Self-lifting method for large scale steel structure supporting platform in limited space

A technology for supporting platforms and confined spaces, which is applied to the preparation of building components on site, pillars, building structures, etc., and can solve the problems of inability to meet the progress requirements and cost control of large-scale steel structure projects, construction safety cannot be guaranteed, and increase construction consumables Convenience and quickness of installation and disassembly, improvement of cycle life and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments.

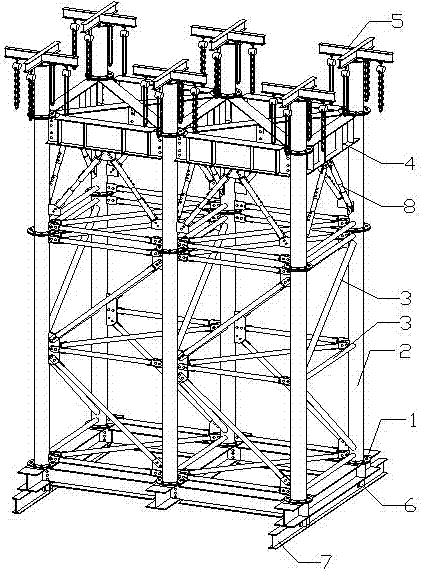

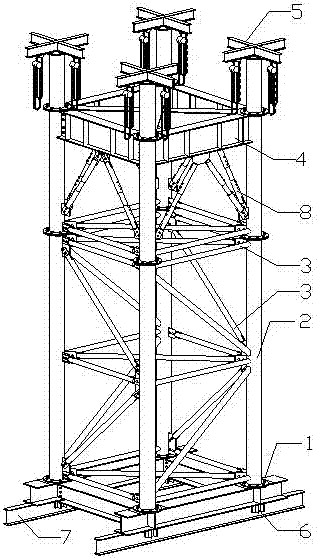

[0039] Such as Figure 1-6 As shown, a self-elevating method for a large-scale steel structure support platform in a confined space is characterized in that the method is based on a self-elevating steel structure support platform, which includes a sliding slide formed by two parallel-set I-beams or steel rails. Track 7, and several self-elevating steel structure sliding measure brackets arranged side by side on the sliding track 7; the self-elevating steel structure sliding measure support includes base 1, standard section, platform beam adjustment section and Lifting frame 5:

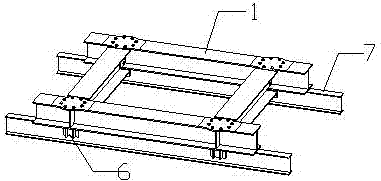

[0040] The base 1 includes two load-bearing beams arranged horizontally and parallel to each other, and two base connecting beams; the load-bearing beams are respectively placed on the upper end faces of the I-beams or rails; Fix the limit plate 6 to prevent the base from turning over th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com