Fuel tank

A fuel tank and fuel tank technology, which is applied in the layout, power plant, transportation and packaging combined with the fuel supply of the internal combustion engine, can solve the problem of not being able to absorb oil, and achieve the effects of improving service life, easy manufacturing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

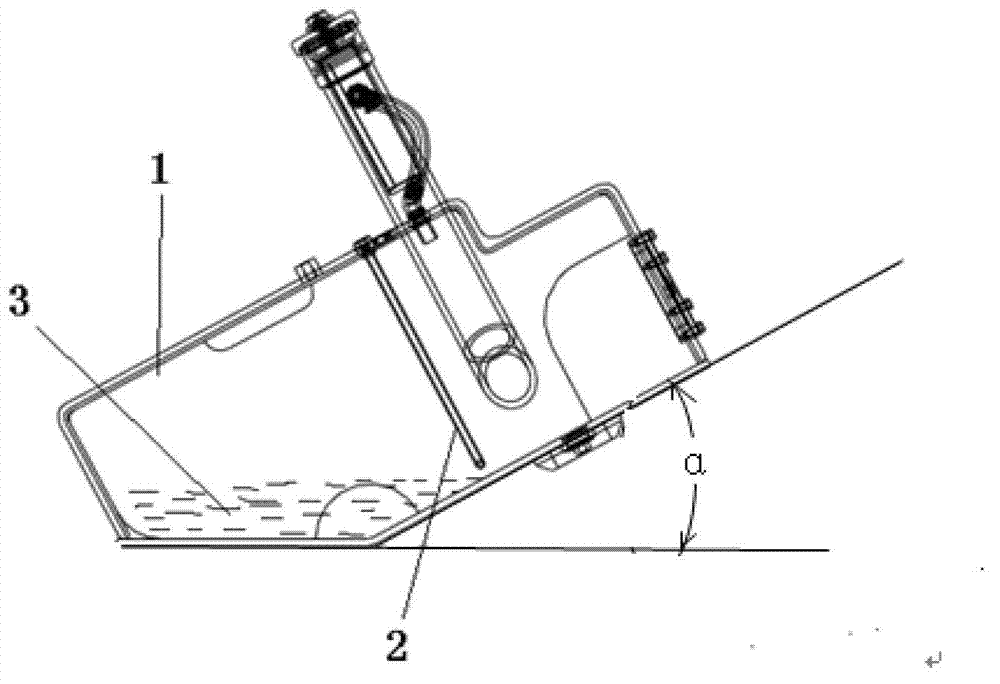

[0021] Figure 2 to Figure 4 A preferred implementation of the present invention is shown, and the implementation of this example can be applied to other construction machinery equipment.

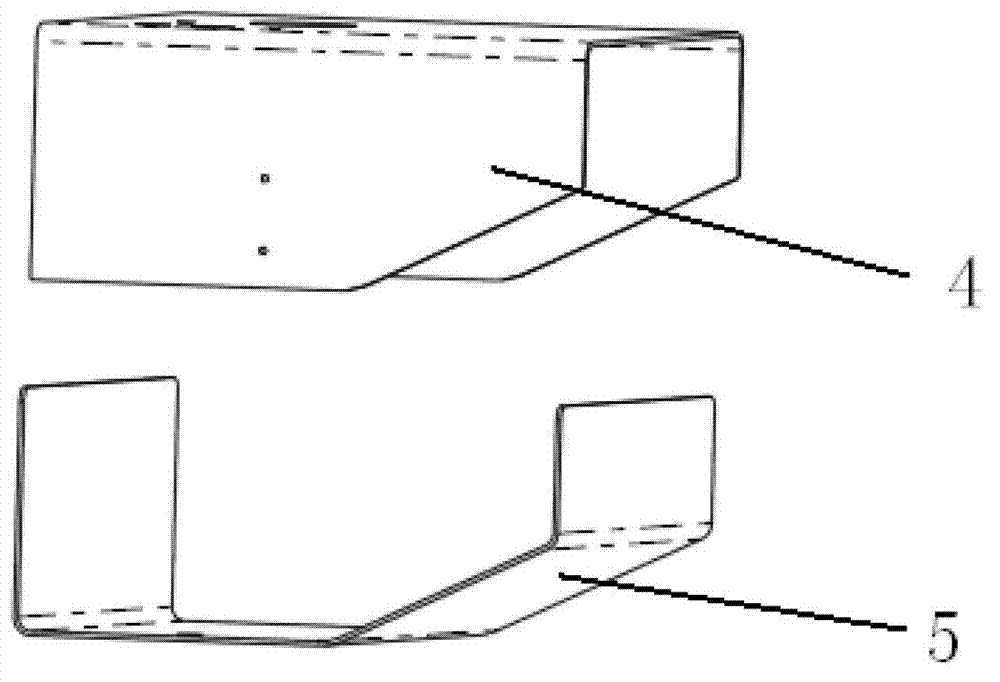

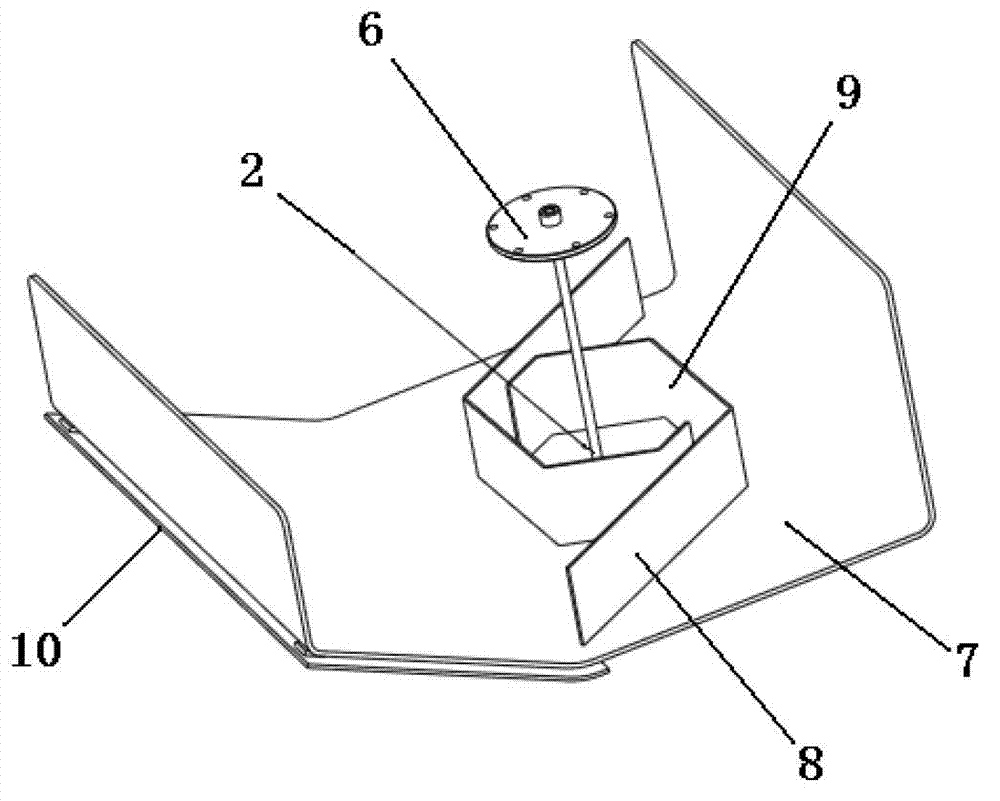

[0022] Such as figure 2 As shown, the tank body 1 of the fuel tank in this embodiment is composed of an upper bent plate 4 and a lower bent plate 5, both of which are U-shaped, and they are interlocked and welded Form a box body, wherein the upper bent plate 4 forms the left side plate, right side plate and top plate of the box body, and the lower bent plate 5 forms the rear side plate, front side plate and bottom plate of the box body. Wherein the rear half of the base plate is upwardly warped, and the outer side of the warped part is fixed with a guard plate 10 by bolts, which can be replaced after the guard plate 10 is bumped, deformed and damaged. Such as image 3 As shown, an oil suction device 6 is installed on the top plate of the box body 1, and the oil suction pipe 2 of the oil...

Embodiment 2

[0024] Such as Figure 5 Image 6 As shown, in this embodiment, the coaming plate 13 forms a vertical mouth-shaped oil collection chamber on the bottom plate 7 of the box body, and a front oil collection inlet 16 is provided in front of the mouth-shaped coaming plate 13. The rear of the font coaming 13 is provided with a rear oil collection inlet 17, and in front of the coaming 13 are provided with two front vertical plates 14 arranged in a figure-of-eight shape to form a figure-of-eight oil collection port with an opening facing forward. There are two parallel inner vertical plates 15 in the cavity to form a long and narrow channel, one end of which is in communication with the front oil collecting inlet 16 of the coaming plate, and the other end extends beyond the oil suction port of the oil suction device in the oil collecting cavity To the rear coaming plate, the long and narrow channel forms an oil collecting channel with the oil collecting port and the front oil collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com