Patents

Literature

230 results about "Nickel ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel ferrite, for instance, is NiFe2O4, and manganese ferrite is MnFe2O4; both are spinel minerals. The garnet mineral known as YIG, containing the rare-earth element yttrium, has the formula Y3Fe5O12; it is used in microwave circuitry.

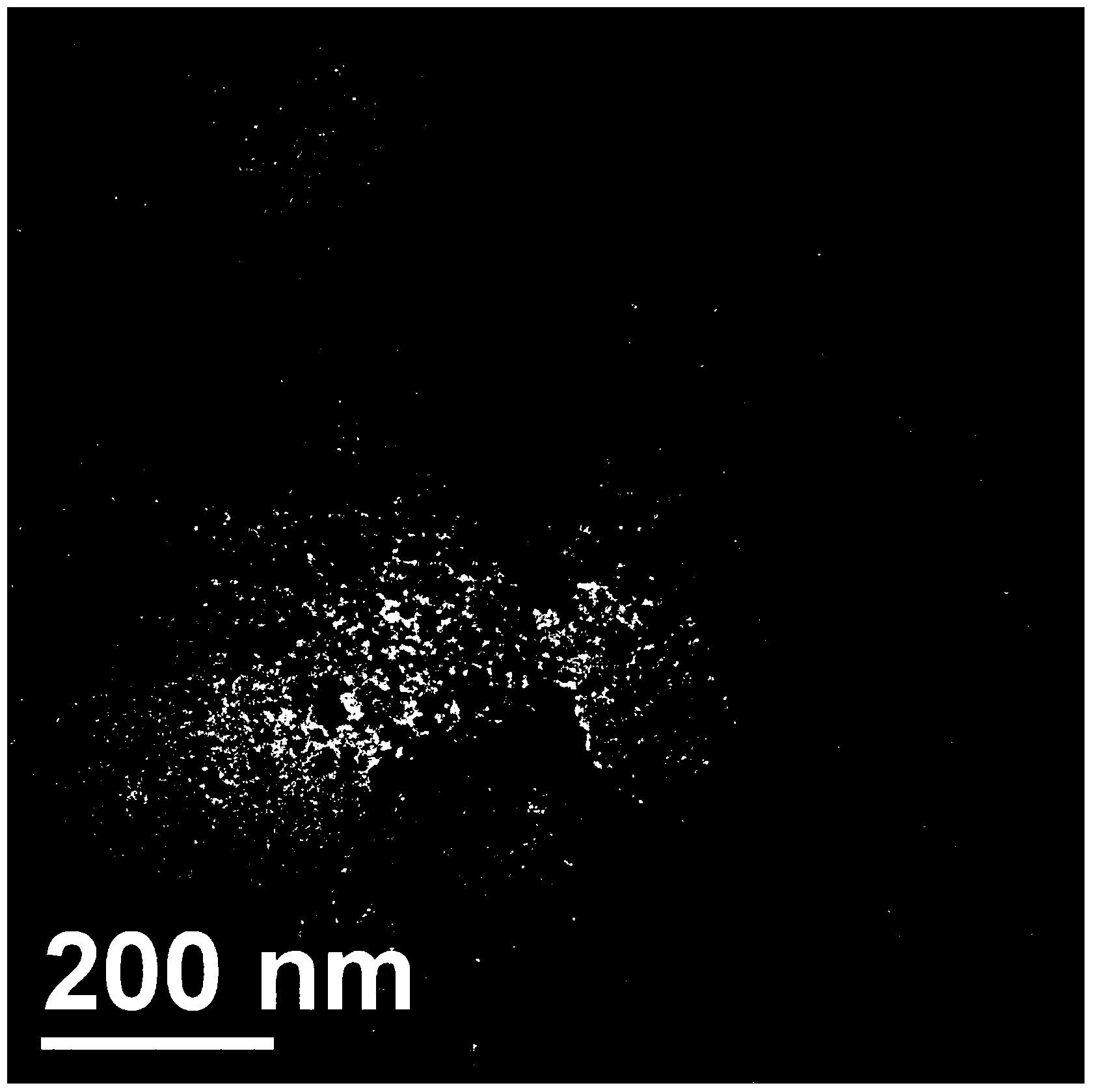

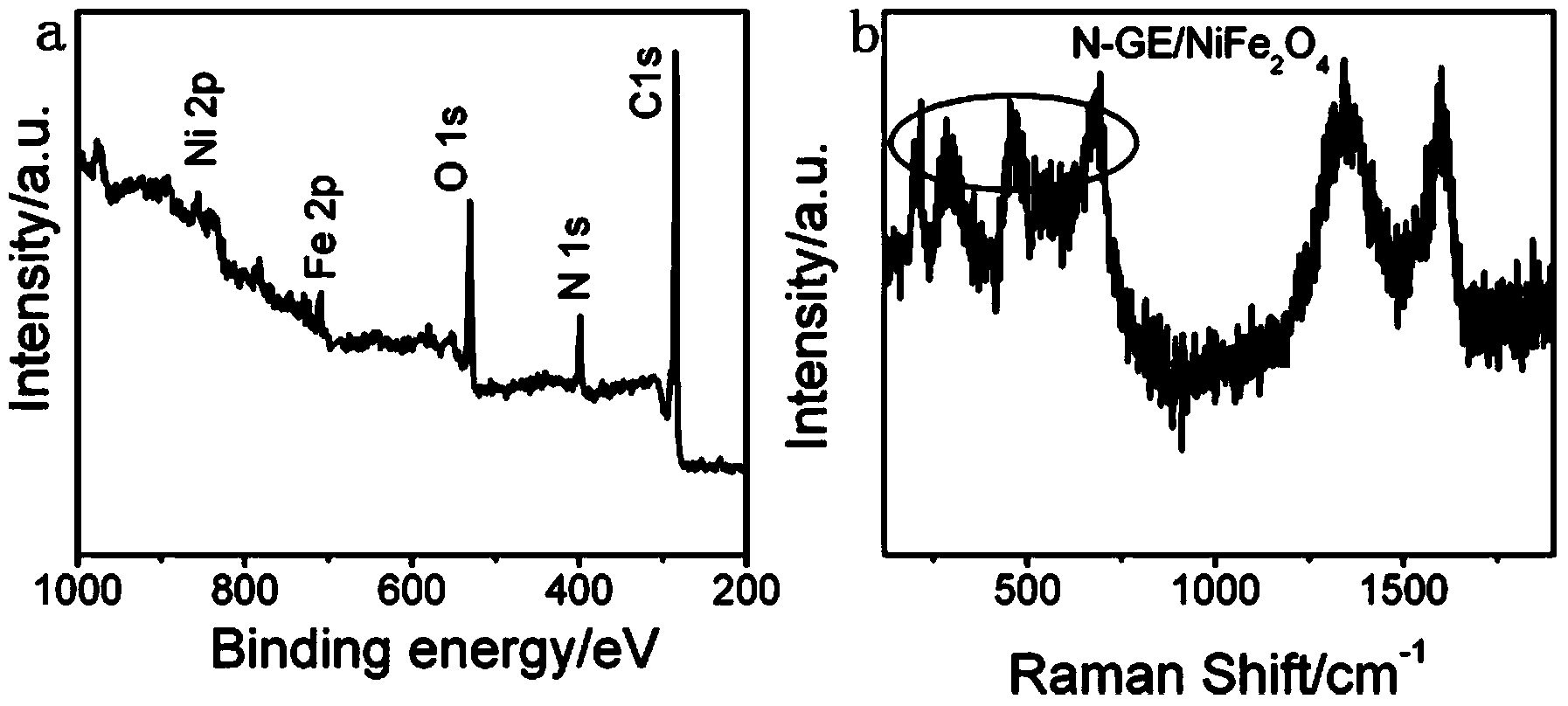

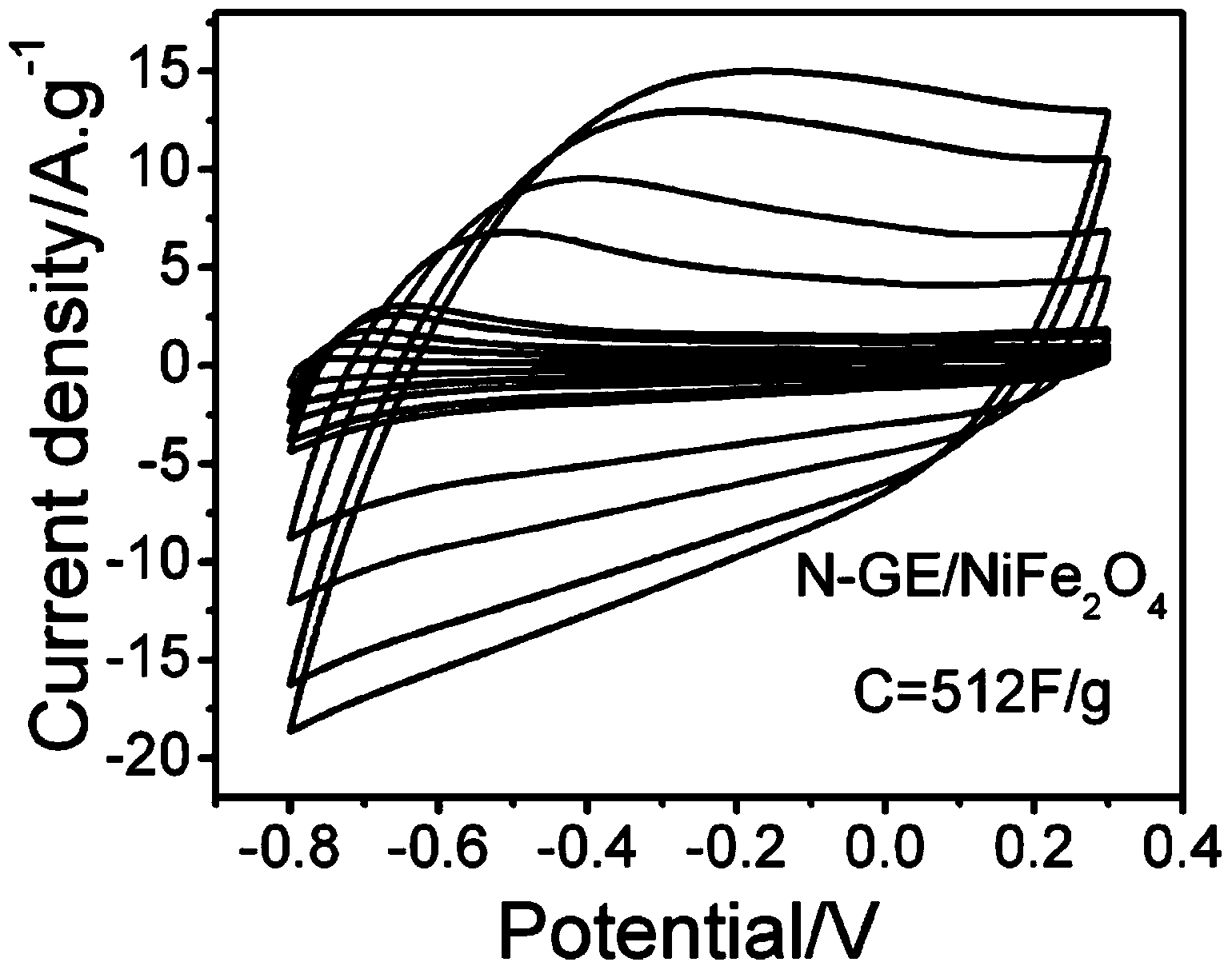

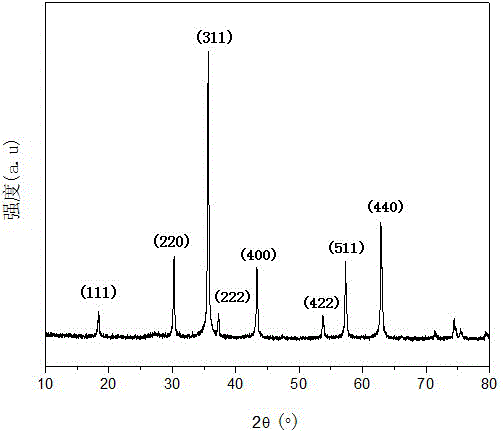

N-doped graphene/nickel ferrite nanometer compound material and preparation thereof

InactiveCN103871755AReduce pollutionPollution compensationMaterial nanotechnologyHybrid capacitor electrodesDoped grapheneNitrogen doped graphene

The invention discloses an N-doped graphene / nickel ferrite nanometer compound material and a preparation method thereof. The preparation method comprises the following steps: performing ultrasonic dispersion on graphite oxide in water, thereby acquiring a graphite oxide solution; adding ferric nitrate and nickel nitrate into the graphite oxide solution and continuing to perform ultrasonic dispersion; adding urea into the mixed solution; transferring the mixed solution into a three-neck flask; after oil-bath heating reaction, centrifugally washing and drying a product, thereby acquiring the N-doped graphene / nickel ferrite nanometer compound material. According to the method, the urea is adopted for reducing the graphite oxide; while reducing, nitrogen atoms are doped on the surface of the graphene; the surface chemical property of the graphene is changed and the surface defect of a chemical method for preparing the graphene is overcome by the doping of the nitrogen atoms; alkalinity is supplied through the urea hydrolysis, so that nickel ferrite is formed on the surface of the N-doped graphene; the accumulation and agglomeration of the graphene in layers can be further stopped by the nanometer particles of the nickel ferrite, so that the electrochemical property of the compound material is increased.

Owner:NANJING UNIV OF SCI & TECH +1

Preparation method of heterogeneous Fenton catalyst, and method for visible photocatalytic degradation of organic pollutants

InactiveCN102989460AThe method is simpleQuick and effective removalWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationUltrapure water

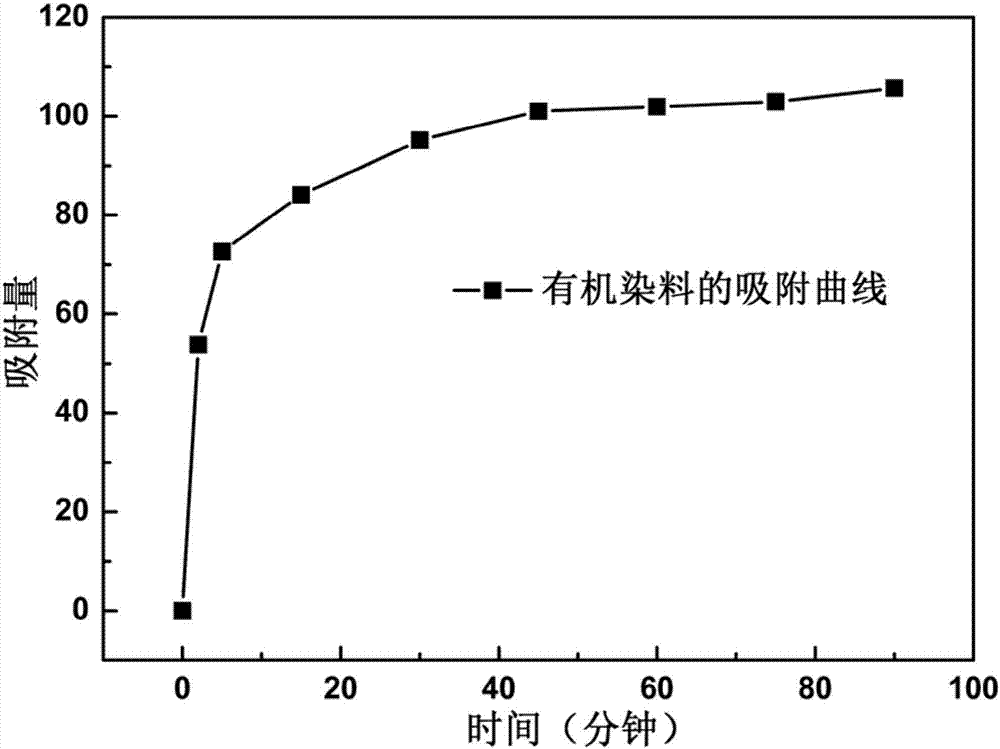

The invention provides a preparation method of a heterogeneous Fenton catalyst. The preparation method comprises the following steps: weighing ferric trichloride or ferric nitrate and nickel sulfate which are raw materials according to a molar ratio of Fe:Ni of 2:1, respectively dissolving the raw materials in ultrapure water to obtain two solutions, and uniformly mixing to obtain a mixed solution; and adding certain masses of NaOH, and graphene or graphite oxide or active carbon to the mixed solution, stirring, transferring to a reaction kettle, heating for 10min, separating in a magnetic field, washing, and drying to obtain the heterogeneous Fenton catalyst. The invention also provides a method for the visible photocatalytic degradation of organic pollutants through using the heterogeneous Fenton catalyst. The heterogeneous Fenton catalyst prepared through the preparation method is mixed with oxalic acid to degrade organic stimulating pollutants under visible lights. The organic pollutant degradation method is simple and is easy to implement, the catalyst can be separated from the solution through the applied magnetic field, and the carbon material-nickel ferrite composite catalyst can be recycled; and the method enables the chroma of polluted water to be rapidly and effectively removed.

Owner:SUZHOU UNIV OF SCI & TECH

Preparation method of graphite-type carbon nitride composite nickel ferrite magnetic photocatalytic material

ActiveCN104923276AImprove photocatalytic activityHelp recyclePhysical/chemical process catalystsWater/sewage treatment by irradiationMass ratioSynthesis methods

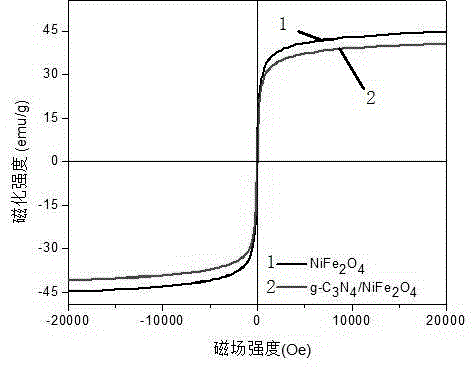

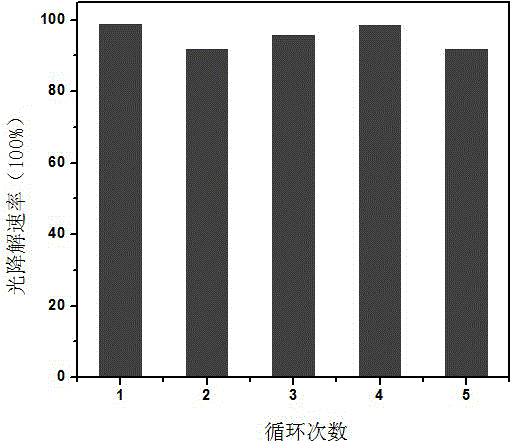

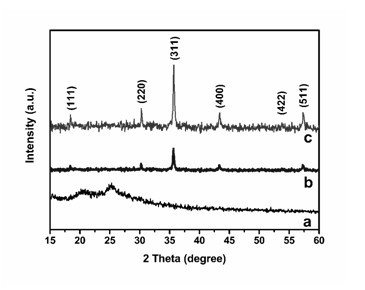

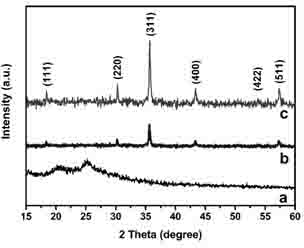

The invention relates to the field of photocatalysis, and specifically relates to a preparation method of a graphite-type carbon nitride composite nickel ferrite magnetic photocatalytic material. According to the invention, magnetic nickel ferrite is combined to graphite-type carbon nitride with a chemisorption method, wherein the mass ratio of graphite-type carbon nitride to nickel ferrite is 1:5-1:25. The synthesis method comprises the following steps: carbon nitride and nickel ferrite with a certain mass ratio are added into anhydrous ethanol, and are dispersed and stirred for a certain period of time; and heat treatment is carried out under a certain temperature. The catalyst provided by the invention has good magnetism, good dispersion and good stability. After 5 photo-degradation cyclic experiment, the catalyst can still maintain relatively high catalytic activity. Under visible light, the g-C3N4 / NiFe2O4 can be excited to produce light-induced electrons and holes, and can be subjected to a light Fenton reaction with hydrogen peroxide, such that methylene blue high-efficiency degradation can be realized.

Owner:南通市金宏电化设备有限公司

Ferrate/polyaniline magnetic nanometer catalytic agent and preparation method thereof

InactiveCN102626658AMagnetic hasEasy to recycleWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystPolymer science

The invention adopts an in-situ oxidation polymerization method and enables the polyaniline to be wrapped on the surface of the magnetic ferrate, and a series of ferrate / polyaniline magnetic nano composite materials can be prepared by using the method and comprise cobalt ferrite / polyaniline, nickel ferrite / polyaniline, copper ferrite / polyaniline, zinc ferrite / polyaniline and manganese ferrite / polyaniline and the like. A prepared ferrate / polyaniline magnetic nanometer catalytic agent has obvious preferential adsorption performance and good photoelectrical activity, and has good application prospects and economic benefits in the fields of adsorption, photocatalysis, lithium ion batteries and the like.

Owner:NANJING UNIV OF SCI & TECH

Preparation of magnetic heterogeneous light Fenton catalyst and method for degrading organic pollutants

ActiveCN102125848AIncrease profitGood effectMetal/metal-oxides/metal-hydroxide catalystsCatalyst degradationPhotocatalytic reaction

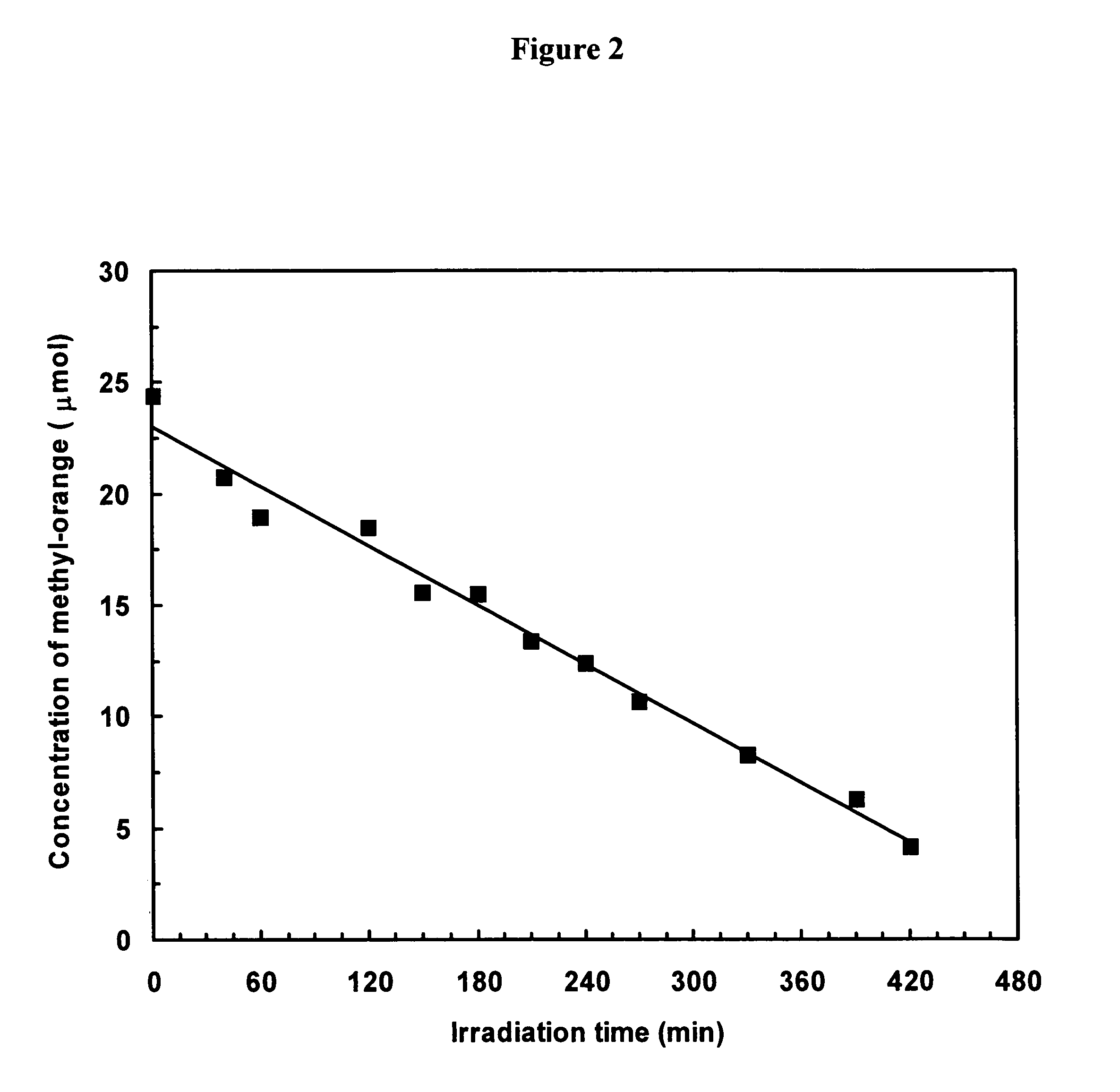

The invention provides preparation of a magnetic heterogeneous light Fenton catalyst. The preparation comprises the following steps of: preparing mixed solution by using ferric trichloride and nickel sulfate as raw materials, and performing heating, separation, washing and drying on the mixed solution to obtain the magnetic heterogeneous light Fenton catalyst NiFe2O4. The invention also provides a method for degrading organic pollutants by using the magnetic heterogeneous light Fenton catalyst. The method for degrading the organic pollutants comprises the following steps of: placing organic pollutant solution into a reaction container; adding a proper amount of oxalic acid into the reaction container; adding a proper amount of magnetic heterogeneous light Fenton catalyst into the reactioncontainer; and performing photocatalysis reaction under the irradiation of visible ultraviolet light. The magnetic heterogeneous light Fenton catalyst NiFe2O4 improves the utilization rate of sunlight; and the magnetic heterogeneous light Fenton catalyst has good effect on nickel ferrite photocatalysis of the organic pollutants and high degradation rate.

Owner:苏州尼普环境科技有限公司

Preparation method of multiaperture ferrite

InactiveCN103101980AEasy to prepareThe reaction raw materials are simple and cheapIron compoundsCobalt compoundsFluid phaseFerrite powder

The invention provides a method for preparing multiaperture spherical magnetic ferrite (zinc ferrite, nickel ferrite, cobalt ferrite and manganese ferrite) by taking dodecylamine as a precipitator by a solvothermal method. The preparation method is characterized in that an ethylene glycol solution of ferric trichloride and chloride is used as a reaction solution; dodecylamine is used as the precipitator; and the ethylene glycol solution and the dodecylamine are stirred and mixed uniformly at the room temperature to form a liquid phase reaction solution; and the liquid phase reaction solution is transferred to a reaction kettle for hydrothermal reaction at 180-250 DEG C. Products are separated, washed and dried to obtain corresponding multiaperture ferrite powder after reaction. The preparation method has the characteristics of being low in raw materials, simple in process, convenient in operation, controllable in shape, and the like.

Owner:LUDONG UNIVERSITY

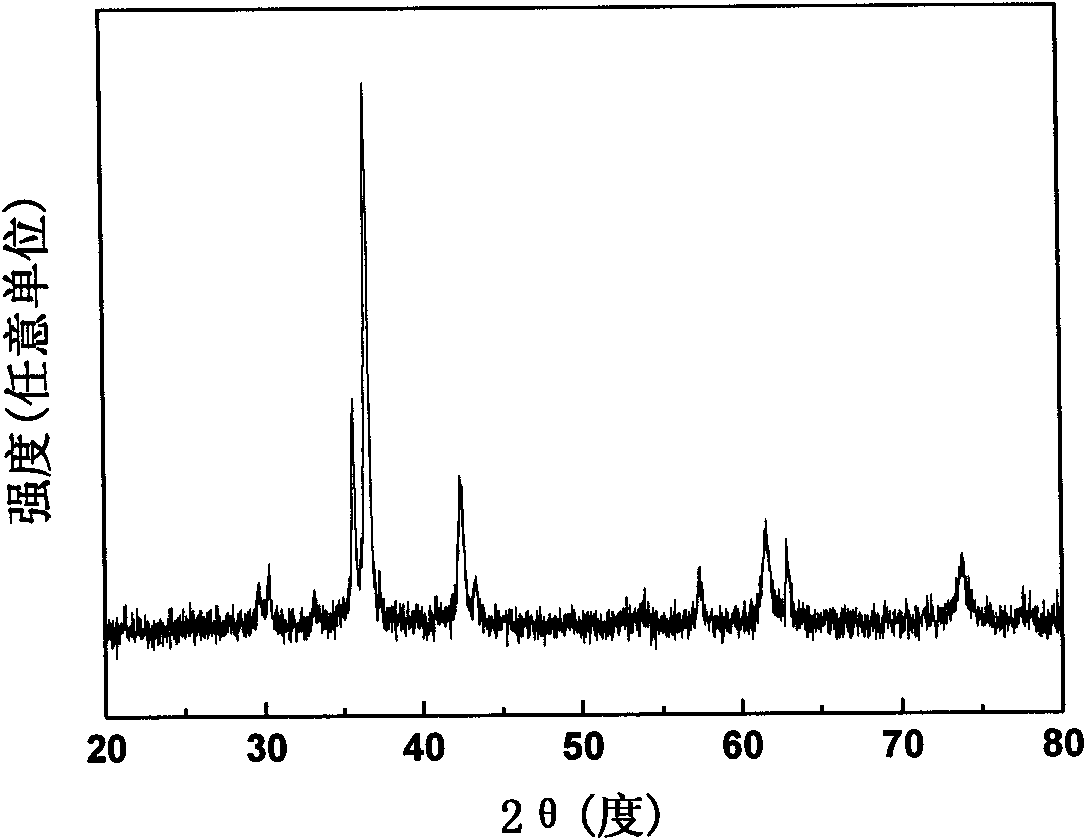

Method for preparing cobalt-nickel ferrite/graphene magnetic nanocomposite powder by alcohol thermal method

InactiveCN102276244ASimple processLow requirements for production equipmentPolyethylene glycolMagnetization

The invention relates to a method for preparing cobalt-nickel ferrite / graphene magnetic nanocomposite powder by alcohol thermal method, comprising: (1) dispersing graphite oxide and metal salt into ethylene glycol solution respectively at room temperature, and waiting After dissolving, add polyethylene glycol and anhydrous sodium acetate to the metal salt solution, stir and mix the graphite oxide solution and the metal salt solution to form a reaction solution; (2) Pour the above reaction solution into the reaction kettle and heat up to 180-220 °C, react for 8-16 hours; after the reaction, cool to room temperature, collect the product with a magnet, wash with deionized water and absolute ethanol, and dry to obtain the product. The invention has simple process, low requirements on production equipment, and is easy for industrialized production; the prepared cobalt-nickel ferrite / graphene magnetic nanocomposite powder is well compounded with graphene, and has good dispersibility on the surface and layer of graphene, and the composite powder The volume resistivity is small, the magnetization intensity is high, and it has a good application prospect.

Owner:DONGHUA UNIV

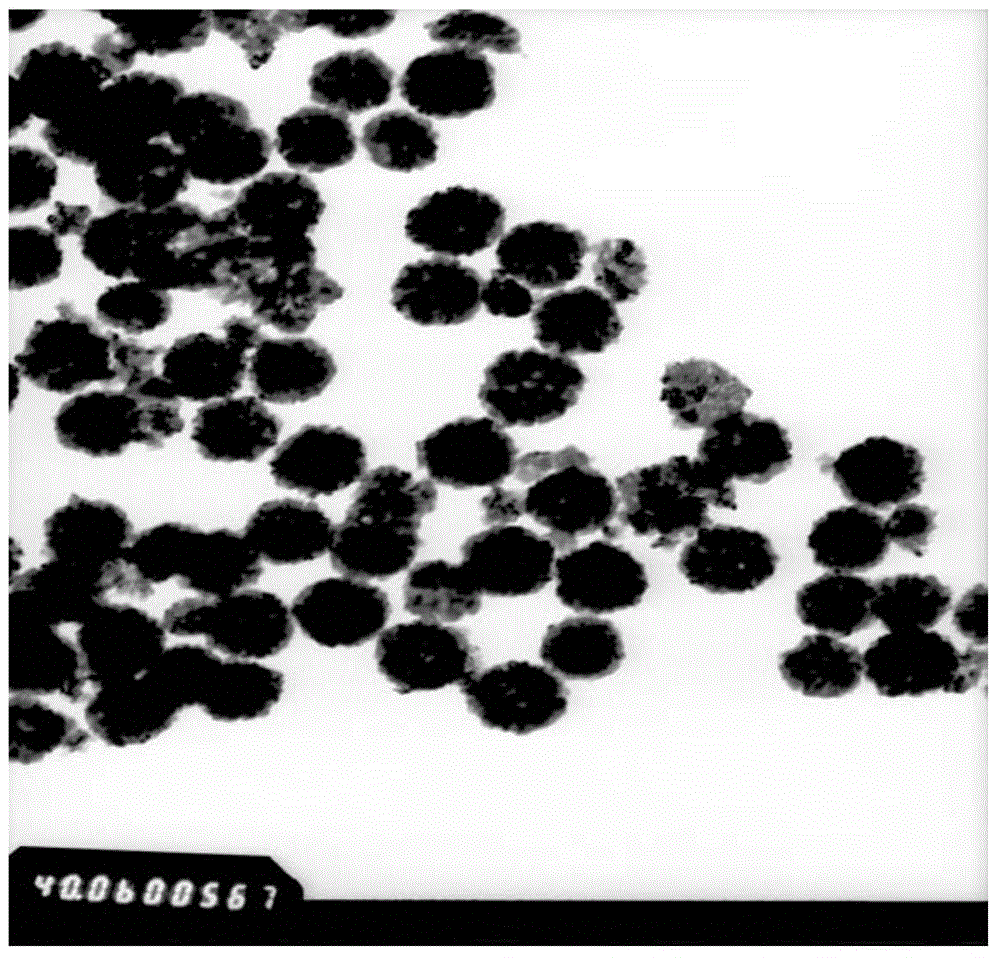

Nano-superstructure polyporous material of ferrite and method of preparing the same

The invention relates to a ferrite nanometer superstructure porous material and a method for preparing the same, in particular to a method for preparing a nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The preparation method comprises that: sodium oxalate is used as a precipitator, the soluble nickel, cobalt or zinc salt used as a raw material reacts with the soluble iron salt to prepare a precursor of oxalate, and the precursor is degraded by calcination at certain temperature to obtain the nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material. The nickel ferrite, cobalt ferrite or zinc ferrite nanometer superstructure porous material synthesized by the method has the advantages of high purity, uniform size, good dispersibility, mild reaction conditions, simple equipment, easily controlled process conditions and low cost, and meets the need of the actual production.

Owner:HUAZHONG NORMAL UNIV

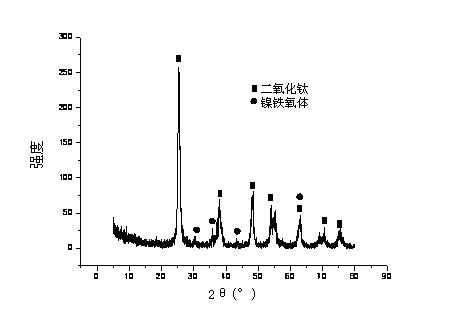

Process for preparing composite photocatalyst capable of magnetic separating

InactiveCN1724164AImprove bindingStrong magnetismCatalyst activation/preparationSilicon dioxideNanometre

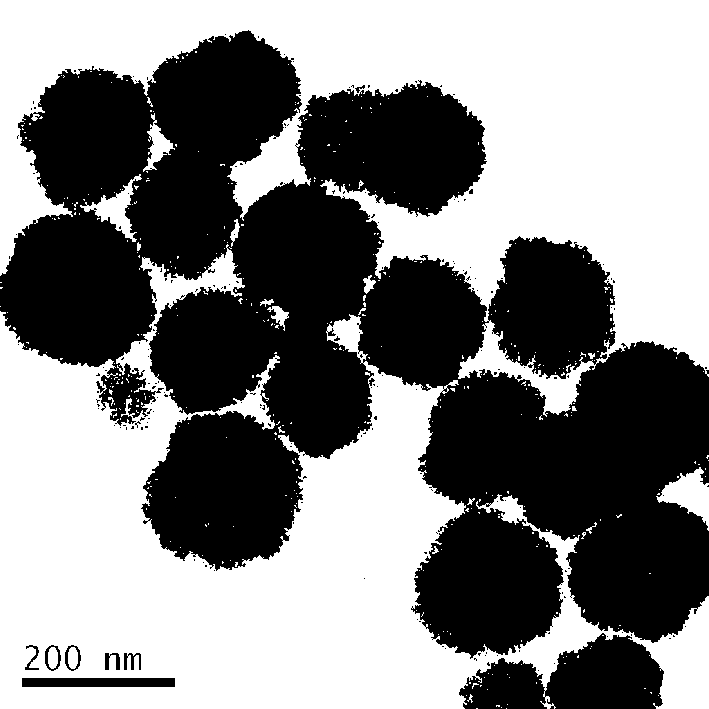

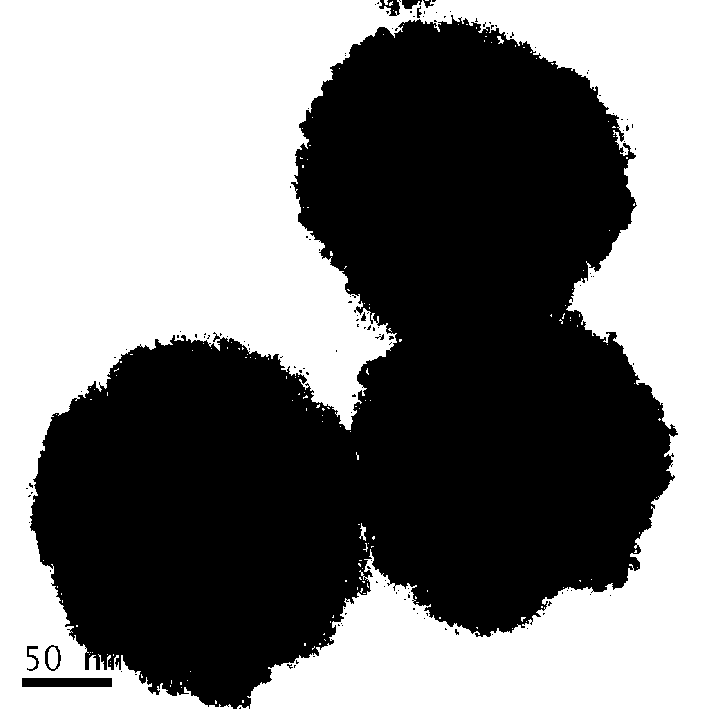

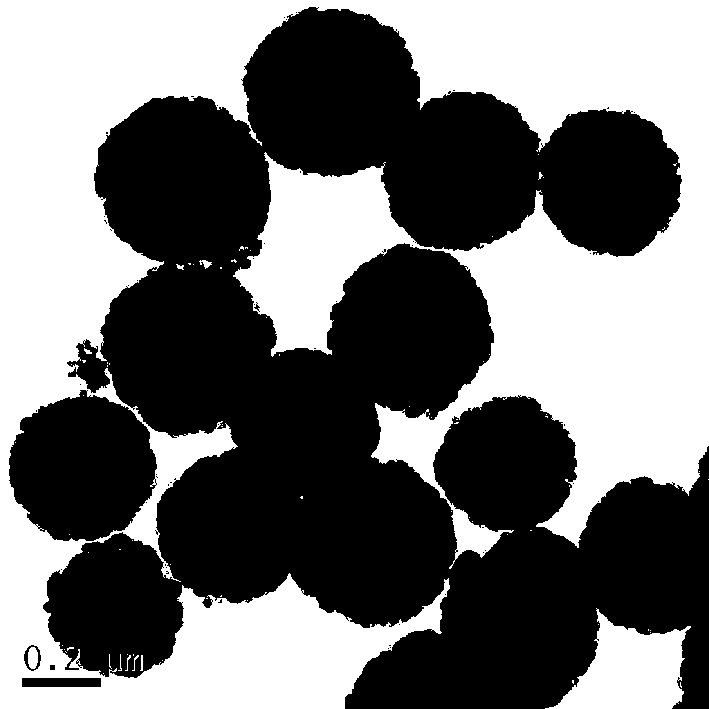

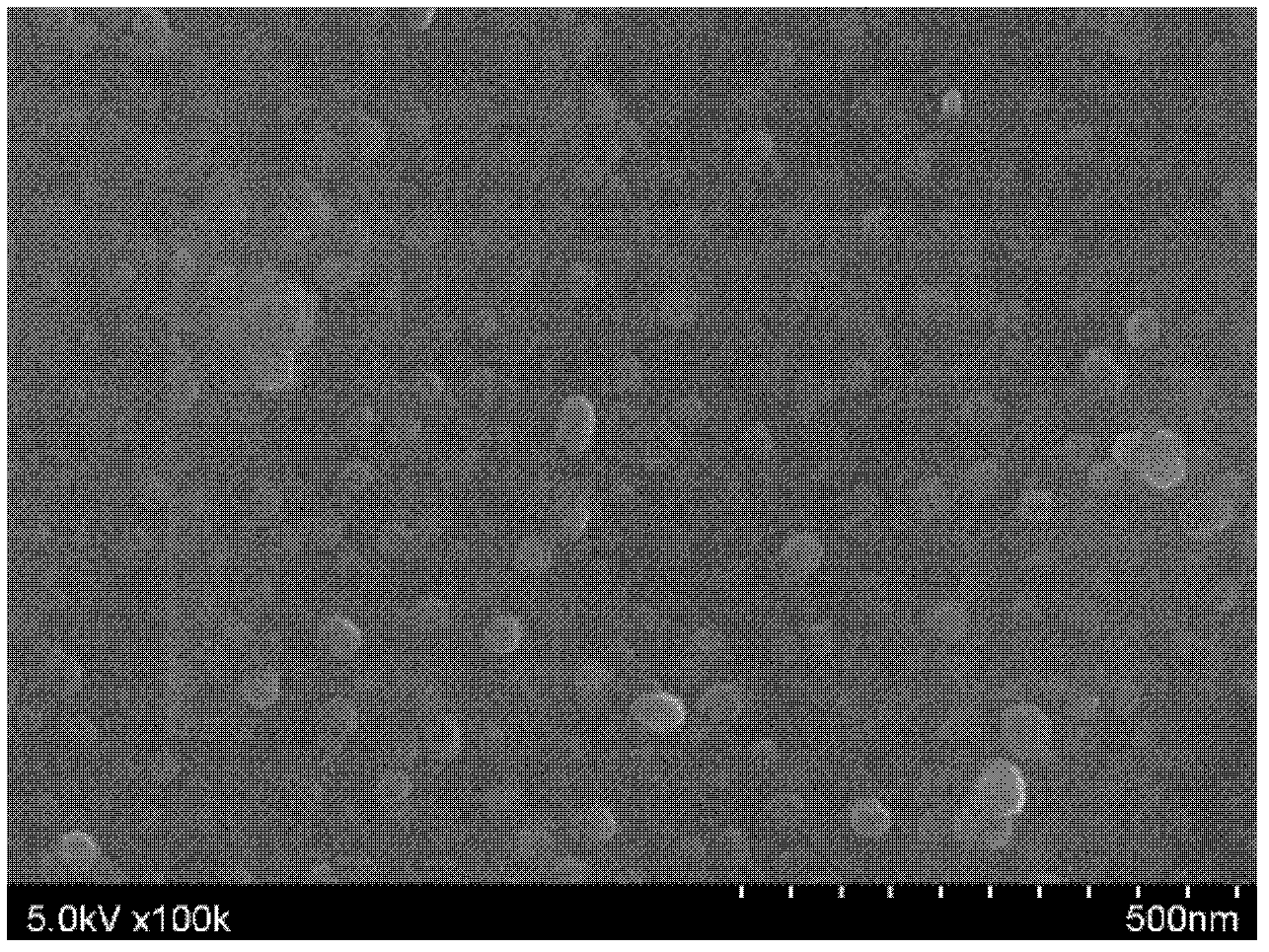

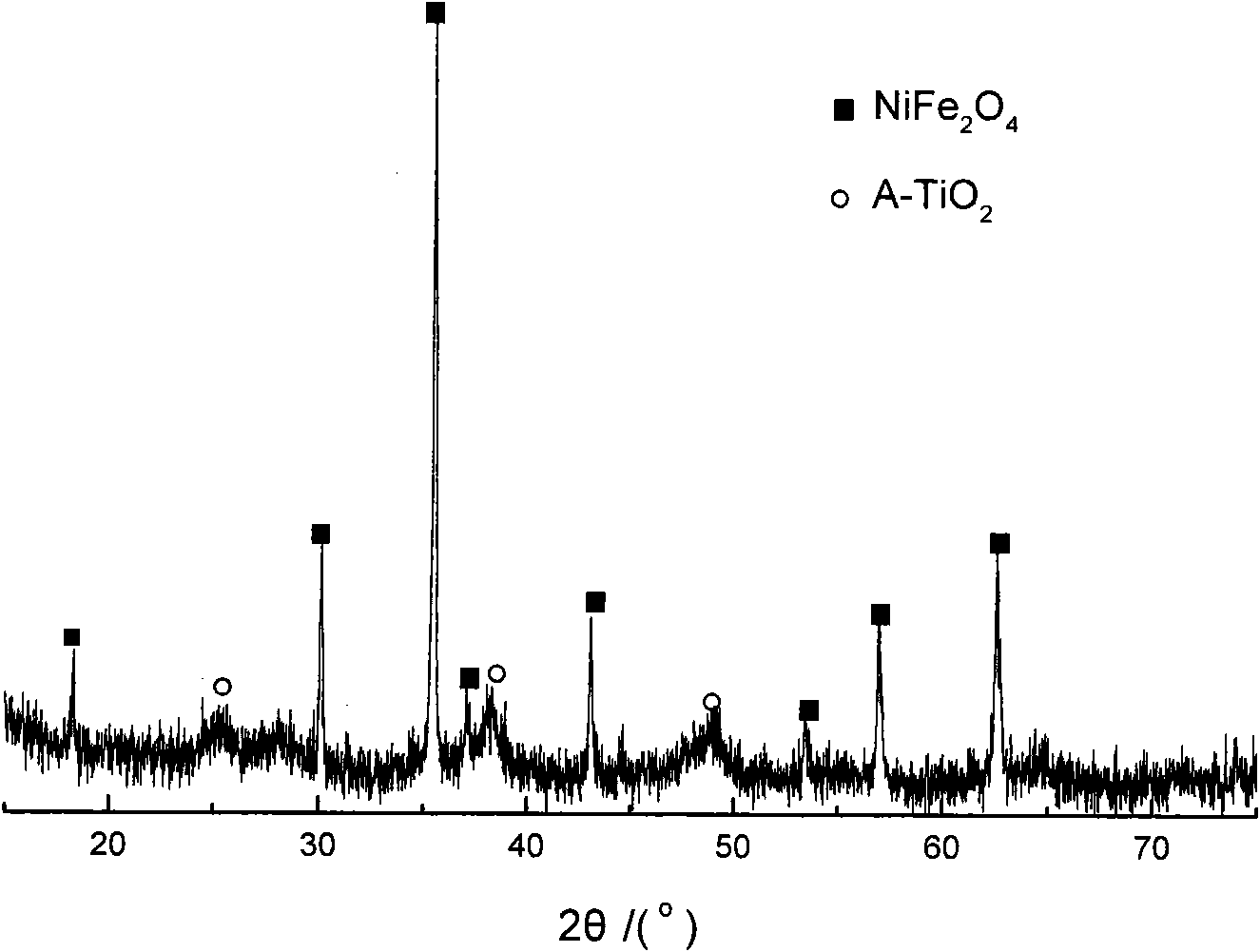

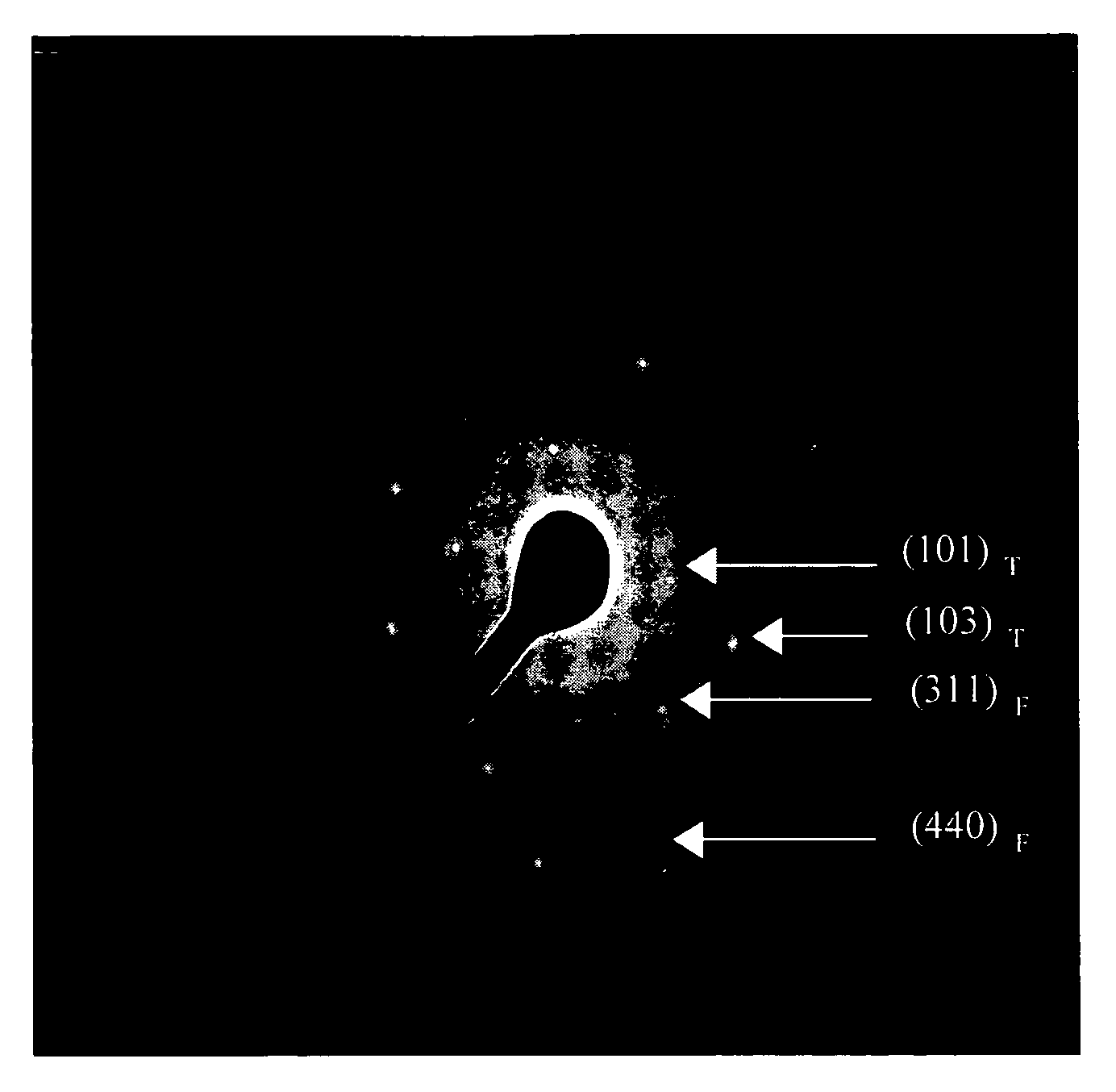

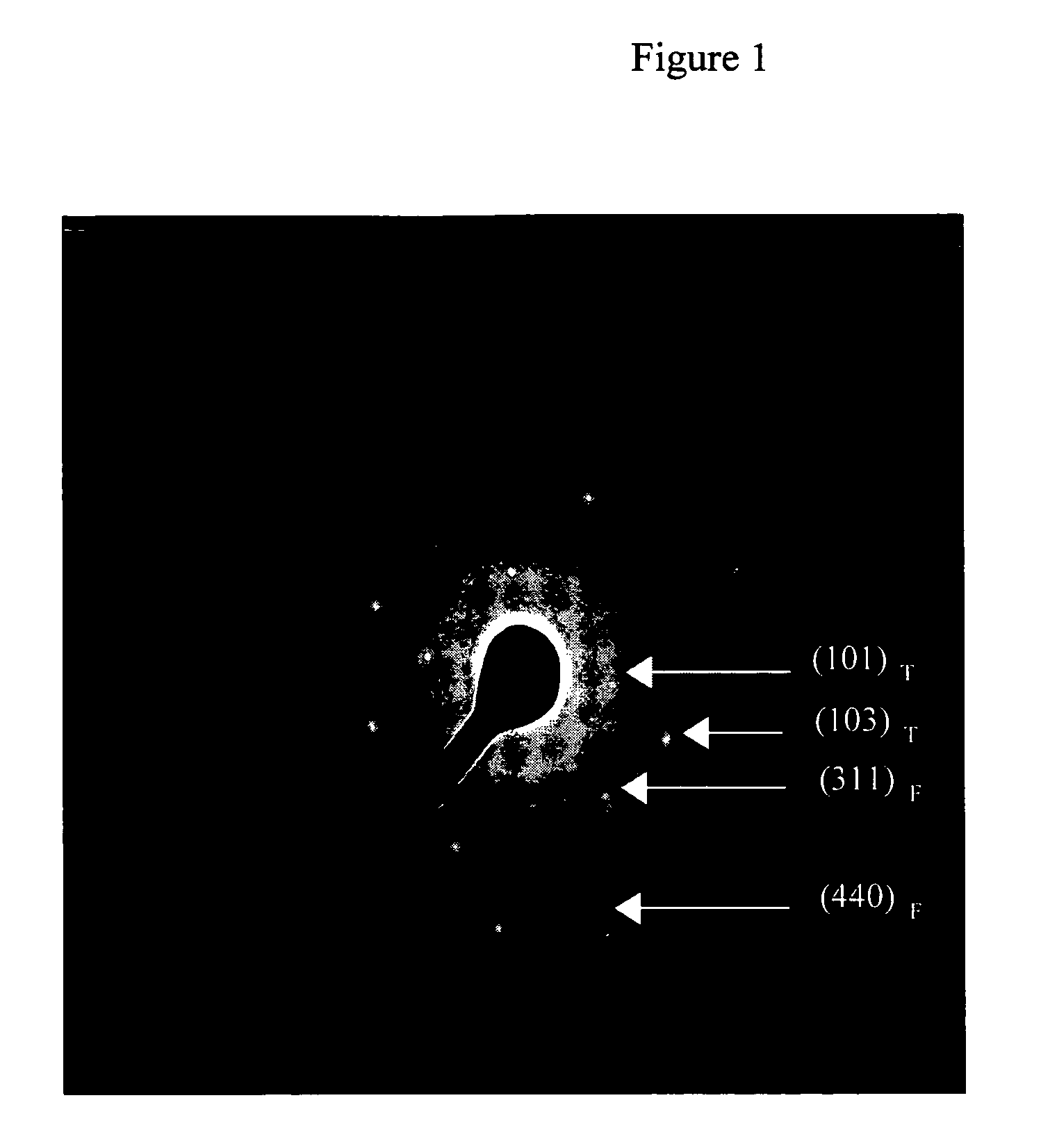

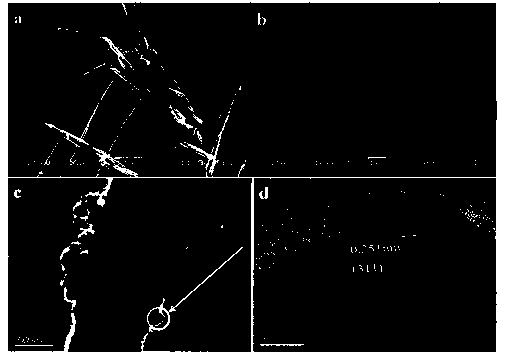

A process for preparing the magnetically separable composite photo-catalyst includes such steps as synthesizing the nickel ferrite nano-particles as magnetic carrier by low-temp catalytic phase transfer method, liquid-phase depositing SiO2 nano-particles on the surface of nickel ferrite nano-particle, and coating TiO2 nano-particles. Its granularity is less than 15 nm, providing huge surface area.

Owner:SHANGHAI JIAO TONG UNIV

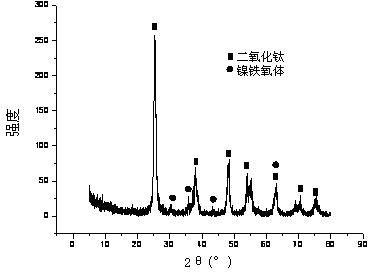

Preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst

ActiveCN101579628AGood dispersionLarge and adjustable package volumeWater/sewage treatment by irradiationWater contaminantsParticulatesNickel salt

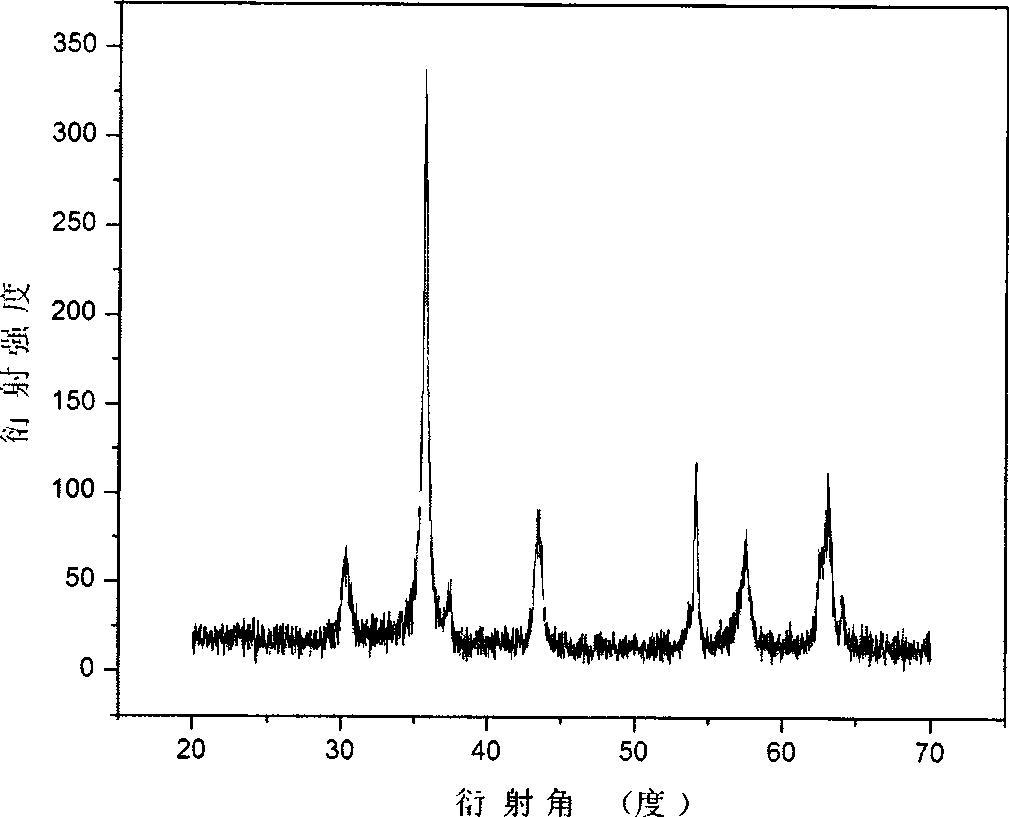

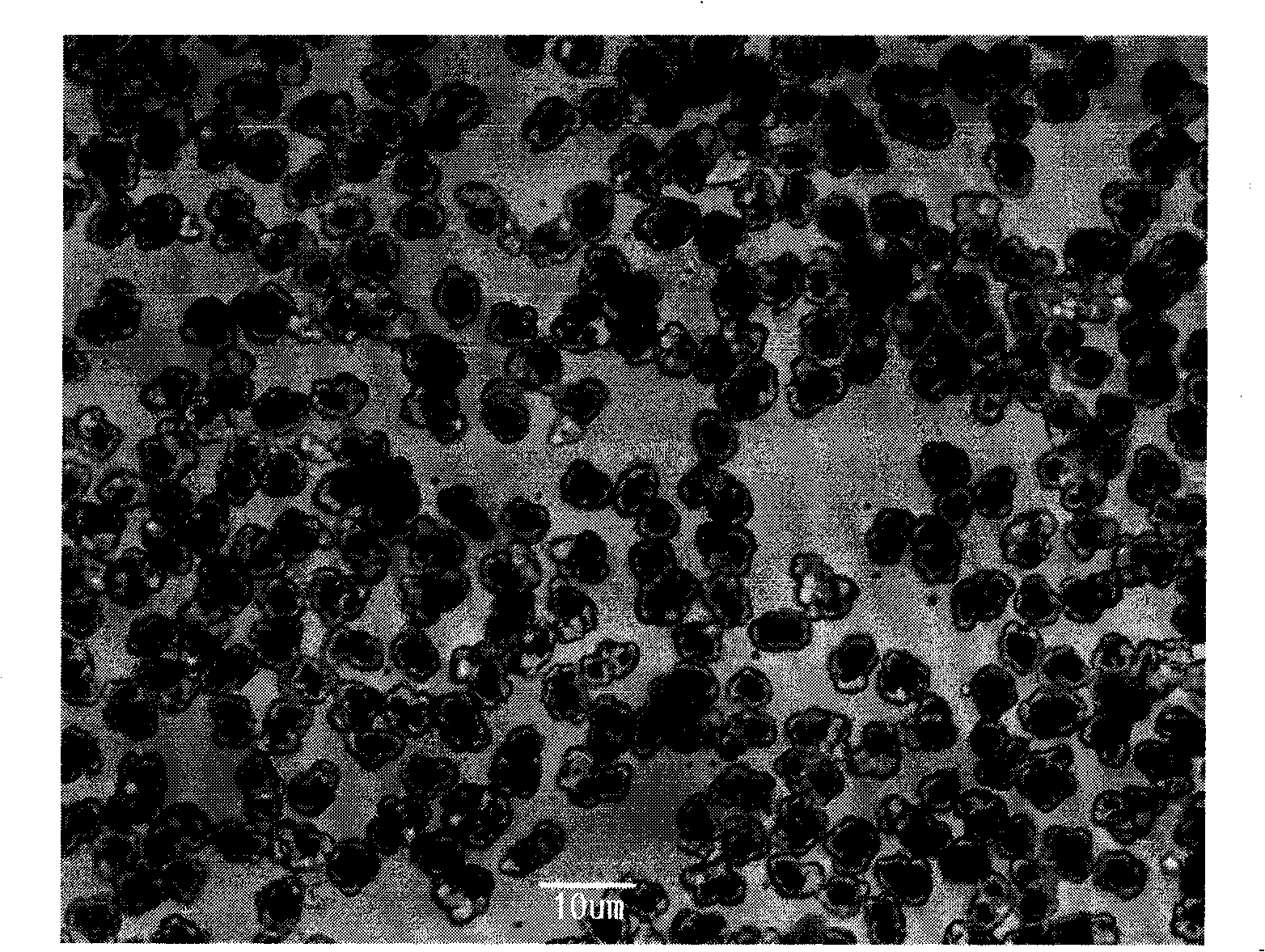

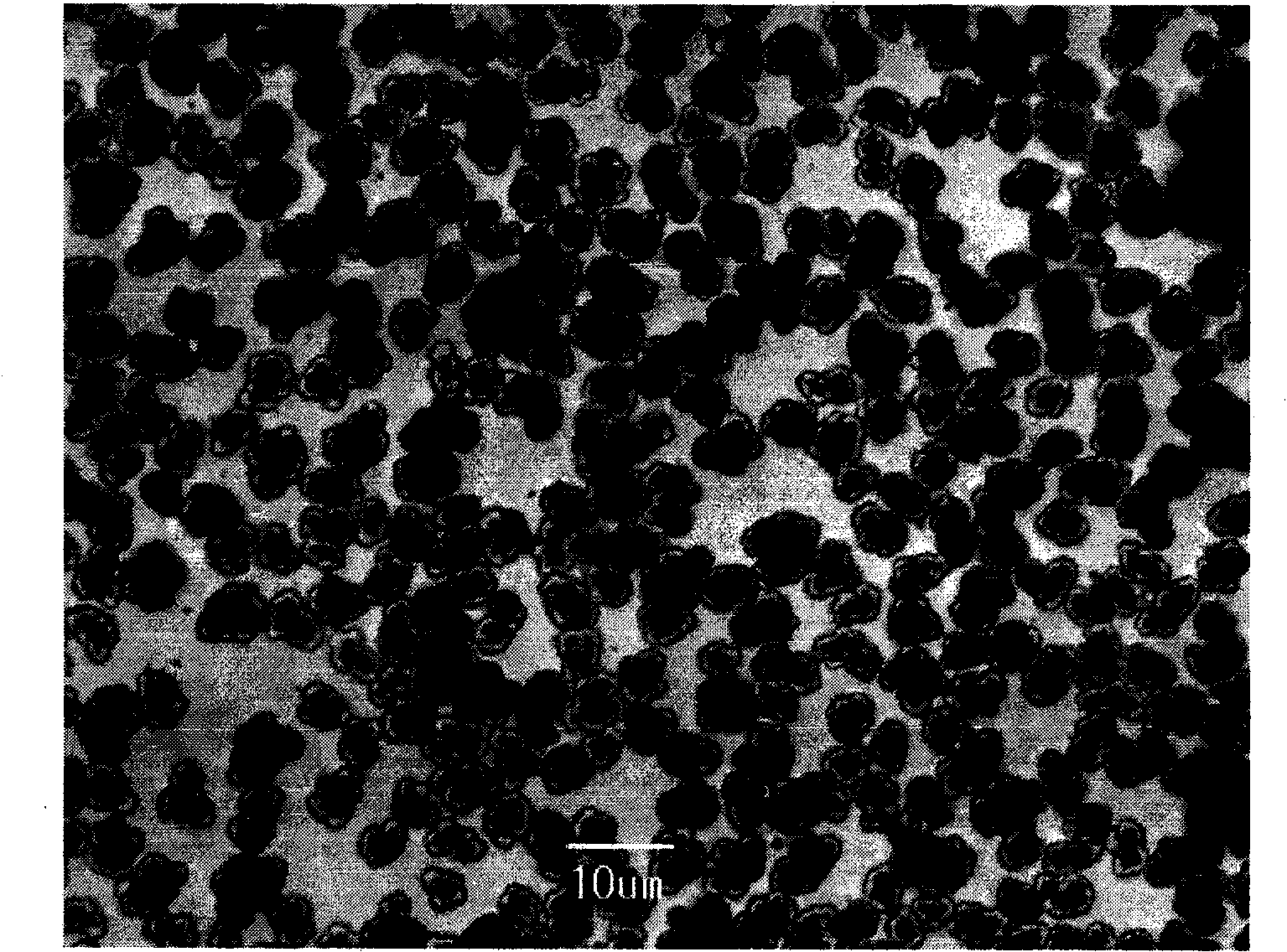

The invention provides a preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst with micron grade micron order as carrier; the preparation process includes the following steps: adding green copperas solution and oxalic acid solution into the nickel salt solution for reaction to obtain the mixture precipitate of oxalate of nickel oxalate and iron oxalate; then baking to obtain the micron grade nickel ferrite powder; adding the titanic sulfate solution into the suspension of micron grade nickel ferrite powder so as to crystallize the titanium ions on the suspended particulates in the suspension to form a wrapping layer and obtain the nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst product. The magnetic loaded type titanium dioxide photo-catalyst prepared by the method of the invention has good dispersibility; and the particle diameter of the particles is about 5 mum; the titanium dioxide is obviously wrapping on the surface of the nickel ferrite to form a core / shell structure with large wrapping capacity as well as adjustable and homogenous distribution; the specific surface is 90-110 m / g; and the photo-catalyst has the feature of strong soft magnetism, can be rapidly recycled in aqueous solution and has higher catalytic activity, so that organic wastewater can be completely degraded. The preparation technology is simple, the cost is low, and large-scale production is easily realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

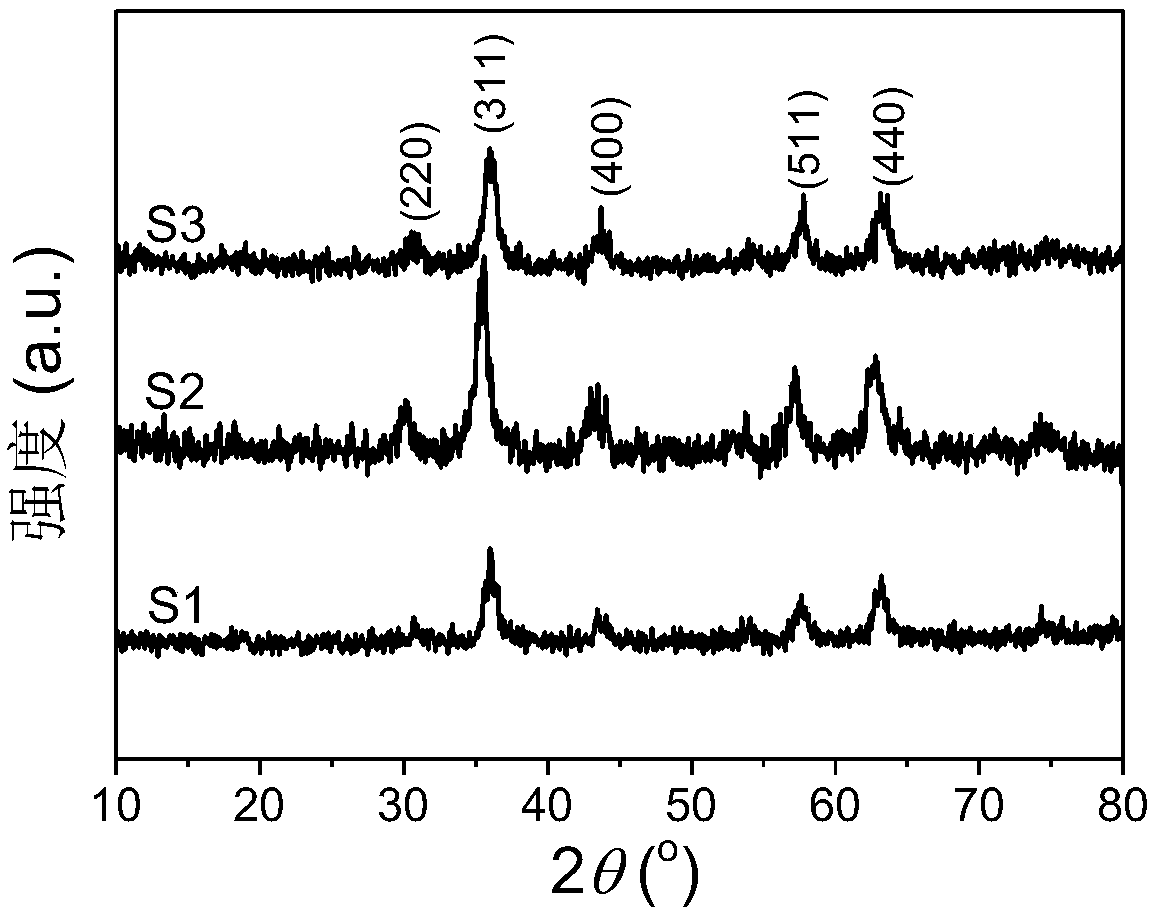

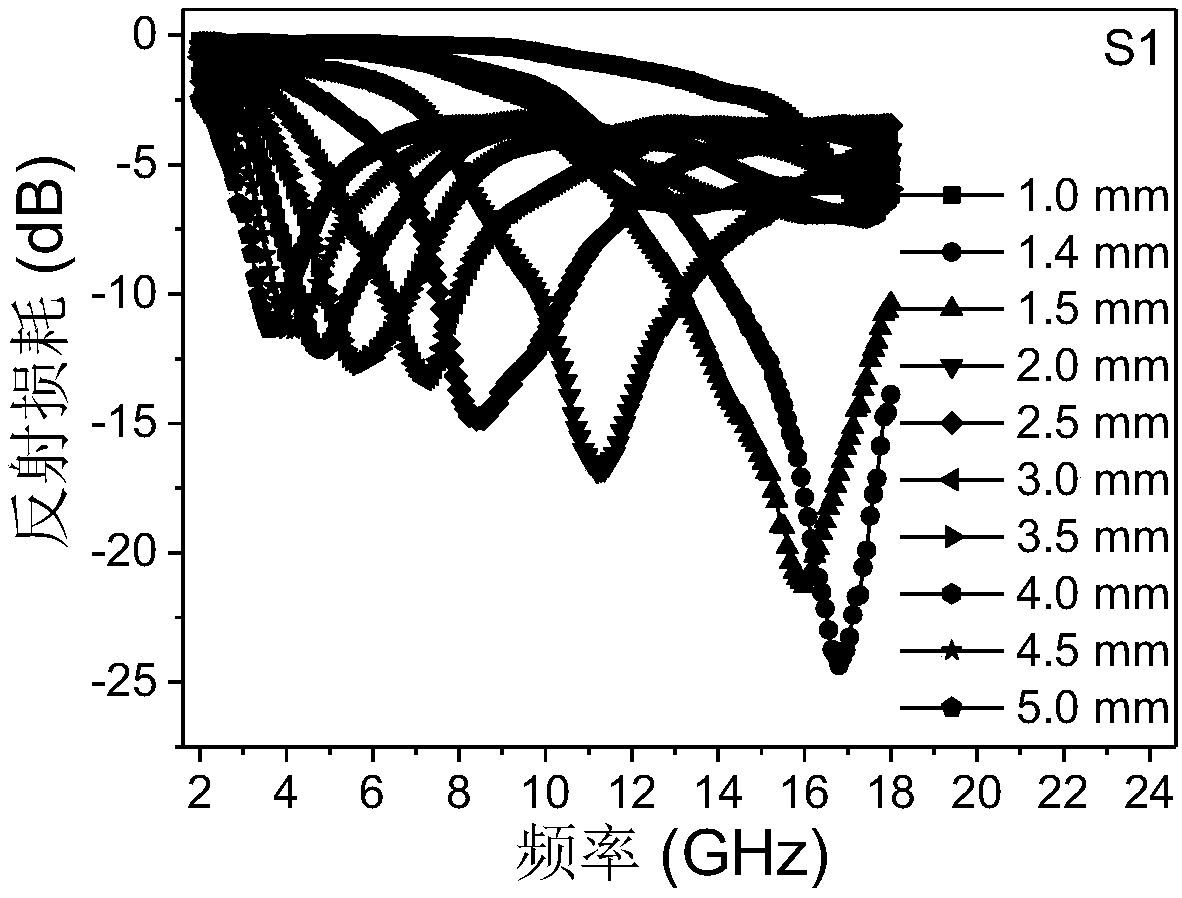

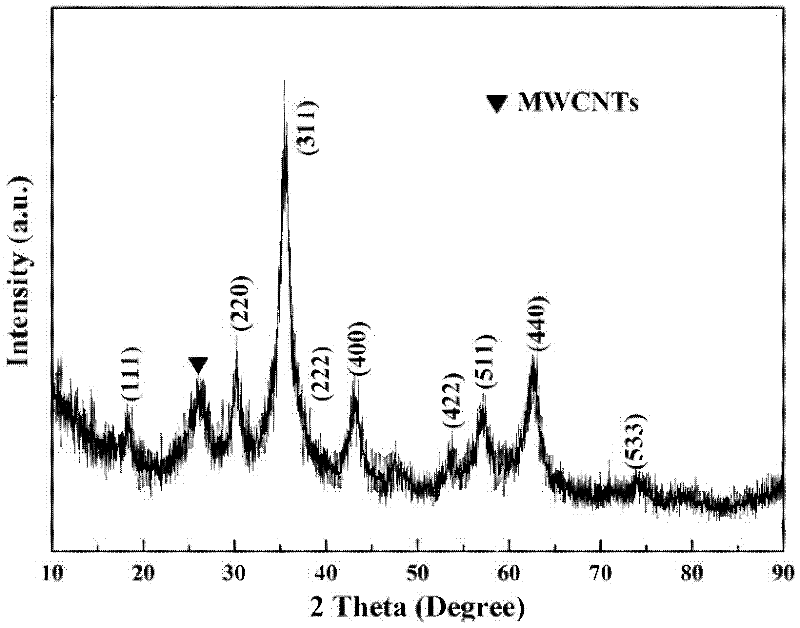

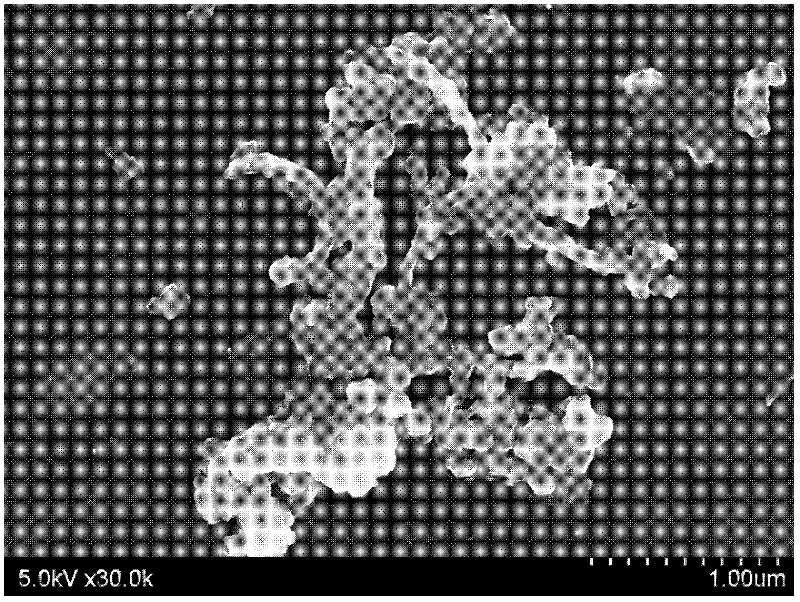

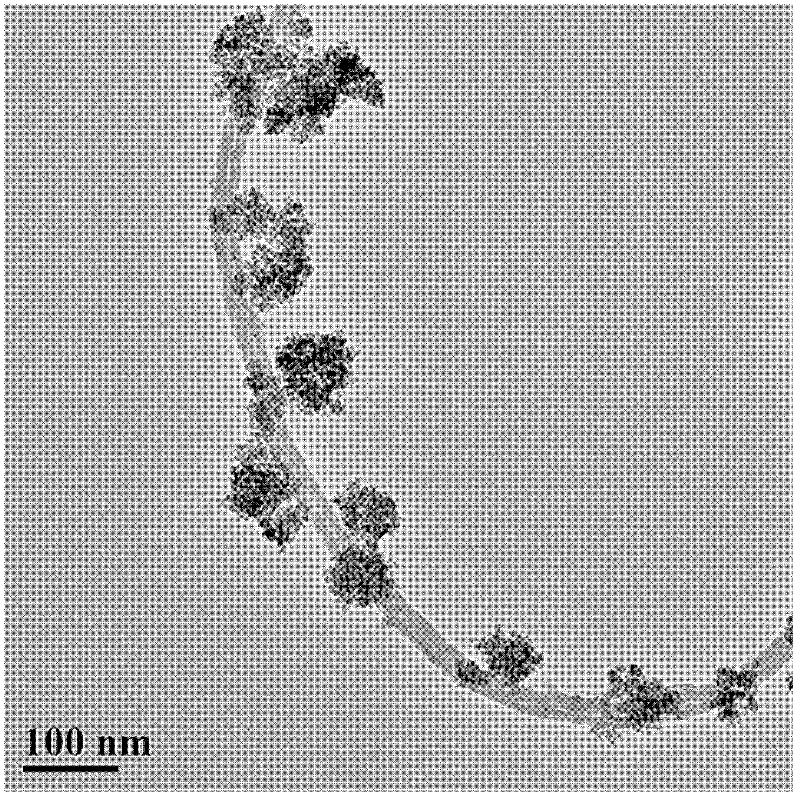

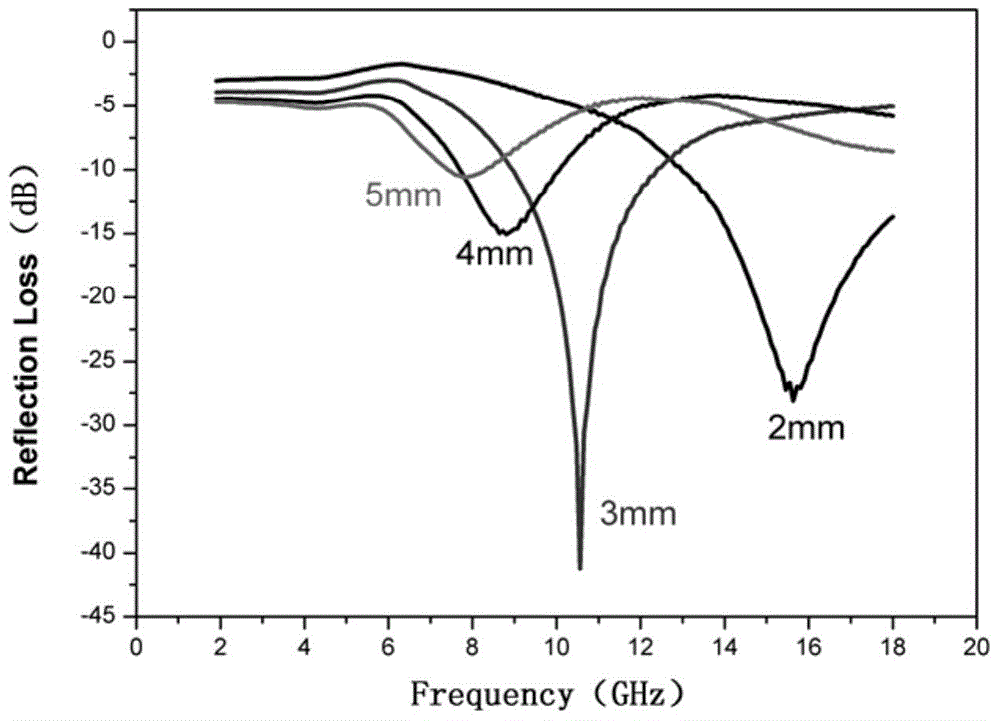

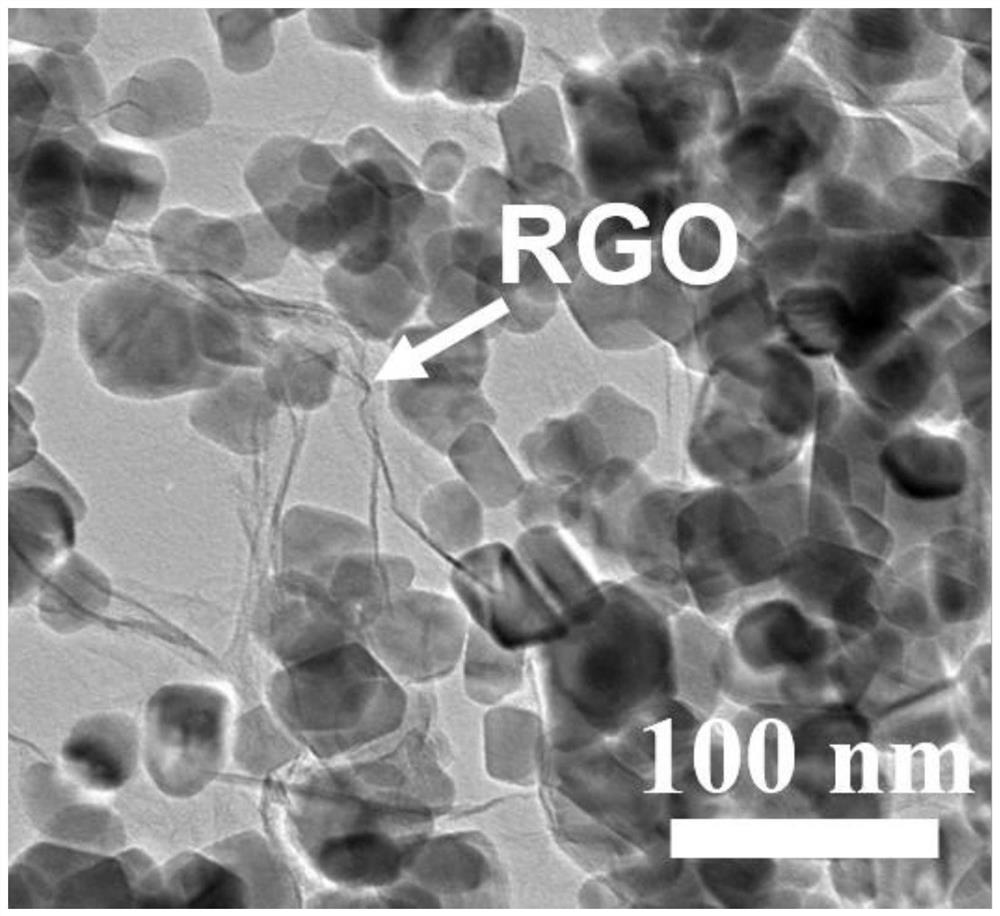

Preparation method of reduced graphene oxide/multi-walled carbon nanotube/nickel ferrite three-element nano composite wave-absorbing material

ActiveCN108690556ASimple and fast operationImprove conductivityOther chemical processesMagnetic/electric field screeningCarbon nanotubeElectromagnetic shielding

The invention discloses a reduced graphene oxide / multi-walled carbon nanotube / nickel ferrite (RGO / MWCNTs / NiFe2O4) three-element nano composite wave-absorbing material and a preparation method thereof.The RGO / MWCNTs / NiFe2O4 three-element nano composite material with a local three-dimensional conducting network structure is prepared by adopting graphene oxide (GO), the multi-walled carbon nanotube,nickel nitrate hexahydrate and iron nitrate nonahydrate as precursors and carrying out one-step hydrothermal reaction. The preparation method is pollution-free and environmentally friendly, has no production of any toxic and harmful side products, and is simple in preparation process and low in cost; the prepared three-element nano composite wave-absorbing material is strong in capability of absorbing electromagnetic waves, wide in absorbing frequency band, small in thickness and low in density, can realize effective absorption of the electromagnetic waves with different wavebands by adjusting the content of MWCNTs in the composite material and the thickness of a coating layer, and has an important application value in the fields of electromagnetic absorption and electromagnetic shielding.

Owner:ANHUI UNIV OF SCI & TECH

Modification method of nickel ferrite negative electrode material

InactiveCN106531994AImprove conductivityImprove cycle performanceCell electrodesSecondary cellsCarbon layerGraphite

The invention discloses a modification method of a nickel ferrite negative electrode material. The method comprises the steps of firstly synthesizing a NiFe2O4 / graphene composite material, carrying out carbonizing treatment at a high temperature, and evenly coating the surface of the NiFe2O4 / graphene composite material with a carbon layer. According to the material obtained through the modification method, the initial discharge capacity is greater than 1237mAh / g and the capacity retention ratio after 100 cycles is greater than 96%. Therefore, according to the modification method, the conductivity of the material is improved, the reversibility in charge and discharge processes is improved and the cycle performance of the material is improved.

Owner:WUXI MINGSHENG STRONG BLOWER

Preparation method of TiO2/SiO2/NiFe2O4 magnetic composite photocatalyst

InactiveCN102430410AReduce contentReduce the adverse effects of photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsCalcinationMaterials science

The invention relates to a preparation method of a TiO2 / SiO2 / NiFe2O4 magnetic composite photocatalyst. The method is mainly characterized in that a hydrothermal method is utilized to prepare magnetic nickel ferrite particles, a hydrolytic precipitation method is utilized to coat a silicon dioxide layer outside the nickel ferrite particles, and a sol-gel method is utilized to deposit TiO2 on the SiO2 / NiFe2O4 surface by using SiO2 / NiFe2O4 as a magnetic core and tetrabutyl titanate as a precursor. The invention has the following advantages: the particles of the material are small, and TiO2 and NiFe2O4 are isolated by the silicon dioxide; and thus, the photocatalysis performance of the titanium dioxide is not influenced by the nickel ferrite, and the titanium dioxide can be effectively recycled through an external magnetic field. In addition, the magnetic substance used in the method is nickel ferrite with stable properties, and the magnetic performance of the nickel ferrite can not be influenced by high-temperature calcination.

Owner:SHANGHAI UNIV

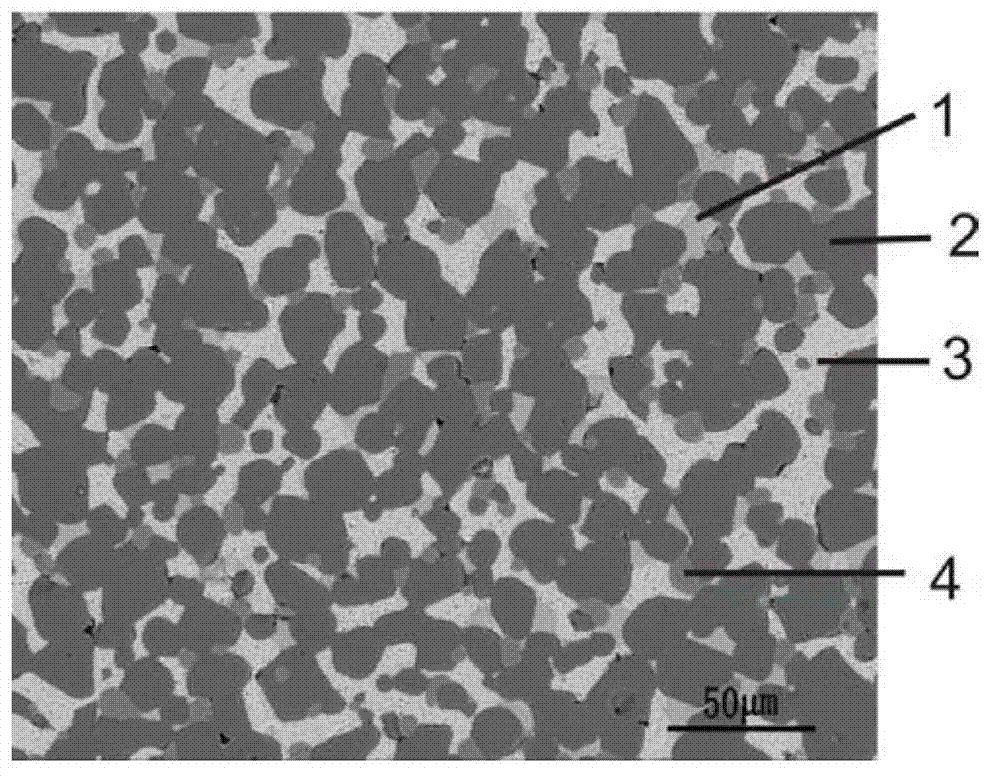

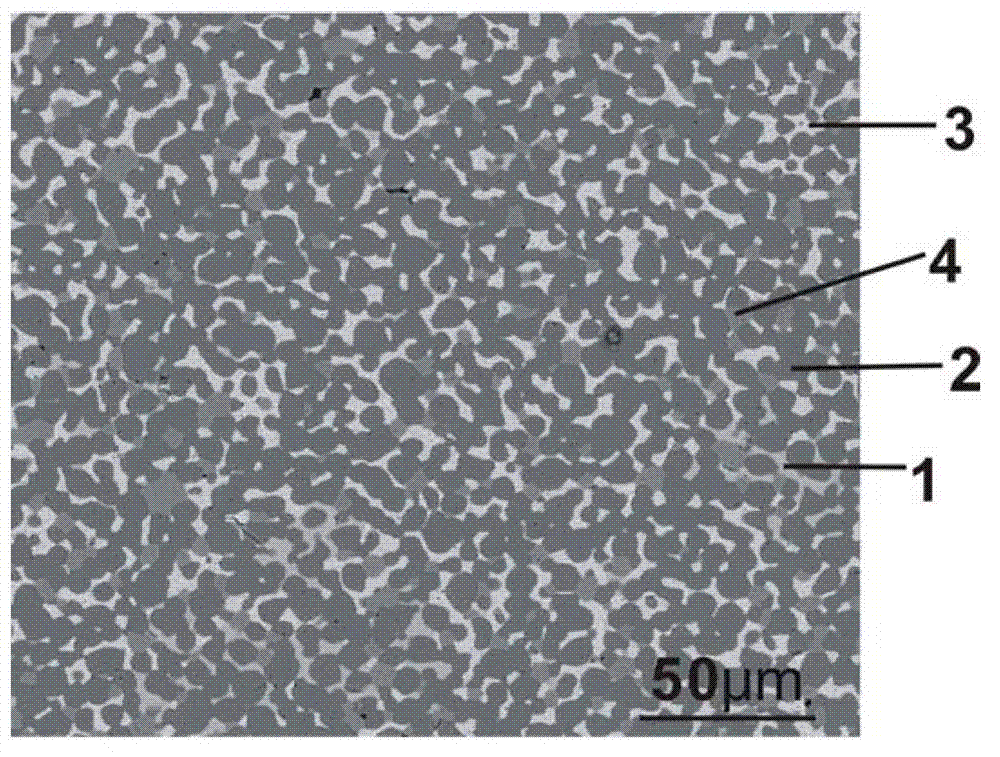

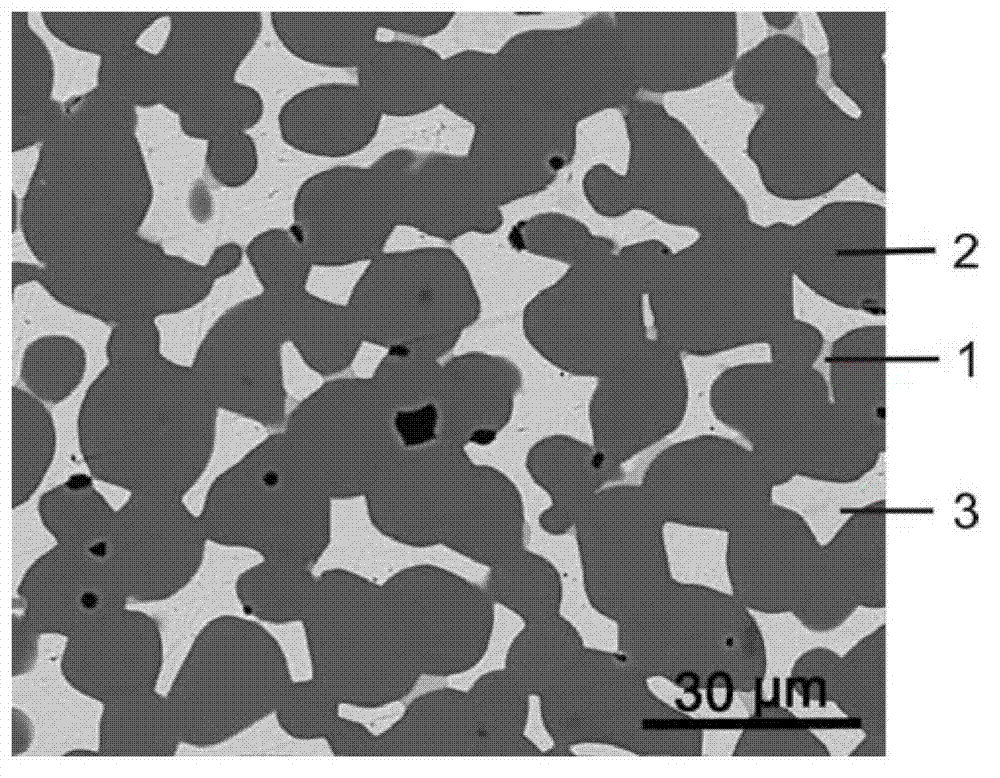

Nickel ferrite-copper metal ceramic inert anode material and preparation method

The invention relates to a nickel ferrite-copper metal ceramic inert anode material which comprises a ceramic phase and a metal phase, wherein the ceramic phase is nickel ferrite or nickel ferrite base composite ceramic; and the metal phase consists of metal copper and cuprous oxide, and the cuprous oxide accounts for 1-20% of the total mass of the metal phase. In the preparation process, the content of the cuprous oxide in the metal phase is controlled through controlling the oxygen partial pressure of a nitrogen protection atmosphere so as to improve the wettability of the nickel ferrite and the copper and achieve the sintering infiltration preparation of the ceramic phase and the metal phase. The metal phase and the ceramic phase of the nickel ferrite-copper metal ceramic inert anode material are in a three-dimensional reticular through structure, wherein the sintering density is higher than 98%, the electric conductivity of the metal ceramic material is more than 200S / cm at a temperature of 900 DEG C, the heat conductivity is up to 40W / (m.K) at the room temperature, and the metal ceramic material cannot be cracked through temperature difference thermal shock at the temperature of 400 DEG C. The problems of difficult sintering densification of the nickel ferrite and the copper, sintering overflow of the metal phase and material thermal shock and cracks are effectively solved, and compared with a material prepared by a conventional mixed powder sintering process, the electric conductivity and the thermal shock resistance of the nickel ferrite-copper metal ceramic material are greatly improved.

Owner:CENT SOUTH UNIV

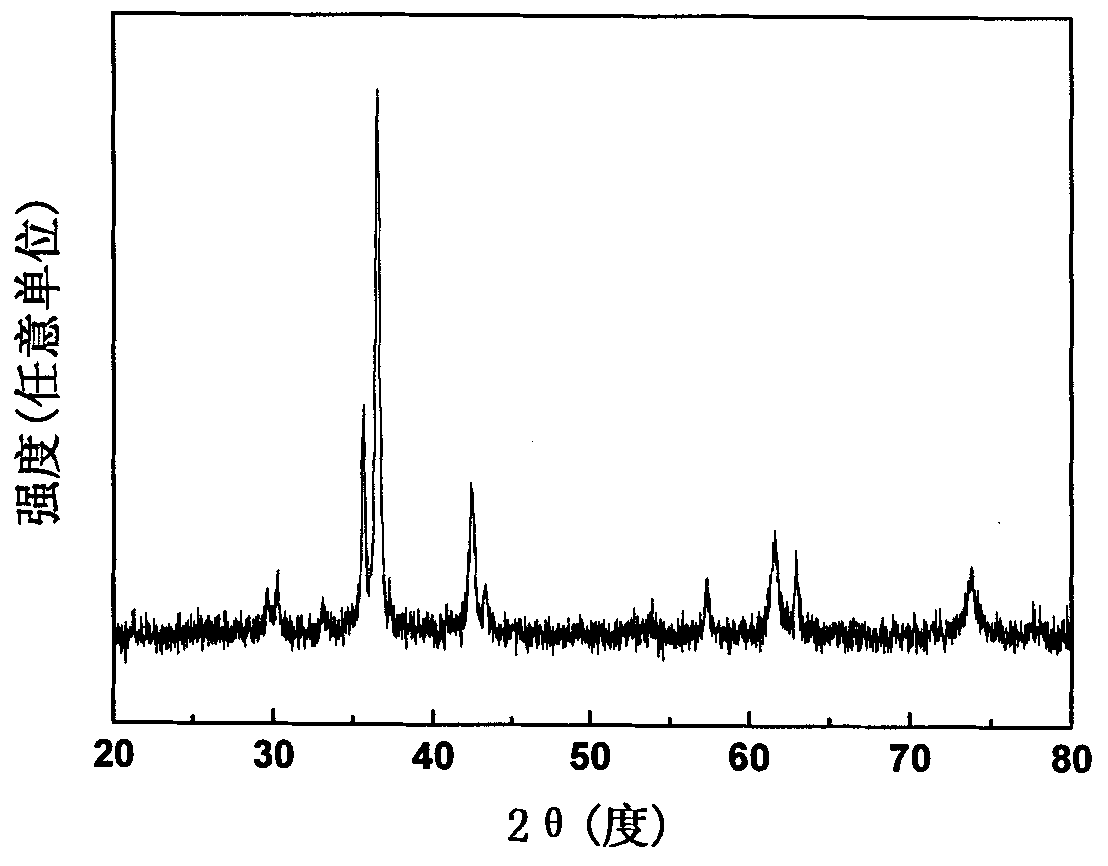

Preparation method of magnetic nano compound material of cobalt-nickel ferrite/multi-wall carbon nano pipe

InactiveCN102350282ASimple processLow requirements for production equipmentMicroballoon preparationMicrocapsule preparationNickel saltCarbon nanotube

The invention relates to a preparation method of a magnetic nano compound material of a cobalt-nickel ferrite / multi-wall carbon nano pipe, which comprises the following steps of: (1) carrying out acidifying treatment on the surface of cobalt-nickel ferrite by using acid with strong oxidizing property; and (2) dispersing a multi-wall carbon nano pipe after the acid treatment into a glycol water solution at room temperature, then adding iron salt, cobalt salt and nickel salt and adding polyethylene glycol and anhydrous sodium acetate after completely dissolving so as to form reaction liquid; and putting the reaction liquid into a reaction kettle, heating to react for 8 to 16h, then cooling to the room temperature, collecting a product by using a magnet, then washing and finally drying so as to obtain the magnetic nano compound material of the cobalt-nickel ferrite / multi-wall carbon nano pipe. The preparation method disclosed by the invention is simple and is easy for industrialized production; and the prepared Col-xNixFe2O4 / MWCNTs magnetic nano compound material has pure crystalline phase, good dispersivity, smaller crystal grains and high magnetization intensity.

Owner:DONGHUA UNIV

Method for preparing nano magnetic silicon ball

InactiveCN1935743ASolving Dispersion ProblemsImprove practicalityPhysical/chemical process catalystsInorganic material magnetismNickel saltIron salts

The invention is a nano magnetic silicon ball preparing method, applicable to the fields of chemical engineering, environmental protection and biomedicine, firstly selecting bivalent iron salt as catalyst, and by low temperature catalytic phase conversion method, catalytically converting bivalent nickel salt and trivalent iron salt into magnetic nickel ferrite nano particles, dispersing them into reverse micelle solution under the action of surface active agent, coating SiO2 on them by gelatination to form nano magnetic silicon balls, 50nm-sized , where the mass ratio of nickel ferrite nano particle to SiO2 coating is less than 10. And it provides huge surface area for loading of active components in different application fields. And loading TiO2 photocatalyst on the nano magnetic silicon balls can make magnetically separable photocatalyst, able to be effectively used for water treatment.

Owner:SHANGHAI JIAO TONG UNIV

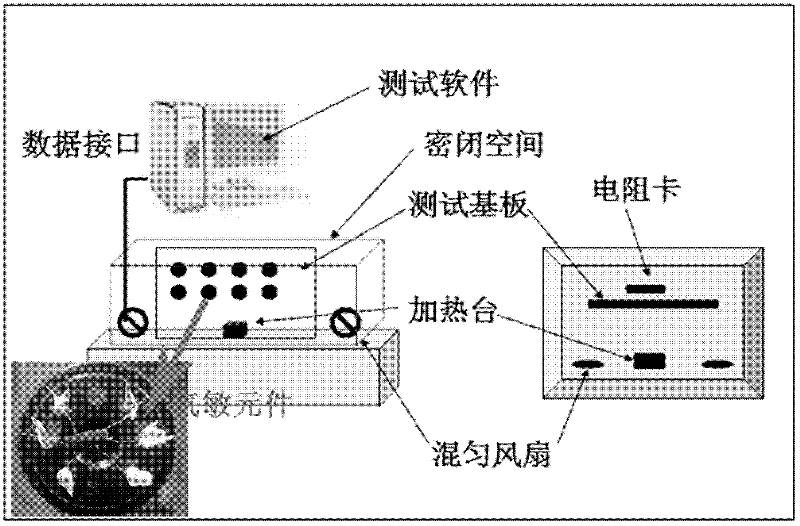

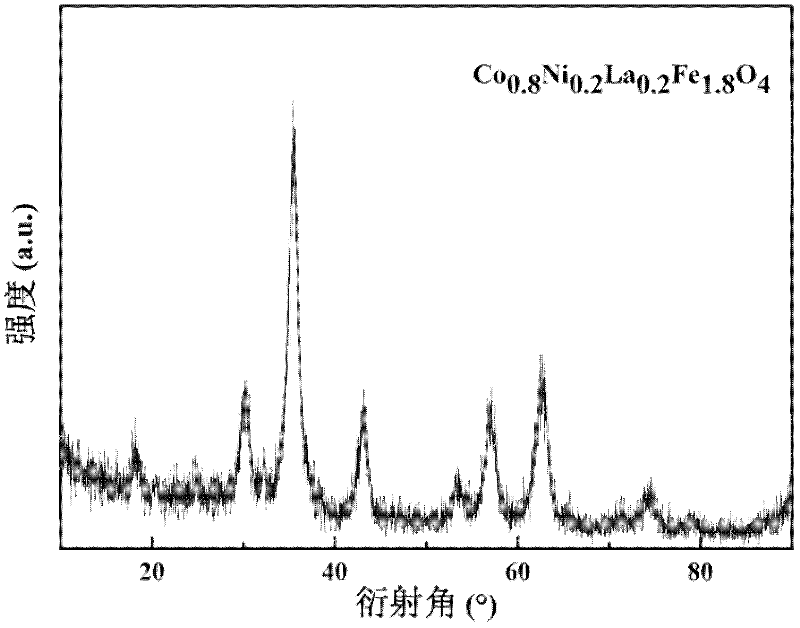

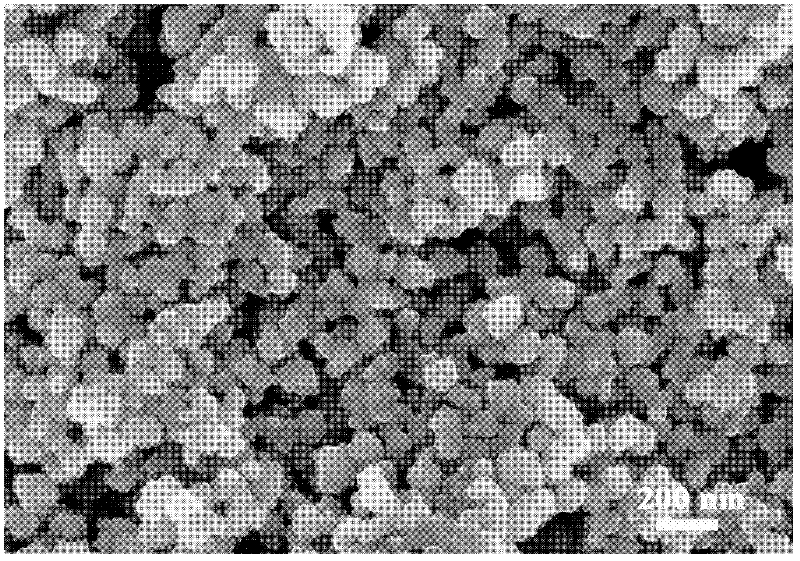

Preparation methods of lanthanum-doped cobalt nickel ferrite gas-sensitive powder and gas sensor

The invention relates to preparation methods of lanthanum-doped cobalt nickel ferrite gas-sensitive powder and a gas sensor. The preparation method of the gas-sensitive powder comprises the following steps: (1) soluble cobalt salt, nickel salt, lanthanum salt and ferric salt are mixed and dispersed into ethylene glycol, and sodium acetate anhydrous is added and stirred to form reaction solution; and (2) the reaction solution is heated and reacted, then is cooled to room temperature after the reaction, and washed, centrifugated and dried. The preparation method of the gas sensor comprises the following steps: the gas-sensitive powder and terpilenol solution of ethyl cellulose are mixed and ground to form gas-sensitive slurry; and then the gas-sensitive slurry is uniformly coated to an Al2O3 ceramic tube with an Au electrode, conducted to gas drying and calcination, and installed on a testing base, and then the gas sensor is obtained after ageing. The preparation methods are simple, the requirement on the production equipment is low, the industrial production is easy, and the prepared gas-sensitive powder has good selectivity, good chemical stability and good sensitivity.

Owner:DONGHUA UNIV

Preparation method of Cu2O/NiFe2O4 magnetic composite

The invention relates to a preparation method of a Cu2O / NiFe2O4 magnetic composite, belonging to the technical field of preparation of magnetic composite material. The method of the invention is characterized by comprising the following steps: dissolving iron salt and nickel salt in distilled water according to a certain ratio, then adding surfactant polyvinylpyrrolidone, adjusting the pH value of the solution to 9-11 with sodium hydroxide, then pouring the reaction solution in a high-pressure reaction tank and placing in a muffle furnace to keep temperature for 8-10 hours at 200-250 DEG C for fully reacting; washing the product, performing suction filtration and vacuum drying to obtain magnetic nickel ferrite power for standby; then dissolving copper salt and glucose in distilled water with a certain volume, adding the prepared nickel ferrite power in the obtained solution; stirring evenly, adding defined amounts of NaOH solution and hydrazine hydrate solution, continuously stirring to fully react; and then washing, performing suction filtration and vacuum drying, and finally obtaining the Cu2O / NiFe2O4 magnetic composite power.

Owner:SHANGHAI UNIV

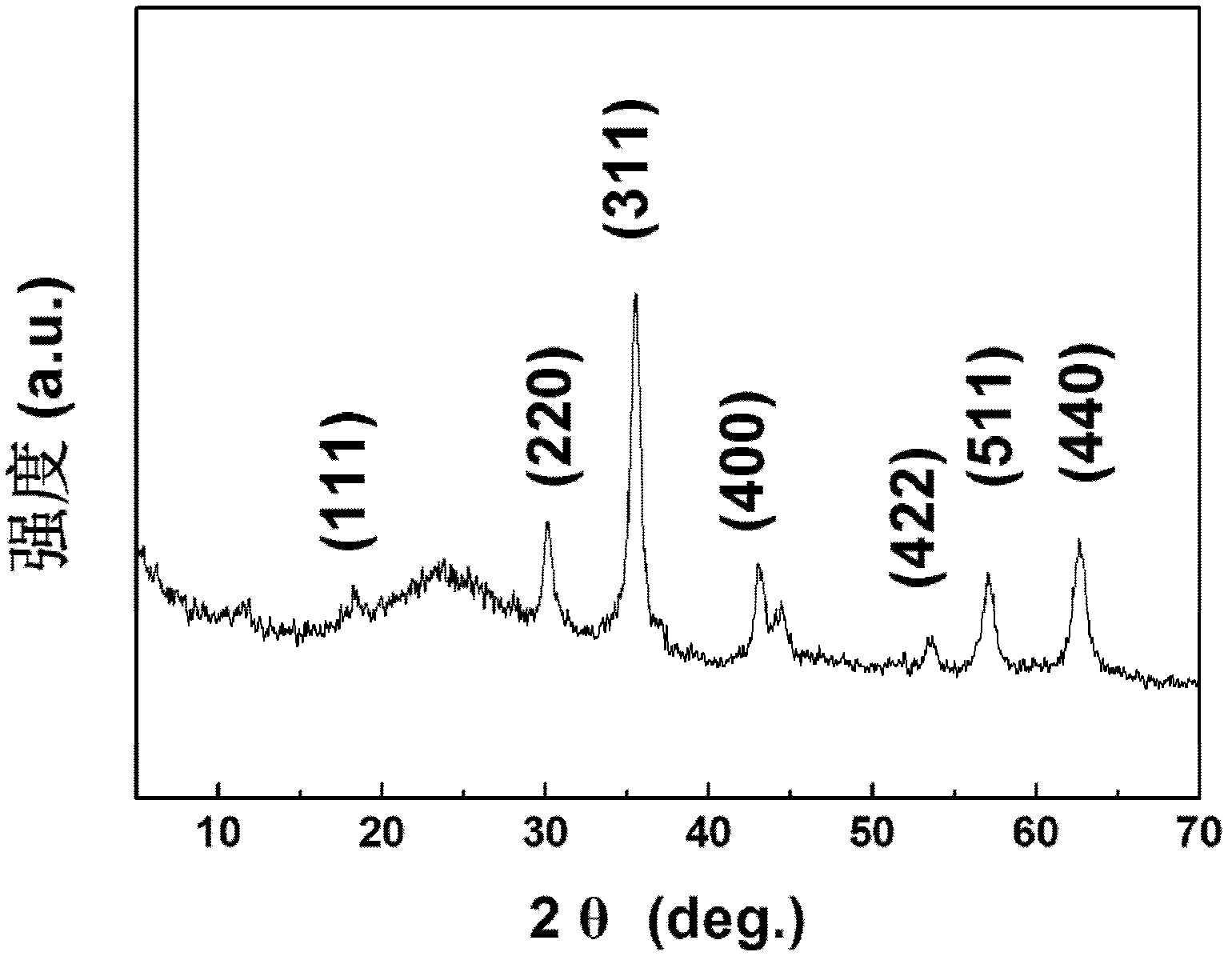

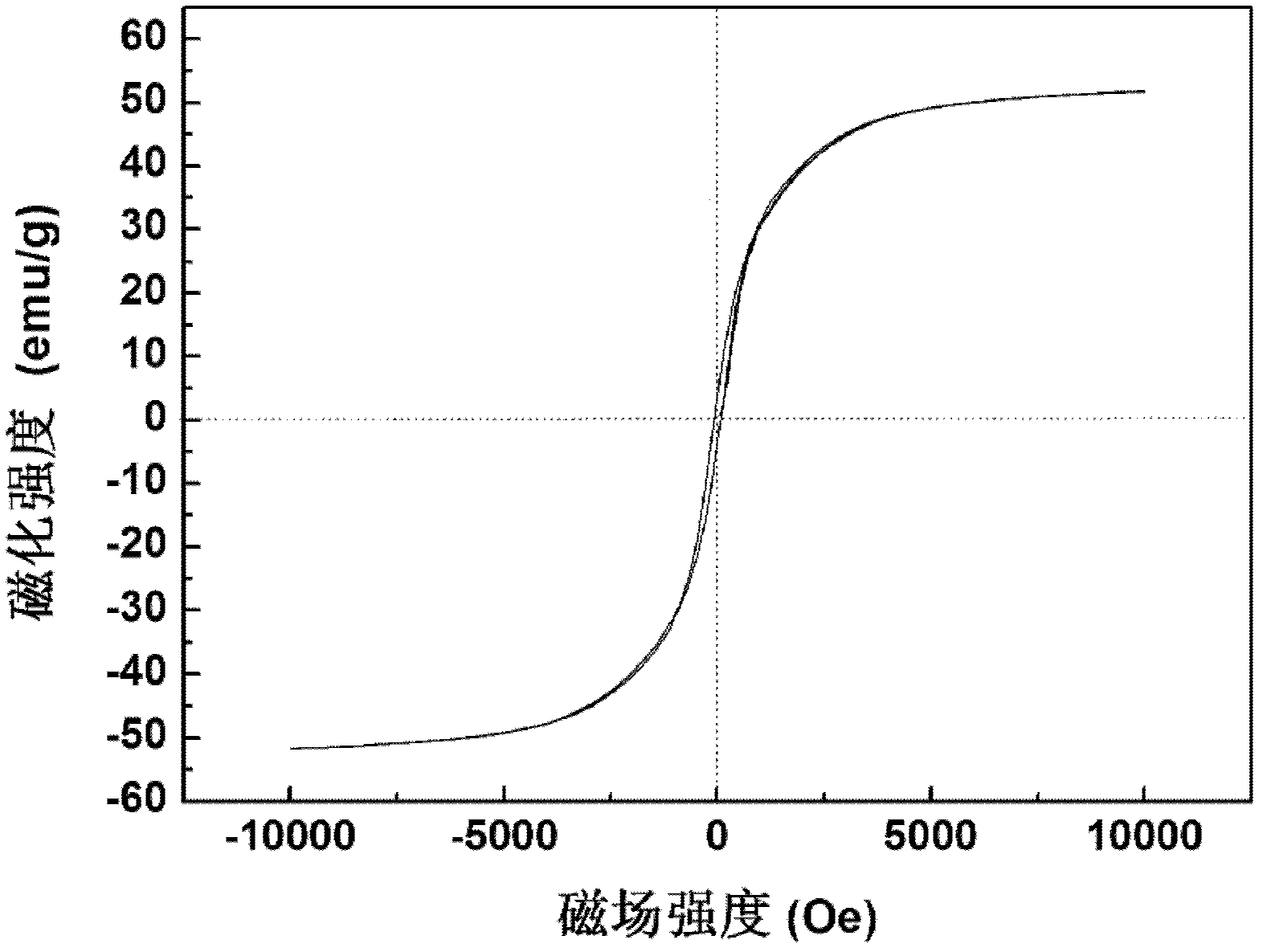

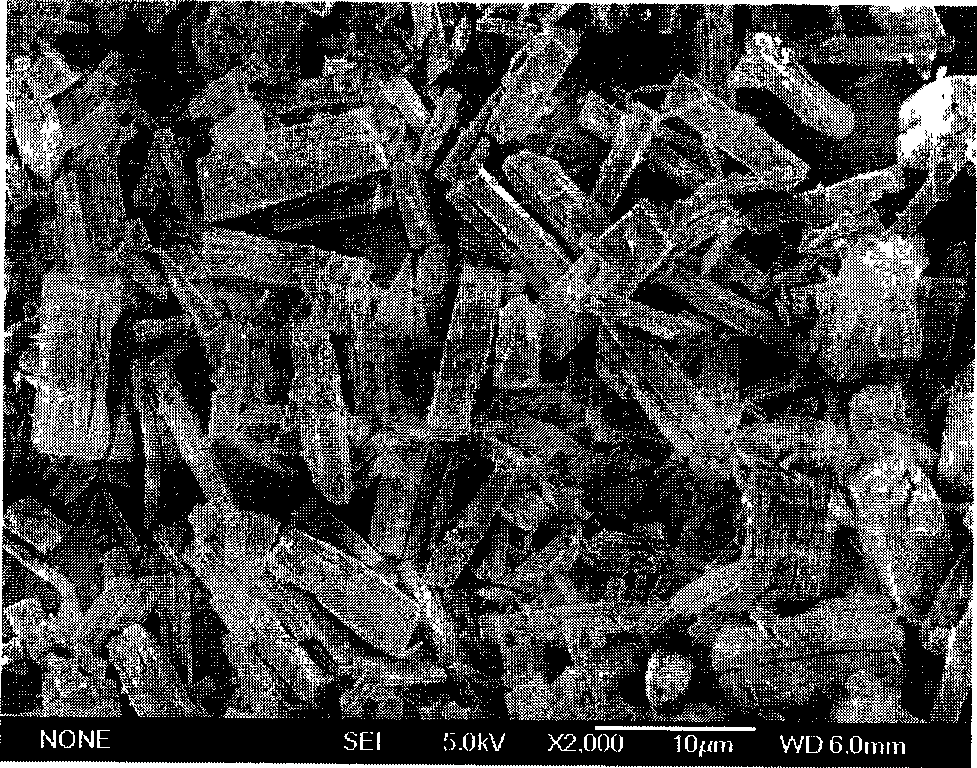

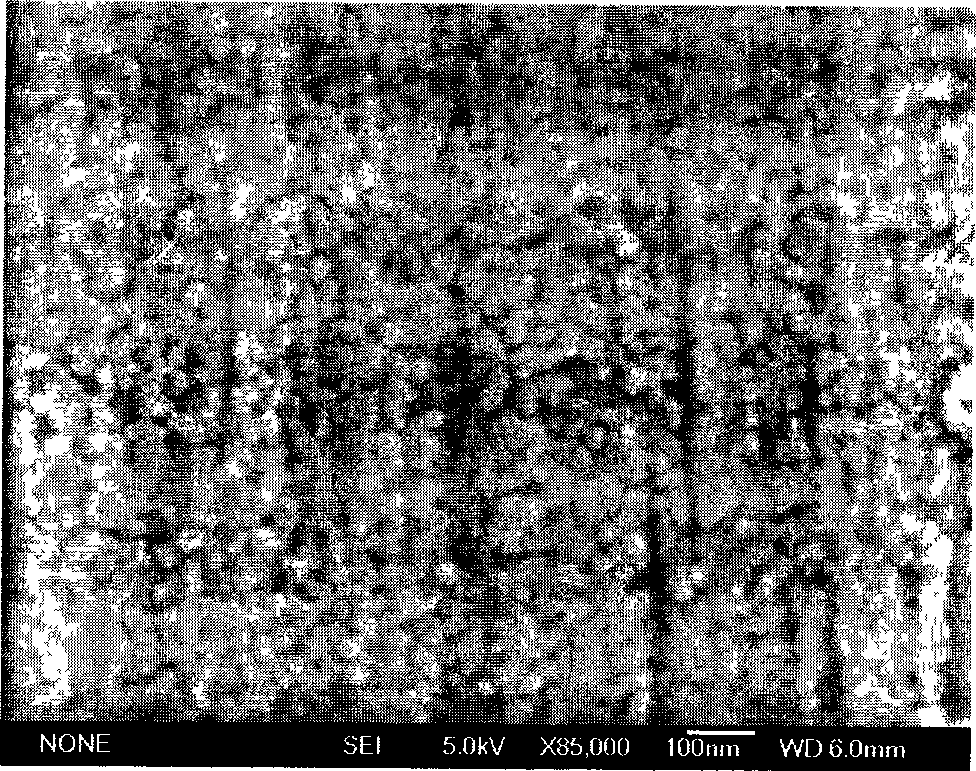

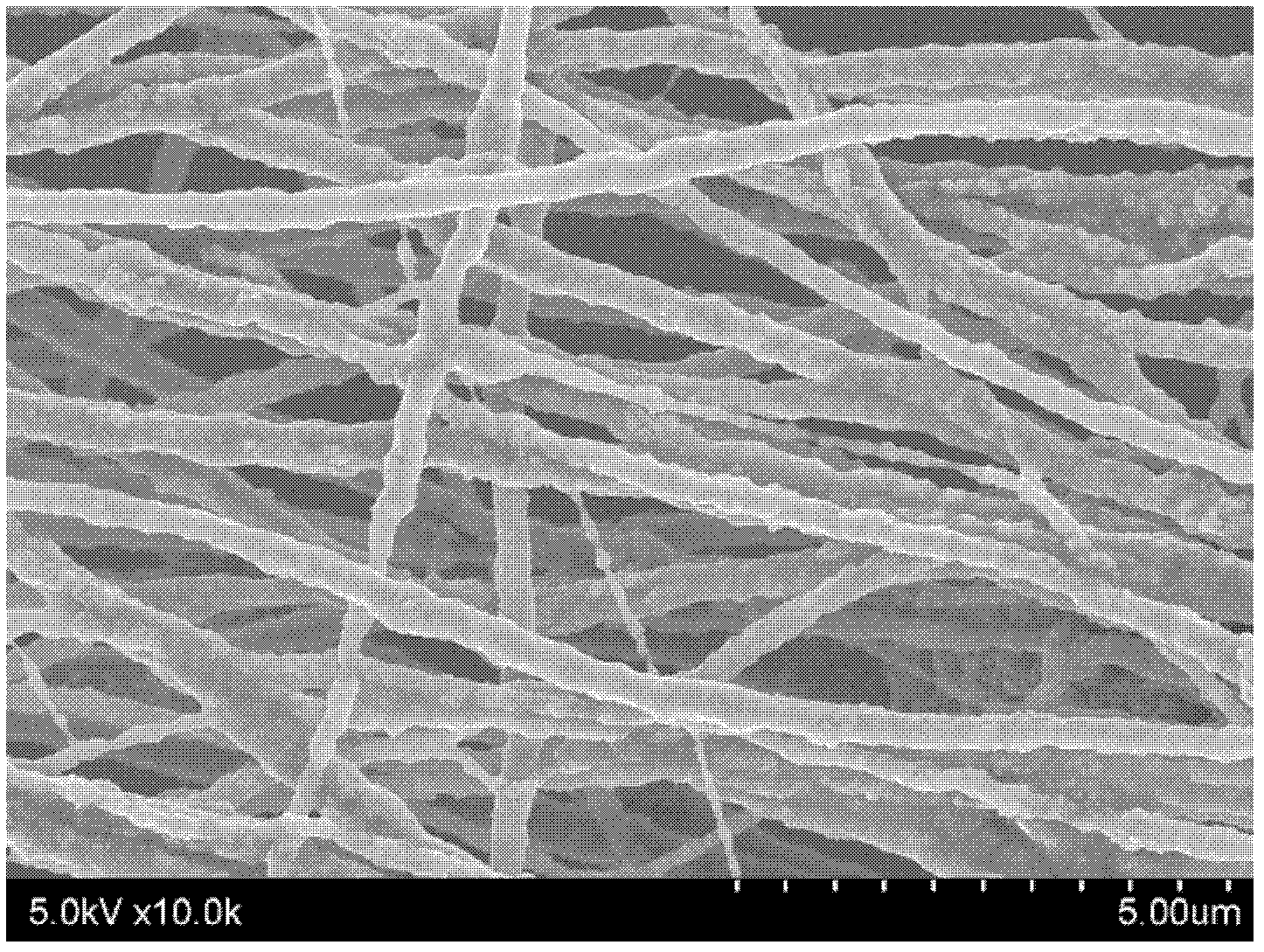

Preparation method of nickel ferrite magnetic nanofiber material

The invention provides a new preparation method of a nickel ferrite magnetic nanofiber material, belonging to the technical field of a material. The preparation method comprises the following steps: by taking Fe(NO3)3.9H2O and Ni(NO3)2.6H2O as raw materials, an absolute ethyl alcohol as a solvent and cotton fiber as a template, preparing the nickel ferrite magnetic nanofiber material in one step by means of a solvothermal method (TASTM) under the condition of not adding other additive (such as a precipitator). The prepared material has a spinel structure, duplicates the microstructure of the cotton fiber, and has excellent crystallization performance and magnetic performance, so that the application range of NiFe2O4 nanomaterial can be effectively expanded. In addition, the method also has the advantages of low preparation temperature, simple technology, high yield, no high-temperature crystallization treatment and the like, and is environmental friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for preparing graphene/ferrite composite nanometer microspheres having high magnetic-electric performances

InactiveCN104941543ALarge specific surface areaStrong magneticMicroballoon preparationMicrocapsule preparationMaterials preparationMicrosphere

The invention belongs to the field of novel material preparation and provides a method for preparing graphene / ferrite composite nanometer microspheres having high magnetic-electric performances. Ferrites are manganous ferrite and nickel ferrite. According to the method, first graphene oxide is prepared, and then graphene / manganous ferrite or graphene / nickel ferrite composite nanometer microspheres are synthesized in one step through a hydrothermal method (a solvothermal method). The synthesizing method is simple. The obtained graphene / manganous ferrite or graphene / nickel ferrite composite nanometer microspheres are high in specific surface area and have high magnetism; and by controlling the ratio of graphene oxide to manganous ferrite or the ratio of graphene oxide to nickel ferrite, it is guaranteed that the composite nanometer microspheres can achieve very good wave-absorbing properties. Prepared graphene / manganous ferrite and graphene / nickel ferrite nanocomposite materials not only have excellent electromagnetic loss performances, but also can serve as a light and high-strength wave-absorbing material to be applied to the fields of sewage treatment, energy, stealth and electronics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation of cobalt nickel ferrite/ polyvinyl pyrrolidone composite magnetic nano fibers

InactiveCN102251305ASolve the problem of uneven diameter distributionSimple processFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberElectrospinning

The invention relates to a preparation method of cobalt nickel ferrite / polyvinyl pyrrolidone (PVP) composite magnetic nano fibers. The preparation method comprises the following steps of: (1) preparing modified Co1-xNixFe2O4 nano particles; and (2) preparing PVP ethanol solution, uniformly dispersing the modified Co1-xNixFe2O4 nano particles obtained in the step (1) into the PVP ethanol solution, stirring the solution for 12 to 24 hours to obtain Co1-xNixFe2O4 / PVP mixed solution, and performing electrostatic spinning by using the Co1-xNixFe2O4 / PVP mixed solution as spinning stock solution to obtain the cobalt nickel ferrite / PVP composite magnetic nano fibers. The preparation method is simple, can effectively improve the dispersibility of the magnetic particles in the polymer solution,has low requirement for production equipment, and is easy to realize industrialized production; and the diameter of the prepared magnetic fibers is distributed uniformly and in a range of 300 to 500 nanometers, and the magnetic fibers have good magnetic performance.

Owner:DONGHUA UNIV

Nickel ferrite nano-particle electrode material, preparation method and use

InactiveCN106971855AImprove conductivityEasy insertion/extractionMaterial nanotechnologyHybrid capacitor electrodesNickel saltVacuum drying

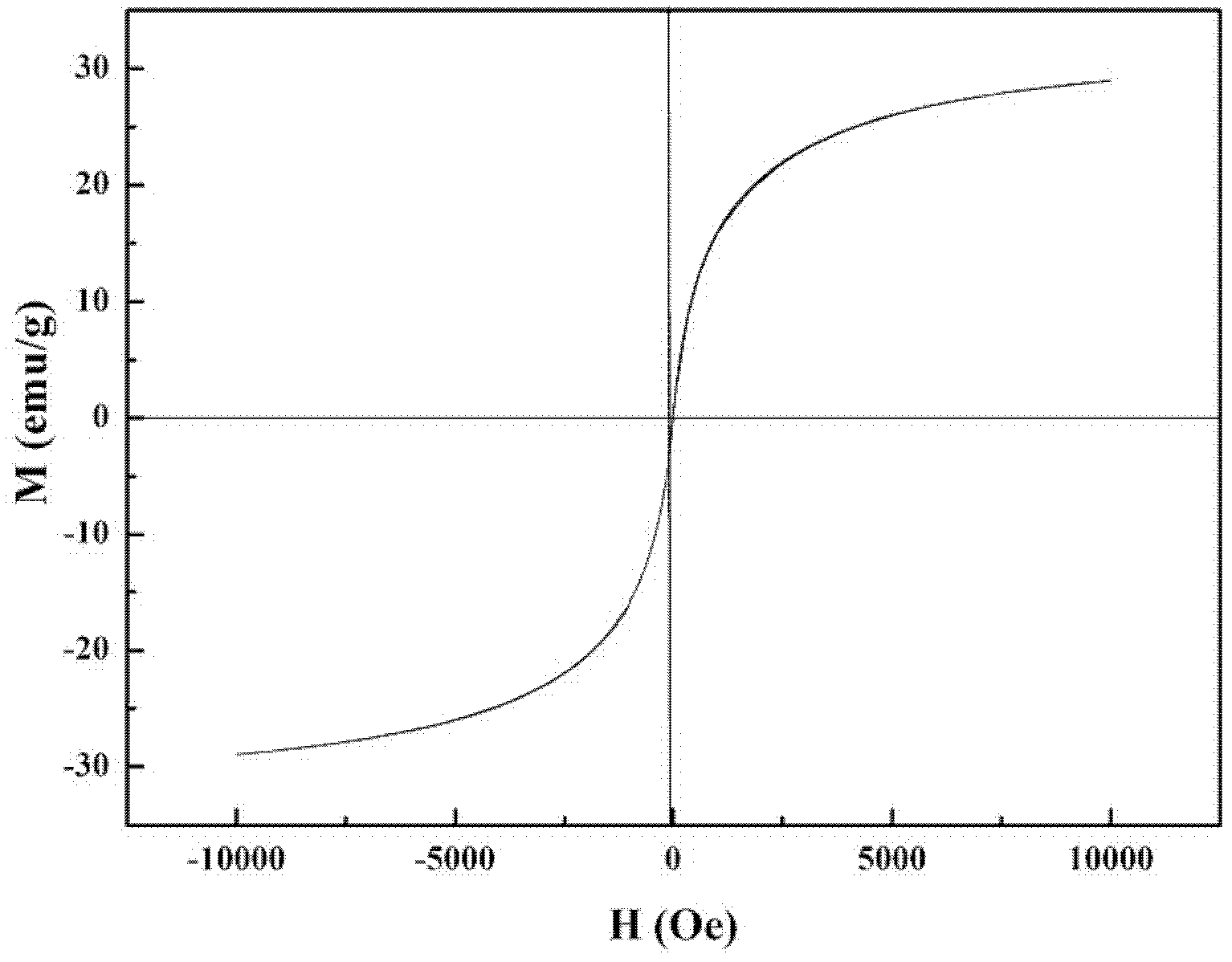

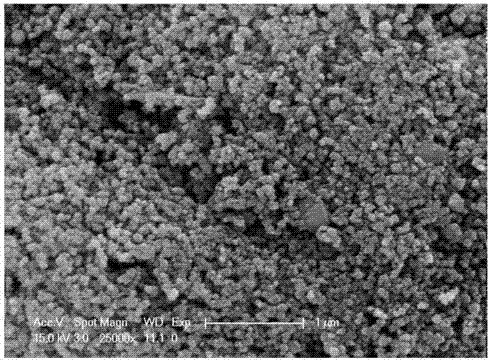

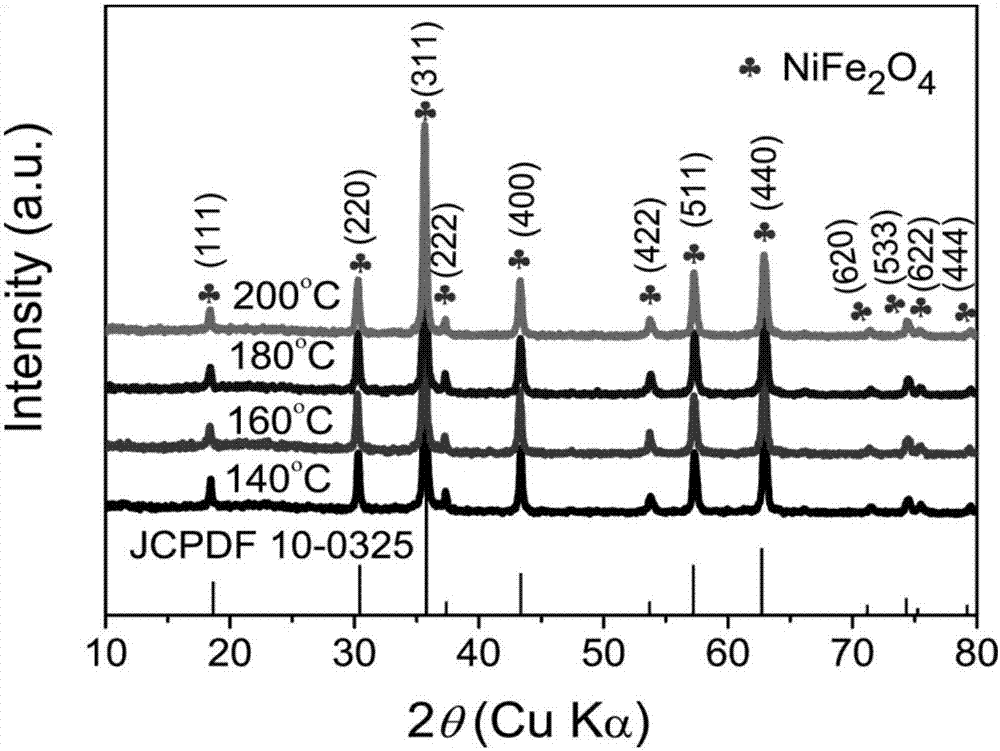

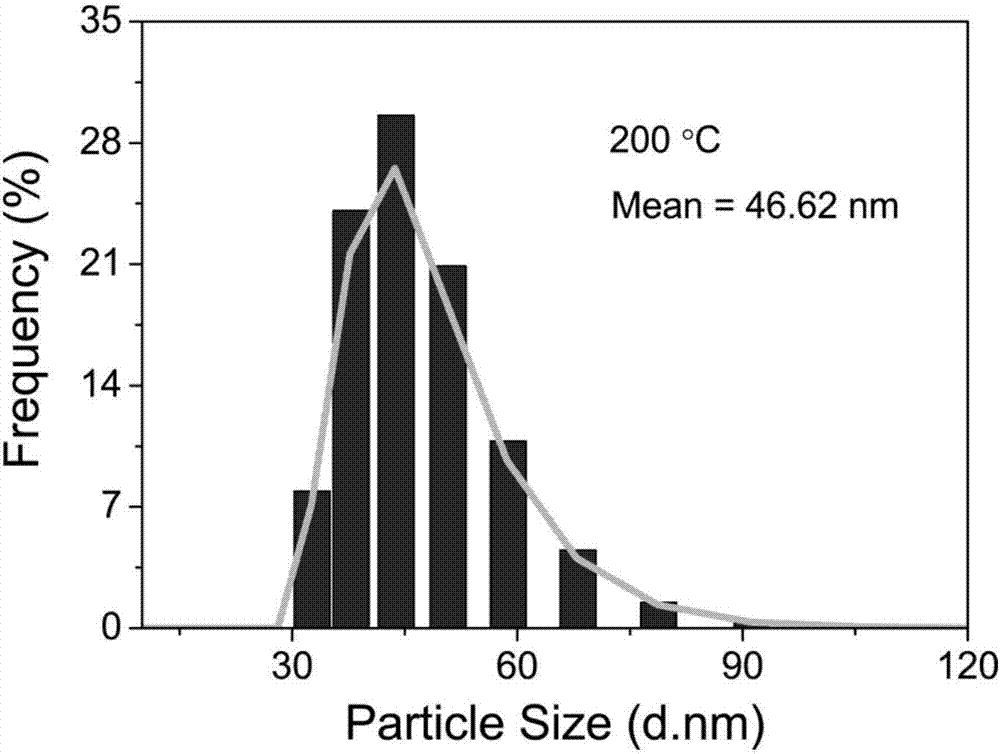

The invention provides a nickel ferrite nano-particle electrode material, a preparation method and use. The preparation method comprises steps of step 1, adding powder of nickel salt, ferric salt, hexamine and ammonium fluoride into distilled water, carrying out ultrasound and using a magnetic stirrer to stir to allow the obtained substance to be mixed uniformly so as to obtain a precursor solution for standby; and step 2, pouring the precursor solution obtained in the step 1 into a reaction kettle with a polytetrafluoroethylene substrate for sealing, arranging the reaction kettle in a drying oven, controlling the temperature of the drying oven to between 140 and 200 DEG C, carrying out a hydrothermal reaction, cooling to the room temperature, and carrying out cleaning and vacuum drying to obtain the nickel ferrite nano-particle electrode material. According to the invention, the simple method for preparing the nickel ferrite nano-particle electrode material by use of enriched sources and low cost raw materials is provided; and the prepared electrode material can be further used as the electrode material of a super capacitor.

Owner:JIANGSU UNIV

Preparation of titania coated nickel ferrite nanoparticles

A method for preparing composite nanoparticles comprised of a nickel ferrite core having a photocatalytic shell comprised of titania. The method is a combined reverse micelle plus chemical precipitation method that can be controlled to produce nanoparticles having a substantially uniform size and spherical shape.

Owner:UNIVERSITY OF LOUISIANA AT LAFAYETTE

Visible-light responsive magnetic photocatalytic material and preparation method thereof

The invention belongs to the technical field of preparation of photocatalytic materials and particularly relates to a visible-light responsive magnetic photocatalytic material and a preparation method thereof. The visible-light responsive magnetic photocatalytic material provided by the invention is formed by forming a heterojunction through loading nickel ferrite on the surface of bismuth oxide; the molecular formula is NiFe2O4 / Bi2O3 and the structural form is that nickel ferrite grains are compounded on the surface of the rod-shaped bismuth oxide. The visible-light responsive magnetic photocatalytic material provided by the invention has the good photocatalytic efficiency under the illumination of visible light; in the process of degrading tetracycline, the degradation efficiency is up to 90.78% when an optimal preparation condition is utilized; meanwhile, the separation of a catalyst and a reaction system is convenient to realize under an applied magnetic field, so that the visible-light responsive magnetic photocatalytic material has a good industrial application prospect.

Owner:JIANGSU UNIV

Water treatment nickel-based self-growing three-dimensional material and preparation method thereof

InactiveCN107308922AEasy to handleIncrease contact areaOther chemical processesWater contaminantsNickel saltIron salts

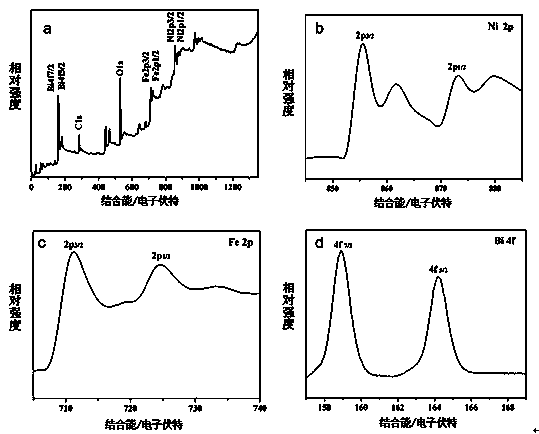

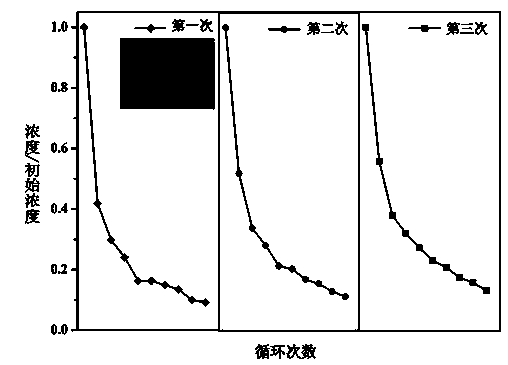

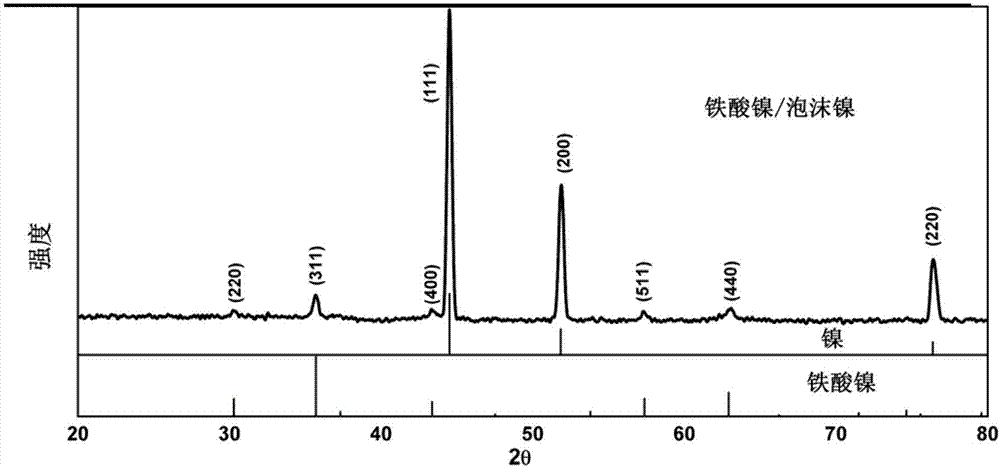

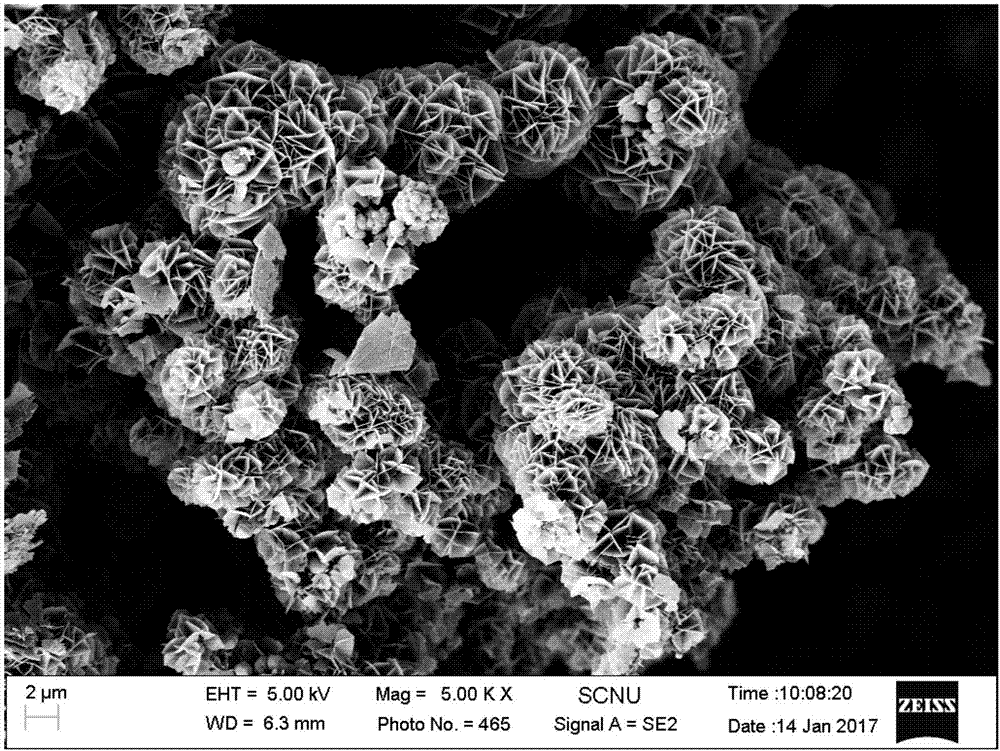

The invention discloses a water treatment nickel-based self-growing three-dimensional material and a preparation method thereof. The method includes the steps: (1) cleaning a metal substrate by surface treating agents to obtain a metal substrate I; (2) dissolving nickel salt and ferrous iron salt in solvents, adding precipitating agents and protective agents and uniformly stirring materials to obtain mixed solution; (3) pouring the mixed solution obtained in the step (2) into the metal substrate I obtained in the step (1), performing reaction under the condition of 110-130 DEG C, and then washing and drying precipitates to obtain a nickel ferrite / foam nickel composite precursor material; (4) calcining the nickel ferrite / foam nickel composite precursor material obtained in the step (3) to obtain the water treatment nickel-based self-growing three-dimensional material. The method is simple, easy, low in cost, green and environmentally friendly. The prepared nickel-based self-growing three-dimensional material is large in specific surface area, and organic dyestuff and heavy metal ions in sewage can be effectively removed.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Nickel ferrite based lithium-ion hybrid capacitor and preparation method thereof

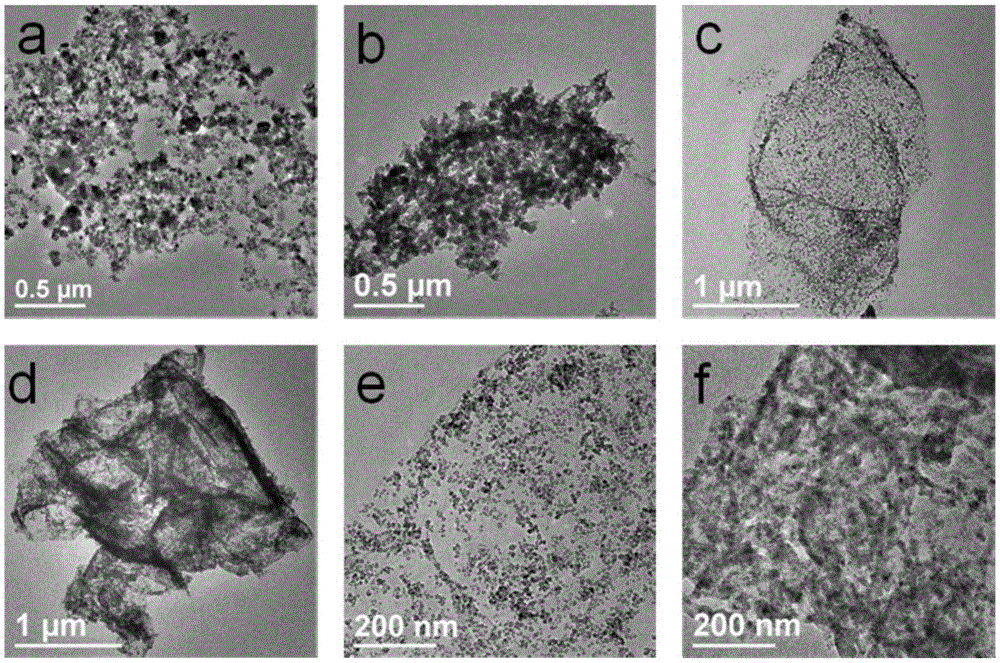

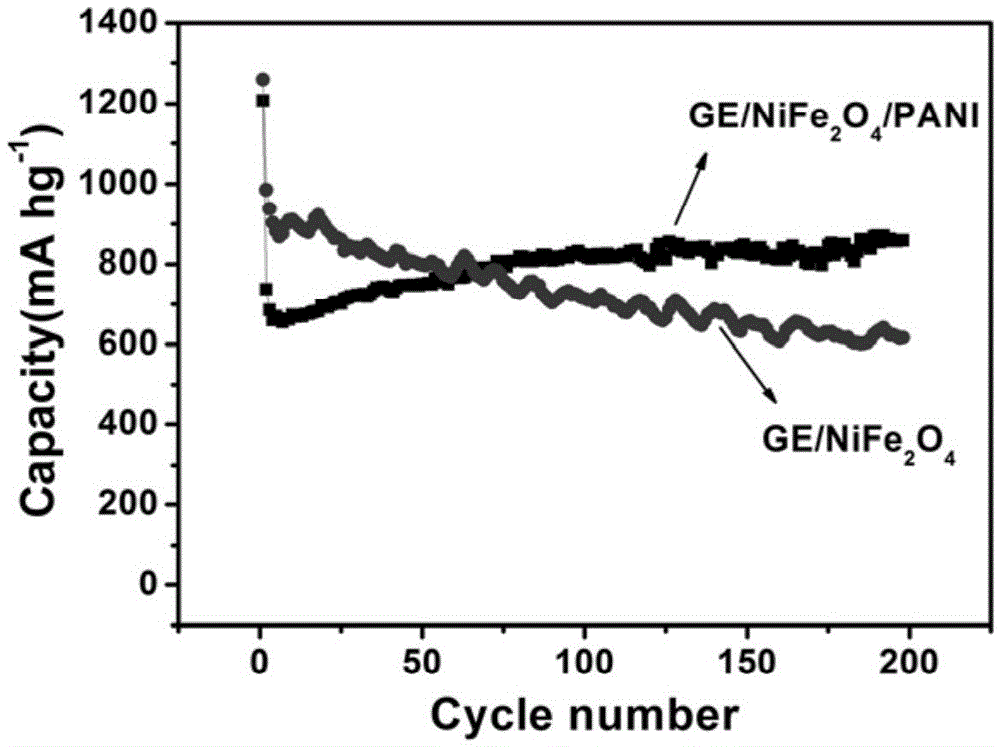

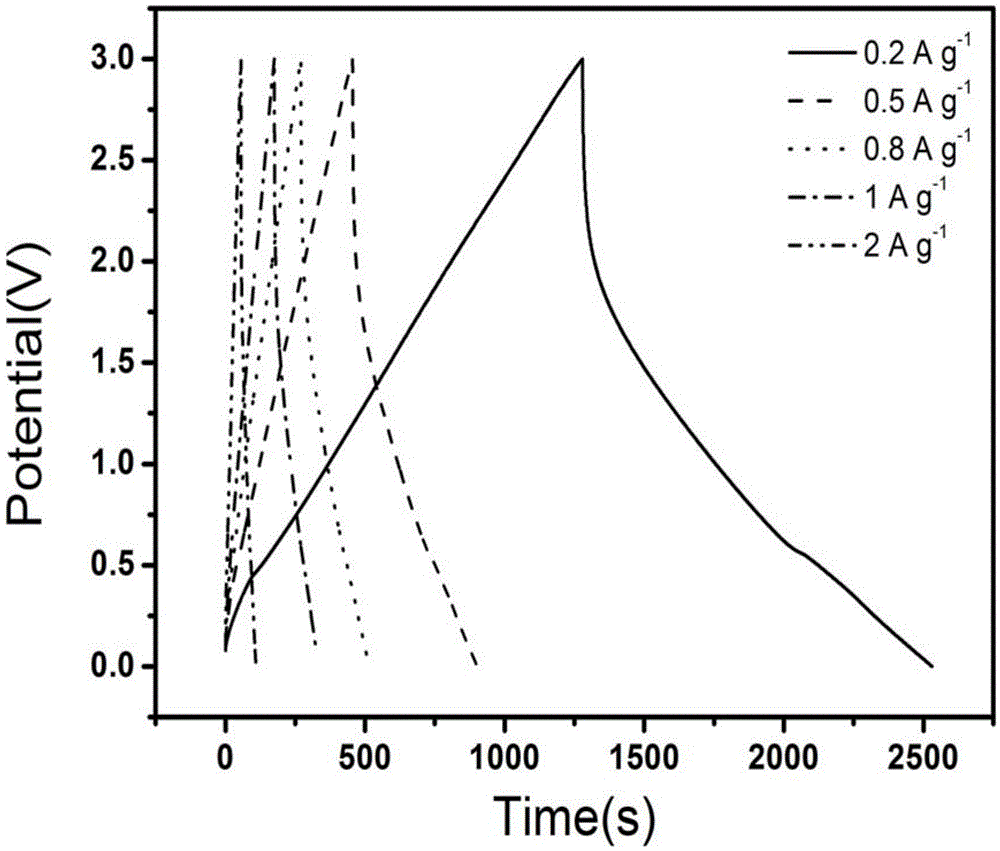

InactiveCN105679547AImprove cycle lifeIncrease capacityHybrid capacitor electrodesDouble layer capacitorsHigh energyIn situ polymerization

The invention discloses a nickel ferrite-based lithium ion hybrid capacitor and a preparation method thereof. The method uses a mixed material of activated carbon and graphene as the positive electrode material; disperses the carbon material with ethanol, dissolves iron nitrate, nickel nitrate and urea, and obtains a binary composite material precursor through solvothermal reaction, and in situ polymerizes aniline on the precursor to obtain iron A nickel-based ternary composite material is used as the negative electrode material and pre-intercalated with lithium; lithium hexafluorophosphate is used as the electrolyte to assemble a lithium-ion hybrid capacitor. The lithium-ion hybrid capacitor negative electrode material prepared by the invention has a stable structure, a simple preparation method, no need for high-energy consumption follow-up treatment such as high-temperature calcination, high capacity, small internal resistance, and good cycle stability. The lithium-ion hybrid capacitor prepared by the invention has excellent performance, a large operating voltage range, high energy density and power density, and broad application prospects.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of ultrathin paper-base wave-absorbing material

InactiveCN107418512AGood absorbencyImprove smoothnessOther chemical processesFiberSecondary emission

Owner:赵顺全

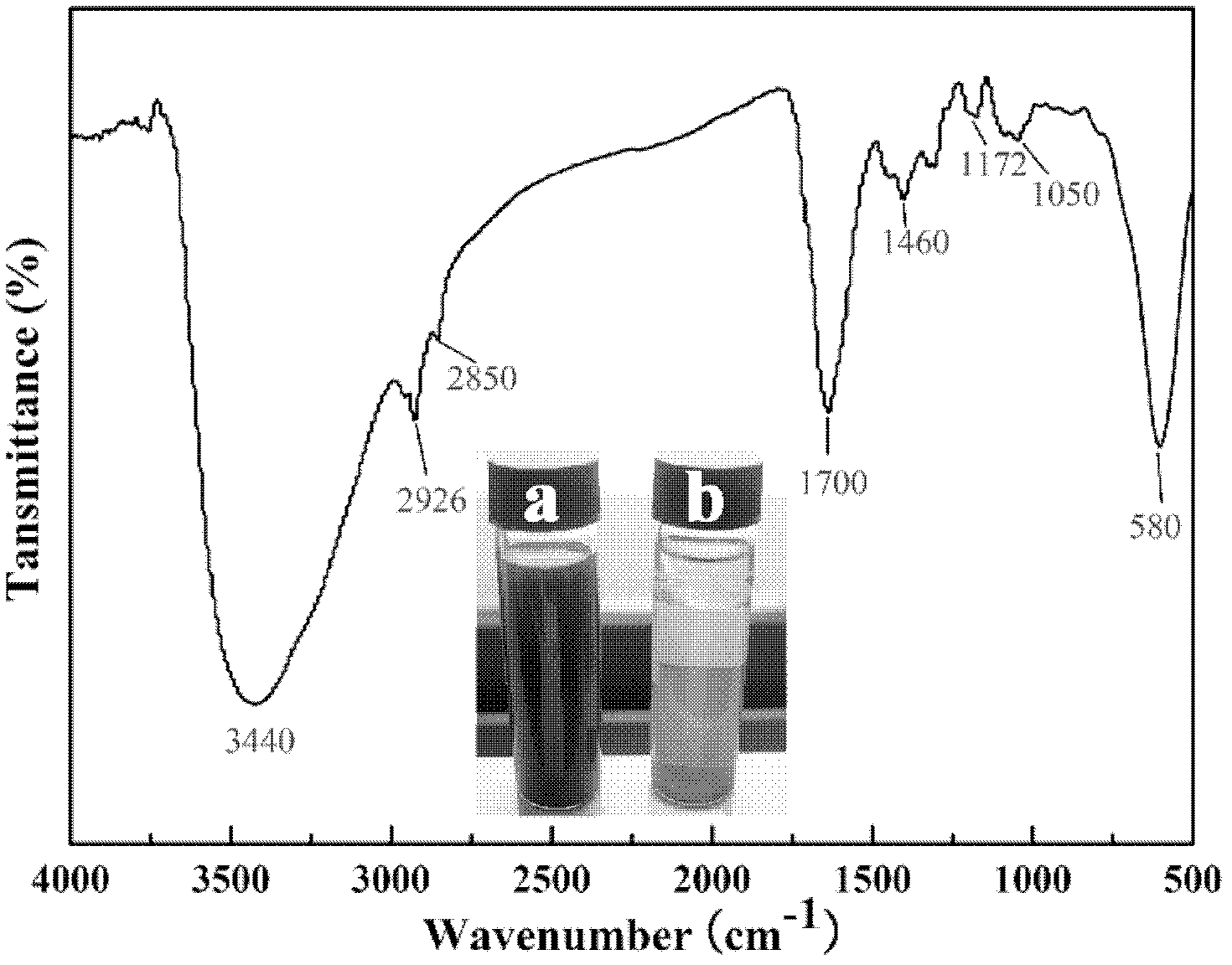

Magnetic reduction graphene oxide nano composite material and preparation method and application thereof

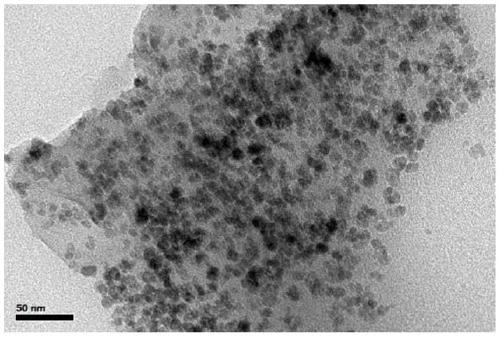

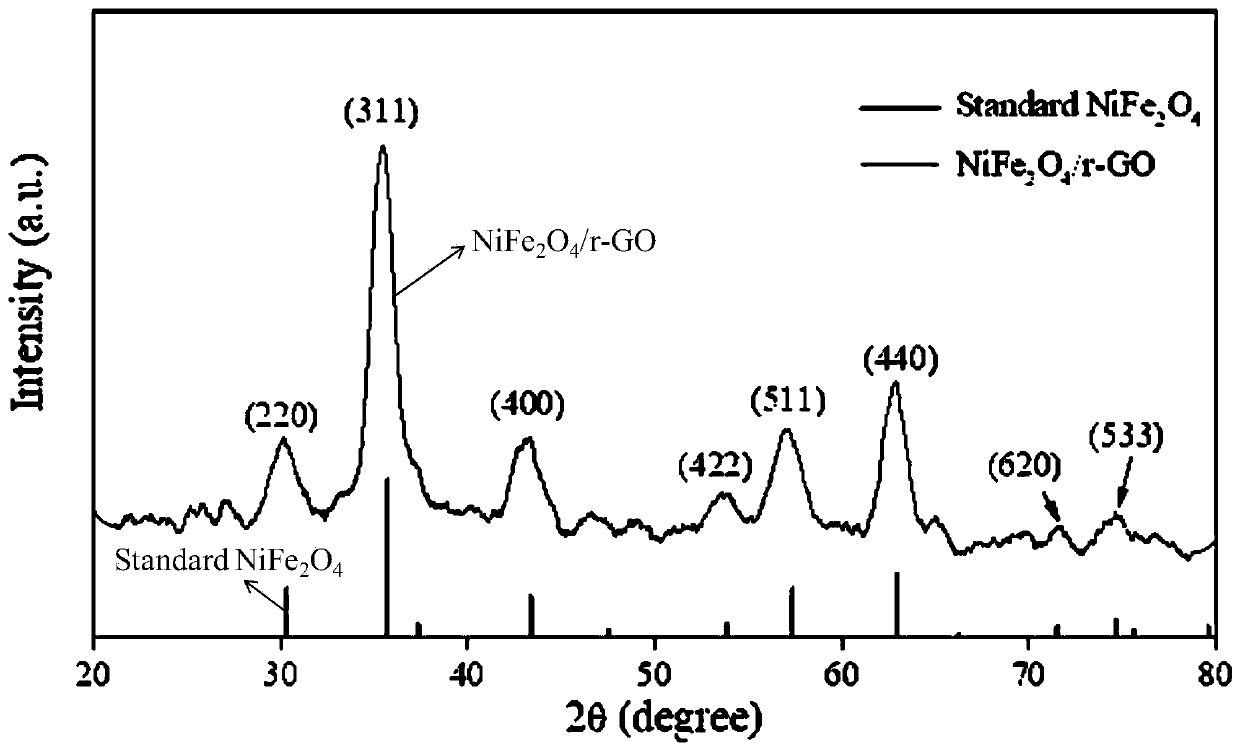

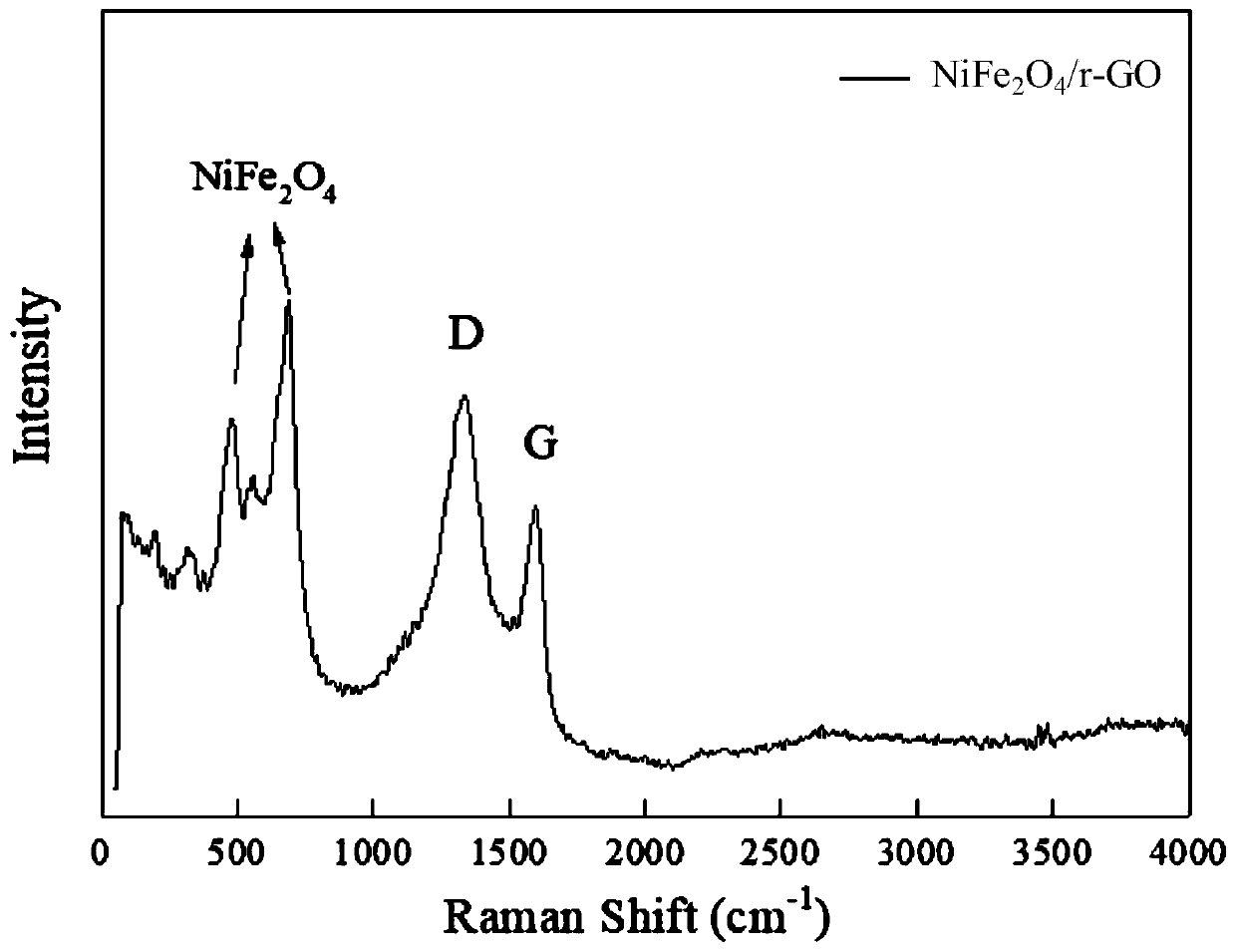

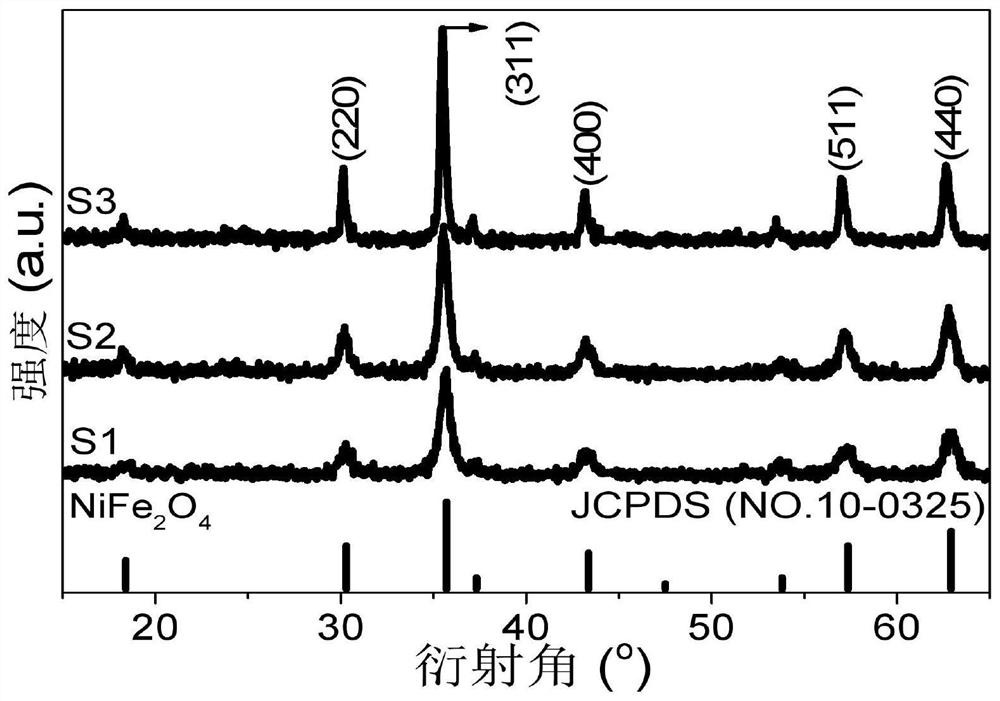

InactiveCN109896520AImprove microwave absorption performanceSolve reunionMagnetic/electric field screeningGrapheneNickel saltIron salts

The invention relates to a magnetic reduction graphene oxide nano composite material and a preparation method and application thereof. The nano composite material comprises reduced graphene oxide andmagnetic nickel ferrite nanocrystalline with the average particle diameter of 6-12 nm uniformly deposited on the surface of the reduced graphene oxide. The method comprises the following steps: uniformly dispersing graphene oxide with deionized water to obtain graphene oxide dispersion liquid; adding divalent nickel salt and trivalent iron salt into the graphene oxide dispersion liquid, and uniformly stirring to obtain a first mixed solution; adding ammonia water into the first mixed solution to adjust the first mixed solution to be alkaline to obtain a second mixed solution; and carrying outhydrothermal treatment on the second mixed solution to obtain the nano composite material. The nano composite material has strong absorption strength, wide absorption bandwidth and double-band microwave absorption performance. The process is simple and convenient, the agglomeration problem of reduced graphene oxide and magnetic small-size nanocrystals can be avoided, and the microwave absorption performance and the effective absorption bandwidth of the composite material are improved.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

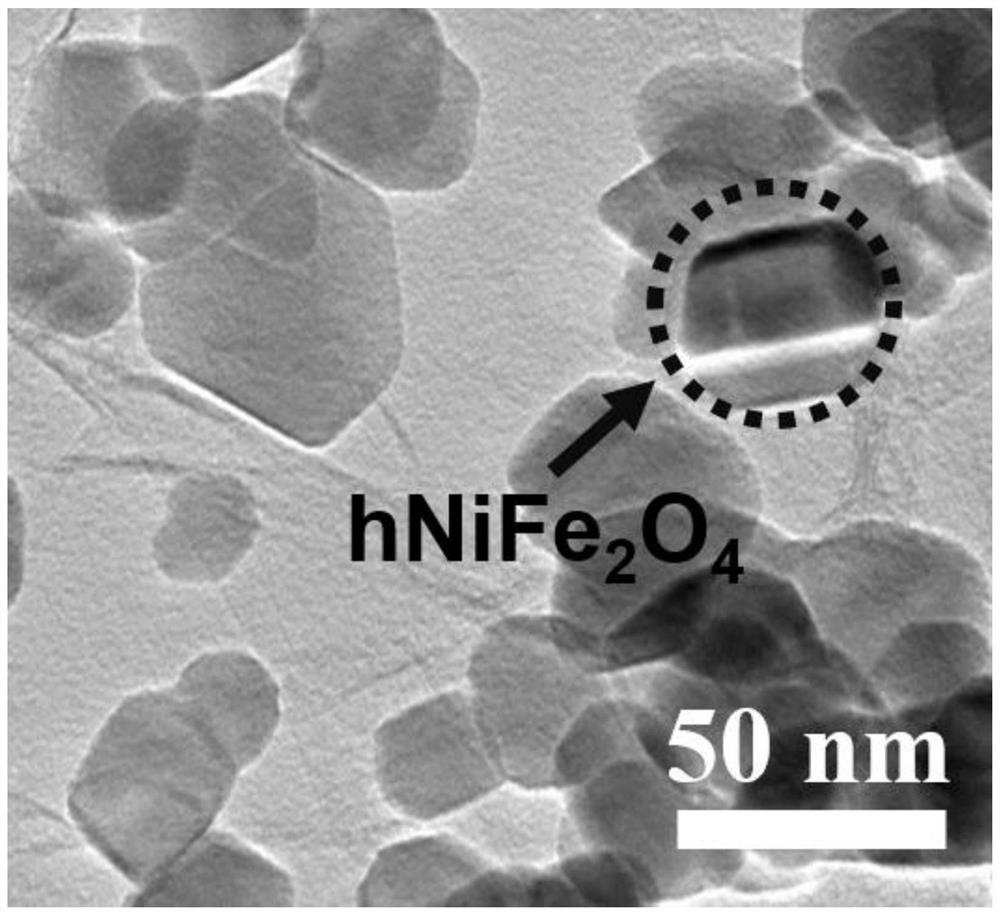

Nitrogen-doped graphene nickel ferrite composite wave-absorbing material and preparation method thereof

ActiveCN112375541AThe reaction method is simpleMaterials are readily availableOther chemical processesDoped grapheneElectromagnetic shielding

The invention discloses a nitrogen-doped graphene nickel ferrite composite wave-absorbing material and a preparation method thereof. A nitrogen-doped reduced graphene oxide / hexagonal nickel ferrite nano composite material is prepared by taking graphene oxide (GO) as a template, taking ferric nitrate nonahydrate and nickel nitrate hexahydrate as precursors and taking hydrazine hydrate as a nitrogen-doped reagent through a simple one-step hydrothermal method. The nano composite material prepared by the invention is formed by entangling a large number of hexagonal nickel ferrite particles in nanosize by two-dimensional folded graphene, has strong electromagnetic wave absorption capability, wide absorption frequency band and small matching thickness, and can generate double absorption peaks at low frequency (3-6GHz) and high frequency (12-18GHz); and the nitrogen doping amount of graphene in the composite material can be changed by controlling the adding volume of hydrazine hydrate, meanwhile, effective attenuation of the composite material to electromagnetic waves under different wave bands can be achieved by changing the matching thickness, and the composite material has important application value in the fields of electromagnetic wave absorption and electromagnetic shielding.

Owner:安徽理工大学环境友好材料与职业健康研究院(芜湖)

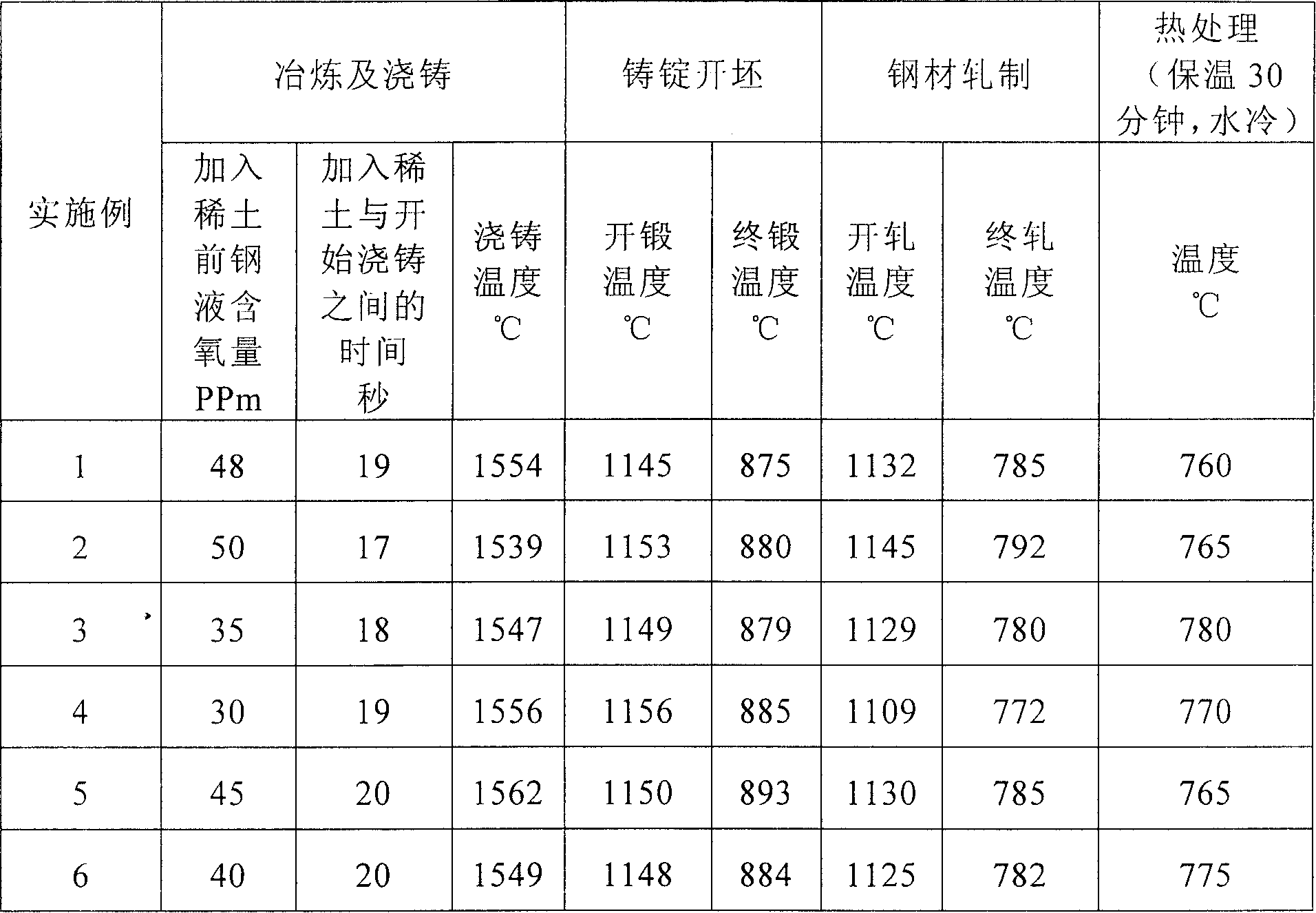

High ductility nickel-free ferrite stainless steel and manufacturing method thereof

InactiveCN101168822AImprove performanceImprove impact toughnessTemperature control deviceMetal rolling arrangementsRare earthPrice ratio

The invention relates to a high tenacity non-nickel ferrite stainless steel. The components has the mass percentage that: C occupies 0.03 to 0.08 percent, Si is lower than or equal to 1.0 percent, Mn is lower than or equal to 1.0 percent , S is lower than or equal to 0.030 percent , P is lower than or equal to 0.035 percent, Cr occupies 16 to 21 percent, N occupies 0.01 to 0.03 percent, is lower than or equal to 0.0050 percent, rear earth RE occupies 0.02 to 0.1 percent, and the residual is Fe and inevitable foreign impurities. The utility model provides a manufacture method that: firstly, smelting and casting are performed, the time between the adding of rear earth metal and the steel casting is strictly controlled to be lower than or equal to 25 seconds; the casting temperature is controlled at 1550 plus or minus 5 DEG C; secondly, casting ingot or casting blank cogging is performed, the casting ingot or the casting blank can adopt forging cogging or continuous casting continuous rolling, the heating temperature of the casting ingot or the casting blank is 1150 plus or minus 10 DEG C, and the final forging temperature is not lower than 900 DEG C, and the casting ingot or the casting blank is performed with water cooling. thirdly, steel material rolling is performed, the heating temperature is 1160 plus or minus 10 DEG C, the rolling starting temperature is controlled between 1100 to 1150 DEG C, and the final rolling temperature is controlled to be lower than or equal to 800 DEG C, and the casting ingot or the casting blank is performed air cooling; finally, heat treatment is performed. The invention can obviously lengthen the service life under the low temperature condition, and compared with ultra low carbon and nitrogen and nickel-bearing ferrite stainless steel, the performance-price ratio is high.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com