Method for manufacturing duplex stainless steel middle assembly plate frame of chemical tanker

A duplex stainless steel and manufacturing method technology, applied in shipbuilding, manufacturing tools, ship design, etc., can solve the problems affecting the shipbuilding cycle, the surface damage of the base metal, and large welding deformation, so as to shorten the construction cycle and reduce welding , Reduce the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the manufacturing method of the duplex stainless steel intermediate frame of a kind of chemical tanker of the present invention is described in further detail, in order to understand the application process of the method of the present invention more clearly, but can't use this Limit the protection scope of the present invention.

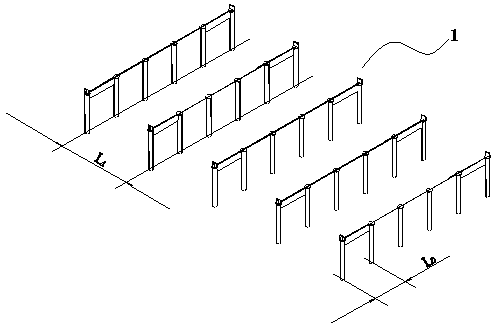

[0036] Such as Figure 1~Figure 11 As shown, the present embodiment is a method for manufacturing a duplex stainless steel intermediate frame for a chemical tanker. The manufacturing method includes the following steps:

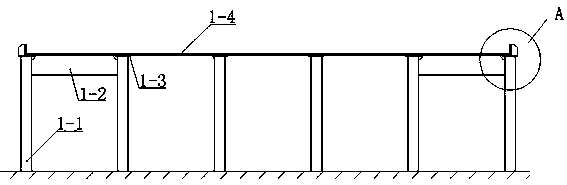

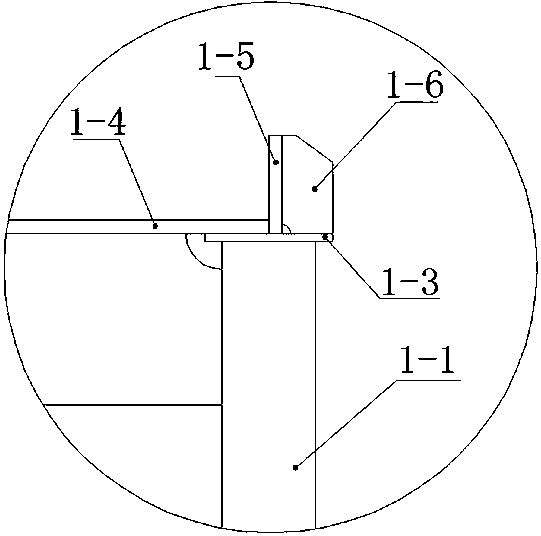

[0037] S1, production of special tire frame for duplex stainless steel panel, such as figure 1 As shown, the round tube column 1-1 is set up on the workshop floor, the connecting plate 1-2 is set between the two adjacent round tube columns 1-1 on the outside, and the top of each round tube column 1-1 is burnt Weld the circular top plate 1-3, and weld the stainless steel round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com