Patents

Literature

224results about How to "Reduce interfacial energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

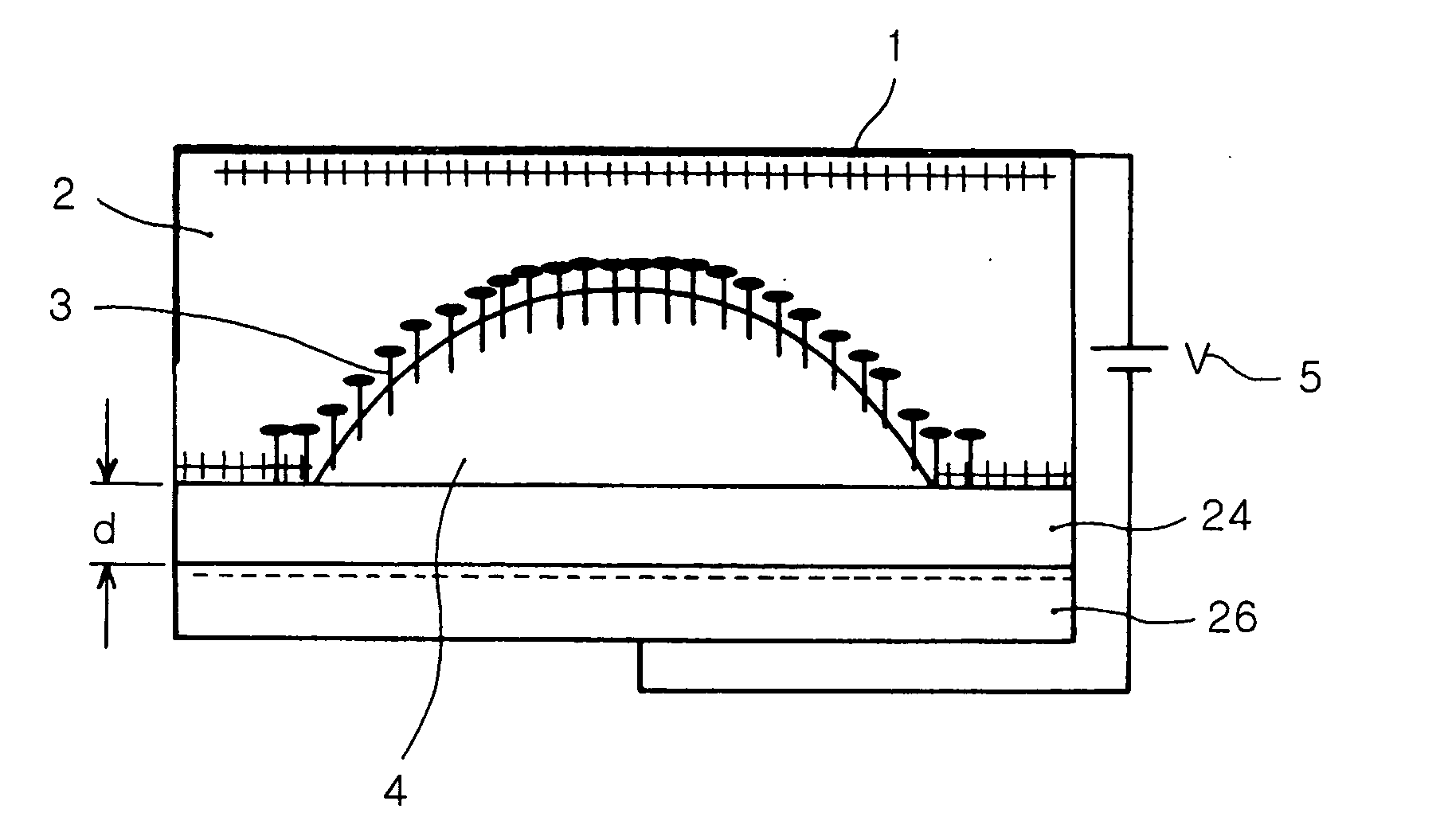

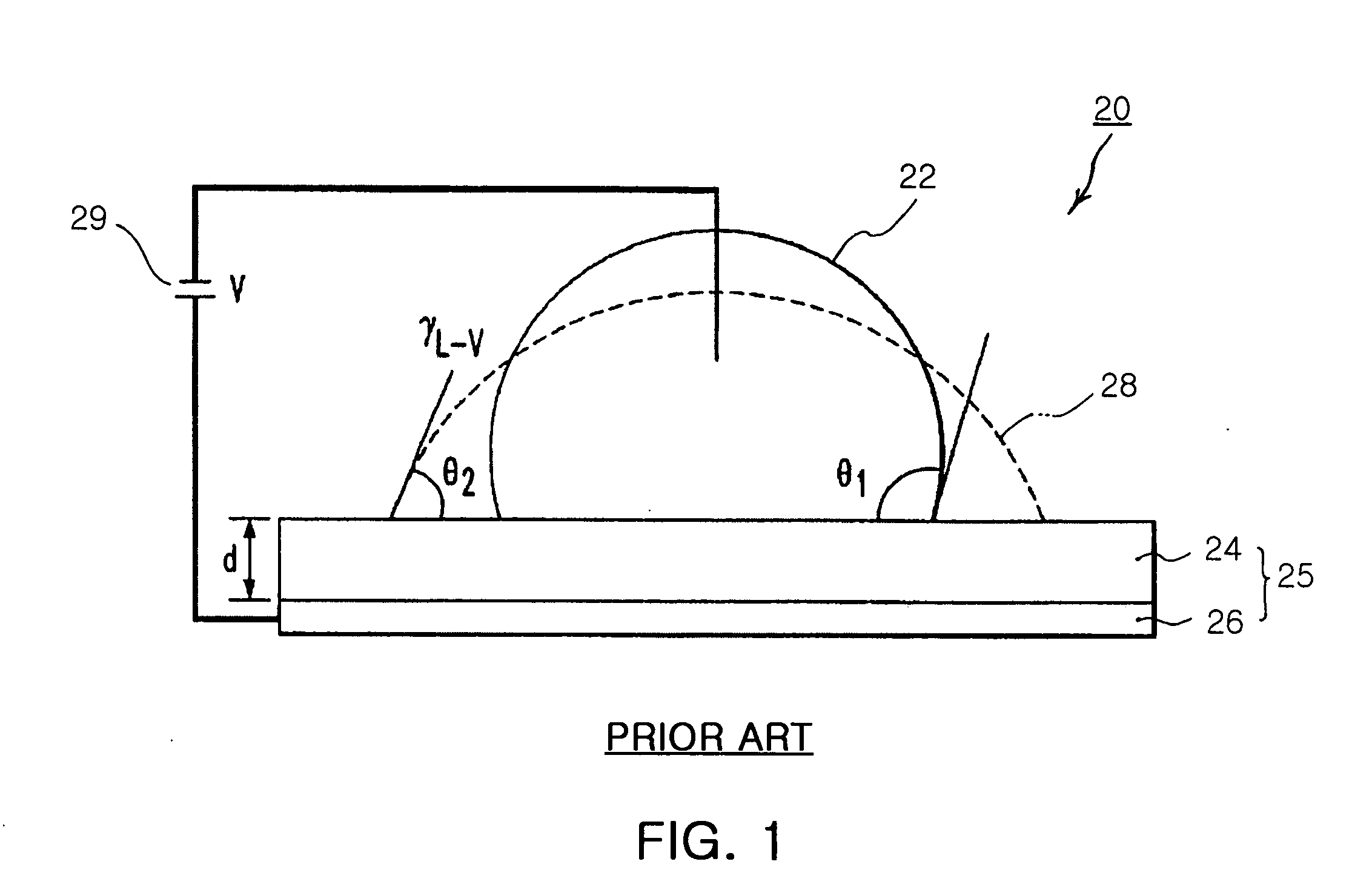

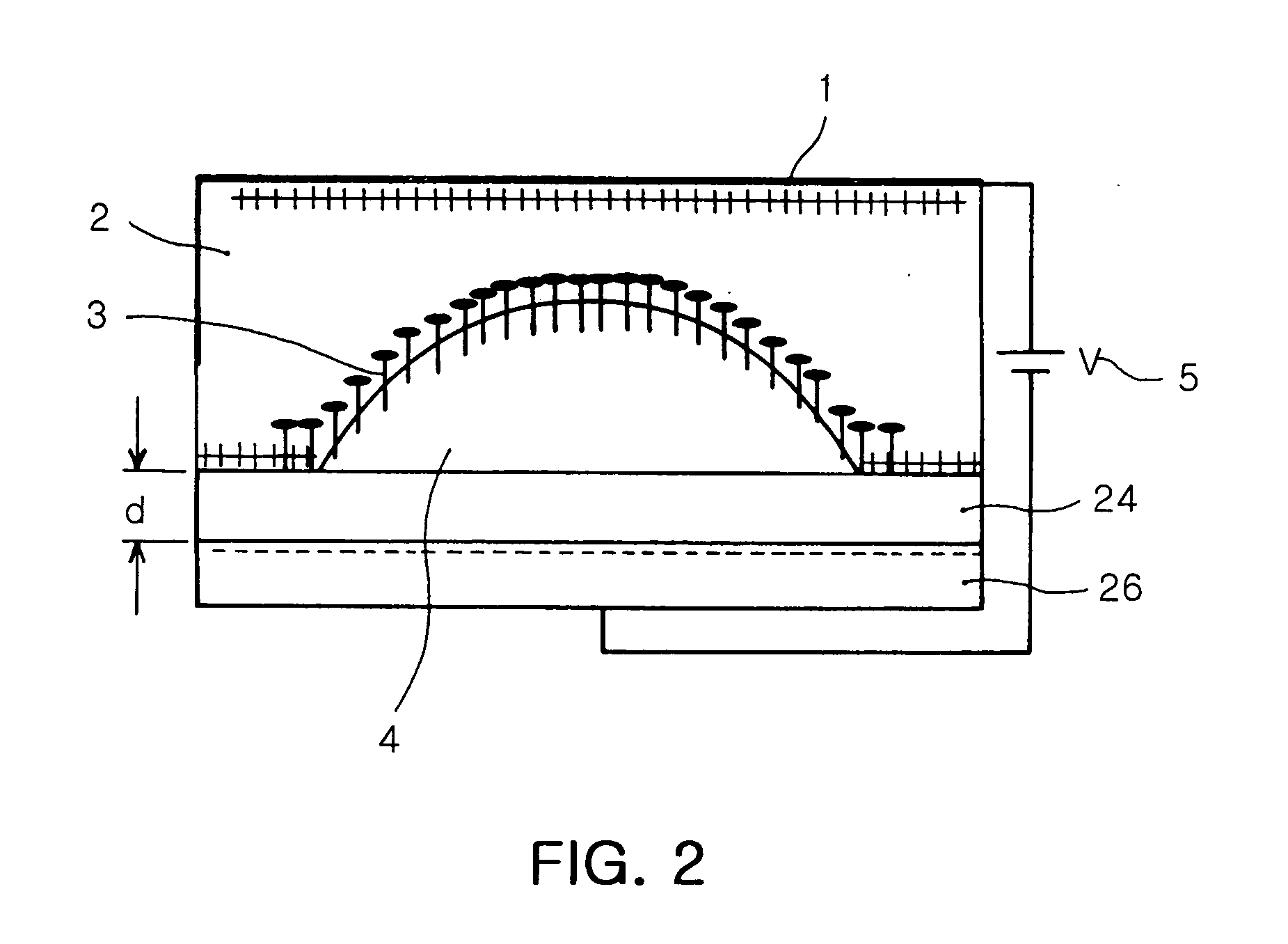

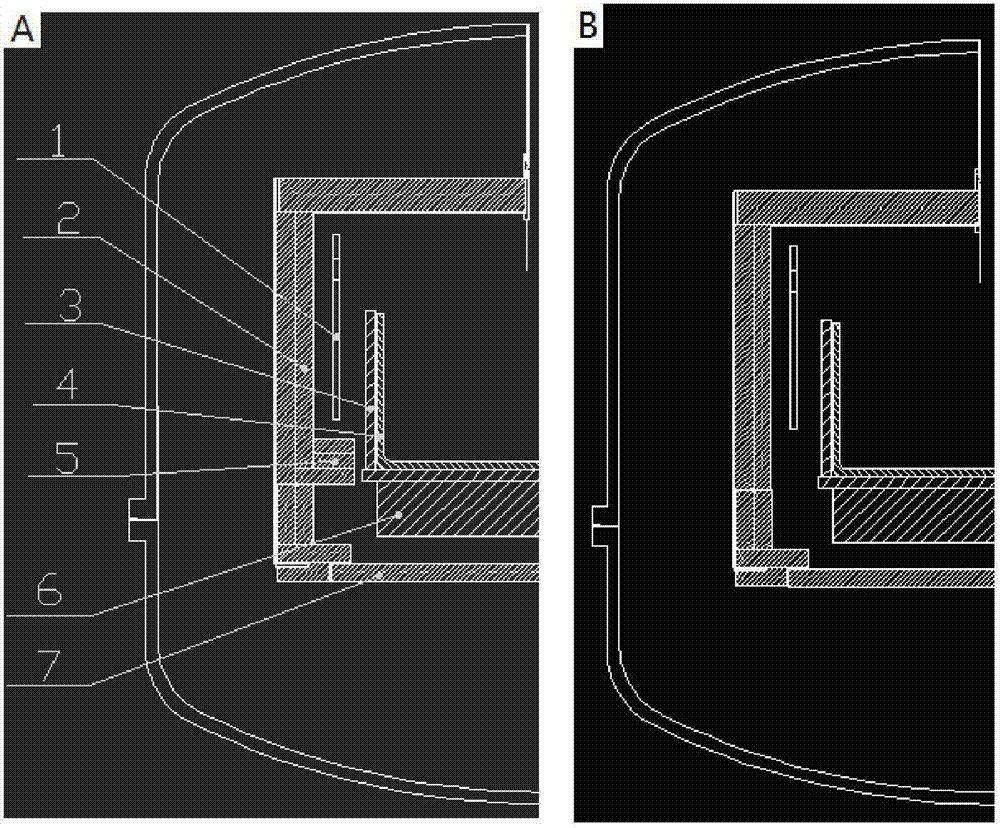

Variable focus liquid lens with reduced driving voltage

ActiveUS20060151754A1Reliability be ensureLow driving voltageConductive materialOrganic conductorsChemistryVoltage

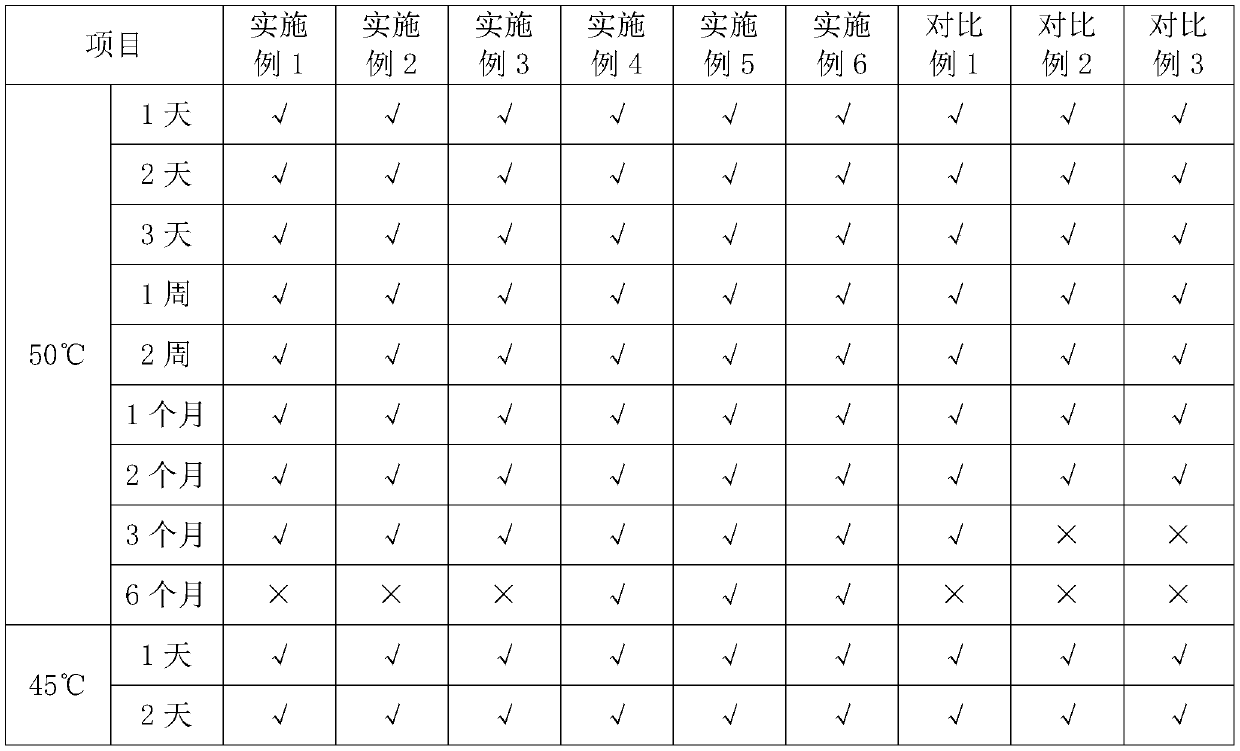

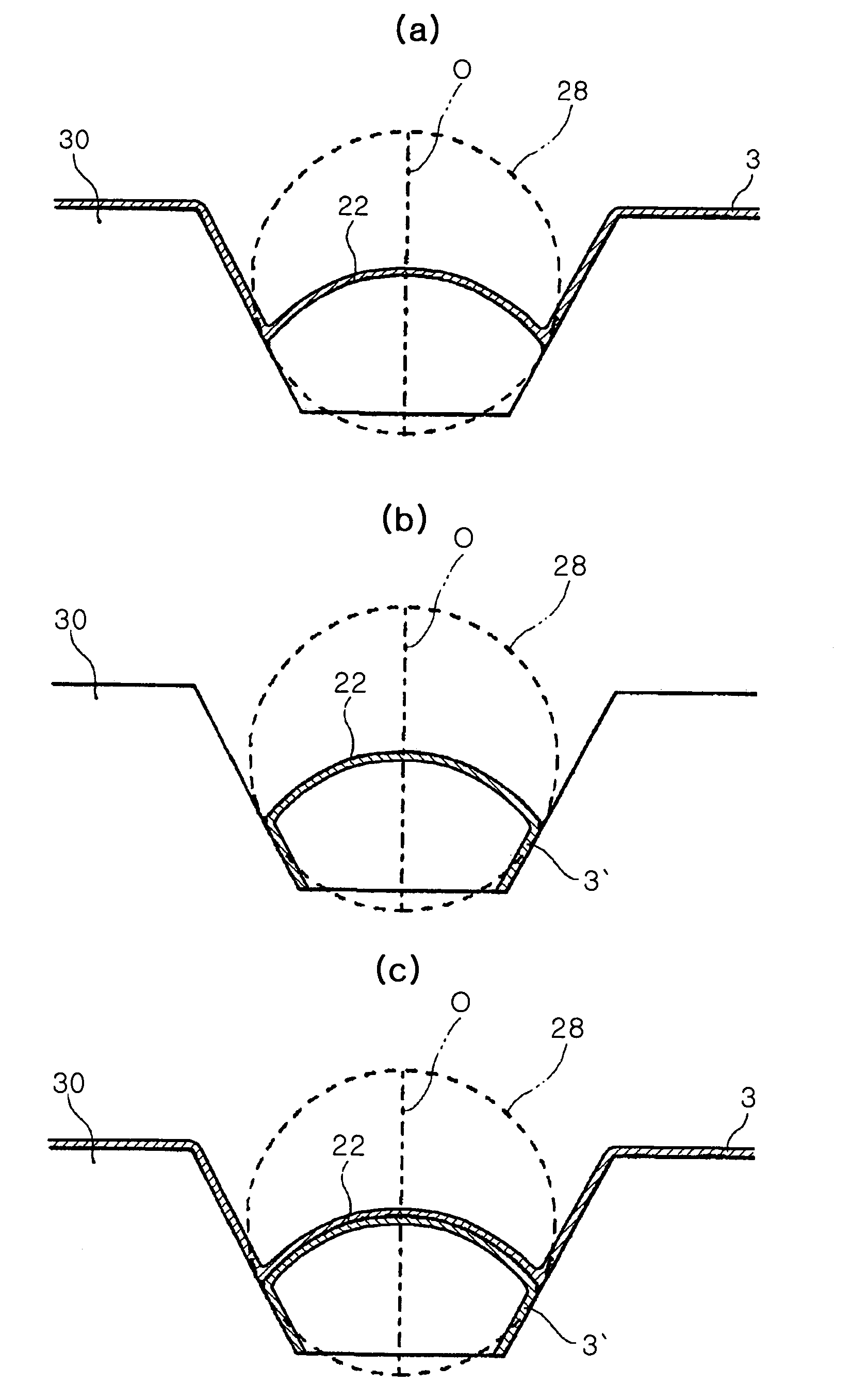

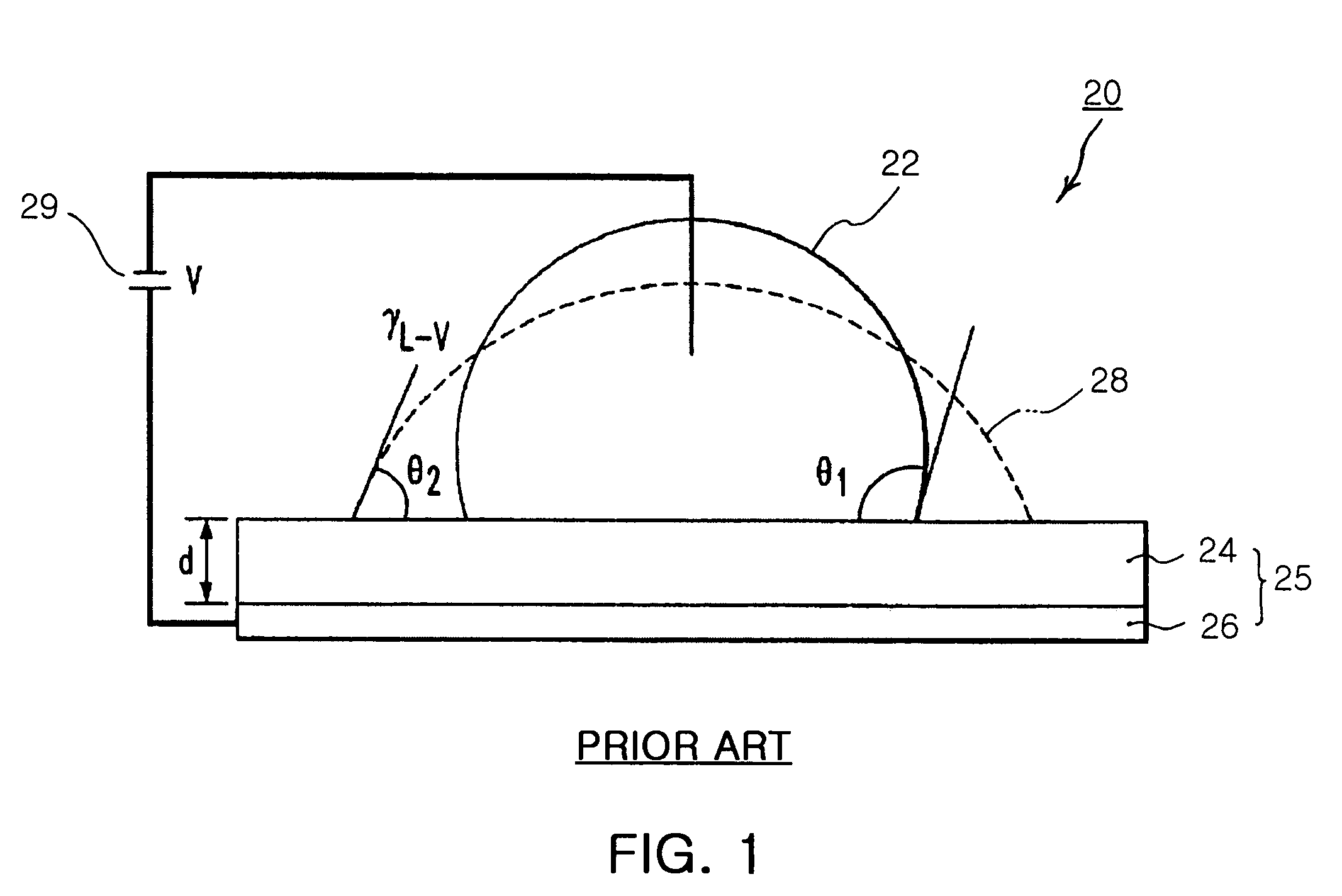

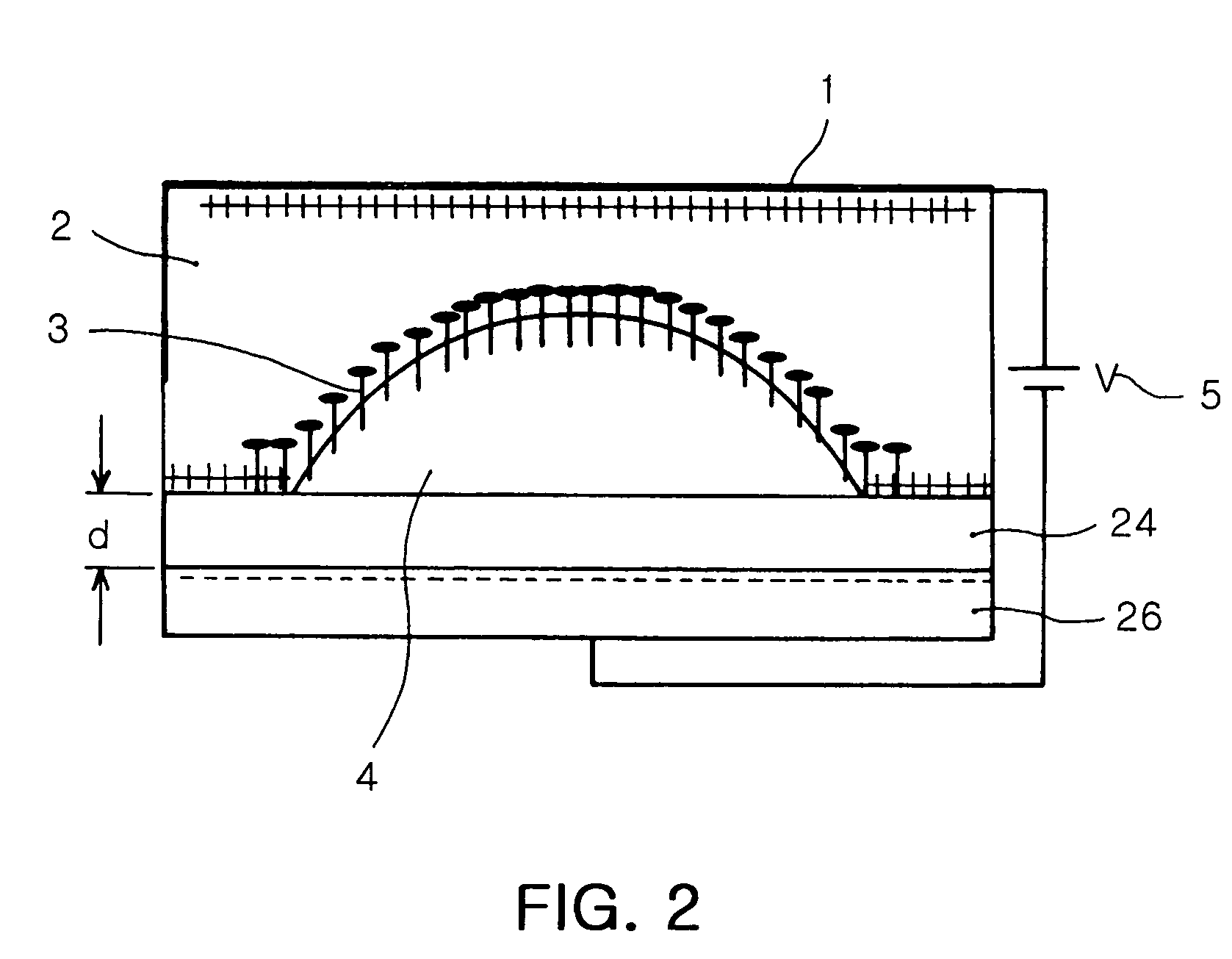

The invention provides a variable focus liquid lens using electrowetting, comprising a conductive first liquid and an insulating second liquid. At least one of the first liquid composed of electrolyte and the second liquid composed of insulating liquid contains a surfactant for reducing interfacial energy between the first and second liquids. An interfacial portion between the first and second liquids is gathered by surfactant to reduce driving voltage. The variable focus liquid lens according to the invention has about 50% lower driving voltage required for changing focus, ensuring stability of the two fluids.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

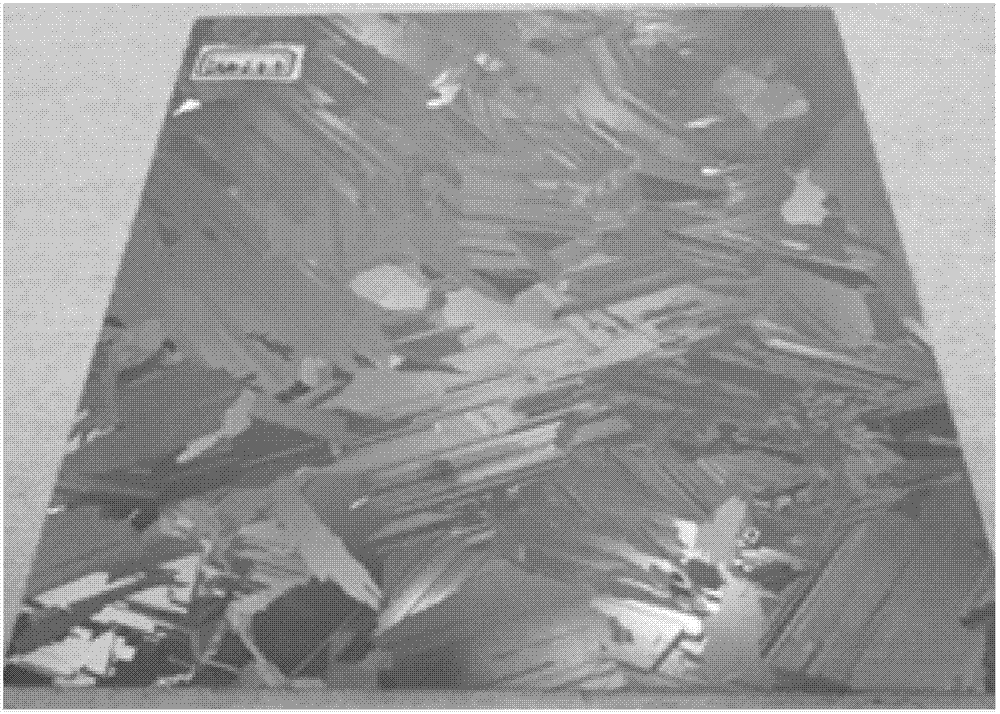

Preparation method of polycrystalline silicon

ActiveCN103469293AEasy to operateGuaranteed not to be completely meltedPolycrystalline material growthFrom frozen solutionsThermal insulationPhysical chemistry

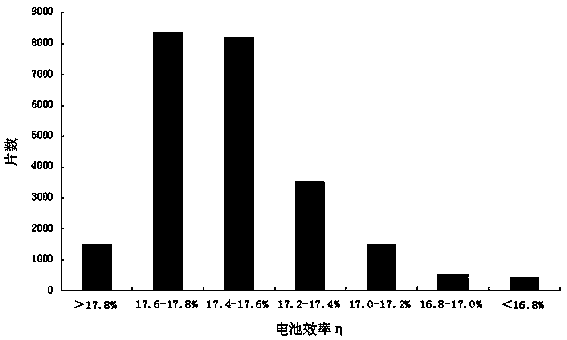

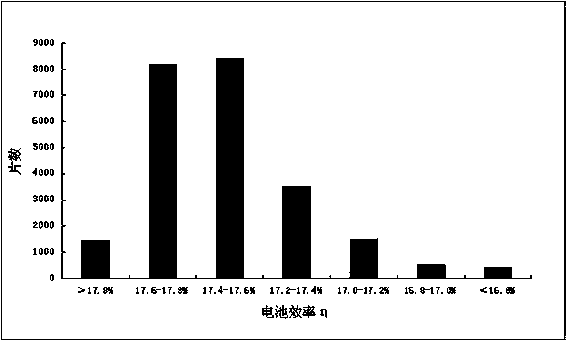

The invention discloses a preparation method of polycrystalline silicon. The preparation method of the polycrystalline silicon comprises the following steps: firstly carrying out pre-treatment on a quartz crucible, then paving a crystalline silicon chip material layer at the bottom of the quartz crucible, then placing silicon and mother alloy into the quartz crucible, charging, vacuumizing, and heating to melt silicon; after melting is finished, controlling the temperature of a heater to be 1540-1570 DEG C, lifting a thermal insulation cage until aperture a is 5-20mm, and controlling temperature TC2 to be no more than 1425 DEG C until broken polycrystals at the bottom are just molten, performing a temperature-fall period, and slowly opening the thermal insulation cage while slowly cooling in gradient; finally growing crystals, so that the polycrystalline silicon containing massive twin crystals is formed. A polycrystalline silicon slice prepared by adopting the preparation method is uniform in grain size, the battery efficiency is 0.2-0.3% higher than that of common polycrystalline silicon, the average battery efficiency of the whole silicon slice is more than 17.5%, and ratio of the silicon slice with the efficiency more than 17.4% is more than 65.0%.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

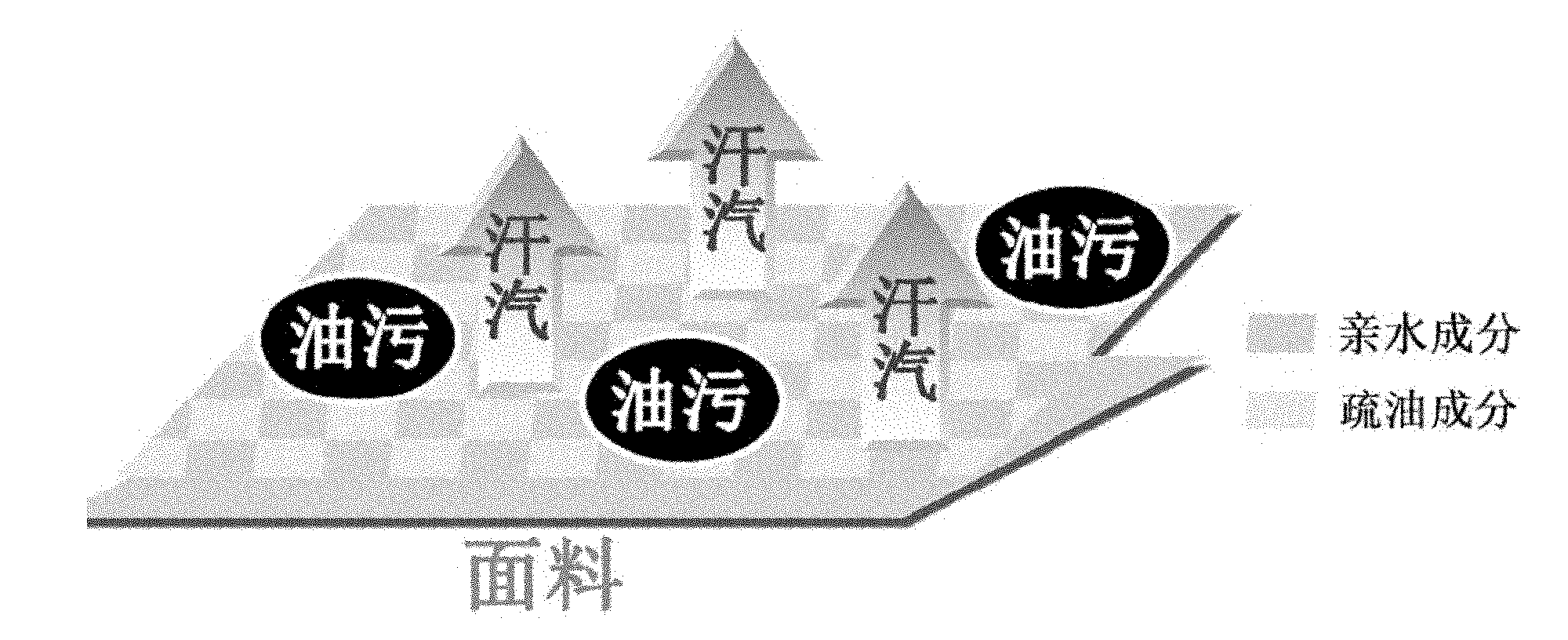

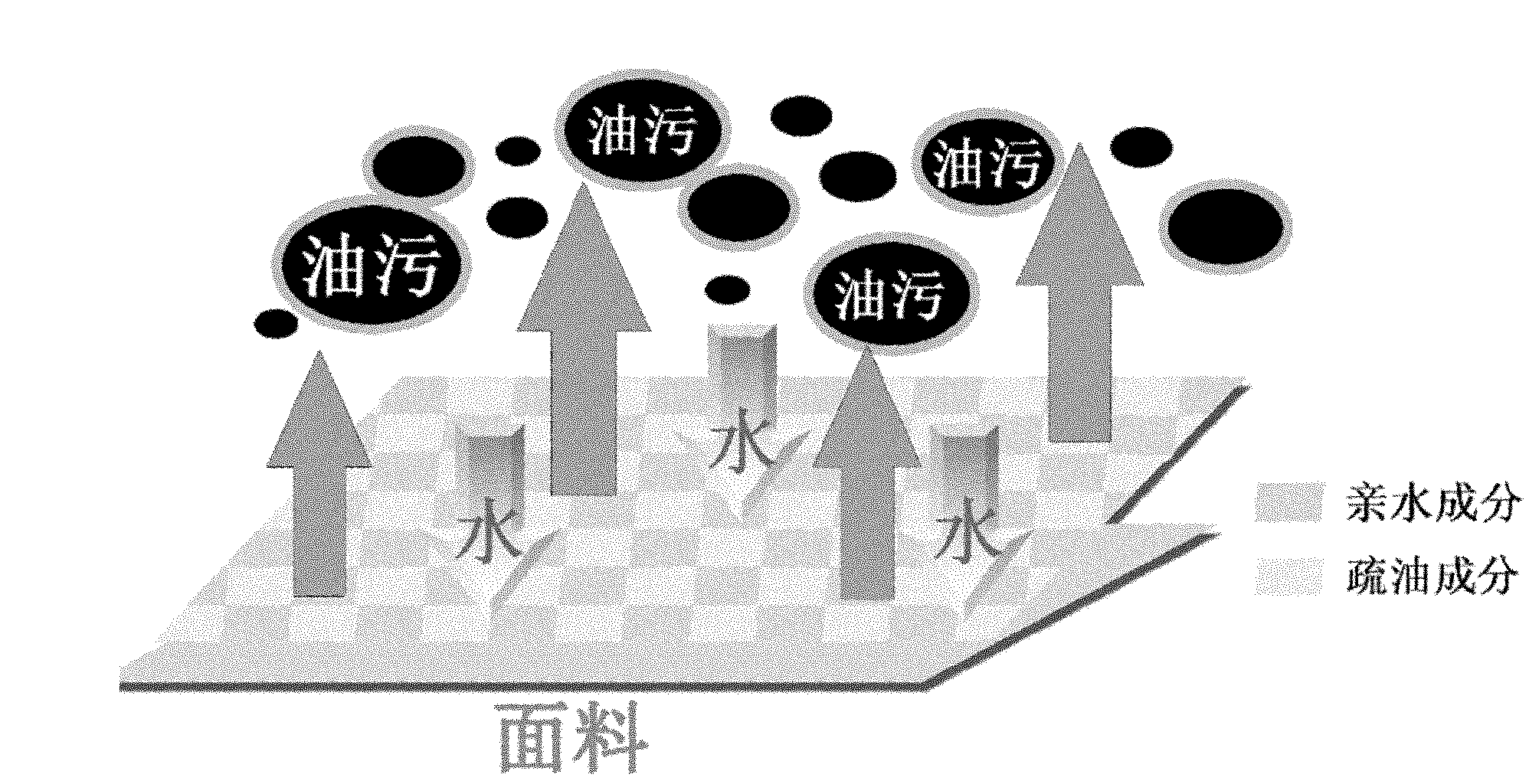

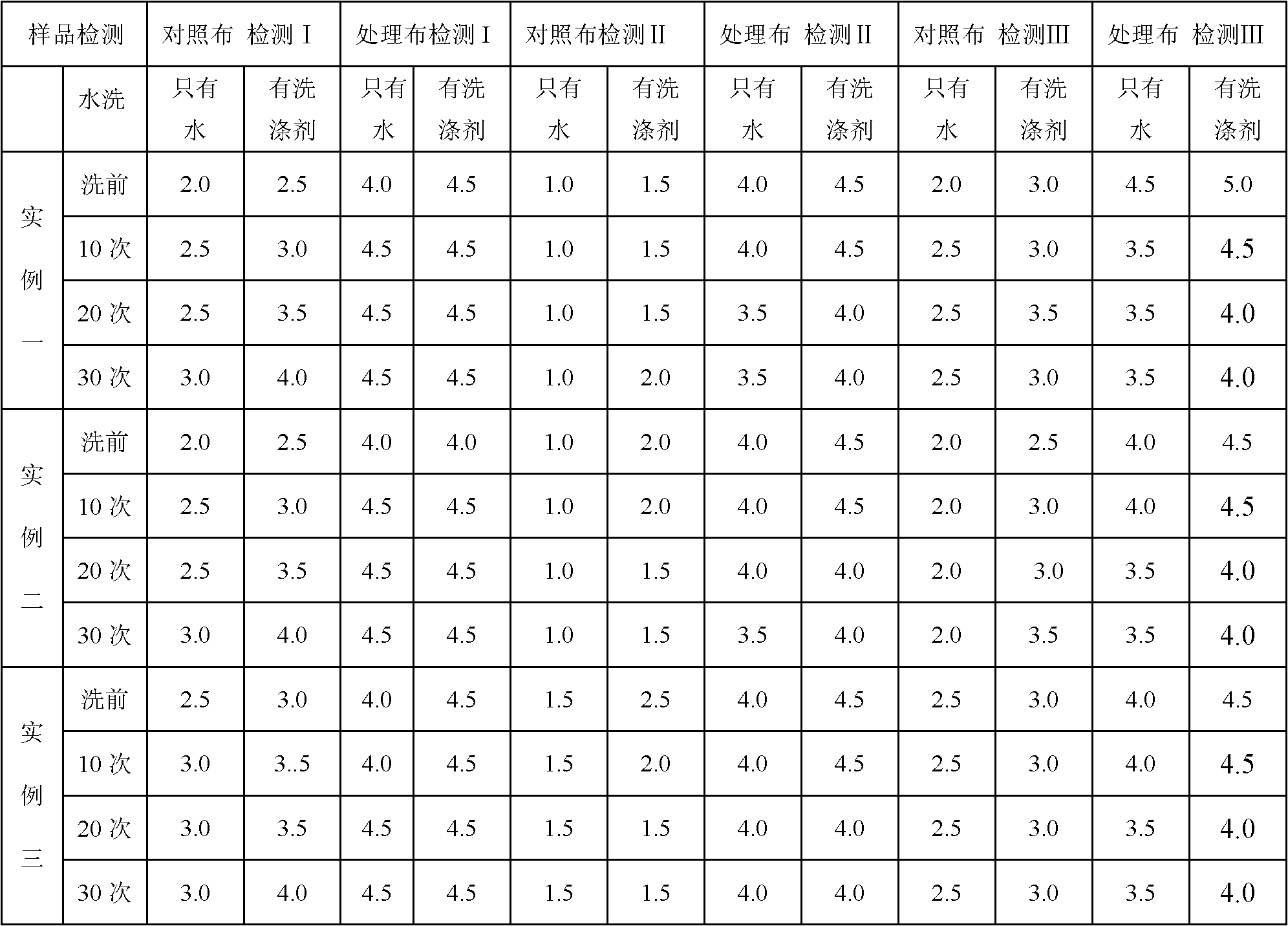

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

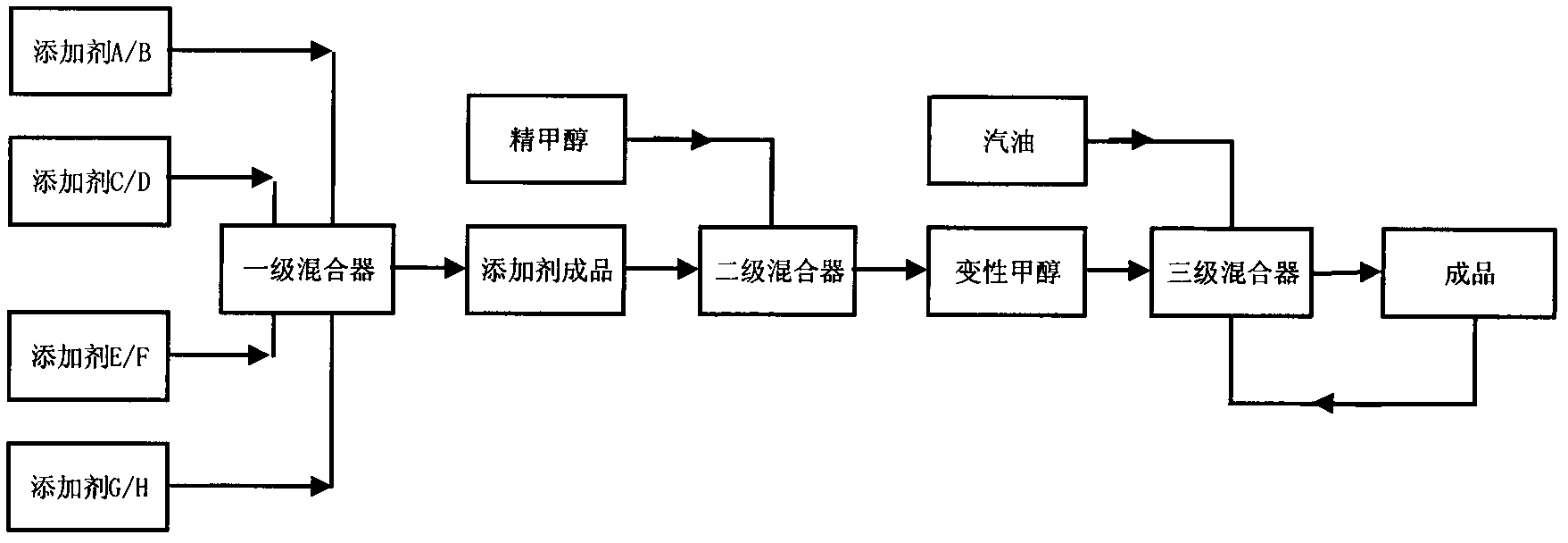

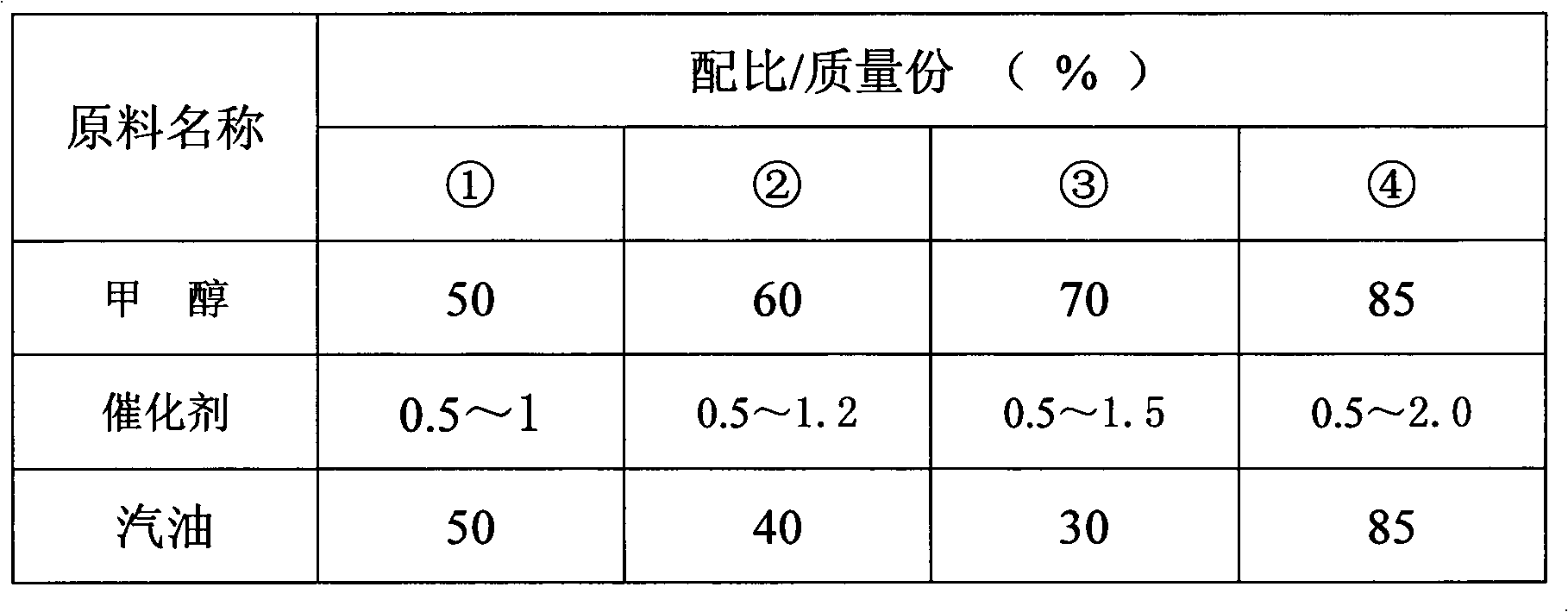

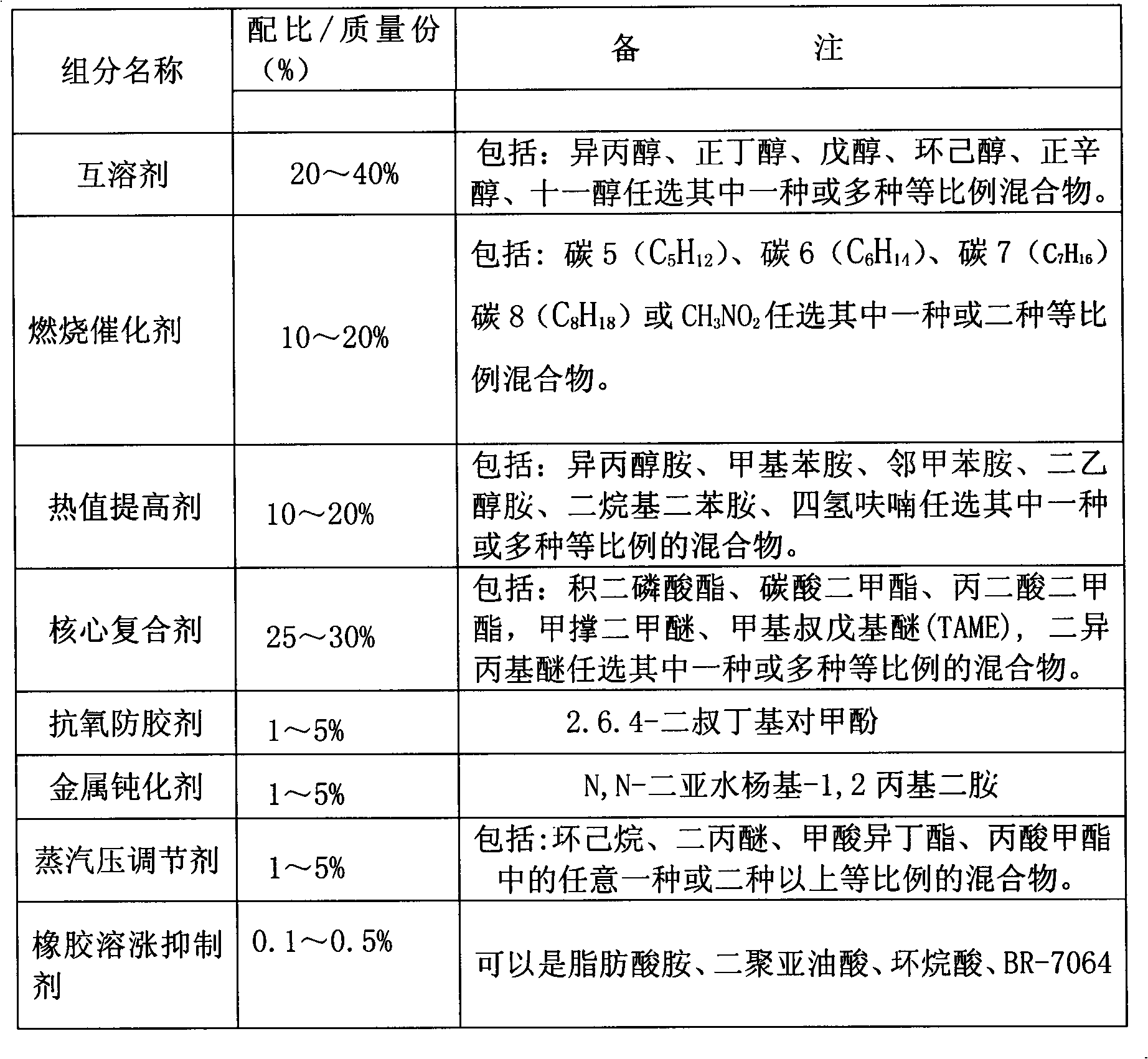

Large-proportion methanol gasoline catalyst and preparation method

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

High-damping magnesium alloy containing quasicrystal reinforcing phase and preparation method thereof

The invention discloses a high-damping magnesium alloy containing quasicrystal reinforcing phase and a preparation method thereof. The high-damping magnesium alloy containing quasicrystal reinforcing phase comprises the following alloy components in percentage by weight: 0.9%-1.0% of zinc, 0.15-0.2% of yttrium and 0.6% of zirconium, wherein, zinc and magnesium are industrial pure zinc and industrial pure magnesium; alloy elements, namely, yttrium and zirconium respectively adopt the preliminary alloy form of magnesium-30% of yttrium and magnesium-30% of zirconium to be added in; the high-damping magnesium alloy containing quasicrystal reinforcing phase is prepared by preheating, smelting and shaping. The invention takes zinc, yttrium and zirconium as alloy elements, the atom content ratio of zinc to yttrium in the alloy is controlled to 5-6, so that the formed icosahedron quasicrystal phase has special crystal structure, which ensures the stability of interface combination. The high-damping magnesium alloy containing quasicrystal reinforcing phase of the invention can effectively prevent dislocation slippage and twin crystal expansion, performs favourable strengthening function, effectively overcomes the contradictoriness between the strength and the damping performance in the magnesium base high-damping structure material, has favourable anti-corrosion performance and is a magnesium alloy with comprehensive performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Block polymer with multi-response property for temperature and carbon dioxide and preparation method thereof

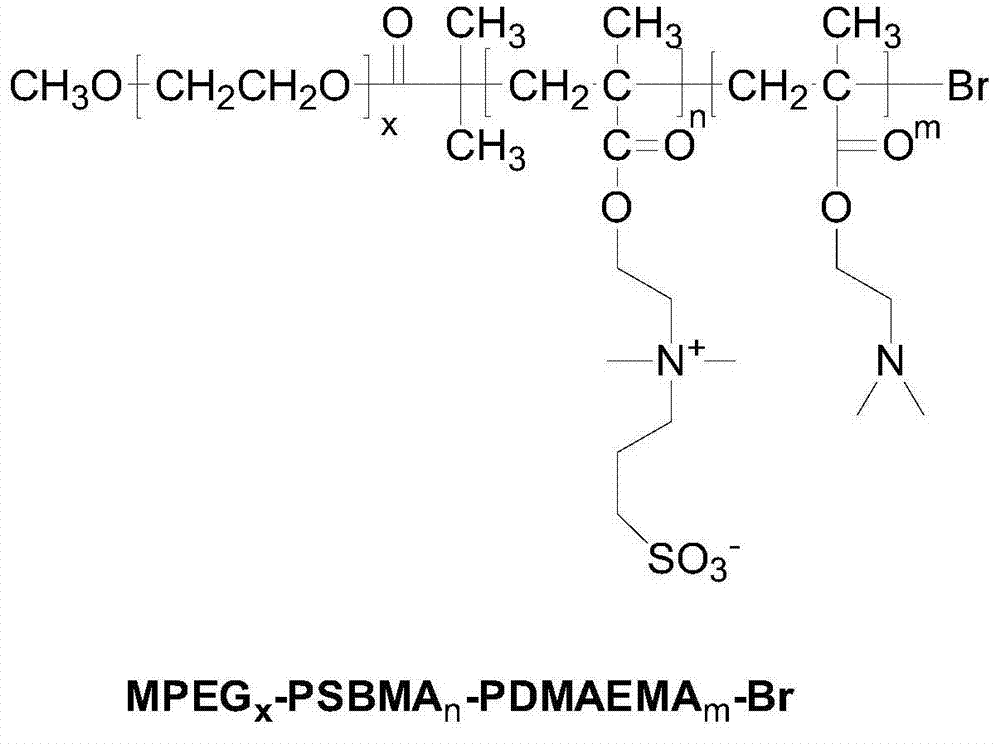

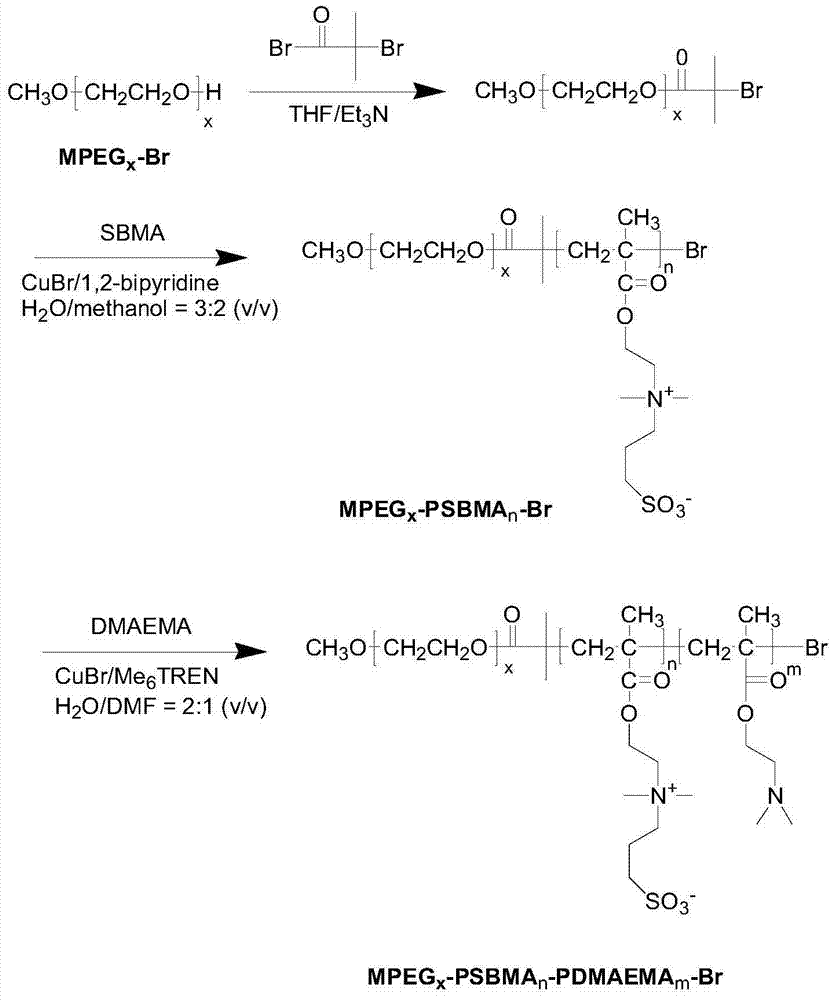

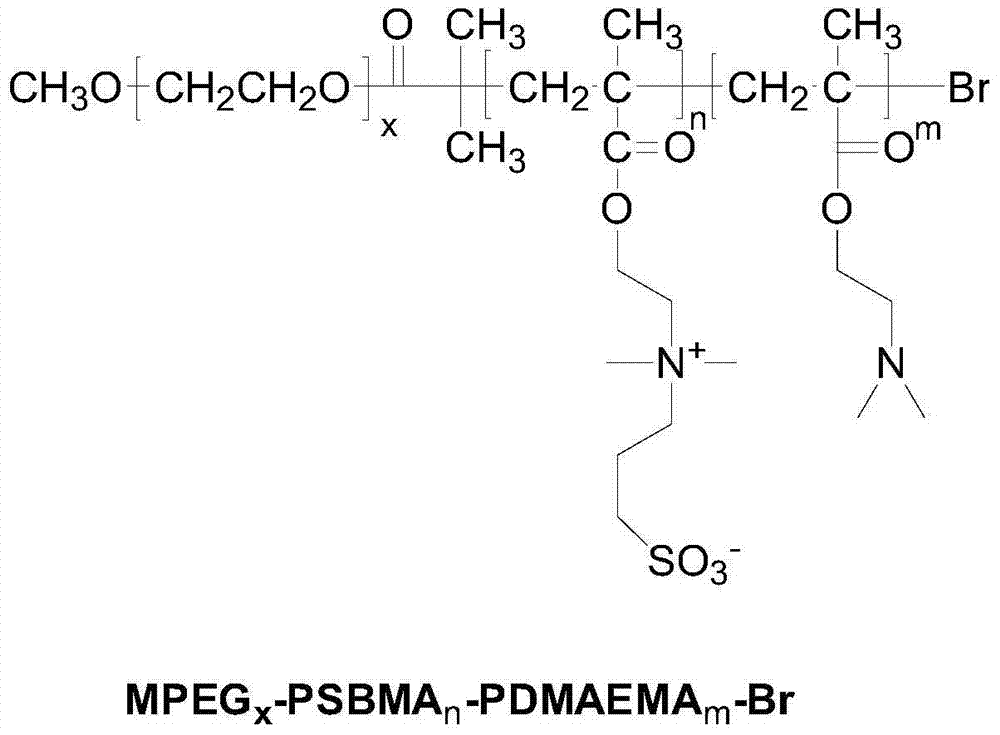

InactiveCN104262555AImprove stabilityMulti-responsivePharmaceutical non-active ingredientsAminoethyl methacrylateBetaine

The invention discloses a triblock polymer with a multi-response property for temperature and carbon dioxide. The polymer is methoxy polyethylene glycol-b-polyethylmethacrylate dimethyl betaine-b-poly dimethyl aminoethyl methacrylate; bromine-terminated methoxy polyethylene glycol serves as a macro-molecule initiator, and the triblock polymer is synthesized through an atom transfer radical polymerization reaction. The method is mild in reaction conditions, simple in operation and high in product yield; compared with an ordinary free radical polymerization reaction, the molecular structures of products are more regular, the molecular weight is controllable, and the distribution is narrower. The polymer disclosed by the invention contains a non-ionic polymer block (MPEG), a cationic polymer block (PDMAEMA) and a zwitterionic polymer block (PSBMA) at the same time, has good biocompatibility and biological fouling resistance, has the multi-response property for the temperature and the carbon dioxide in solution, and can serve as a carrier to realize load, transmission and target control release for medicine.

Owner:SHANDONG JIAOTONG UNIV

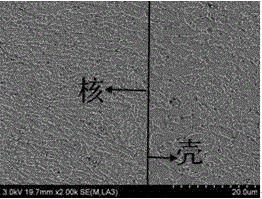

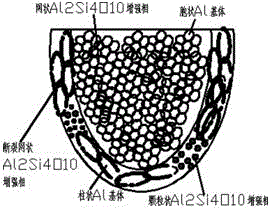

Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

ActiveCN105328186AGood comprehensive mechanical propertiesImprove the overall mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser printingAluminium

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

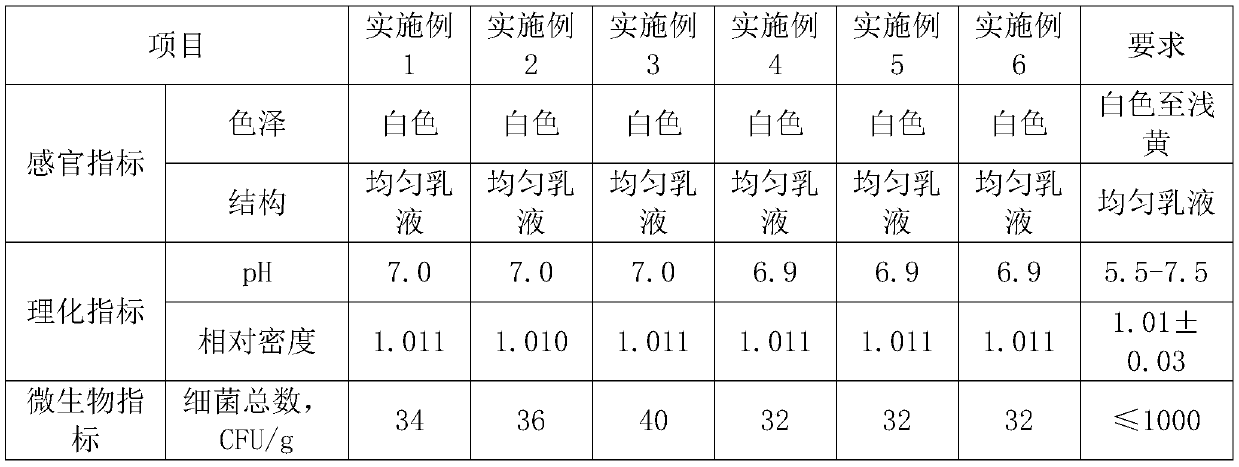

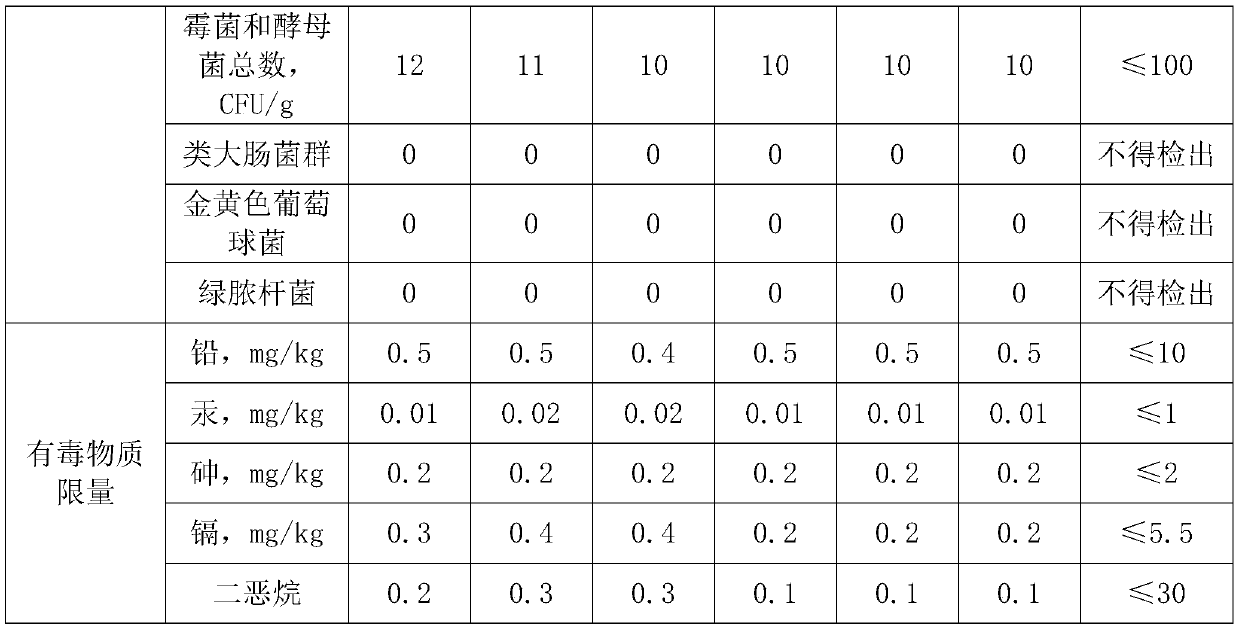

Anti-aging repair essence and preparation method thereof

ActiveCN110960453ATo promote metabolismEasy to synthesizeCosmetic preparationsToilet preparationsBiotechnologyPOMEGRANATE SEED OIL

The invention discloses an anti-aging repair essence and a preparation method thereof. The anti-aging repair essence comprises the following components: water, 2-methyl-1,3-propanediol, a sodium polyglutamate humectant, a sodium of polyaspartic acid humectant, a sugar alcohol humectant, glycereth-26, bis-PEG-15 methyl ether dimethicone, a thickener, erythritol and acetyl chitin, coconut oil, argania spinosa kernel oil, pomegranate seed oil, mango seed fat, dioctyl carbonate, an emulsifier, a silicone oil emollient, butanediol, 4'-hydroxyacetophenone, 1,2-hexanediol, a bifida ferment lysate composition, a peptide composition and a trifluoroacetyl tripeptide-2 composition. The emulsifier comprises hydrogenated lecithin, C12 to C16 alcohol and palmitic acid. The essence disclosed by the invention has the effects of moisturizing the skin, maintaining moisture, moistening the skin, resisting aging, repairing the skin, resisting oxidation and slowing down the growth of wrinkles, and the whole system is high in stability and not easy to layer or precipitate.

Owner:HANGZHOU FACECARE COSMETICS

Variable focus liquid lens with reduced driving voltage

ActiveUS7312929B2ReliabilityReduce the driving voltageConductive materialOrganic conductorsElectricitySURFACTANT BLEND

The invention provides a variable focus liquid lens using electrowetting, comprising a conductive first liquid and an insulating second liquid. At least one of the first liquid composed of electrolyte and the second liquid composed of insulating liquid contains a surfactant for reducing interfacial energy between the first and second liquids. An interfacial portion between the first and second liquids is gathered by surfactant to reduce driving voltage. The variable focus liquid lens according to the invention has about 50% lower driving voltage required for changing focus, ensuring stability of the two fluids.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Biodegradable active medical tissue adhesive and its preparation method

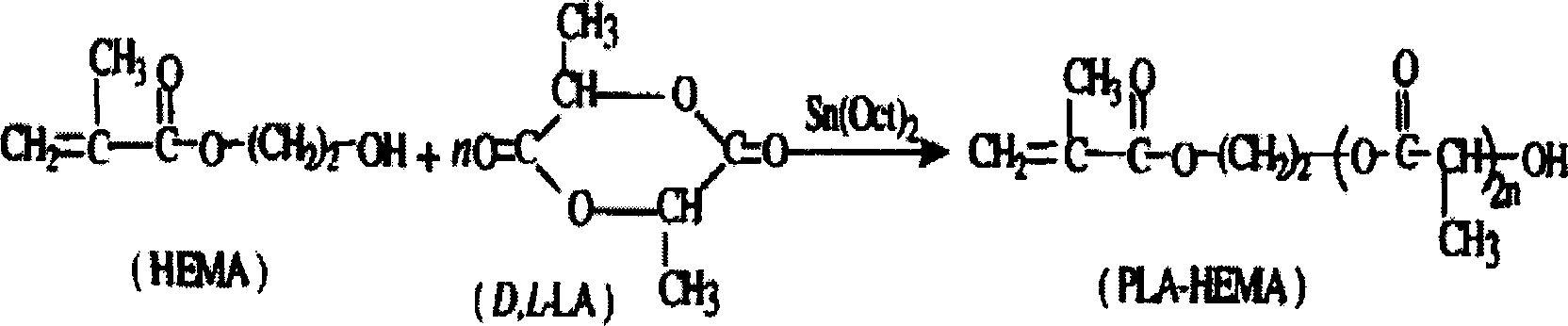

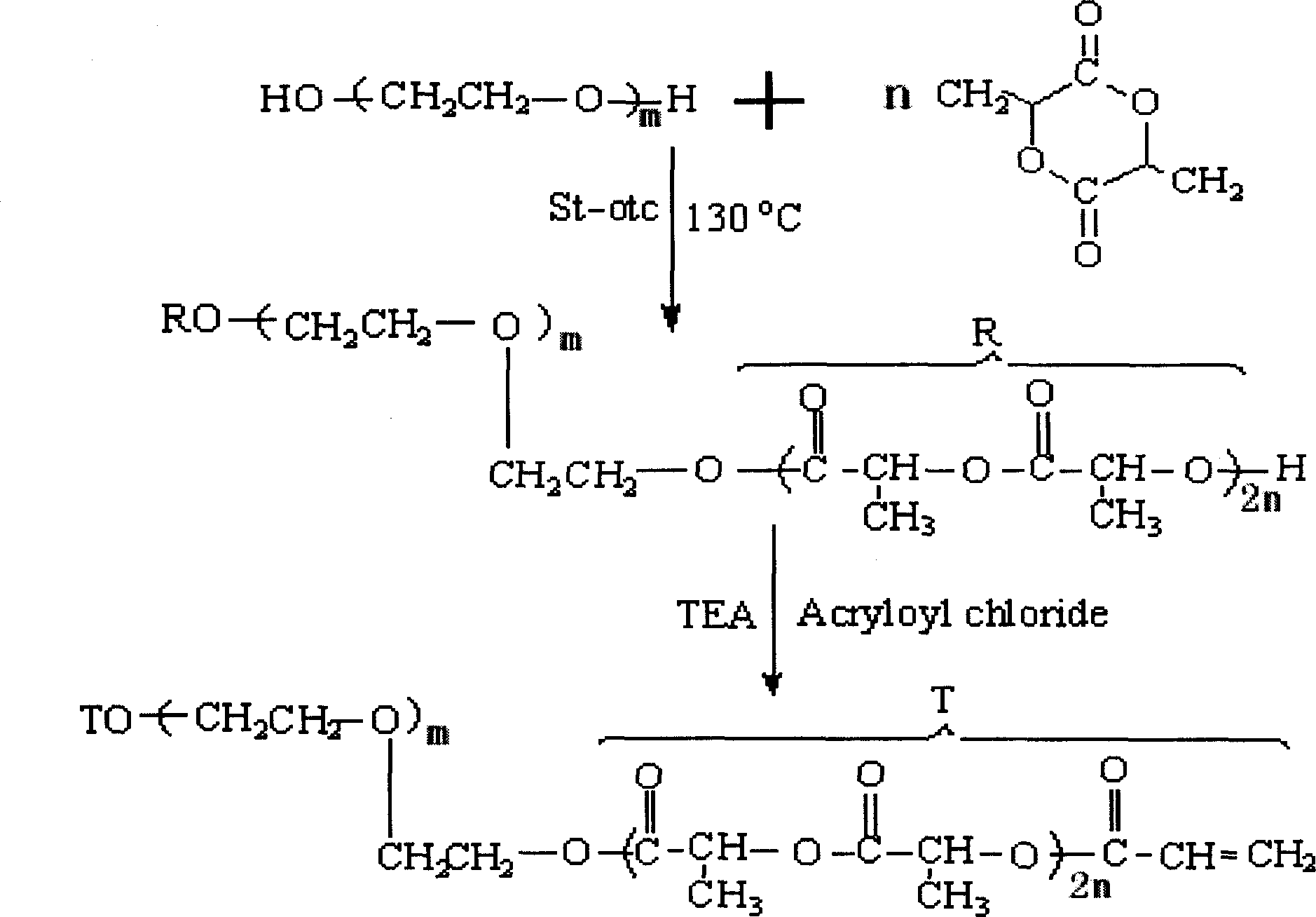

InactiveCN100998889AAdjustable mechanical propertiesLow heat of polymerizationImpression capsSurgical adhesives(Hydroxyethyl)methacrylateHard tissue

A biodegradable and bioactive medical tissue adhesive with high bilcompatibility and adjustable mechanical strength and degradating speed for adhering soft tissue and hard tissue is prepared from the liquid phase (hydroxyethyl methylacrylate ring- opening polymerized cycloester type macro-molecular monomer), the alcohol type compound (biodegradable cross-linking agent, vinylpyrrolidone, N,N-dimethyl p- tolueneamine, or hydroquinone), and the solid phase (encapsulated natural powder, pore-forming agent, and benzoly peroxide) through mixing.

Owner:广州暨科拓源生物材料科技开发有限公司

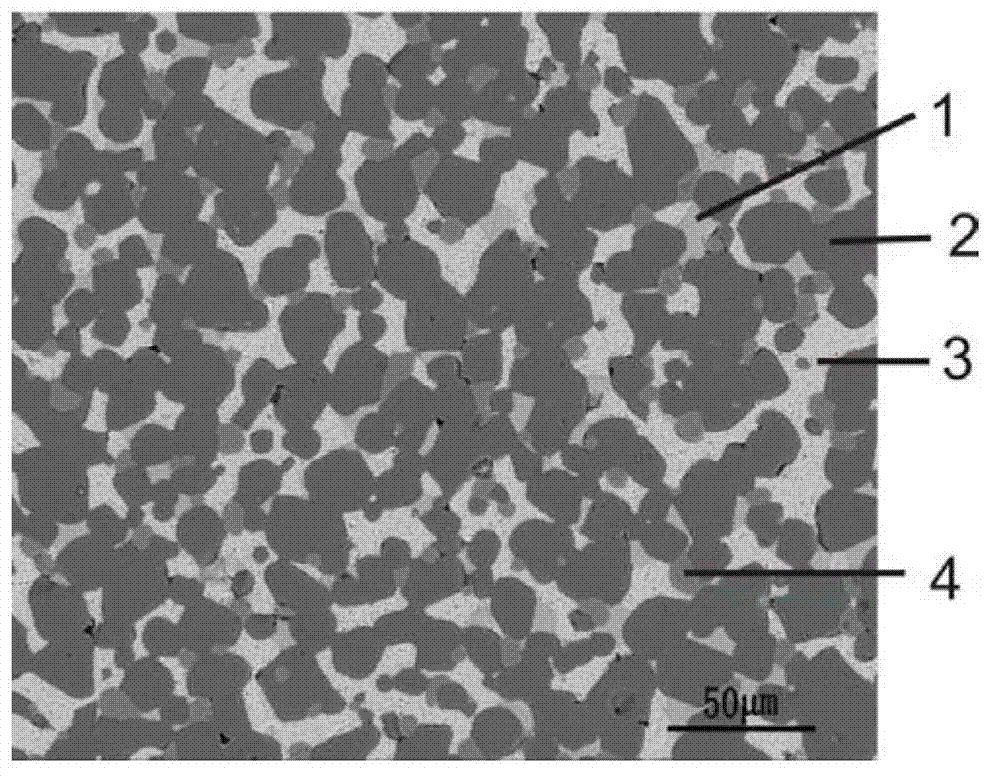

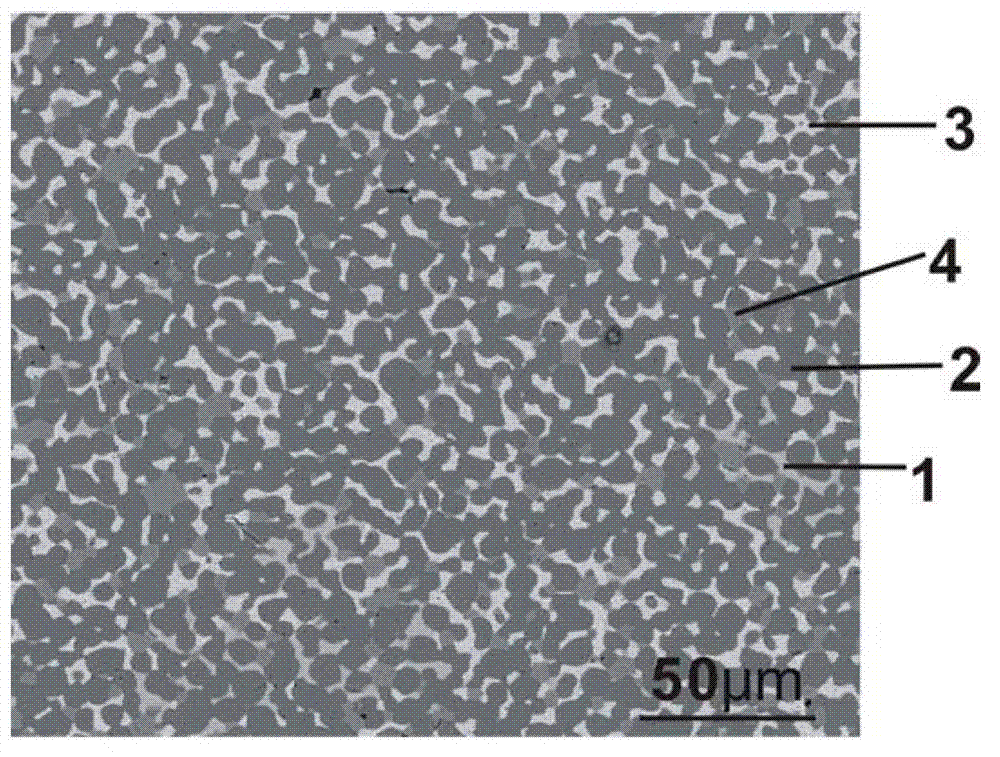

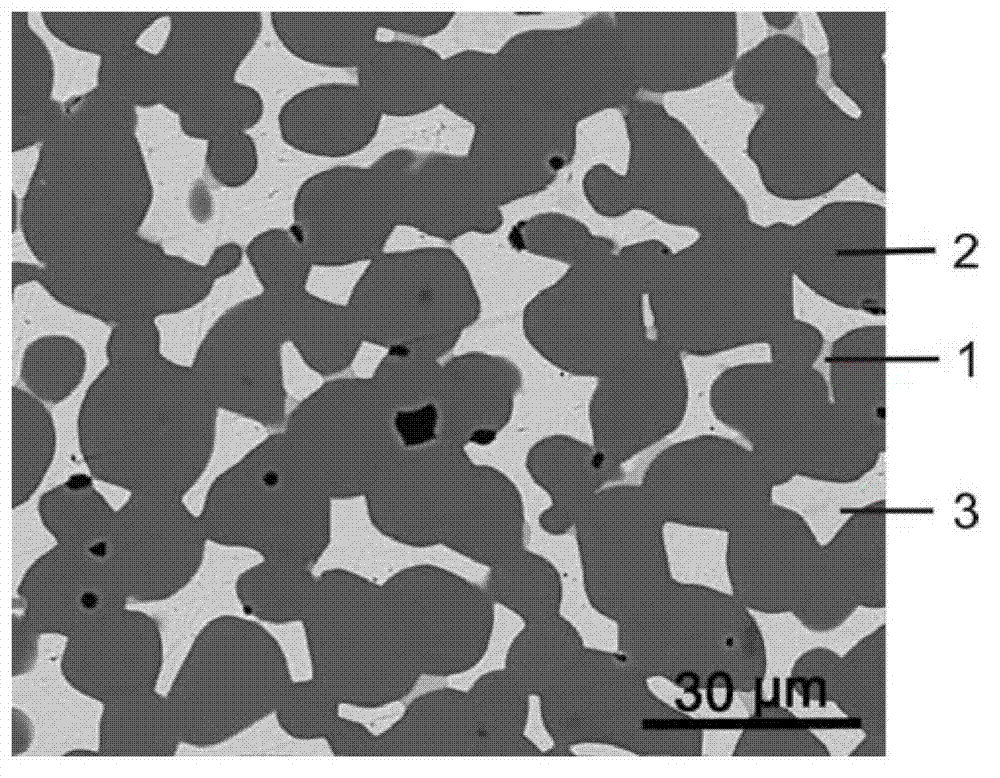

Nickel ferrite-copper metal ceramic inert anode material and preparation method

The invention relates to a nickel ferrite-copper metal ceramic inert anode material which comprises a ceramic phase and a metal phase, wherein the ceramic phase is nickel ferrite or nickel ferrite base composite ceramic; and the metal phase consists of metal copper and cuprous oxide, and the cuprous oxide accounts for 1-20% of the total mass of the metal phase. In the preparation process, the content of the cuprous oxide in the metal phase is controlled through controlling the oxygen partial pressure of a nitrogen protection atmosphere so as to improve the wettability of the nickel ferrite and the copper and achieve the sintering infiltration preparation of the ceramic phase and the metal phase. The metal phase and the ceramic phase of the nickel ferrite-copper metal ceramic inert anode material are in a three-dimensional reticular through structure, wherein the sintering density is higher than 98%, the electric conductivity of the metal ceramic material is more than 200S / cm at a temperature of 900 DEG C, the heat conductivity is up to 40W / (m.K) at the room temperature, and the metal ceramic material cannot be cracked through temperature difference thermal shock at the temperature of 400 DEG C. The problems of difficult sintering densification of the nickel ferrite and the copper, sintering overflow of the metal phase and material thermal shock and cracks are effectively solved, and compared with a material prepared by a conventional mixed powder sintering process, the electric conductivity and the thermal shock resistance of the nickel ferrite-copper metal ceramic material are greatly improved.

Owner:CENT SOUTH UNIV

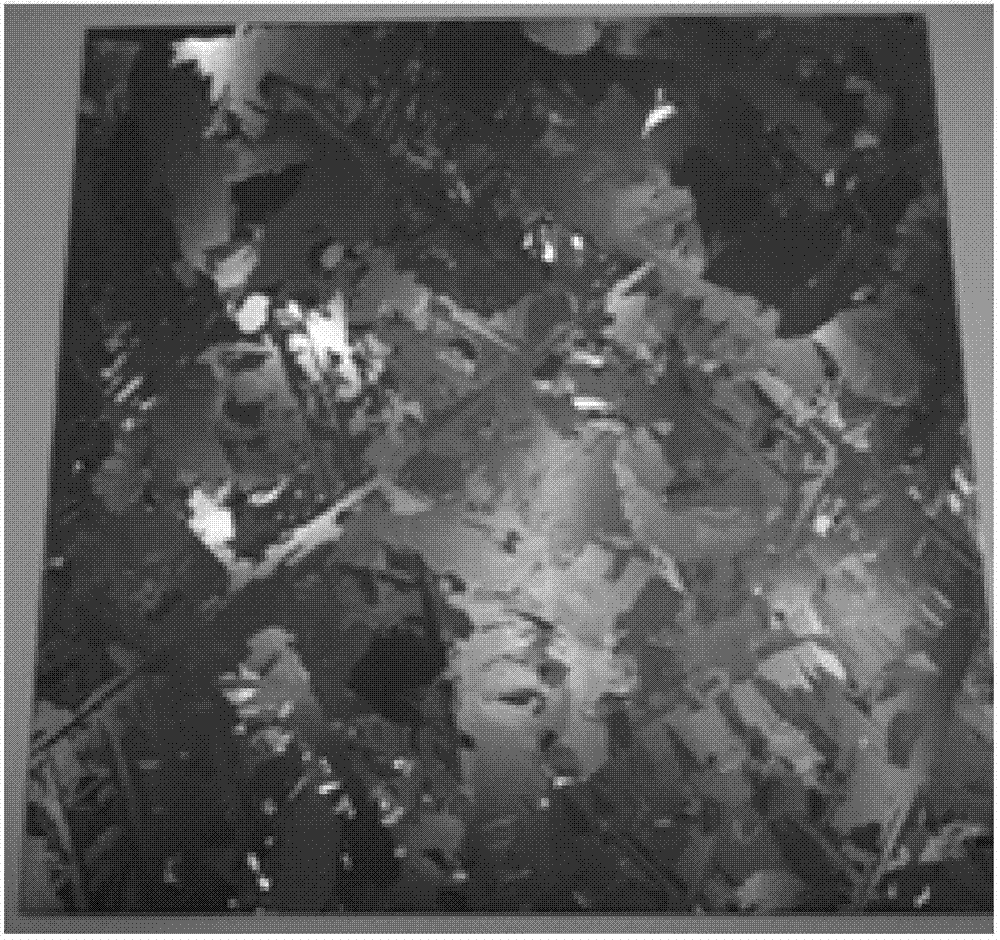

Ingot casting process for high-efficiency polycrystalline silicon

ActiveCN102899720AEasy to operateLow costPolycrystalline material growthSingle crystal growth detailsCrystal twinningIngot casting

The invention discloses an ingot casting process for high-efficiency polycrystalline silicon. The process comprises the steps of (1) arranged heat-insulating strips below heaters on two sides of an ingot casting furnace; (2) filling a silicon material and an electroactive doping agent into a quartz crucible, and sending the quartz crucible into the ingot casting furnace; (3) heating to completely melt the silicon raw material and the electroactive doping agent; (4) adjusting the temperature of heaters to be in a range of 1425-1440 DEG C at the initial period of crystal growth, quickly opening a heat-insulating bottom plate, and adjusting the opening the heat-insulating bottom plate to be in a range of 1-8cm, wherein a layer of dendritic crystals are grown longitudinally along the bottom of the crucible; and (5) controlling the temperature gradient of a solid-liquid phase at the middle period and the later period of crystal growth, keeping a straight solid-liquid interface with dendritic crystals at the bottom serving as seed crystals, and producing polycrystalline silicon containing a large amount of twin crystals through directional solidification in a vertical upward direction. Polycrystalline silicon chips are produced by the ingot casting process, the battery efficiency is 0.4-0.6% higher than that of ordinary polycrystalline silicon, the average battery efficiency of integrated ingot silicon chips reaches 17.5%, and the maximum efficiency can be up to 18%.

Owner:东海晶澳太阳能科技有限公司 +1

Microemulsion type cleaning agent and preparation method thereof

ActiveCN105238578AImprove hydrophilicityEnhance the ability to dissolve oil stainsSurface-active detergent compositionsDetergent solventsMicroemulsionSolvent

The invention relates to a microemulsion type cleaning agent and a preparation method thereof. The cleaning agent mainly comprises the following components: fatty alcohol-polyoxyethylene ether (AEO), a cosurfactant, an oil solvent and pure water. The microemulsion type cleaning agent disclosed by the invention has the characteristics of good stability, strong dissolving and removal capacities to oil stains and ink of clothes, simple preparation process, etc.. The microemulsion type cleaning agent provided by the invention, when diluted for washing, can form nanometer oil drops with a stable structure and still has high cleaning ability; meanwhile, the cleaning agent has the advantages of no residues, easily-available raw materials and degradability.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Warm-mixed type water damage resisting asphalt pavement reinforcing agent and preparation method thereof

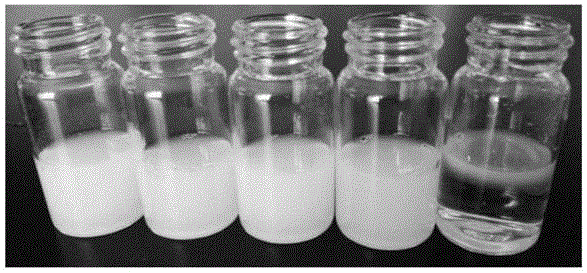

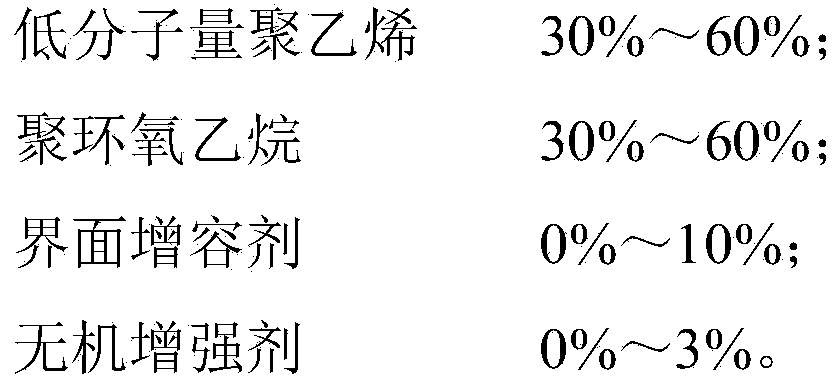

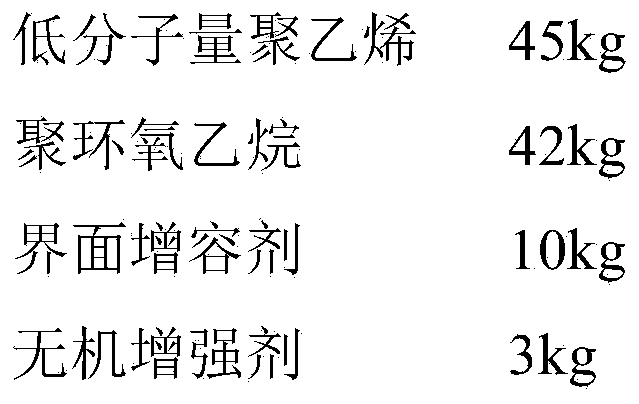

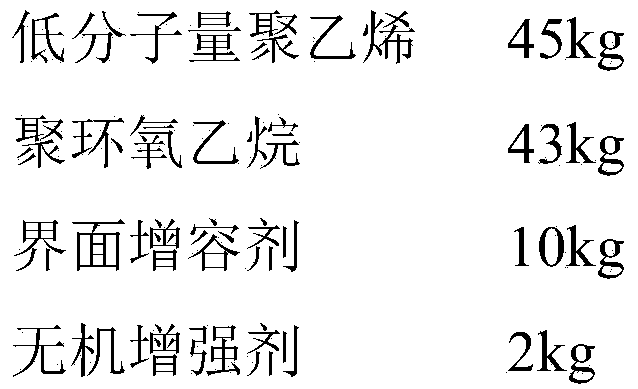

ActiveCN104327524ALow viscosityReduce interfacial energyBuilding insulationsPolyethylene oxideRoad surface

The invention discloses a warm-mixed type water damage resisting asphalt pavement reinforcing agent which comprises the following components in percentage by mass: 30-60 percent of low molecular weight polyethylene, 30-60 percent of polyethylene oxide, 0-10 percent of an interface compatibilizer and 0-3 percent of an inorganic reinforcing agent. The interface compatibilizer is used for reducing interface energy between the asphalt pavement reinforcing agent and asphalt and aggregate so that the coating capability between an asphalt cementing material and the aggregate is greatly increased and the water damage resistance of an asphalt mixture is improved; when the temperature is reduced below a melting point of the asphalt pavement reinforcing agent, plastic components in the asphalt pavement reinforcing agent are separated out by crystallization; due to a nucleation effect of the inorganic reinforcing agent, the plastic components separated out by crystallization grow radially by taking the inorganic reinforcing agent as center; due to a compatibilization effect of the interface compatibilizer, the plastic components form a good adhered netlike structure with the asphalt and the aggregate, so that the high-temperature stability and high-temperature anti-track performance of the asphalt mixture are greatly improved.

Owner:南京交科瑞路技术有限公司

Odorless color asphalt composition and preparation method thereof

InactiveCN108276784AGood storage stabilityReduce interfacial energyBuilding insulationsActive agentFlue gas

The invention provides an odorless color asphalt composition, which is prepared from the following components by weight: 40-50 parts of base oil, 15-20 parts of a petroleum resin, 20-30 parts of a thermoplastic styrene-butadiene rubber, 1-2 parts of an anti-aging agent, 0.5-1 part of a tackifying aid, 0.5-1.2 parts of an odor inhibitor, and 0.5-0.8 part of an interface active agent. According to the present invention, the odorless color asphalt composition acts through the odor inhibitor and the interface active agent so as to reduce the formation and volatilization of H2S, SO2, NOX and otherasphalt flue gases during color asphalt production and construction and significantly eliminate the odor, wherein the asphalt performance is not significantly changed, and the environment protection and the health of personnel can be easily achieved. The present invention further provides a preparation method of the odorless color asphalt composition.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Preparation method of high-purity superfine cobalt oxalate powder

ActiveCN104478699AHigh chemical purityLarge particle sizeCarboxylic acid salt preparationMicrometerGranularity

The invention provides a preparation method of high-purity superfine cobalt oxalate powder, which comprises the following steps: adding a certain amount of additive into a cobalt salt solution with a certain concentration, adding a certain amount of ammonia water into an ammonium oxalate solution with a certain concentration, and adding the two solutions into a reaction kettle to react according to a certain mole ratio in a parallel-flow uniform speed spray mode while controlling the reaction temperature at 15-55 DEG C, the pH value of the reaction solution at 6-7 and the stirring rate at 10-100 rpm / minute; and after finishing feeding, aging, washing, carrying out solid-liquid separation, and drying to finally obtain the high-purity superfine cobalt oxalate powder body. The cobalt oxalate powder prepared by the preparation method has the advantages of fewer impurities, high purity and high flowability, the average particle size is 0.5-1.5 micrometers, the particle size distribution is uniform, and the shape is subsphaeroidal. The preparation method has the advantages of simple and controllable technique, high production efficiency and stable product quality, and is suitable for large-scale industrial production.

Owner:GUANGDONG GUANGHUA SCI TECH

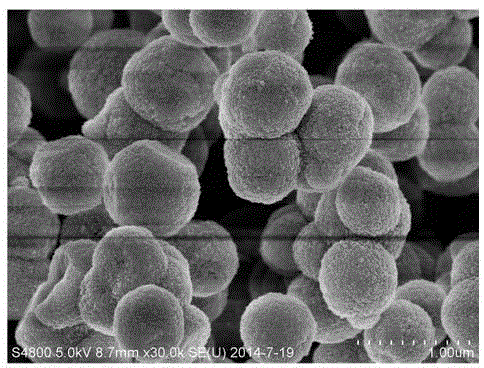

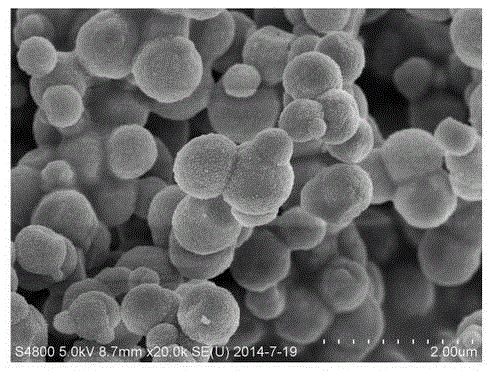

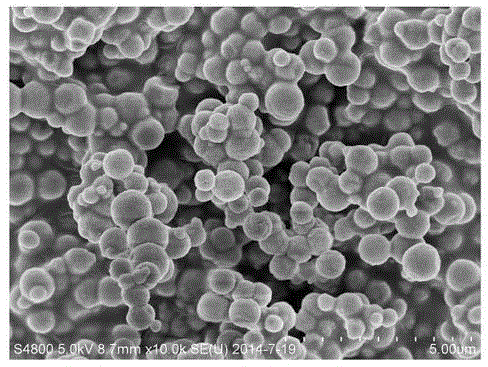

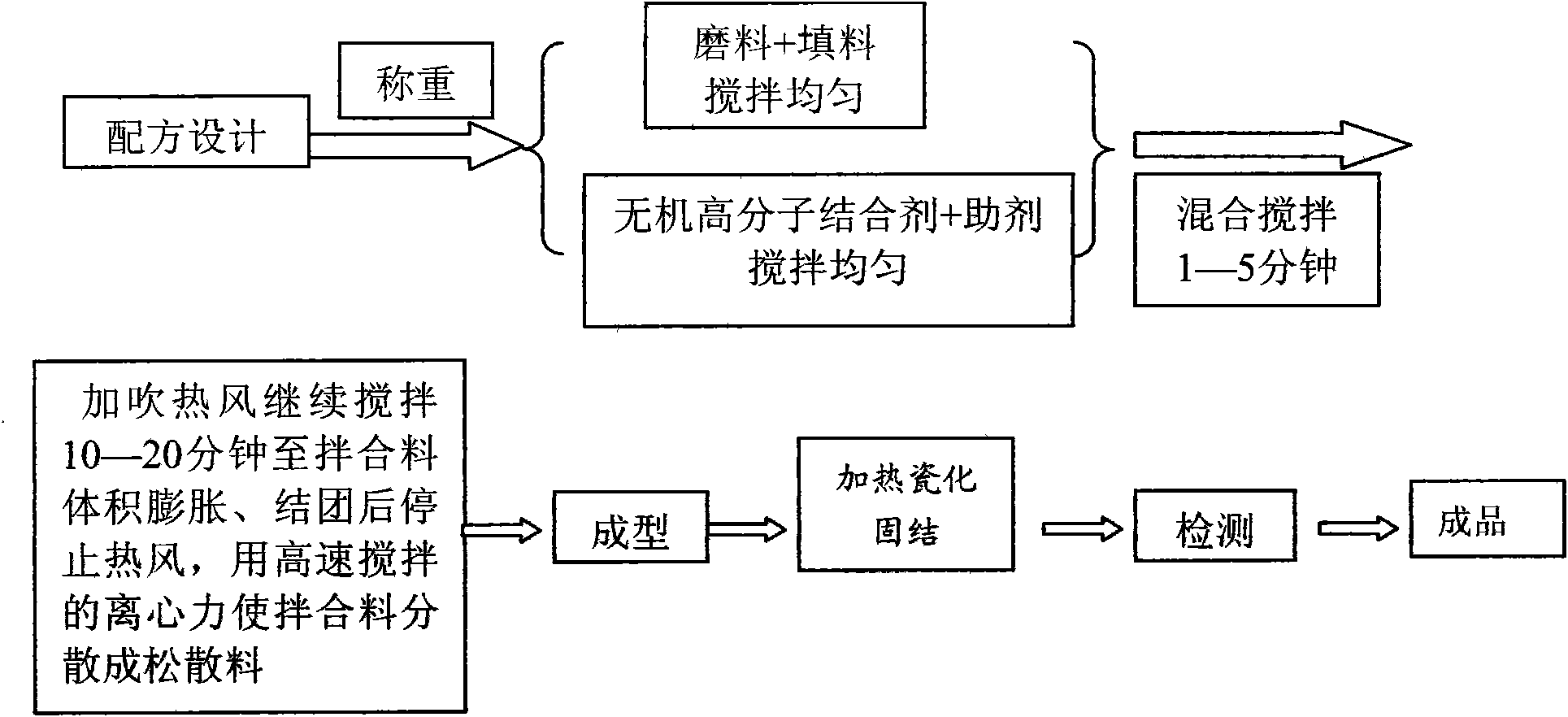

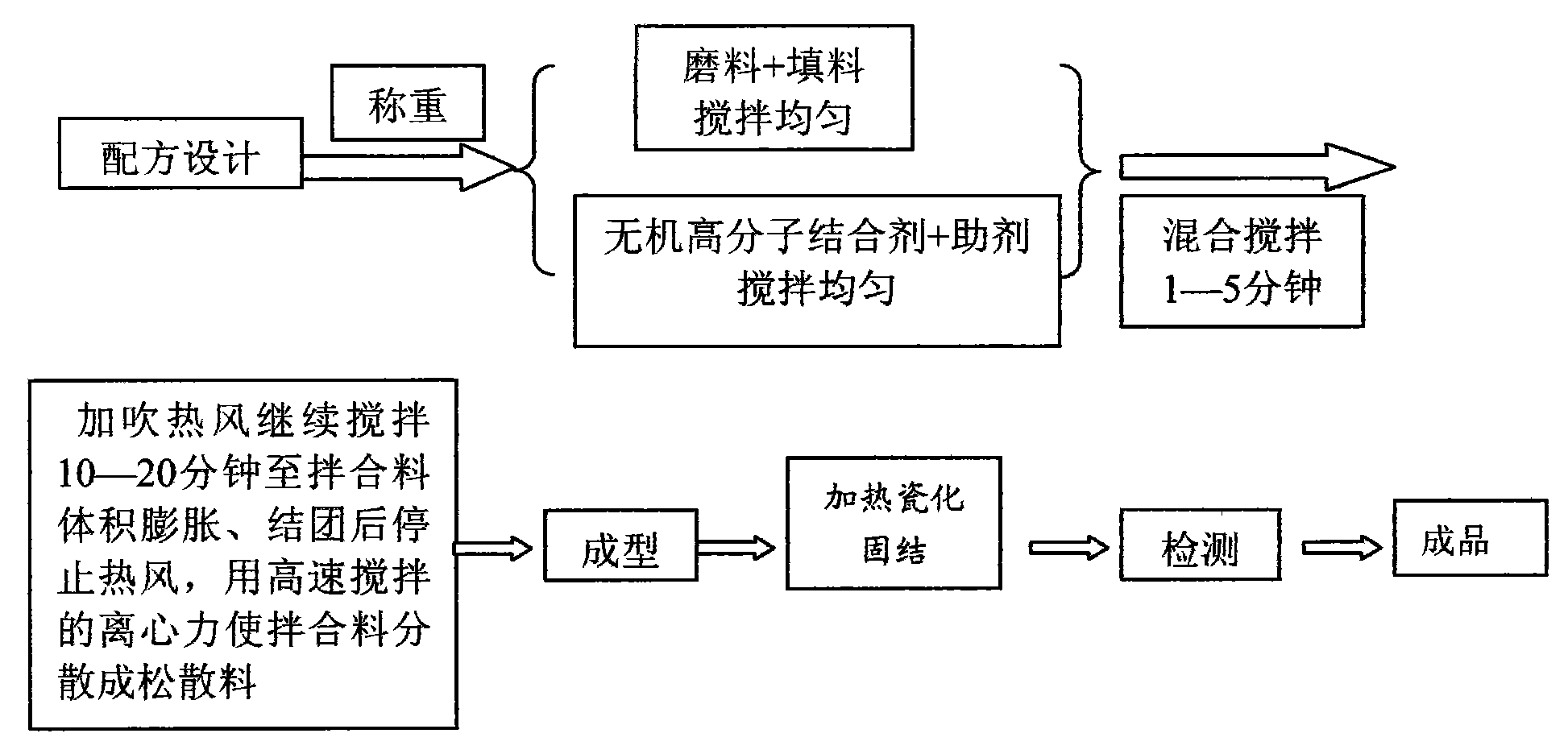

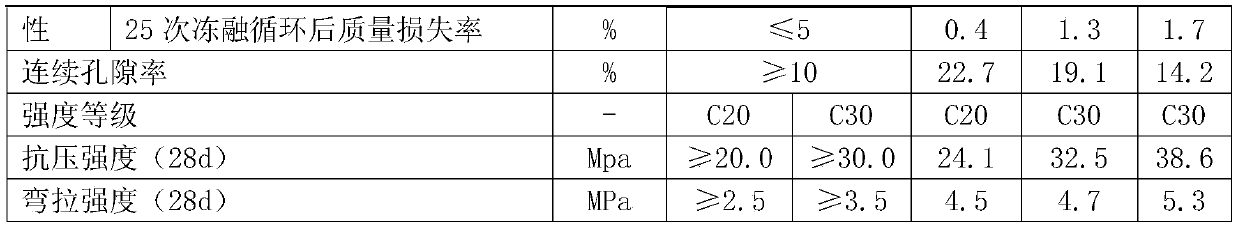

Preparation method of inorganic high molecular abrasive tool

InactiveCN101927464AHigh bonding strengthImprove wettabilityAbrasion apparatusGrinding devicesCompression moldingPolymer science

The invention relates to a preparation method of an inorganic high molecular abrasive tool, which comprises the following steps: designing the formula of the product according to the product standard, weighing the materials according to the proportion, evenly stirring, and blowing with hot air until the mixture expands in volume, cakes and forms wires; after 1-5 minutes, stopping the hot air, stirring at high speed until the abrasive grains are dispersed, compression-molding, and heating the molded abrasive tool so that the abrasive tool is vitrified and solidified; and finally, processing the vitrified and solidified abrasive tool, trimming and detecting to obtain the finished product. The invention solves the technical problems of complex production technique, high energy consumption, environment pollution, easy burnout at high temperature and unstable chemical properties of the existing abrasive tool. The abrasive tool produced by the method has the advantages of wide applicability, unique function, environmental protection, energy saving, high quality, high performance and the like.

Owner:黄曦

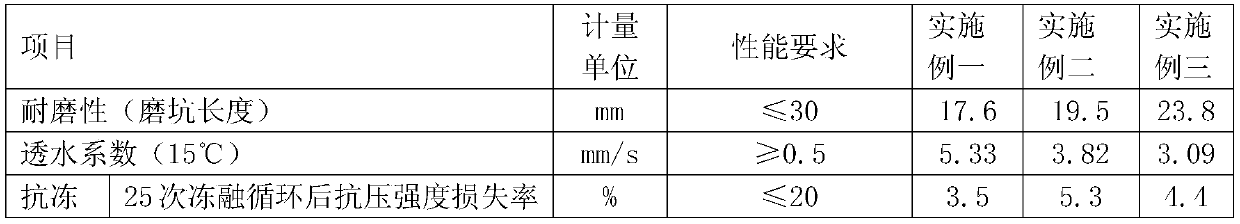

Carbon dioxide cured prefabricated water-permeable concrete and preparation method thereof

ActiveCN109824321ALow alkalinity requirementLow Pre-Care RequirementsEnvironmental resistanceCellulose

The invention discloses a carbon dioxide cured prefabricated water-permeable concrete and a preparation method thereof. The water-permeable concrete is composed of following components in parts by weight: 55 to 80 parts of regenerated aggregate, 7 to 30 parts of nickel slag sand, 18 to 40 parts of cementing material, 5 to 25 parts of water, 0.01 to 2 parts of naphthalene water reducer, 0 to 0.02 part of cellulose ether, and 0 to 0.01 part of welan gum. The cementing material is composed of following components in parts by weight: 70 to 90 parts of common silicate cement, 5 to 15 parts of fly ash, 10 to 30 parts of steel slag, 5 to 15 parts of lime or lime slag, and 0.02 to 1 part of nano calcium carbonate. The technology is simple, the structure advantage of water-permeable concrete and the properties of industrial byproducts such as nickel slag, steel slag, fly ash, and the like are fully utilized; carbon dioxide curing is utilized to realize rapid, efficient and environmentally friendly production; high strength, durable and water permeable concrete is obtained, the energy consumption is reduced, the industrial tail gas, metallurgy slag, and building waste are effectively utilized, and good economic benefits, social benefits, and environmental benefits are generated.

Owner:SOUTHEAST UNIV

Pseudo-crystal reinforced high zinc magnesium alloy and method for manufacturing same

The invention discloses a quasi-crystalline reinforced high-zinc magnesium alloy and making method, which comprises the following parts: 2.50-5.00% Al, 6.00-20.00% Zn, 40-1.00% Y0., 0.40-1.20% Mn, 0.003-0.005% Ni, 0.03-0.05% Fe, 0.03-0.05% Cu and Mg. the cast shaped tissue is alpha-Mg+Tau (Mg32(Al, Zn)49)+phi (Al2Mg5Zn2)+, which is displayed in the alpha-Mg or tao-phase and phi-phase rim constituted by MgxZnuYtMnw magnesium-based four-phased composite tissues of quasi-crystalline with relative bulk at 1.50-4.00% in the high-zinc magnesium alloy material.

Owner:TAIYUAN UNIV OF TECH

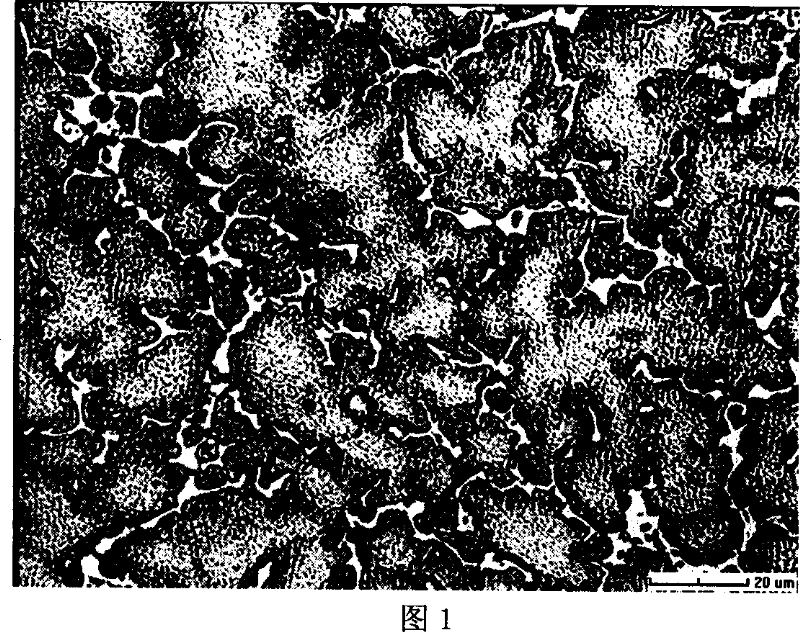

Preparation method for aluminium oxide porous ceramic

The invention provides a preparation method for aluminium oxide porous ceramic. Freeze drying and direct foaming are combined, a surfactant is utilized for modifying particle surfaces and further for enabling particles to have partial hydrophobicity, and particles with the partial hydrophobicity are utilized for stabilizing foams, so that the porous ceramic with high mechanical strength and relatively more closed pores is obtained. According to the preparation method, propyl gallate is utilized for modifying aluminium oxide particles and further for enabling aluminium oxide particles to have partial hydrophobicity, because solid particles with partial hydrophobicity has extremely high adsorption energy at a gas-liquid interface, the aluminium oxide particles are absorbed at a gas-liquid interface in an almost irreversible form, thus a low-energy-state gas-solid interface replaces the high-energy-state gas-liquid interface, and therefore the interfacial energy is reduced, the foam stability is substantially improved, the foam collapse time is prolonged, the pore structure in a dried blank body is guaranteed to be complete, and also the clear dimension of a sample is guaranteed to be unchanged by utilizing the freeze drying process for drying. The prepared aluminium oxide porous ceramic has the density of 0.35-0.65 g / cm<3>, the porosity of 75-90% and the compressive strength of 1.5-16 MPa.

Owner:ZHENGZHOU UNIV

SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material and preparation method thereof

The invention discloses a SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material and a preparation method thereof, relating to a superhigh temperature ceramic composite material and a preparation method thereof. The invention solves the technical problems of low density and high cost of ZrC-based superhigh temperature ceramic in the prior art.The SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material comprises SiC nanoparticle, SiC whisker and ZrC matrix, wherein, the SiC nanoparticle and SiC whisker as a reinforcing phase exist in the ZrC matrix. The preparation method comprises the following steps: dispersing the SiC whisker through ultrasonic waves, mixing the dispersed SiC whisker with SiC nanoparticle and ZrC powder, then carrying out ball milling and drying, and putting the mixed powder in a graphite die for hot pressed sintering to obtain the SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material. The prepared SiC nanoparticle and SiC whisker hybrid toughened ZrC-based superhigh temperature ceramic composite material has a density of 96-100 % and low cost, and can be applied in solid rocket engines or superspeed aircrafts.

Owner:HARBIN INST OF TECH

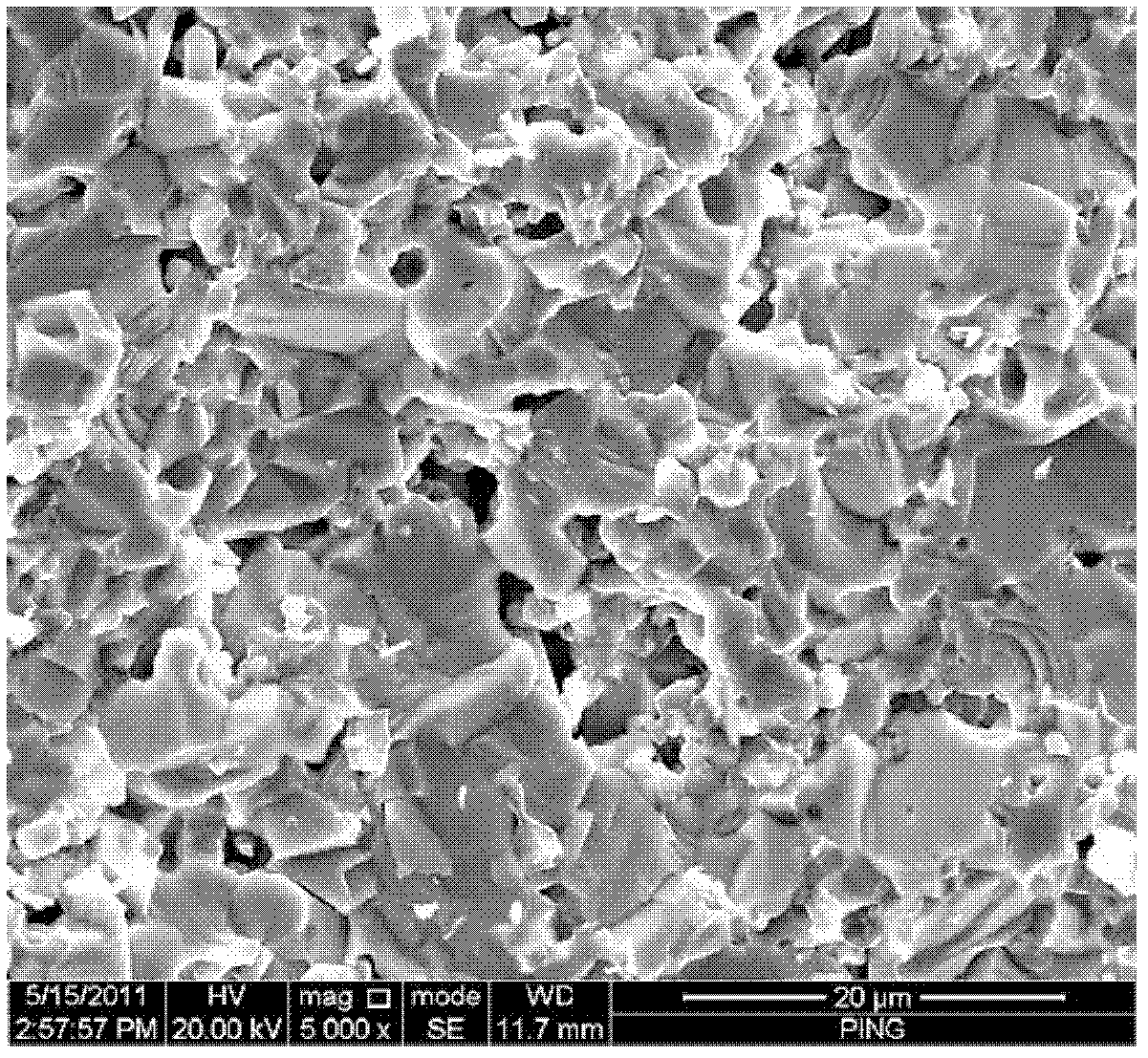

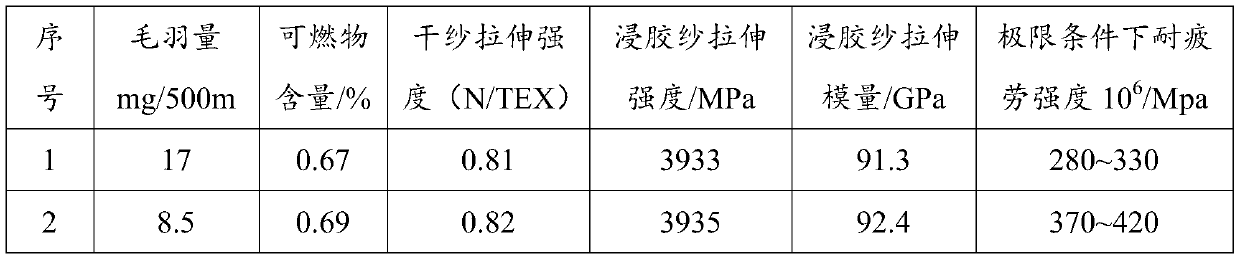

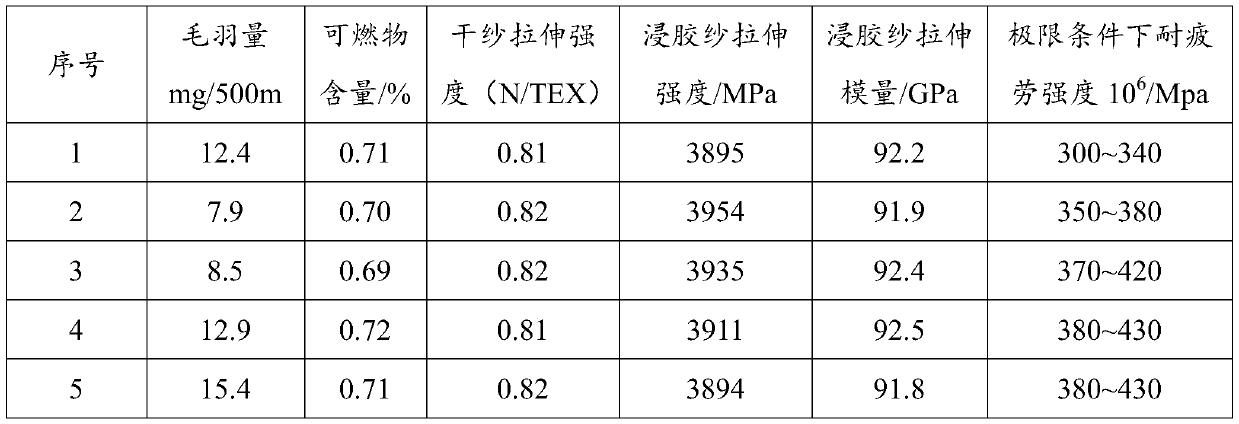

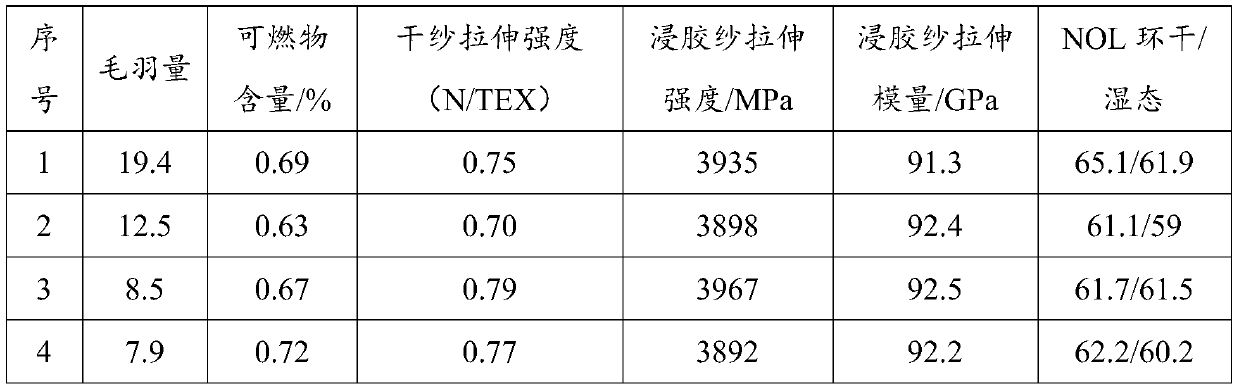

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

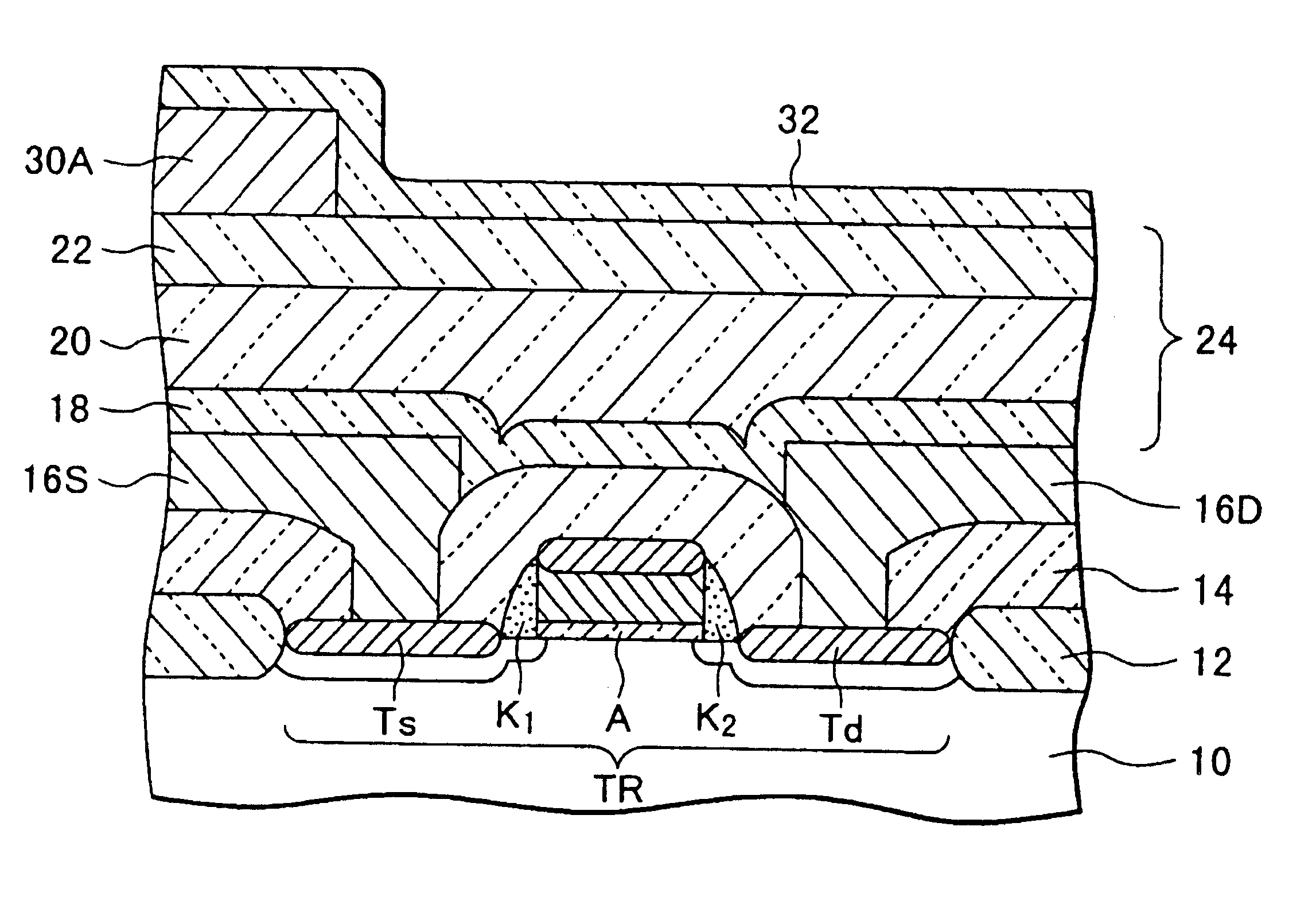

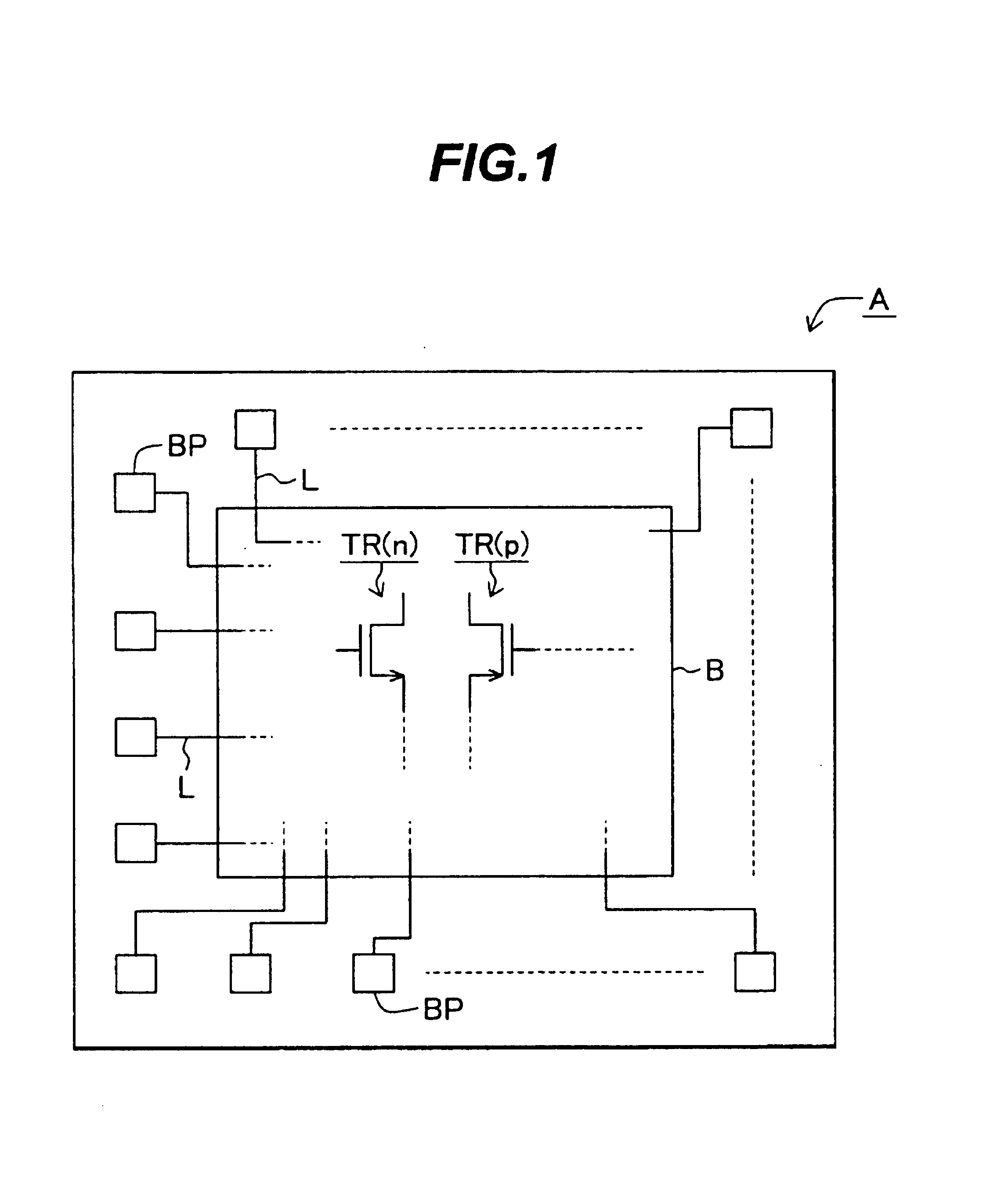

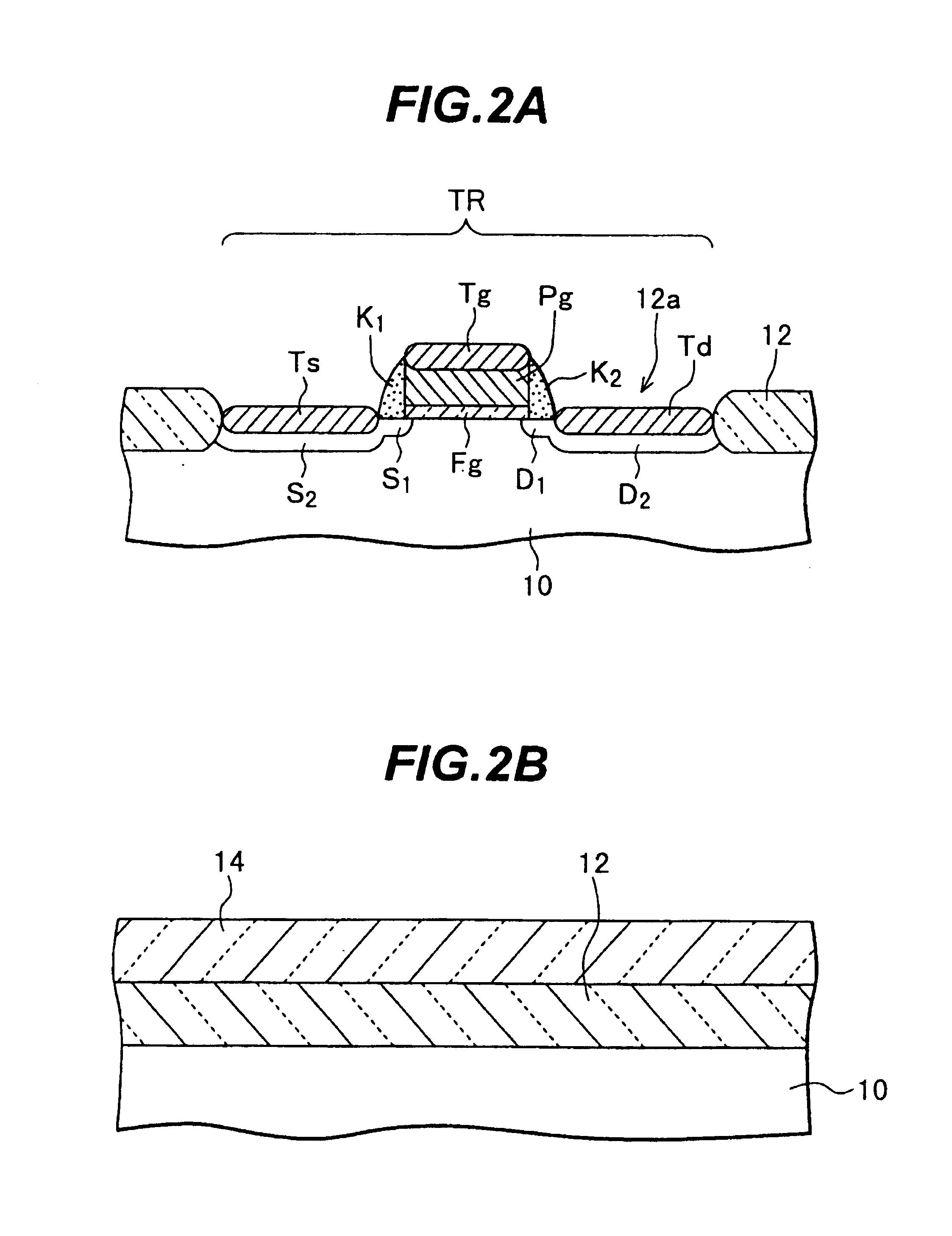

Manufacture method for semiconductor device with small variation in MOS threshold voltage

InactiveUS6888183B1Easy to fallReduce interface state densityTransistorSemiconductor/solid-state device detailsSilicon oxideEngineering

After a MOS type transistor is formed on the surface of a semiconductor substrate, an interlayer insulating film covering the transistor is formed. The insulating film includes a silicon oxide film made of hydrogen silsesquioxane resin in a ceramic state. After a wiring layer is formed on the insulating film, a silicon oxide film as a surface protection film is formed on the insulating film, covering the wiring layer. In order to reduce process damages, heat treatment is performed 30 minutes at 400° C. in a nitrogen gas atmosphere. With this heat treatment, hydrogen in the silicon oxide film is released and diffuses into the channel region of the transistor to lower interfacial energy levels. Since the silicon nitride film does not transmit hydrogen, it is not necessary for the heat treatment atmosphere to contain hydrogen. A variation in threshold voltages of MOS type transistors can be easily lowered.

Owner:YAMAHA CORP

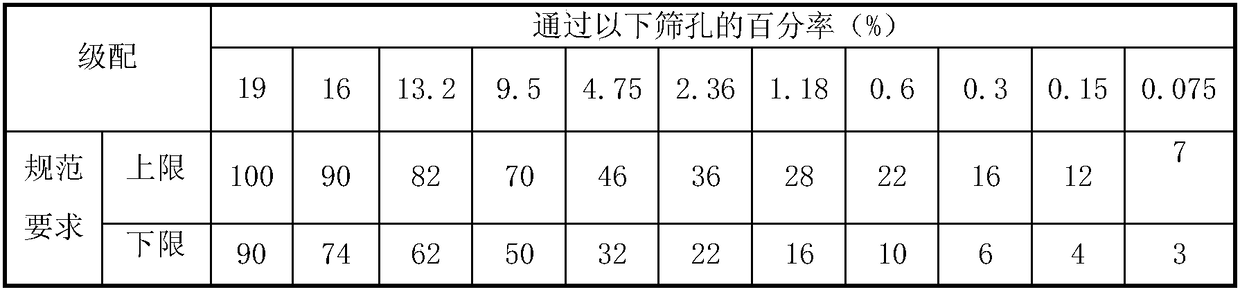

Odorless asphalt mixture and preparation method thereof

The present invention provides an odorless asphalt mixture, which comprises the following raw materials by weight: 40-60 parts of asphalt, 850-950 parts of aggregate, 20-100 parts of mineral powder, 0.2-1 part of an odor inhibitor, and 0.1-0.5 part of an interface active agent. According to the present invention, the odorless asphalt mixture acts through the odor inhibitor and the interface activeagent so as to effectively inhibit the formation and volatilization of H2S, SO2, NOX and other asphalt flue gases during asphalt mixture production and construction and significantly eliminate the odor, wherein the asphalt performance is not significantly changed; and the odorless asphalt mixture has characteristics of environmental protection, energy saving, consumption reducing, high cost performance ratio, convenient construction and the like. The present invention further provides a preparation method of the odorless asphalt mixture.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

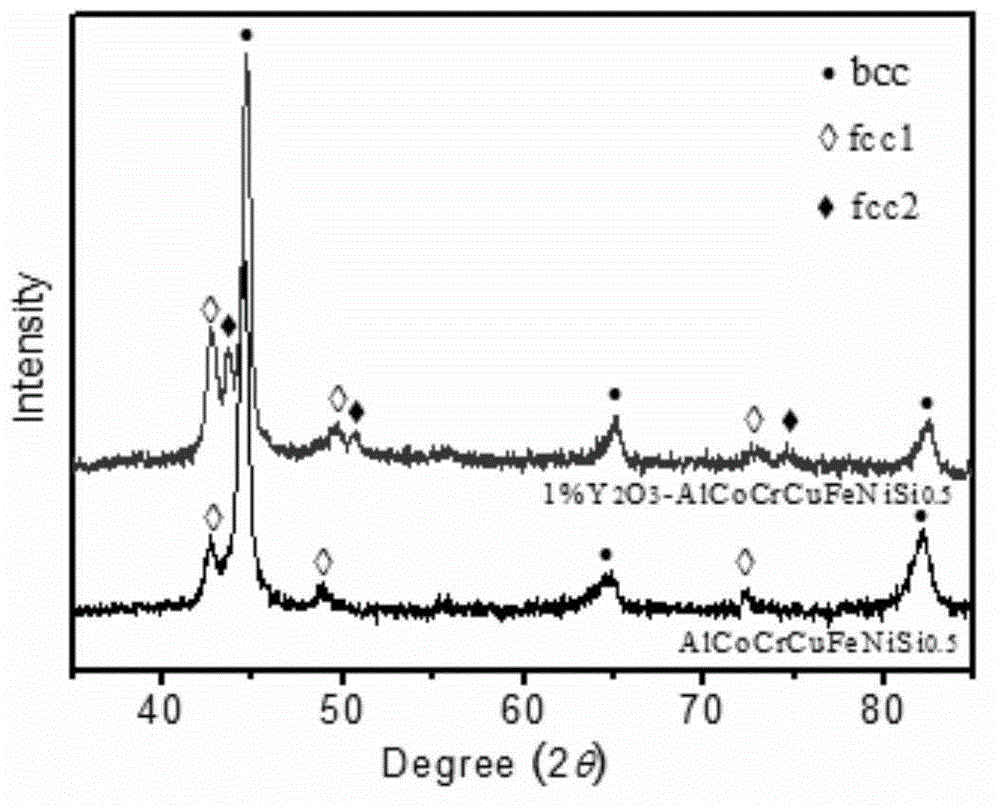

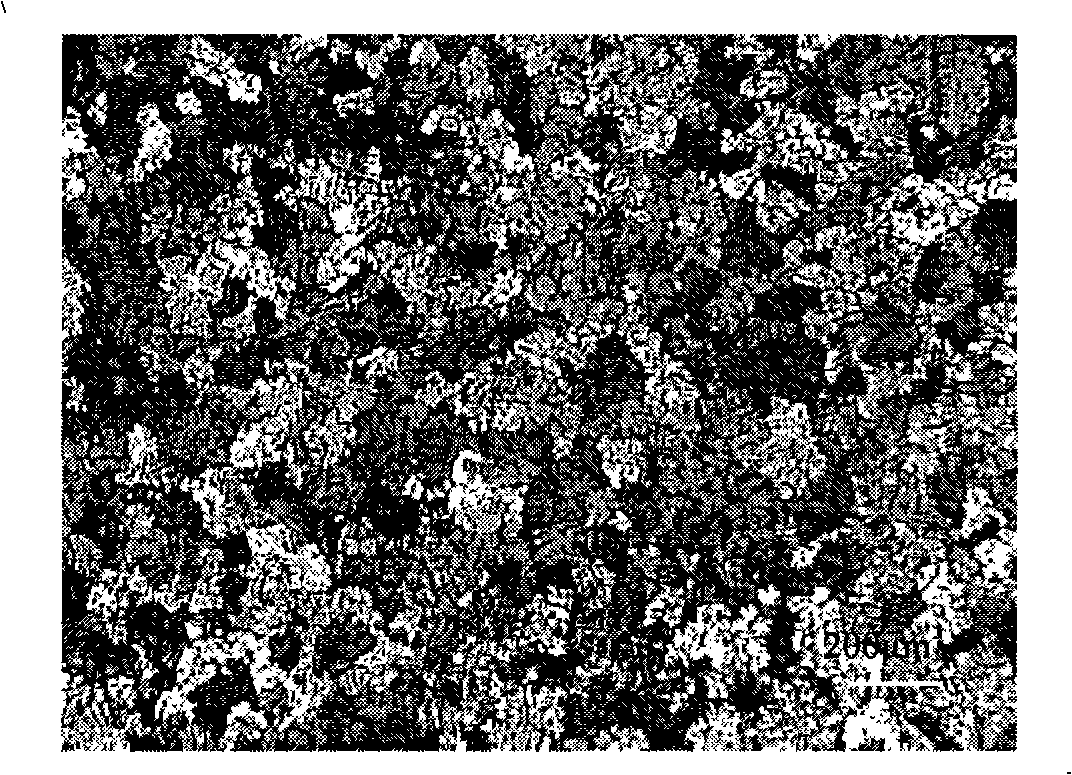

Cu-containing high-entropy alloy coating with liquid phase separation tissue and preparation method thereof

ActiveCN104911581AOptimize the preparation processChange the single-phase structureMetallic material coating processesHigh entropy alloysSingle phase

The invention discloses a Cu-containing high-entropy alloy coating with liquid phase separation tissue and a preparation method thereof, and belongs to the field of alloy material design. According to the invention, a small amount of nano Y2O3 (mass fraction of 0.5-3%) is added to the Cu-containing high-entropy alloy composition, and can promote laser cladding of the Cu-containing high-entropy alloy coating and formation of liquid phase separation tissue. The Cu-containing high-entropy alloy is composed of five or more metallic or non-metallic elements, and the compulsory Cu element accounts for 15-35% of the total moles of the high-entropy alloy composition. The nano Y2O3 has a large surface effect and small size effect, can promote separation of liquid copper from the alloy melt in the laser cladding of Cu-containing high-entropy alloy coating; and a large number of copper-rich particles in dispersed distribution grow in situ on the coating solidified matrix tissue, thus changing the single-phase structure of the coating, and providing a novel method for designing complex phase tissue and expanding capability of the high-entropy alloy by liquid phase separation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

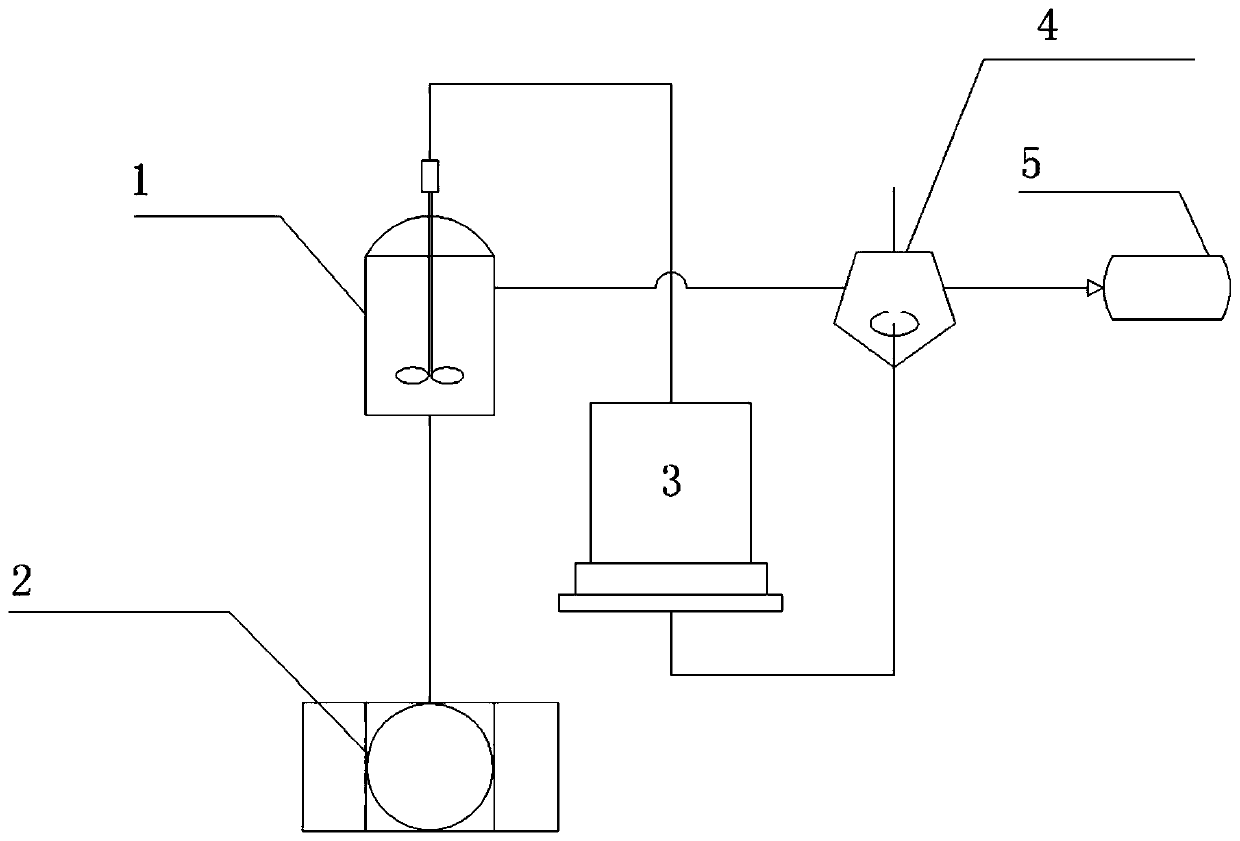

Cleaning agent for treating polymer-containing oil sludge and treatment method thereof

InactiveCN110240373ANo secondary environmental pollutionNo secondary treatment requiredInorganic/elemental detergent compounding agentsSludge treatment by de-watering/drying/thickeningCollection systemFiltration

The invention discloses a cleaning agent for treating polymer-containing oil sludge and a treatment method thereof. The cleaning agent is prepared by mixing 0.1-5% of a biological enzyme, 0.1-20% of a polymer digester, 1-5% of a low-density nano material, 1-10% of an alkali, 0.01-2% of an auxiliary agent and water according to the mass ratio. The treatment method comprises the following steps of: (1) putting a certain volume of oil sludge into a stirring and mixing device according to a mud-water ratio set by the water content of the oil sludge; after the biological enzyme, the polymer digester and the low-density nano material are prepared into the cleaning agent, pumping the cleaning agent to the stirring and mixing device; (2) pumping the cleaning agent into the stirring device, and heating the system; (3) starting a stirring and circulating system for stirring, mixing and flushing; (4) allowing flushing liquid to enter an oil-gas-water separation device for oil-gas-water separation, allowing separated oil to enter a collection and transportation system, performing evacuation after escaping gas reaches the standard, allowing the separated cleaning agent to enter a biological nano bubble generation device for recycling; and (5) allowing clean sediment to enter a sediment collection system, or directly discharging after pressure filtration and air drying of the clean sediment.

Owner:菁华绿尔生态环境科技(天津)有限公司

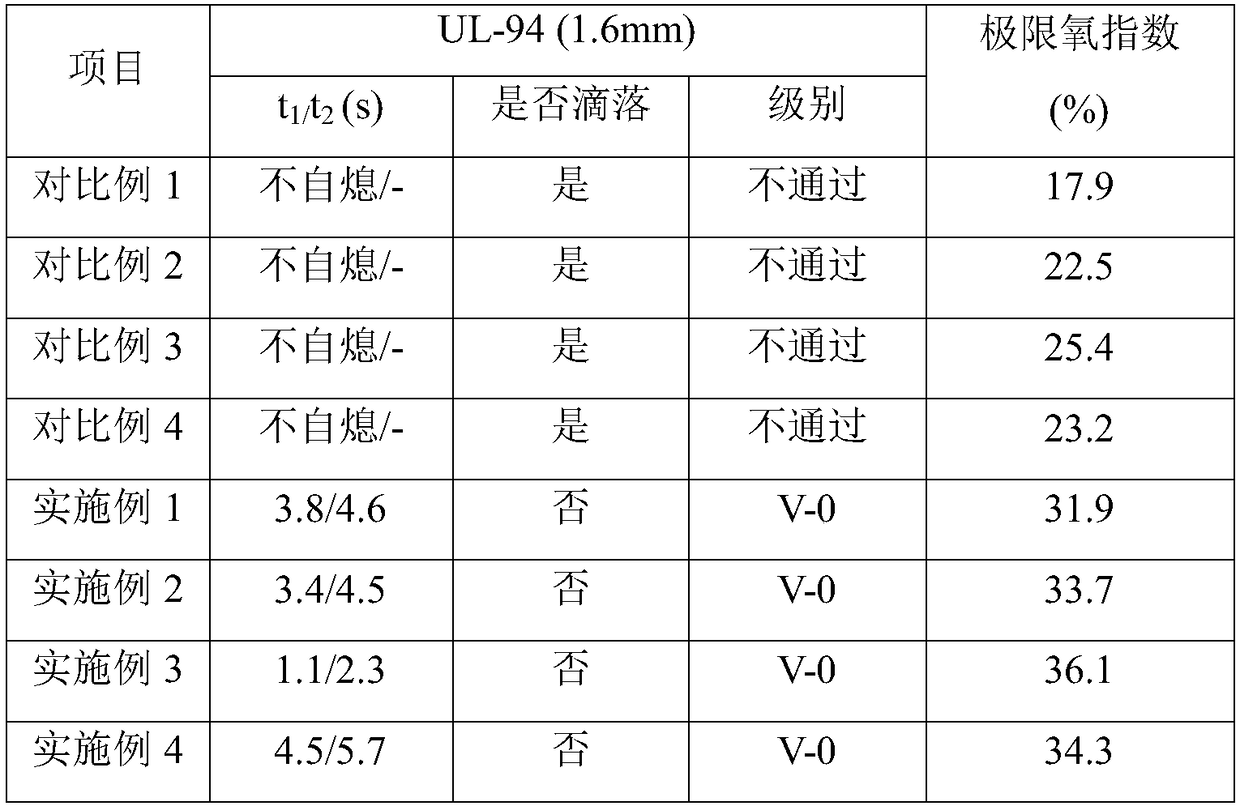

Nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material and preparation method thereof

The invention belongs to the technical field of macromolecular materials, and relates to a nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material and a preparation method thereof, wherein the composite material is prepared from the following substances in parts by weight: 60-90 parts of a polymer, and 10-40 parts of a nitrogen-phosphorus-silicon modified graphene flame retardant. All the components are weighed according to the weight percentage and are mixed uniformly, and then the mixture is added into a twin-screw extruder, melted and mixed andthen subjected to injection molding into corresponding sample strips by an injection moulding machine, or the mixture is melted and blended by an internal mixer and is subjected to compression moulding forming by a mould with a certain size on a plate vulcanizing machine, or a method of solidifying moulding by a curing agent is adopted. The nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material provided by the invention has the advantages of high charring property, and excellent flame retardancy and thermal stability, and can be applied to flame retardancy of materials such as electric cables, automobiles and packages.

Owner:SICHUAN UNIV

Aluminum alloy refiner and aluminum alloy produced with the refiner

InactiveCN101294247AImproved post-processing performanceSimplify the joining processCrystalliteAluminium alloy

The invention discloses an aluminum alloy refiner and an aluminum alloy which is prepared by using the refiner. The aluminum alloy refiner is Zr-Cr-Nb, wherein, Zr, Cr, and Nb elements account for 0.2 to 0.5 percent of total mass percent of the alloy which is obtained from the preparation. By using the refiner, the aluminum alloy is prepared and obtained, the grains of which are small. When the refiner is used for preparing the aluminum alloy, the lattice type and the parameter of Al3Zr can be adjusted to form stable a L12 structure, the interfacial energy and the mispairing degree are reduced, the grain refining effect is increased, the fine uniform equiaxial cast structure is facilitated to be formed, and the subsequent processability of the aluminum alloy is increased. The adding technology of the refiner is simple, the price of the Zr, the Cr and the Nb is relatively cheap, and the aluminum alloy refiner and the aluminum alloy are applied to the industrialized production.

Owner:CENT SOUTH UNIV

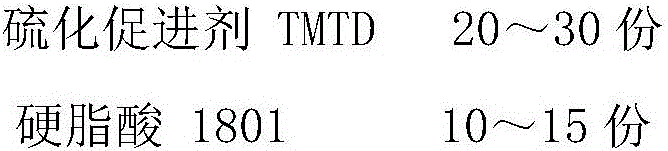

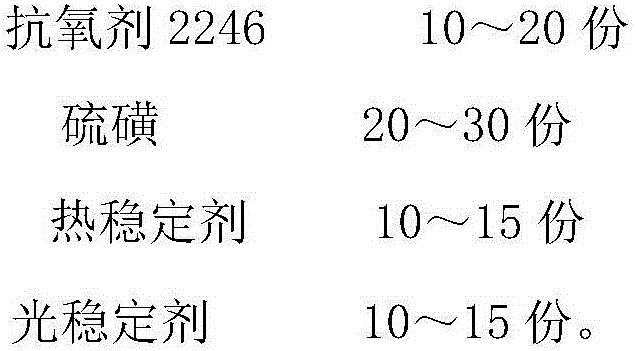

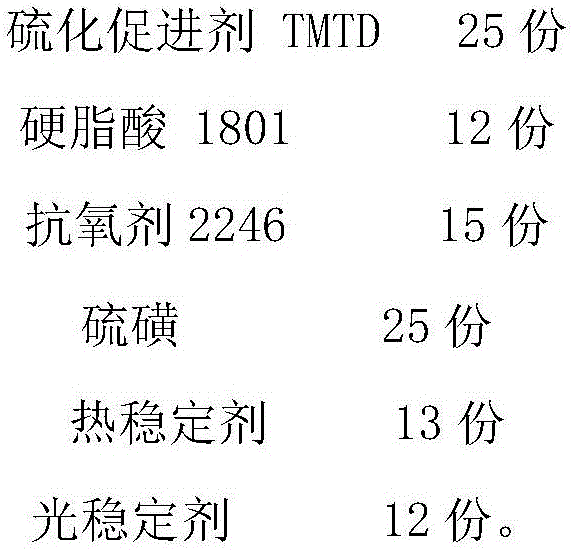

SBS-modified asphalt stabilizing agent

InactiveCN105733283AReduce the use of additivesGuaranteed qualityBuilding insulationsVulcanizationStearic acid

The invention discloses an SBS-modified asphalt stabilizing agent.The SBS-modified asphalt stabilizing agent is prepared from, by weight, 20-30 parts of a vulcanization accelerator TMTD, 10-15 parts of stearic acid 1801, 10-20 parts of an antioxidant 2246, 20-30 parts of sulphur, 10-15 parts of a heat stabilizer and 10-15 parts of a light stabilizer.After SBS and asphalt are mixed and milled under the action of a shear colloid mill, the SBS-modified asphalt stabilizing agent is added, and stirring is performed for 1.5-2 hours at the temperature of 175 DEG C-185 DEG C.The SBS-modified asphalt stabilizing agent can promote compatibility of the SBS and the asphalt substrate and decrease the adding dosage of the SBS, can improve the heat storage stability of the SBS-modified asphalt to prevent separation from occurring and can increase the content of aromatic ingredients and increase the compatibility rate of the asphalt substrate and the SBS.

Owner:WUXI HUATONG ASPHALT NEW TECH DEV

SiC-Al3Ti enhanced aluminum-based composite material preparing method

ActiveCN110129624AImprove wettabilityReduce interfacial energyAlloy elementAluminum matrix composites

The invention discloses a SiC-Al3Ti enhanced aluminum-based composite material preparing method, and relates to the technical field of aluminum-based composite materials. The problems that in the prior art, SiC particles are prone to being aggregated, the alloy element Mg and the metamorphic element Sr are prone to getting burning losses, and consequently the performance of an aluminum-based composite material is poor are solved. Specifically, high-temperature melt with a SiC-Al3Ti composite powder prefabricated block is prepared, the temperature of the high-temperature melt is 850-900 DEG C,low-temperature melt prepared through pure magnesium, an aluminum copper intermediate alloy and an aluminum strontium intermediate alloy is added in an alloy, the temperature of the low-temperature melt is 580-620 DEG C, then, the low-temperature melt is added in the high-temperature melt, and an aluminum-based composite material is obtained. Due to high-low-temperature mixed treatment, an Al3Ti intermetallic compound can be better formed at the high temperature so that good interface bonding can be kept between SiC and an aluminum base body, and base body grains are refined. According to themethod, the preparing technology is simple in operation, and the comprehensive performance of the aluminum-based composite material can be effectively improved.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com