Nickel ferrite based lithium-ion hybrid capacitor and preparation method thereof

A hybrid capacitor, nickel ferrite-based technology, applied in the direction of hybrid capacitors, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems that are not suitable for large-scale industrial production, large energy consumption, cumbersome steps, etc. Achieve the effect of low production cost, high energy density and power density, simple and safe method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

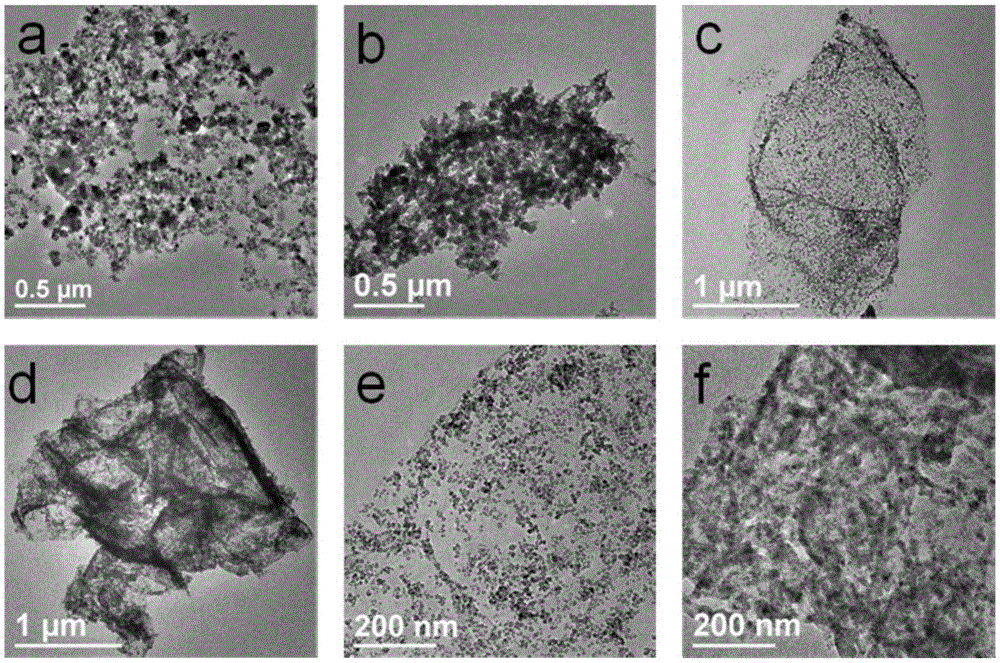

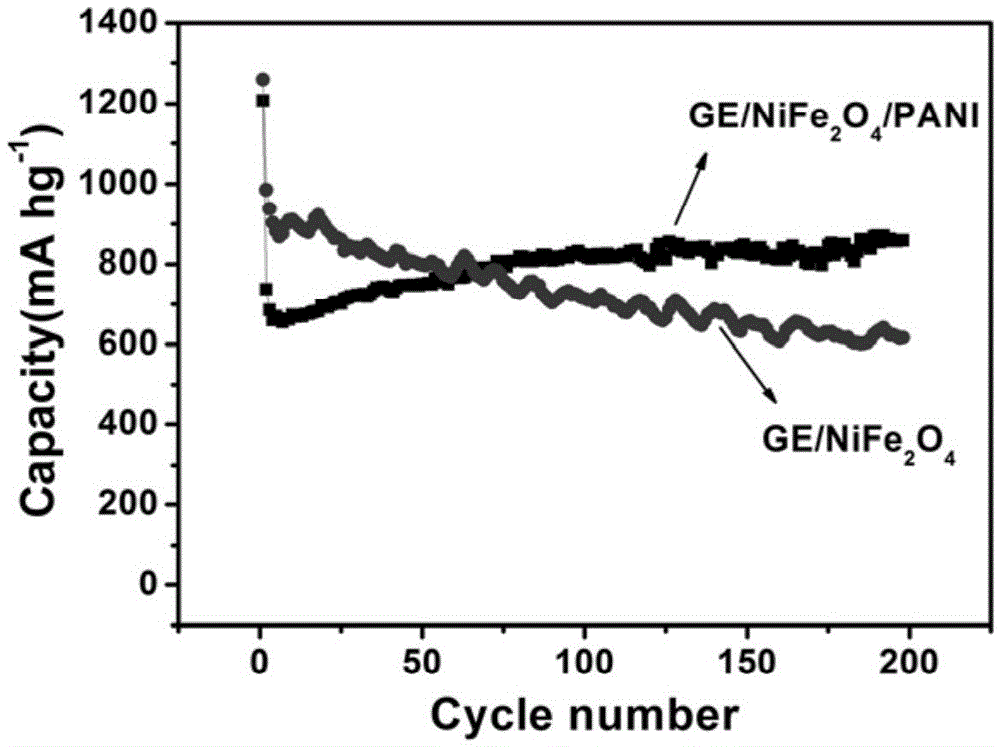

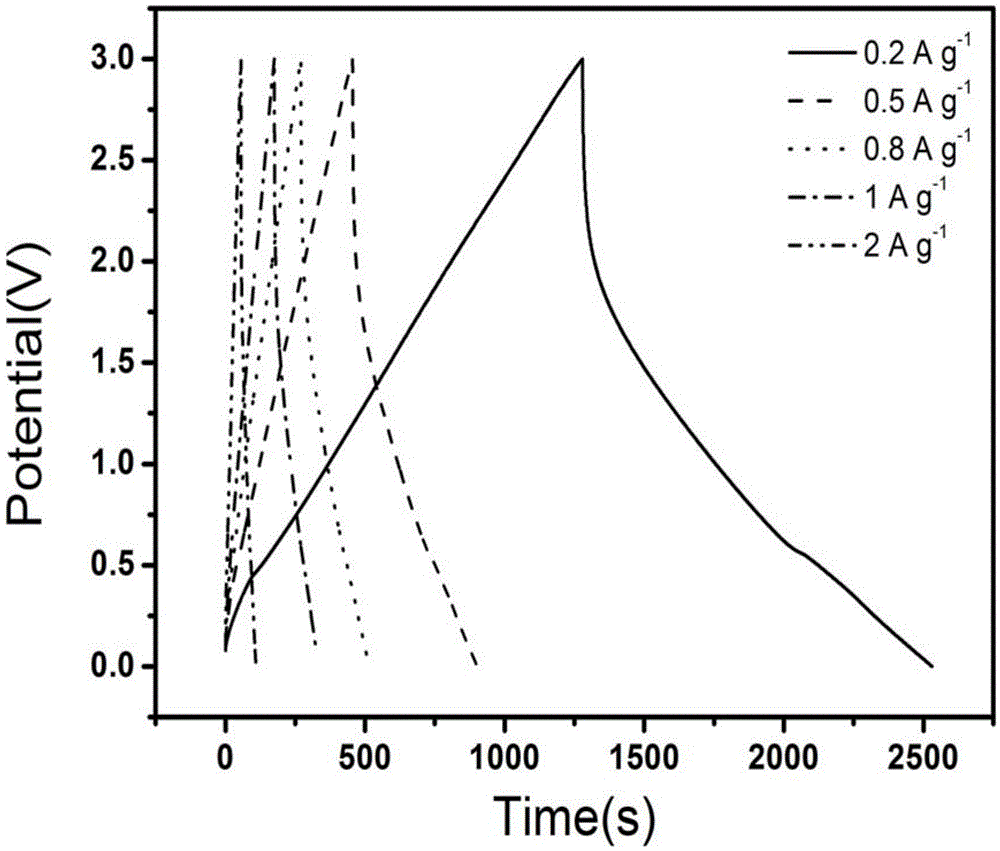

Embodiment 1

[0031] The activated carbon and graphene are mixed in a mass ratio of 98:2 to obtain a positive electrode material. The positive electrode material, conductive carbon black, and polyvinylidene fluoride were slurried in a mass ratio of 8:1:1, coated on aluminum foil, and dried as a positive electrode; weigh 0.37g nickel nitrate and 1.04g iron nitrate in turn, Dissolve in 10mL ethanol, add to 50mL 1mgmL that has been ultrasonically peeled for 2h -1 Add 0.5g of urea to the ethanol suspension of activated carbon and react at 180℃ for 18h. After the reaction, use deionized water and ethanol to wash by centrifugation. Then take 100mg of the product from the previous step and disperse it in 200mL of ethanol. Add 200μL of aniline monomer After stirring, add 0.18 mL of hydrochloric acid and 490 mg of ammonium persulfate, react for 9 hours in an ice bath, centrifuge, wash, and dry to obtain a nickel ferrite-based ternary composite material to obtain a negative electrode material. It is s...

Embodiment 2

[0034] The activated carbon and graphene are mixed in a mass ratio of 90:10 to obtain a positive electrode material. The positive electrode material, conductive carbon black, and polyvinylidene fluoride were slurried in a mass ratio of 8:1:1, coated on aluminum foil, and dried as a positive electrode; weigh 0.37g nickel nitrate and 1.04g iron nitrate in turn, Dissolve in 10mL ethanol, add to 50mL 3mgmL that has been ultrasonically peeled for 2h -1 Add 5g of urea to the ethanol suspension of graphite oxide, and react at 180℃ for 24h. After the reaction, wash with deionized water and ethanol by centrifugation. Then take 100mg of the product from the previous step and disperse it in 50mL of ethanol. Add 100μL of aniline monomer After stirring, add 0.09mL hydrochloric acid and 245mg ammonium persulfate, react for 15h in an ice bath, centrifuge, wash, and dry to obtain a nickel ferrite-based multi-element composite material. It is slurried with conductive carbon black and polyvinyli...

Embodiment 3

[0038] The activated carbon and graphene are mixed in a mass ratio of 95:5 to obtain a positive electrode material. The positive electrode material, conductive carbon black, and polyvinylidene fluoride were slurried in a mass ratio of 8:1:1, coated on aluminum foil, and dried as a positive electrode; weigh 0.37g nickel nitrate and 1.04g iron nitrate in turn, Dissolve in 10ml of ethanol, add to 50ml of 2mgmL that has been ultrasonically peeled for 2h -1 Add 2.5g of urea to the graphene oxide suspension and react at 180°C for 20 hours. After the reaction, use deionized water and ethanol to wash by centrifugation. Then take 100mg of the product from the previous step and disperse it in 100mL of ethanol. Add 50μL of aniline monomer. After stirring, add 0.045mL hydrochloric acid and 126mg ammonium persulfate, react for 12h in an ice bath, centrifuge, wash, and dry to obtain a nickel ferrite-based multi-element composite material. It is slurried with conductive carbon black and polyv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com