Method of manufacturing car axle case and car axle case manufactured by same

A manufacturing method and technology for axle housings, which are applied to axles, wheels, vehicle parts, etc., can solve the problems of high labor intensity, insufficient strength and rigidity of automobile axle housings, waste of resources, etc., and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the invention is described.

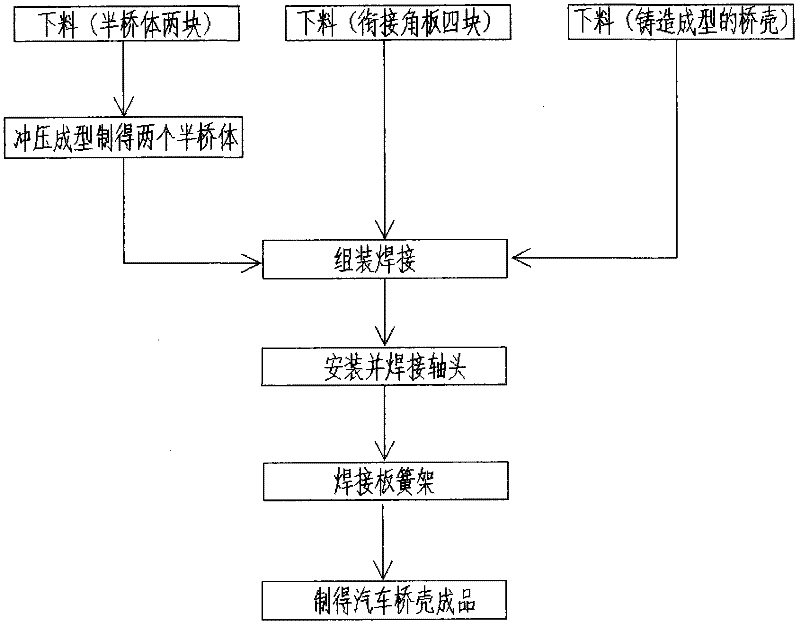

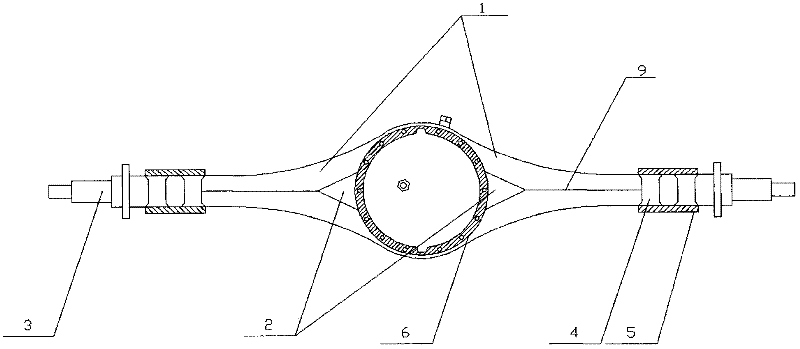

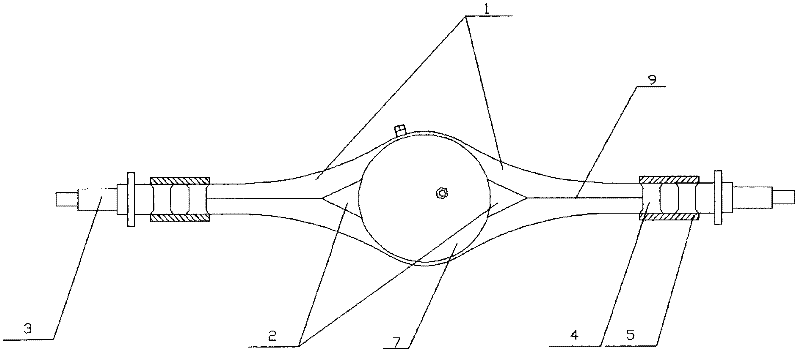

[0037] Such as Figure 1-Figure 3 as shown, figure 1 It is a flow chart of the manufacturing method in the prior art. figure 2 It is a schematic front view of an automobile axle housing in the prior art. image 3 Schematic rear view of an automobile axle housing in the prior art. When manufacturing automobile axle housings in the prior art, the first step is blanking, which includes two half-bridge body plates, four connecting angle plates, and the cast axle housing 7 . In the second part, the two half-bridge bodies 1 are made of two half-bridge bodies 1 through a punching machine, and the redundant edges on the half-bridge bodies 1 are cut, and the two half-bridge bodies 1 are butt-welded together. At the same time, the Four connecting angle plates are welded on two half bridge bodies 1 to form the bridge body 10 of the automobile axle housing (two connecting angle plates are welded on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com