Beam-column node of double-round steel pipe concrete column and construction method

A concrete column and beam-column joint technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of large welding residual stress, slow construction speed, and many welds, so as to achieve fewer welds and quick construction , to avoid the effect of deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

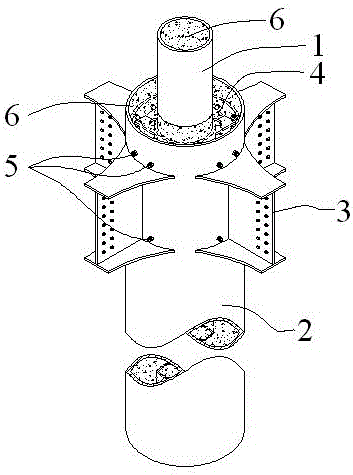

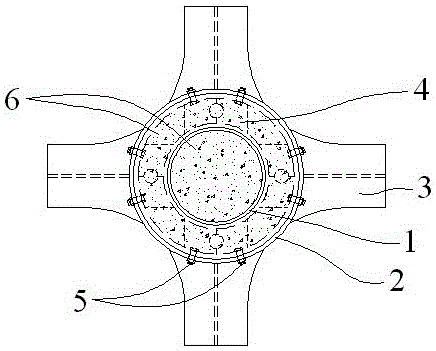

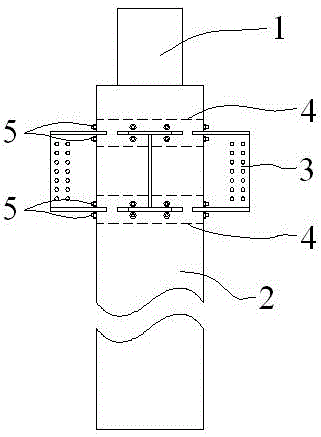

[0022] Such as Figure 1-3 As shown, a beam-column joint of a double-circular steel tube concrete column consists of inner steel tube (1), outer steel tube (2), connecting beam section (3), inner connector (4), high-strength bolts (5) and concrete ( 6) Composition; the sections of the inner steel pipe (1) and the outer steel pipe (2) are both circular, the axis of the inner steel pipe (1) coincides with the axis of the outer steel pipe (2), and the lower end of the inner steel pipe (1) and the outer steel pipe (2) ) is flush with the lower end, and the upper end of the inner steel pipe (1) protrudes 500mm from the upper end of the outer steel pipe (2); the connecting beam section (3) is welded on the outer steel pipe (2), and the flange plate of the connecting beam section (3) is located on two turns of high-strength bolts ( 5); the inner connecting piece (4) is located between the inner steel pipe (1) and the outer steel pipe (2), the inner connecting piece (4) is set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com