Patents

Literature

50results about How to "High preparation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

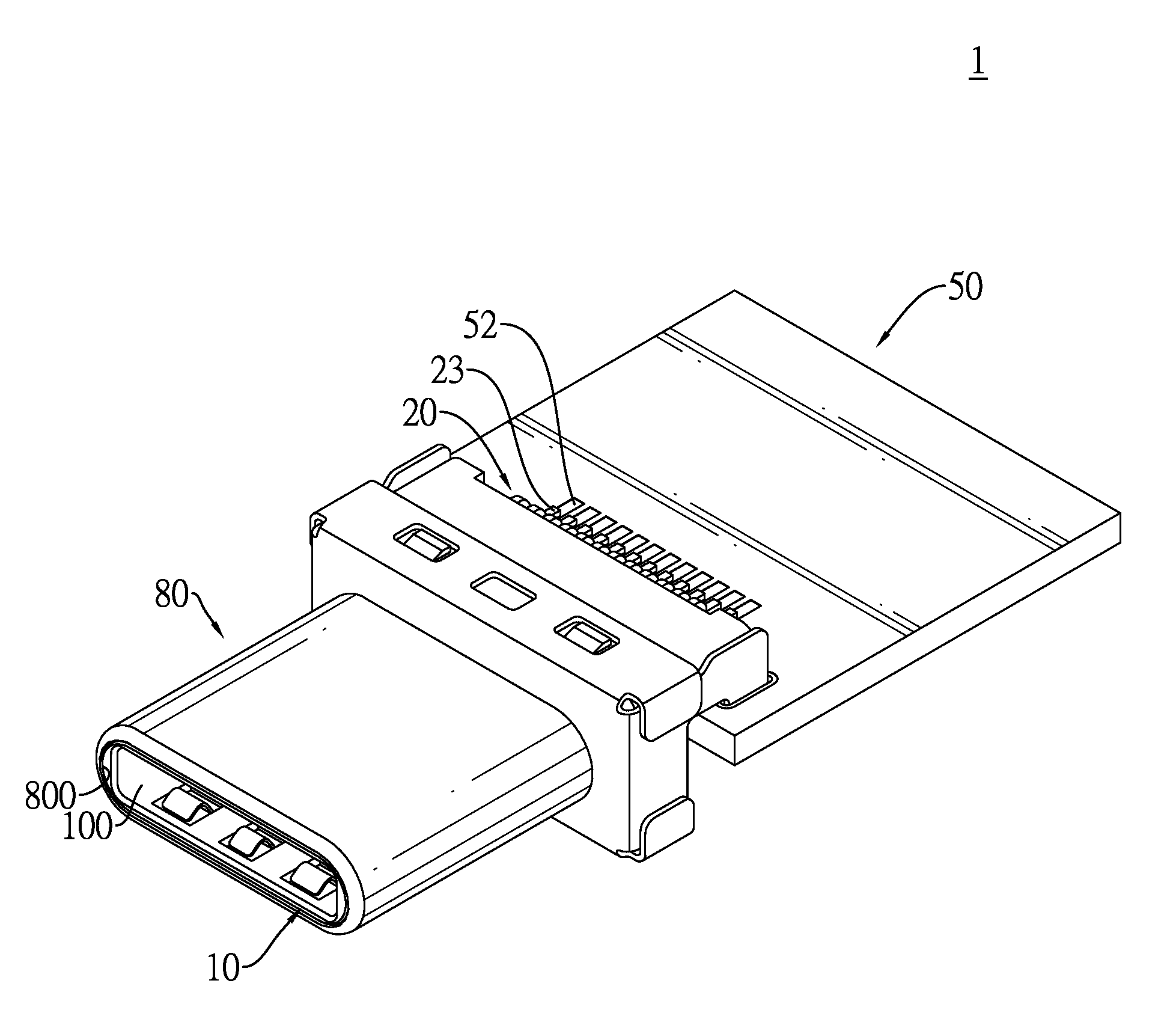

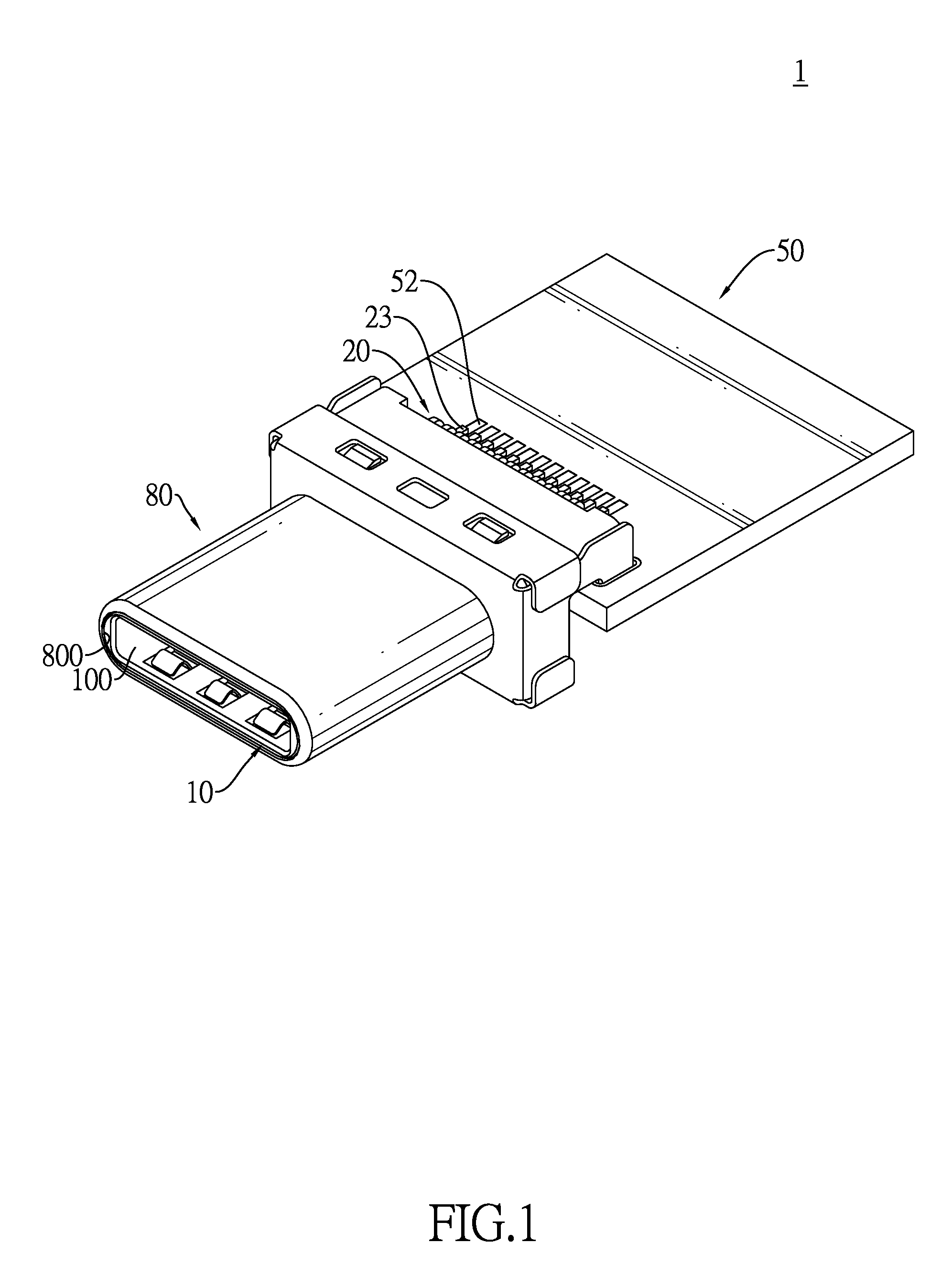

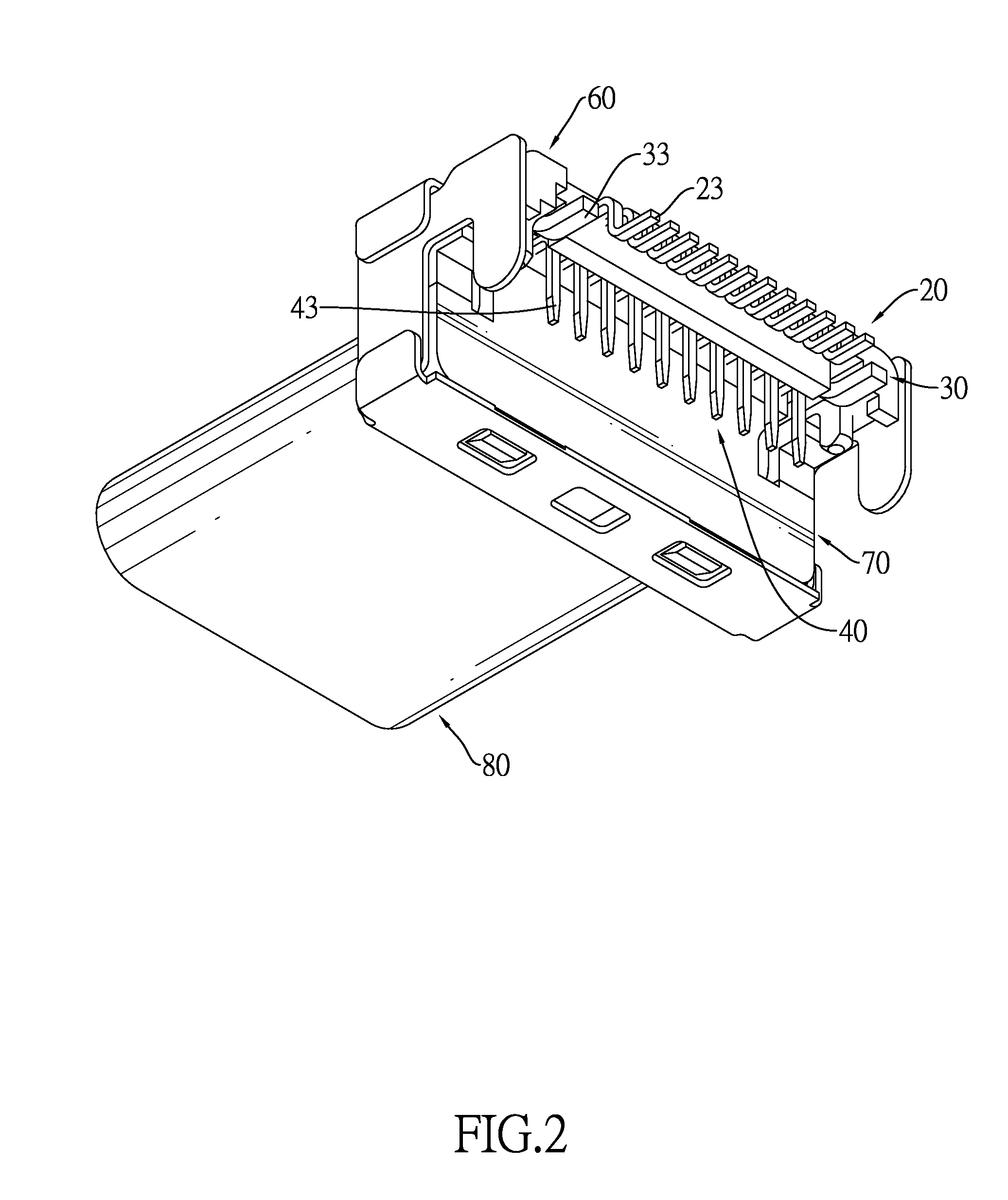

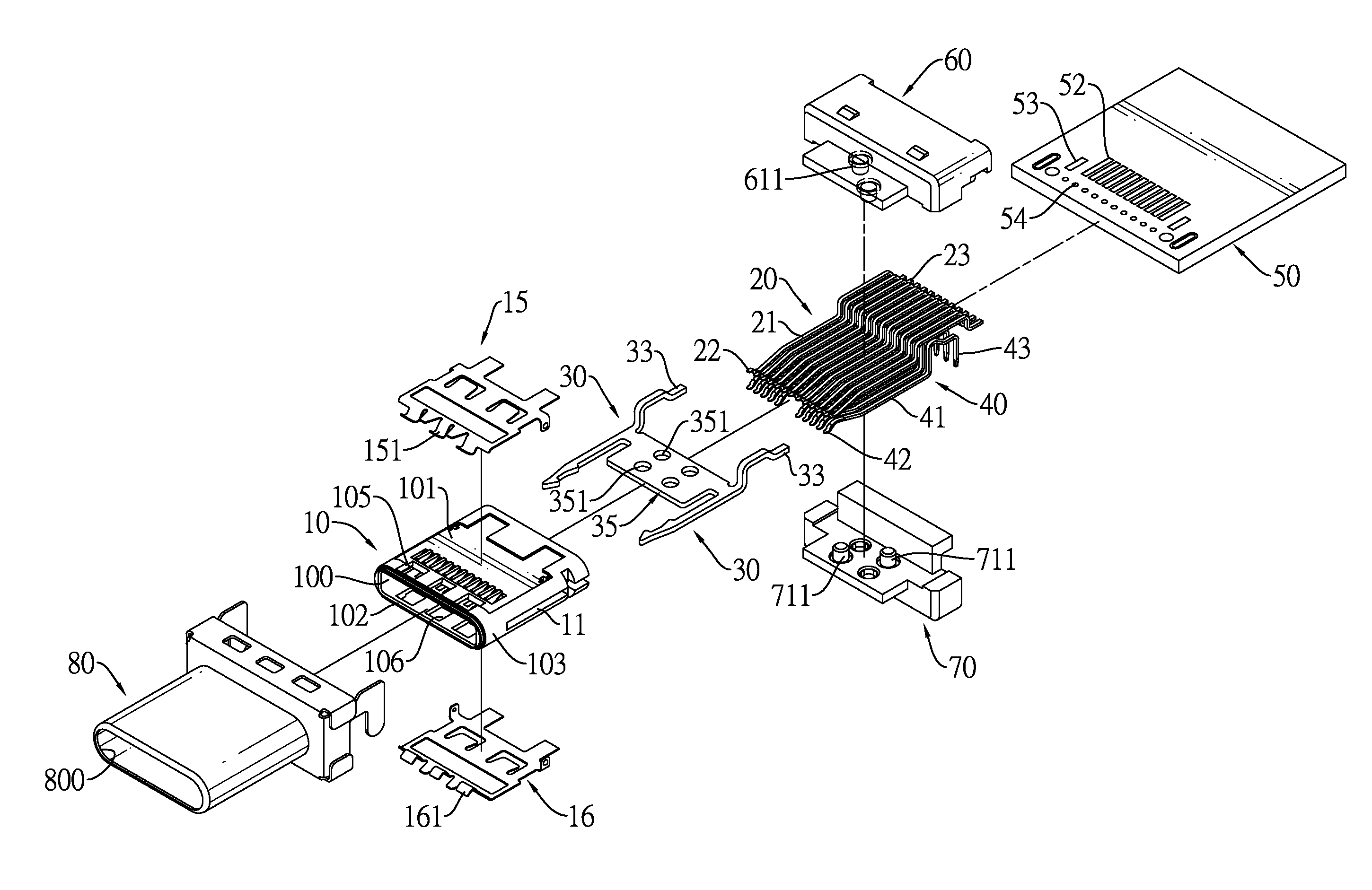

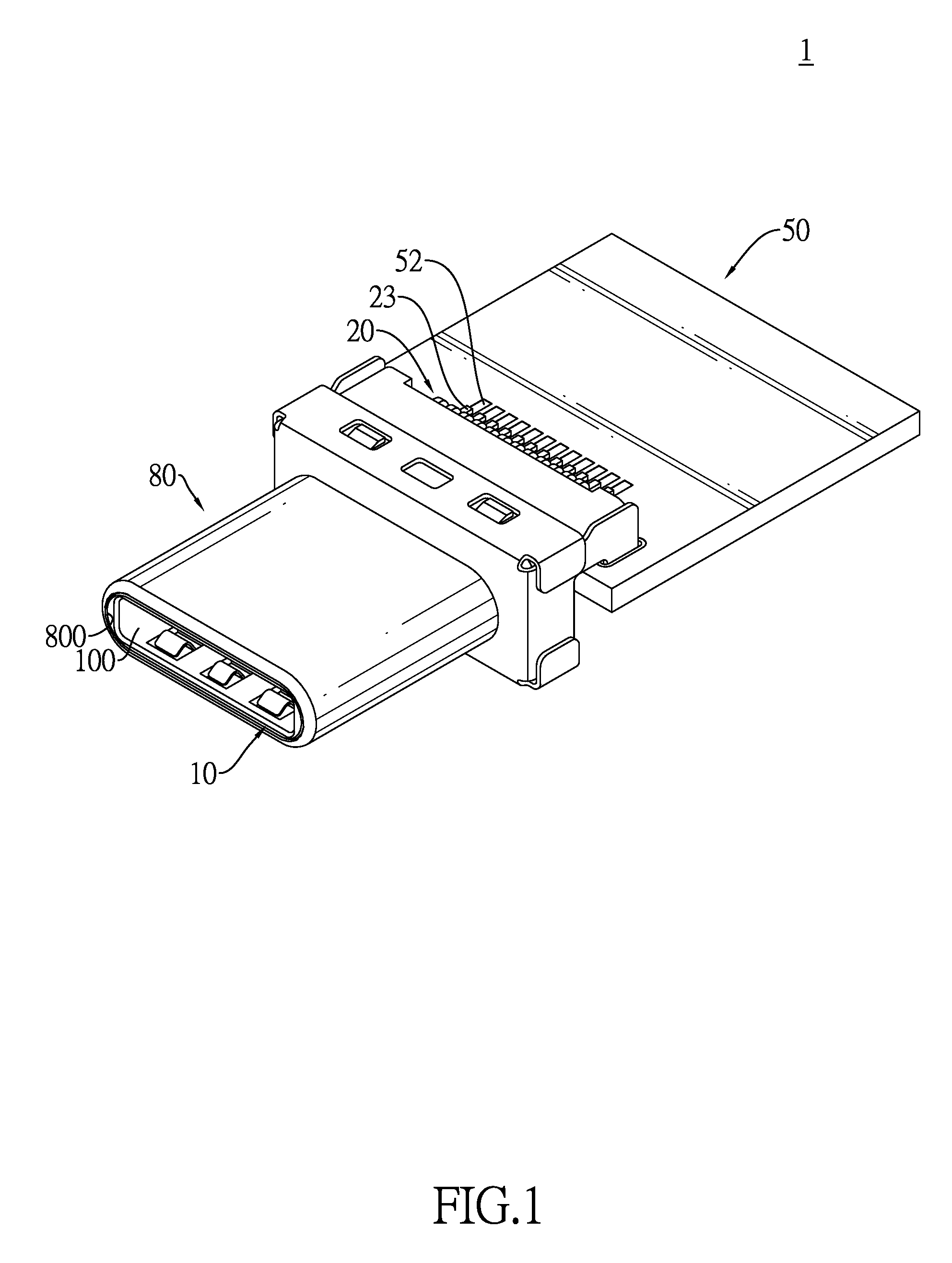

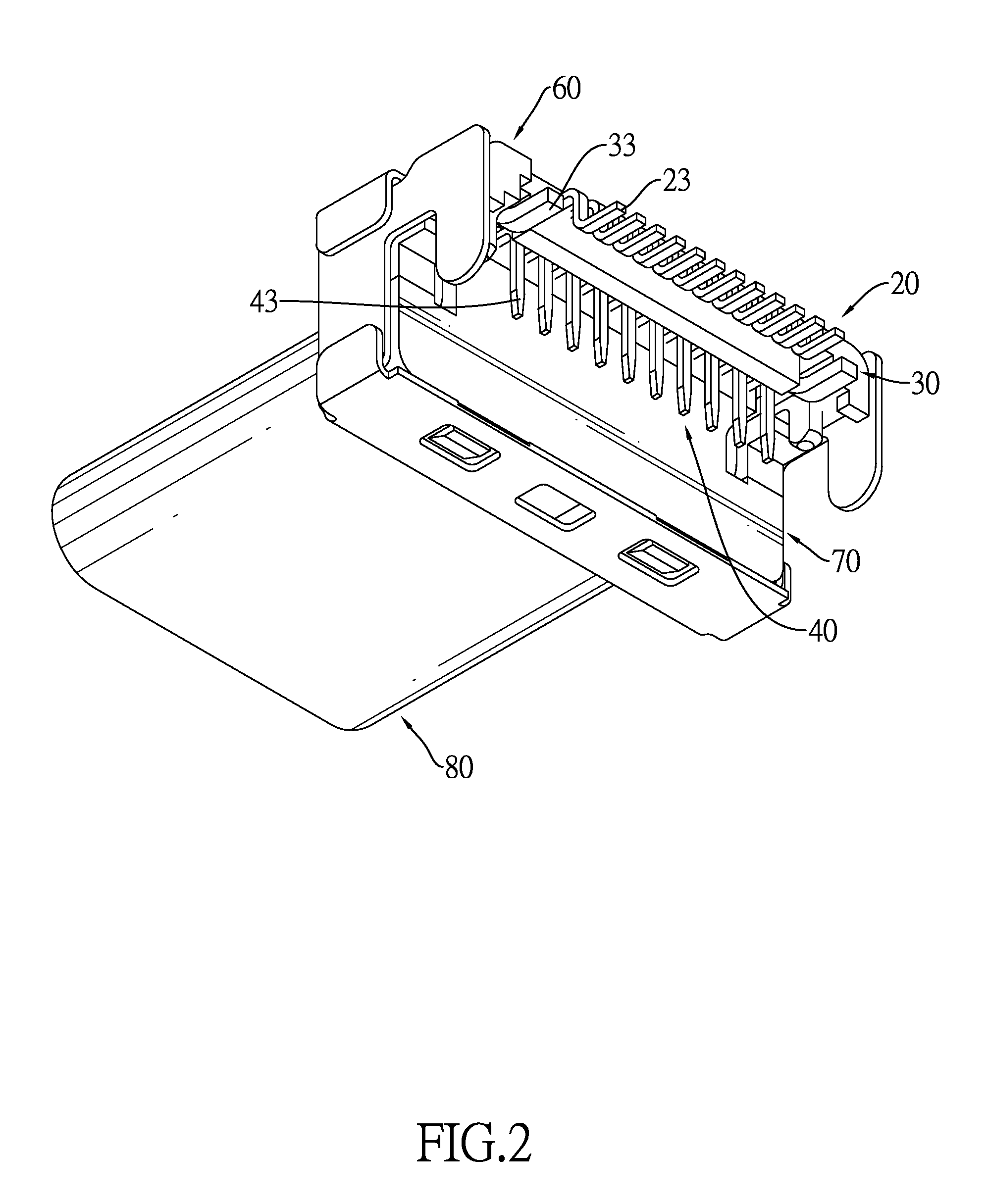

Electrical plug connector assembly

ActiveUS20160156114A1Reduce weldingHigh preparation ratePrinted circuit aspectsCoupling contact membersProduction rateEngineering

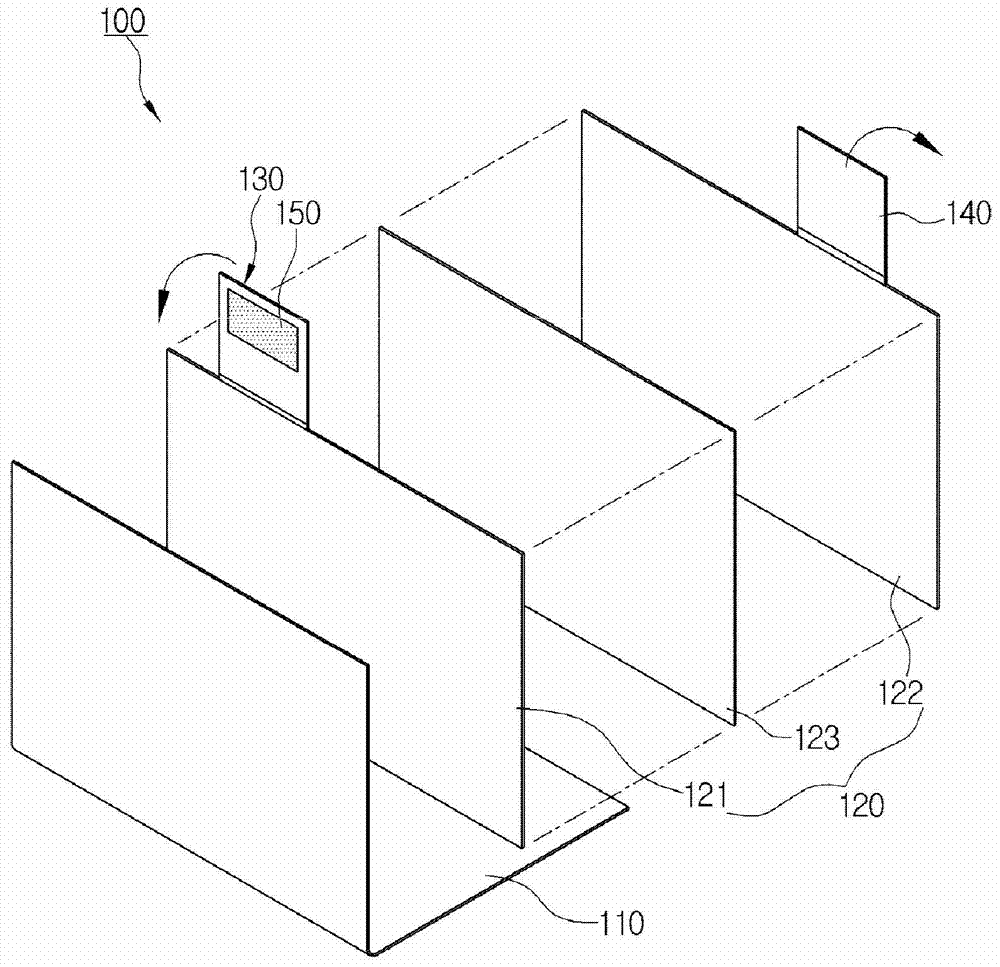

An electrical plug connector assembly has an insulative housing, a first terminal set, a second terminal set and a circuit board. The first and second terminal sets are mounted in the insulative housing. The first terminal set has multiple first conductive terminals each including a first soldering section. The second terminal set has multiple second conductive terminals each including a second soldering section. The first and second soldering sections are soldered on an identical surface of the circuit board such that only one single soldering process is required to solder all of the first and second conductive terminals to the circuit board. The production rate of the electrical plug connector assembly is therefore improved.

Owner:ADVANCED CONNECTEK INC

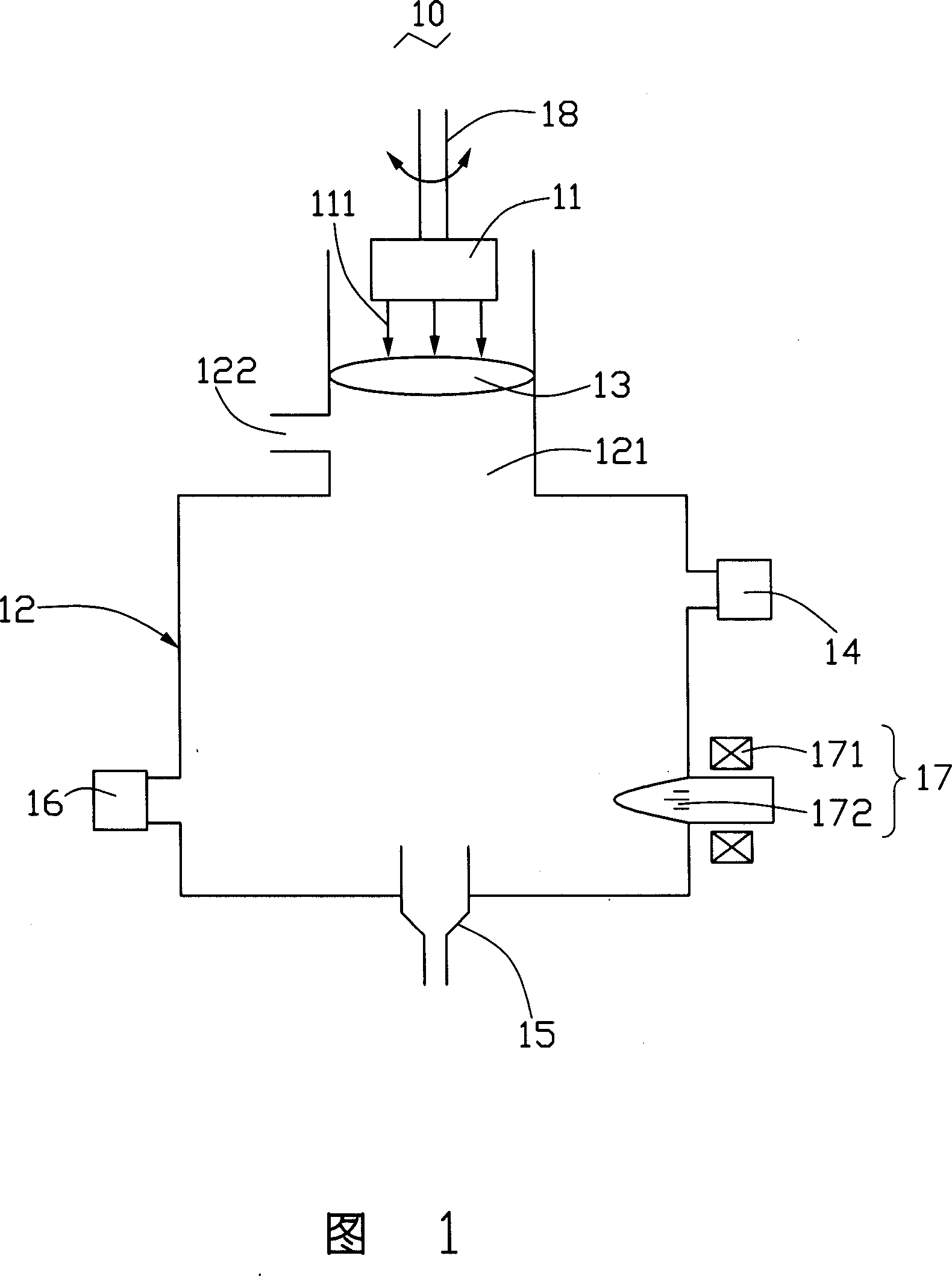

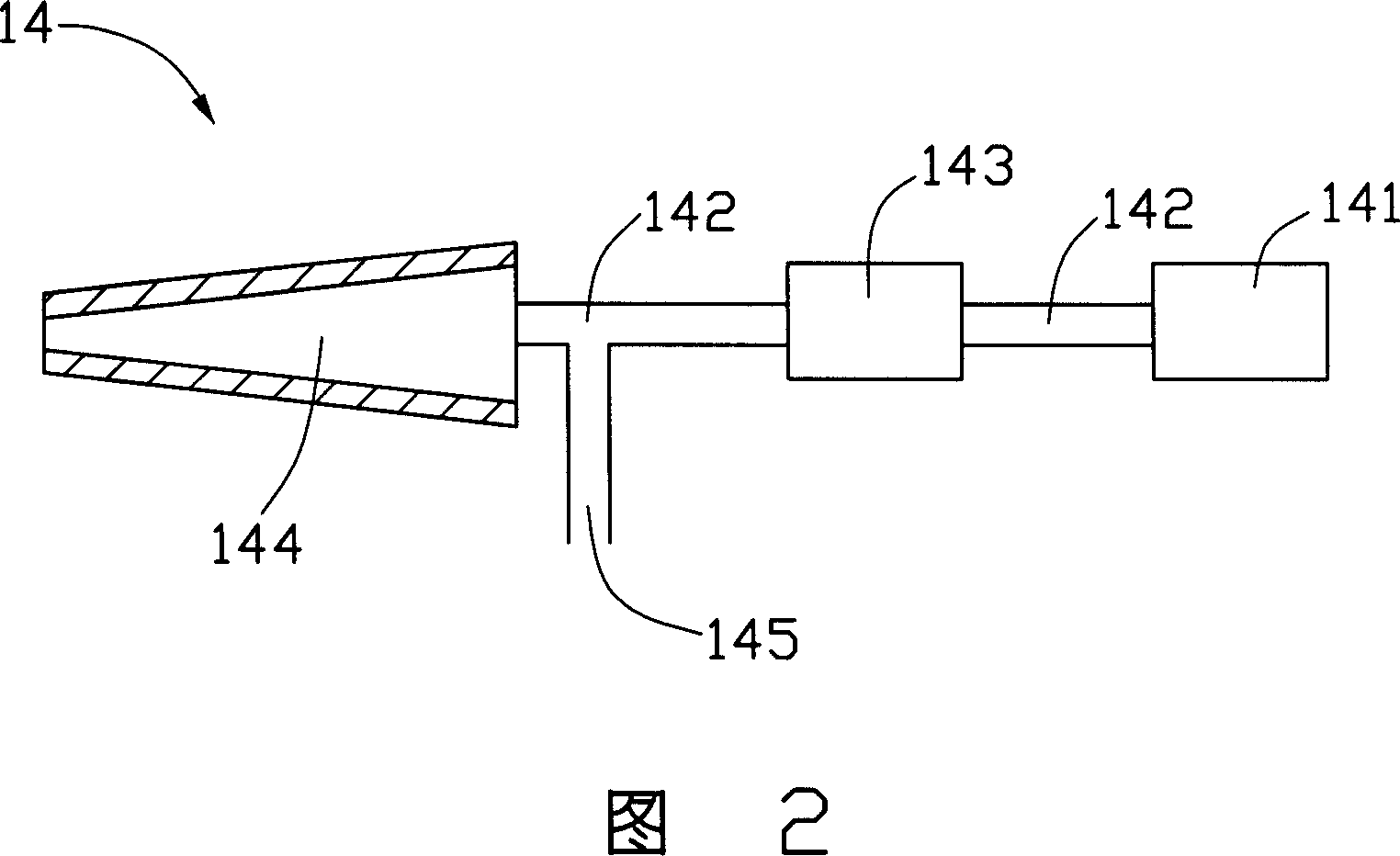

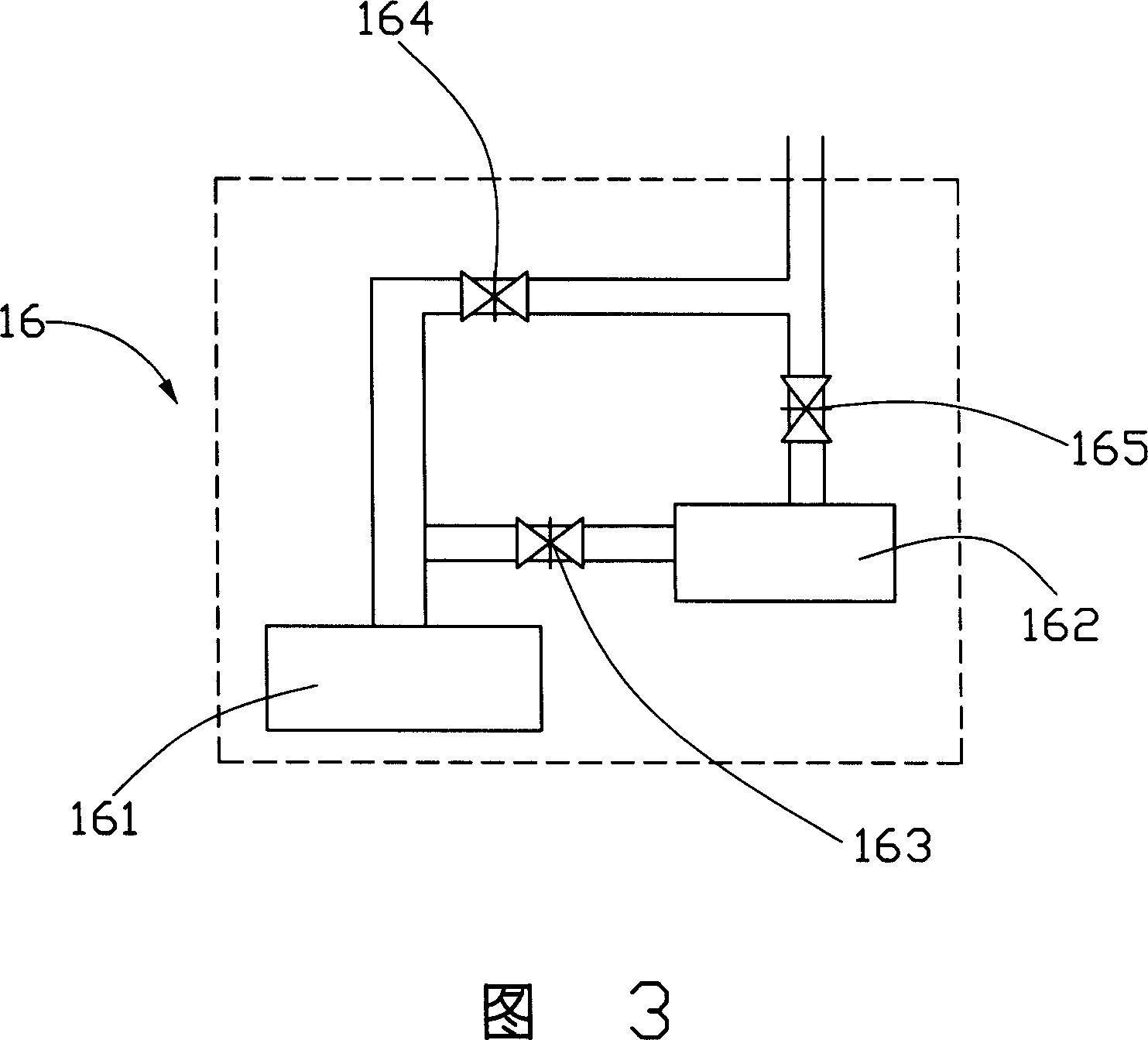

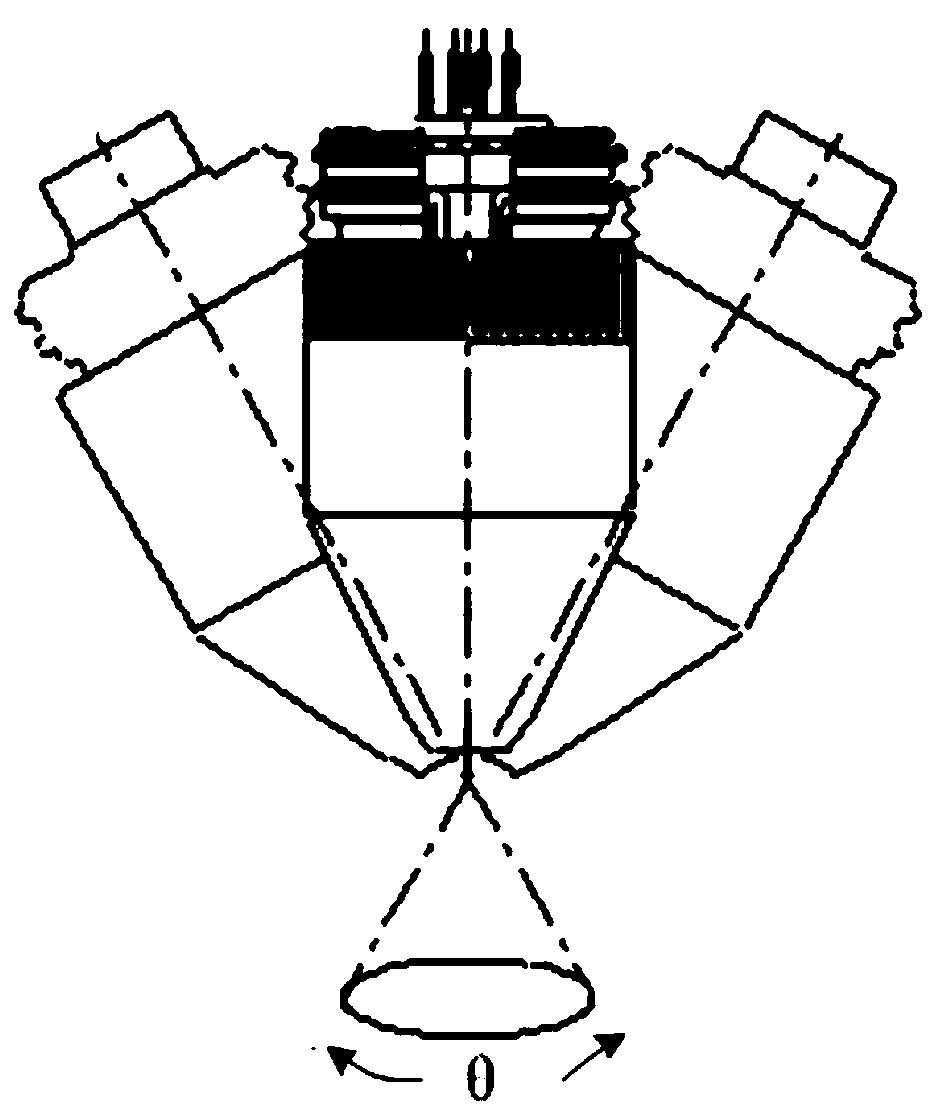

Nano powder preparing device and preparing method thereof

InactiveCN1927447AHigh preparation rateIncrease profitNanotechnologyEnergy based chemical/physical/physico-chemical processesMicrowaveProduct gas

The invention provides a manufacturing apparatus for nanometer powder, The apparatus contains: a reaction room with an incidence window; an laser generator used to generate laser; an optical system, which is located on the incidence window and used to focus the laser generated by the laser generator, and then the focused laser enters the reaction room through the incidence window; at least one input device of reaction air providing air for the reaction room; a vacuumizing device used to vacuumize the reaction room; a powder collecting unit to collect the powder produced by reaction of air; and a microwave generator used to generate the microwave which causes the cyclotron resonance of the microwave electron. The invention also provides a manufacturing method for nanometer powder.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

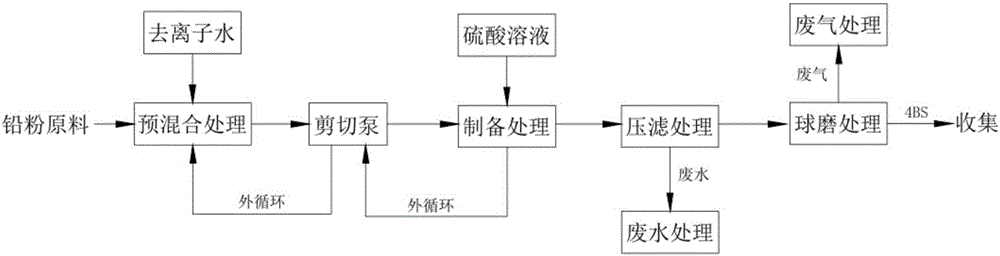

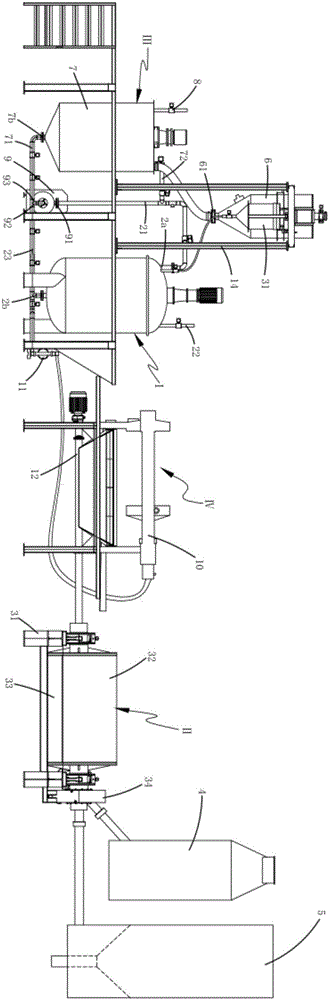

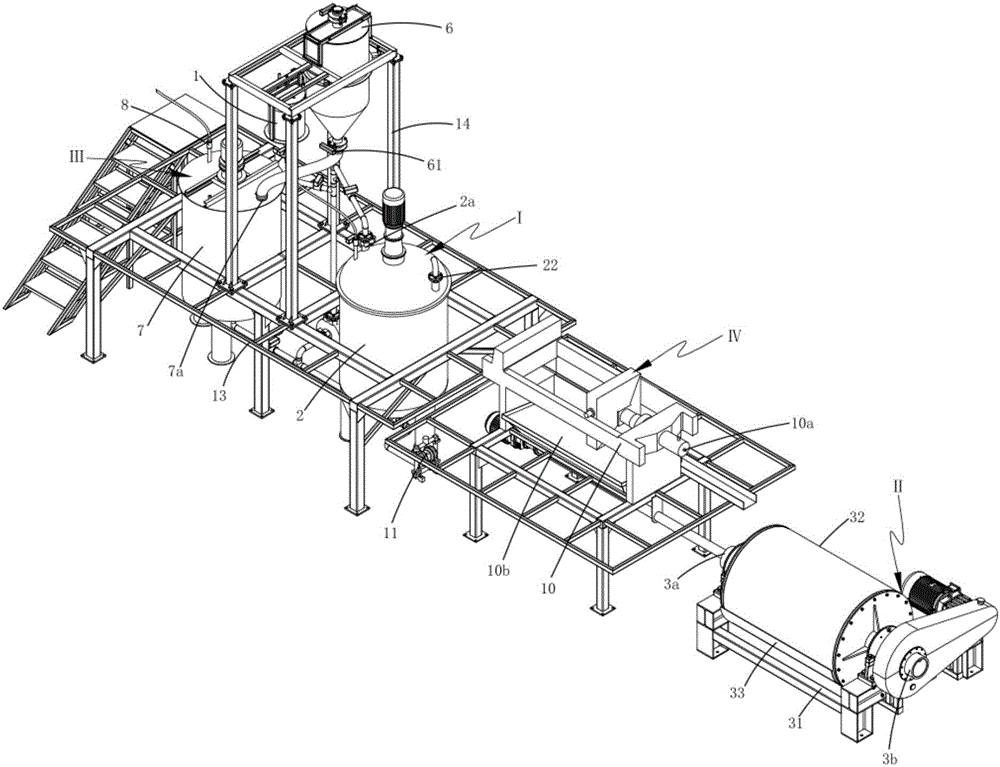

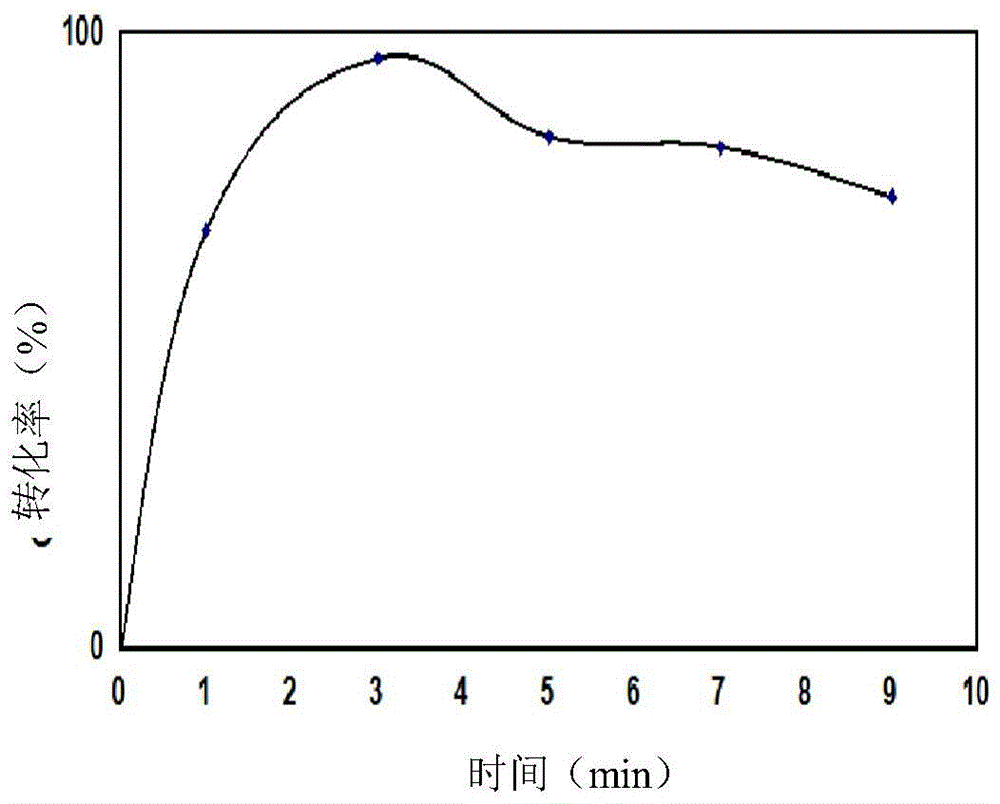

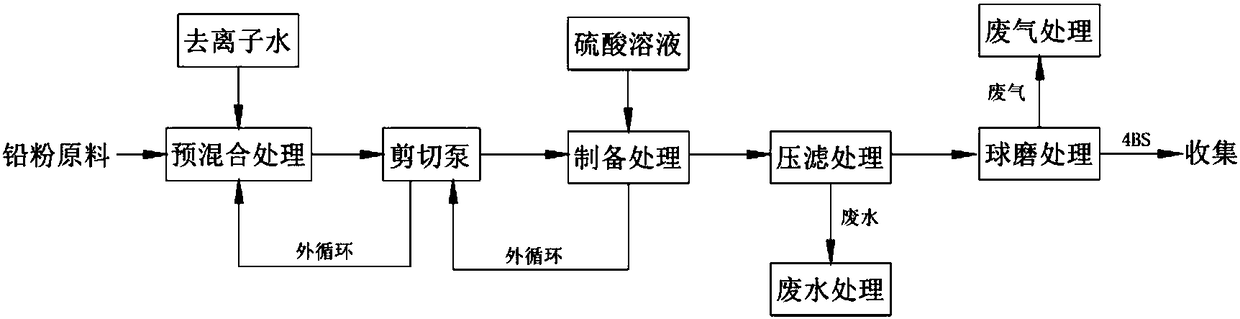

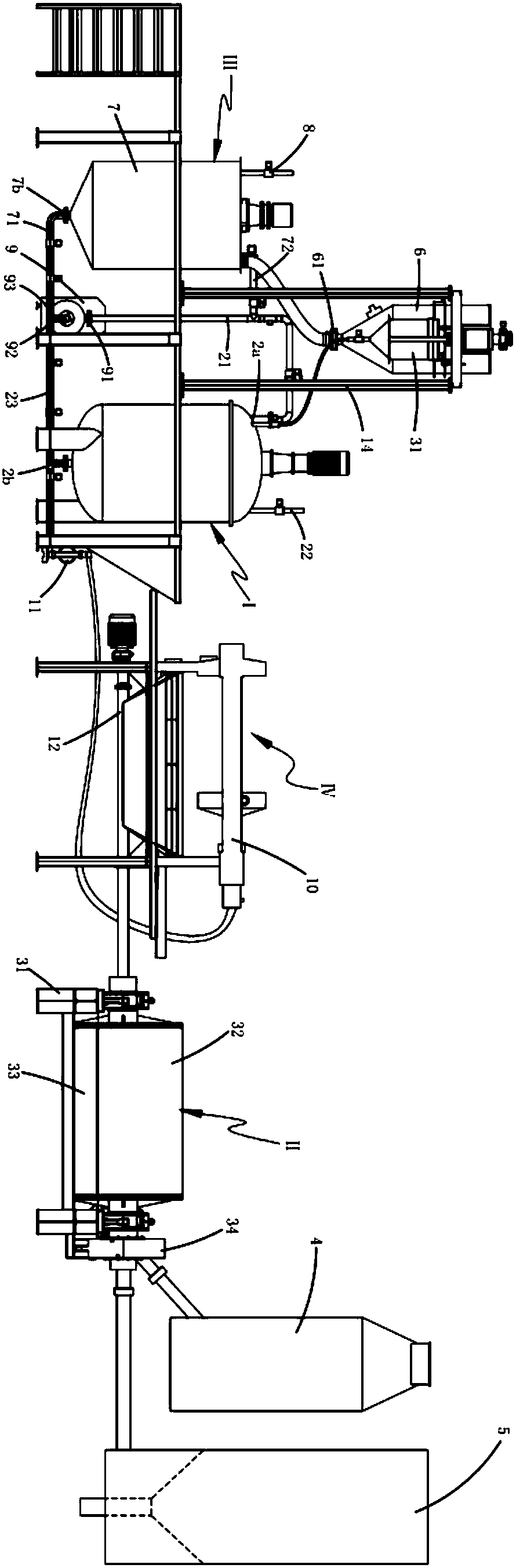

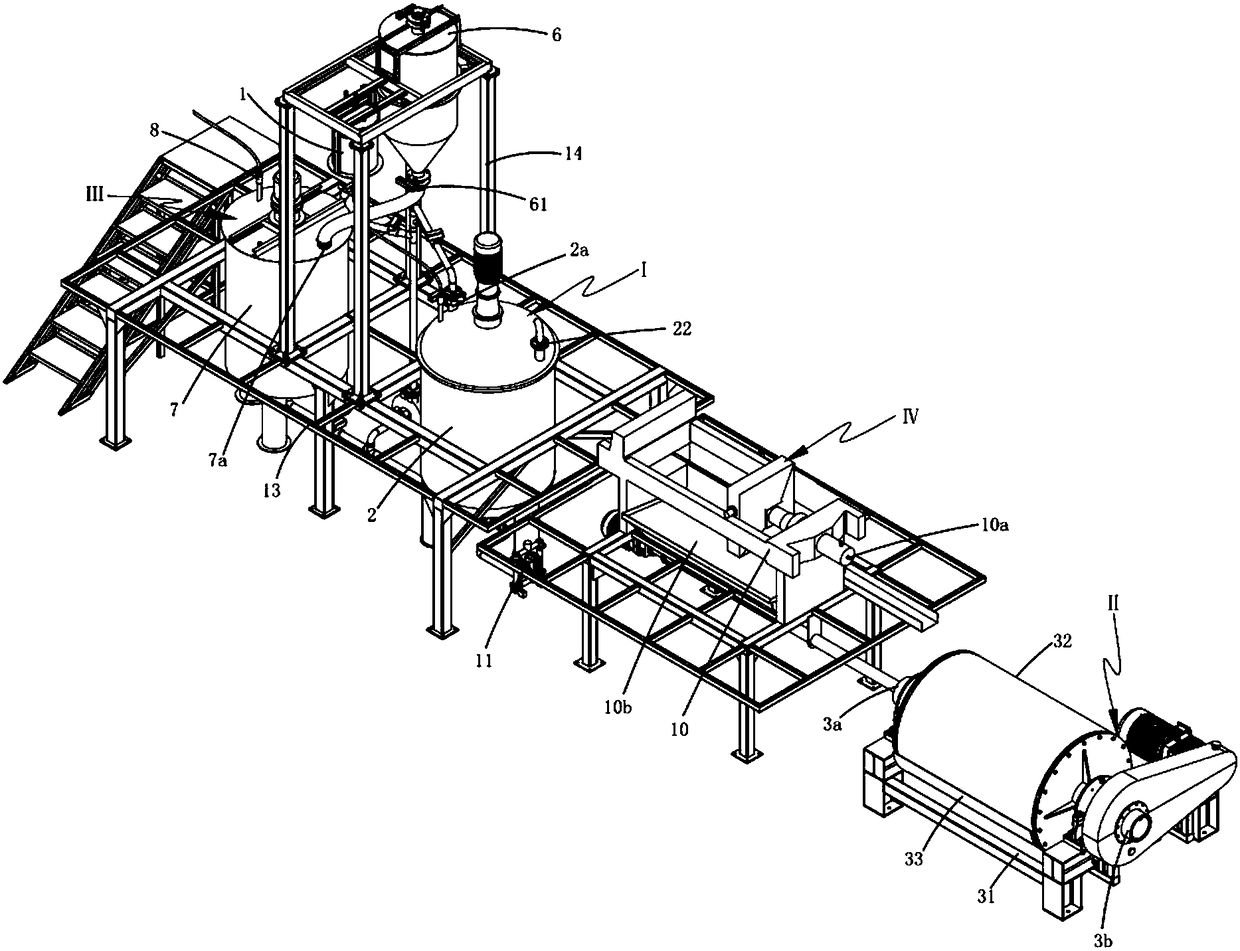

Production process and device for tetrabasic lead sulfate (4BS)

The invention relates to a production process for tetrabasic lead sulfate (4BS). The process includes the following steps that (1) preparation treatment is conducted, specifically, lead which is subjected to a pre-mixing reaction is delivered into a reaction kettle through a shear pump, a sulfuric acid solution is added into the reaction kettle while internal circulation type stirring is conducted, meanwhile, part of compressed air is led into the reaction kettle, after the sulfuric acid solution is added, the shear pump is started, the reaction kettle is heated, after internal and external circulation type uniform stirring, heating is stopped, the shear pump is shut down, internal circulation type stirring in the reaction kettle is maintained, and meanwhile, compressed air is led into the reaction kettle to cool lead slime; and (2) ball milling is conducted, specifically, the lead slime obtained in the step (1) is conveyed into a dry ball mill, heating drying and a ball milling reaction are conducted synchronously, and the 4BS is obtained. The invention further provides a production device for the 4BS. According to the production process and device, the preparation reaction time is short, the formed 4BS is small in grain size, uniform and controllable, and the average grain size of the obtained 4BS is 2 [mu]m or less.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

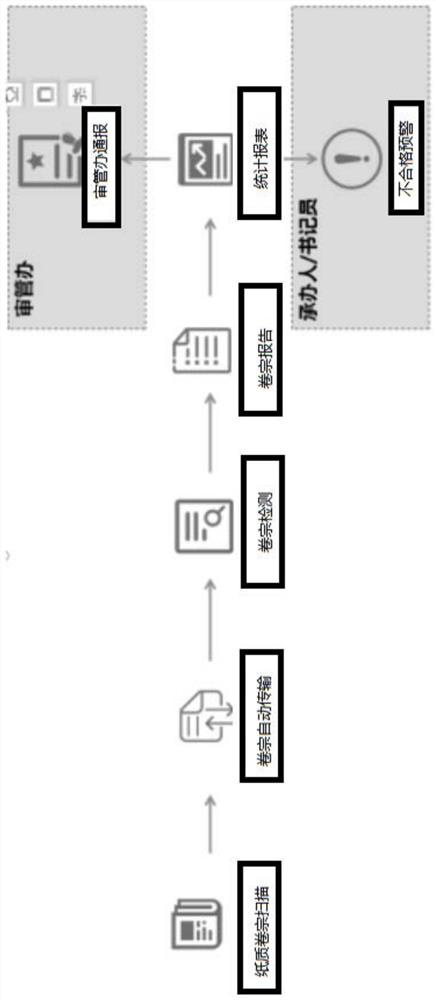

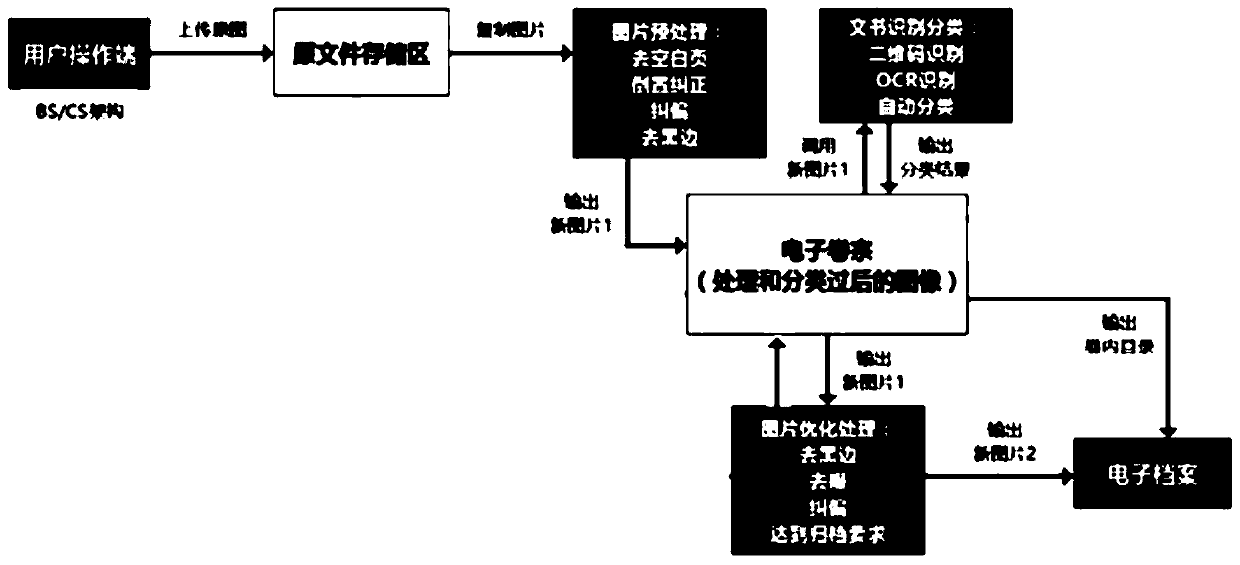

Electronic file quality inspection and supervision system

PendingCN112102117AEasy to operatePromote the improvement of production rateDatabase updatingDatabase management systemsElectronic documentStatistical Report

The invention discloses an electronic file quality inspection and supervision system. The system comprises a file collection module, a file transmission module, a file detection module, a quality query module, a statistical report module, an early warning module and a system setting module. The electronic file quality inspection and supervision system is very simple and fast to operate, greatly makes up for the defects of manual supervision, achieves timely early warning of electronic file errors, reminds a carrier to change errors and supplements uploading, generates various statistical reports according to user requirements, is more visual and persuasive, can generate case reports through one key, and improves the user experience. The improvement of the manufacturing rate of electronic documents of courts at all levels is promoted.

Owner:武汉市润普网络科技有限公司

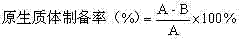

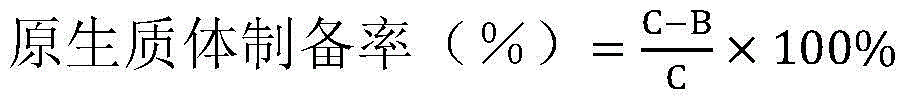

Method for preparing and regenerating lysine bacillus protoplast capable of degrading MC-LR

ActiveCN103013848AHigh preparation rateHigh activityBacteriaMicroorganism based processesBacillus sphaericusProtoplast

The invention discloses a method for preparing and regenerating a lysine bacillus protoplast capable of degrading MC-LR and relates to the technical field of methods for preparing and regenerating protoplasts in bioengineering. According to the method, the protoplast fusion technology for establishing engineering bacteria is taken as the basis, and the lysine bacillus protoplast is prepared from the separated MC-LR high-efficiency degrading bacteria T1(Bacillus sphaericus) protoplast. According to the research, an inactivated protoplast fusion method is selected, so that the workload is reduced, and the quality of a fusant in the subsequent research is guaranteed. The method for preparing and regenerating the protoplast is simple in process, convenient to operate and high in repeatability; and the obtained protoplast preparation rate can be up to 96.64 percent, the regeneration rate can be 83.95 percent, the protoplast is high in preparation rate and high in activity, and the preparation and regeneration of the subsequent fusant are facilitated.

Owner:安徽水韵环保股份有限公司

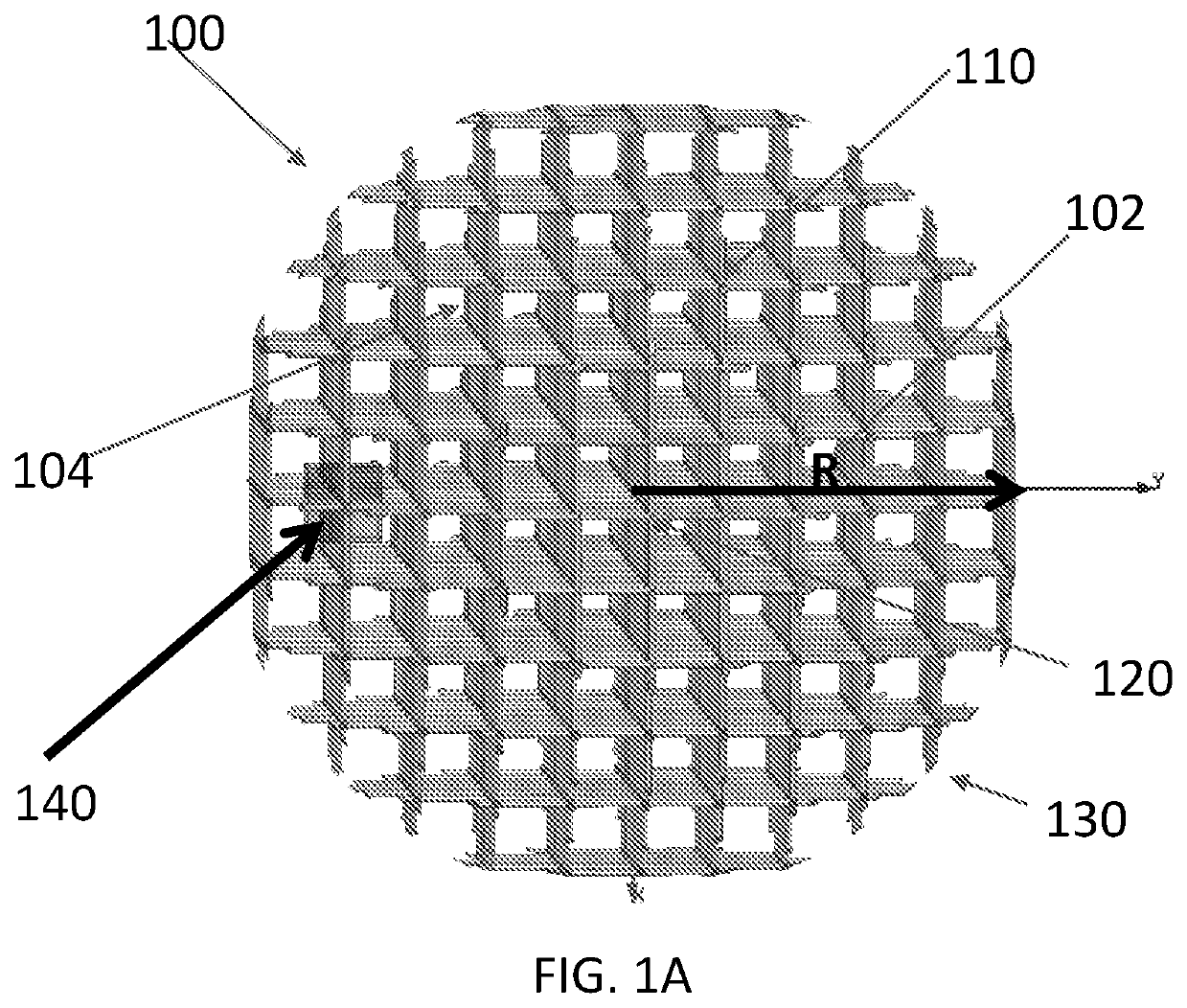

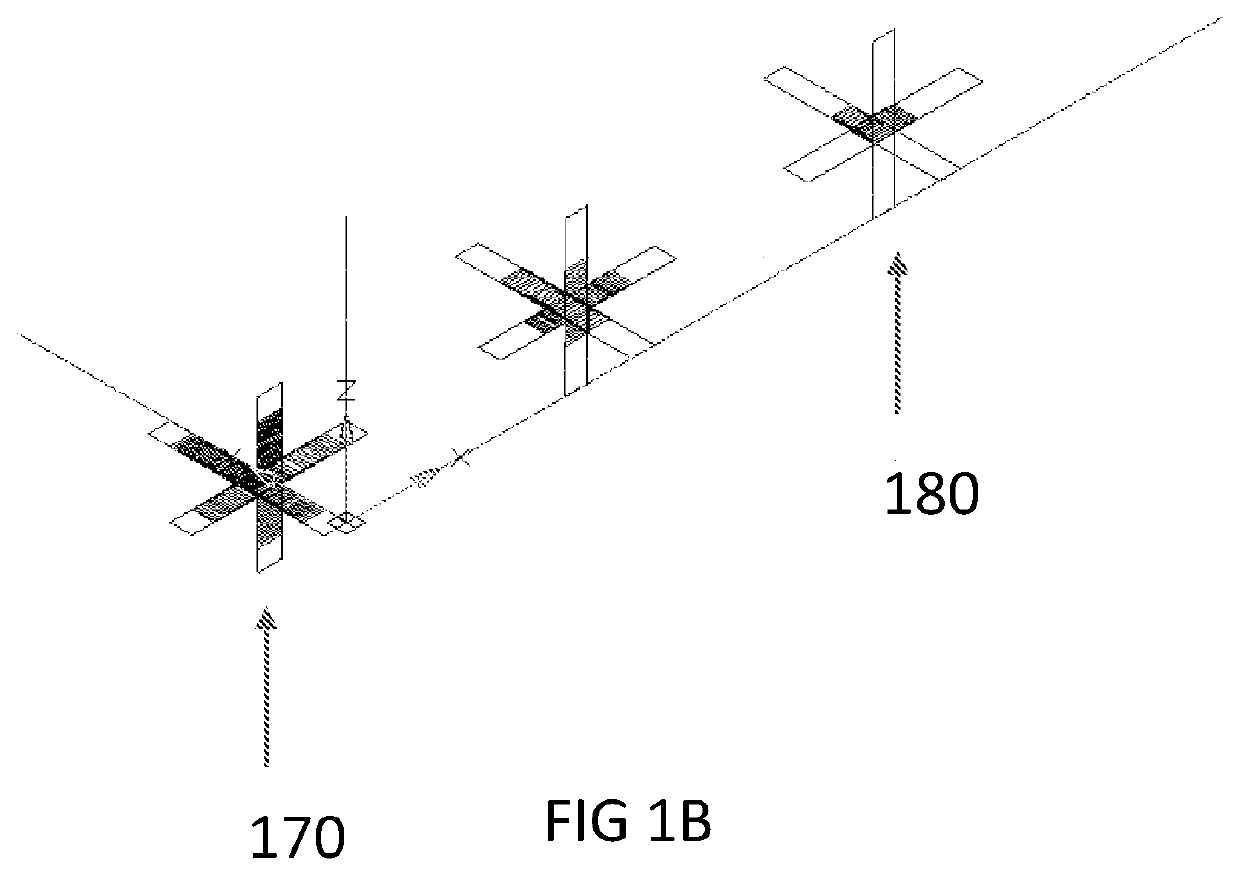

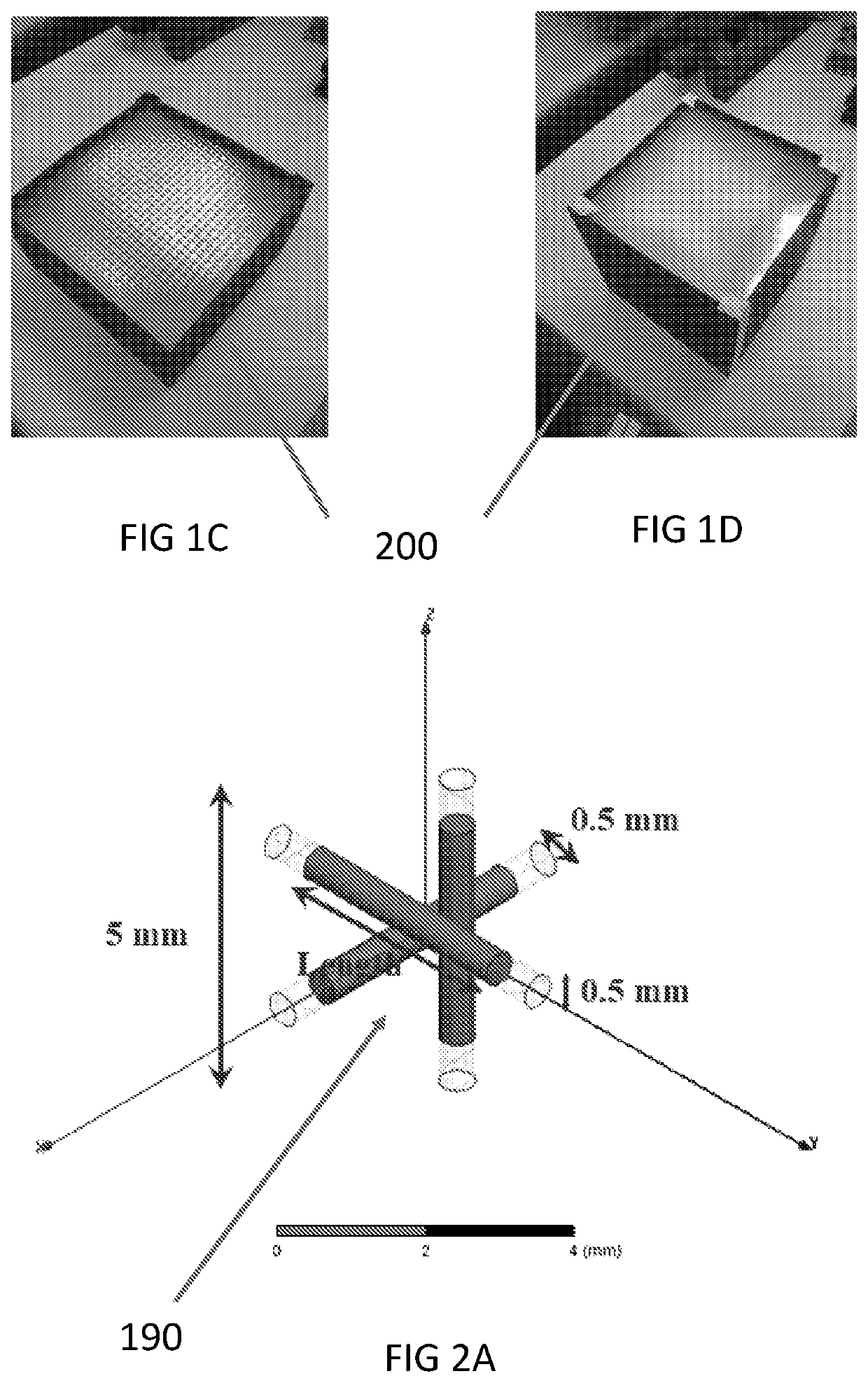

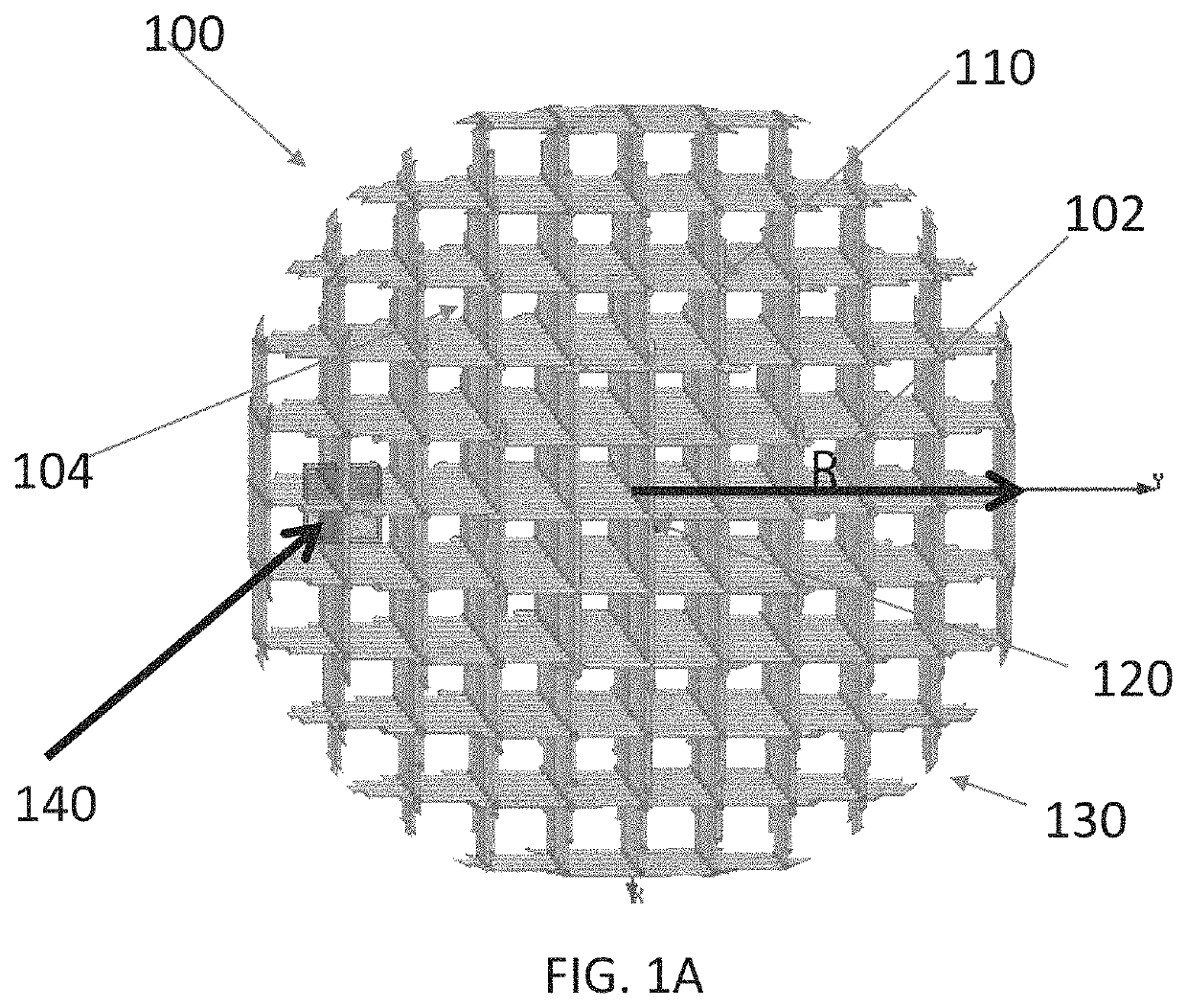

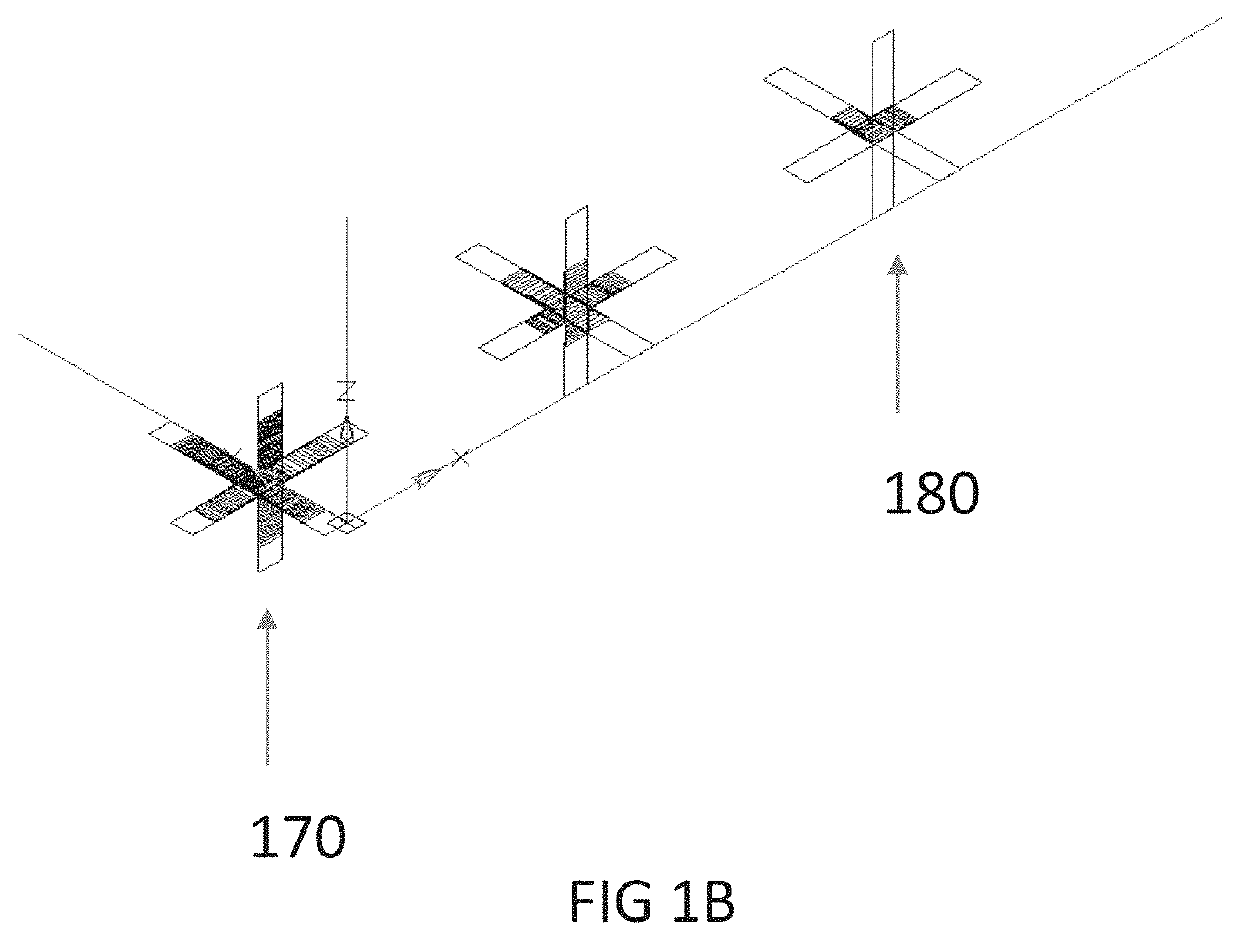

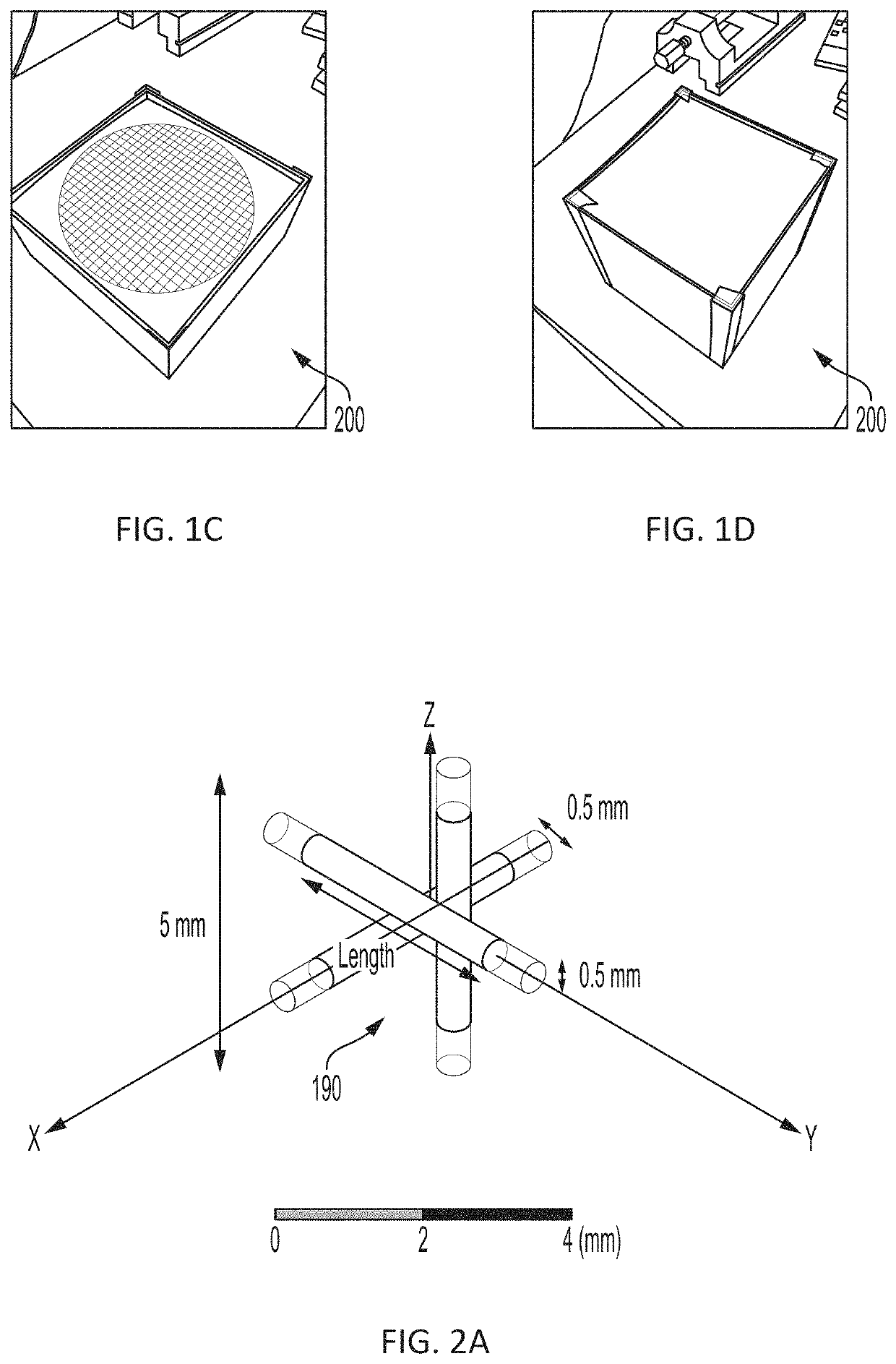

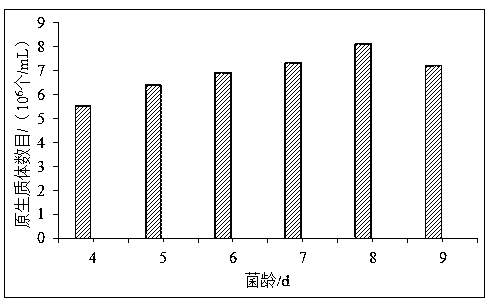

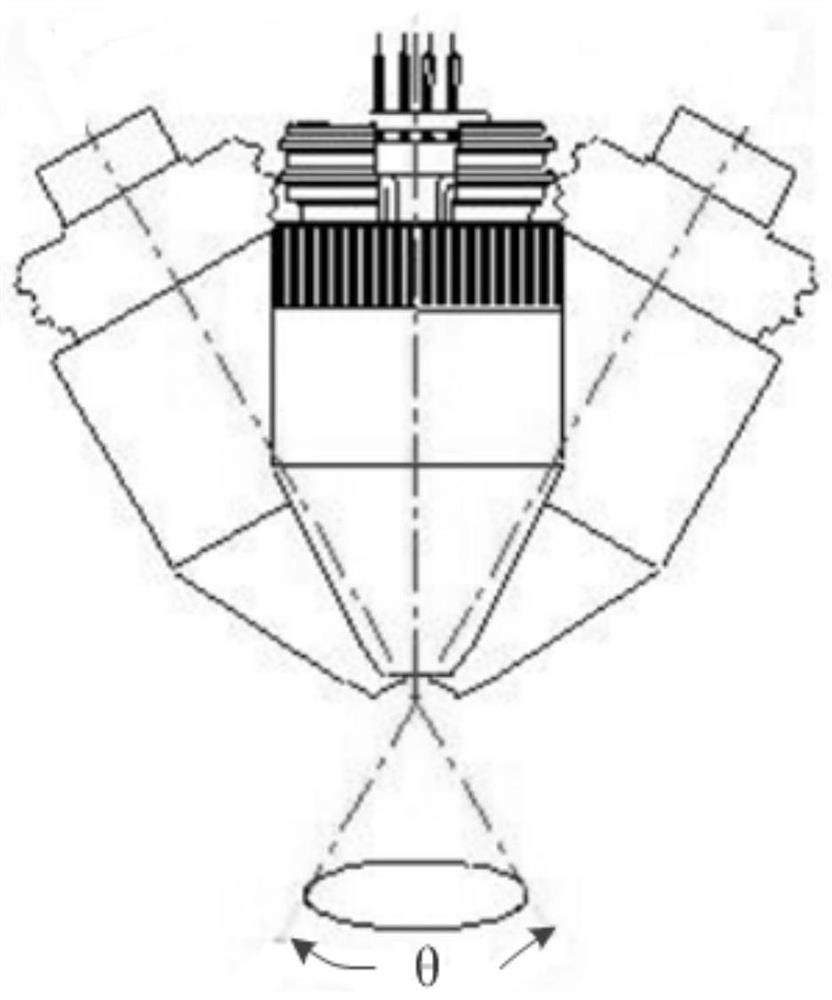

Novel hollow light weight lens structure

A hollow light-weight, low-cost, and high-performance 3D Luneburg lens structure using partially-metalized thin film, string, threads, fiber or wire base metamaterial to implement the continuously varying relative permittivity profile, characteristic of Luneburg lens structures, is disclosed. The hollow light-weight lens structure is based on the effective medium approach and may be implemented by a number of means. Further, most of the volume of the lens structure is free-space, thus the weight of the lens is significantly less than conventional 3D Luneburg lens structures of the same dimensions.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Electrical plug connector assembly

ActiveUS9538652B2High preparation rateReduce weldingPrinted circuit aspectsCoupling contact membersProduction rateEngineering

An electrical plug connector assembly has an insulative housing, a first terminal set, a second terminal set and a circuit board. The first and second terminal sets are mounted in the insulative housing. The first terminal set has multiple first conductive terminals each including a first soldering section. The second terminal set has multiple second conductive terminals each including a second soldering section. The first and second soldering sections are soldered on an identical surface of the circuit board such that only one single soldering process is required to solder all of the first and second conductive terminals to the circuit board. The production rate of the electrical plug connector assembly is therefore improved.

Owner:ADVANCED CONNECTEK INC

Hollow light weight lens structure

A hollow light-weight, low-cost, and high-performance 3D Luneburg lens structure using partially-metalized thin film, string, threads, fiber or wire base metamaterial to implement the continuously varying relative permittivity profile, characteristic of Luneburg lens structures, is disclosed. The hollow light-weight lens structure is based on the effective medium approach and may be implemented by a number of means. Further, most of the volume of the lens structure is free-space, thus the weight of the lens is significantly less than conventional 3D Luneburg lens structures of the same dimensions.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

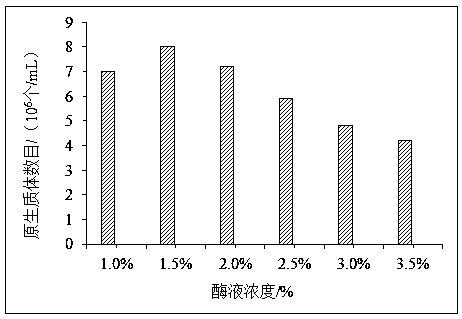

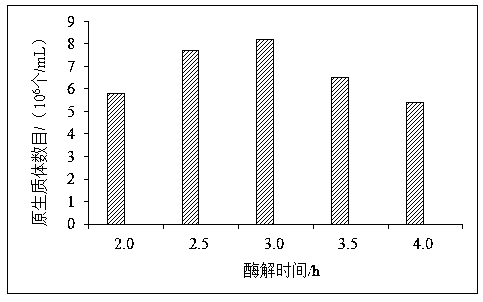

Preparation method of lignocellulose degrading strain protoplast

The invention discloses a preparation method of a lignocellulose degrading strain protoplast. The preparation method comprises the following steps: after activating ganoderma lipsiense strains, inoculating a high-quality strain into a liquid strain activation medium for expansion culture, and selecting a 9-day mycelium to prepare the protoplast; conducting washing, sterile water washing and osmotic pressure stabilizer washing on the mycelium sequentially, adding 30 mL of mercaptoethanol for shock treatment, filtering after hyphae are broken, then washing with 0.7 mol / L of MgSO4 solution, centrifuging, taking a precipitate with a supernatant removed, removing moisture, placing the mycelium precipitate and 1.0% lywallzyme solution in the proportion of 1:10 by weight in a centrifuge tube, shaking evenly, hydrolyzing for 3.0 h and filtering. The precipitate obtained after centrifugation of the obtained filtrate is the protoplast of the mycelium of ganoderma lipsiense. The protoplast preparation rate is reaches high up to 9.15*106 cells / mL.

Owner:JILIN AGRI SCI & TECH COLLEGE

Preparation and regeneration method of zymononas mobilis protoplast

InactiveCN104388358AHigh activityEasy to manufactureBacteriaMicroorganism based processesProtoplastThallus

The invention discloses a preparation and regeneration method of zymononas mobilis protoplast. The preparation and regeneration method comprises the following steps: preparing a bacterium inclined cultivation medium, activating a thallus, preparing a seed culture liquid, performing enzymolysis on cell walls, preparing protoplast suspension, and regenerating protoplast. By adopting the preparation and regeneration method of the zymononas mobilis protoplast, the preparation rate of the protoplast of the zymononas mobilis can be up to 90.0% at most, the regeneration rate can be up to 22.4%, the operation process is simple, high in repeatability and high in preparation rate, the activity of the protoplast is relatively well maintained, and the later preparation and the screening of fusant are facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

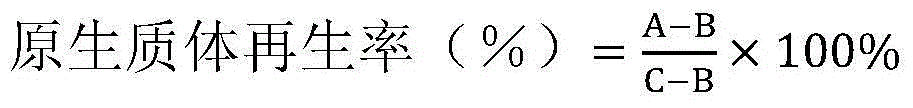

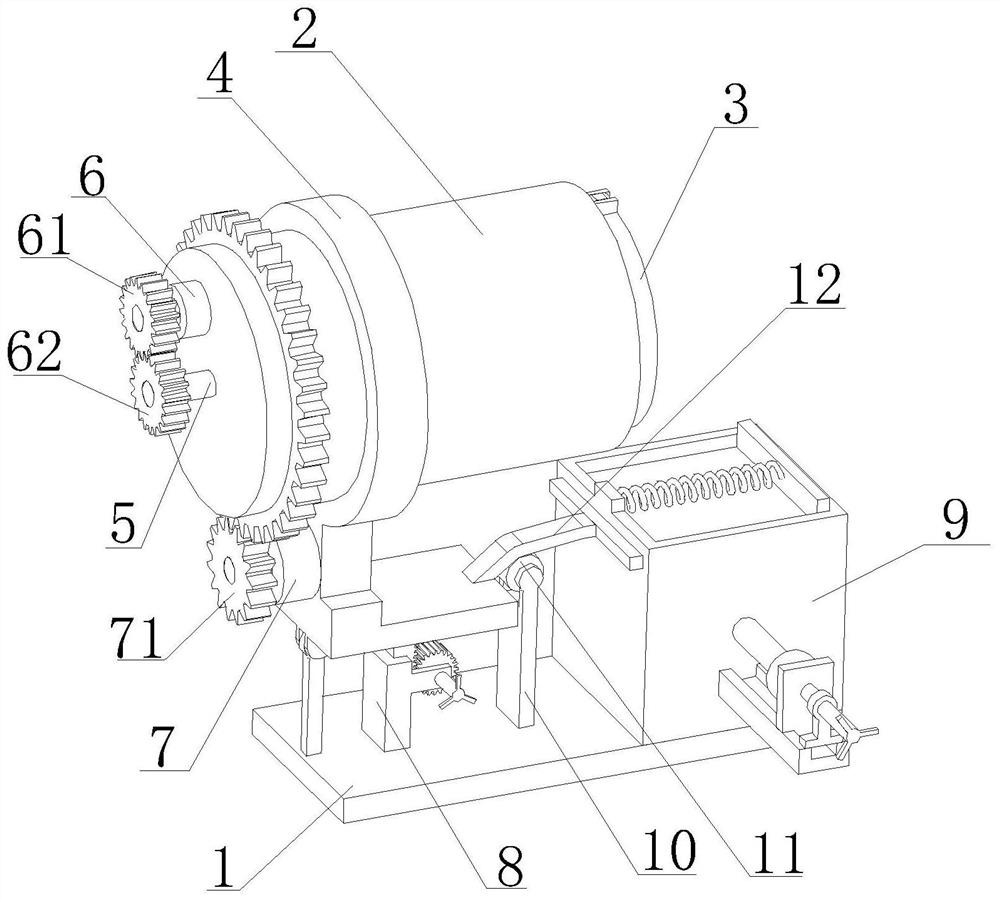

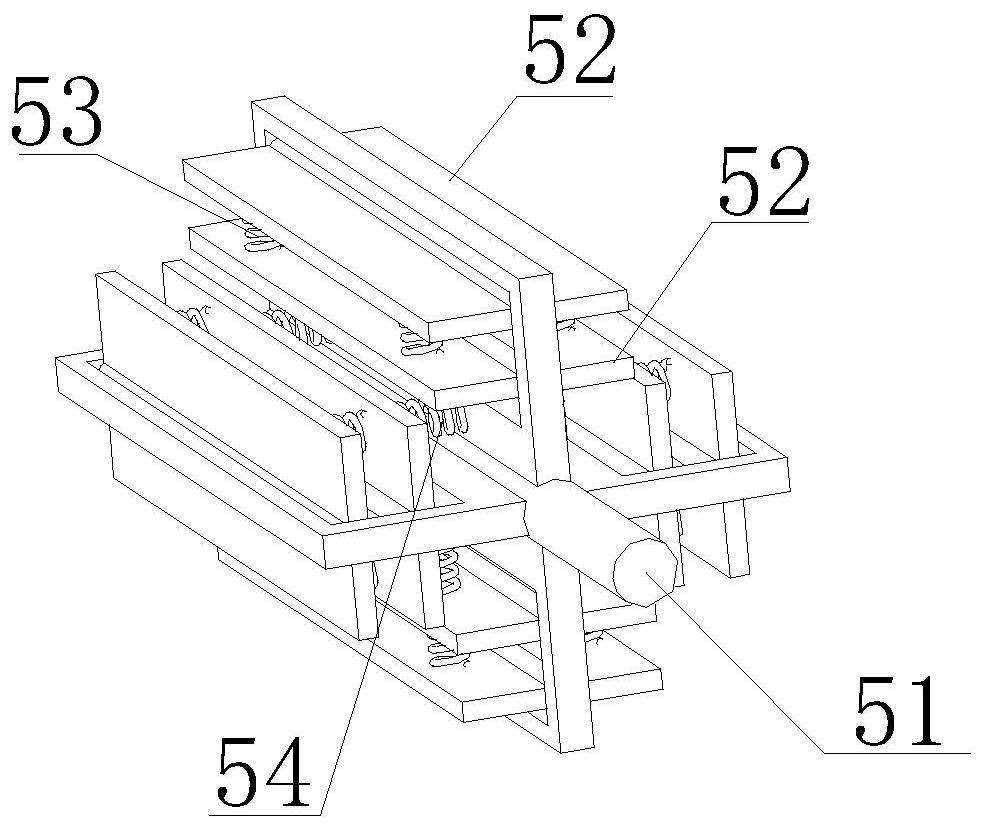

Phosphate fertilizer preparation device and method

The invention discloses a phosphate fertilizer preparation device and method, and belongs to the field of phosphate fertilizer production. The phosphate fertilizer preparation device comprises a barrel, a crushing mechanism, a supporting frame, a turnover mechanism, a bottom plate and a grinding mechanism, The crushing mechanism is mounted in the barrel to cut and crush a dephosphorized steel slag; the supporting frame is rotationally connected to the lower end of the barrel, so that the barrel rotates to enhance the crushing effect on the dephosphorized steel slag; the turnover mechanism is mounted at the lower end of the supporting frame, so that turnover of the barrel is achieved, and discharging and feeding are facilitated; the grinding mechanism is mounted at the upper end of the bottom plate to crush and grind the dephosphorized steel slag; and a sliding plate is slidably connected to the upper end of a box body, so that the box body is covered, and the dephosphorized steel slag is prevented from jumping out during grinding. The phosphate fertilizer preparation method comprises the following steps of crushing and grinding, adding hydrochloric acid and adding alkaline substances.

Owner:ANHUI UNIV OF SCI & TECH

Electronic file case-following production method

PendingCN110232046AHigh preparation rateReduce workloadImage enhancementCharacter and pattern recognitionFile associationMethods of production

The invention provides an electronic file case-following production method, which comprises the following steps: 1) acquiring an image of a file, and uploading the acquired image to a processing server to form a storage directory; 2) judging the state of the storage directory, and if the state value of the storage directory is not null, copying the image under the storage directory; 3) performingcorrection, black edge removal, noise point removal, blank page removal and inverted rotation processing on the copied image; 4) detecting after the step 3), checking whether the filing requirement ismet, if so, turning to the step 5), and if not, turning to the step 3); and 5) obtaining text contents in the image and the text through OCR, extracting corresponding file titles and page number information according to a text format, judging file relevance, sorting the image and the text file according to the file titles and page number information, and performing file classification according to a corresponding matching rule. Wherein the matching rule is a directory name to which the file title corresponds.

Owner:武汉市润普网络科技有限公司

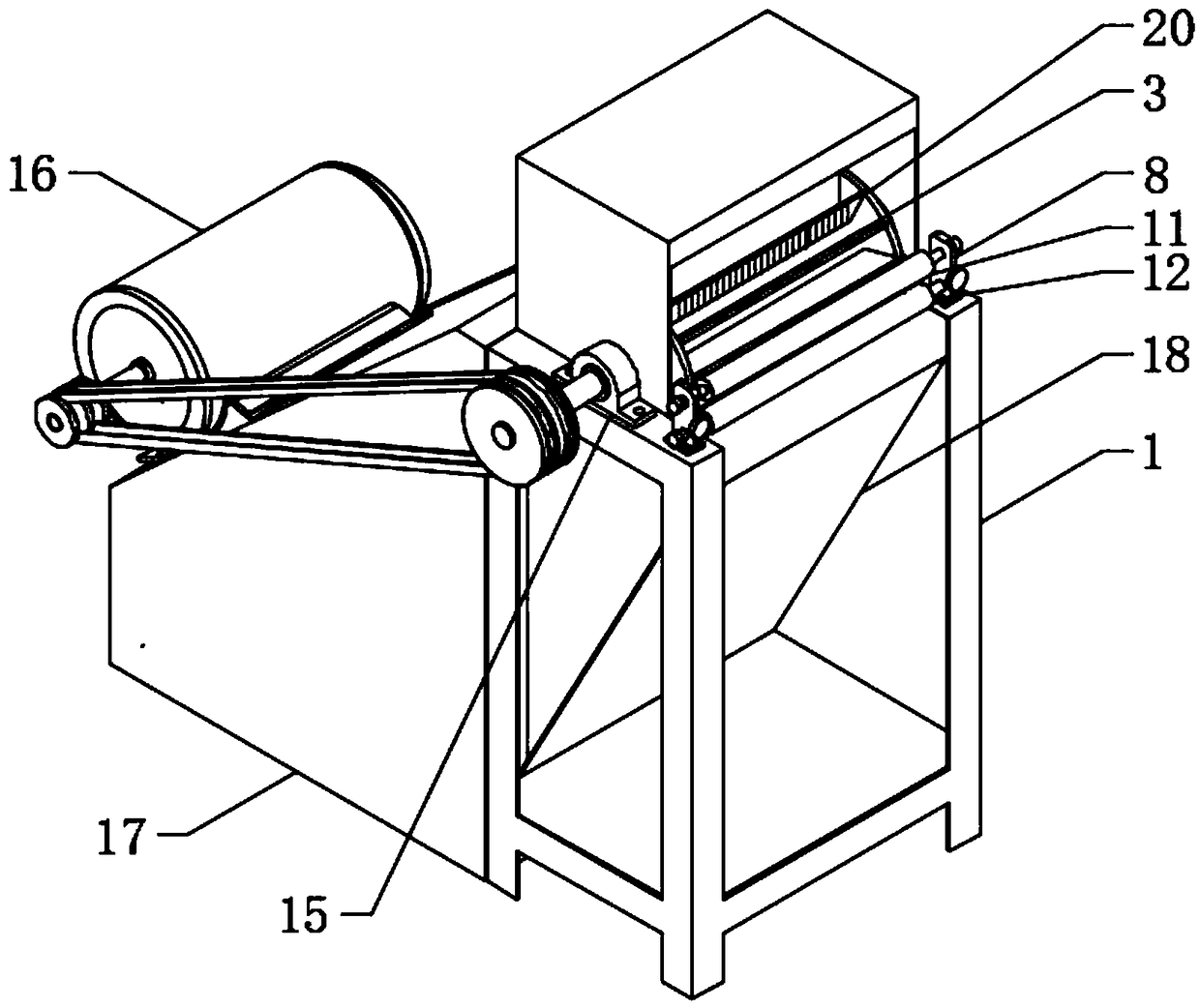

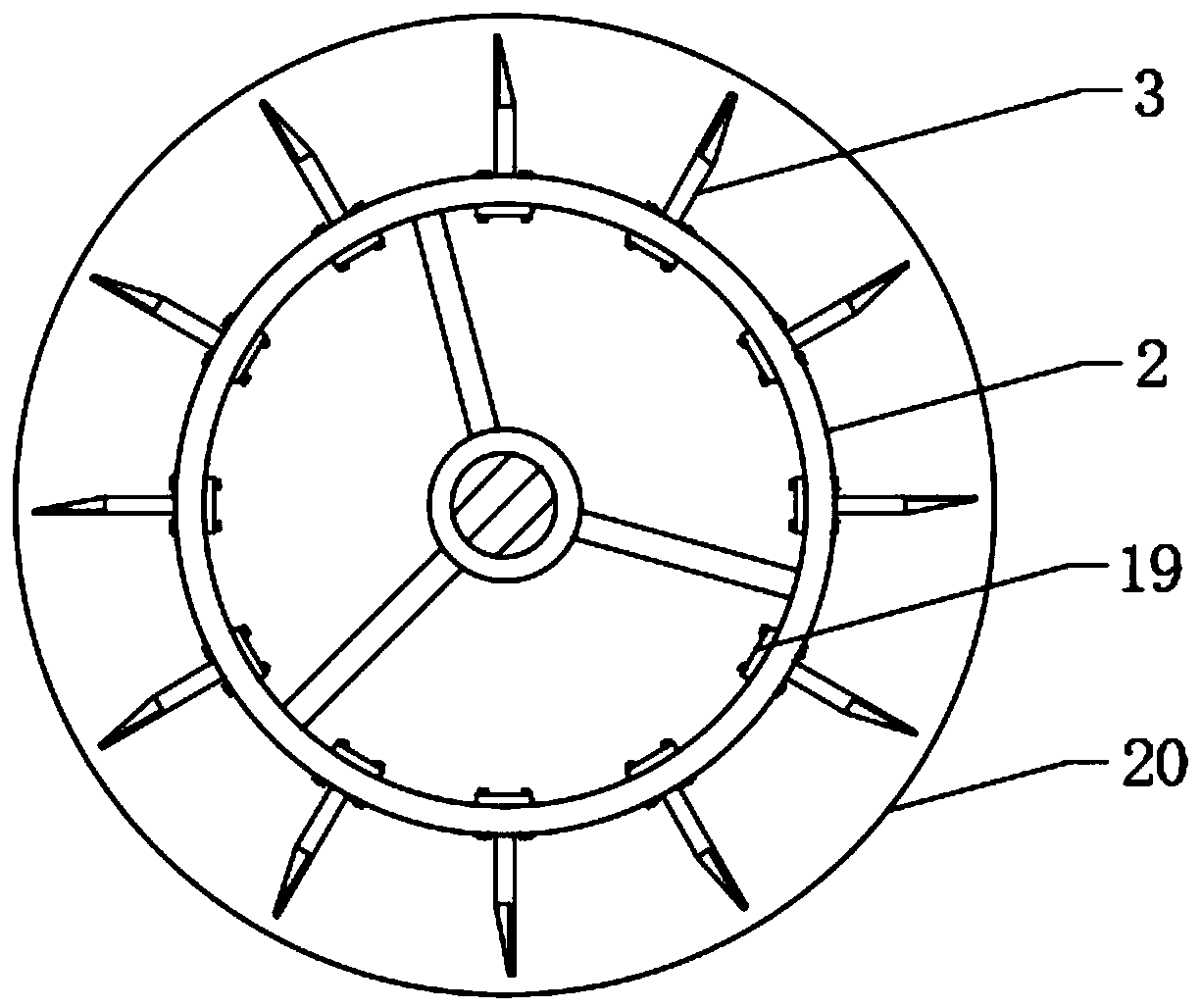

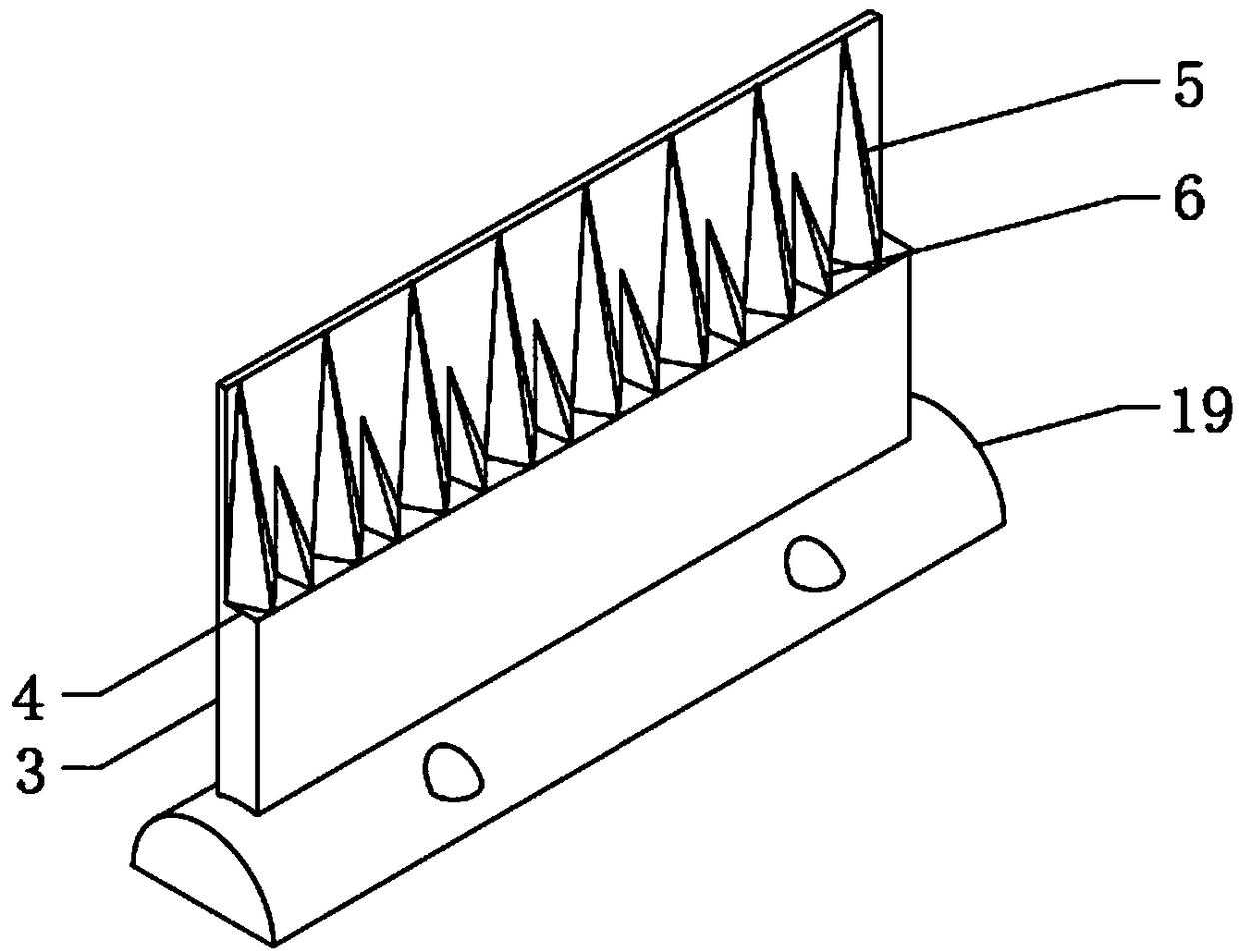

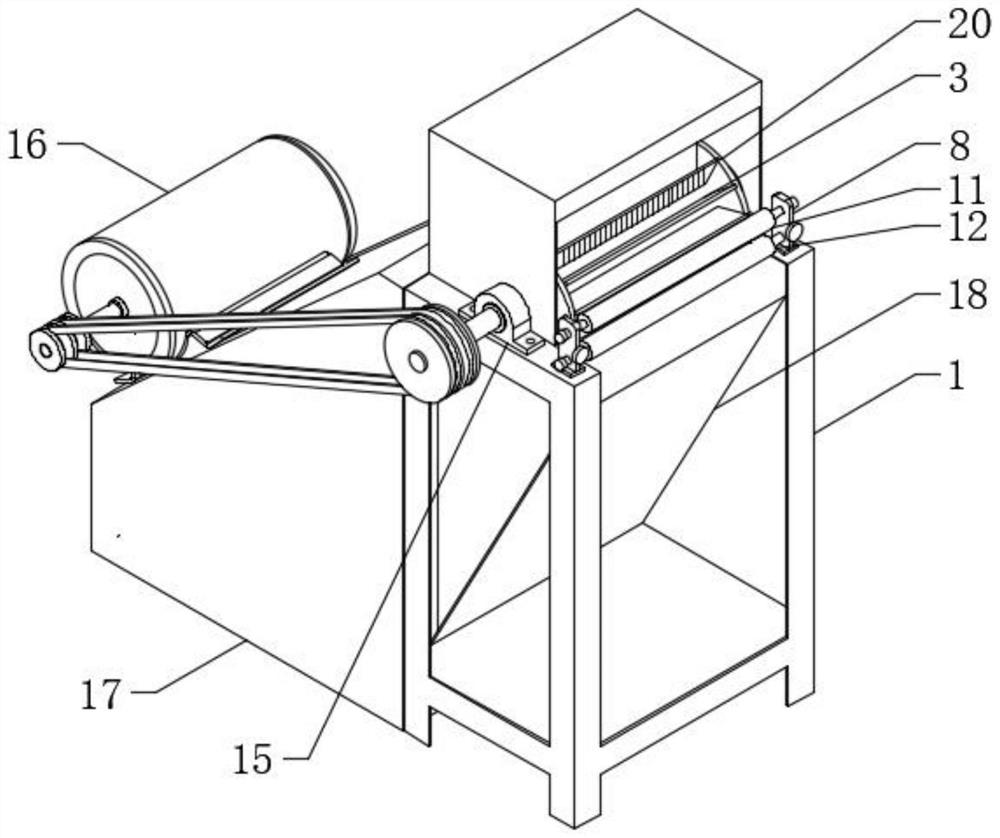

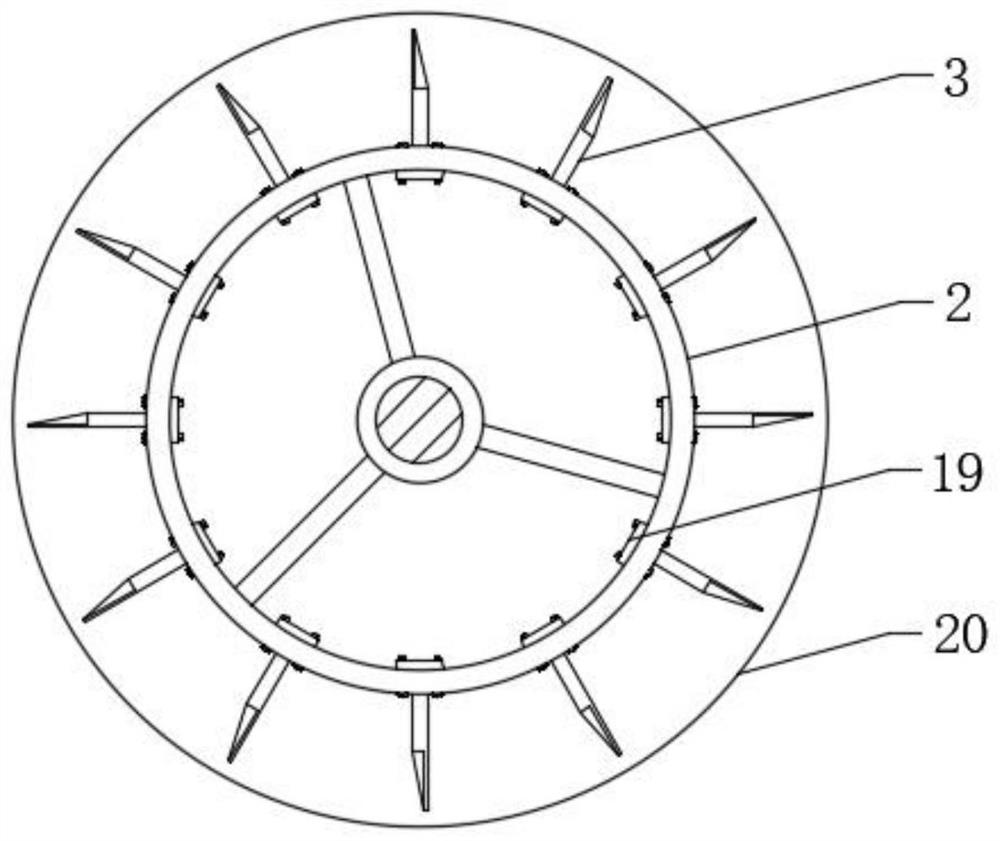

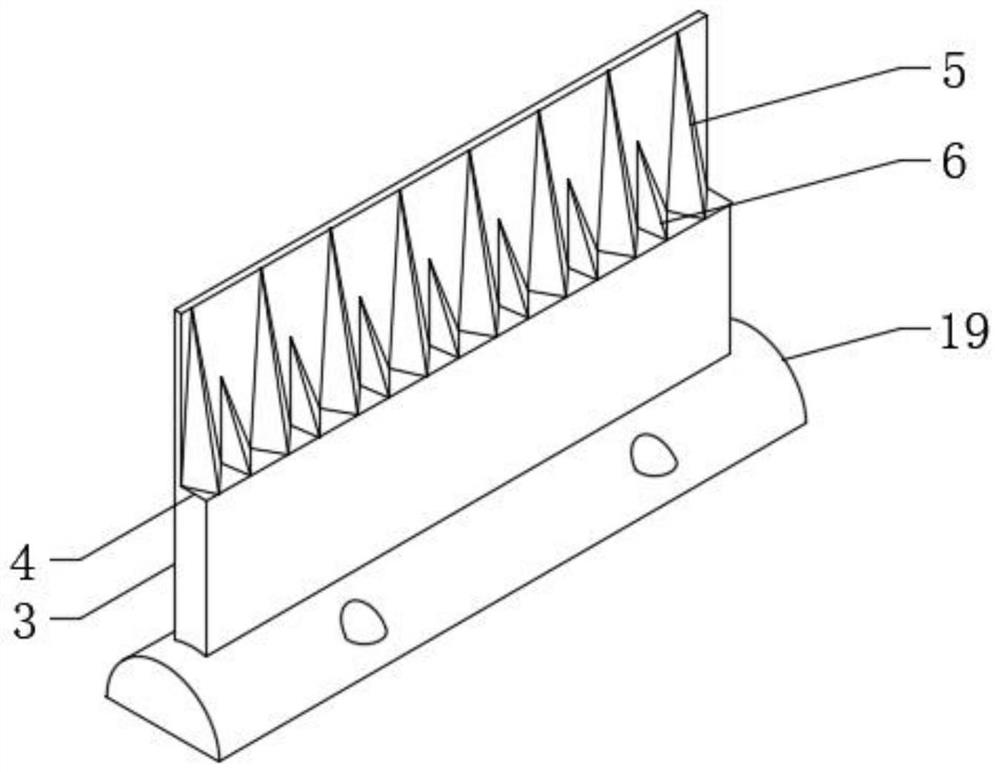

Leafcutter ant palate-based bionic banana fiber extraction device

The invention discloses a leafcutter ant palate-based bionic banana fiber extraction device. The device comprises a rack, a cutting mechanism and a flattening mechanism located on the front side of the cutting mechanism, the cutting mechanism comprises a fixed knife wheel, a fixed knife is arranged on the surface of the fixed knife wheel, an L-shaped notch is formed in the front end of the fixed knife, big tooth edges and small tooth edges are staggerly distributed at the L-shaped notch, the flattening mechanism comprises an upper pressing roller and a lower pressing roller which are vertically arranged in parallel, an upper block sleeves the upper pressing roller, a lower block sleeves the lower pressing roller, and the top of the rack is in bolt connection with a support which is internally provided with the upper block and the lower block. Accordingly, by means of V-shaped cutting edges formed between the big tooth edges and the small tooth edges, the impurity rate and winding blocking can be effectively reduced, due to the fact that the impurity rate is reduced, the finally actually prepared fiber preparation rate is increased, the contact area between the fixed knife and the fiber surface is increased, the processing efficiency is improved, damage of the fixed knife to banana fiber in the processing process is reduced, the finished product rate is increased, and blocking is reduced.

Owner:徐莎莎

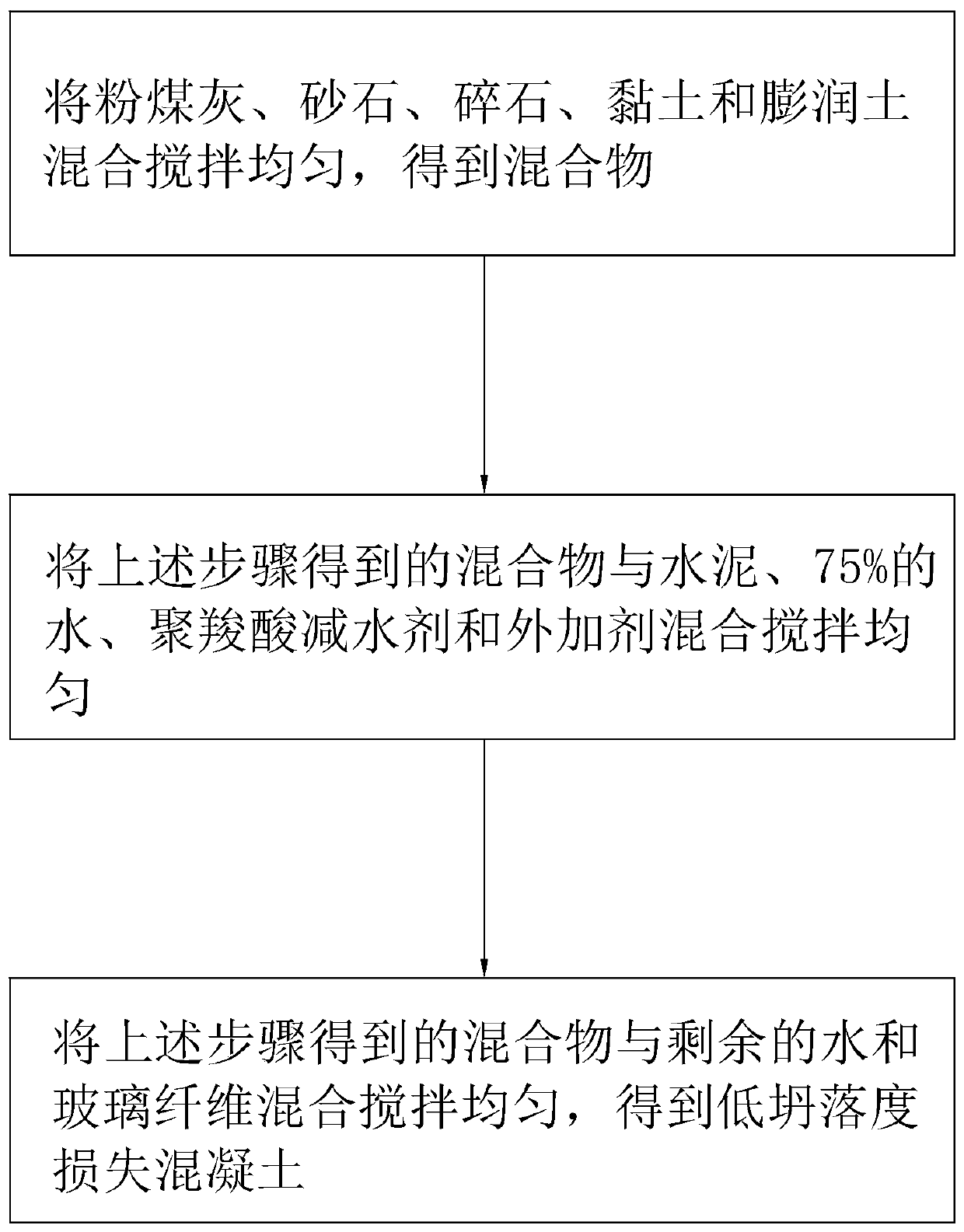

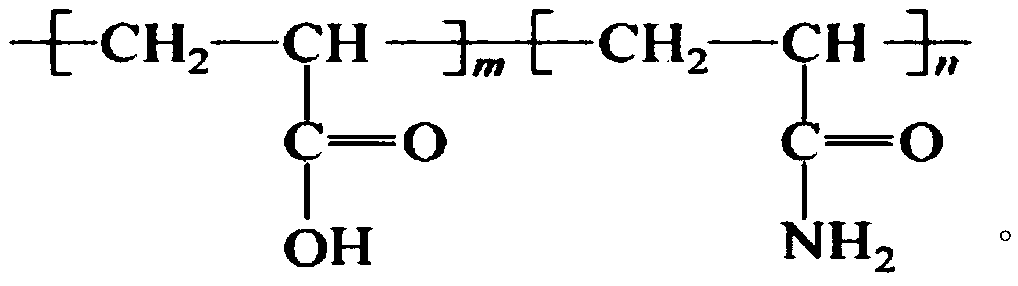

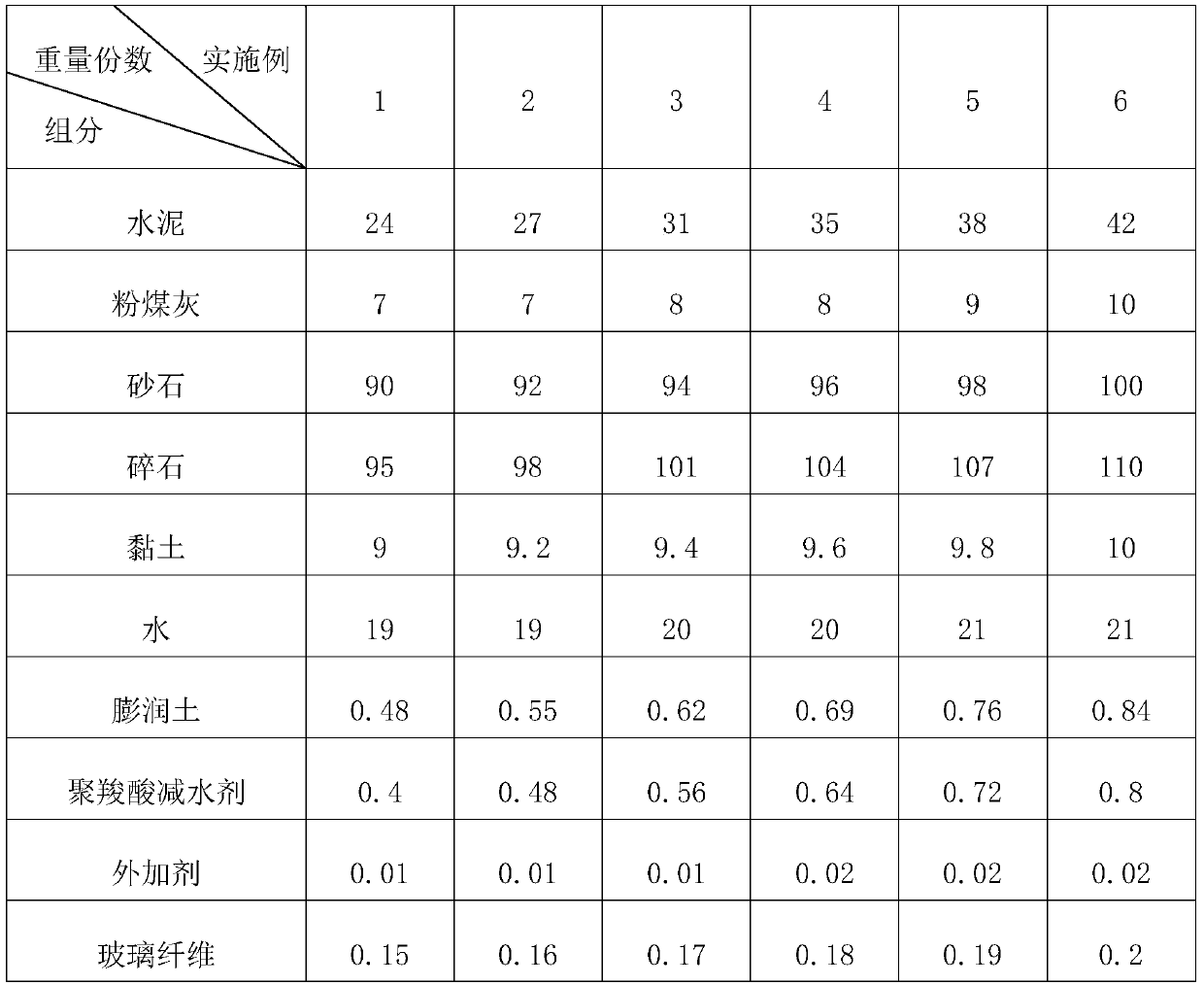

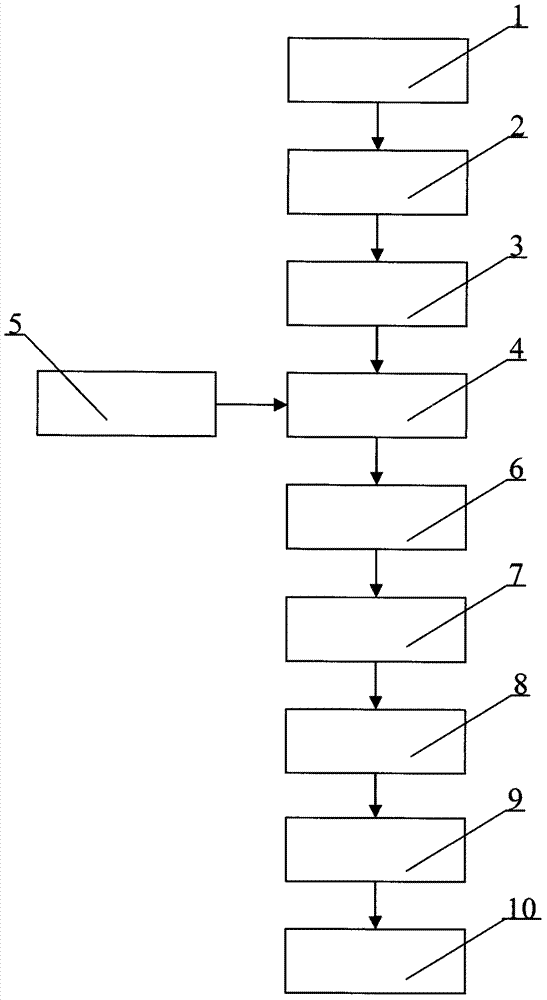

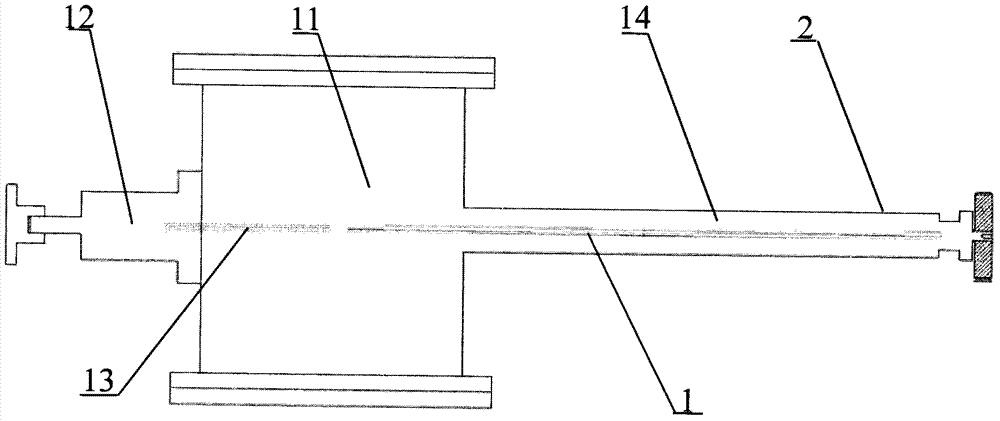

Low-slump loss concrete and preparation method thereof

Relating to the technical field of concrete, the invention discloses a low-slump loss concrete and a preparation method thereof. According to technical key points, the low-slump loss concrete comprises the following components by weight: 24-42 parts of cement; 7-10 parts of fly ash; 90-100 parts of sandstone; 95-110 parts of gravel; 9-10 parts of clay; 19-21 parts of water; 0.48-0.84 part of bentonite; 0.4-0.8 part of a polycarboxylate superplasticizer; 0.01-0.02 part of an admixture; and 0.15-0.2 part of glass fiber; wherein the admixture is prepared by the steps of: adding isopropanol and water into a reaction kettle, mixing the substances uniformly, performing heating, adding acrylic acid and an initiator dropwise at the same time, then carrying out heat preservation reaction for 2h, performing cooling to 25DEG C, and using a NaOH solution with a mass fraction of 30% to adjust the pH to 9-11. The concrete prepared according to the formula provided by the invention has the advantagesof small slump loss and high strength.

Owner:上海浦盈混凝土有限公司

Method for producing graphene by voltaic arc negative pressure

The invention discloses a method for producing graphene by voltaic arc negative pressure. An lengthened graphite rod is put into a cathode propulsion device, the constant distance between the lengthened graphite rod in a cathode and a short graphite rod in an anode is 1-3mm, a pipeline is cleaned with a hydrogen gas and a helium gas, the interior of a vacuum cavity is filled with a hydrogen gas and a helium gas at the ratio of 1:1 until the pressure value is -1x10<-5> to -2x10<-5>MPa, a voltaic arc electric discharge device is turned on, after a current is 140A-200A, electric discharging is performed, and a voltaic arc is formed between the anode graphite rod and the cathode graphite rod. The method provided by the invention has the characteristics that the voltaic arc negative pressure isused to prepare the graphene, the negative pressure environment satisfies the pressure required for the preparation of the graphene, besides the helium gas, injected gases also add the hydrogen gas with good conductivity, so that the current of preparation of the graphene and the production dangerousness are reduced, energy sources are saved, the filling amount of the hydrogen gas and the heliumgas and the number of replacement of the graphite rod are reduced, the preparation rate is high, raw materials can be fully utilized, work is saved, labor is saved, and the production costs are reduced.

Owner:HEILONGJIANG HUASHENG GRAPHITE CO LTD

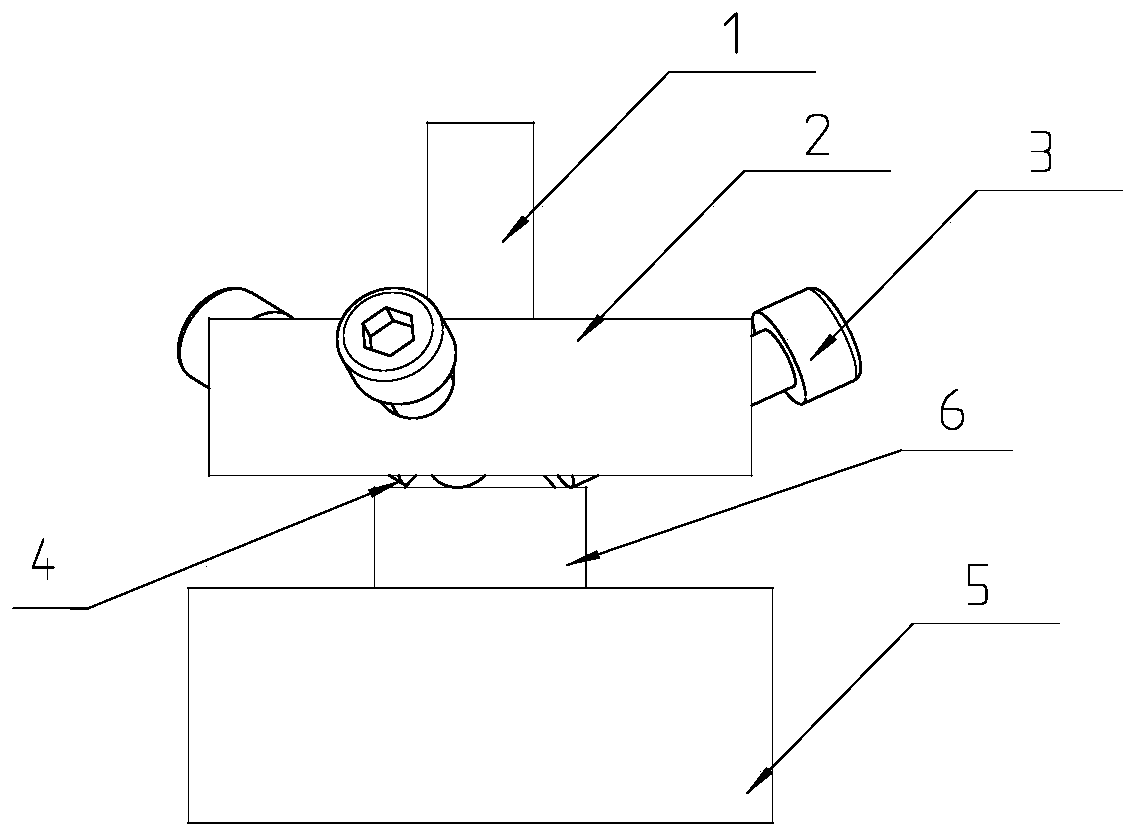

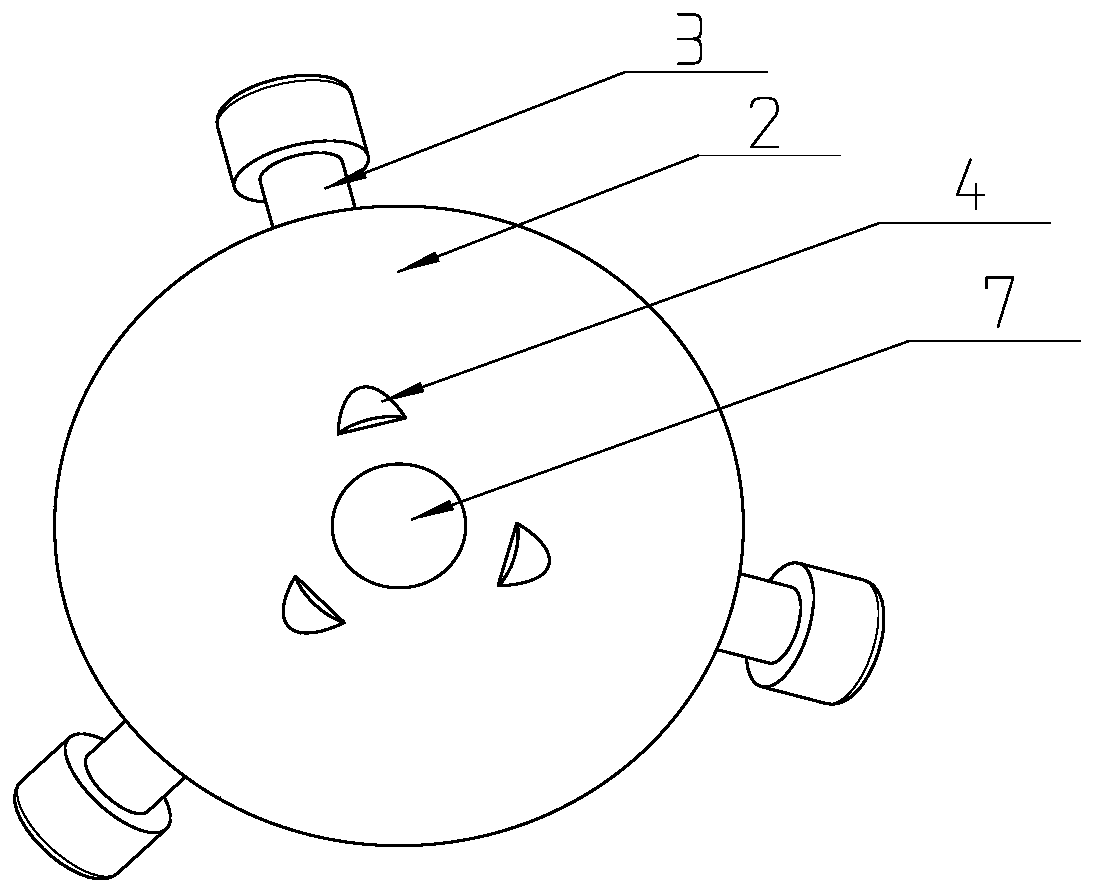

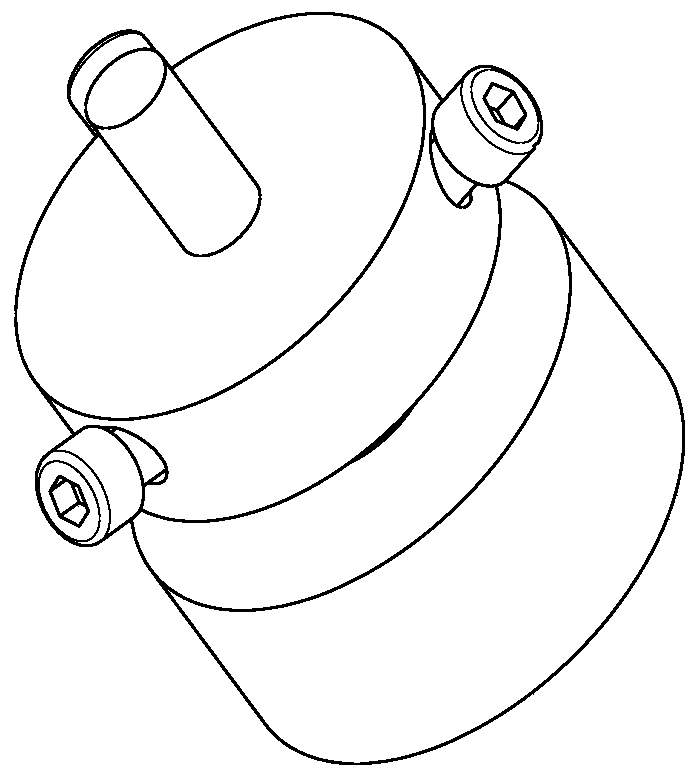

Roller type bearing spinning closing-in device and using method thereof

ActiveCN110947814AReduce the difficulty of structure manufacturingLow costStructural engineeringMechanical engineering

The invention relates to a roller type bearing spinning closing-in device. The device comprises a tool handle, a spinning head, embedded bolts, a bolt rod, a round frame base and a guide shaft. A plurality of bolt holes are formed in the spinning head, the bolt holes run through the spinning head, the bolt holes are formed at equal angles with the central axis of the spinning head as the axis, theincluded angle between each bolt hole and the horizontal plane is 25 degrees, the tool handle is perpendicular to the spinning head and located in the middle of the spinning head, the guide shaft iscylindrical, the outer circle diameter of the guide shaft is matched with the size of an inner hole of a to-be-machined bearing, and the length of the guide shaft is matched with the thickness of theto-be-machined bearing. The guide shaft is cylindrical, the outer circle diameter of the guide shaft is matched with the size of the inner hole of the to-be-machined bearing, and the length of the guide shaft is matched with the thickness of the to-be-machined bearing. The device is simple in structure, self-manufacturing and reconstruction can be realized, production is simple and convenient, themachining mode is simple, abrasion of the closing-in device is reduced, and the service life of the closing-in device is effectively prolonged.

Owner:AVIC SAC COMML AIRCRAFT

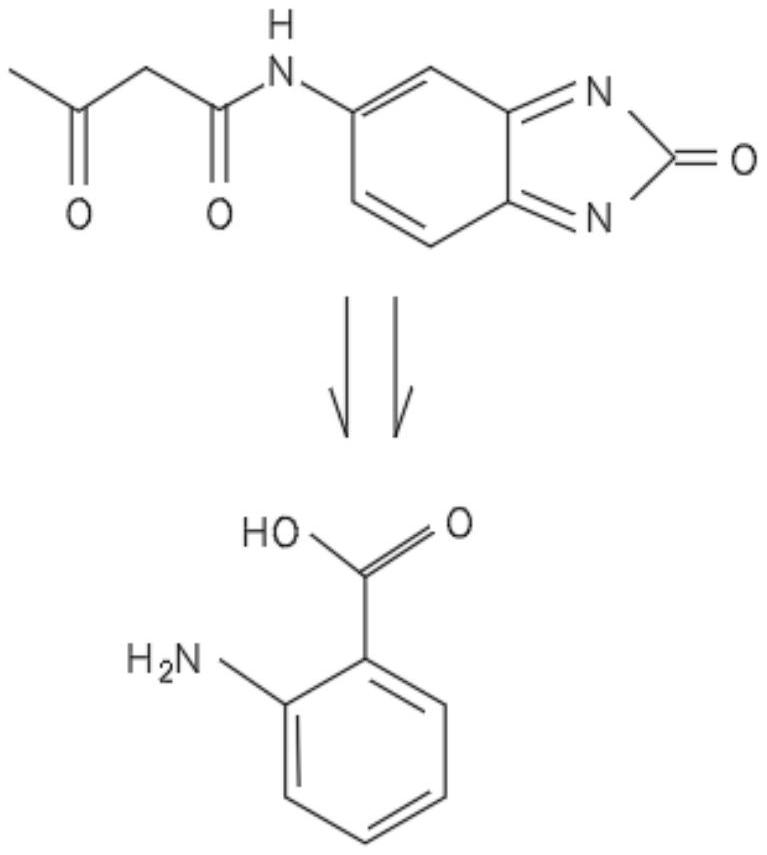

Preparation method of environment-friendly pigment yellow 151

PendingCN113861718ASimple to use and dischargeHigh preparation rateMonoazo dyesAnthranilic acidAqueous solution

The invention provides a preparation method of environment-friendly pigment yellow 151, relates to a preparation method for preparing pigment yellow 151 by reacting an intermediate with water bath heating, and belongs to the field of chemical production. According to the preparation method for preparing the pigment yellow 151 by matching overall gradient heating with stirring to carry out rapid dispersion reaction and combining an intermediate with an alkaline aqueous solution of from o-phenylenediamine and urea which are used as raw materials to prepare the intermediate, the intermediate reacts with an anthranilic acid alkaline aqueous solution, the temperature and stirring are matched to carry out high-efficiency reaction, high-efficiency dispersion preparation is carried out, and the obtained component is uniform; and heating and vacuum treatment is adopted in the whole reaction, so high preparation rate, full reaction and reduction of the production cost are achieved.

Owner:GAOYOU HUABAO PIGMENT

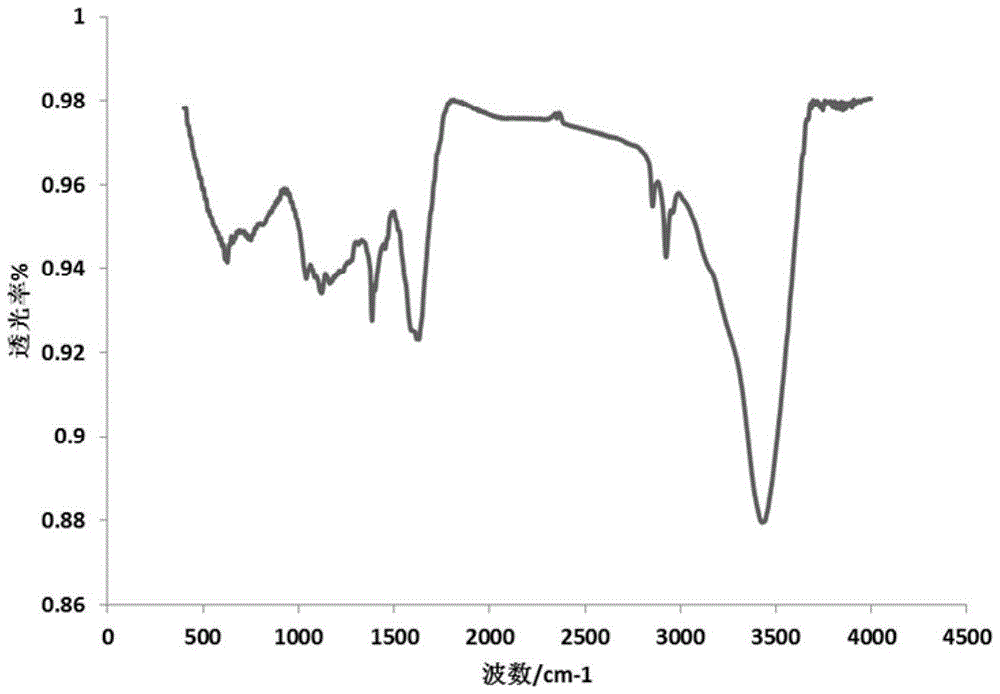

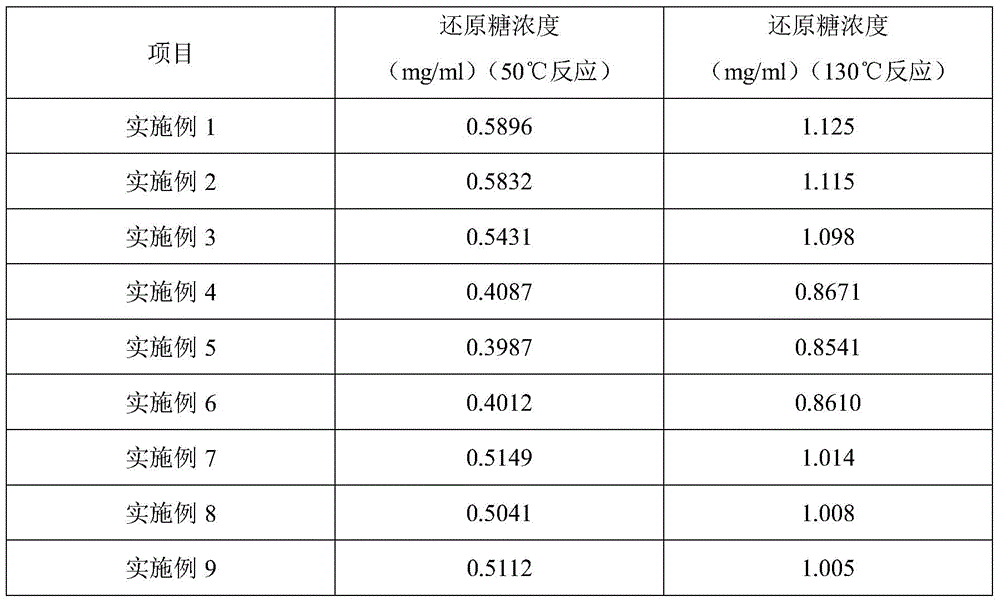

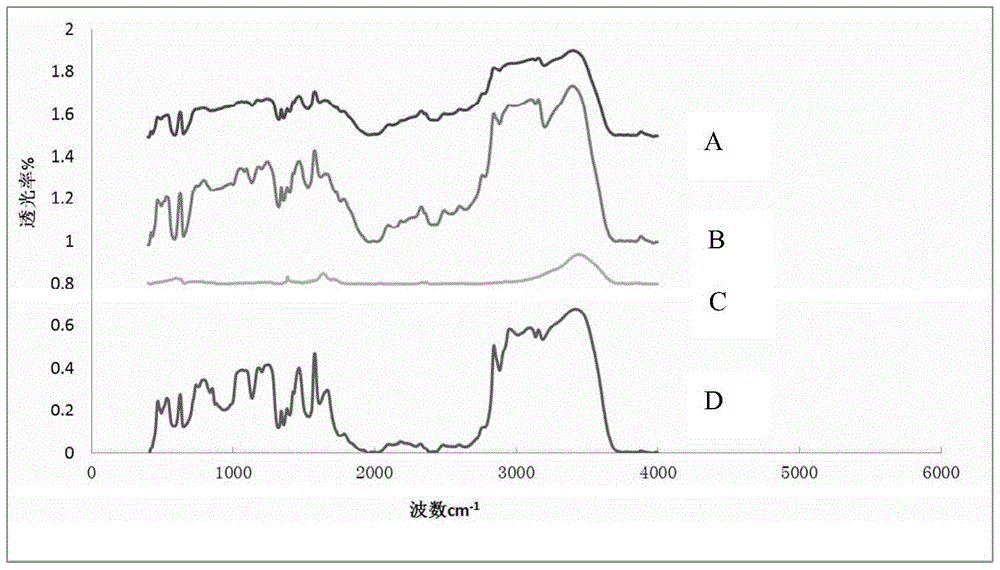

Method for preparing simulated cellulose enzyme from mixed acid

InactiveCN104437629ASimple processHigh preparation rateOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseCarboxylic acid

The invention discloses a method for preparing a simulated cellulose enzyme from mixed acid. According to the method, the simulated enzyme is synthesized at high selectivity and high yield through one-step synthesis reaction by taking polybasic carboxylic acid, inorganic acid and an ionic liquid as raw materials. The synthesized enzyme can be used for efficiently degrading cellulose to prepare reducing sugar. The simulated enzyme can be recycled for many times. The simulated cellulose enzyme prepared by using the method is good in catalytic effect and is not easily degraded so as to be the simulated cellulose enzyme with an application potential.

Owner:JIANGSU UNIV OF SCI & TECH

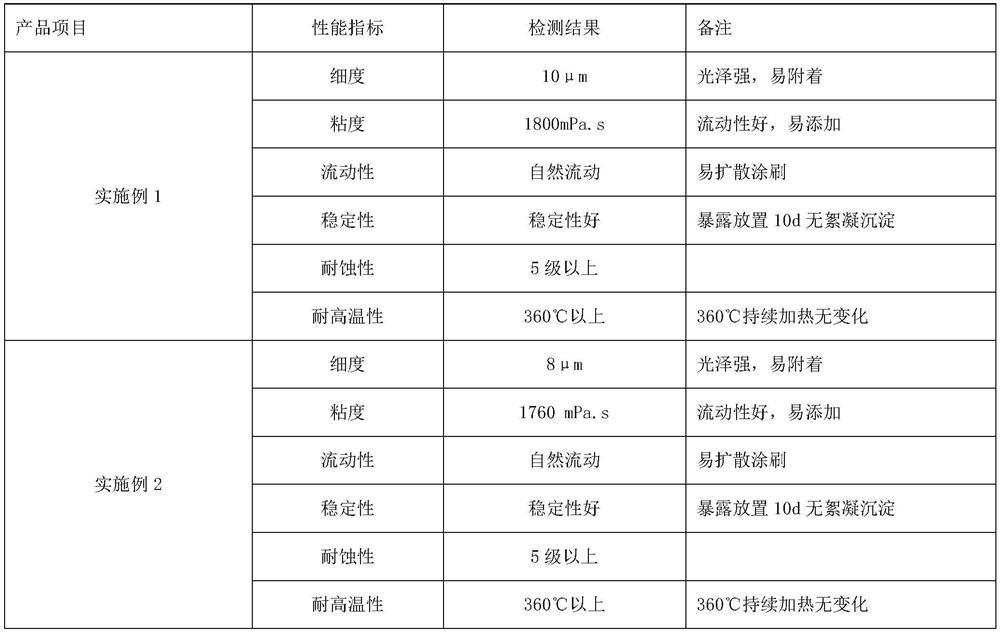

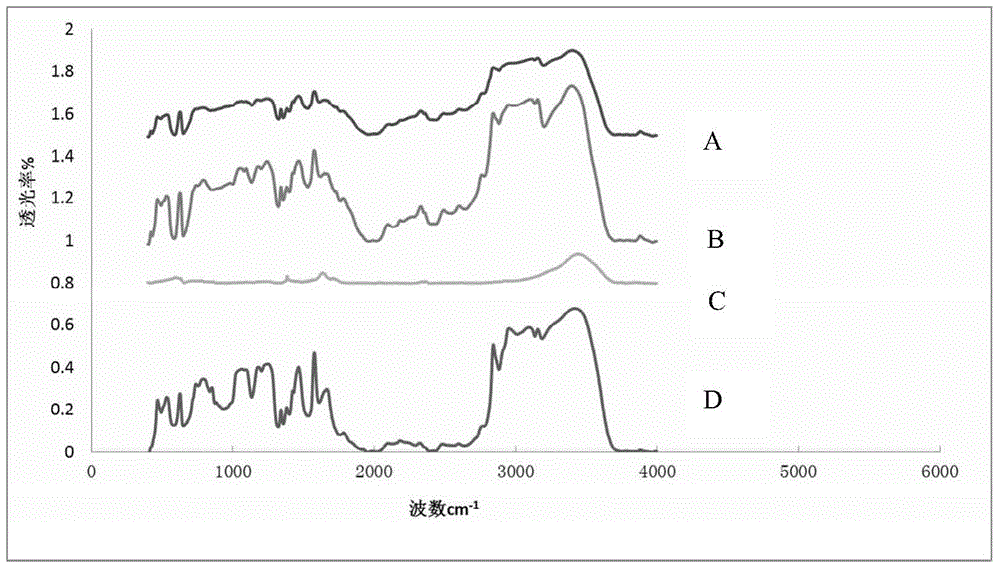

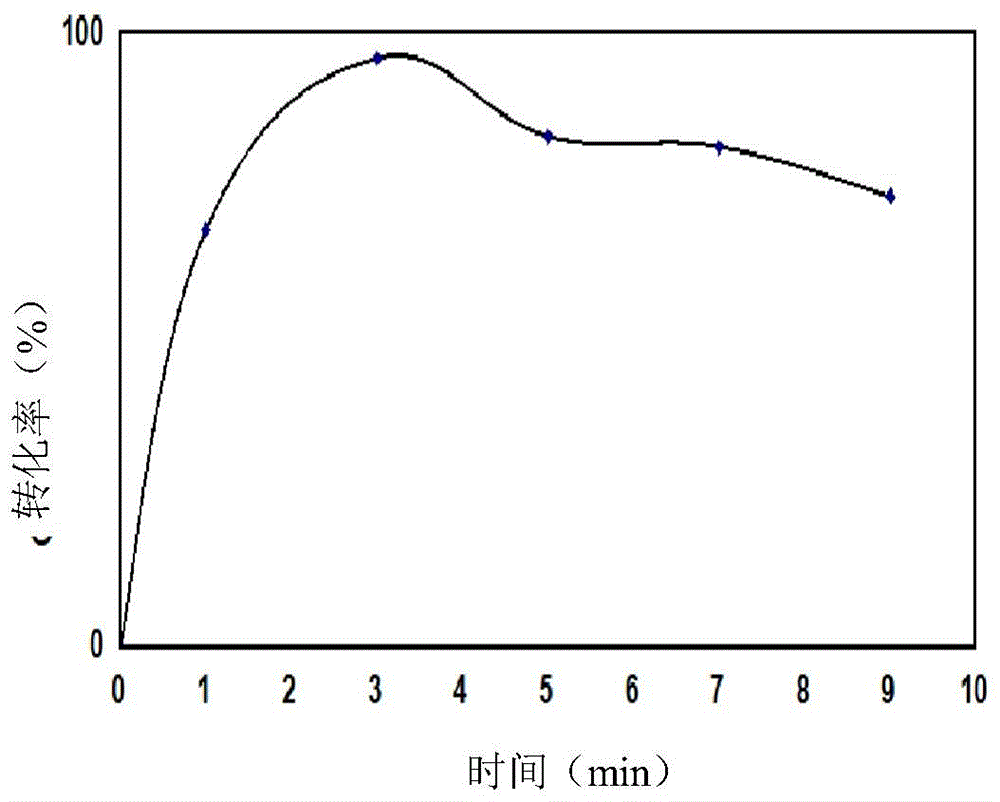

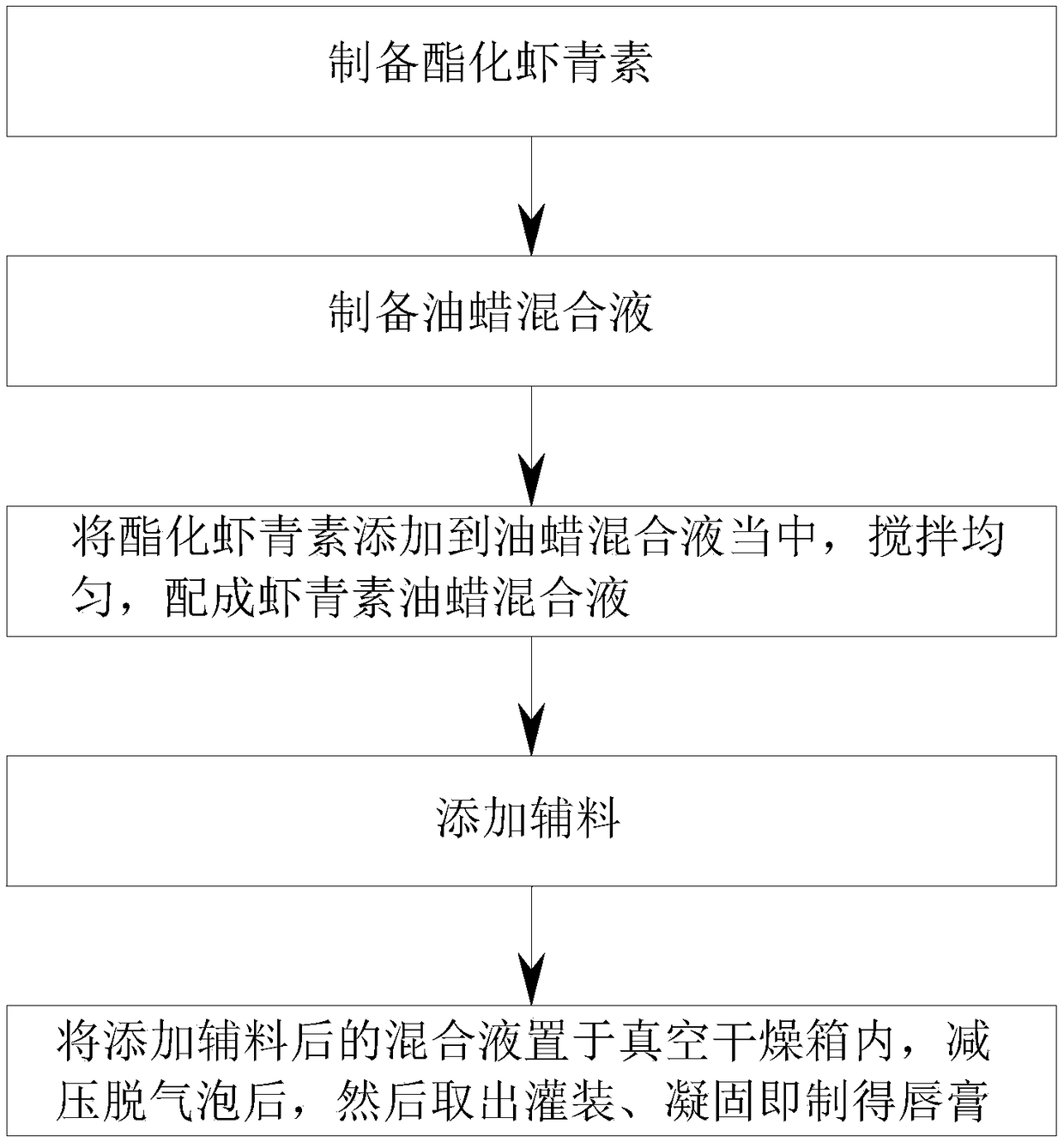

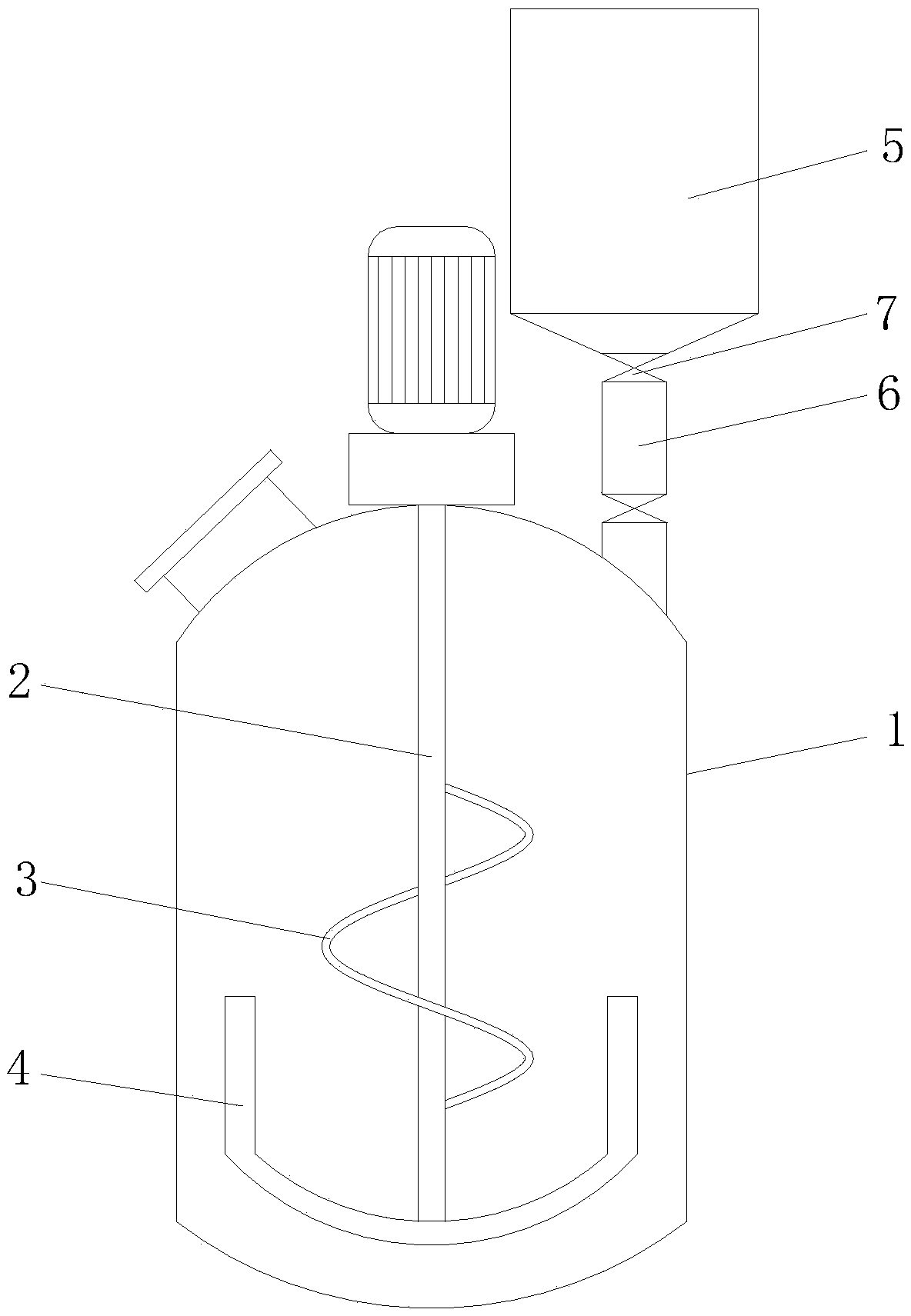

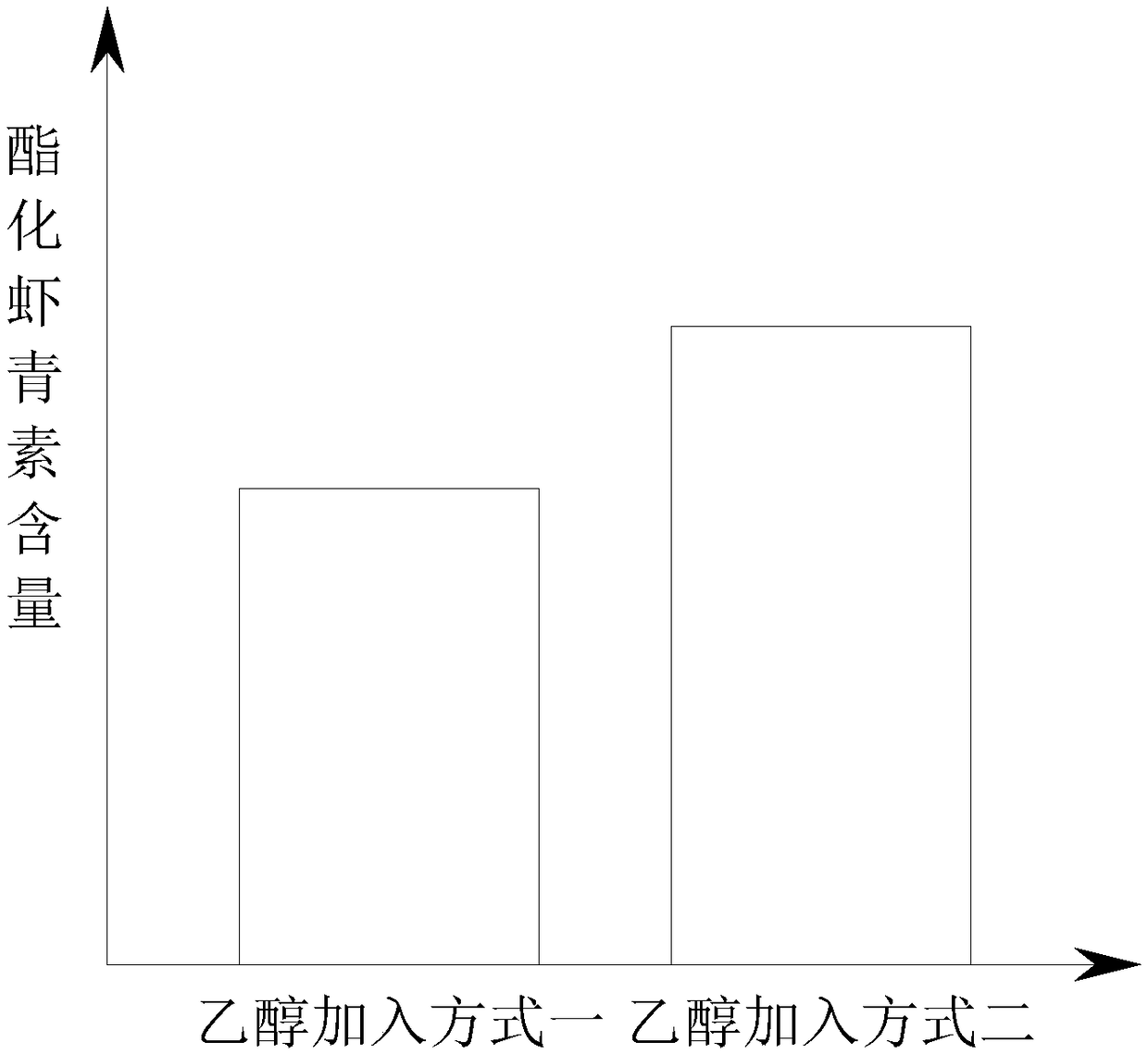

Astaxanthin lip balm and preparation method thereof

InactiveCN109276508AImprove stabilityStrong fragranceCosmetic preparationsOrganic chemistryWaxSpiral blade

The invention discloses an astaxanthin lip balm and a preparation method thereof. The preparation method comprises: S1: extracting esterified astaxanthin from a raw material through a supercritical fluid extraction method; step S2, preparing an oil wax mixing liquid; S3, adding the esterified astaxanthin prepared in the step S1 to the oil wax mixing liquid prepared in the step S2, and stirring bya stirring device until the astaxanthin is completely dissolved to form a uniform viscous solution so as to prepare an astaxanthin-oil wax mixing liquid; S4, sequentially adding an auxiliary materialto the astaxanthin-oil wax mixing liquid prepared in the step S3, and completely mixing by the stirring device; and S5, placing the mixed solution obtained in the step 4 in a vacuum drying oven, carrying out pressure reducing bubble removing, taking out, filling, and solidifying to obtain the lipstick. According to the present invention, by arranging the stirrer, the spiral blade, the frame type blade, the ethanol hopper and the metering cylinder, the problems of low preparation efficiency and serious waste of raw materials in the traditional astaxanthin lip balm and the preparation method thereof can be solved.

Owner:昆明白鸥微藻技术有限公司

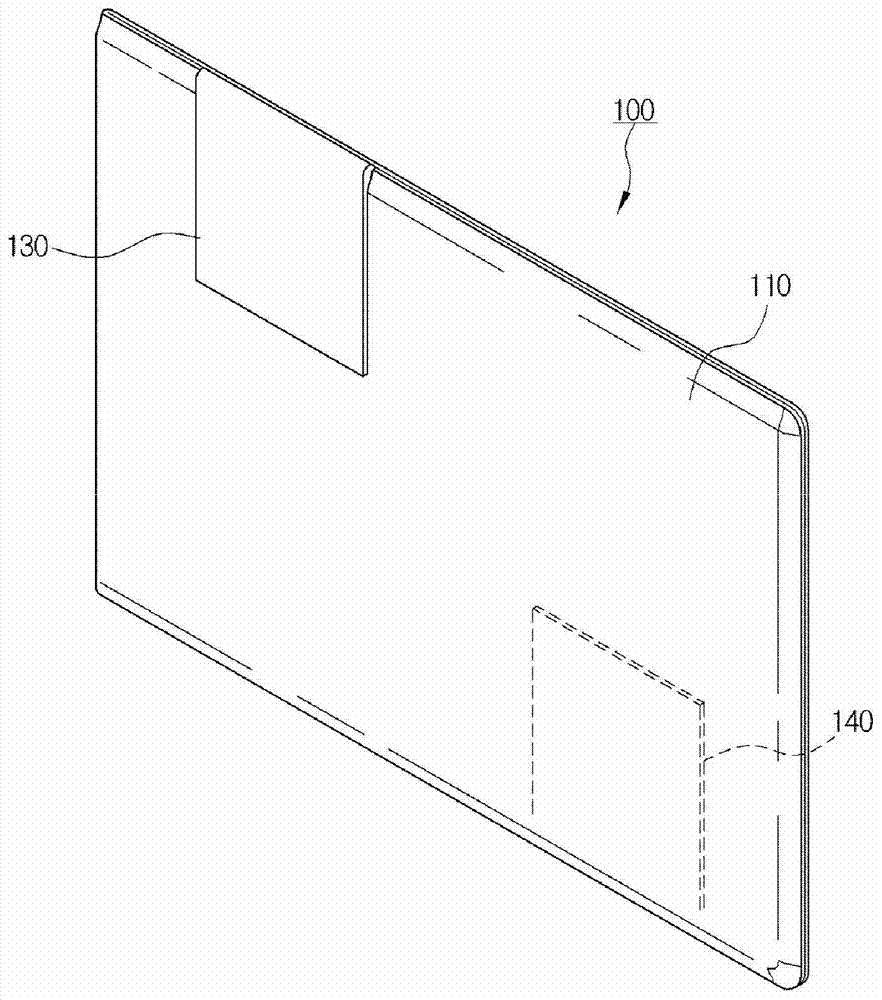

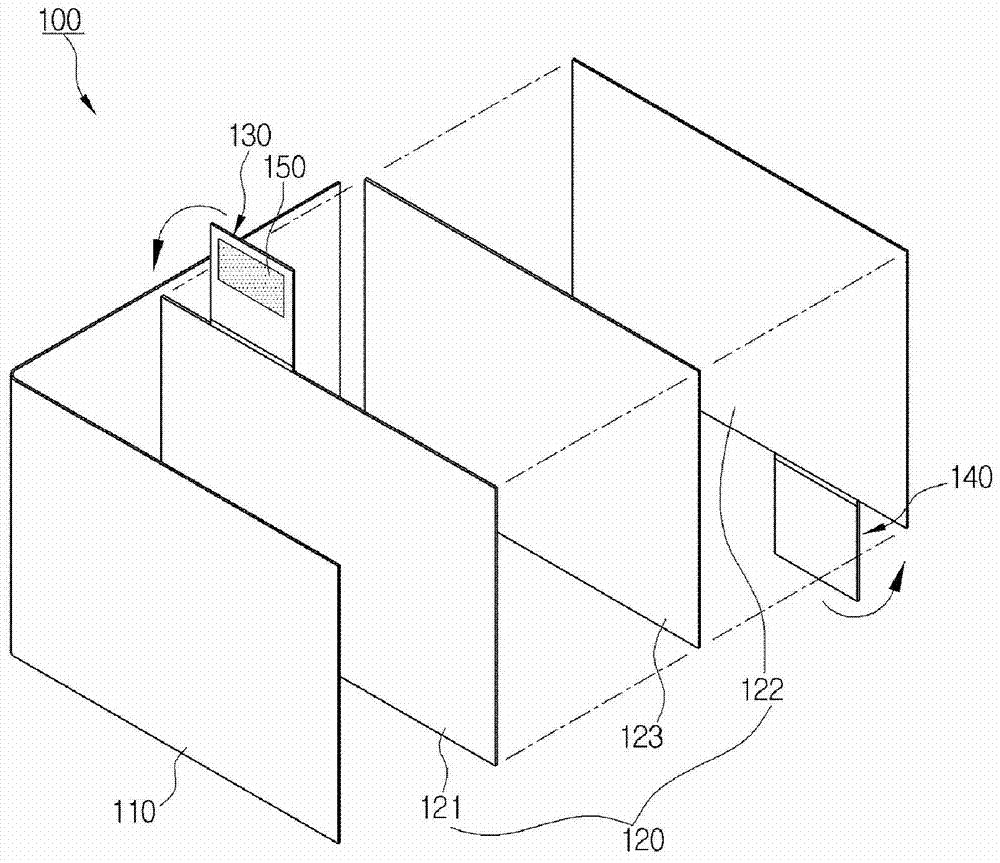

Battery cell, manufacturing method thereof, and battery module including the same

InactiveCN103843166AEasy to manufactureEasy access to power connectionsFinal product manufactureSmall-sized cells cases/jacketsBattery cellElectrical and Electronics engineering

Provided are a battery cell, a manufacturing method thereof, and a battery module including the same. According to the present invention, first and second electrode taps are formed at both sides of a case so as to be closely adhered thereto, respectively, such that the battery cell may be easily manufactured and the battery module may be easily formed by stacking.

Owner:SK INNOVATION CO LTD

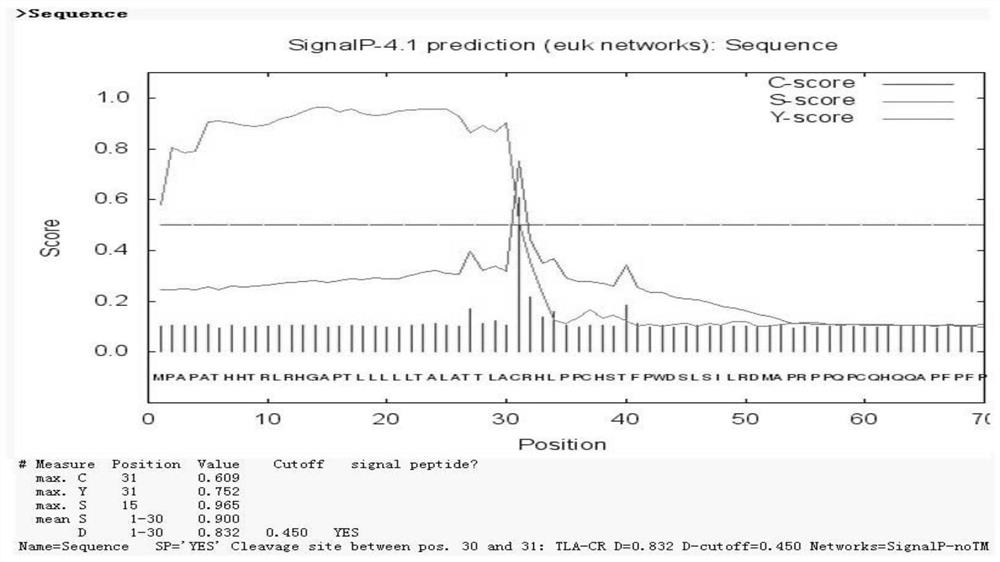

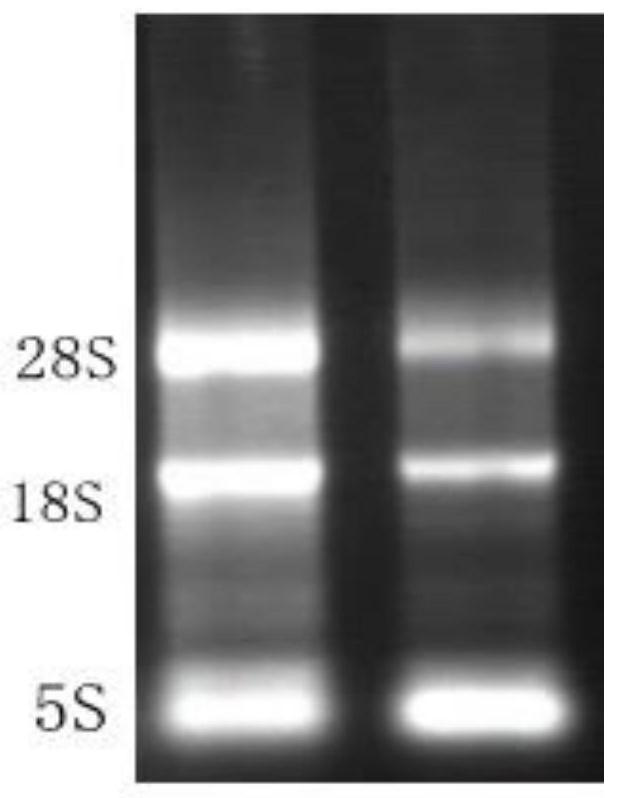

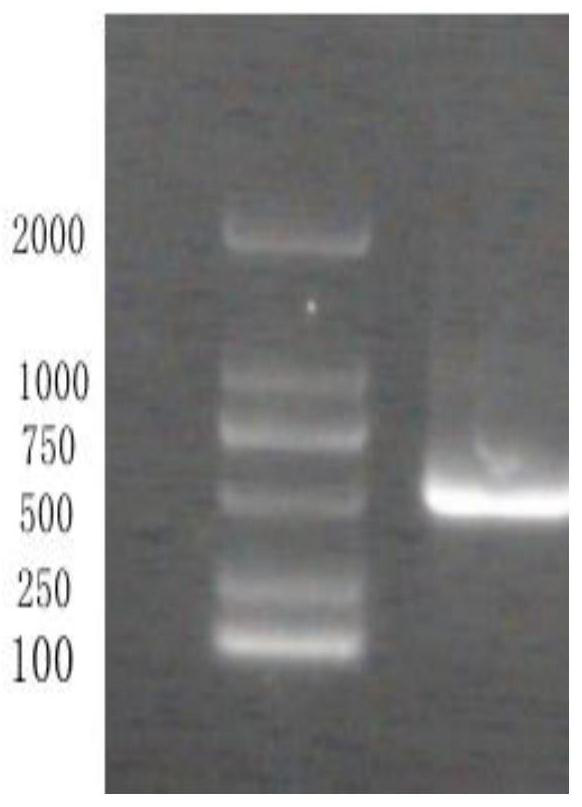

Cloning expression and polyclonal antibody preparation of black-headed gull IFN alpha protein

PendingCN111925433APublic health impactHigh preparation rateSerum immunoglobulinsImmunoglobulins against cytokines/lymphokines/interferonsVeterinary public healthImmunogenicity

The invention relates to cloning expression and polyclonal antibody preparation of black-headed gull IFN alpha protein and belongs to the technical field of bioengineering. The invention provides cloning expression and polyclonal antibody preparation of the black-headed gull IFN alpha protein. Part of fragments of the black-headed gull alpha interferon gene are cloned, a prokaryotic expression recombinant vector is constructed, recombinant protein is obtained to prepare a polyclonal antibody, a theoretical basis is provided for later researches on the antiviral activity of the polyclonal antibody and the antiviral mechanism of the black-headed gull alpha interferon gene, a new path is developed for prevention and control of epidemic diseases of black-headed gulls, and veterinary public health is deeply affected. When rabbits are immunized, a Freund's complete adjuvant and an incomplete adjuvant are selectively applied to be matched with protein injection, and the polyclonal antibody can be efficiently and rapidly prepared. The agar diffusion test proves that the recombinant protein of partial segment of the black-headed gull IFN alpha gene has favorable immunogenicity, and the titer of the antibody can reach 1: 8. The method can be well used for subsequent researches on the antiviral mechanism of the black-headed gull IFN alpha protein.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

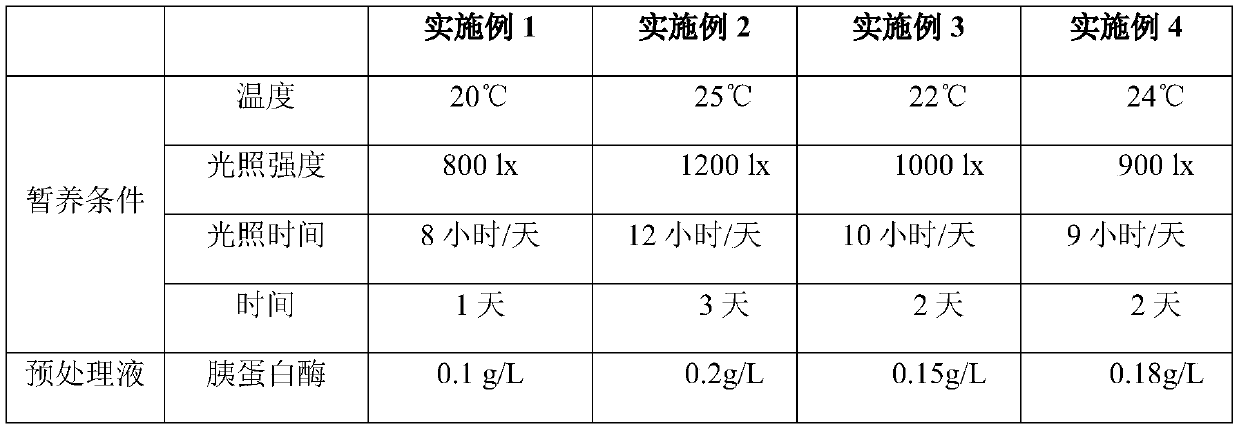

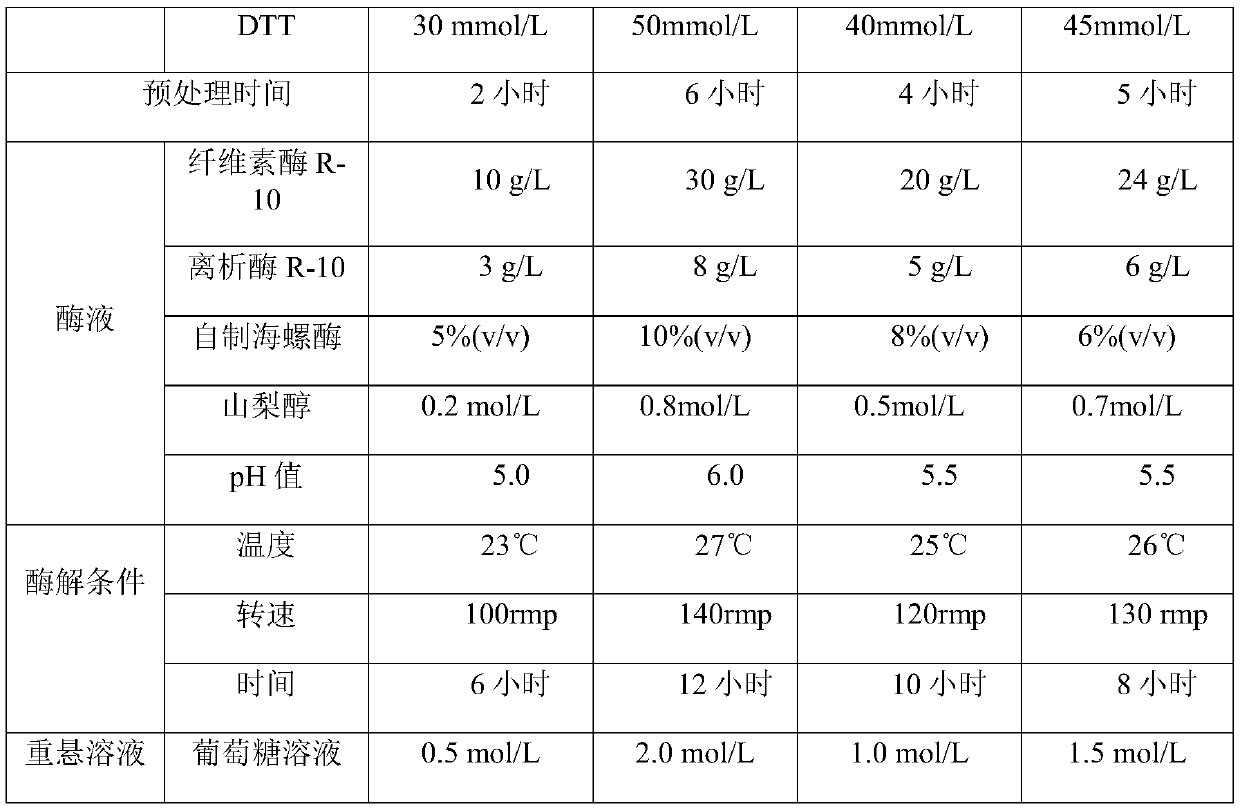

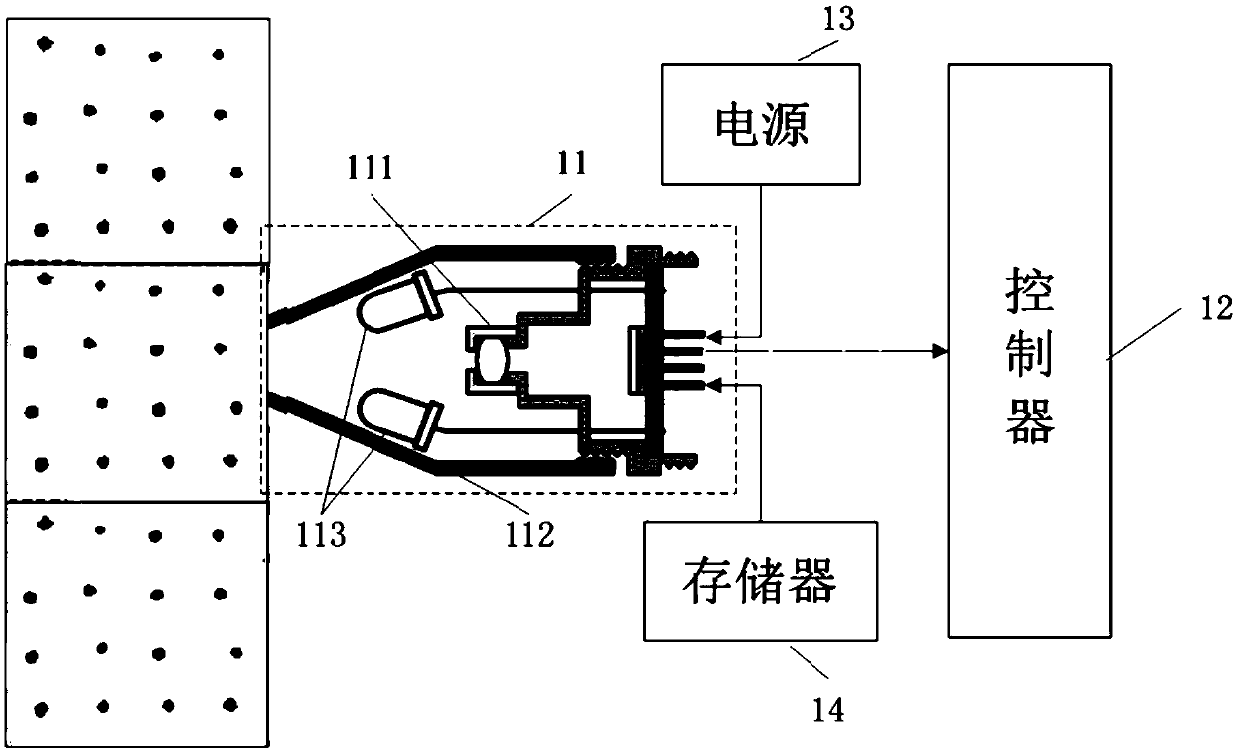

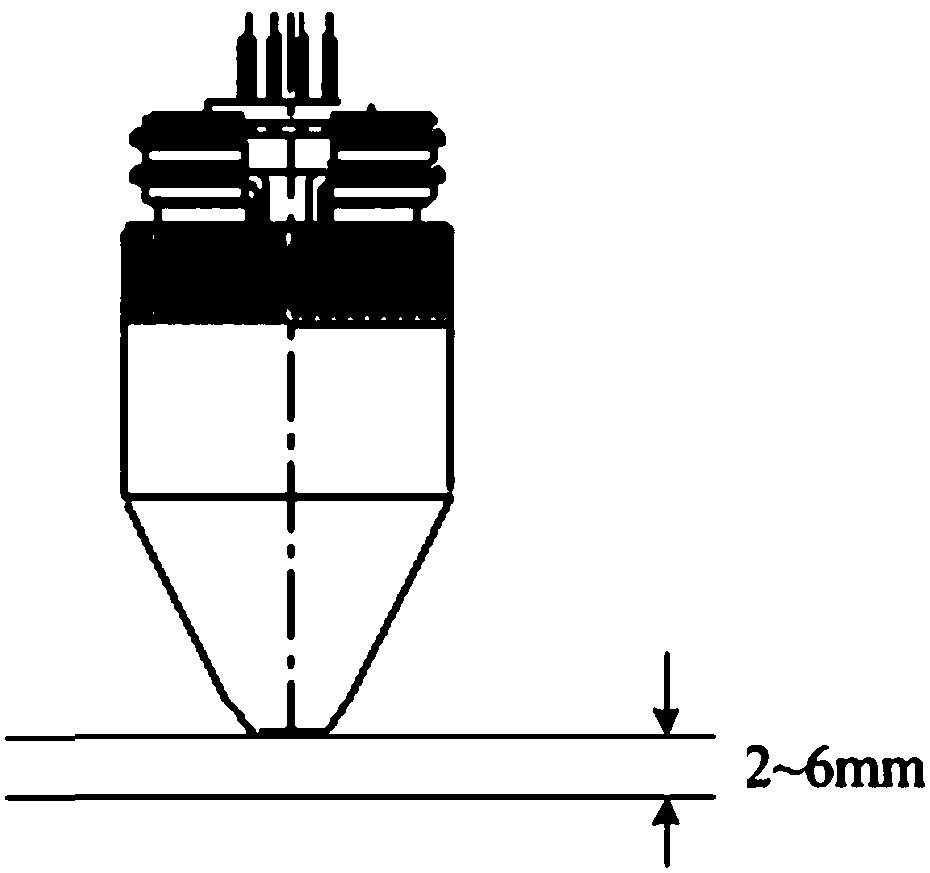

Preparation method of thalassia hemperichii protoplast

The invention discloses a preparation method of a thalassia hemperichii protoplast and belongs to the field of plant cell engineering. The preparation method comprises the following steps: S1, takingyoung leaves of thalassia hemperichii, washing them with sterile seawater, and temporarily culturing them to obtain a raw material 1; S2, putting the raw material 1 obtained in the step S1 into a pretreatment liquid for soaking to obtain a raw material 2; S3, taking out the raw material 2 obtained in the step S2, sucking dry water, cutting them into blocks, adding enzyme liquid for enzymolysis, and obtaining enzymolysis tissues; S4, filtering the enzymolysis tissue obtained in the step S3 to obtain filtrate; S5, centrifuging the filtrate obtained in the step S4, discarding the supernatant, suspending the precipitate with a resuspension solution, centrifuging, and discarding the supernatant to obtain a precipitate; S6, suspending the precipitate obtained in S5 with a resuspension solution to obtain the thalassia hemperichii protoplast. The preparation method of the thalassia hemperichii protoplast is established for the first time, and the thalassia hemperichii protoplast obtained by the method is high in yield and high in survival rate.

Owner:HAINAN ACADEMY OF OCEAN & FISHERIES SCI

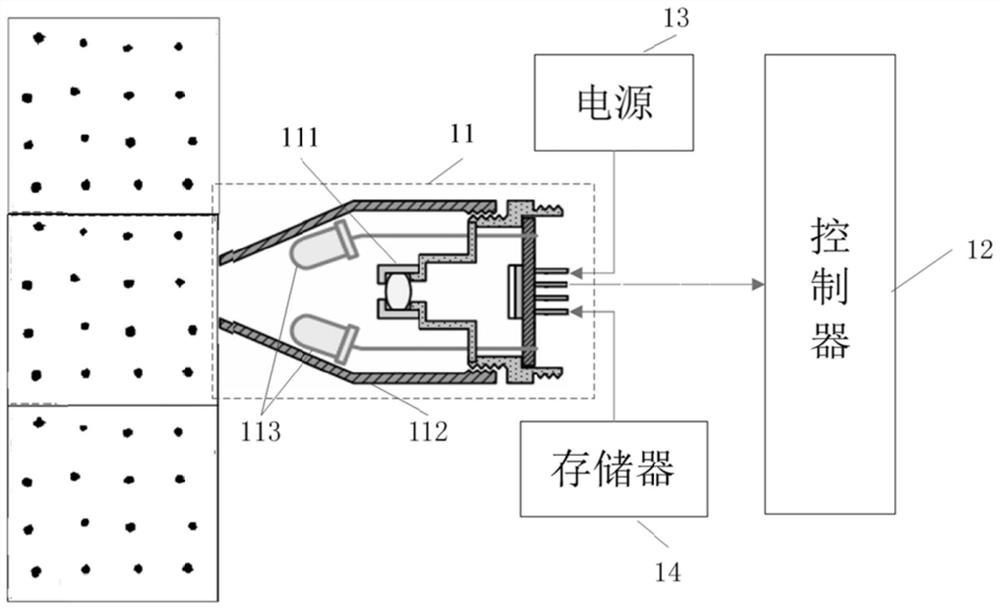

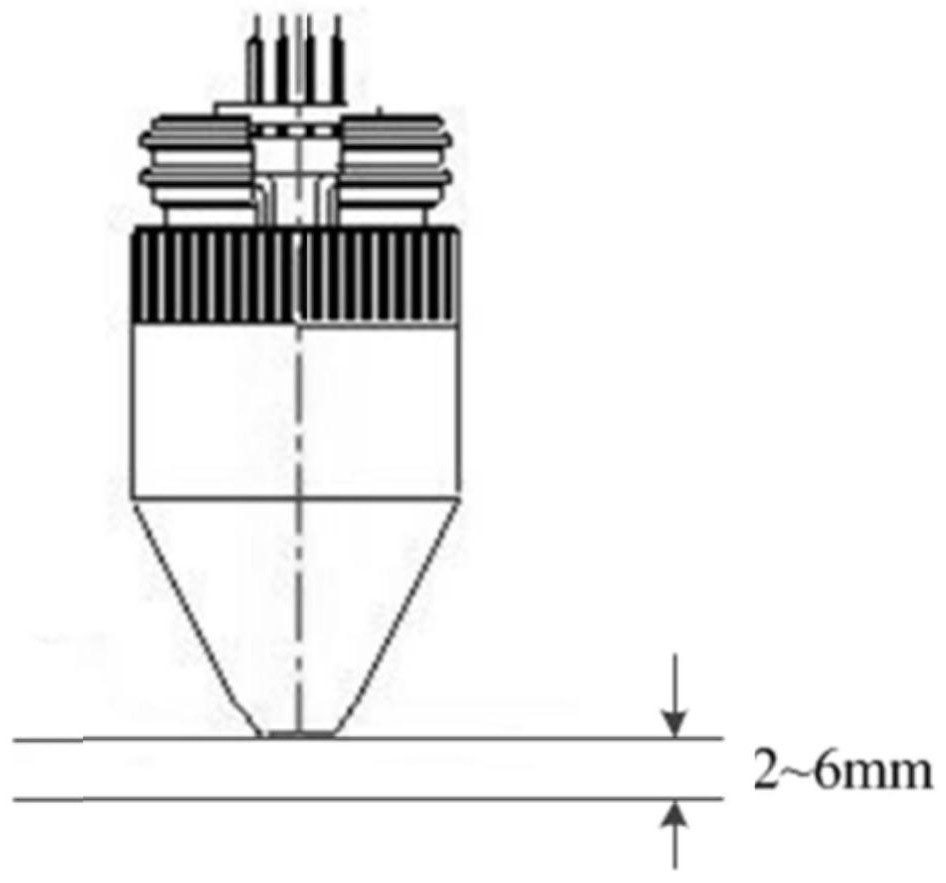

Method for preparing capsules by beverage preparation device and machine-readable storage medium

ActiveCN110786737AEasy to identifyHigh preparation rateBeverage vesselsSensing by electromagnetic radiationProcess engineeringImage pair

The embodiment of the invention provides a method for preparing capsules by a beverage preparation device and a machine-readable storage medium, which belong to the technical field of product identification and solve the problem of incomplete identification of information on the capsules in the prior art. The method for preparing the capsules by the beverage preparation device comprises the following steps of: obtaining an image to be identified on a diaphragm, wherein the obtained image to be identified includes a plurality of micro image units; determining a code combination corresponding tothe obtained image to be identified according to the corresponding relationship between the micro image units and preset codes; matching the type code corresponding to the type of a beverage preparedon the beverage preparation device with the code combination to obtain a similarity threshold value between each type code and the code combination; determining the beverage type corresponding to thetype code to which the maximum value in the similarity threshold value belongs as the type of the beverage to be prepared; and preparing the capsule according to preset preparation parameters corresponding to the type of the beverage to be prepared. The embodiment of the invention is applicable to the process of preparing the capsules by the beverage preparation device.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

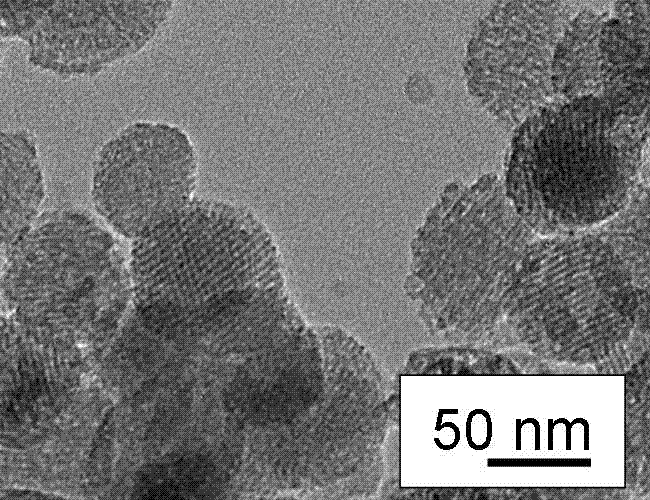

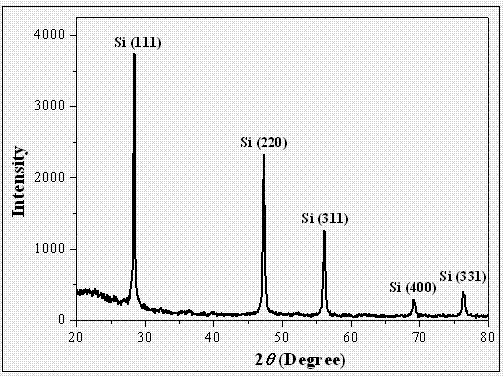

A kind of ordered mesoporous silicon nanomaterial with mcm-41 molecular sieve structure and its preparation method

InactiveCN103073017BIncrease the areaHigh pore volumeMaterial nanotechnologyCrystalline aluminosilicate zeolitesNano structuringPhotoluminescence

The invention relates to an ordered mesopore silicon nano material with an MCM-41 molecular sieve structure and a preparation method, which belongs to the technical field of an inorganic nano material. Magnesium heat reduction reaction is adopted, the silicon dioxide-based MCM-41 mesoporous moledular sieve with a regular porous structure is used as precursor, and the mesopore monatomic silicon material is produced under a low temperature. Since the temperature of the magnesium heat reduction process is low, a microstructure of the molecular sieve is reserved in the reaction process, the mesopore silicon produced through the method is a mesopore silicon nano material with the MCM-41 molecular sieve strcutre and has characteristics of uniformity in appearance, continuity and orderliness in porous structure, uniformity in porous walls, high specific surface area and obvious photoluminescence properties. The ordered mesopore silicon nano material has wide application prospect in the fields such as lithium-ion batteries, photoelectric materials and gas sensors. Due to the adoption of the ordered mesopore silicon nano material with the MCM-41 molecular sieve structure and the preparation method, a novel through is provided for preparing the porous silicon nano material with a special shape and ordered porous structure.

Owner:CHONGQING UNIV OF ARTS & SCI

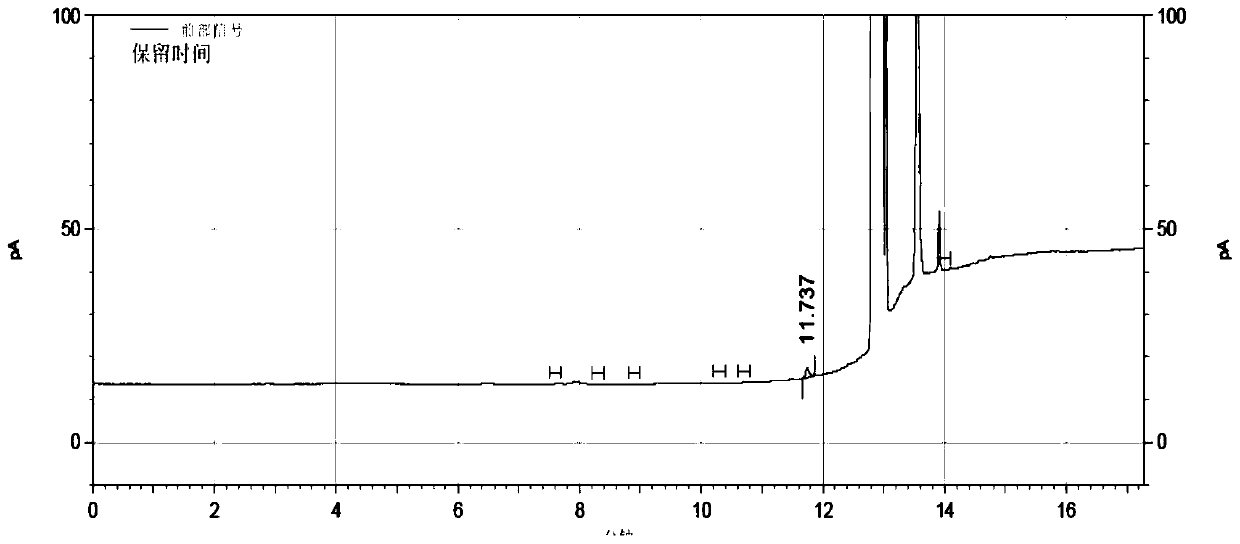

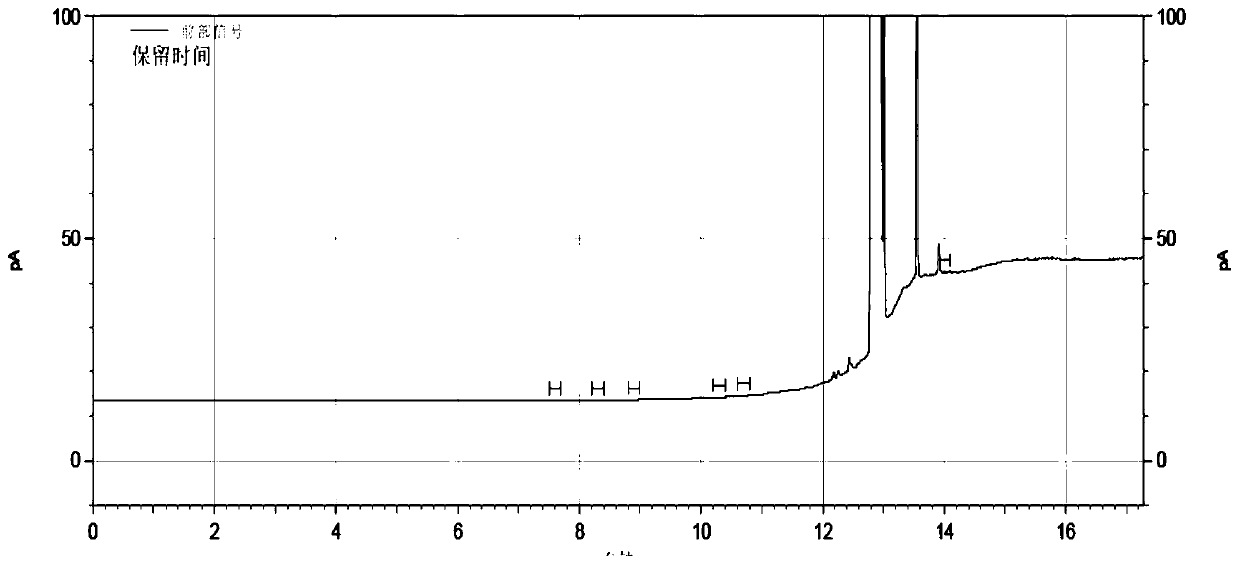

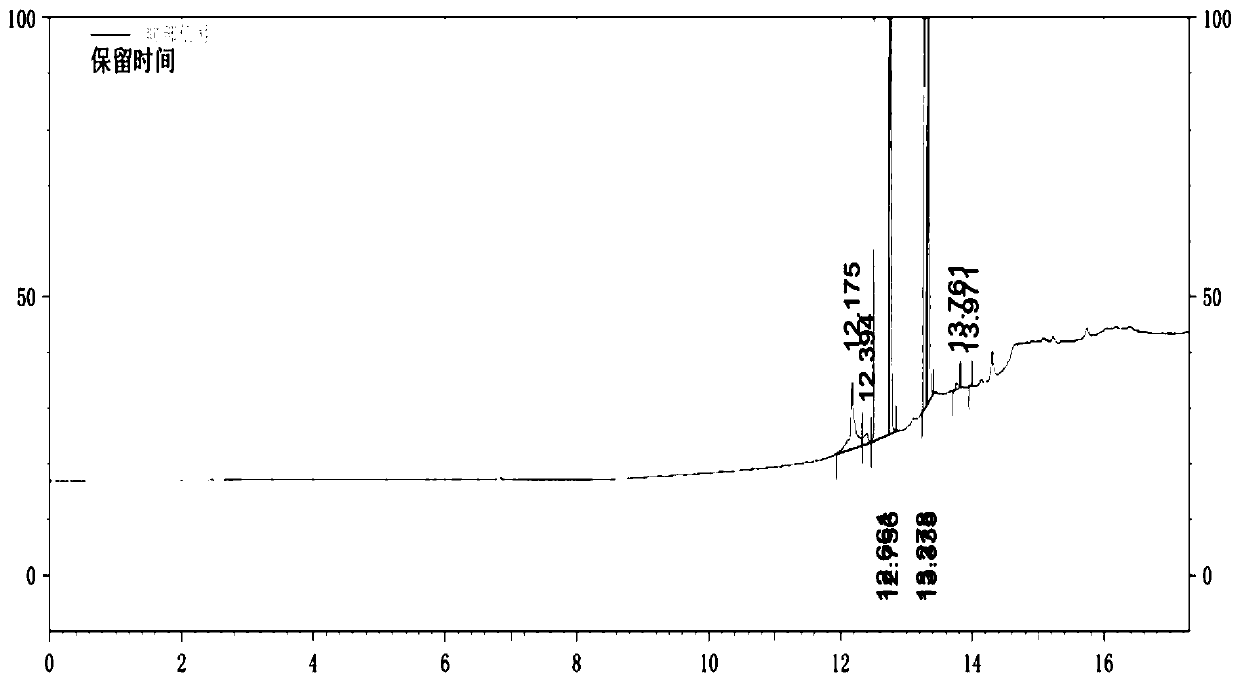

Purification method of NN dimethyl acetamide

PendingCN110483325AHigh purityEasy to separateCarboxylic acid amide separation/purificationPurification methodsEngineering

The invention discloses a purification method of NN-dimethylacetamide, which is characterized by comprising the following steps of (1) connecting a container filled with the industrial-grade NN-dimethylacetamide with a condenser connected with a water circulating vacuum pump, placing the container in a heating device, and connecting the other end of the condenser with a collection device through apacked column; (2) setting the ultrahigh temperature of the heating device to be 200 DEG C; (3) turning on the power supply of the water circulation vacuum pump, controlling the vacuum degree to be -0.080 to -0.090, and keeping the boiling temperature of the NN-dimethylacetamide in the container to be 115 to 125 DEG C; and (4) carrying out total reflux when liquid drips in the condenser, and turning on the power supply of the collection device after total reflux so as to collect the purified NN-dimethylacetamide, wherein the collection of the NN-dimethylacetamide in the step (4) is divided into four stages, the volume ratio of the reagents collected in sequence is 7: 16: 8: 9, and the reagent collected at the third stage is the high-purity NN-dimethylacetamide.

Owner:新乡双鹭药业有限公司

Method for preparing capsules by beverage preparation device and machine-readable storage medium

ActiveCN110786737BEasy to identifyHigh preparation rateBeverage vesselsSensing by electromagnetic radiationProcess engineeringImage pair

Embodiments of the present invention provide a method for preparing capsules by a beverage preparation device and a machine-readable storage medium, which belong to the technical field of product identification and solve the problem of incomplete identification of information on capsules in the prior art. The method includes: acquiring an image to be identified on the diaphragm, the acquired image to be identified includes a plurality of micro image units; according to the corresponding relationship between the micro image units and preset codes, determining the corresponding Code combination; match the type code corresponding to the beverage type prepared on the beverage preparation device with the code combination to obtain the similarity threshold of each type code and the code combination; combine the maximum value of the similarity threshold The type of drink corresponding to the type code is determined as the type of drink to be prepared; the capsule is prepared according to the preset preparation parameters corresponding to the type of drink to be prepared. The embodiment of the present invention is applicable to the process of preparing capsules by a beverage preparation device.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

A bionic banana fiber extraction device based on the mandible of leaf-cutter ants

ActiveCN109457300BAvoid damageHigh preparation rateMechanical fibre separationLarge toothSmall tooth

The invention discloses a banana fiber extraction device based on the bionicity of the upper jaw of leaf-cutter ants, which includes a frame, a cutting mechanism, and a flattening mechanism located on the front side of the cutting mechanism. The front end of the knife and the fixed knife is provided with L-shaped notches, and the L-shaped notches are staggered with large and small tooth edges. The flattening mechanism includes two upper and lower pressure rollers arranged in parallel up and down. The upper pressure roller is sleeved with an upper The lower pressure roller is sleeved with the lower block, the top of the frame is bolted to the support, and the upper block and the lower block are arranged in the support. The present invention can effectively reduce the content of The impurity rate and winding blockage reduce the impurity content rate, improve the final fiber preparation rate, increase the contact area between the fixed knife and the fiber surface, improve the processing efficiency, and reduce the damage of the fixed knife to the banana fiber during processing. Yield reduces clogging.

Owner:徐莎莎

A kind of preparation method of simulated cellulase

InactiveCN104437633BHigh preparation rateEasy to makeOrganic-compounds/hydrides/coordination-complexes catalystsFiberCatalytic effect

The invention discloses a method for preparing simulated cellulase. The method comprises the following steps: taking a cellulose material, washing, removing the impurities, drying, grinding, and screening, thereby obtaining cellulose powder; uniformly mixing and stirring the obtained cellulose powder with ionic liquid according to a mass ratio of 1-20:100, preserving the temperature, performing assisted microwave treatment so as to expand the fibers, washing to remove the ionic liquid, and drying to remove the moisture, thereby obtaining a primary sample; adding the obtained primary sample into a crucible, putting the crucible into a tube furnace, and performing heating treatment under gas protection; adding a mixed acid, adding water and washing to remove the impurities, and drying to obtain dried powder, thereby obtaining the sample powder; adding the obtained sample powder into an organic base, stirring, heating, reacting, and washing by using a cleaning solvent, thereby obtaining the simulated cellulase. The simulated cellulase prepared by the method is high in binding ability with a substrate (a cellulose material) and good in thermal stability, high-temperature catalysis can be performed, the catalytic effect is good, the cost of the raw materials is low, and the cellulase can be repeatedly utilized.

Owner:JIANGSU UNIV OF SCI & TECH

A kind of preparation method of mixed acid simulated cellulase

InactiveCN104437629BSimple processHigh preparation rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic effectCarboxylic acid

The invention discloses a method for preparing a simulated cellulose enzyme from mixed acid. According to the method, the simulated enzyme is synthesized at high selectivity and high yield through one-step synthesis reaction by taking polybasic carboxylic acid, inorganic acid and an ionic liquid as raw materials. The synthesized enzyme can be used for efficiently degrading cellulose to prepare reducing sugar. The simulated enzyme can be recycled for many times. The simulated cellulose enzyme prepared by using the method is good in catalytic effect and is not easily degraded so as to be the simulated cellulose enzyme with an application potential.

Owner:JIANGSU UNIV OF SCI & TECH

A kind of production process and equipment of tetrabasic lead sulfate

The invention relates to a production process for tetrabasic lead sulfate (4BS). The process includes the following steps that (1) preparation treatment is conducted, specifically, lead which is subjected to a pre-mixing reaction is delivered into a reaction kettle through a shear pump, a sulfuric acid solution is added into the reaction kettle while internal circulation type stirring is conducted, meanwhile, part of compressed air is led into the reaction kettle, after the sulfuric acid solution is added, the shear pump is started, the reaction kettle is heated, after internal and external circulation type uniform stirring, heating is stopped, the shear pump is shut down, internal circulation type stirring in the reaction kettle is maintained, and meanwhile, compressed air is led into the reaction kettle to cool lead slime; and (2) ball milling is conducted, specifically, the lead slime obtained in the step (1) is conveyed into a dry ball mill, heating drying and a ball milling reaction are conducted synchronously, and the 4BS is obtained. The invention further provides a production device for the 4BS. According to the production process and device, the preparation reaction time is short, the formed 4BS is small in grain size, uniform and controllable, and the average grain size of the obtained 4BS is 2 [mu]m or less.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com