Patents

Literature

824results about How to "Reduce welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

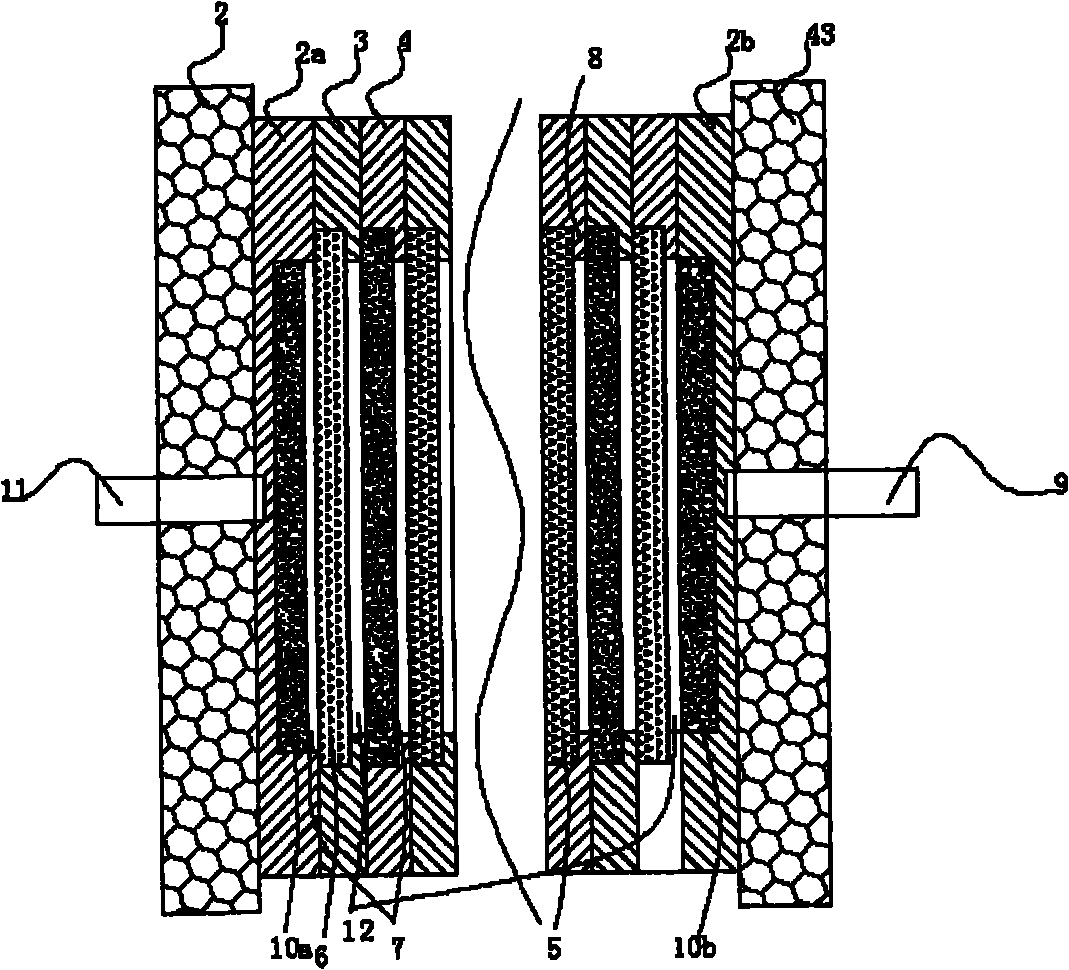

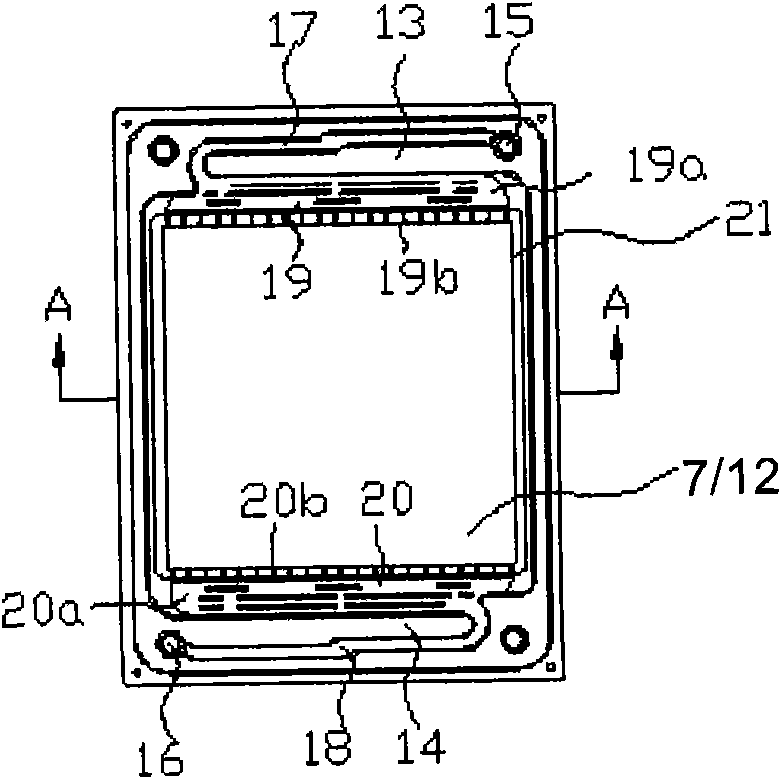

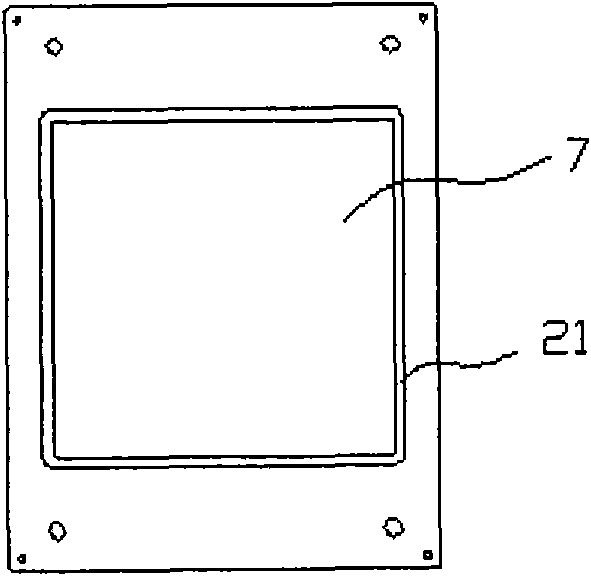

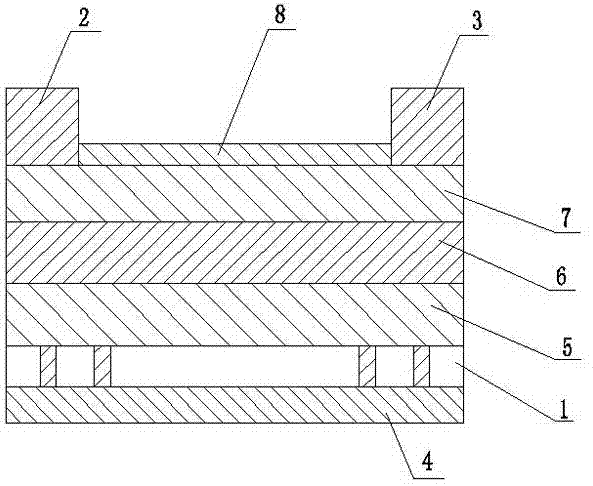

Laser welding method and device for battery component with bipolar structure

InactiveCN102136609AHigh bonding strengthImprove uniformityFinal product manufactureSecondary cellsEngineeringLaser source

The invention relates to a method for welding an insulated frame body and a bipolar plate / a microporous diaphragm of a battery with a bipolar structure by laser, wherein a laser from a laser source is focused on an opaque plate surface of the bipolar plate or the microporous diaphragm through the semitransparent frame body so as to melt an upper and a lower plastic plates of an irradiated part and thus to allow the two plates to be melted together under the effect of pressure. The method of the present invention improves the welding efficiency and greatly reduces reject rate. Besides, the method of the invention has the advantages of labor force saving and cost saving. The present invention also relates to a device of for welding the insulated frame body and the bipolar plate / the microporous diaphragm of the battery with a bipolar structure by laser.

Owner:CHANGCHUN NETPOWER TECH

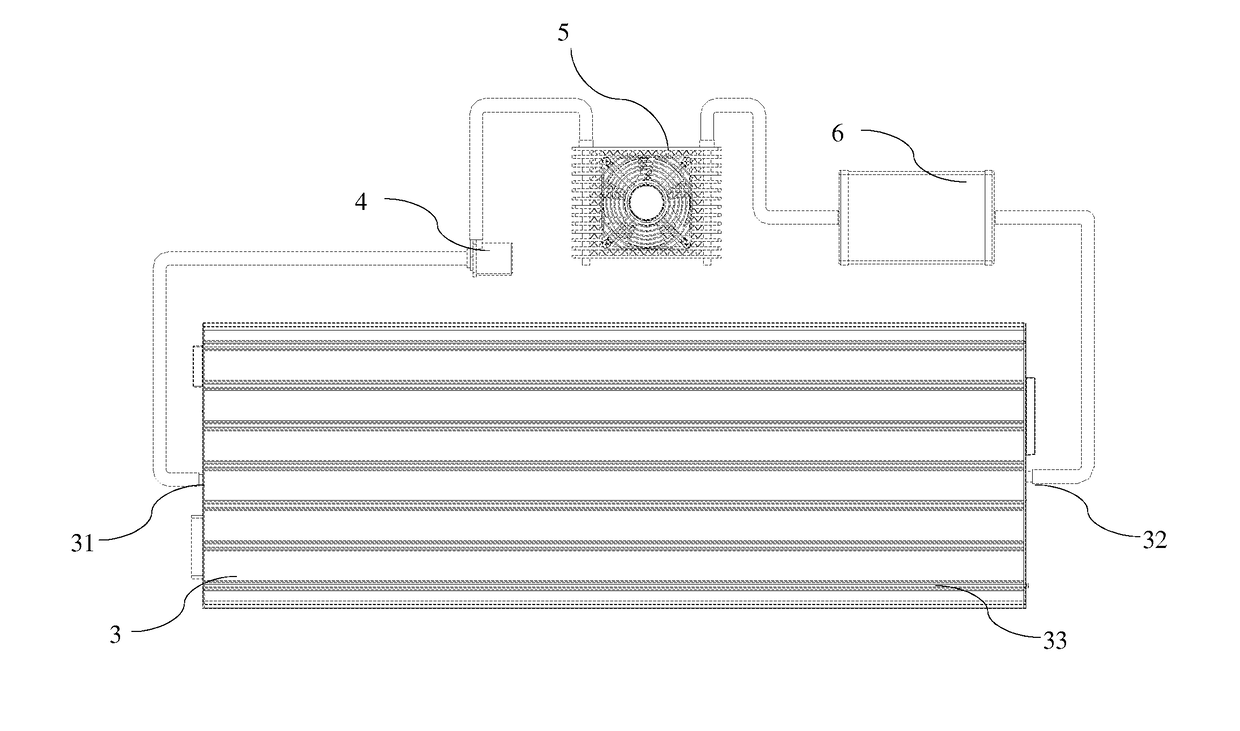

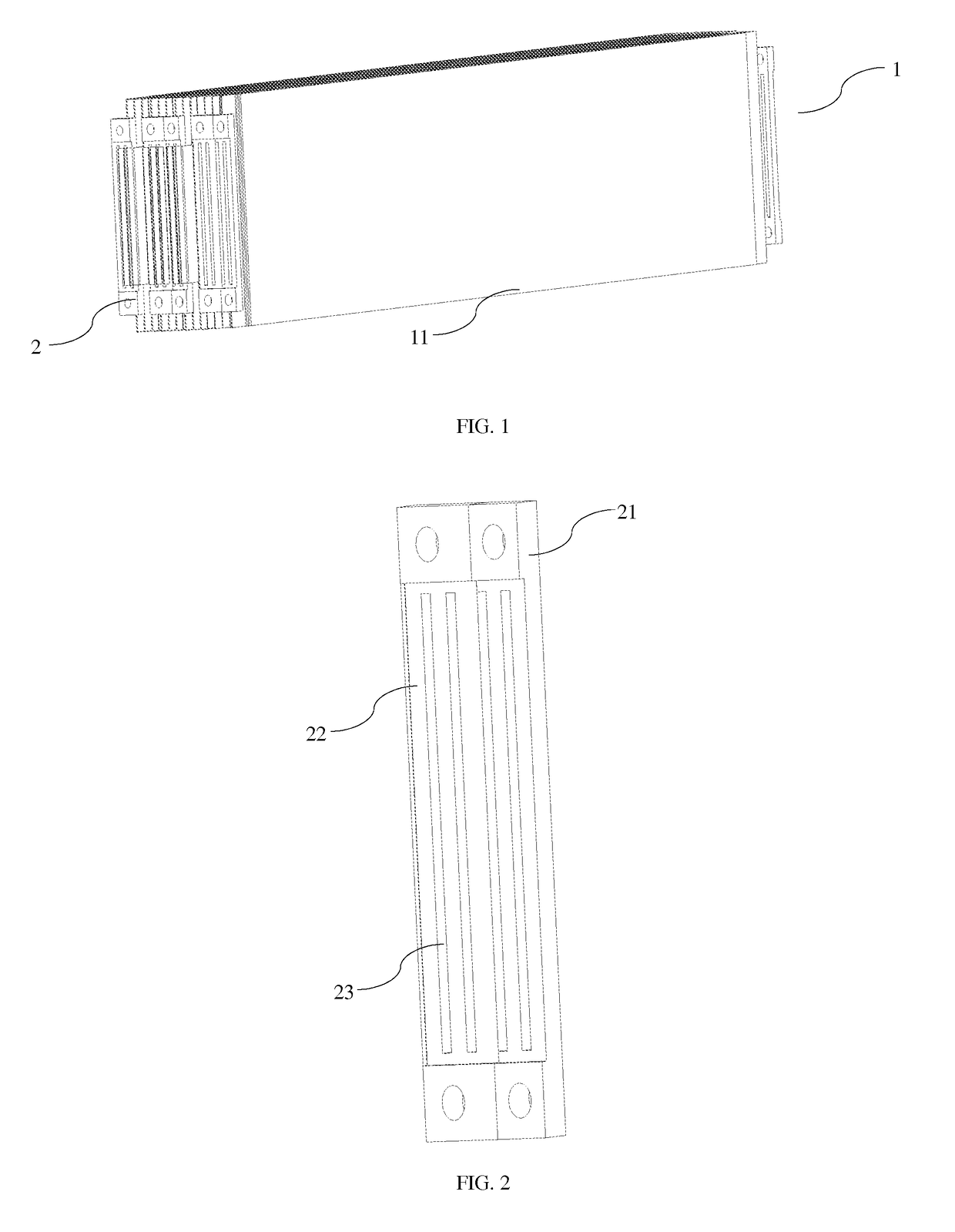

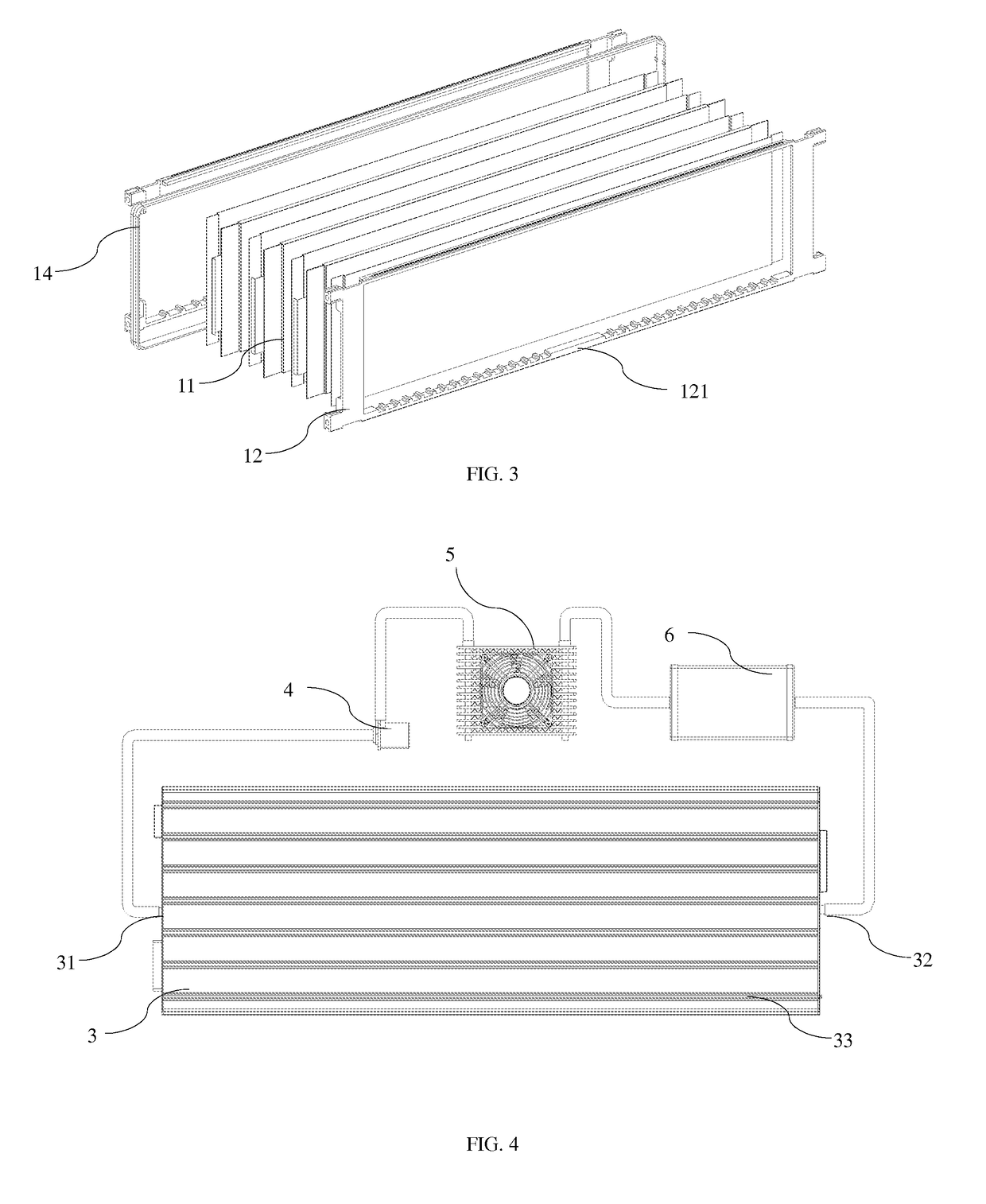

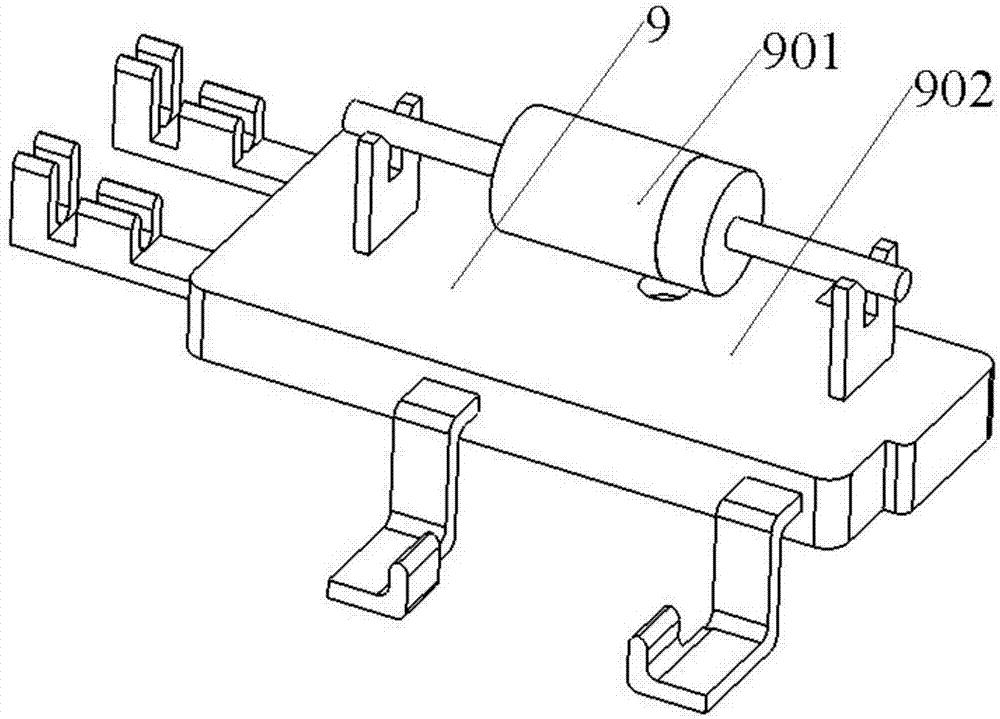

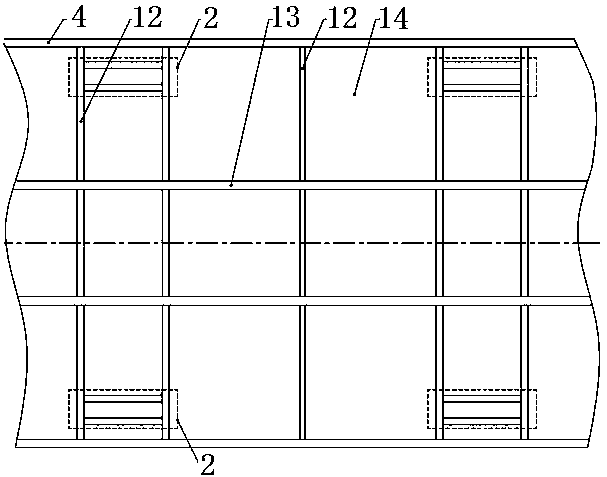

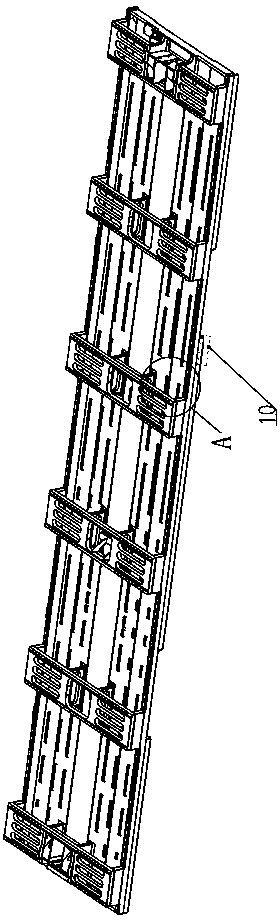

Liquid-cooled battery pack system

ActiveUS20170162923A1Improve securityIncrease energy densitySecondary cellsCell component detailsEngineeringDesoldering

The present invention provides a battery module and a liquid-cooled battery system that uses it, a battery cell and a current collector sheet, on the premise that the materials like the electrode and separator and so on are completely the same, energy density of the battery pack is greatly increased; the cell and the current collector sheet are fully welded connections, the joints are fewer and it is not prone to produce desoldering, also ensuring the stability of the of the cell tab and high current carrying capacity, and when putting the parallel battery module in series, the use of wires are avoided, thus reduces the volume of the battery pack; the innovative design for the liquid-cooled battery pack system, improves the thermal balance between the cells, and the heat-dissipation in battery pack distributes more evenly, the insulation property of the battery package is highly improved, controlling the heat-dissipation capacity of the system by adjusting the flow rate of the circulating pump, not only the unnecessary energy consumption can be avoided, but also have a better impact resistance.

Owner:MICROVAST

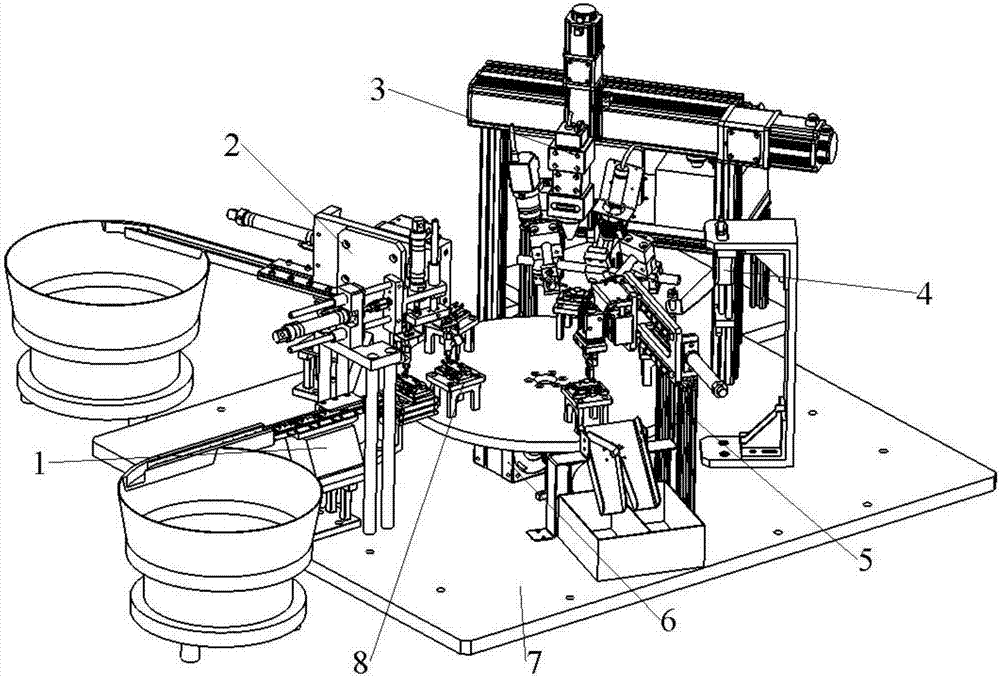

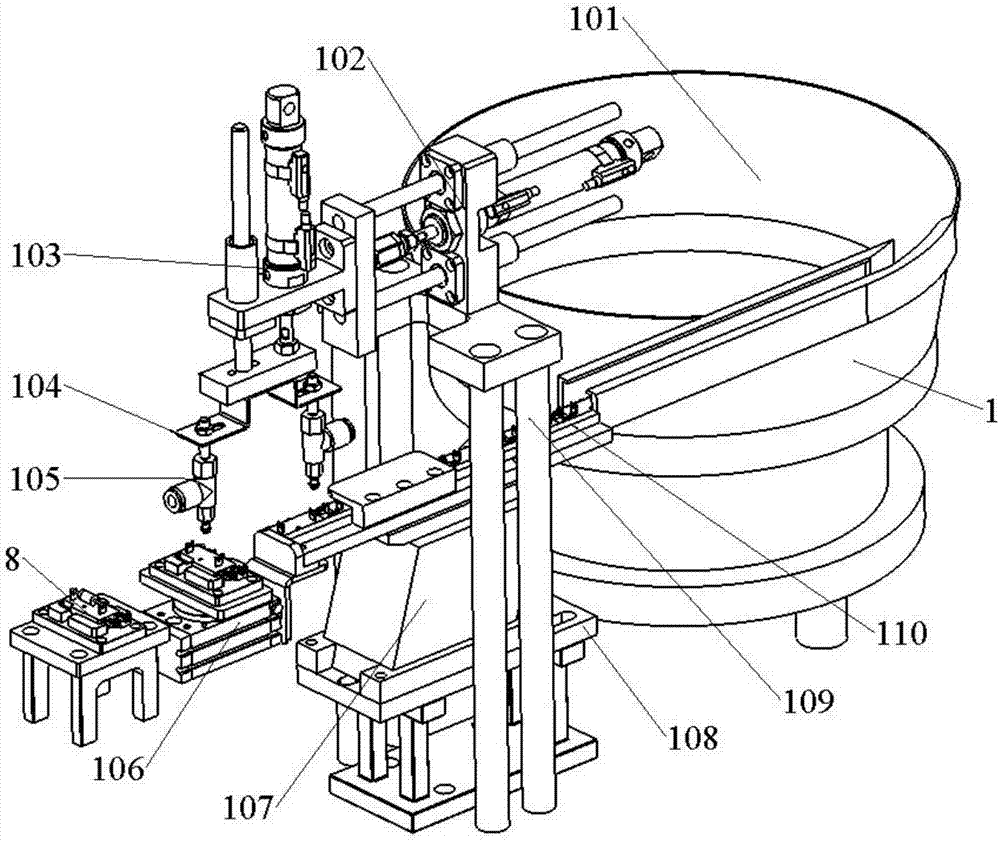

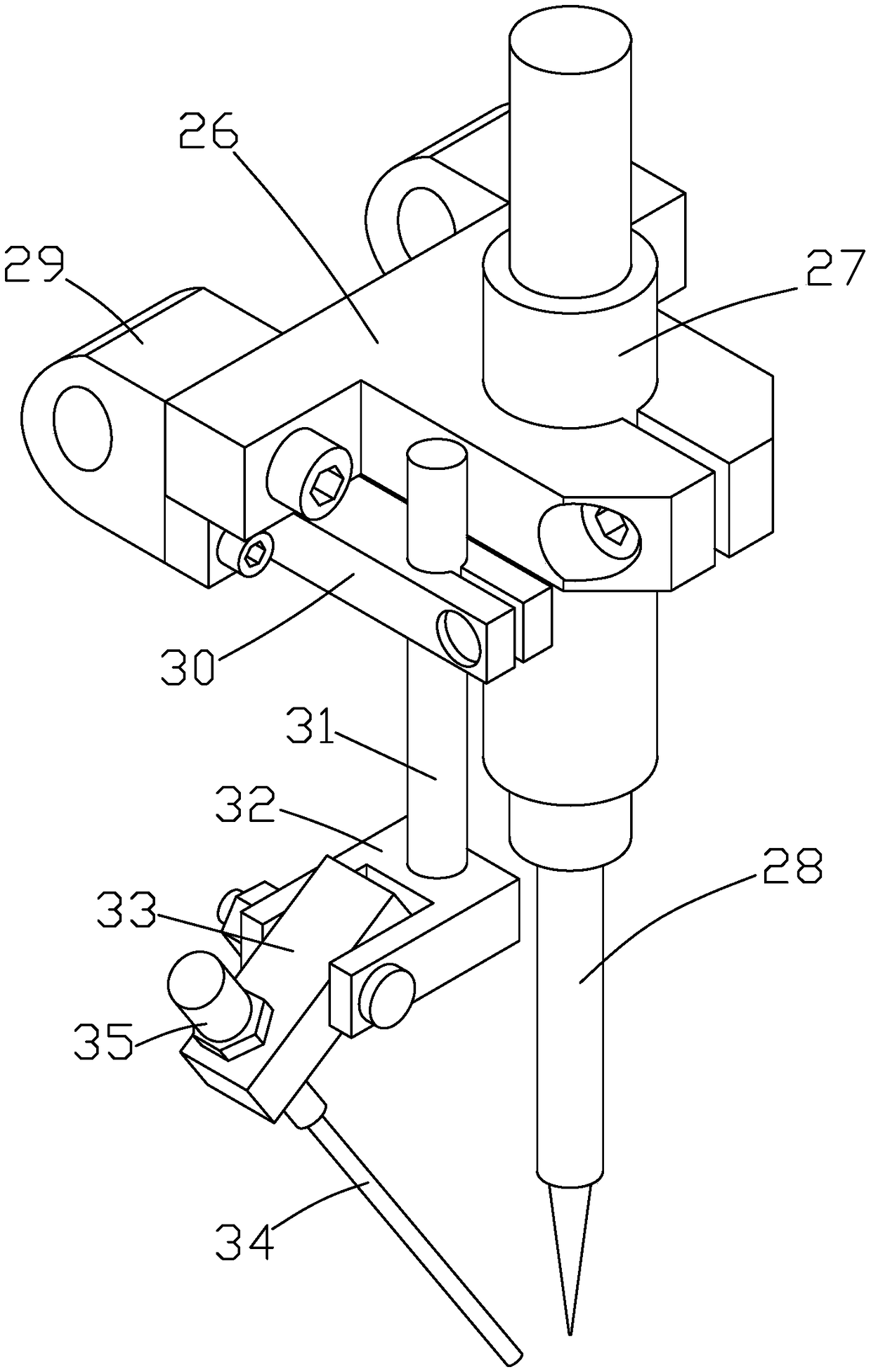

Laser tin welding method and device for rectifier diode assembly parts

ActiveCN107309517AImprove the accuracy of laser processingAccurate solder jointsWelding/cutting auxillary devicesAuxillary welding devicesLiquid stateRectifier diodes

The invention provides a laser tin welding method for a rectifier diode assembly parts. The method comprises the steps of adopting a laser beam under a positive defocus status for pre-heating an area to be welded; utilizing an automatic wire feeding assembly for feeding a tin wire to a position right above the area to be welded, wherein the laser beam is acted on the tin wire through a negative defocus manner so as to quickly heat and melt the tin wire, and a melted liquid-state tin material drips on a contact surface between a rectifier diode tinning axial lead and a base pin; utilizing an ultrasonic vibrator for vibrating with fixed frequency, continuously soaking the pin and the lead at the welded part through the tin material, and forming a laser tin welding joint after cooling; and adopting the same method for welding the right side. According to the welding method, the strength and the quality of the welding joint are improved. The invention further designs an automatic laser tin welding device, which can be used for implementing the following processes such as automatic feeding and discharging, automatic laser tin welding, product quality detecting, and quality goods and inferior-quality product sorting, so that the automatic diode packaging with high efficiency, high accuracy and high quality can be realized.

Owner:XIAN KING BROTHER CIRCUIT TECH

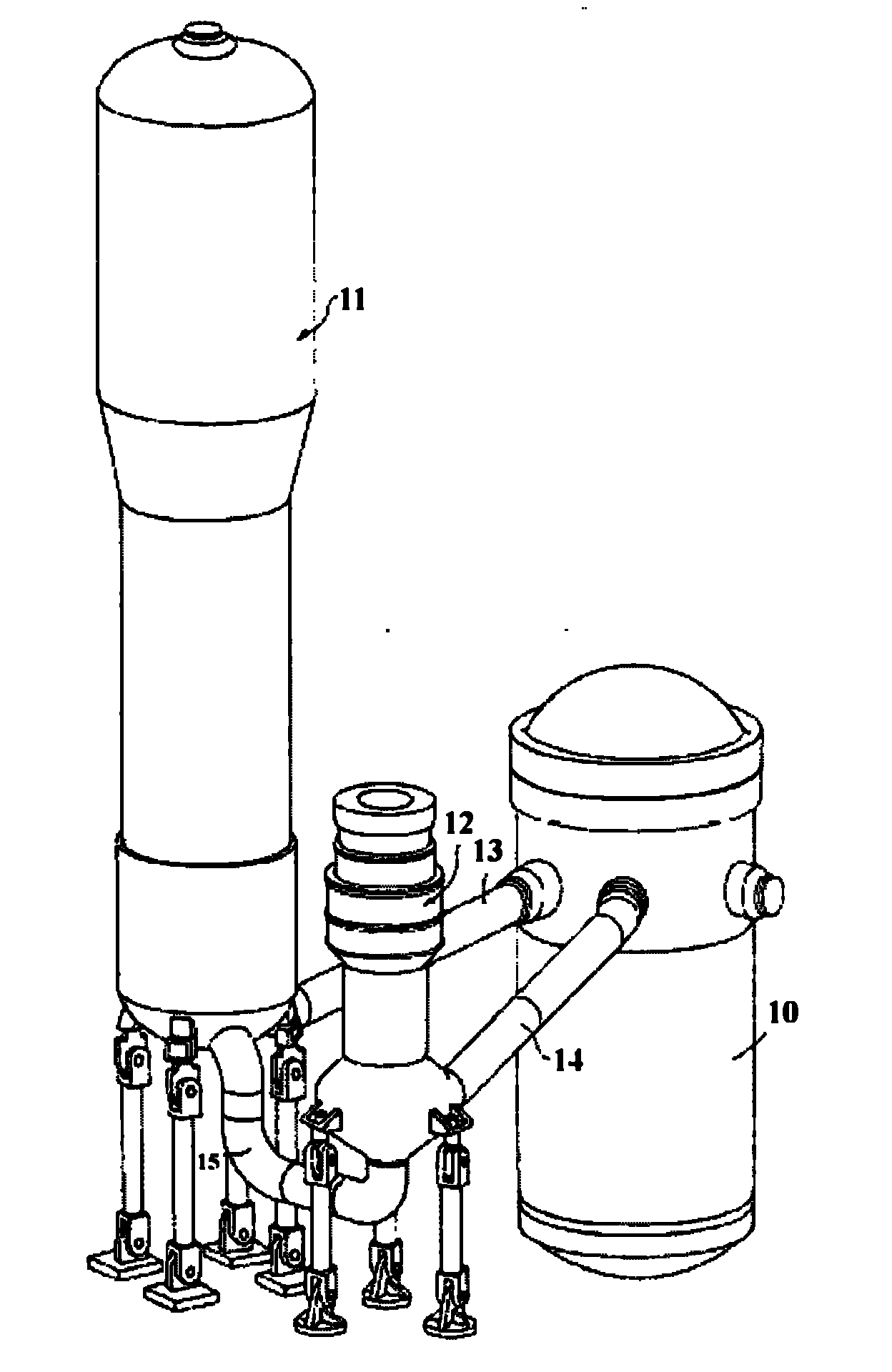

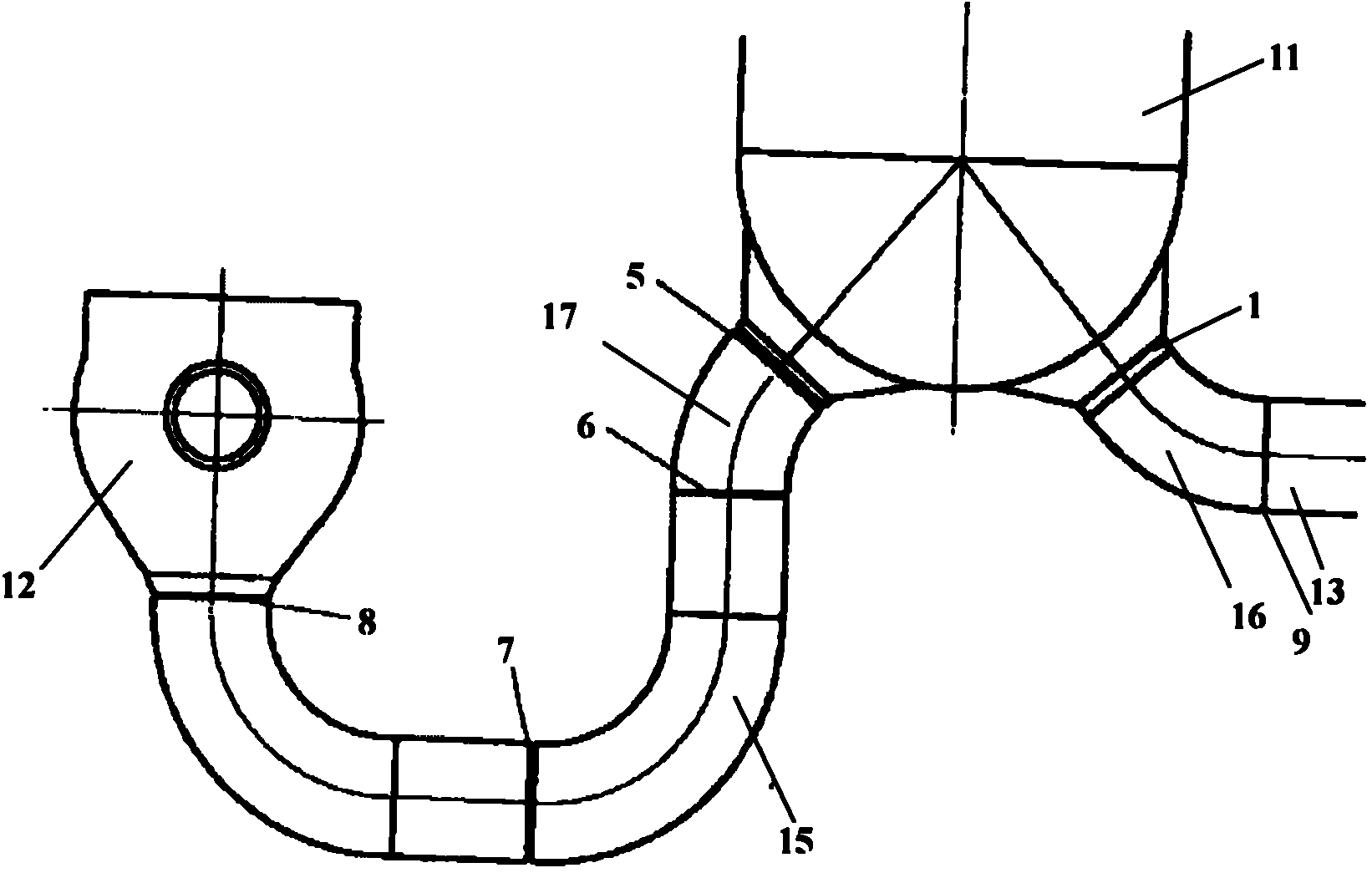

Method for mounting main pipeline and main loop of pressurized water reactor nuclear power station steam generator

ActiveCN101839467AAvoid inconvenienceEasy to controlNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention discloses a method for mounting a main return loop of a nuclear power station pressurized water reactor coolant system, which is characterized in that: a main pipeline heat section bend (16) and a main pipeline transition section bend (17) are welded at a loop nozzle of a lower seal end of the used steam generator (1); during mounting, a welding line (9) between a main pipeline heat section (13) and the main pipeline heat section bend (16) on the lower part of the steam generator (11) and a welding line (2) between the main pipeline heat section (13) and a reactor pressure container (10) can be assembled and welded simultaneously. In addition, the working amount for a welding line (5) is reduced during mounting. The mounting method can better control and guarantee the assembling and welding quality, improve the working efficiency, reduce the mounting time, and shorten the construction period.

Owner:CHINA NUCLEAR POWER ENG CO LTD

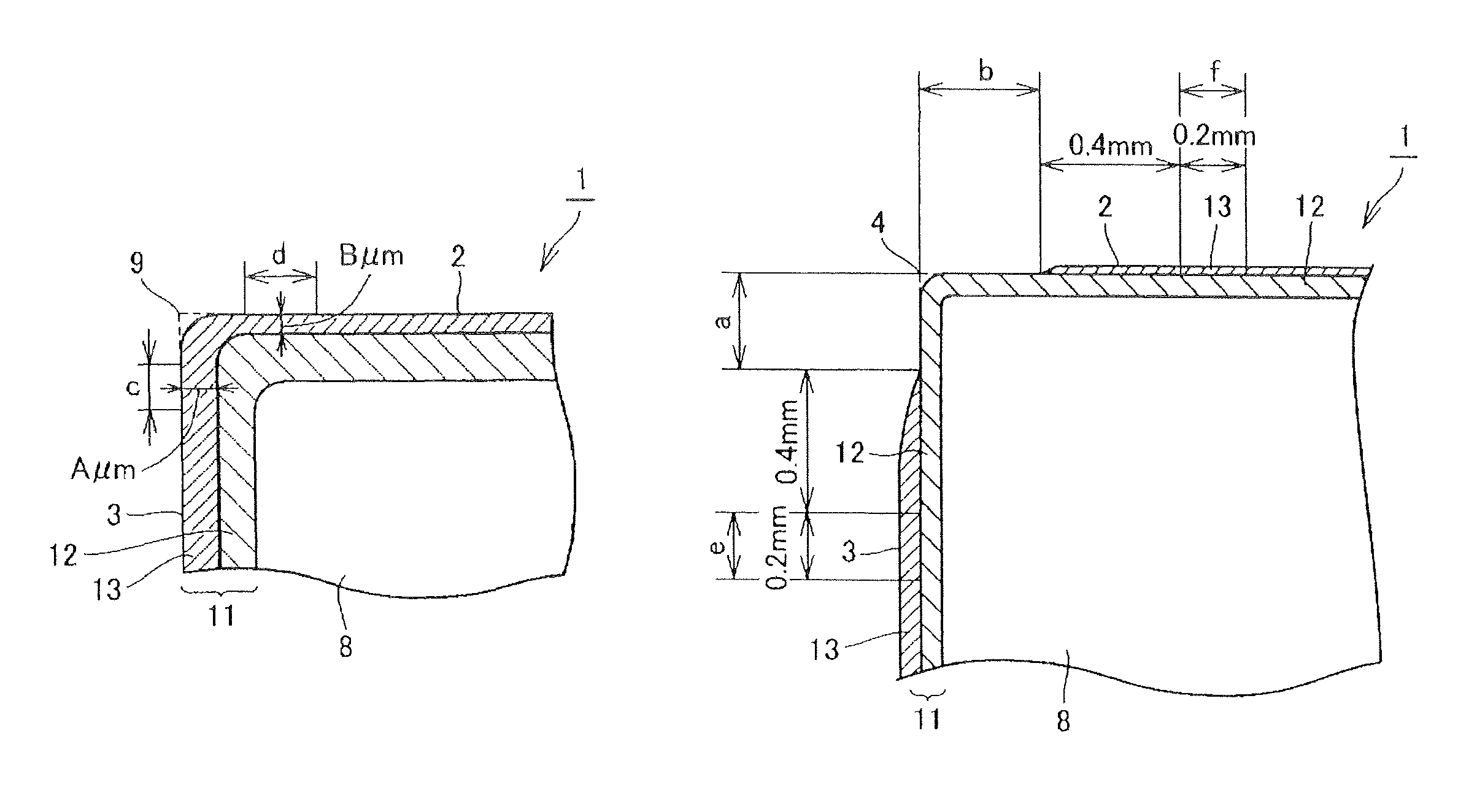

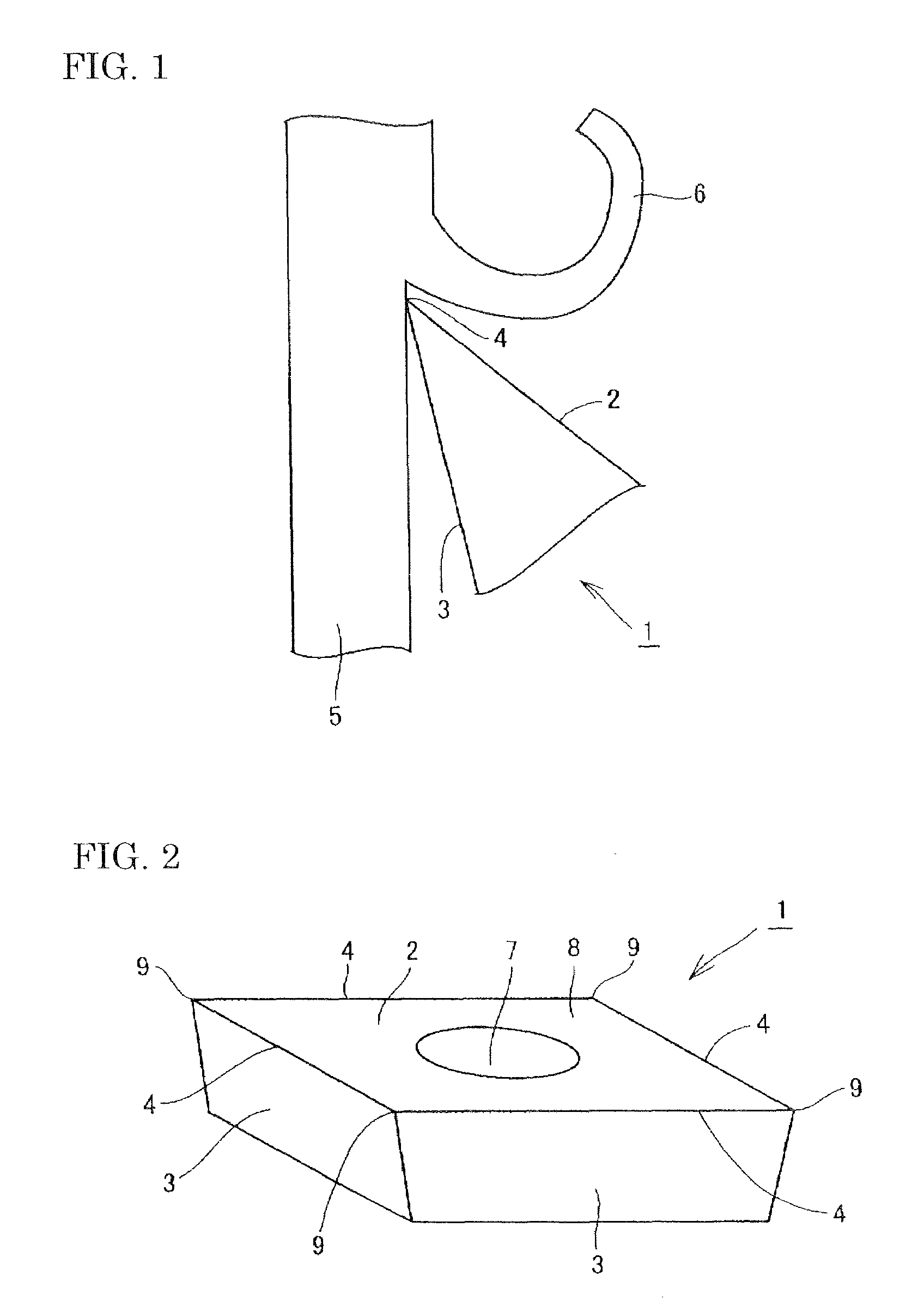

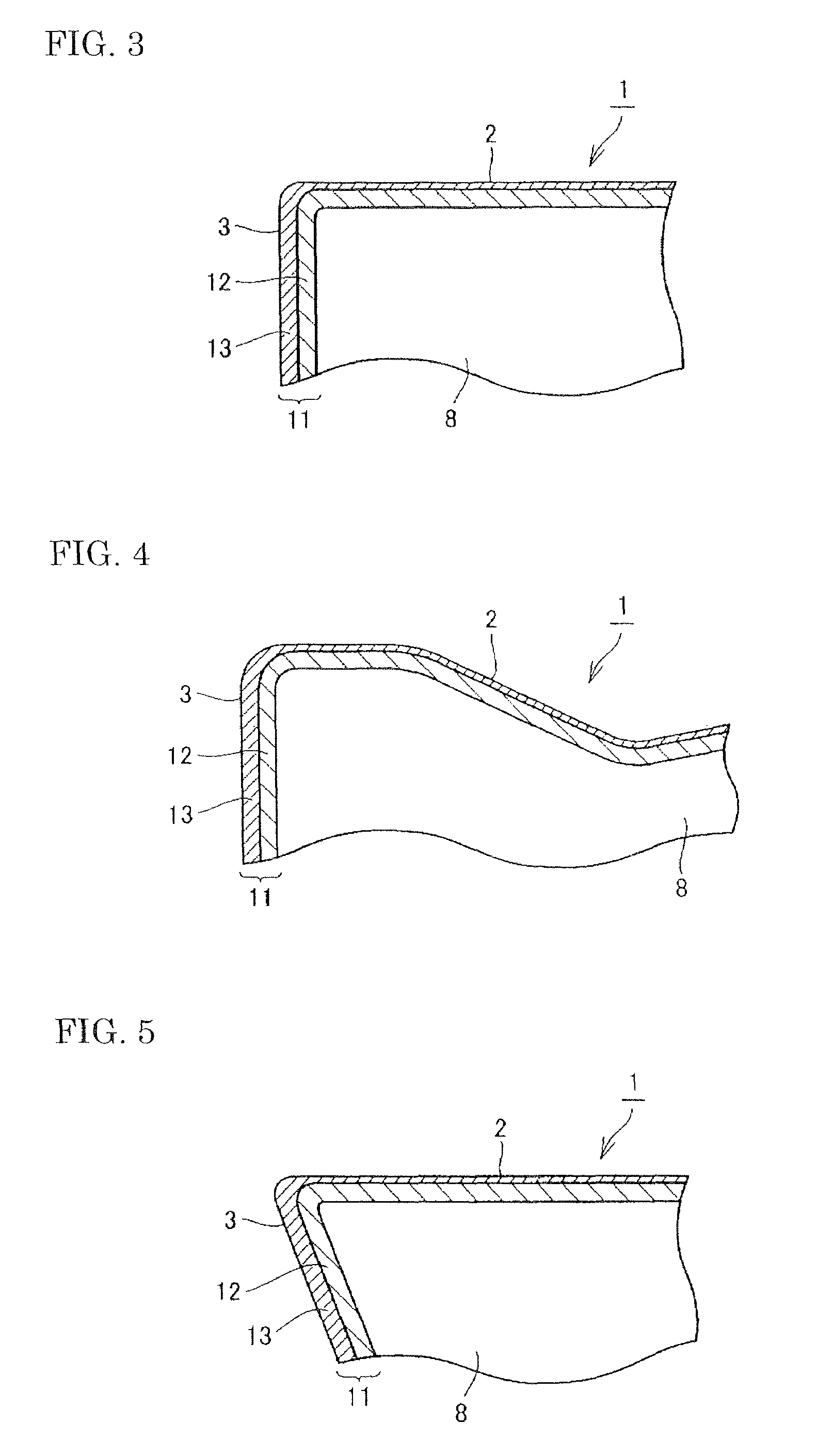

Indexable insert

ActiveUS7695222B2Inhibit deteriorationReduce weldingTransportation and packagingCutting insertsChemical compoundNitrogen

An indexable insert (1) of the present invention includes a substrate (8) and a coating layer which includes inner layer and an outer layer. The inner layer includes an alumina layer or an alumna-containing layer serving as an outermost layer in contact with the outer layer, and the outer layer is composed of at least one metal selected from the group consisting of the periodic table group IVa elements, Va elements, and VIa elements, Al, and Si or a compound of at least one of the metals and at least one element selected from the group consisting of carbon, nitrogen, oxygen, and boron. In addition, the outer layer, in a portion involved in cutting, satisfies B / A≦0.9 wherein A μm is the average thickness on the flank face (3) side, and B μm is the average thickness on the rake face (2) side.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

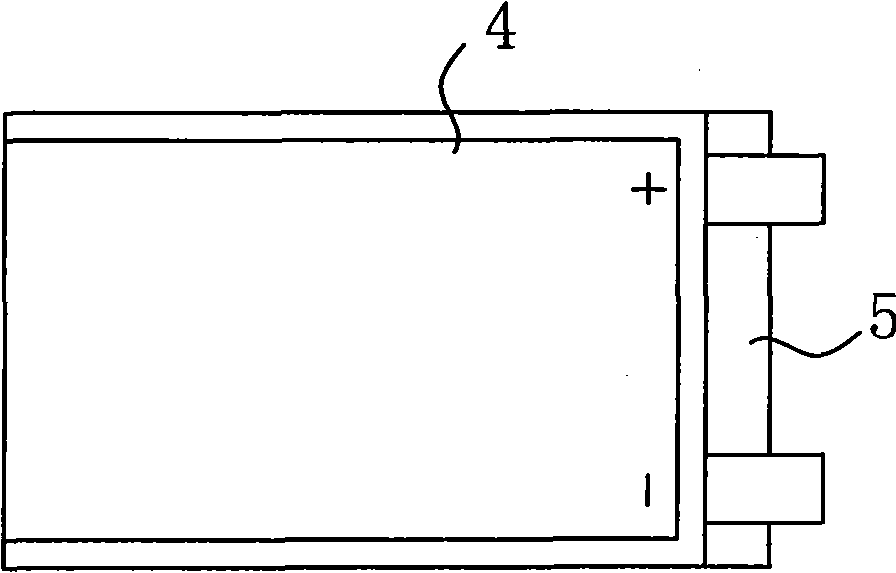

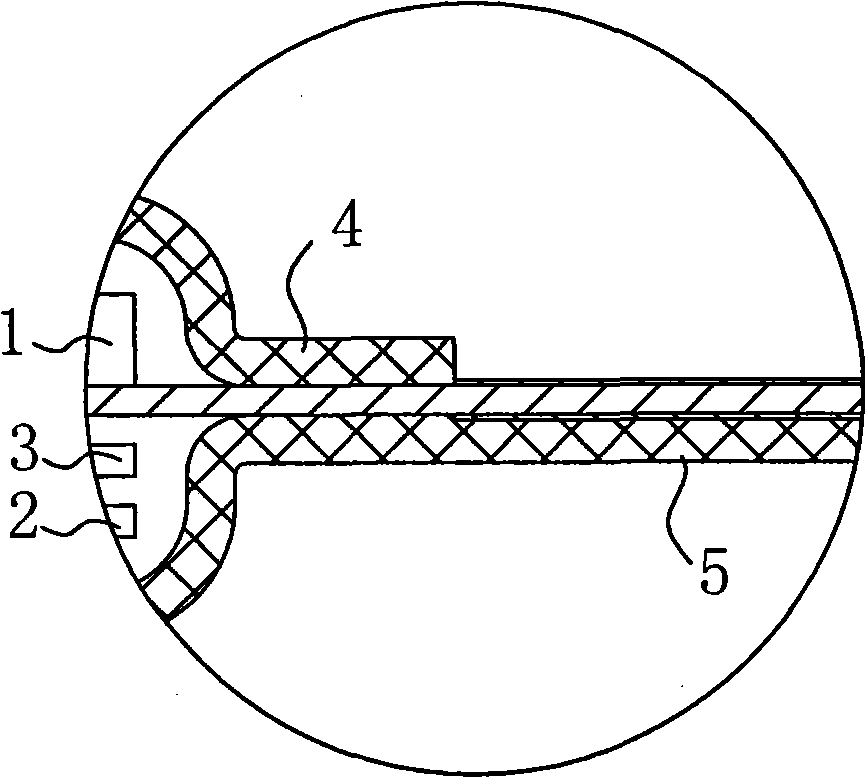

Ultrathin lithium-manganese polymer battery and processing method thereof

ActiveCN101867059AIncrease profitGood molding effectFinal product manufactureElectrode carriers/collectorsManganesePolypropylene

The invention discloses an ultrathin lithium-manganese polymer battery and a processing method thereof, belonging to the technology of lithium and manganese batteries. The technical scheme is that the ultrathin lithium-manganese polymer battery comprises an anode, a cathode, a diaphragm and an external packaging film. The anode consists of current collector aluminum foil, manganese dioxide, a conductive agent and a binder, the thickness of the anode is 0.03-0.2 mm, and the lead of the anode is formed in such a way that the extending part of the current collector aluminum foil outside the external packaging film is compounded with polypropylene or polyethylene. The cathode consists of a metal lithium sheet and a nickel strap or a copper strap or a steel strap, and the lead of the cathode is formed in such a way that the extending part of the nickel strap or the copper strap or the steel strap outside the external packaging film is compounded with polypropylene or polyethylene. The integral thickness of the battery is 0.3-0.5 mm. The processing method comprises the following steps of: (1) preparing the anode; (2) preparing the cathode; and (3) laminating and combining for molding. The invention solves the technical problem of great thickness of a traditional polymer battery, and has important significance for the generalization of various active identification cards.

Owner:深圳市超壹新能源科技有限公司

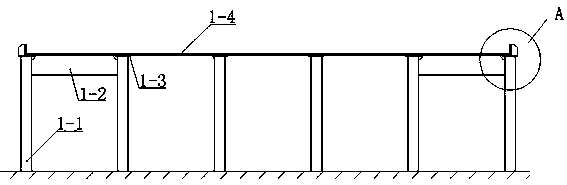

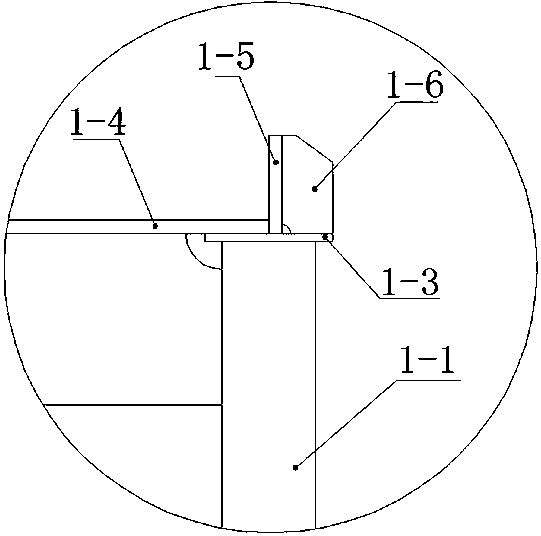

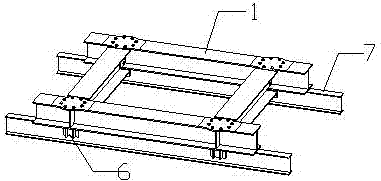

Chassis structure of vehicle body of magnetic levitation vehicle

ActiveCN103407454AImprove structural rigidityImprove sound insulationUnderframesAxle-box lubricationWeld seamUltimate tensile strength

The invention discloses a chassis structure of a vehicle body of a magnetic levitation vehicle. The chassis structure of the vehicle body of the magnetic levitation vehicle aims at solving the problems that the existing chassis structures of vehicle bodies of vehicles are large in welding amount, multiple in part and insufficient in strength. The chassis structure of the vehicle body of the magnetic levitation vehicle comprises a square-shaped chassis frame which is formed by two chassis end beams and two chassis side beams through fixed connection; the two chassis side beams are connected through a long floor; the front end and the rear end of the long floor are connected onto the two chassis end beams; the lower portion of the chassis frame is provided with a plurality of groups of sliding platform beams; two ends of every group of sliding platform beams are fixed on the corresponding chassis side beams; the lower surface of every group of sliding platform beams is provided with a guide groove; the connecting positions of the two chassis end beams and the long floor are provided with horizontal damper installing bases. According to the chassis structure of the vehicle body of the magnetic levitation vehicle, the structural stiffness is large, the accuracy of the flatness and straightness of the sliding platform beams is high, the sound insulation effect is good, welding seams are less, and the chassis equipment is convenient to suspend.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

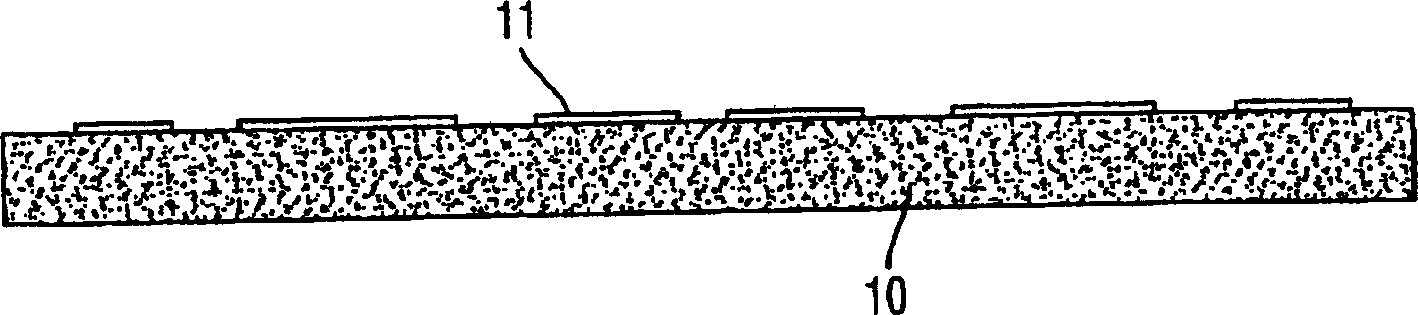

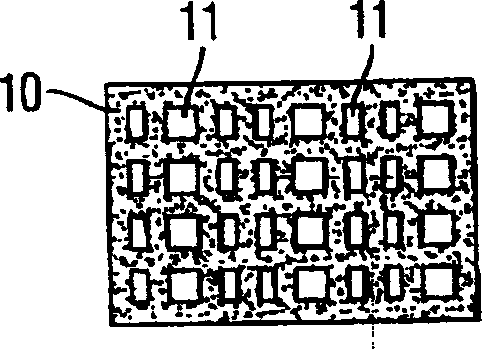

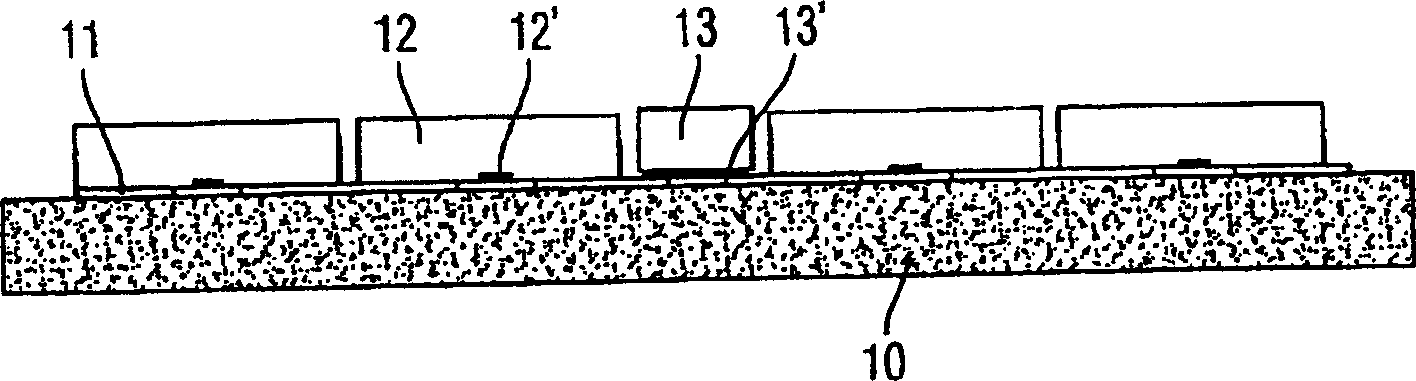

Semiconductor module and method for mfg. semiconductor module

InactiveCN1477688AReduce weldingImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductorEngineering

Production of a semiconductor module (31) comprises: (a) applying a structured connecting layer (11) on a supporting substrate; (b) applying active switching units (12) and / or passive switching units (13) with contact surfaces (12', 13') pointing to a transfer substrate on the structured connecting layer; (c) connecting the switching units with each other using a filler (14) between the units; (d) removing the transfer substrate; and (e) applying electrical connecting units (16) to selectively contact the contact surfaces of the switching units. An Independent claim is also included for a semiconductor module produced by the above process.

Owner:INFINEON TECH AG

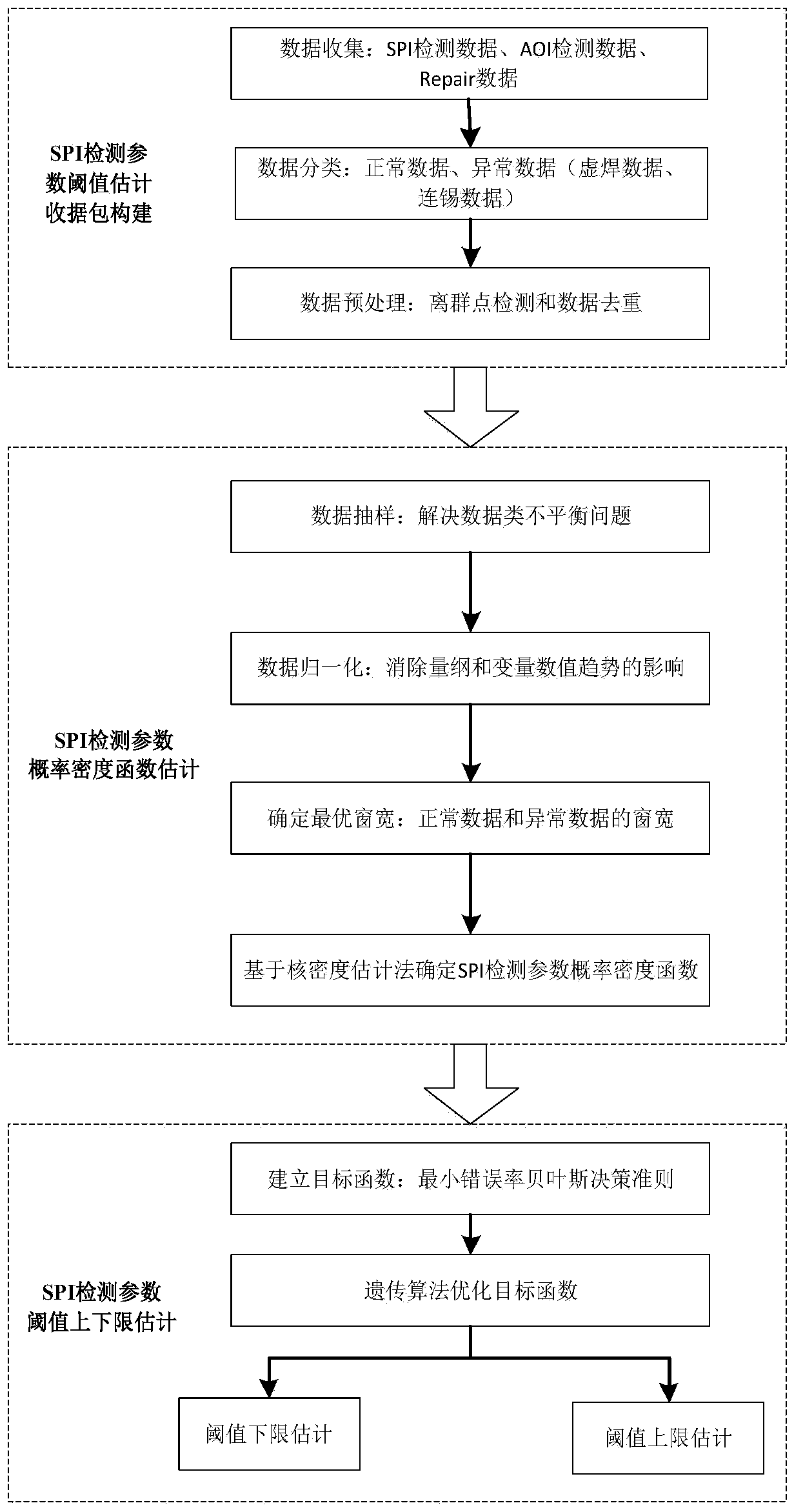

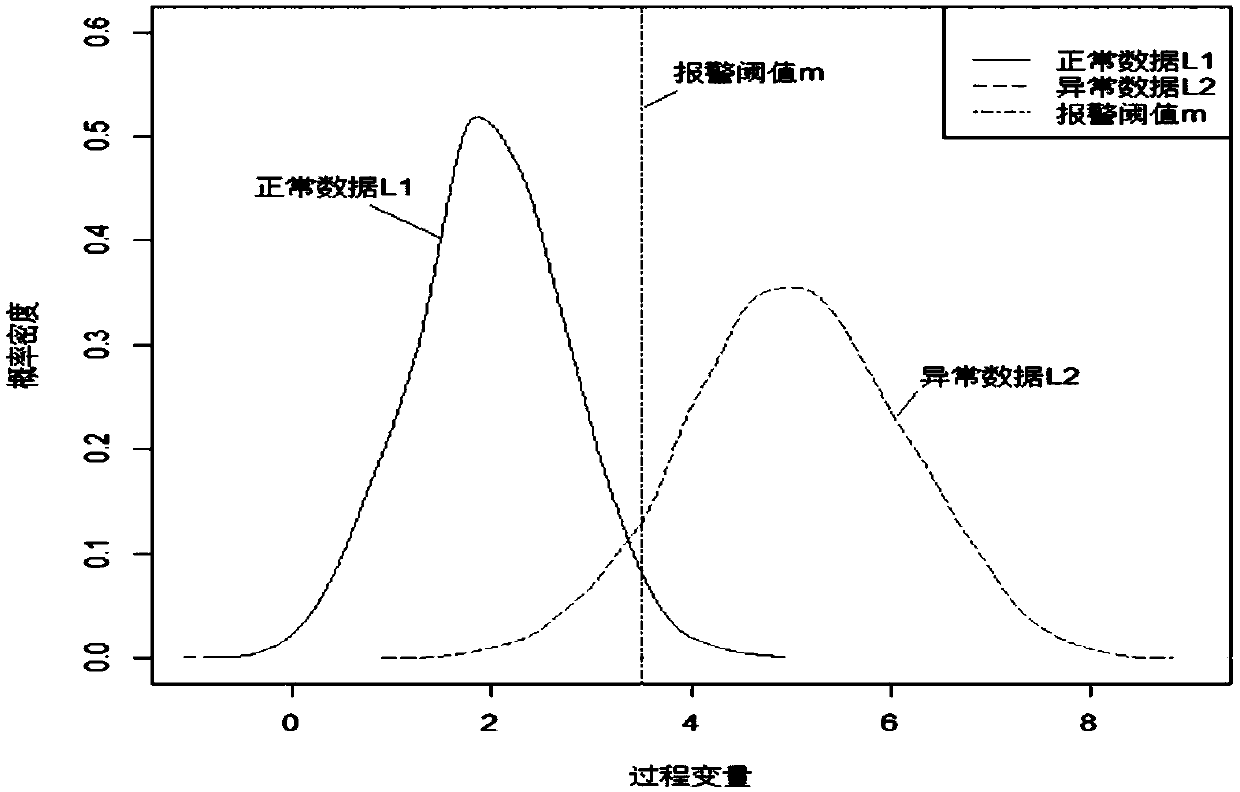

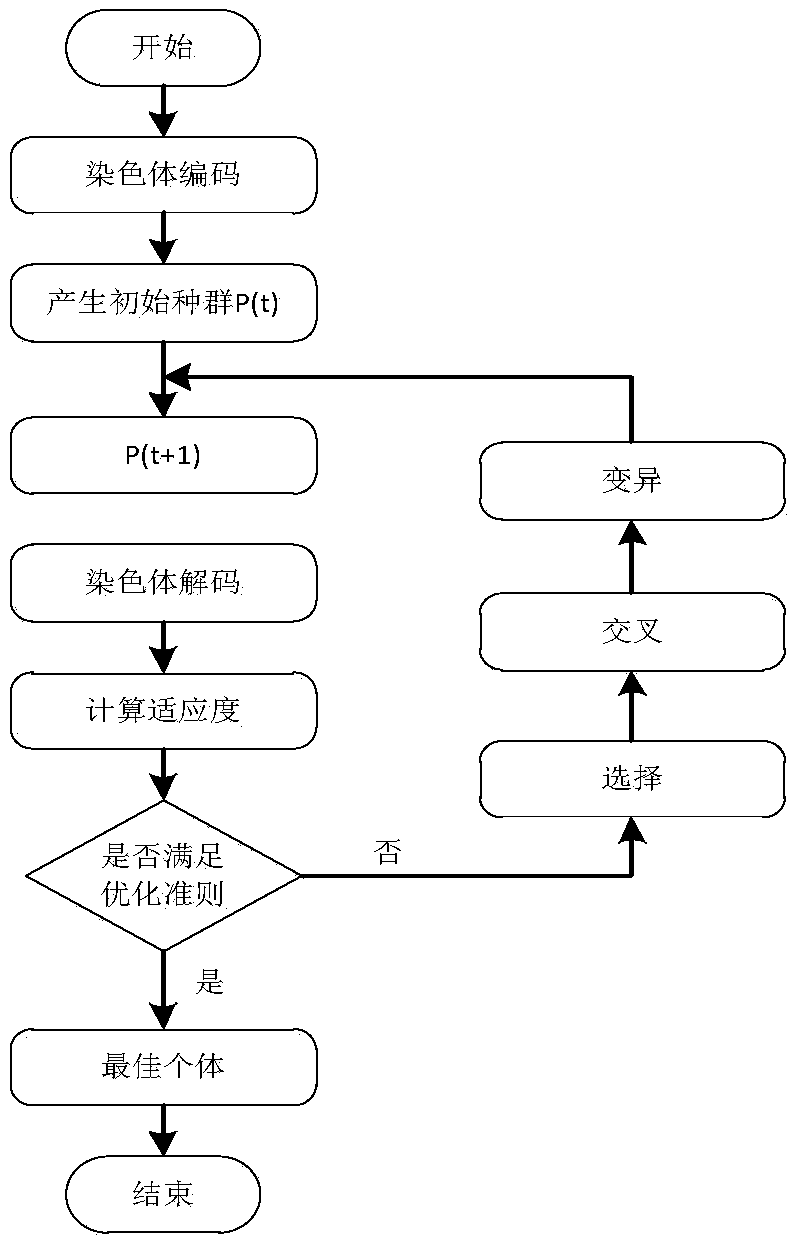

Solder paste detection threshold optimization method based on SMT big data

ActiveCN108960306AReduce weldingReduce the number of solder jointsCharacter and pattern recognitionGenetic algorithmsSolder pasteGenetic algorithm

The present invention provides a solder paste detection threshold optimization method based on SMT big data. The problems are mainly solved that a traditional artificial experience SPI threshold setting method cannot effectively discover potential badness in the PCB printing process and cannot reduce the cold solder joint and continuous tin electrodeposit defects caused by the solder paste amount.The method comprises the steps of: constructing a threshold estimation data packet; estimating an SPI parameter state; optimizing an SPI threshold, taking an SPI detection value as an operation variable to allow a corresponding value to be a target function when the sum of a misjudgment rate and a misdetection rate reaches the lowest, employing a genetic algorithm to perform optimization of the target function to obtain an optimization threshold, and setting the obtained optimization threshold as the SPI threshold of the surface mounting technology. The design of the solder paste detection threshold optimization method is rigorous and complete, the threshold value setting method has theoretical property and feasibility to effectively control the defects such as cold solder joint and continuous tin electrodeposit caused by the solder paste amount to flow into the surface mounting technology (SMT) later process so as to improve the whole yield of a PCB.

Owner:XIDIAN UNIV

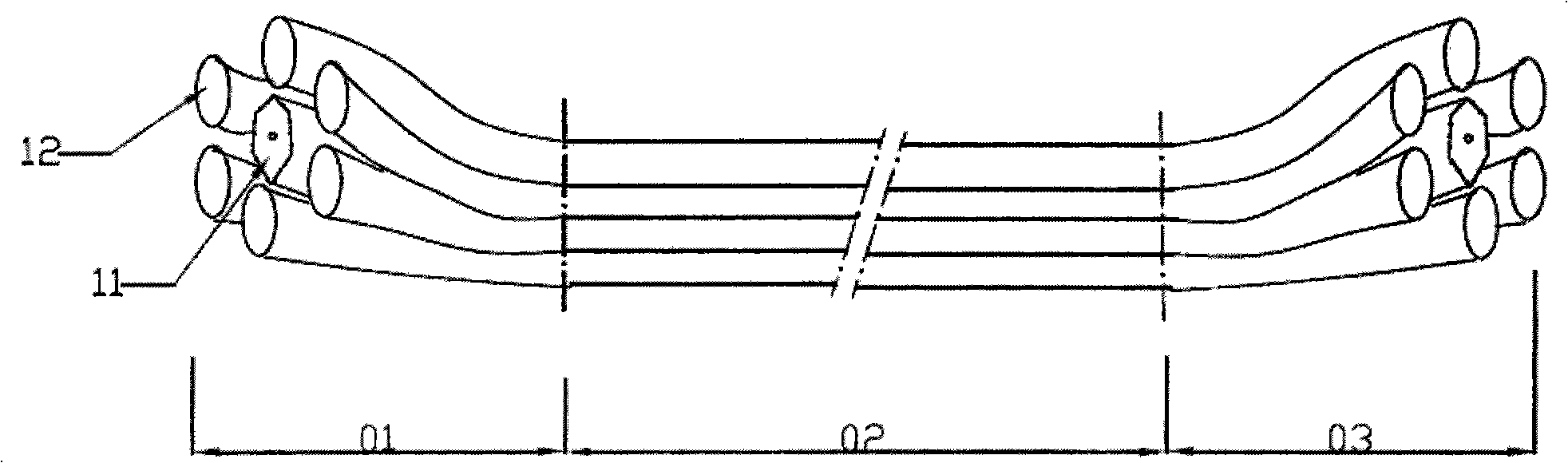

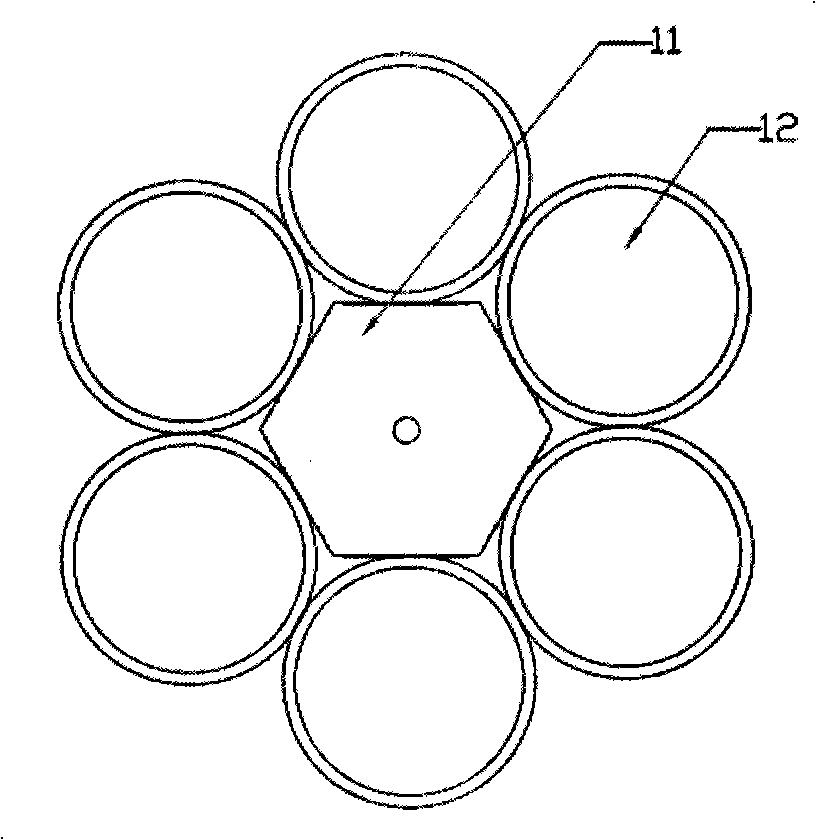

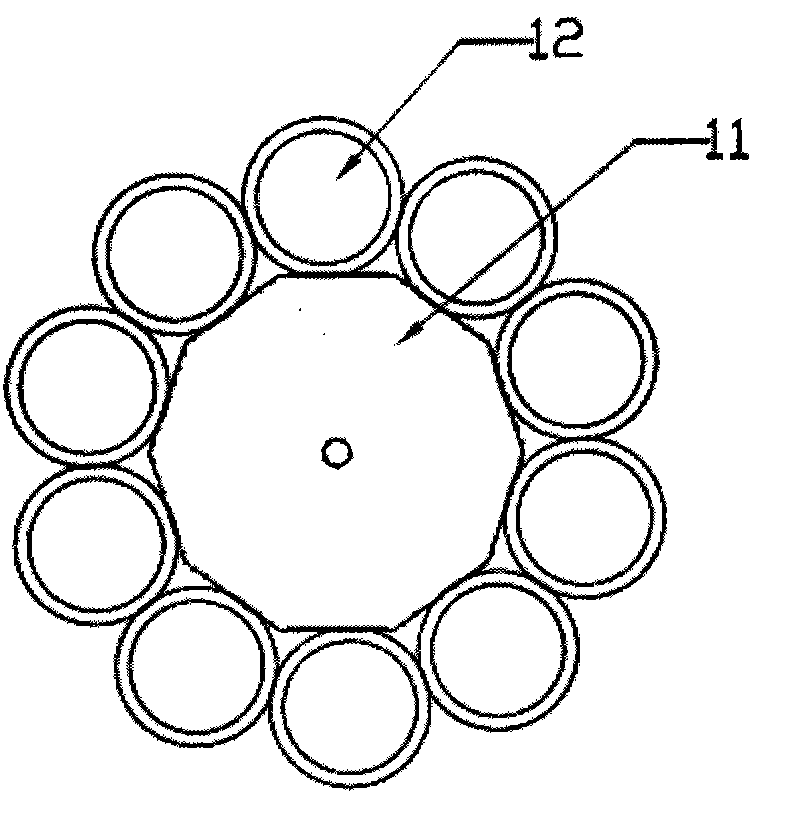

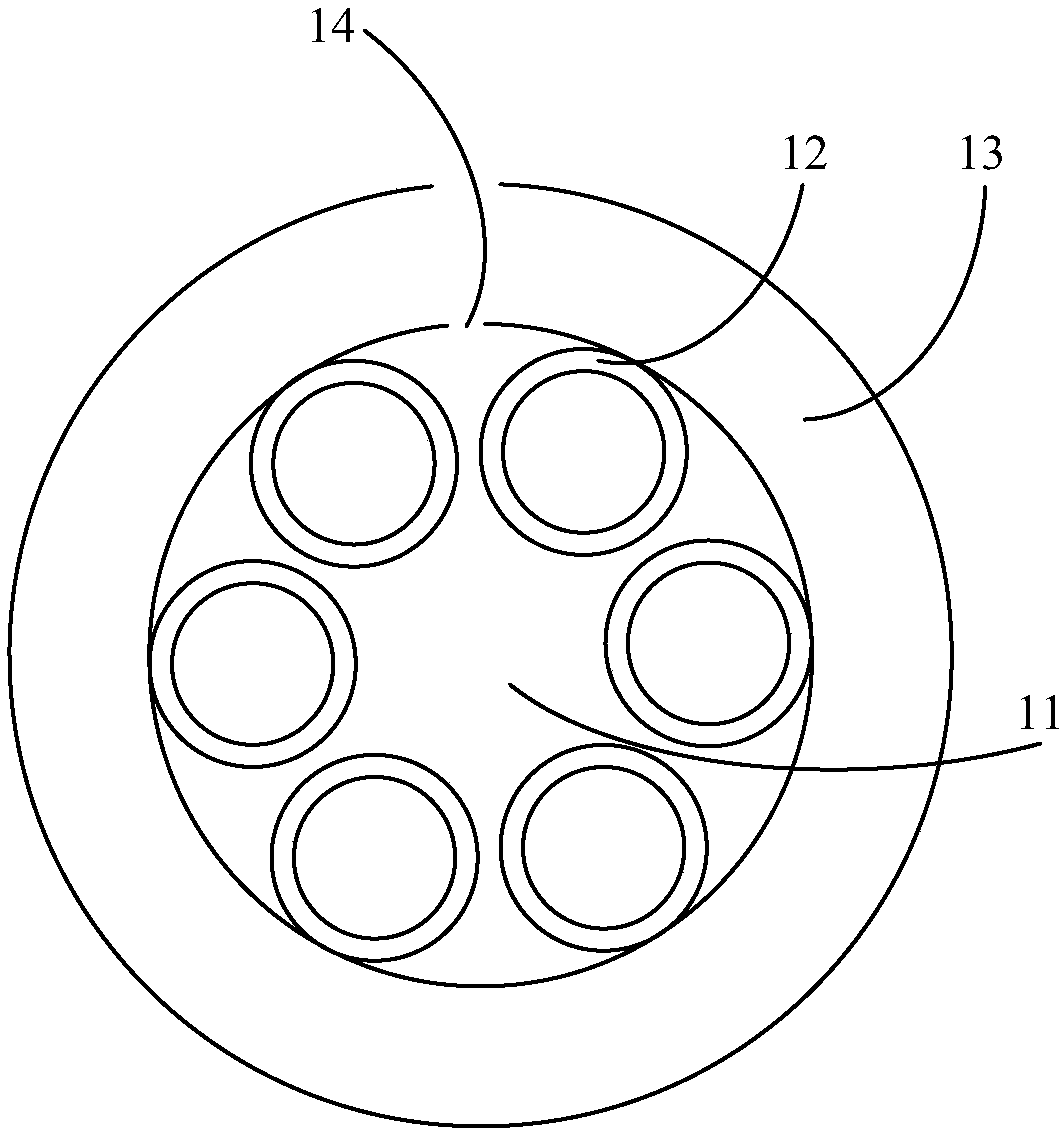

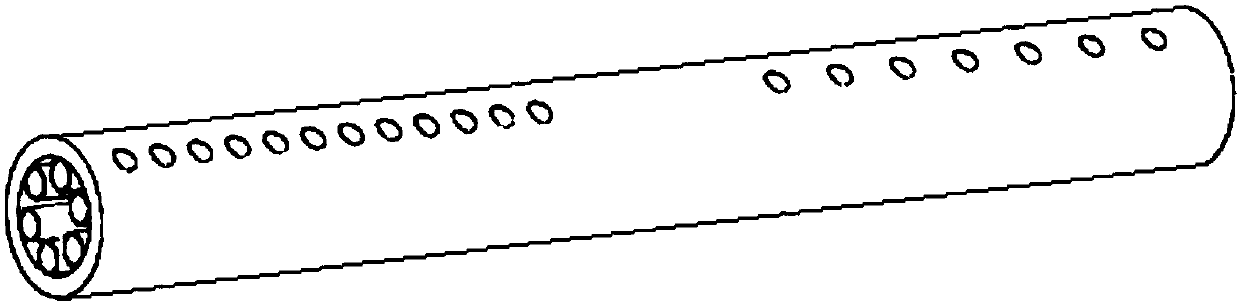

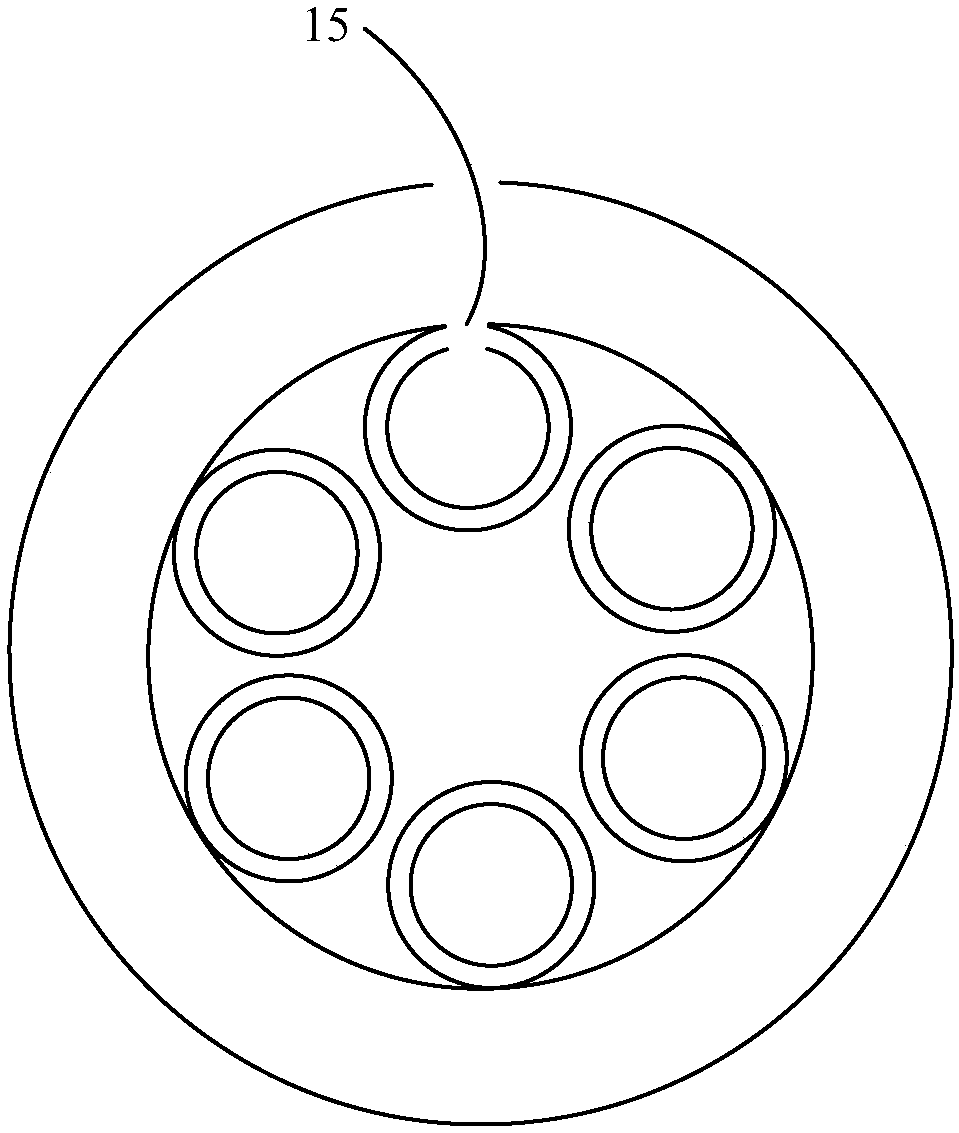

Full optical fiber laser synthesizer and preparation method thereof

The invention discloses a novel all optical fiber laser synthesizer which is used for high-power optical fiber lasers and amplifiers and a preparation method thereof. The novel full optical fiber laser synthesizer is composed of an optical fiber bundle consisting of a plurality of optical fibers with a certain diameter, wherein the optical fiber bundle comprises a rare earth doped fiber 11 in the middle and a plurality of multimode optical fibres 12, the shape of the rare earth doped fiber 11 the coating of which is removed is regular polygon, and the shape of the multimode optical fibre the coating of which is removed is round; all optical fibers in a middle position 02 are tight and close, and the outer surface of the optical fiber bundle is coated with a coating with the refractive index lower than that of pure quartz; and all optical fibers on two end parts 01 and 03 of the optical fiber bundle can be separated, and each optical fiber is independently coated with a coating. The fiber bundle is formed by carrying out wiredrawing on the corresponding optical fiber preform bunch on an optical fiber wire drawer tower in the mode of designed arrangement. The full optical fiber laser synthesizer of the invention has simple preparation process, is suitable to be produced in large batch and has the characteristics of high reliability and low insertion loss.

Owner:HUAZHONG UNIV OF SCI & TECH

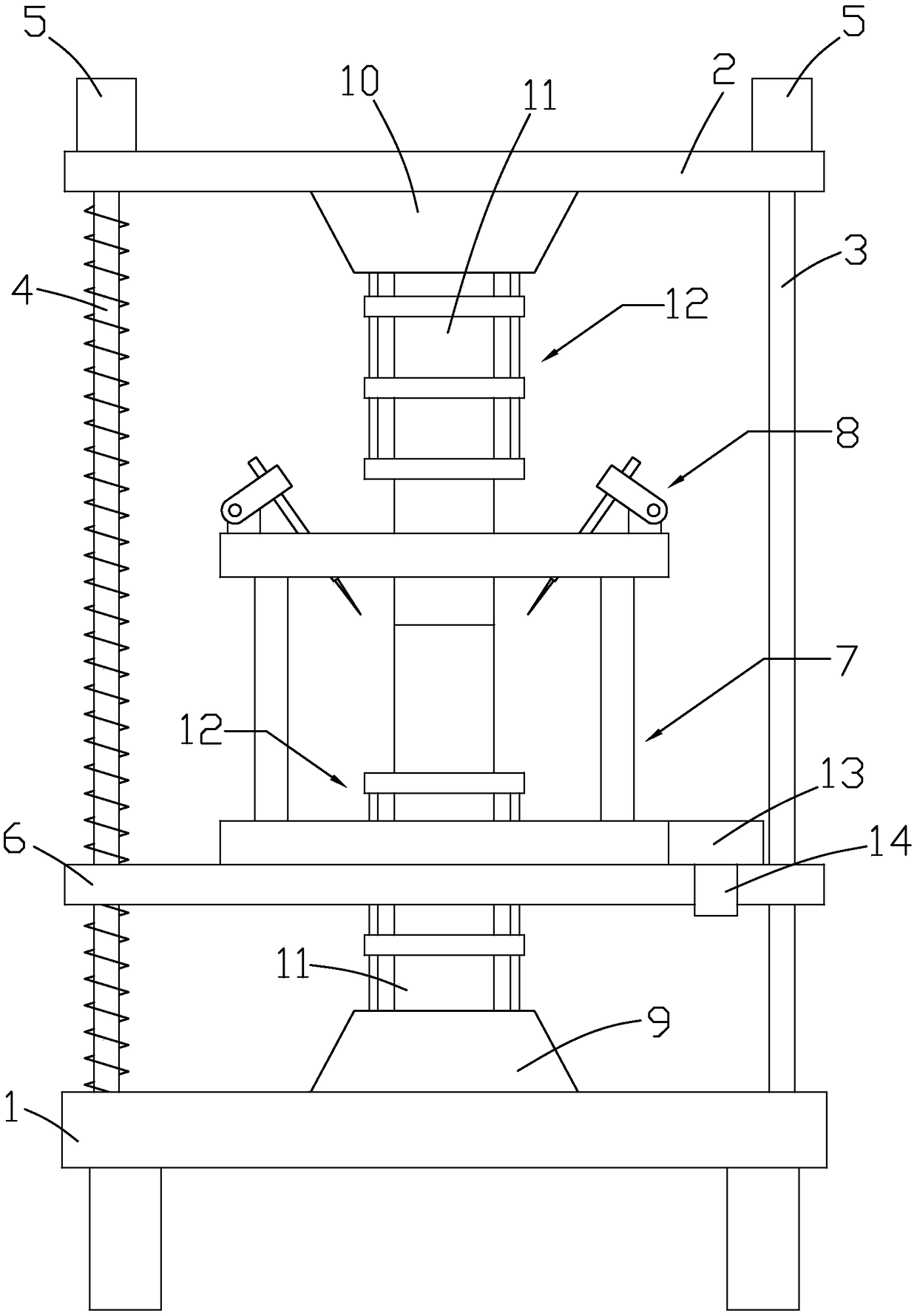

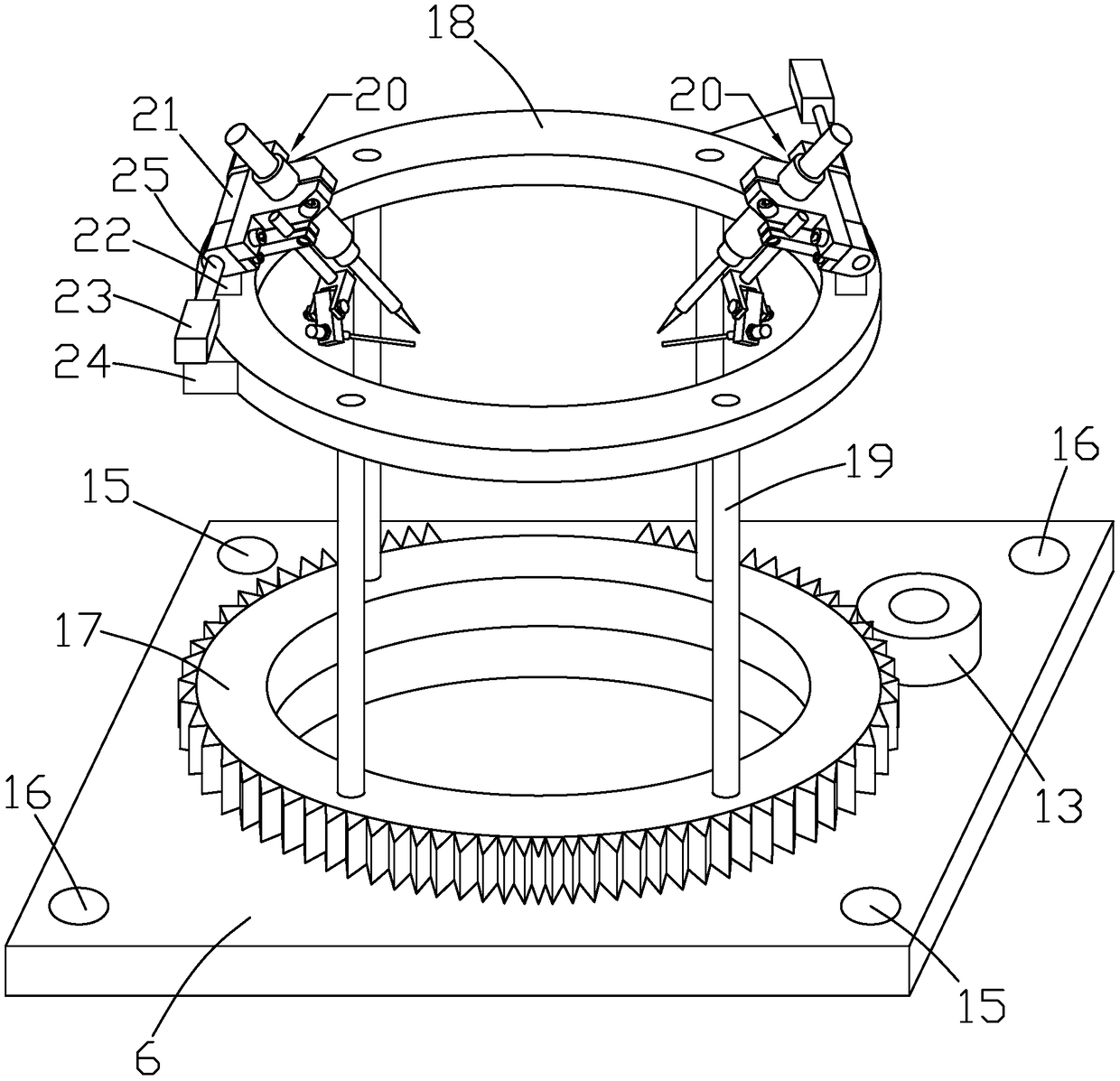

Welding device for pipeline sealing connection

ActiveCN109434341ASmooth rotationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses a welding device for pipeline sealing connection. The welding device for pipeline sealing connection comprises a base, a locating plate, a rotating mechanism, a welding mechanism and clamping and locating mechanisms. The base is connected with the locating plate through a stand column and a threaded rod. First motors are arranged at the top end of the threaded rod, and a lifting plate is connected between the stand column and the threaded rod in a moving mode. The rotating mechanism is connected to the lifting plate in a rotating mode, and the welding mechanism is connected to the rotating mechanism. A lower locating platform and an upper locating platform are arranged on the top surface of the base and the bottom surface of the locating plate correspondingly, and the clamping and locating mechanisms are arranged on the lower locating platform and the upper locating platform. Two pipeline test pieces are limited in the upper clamping and locating mechanism and the lower clamping and locating mechanism correspondingly and located on the same vertical straight line. The welding device for pipeline sealing connection is simple in structure and high in practicability, can conduct clamping and locating operation on two pipelines in the up-and-down direction, and can also adjust the height and the position of a welding mechanism, the requirement for sealing welding of pipelines with different lengths is met, the practicability of the welding device is greatly improved, and the working range of the welding device is greatly broadened.

Owner:纳木博(常州)智能装备有限公司

Preparation method for flake-like aluminium powder pigment

The invention discloses a preparation method for a flake-like aluminium powder pigment, and the method comprises the following steps: putting 1-1.5 tons of steel balls of which the diameter is 0.8-1.5mm, 1-10mu m of spherical aluminium powder, 150#or 200# solvent oil and accessory ingredients into a ball mill at a certain ratio; introducing nitrogen for protection; after the ball mill carries outball milling at a higher speed for 5-7 hours, slowing the revolving speed to carry out ball milling for 1.5-3 hours; after ball milling is finished, adding 80-120kg of 150# or 200# solvent oil for diluting; pressing out the diluted aluminium slurry by virtue of an air pump; screening and grading by virtue of a vibrating screen; carrying out filter pressing by a use of a plate and frame type filter press; separating solid and liquid to obtain a filter cake of which the solid content is 70-80%; adding a 150#or 200# diluted phenolic antioxidant; kneading in a kneader for 40-60 minutes; and packaging. By utilizing the preparation method disclosed by the invention, silver dollar type flake-like metal particles with even particle diameter can be obtained, the product performance is improved, the coating effect of the aluminium particle is improved, the phenomenon of silver drop can be solved, the surface of the aluminium particle is smooth and flat, and the welding, burr and the like of thealuminium particle can be reduced.

Owner:HEFEI SUNRISE PIGMENTS

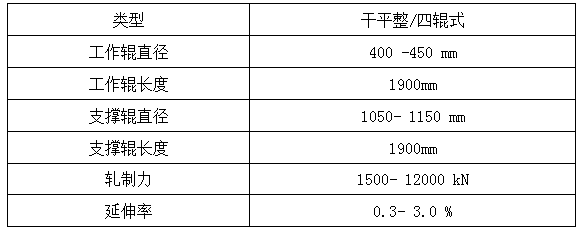

Method for producing non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and pickling galvanization continuous production line

ActiveCN108480416AFlexible temperature adjustmentShorten the lengthHot-dipping/immersion processesFurnace typesAcid washingContinuous casting

The invention relates to a method for producing a non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and a pickling galvanization continuous production line. The method comprises the following steps of totally-headless sheet billet continuous casting and rolling, pickling, smoothing, heating, non-spangle galvanization, finishing, passivation and coiling to form a non-spangle hot-galvanized roll. By means of the method, the non-spangle continuous pickling hot-galvanized plate with the specification being (0.8-4.0)*(900-1650) mm is producedin a hot rolling manner, the technological process is shortened, energy is saved, a product is good in surface quality, high in size precision and stable in performance, the production cost is lowered, parts of cold-rolling base material galvanized products can be replaced by the product, and the blank of heat-based continuous pickling galvanizing production is filled up.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

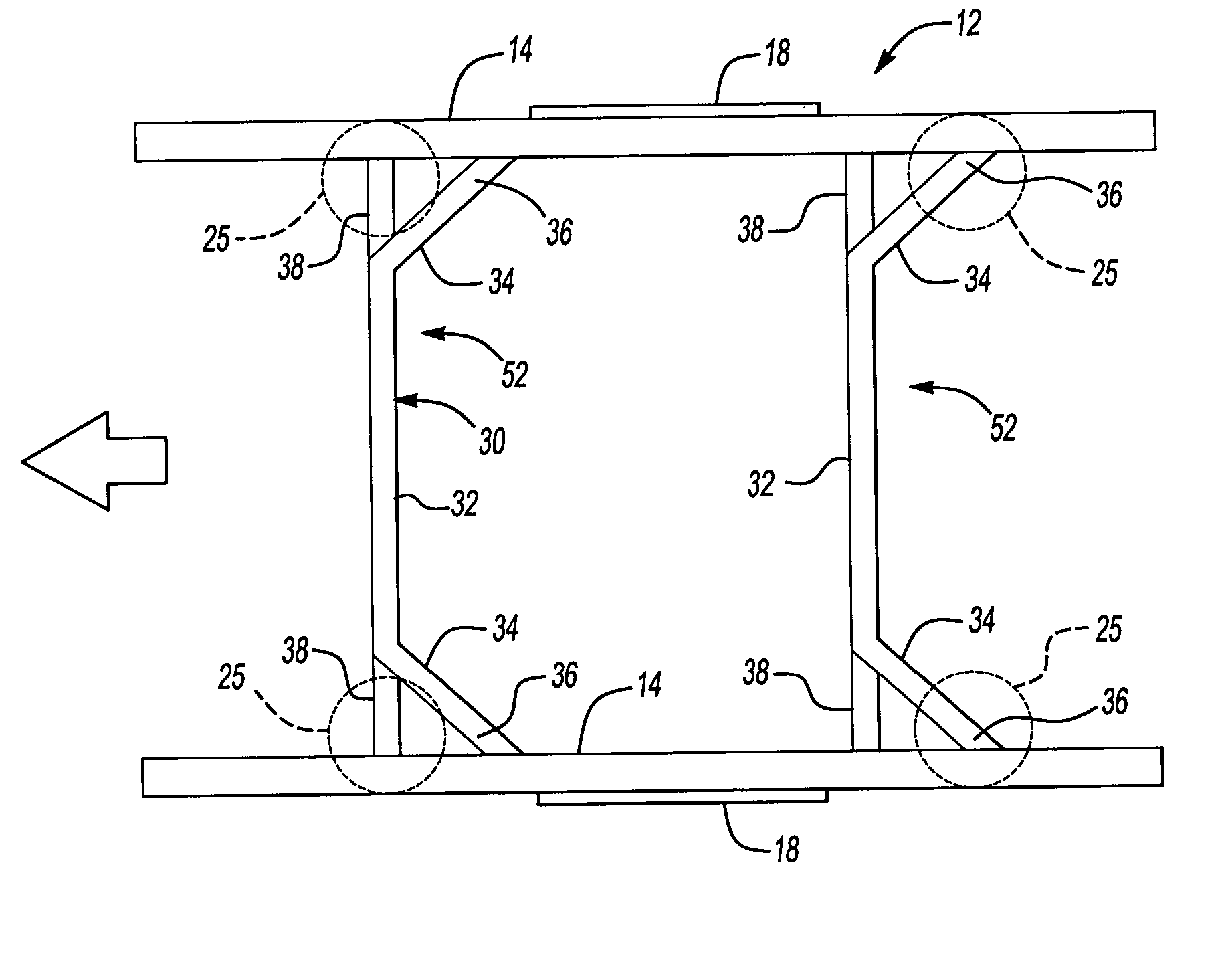

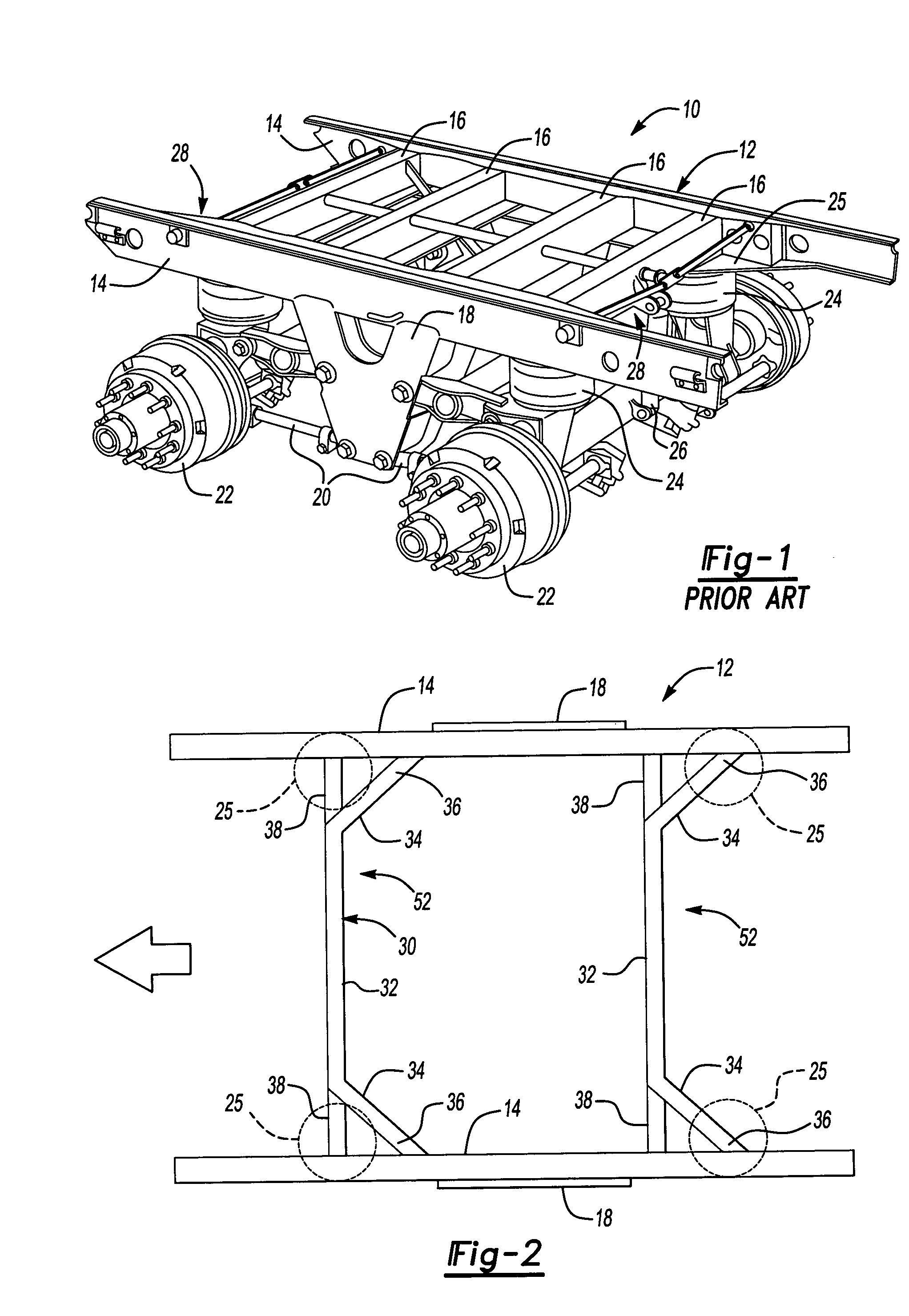

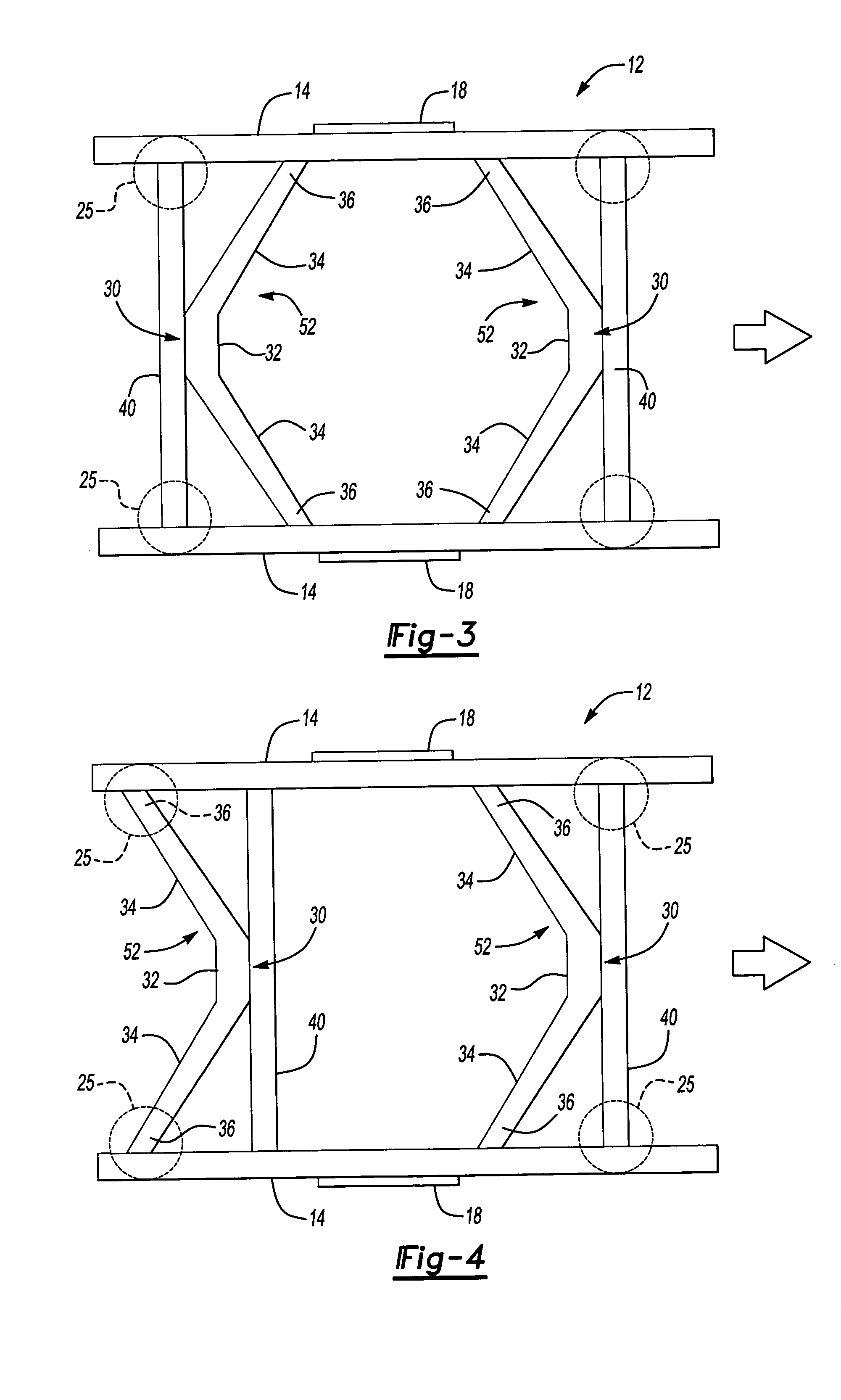

Reinforced tractor-trailer slider

InactiveUS20050051991A1Improved slider frame configurationReduce weldingUnderstructuresTractor-trailer combinationsEngineeringTractor trailer

This present invention provides a suspension slider assembly for a vehicle trailer comprising first and second spaced apart longitudinal members. A structure having a generally continuous, uniform wall is secured between the longitudinal members. The structure also includes a lateral portion extending between the longitudinal members. The wall includes a central portion adjoining opposing first and second angled portions that extend from the central portion at an angle relative to the lateral portion and longitudinal members.

Owner:ARVINMERITOR TECH

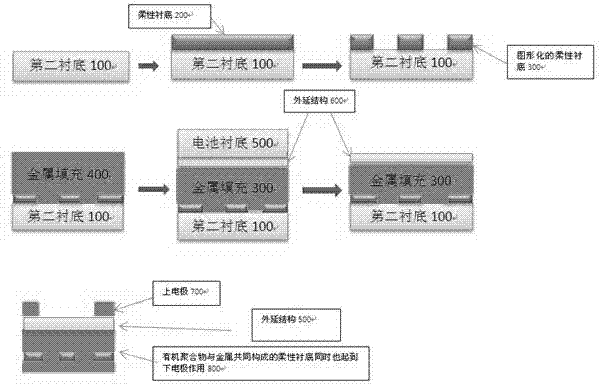

Flexible multi-joint GaAs solar battery and manufacturing method thereof

ActiveCN103594539ASave spaceUnbreakableFinal product manufacturePhotovoltaic energy generationSemiconductor materialsEngineering

The invention discloses a flexible multi-joint GaAs solar battery and a manufacturing method of the flexible multi-joint GaAs solar battery, and belongs to the technical field of semiconductor materials. Firstly, a flexible substrate and a battery epitaxial structure which is bonded with metal in the same way and composed of a base battery, a middle battery and a top battery are respectively prepared, and a first battery substrate is manufactured at the outer side of the top battery; secondly, a Ti layer, a Pt layer and an Au layer are sequentially plated on the back of the base battery of the battery epitaxial structure in an vacuum evaporation mode, and the battery epitaxial structure is bonded with a metal layer fully covering the outer surface of a polyimide coating; thirdly, Si3N4 deposits on the surface of the bonded metal layer, and then the first battery substrate on the battery epitaxial structure is removed through alkaline corrosion liquid; fourthly, two upper electrodes and an antireflection film are manufactured on the top battery of the battery epitaxial structure; finally, after a manufactured chip and a Si wafer are bonded on a second substrate through photoresist, and then the second substrate is removed through alkaline corrosion liquid. The manufactured flexible multi-joint GaAs solar battery is wholly flexible, can be applied to surfaces of different shapes, and is not broken easily.

Owner:YANGZHOU CHANGELIGHT

Method for manufacturing duplex stainless steel middle assembly plate frame of chemical tanker

ActiveCN109552552ANo damageGuaranteed accuracyVessel designingLoad accommodationMetallurgyCompound (substance)

The invention discloses a method for manufacturing a duplex stainless steel middle assembly plate frame of a chemical tanker. The method comprises the following steps: S1, the fabrication of a specialtire frame for duplex stainless steel spliced plates, S2, the splicing of the duplex stainless steel plates; S3, the fabrication of the duplex stainless steel middle assembly tire frame; and S4, thefabrication of the duplex stainless steel middle assembly. The method uses a special duplex stainless steel spliced plate tire frame, ensures the precision of the spliced plates, reduces the consumption of the tire frame material, and reduces the mechanical damage to the surface of the duplex stainless steel plate. In the process of splicing the duplex stainless steel plate, a forced weight restrained deformation method is provided so as to reduce the welding deformation during the splicing process. The method utilizes a dummy compartment to control the assembly precision of flat-bulb steel, and provides a flat-bulb steel and duplex stainless steel welding sequence method so as to avoid a large workload in a subsequent precision correction process and shorten a product construction period.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Method for manufacturing holographic mother board by using laser welding imposition

InactiveCN101618627AImprove cutting accuracyReduce weldsLaser beam welding apparatusPrinting formes reproductionThermal deformationEngineering

The invention relates to a method for manufacturing a holographic mother board by using a laser welding imposition, which comprises the following steps: arranging nickel boards of unit holographs according to the requirements, and welding each unit holograph by using the laser energy to manufacture a holographic mother board which has a large dimension and comprises a plurality of unit holographs. The invention has the advantages that the method can be used for splicing unit holographs of arbitrary dimensions and is particularly suitable for splicing unit holographs of large dimensions; the laser welding has the characteristics of fine, smooth and flat welding joints, small thermal deformation and the like and can realize digitally-controlled automatic operation, thus the splicing speed is quick, and the splicing precision is high; and the holographic mother board formed by welding can be electroformed and reproduced into a plurality of mother boards, and the large board formed by laser welding can be also directly arranged on a moulding press for use.

Owner:HUBEI XINGLONG PACKAGING MATERIAL

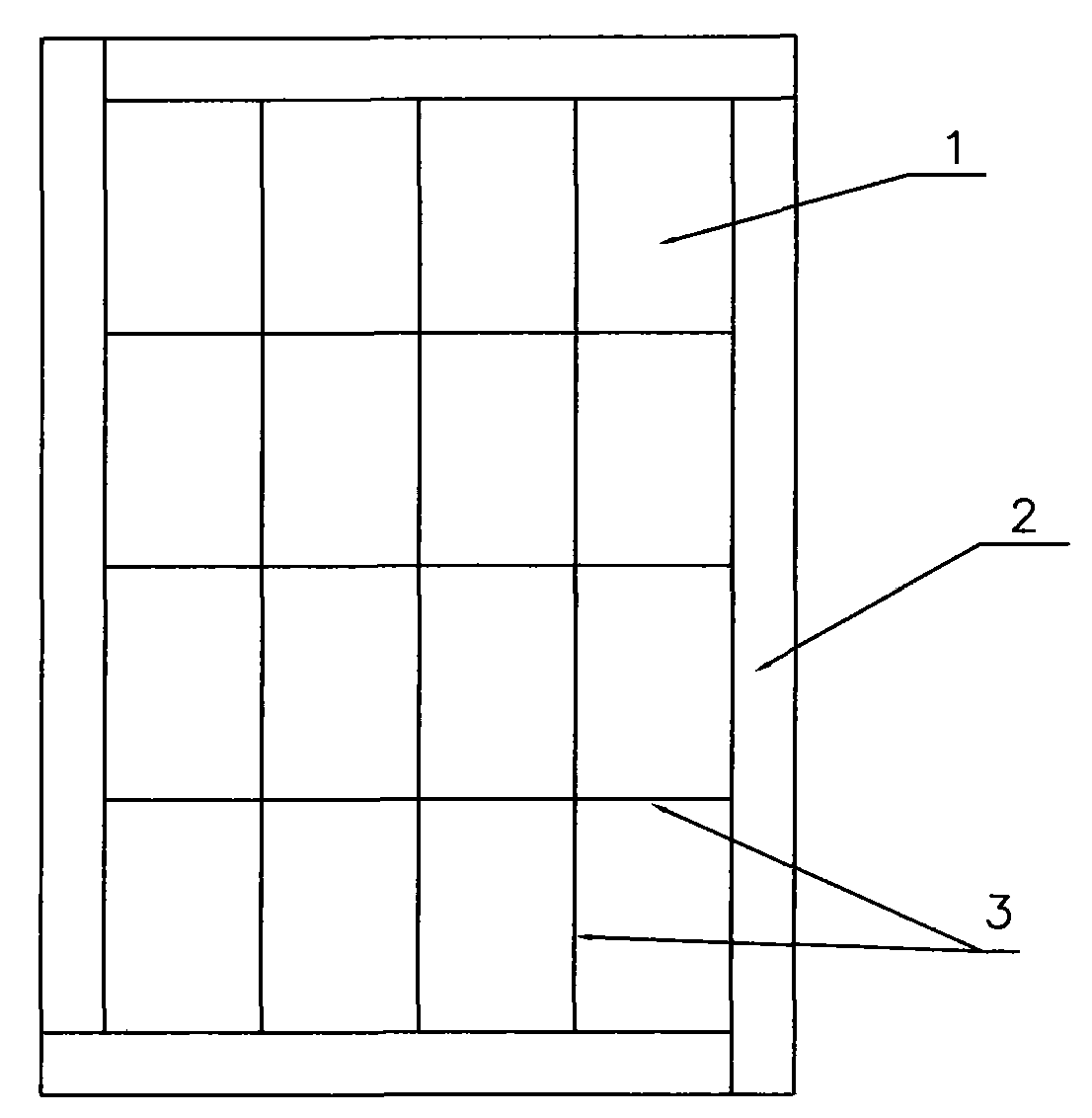

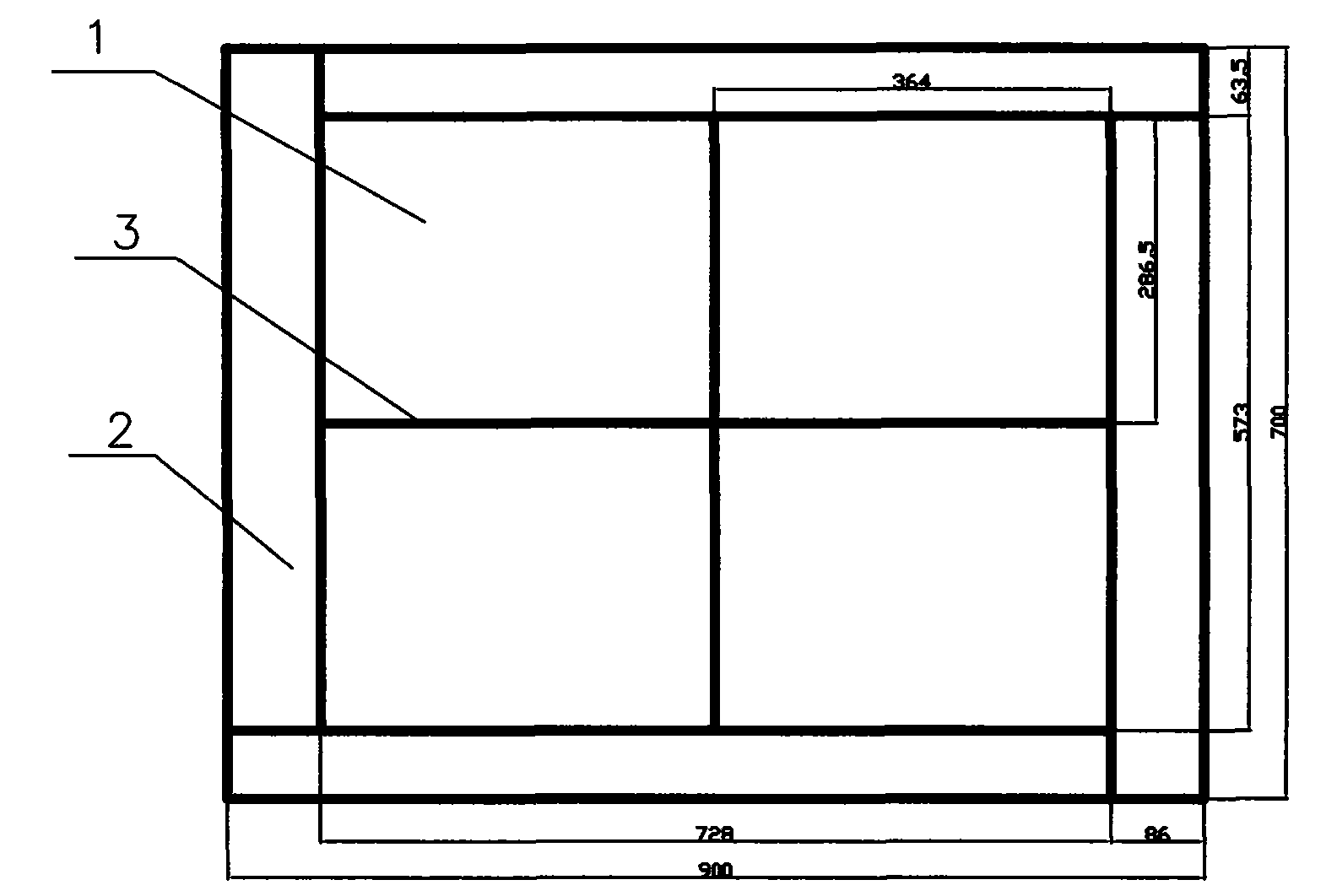

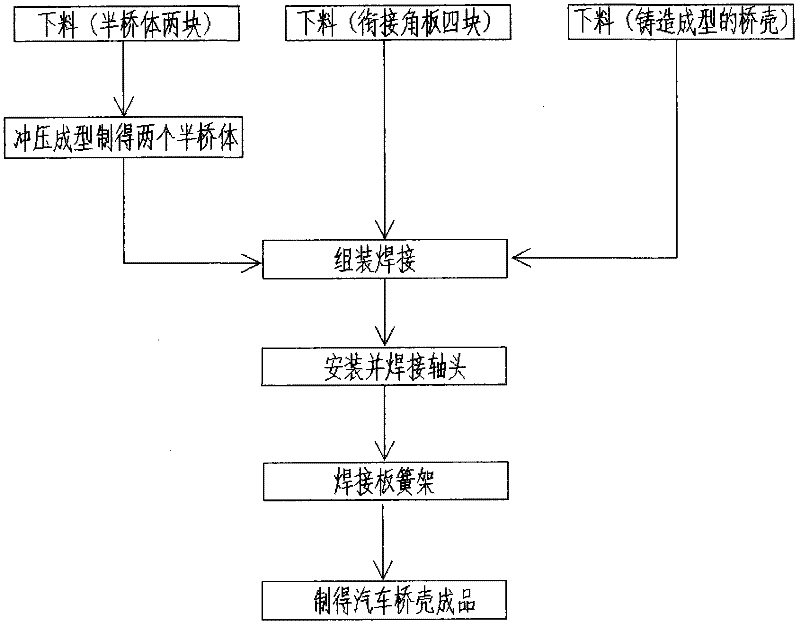

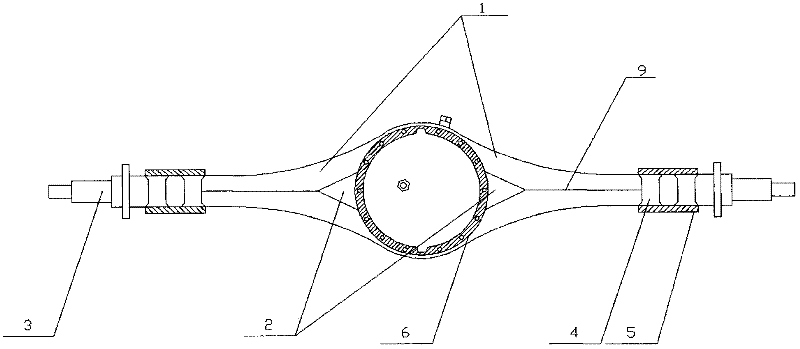

Method of manufacturing car axle case and car axle case manufactured by same

The invention discloses a method for manufacturing a car axle case, which comprises the following steps of: A, blanking and making a flitch; B, downwardly punching the middle part of the flitch obtained in the step A; C, extruding two sides of the flitch by a hydraulic machine to upwardly bend the flitch; D, inwardly bending the end part of the upwardly bent flitch, and aligning two end parts of the bent flitch to each other; E, after aligning the two ends of the flitch to each other, cutting surplus burrs on the end parts of the flitch, and welding; F, mounting and welding spindle noses, and welding seal edges and plate spring frames; and G, obtaining the car axle case as a finished product. The method has the advantages of low manufacturing cost, simple manufacturing technology, once molding of product, few welding seams, high strength and rigidity of product, high qualification rate and small labor intensity of workers.

Owner:QINGDAO SHUNLIAN AUTO PARTS MFG

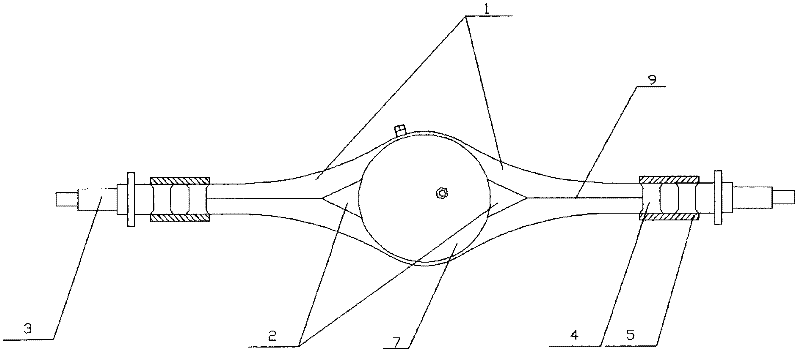

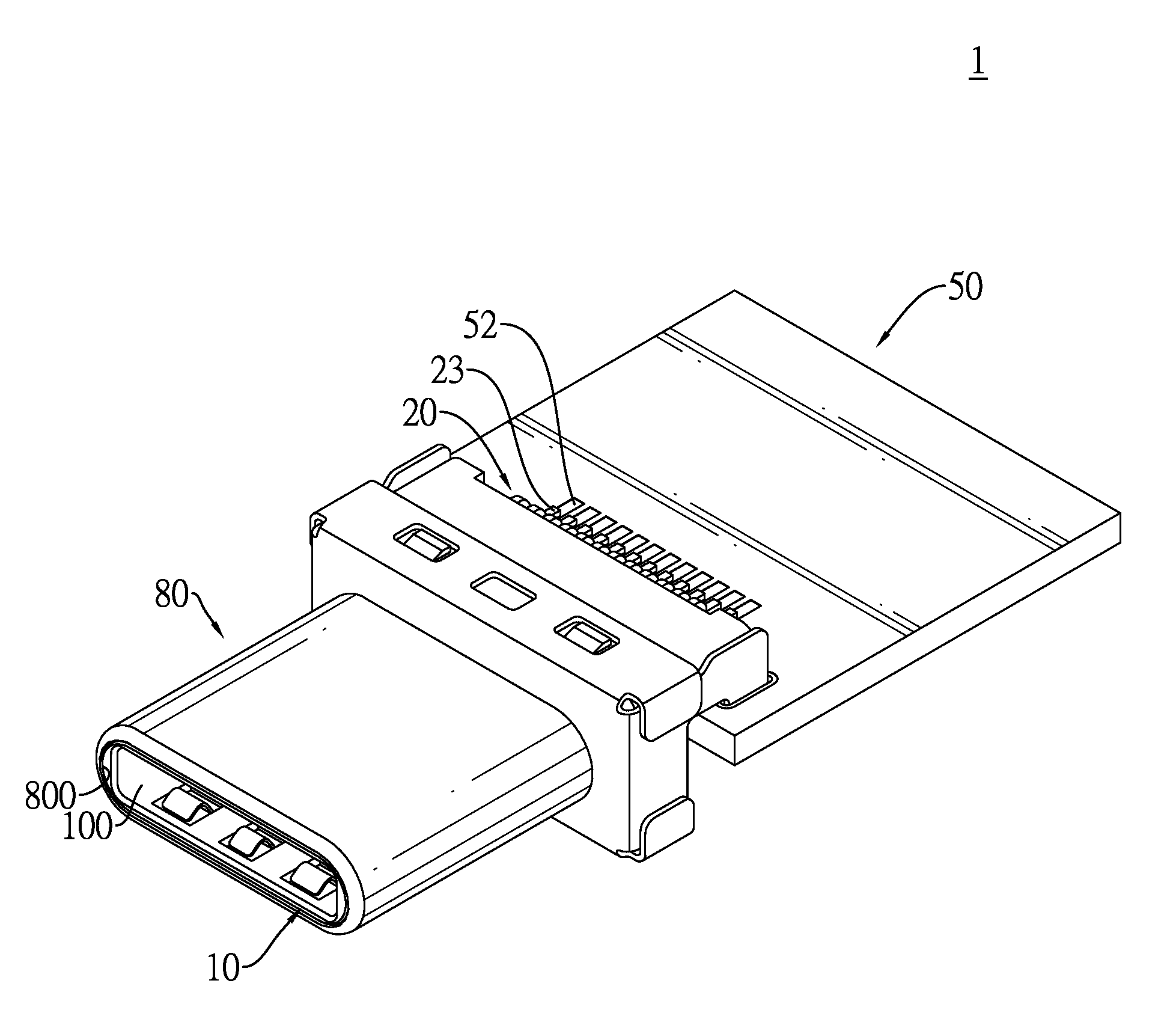

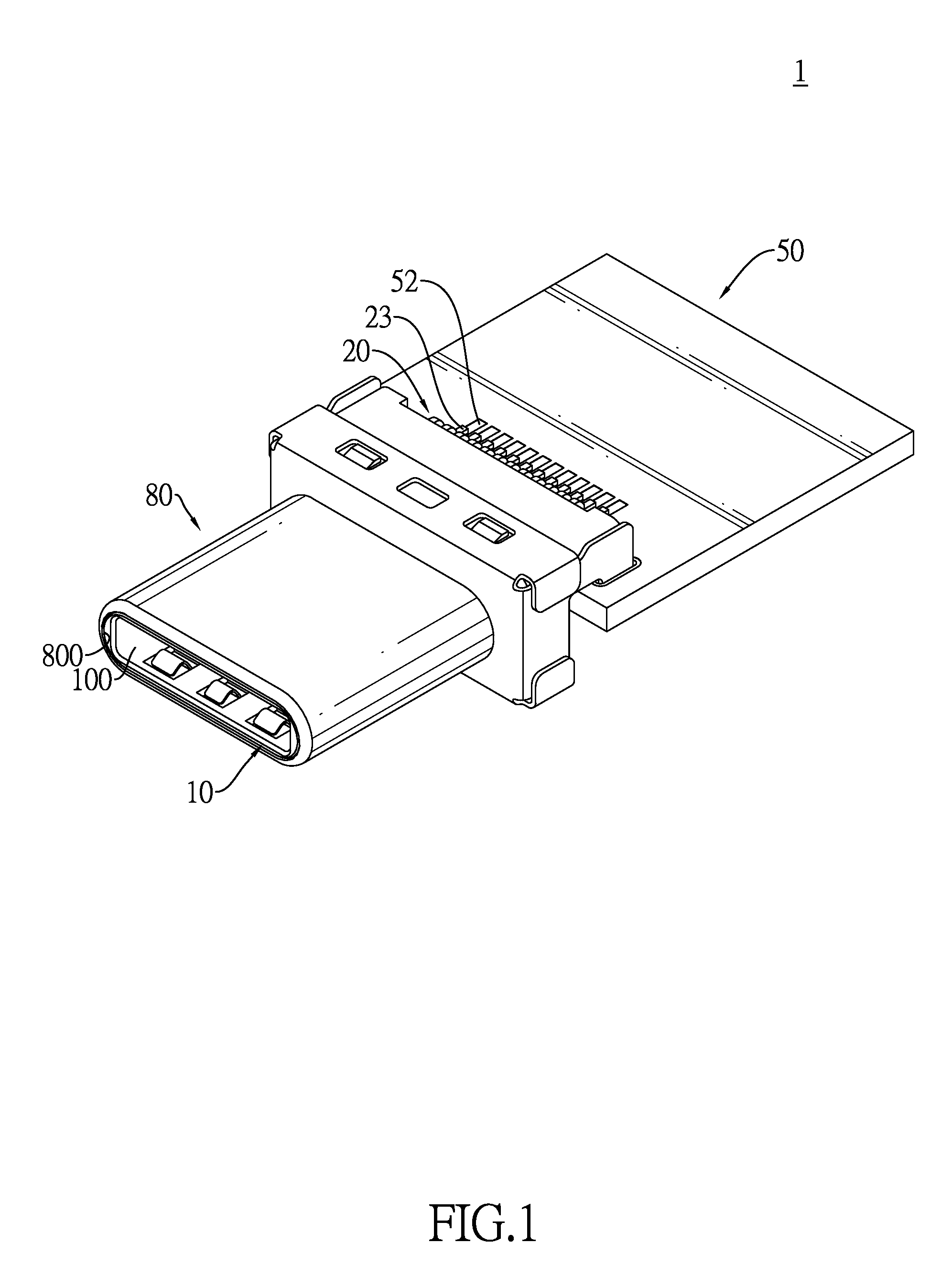

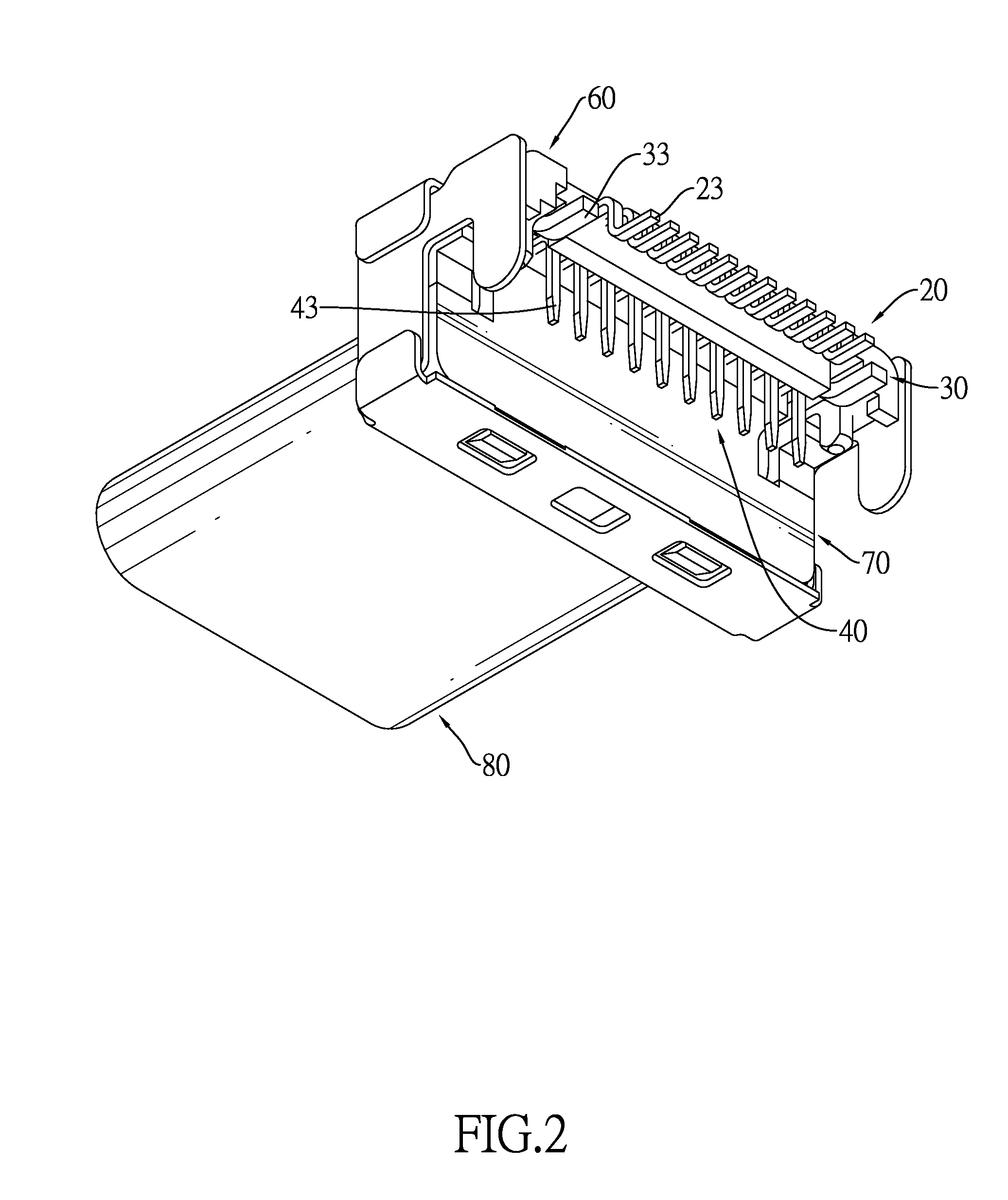

Electrical plug connector assembly

ActiveUS20160156114A1Reduce weldingHigh preparation ratePrinted circuit aspectsCoupling contact membersProduction rateEngineering

An electrical plug connector assembly has an insulative housing, a first terminal set, a second terminal set and a circuit board. The first and second terminal sets are mounted in the insulative housing. The first terminal set has multiple first conductive terminals each including a first soldering section. The second terminal set has multiple second conductive terminals each including a second soldering section. The first and second soldering sections are soldered on an identical surface of the circuit board such that only one single soldering process is required to solder all of the first and second conductive terminals to the circuit board. The production rate of the electrical plug connector assembly is therefore improved.

Owner:ADVANCED CONNECTEK INC

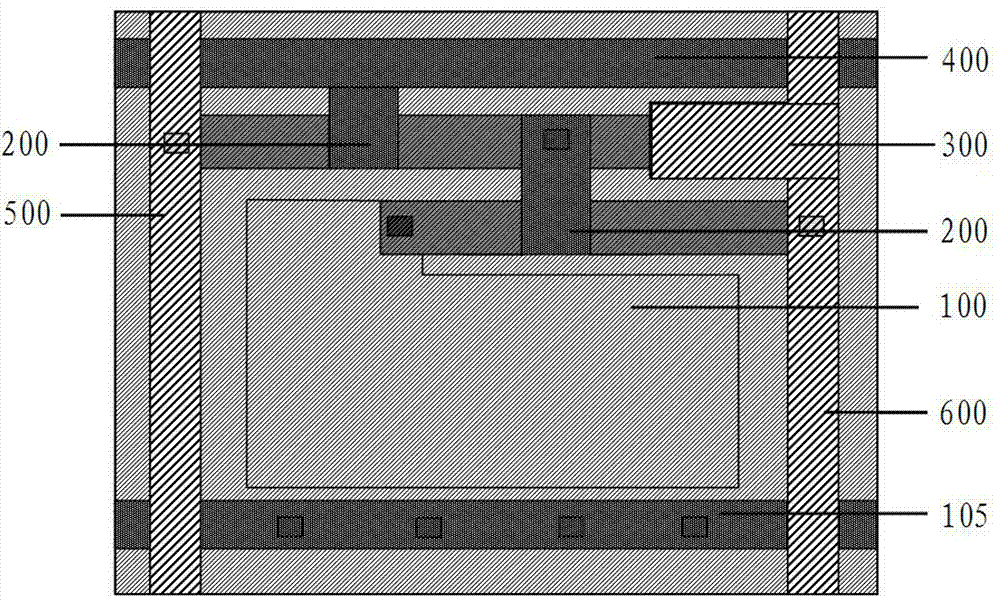

Micro LED light-emitting display array pixel unit structure and fabrication method thereof

InactiveCN108010933ARealize active driveImprove integration densitySolid-state devicesSemiconductor devicesLED displayEngineering

The invention relates to a micro LED light-emitting display array pixel unit structure and a fabrication method thereof. The micro LED light-emitting display array pixel unit structure comprises a display pixel unit body, wherein the display pixel unit body comprises a light-emitting diode, a light-emitting diode driving circuit and a lead, wherein the light-emitting diode is manufactured by integration of an epitaxial wafer grown on a substrate, and the lead is used for connecting the outside. Three parts required by manufacturing of the display pixel unit are integrated with the epitaxial wafer by a semiconductor processing technology, the pixel light-emitting unit and the control circuit are integrated, so that the welding process with complicated process and low reliability is omitted,the fabrication process is simple, and active driving of a micro LED display array can be achieved without independently fabricating a pixel driving circuit; and moreover, the integration density andthe reliability of the micro LED display array are effectively improved, the display effect with high-speed scanning, high definition and high quality can be achieved, the demand of next-generation display application is satisfied, and industrialization is promoted.

Owner:GUANGDONG INST OF SEMICON IND TECH

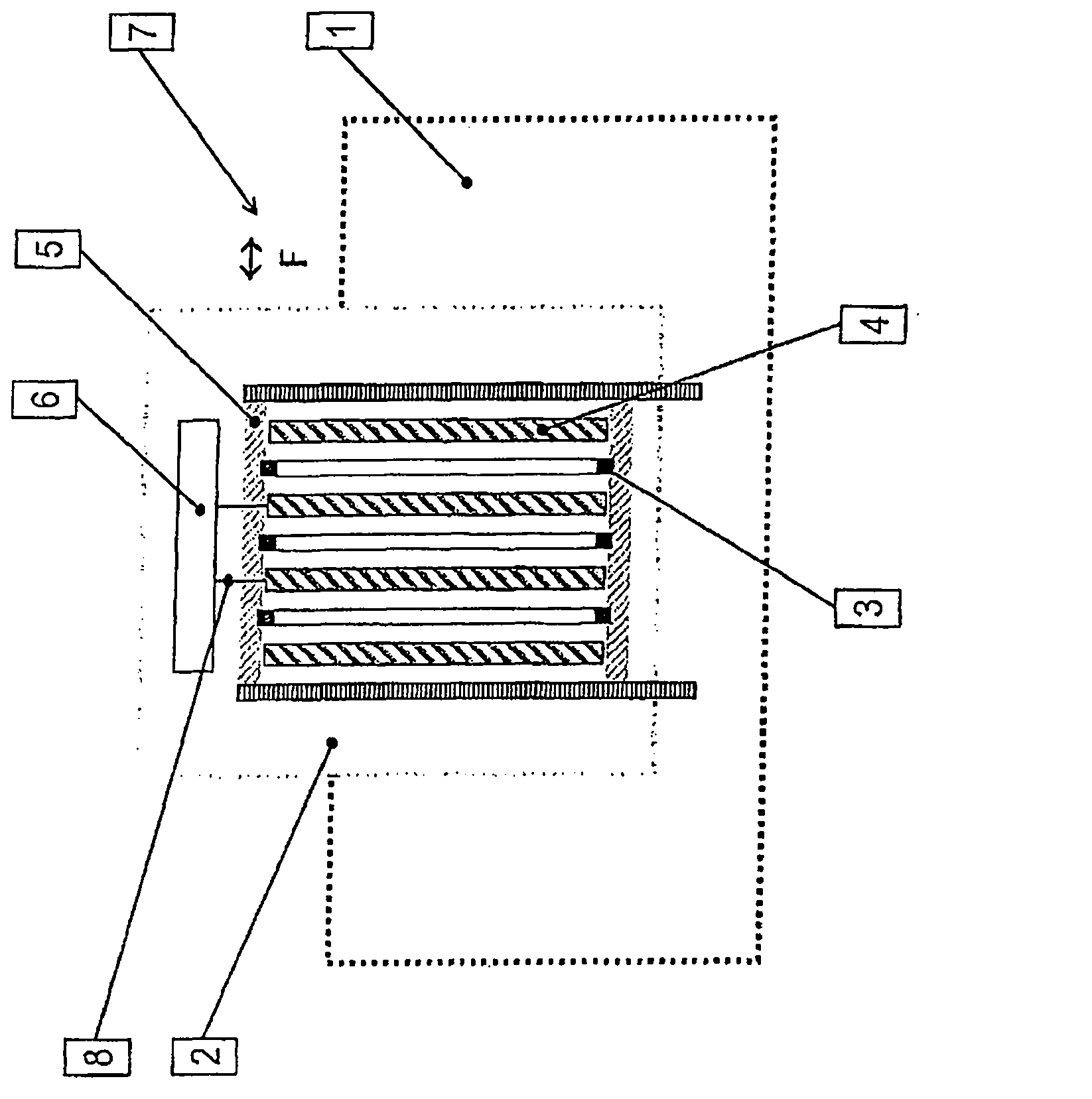

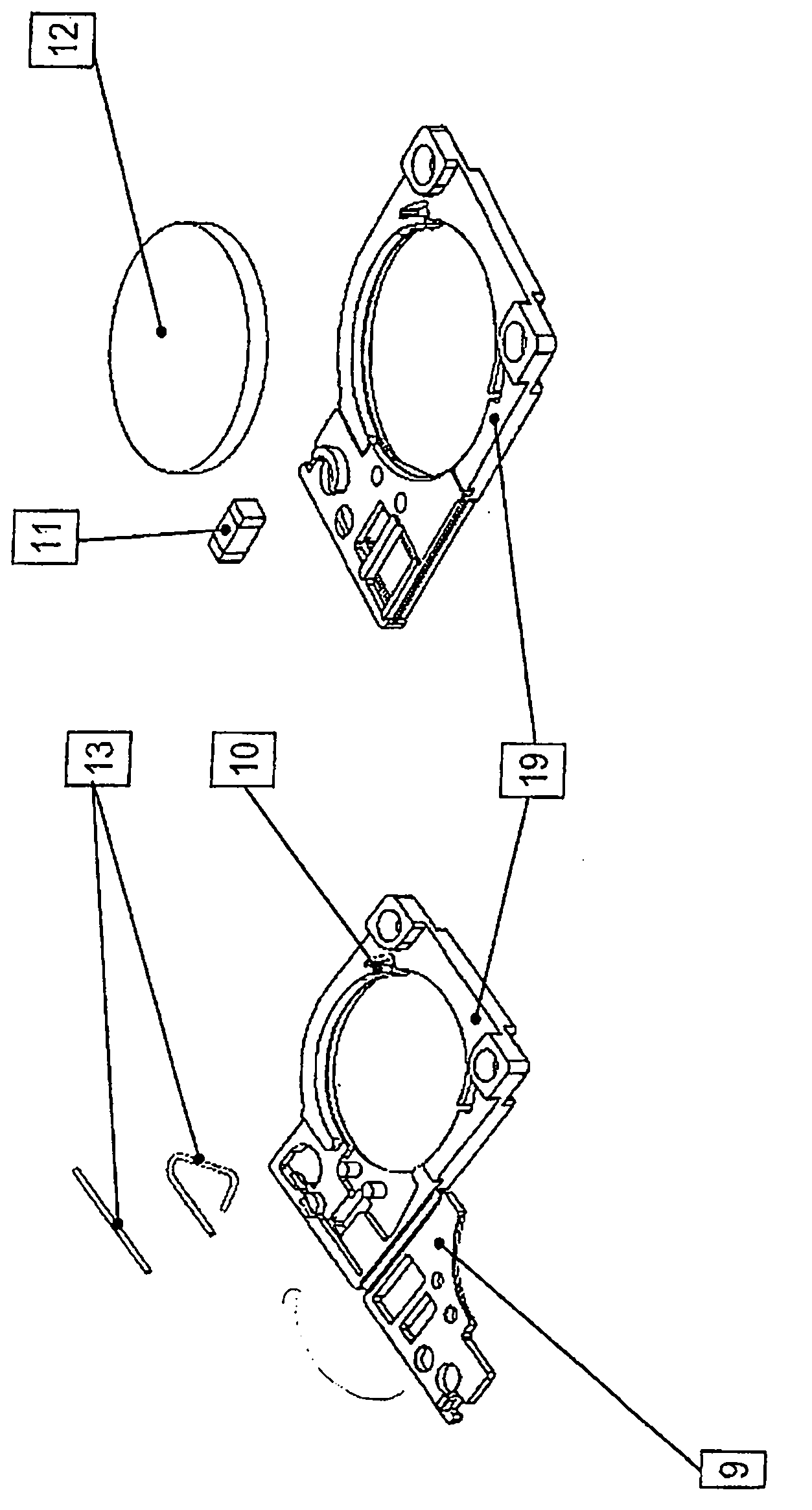

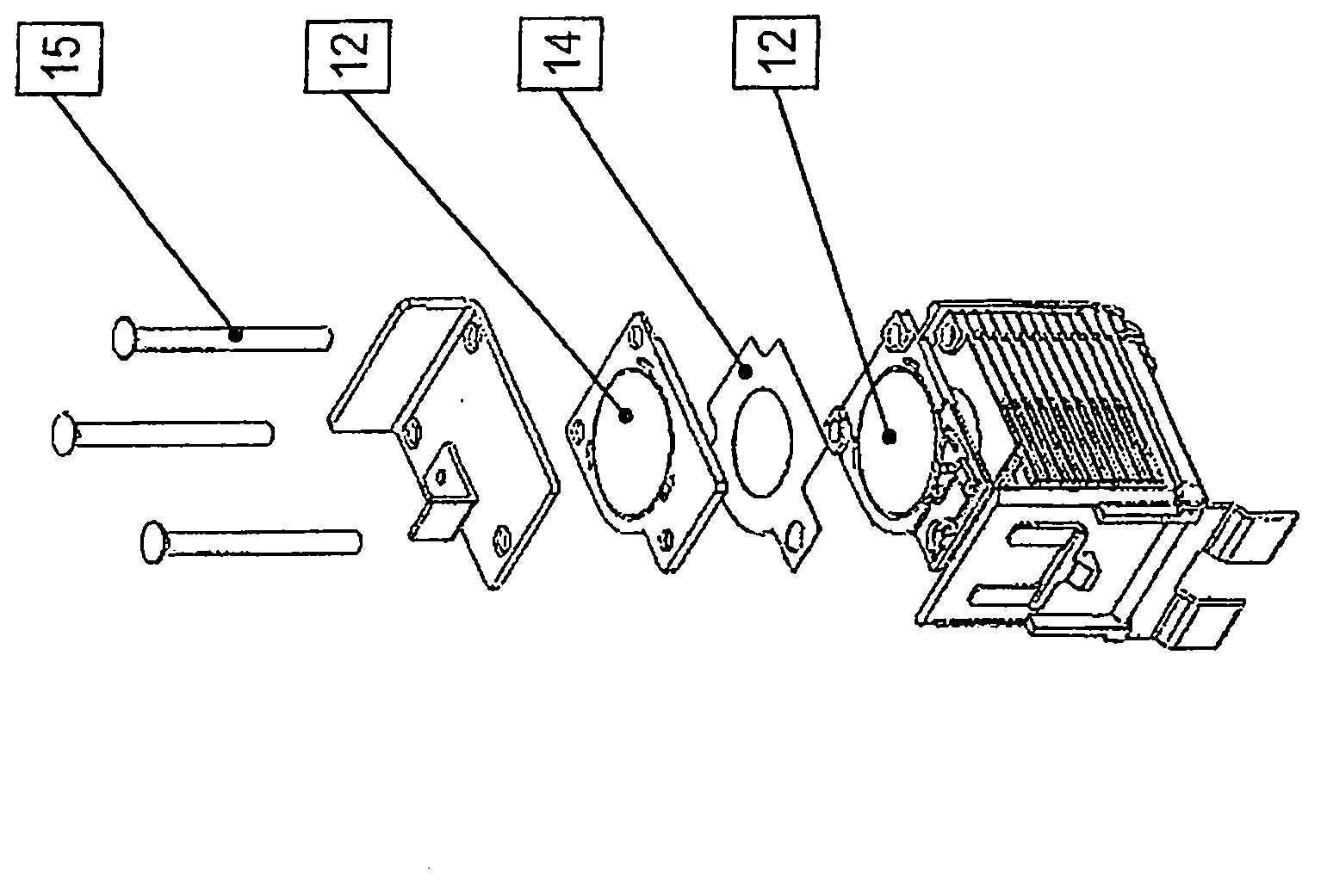

Spark gap having a plurality of series-connected individual spark gaps, which are located in a stack arrangement

ActiveCN103181041AAvoid dischargeSimple designOvervoltage arrestors using spark gapsEngineeringSpark gap

The invention relates to a spark gap having a plurality of series-connected individual spark gaps which are in a stack arrangement, are separated from one another by dielectric discs (14) and are provided with a spring contact (13), wherein the individual spark gaps have annular or disc-type electrodes (12), and furthermore having control elements (11) for influencing the voltage distribution over the stack arrangement. According to the invention, the annular or disc-type electrodes (12) which are required to form one of the respective individual spark gaps are each inserted into one insulation body (19) and are held centred by it. The respective dielectric discs (14) are located between the insulation bodies (19), and are fixed by them. A recess is provided in the insulation body (19) in order to hold and centre the electrodes (12), and its shape is complementary to the contour of the respective electrode (12), with the recess having sprung centring projections (10) or centring tabs, which are at least partially flexible, on the internal circumference side.

Owner:デーンエスエープルスツェオーカーゲー

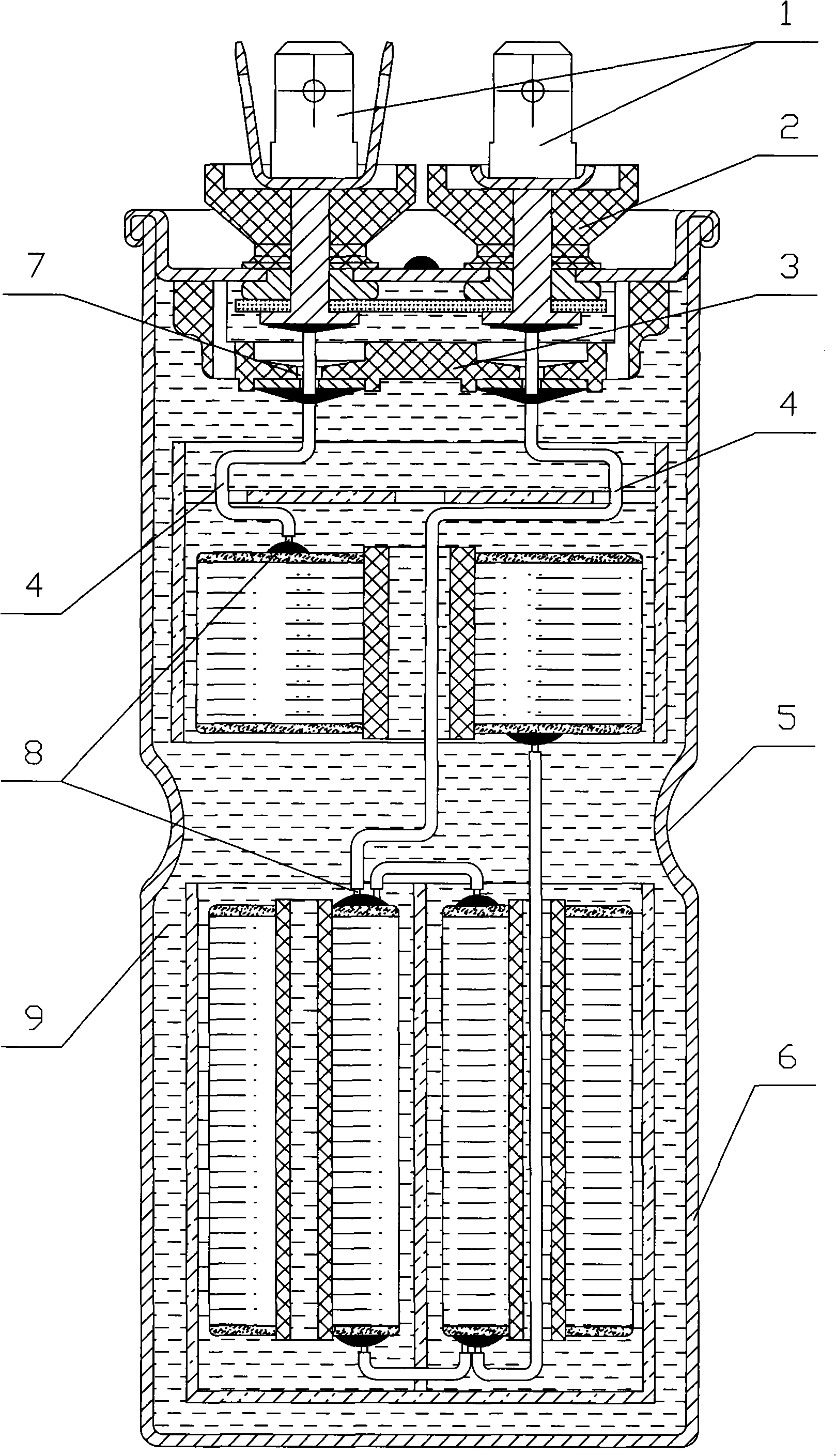

Firing and explosion prevention high voltage capacitor

InactiveCN101527200APrevent fallingWill not burn and explodeFixed capacitor housing/encapsulationHigh voltage capacitorsHigh pressure

The invention discloses a firing and explosion prevention high voltage capacitor, comprising a metal enclosed shell (6) and a shell cover component (2) with two exterior connection terminals (1); the shell (6) is internally provided with a set of capacitor cores connected in parallel and series; the two connection ends (8) of the capacitor core set are respectively connected with the two exterior connection terminals (1) by lead wires (4); the shell (6) is filled with steeping fluid (9) which is 330 methyl silicone oil; and the middle part of the shell (6) is provided with an annular groove (5) arranged in circumferential direction along the shell (6). With the above structure adopted, as the steeping fluid in the capacitor is 330 methyl silicone oil, the flaming-free property ensures that the capacitor can not fire or explode when the electric quantity is too large or the capacitor leaks; meanwhile the capacitor can be bound on other parts by the annular groove to avoid falling off during use.

Owner:NINGBO BICAI IND

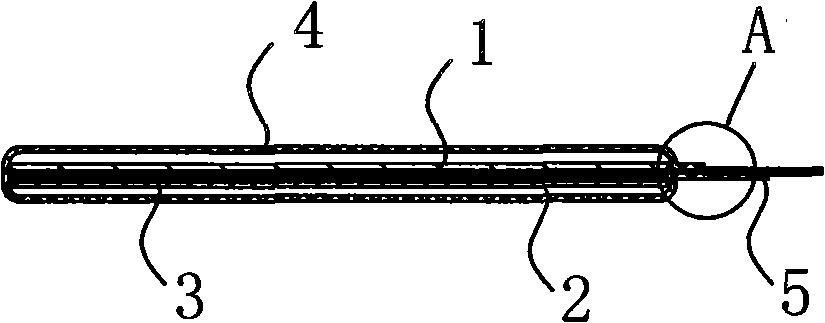

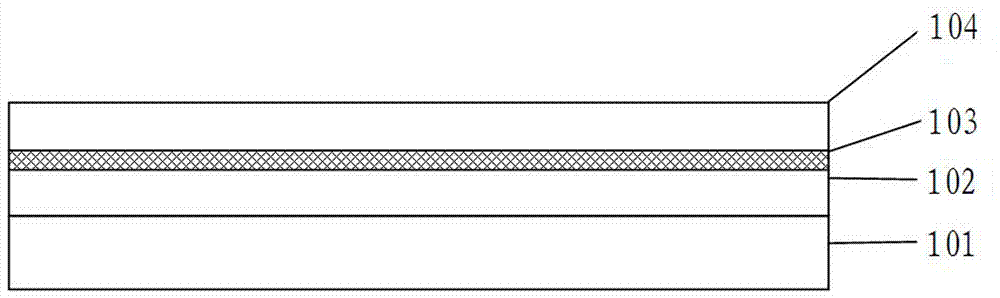

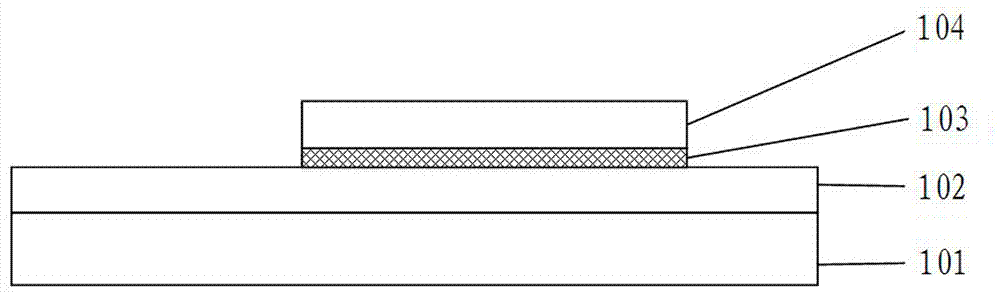

Sensing optical fiber and optical fiber sensing device

InactiveCN107941335AReduce weldingReduce the number of cutsCladded optical fibreOptical waveguide light guideFiberResonance

The invention provides a sensing optical fiber, and the optical fiber is a hollow anti-resonance optical fiber. The hollow anti-resonance optical fiber comprises a cladding region formed by a miniature capillary tube, a hollow tube, and a fiber core region which is surrounded by the cladding region. The hollow tube is disposed at an outer side of the cladding region in a cup joint manner. The refractive index of the fiber core region is lower than the refractive index of the cladding region. Each pre-selection position in each group of pre-selection positions on the side surface of the hollowtube is provided with a through hole, and all pre-selection positions in each group are arranged in the direction of the central axis of the sensing optical fiber. During the detection of various types of to-be-detected substances, the optical fiber can reduce the number of fusing and cutting times of the sensing optical fiber, reduces the workload of detection, and improves the accuracy of a detection result.

Owner:BEIJING UNIV OF TECH

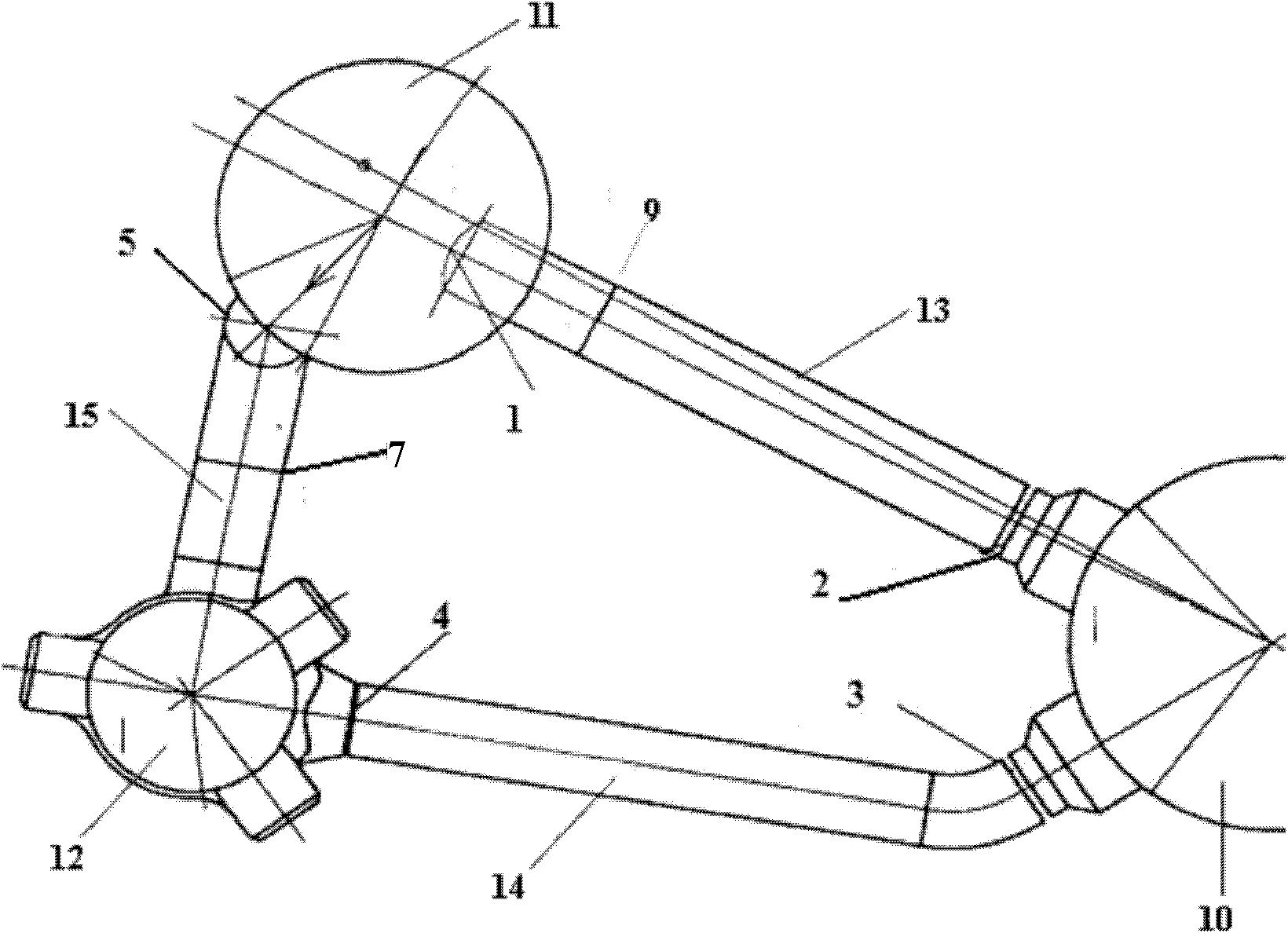

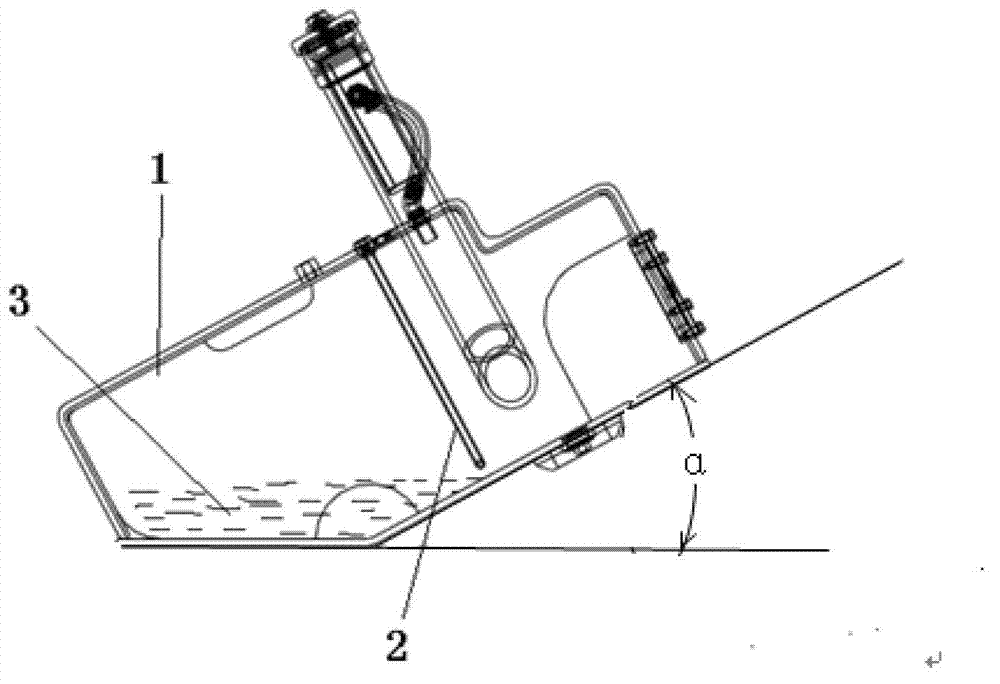

Fuel tank

The invention relates to a fuel tank and overcomes defects that a fuel sucking pipe of the existing fuel tank cannot suck fuels when the fuel amount is small and the fuel tank slants. The fuel tank comprises a tank body, wherein a fuel sucking device is arranged in the tank body, and a vertically upward coaming is arranged on a base board disposed in the tank body and encloses a fuel collection accommodating cavity on the base plate of the tank body surrounding a fuel sucking port of the fuel sucking device. A fuel collection channel attached to the base plate of the tank body and connecting the inside and the outside of the fuel collection accommodating cavity is arranged on the coaming in the horizontal direction, and two ends of the fuel collection channel are respectively located in the front of and at the back of the fuel sucking port. When the fuel tank slants back and forth, the fuels on the periphery of the coaming can be collected into the fuel collection accommodating cavity through the fuel collection channel, the fuels entering the fuel collection accommodating cavity cannot flow out of the fuel collection accommodating cavity along with slanting of the fuel tank, therefore the fuel sucking port is ensured to be soaked into the fuels and suck the fuels at any time, residual fuels in a diesel tank can be used maximally, and the practical use ratio of the fuel tank volume is improved.

Owner:GUANGXI LIUGONG MASCH CO LTD

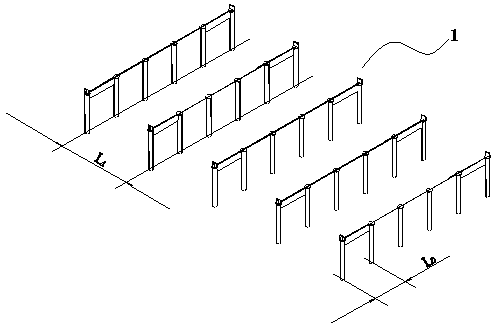

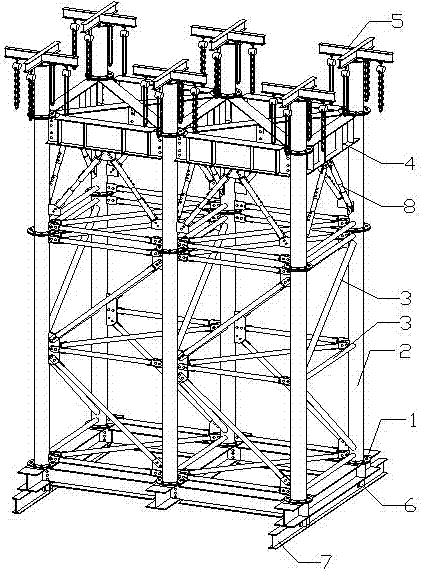

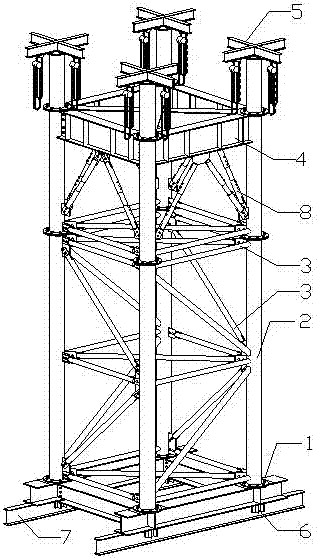

Self-lifting method for large scale steel structure supporting platform in limited space

The invention discloses a self-lifting method for a large scale steel structure supporting platform in a limited space, and the method bases on a self-lifting steel structure supporting platform. The self-lifting steel structure supporting platform comprises a sliding orbit composed of two joist steels or steel rail which are arranged in parallel and a plurality of self-lifting steel structure sliding measure supports arranged on the sliding orbit side by side; each self-lifting steel structure sliding measure support comprises a base, standard mast sections, a platform beam adjusting section and a lifting frame. Operation steps comprise that quantity of needed self-lifting steel structure sliding measure supports is measured, then the sliding orbit and the base are installed, and N of the standard mast sections, the platform beam adjusting section and the lifting frame are installed on each base in sequence. According to the requirement for construction height, a rectangular ring beam is lifted to a pointed elevation position by one of the top lifting frame and is fixed. According to the self-lifting steel structure supporting platform and the self-lifting method, lifting work of a large scale supporting structure can be conducted by fully relying on manpower, mounting and dismounting are convenient, efficiency is high, needed materials are less, cost is low, and cycle use can be achieved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

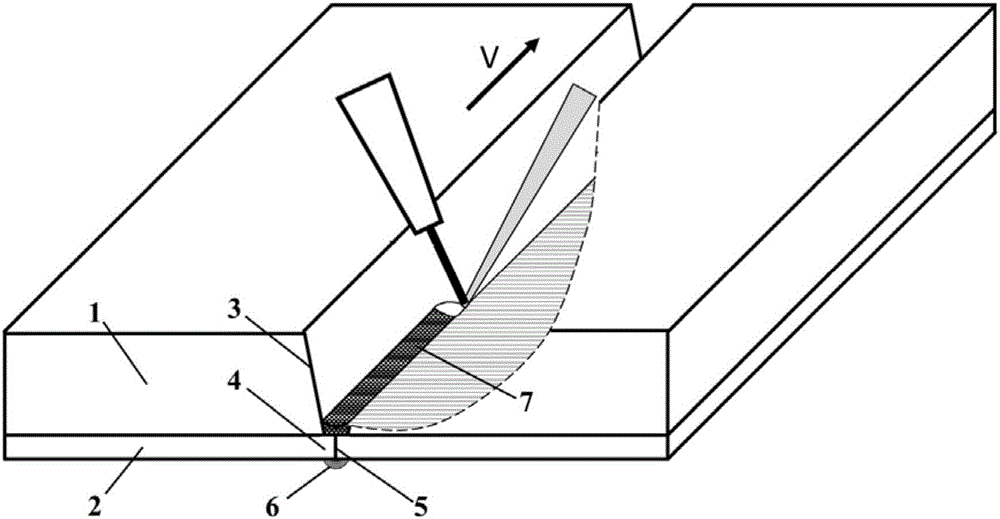

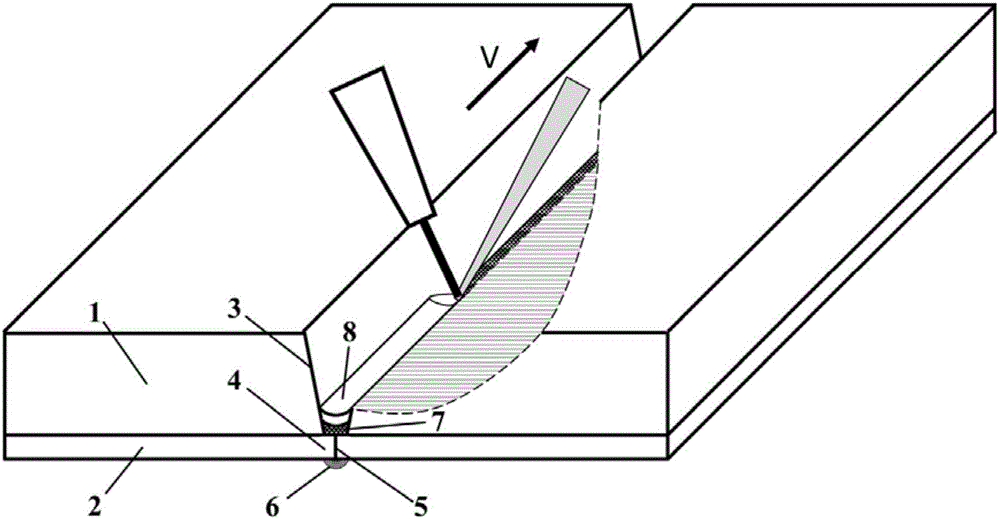

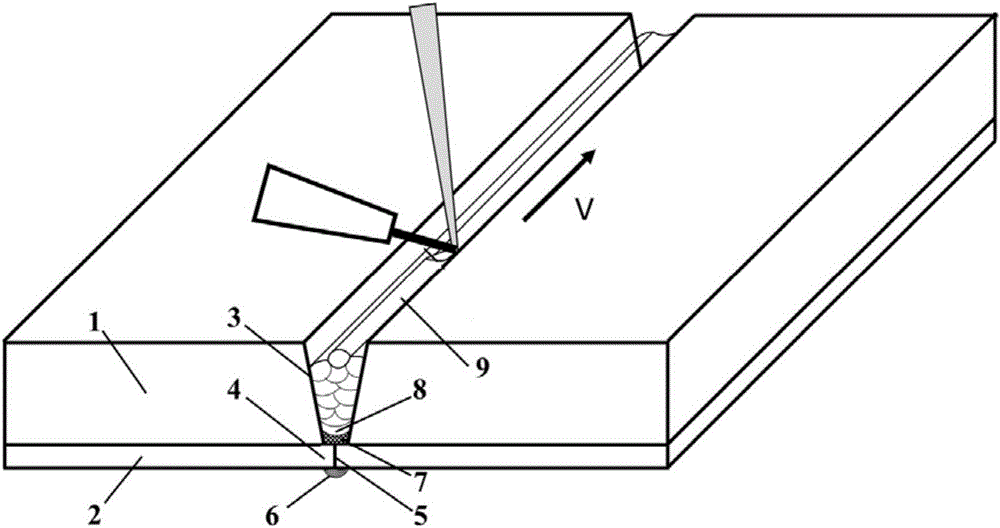

Laser wire filling and butt welding method for titanium-steel composite plate with T2 red copper serving as transition layer

ActiveCN106112263AAvoid it happening againMitigation of Thermal Stress MismatchLaser beam welding apparatusButt weldingTitanium

The invention discloses a laser wire filling and butt welding method for a titanium-steel composite plate with T2 red copper serving as a transition layer. The method comprises the following steps: (1) machining two titanium-steel composite plates to be subjected to butt welding; (2) butting and assembling the two titanium-steel composite plates to be subjected to butt welding; (3) performing laser backing welding on a gap between titanium plates of the two titanium-steel composite plates to be subjected to butt welding to form a laser backing welding line; (4) covering the lower surface of the laser backing welding line with titanium welding wires by adopting laser wire filling welding to form a titanium wire welding line, and overlaying a layer of T2 red copper at the bottom of a V-shaped groove to form a transition layer welding line; (5) overlaying a first layer of steel welding bead on the upper surface of the transition layer welding line; and (6) overlaying a second layer of steel welding bead on the upper surface of the first layer of steel welding bead by adopting the laser wire filling method. According to the method, the problems of high welding heat stress and serious mismatch of heat stress between metal layers due to the formation of brittle intermetallic compounds in the butt welding process of the titanium-steel composite plate can be effectively solved.

Owner:XI AN JIAOTONG UNIV

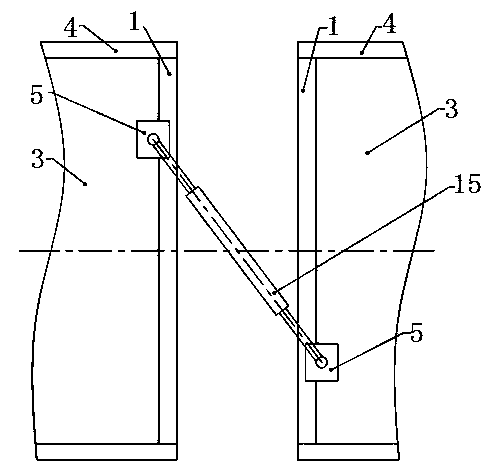

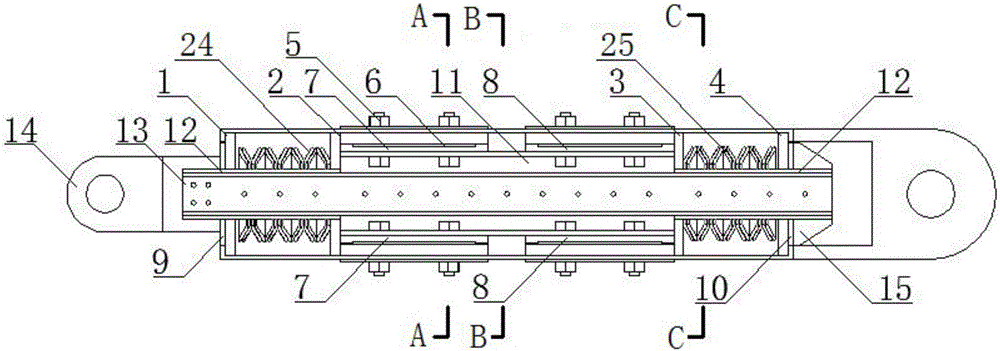

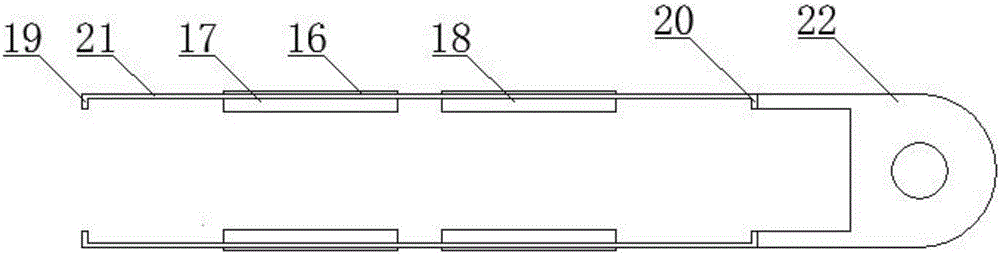

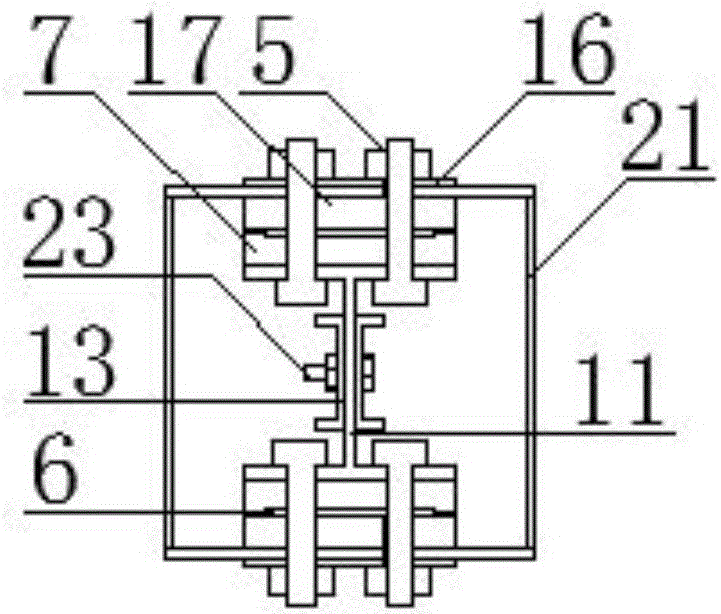

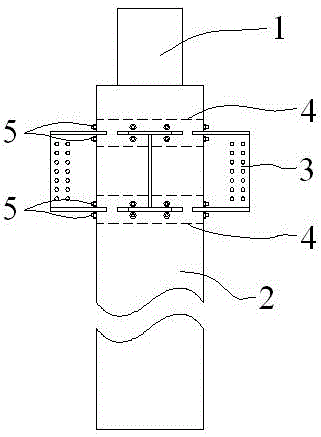

Prefabricated self-centering energy dissipation bracing with I-shaped inner tube and prestressed disc springs

ActiveCN106223696AReduce weldingImprove mechanical performanceProtective buildings/sheltersShock proofingShaped beamEngineering

The invention relates to a prefabricated self-centering energy dissipation bracing with I-shaped inner tube and prestressed disc springs. An outer tube left retainer and an outer tube right retainer are fixed to upper and lower inner walls of an outer tube steel plate; the inner tube includes an inner tube middle HW shaped beam and inner tube bilateral I-shaped beams welded to two ends of the inner tube middle HW shaped beam; the parts of upper and lower flange outer sides of the inner tube middle HW shaped beam corresponding to the outer tube left retainer and the inner tube right retainer are fixedly provided with an inner tube left friction pad and an inner tube right friction pad respectively, a first disc spring and a second disc spring sleeve the inner tube bilateral I-shaped beams, a first disc spring left retaining plate and a first disc spring right retaining plate are arranged on two sides of the first disc spring, and a second disc spring right retaining plate and a second disc spring right retaining plate are arranged on two sides of the second disc spring. The prefabricated self-centering energy dissipation bracing with I-shaped inner tube and prestressed disc springs is of prefabricated type, is free to assemble, has reduced welding and accordingly better load-carrying capacity, and is low in processing cost and simple to mount.

Owner:BEIJING JIAOTONG UNIV

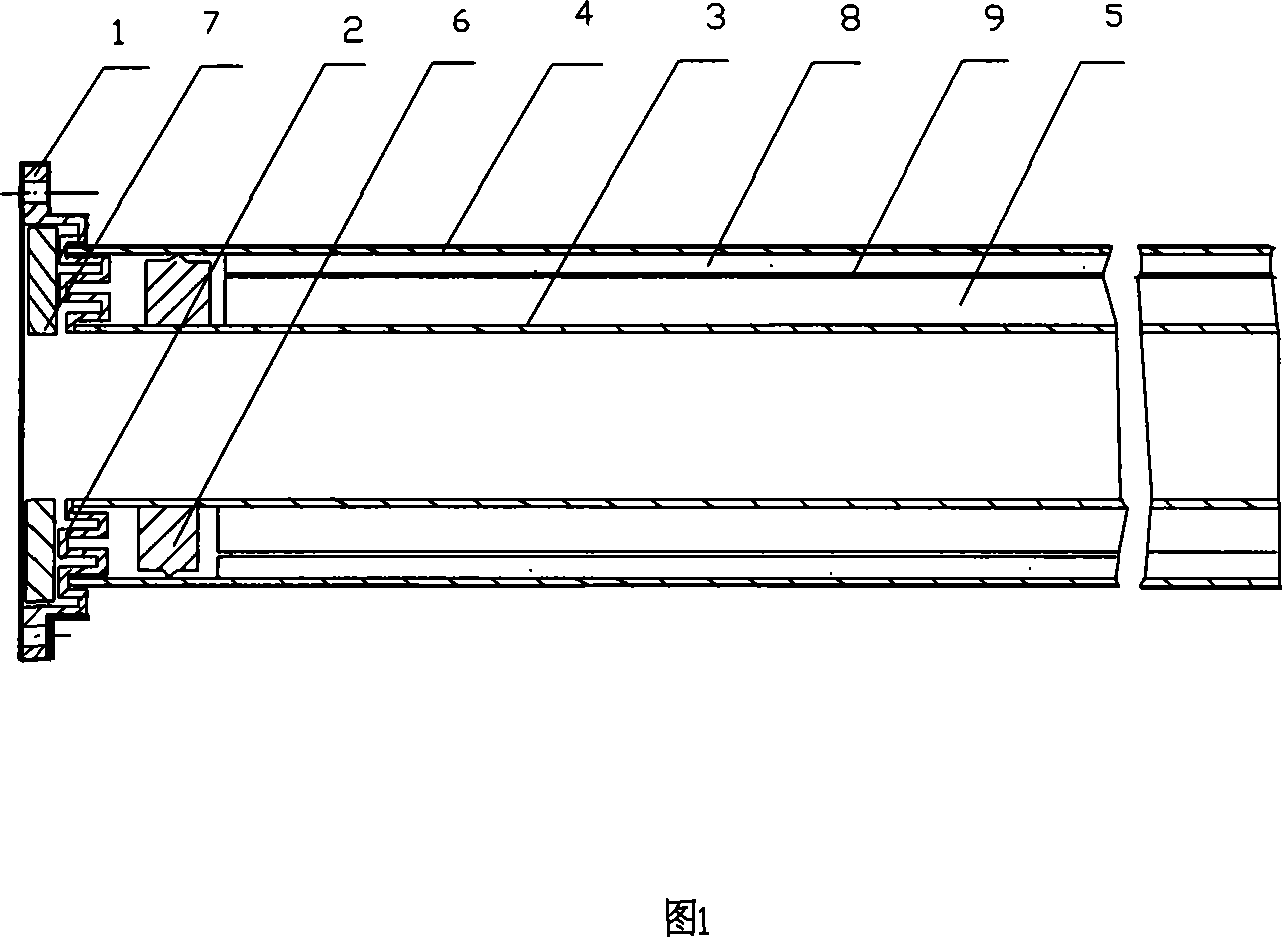

Heat proof vacuum tube

InactiveCN101093045ALow costWide range of usesFlanged jointsThermal insulationEngineeringSupport point

This invention relates to a heat-preservation vacuum tube including a flange, a tube and a bushing, in which at least one flange is set with ripple joints in the flanges at both ends of the vacuum tube to form a vacuum cavity with the tube and the bushing, several axial and radial continuous or discontinuous support tendons, support loops or support points are supported on the inside wall of the bushing, and the ripple structure on the flange can improve its stress relation and the elastic pad inside can reduce resistance of pipelines and keeps warm at the end and welding lines are less.

Owner:张丽娟

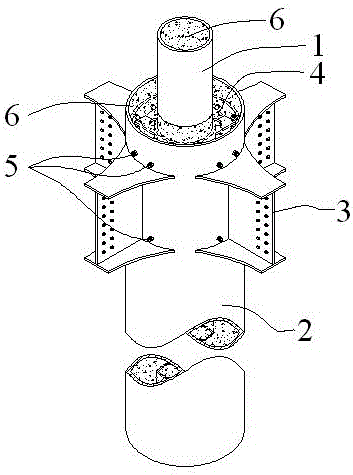

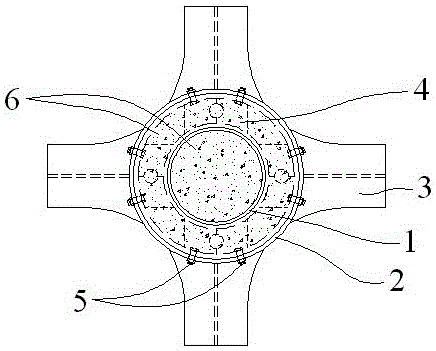

Beam-column node of double-round steel pipe concrete column and construction method

InactiveCN105926780AEasy constructionSmooth connectionBuilding material handlingWeld seamMaterials science

The invention relates to a beam-column node of a double-round steel pipe concrete column and a construction method. The beam-column node consists of an inner steel pipe, an outer steel pipe, a connecting beam section, an inner connecting part, high-strength bolts and concrete, wherein the axis of the inner steel pipe is coincided with the axis of the outer steel pipe, and the upper end of the inner steel pipe extends for 500mm out of the upper end of the outer steel pipe; the connecting beam section is welded on the outer steel pipe, and a flange plate of the connecting beam section is positioned between the two high-strength bolts; the inner connecting part is positioned between the inner steel pipe and the outer steel pipe, is sheathed on the inner steel pipe, and is fixedly arranged on the outer steel pipe by the high-strength bolts; the concrete is put into the inner steel pipe and the outer steel pipe. In the construction process of the beam-column node, the inner connecting part is fixedly arranged on the outer steel pipe by the high-strength bolts, then the outer sleeve pipe is sheathed onto the inner steel pipe, the inner steel pipe penetrates through an inner ring steel pipe of the inner connecting part, and finally the concrete is cast. The beam-column node has the advantages that the number of welding seams is fewer, the construction is quick, the stress property is good, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com