Microemulsion type cleaning agent and preparation method thereof

A technology of cleaning agent and microemulsion, which is applied in the field of cleaning agent and its preparation, can solve the problems of reduced cleaning effect, structural damage of cleaning agent microemulsion, and difficulty in forming a stable oil-in-water structure, so as to improve stability, The effect of enhancing the ability to dissolve oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

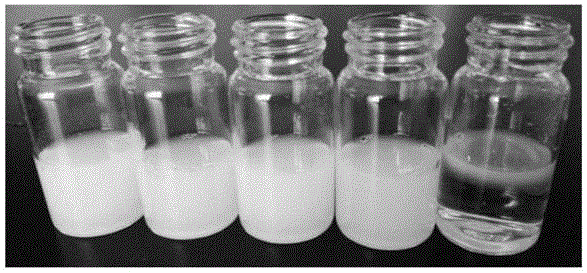

Image

Examples

Embodiment 1

[0027] Example 1: 8.5 parts of AEO-7, 12 parts of AEO-9, 8.5 parts of octylbishydroxyethylmethylammonium chloride, 15 parts of limonene, and 56 parts of pure water.

[0028] The preparation method of the cleaning agent in this example is: first add limonene, octylbishydroxyethylmethylammonium chloride, AEO-7 and AEO-9 into the reaction kettle, stir at room temperature for 20 minutes, mix well, and form a uniform and transparent solution, and then add the remaining amount of pure water, and mechanically stir for 20 minutes to form a uniform transparent microemulsion, and obtain a microemulsion type cleaning agent after standing for defoaming.

Embodiment 2

[0031] Example 2: 10 parts of AEO-7, 10 parts of AEO-9, 9 parts of butylbishydroxyethylmethylammonium bromide, 20 parts of kerosene, and 51 parts of pure water.

[0032] The preparation method of the cleaning agent in this example is: first add kerosene, butylbishydroxyethylmethylammonium bromide, AEO-7 and AEO-9 into the reaction kettle, stir at room temperature for 30 minutes, mix well, and form a uniform and transparent solution, and then add the remaining amount of pure water, and mechanically stir for 25 minutes to form a uniform transparent microemulsion, and obtain a microemulsion type cleaning agent after standing for defoaming.

Embodiment 3

[0037] Example 3: 12 parts of AEO-7, 8.5 parts of AEO-9, 10 parts of pentylbishydroxyethylmethyl ammonium bromide, 15 parts of kerosene, 15 parts of ExxsolD40, 39.5 parts of pure water.

[0038] The preparation method of the cleaning agent in this example is: first add kerosene, ExxsolD40, amylbishydroxyethylmethyl ammonium bromide, AEO-7 and AEO-9 into the reaction kettle, stir at room temperature for 30 minutes, mix well, and form Uniform and transparent solution, then add the remaining amount of pure water, and mechanically stir for 30 minutes to form a uniform and transparent microemulsion. After standing still for defoaming, a microemulsion type cleaning agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com