Layer-by-layer self-assembling oxidized graphene nano-filtration membrane and preparation method thereof

A layer-by-layer self-assembly and nanofiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems that cannot be widely used and do not have characteristics, so as to avoid harsh requirements and achieve large-scale application Prospect, effect of increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

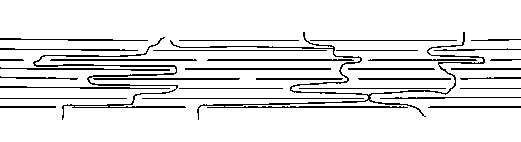

Image

Examples

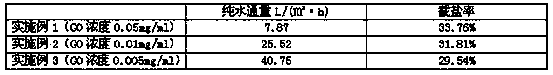

Embodiment 1

[0033] 1. Hummers method prepares graphene oxide solution

[0034] Put 1g of expandable graphite in a three-necked flask, add 100ml of concentrated sulfuric acid into the three-necked flask, and keep the temperature of the mixture below 4°C in an ice-water bath, then slowly add 3g of potassium permanganate, continue stirring in the ice-water bath for 30min, and then Raise the temperature to 30-40°C in a constant temperature water bath, stir for 2.5 hours; slowly add deionized water to the three-necked flask until no bubbles are generated in the reaction system, ensure that the reaction system does not boil during the dropwise addition, and place it in a constant temperature water bath after the dropwise addition Raise the temperature to 90-100°C and stir for 15 minutes, then transfer to a beaker to cool naturally, and then add 15ml of 30% hydrogen peroxide solution, the solution turns into a bright yellow suspension.

[0035] The above obtained suspension was filtered with qu...

Embodiment 2

[0040] 1. Hummers method prepares graphene oxide solution

[0041] Put 1g of expandable graphite in a three-necked flask, add 100ml of concentrated sulfuric acid into the three-necked flask, and keep the temperature of the mixture below 4°C in an ice-water bath, then slowly add 3g of potassium permanganate, continue stirring in the ice-water bath for 30min, and then Raise the temperature to 30-40°C in a constant temperature water bath, stir for 2.5 hours; slowly add deionized water to the three-necked flask until no bubbles are generated in the reaction system, ensure that the reaction system does not boil during the dropwise addition, and place it in a constant temperature water bath after the dropwise addition Raise the temperature to 90-100°C and stir for 15 minutes, then transfer to a beaker to cool naturally, and then add 15ml of 30% hydrogen peroxide solution, the solution turns into a bright yellow suspension.

[0042]The suspension obtained above was filtered with qual...

Embodiment 3

[0047] 1. Hummers method prepares graphene oxide solution

[0048] Put 1g of expandable graphite in a three-necked flask, add 100ml of concentrated sulfuric acid into the three-necked flask, and keep the temperature of the mixture below 4°C in an ice-water bath, then slowly add 3g of potassium permanganate, continue stirring in the ice-water bath for 30min, and then Raise the temperature to 30-40°C in a constant temperature water bath, stir for 2.5 hours; slowly add deionized water to the three-necked flask until no bubbles are generated in the reaction system, ensure that the reaction system does not boil during the dropwise addition, and place it in a constant temperature water bath after the dropwise addition Raise the temperature to 90-100°C and stir for 15 minutes, then transfer to a beaker to cool naturally, and then add 15ml of 30% hydrogen peroxide solution, the solution turns into a bright yellow suspension.

[0049] The suspension obtained above was filtered with qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com