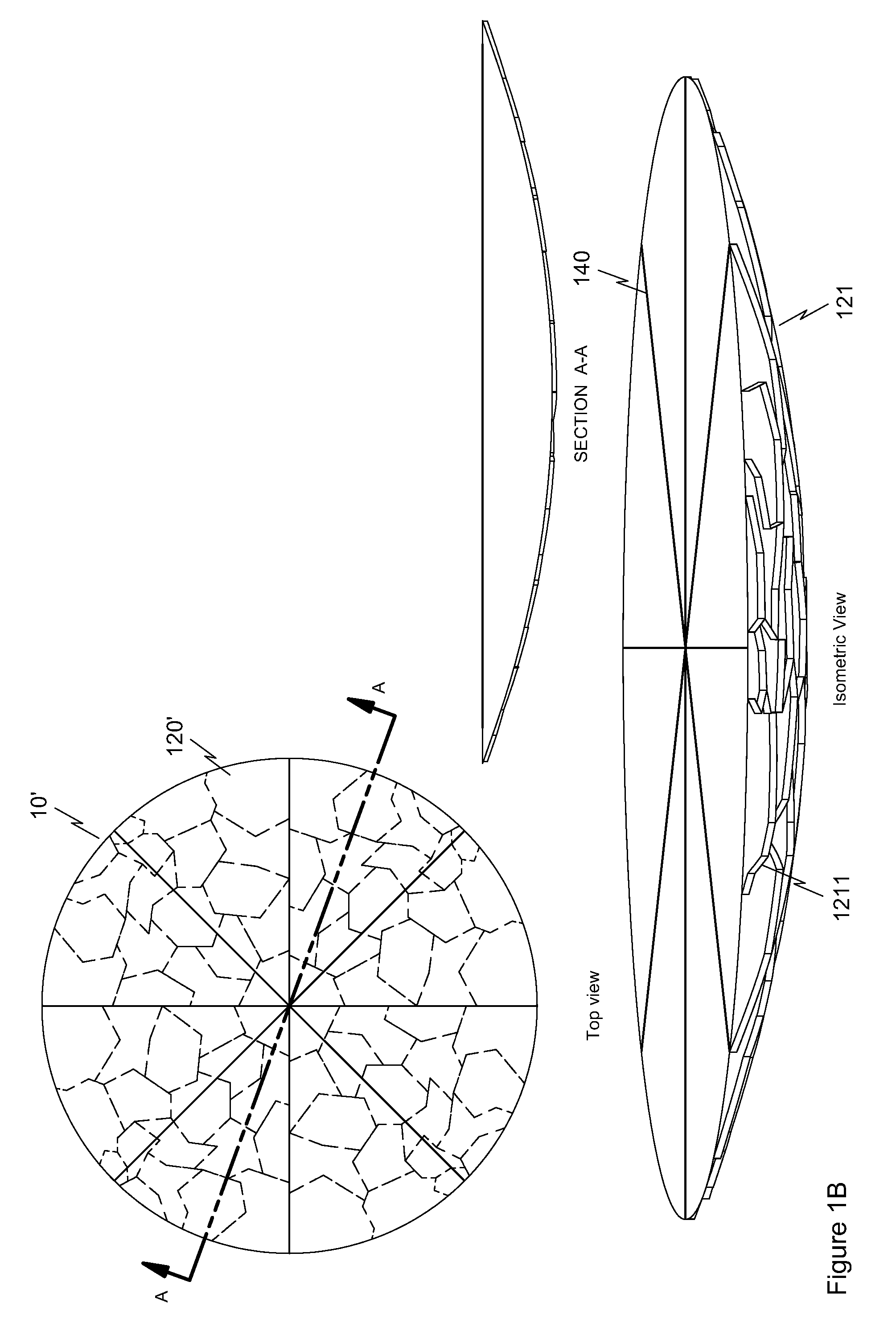

Systems for cost-effective concentration and utilization of solar energy

InactiveUS20100263709A1Increase concentrationSolar heating energySolar heat devicesSpace-based solar powerCombustion

The present invention is primarily directed to cost-effective systems for using large reflective elements that track the sun on two axes to concentrate solar energy onto a receiver that can convert the sun's optical energy to a form usable for extensive displacement of combustion of fossil fuels. The structures of the tracker frame, tracking mechanism and tracker supports are co-optimized with the optical elements and the receiver for high efficiency, low cost, and ease of assembly, making moderate and large-scale implementations cost-competitive with fossil fuels for peak power, and, with suitable storage, for base-load power and dispatchable peaking power in sunny locations. Improvement to small-tracker two-axis systems and one-axis tracking systems that focus in two dimensions are also included, as are improvements in systems for space-based solar power.

Owner:NORMAN RICHARD

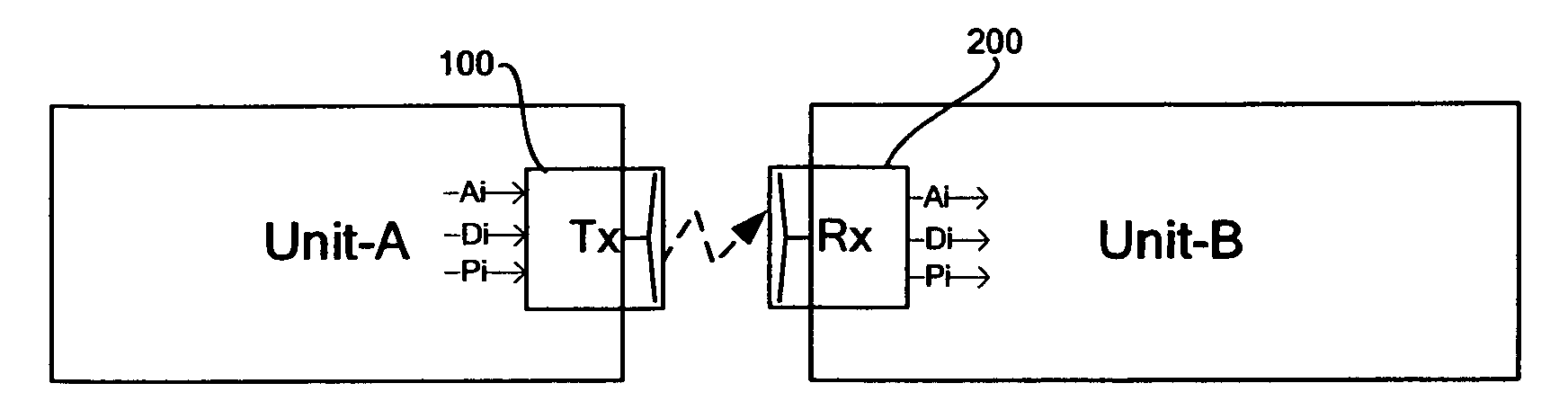

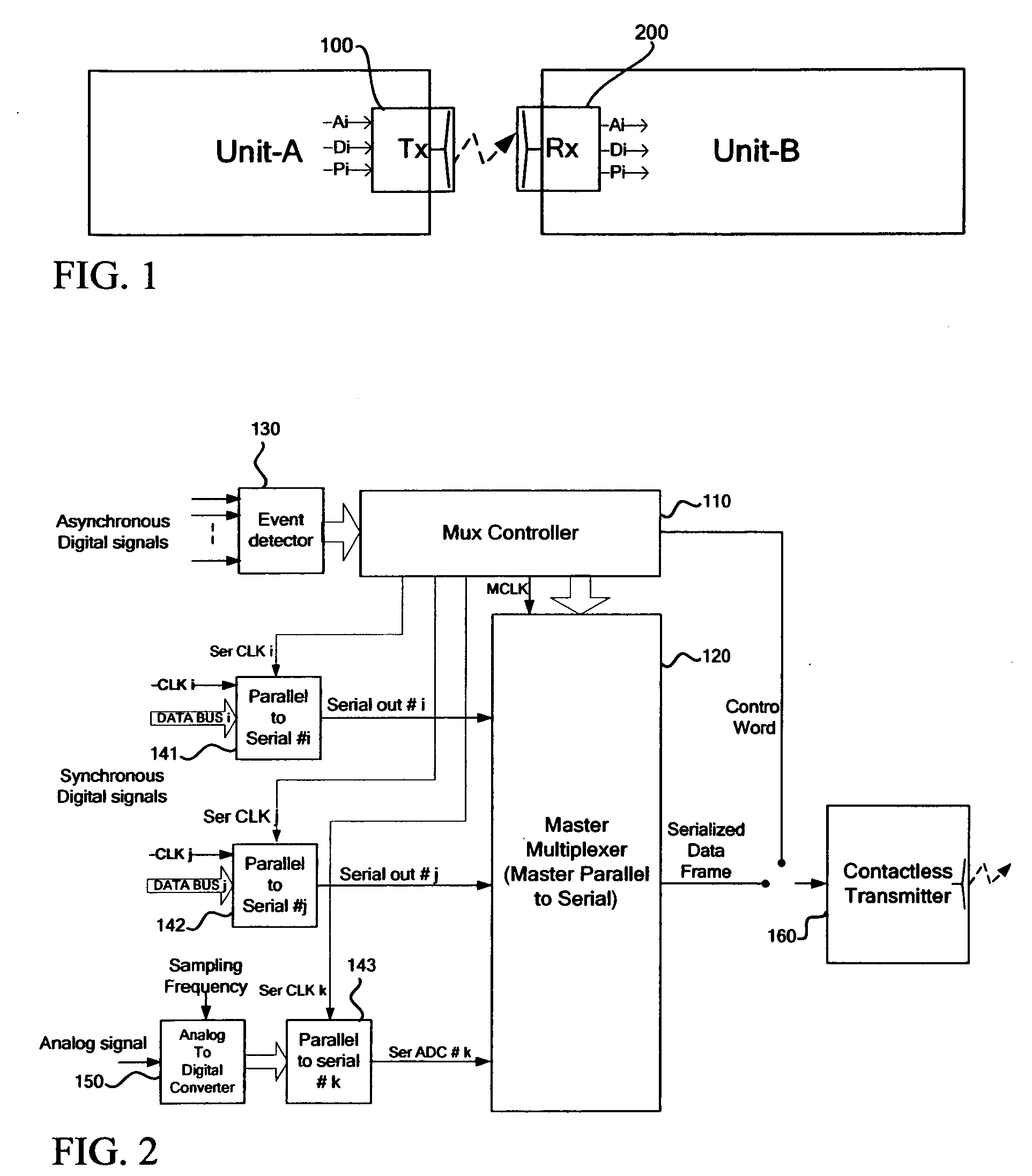

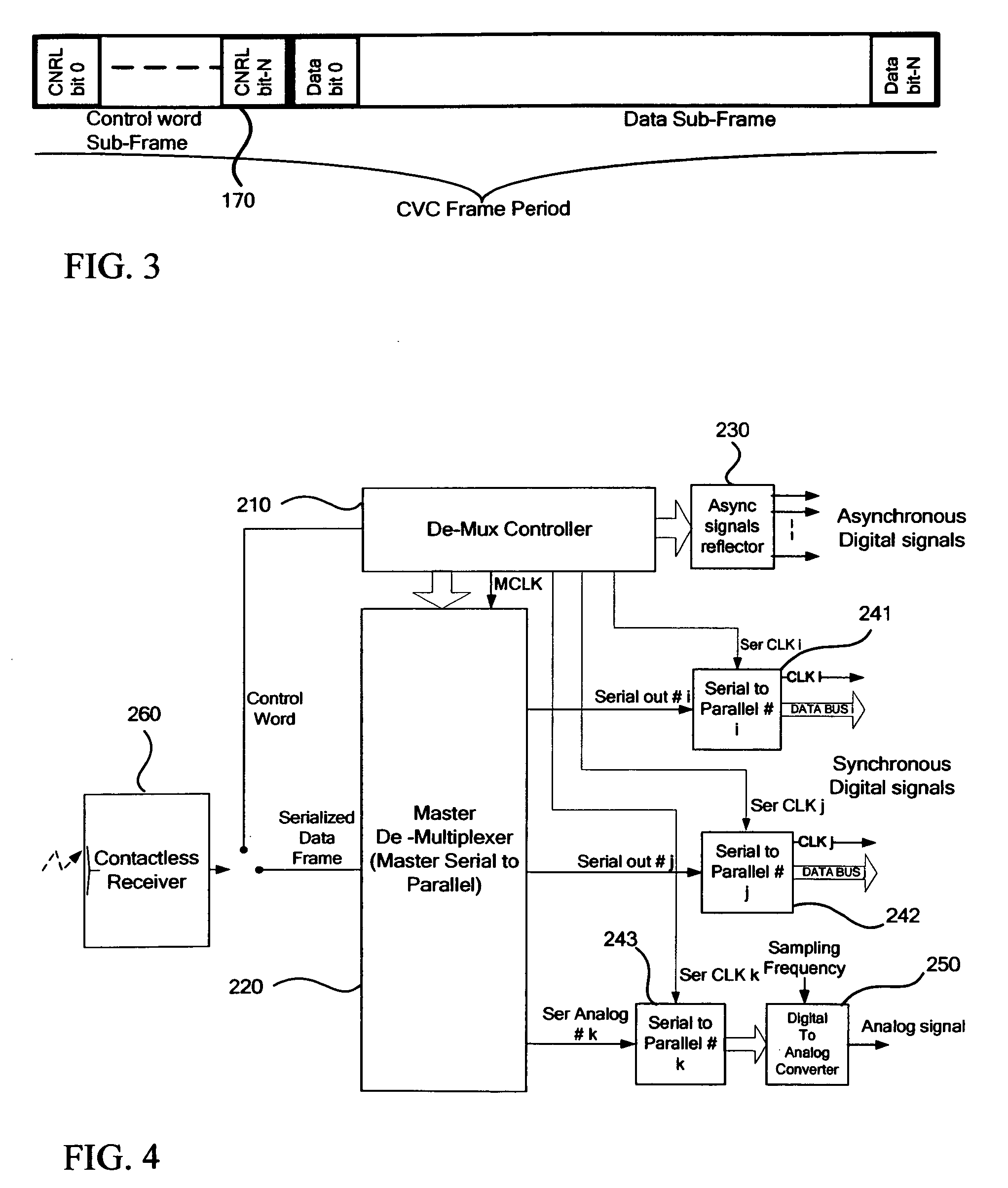

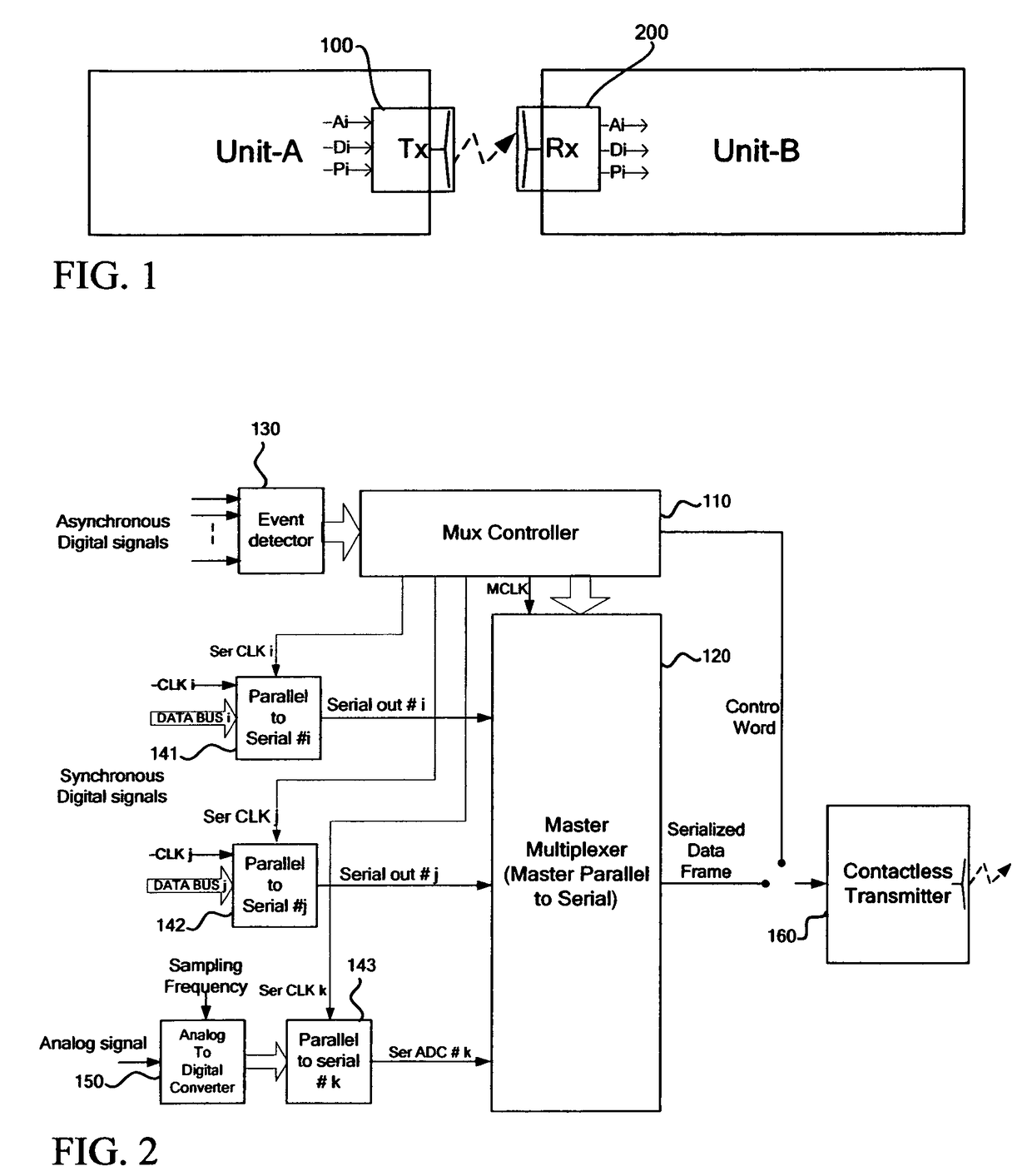

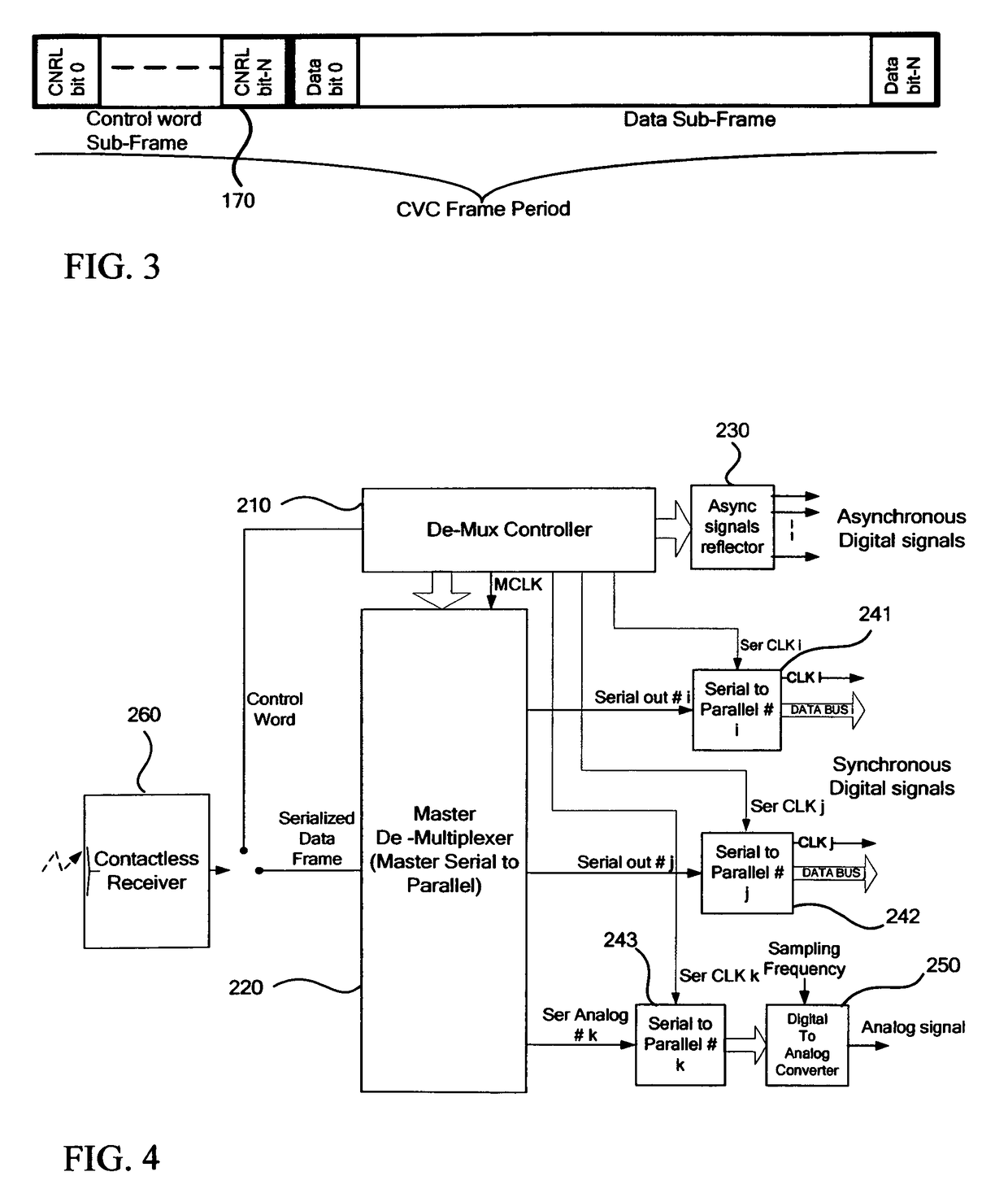

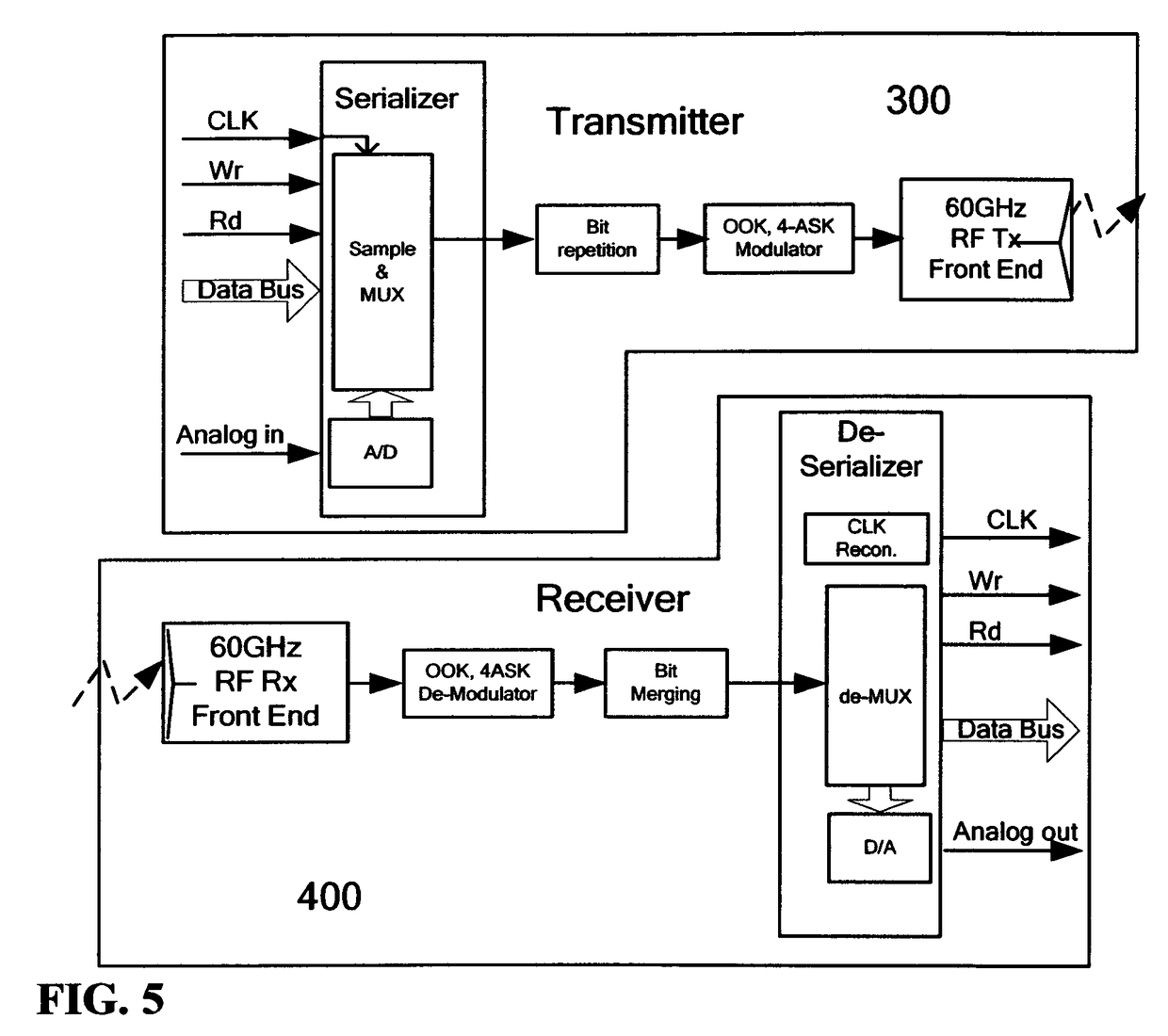

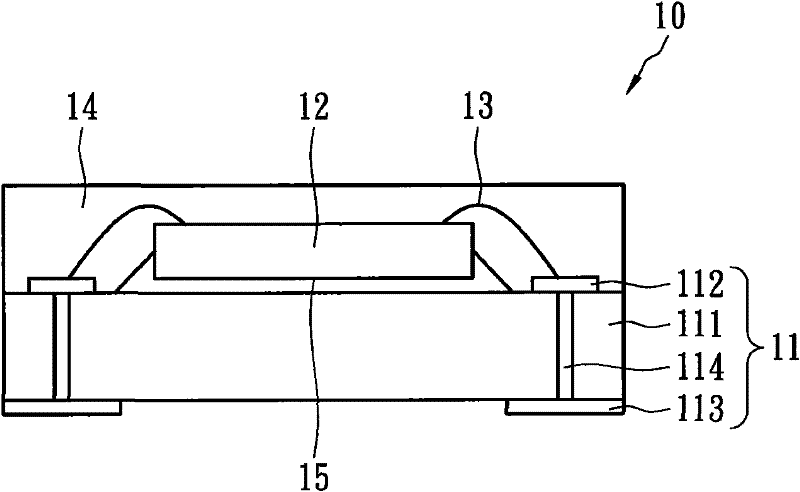

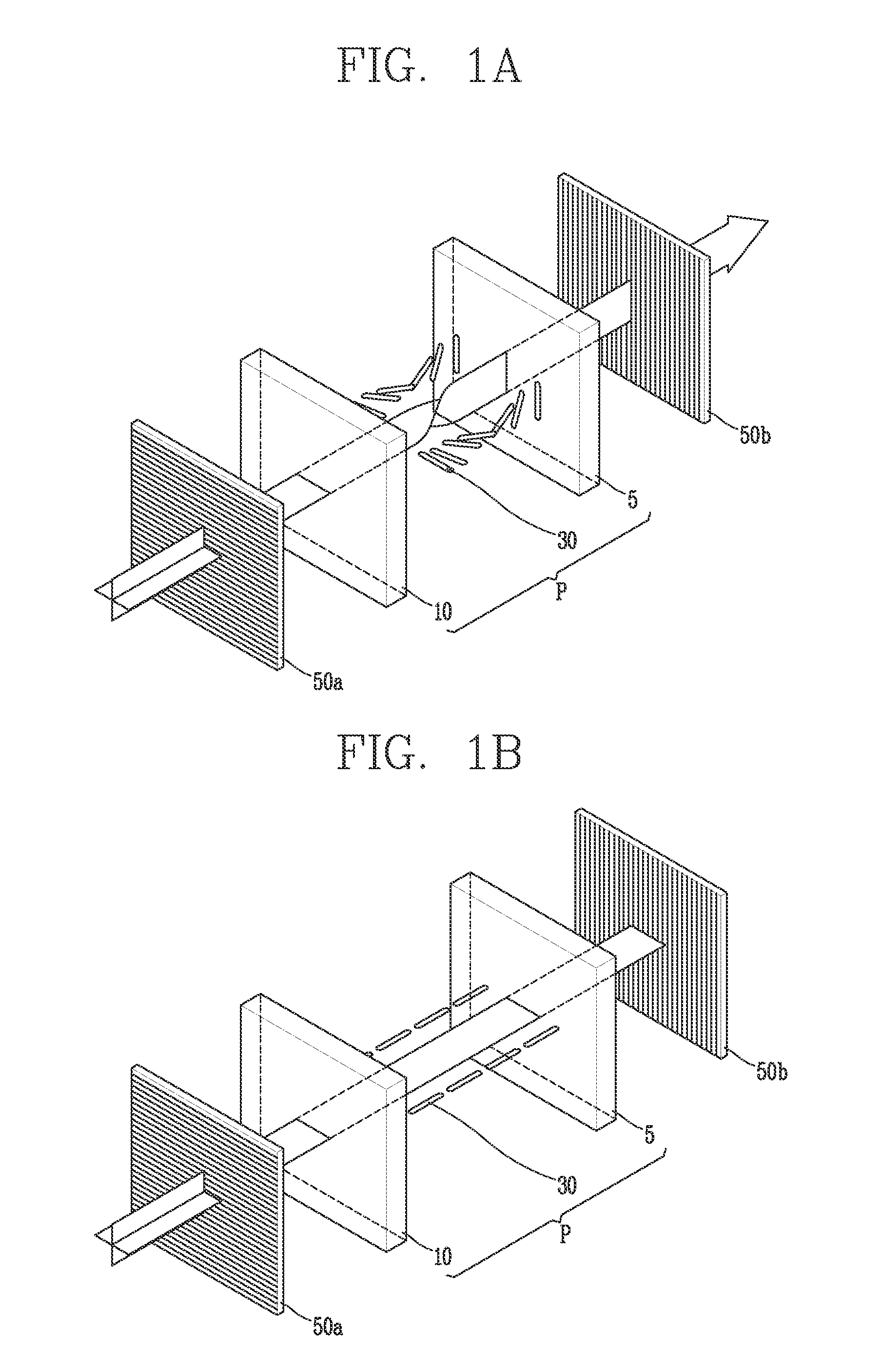

Virtual connector based on contactless link

InactiveUS20090098826A1Easy to integrateLow powerNear-field transmissionRadio transmissionPhysical layerEngineering

The today's mobile handheld and portable devices become slim and thin while need to communicate with other devices and accessories that are attached or at very short range. The interface (contact based physical connector) becomes a real challenge and unreliable to the consumer that needs to attached and detach its device several times a day.It is an object of the present invention to provide system and method of replacing a contact based physical interface (connector) with very short range wireless (contactless) interface. This technique is called “contactless virtual connector” or CVC. The method of the present invention is based on a transmission of a very low power and wideband RF signal. The new innovating mechanism replaces the traditional physical connector with new radiated signal technique that consumes very low power and may be cost competitive with the today's physical connectors.The innovated contactless technology may be used for small flexi-cable replacement in the handheld devices as flip or slider based handheld devices. Although the contactess technique is a wireless based solution, yet, the link may be well secured at the Physical layer when the near-field technique is used.

Owner:ZACK RAFI

Virtual connector based on contactless link

InactiveUS8121542B2Easy to integrateLow powerNear-field transmissionRadio transmissionPhysical layerEngineering

Owner:ZACK RAFI

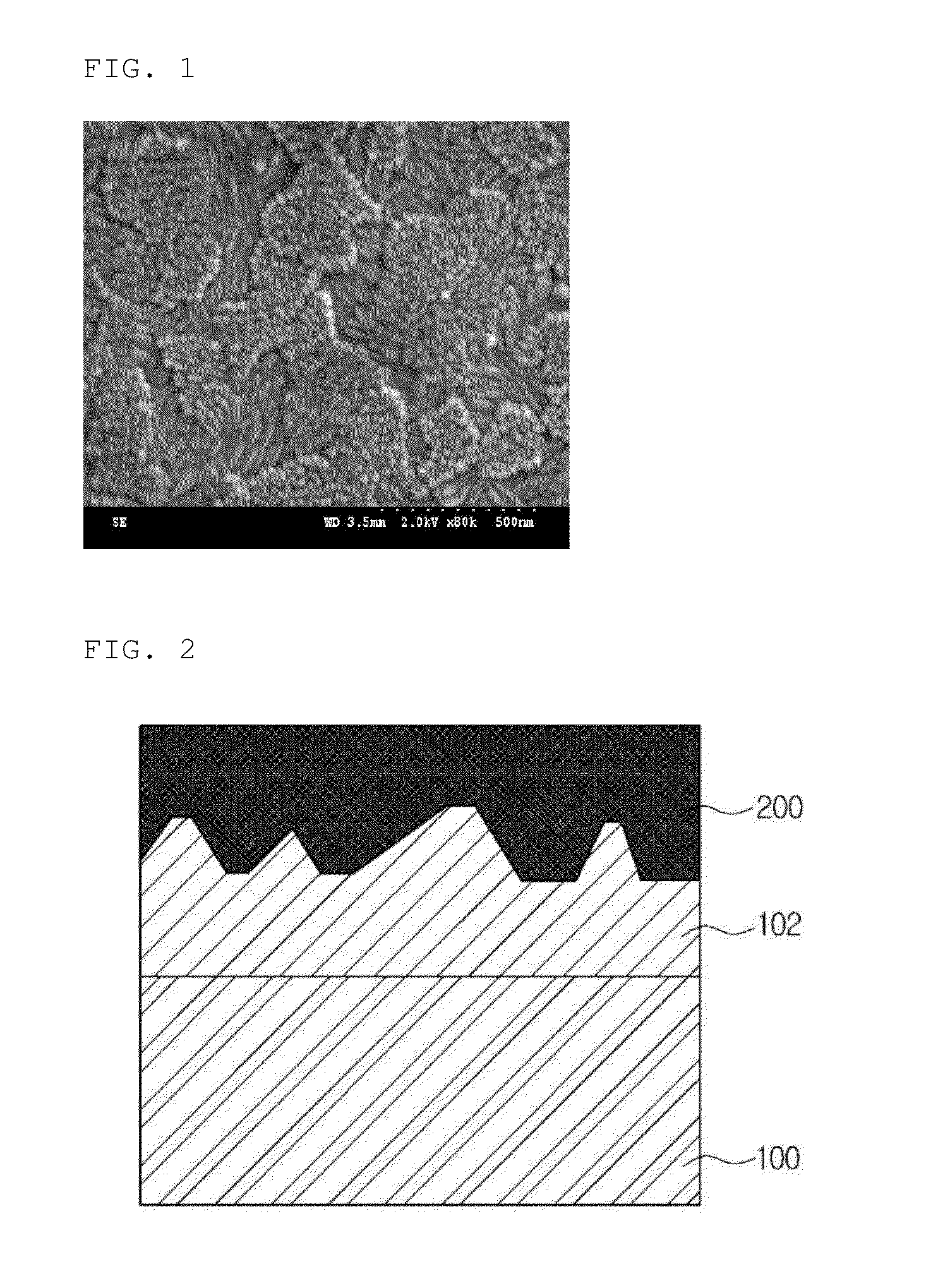

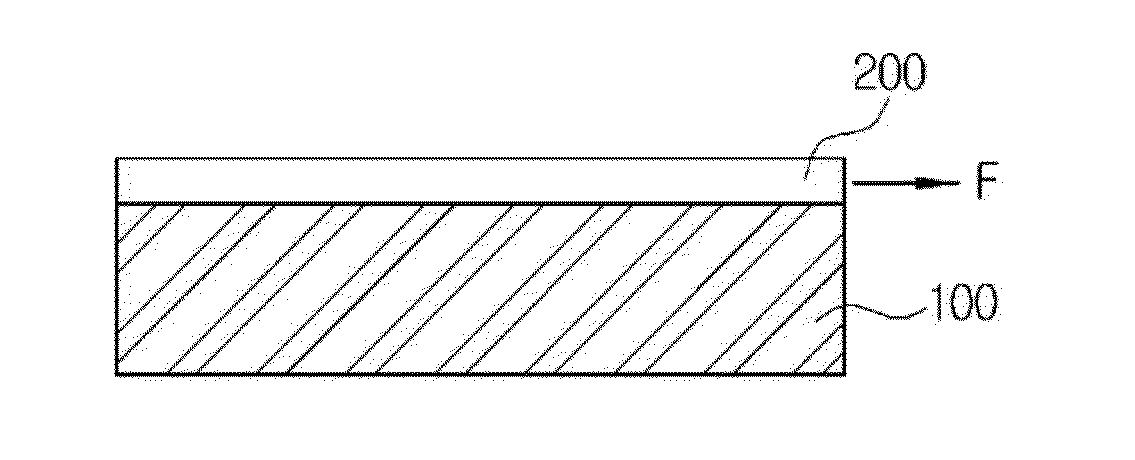

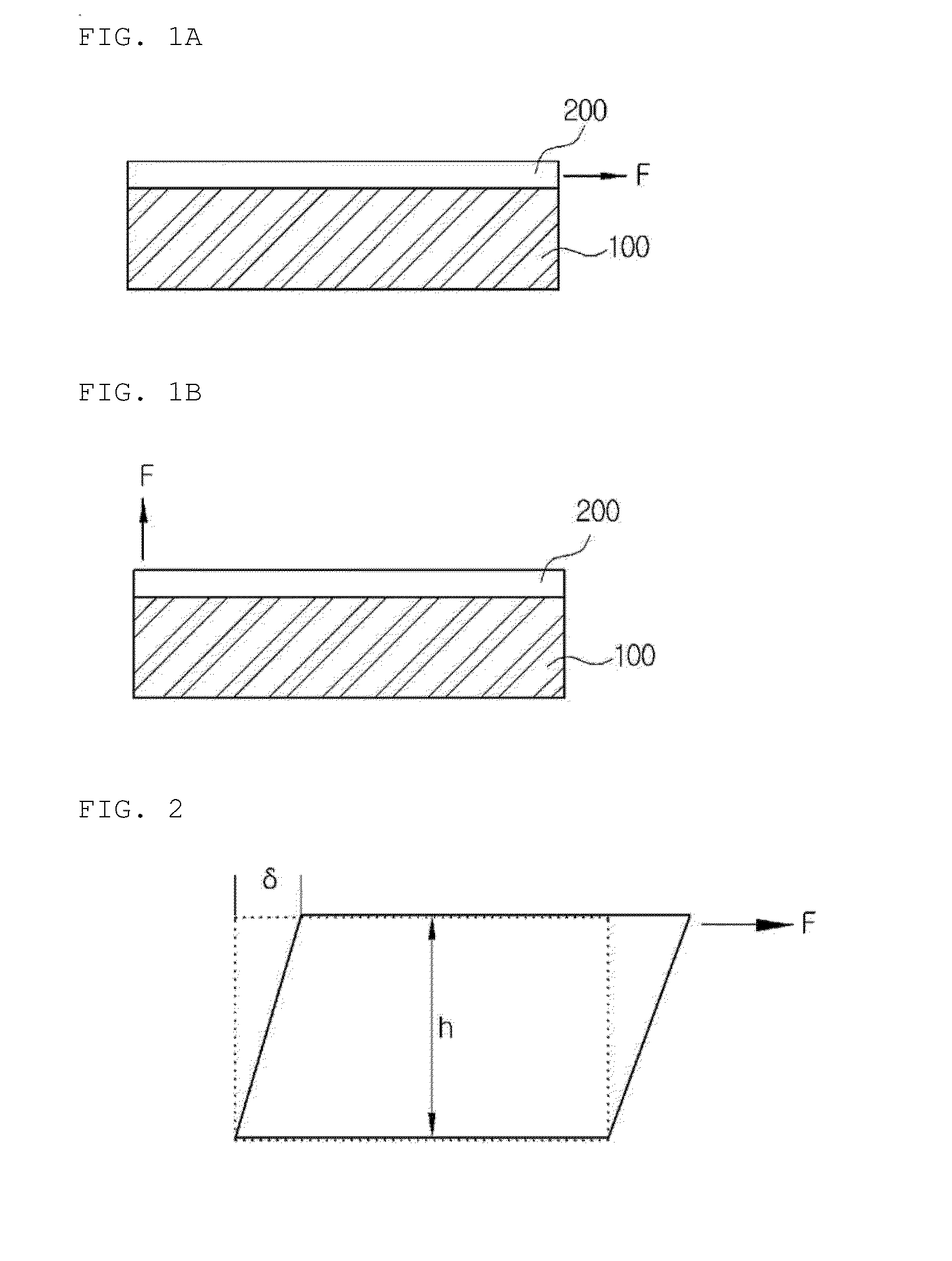

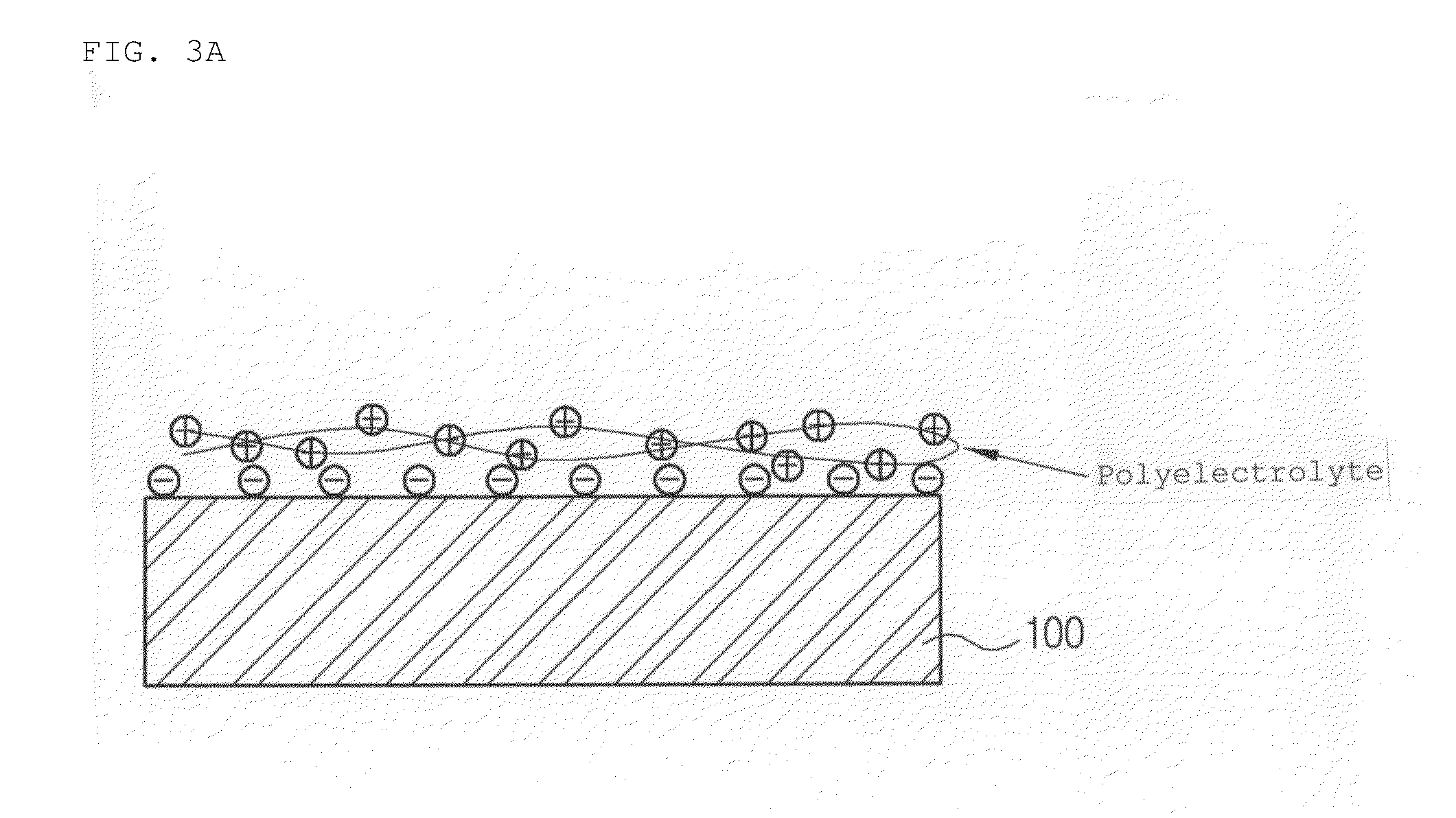

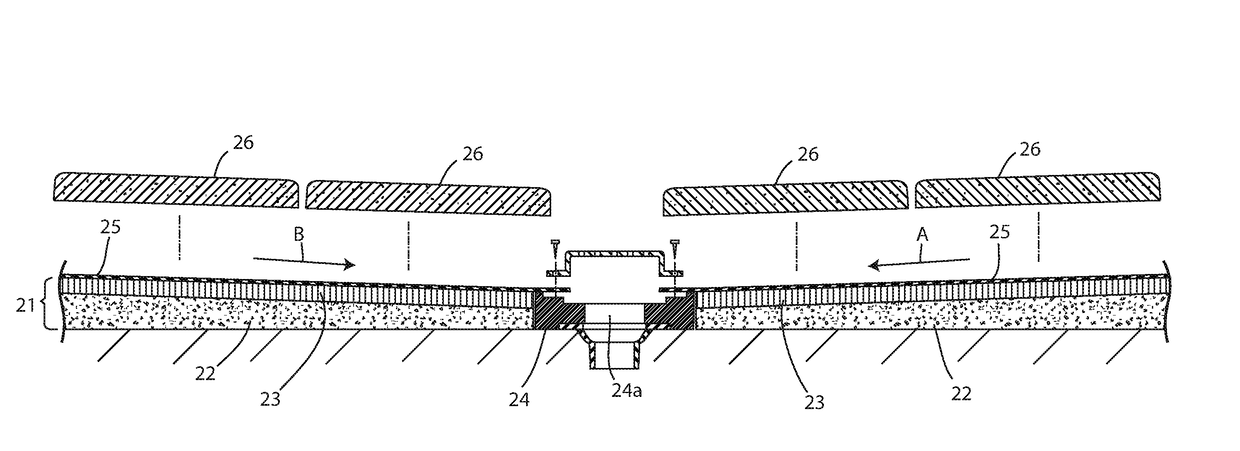

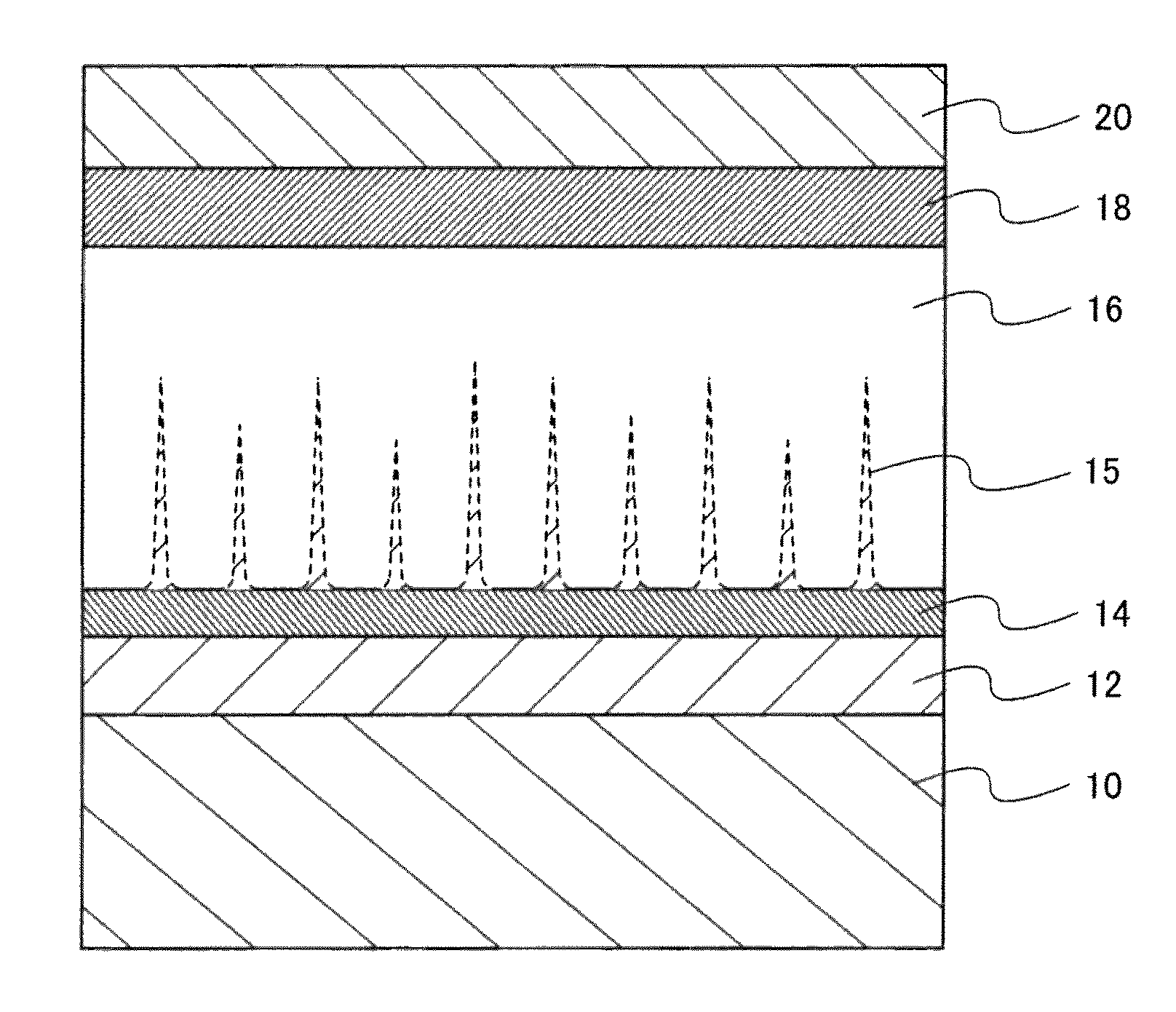

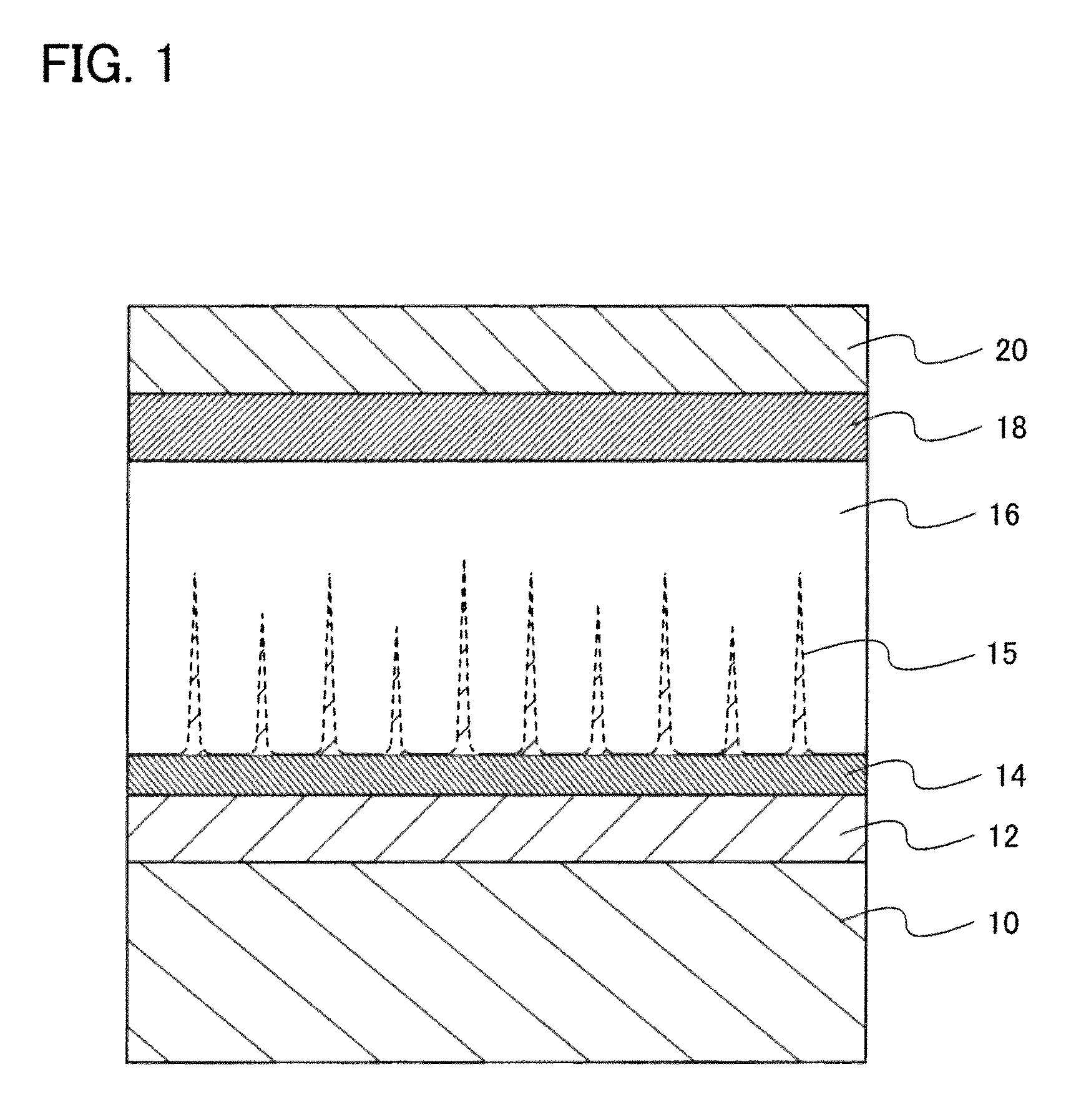

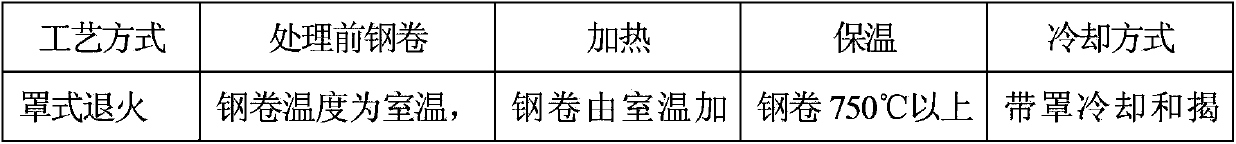

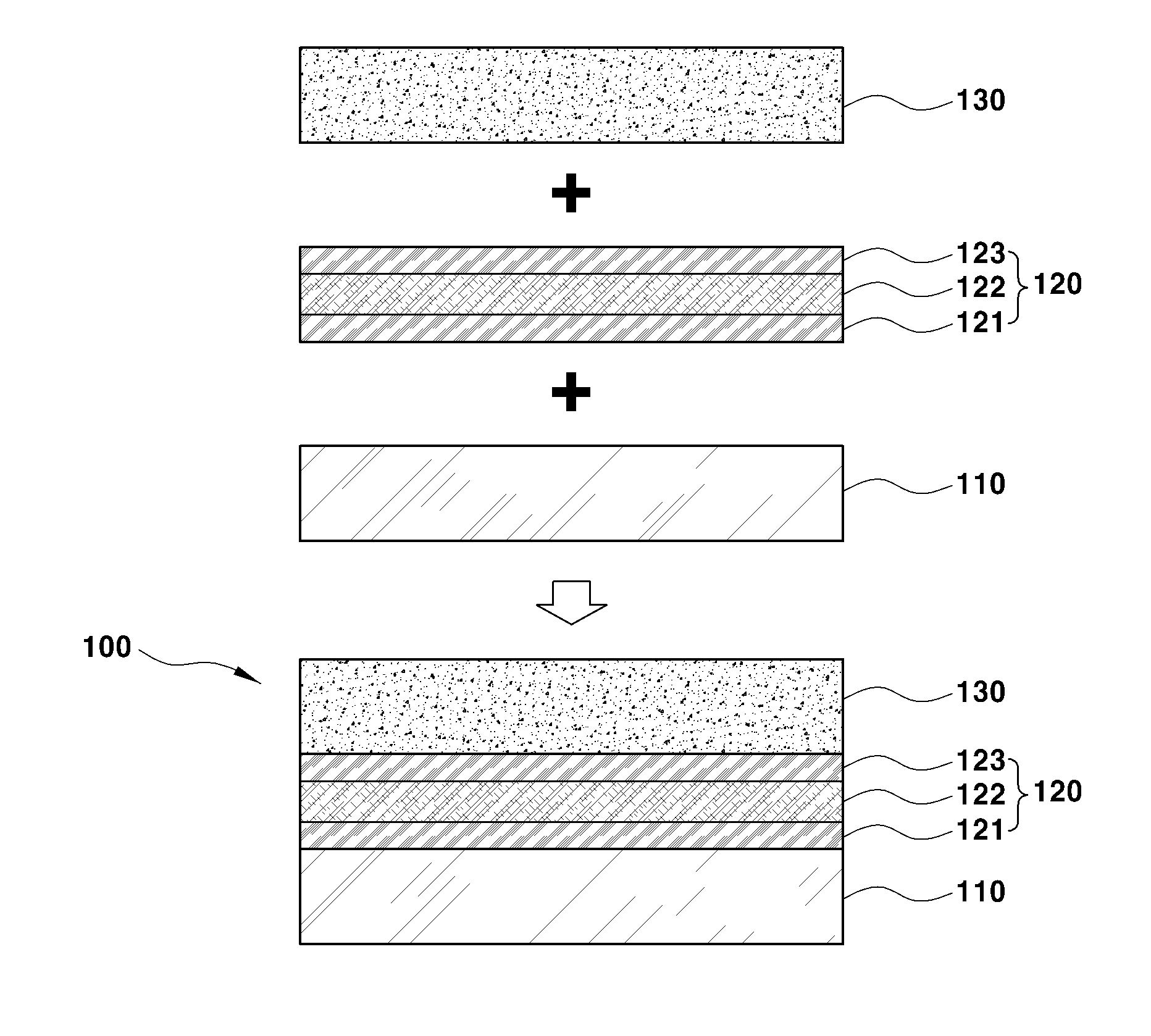

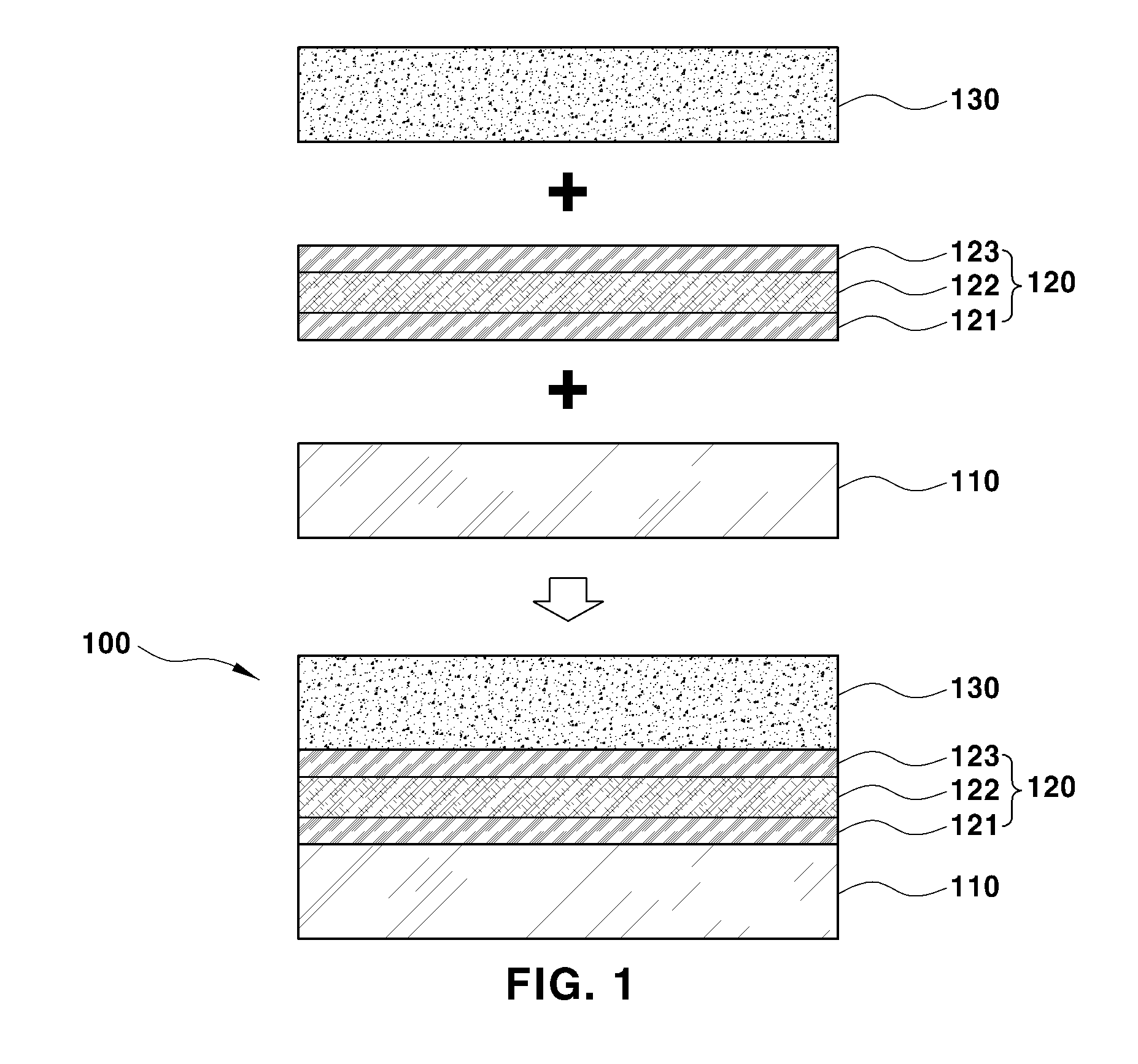

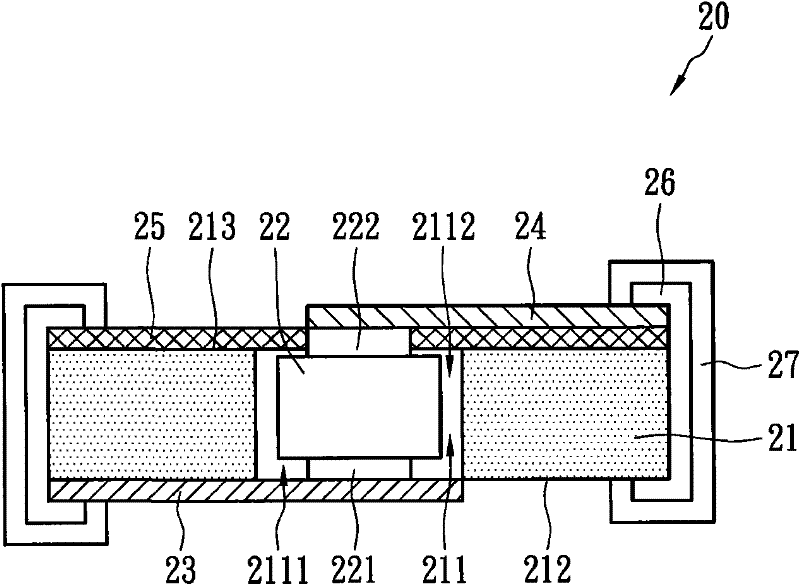

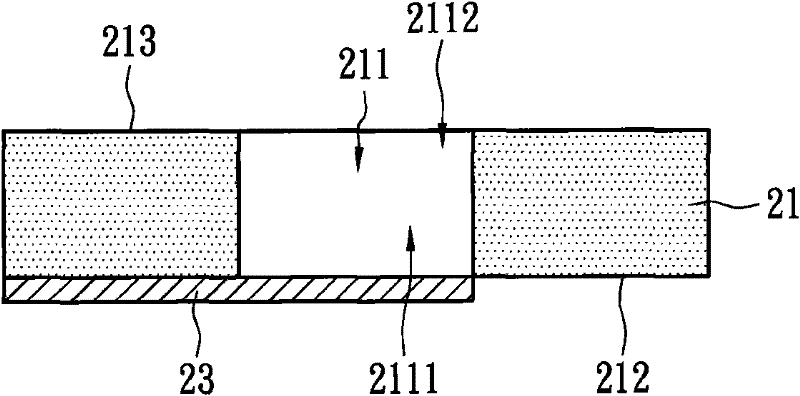

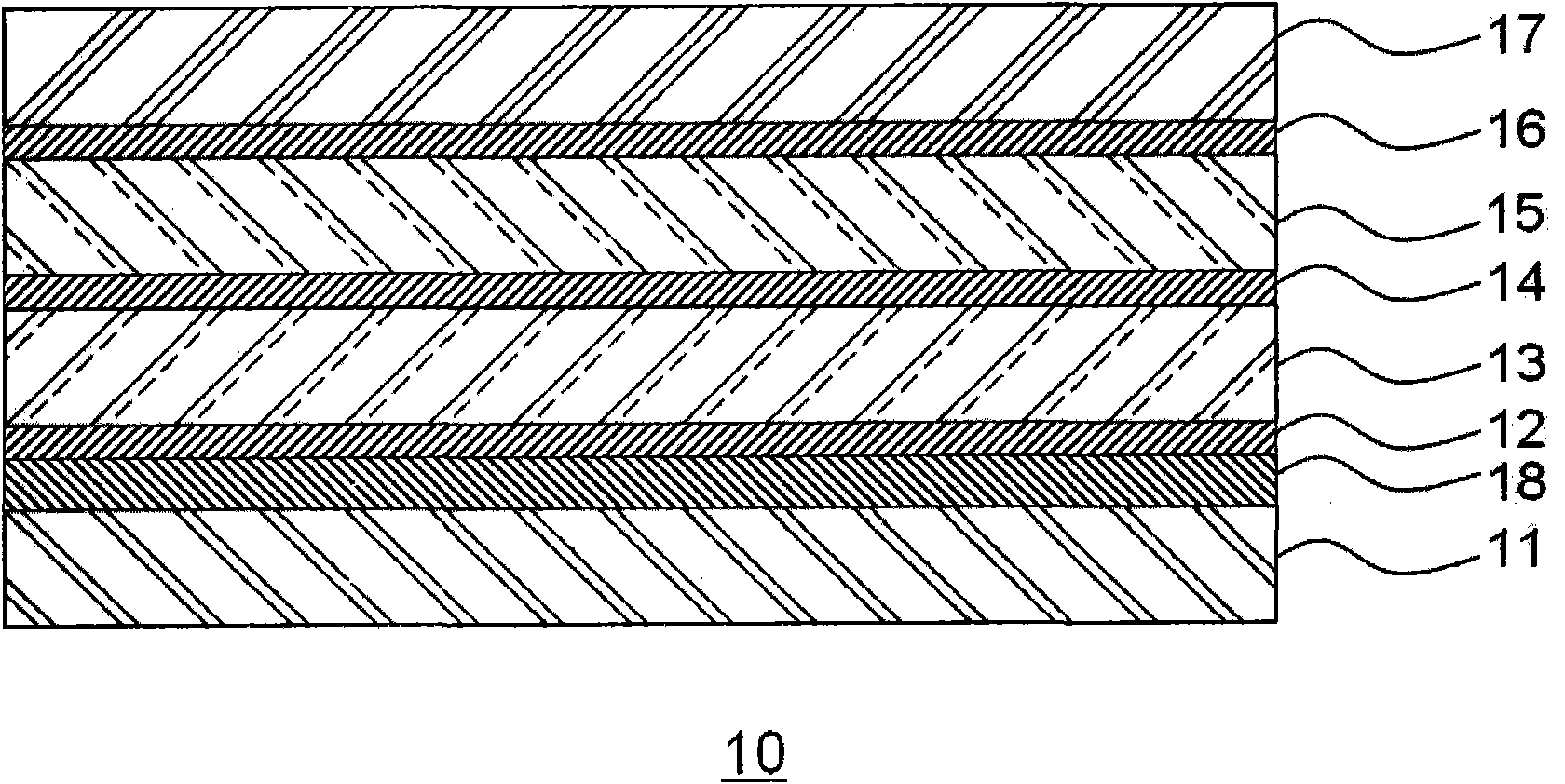

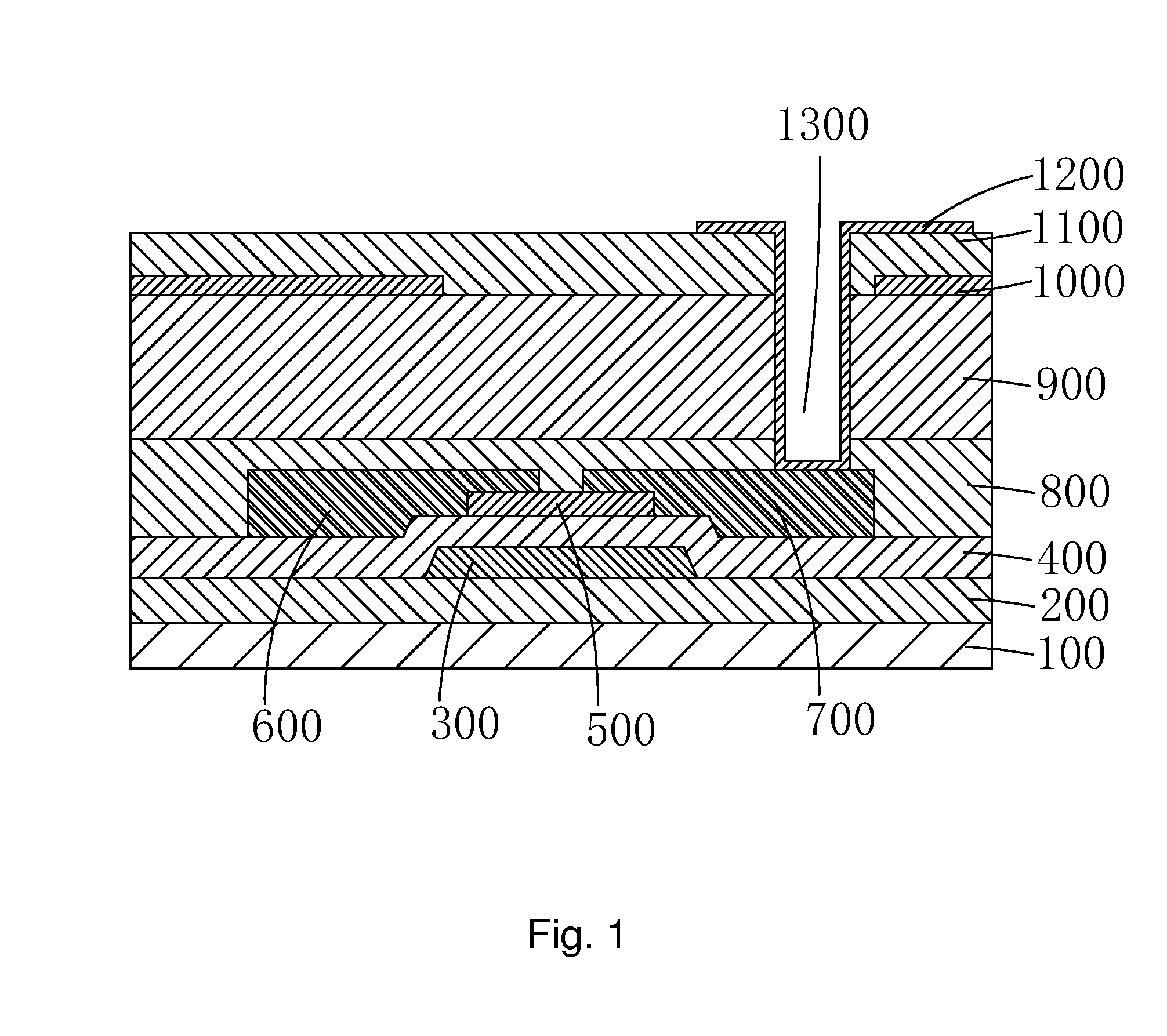

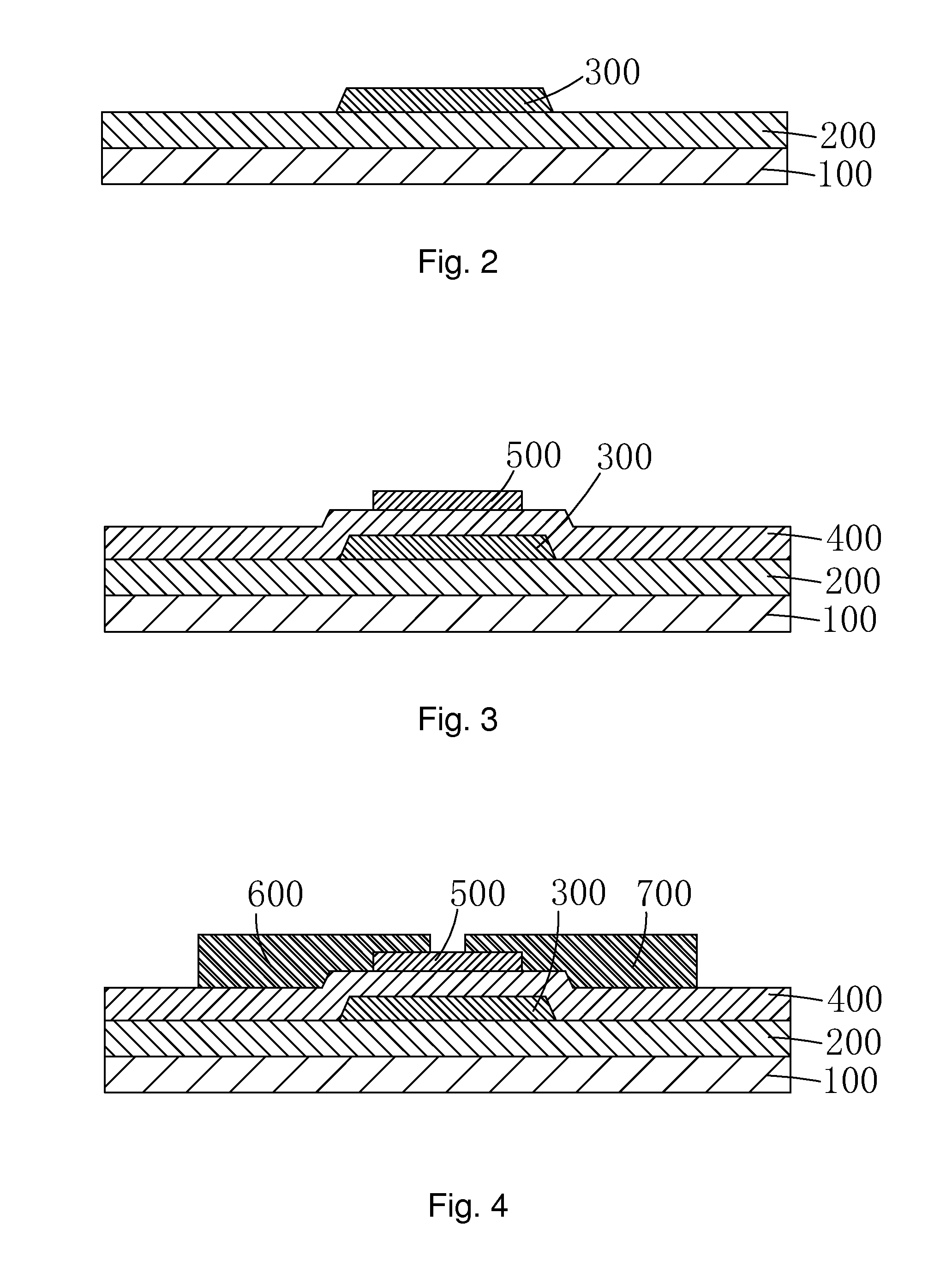

Supporting substrate for manufacturing flexible information display device, manufacturing method thereof, and flexible information display device

InactiveUS20150060870A1Low investment costIncrease equipment costLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device capable of easily separating the flexible information display device from the supporting substrate without deforming or damaging the flexible information display device, a manufacturing method thereof, and a flexible information display device manufactured thereby. The supporting substrate for manufacturing a flexible information display device includes: a coating layer formed therein with a plurality micro-protrusions formed on the supporting substrate; and a temporary bonding / debonding layer formed on the coating layer and including an adhesive material mechanically interlocked with and bonded to the supporting substrate through Van der Waals bonding force. The method provides a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

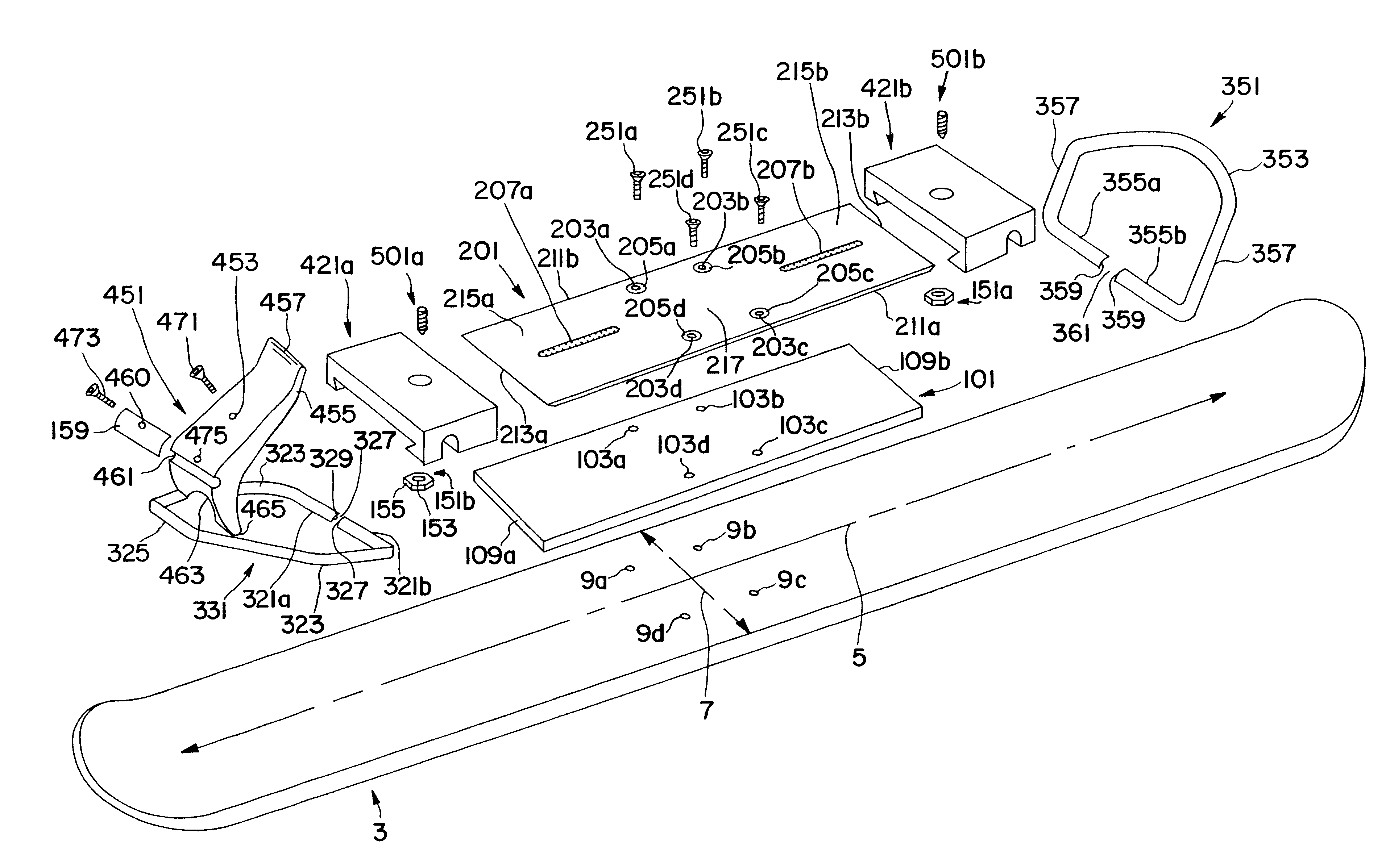

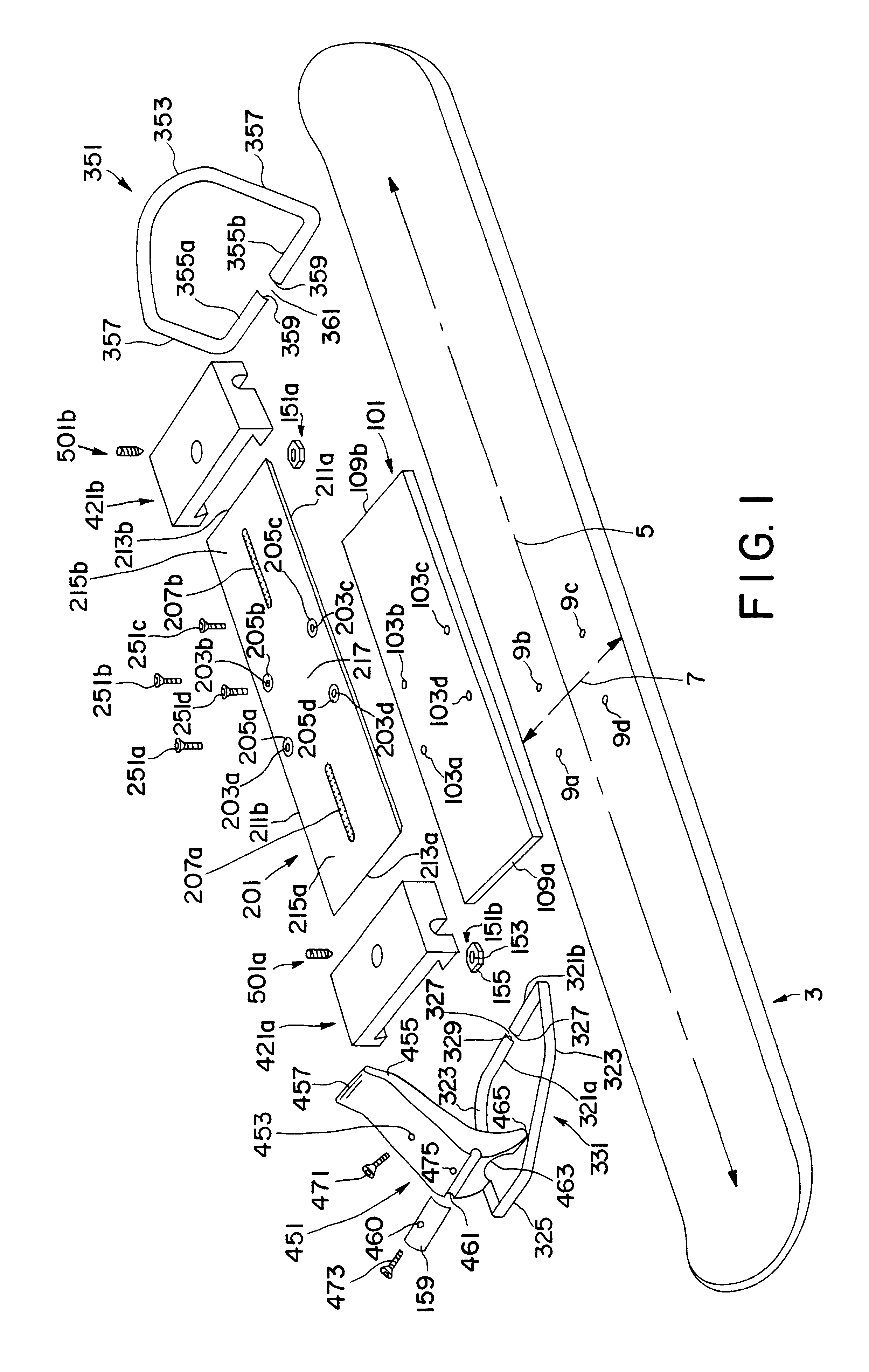

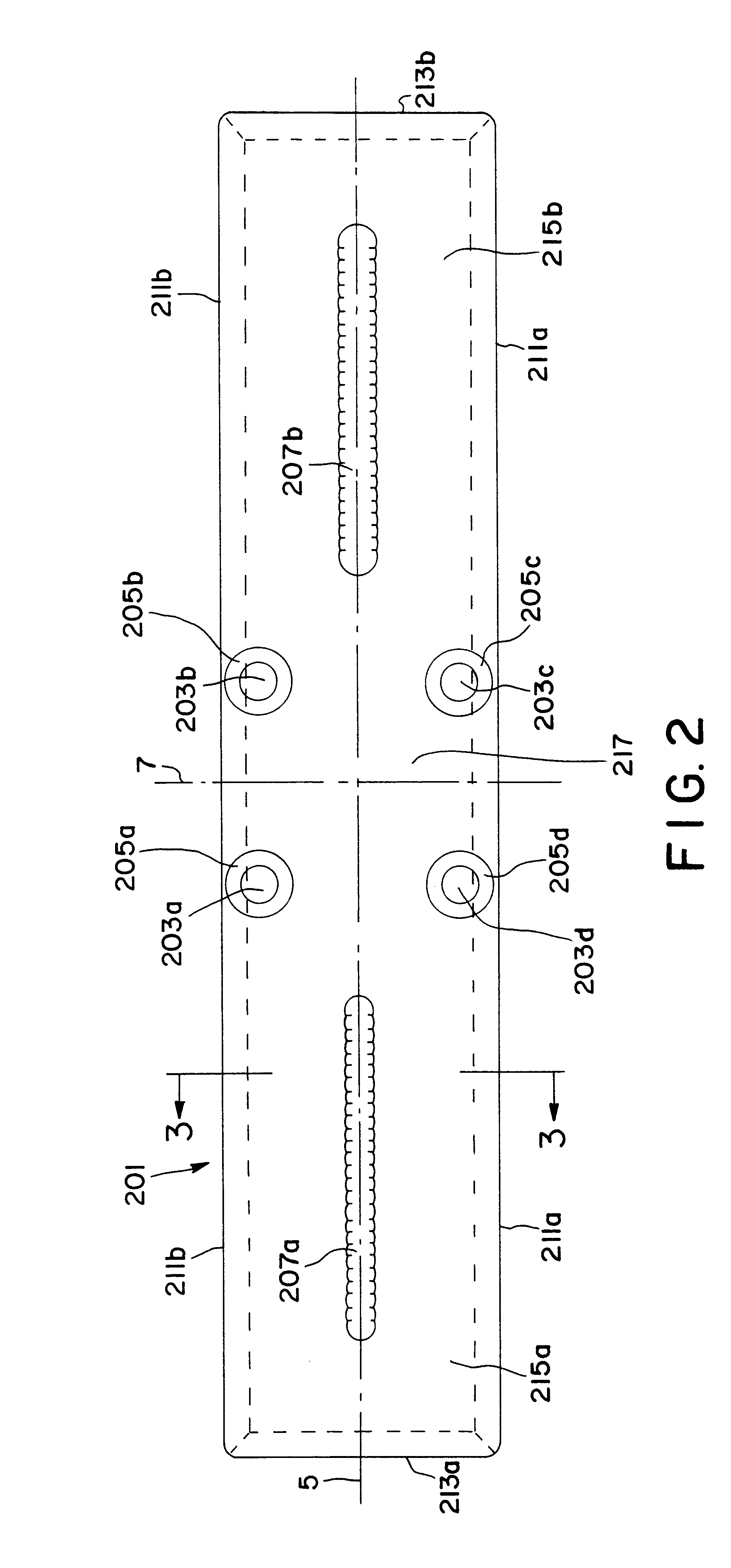

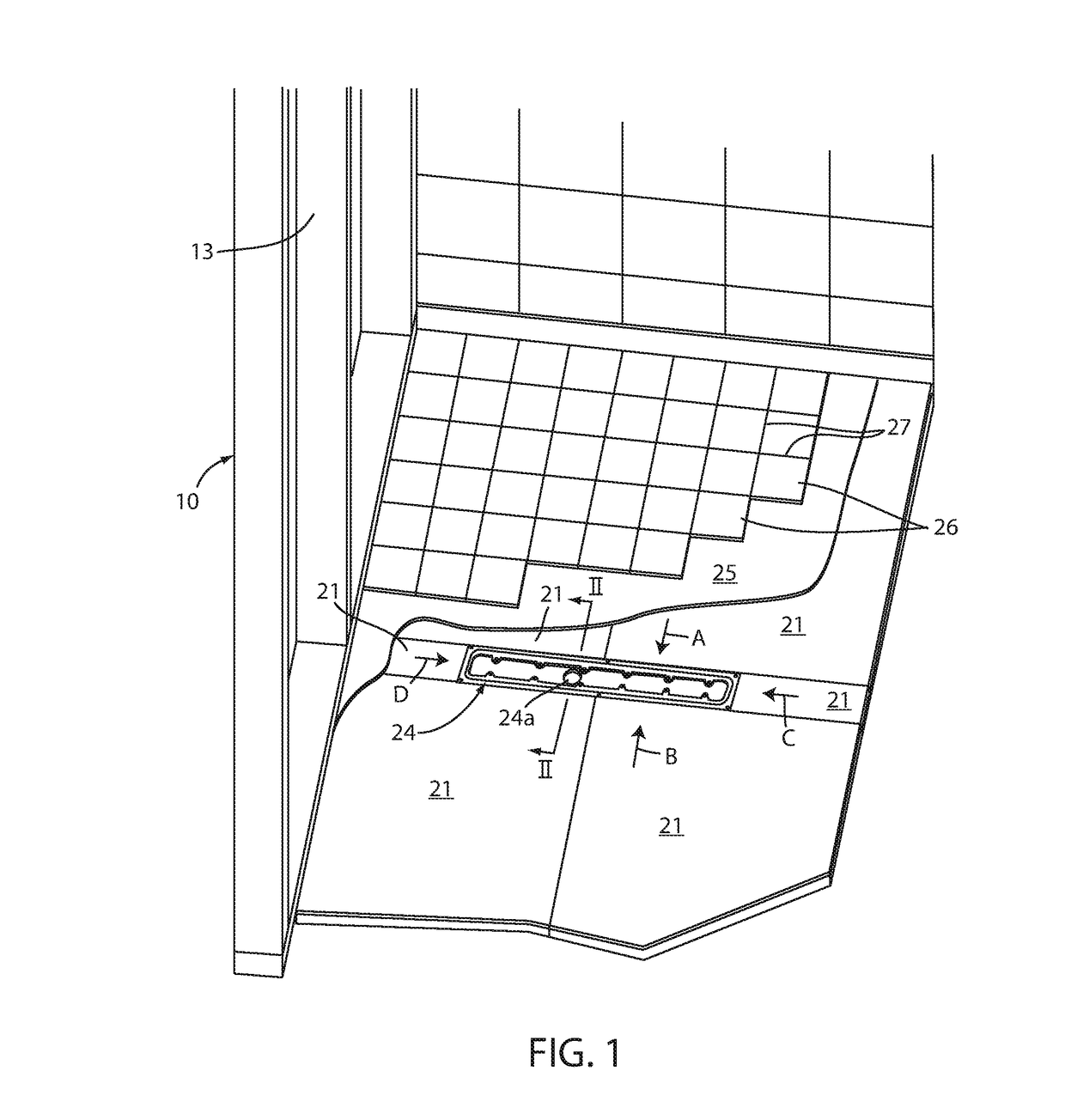

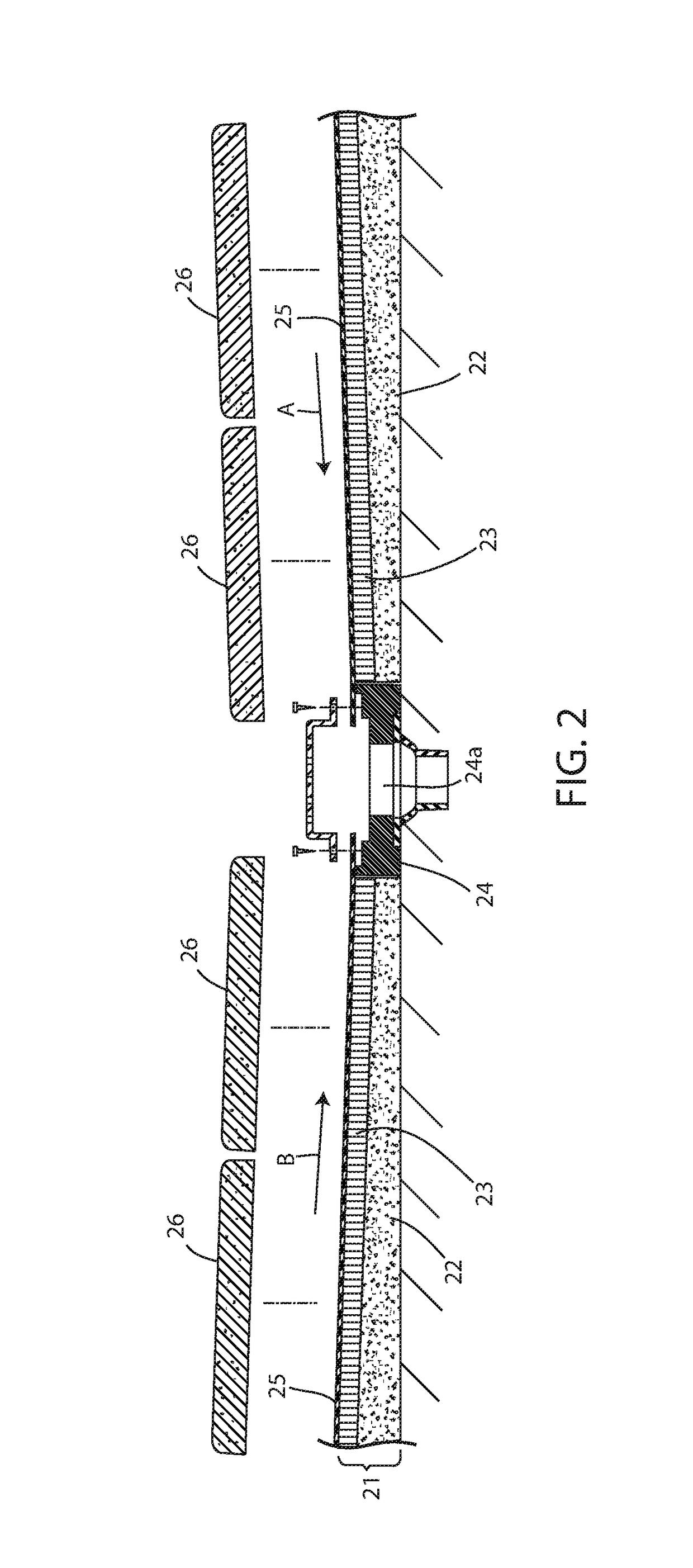

Boot binding system

A boot binding system is shown for use especially on skiboards, having a binding plate, boot supports, bails, a lever, a resilient material, and a size adjustment locking mechanism. Boot supports and binding plate are complimentary shaped for slideable affixation to each, without requiring additional fasteners. A simple fastener locks the relative position of the boot support on the binding plate while also immobilizing any boot support motion. In the locked position, the fastener mates with counterbores in the binding plate's surface. The binding plate is rectangular in top view and its longitudinal edges have a chamfer, which complements a chamfer on the boot supports. The binding plate has mounting holes in its central region, which are used to affix the binding to a skiboard. Resilient material exists between the binding plate and the skiboard, thereby allowing the skiboard to flex more freely. The boot supports have slots to retain the bails. The lever also has a slot to accept a bail. The binding is simple to manufacture and assemble making it cost competitive for production. An alternate embodiment includes a version that eliminates the need for resilient material. A second alternate embodiment eliminates the central mount and mounts to the skiboard in the region of the boot supports.

Owner:CARON ALPINE TECH

Supporting substrate for manufacturing flexible informaiton display device using temporary bonding/debonding layer, manufacturing method thereof, and flexible information display device

InactiveUS20150060869A1High resolutionAvoid low process precisionLiquid surface applicatorsElectric shock equipmentsDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device using a temporary bonding / debonding layer, a manufacturing method thereof, and a flexible information display device. A supporting substrate for manufacturing a flexible information display device, the supporting substrate comprising: a temporary bonding / debonding layer having a thickness in a range of 0.1 nm to 1000 nm and comprising an adhesive material bonded to the supporting substrate through Van der Waals bonding force. Provided is a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

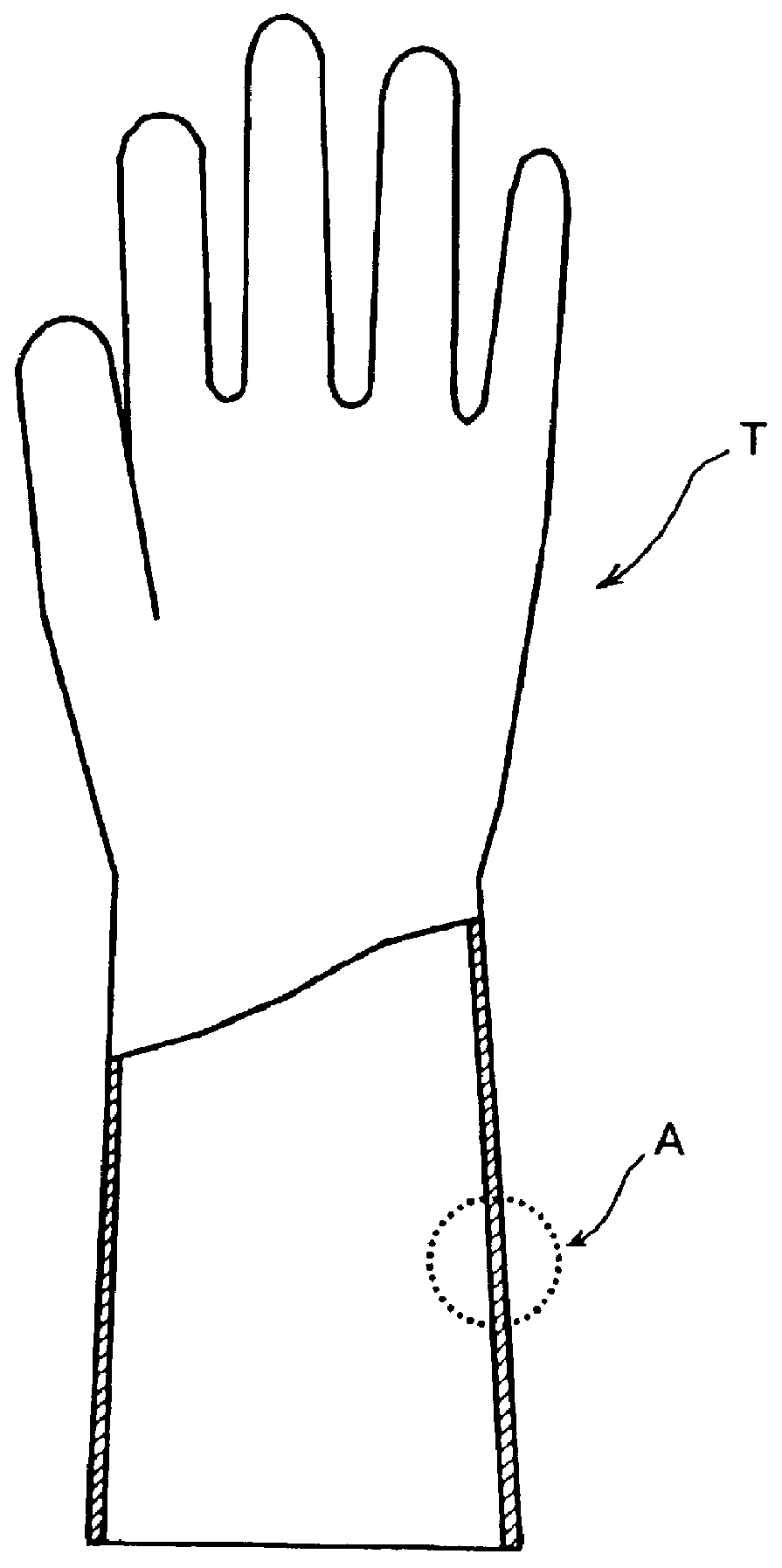

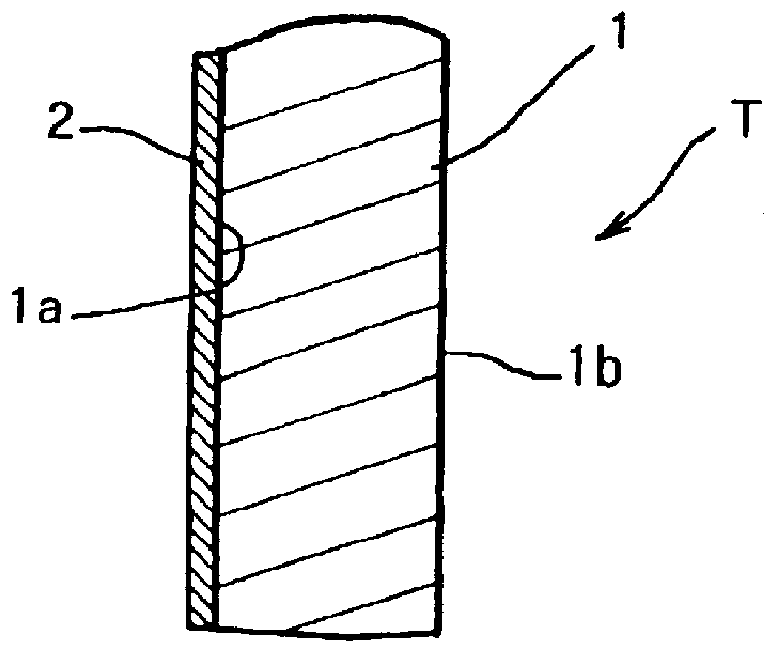

Glove made of polyvinyl chloride resin

InactiveUS6012169AReduce layeringReduce layer thicknessGarment special featuresAntifouling/underwater paintsCost competitivenessAntimicrobial

Owner:SHOWA CORP

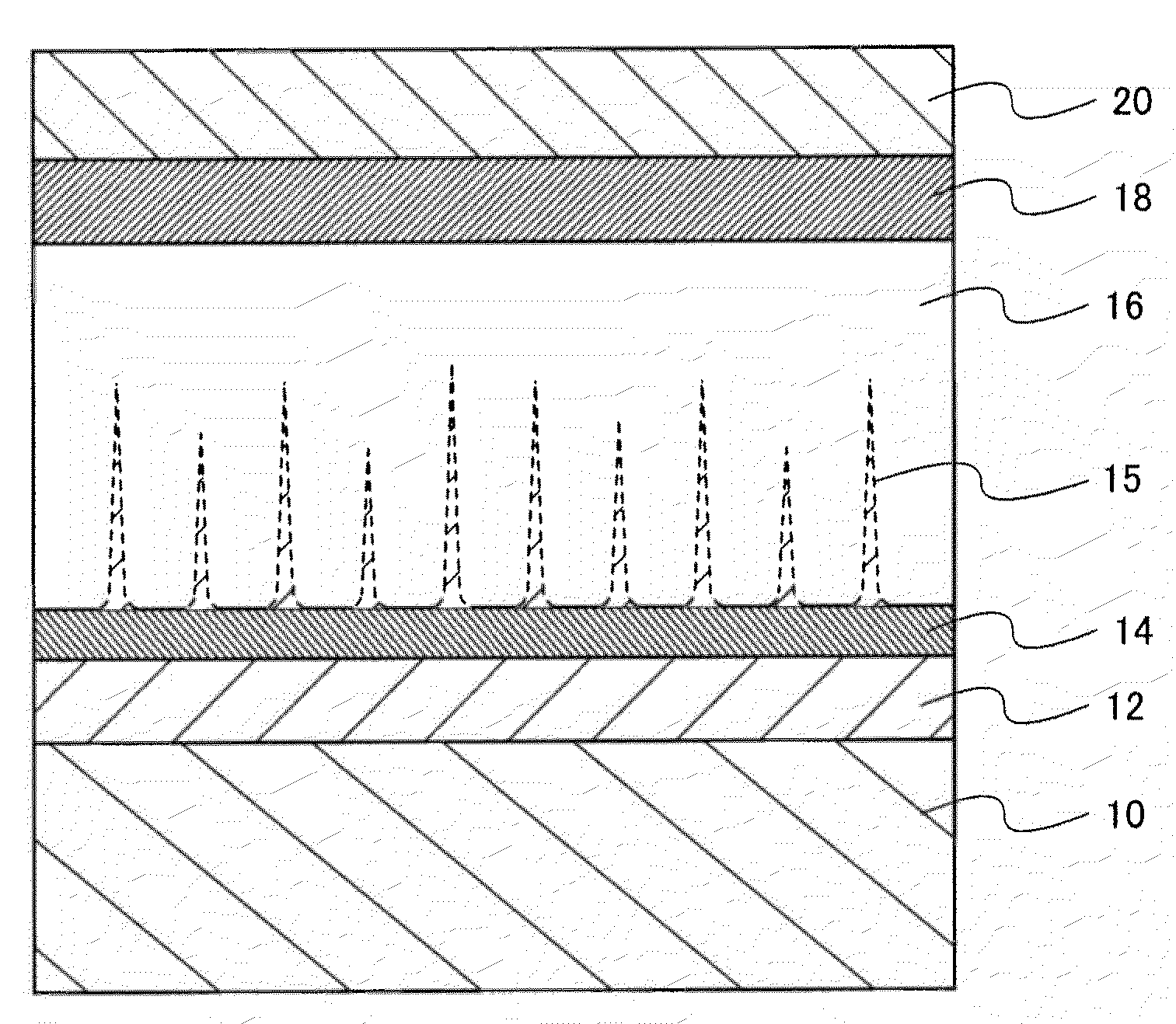

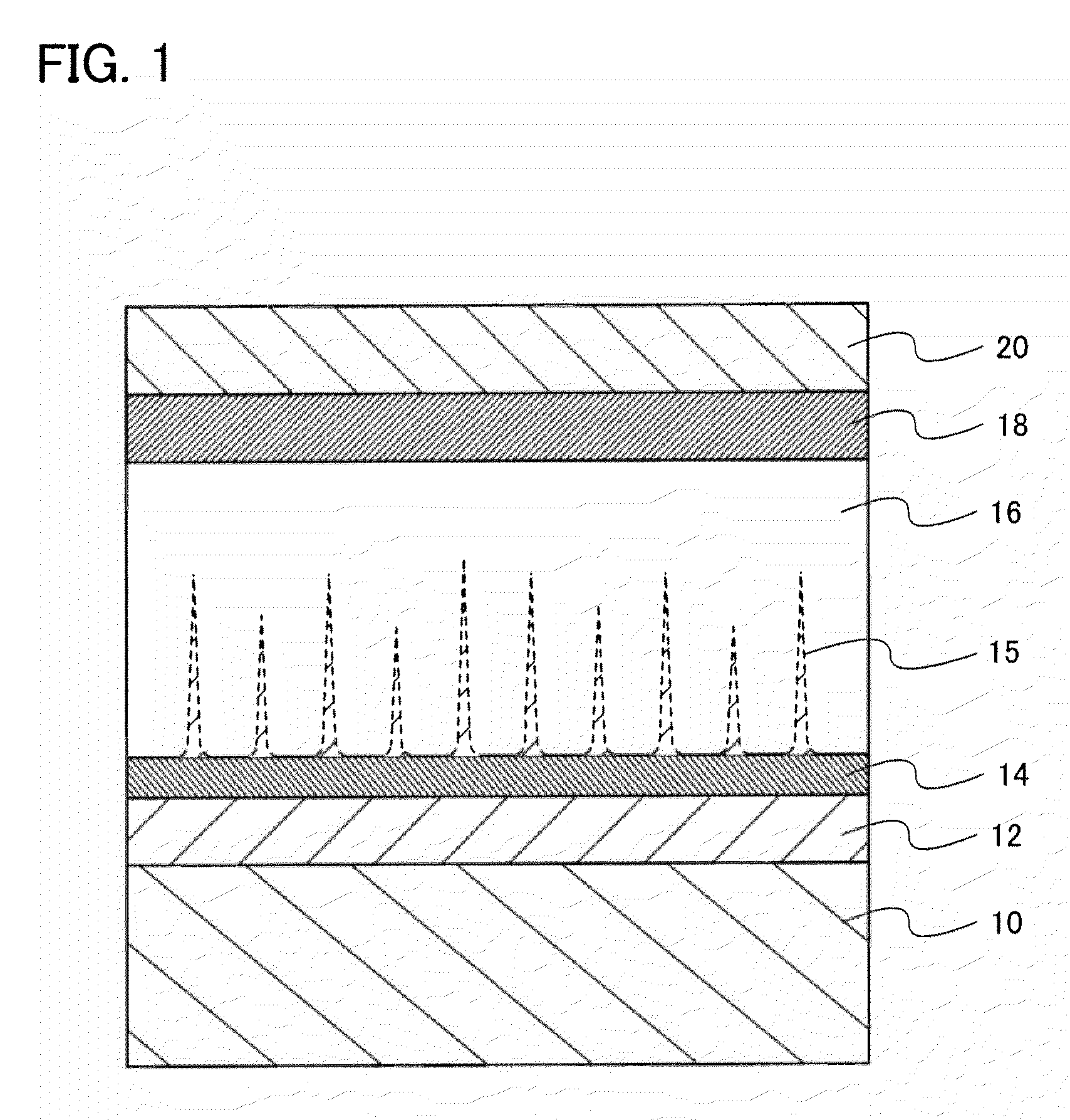

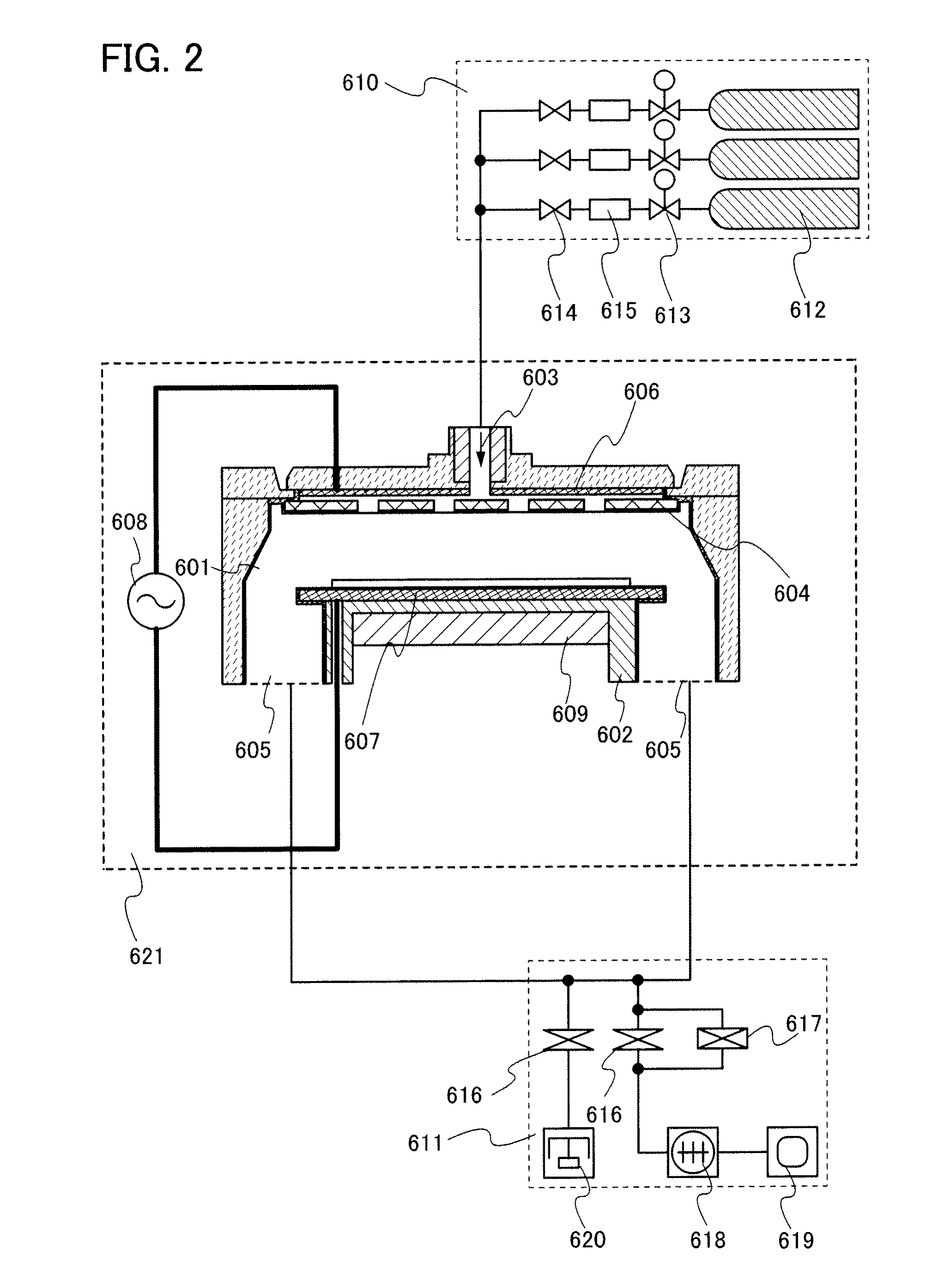

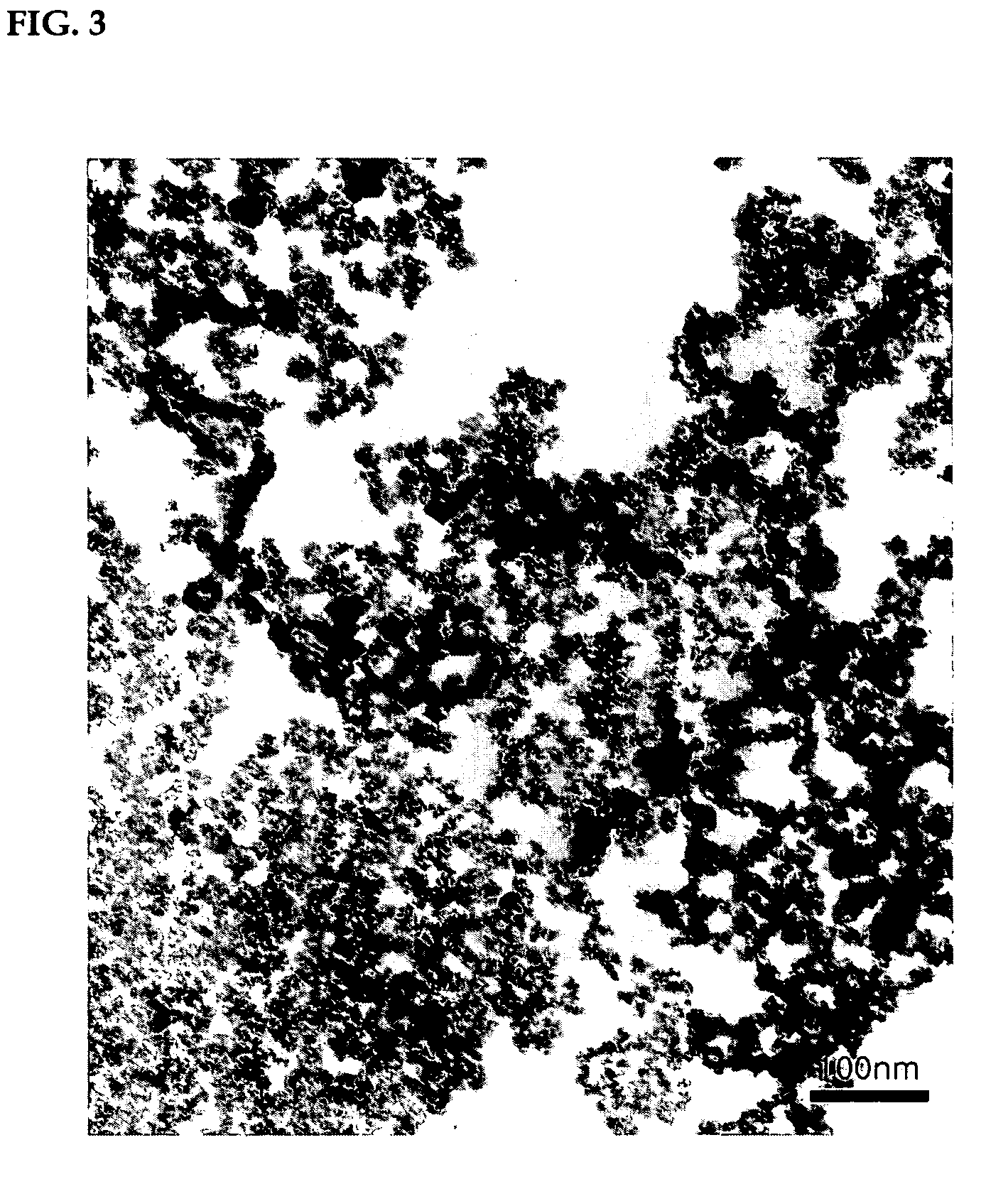

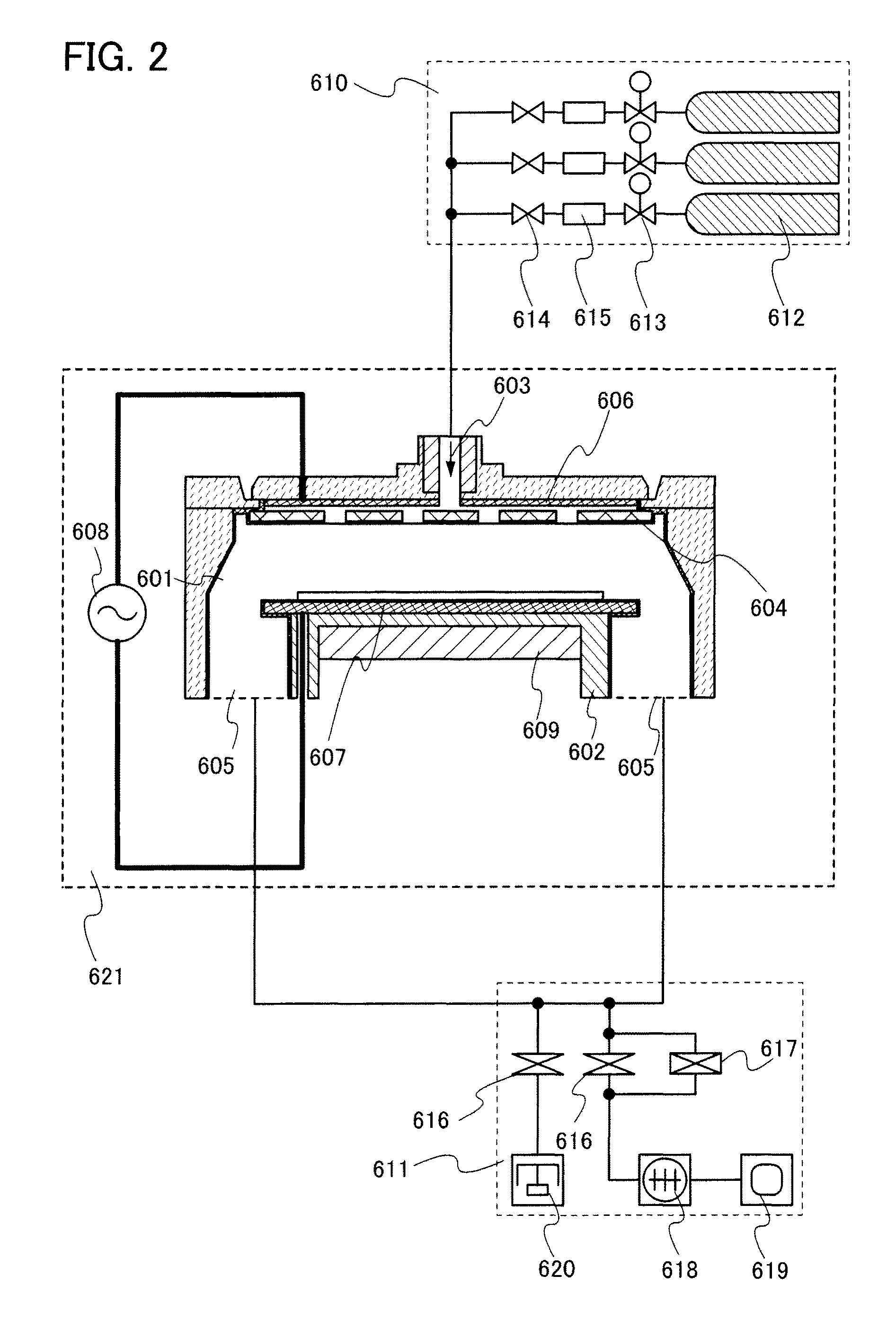

Photoelectric conversion device and method for manufacturing the same

InactiveUS20090267066A1Improve productivityLow costSemiconductor/solid-state device manufacturingSpecial surfacesHydrogenSilanes

To provide a photoelectric conversion device with improved photoelectric conversion characteristics and cost competitiveness. A photoelectric conversion device including a semiconductor junction has a semiconductor layer in which a needle-like crystal is made to grow over an impurity semiconductor layer. The impurity semiconductor layer is formed of a microcrystalline semiconductor and includes an impurity imparting one conductivity type. An amorphous semiconductor layer is deposited on a microcrystalline semiconductor layer by setting the flow rate of a dilution gas (typically silane) to 1 time to 6 times the flow rate of a semiconductor source gas (typically hydrogen) at the time of deposition. Thus, a crystal with a three-dimensional shape tapered in a direction of the deposition of a film, i.e., in a direction from the microcrystalline semiconductor layer to the amorphous semiconductor layer is made to grow.

Owner:SEMICON ENERGY LAB CO LTD

Damage-resistant shower base and installation method

A shower base includes a combination slab where a foam slab (tapered or flat or multi-tapered) having a sloped upper surface is covered with a thin deformation-resisting honeycomb slab (e.g., 0.25-0.30 inch thickness, or more or less). A waterproof membrane and tile are installed on the shower base at the installation site. The method of installation includes installing the premanufactured combination slab at an installation site, and applying a waterproof membrane and thinset-bonded tile with gap-filling grout. This provides a high quality, flexible design that is both efficient and cost-competitive after installation. The honeycomb is sufficiently thick to overcome compression and deformation issues prevalent during tile installation.

Owner:NOBLE CO LTD

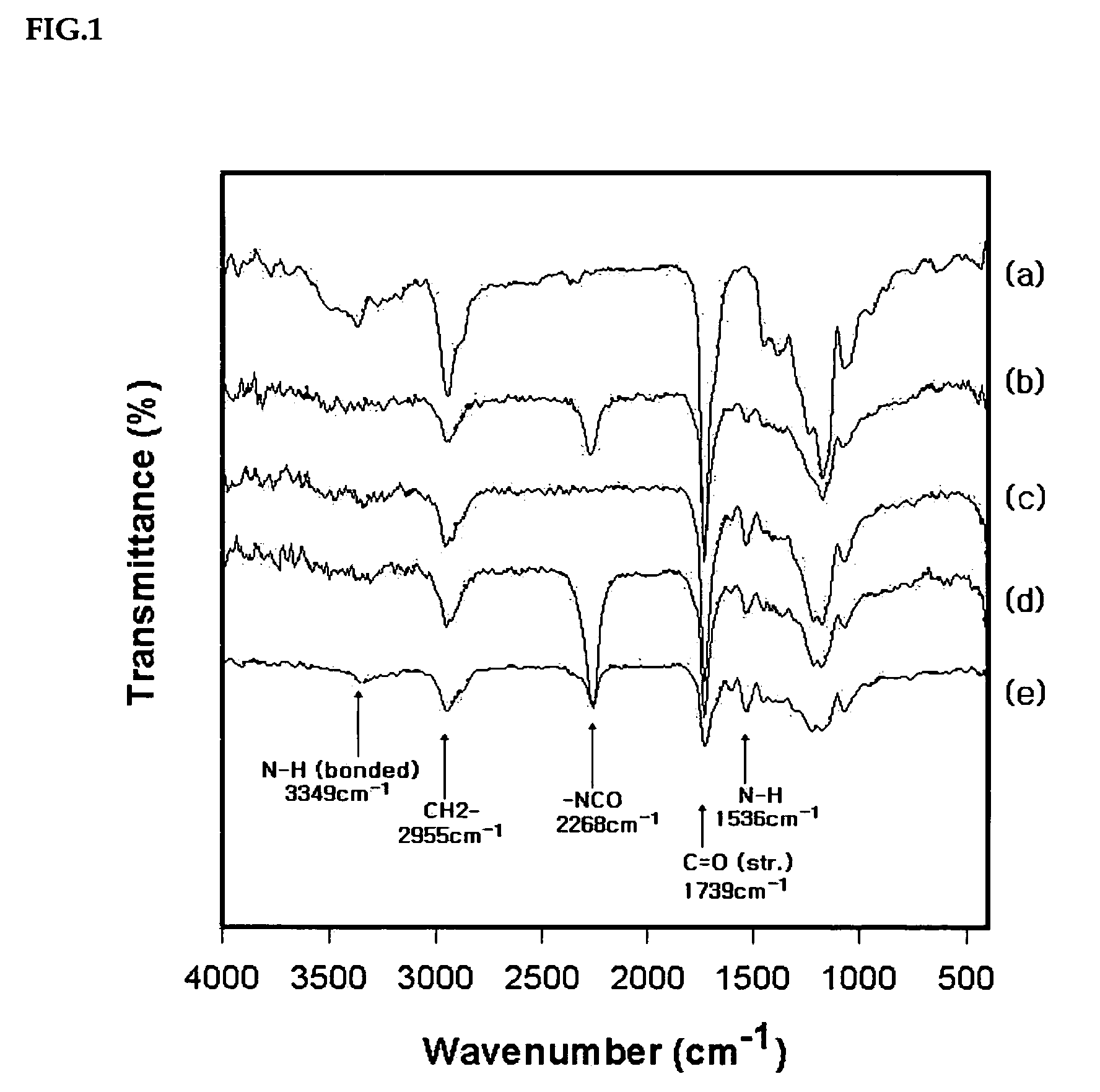

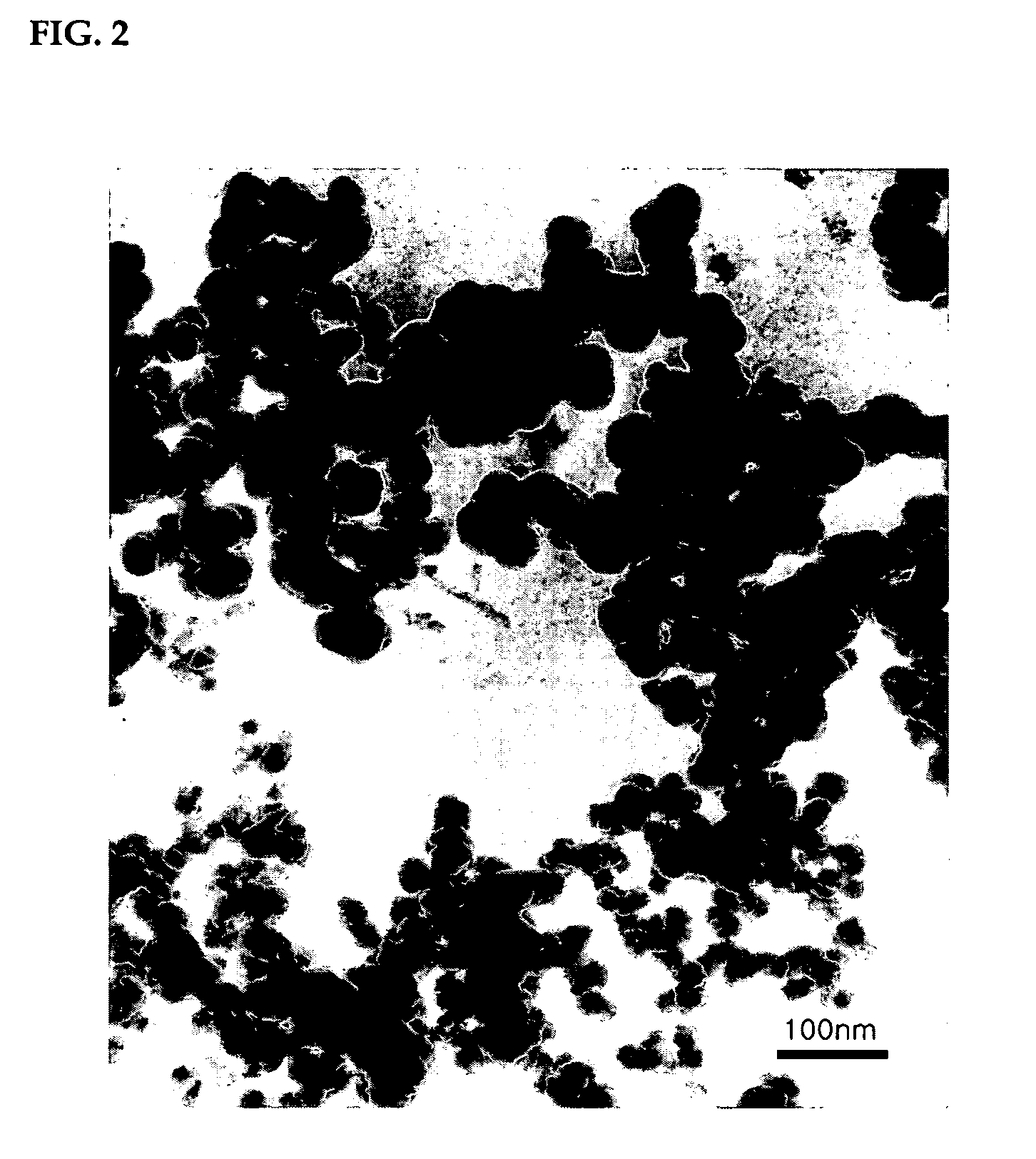

Method of preparing water-dispersible poly (urethane-urea) having aromatic-aliphatic isocyanate

Owner:YONSEI UNIVERSITY

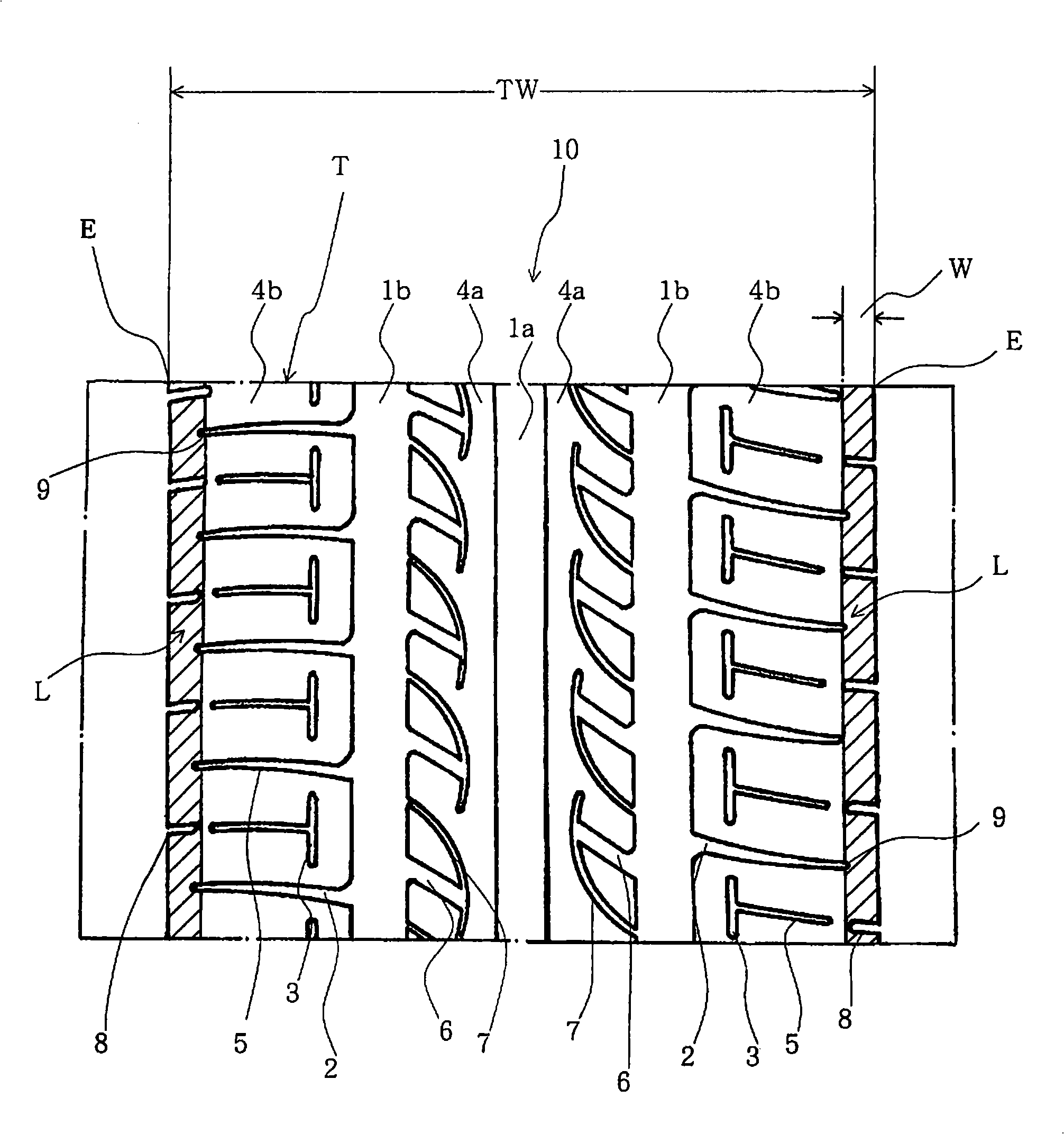

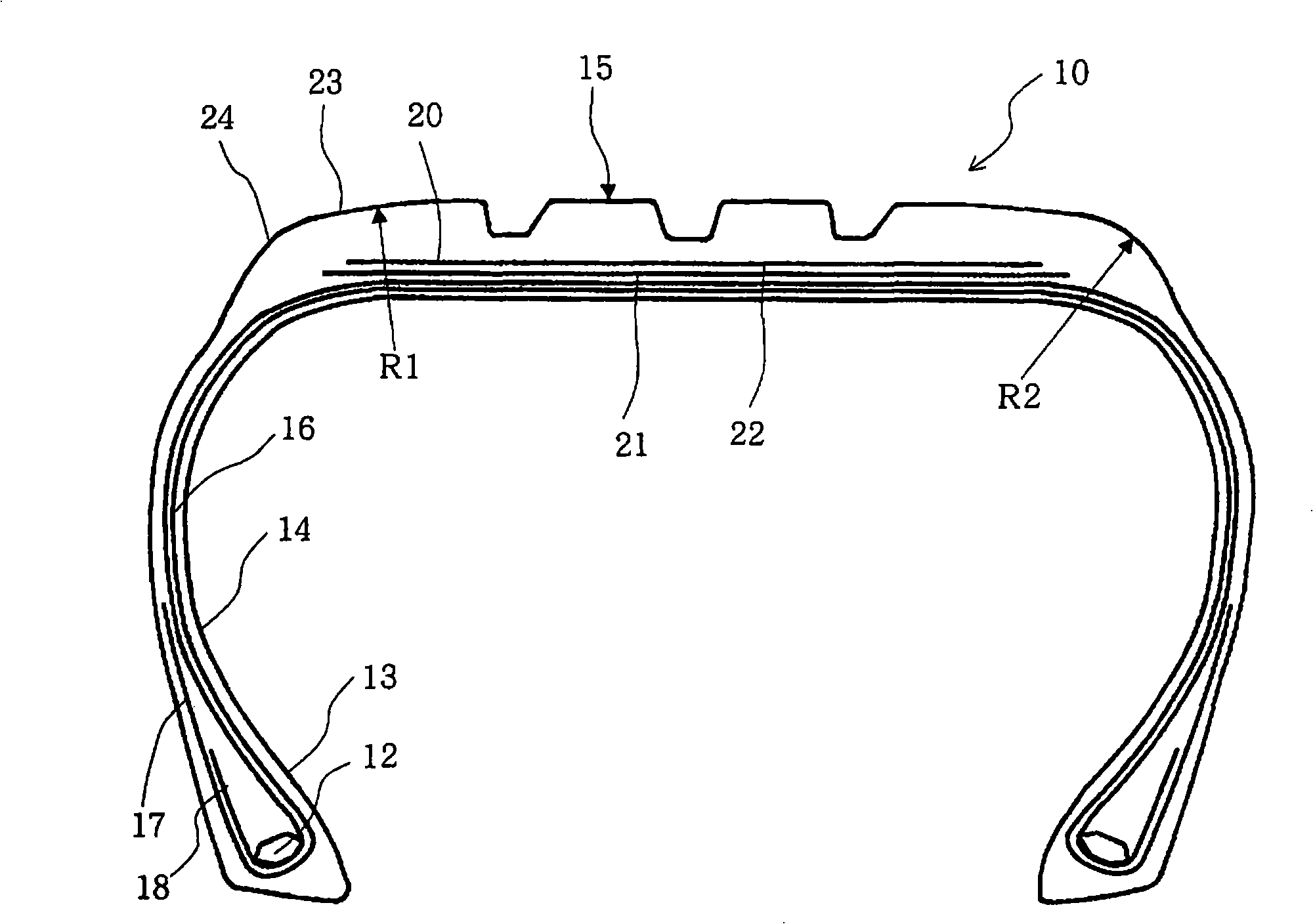

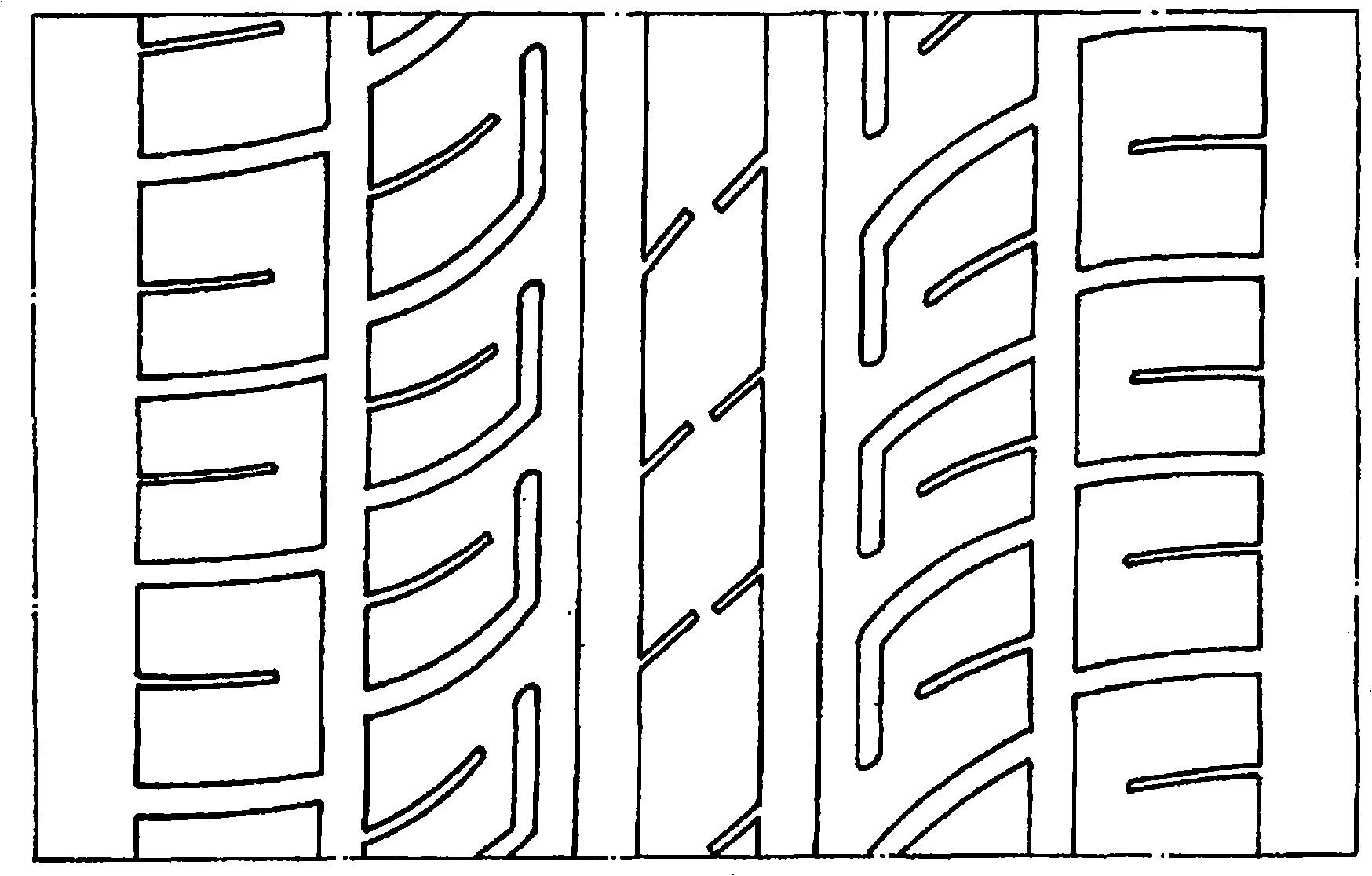

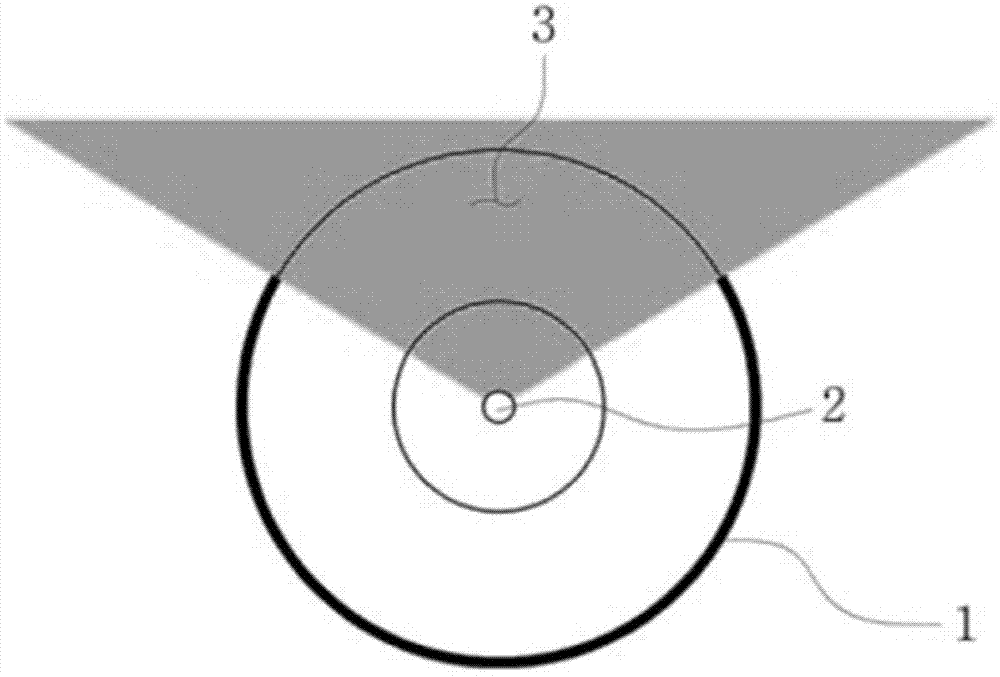

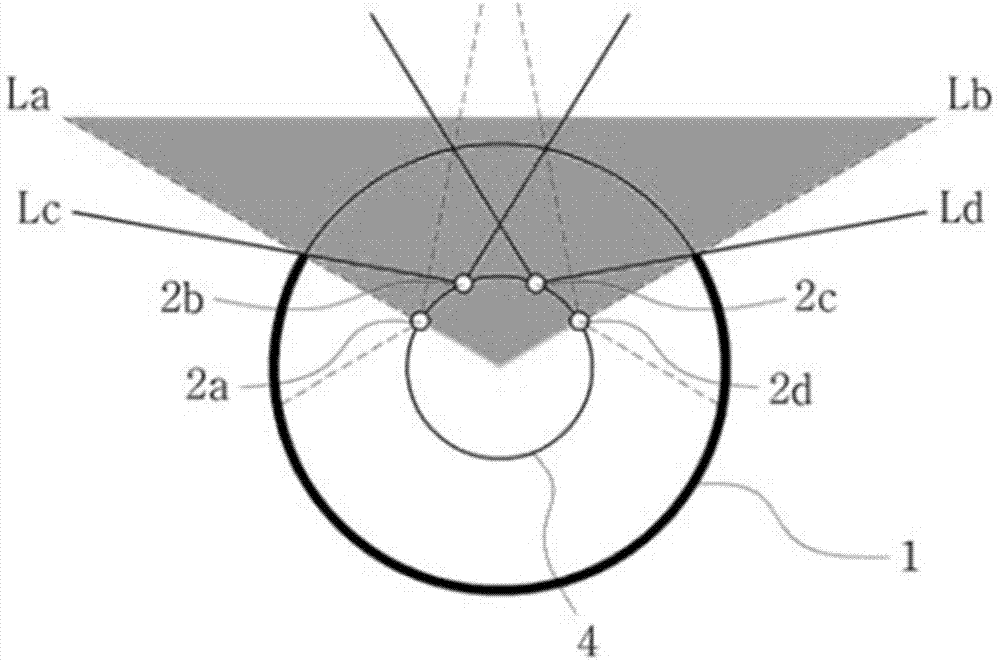

Pneumatic belt tire

InactiveCN101306631AImprove partial wearMaintain cost competitivenessPneumatic tyre reinforcementsTyre tread bands/patternsCost competitivenessGrounding line

The invention provides a pneumatic radial tire having cost competition and improving the bias abrasion performance to the tire shoulder by seeking for the optimization of the ground shape and the ground pressure. The pneumatic radial tire has a translot (2) having a plurality of circumferential main slots (1a, 1b) at the tread portion of the tire and extending along the width direction of the tire and a tread pattern for forming a plurality of ground lines (4a, 4b). In the tier shoulder ground line (4b) comprising ground end (E), a translot (2) extending from the circumferential main slots (1b) nearest to the ground end to the ground end (E) is stopped near the ground end, and continuous ground portions (L) are formed near the ground end. Side of the main slots (1b) of the tier shoulder ground line (4b) is approximately parallel to the intermittent slit auxiliary slot (3).

Owner:BRIDGESTONE CORP

Photoelectric conversion device and method for manufacturing the same

InactiveUS7888167B2Reduce the ratioImprove cost competitivenessSemiconductor/solid-state device manufacturingCoatingsHydrogenSilanes

To provide a photoelectric conversion device with improved photoelectric conversion characteristics and cost competitiveness. A photoelectric conversion device including a semiconductor junction has a semiconductor layer in which a needle-like crystal is made to grow over an impurity semiconductor layer. The impurity semiconductor layer is formed of a microcrystalline semiconductor and includes an impurity imparting one conductivity type. An amorphous semiconductor layer is deposited on a microcrystalline semiconductor layer by setting the flow rate of a dilution gas (typically silane) to 1 time to 6 times the flow rate of a semiconductor source gas (typically hydrogen) at the time of deposition. Thus, a crystal with a three-dimensional shape tapered in a direction of the deposition of a film, i.e., in a direction from the microcrystalline semiconductor layer to the amorphous semiconductor layer is made to grow.

Owner:SEMICON ENERGY LAB CO LTD

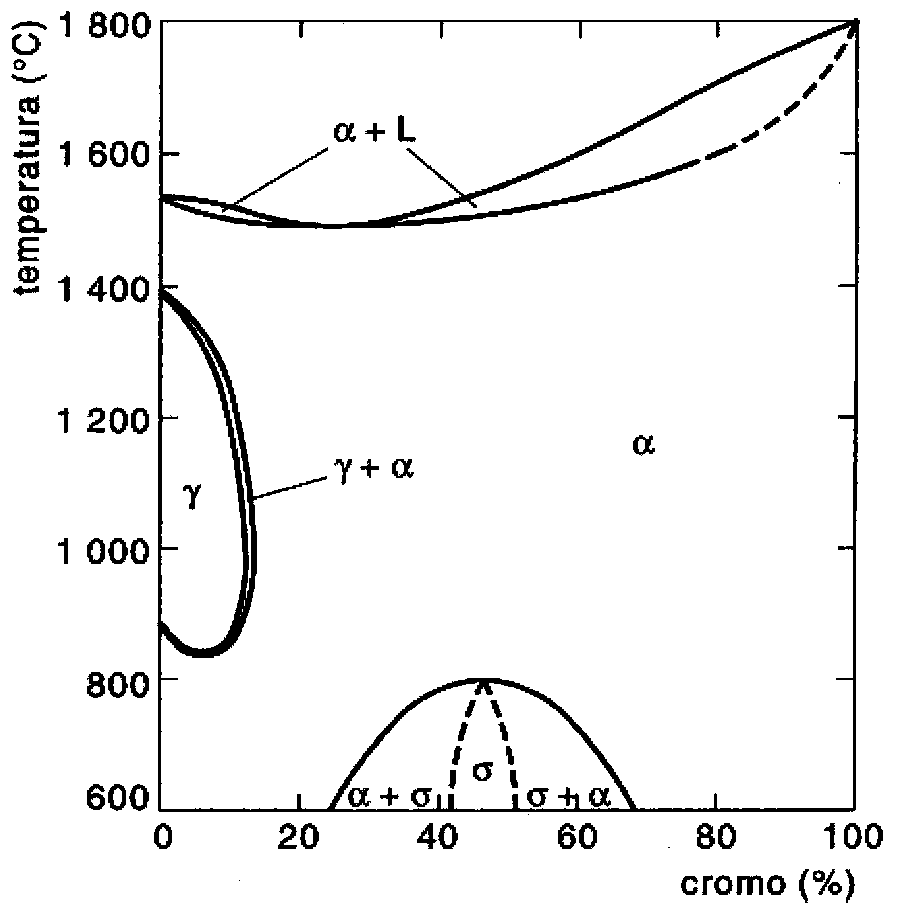

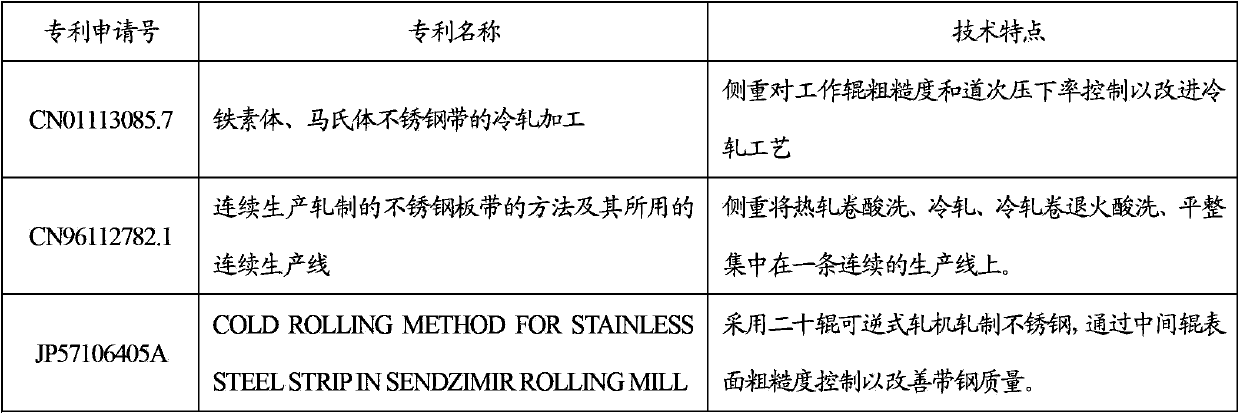

Manufacturing method for medium chrome ferrite stainless steel

InactiveCN103966409ASimplify the process flowImprove cost competitivenessRoom temperatureStrip steel

The invention provides a manufacturing method for medium chrome ferrite stainless steel. The method consists of the processes of: smelting, continuous casting, hot rolling, coiling, acid pickling, cold rolling, cold coiling annealing and pickling. In the hot rolling process, subjecting a hot rolled black coil to hot rolling at a finishing rolling temperature of 860-1000DEG C, and conducting coiling at 750-850DEG C; after coiling, subjecting the hot coil to heat preservation in a heat preservation pit directly, controlling the temperature of the hot coil sent into the heat preservation pit greater than 750DEG C, slowly cooling a steel coil at a cooling speed of less than 20DEG C / h, taking the steel coil out of the pit when the temperature of the steel coil is lower than 200DEG C, and performing air cooling to room temperature; subjecting the hot rolled black coil to acid pickling directly on a continuous acid pickling line, and removing the surface oxide scale; after acid pickling, conducting cold rolling on the steel coil; carrying out recrystallization and continuous annealing on cold-rolled strip steel; and performing acid pickling to remove the surface oxide scale, and at the same time conducting passivation treatment on the strip steel. The method provided by the invention omits the process of hot coil bell-type furnace annealing, simplifies the process flow, and strengthens the cost competitiveness. Compared with single-stand reversible rolling, cold continuous rolling has the advantages of high production efficiency and low cost.

Owner:BAOSTEEL STAINLESS STEEL

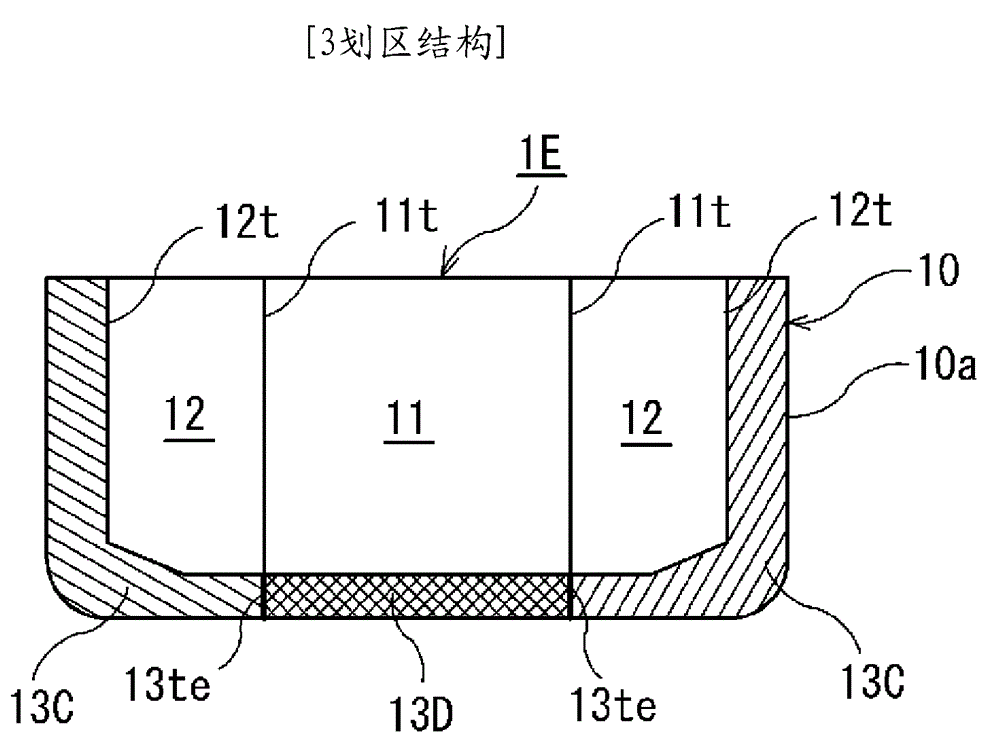

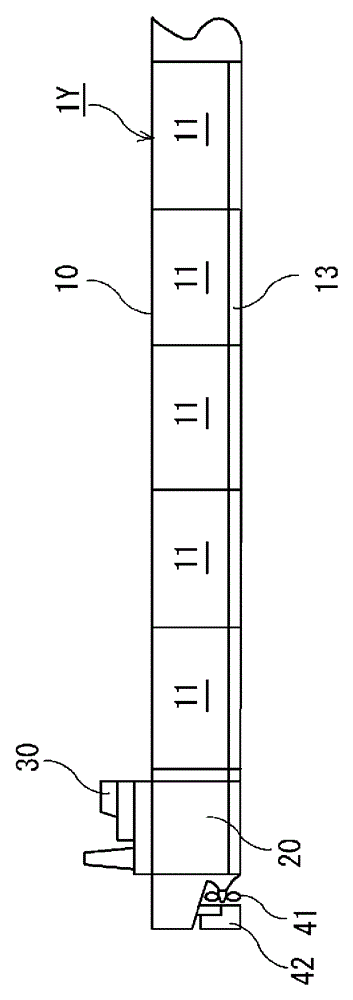

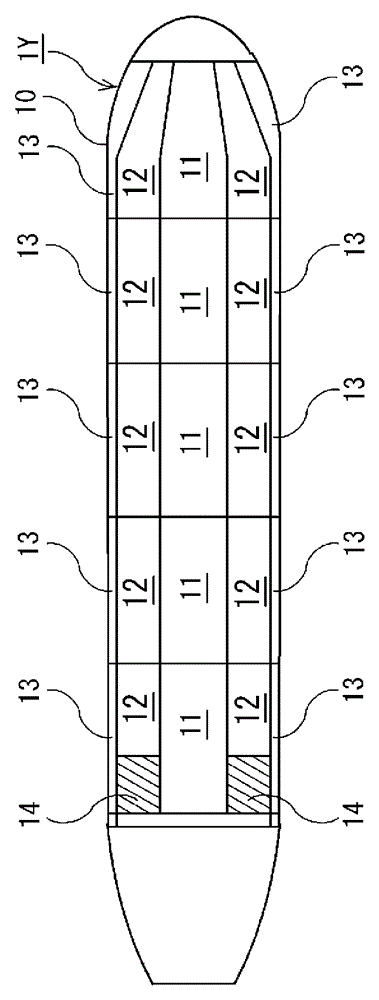

Navicular structure and method for designing navicular structure

ActiveCN105209334ACheap and fast supplyEasy to useHull interior subdivisionCollision preventionMarine engineeringBeam direction

A navicular structure having a tank structure shared between a tanker and a floating offshore storage structure, and a method for designing a navicular structure; wherein wing cargo tanks (12) and shipboard and ship-bottom sections (13) are provided sequentially toward both outer sides of the ship from middle center cargo tanks (11) in bilateral symmetry in the beam direction, the tanks excluding slop tanks (14) are counted, and the number (Nw) of wing cargo tanks (12) on one side of the ship is set greater than the number (Nc) of center cargo tanks (11). A section placement particularly resistant to shipboard damage is thereby planned with as little increase as possible in the number of costly tanks, i.e., in the surface area of the watertight bulkheads for partitioning the tanks, the tanker remains easy to use, the cost is kept competitive, and the section placement can be used in a floating offshore storage structure. A floating offshore storage structure that has reduced design costs and shortened lead time is provided inexpensively and quickly.

Owner:MITSUI ENG & SHIPBUILD CO LTD

Formulations of peg-interferon alpha conjugates

Lyophilized and stabilized formulations of PEG-Interferon alpha conjugates and the process for their preparation that reduces lyophilization cycle time and are more cost competitive.

Owner:CADILA HEALTHCARE LTD

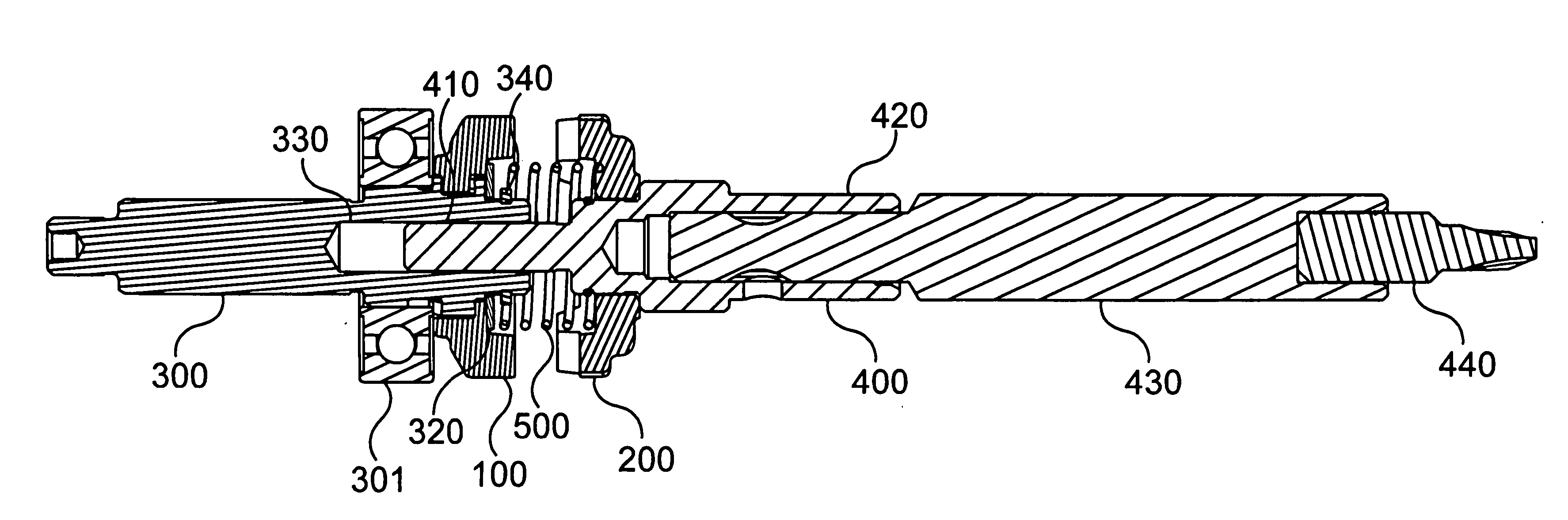

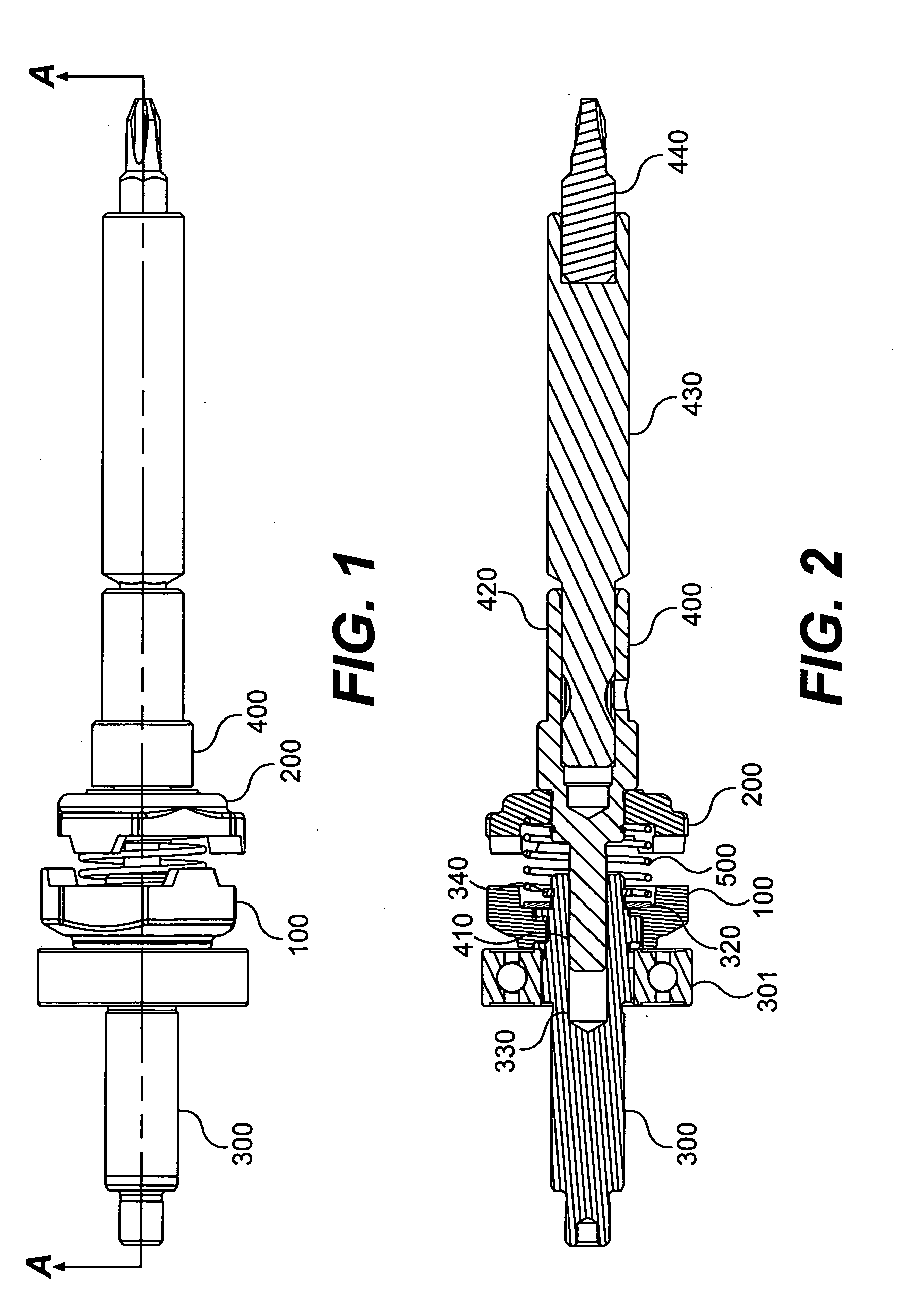

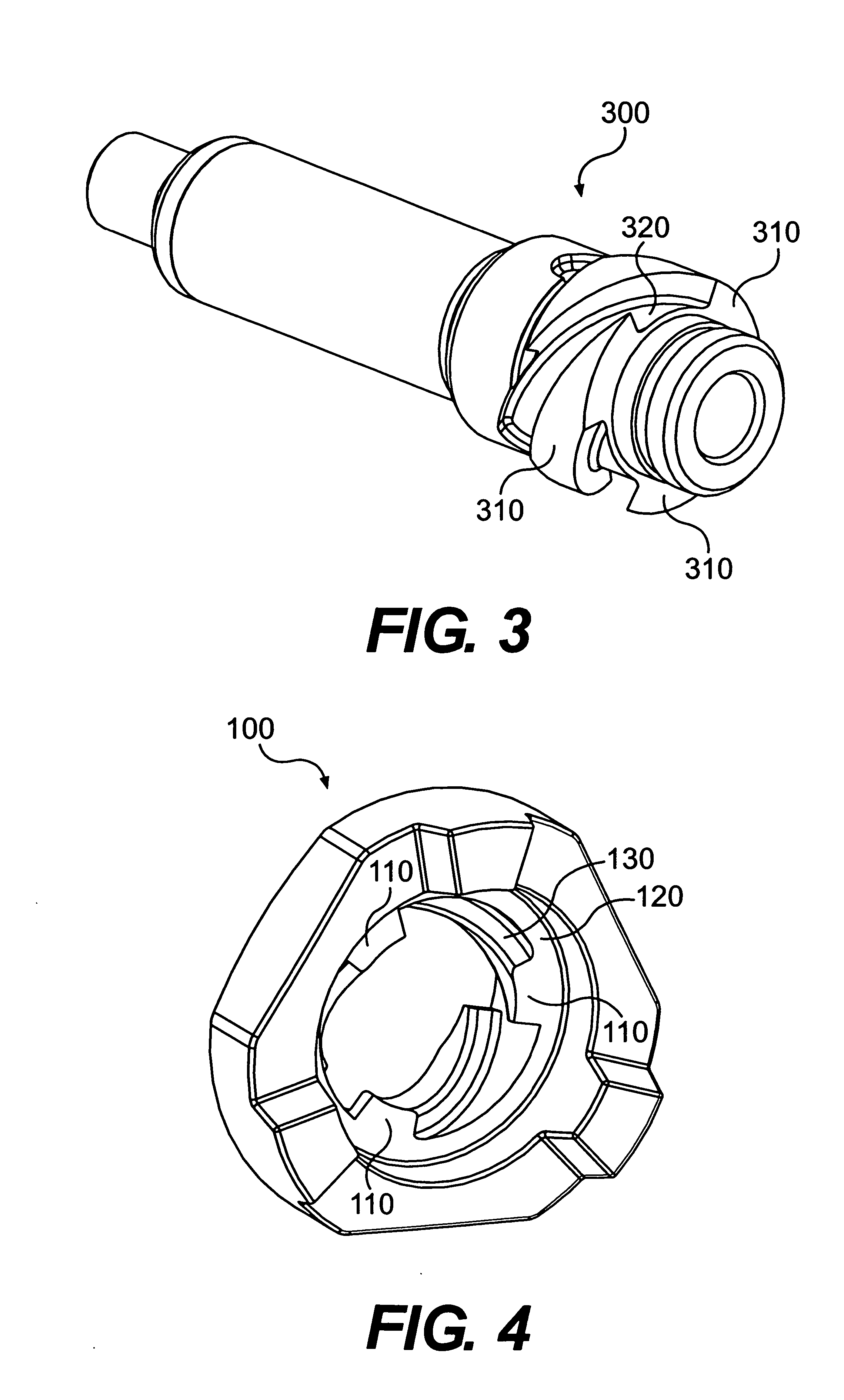

Material and process of manufacture of steel components for screw gun clutches

A process for manufacturing highly wear and fatigue resistant steel components for power tools includes melting and mixing together a readily available base steel and alloying elements. The molten steel is cast into near-net-shape in an investment casting process. This method is cost competitive with forming the same component from steel with fewer alloying elements. In particular, clutch plates for a drill / driver or screw gun can be formed in this manner from a steel containing relatively large amounts of nickel and chromium, such as SAE 9310 steel, or from a steel containing a relatively large total amount of molybdenum and tungsten, such as AISI M2 steel.

Owner:CHATERJEE BIMAL KUMAR +3

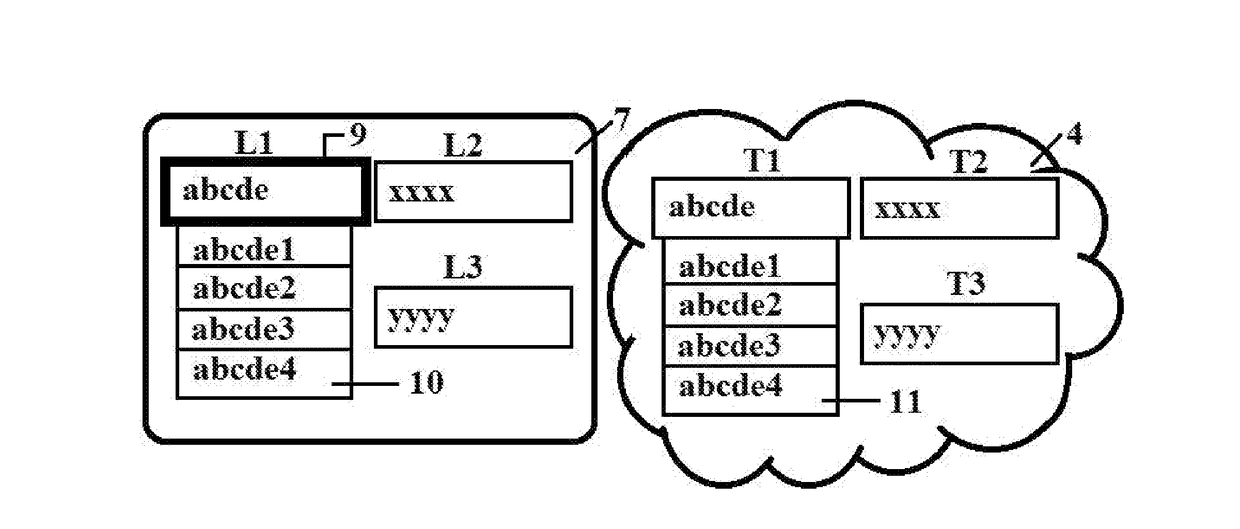

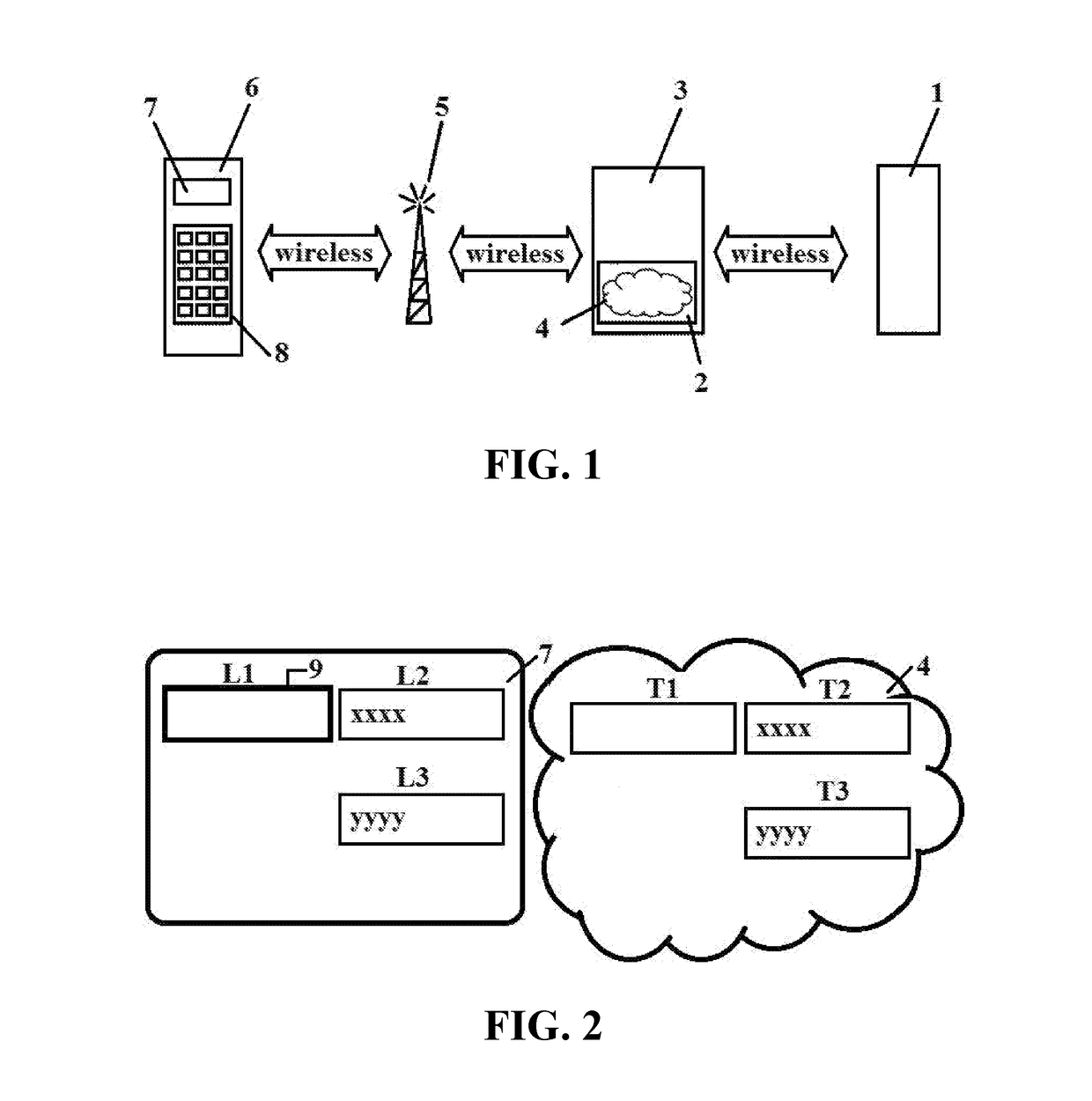

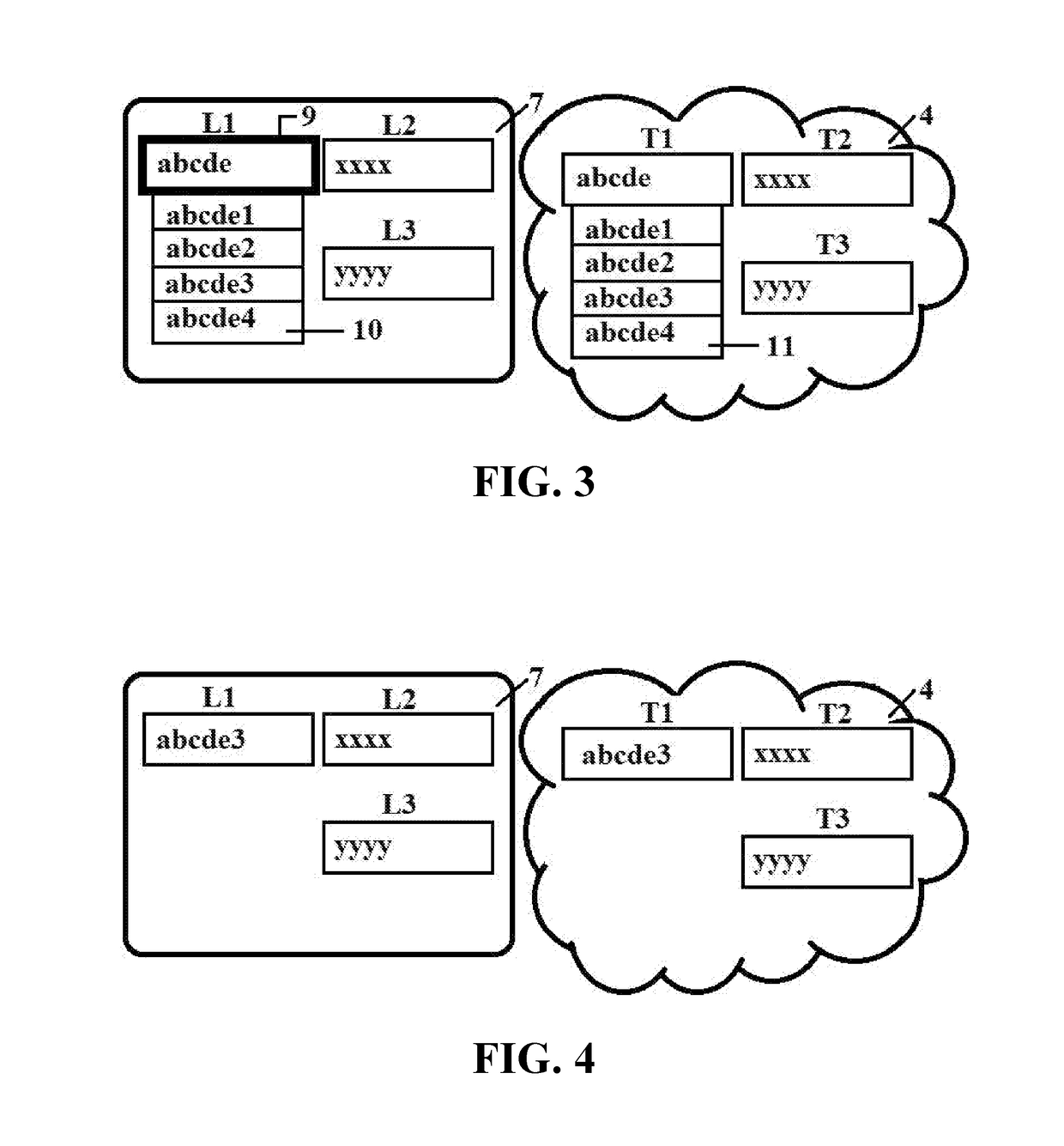

System for reducing user-perceived lag in text data input and exchange with a server

ActiveUS20180157501A1Reduces likelihood and durationReduce the amount requiredNatural language data processingTransmissionInternet contentUser perception

The invention discloses a system for accessing and viewing Internet content on a portable device by means of a proxy server. The server requests web content, renders it and sends compressed image parts to the device. In order for the device to be cost-competitive, its processing operations are generally limited to decompressing image parts and displaying them. The server sends information to the device that allows it to locally create, display and manage text boxes, in which the user can type immediately. As a user types into a local text box, text input data is communicated to the server and processed therein before further requests for web content. By simultaneously managing multiple text boxes locally, the present invention reduces instances of data transfer from the server to the device, which decreases the likelihood of lag and improves the performance of the device.

Owner:TULI RAJA SINGH

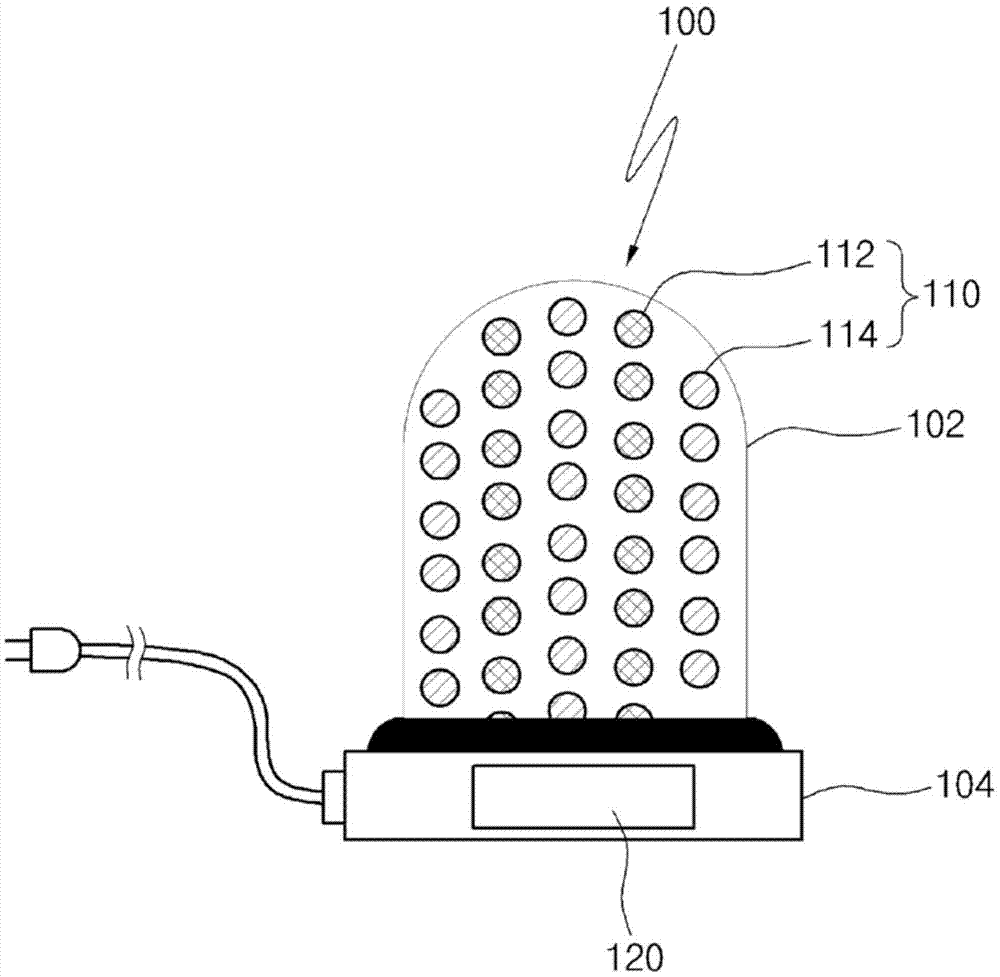

Marine led navigation lights

ActiveCN103697370AAvoid collisionStrong impact resistanceLighting applicationsNon-electric lightingComputer moduleEngineering

The invention provides marine LED navigation lights which performs primary restriction on angle of light emitted from an LED through forming a shielding component by LED modules and performs secondary restriction on angle of the light emitted from the LED through forming a locking part at a housing, so that collision between ships can be prevented without breaking through International Regulations for Preventing Collisions at sea. Furthermore the invention provides the marine LED navigation lights which have advantages of high impact resistance, long service life, remarkable power and maintenance cost reduction and cost competitiveness improvement through replacing existing incandescent lamps by LEDs. The marine LED navigation lights provided by the invention comprise the components of: a housing which accepts a main board in the internal space; a plurality of LED modules which are arranged on a main substrate and is provided with a plurality of LEDs for emitting light; and a cover which covers the upper part of the housing, wherein the LED module comprises the following components: a heat radiating board which is internally provided with a central hole; LEDs which are formed outside the heat radiating board and are used for emitting light; and heat radiating fins which are formed in the central hole of the heat radiating board and are used for radiating heat transmitted from the LEDs.

Owner:KUK DONG ELECOM

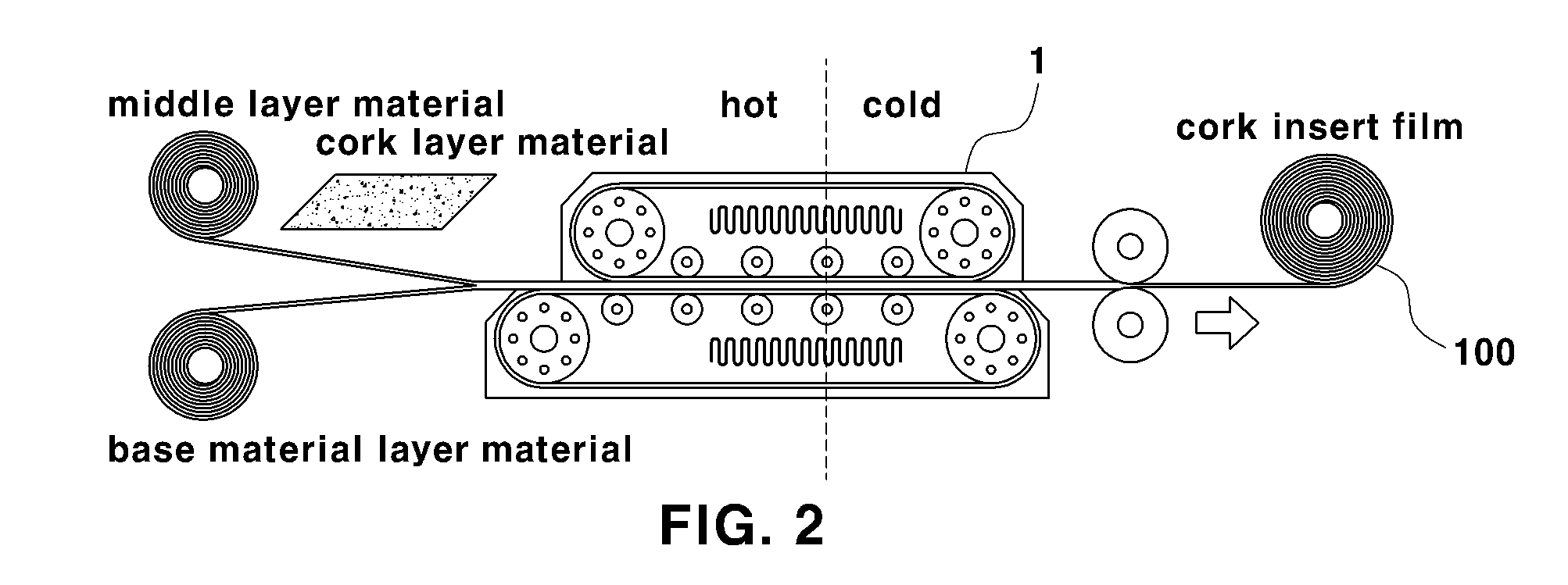

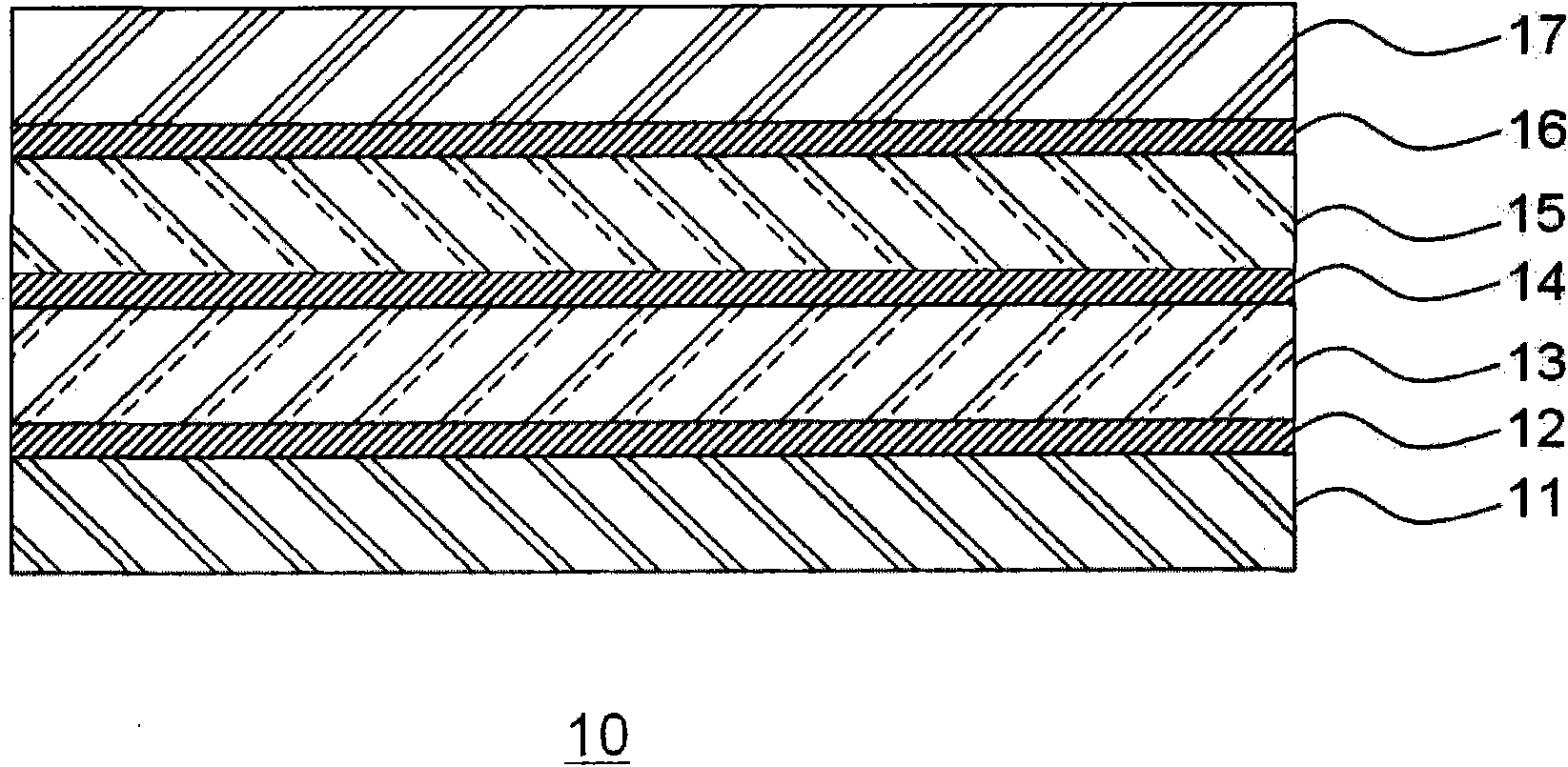

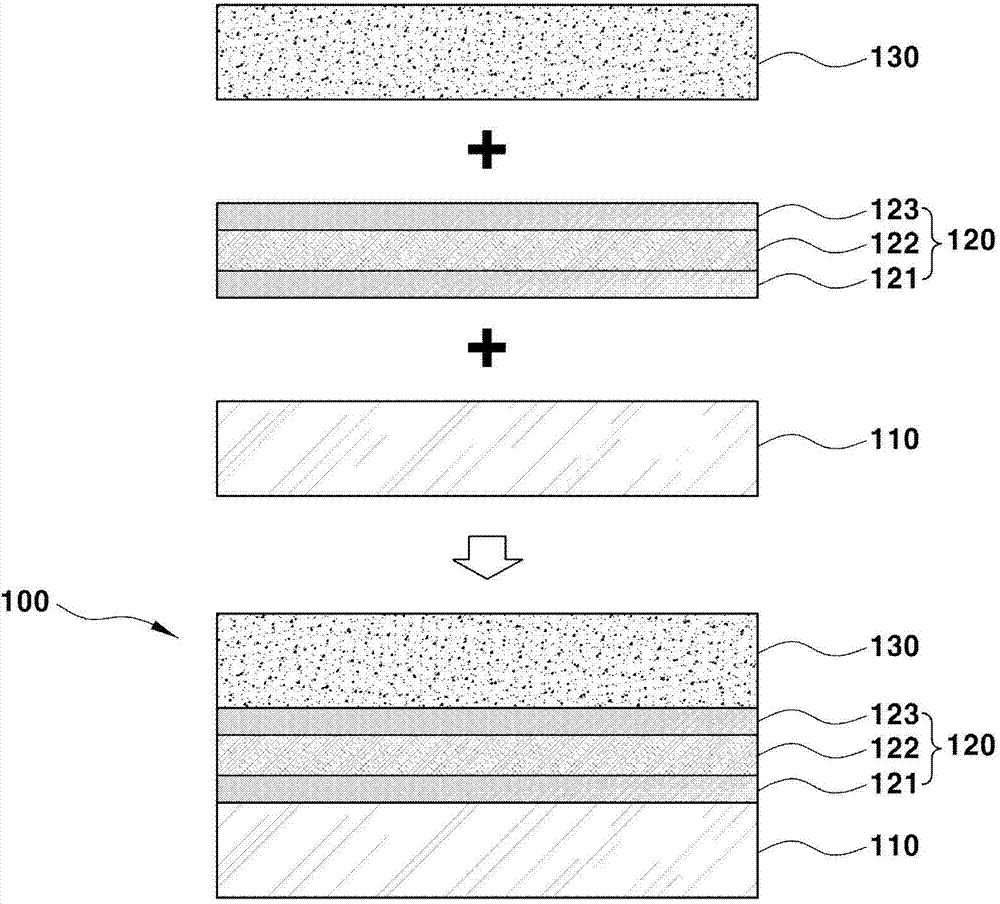

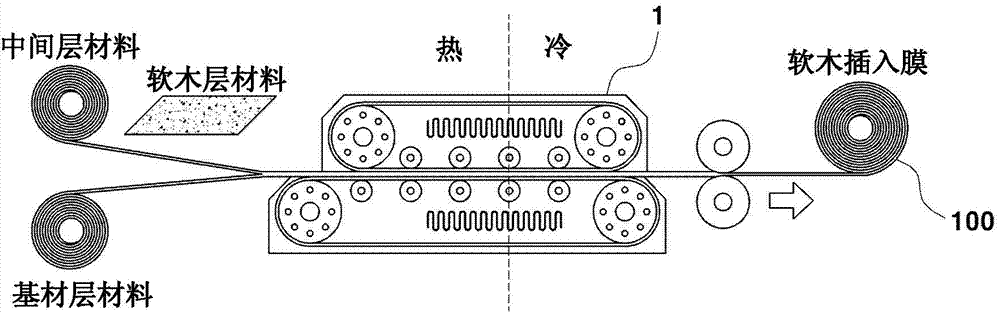

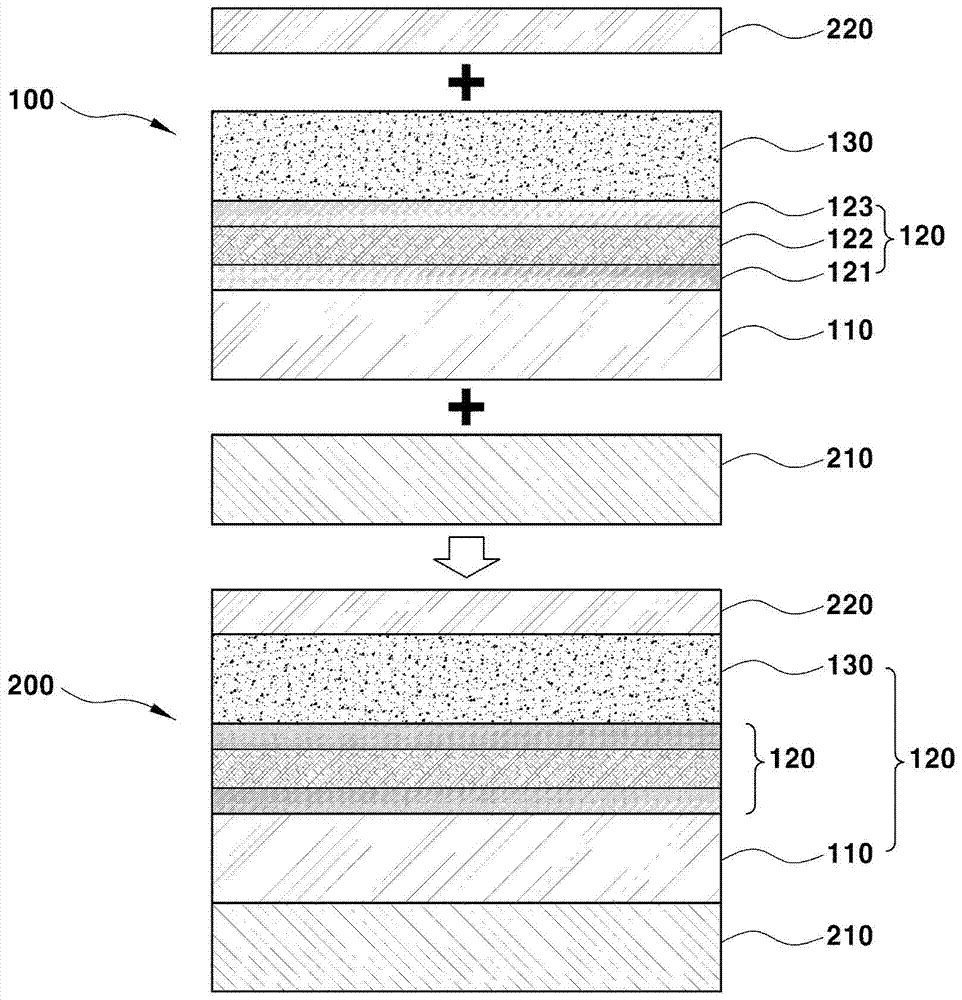

Decoration film using natural cork materials and method for manufacturing the same

InactiveUS20150174853A1Low costGood lookingOrnamental structuresSynthetic resin layered productsSolid woodEngineering

Disclosed is a decoration film using natural cork materials which has cost competitiveness over the conventional real wood parts and can be manufactured in an open skin type by implementing natural wooden feature on the surface. Methods of manufacturing the decoration film are also disclosed. In particular, the decoration film using natural cork materials includes: a base material layer as the bottom layer; a middle layer bonded onto the base material layer; and a cork layer that is the top layer bonded onto the middle layer. The middle layer of the decoration film includes a bottom bonding layer, a non-woven fabric layer bonded onto the bottom bonding layer, and a top bonding layer bonded onto the non-woven fabric layer.

Owner:HYUNDAI MOTOR CO LTD

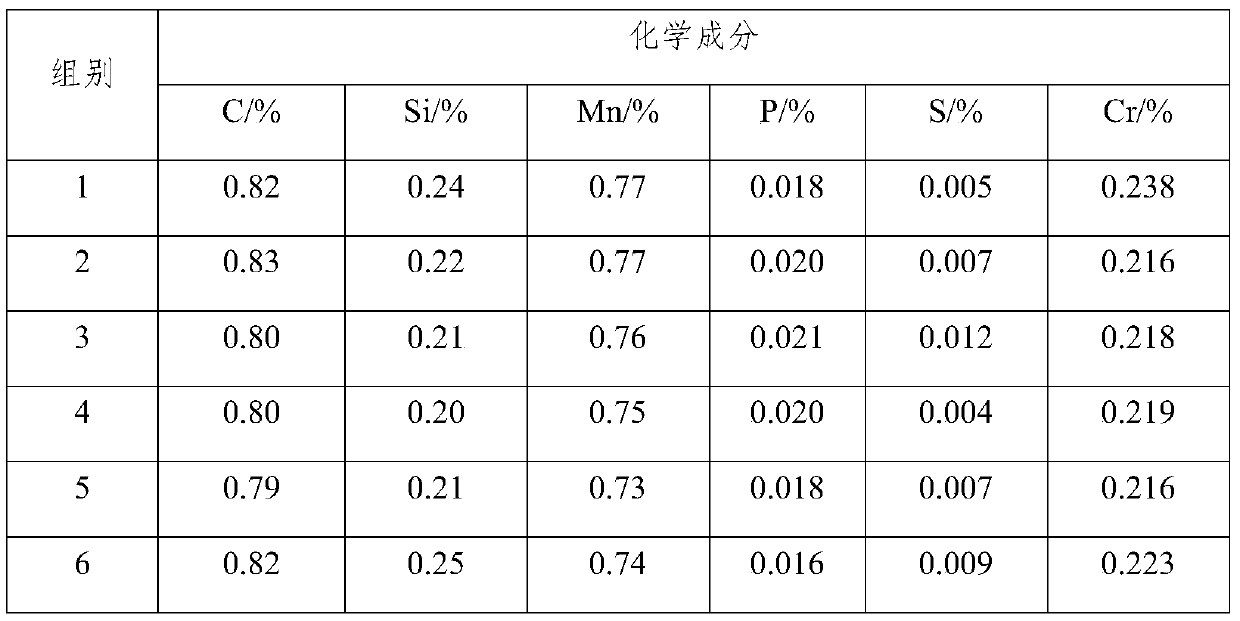

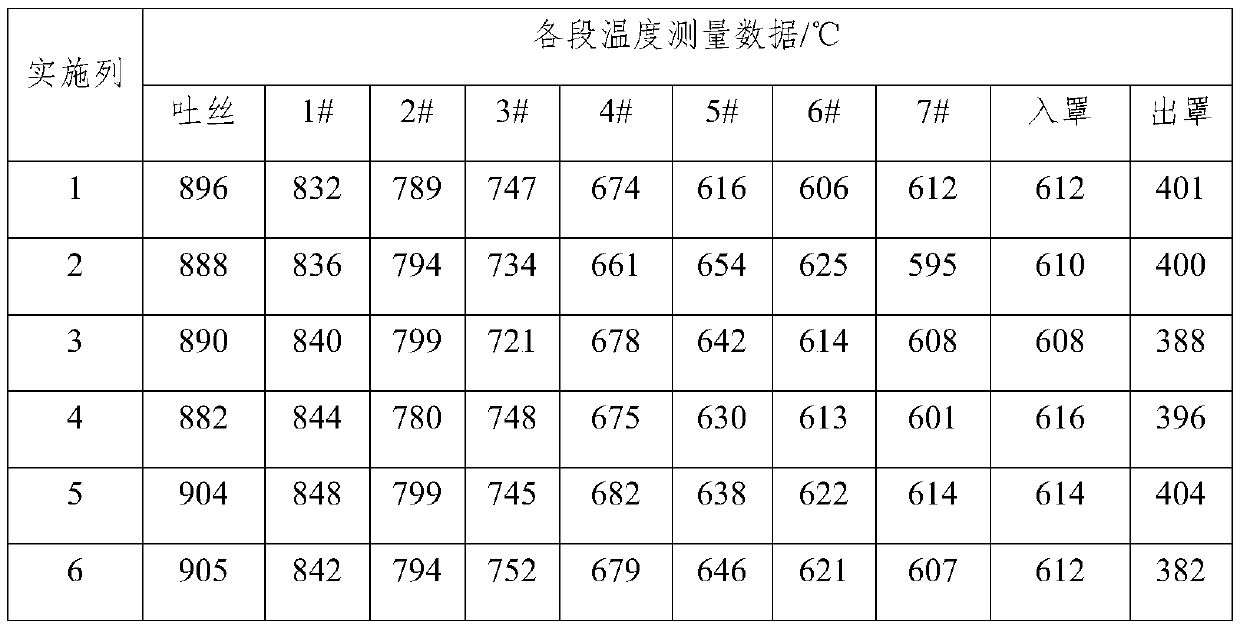

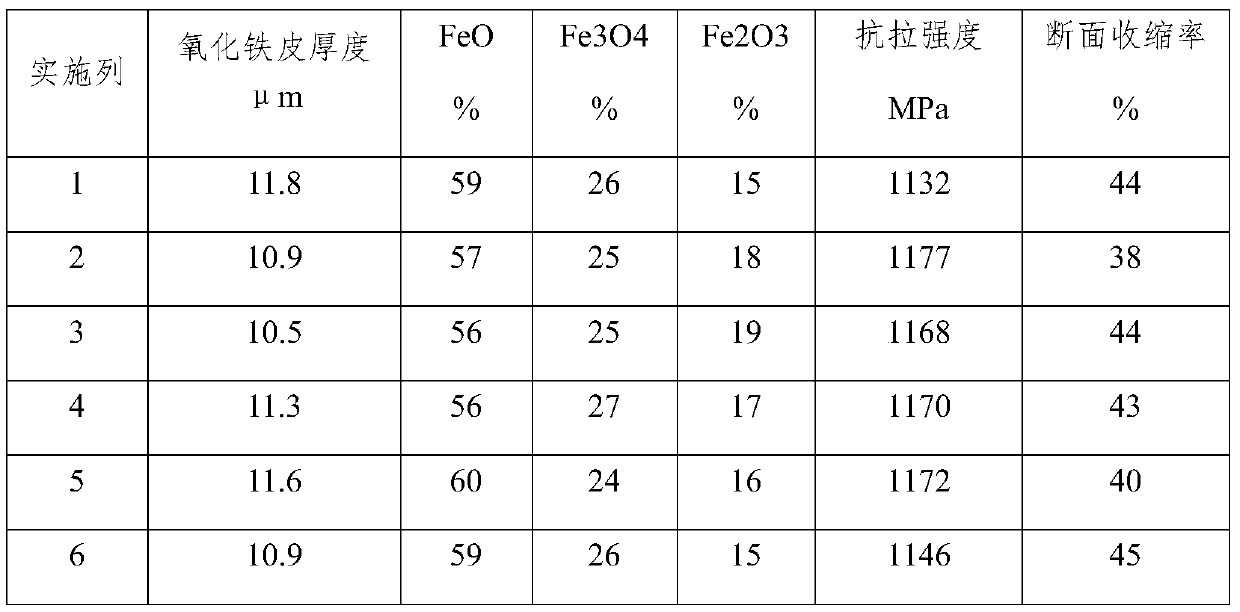

Controlled production method for pickling-free SWRH82B hot rolled wire rod oxidized iron sheet

InactiveCN110340155ARaise spinning temperatureGood peeling effectTemperature control deviceMetal rolling arrangementsWire rodWater cooling

The invention relates to the technical field of smelting, in particular to a controlled production method for a pickling-free SWRH82B hot rolled wire rod oxidized iron sheet. The wire rod spinning temperature is increased by controlling the rolling temperature and intensive pressure water cooling of a control wire rod generated on the wire rod surface oxidized iron sheet; and then a roller way, afan and an insulating cover are controlled to cooperate with one another, the wire rod cooling rate is adjusted, thickening of the oxidized iron sheet is achieved, the stripping performance of the wire rod is improved, not only can the pickling-free direct drawing process requirements of a machining user be met, but also the surface treatment cost of the wire rod can be reduced, and the wire rod product adaptability and the low-cost competitiveness of the user are improved.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Die size semiconductor element package and manufacturing method thereof

InactiveCN102270622ALow costSimple processSemiconductor/solid-state device detailsSolid-state devicesEngineeringCost competitiveness

A chip size semiconductor element package and its manufacturing method. The chip size semiconductor element package includes a bare chip, an insulating substrate with a through hole, a first metal layer, a second metal layer and an insulating layer. The first metal layer is disposed on the first surface of the insulating substrate and the first opening of the through hole. The insulating layer covers the second surface of the insulating substrate and surrounds the second opening of the through hole. The second metal is disposed on the insulating layer and the second opening. The bare chip is arranged in the through hole and includes a first electrode and a second electrode. The first electrode is electrically connected to the first metal layer, and the second electrode is electrically connected to the second metal layer. The invention not only saves material cost, but also simplifies the process to improve the yield rate and the competitiveness of the manufacturing cost.

Owner:INPAQ TECH

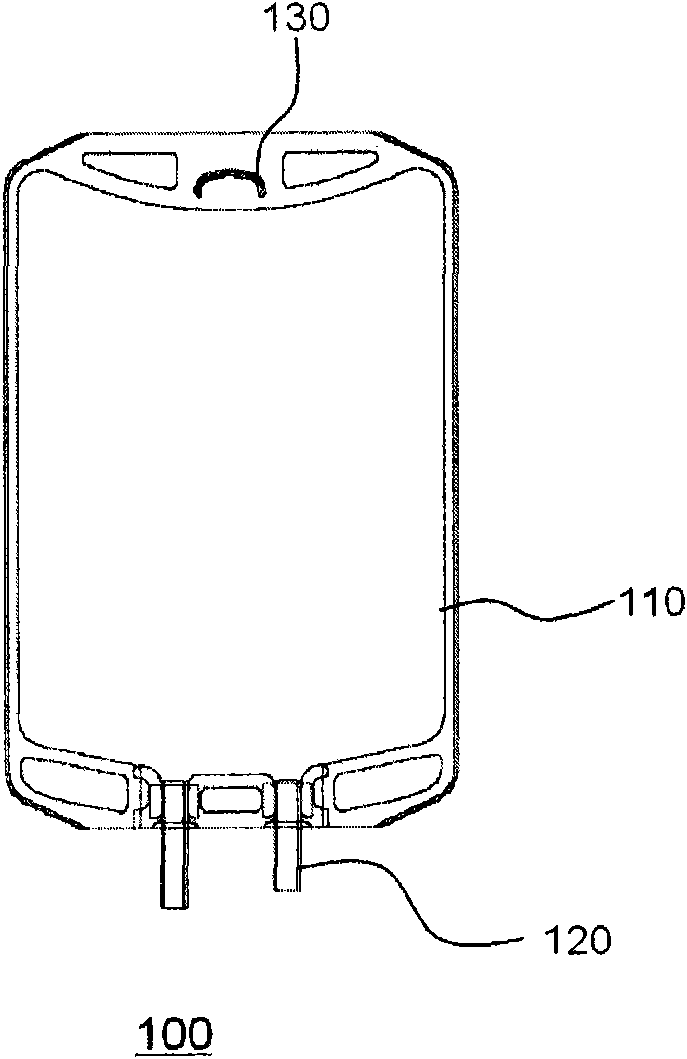

High barrier multilayer film for functional medical solution product

ActiveCN101909890AHigh transparencyImprove heat resistanceSynthetic resin layered productsDomestic containersPolymer scienceHeat resistance

The present invention relates to a high barrier multilayer film for functional medical solution product comprising in order, an outer layer comprising polyethyleneterephthalate deposited inorganic oxide thereon; a first adhesive layer comprising ester type polyurethane; a first intermediate layer comprising ethylene vinyl alcohol copolymer; a second adhesive layer comprising ester type polyurethane; a second intermediate layer comprising polyamide; a third adhesive layer comprising ester type polyurethane; and an inner layer comprising propylene-based polymer. The multilayer film has the merits of improved transparency, heat resistance, sealing property, durability, competitive price, oxygen barrier property and less pinhole, so that may be applied to a outer bag of pouch type container of medical solution.

Owner:CHIYUUGAI

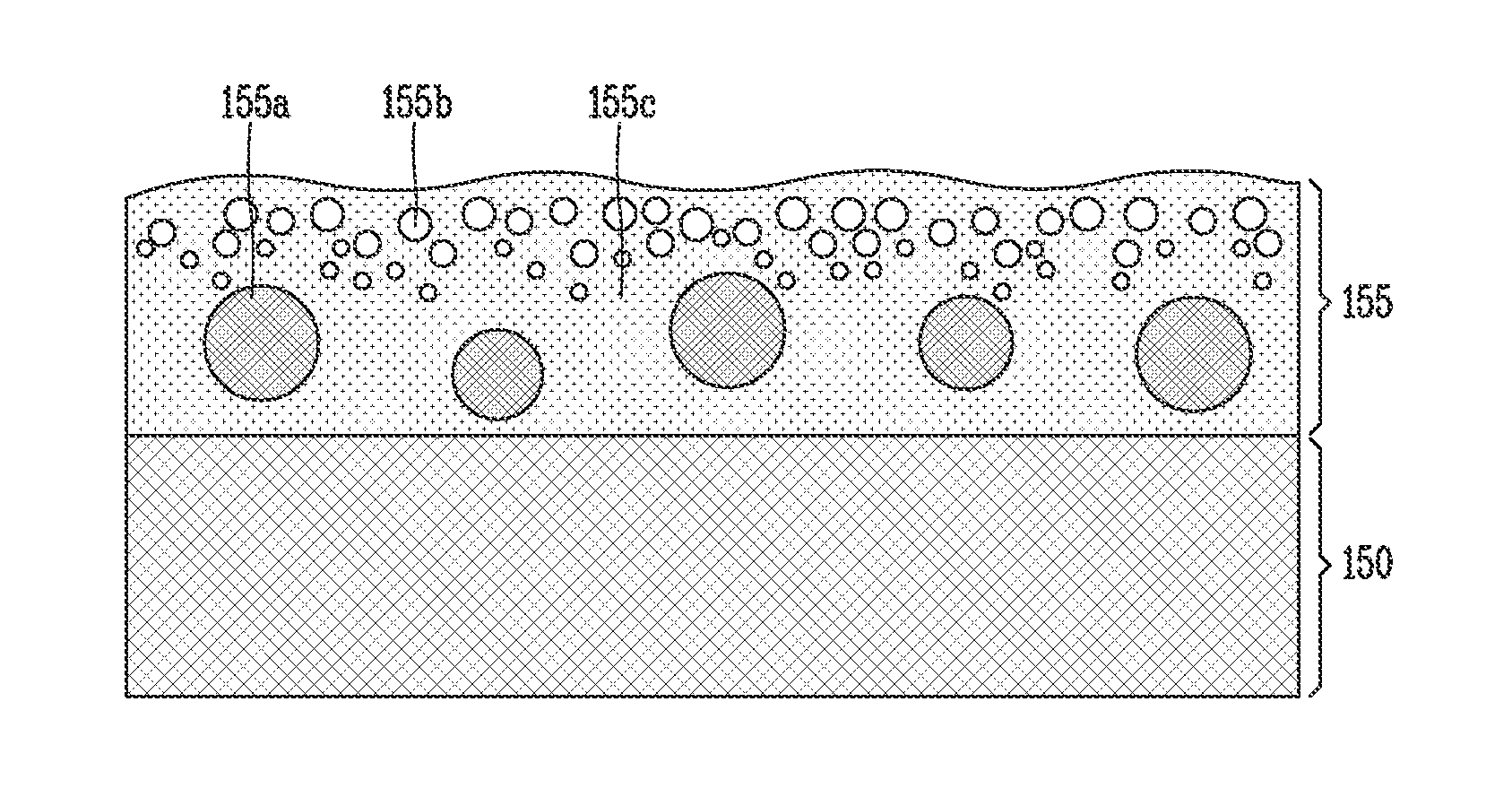

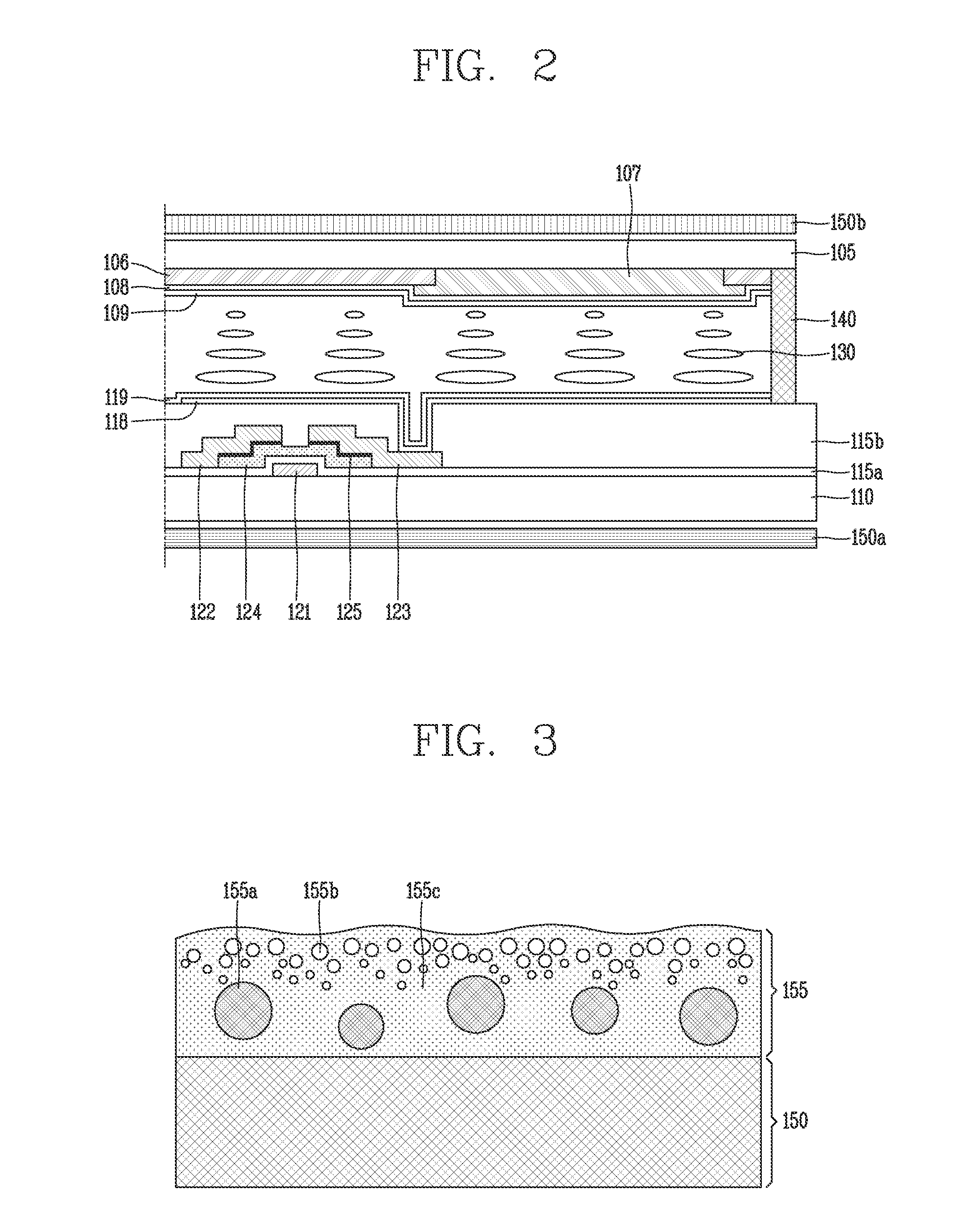

Polarizing plate, liquid crystal display device having the same and method of fabricating the polarizing plate

ActiveUS20150362648A1Preventing glare and reflection of external lightPolarising elementsCoatingsLiquid-crystal displayPolarizer

A polarizing plate, a liquid crystal display device having the polarizing plate and a method of fabricating the polarizing plate are characterized by forming an anti-glare / reflection layer, which is formed into a single layer through one coating process using a phase separation resulting from a weight difference between polymer beads and air bubbles. This may result in ensuring cost competitiveness.

Owner:LG DISPLAY CO LTD

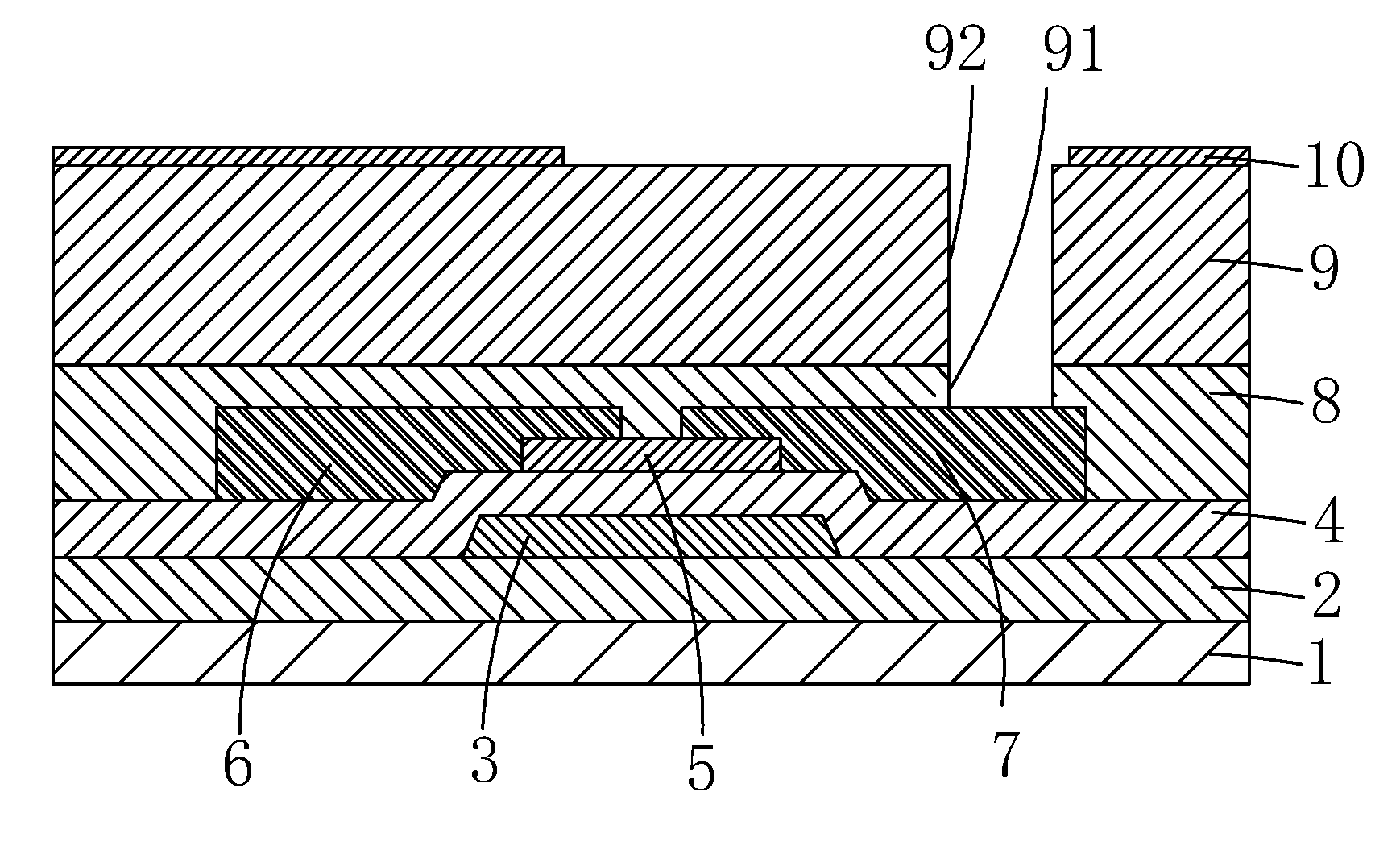

Manufacturing method of TFT substrate structure

ActiveUS20170018579A1Increase the aperture ratioIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransparent conducting film

The present invention provides a manufacturing method of a TFT substrate structure, which includes sequentially forming a first passivation layer, a planarization layer, and a first transparent conductive film and then first subjecting the first transparent conductive film to patterning to form a first pixel electrode and thereafter, a photolithographic process is applied to the planarization layer for exposure and thus forming a first via located above and corresponding to a drain terminal, followed by using the planarization layer as a self-aligning mask to apply dry etching to the first passivation layer for etching to form a second via that corresponds to the first via, whereby residues of the first transparent conductive film in the first and second vias can be effectively prevented and product yield is enhanced. Further, on mask can be saved to prevent reduction of aperture ratio caused by misalignment thereby improving the production efficiency, reducing production cost, and increasing cost-related competition power of products.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

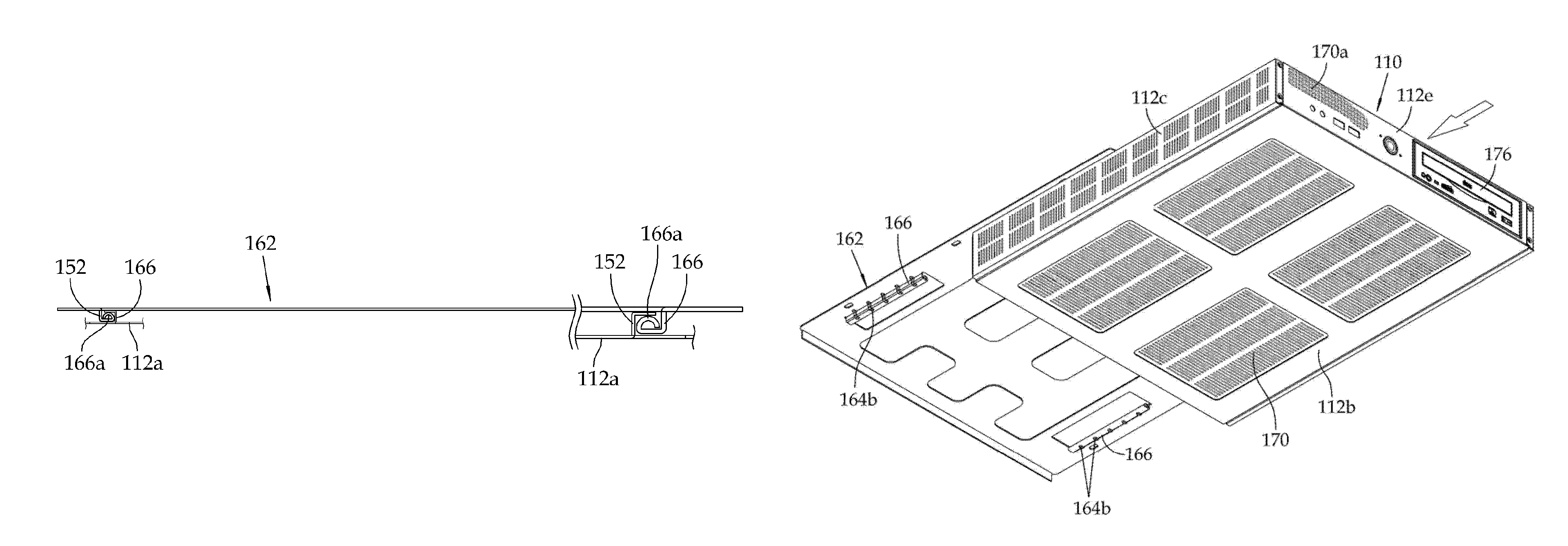

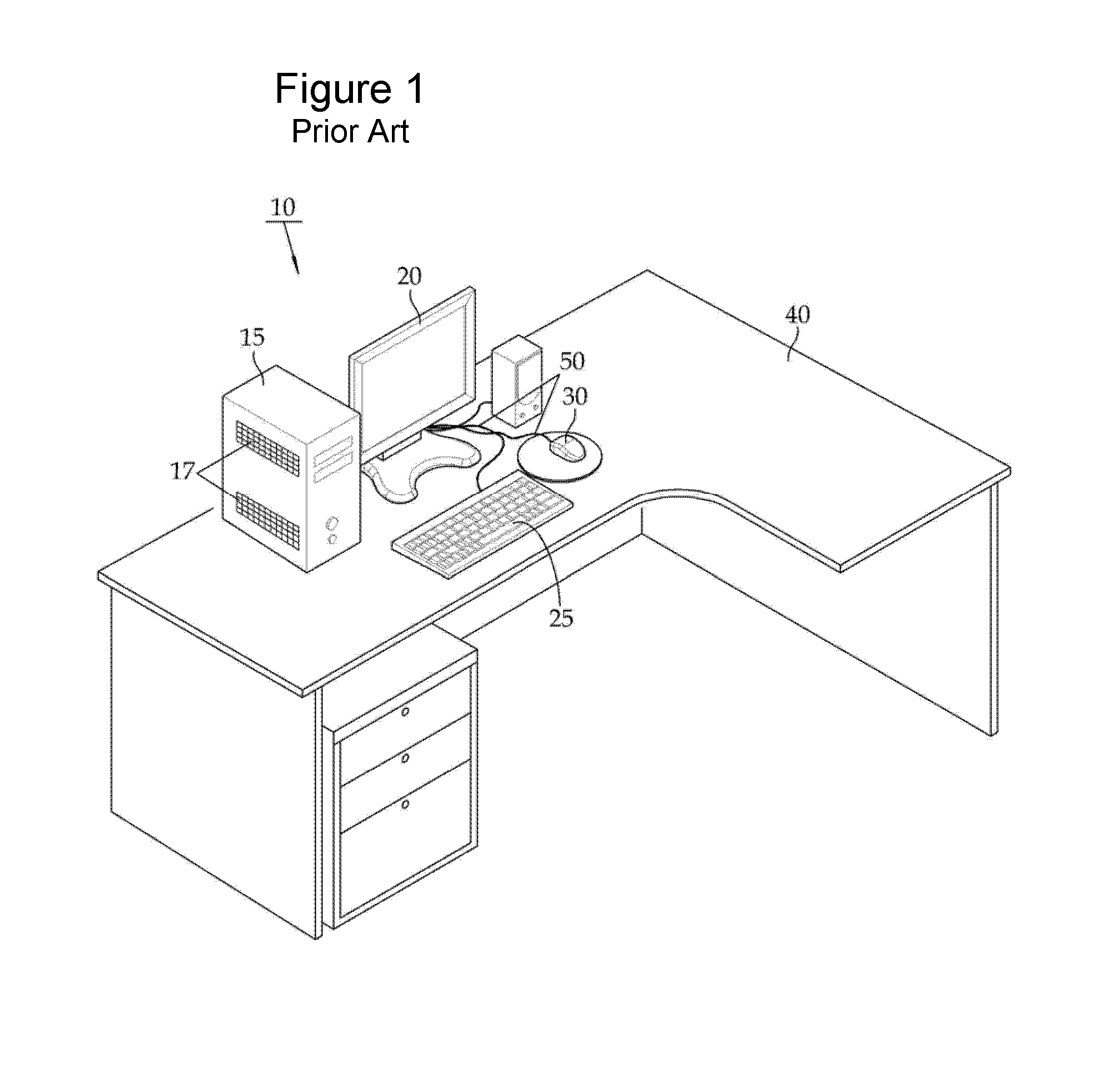

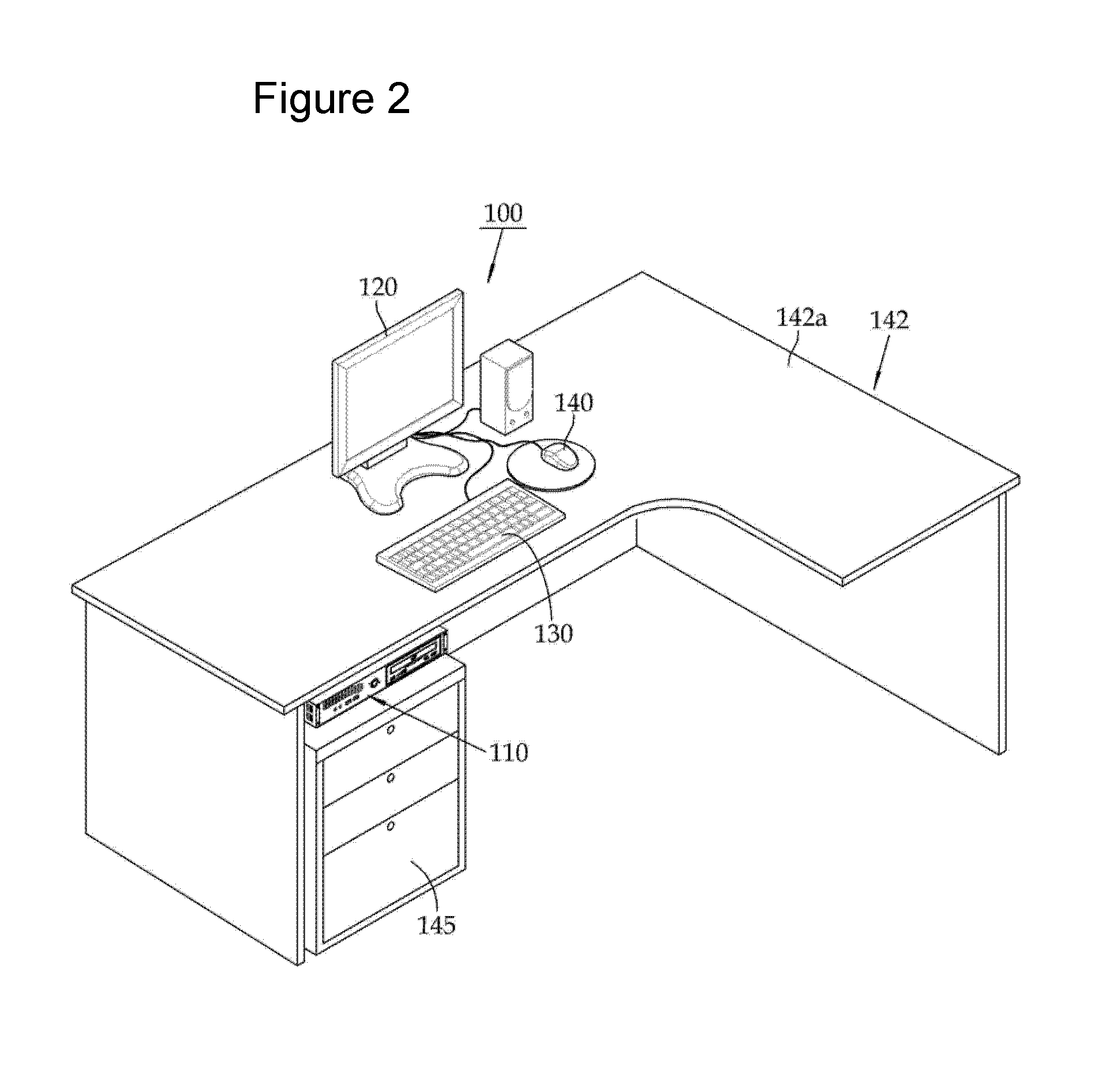

Computer attachable to an undersurface of a desk

InactiveUS8027155B2Space maximizationQuality improvementOffice tablesDigital data processing detailsComputerized systemEngineering

A computer attachable to an undersurface of a desk is disclosed, in which an office space can be maximized by allowing a body part to horizontally slide into an undersurface of an upper board of a desk, and complicated electric wires can be arranged clean, and an office interior can be cleaned, and a compact size computer system can be obtained while using typical size computer elements, which lead to a cost competitive excellent quality computer system.

Owner:BAE SUNG WOO

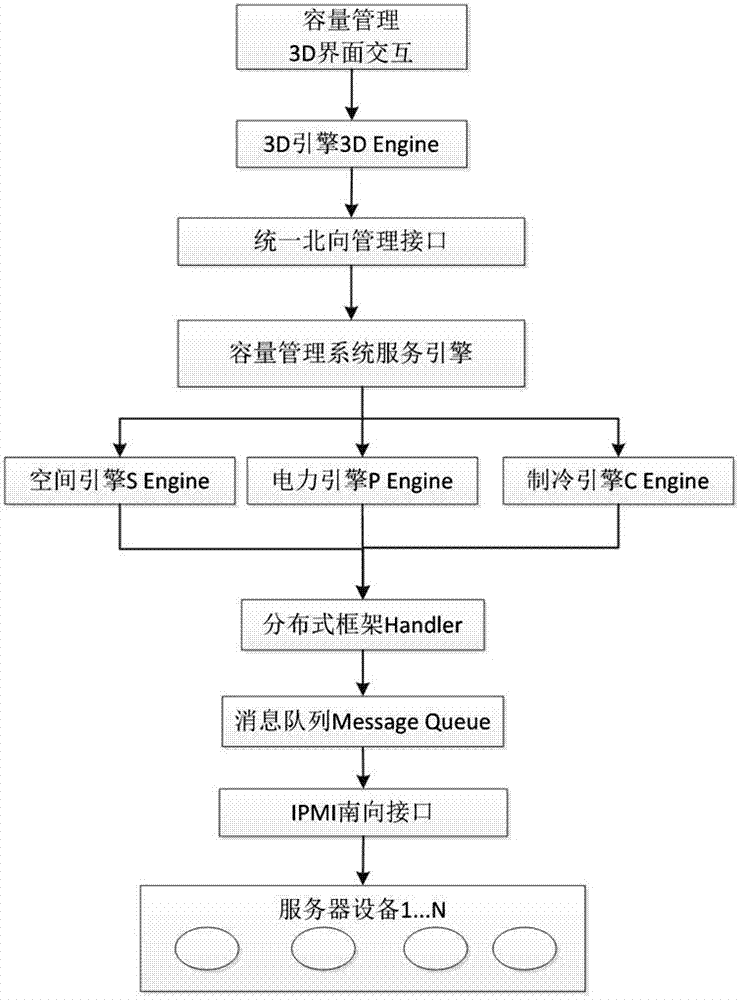

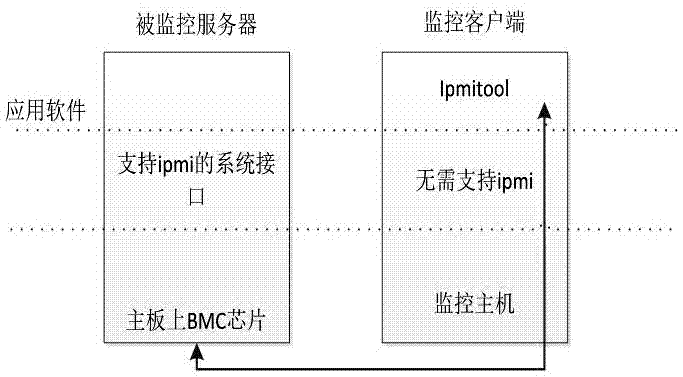

MDC-based capacity management design method

ActiveCN107086936AImprove operational efficiencySupport centralized management modeData switching networksHTML5Computer architecture

The invention provides a MDC-based capacity management design method and belongs to the field of MDCs (modular data center), communication rooms and the like. The design method uses an IPMI intelligent platform management interface, a distributed processing framework, a message queue, a Web 3D engine, a JS language, HTML5 and C ++, runs a main program by using a standardized interface mode, simplifies a debugging workload in a system docking process, achieves automatic interface data filling and automatic capacity verification by a service-oriented design mode, and defines data addition, deletion and modification operations of an operation flow. The modular design mode can improve the operating efficiency of a data center capacity management system, can support the centralized management mode of multiple MDCs, and provides an advanced, stable and cost-competitive design method for the rack-based capacity management of the data center for a server.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Decoration film using natural cork materials and method for manufacturing the same

InactiveCN104723632AOrnamental structuresSynthetic resin layered productsSolid woodCost competitiveness

Disclosed is a decoration film using natural cork materials which has cost competitiveness over the conventional real wood parts and can be manufactured in an open skin type by implementing natural wooden feature on the surface. Methods of manufacturing the decoration film are also disclosed. In particular, the decoration film using natural cork materials includes: a base material layer as the bottom layer; a middle layer bonded onto the base material layer; and a cork layer that is the top layer bonded onto the middle layer. The middle layer of the decoration film includes a bottom bonding layer, a non-woven fabric layer bonded onto the bottom bonding layer, and a top bonding layer bonded onto the non-woven fabric layer.

Owner:HYUNDAI MOTOR CO LTD

Large-diameter wear-resistant steel ball and production process thereof

ActiveCN103320695ALow costImprove cost competitivenessFurnace typesGrain treatmentsSteelmakingProduction line

The invention discloses a large-diameter wear-resistant steel ball. The large-diameter wear-resistant steel ball comprises the following materials in percentage by weight: 0.6-07% of C, 0.95-1.25% of Mo, 0.01-0.02% of Ti, 0.25-0.45% of Si, not more than 0.03% of S, not more than 0.035% of P, not more than 0.2% of Cu, and the balance of Fe. The production of the large-diameter wear-resistant steel ball has the beneficial effects as follows: 1, according to the most advanced international qualification of large-diameter (120-200mm) forged balls, a material superior to domestic high-carbon alloy steel is developed by combining advantages of an existing domestic steelmaking technology and a precious metal mineral resource condition, and the cost can be lower than one fifth, so that the product cost competitiveness is increased after utilization; and 2, a novel, efficient and large-diameter wear-resistant forged steel ball with the leadership in domestic and overseas markets can be produced by combining an existing roll forging steel ball automatic production line with the technology provided by the invention, so that the domestic blank is filled up, and meets the requirements on installation and use of domestic and overseas large-scale ball mills.

Owner:SHANDONG HUAMIN STEEL BALL

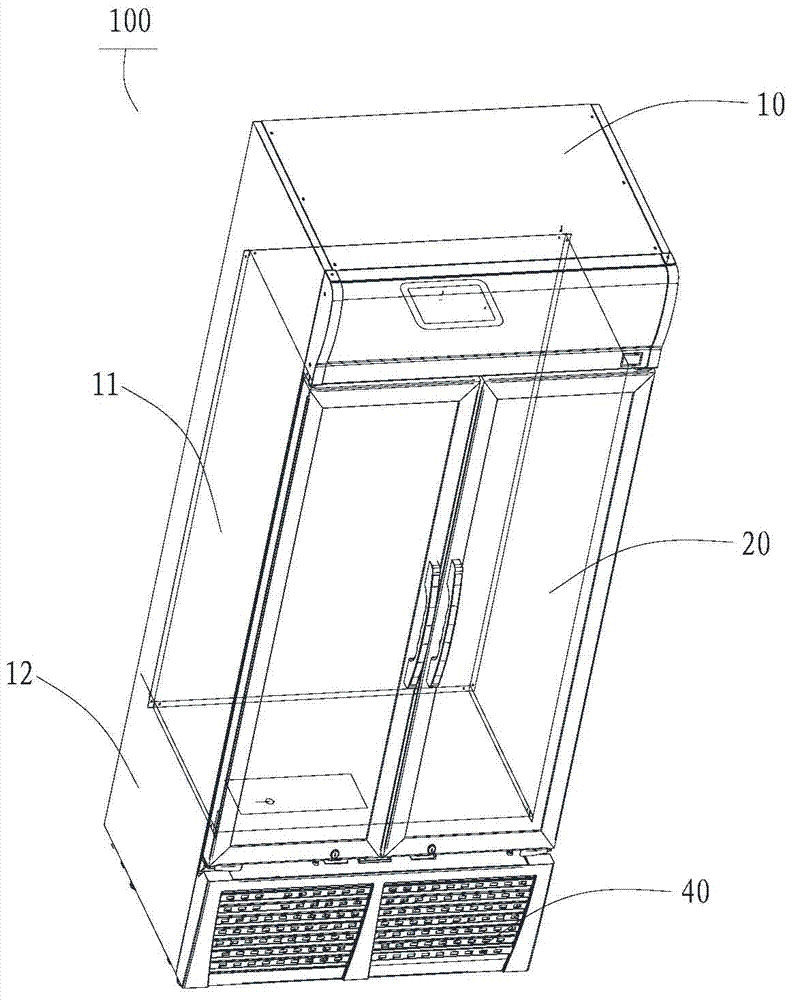

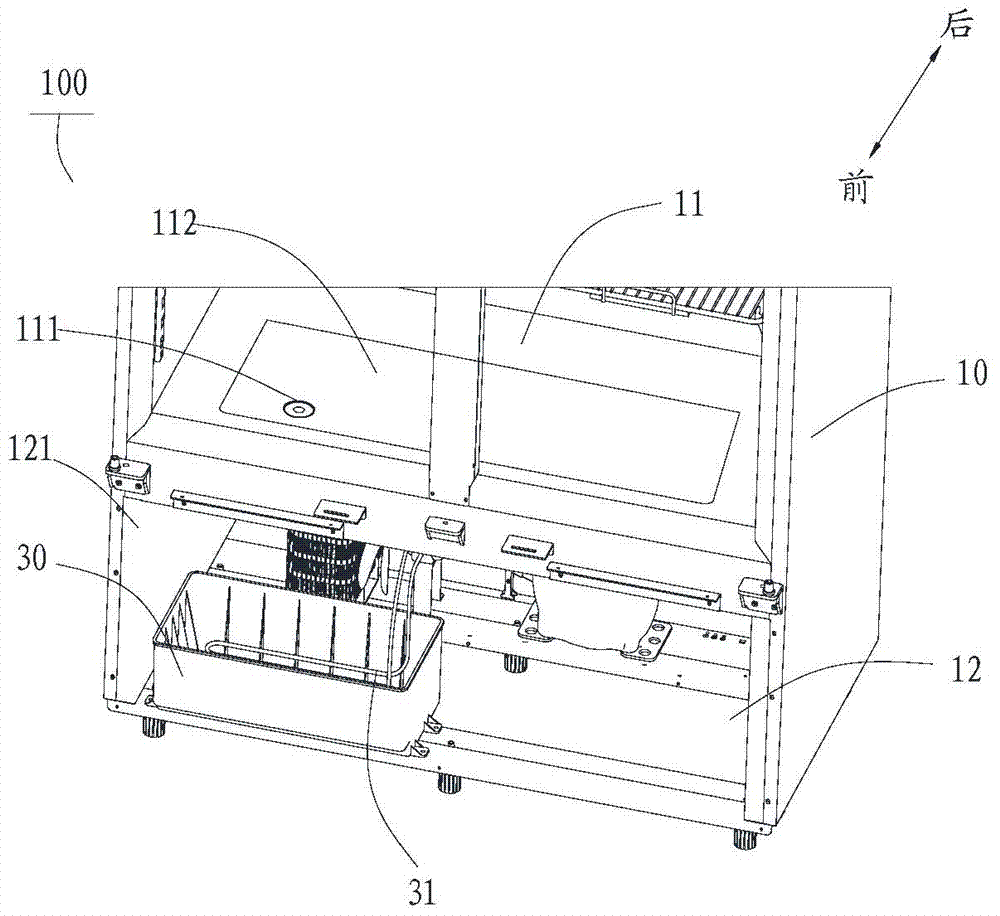

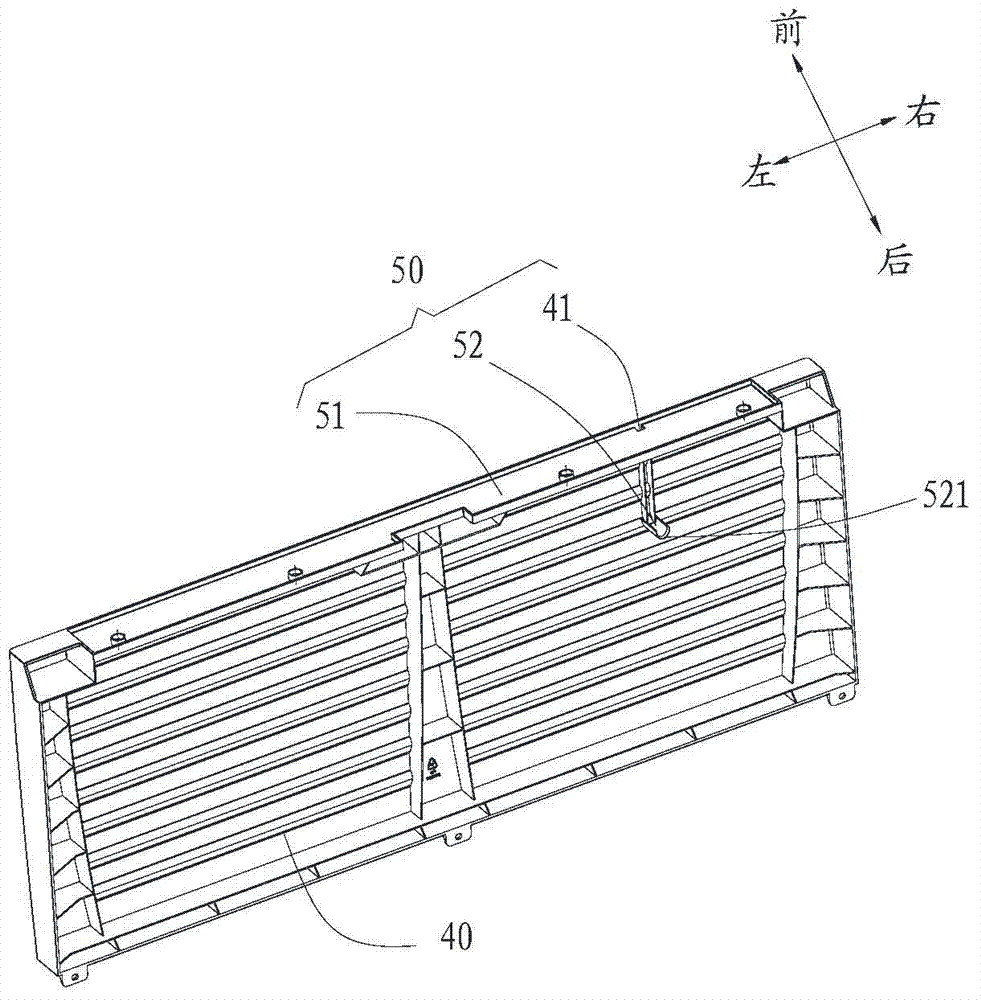

Display cabinet

InactiveCN103519610ASolve processing problemsAvoid safety hazardsShow cabinetsEngineeringDisplay cabinet

The invention discloses a display cabinet which comprises a cabinet body, a glass door, a water collection tank and an air outlet cover. The cabinet body is provided with a refrigeration chamber and a compressor cabin, wherein the bottom surface of the refrigeration chamber is provided with a water outlet hole communicated with the compressor cabin, and the front side of the compressor cabin is provided with an opening. The glass door is connected with the cabinet body so that the refrigeration chamber can be opened and closed. The water collection tank is arranged in the compressor cabin and located below the water outlet hole. The air outlet cover is arranged at the opening and provided with a flow passage opposite to the glass door, and the flow passage is communicated with the water collection tank. According to the display cabinet, the flow passage is arranged at the position, opposite to the glass door, of the air outlet cover so that condensed water generated by the glass door can be guided into the water collection tank, the condensed water of the glass door can be processed on the condition that the number of glass layers of the glass door is not changed, and cost competitiveness of the display cabinet is improved. Meanwhile, potential safety hazards to a user due to the fact that the glass door is too heavy are also avoided.

Owner:HEFEI HUALING CO LTD

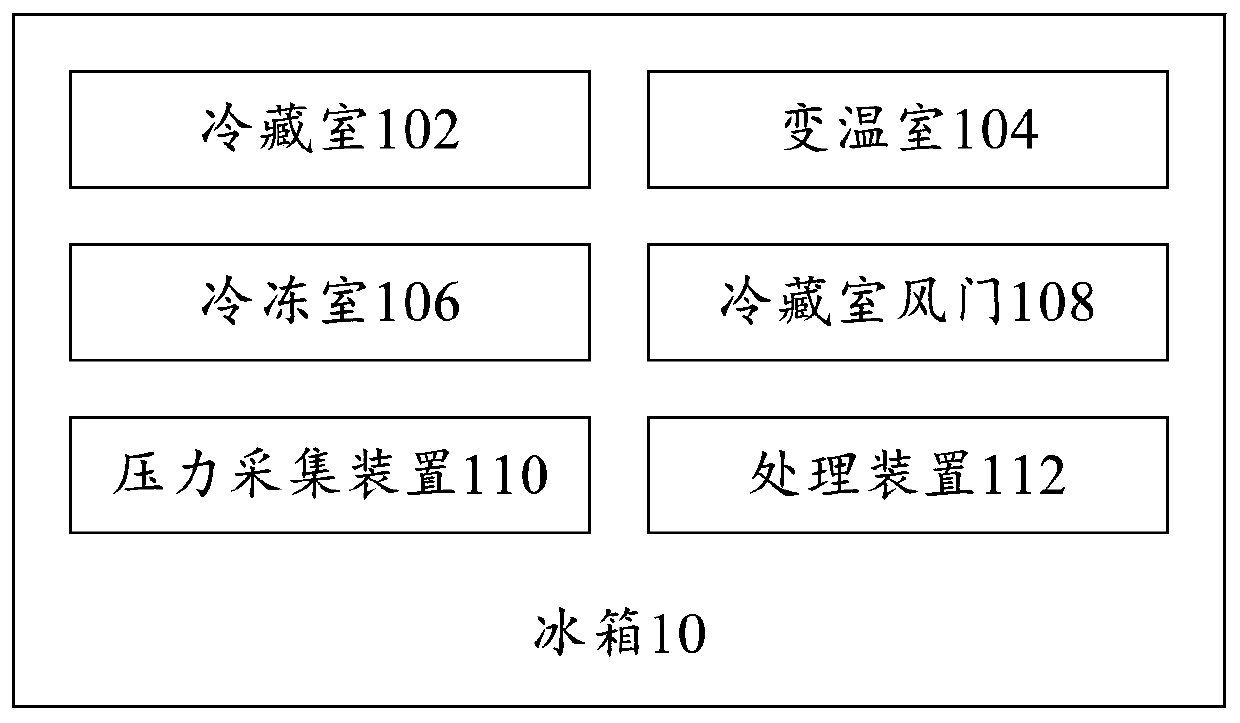

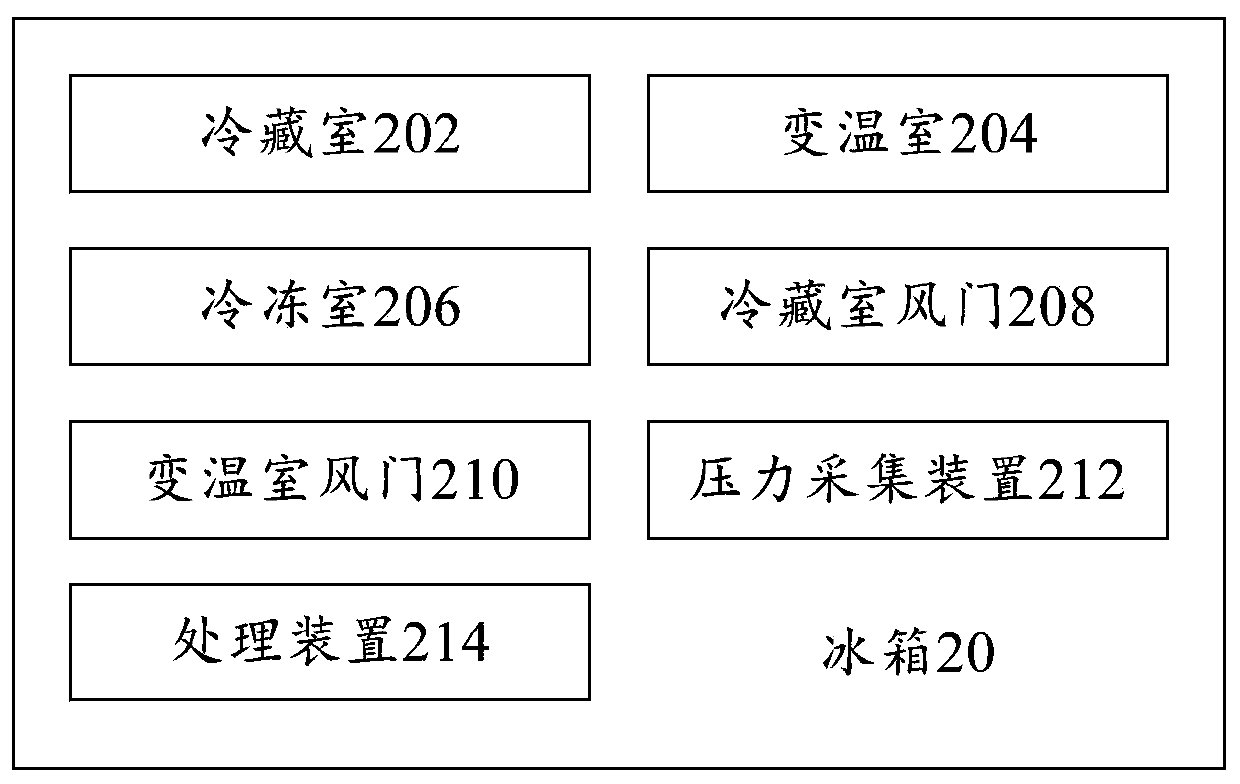

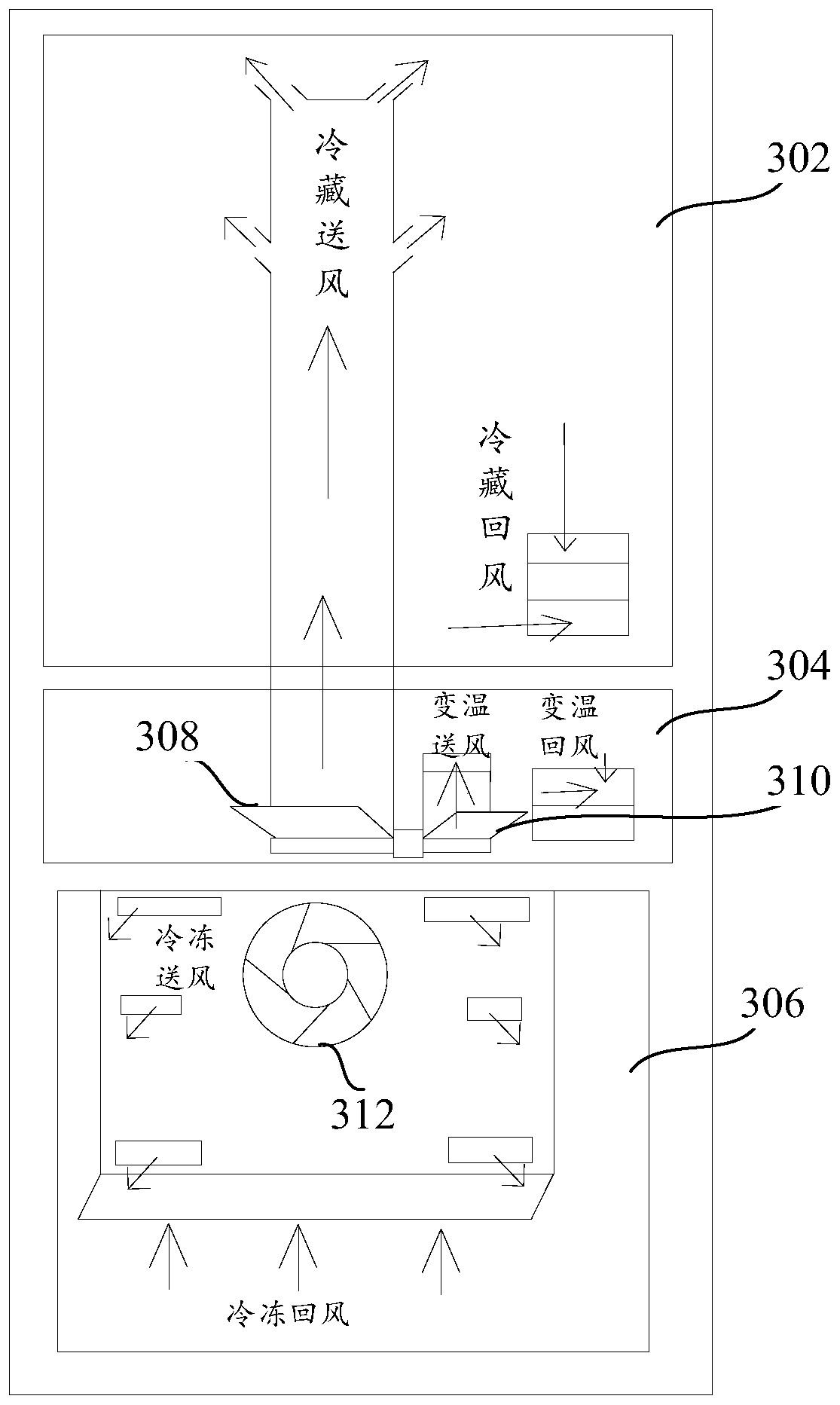

Refrigerator, control method of refrigerator and computer readable storage medium

ActiveCN109737672AAvoid enteringSolve condensationLighting and heating apparatusDomestic refrigeratorsPositive pressureEngineering

The invention provides a refrigerator, a control method of the refrigerator and a computer readable storage medium. The refrigerator comprises a refrigerating chamber, a temperature change chamber, afreezing chamber, a refrigerating chamber air door arranged between the refrigerating chamber and the freezing chamber, a pressure collection device connected with the refrigerating chamber or the temperature change chamber or the freezing chamber and used for collecting the pressure of the refrigerating chamber or the temperature change chamber or the freezing chamber of the refrigerator and a processing device. The processing device is used for acquiring the opening and closing state information of the refrigerating chamber air door and adjusting the operation parameters of the refrigeratoraccording to the opening and closing state information of the refrigerating chamber air door under the condition that the pressure of the refrigerating chamber or the temperature change chamber or thefreezing chamber is negative pressure. It is guaranteed that the refrigerator is in a micro negative pressure or positive pressure state; inner condensation caused by the situation that hot and dampair enters refrigerator chambers due to negative pressure is avoided; a container structure does not need to be changed, and hot sources such as anti-condensation pipes and heating wires do not need to be additionally mounted; the problem of condensation in the refrigerator is solved with the cost unchanged; and cost competitiveness and excellent quality are guaranteed synchronously.

Owner:HEFEI HUALING CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com