A kind of preparation method of mixed acid simulated cellulase

A technology of cellulase and mixed acids, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to achieve good fiber degradation effect, high preparation rate, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

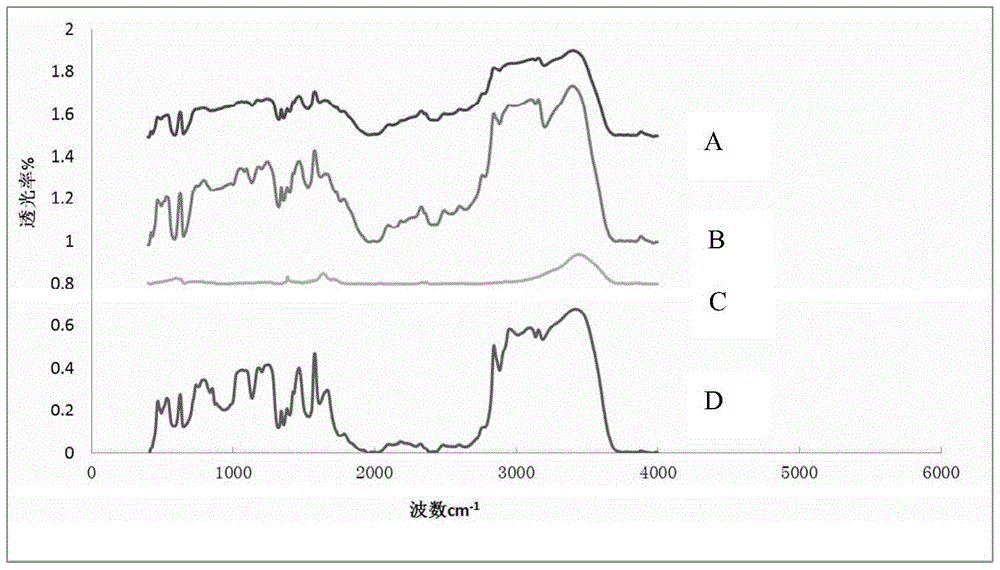

[0022] Put 0.1 g of oxalic acid, 0.1 g of succinic acid and 0.05 g of sulfuric acid into a three-necked round bottom flask, slowly add 100 g of ionic liquid [AMIM]Ac at room temperature, and stir magnetically at 80°C to obtain a colorless liquid. Ether extraction and ethyl acetate were used to extract 3 times to remove impurities; and low-boiling impurities such as water were removed by vacuum distillation to obtain the simulated enzyme.

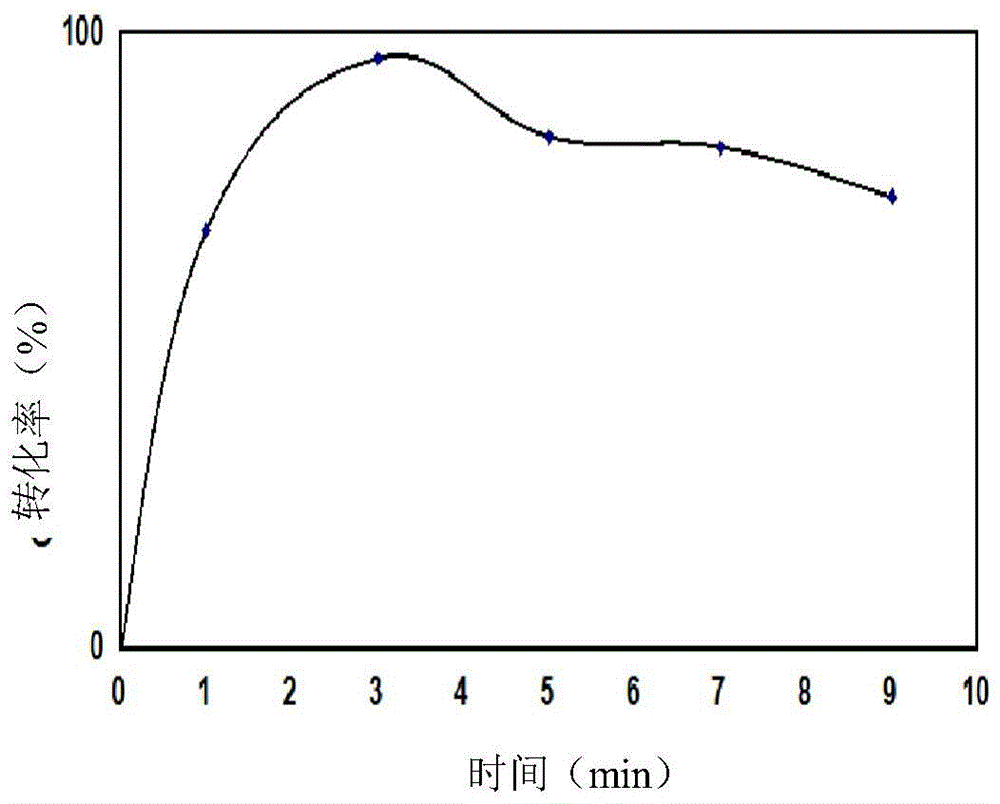

[0023] Enzymatic hydrolysis of cellulose with simulated enzyme: Add 20g of simulated enzyme into the microwave reaction tube, weigh 0.2g of microcrystalline cellulose and add it into the microwave reaction tube. Put it in a microwave reactor with a microwave of 500W and react at 190°C to degrade the cellulose for 4 minutes and the conversion rate can reach 96.5%.

Embodiment 2

[0025] Put 0.1 g of malonic acid, 0.1 g of succinic acid and 0.05 g of sulfuric acid into a three-neck round bottom flask, slowly add 100 g of ionic liquid [MMIM][DMP] at room temperature, and stir magnetically at 20°C to obtain a light yellow liquid. Ether extraction and ethyl acetate were used to extract 3 times to remove impurities; and low-boiling impurities such as water were removed by vacuum distillation to obtain the simulated enzyme.

[0026] Enzymatic hydrolysis of cellulose with simulated enzyme: Add 20g of simulated enzyme into the microwave reaction tube, weigh 0.2g of microcrystalline cellulose and add it into the microwave reaction tube. Place in a microwave reactor with a microwave of 500W and react at 190°C to degrade the cellulose for 4 minutes and the conversion rate can reach 97.2%.

Embodiment 3

[0028] Put 0.1 g of malonic acid, 0.1 g of succinic acid and 0.01 g of hydrochloric acid into a three-neck round bottom flask, slowly add 100 g of ionic liquid [BmpyM]Cl at room temperature, and stir magnetically at 20°C to obtain a light yellow liquid. Ether extraction and ethyl acetate were used to extract 3 times to remove impurities; and low-boiling impurities such as water were removed by vacuum distillation to obtain the simulated enzyme.

[0029] Enzymatic hydrolysis of cellulose with simulated enzyme: Add 20g of simulated enzyme into the microwave reaction tube, weigh 0.2g of microcrystalline cellulose and add it into the microwave reaction tube. Place in a microwave reactor with a microwave of 500W and react at 190°C to degrade the cellulose for 4 minutes and the conversion rate can reach 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com