Preparation method of polymer/graphene nano composite membrane

A nanocomposite and graphene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of microbial and extracellular polymer contamination, difficulty in large-scale application, poor hydrophilicity, etc., and achieve irreversibility Reduced pollution level, improved hydrophilicity, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

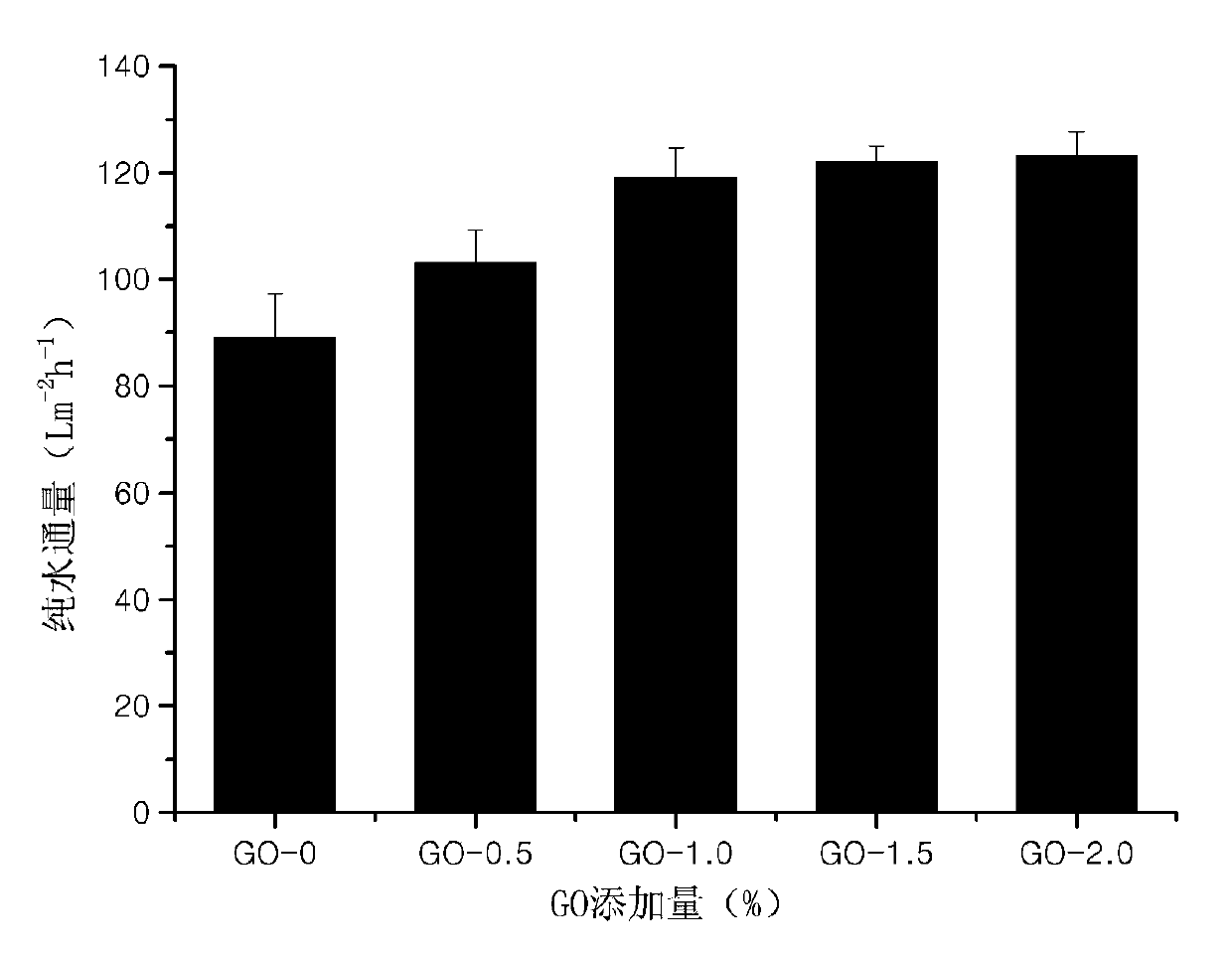

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of a kind of polymer / graphene nanocomposite film of this embodiment is realized by following steps:

[0015] 1. Take 0.01-30 parts of graphene nanomaterials, 5-40 parts of polymers, 30-90 parts of organic solvents, 1-50 parts of organic additives, and 0.1-30 parts of inorganic additives in parts by mass;

[0016] 2. Add the graphene nanomaterial weighed in step 1 into an organic solvent for ultrasonic dispersion, wherein the ultrasonic dispersion power is 50w to 1000w, and the ultrasonic dispersion time is 0.1h to 10h to obtain a graphene nanomaterial suspension;

[0017] 3. Add the polymer, organic additives and inorganic additives weighed in step 1 to the graphene nanomaterial suspension obtained in step 2. After sealing, heat to 20°C-90°C and stir for 2h-48h, then stand still for degassing 1h~96h, get the casting solution;

[0018] 4. The casting solution prepared in step 3 is made into a coagulation bath medium with a...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the graphene nanomaterial is a mixture of one or more of graphene, graphene oxide and modified graphene in any ratio; Among them, the modified materials of modified graphene are polyethylene glycol, polymethyl methacrylate, polyacrylamide, polyvinyl alcohol, C5-C18 quaternary ammonium salt type cationic surfactant, anionic surfactant, nonionic surfactant, etc. Type surfactant, polystyrene, polyguiroxane, N-vinyl-pyrrolidone, 2-hydroxy-ethyl-methacrylic acid, N-vinyl caprolactam, chitosan, phosphorylcholine polymer, egg A mixture of one or more of phospholipids and 2-methacryloylethoxybutyl carbamate in any ratio. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the polymer is polyethylene, polypropylene, polyvinyl chloride, polyvinylidene fluoride, polysulfone, polyethersulfone, polyacrylonitrile , polyetherimide, cellulose acetate, aromatic polyamide, aromatic polyamide urea and sulfonated polyaryl ether sulfone or a mixture composed of any ratio. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com