Patents

Literature

4459 results about "Ground line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dipole antenna of RF chip

ActiveCN101740862AReduce the impactImproving Impedance MatchingRadiating elements structural formsSlot antennasImpedance matchingDipole antenna

Owner:KUANG CHI INST OF ADVANCED TECH

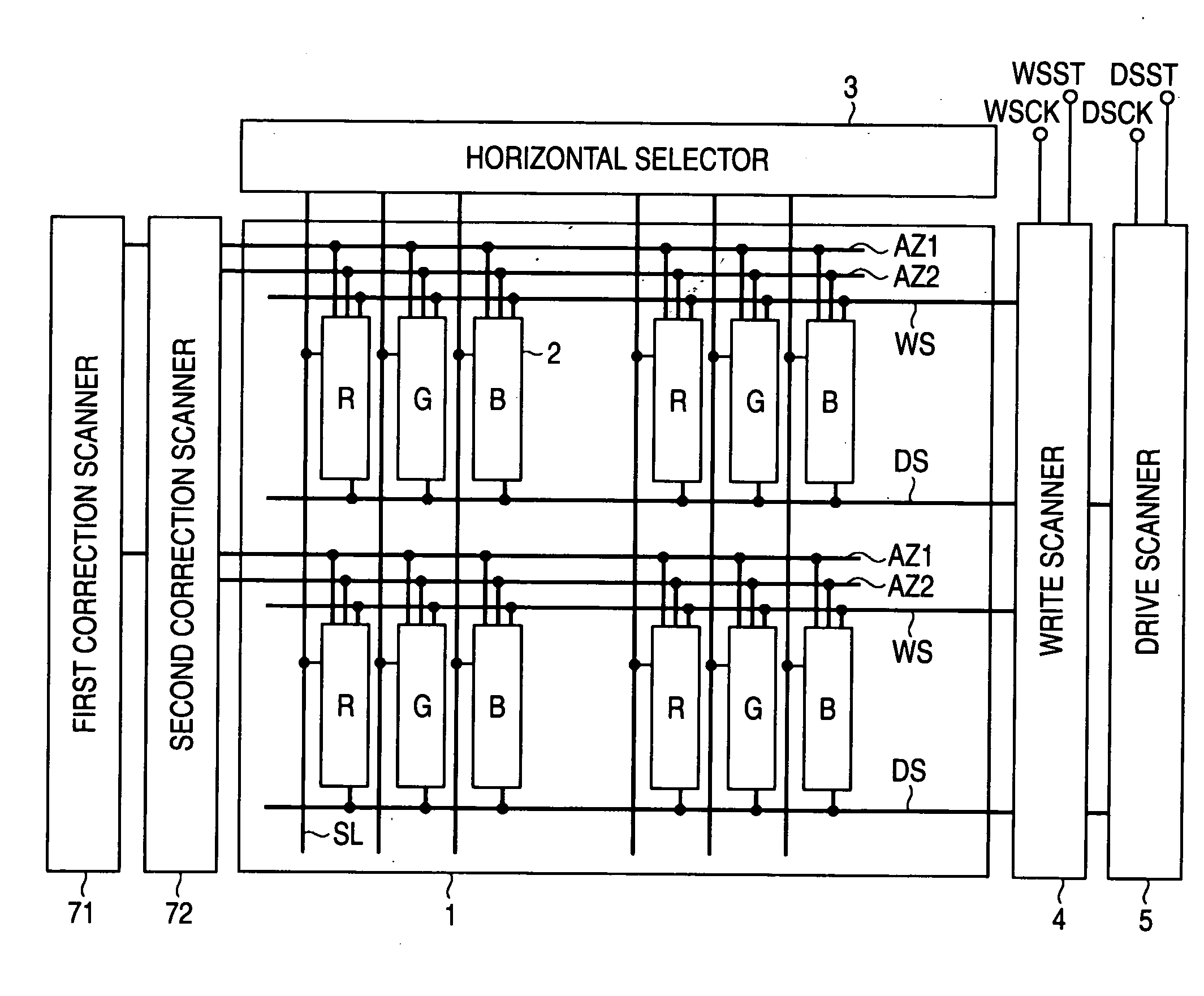

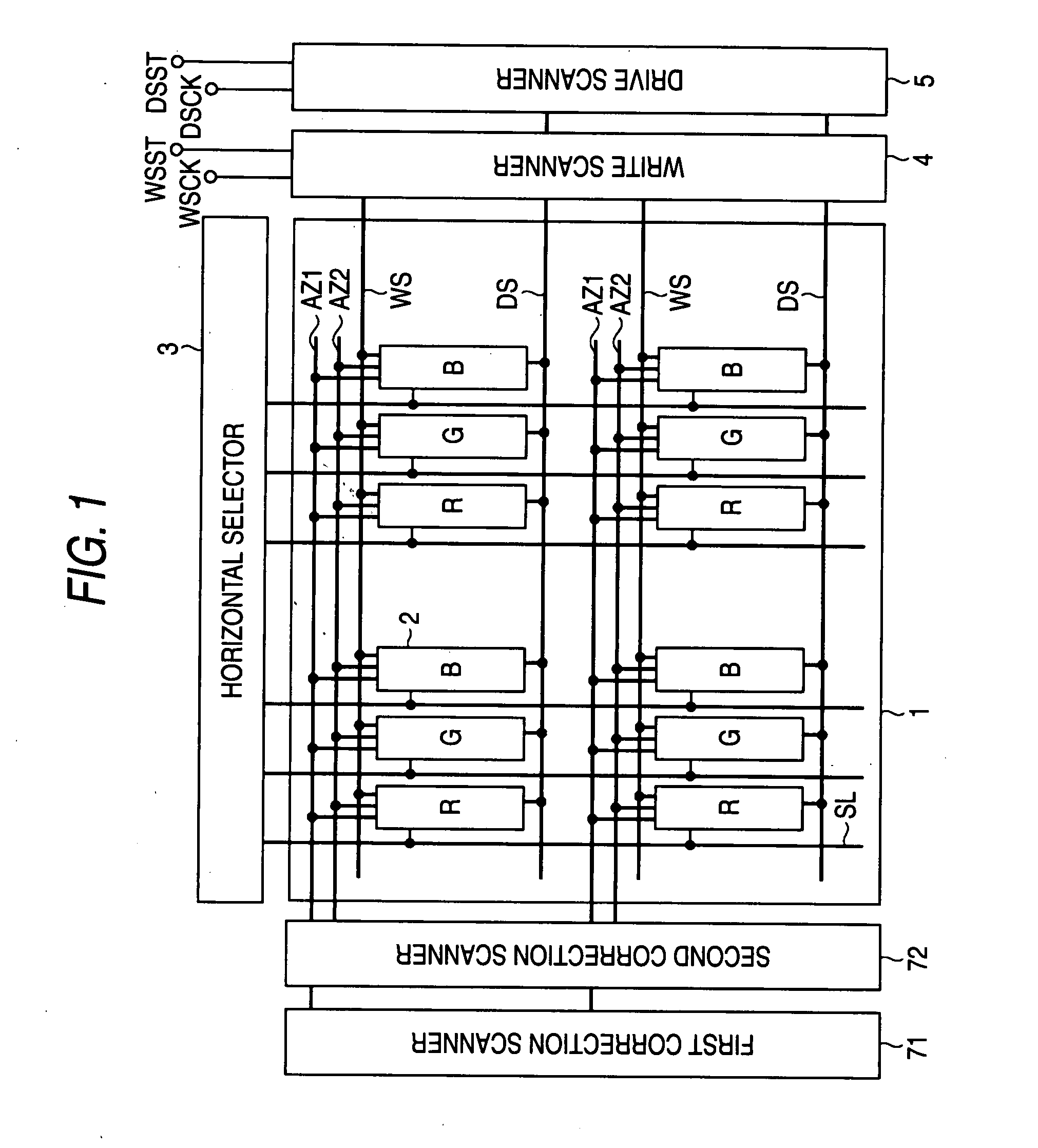

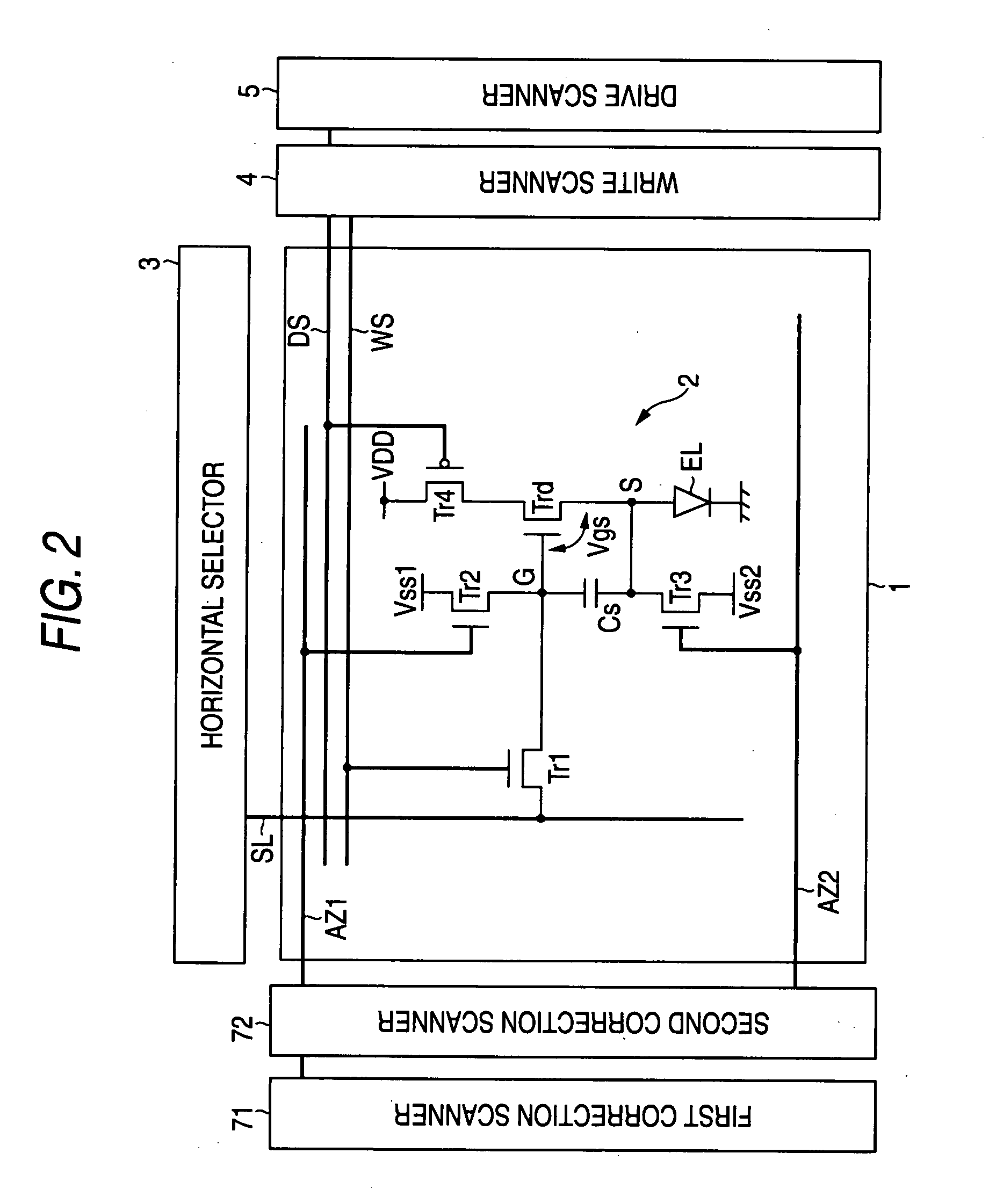

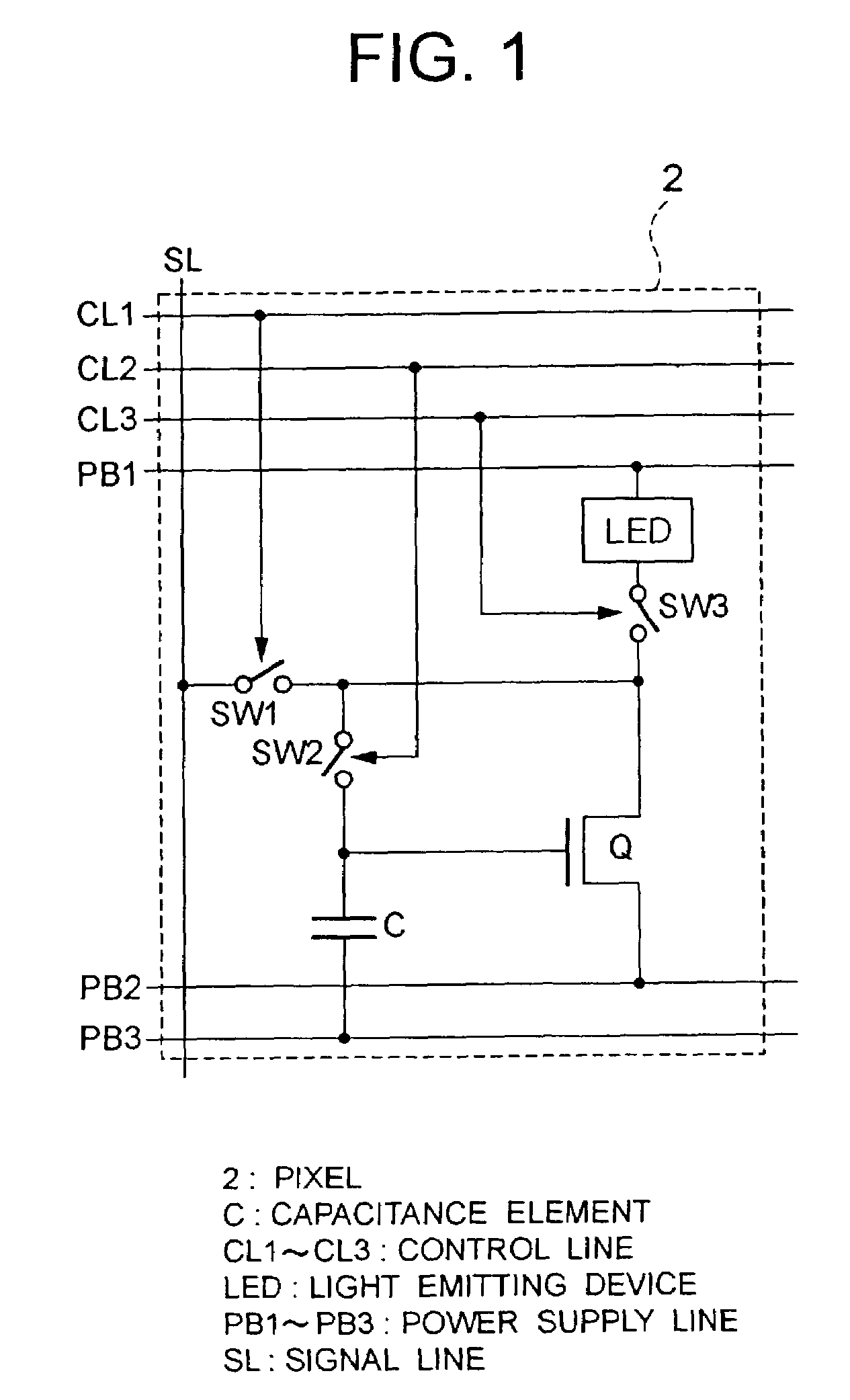

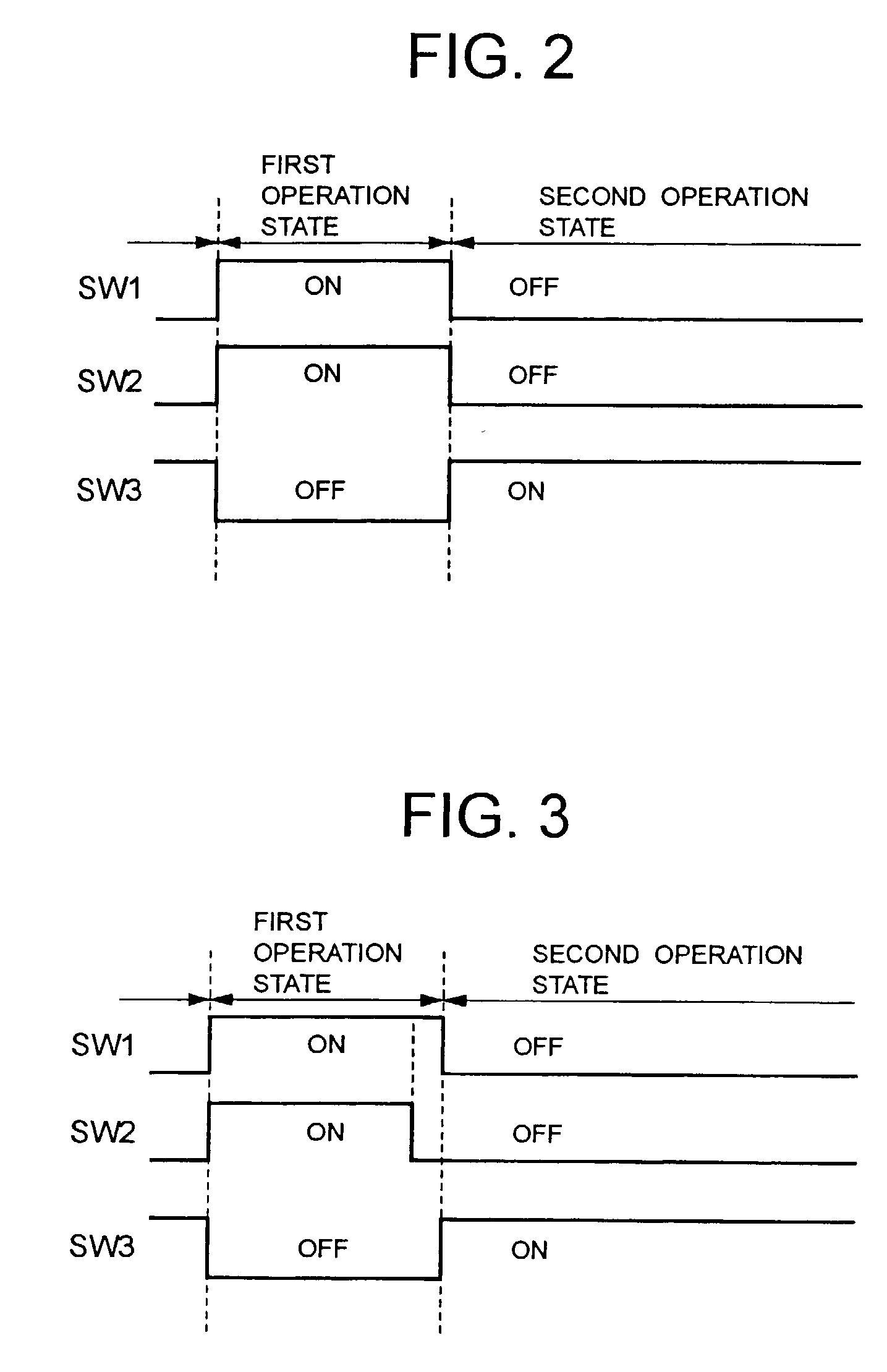

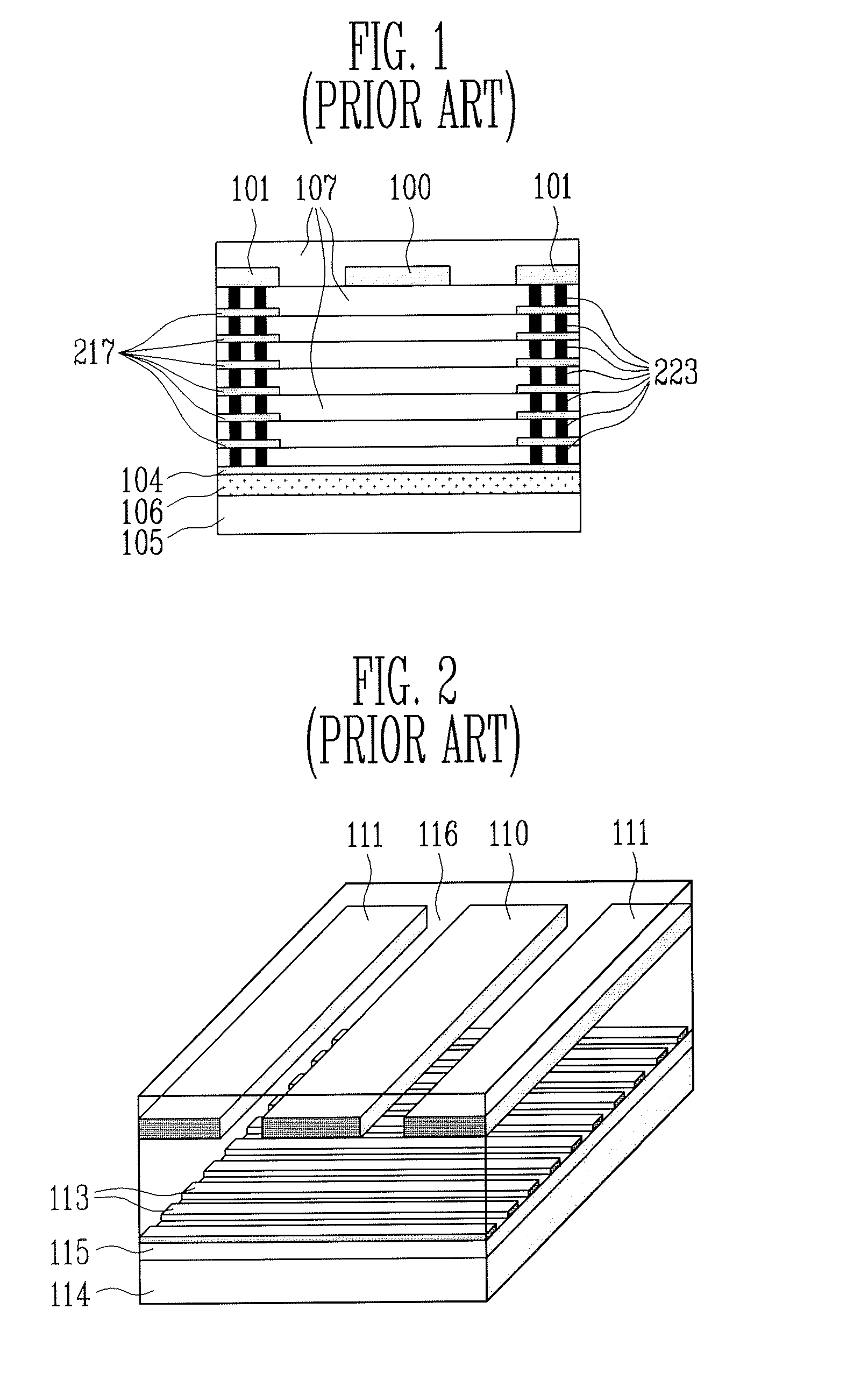

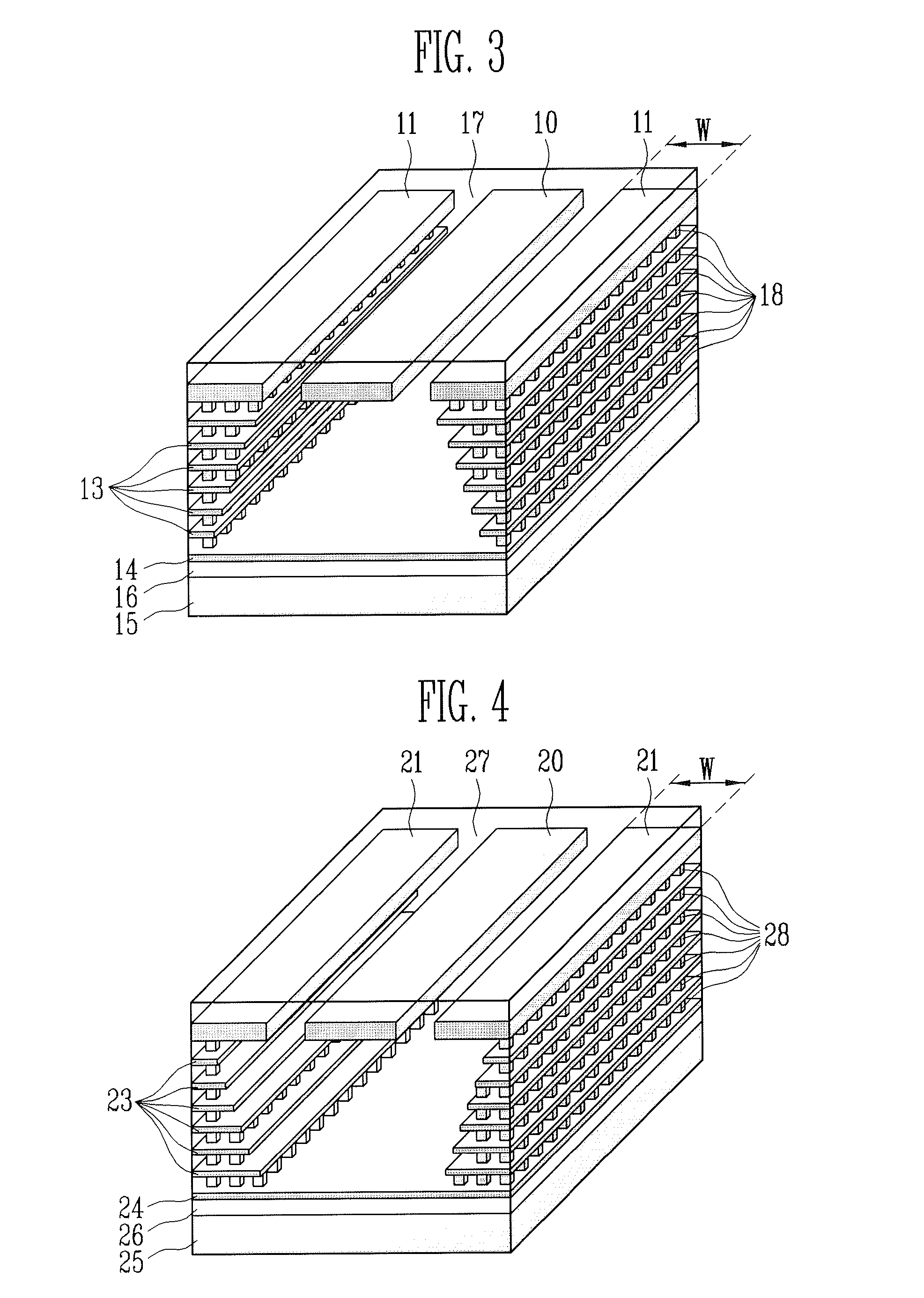

Display device and electronic equipment

ActiveUS20080042948A1Amount of signal becomes smallReduce semaphoreElectrical apparatusStatic indicating devicesScan lineControl signal

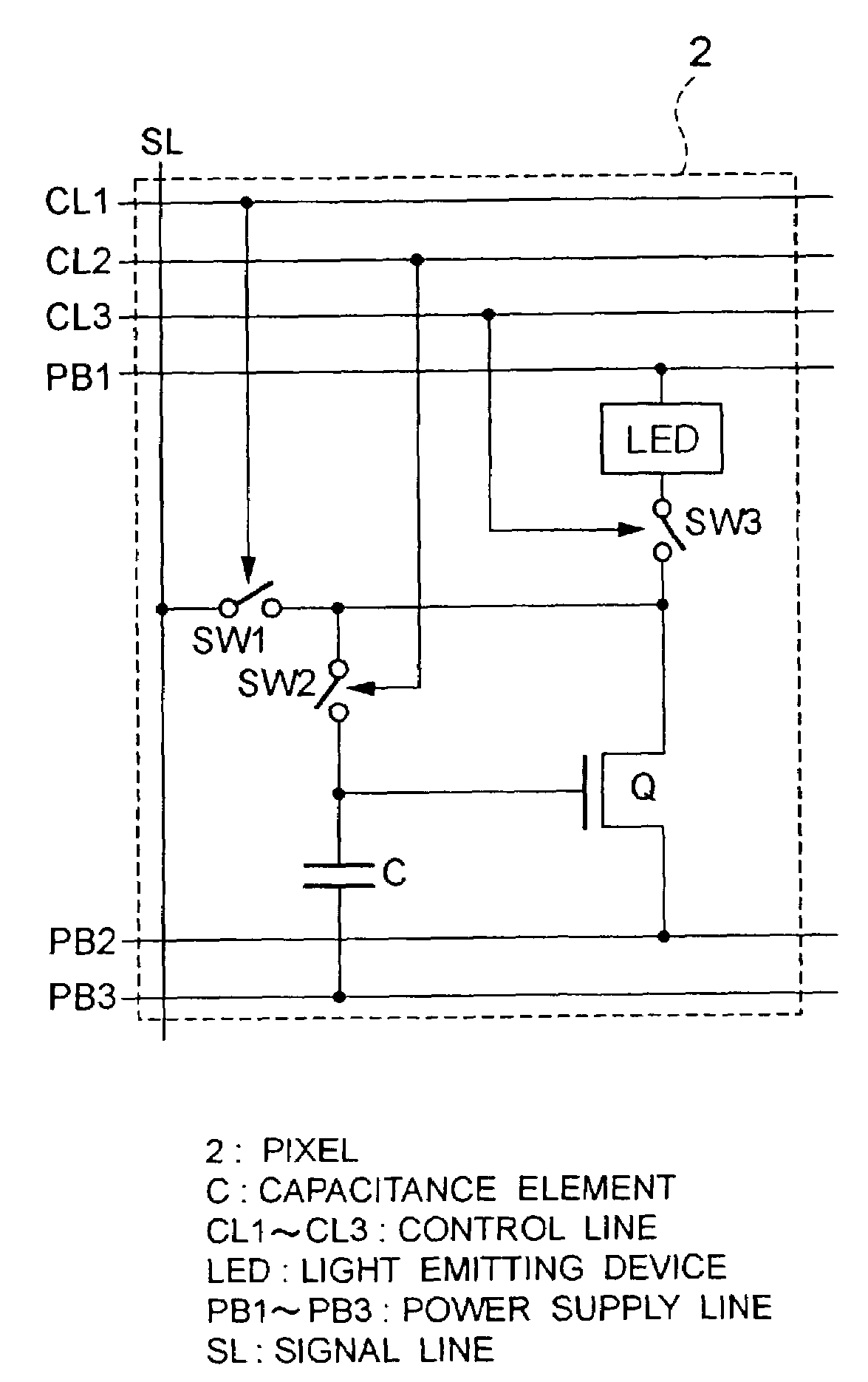

A display device is disclosed. The display device includes: a pixel array part; and a drive part that drives the pixel array part. The pixel array part includes row-wise first scan lines and second scan lines, column-wise signal lines, pixels arranged in a matrix form on parts where the lines intersect, and power supply lines and ground lines that supply power to the respective pixels. The drive part includes a first scanner that sequentially supplies first control signals to the respective first scan lines and line-sequentially scans the pixels in units of rows, a second scanner that sequentially supplies second control signals to the respective second scan lines according to the line-sequential scan, and a signal selector that supplies video signals to the column-wise signal lines according to the line-sequential scan.

Owner:JOLED INC

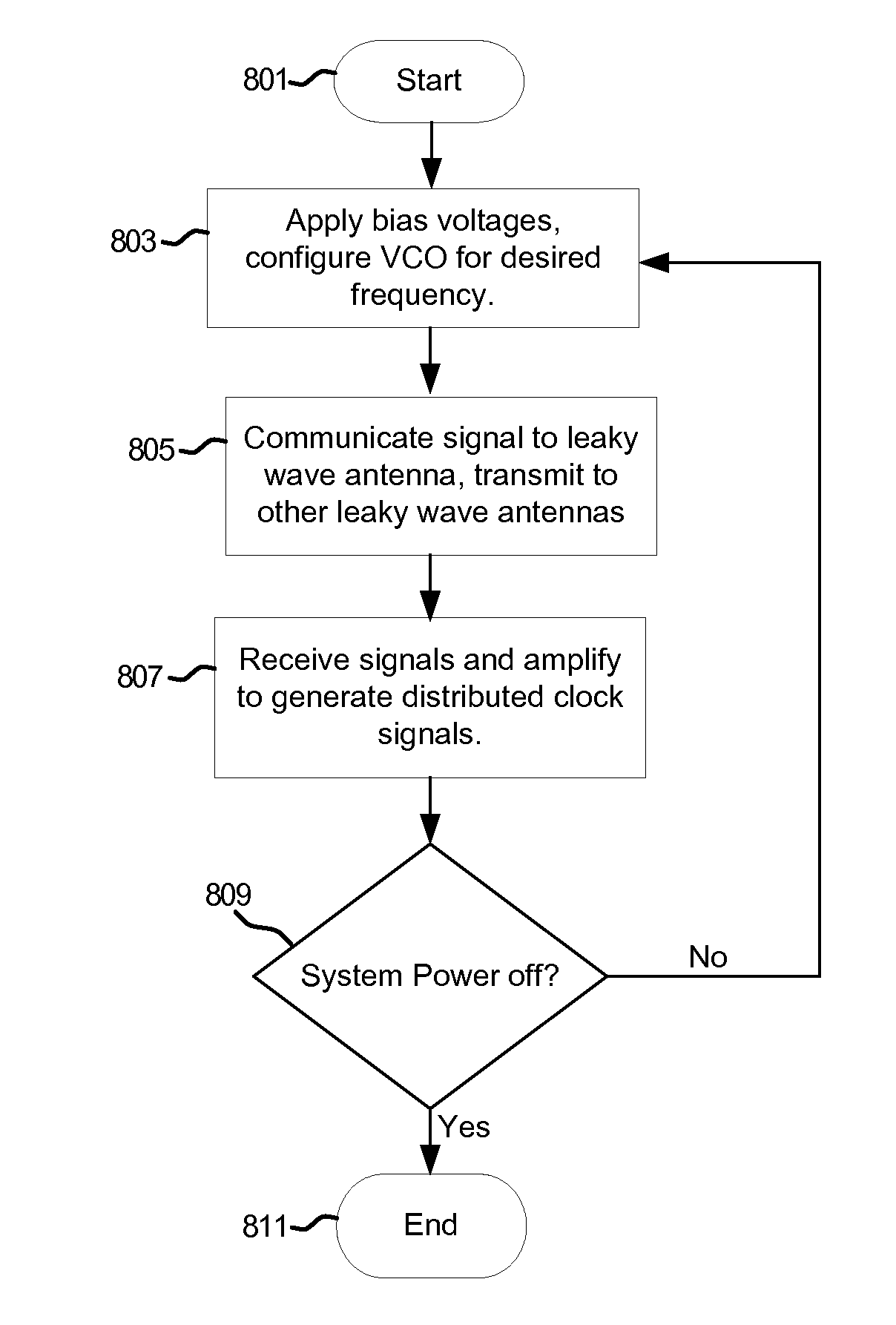

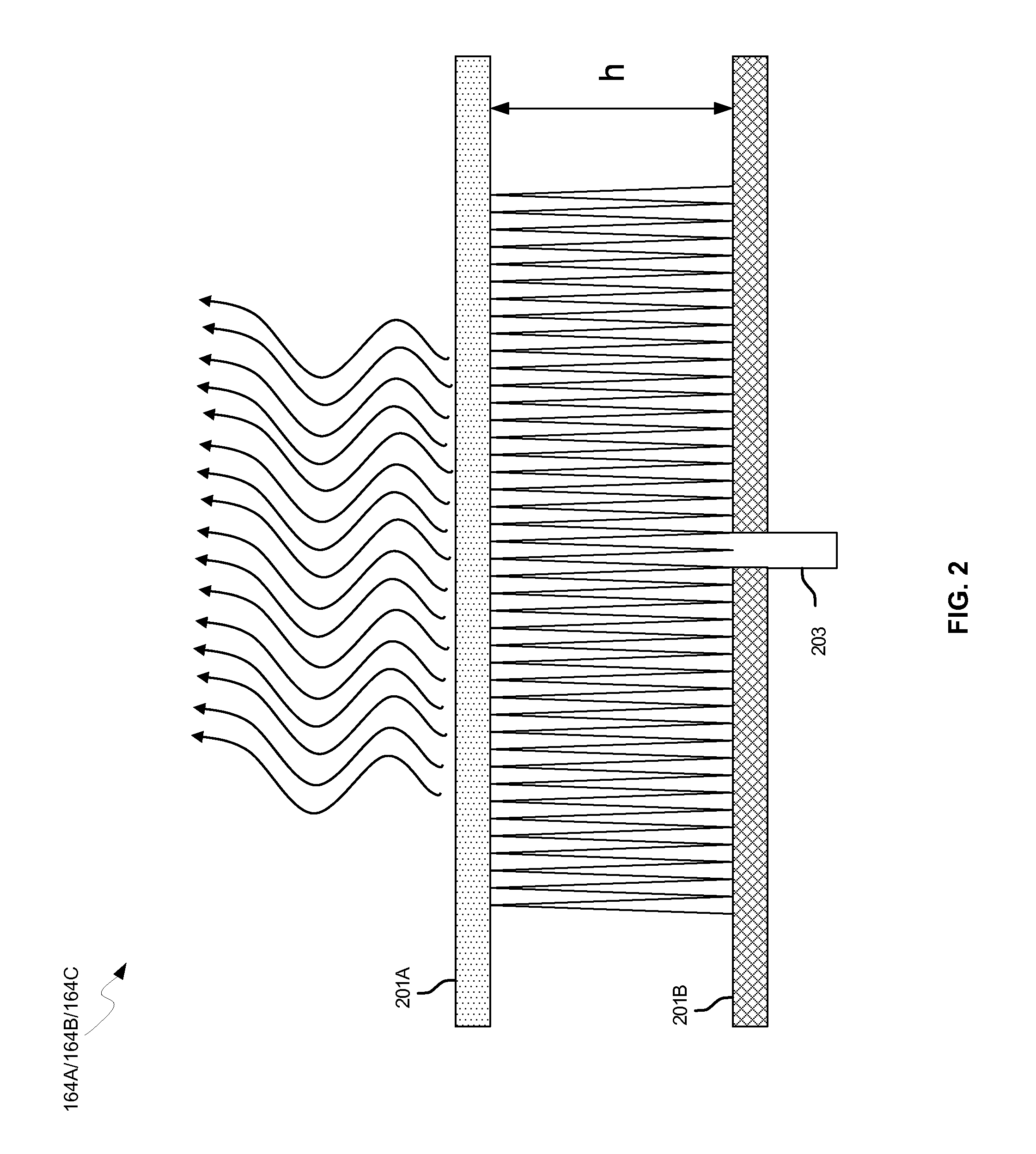

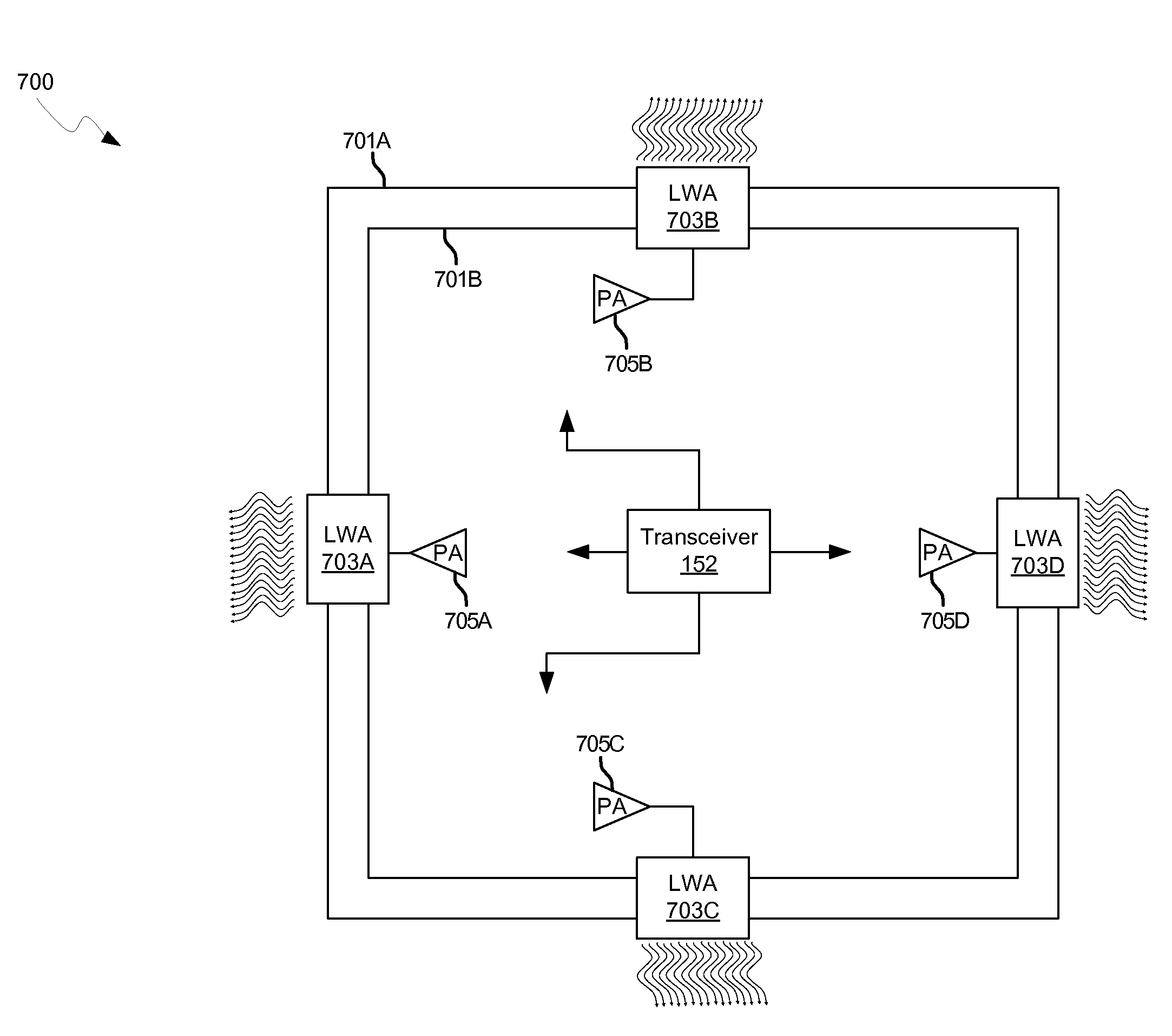

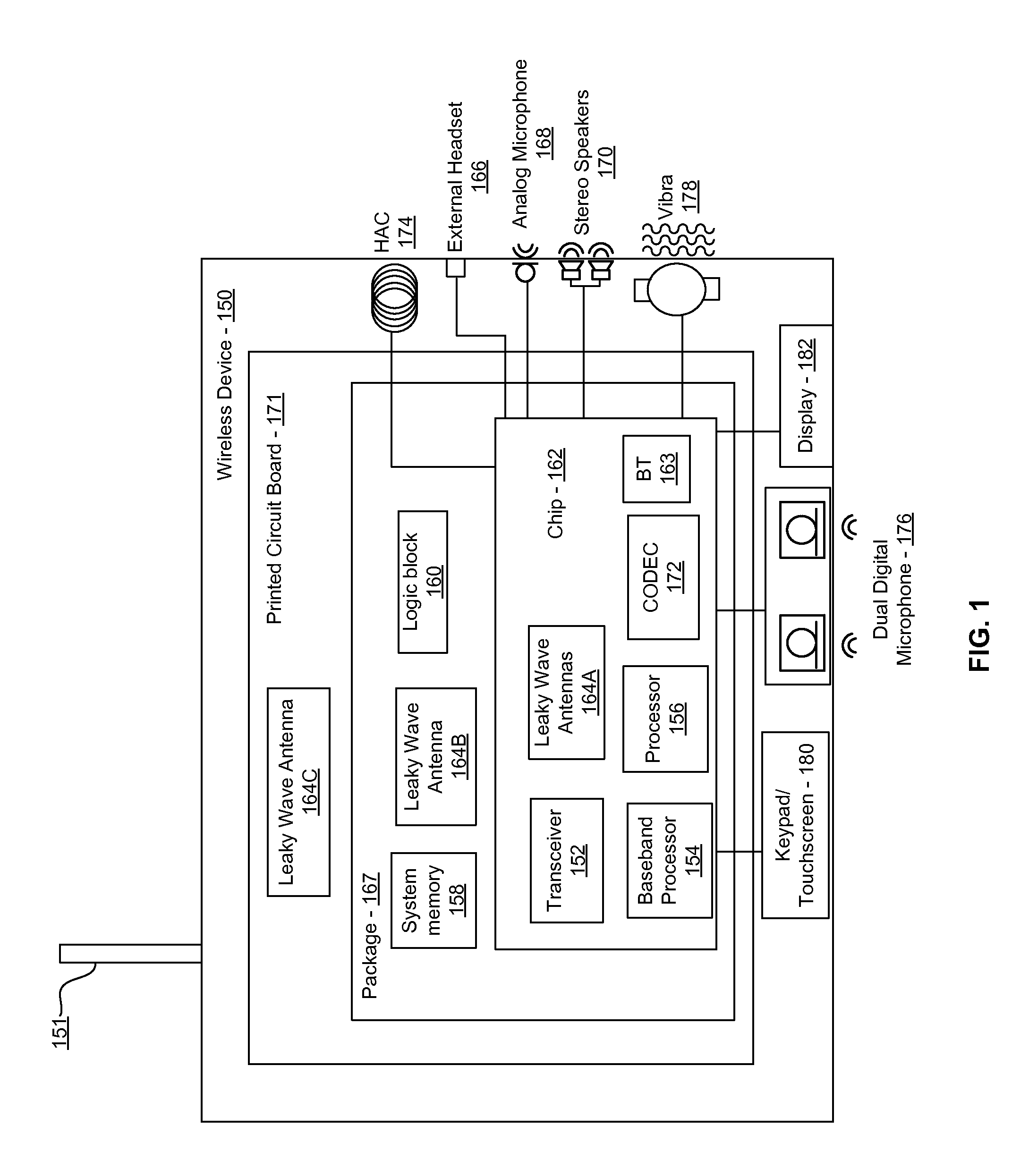

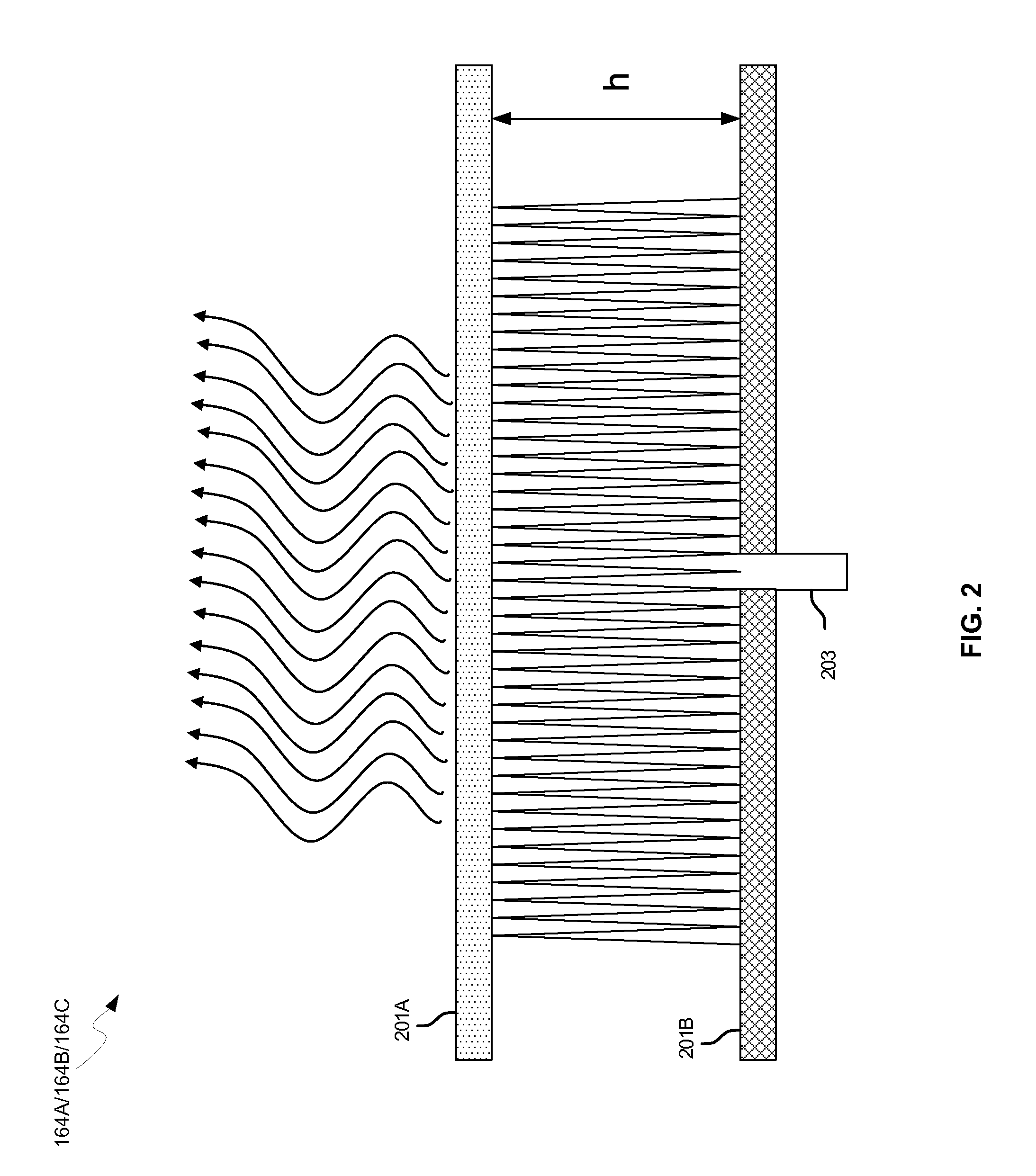

Method and system for an integrated voltage controlled oscillator-based transmitter and on-chip power distribution network

Methods and systems for an integrated voltage controlled oscillator (VCO)-based transmitter and on-chip power distribution network are disclosed and may include supplying bias voltages and / or ground to a chip utilizing conductive lines. One or more VCOs and low-noise amplifiers (LNAs) may each be coupled to a leaky wave antenna (LWA) integrated in the bias voltage and / or ground lines. One or more clock signals may be generated utilizing the VCOs, which may be transmitted from the LWAs coupled to the VCOs, to the LWAs coupled to the LNAs. RF signals may be transmitted via the LWAs, and may include 60 GHz signals. The LWAs may include microstrip and / or coplanar waveguides, where a cavity length of the LWAs may be dependent on a spacing between conductive lines in the waveguides. The LWAs may be dynamically configured to transmit the clock signals at a desired angle from a surface of the chip.

Owner:AVAGO TECH INT SALES PTE LTD

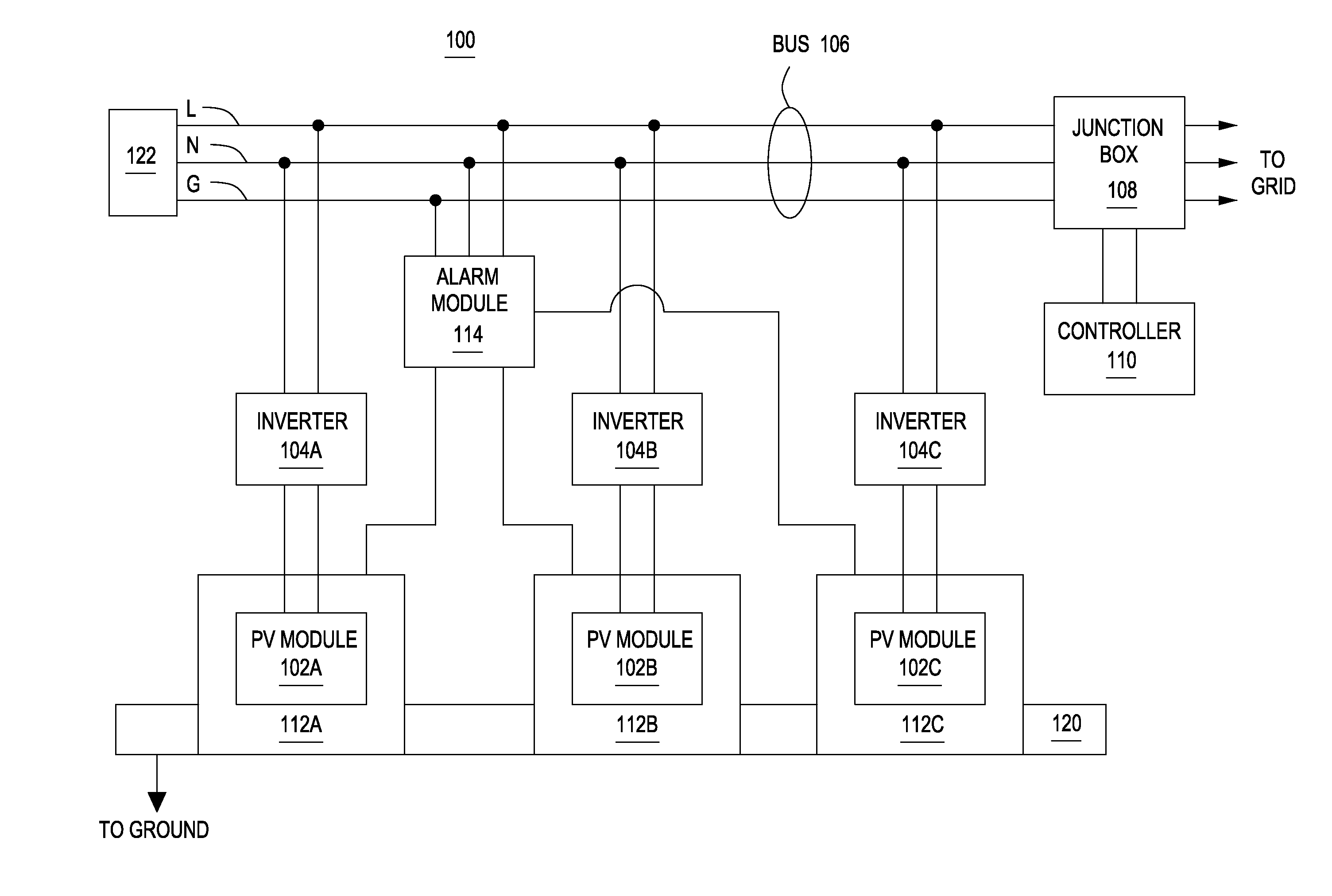

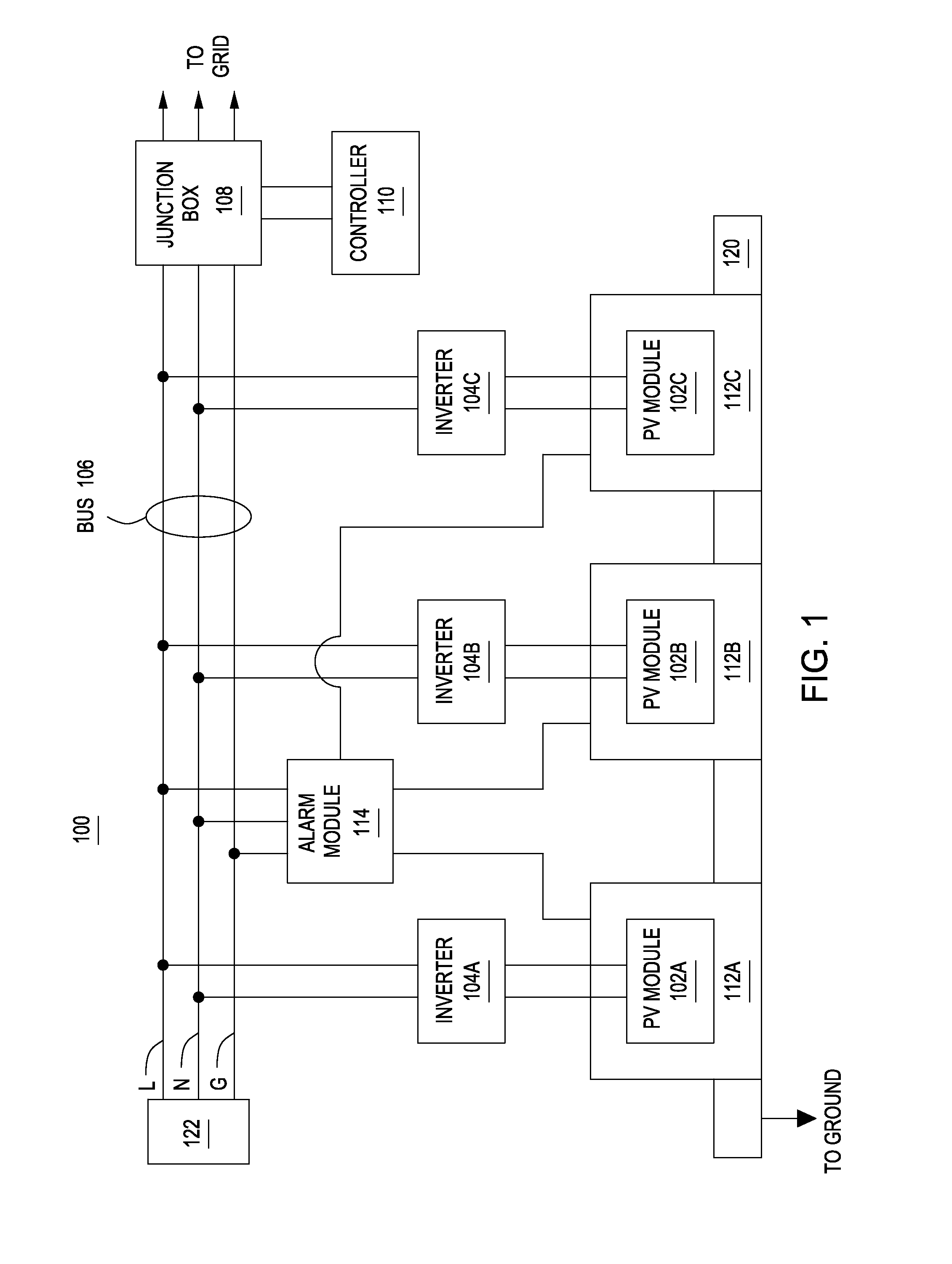

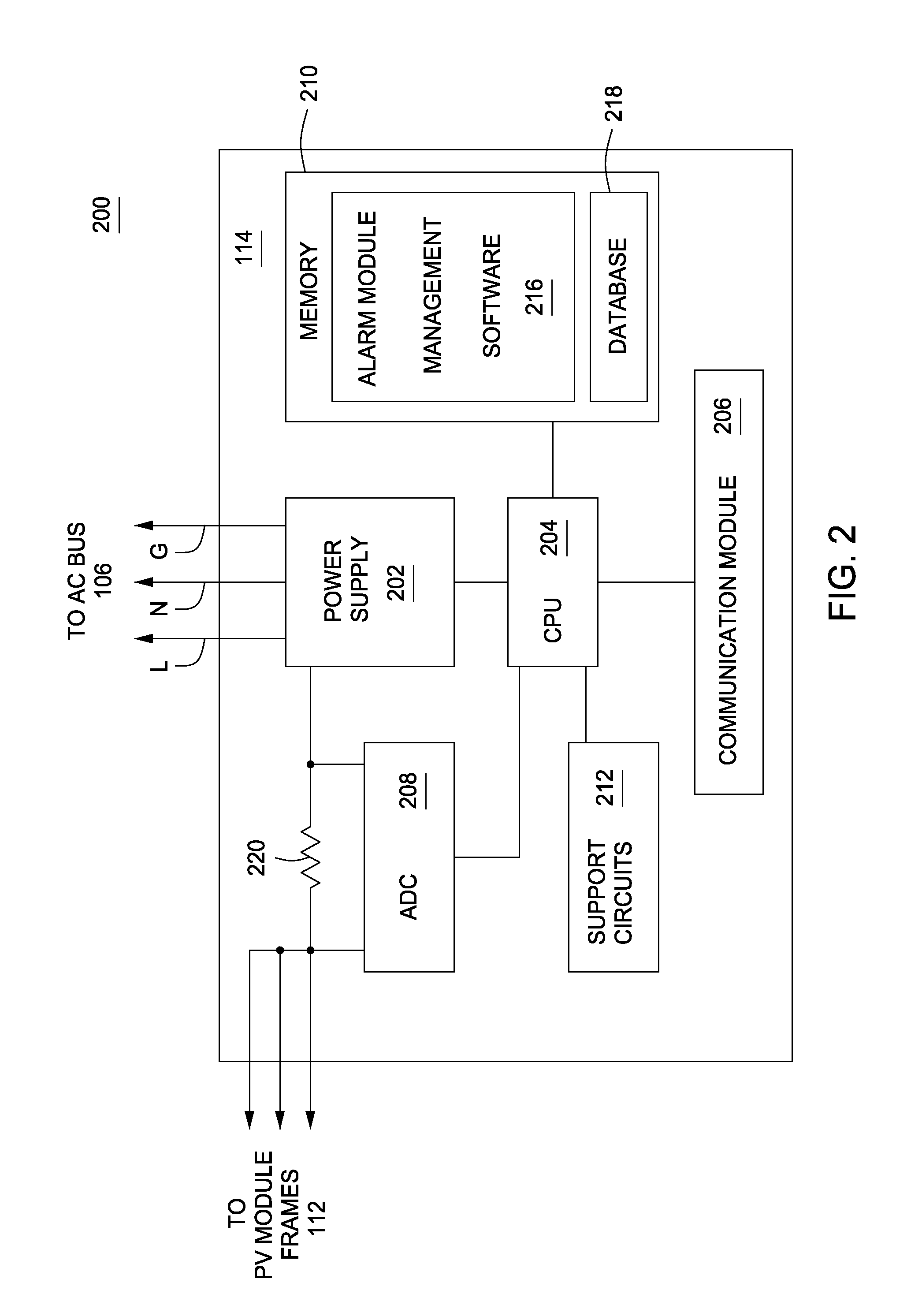

Method and apparatus for indicating a disconnection within a distributed generator

A method and apparatus for indicating a disconnection within a Distributed Generator (DG). In one embodiment, the apparatus comprises an alarm module electrically coupled to a conductive portion of a component within the DG, wherein the conductive portion is grounded via a ground rod system, and wherein the alarm module (i) is further coupled to a ground line, (ii) couples a monitoring current to the conductive portion, (iii) monitors flow of the monitoring current to determine a change in the flow, and (iv) generates, as a result of the change in the flow, a notification of the disconnection.

Owner:ENPHASE ENERGY

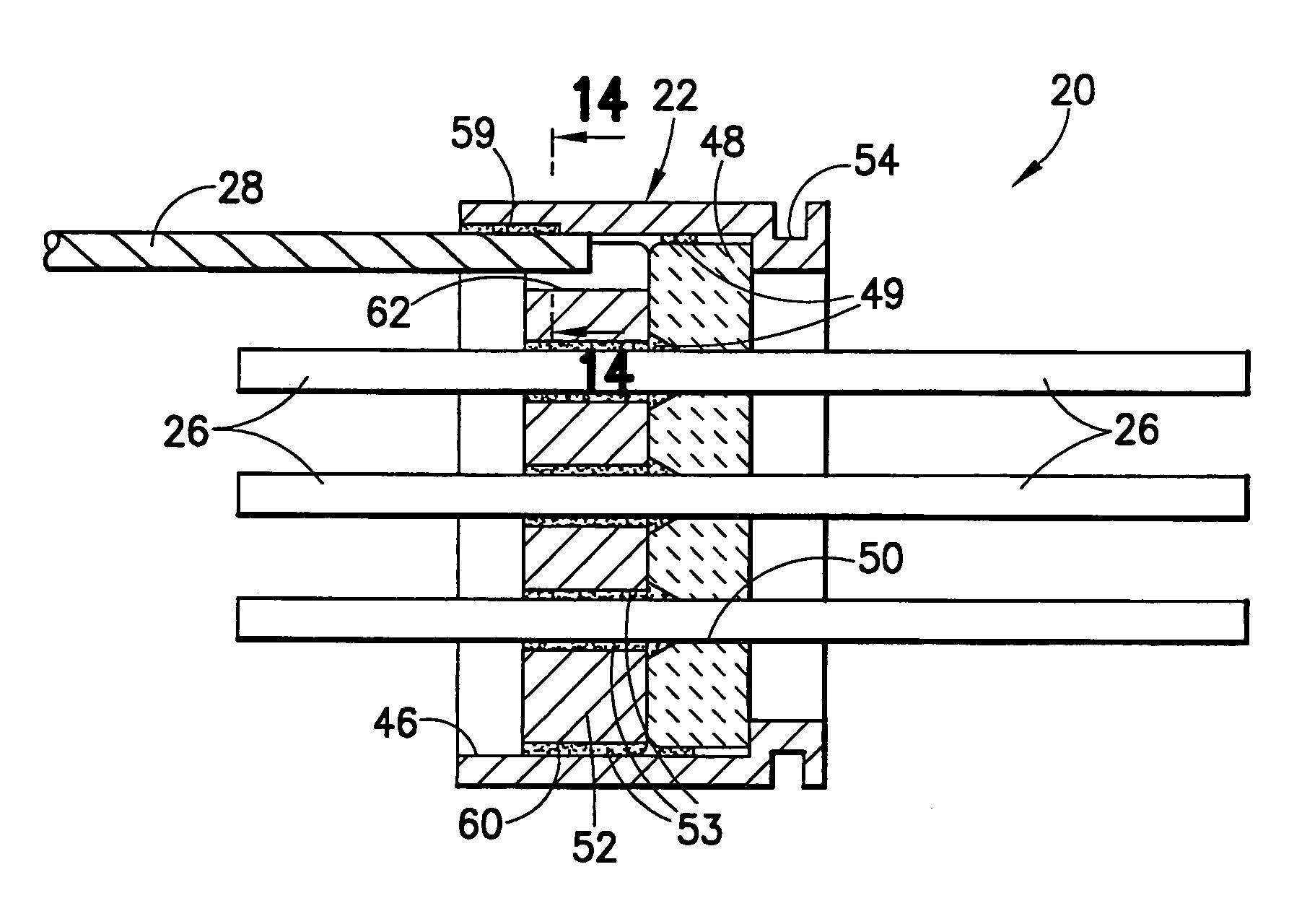

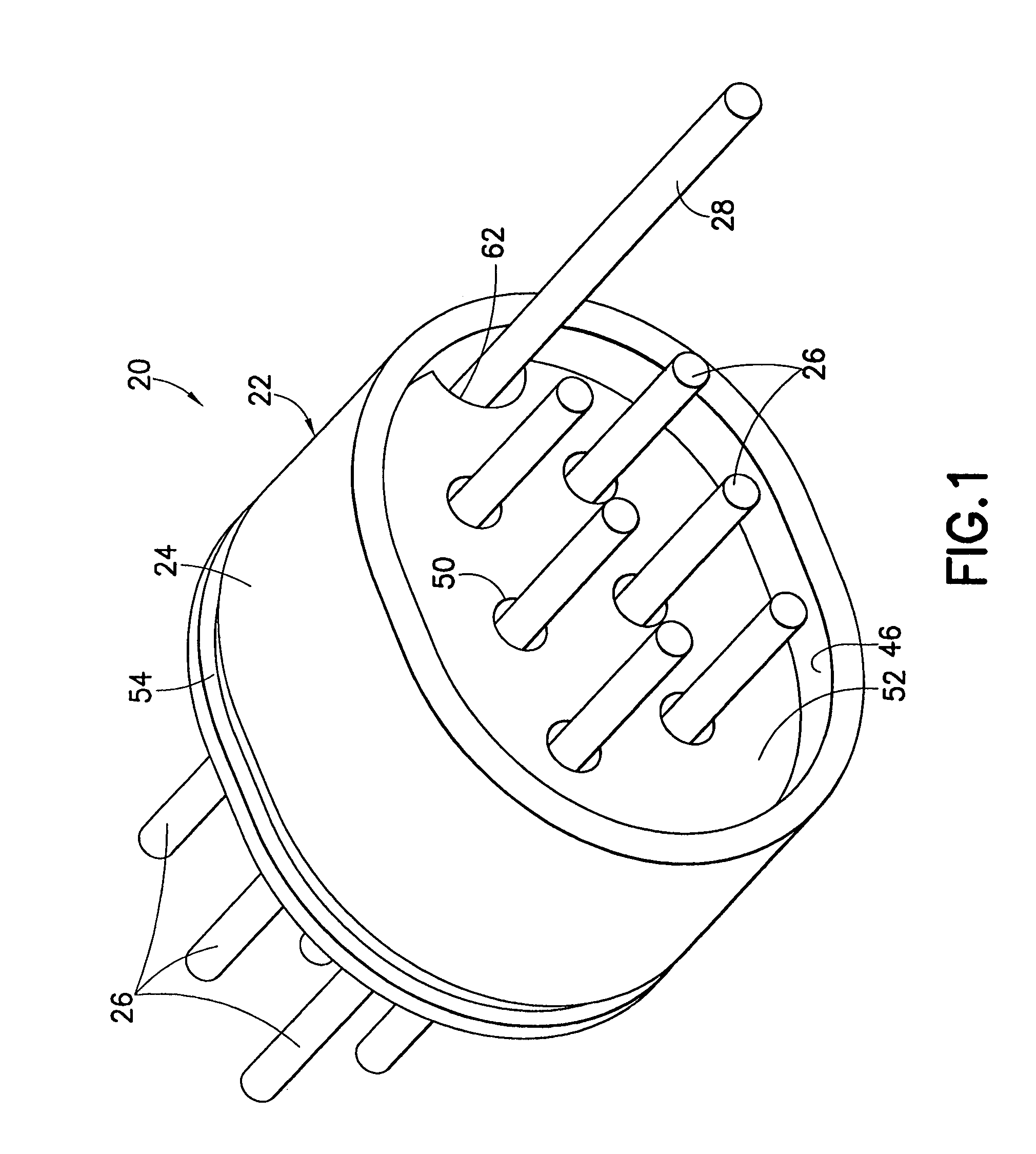

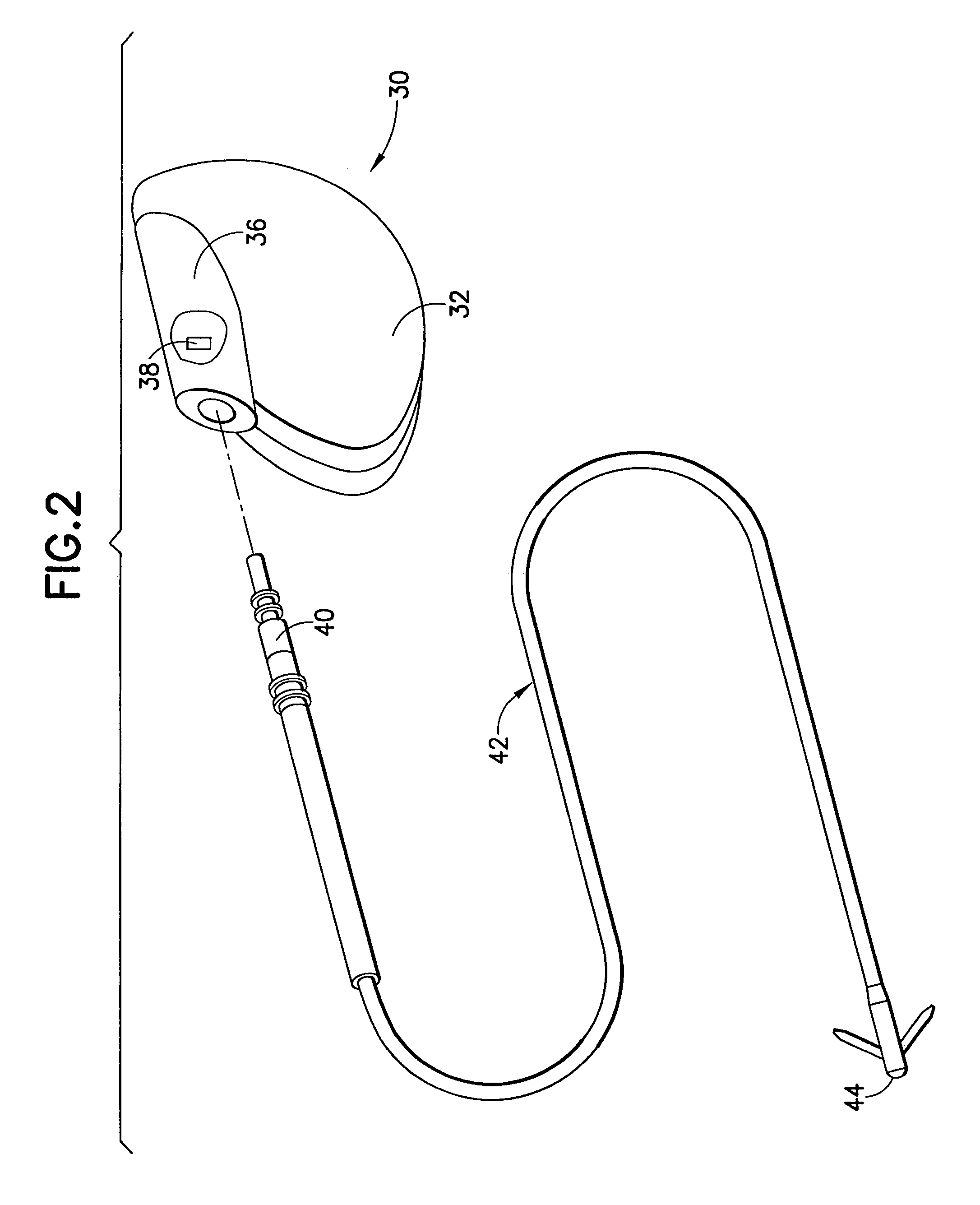

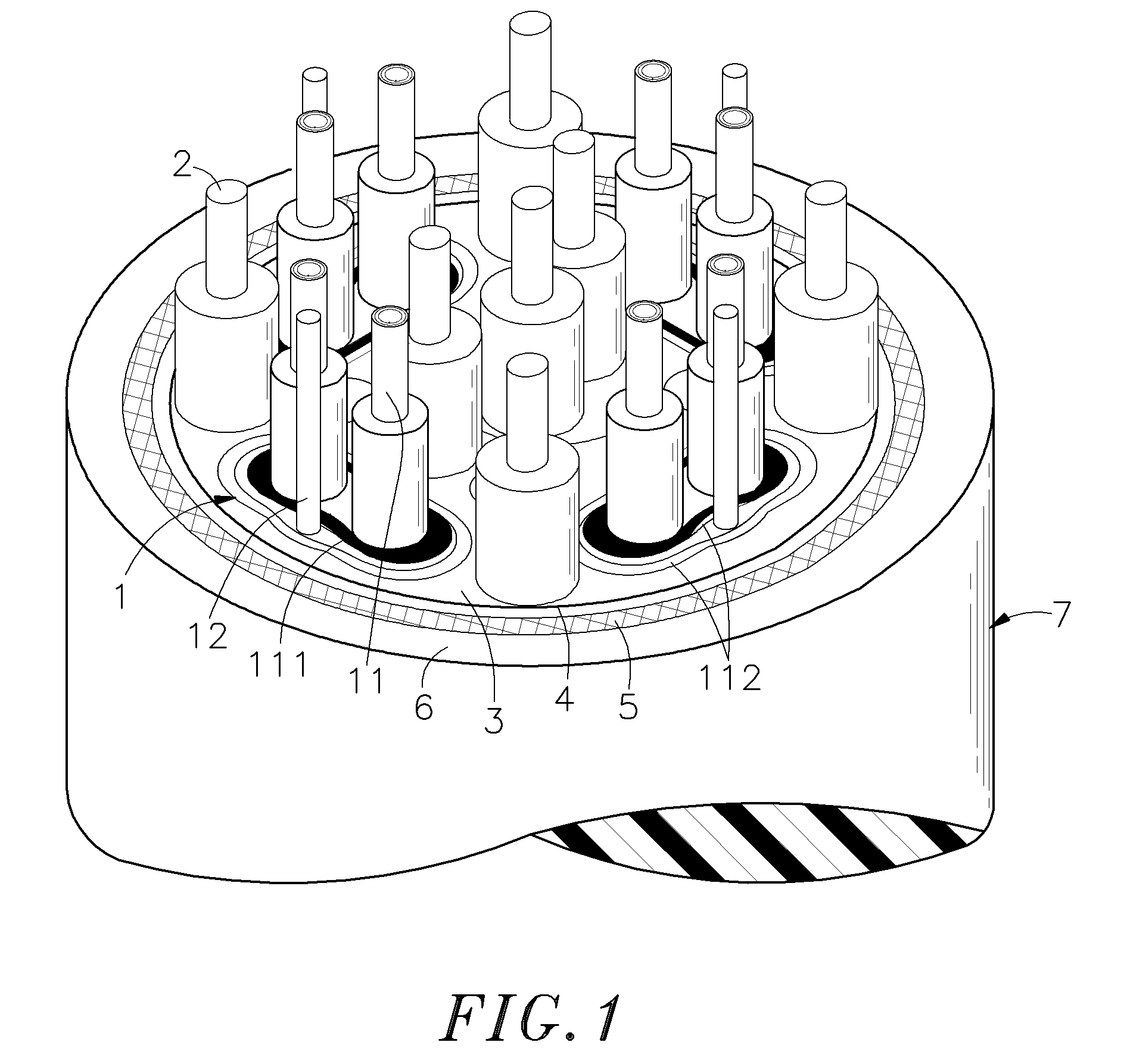

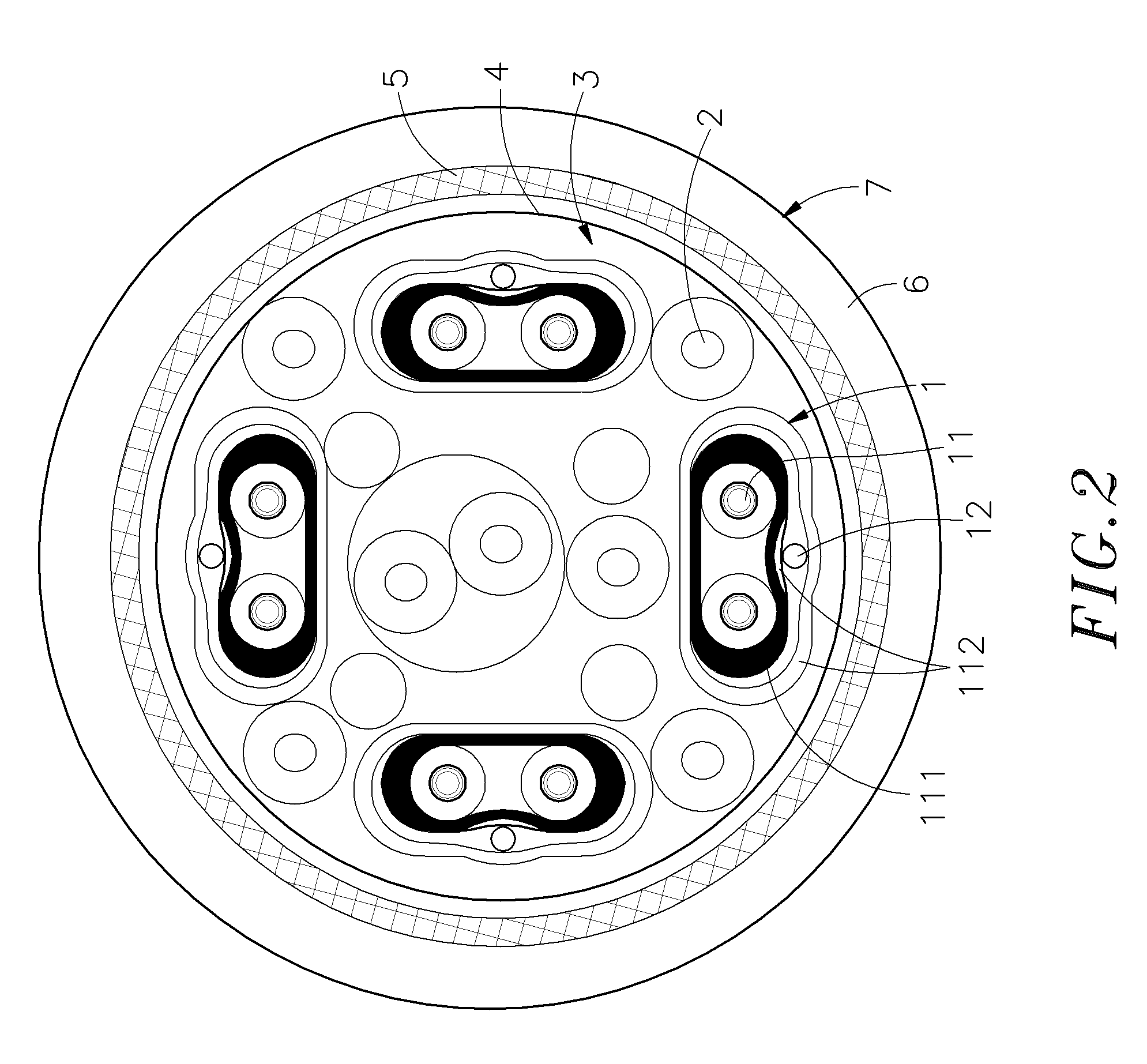

Internally grounded filtering feedthrough

ActiveUS7046499B1Save additional assembly stepMinimize functional impactAnti-noise capacitorsElectrotherapyCounterboreFilter capacitor

A feedthrough device includes a conductive ferrule having an outer peripheral surface defining the outermost boundary of the feedthrough device, an insulator, a lead wire electrically isolated from the ferrule extending through the insulator, a filter capacitor adjacent the insulator through which the lead wire extends in conductive relation therewith, and a ground wire coupled to the ferrule and to the insulator within the outermost boundary of the feedthrough device. The ferrule has an inner peripheral surface defining an opening therethrough and each of the insulator and the filter capacitor has an outer peripheral surface proximate the inner peripheral surface, a counterbore in the outer peripheral surface of each of the insulator and filter capacitor, an end of the ground wire being received in the counterbore and brazed to the ferrule and insulator. Alternatively, an end of the ground wire is welded to the inner peripheral surface of the ferrule.

Owner:PACESETTER INC

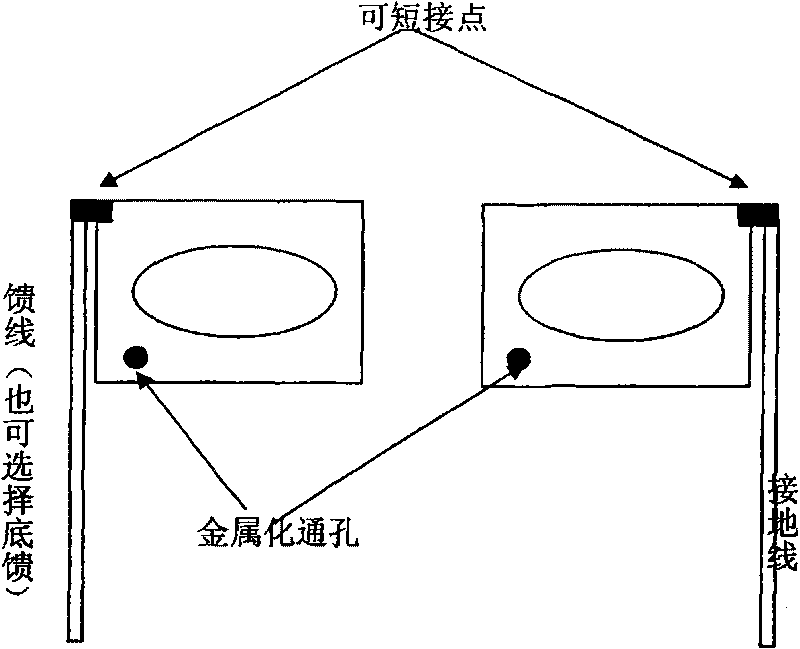

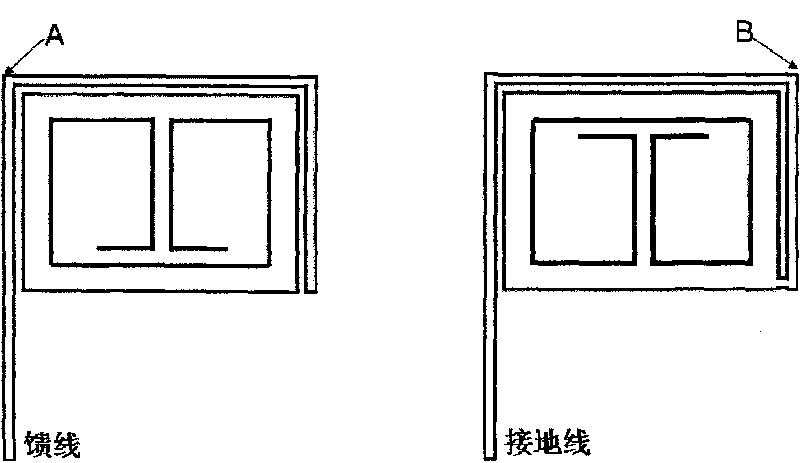

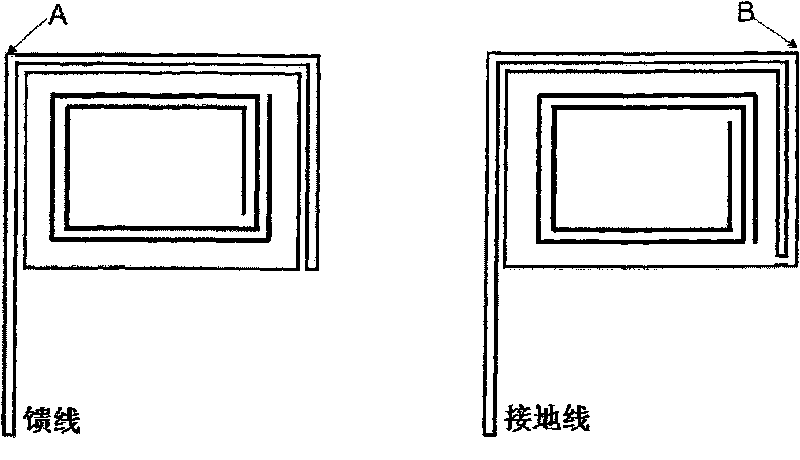

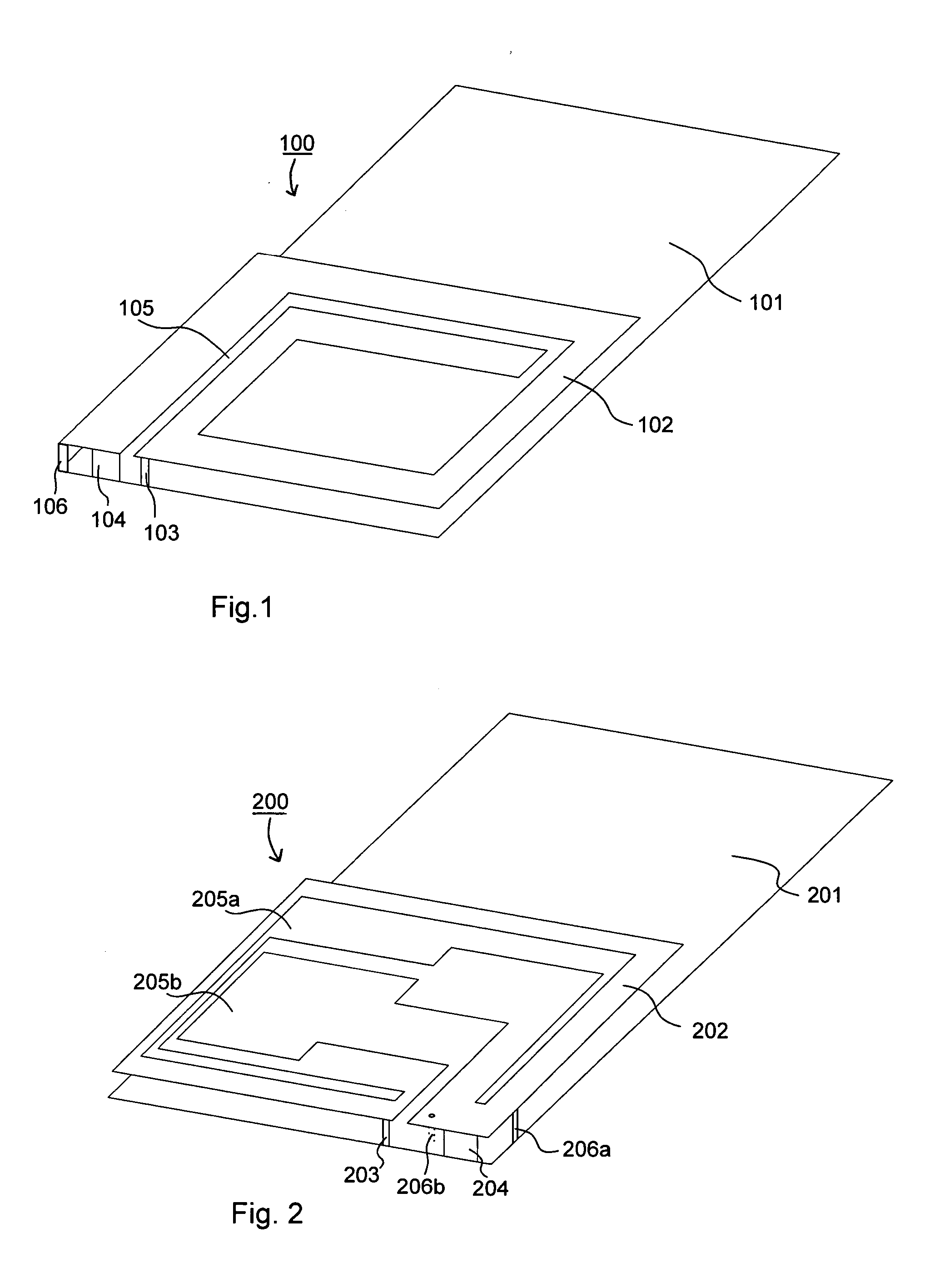

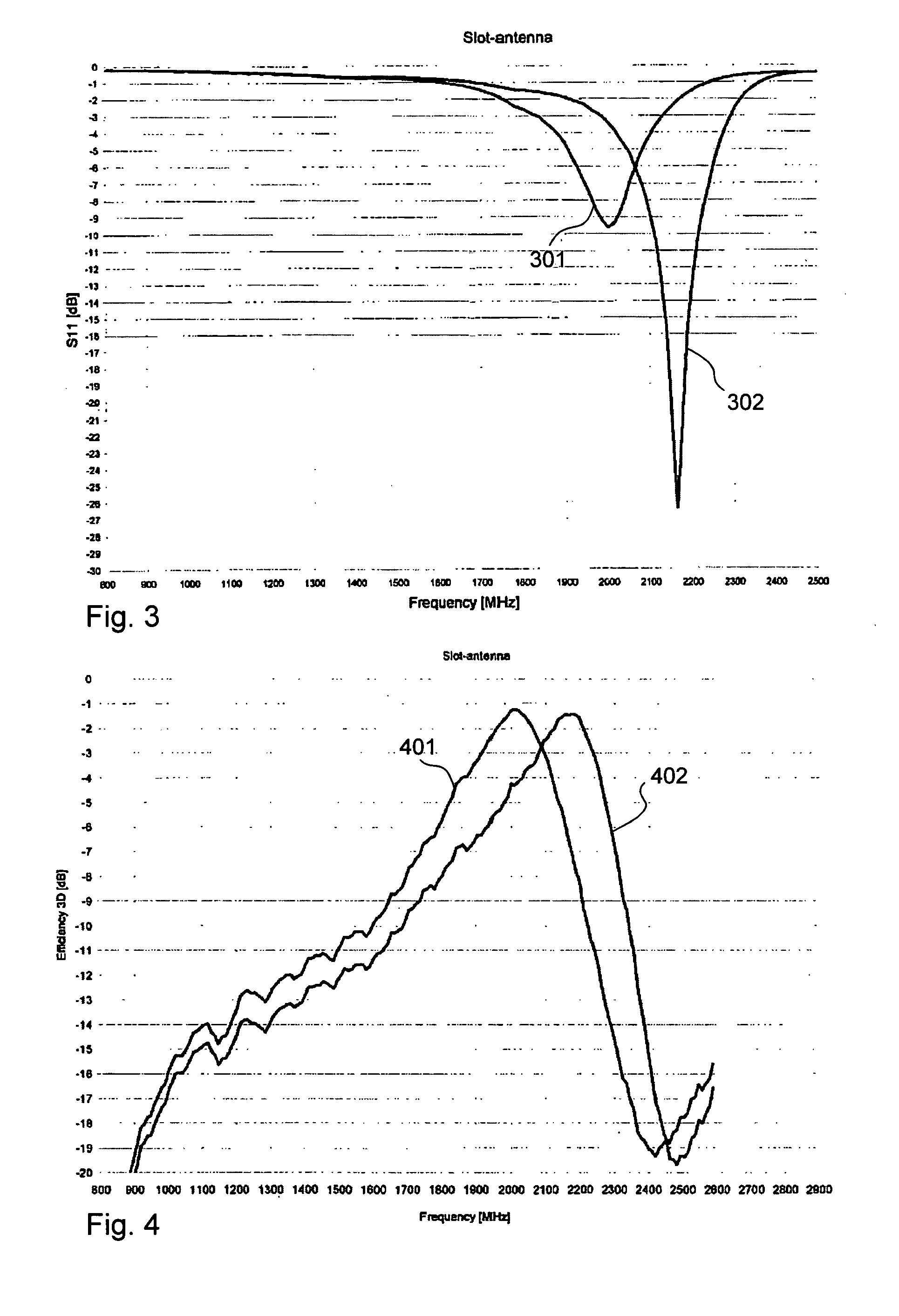

Actively tunable planar antenna

InactiveUS20050264455A1Reduce the overall heightEqually and even efficientSimultaneous aerial operationsAntenna supports/mountingsGround planeFeed point

This invention relates to an actively tunable patch antenna comprising a ground plane, a planar radiator, a feed point, a grounding line and first and second antenna branches separated from each other by a groove, the patch antenna further comprising one or more additional grounding points between the planar radiator and the ground plane. The invention further relates to a mobile terminal utilizing the tunable patch antenna of the invention.

Owner:NOKIA CORP

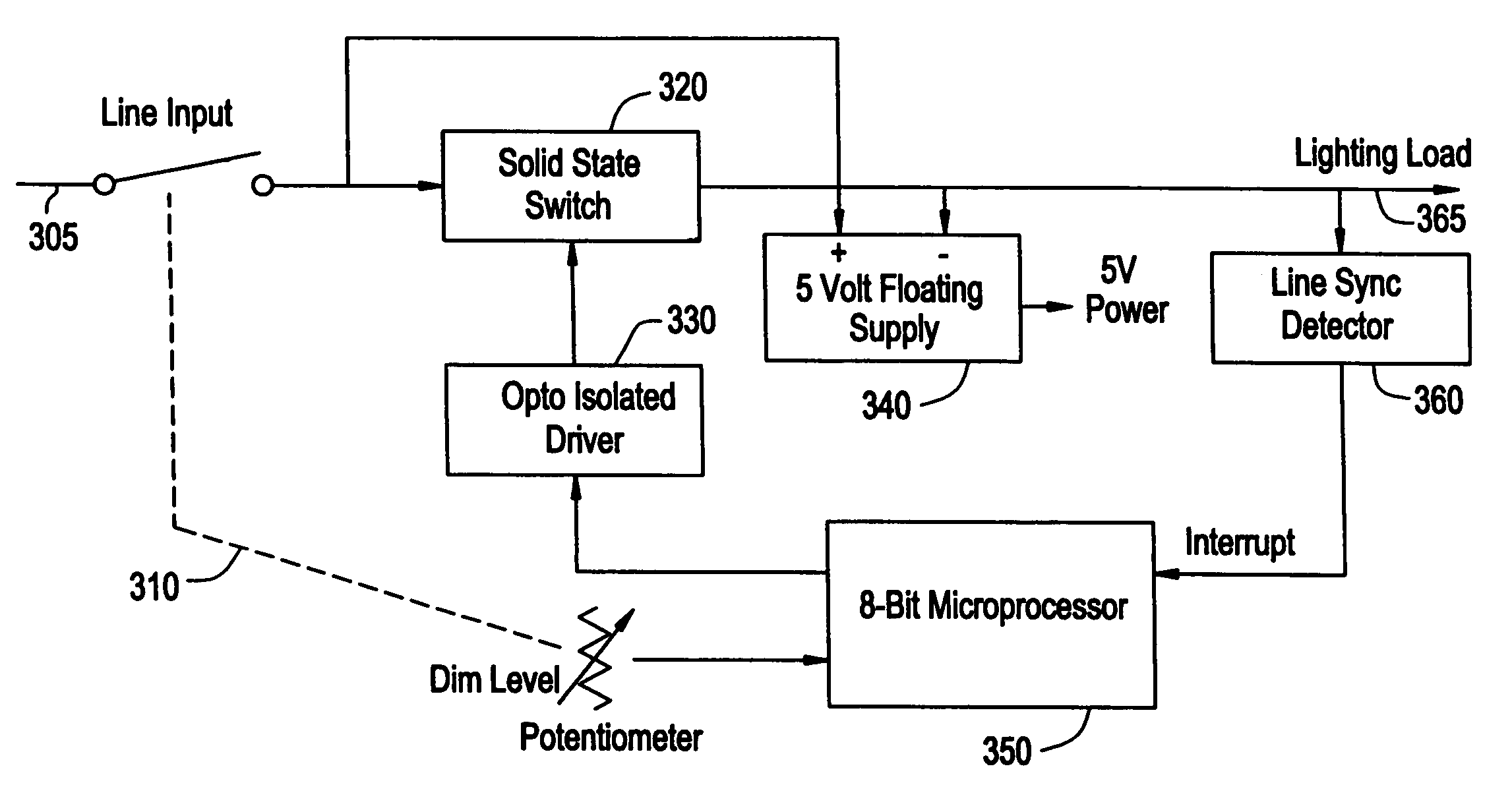

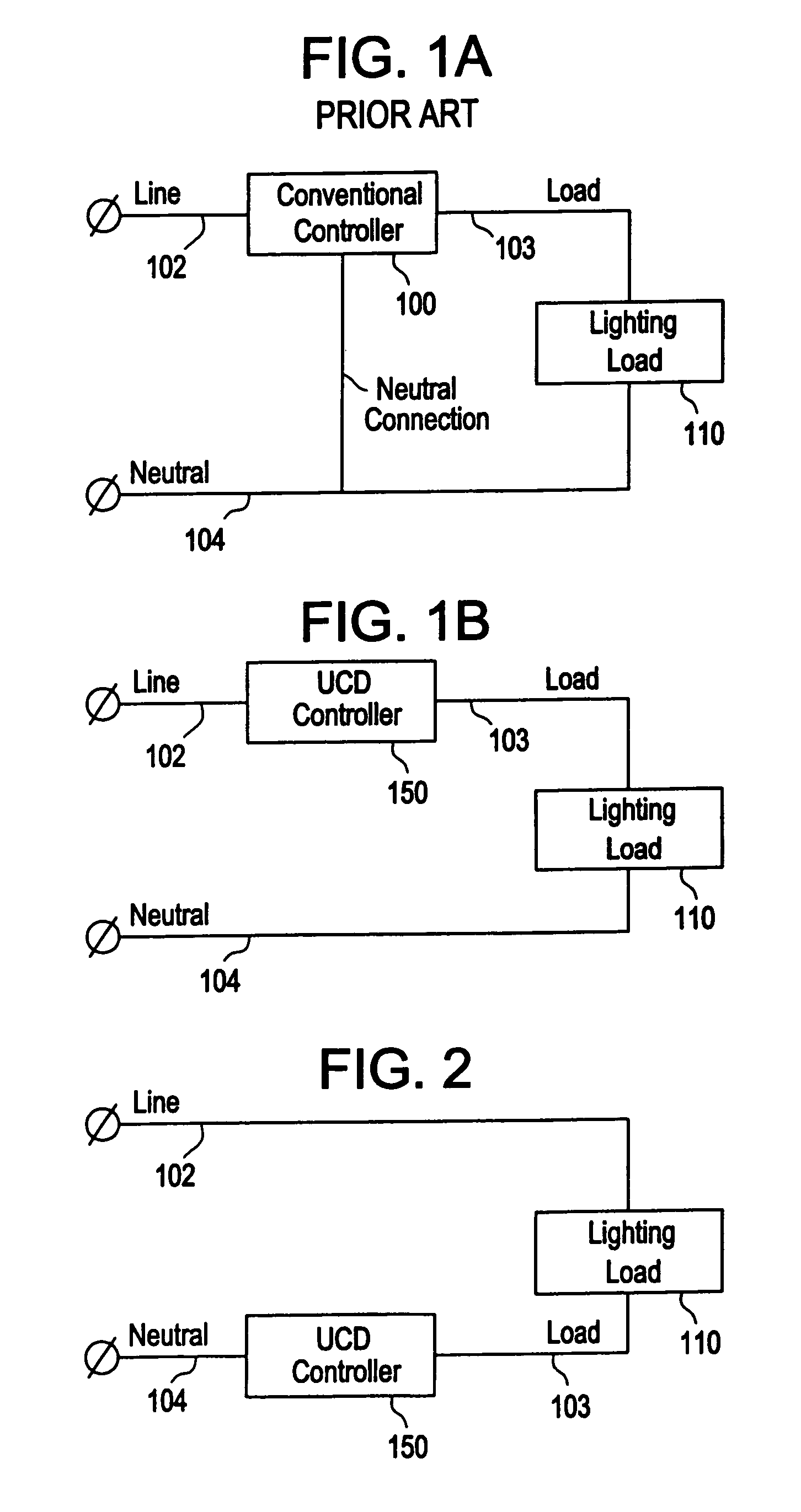

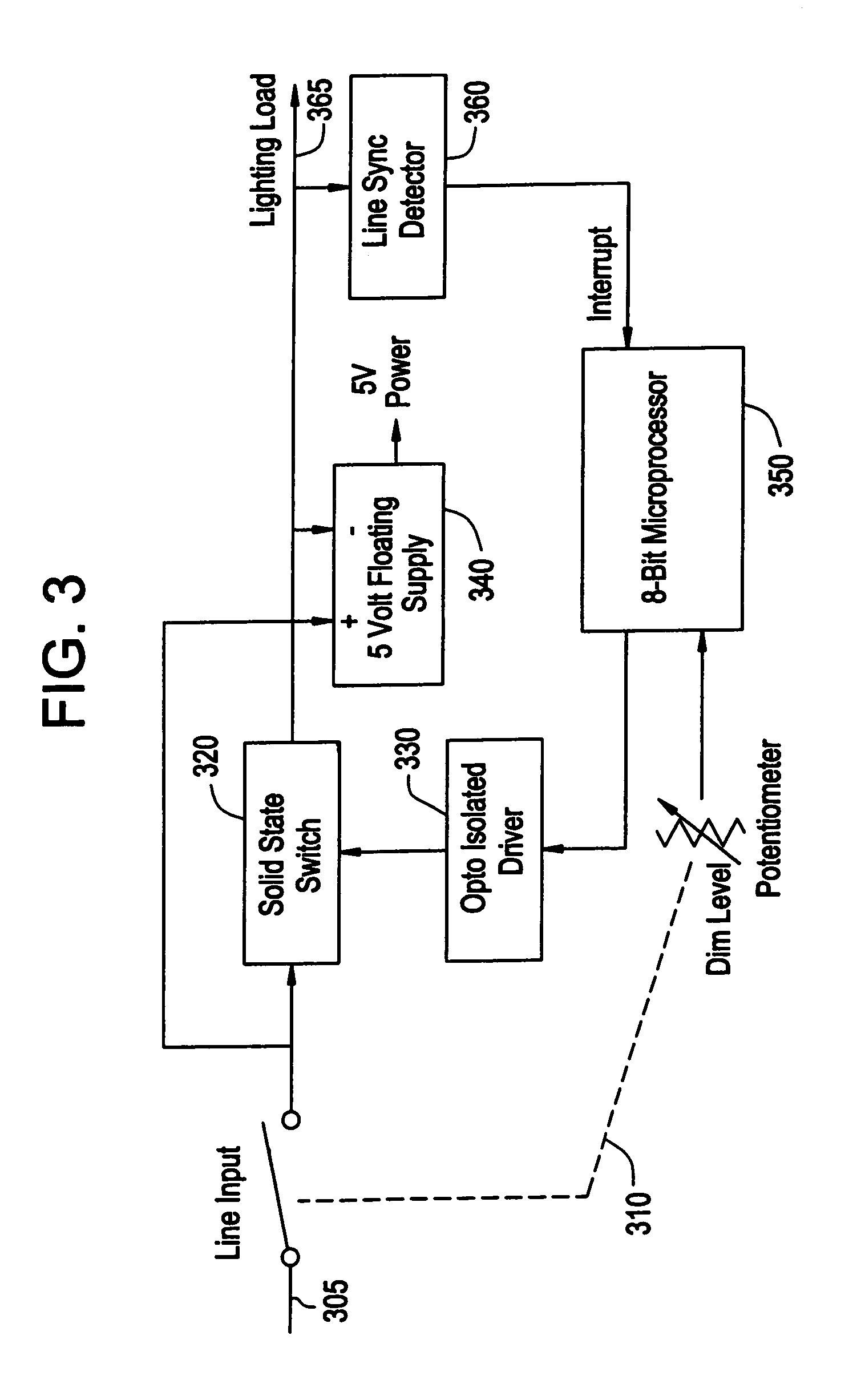

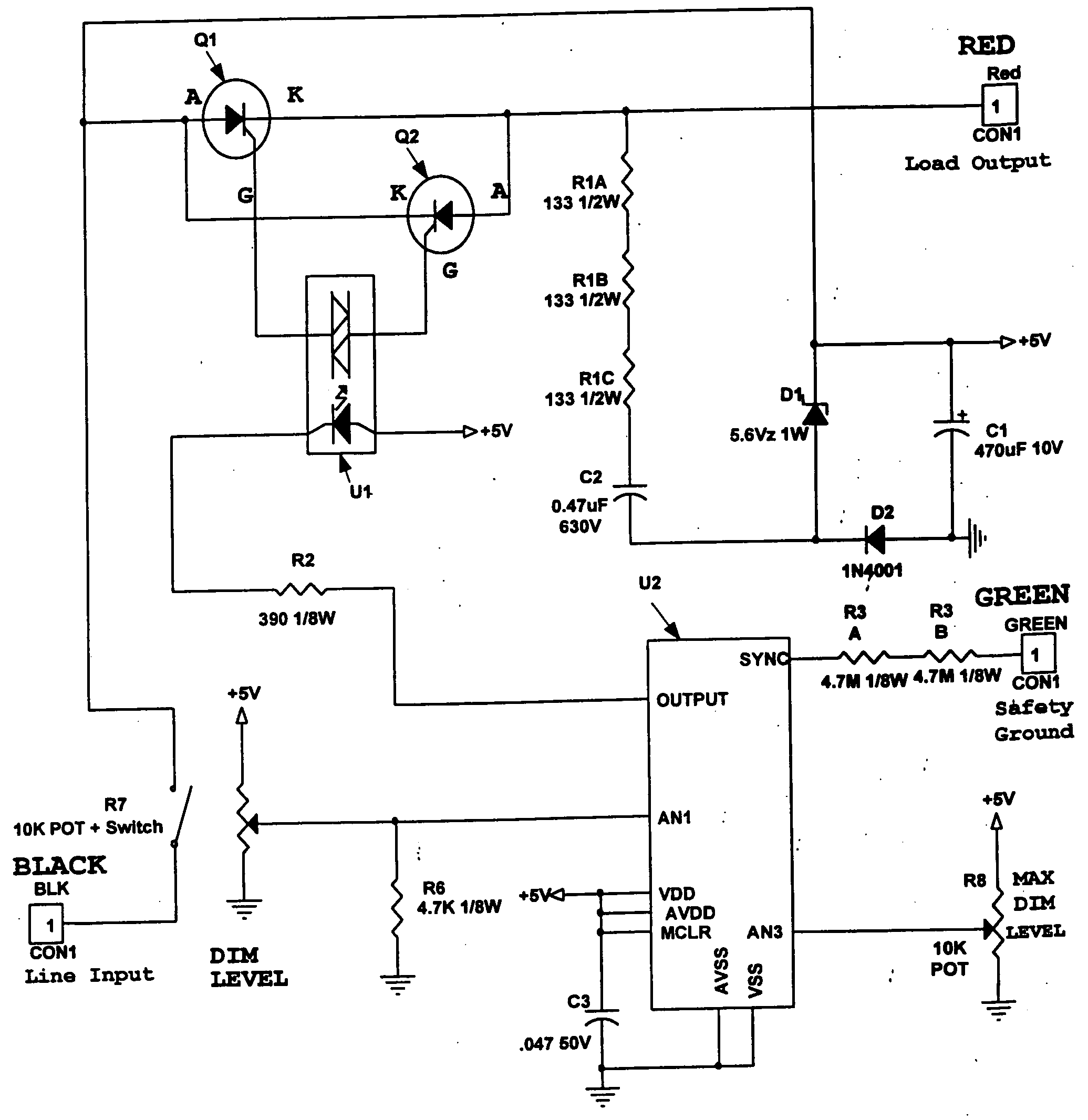

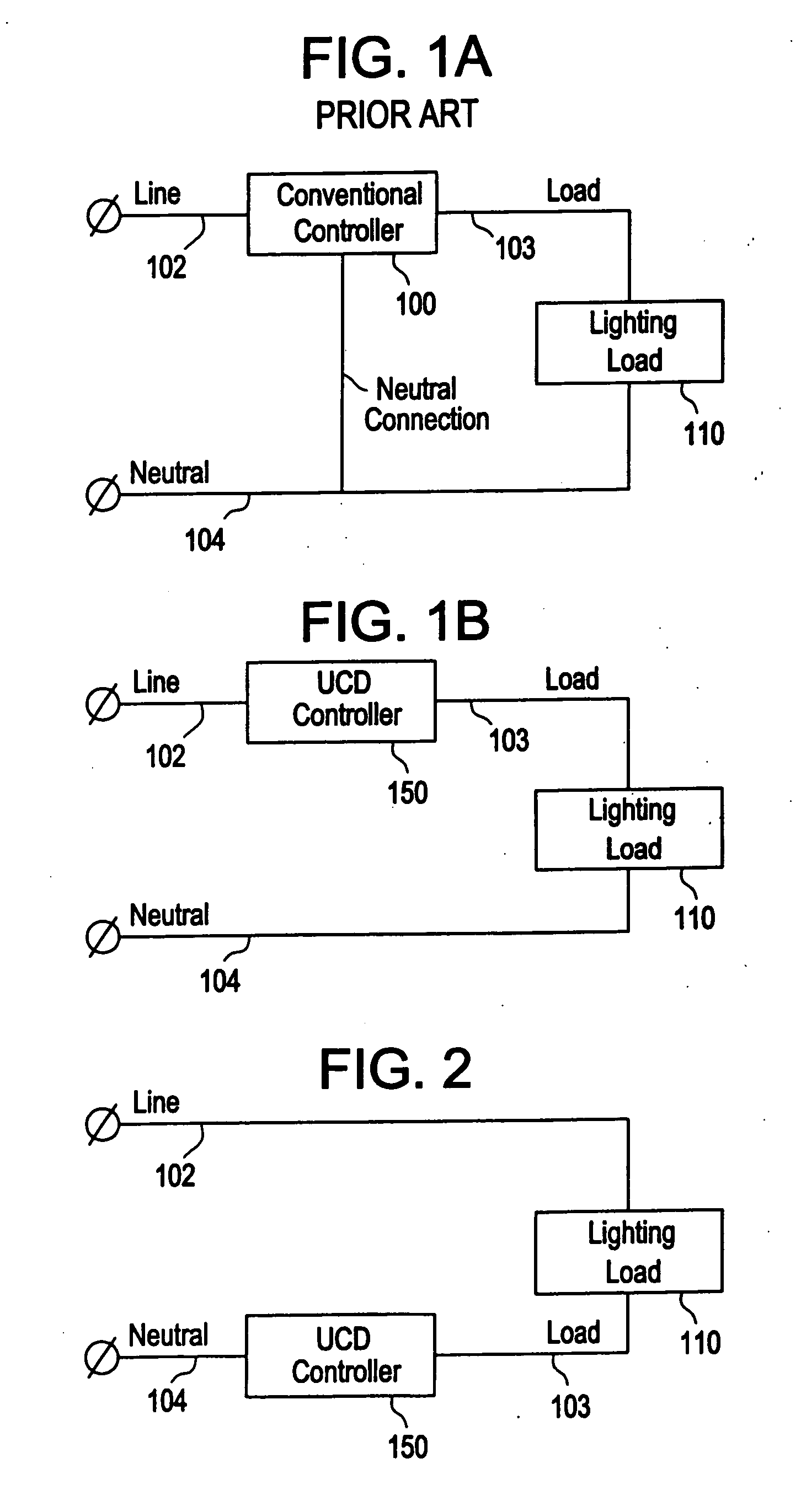

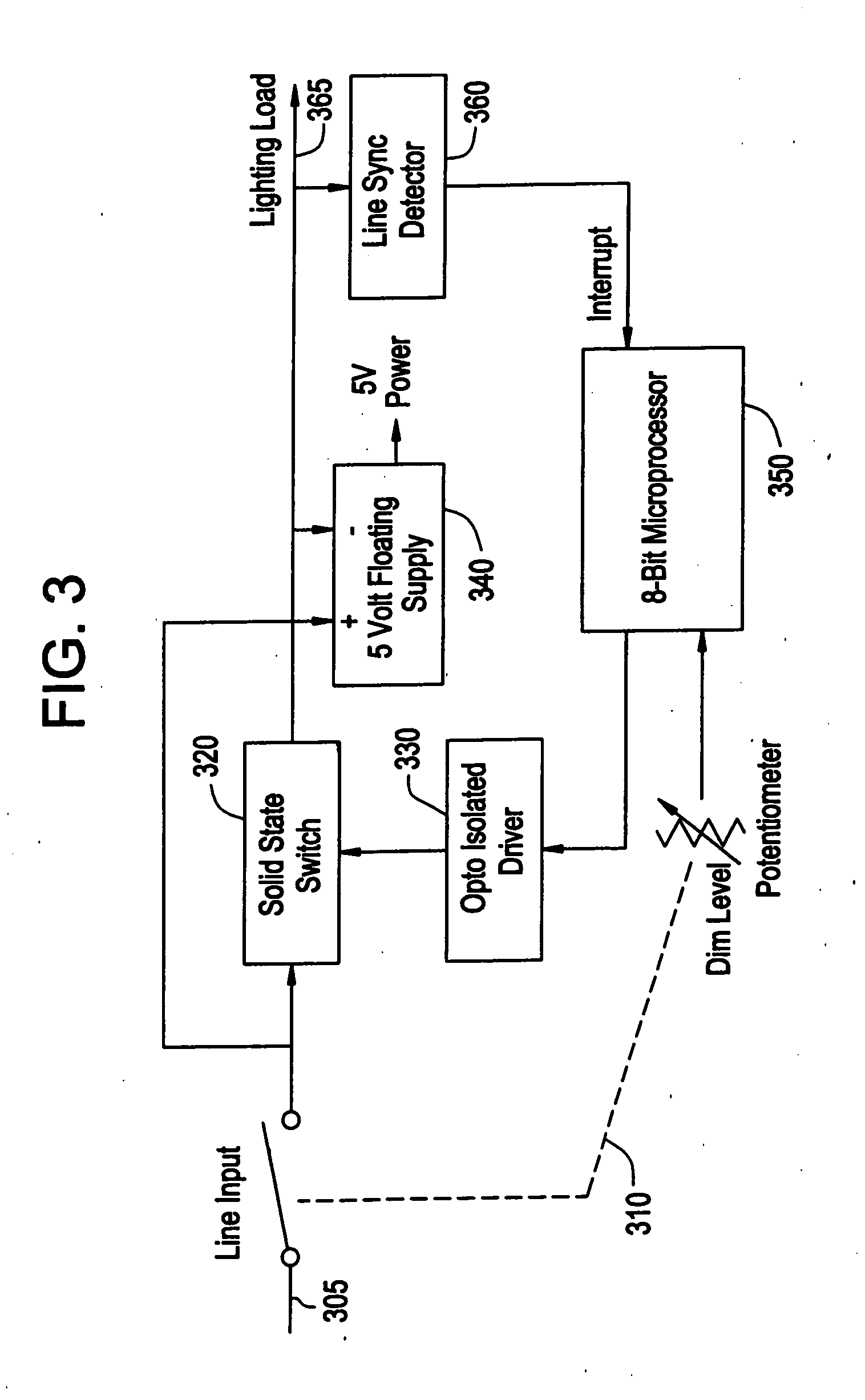

Energy savings device and method for a resistive and/or an inductive load and/or a capacitive load

InactiveUS7164238B2Save energyElectrical apparatusElectric ignition installationElectrical resistance and conductanceCapacitance

An energy savings device for an inductive, a resistive or a capacitive load, such as a fluorescent light fixture having a magnetic ballast or an electronic ballast, which is powered by an AC voltage waveform. The energy savings device includes a setting unit for setting a desired power operating level for the load. The energy savings device also includes a processor configured to receive a signal from the setting unit indicative of the desired power operating level for the load, to determine a phase delay to be provided to an output AC voltage waveform that is to be provided to the load, and to output a control signal as a result thereof. The energy savings device further includes an active element provided between a line that provides the input AC voltage waveform and the load, the active element receiving the control signal and turning off and on at predetermined times in accordance with the control signal, so as to create the output AC voltage waveform from the AC voltage waveform. The processor includes a synchronization circuit that synchronizes to the Green Safety ground line.

Owner:ASTRAL COMM

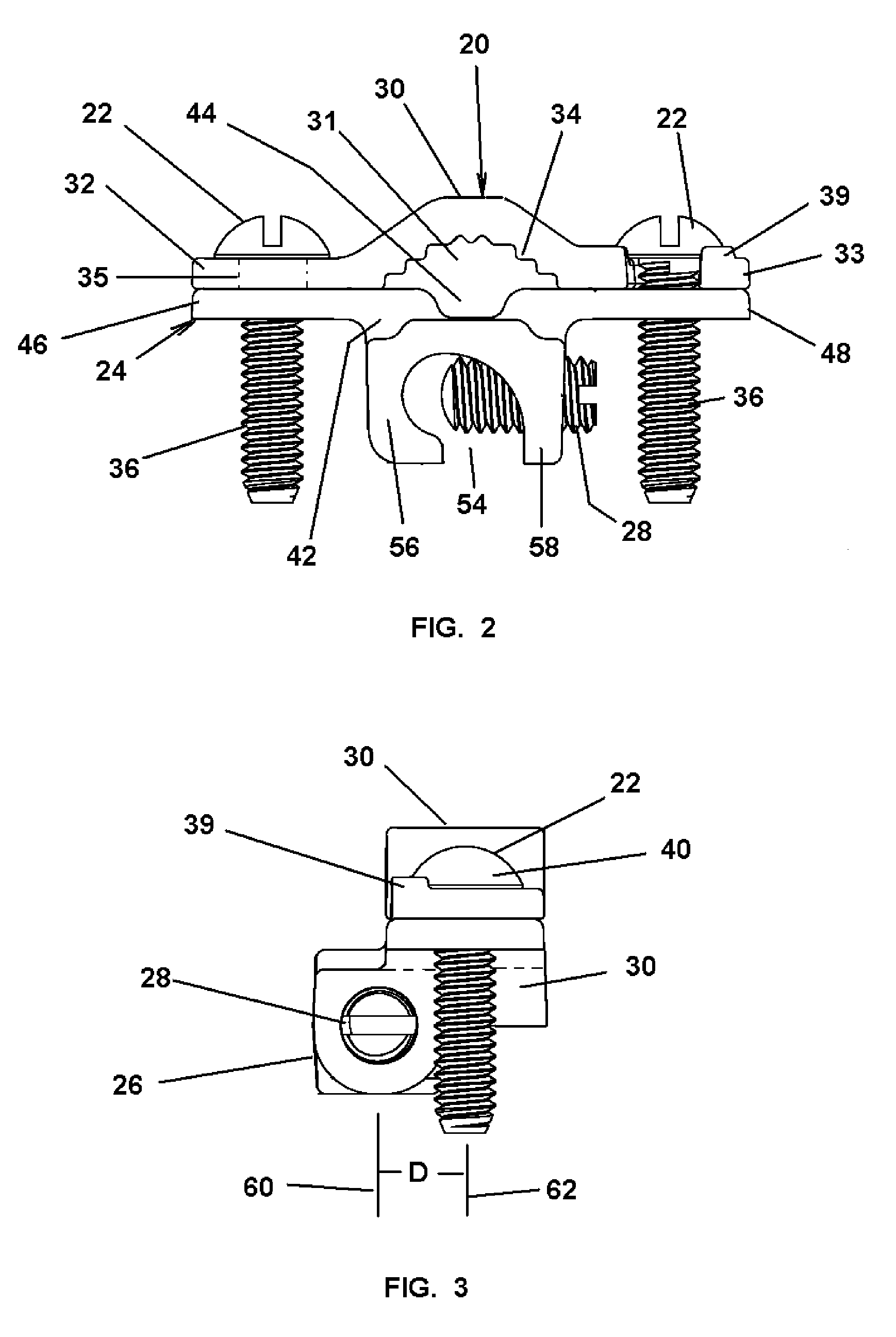

Ground block connector

ActiveUS7029293B2Clamped/spring connectionsCoupling protective earth/shielding arrangementsEngineeringGround line

Owner:TIMES FIBER COMMUNICATIONS INC

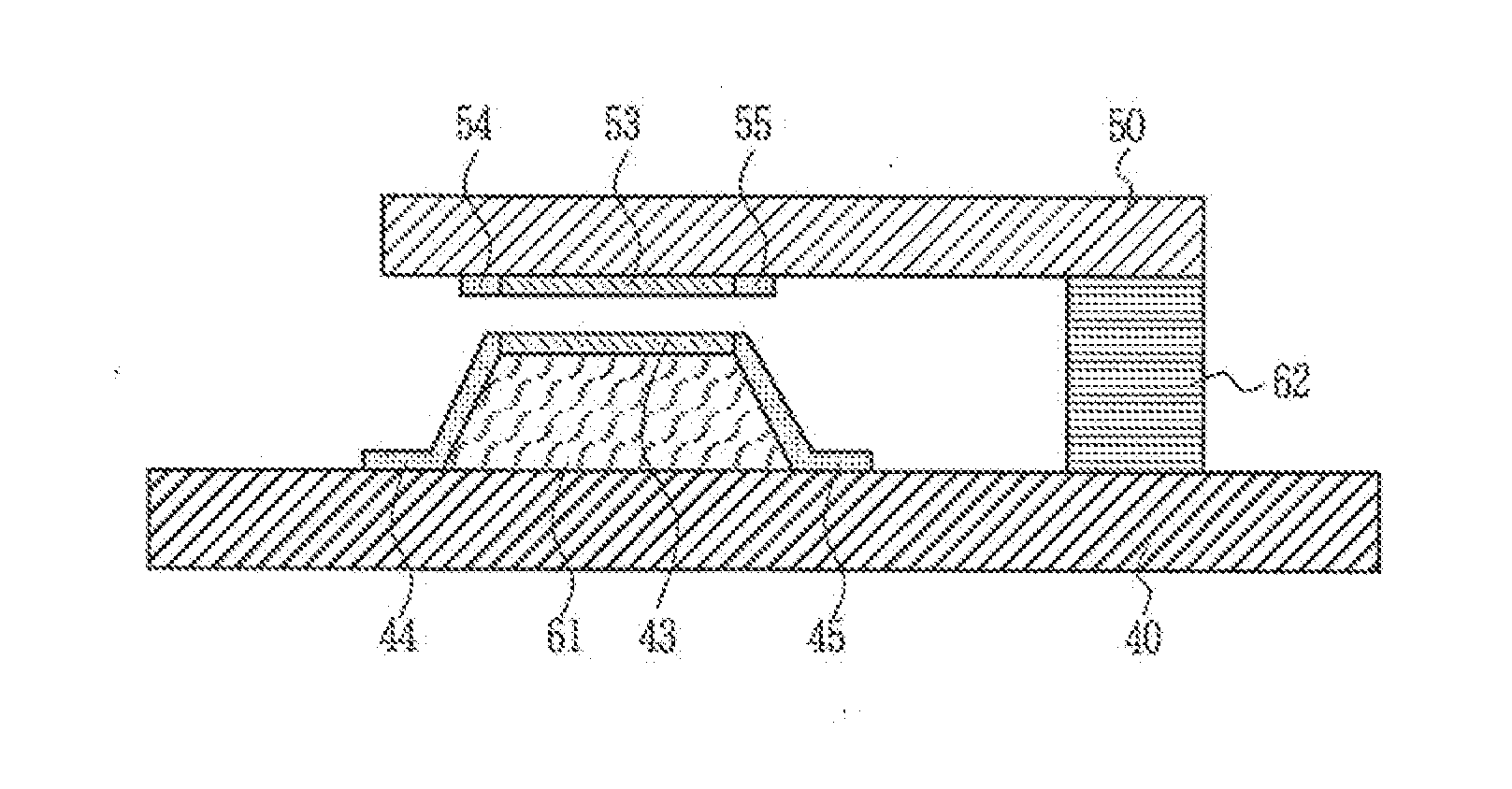

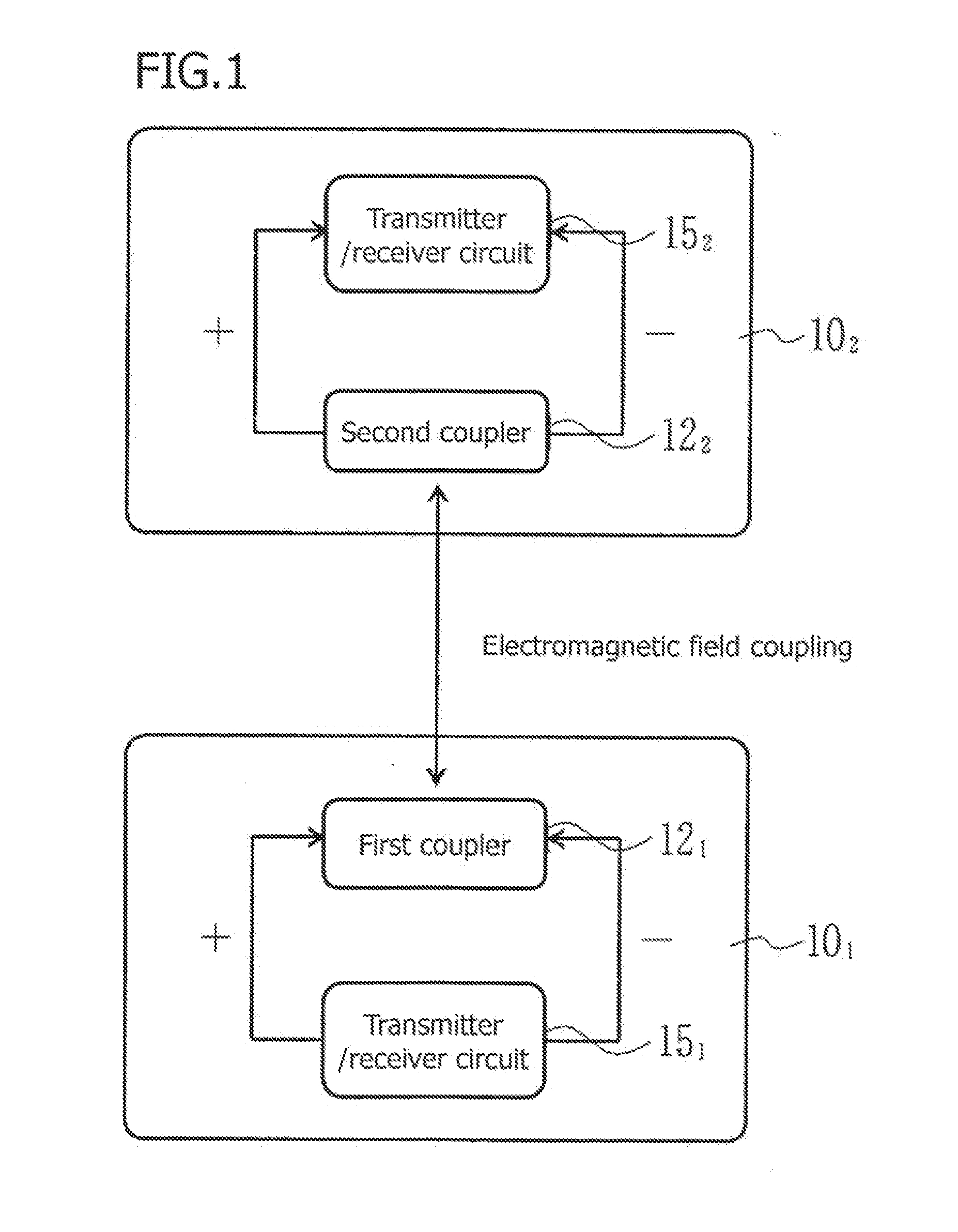

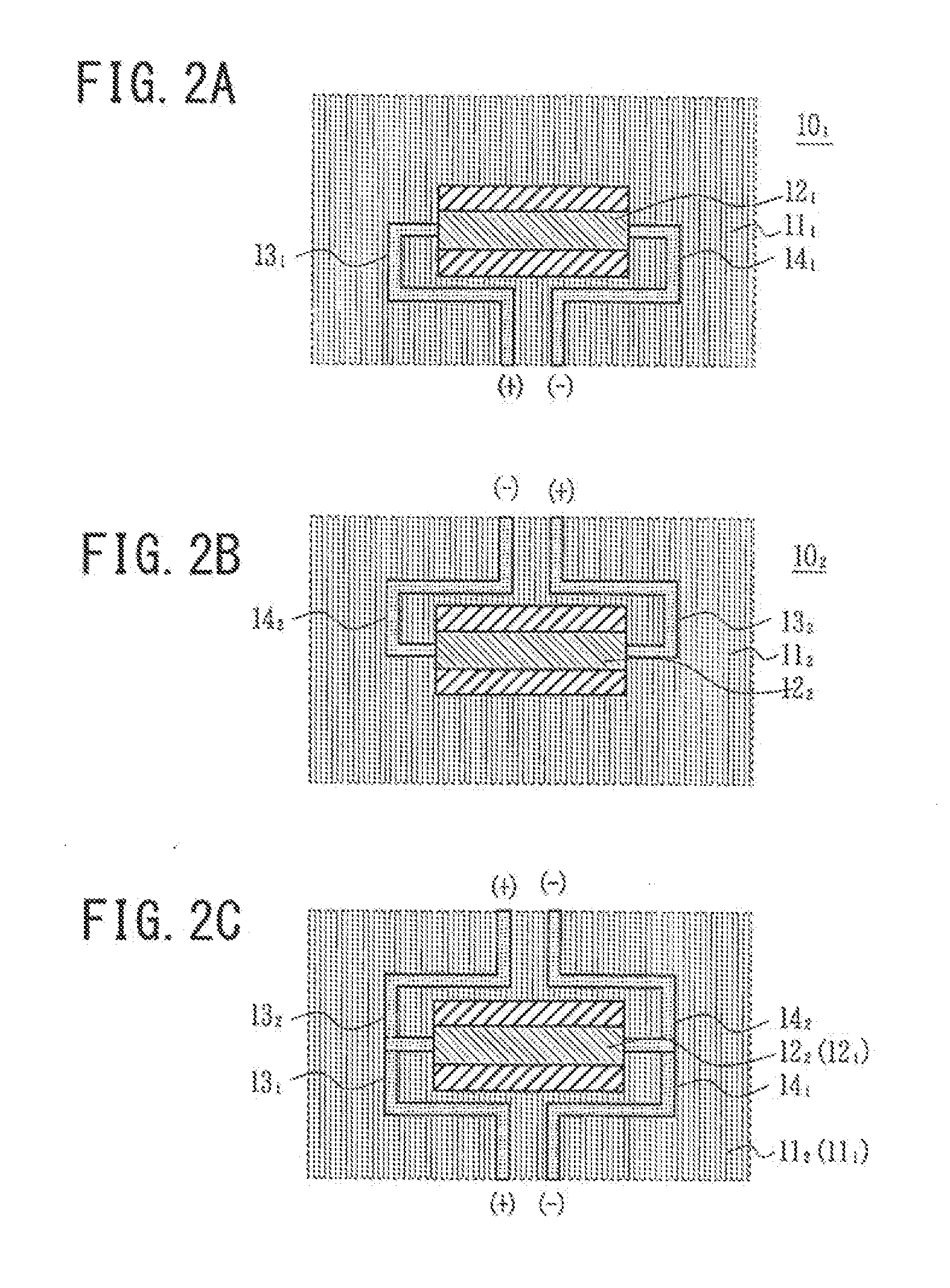

Directional coupling communication apparatus

ActiveUS20150207541A1Reduce reflectionImprove communication reliabilityHigh frequency circuit adaptationsSolid-state devicesCapacitanceCapacitive coupling

The invention relates to a directional coupling communication apparatus where the coupling impedance can be easily matched to reduce reflections, and thus, the speed of communication channels is increased as compared to that with inductive coupling, and at the same time, the reliability of communication is improved by increasing the signal intensity. Modules having a coupler where an input / output connection line is connected to a first end, and either a ground line or an input / output connection line to which an inverse signal of a signal to be inputted into the input / output connection line connected to the above-described first end is inputted is connected are layered on top of each other so that the couplers are couplers to each other using capacitive coupling and inductive coupling.

Owner:KEIO UNIV

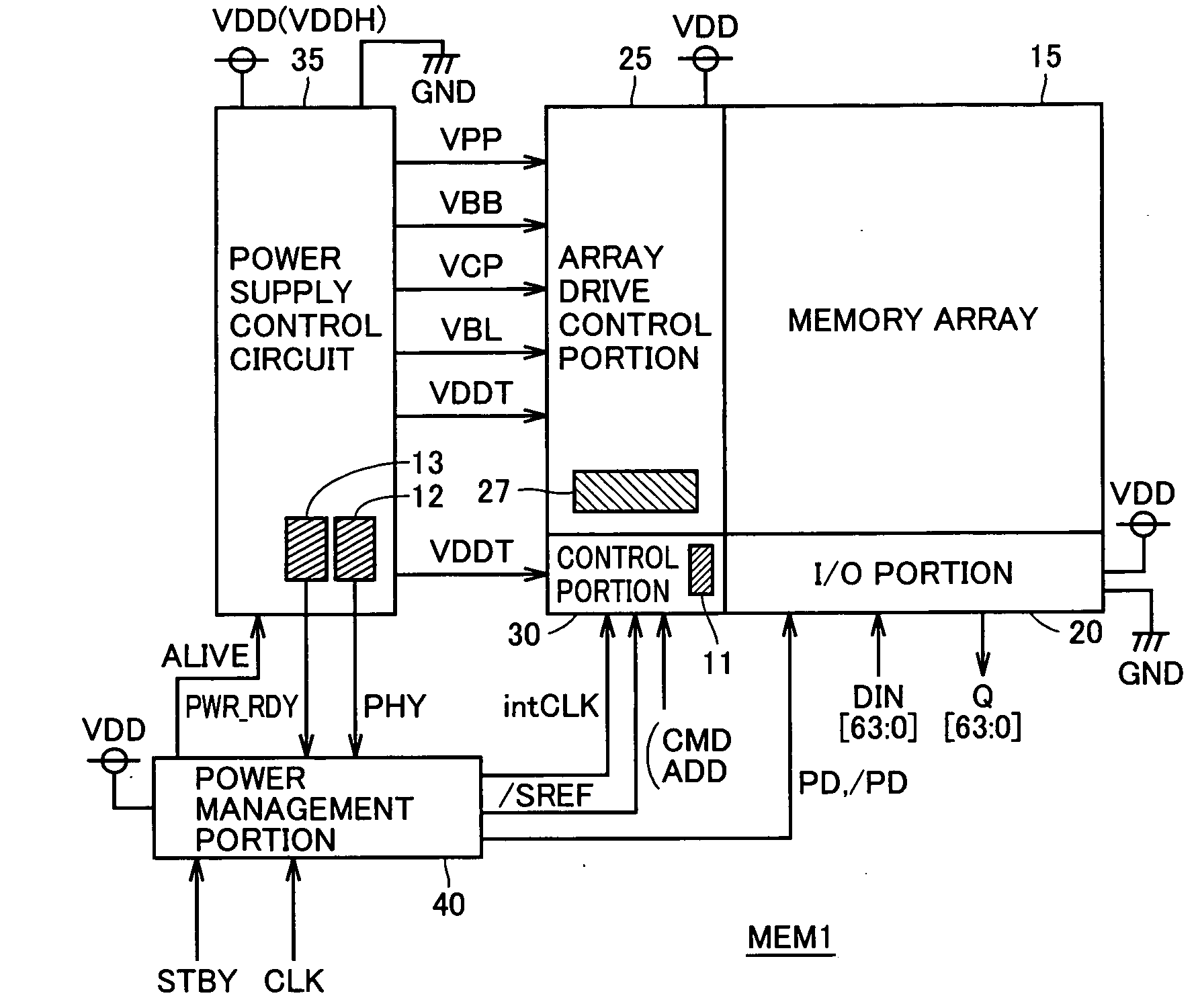

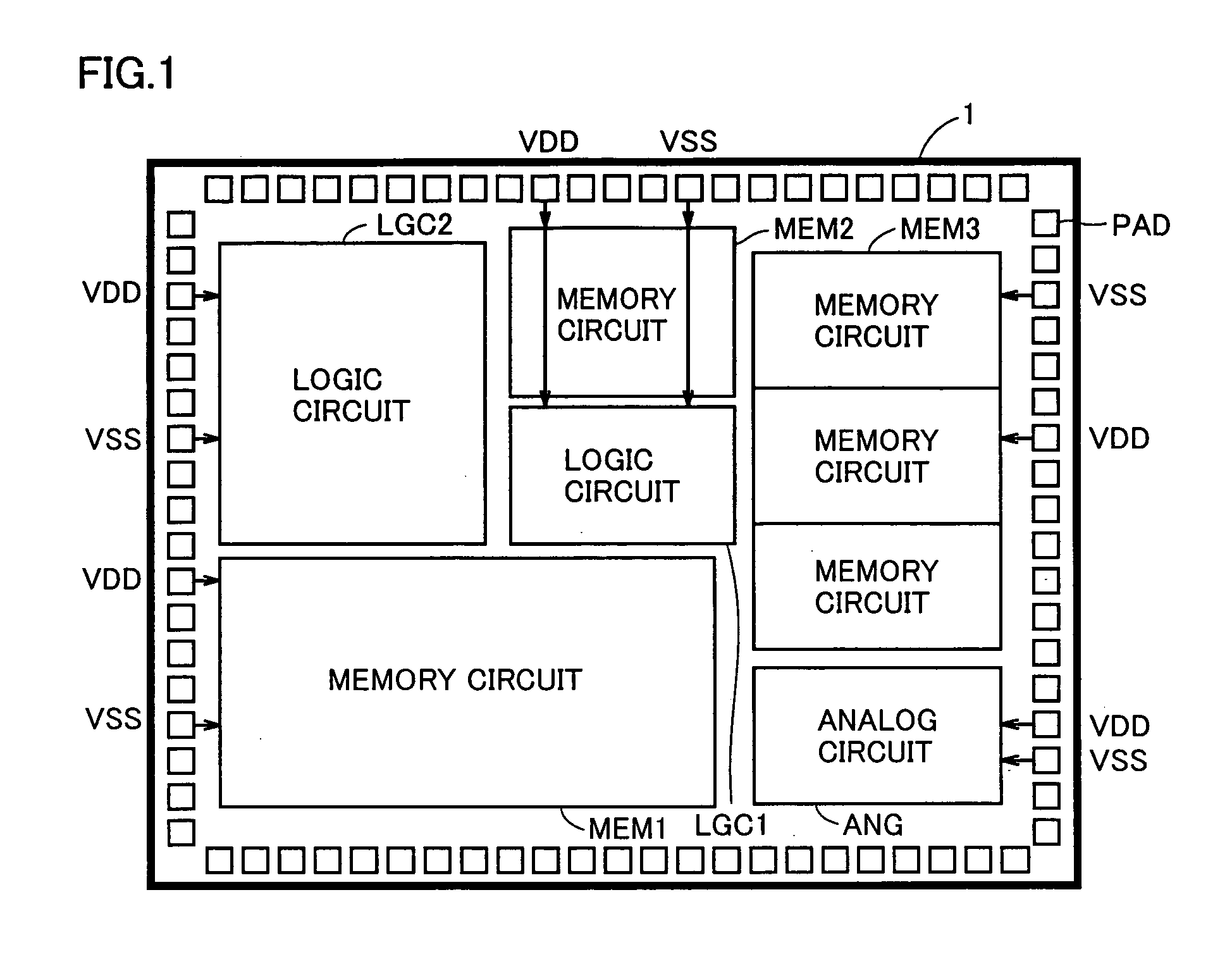

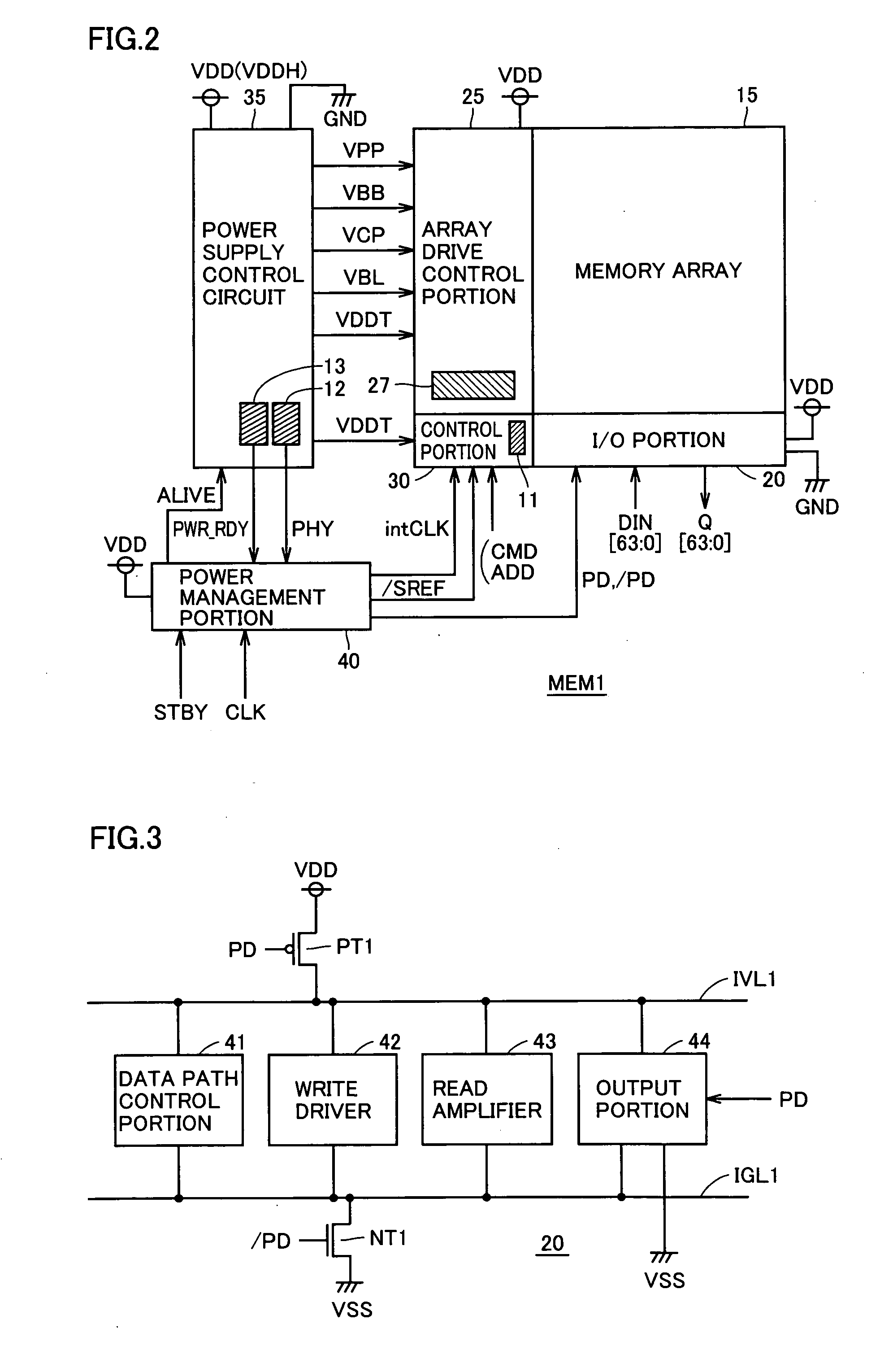

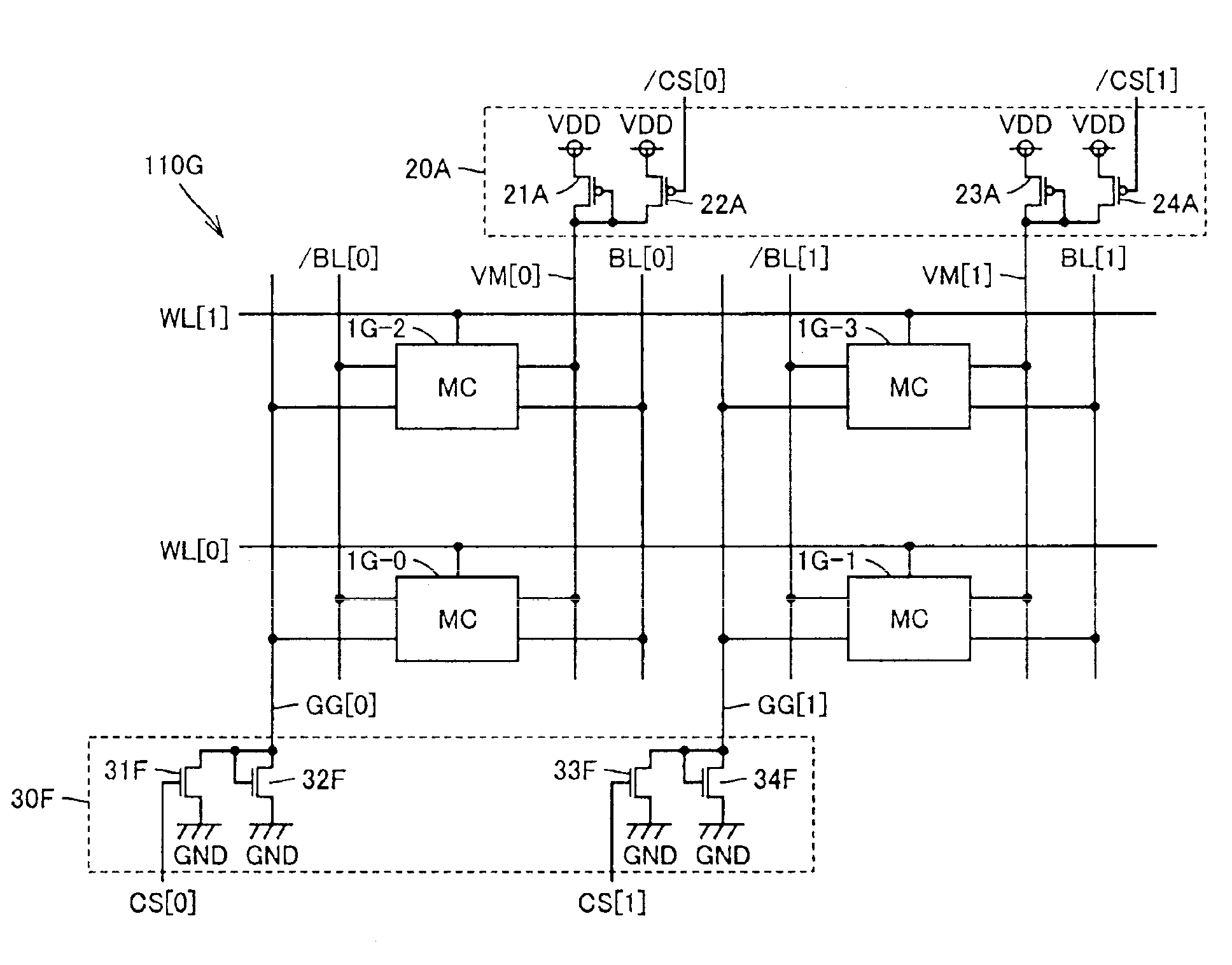

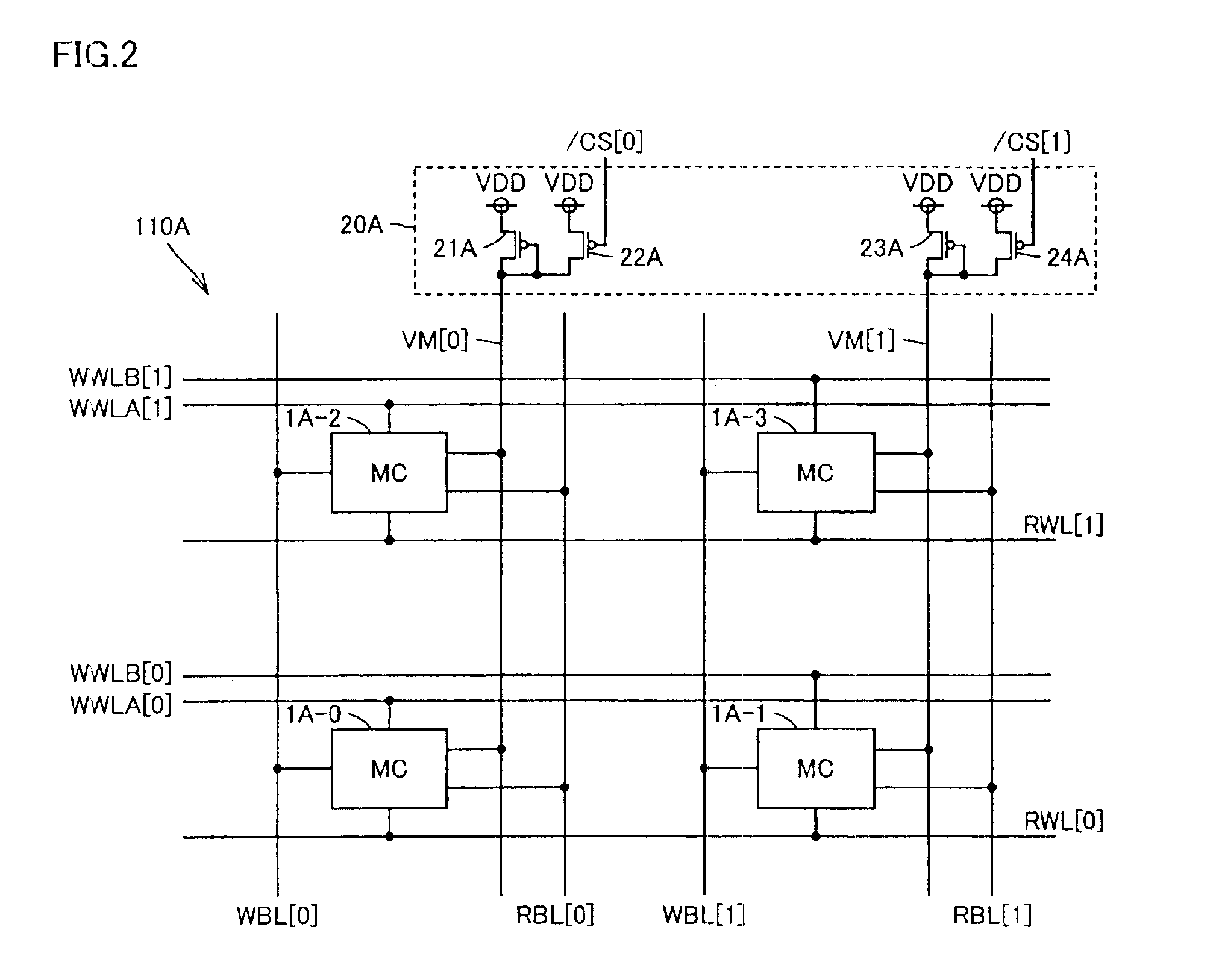

Semiconductor memory device

ActiveUS20080279017A1Bus width can be greatHigh bandwidthRead-only memoriesDigital storageHigh tension lineEngineering

During a stand-by state in which power supply is cut off, a high-voltage power supply control circuit isolates a global negative voltage line transmitting a negative voltage and a local negative voltage line provided corresponding to each respective sub array block from each other and isolates a global ground line and a local ground line transmitting a ground voltage from each other. These local ground line and local negative voltage line are charged to a high voltage level through a high voltage line before cut-off from the corresponding power supply. A leakage current path from a word line to the negative voltage line or the ground line is cut off, so that the word line in a non-selected state can reliably be maintained at a non-selection voltage. Thus, in a low power consumption stand-by mode, data stored in a memory cell can be held in a stable manner.

Owner:RENESAS ELECTRONICS CORP

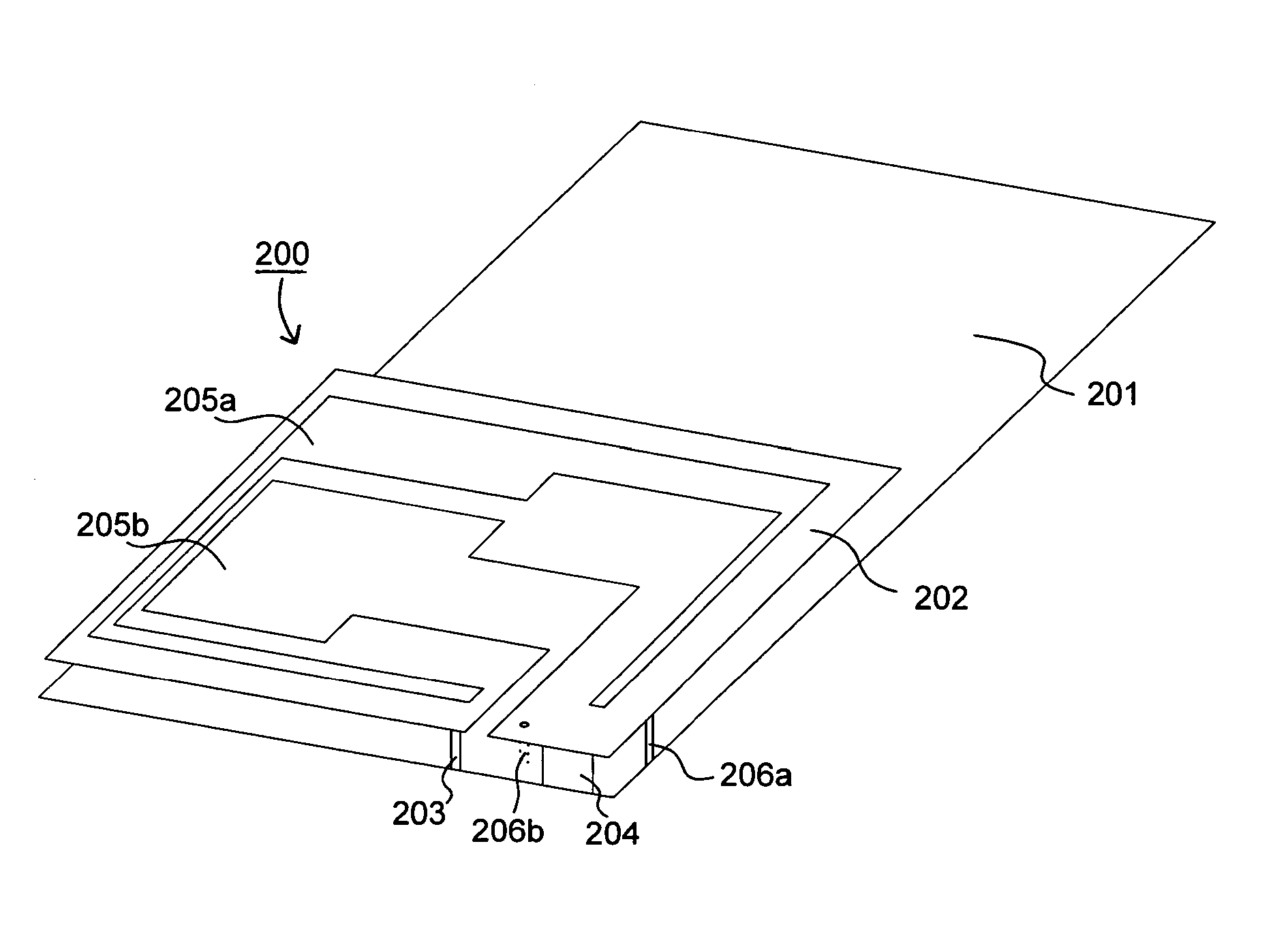

Hybrid ground grid for printed circuit board

InactiveUS7129416B1Efficient routingCross-talk/noise/interference reductionPrinted circuit aspectsGrounding gridPrinted circuit board

Electrical mounting boards and methods for their fabrication and use are disclosed herein. In particular, such mounting boards embodiments utilize hybrid ground lines interconnected through a substrate core to form multilayer ground grids. Such hybrid ground lines include groups of substantially parallel ground lines configured such that the groups of ground lines are positioned in transverse arrangement with other groups of ground lines formed on the same level. Such implementations have many uses, including, but not limited to, the ability to more efficiently route signal lines and connect electrical components on a circuit board.

Owner:APPLE INC

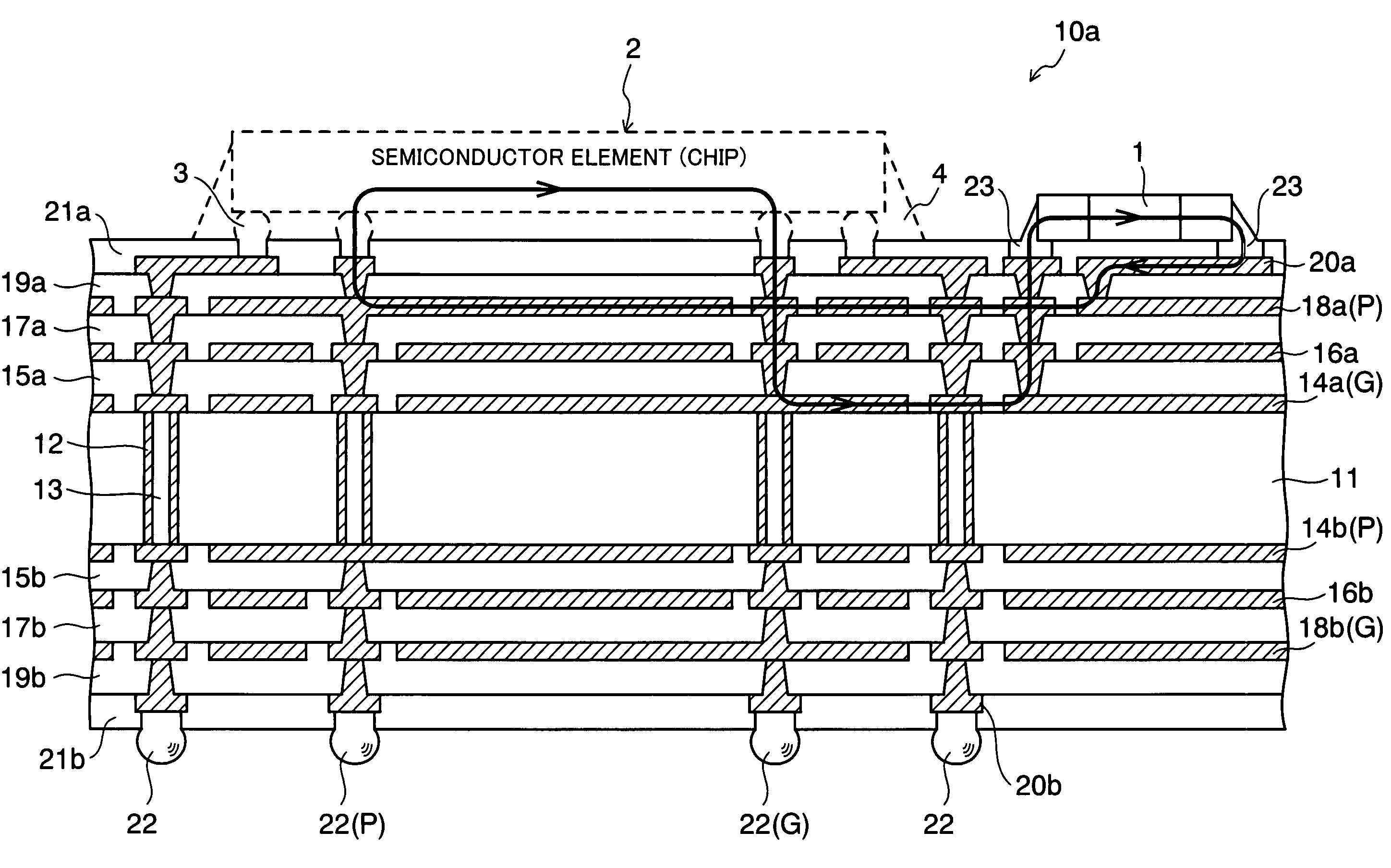

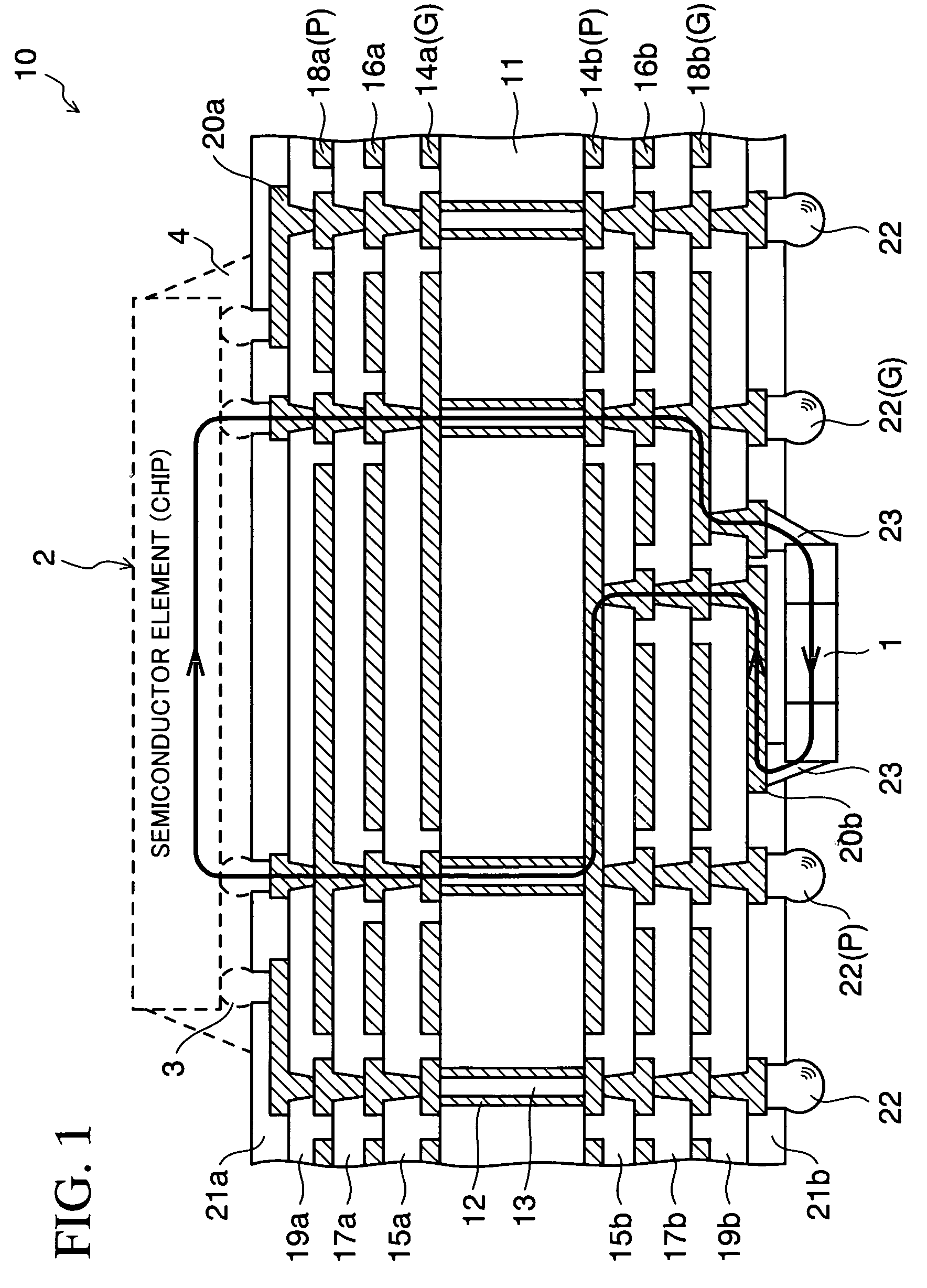

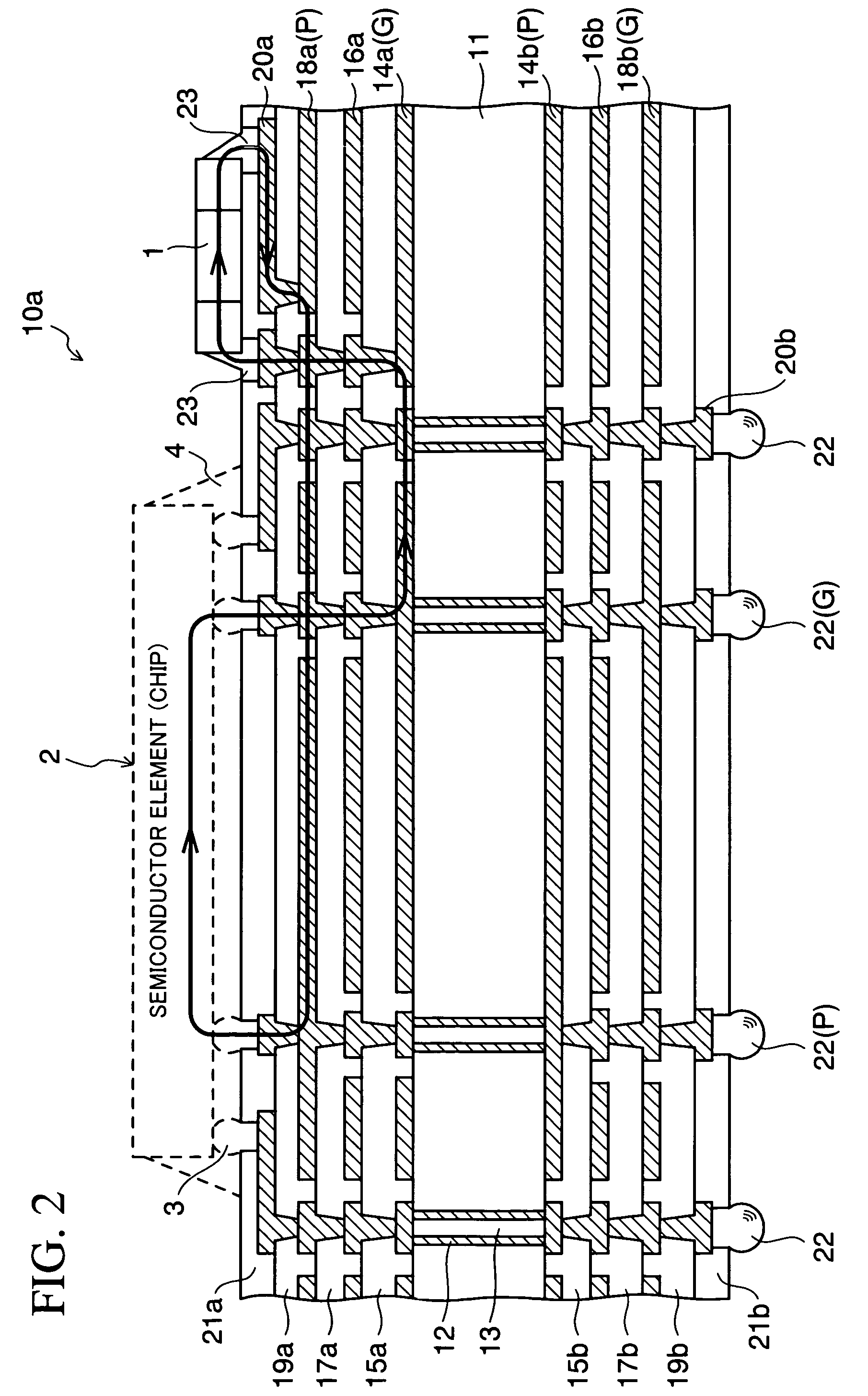

Wiring board mounting a capacitor

ActiveUS7279771B2Guaranteed uptimeEffective decouplingFinal product manufactureSemiconductor/solid-state device detailsElectrical conductorDecoupling capacitor

In a capacitor-mounted wiring board, a plurality of wiring layers each patterned in a required shape are stacked with insulating layers interposed therebetween and are connected to each other via conductors formed to pierce the insulating layers in the direction of thickness. A decoupling capacitor is electrically connected to a wiring layer used as a power supply line or a ground line in the vicinity of the wiring layer, and mounted such that, when a current is passed through the capacitor, the direction of the current is reversed to that of the current flowing through the relevant wiring layer.

Owner:SHINKO ELECTRIC IND CO LTD

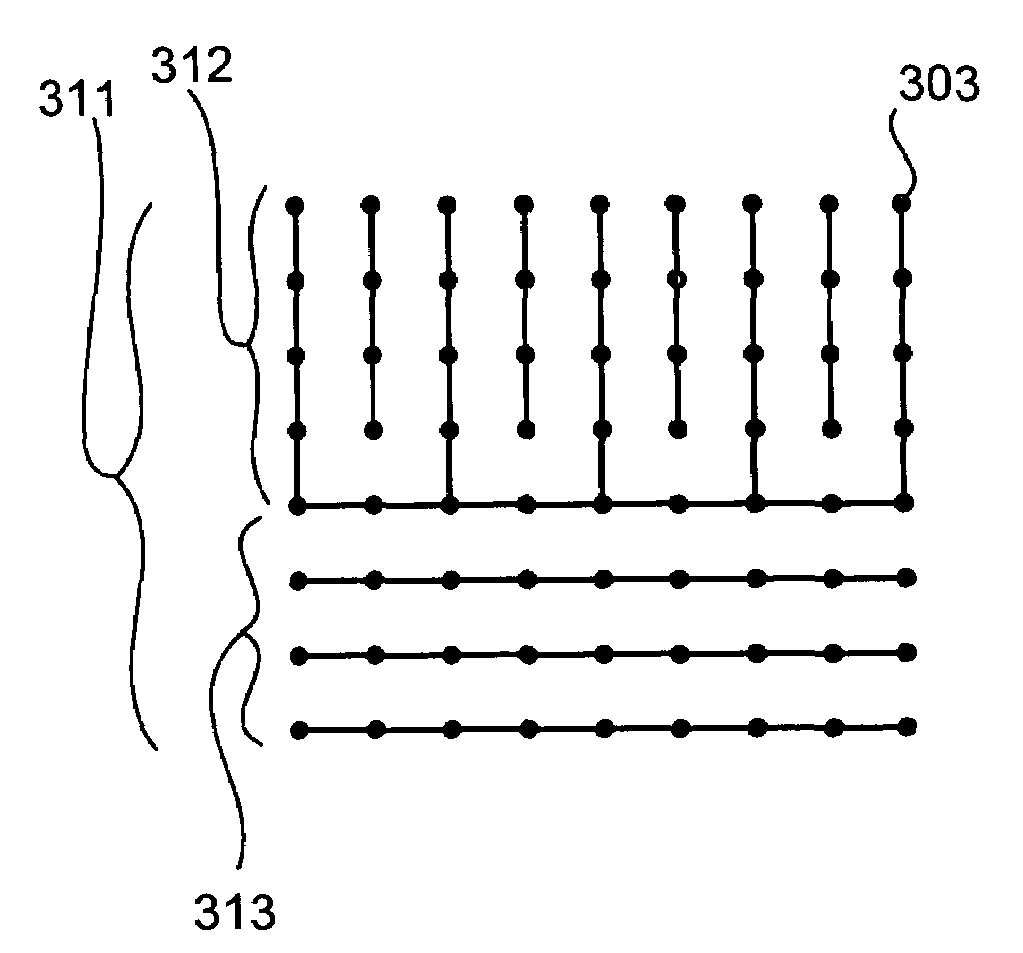

Memory circuit having memory cells which have a resistance memory element

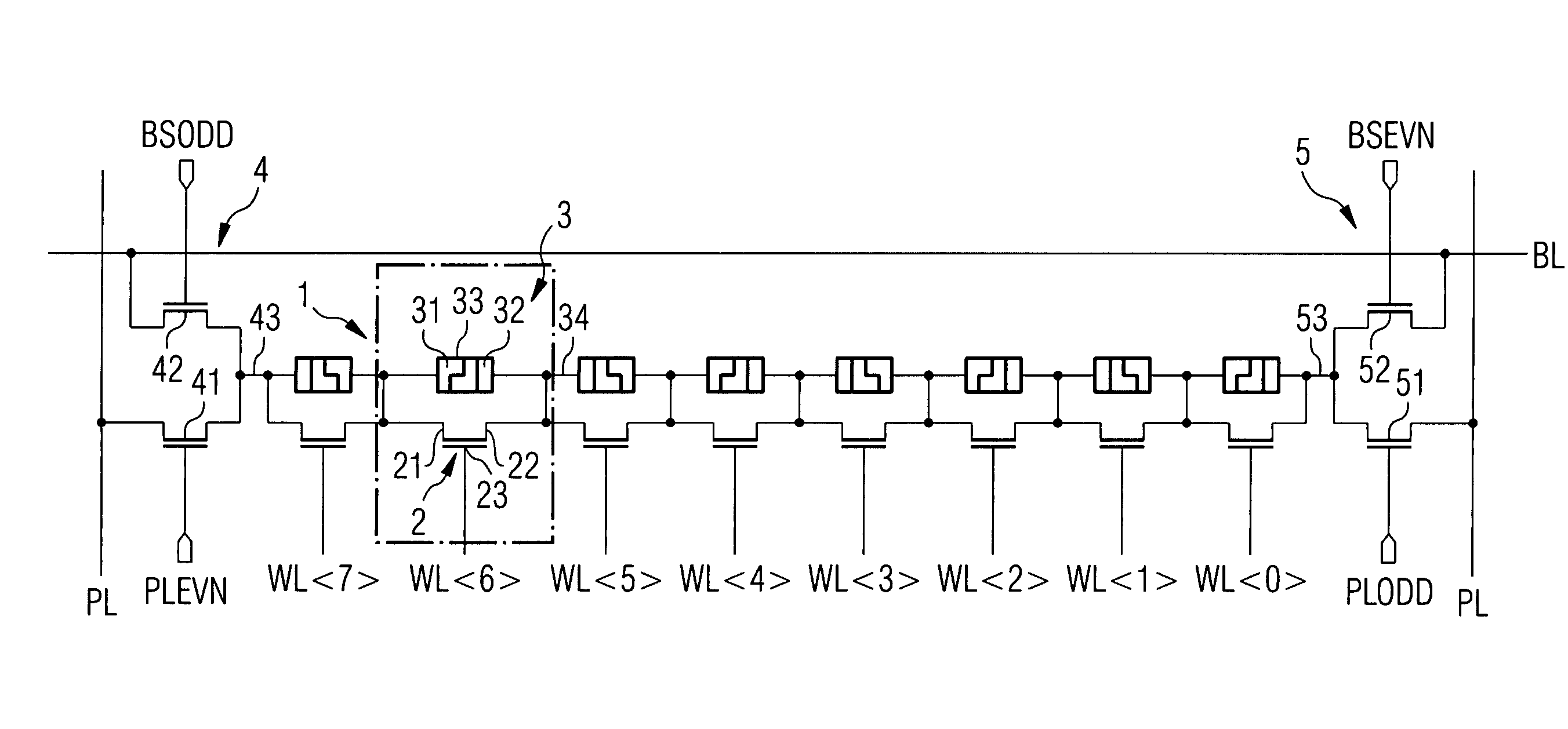

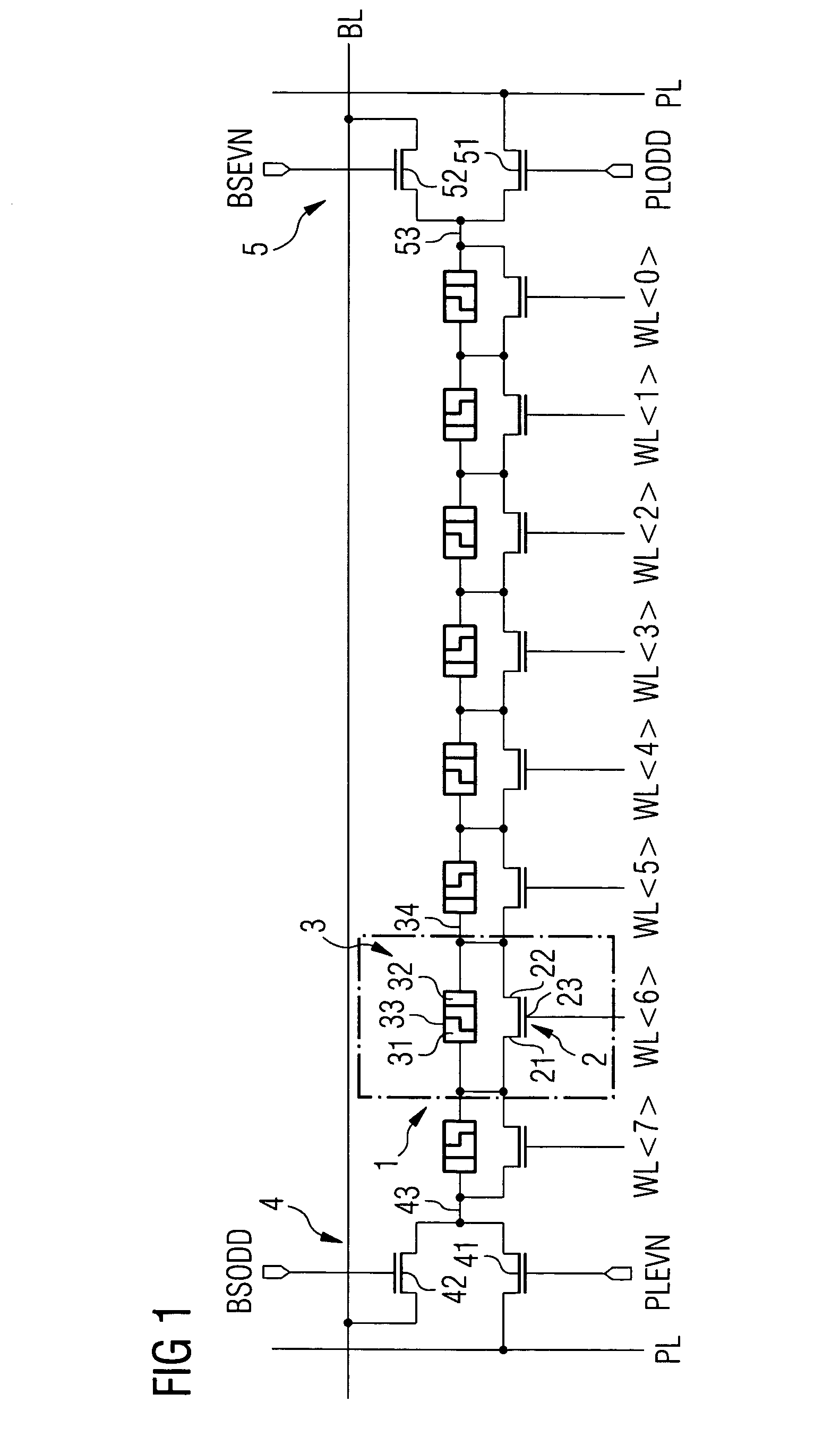

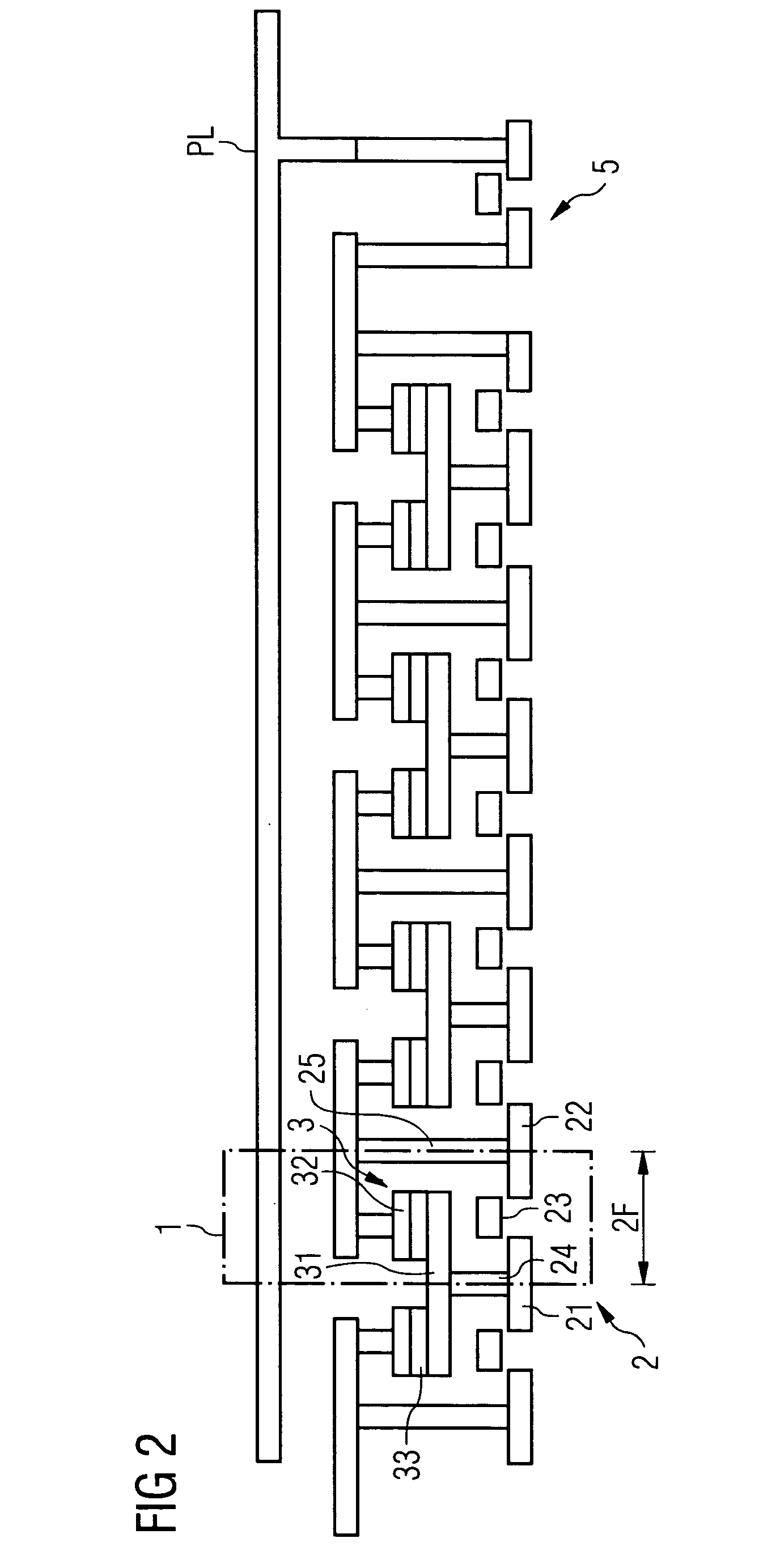

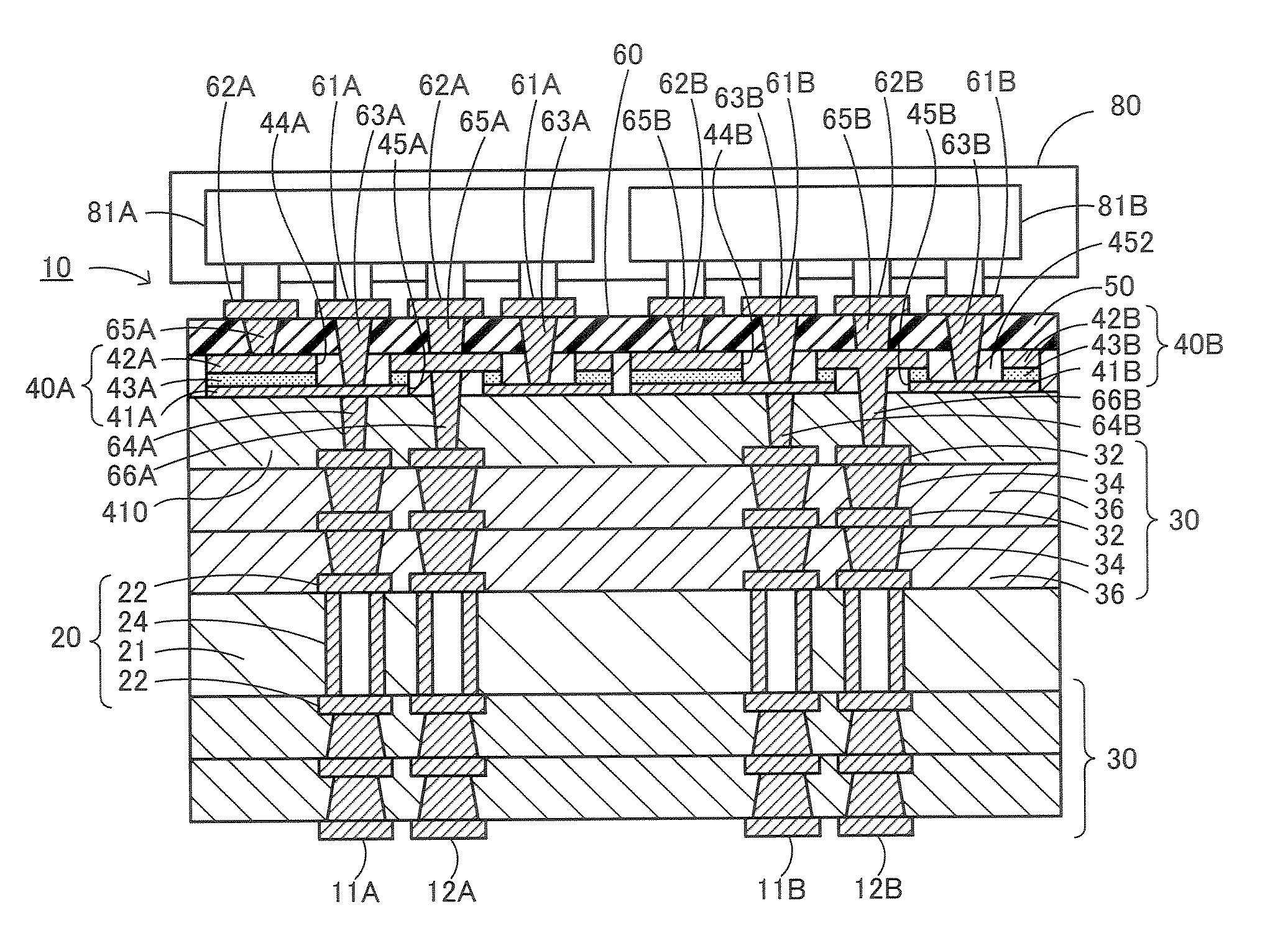

InactiveUS7251152B2Minimal area requirementEffective shielding against interferenceNanoinformaticsRead-only memoriesBit lineHemt circuits

In a memory circuit having memory cells which are connected in series between a ground line PL and a bit line BL and in each case have a resistance memory element said element having a bipolar switching behavior having an anode electrode and a cathode electrode, and a drive transistor connected in parallel with the resistance memory element, the drive transistors of the memory cells in each case are connected to a word line in order to switch the drive transistor on and off in such a way that a current path is formed via the associated drive transistor in a non-activated state of a memory cell and a current path is formed via the associated resistance memory element in an activated state of a memory cell, a first changeover switch being arranged at one end and a second changeover switch at other ends of the series of memory cells in order alternately to produce a connection between the series-connected memory cells and the ground line and the bit line in a manner dependent on an applied address.

Owner:POLARIS INNOVATIONS LTD

Printed wiring board

ActiveUS20090290316A1Decoupling effect decreaseGood decoupling effectSemiconductor/solid-state device detailsPrinted circuit aspectsDual coreVoltage variation

A printed wiring board includes a mounting portion on which a dual core processor including two processor cores in a single chip can be mounted, power supply lines, ground lines, and a first layered capacitor and a second layered capacitor that are independently provided for each of the processor cores, respectively. Accordingly, even when the electric potentials of the processor cores instantaneously drop, an instantaneous drop of the electric potential can be suppressed by action of the layered capacitors corresponding to the processor cores, respectively. In addition, even when the voltage of one of the processor cores varies, the variation in the voltage does not affect the other processor core, and thus malfunctioning does not occur.

Owner:IBIDEN CO LTD

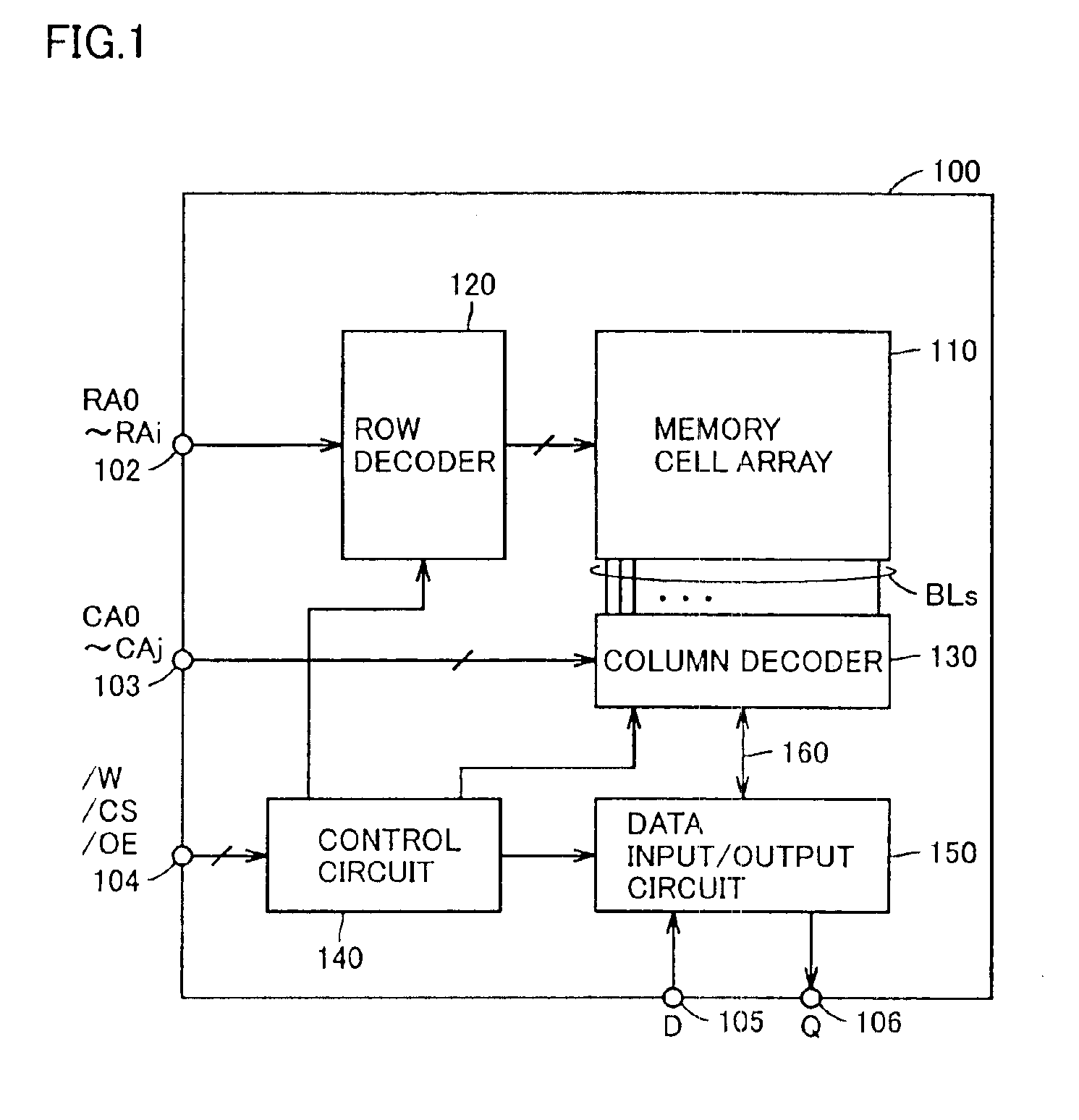

Semiconductor memory device capable of controlling potential level of power supply line and/or ground line

InactiveUS6903962B2Reduce power consumptionAverage power consumptionDigital storageGate leakage currentControl signal

Level control signals are both set to H level, and potentials of power supply lines are both set to be lower than a power supply potential. In this manner, a gate leakage current during waiting and writing operation of a memory cell array can significantly be reduced. The level control signals are set to L level and H level respectively, and solely the potential of one of the power supply lines is set to be lower than the power supply potential. In this manner, power consumption during a reading operation of the memory cell array can be reduced.

Owner:RENESAS ELECTRONICS CORP

Energy savings device and method for a resistive and/or an inductive load and/or a capacitive load

InactiveUS20050104543A1Provide energy savingSave energyElectrical apparatusElectric light circuit arrangementCapacitanceElectrical resistance and conductance

An energy savings device for an inductive, a resistive or a capacitive load, such as a fluorescent light fixture having a magnetic ballast or an electronic ballast, which is powered by an AC voltage waveform. The energy savings device includes a setting unit for setting a desired power operating level for the load. The energy savings device also includes a processor configured to receive a signal from the setting unit indicative of the desired power operating level for the load, to determine a phase delay to be provided to an output AC voltage waveform that is to be provided to the load, and to output a control signal as a result thereof. The energy savings device further includes an active element provided between a line that provides the input AC voltage waveform and the load, the active element receiving the control signal and turning off and on at predetermined times in accordance with the control signal, so as to create the output AC voltage waveform from the AC voltage waveform. The processor includes a synchronization circuit that synchronizes to the Green Safety ground line.

Owner:ASTRAL COMM

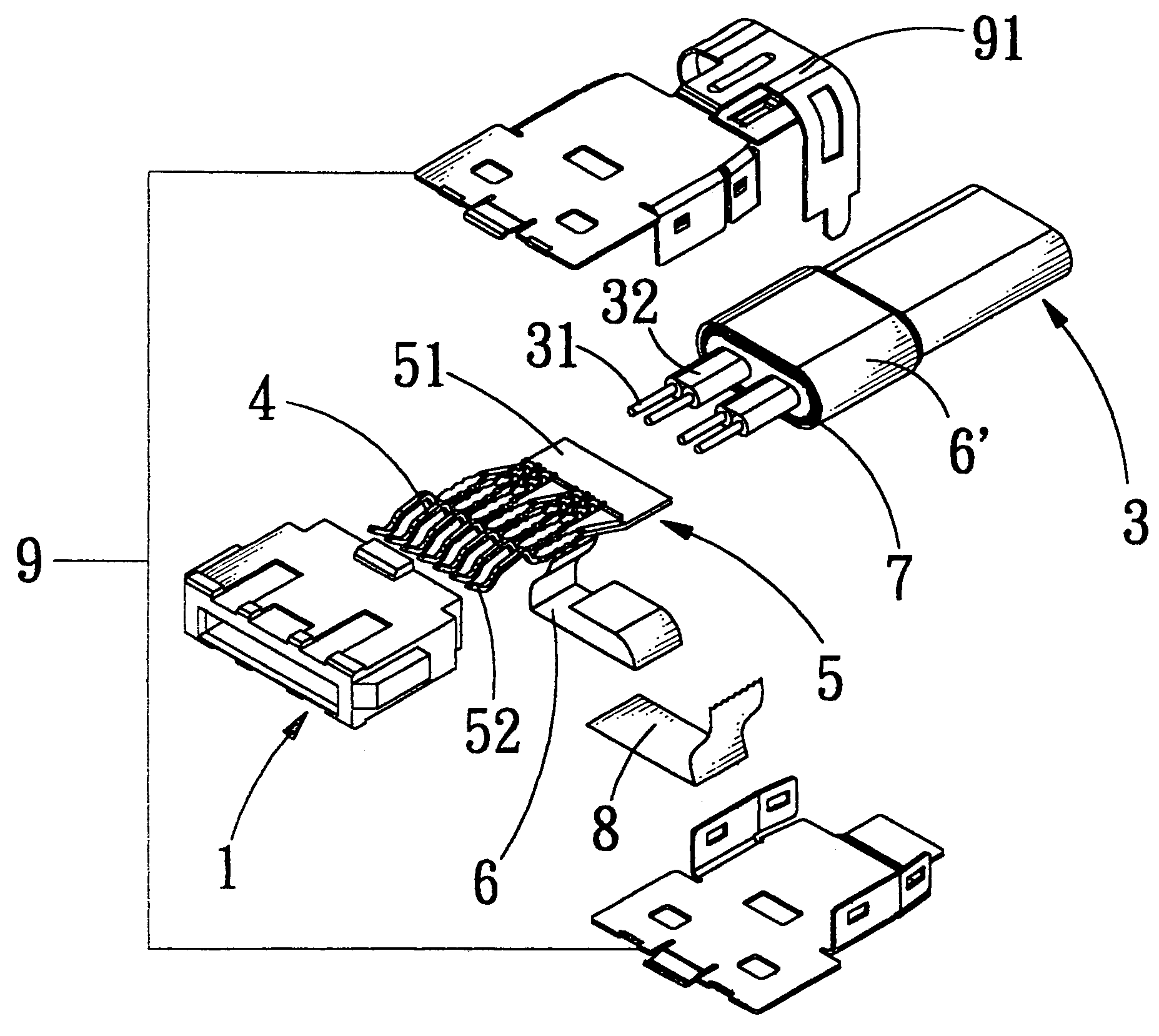

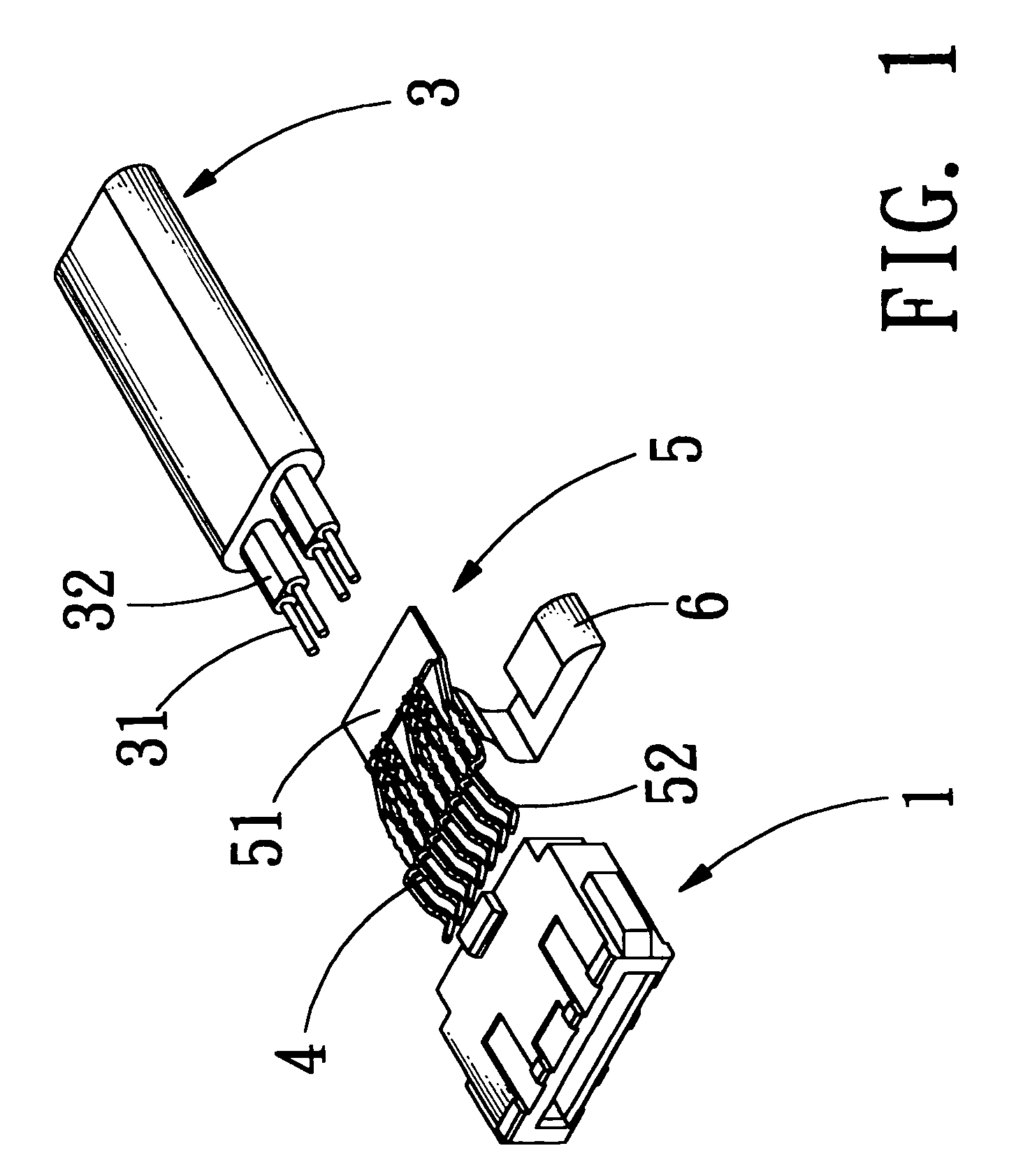

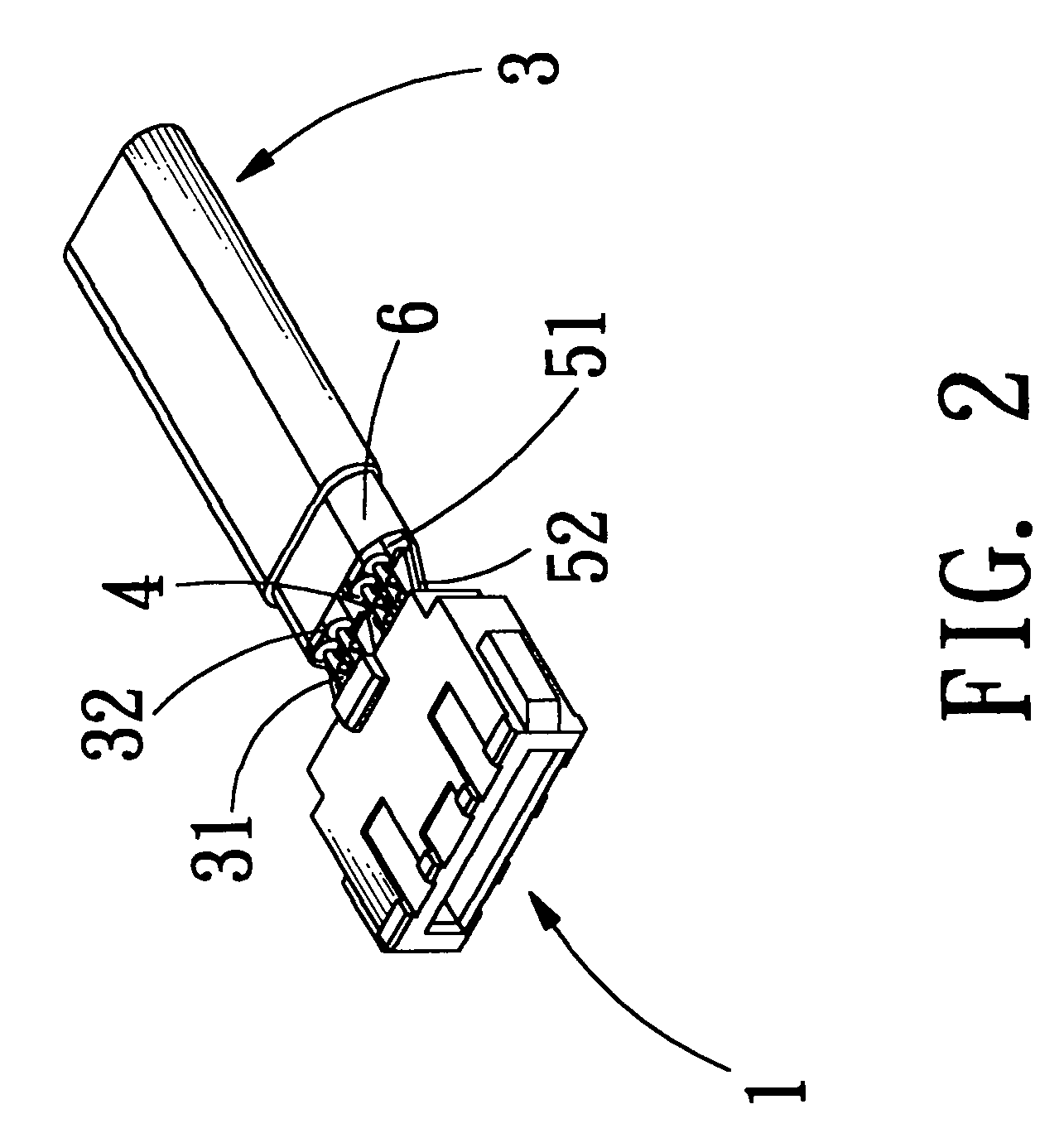

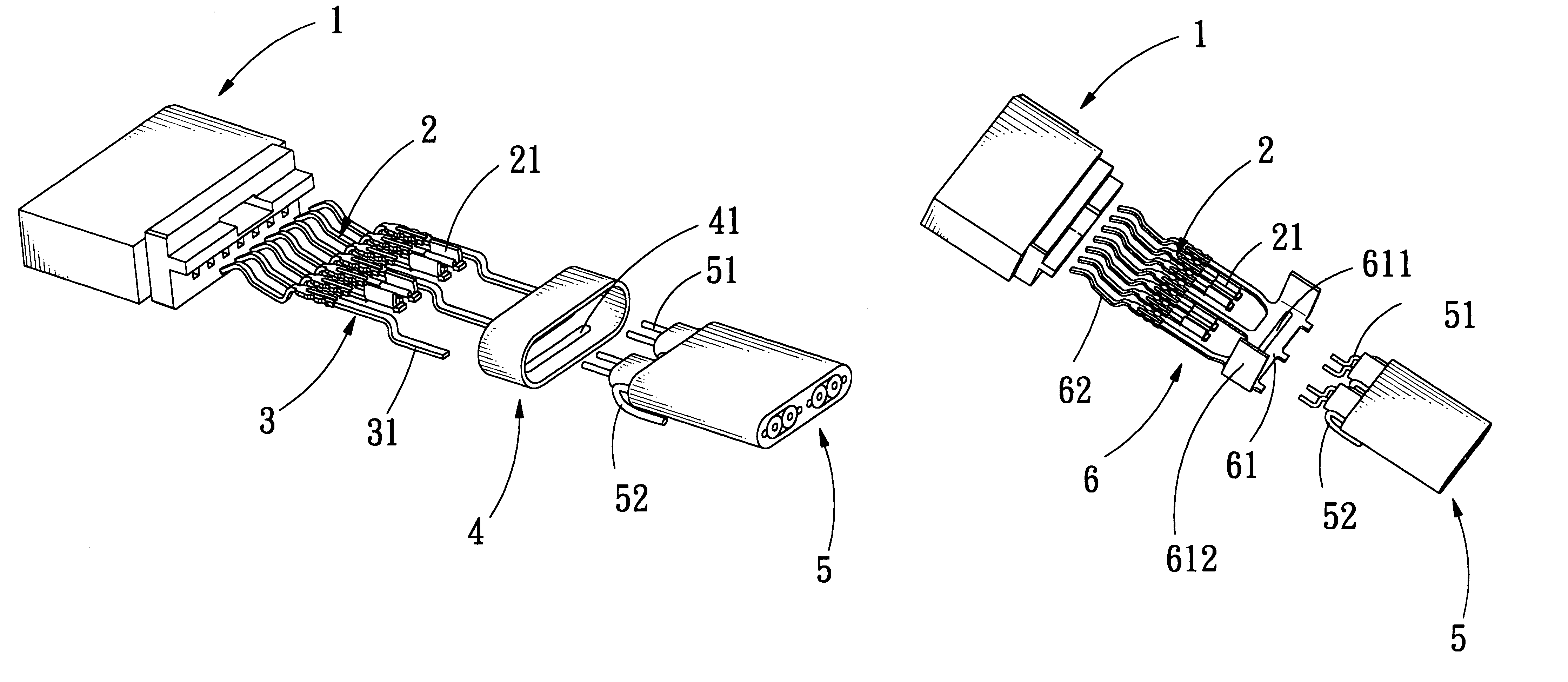

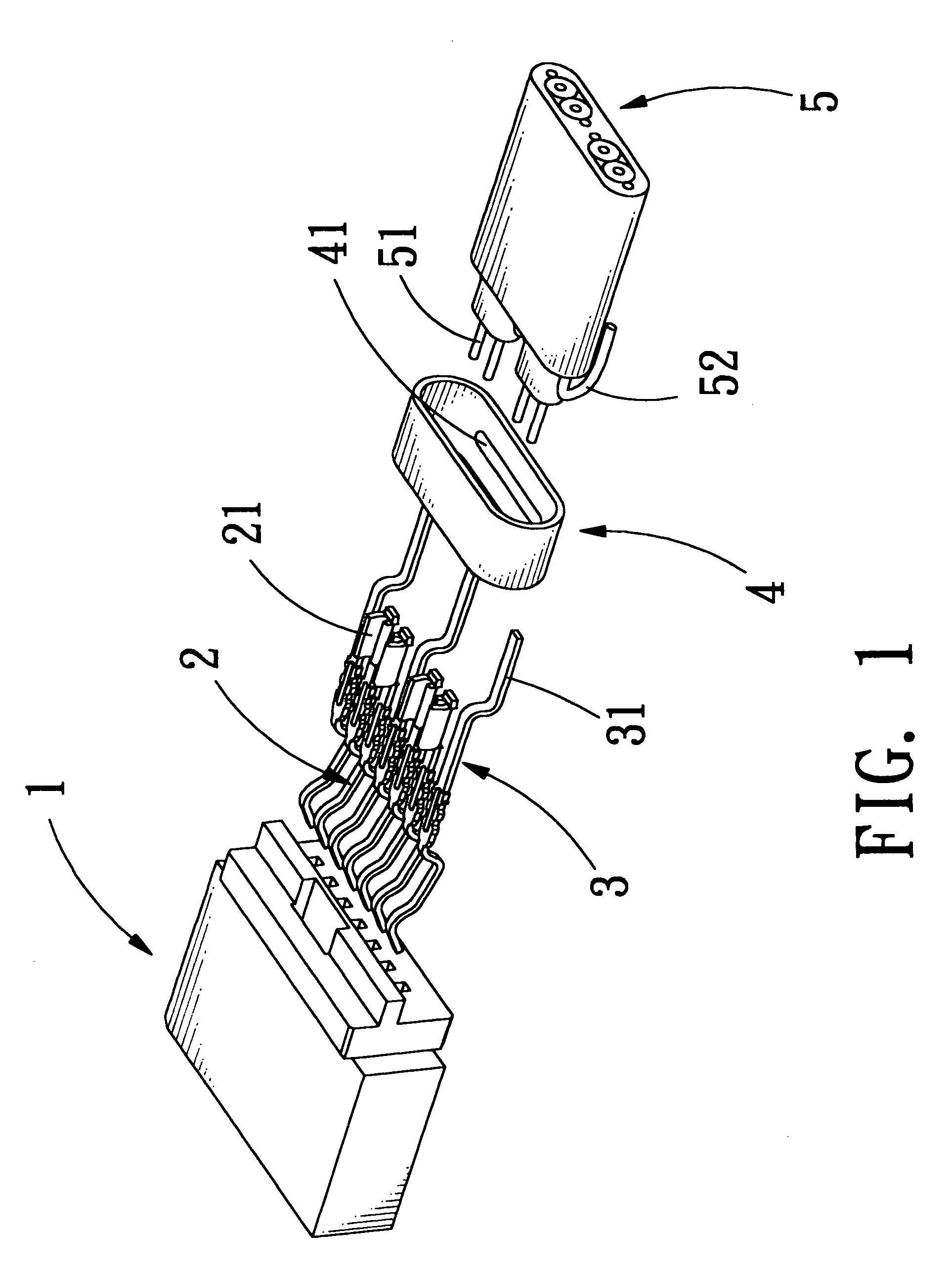

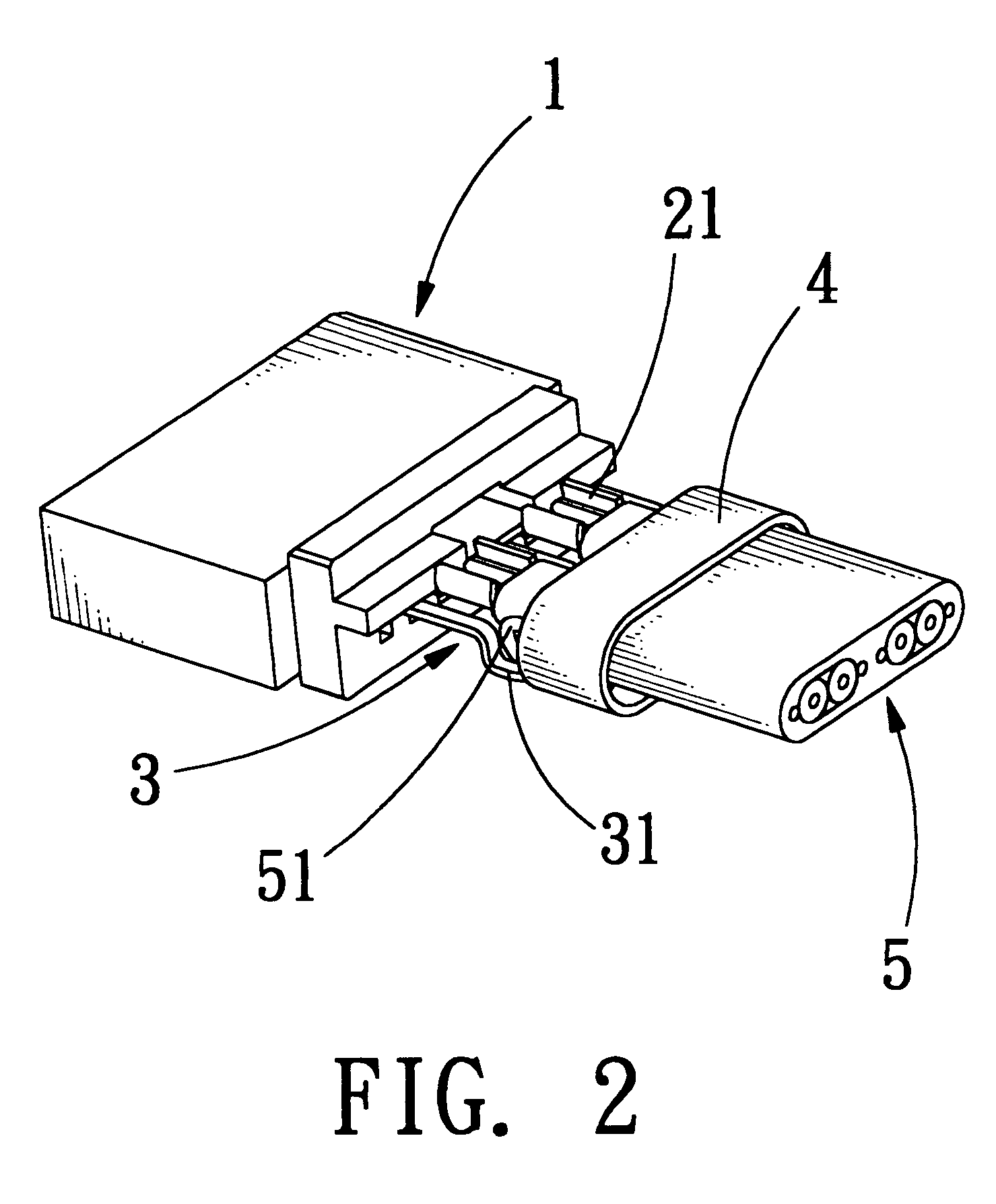

Electrical connector with grounding effect

InactiveUS7214097B1Reduce weldingImprove electrical characteristicsElectrically conductive connectionsTwo-part coupling devicesElectricityBody contact

The present invention relates to an electrical connector with grounding effect, which mainly has grounding part inserted inside the insulating body contacted with the jacket layer enclosed over the signal transmitting units with fixing and contacting effect for generating electrical characteristics, such that the cable assembly of the electrical connector has grounding effect without any grounding line positioned inside cable assembly; wherein, the grounding part has contacting part for providing the jacket layer to contact with, besides it further comprise predetermined grounding terminals extended directly from the grounding part for inserting into the insulating body; such that the cable assembly of the electrical connector of the present invention has grounding effect without any grounding line positioned inside the cable assembly; furthermore, it also can lessen the soldering process and prevent the mistaken probability of the soldering process generated such that the entire assembly process and the relative cost can be reduced.

Owner:ING SHANG LUN

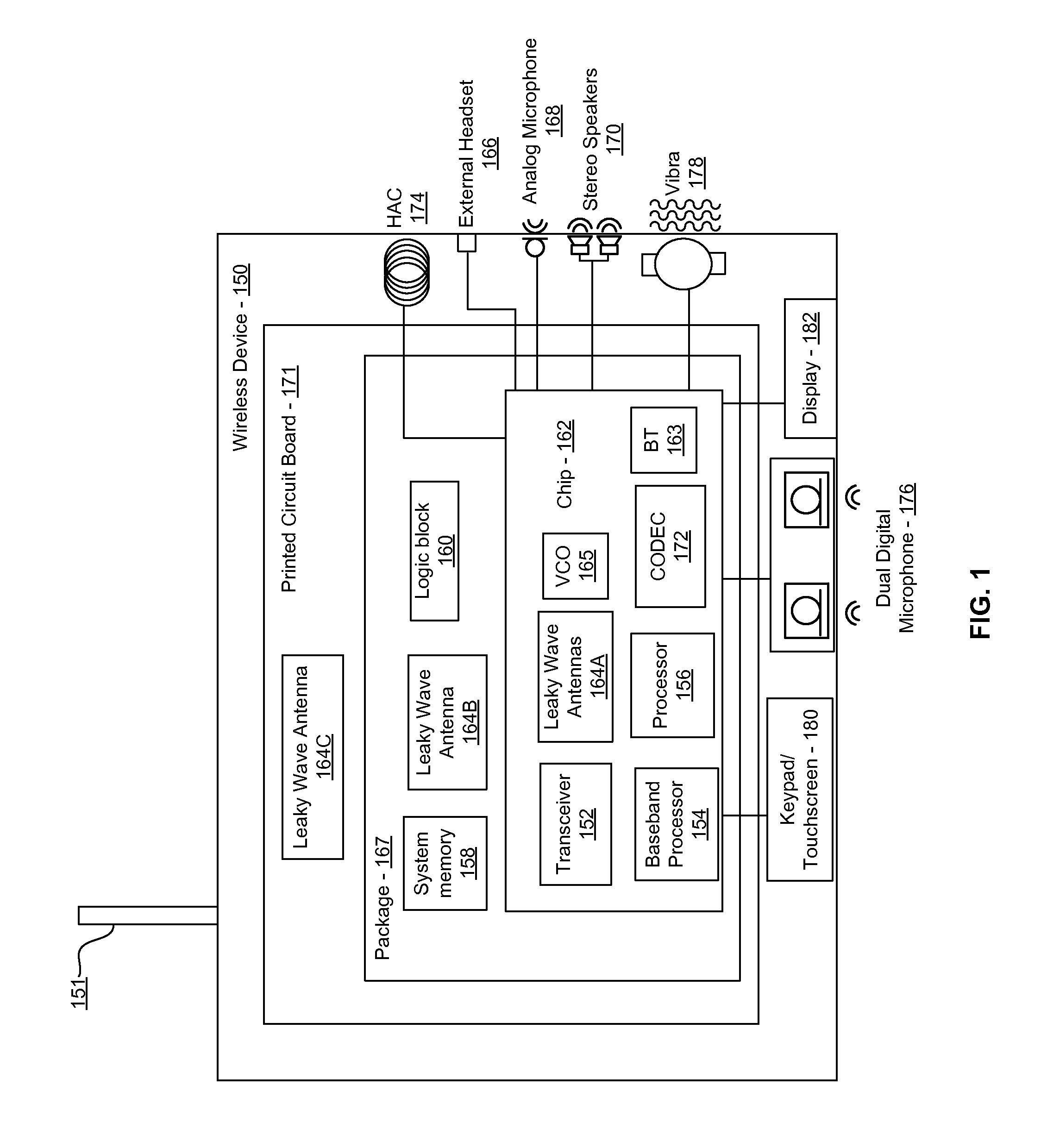

Method and system for an integrated leaky wave antenna-based transmitter and on-chip power distribution

InactiveUS8285231B2Near-field transmissionResonant long antennasAudio power amplifierDistribution method

Methods and systems for an integrated leaky wave antenna-based transmitter and on-chip power distribution are disclosed, and may include supplying one or more bias voltages and ground for a chip including a plurality of power amplifiers (PAs) utilizing bias voltage and ground lines. One or more leaky wave antennas (LWAs) may be communicatively coupled to the power amplifiers. Wireless signals may be transmitted utilizing the LWAs integrated in the lines in the chip. Radio frequency (RF) signals may be transmitted via the plurality of LWAs. The RF signals may include 60 GHz signals and the LWAs may include microstrip and / or coplanar waveguides. A cavity length of the LWAs may be configured by a spacing between conductive lines in the microstrip and / or coplanar waveguides. The LWAs may be configured to transmit the wireless signals at a desired angle from a surface of the chip.

Owner:AVAGO TECH INT SALES PTE LTD

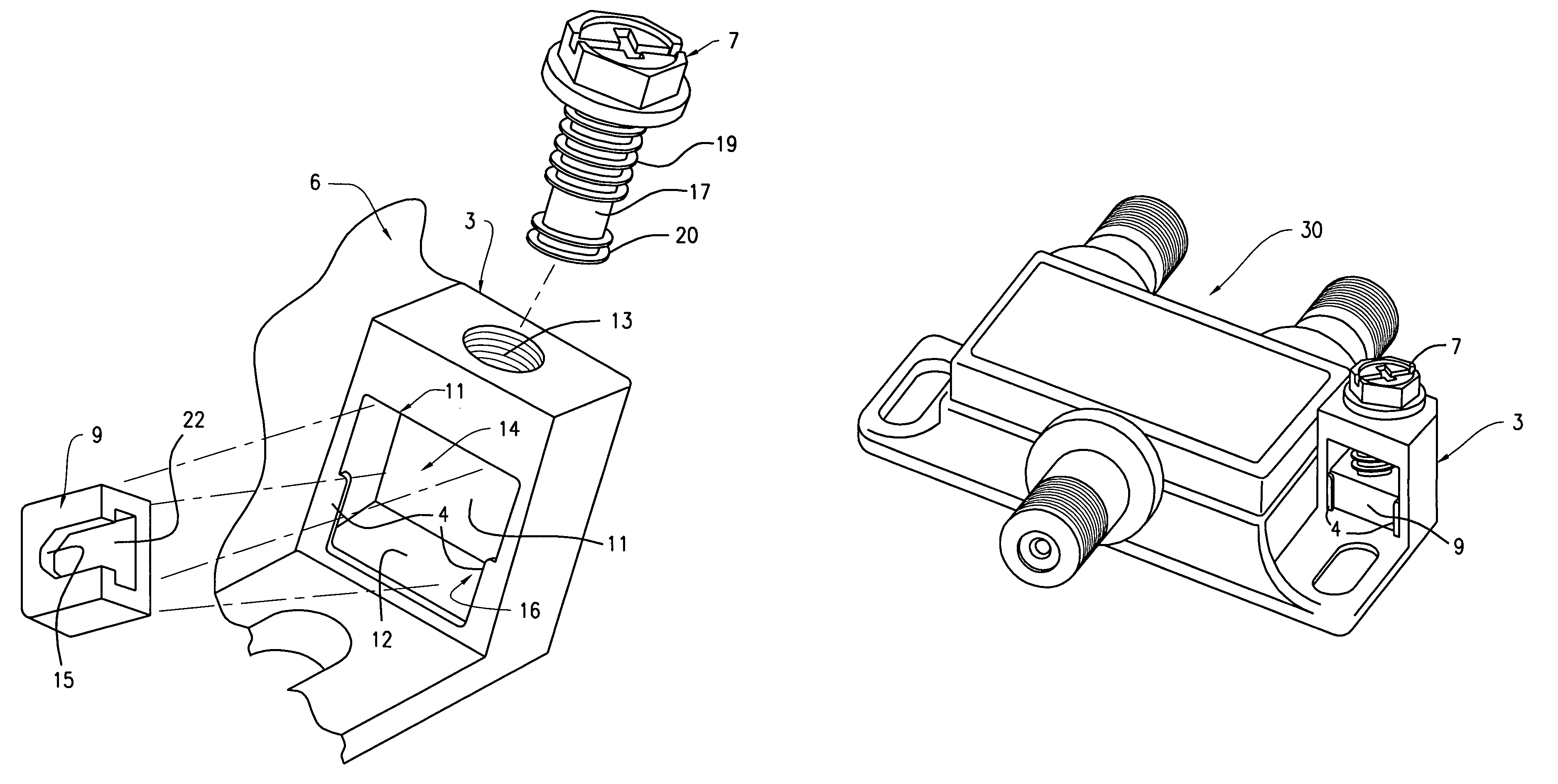

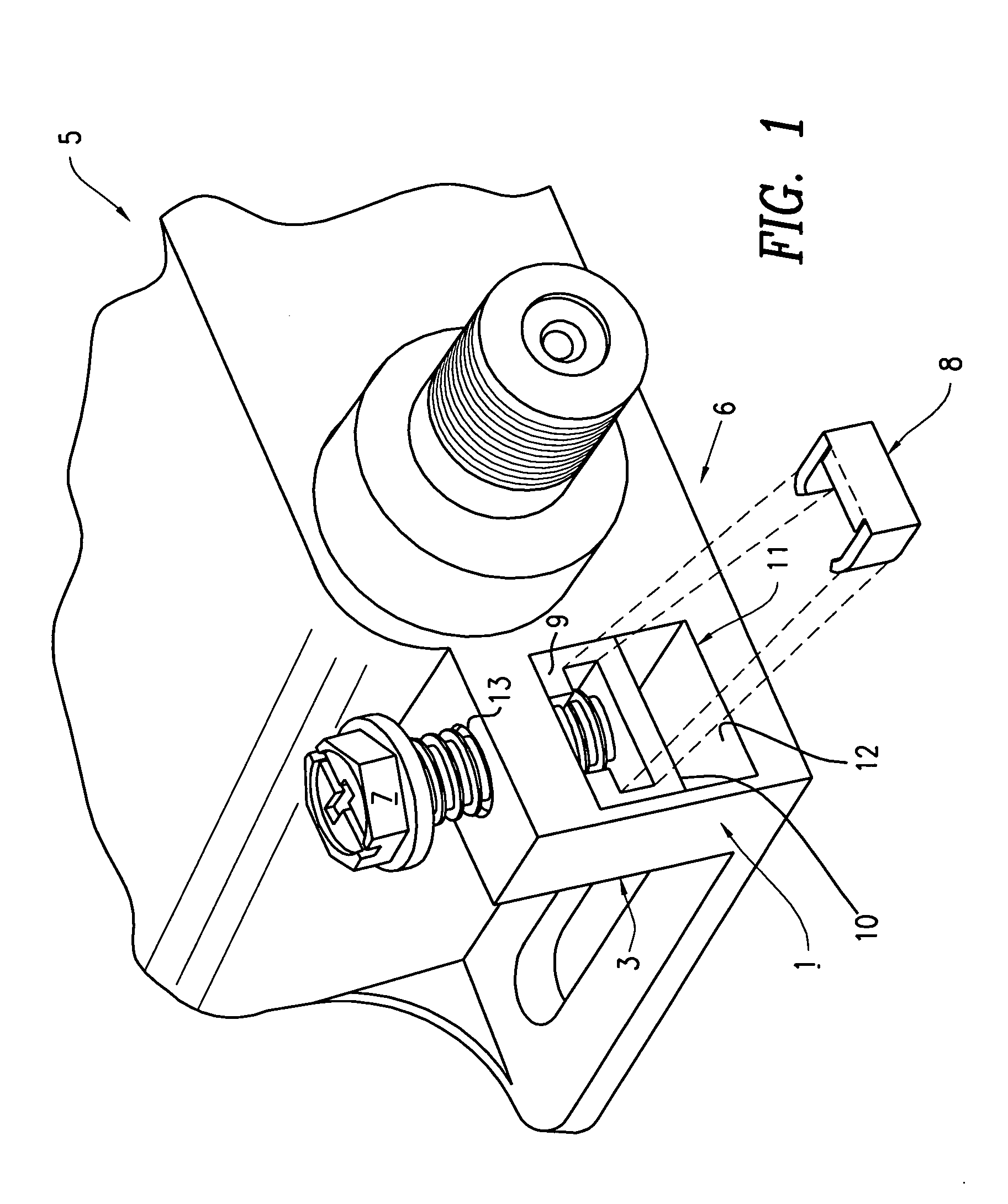

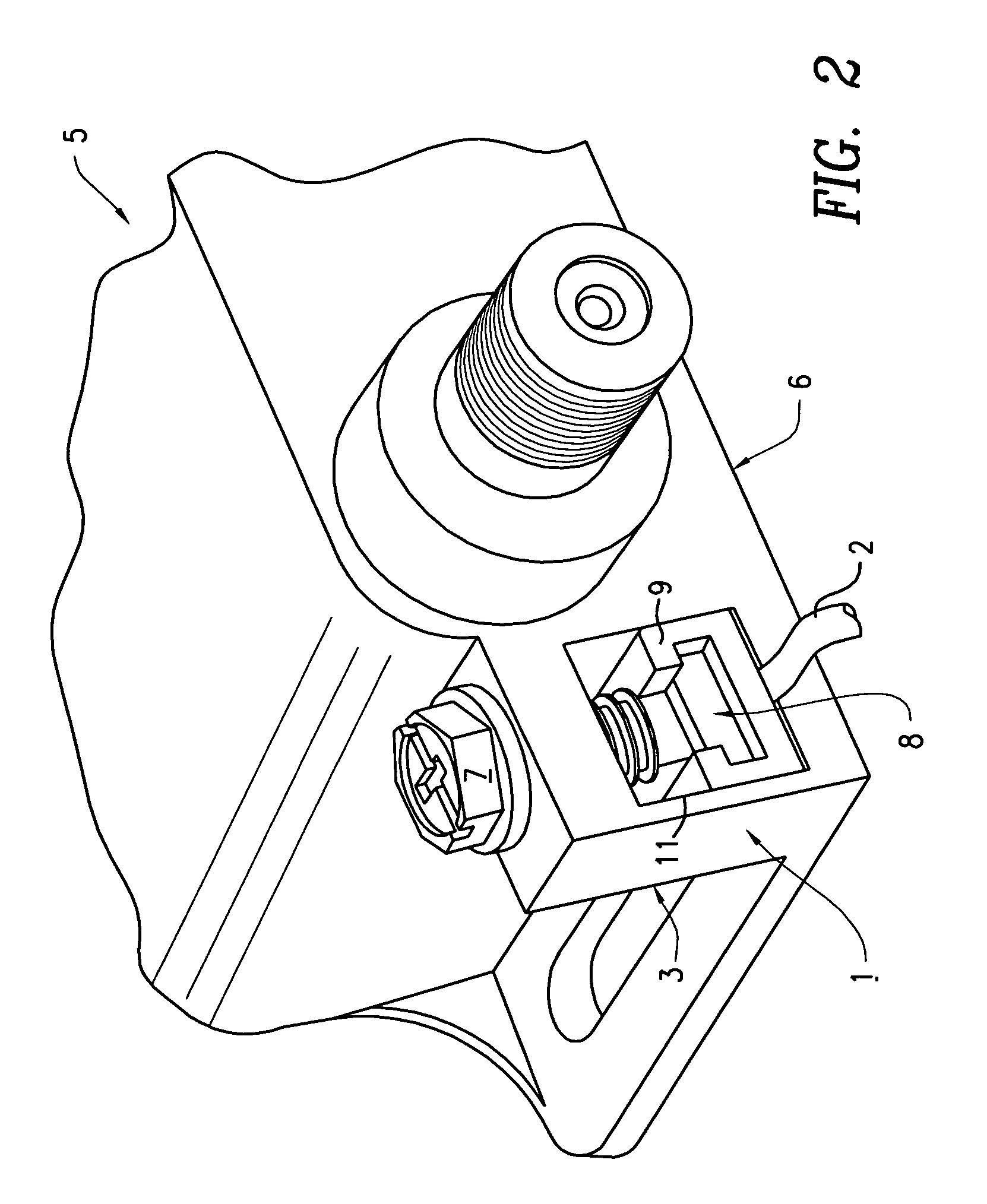

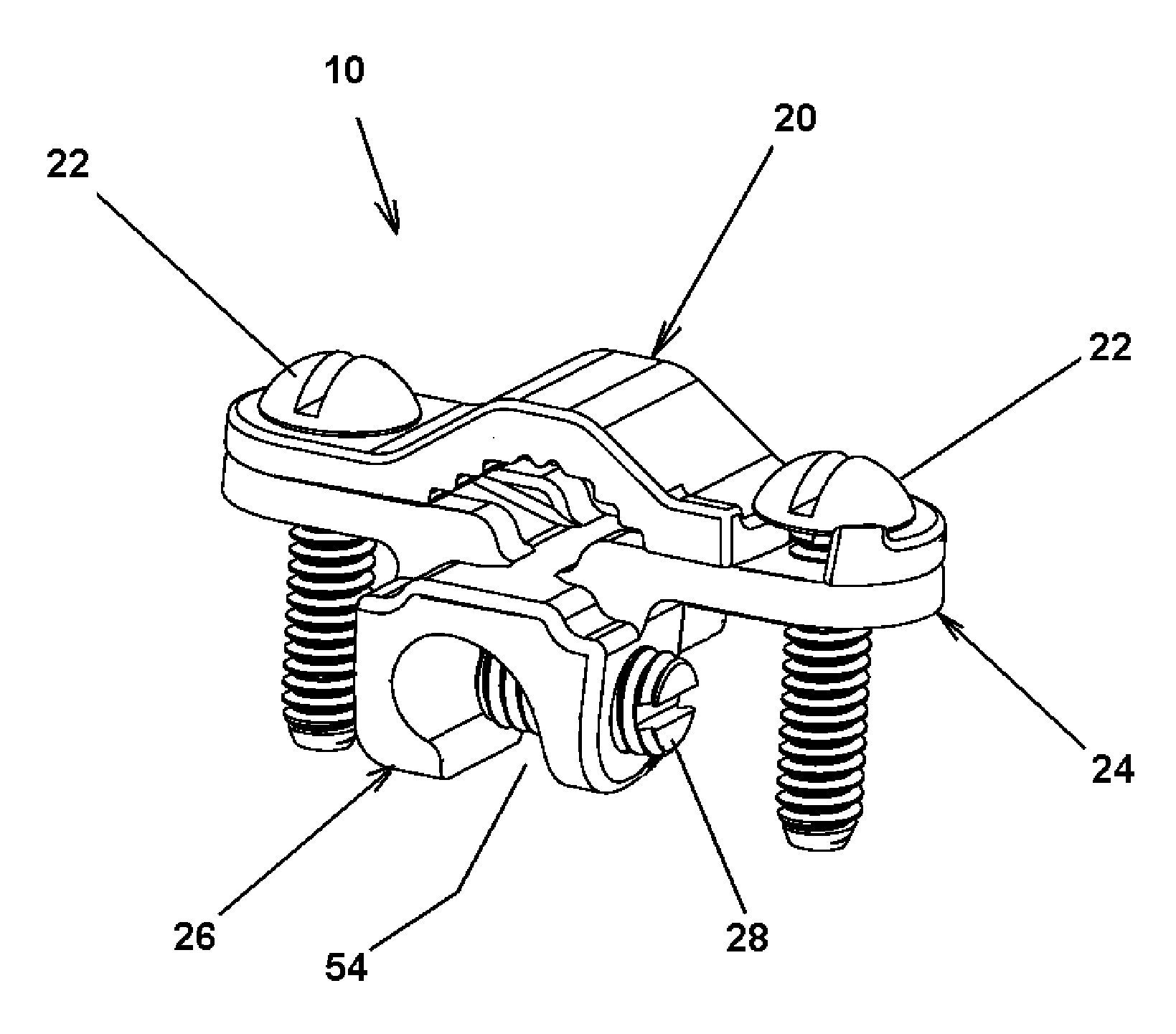

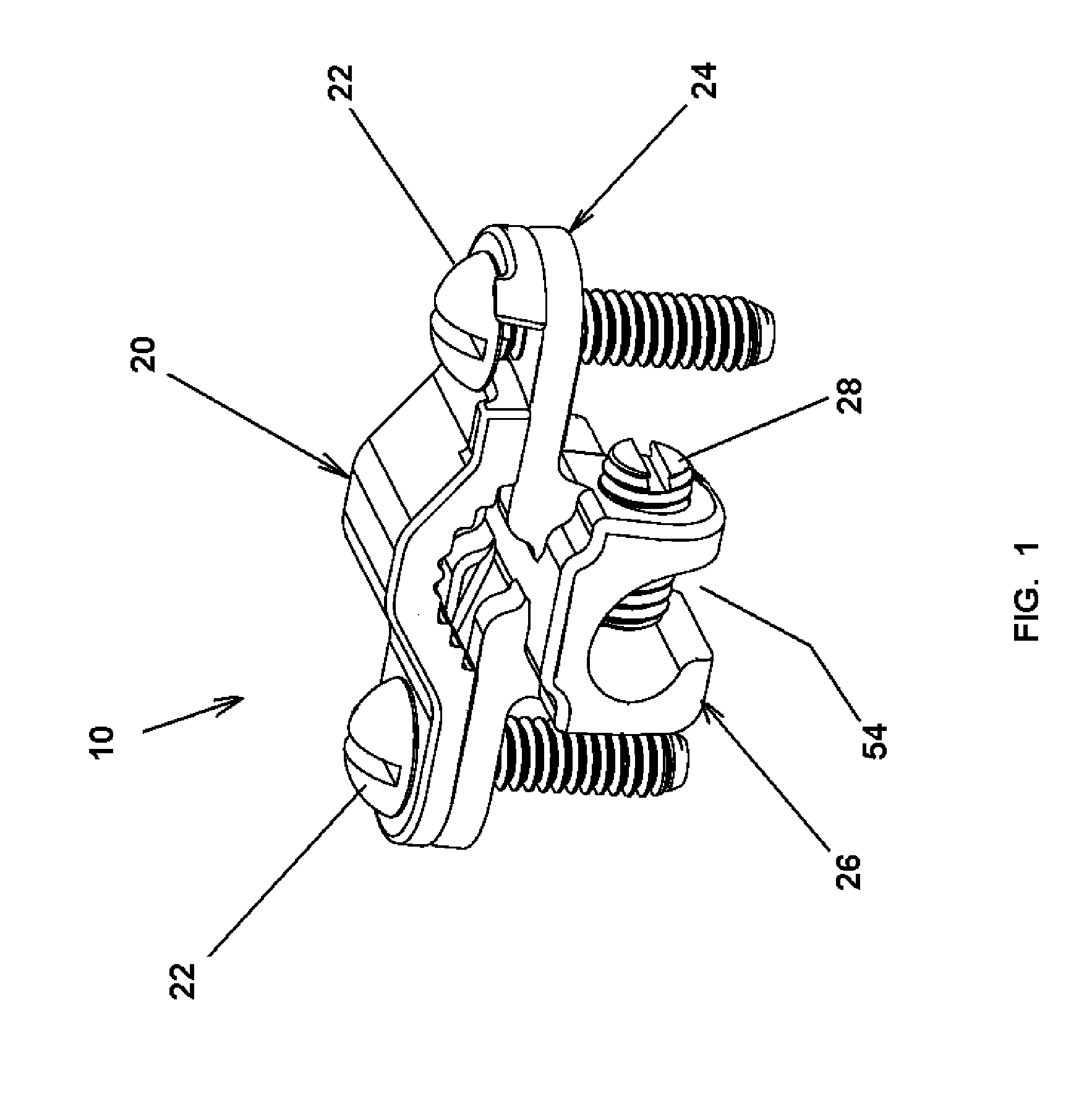

Compact ground clamp

ActiveUS6976857B1Compact assemblyAvoid interferenceClamped/spring connectionsCoupling protective earth/shielding arrangementsSet screwElectrical connection

A ground clamp having upper and lower clamp members interconnected by clamping screws for mechanical and electrical connection with a grounding member, and a frontally projecting boss on the lower clamp member having a downwardly opening slot for receiving a ground wire which is retained by a set screw forward of the clamping screws whereby the various screws may be independently tightened without interference from adjacent screws.

Owner:SIGMA ELECTRIC MFG

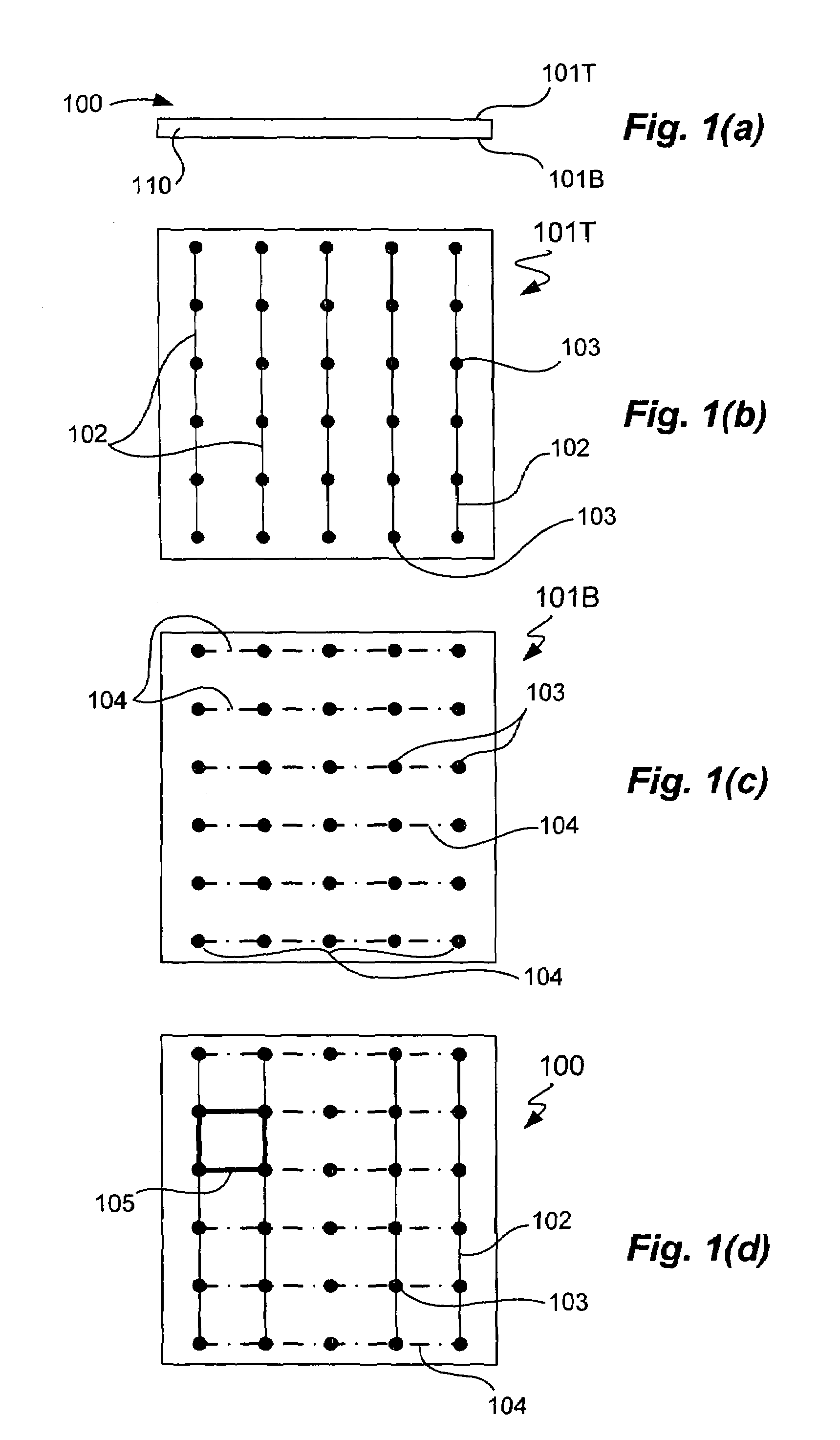

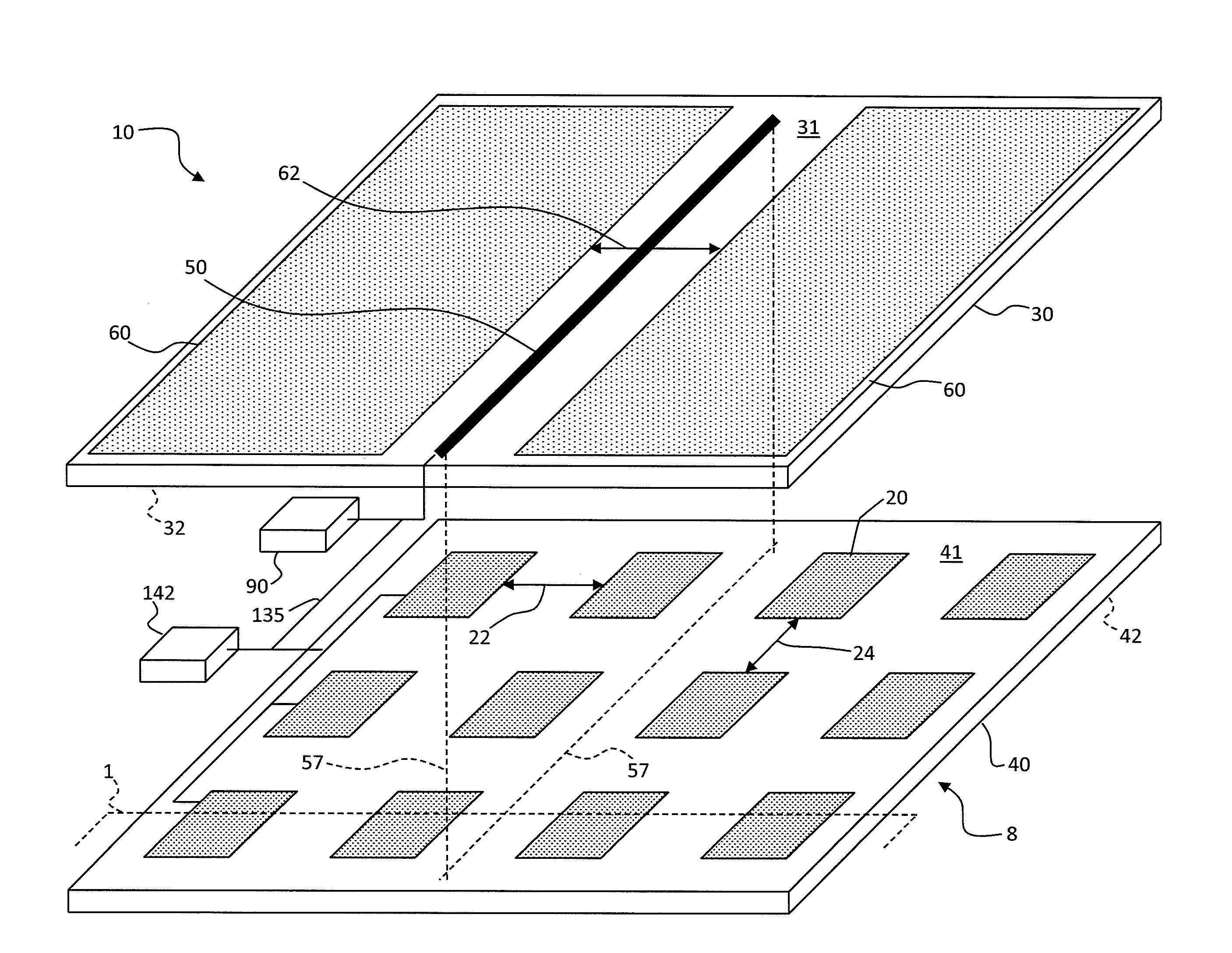

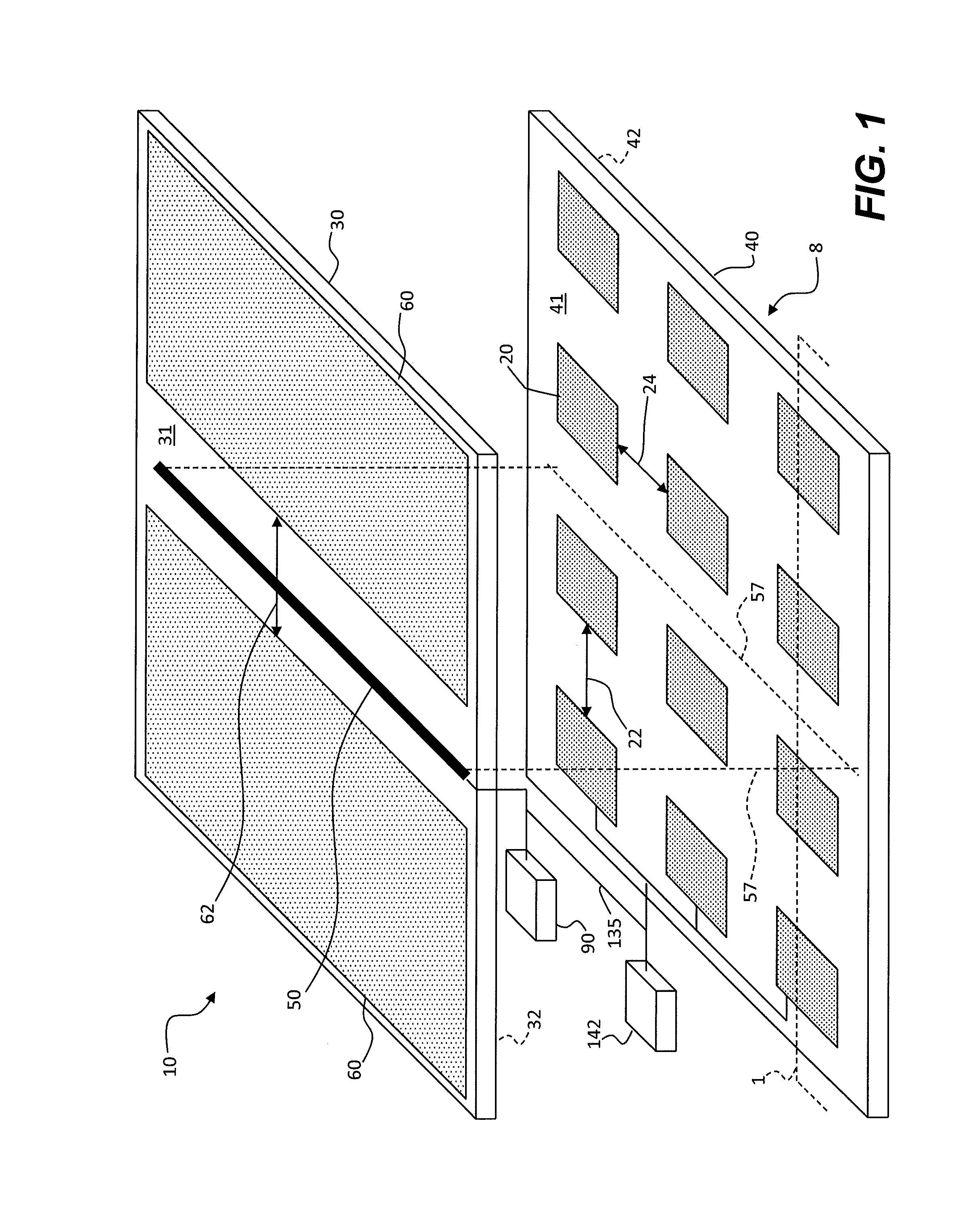

Display apparatus with pixel-aligned ground micro-wire

ActiveUS20140085214A1Reduce electromagnetic interferencePreserve display visibilityInput/output processes for data processingDisplay deviceComputer science

A display apparatus includes a display having an array of pixels formed in rows and columns. The rows of pixels are separated by row inter-pixel gaps and the columns of pixels separated by column inter-pixel gaps. A touch-screen includes a transparent dielectric layer having a row side and an opposed column side located over the display, the touch screen having row electrodes spaced apart by row inter-electrode gaps located on the row side of the transparent dielectric layer and column electrodes spaced apart by column inter-electrode gaps located on the column side of the transparent dielectric layer. The row and column electrodes are separated by the transparent dielectric layer. Ground lines are located on the row side between neighboring row electrodes in the row inter-electrode gaps and between the pixels in a row inter-pixel gap.

Owner:EASTMAN KODAK CO

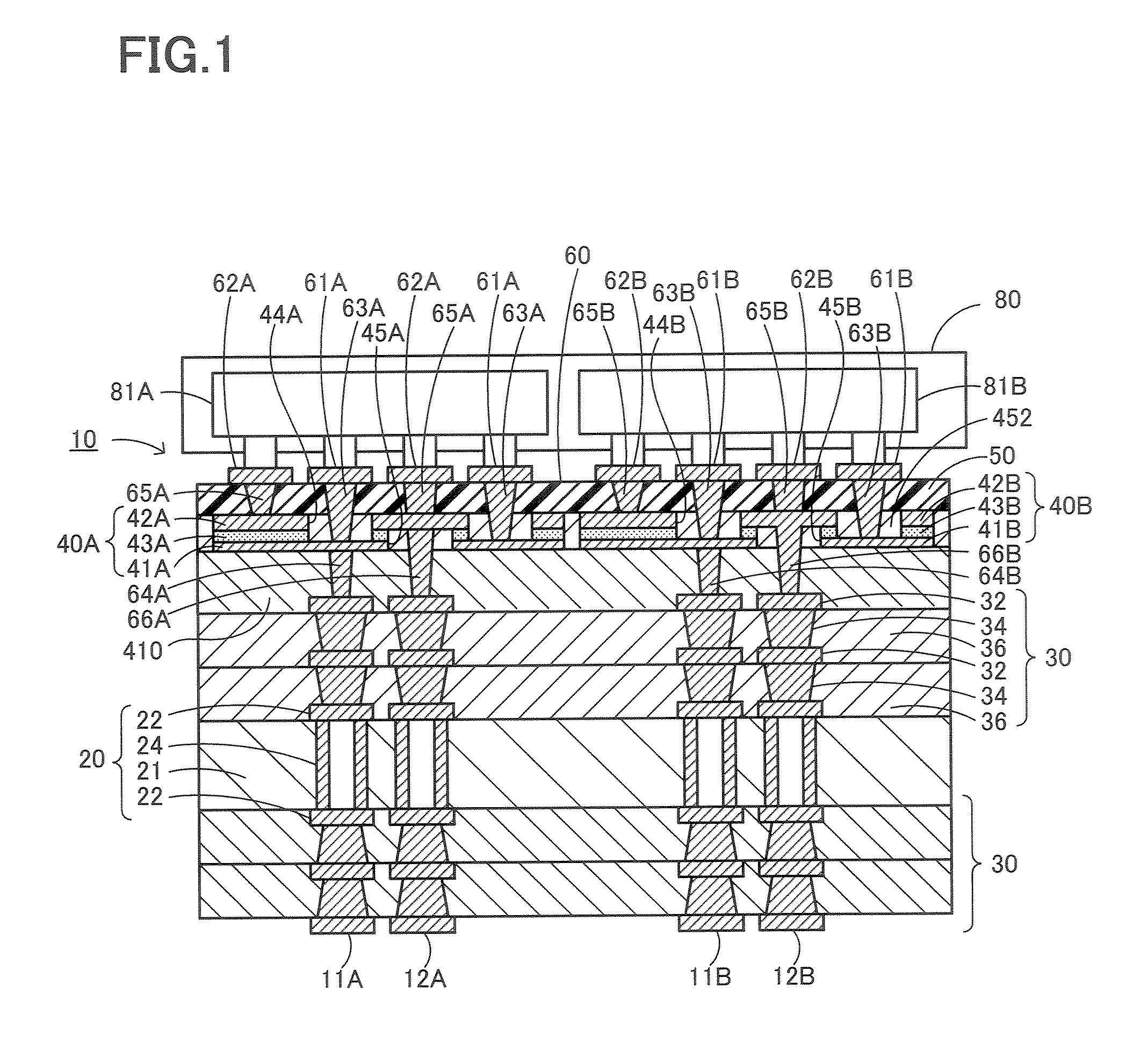

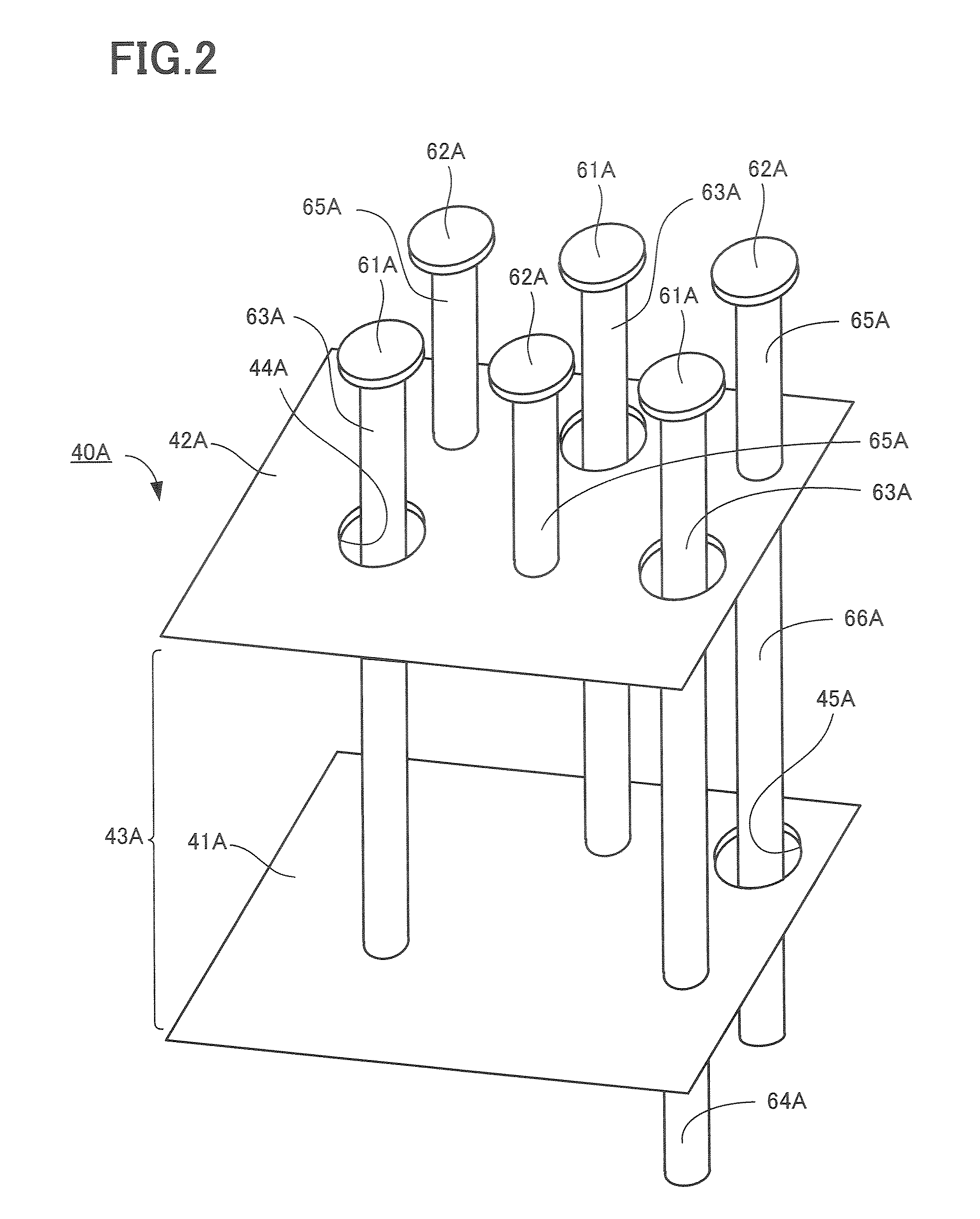

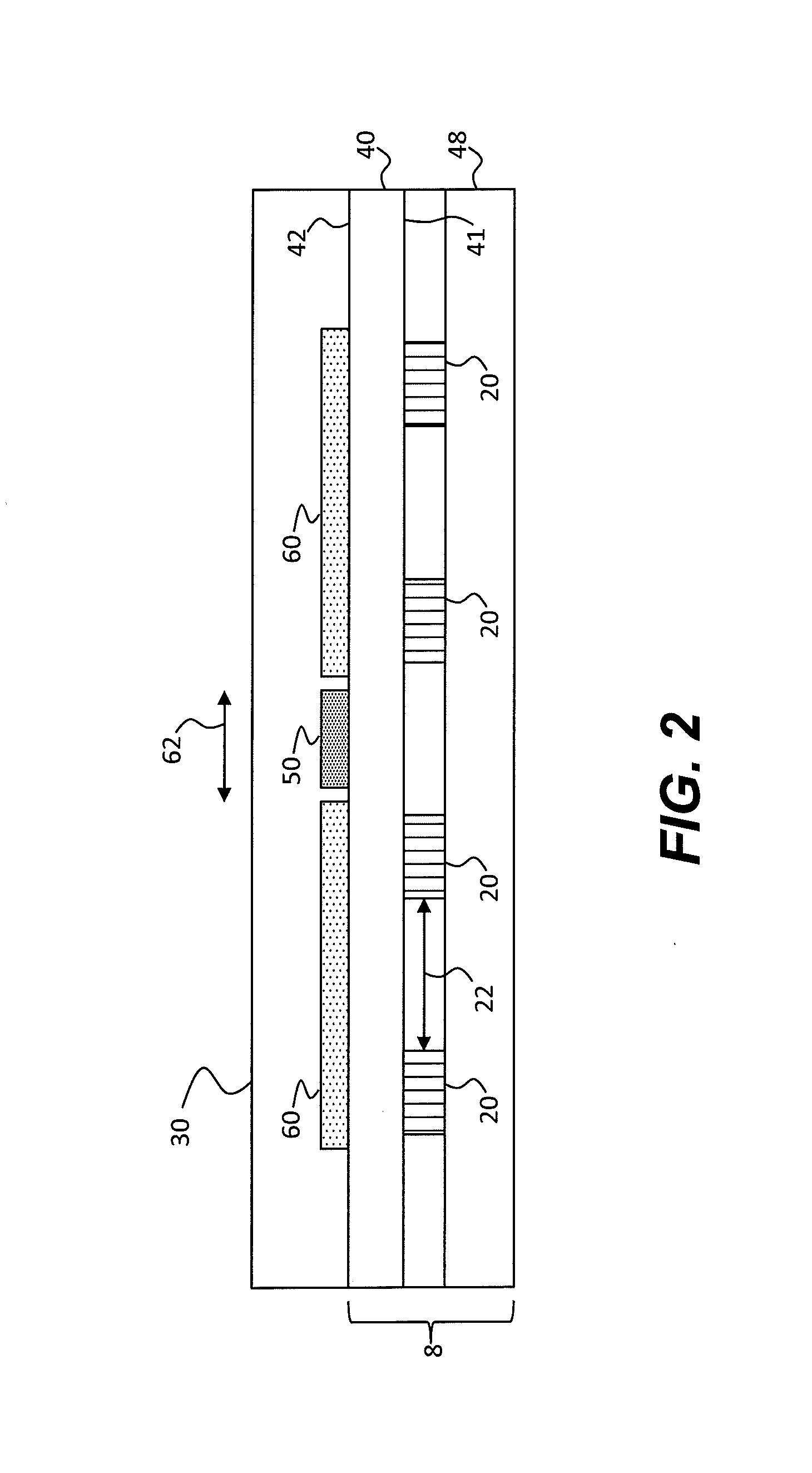

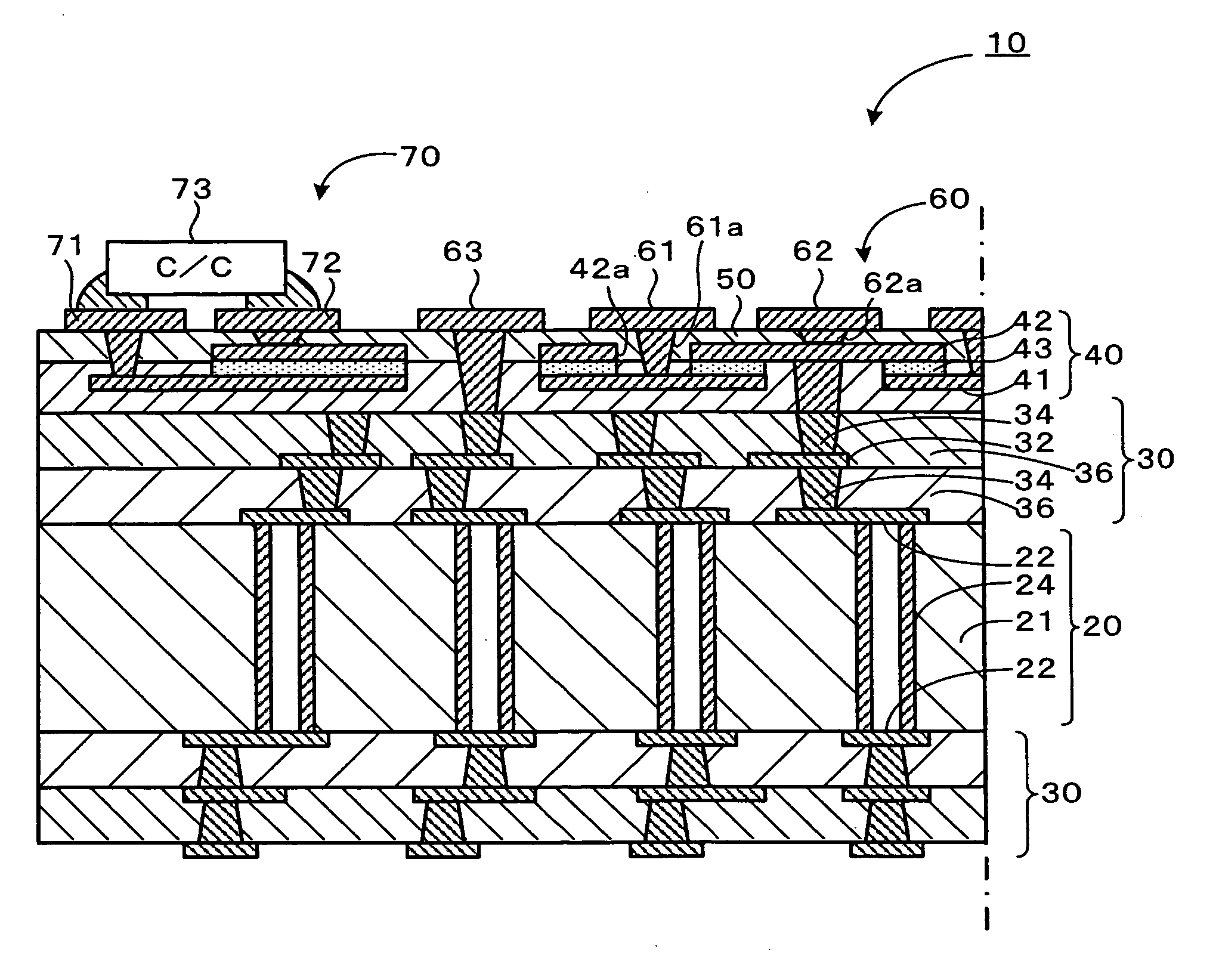

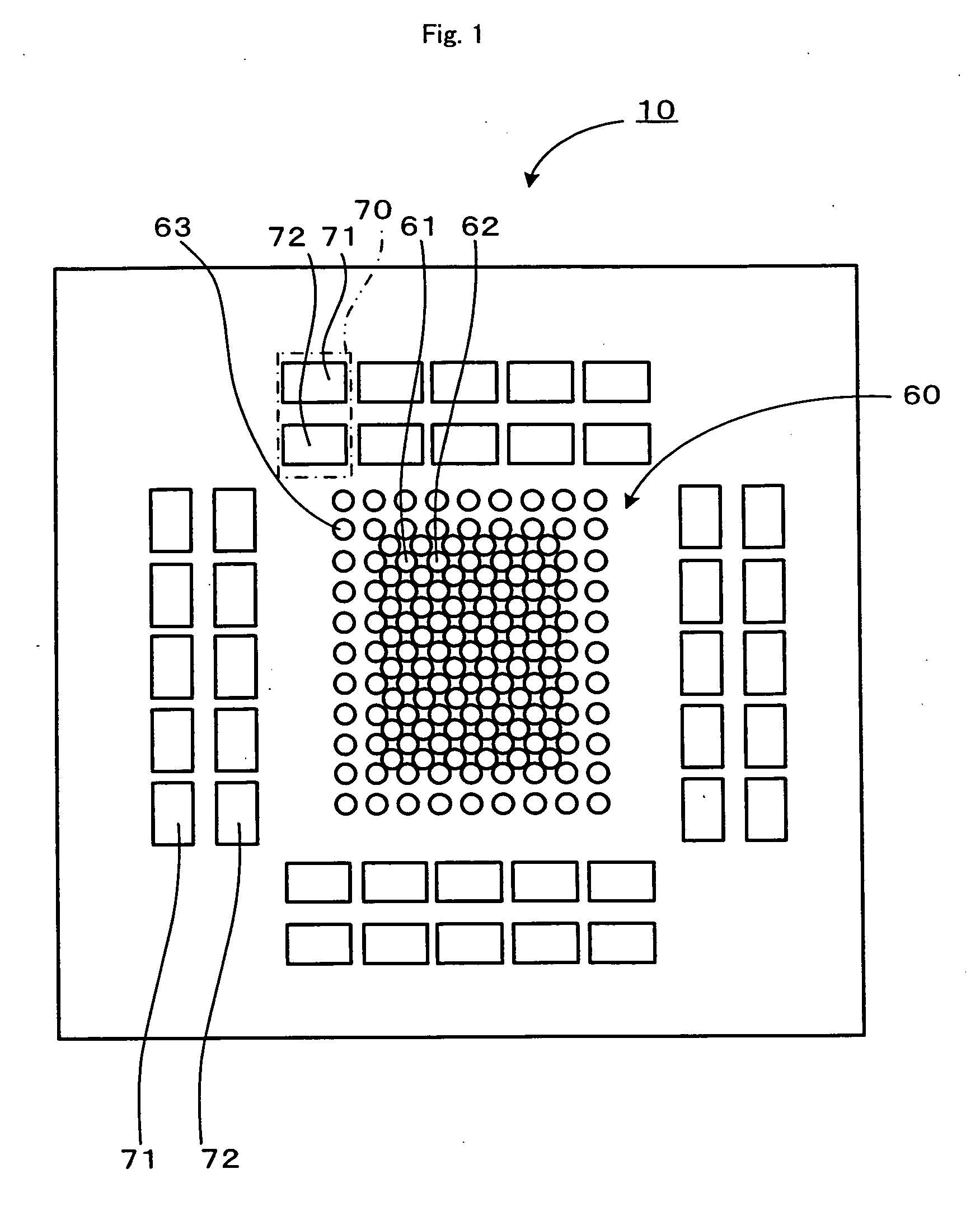

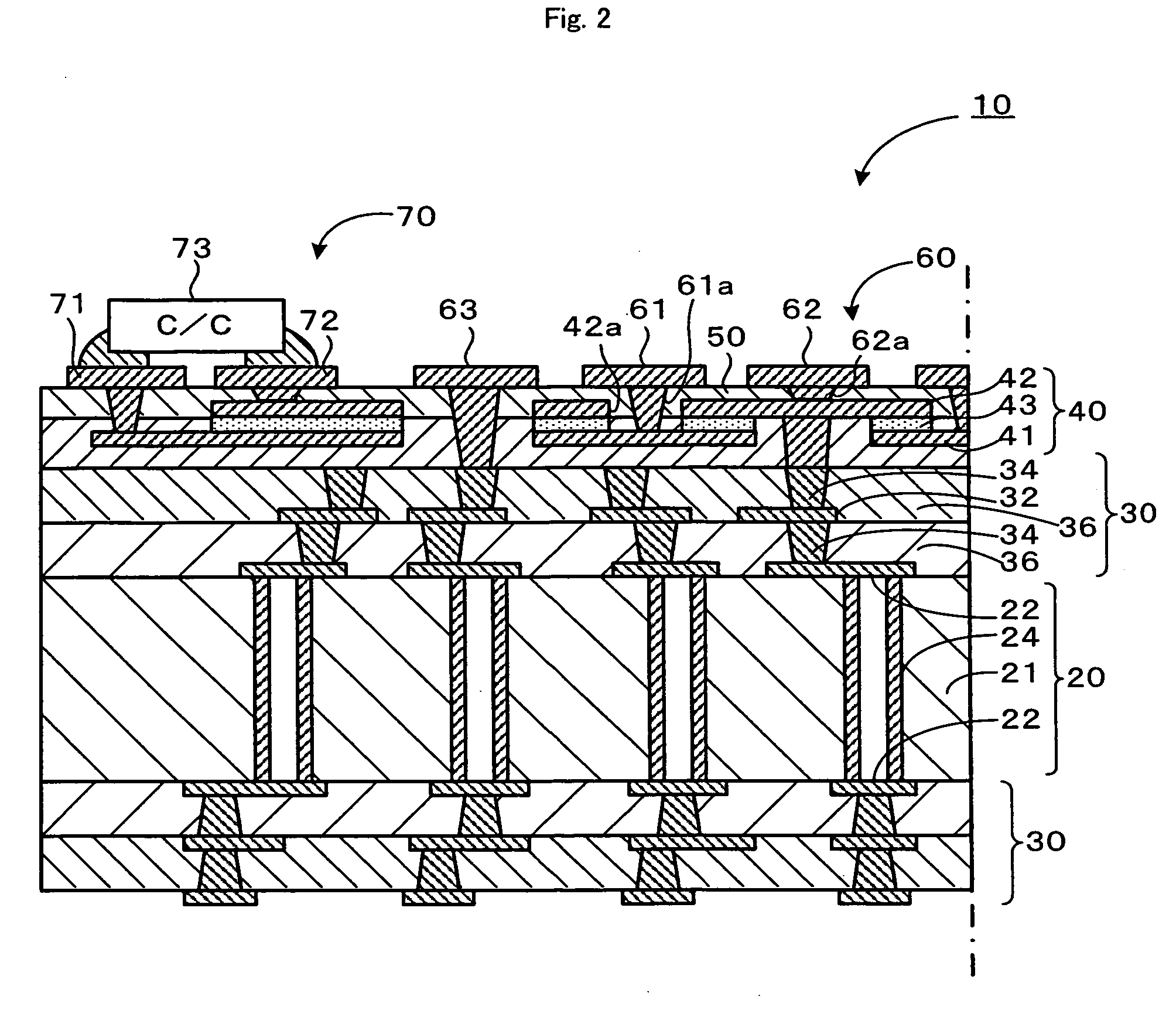

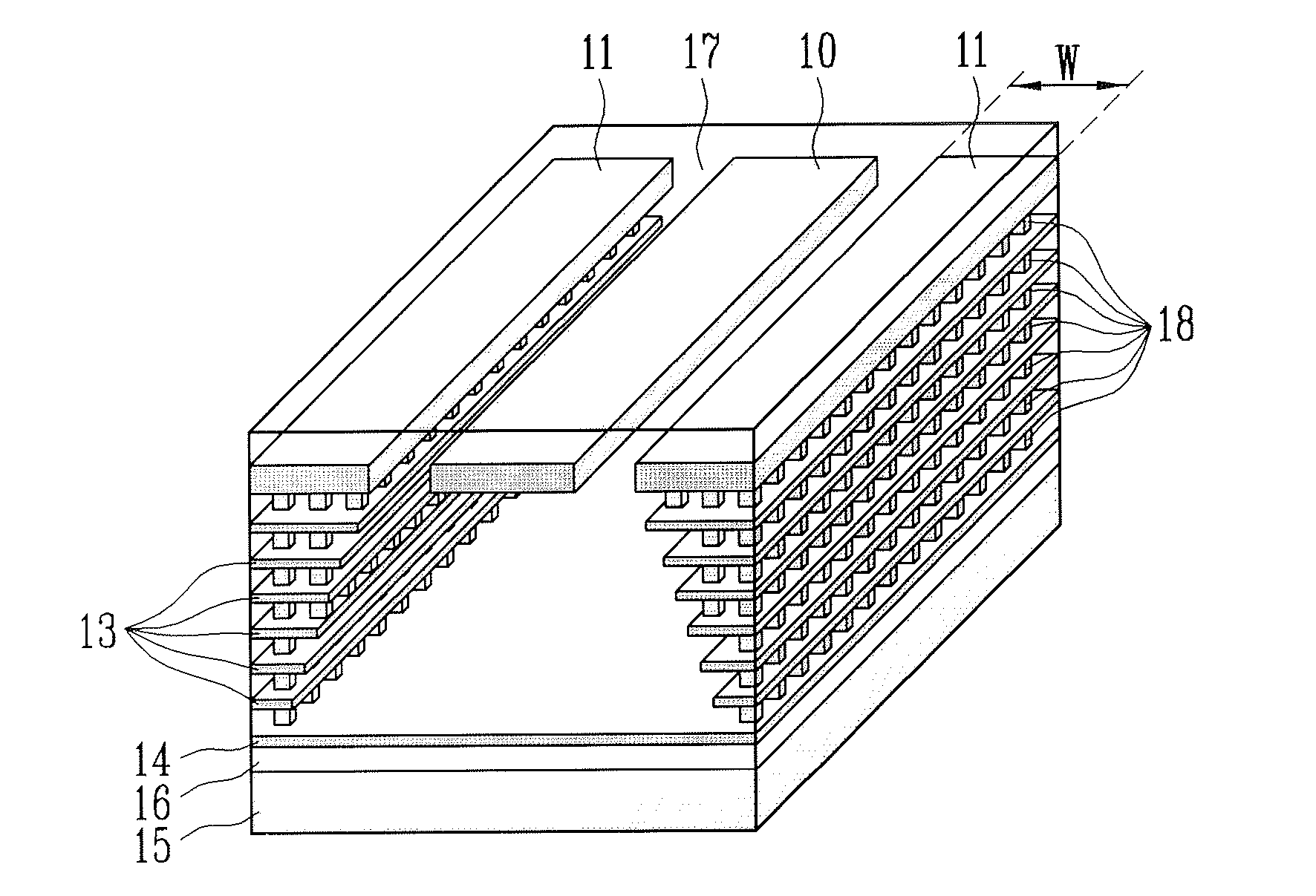

Multilayer printed wiring board

ActiveUS20060137905A1High capacitanceAdequate decoupling effectCross-talk/noise/interference reductionPrinted circuits stress/warp reductionCapacitanceEngineering

A multilayer printed wiring board 10 includes: a mounting portion 60 on the top surface of which is mounted a semiconductor element that is electrically connected to a wiring pattern 32, etc.; and a capacitor portion 40 having a high dielectric constant layer 43, formed of ceramic and first and second layer electrodes 41 and 42 that sandwich the high dielectric constant layer 43. One of either of the first and second layer electrodes 41 and 42 is connected to a power supply line of the semiconductor element and the other of either of the first and second layer electrodes 41 and 42 is connected to a ground line. In this multilayer printed wiring board 10, high dielectric constant layer 43 included in the layered capacitor portion 40, which is connected between the power supply line and the ground line, is formed of ceramic. With this structure, the static capacitance of the layered capacitor portion 40 can be high, and an adequate decoupling effect is exhibited even under circumstances in which instantaneous potential drops occur readily.

Owner:IBIDEN CO LTD

Current load device and method for driving the same

This invention provides a precise current load device. A cell includes a power supply line, a ground line, first and second voltage supply lines, a signal line, first, third and fourth control lines, first to fourth switches, a p-type TFT, a capacitance element, and a current load element. A source of the p-type TFT is connected to the power supply line, one terminal of the current load element is connected to the ground line, the first switch is connected between the signal line and a drain of the p-type TFT, the second switch is connected between the drain and the gate of the p-type TFT, the third switch is connected between the drain of the p-type TFT and the current load element, and the fourth switch is connected between the voltage supply line and the current load element.

Owner:HANNSTAR DISPLAY CORPORATION

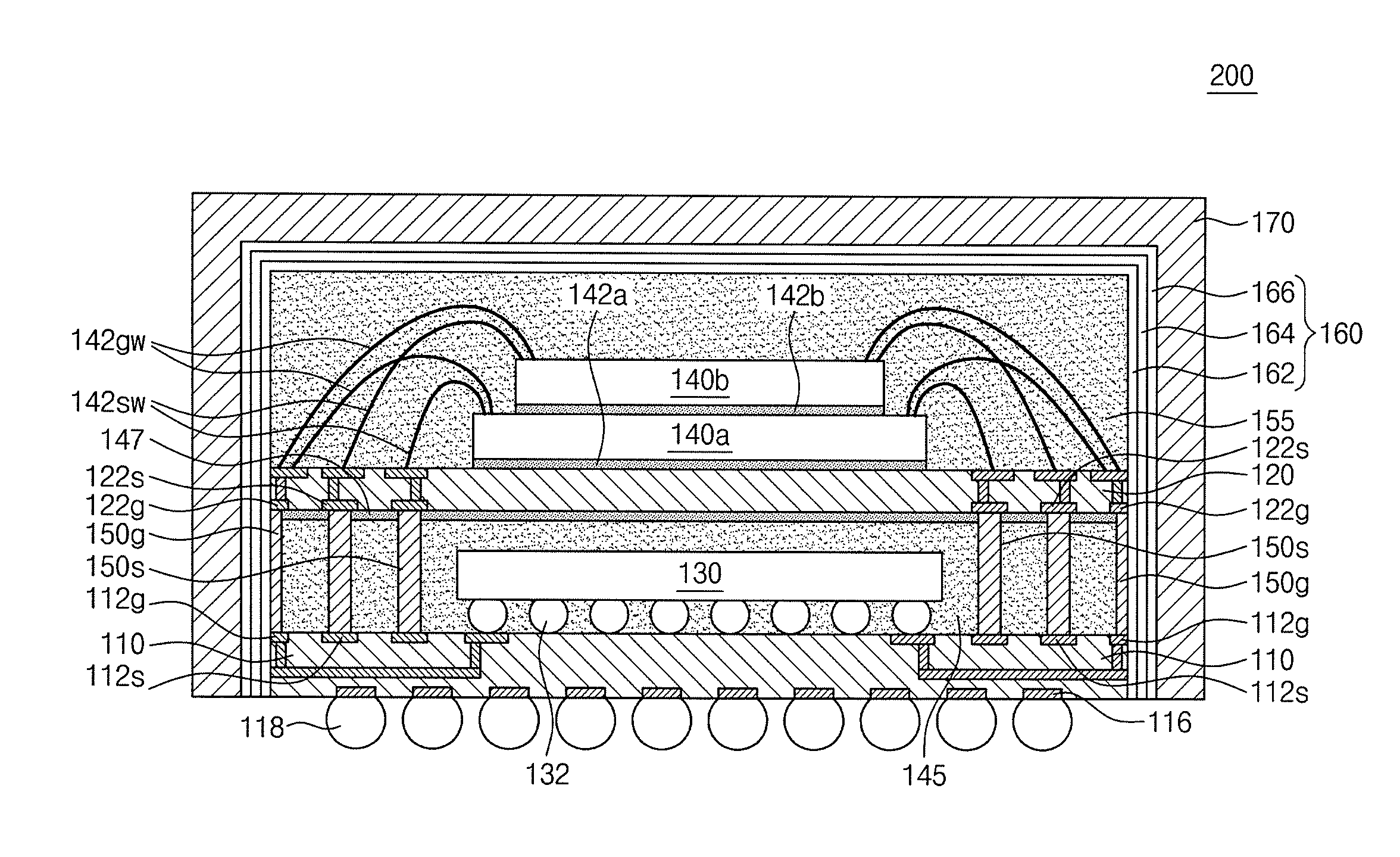

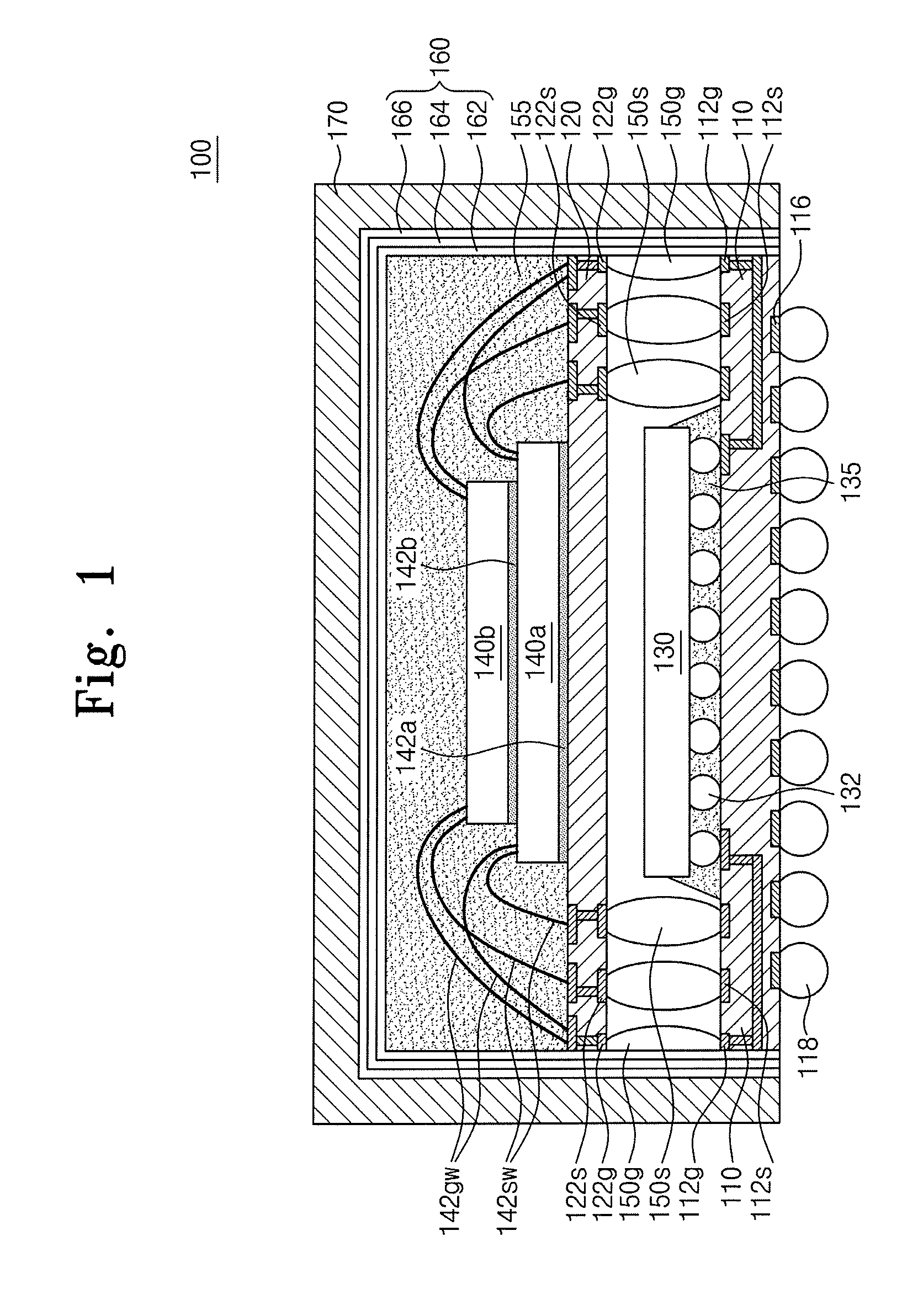

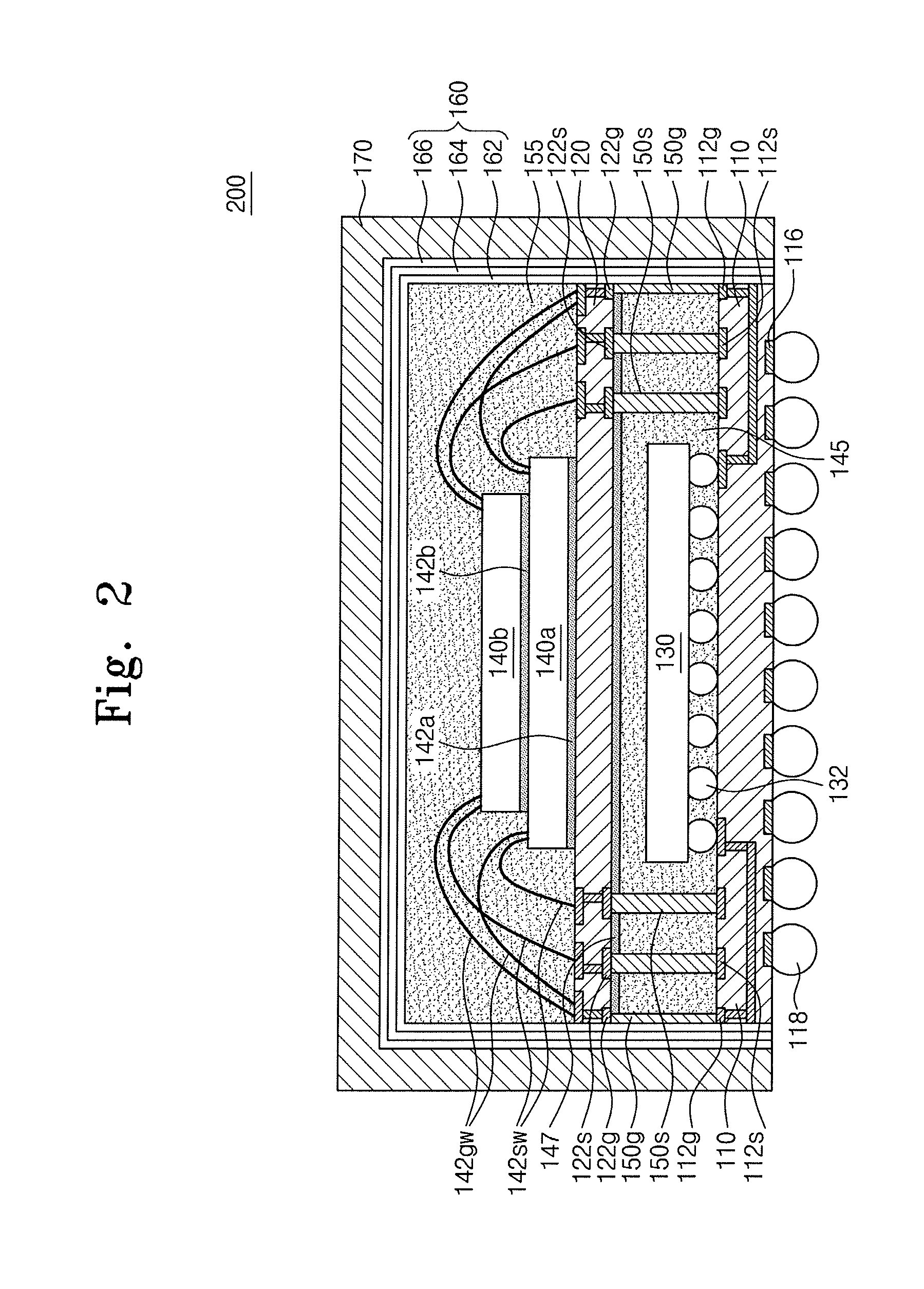

Semiconductor packages

ActiveUS20130214396A1Operational reliability is increasedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package includes a first package including a first wiring board and at least one first semiconductor chip mounted on the first wiring board, a second package stacked on the first package. The second package includes a second wiring board and at least one second semiconductor chip mounted on the second wiring board. The semiconductor package further includes at least one connection terminal connecting a plurality of signal lines of the first and second wiring boards, respectively, with each other. The semiconductor package further includes at least one ground terminal connecting a plurality of ground lines of the first and second wiring boards, respectively, with each other, and includes a side surface, and a shielding member covering a top surface and a side surface of a structure including the first and second packages and the shielding member is disposed on the at least one ground terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

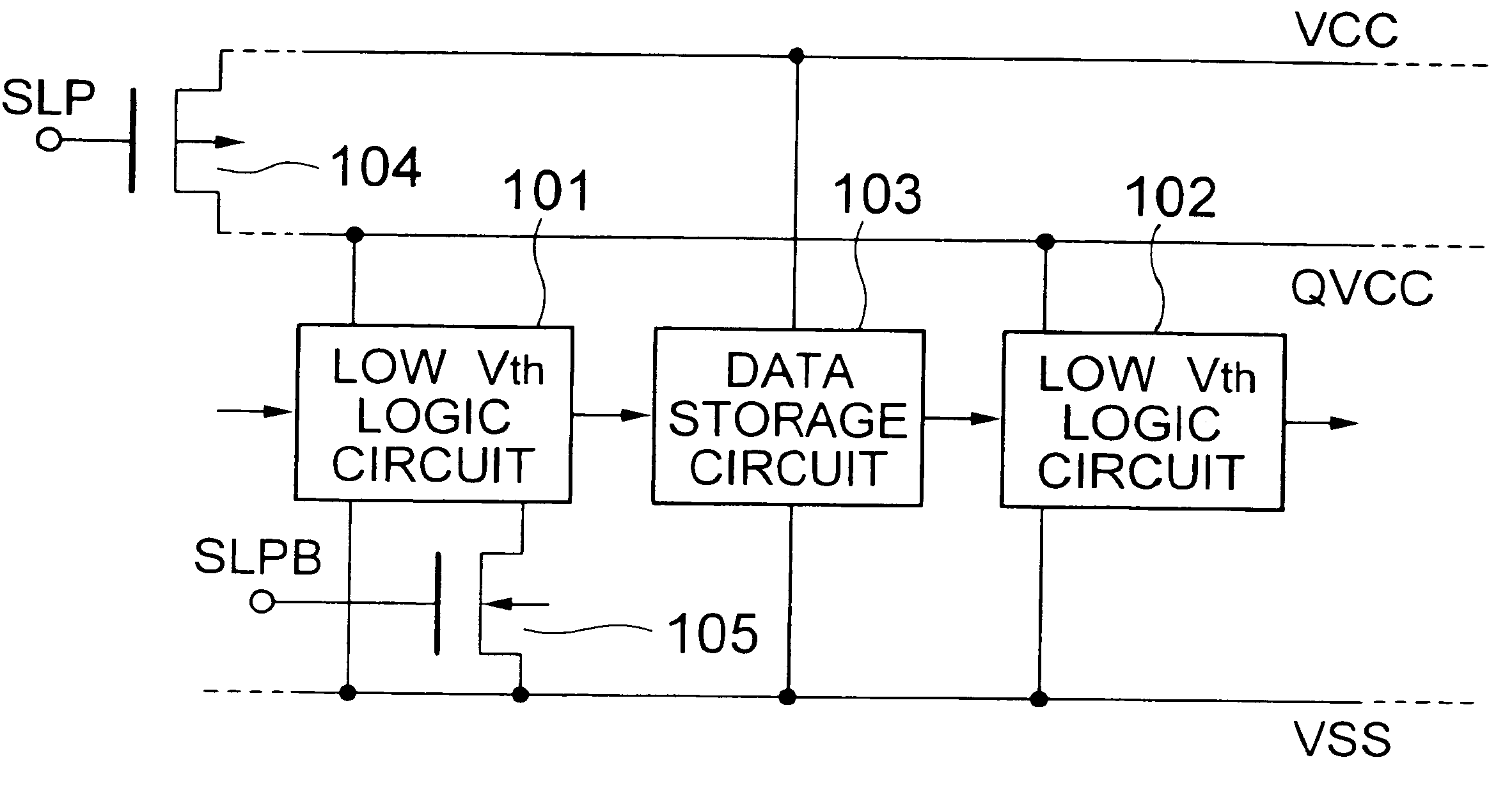

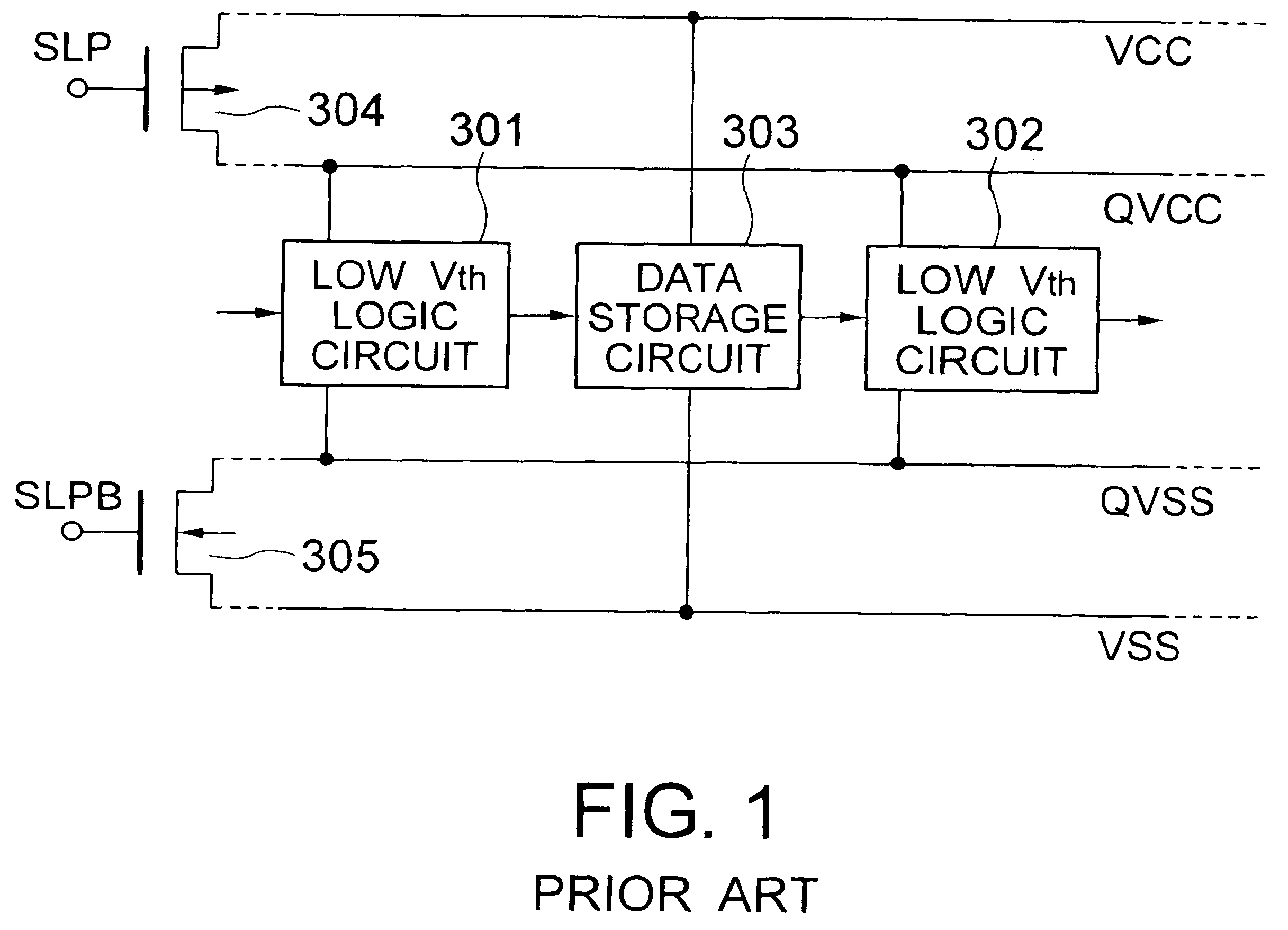

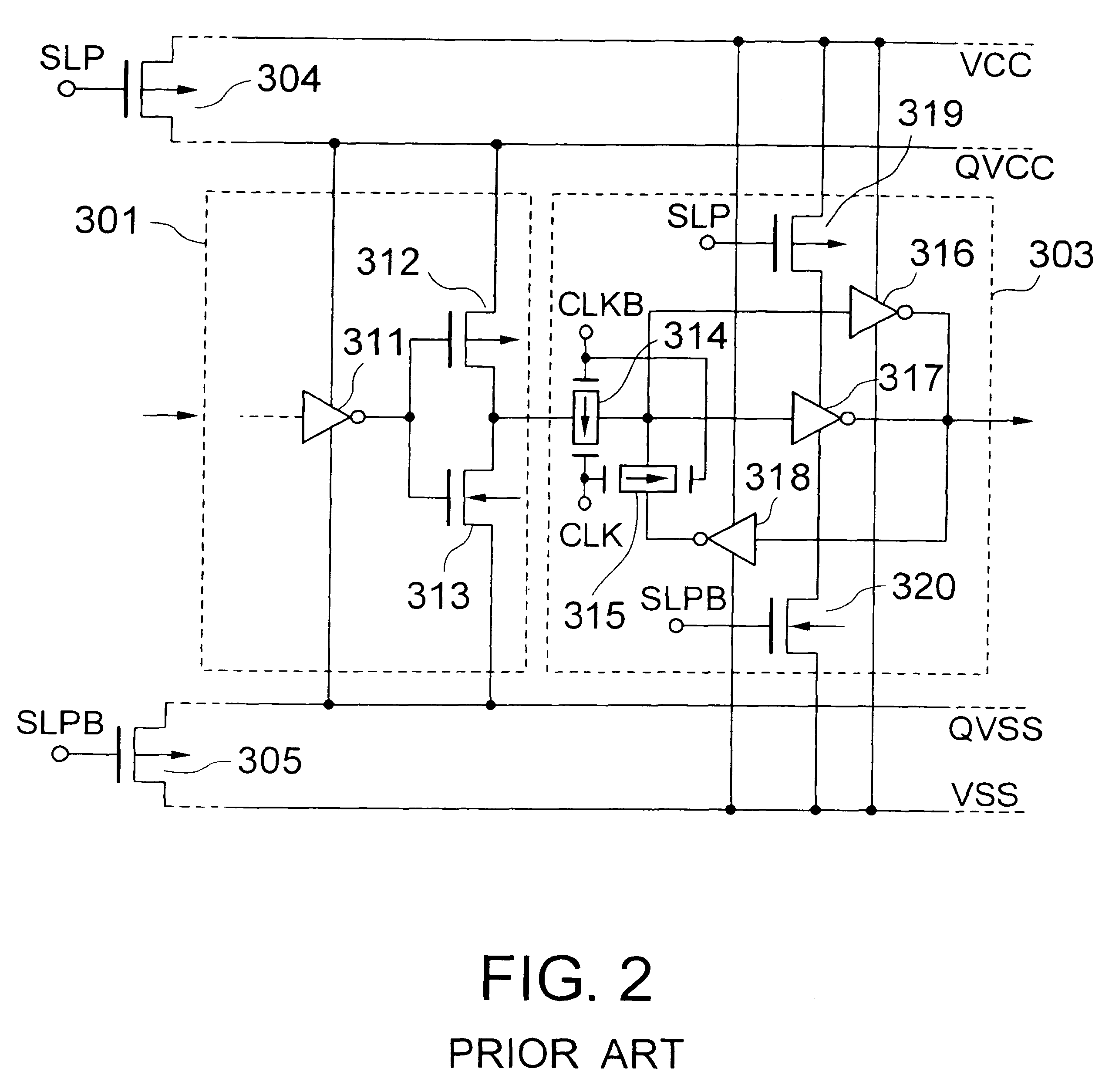

Semiconductor integrated circuit having a sleep mode with low power and small area

InactiveUS6208170B1Reliability increasing modificationsLogic circuits characterised by logic functionEngineeringPower circuits

A semiconductor integrated circuit includes a power supply circuit having a global source line VCC, a local source line QVCC coupled to VCC by a source switching transistor, and a global ground line VSS, a low-threshold logic (combinational) circuit connected between QVCC and VSS, and a data storage (sequential) circuit, connected between VCC and VSS. The data storage circuit includes a low-threshold input section for receiving data from the logic circuit and a high-threshold latch section for latching the data received by the input section. Mode switching transistors are inserted between the low-threshold logic circuit and VSS, between low-threshold input section and VCC and between the low-threshold input section and VSS, for effecting a sleep mode of the semiconductor integrated circuit. Low power dissipation is maintained with a reduced circuit scale.

Owner:RENESAS ELECTRONICS CORP

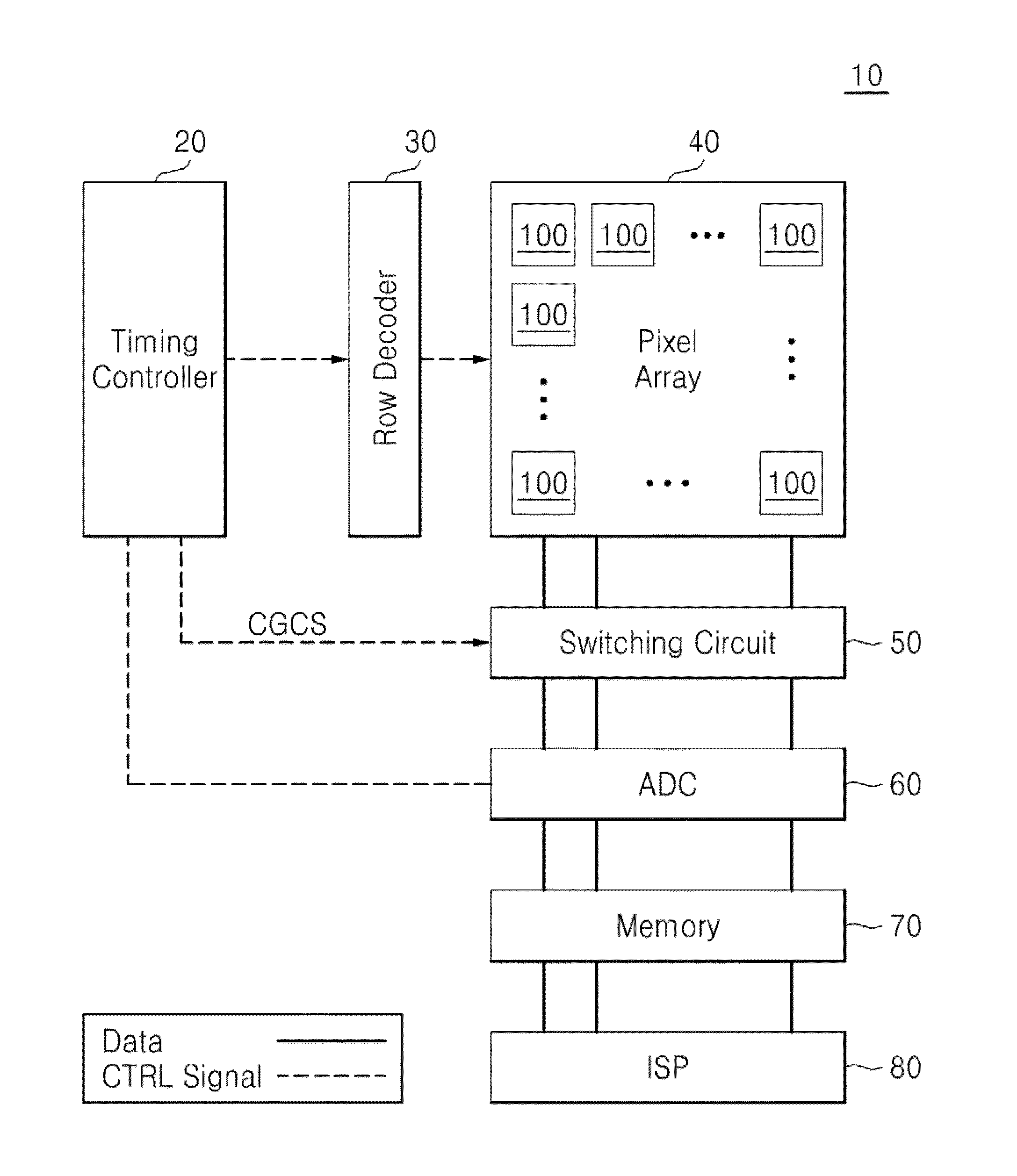

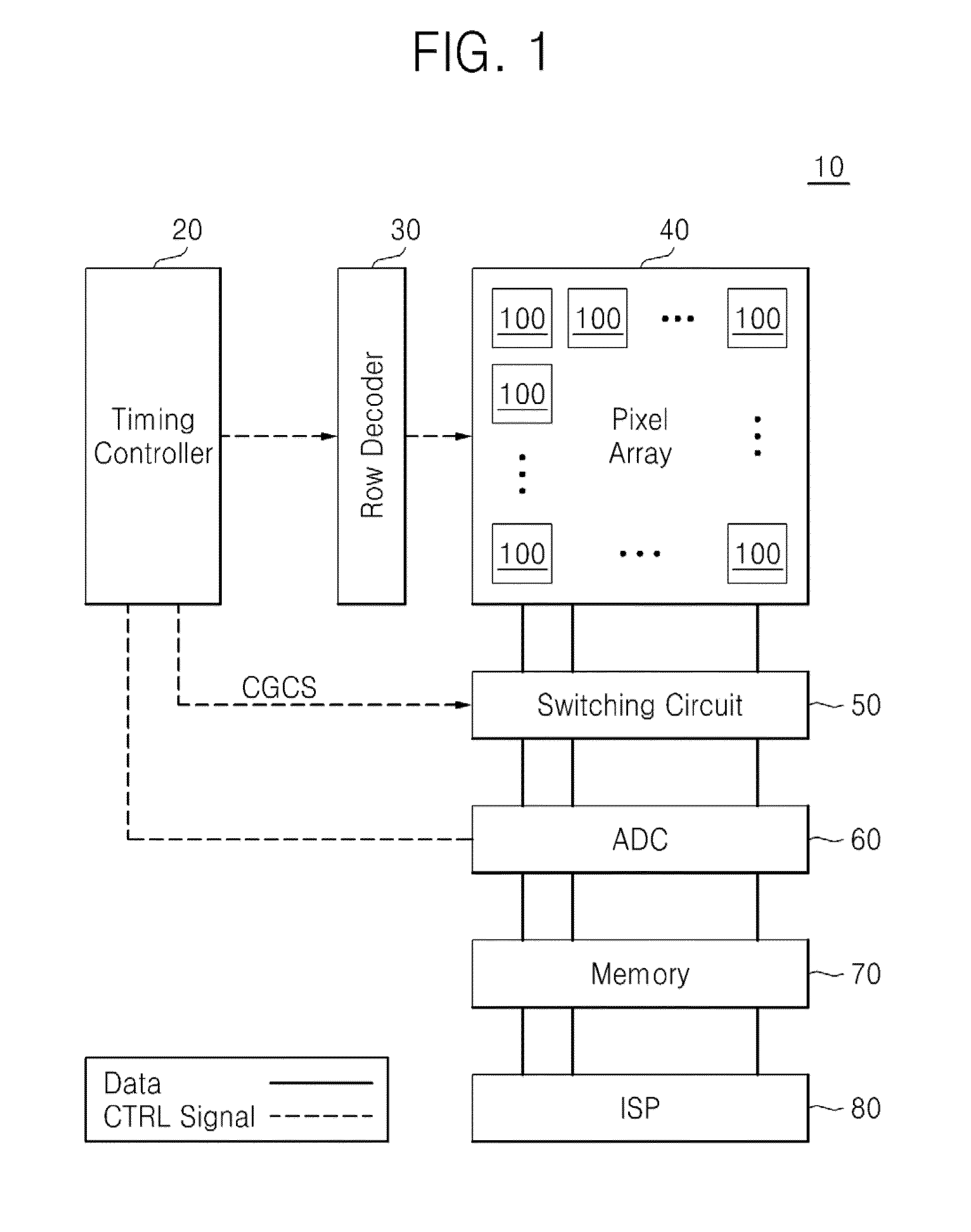

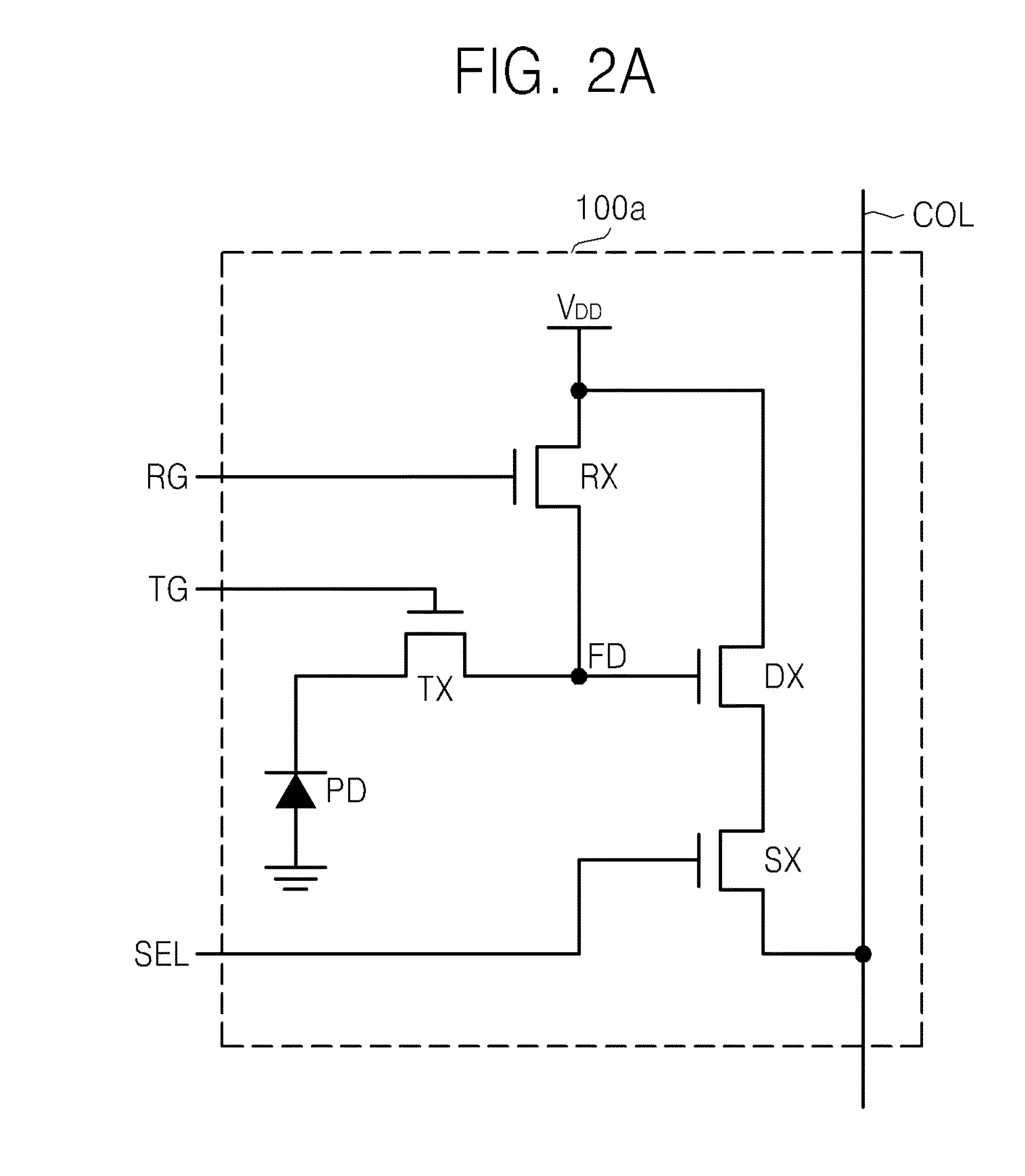

Image sensors and image processing devices including the same

ActiveUS20130141619A1Television system detailsTelevision system scanning detailsImaging processingControl signal

An image sensor may include a photodiode configured to convert an optical signal into photogenerated charge, a sensing node adjacent to the photodiode and configured to sense the photogenerated charge, a read-out circuit configured to convert the photogenerated charge into an electrical signal and to output the electrical signal through an output line, and / or at least one capacitor formed between the sensing node and a conversion gain control line. The conversion gain control line corresponding to the at least one capacitor may be selectively connected to a ground line or the output line based on at least one control signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Multi-metal coplanar waveguide

InactiveUS20070241844A1Reduce decreaseImprove performanceMultiple-port networksSemiconductor/solid-state device manufacturingCMOSCoplanar waveguide

A coplanar waveguide CPW using multi-layer interconnection CMOS technology is provided. In the CPW including an interlayer insulator disposed on a substrate, metal multilayers disposed on the interlayer insulator, and a ground line-a signal line-a ground line formed of an uppermost metal layer, when a ground line of a lowermost layer is connected to the ground line of the uppermost layer, intermediate metal layers are designed to gradually increase or decrease in width, or to be uneven so as to maximize an area where an ultra-high frequency spreads, thereby minimizing CPW loss and maximizing a slow wave effect. As a result, it is possible to improve performance of an ultra-high frequency circuit and miniaturize the circuit.

Owner:ELECTRONICS & TELECOMM RES INST

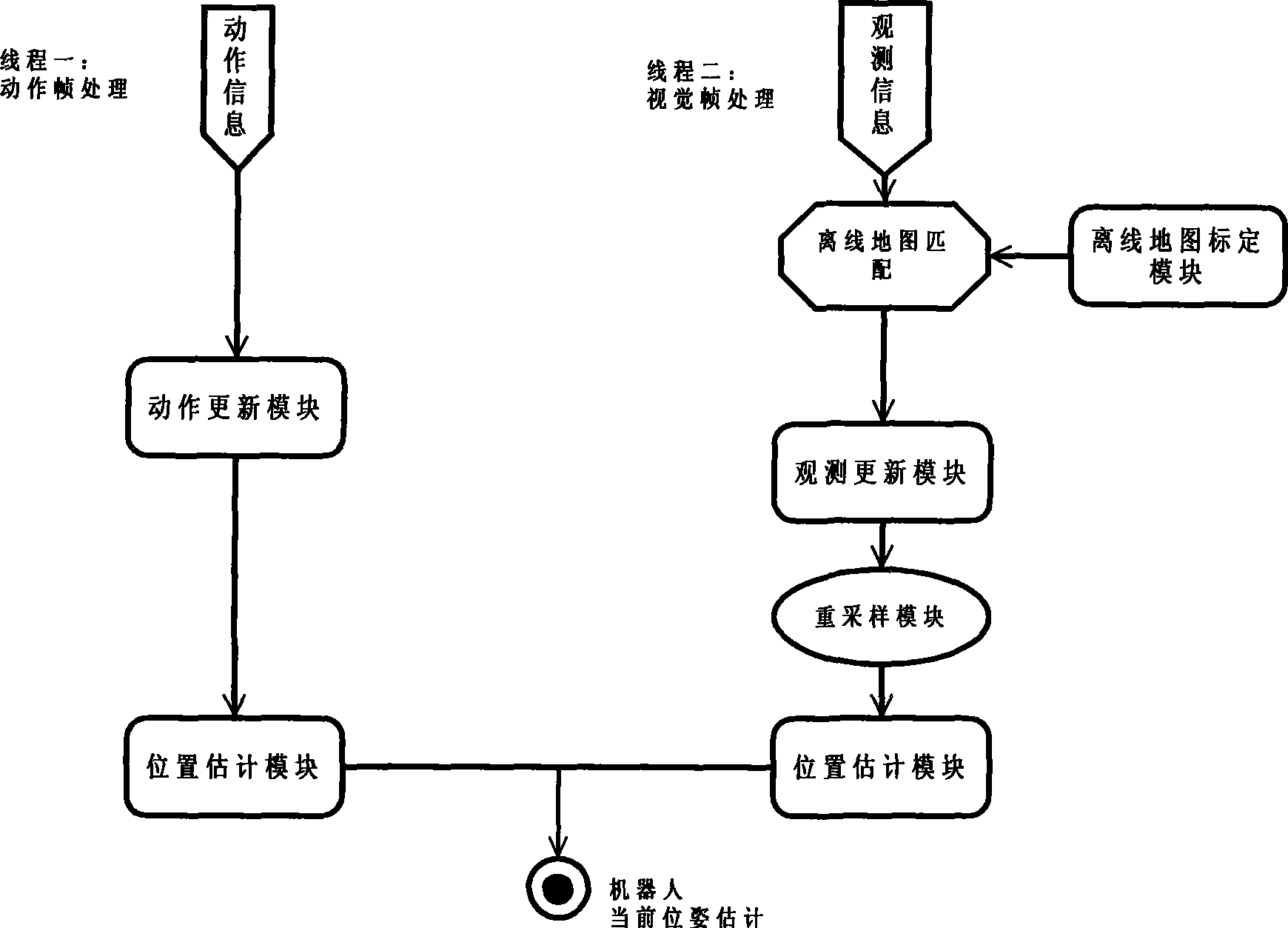

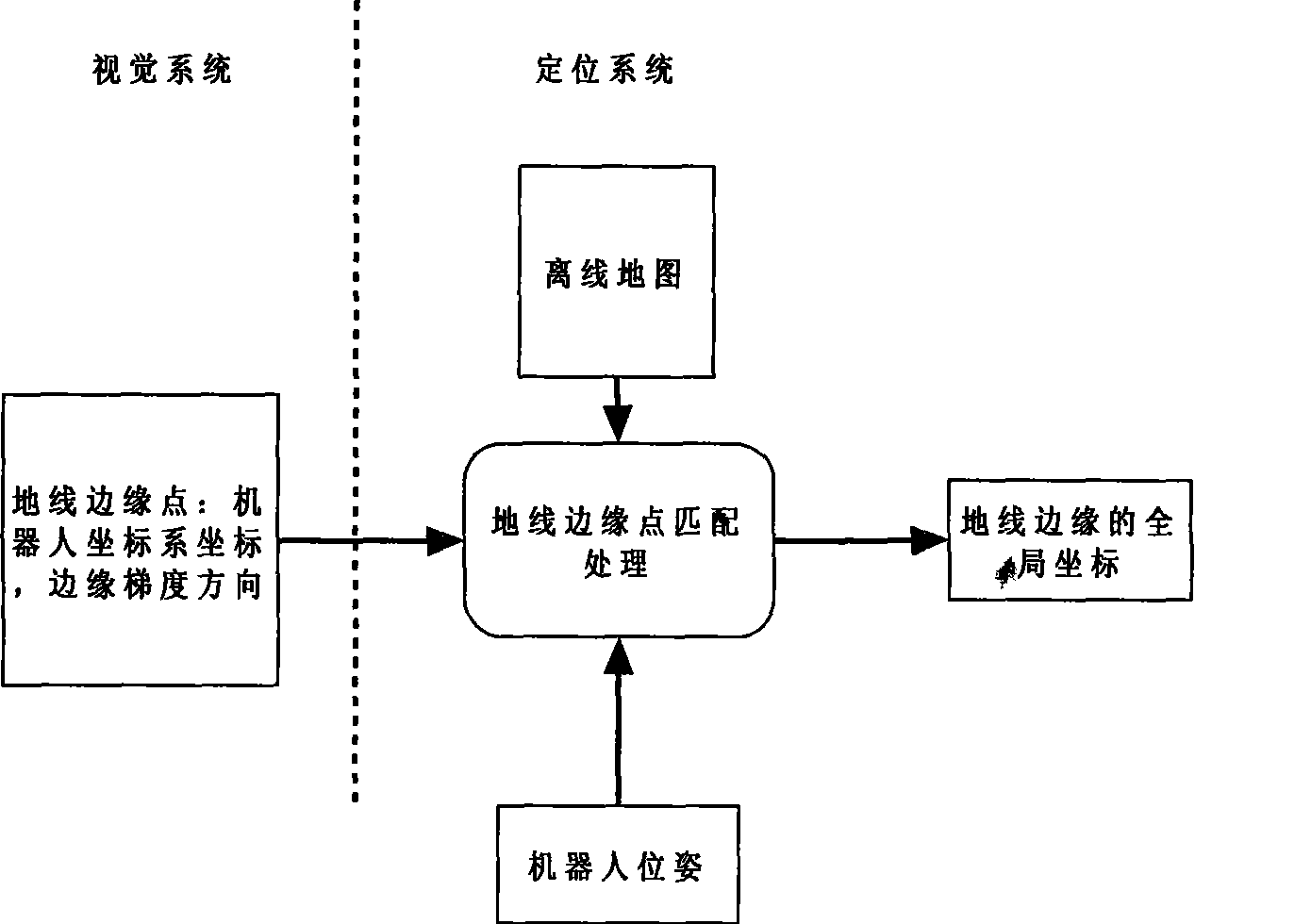

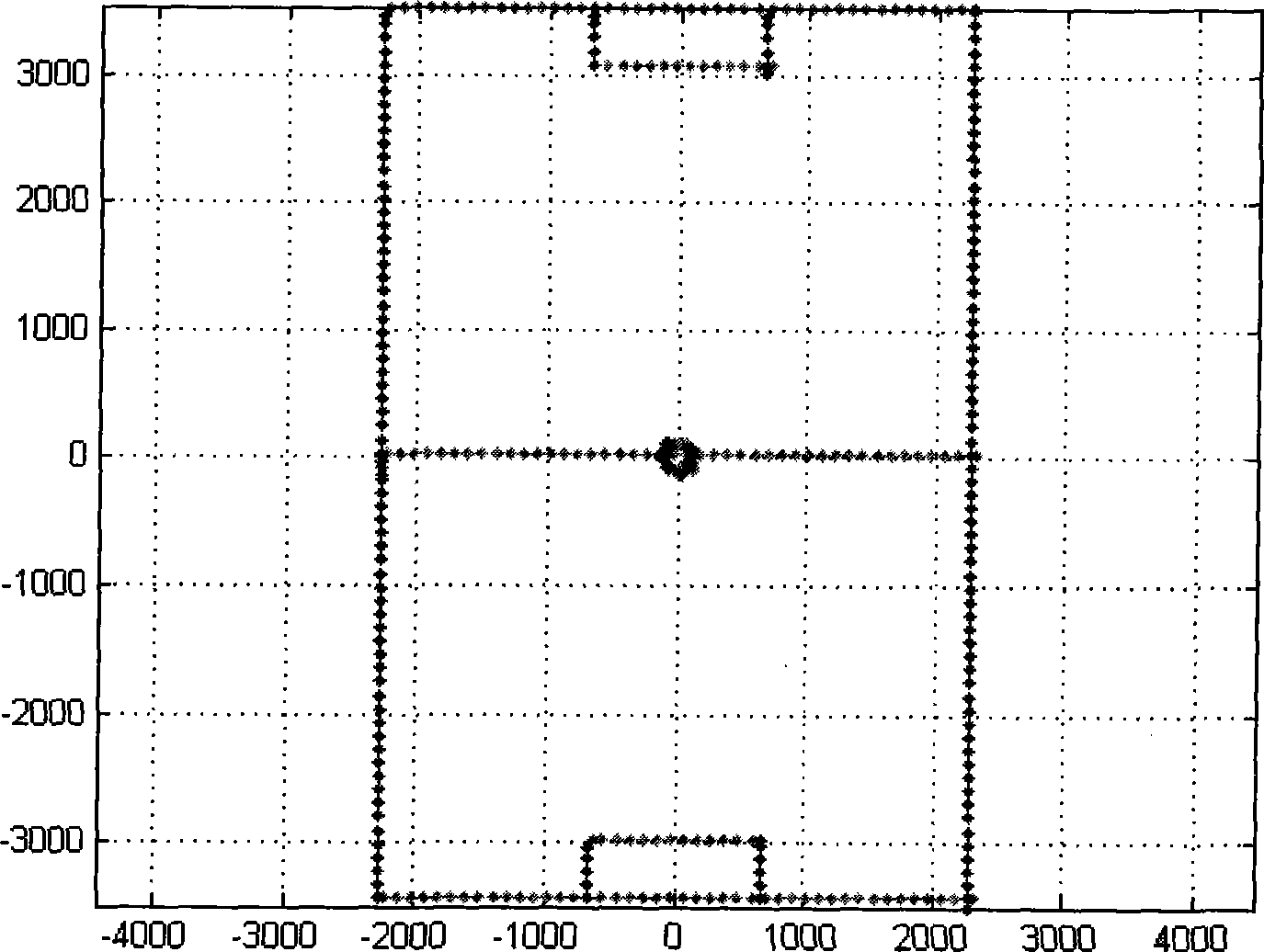

Walking robot positioning system based on monocular cam

ActiveCN101509781ASmall amount of calculationImprove real-time positioningInstruments for road network navigationNavigational calculation instrumentsParticle densityEngineering

The invention discloses a travelling robot positioning system based on a single camera. In the system, a point model is adopted for representing an environmental model, an off-line map is calibrated, an action model and an observation model are established for carrying out position updating and road sign calibration, Monte Carto particle filter technology is adopted, particle swarm distribution with weights is adopted for representing robot pose estimation, the weights and the distribution of particles are updated through road sign matching processing, field particle distribution is rasterized, and a sub-region with maximal particle density is selected for positioning the robot. As an independent platform, the system greatly improves the map calibration technology on the environmental model, has great flexibility on the identification of ground line sections, and just needs re-calibration but not needs model re-establishment after environment change. The model reduces the matching complexity in visual processing and improves calculation efficiency. The Monte Carlo localization algorithm is expanded on the information integration processing technology, thus ensuring the real-time property and robustness of the system.

Owner:TONGJI UNIV

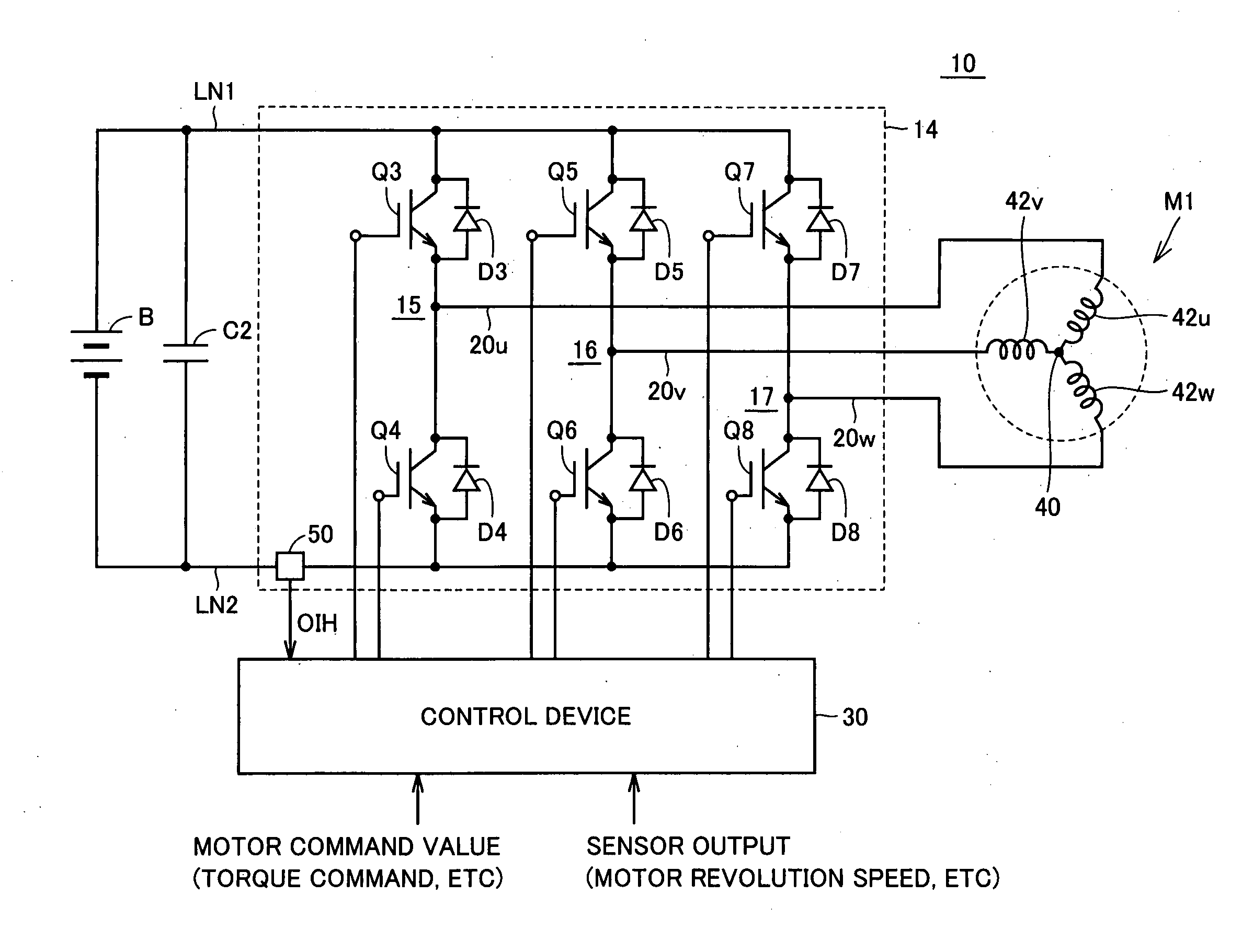

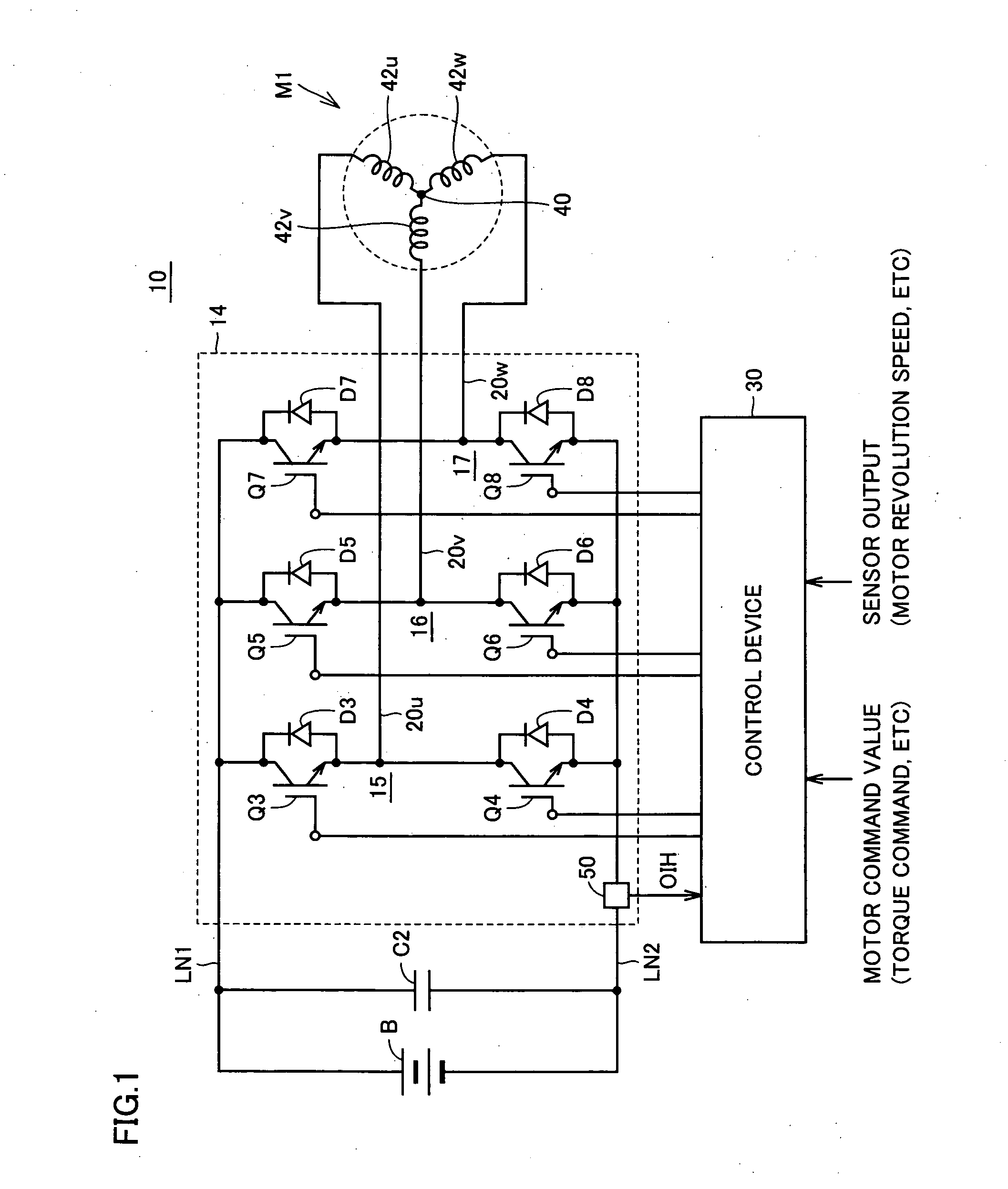

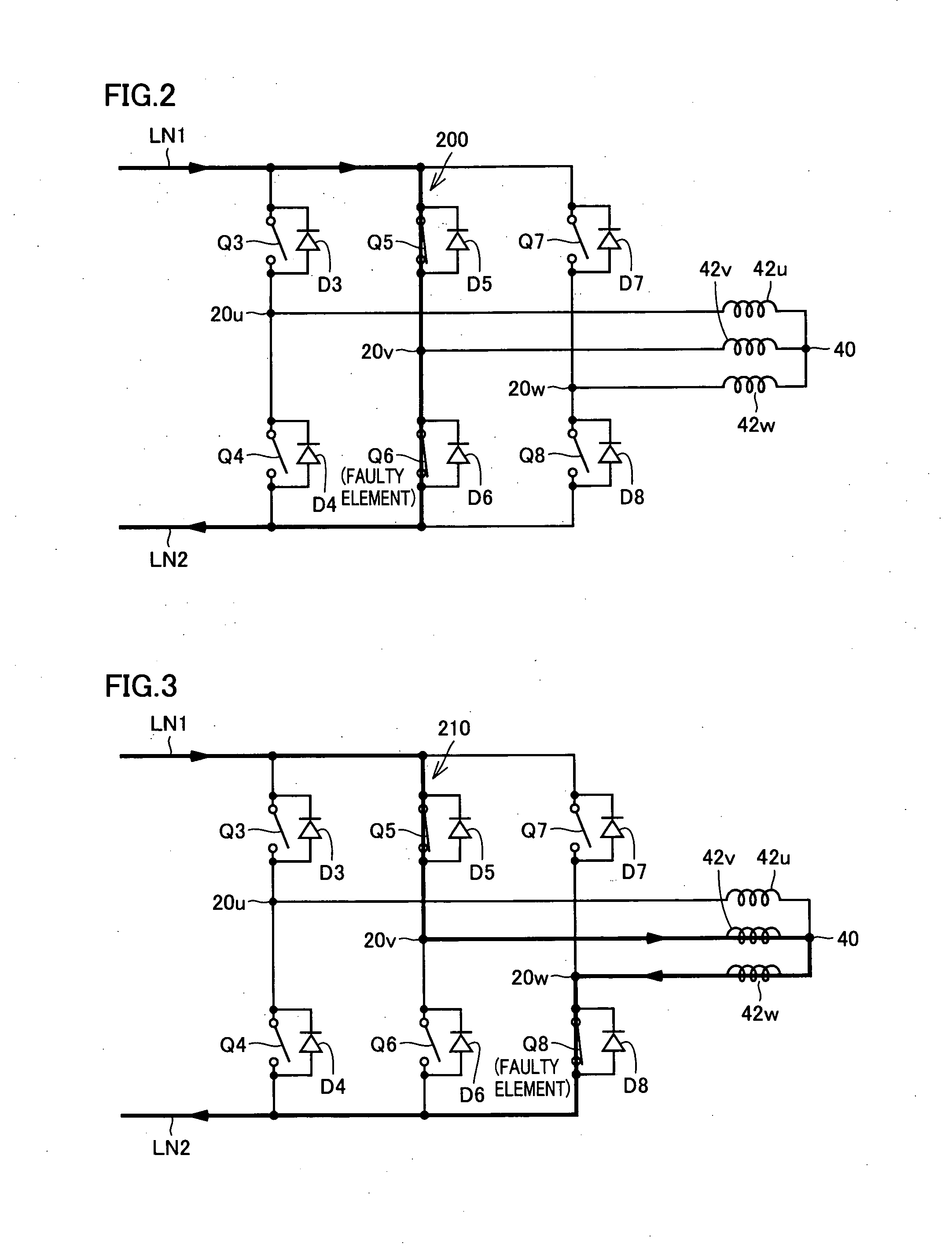

Abnormality detecting device of electric power converting device and abnormality detecting method

ActiveUS20090009920A1Accurately determineDC motor speed/torque controlAsynchronous induction motorsOvercurrentInverter

Each of three-phase arm of an inverter has first and second switching elements connected in series together at a connection point to the corresponding phase coil of the three-phase motor. Control device turns on the first switching element of the i-th (i is a natural number smaller than four) for a predetermined time period, and determines that the second switching element of the i-th arm has a short fault, when an overcurrent exceeding a predetermined threshold is detected within the predetermined time period. The predetermined time period is shorter than a time period from a time point of turning on the first switching element of the i-th arm to a time point of attaining the predetermined threshold by a current flowing through a path extending from a power supply line through the second switching element of the remaining arm other than the i-th arm to a ground line.

Owner:DENSO CORP

Grounding structure of an electrical connector

InactiveUS7052292B2Best electrical characteristicEasy to connect partsCoupling protective earth/shielding arrangementsConnection contact member materialElectricityEngineering

The present invention relates to a grounding structure of an electrical connector suitable for high frequency transmitting. The high frequency connector mainly has a connecting part being combined with a plurality of grounding lines to improve the electrical characteristics of the high frequency connector when it transmits a signal. Wherein, the connecting part further comprises a wing portion and a protrusion portion; thereby the connecting part can engage the grounding terminals with the grounding line of the cable to form electrical contact. Furthermore, one end of the connecting part is extended directly and comprises predetermined grounding terminals, such that the grounding line can be directly connected to connecting part; such as, the electrical connector can have better electrical characteristics and the grounding line can directly be coupled to the grounding terminals without the soldering process by using aforesaid structure meanwhile, the entire assembly process and the relative cost can be lessened.

Owner:ING SHANG LUN

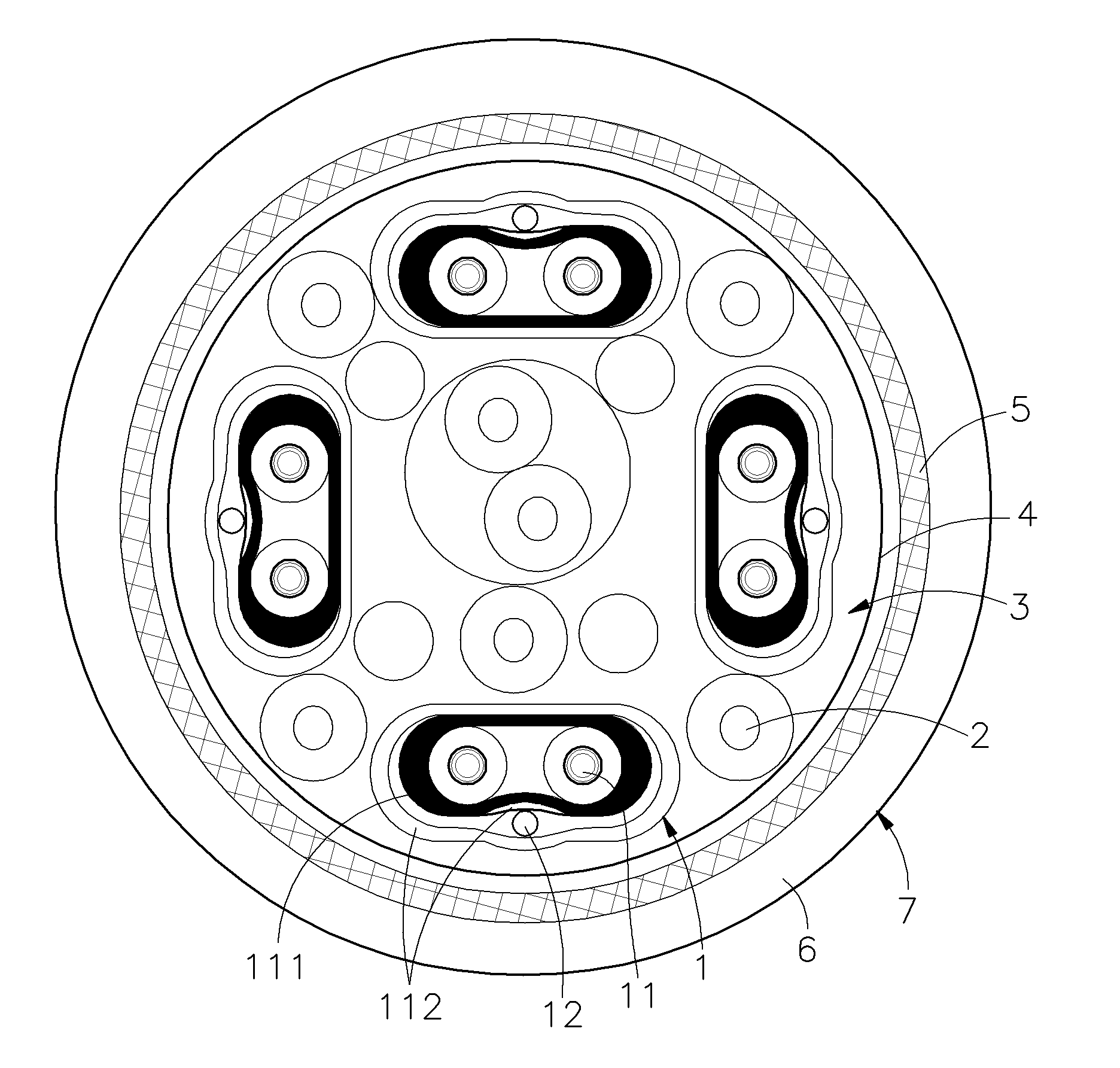

Digital audio video cable

InactiveUS20100084157A1High tensile strengthFlexible mechanical propertyPower cables with screens/conductive layersInsulated cablesCapacitanceInsulation layer

A low-capacitance, interference-free, stretch-prevention and high tensile strength digital audio video cable practical for a long-distance application is disclosed to include an electrical strand formed of multiple high-frequency transmission lines and low-frequency transmission wires and a filler, a tin foil layer surrounding the electrical strand, a braided layer surrounding the tin foil layer, and an outer plastic sheath surrounding the braided layer. Each high-frequency transmission line includes multiple high-frequency transmission wires that are equal in length and arranged in parallel, an insulation layer surrounding the high-frequency transmission wires, two shielding layers surrounding the insulation layer, and a grounding wire set in between the two shielding layers in a middle position relative to the high-frequency transmission wires.

Owner:SURE FIRE ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com