Organosilicon-modified polyurethane-acrylic ester photocurable coating and preparation method thereof

A polyurethane acrylate and light-curing coating technology, which is applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of long coating construction period, less hydrophobic monomer, poor friction resistance, etc., and achieve corrosion resistance and salt resistance Good mist, good adhesion and flexibility, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

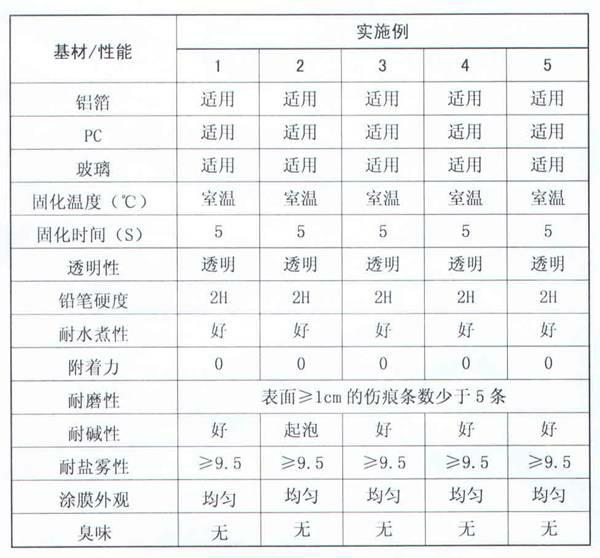

Examples

Embodiment 1

[0030] Weigh 45% of organopolysilane into a container, add 48% of polyurethane acrylate photocurable resin, 4.9% of ethanol and ethylene glycol butyl ether, and 0.1% of wetting agent EW320 (produced by Shanghai Daorun Chemical Co., Ltd. ), mixed for 30 minutes, then added 2% of 2-hydroxy-2-methyl-1-phenylacetone, mixed for 20 minutes to obtain a UV-curable coating, and kept away from light.

Embodiment 2

[0032] Weigh 50% of organopolysilane into a container, add 43% of polyurethane acrylate photocurable resin, 4.9% of isopropyl alcohol and dipropylene glycol methyl ether, and 0.1% of wetting agent BYK333 (produced by BYK, Germany) , mixed for 20 minutes, then added 2% of 1-hydroxy-cyclohexyl benzophenone, mixed for 10 minutes to obtain a UV-curable coating, and stored away from light.

Embodiment 3

[0034] Weigh 20% of organopolysilane into a container, add 60% of polyurethane acrylate photocurable resin, 14.9% of ethanol and dipropylene glycol methyl ether, and 0.1% of wetting agent BYK333 (produced by German BYK company), Mix for 35 minutes, then add 5% 2,4,6-trimethylbenzophenone, mix for 15 minutes to obtain a UV-curable coating, and store in the dark.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com