Impinging stream-rotating disc coupling reaction device and ultrafine magnesium hydroxide fire retardant synthesis method using impinging stream-rotating disc coupling reaction device

A technology of coupling reaction and rotating disk, applied in the direction of magnesium hydroxide, etc., can solve the problems of uncontrollable composition of natural minerals, poor filtering performance of magnesium hydroxide slurry, uneven particle size distribution of magnesium hydroxide, etc., to shorten the mixing time. Time, simple structure, effect of suppressing the growth of crystal nucleus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

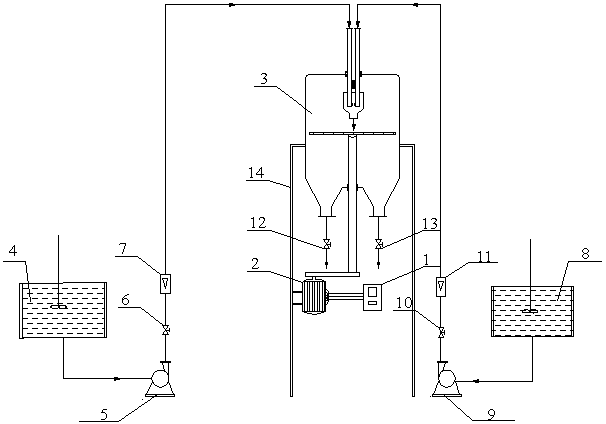

[0032] Example 1: Impinging flow-rotating disk coupling reaction device and its reaction principle

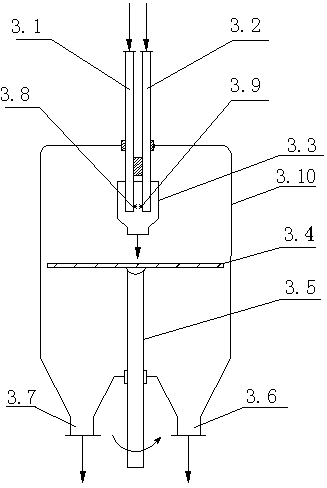

[0033]A new device for synthesizing ultra-fine magnesium hydroxide flame retardant—the impinging flow-rotating disk coupling reaction device includes: impinging flow-rotating disk coupling reactor 3, the impinging flow-rotating disk coupling reactor 3 includes a shell 3.10, There is a disc 3.4 in the center of the housing 3.10, which can rotate with the rotating shaft 3.5 connected below it, and the top of the housing 3.10 is equipped with A liquid inlet pipe 3.1 and B liquid inlet pipe 3.2, A liquid inlet pipe 3.1 and B liquid inlet The lower end of the pipe 3.2 is connected to the liquid redistributor 3.3, and the A liquid inlet pipe 3.1 and the B liquid inlet pipe 3.2 are respectively provided with a liquid A nozzle 3.8 and a B liquid nozzle 3.9, and the two nozzles are arranged symmetrically, and the liquid redistributor 3.3 is installed Above the central position of the di...

Embodiment 2

[0042] Embodiment 2: Impinging flow-rotating disk coupled reaction device is used for synthesizing ultrafine magnesium hydroxide powder

[0043] Adopt technological process of the present invention to attach figure 1 ,

[0044] (1) Turn on the stirring device, prepare a magnesium chloride solution with a concentration of 0.75mol / L in the A storage tank, and prepare a sodium hydroxide solution with a concentration of 1.5mol / L in the B storage tank;

[0045] (2) Turn on the heating and heat preservation device to heat it, and its temperature is controlled at 60°C;

[0046] (3) Turn on the corrosion-resistant pump at the same time, control the volume flow rate of magnesium chloride solution and sodium hydroxide solution at 40L / h by adjusting the flowmeter, and transport the two raw material solutions to the reactor at the same time for liquid-liquid contact reaction. A liquid inlet pipe and B liquid inlet pipe collide with each other at the nozzle of the liquid inlet pipe at an...

Embodiment 3

[0049] Embodiment 3: Impinging flow-rotating disk coupled reaction device is used for synthesizing ultrafine magnesium hydroxide powder

[0050] Adopt technological process of the present invention to attach figure 1 ,

[0051] (1) Turn on the stirring device, prepare a magnesium chloride solution with a concentration of 1.0mol / L in the A storage tank, and prepare a sodium hydroxide solution with a concentration of 2.0mol / L in the B storage tank;

[0052] (2) Turn on the heating and heat preservation device to heat it, and its temperature is controlled at 60°C;

[0053] (3) Turn on the corrosion-resistant pump at the same time, and control the volume flow rate of magnesium chloride solution and sodium hydroxide solution at 30L / h by adjusting the flowmeter, and transport the two raw material solutions to the reactor at the same time for liquid-liquid contact reaction. A liquid inlet pipe and B liquid inlet pipe collide with each other at the nozzle of the liquid inlet pipe at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com