Magnetic microencapsulated phase change energy storage material and preparation method thereof

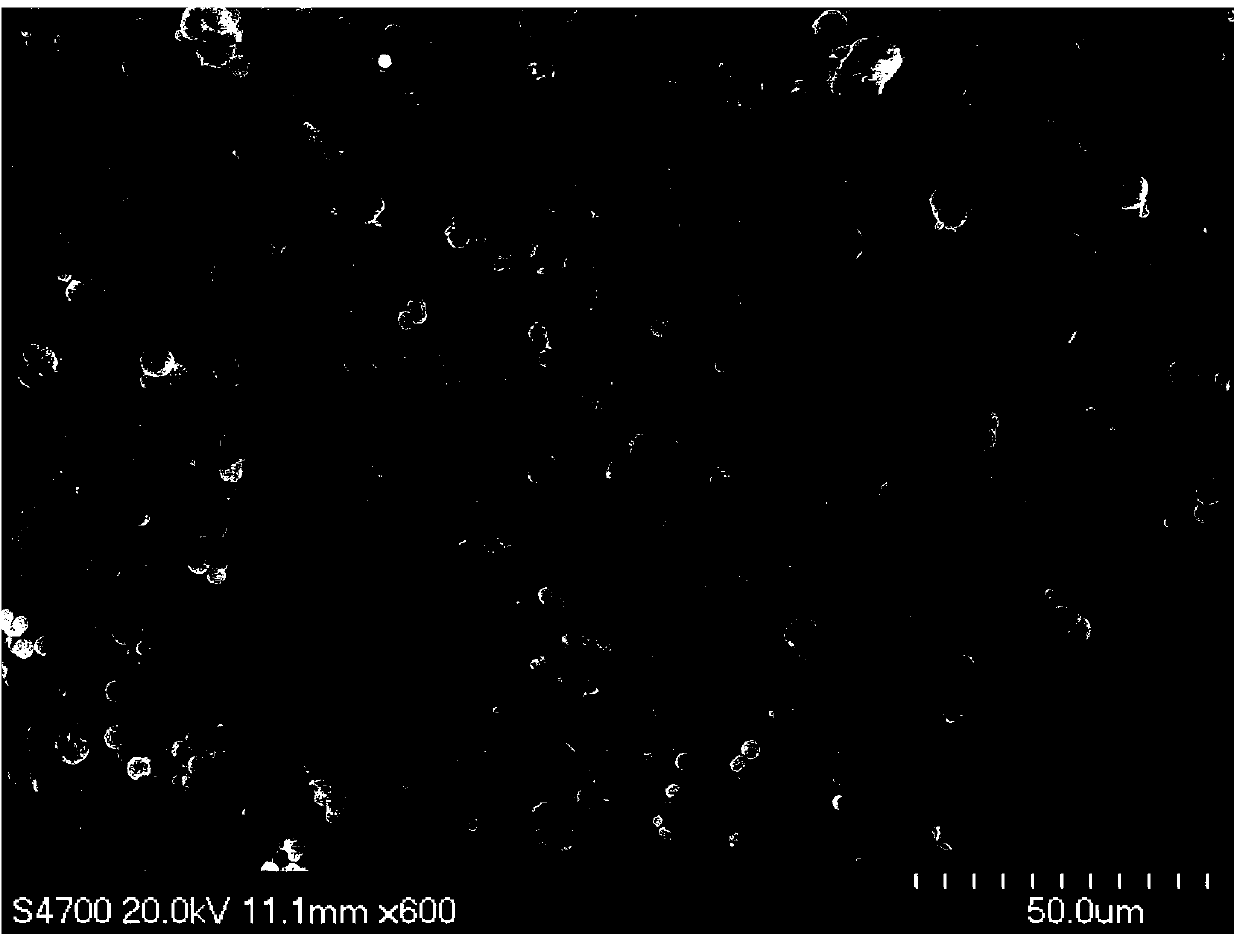

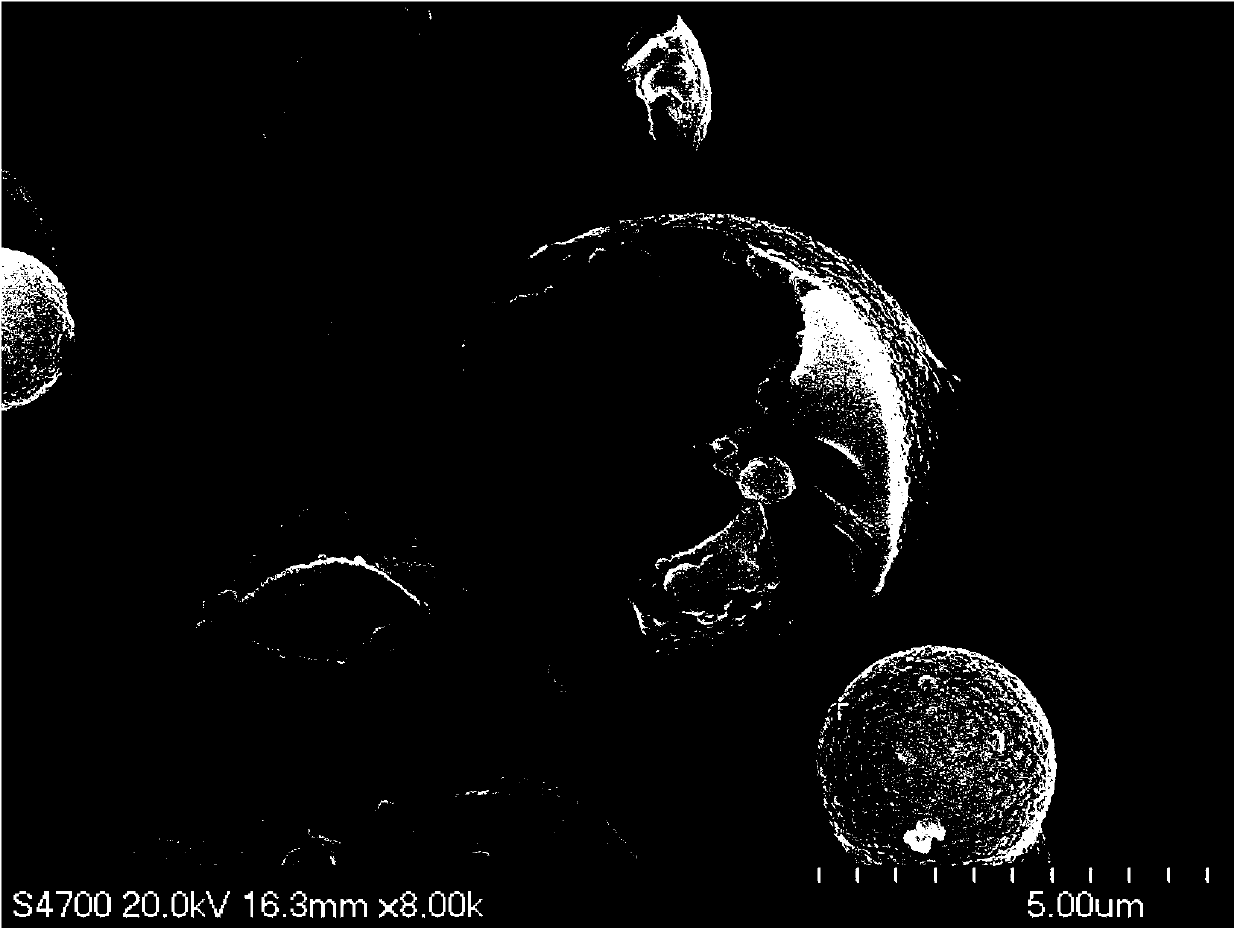

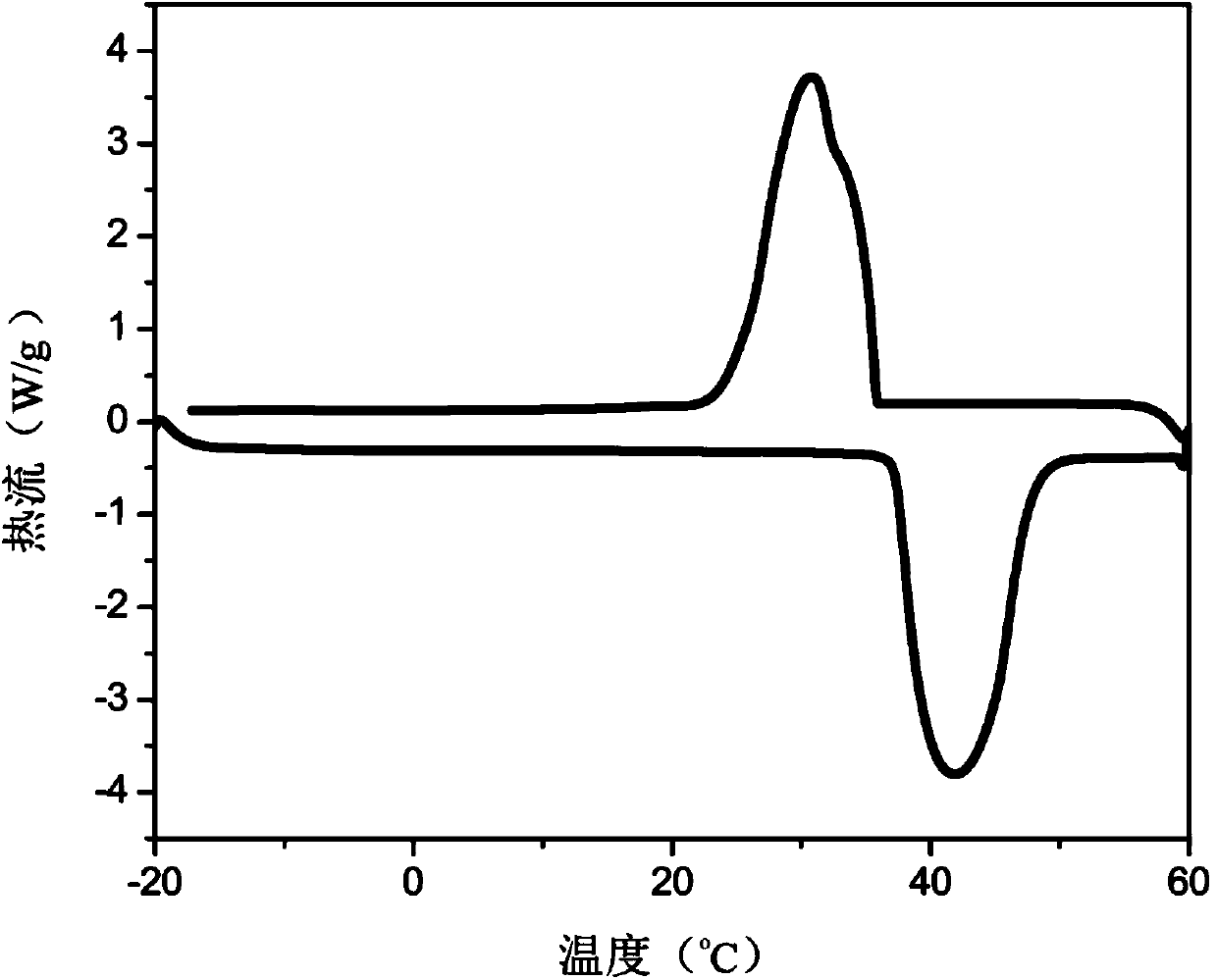

A phase change energy storage material and energy storage material technology, applied in the field of microcapsule organic phase change energy storage material and its preparation, can solve the problems of low strength, achieve low interfacial energy, good phase change performance, and uniform particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, dissolve 0.05mol / L ferric chloride hexahydrate and 0.025mol / L ferrous chloride tetrahydrate in 100mL deionized water, and stir mechanically for 10min at 55°C under the protection of nitrogen to obtain a uniform solution; adjust the pH with ammonia water When the value reaches 10-11, add 0.08g cetyltrimethylammonium bromide to modify ferric oxide nanoparticles, and continue to stir for 20min at 55°C under nitrogen protection; rinse with deionized water and formamide in turn The ferroferric oxide nanoparticles are separated by strong magnetism to remove residual ammonia water and deionized water respectively to obtain ferric oxide nanoparticles. Next, stir 4g of n-eicosane and 4g of tetraethylorthosilicate at 45°C, and heat 0.3g of ferric oxide nanoparticles and 40g of formamide to 45°C; Sonicate for 1 h, add 0.9109 g of cetyltrimethylammonium bromide, and stir at 300 rpm for 1 h to obtain a stable oil-in-water Pickering emulsion. Finally, drop 60mL of 1.78mol / L h...

Embodiment 2

[0032] First, dissolve 0.05mol / L ferric chloride hexahydrate and 0.025mol / L nickel nitrate in 100mL deionized water, and stir mechanically for 10min at 55°C under nitrogen protection to obtain a uniform solution; adjust the pH value to 10~ with ammonia water 11. Add 0.08g of cetyltrimethylammonium bromide to modify the nickel ferrite nanoparticles, and continue to stir for 20min at 55°C under nitrogen protection; rinse the nickel ferrite with deionized water and formamide in turn The nanoparticles are separated by a strong magnetic field to remove residual ammonia water and deionized water respectively to obtain nickel ferrite nanoparticles. Next, stir 4g of n-eicosane and 4g of tetraethylorthosilicate at 45°C, and heat 0.3g of nickel ferrite nanoparticles and 40g of formamide to 45°C; Sonicate for 1 h, add 0.9109 g of cetyltrimethylammonium bromide, and stir at 300 rpm for 1 h to obtain a stable oil-in-water Pickering emulsion. Finally, drop 60mL of 1.78mol / L hydrochloric ac...

Embodiment 3

[0034] First, dissolve 0.05mol / L ferric chloride hexahydrate and 0.025mol / L ferrous chloride tetrahydrate in 100mL deionized water, and stir mechanically for 10min at 55°C under the protection of nitrogen to obtain a uniform solution; adjust the pH with ammonia water When the value reaches 10-11, add 0.08g cetyltrimethylammonium bromide to modify ferric oxide nanoparticles, and continue to stir for 20min at 55°C under nitrogen protection; rinse with deionized water and formamide in turn The ferroferric oxide nanoparticles are separated by strong magnetism to remove residual ammonia water and deionized water respectively to obtain ferric oxide nanoparticles. Next, stir 4g of n-eicosane and 4g of tetraethylorthosilicate at 45°C, and heat 0.3g of ferric oxide nanoparticles and 40g of formamide to 45°C; Sonicate for 1 h, add 0.9109 g of cetyltrimethylammonium bromide, and stir at 300 rpm for 1 h to obtain a stable oil-in-water Pickering emulsion. Finally, drop 60mL of 1.26mol / L h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com