Pneumatic belt tire

A technology for radial tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire treads/tread patterns, etc. To avoid layer bending and other problems, achieve the effect of maintaining cost competitiveness and improving partial wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

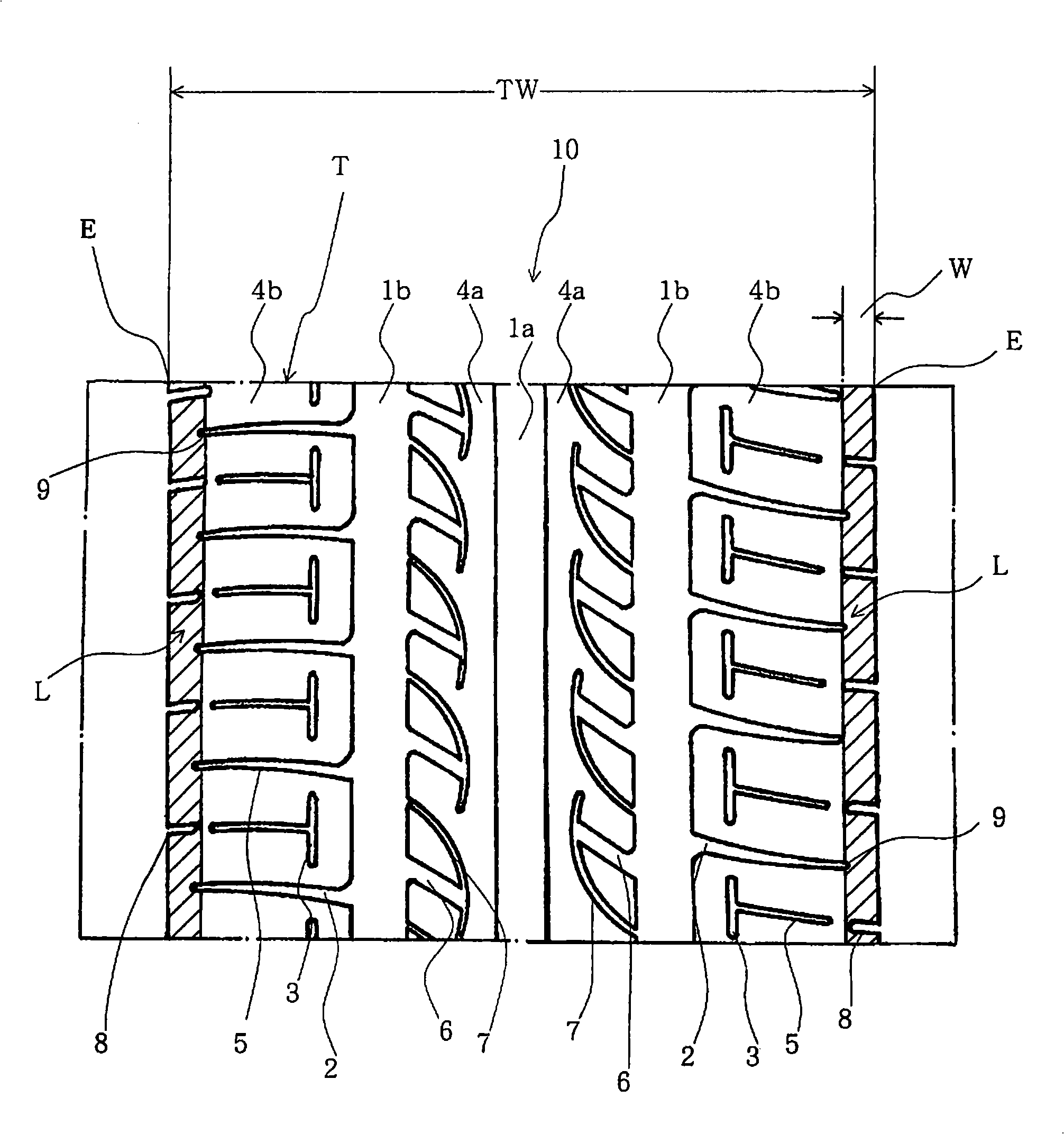

[0039] has been trial-produced with figure 1 A tire with the tread pattern shown and a 2-steel belt structure that satisfies the following conditions.

[0040] Tire size specification: 155 / 65R13 73S

[0041] Tread width TW: 120mm

[0042] The ratio of pattern groove to pattern block area (negative rate): 32%

[0043] Width of circumferential main groove 1a: 18mm, width of 1b: 9.1mm

[0044] Depth of circumferential main grooves 1a, 1b: 6.0mm

[0045] The width of the part of the transverse groove 2 connected with the circumferential main groove 1b: 2.5 ~ 4.5mm (varies with the pitch)

[0046] Depth of transverse groove 2: 5mm

[0047] Width w of the ground portion L: 5mm

[0048] Width of intermittent slit auxiliary groove 3: 1.5mm

[0049] Depth of intermittent gap auxiliary groove 3: 5mm

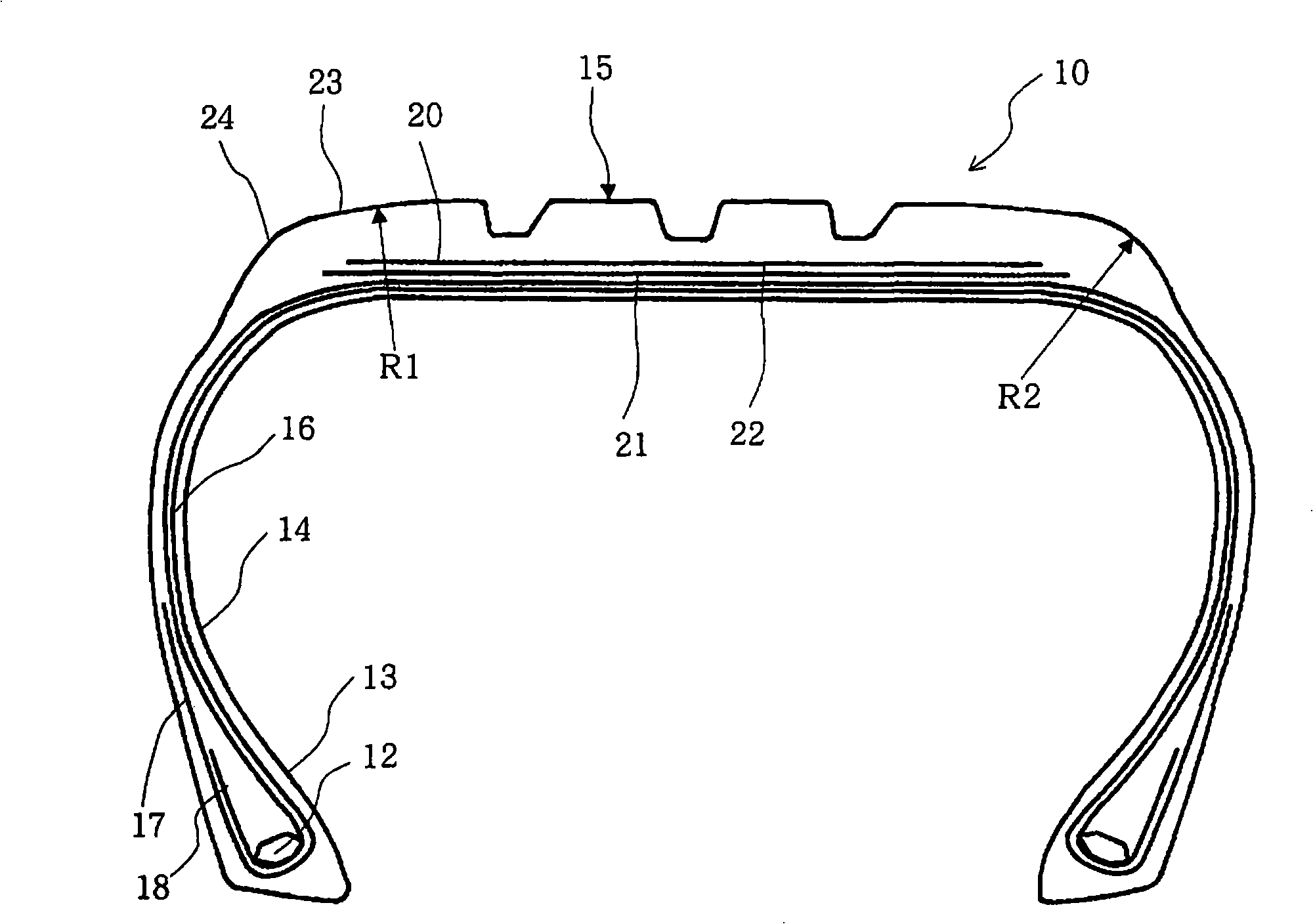

[0050] Radius of curvature R1: 1000mm

[0051] Radius of curvature R2: 5mm

[0052] Conventional Example 1

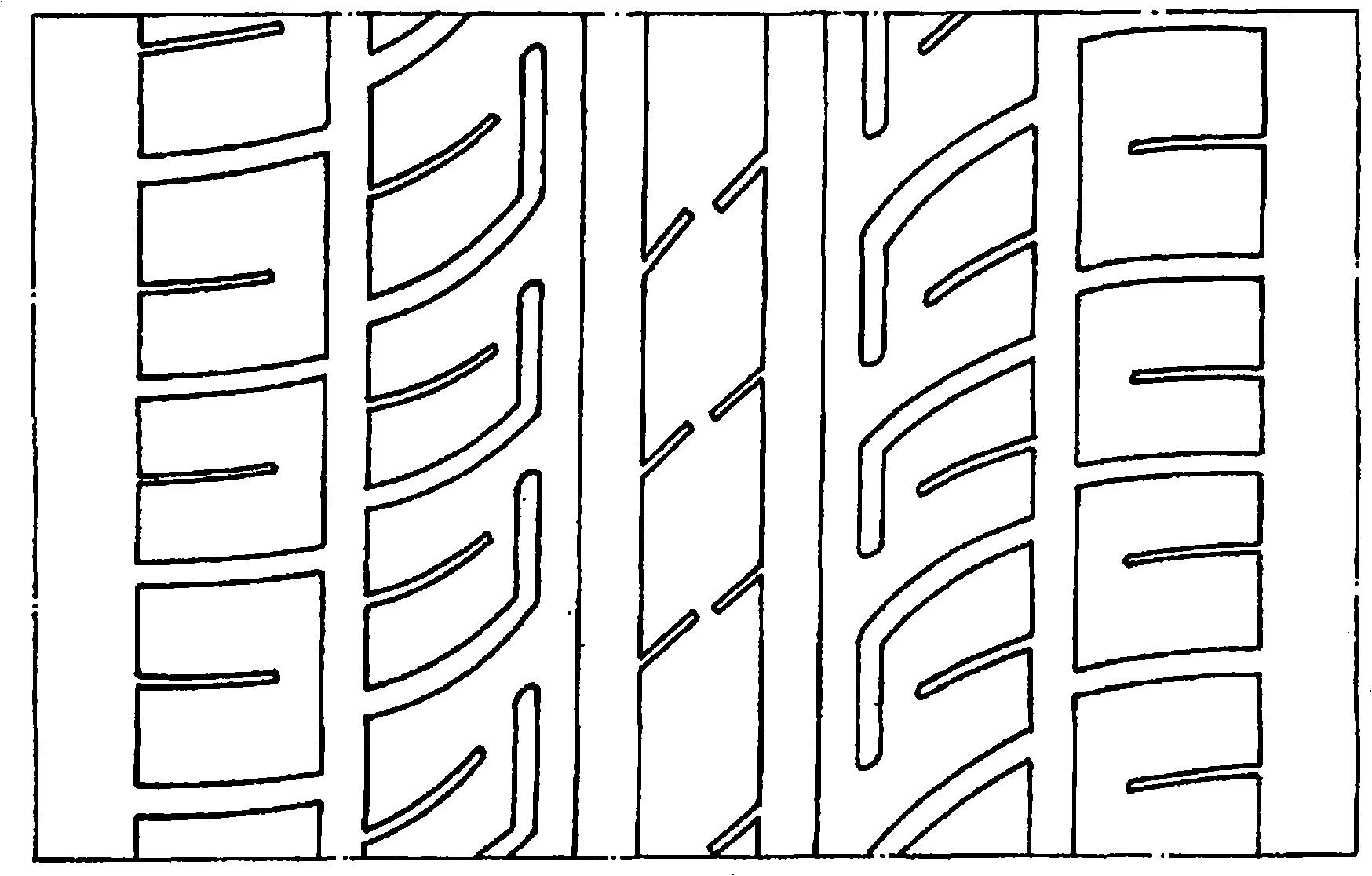

[0053] use has image 3 A known tire having the tread pattern and...

Embodiment 2

[0070] Trial out: In addition to having Figure 4 A tire having one belt reinforcement layer in addition to the tread pattern and two-wire belt structure shown, and satisfying the following conditions.

[0071] Tire size specification: 195 / 65R15 91H

[0072] Tread width TW: 140mm

[0073] Groove to block area ratio: 34%

[0074] Width of circumferential main groove 1a: 9mm, width of 1b: 10.5mm

[0075] Depth of circumferential main grooves 1a, 1b: 7.5mm

[0076] Width of the portion of the transverse groove 2 communicating with the circumferential main groove 1b: 2.5 to 4.5 mm (varies with the pitch)

[0077] Depth of transverse groove 2: 5mm

[0078] Width w of the ground portion L: 5mm

[0079] Width of intermittent slit auxiliary groove 3: 2mm

[0080] Depth of intermittent slit auxiliary groove 3: 6mm

[0081] Radius of curvature R1: 145mm

[0082] Radius of curvature R2: 36mm

[0083] Conventional example 2

[0084] Adopted in previous example 2: with Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com