Prefabricated self-centering energy dissipation bracing with I-shaped inner tube and prestressed disc springs

An energy-dissipating support and I-shaped technology, applied in protective buildings/shelters, building components, building types, etc., can solve problems such as dissipation, achieve good mechanical performance, reduce residual deformation, and reduce welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

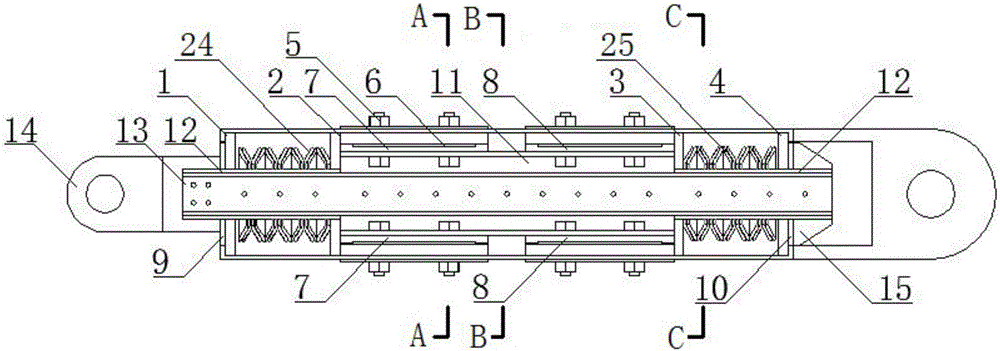

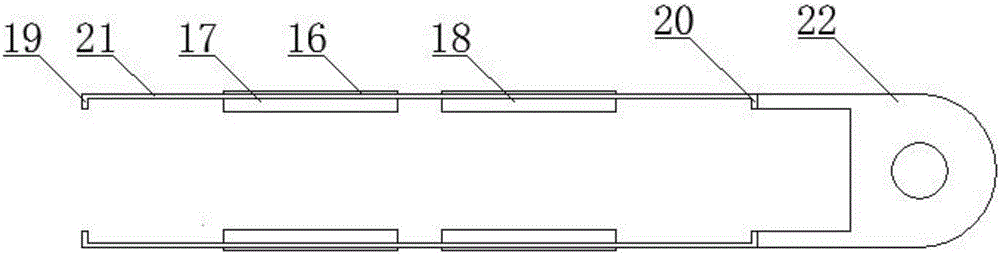

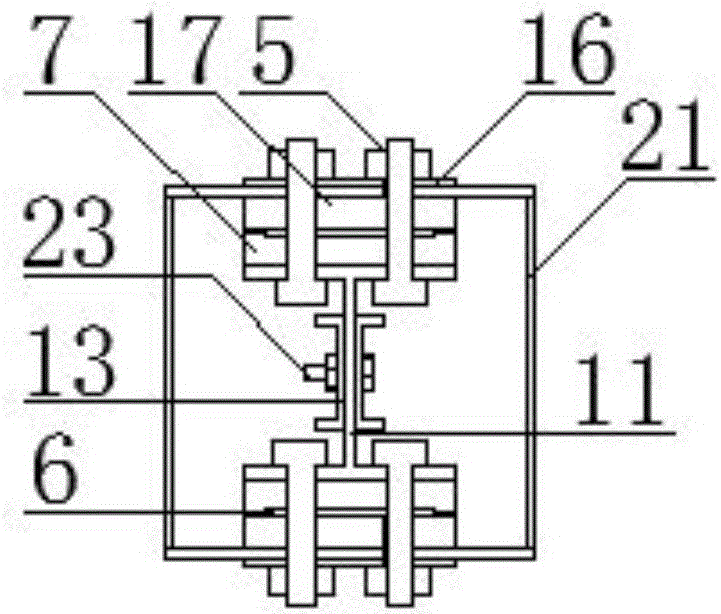

[0029] Such as Figure 1-Figure 5 As shown, an assembled I-shaped inner tube preloaded disc spring self-resetting energy-dissipating support includes a first disc spring 24, a second disc spring 25, an outer tube and an inner tube. The outer tube includes an outer tube with a rectangular cross section. Tube steel plates 21, the two ends of the outer tube steel plates 21 are fixedly provided with outer tube left side baffles 19 and outer tube right side baffles 20, and the upper and lower inner walls of the outer tube steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com