Production process and device for tetrabasic lead sulfate (4BS)

A tetrabasic lead sulfate and production process technology, applied in directions such as lead sulfate, can solve the problems of large crystal particles of reaction products, small 4BS particle size, short reaction time, etc., and achieve shortened stirring and mixing time, product stability, and short preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0058] In the present invention, unless otherwise specified, the raw materials used can be purchased from the market or commonly used in the art. The processes in the following examples are conventional processes in the art unless otherwise specified.

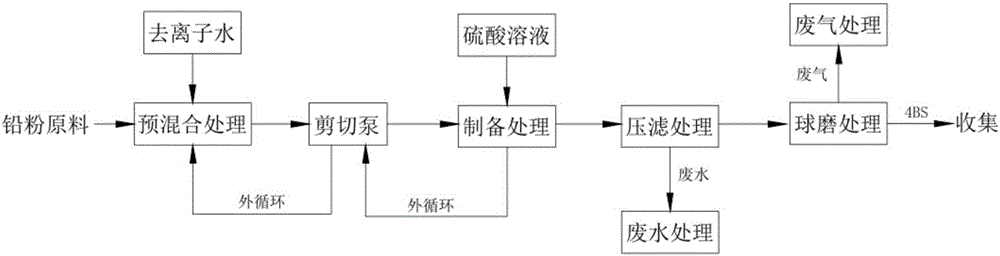

[0059] Refer to the attached figure 1 Describe the production process of tetrabasic lead sulfate according to Embodiment 1 of the present invention. Accurately weigh the lead powder raw material, wherein the lead powder raw material in the present invention is one or more of lead...

Embodiment 2

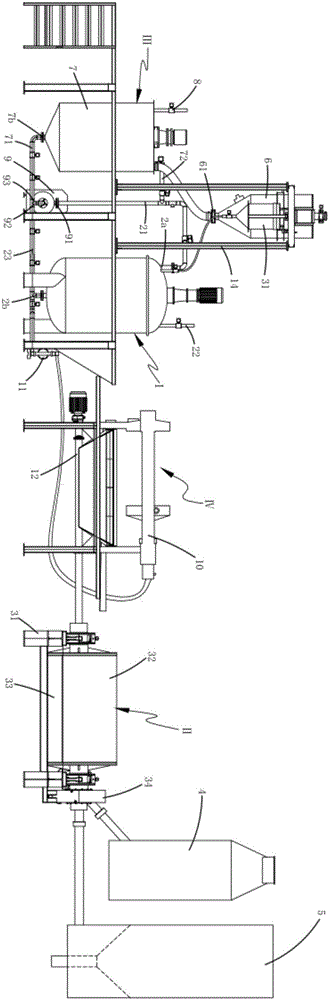

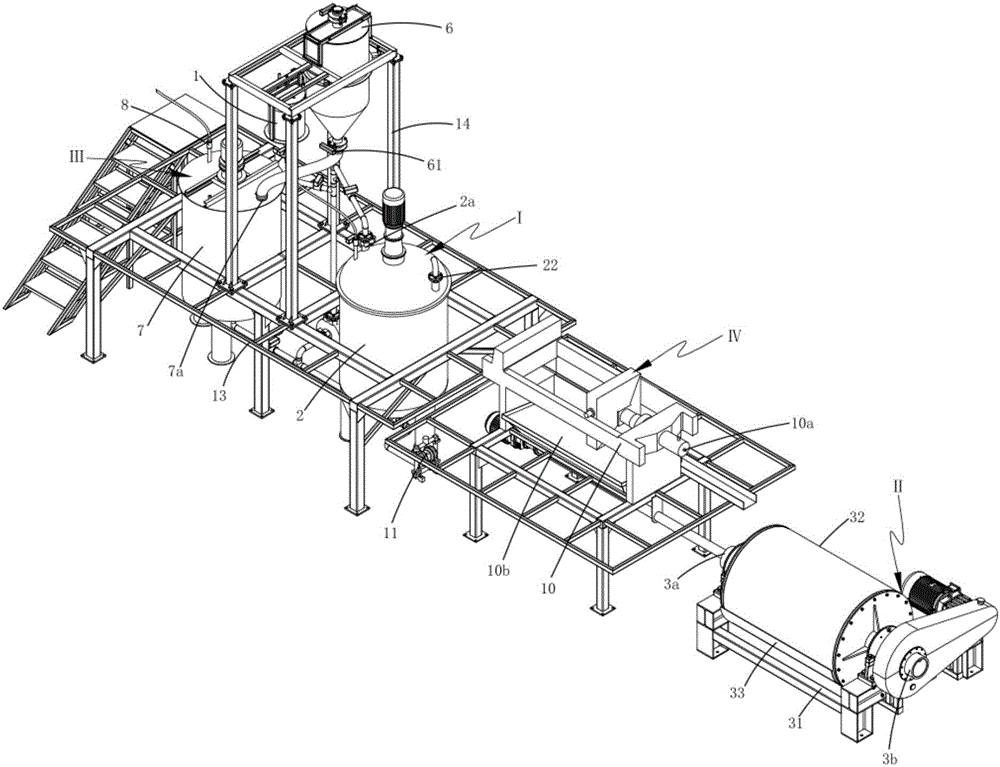

[0076] Refer to the attached figure 2 and image 3 Describe the production equipment of a kind of tetrabasic lead sulfate of embodiment two of the present invention.

[0077] Such as figure 2 and image 3As shown, a production equipment of tetrabasic lead sulfate includes a preparation processing unit I and a ball milling processing unit II; specifically, the preparation processing unit I includes a sulfuric acid dosing device 1 with a concentrated sulfuric acid solution inside, a reaction kettle 2 and a shear pump 9, the material outlet 2b of the reaction kettle 2 is connected with a delivery pipeline a23, the top of which is communicated with the sulfuric acid dosing device 1 through a sulfuric acid delivery pipeline, and the sulfuric acid delivery pipeline is also provided with a communication reaction The compressed air delivery pipeline 22 inside the still 2, it should be noted that, the compressed air delivery pipeline 22 communicates with a split pipeline and leads...

Embodiment 3

[0084] Such as figure 2 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that it also includes a pre-mix processing unit III, and the pre-mix processing unit III includes an automatic powder adding device 6 filled with lead powder raw materials, a mixing tank 7 and a deionization unit. The water delivery pipeline 8, the mixing bucket 7 and the reaction kettle 2 are fixed on the workbench 13, the sulfuric acid dosing device 1 and the automatic powder adding device 6 are fixed on the top of the workbench 13 through the support seat 14, the inlet 7a of the mixing bucket 7 is connected to the The automatic powder adding device 6 is connected, and its outlet 7b is communicated with the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com