Patents

Literature

134results about How to "Adjustable mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

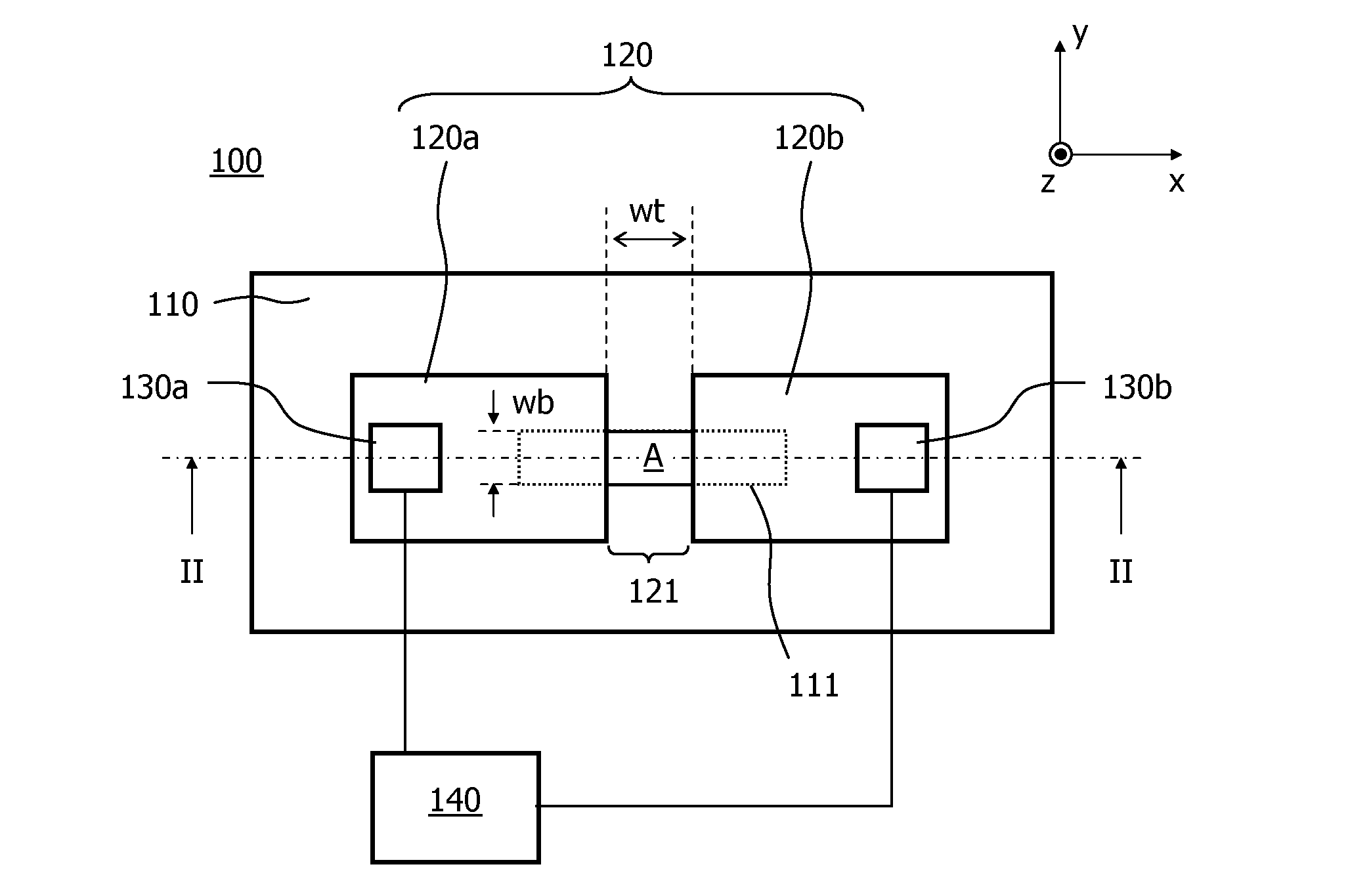

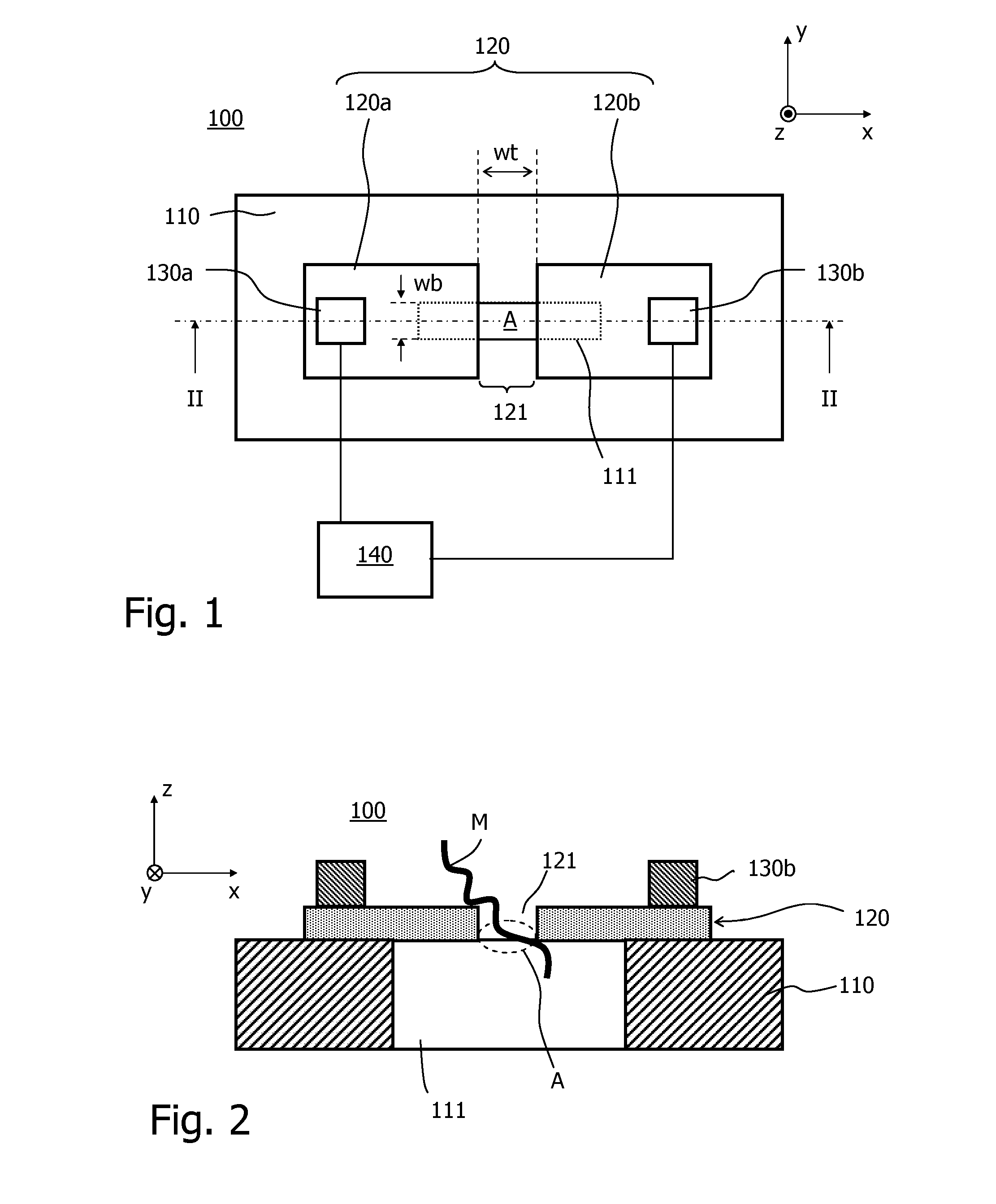

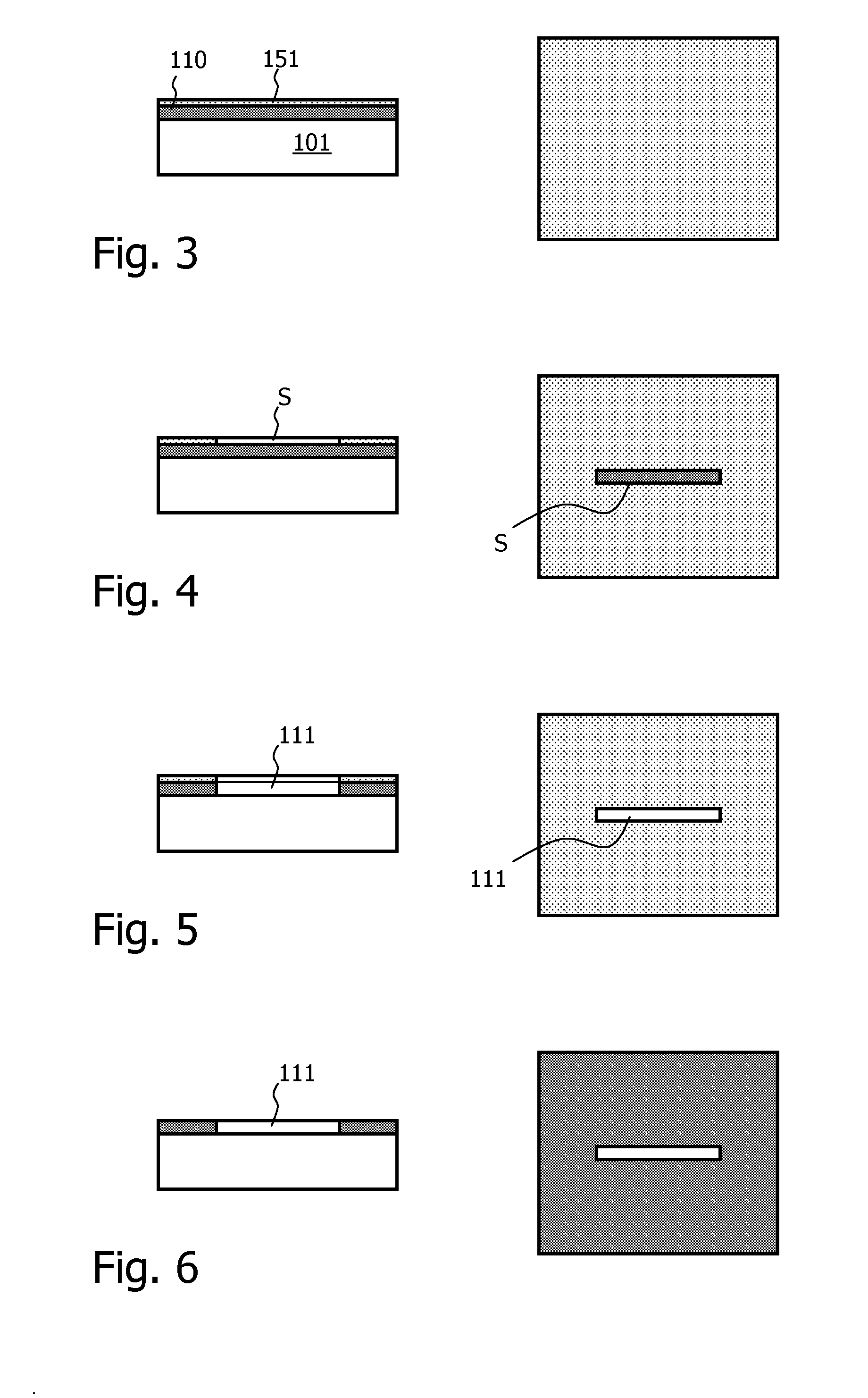

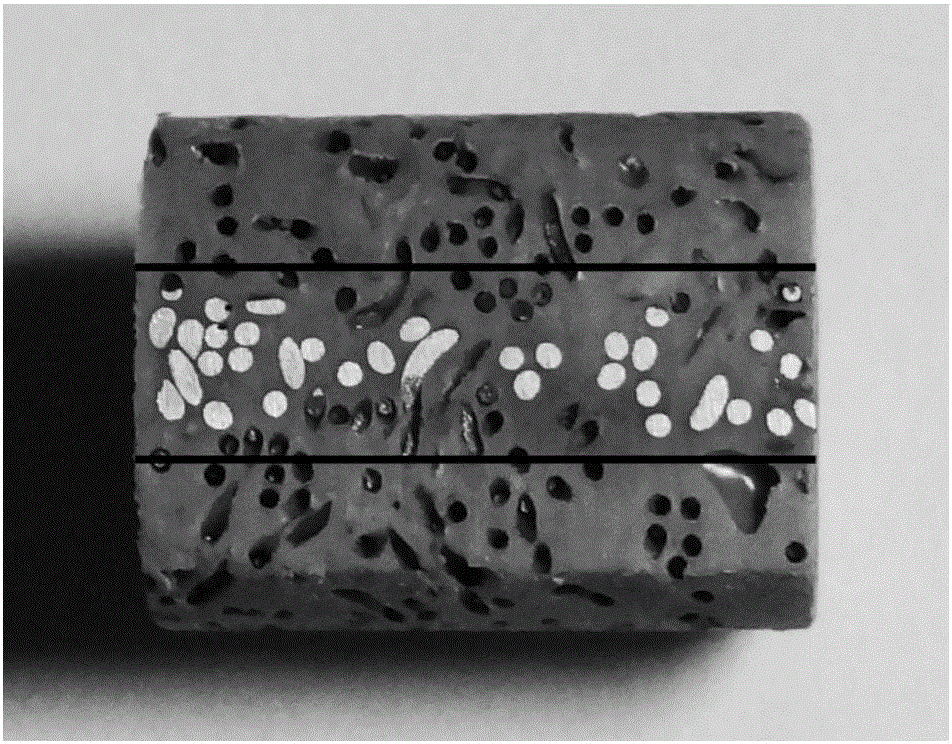

Apparatus for the processing of single molecules

ActiveUS20140349892A1Easy to produceLarge toleranceMaterial analysis by electric/magnetic meansLibraries apparatusEngineeringSingle strand dna

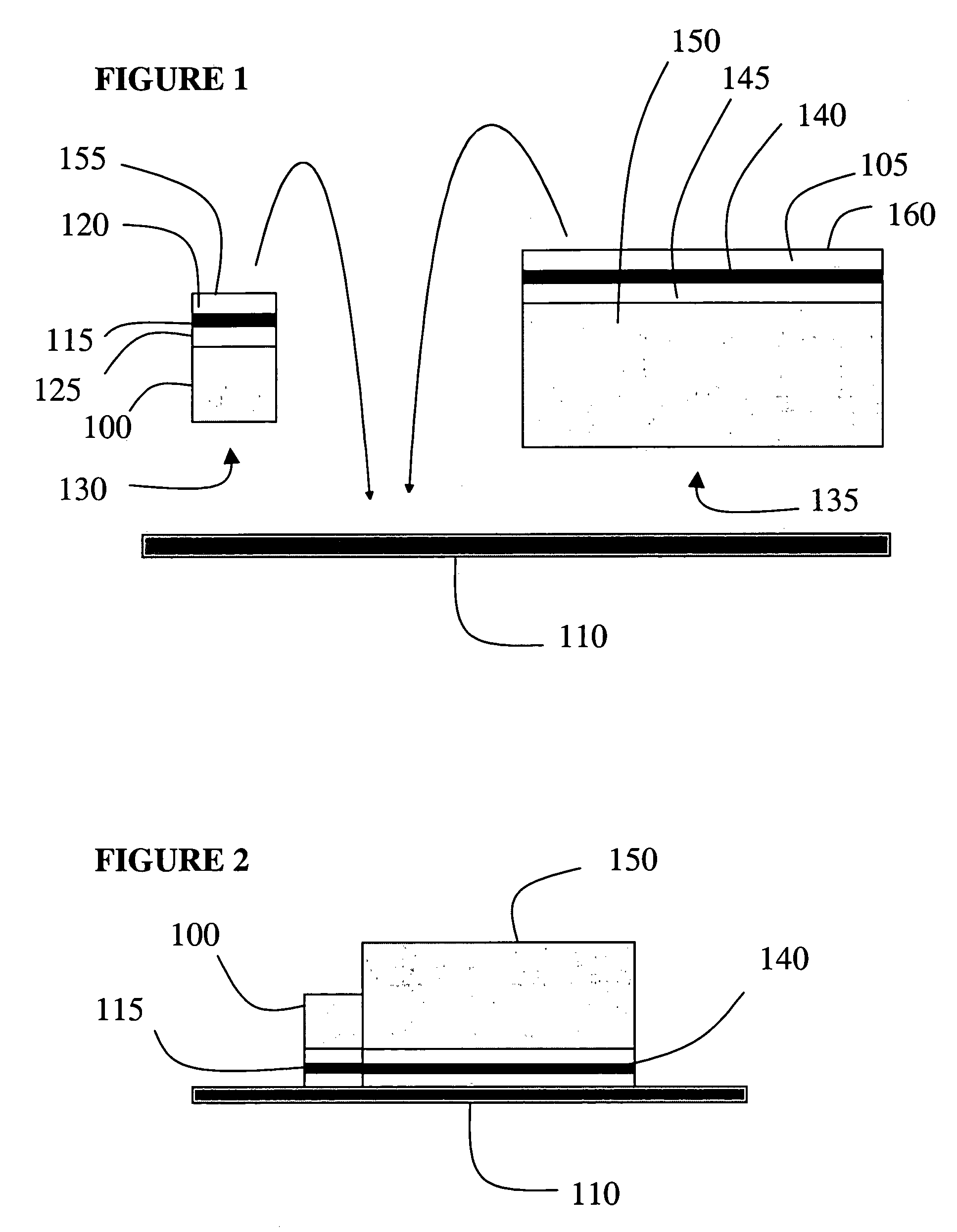

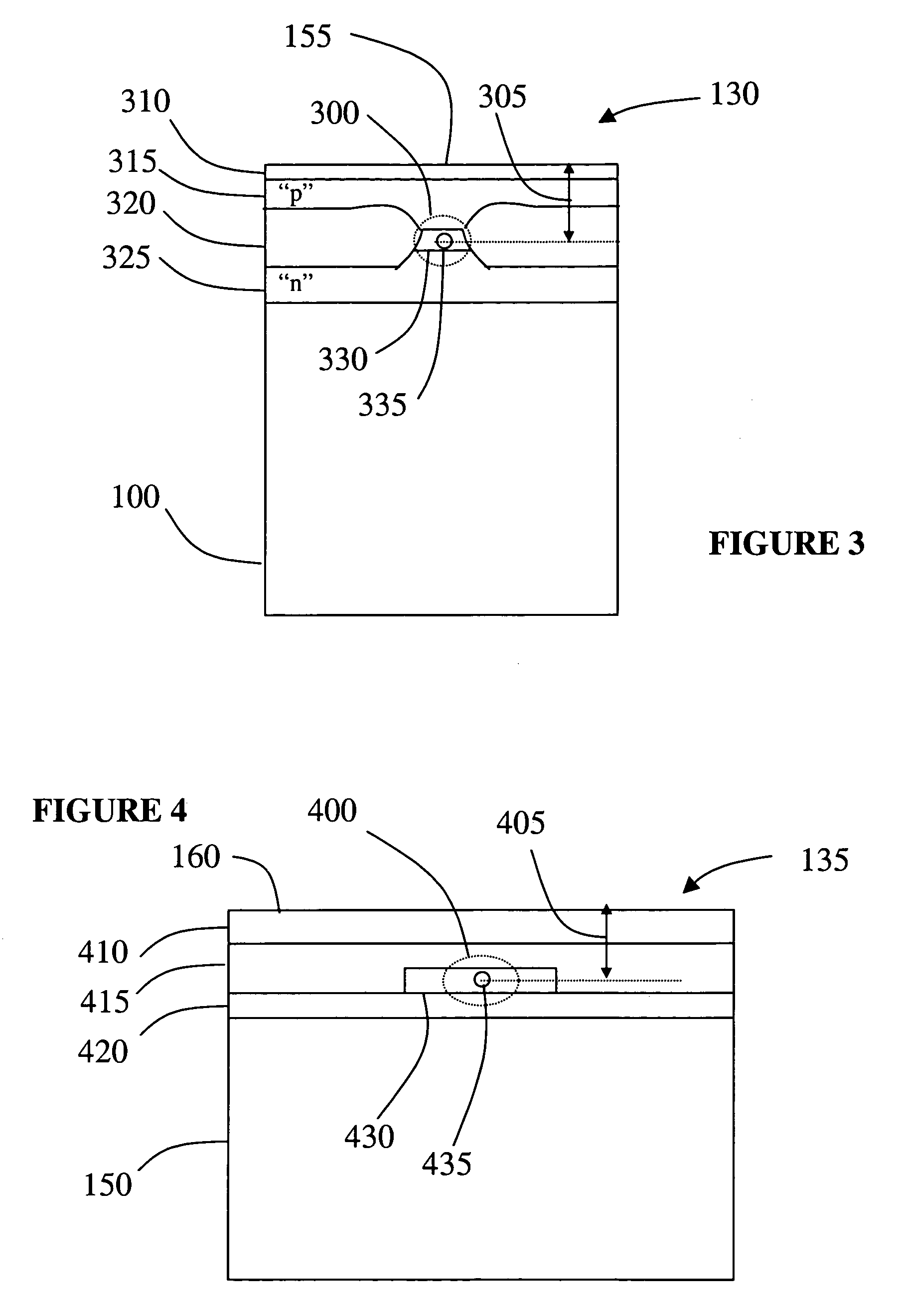

The invention relates to an apparatus(100) and a method for the processing of single molecules, particularly for the sensing or sequencing of single-stranded DNA. A bottom layer(110) and an electrically conductive top layer(120) with a first and a second slit(111,121), respectively, are disposed on top of each other such that an aperture(A) is formed by the slits. The slits(111,121) are preferably perpendicular to each other. An electrical circuit(140) may be connected to the top layer(120), allowing to sense single molecules that pass through the aperture(A).

Owner:KONINKLJIJKE PHILIPS NV

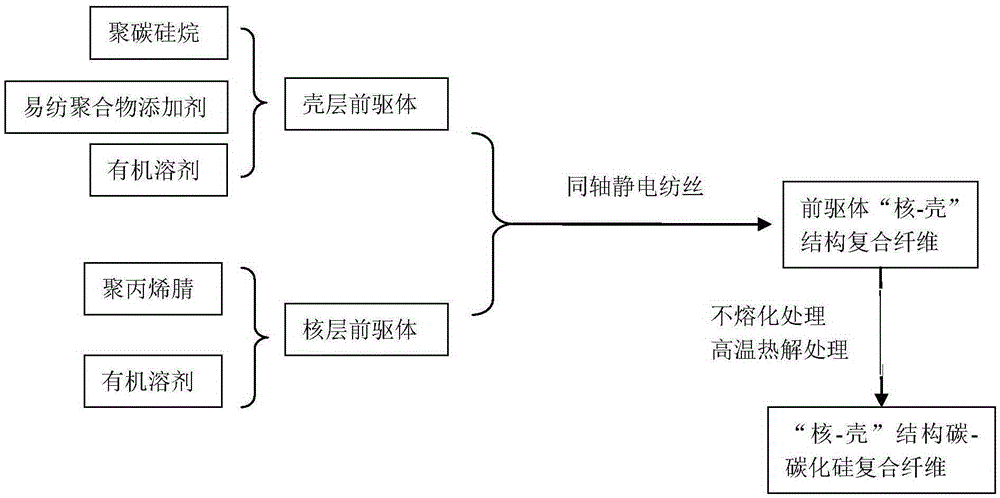

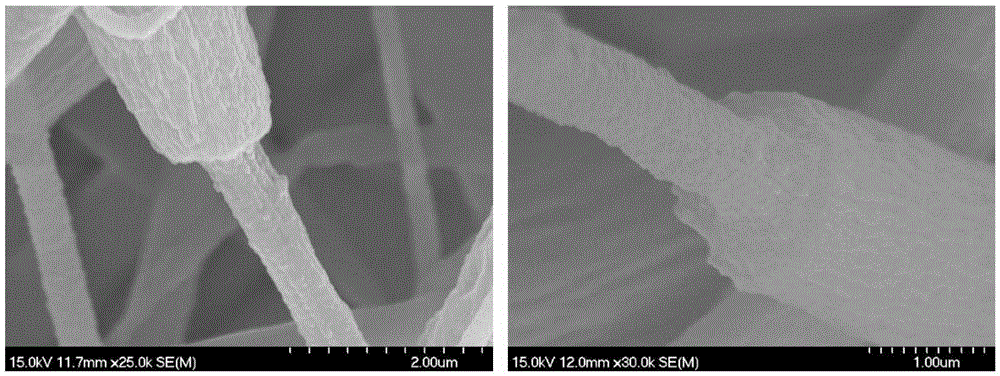

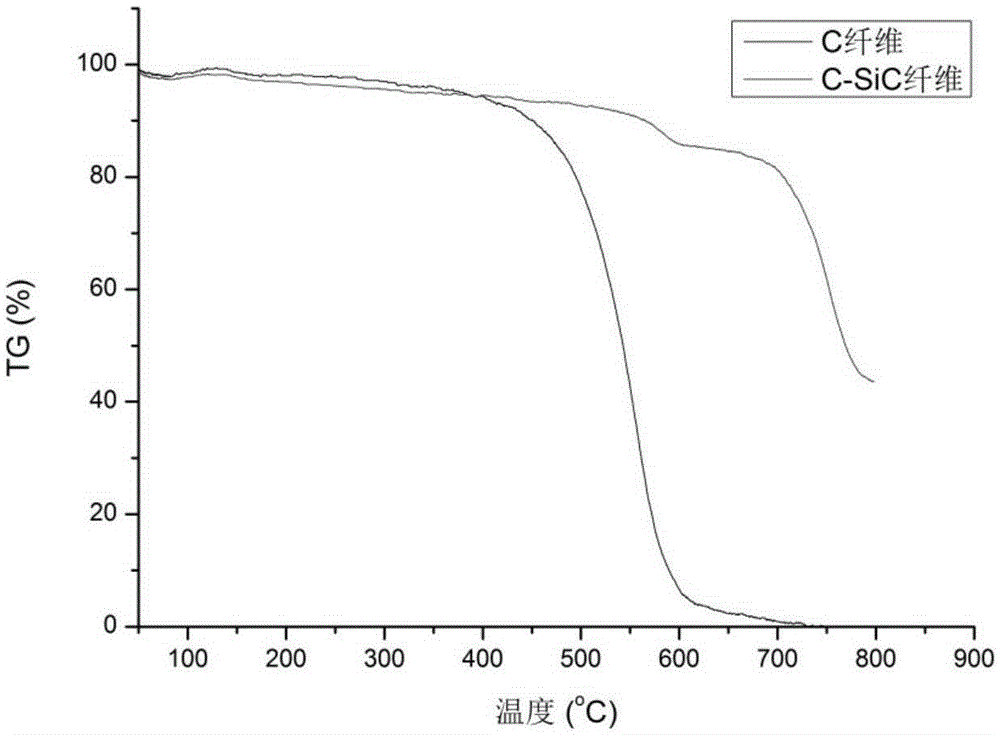

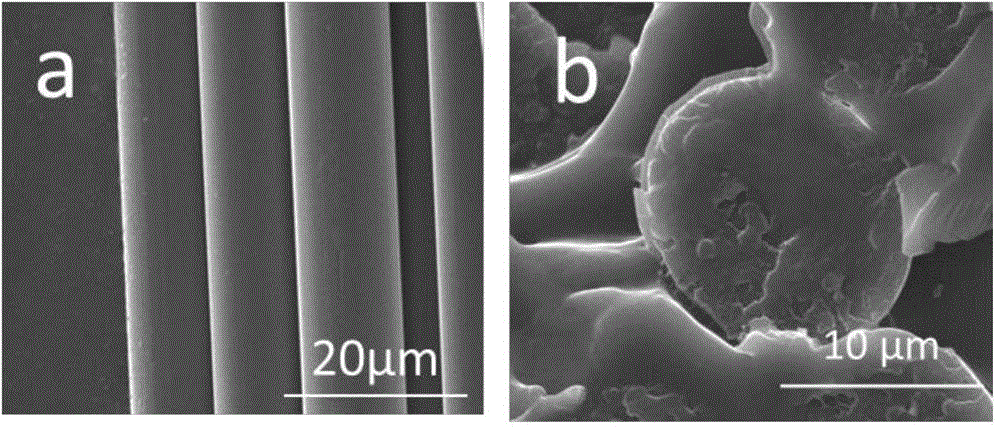

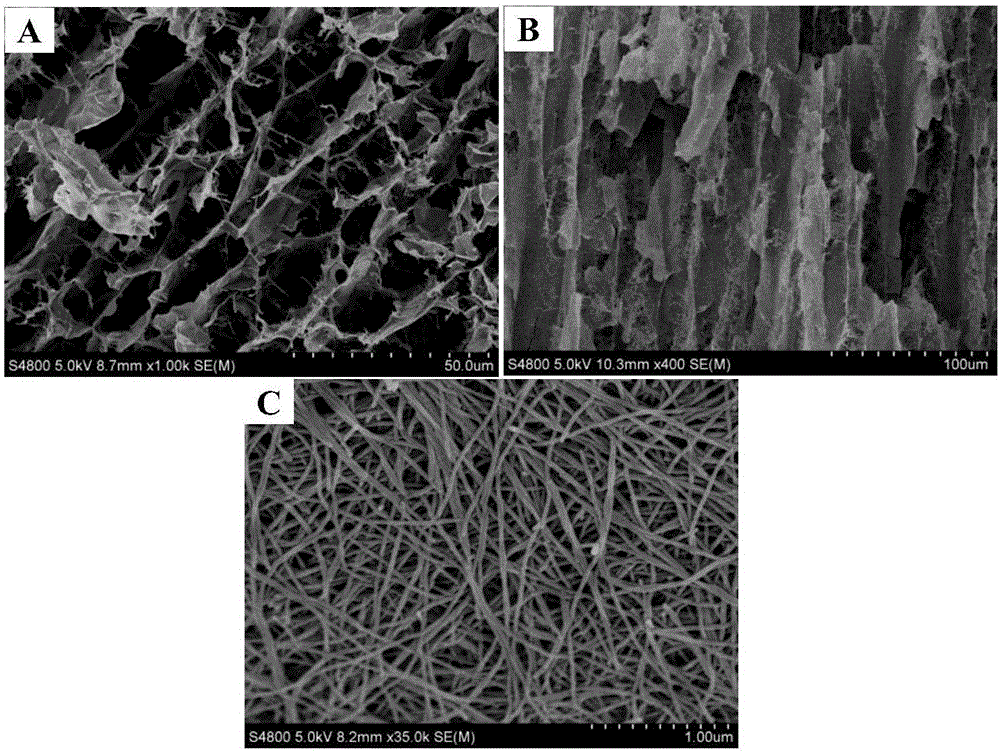

Core-shell structured carbon-silicon carbide composite nano-fibers based on coaxial electrostatic spinning process and preparation method thereof

ActiveCN105256407ATo achieve an organic combinationImprove production efficiencyFilament/thread formingConjugated artificial filamentsMicro structureCarbon fibers

The invention relates to core-shell structured carbon-silicon carbide composite nano-fibers based on a coaxial electrostatic spinning process and a preparation method thereof. The preparation method comprises the following steps: (1) taking a polycarbosilane (PCS) solution and a polyacrylonitrile (PAN) solution as a shell-layer precursor and a core-layer precursor respectively; (2) carrying out electrostatic spinning on the shell / core precursor by using electrostatic spinning equipment with a coaxial needle so as to obtain precursor fibers with a core-shell structure; and (3) carrying out non-smelting treatment and high-temperature pyrolysis treatment on the precursor fibers to finally obtain C-SiC composite fibers with a core-shell structure. The invention provides the novel process method for preparing the core-shell structured composite fibers with carbon fiber cores covering ceramic-phase SiC shells, which have a controllable micro-structure, high efficiency and low cost; and the prepared composite fibers overcome the disadvantage that ceramic fibers are relatively fragile, and functional properties of high intensity and flexibility of the fiber and internal conduction and external insulation are realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

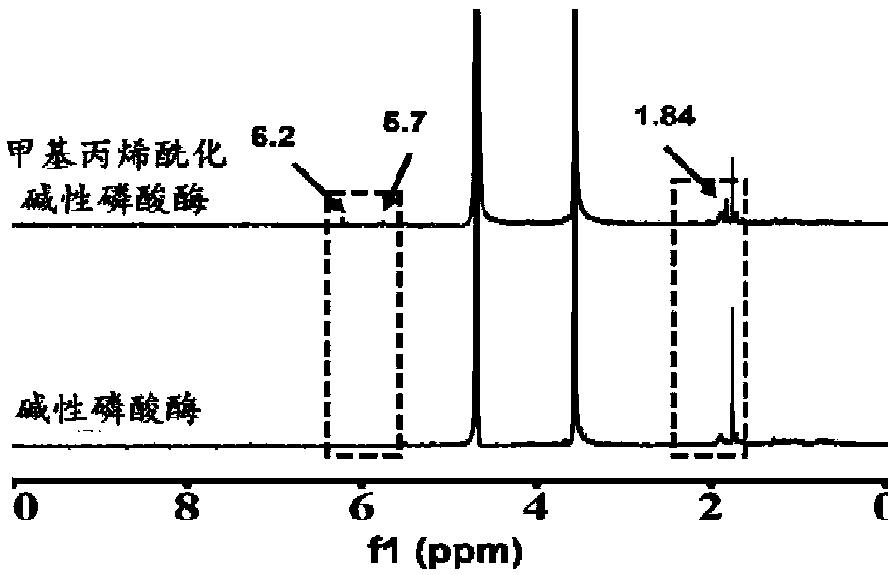

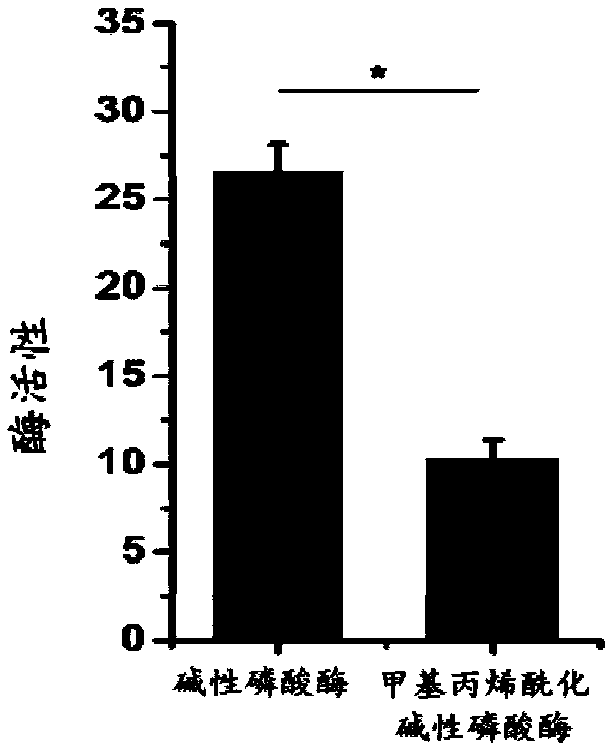

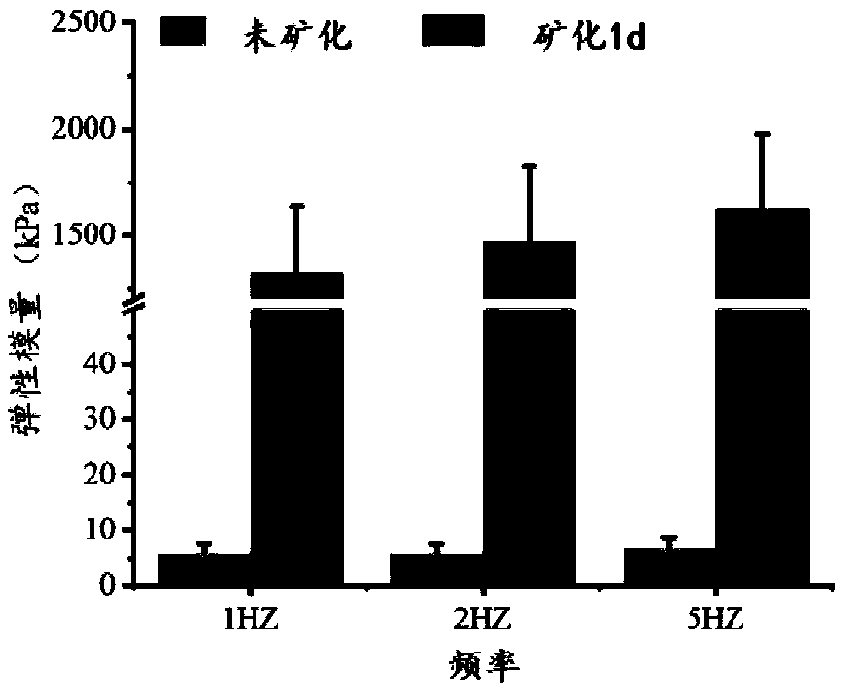

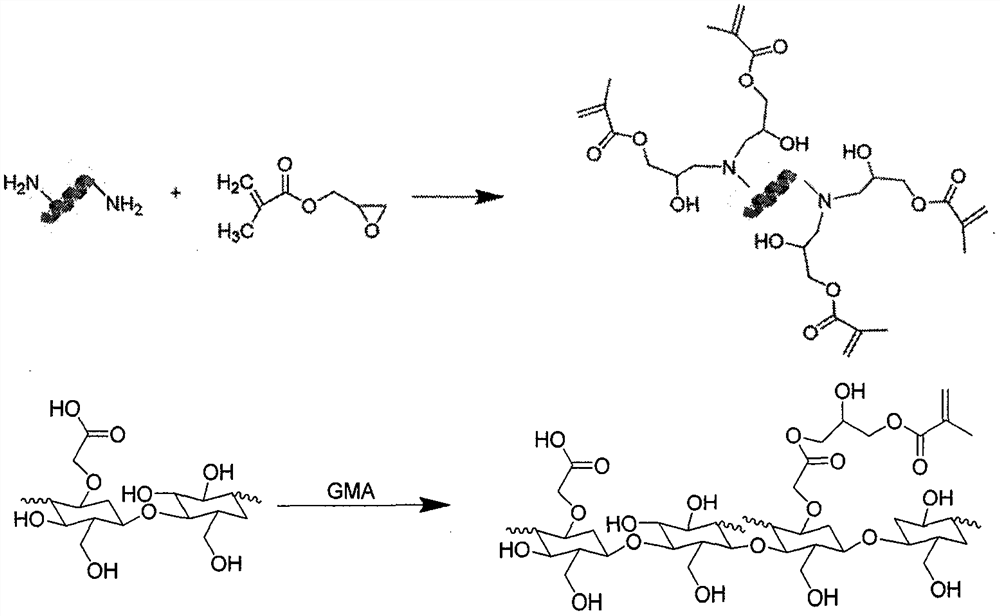

Preparation methods of mineralized hydrogel and biomimetic mineralized bone repair material

The invention discloses preparation methods of mineralized hydrogel and a biomimetic mineralized bone repair material. The mineralized hydrogel is prepared by using a photoactivated biomacromoleculesand a photoactivated phosphatase as raw materials; hydrogel is formed by initiating cross-linking by means of light irradiation or initiating polymerization cross-linking by means of a radical initiator; when the hydrogel is put into mineralized liquid, phosphatase can promote the uniform deposition of phosphate in the gel, so that the uniformly mineralized hydrogel is obtained. Phosphoprotein-like molecules are added during the preparation of the hydrogel; the phosphoprotein-like molecules can promote the uniform deposition of phosphate along a molecular network of biomacromolecules, so thatthe high-strength mineralized hydrogel can be obtained. When the phosphoprotein-like molecules and cells are added during the preparation of the hydrogel, the in-situ loading of the cells can be realized, and the enzyme in a process of bone physiological mineralization can be simulated so as to promote a phosphate mineralization process, so that the biomimetic mineralized bone repair material withhigh strength can be obtained, and the personalized customization of the bionic mineralized bone repair material can be realized; therefore, the preparation methods have a broad application prospectin the field of bone tissue engineering.

Owner:SICHUAN UNIV

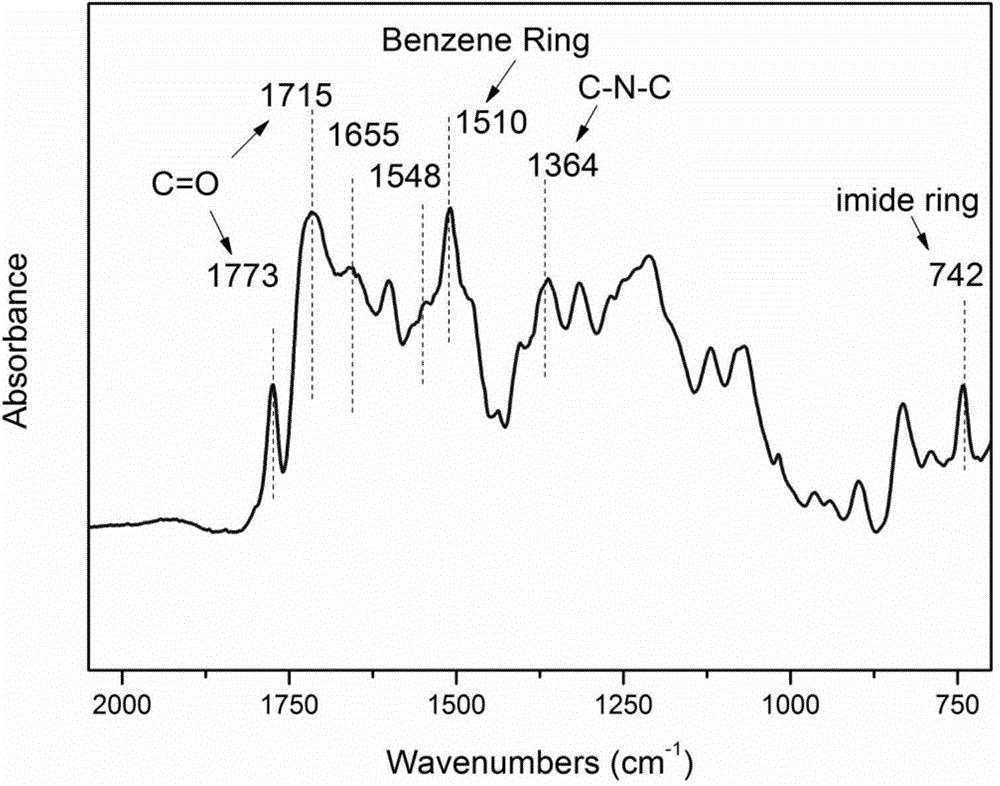

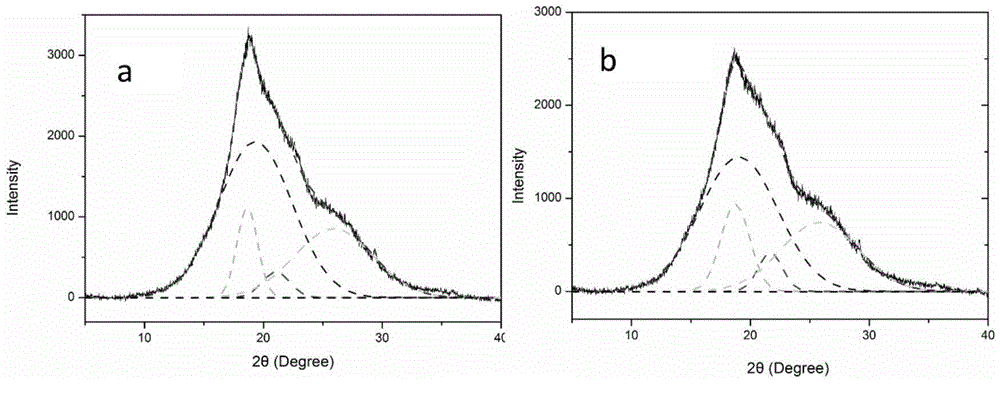

Method for preparing polyimide fibers

InactiveCN104928790AHigh crystallinityImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentFiberImide

A method for preparing polyimide fibers belongs to the field of high-performance organic fibers. The method comprises the following steps: preparing a copolymerized polyamide acid spinning solution through condensation polymerization of dianhydride and diamine; adding acetic anhydride and a catalyst in the polyamide acid spinning solution to obtain partly imidized polyamide acid spinning solution; spinning by adopting a wet or dry-wet spinning process, and solidifying and washing to obtain partly imidized polyimide fibers; conducting thermal imidization on the fibers at gradient temperature, and preparing the polyimide fibers with high strength, high modulus and high mechanical performance. The method provided by the invention is used for preparing the polyimide fibers by combination of chemical imidization and thermal imidization, and can be used for further improving the mechanical performance of the polyimide fibers, thereby meeting requirements of various applications.

Owner:BEIJING UNIV OF CHEM TECH

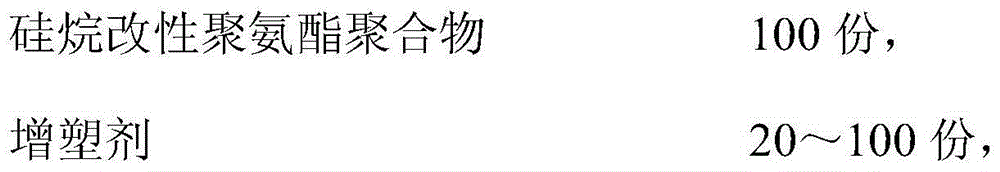

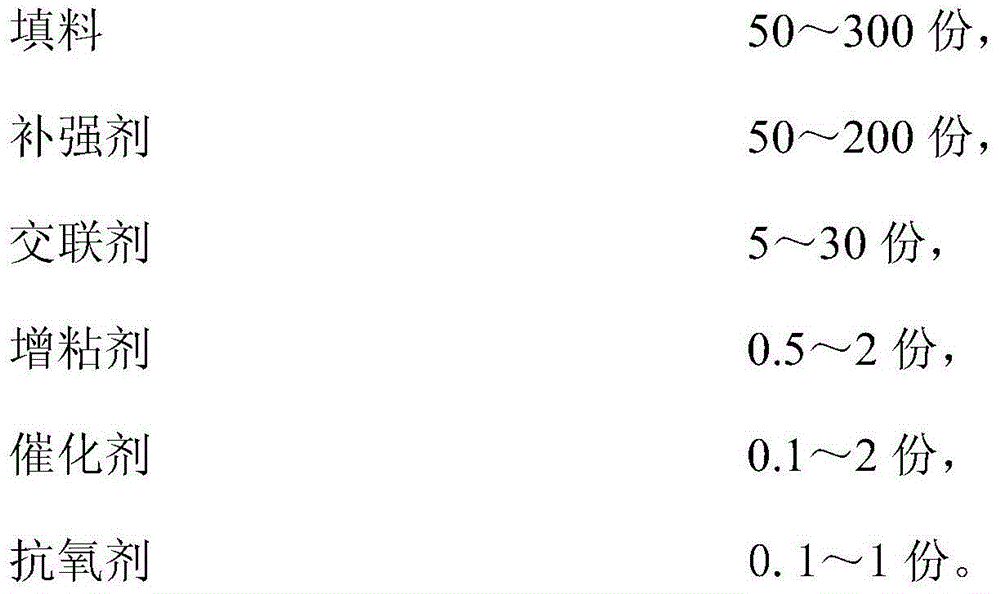

Silicane modified polyurethane sealant used for automobile and preparing method thereof

ActiveCN104694065AImprove mechanical propertiesAdjustable mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPlasticizer

The invention discloses silicane modified polyurethane sealant used for an automobile and a preparing method thereof. Silicane modified polyurethane polymer, plasticizer, filling, reinforcing agents, cross-linking agents, thickening agents, catalytic agents and an antioxidant are used as raw materials. The preparing method includes the steps that firstly, the silicane modified polyurethane polymer and the plasticizer are evenly mixed at the temperature of 80 DEG C-90 DEG C under the vacuum degree of 0.06 MPa-0.09 MPa; then the filling is added, and stirring and mixing are performed evenly; then the reinforcing agents and the antioxidant are added, dehydrated and blended evenly at the temperature of 100 DEG C-120 DEG C under the vacuum degree of 0.06 MPa-0.09 MPa; finally, the cross-linking agents, the thickening agents and the catalytic agents are added and mixed evenly under the vacuum degree of 0.06 MPa-0.09 MPa to obtain the silicane modified polyurethane sealant used for the automobile. Compared with the same kind of materials, the silicane modified polyurethane sealant used for the automobile is wide in selection range of mechanical properties, and can be used for sealing and adhering of different component of the automobile according to different requirements; the water-resistant performance is excellent, and the safety of automobile operation is ensured; meanwhile, the sealant has excellent mechanical performance and adhesive performance, is resistant to aging, and can be widely applied to the field of automobile manufacturing.

Owner:CHENGDU GUIBAO SCI & TECH

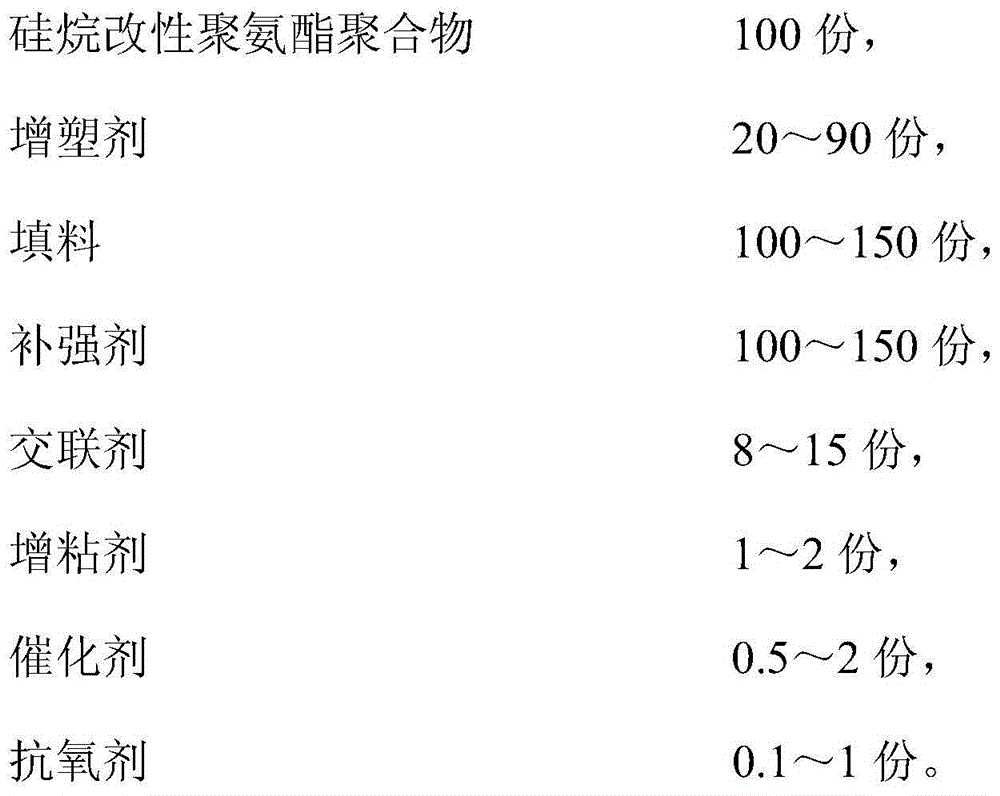

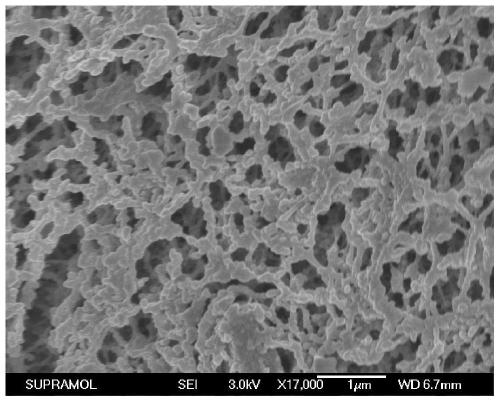

Medical porous polyether-ether-ketone with drug loading function and preparing method and application thereof

ActiveCN106178104AGood mechanical propertiesExcellent bone transportTissue regenerationProsthesisPorosityPressure casting

The invention relates to medical porous polyether-ether-ketone with a drug loading function and a preparing method and application thereof. The medical porous polyether-ether-ketone has a uniform porous structure or gradient change type porous structure, pore size is 0.05-2 mm, and porosity is 10-90%. During preparation, molten polyether-ether-ketone is extruded into preform pores through pressure casting, and then preform is etched off with the chemical method to form the porous polyether-ether-ketone. The material has excellent mechanical property, and pore size and porosity are controllable. The porous structure of the material can be loaded with drugs to prevent infection and promote bone growth and healing. Compared with the prior art, the medical porous polyether-ether-ketone with the drug loading function and the preparing method and application thereof have the advantages that operation is easy, structure is controllable, drug loading is convenient, drug binding is firm, and cost is low.

Owner:SHANGHAI JIAO TONG UNIV

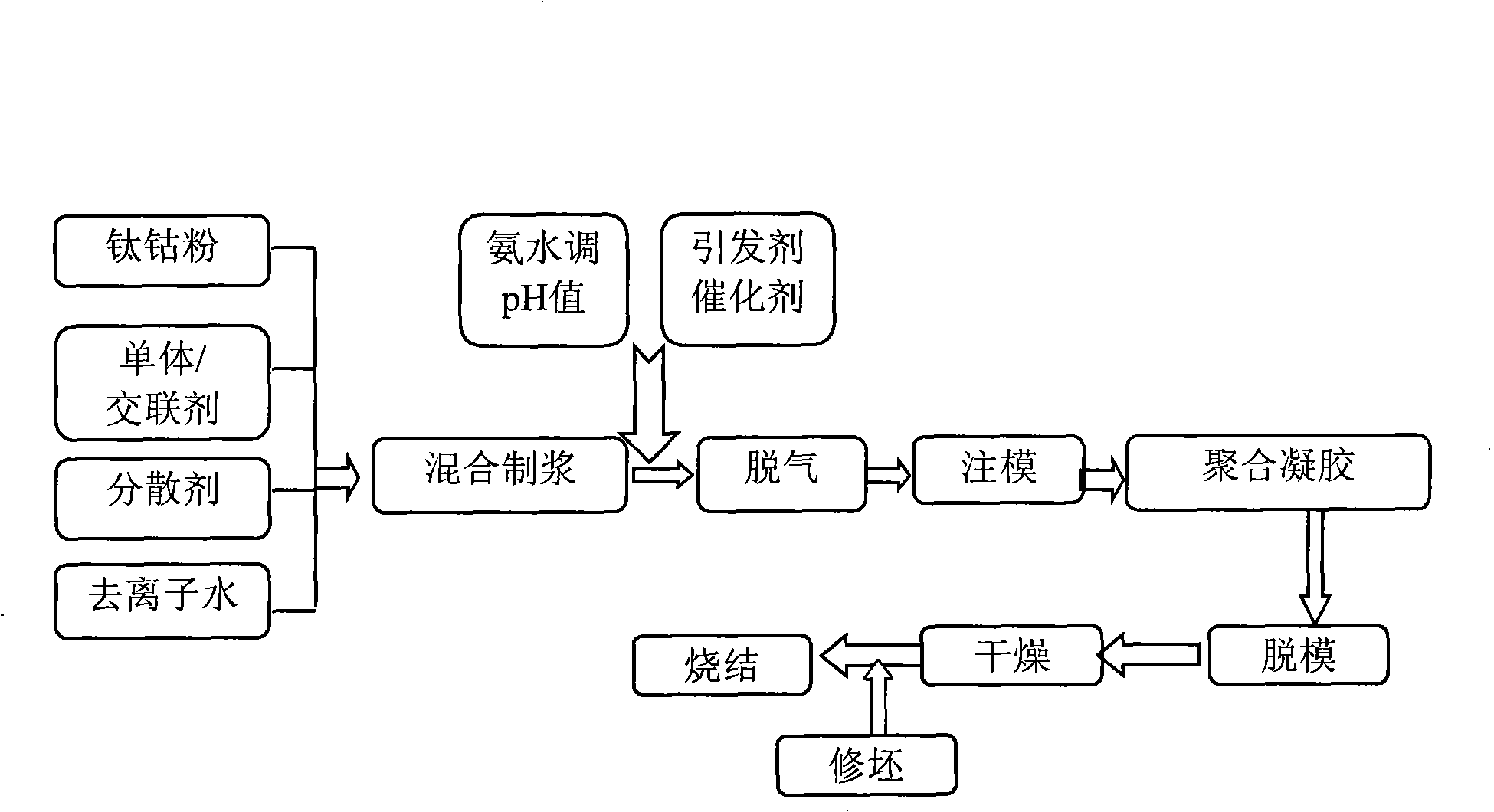

Preparation of gel injection molding of porous titanium-cobalt alloy medical implant article

InactiveCN101279106AExcellent biocompatibility and tissue bindingComplex shapeProsthesisIonDegreasing

The invention relates to a gel casting preparation method for a medical multi-hole titanium-cobalt alloy implant. The gel casting preparation method pertains to the technical field of the medical material preparation. Acrylamide monomer, a crosslinking agent N, N'-methylene-bisacrylamide and deionized water are prepared into a premixed solution with a certain concentration; a dispersing agent oleic acid is added to the premixed solution to lead titanium-cobalt alloy powders to suspend in the premixed solution so as to prepare a slurry body; the pH value is adjusted to 9.0 to 10.0, then a proper amount of catalyst N, N, N', N'-TMEDA (tetramethylethylenediamine) and an evocating agent ammonium persulfate are added to the slurry body and are evenly stirred, then the slurry body is injected to a mold after being degassed; monomers in the mold undergo polymerization, therefore, a meshy structure is formed to cover the titanium-cobalt powders, then a blank body meshy-shaped by large molecules is formed. A product is obtained after the blank body is dried, batched out and sintered. In addition, the porosity and the mechanical property of the multi-hole titanium-cobalt alloy can be changed through adjusting the solid content, so as to meet the performance requirements of various medical implants. The gel casting preparation method for the multi-hole titanium-cobalt alloy medical implant requires no complicate devices and special degreasing techniques, has simple process, can greatly reduce production costs, and is particularly applicable to the medical implants with the characteristics of various specifications and mass production.

Owner:UNIV OF SCI & TECH BEIJING

Application of porous magnesium alloy as carrier in medicine

InactiveCN106267332AGood mechanical propertiesExcellent bone transportSurgeryProsthesisAdsorption equilibriumPlasma electrolytic oxidation

The invention relates to application of a porous magnesium alloy as a carrier in medicine. Drugs can be carried onto the porous magnesium alloy to be used as a blood vessel stent, bone repair or bone propping material. The porous magnesium alloy is prepared by direct foaming, corrosion pore forming, laser drilling, powder metallurgy, quick forming, co-permeation vibration, 3D printing and the like. Laser cladding, microarc oxidation, anode oxidation, osmosis, embedding, solvent evaporation drying, melting, adsorption equilibrium and the like are performed to carry drugs into the porous magnesium alloy surface or the inside of the porous structure, thereby performing the functions of increasing the surface activity, promoting the bone cell growth and differentiation, preventing infection, implementing specific drug delivery and partial drug delivery and the like. The preparation method is simple to operate and easy to implement, and has the advantages of controllable structure, convenient drug carrying, firm drug combination, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

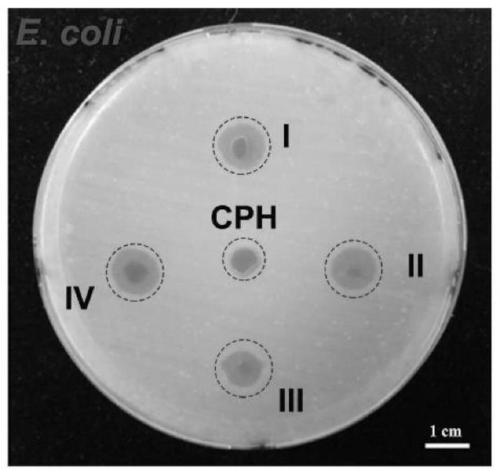

Anti-bacterial-adhesion conductive hydrogel and preparation method and application thereof

ActiveCN110117369AImprove stability and environmental adaptabilityGreat application prospectPharmaceutical delivery mechanismBandagesFunctional polymersBiocompatibility Testing

The invention provides an anti-bacterial-adhesion conductive hydrogel and a preparation method and application thereof, and belongs to the technical field of functional polymer materials. According tothe method, silver nanoparticles modified by synthesized polydopamine are compounded in a solution of a conductive polymer monomer and polyvinyl alcohol, polymerization is initiated by using an initiator, and the conductive hydrogel is prepared in situ. The hydrogel has good biocompatibility, high bioadhesiveness, excellent electrical conductivity, excellent antibacterial properties for Gram-negative bacteria and Gram-positive bacteria and adjustable mechanical properties. The anti-bacterial-adhesion conductive hydrogel can be used as a novel medical polymer wound dressing, which has potential biological and medical application value in promoting wound healing of the body.

Owner:JILIN UNIV

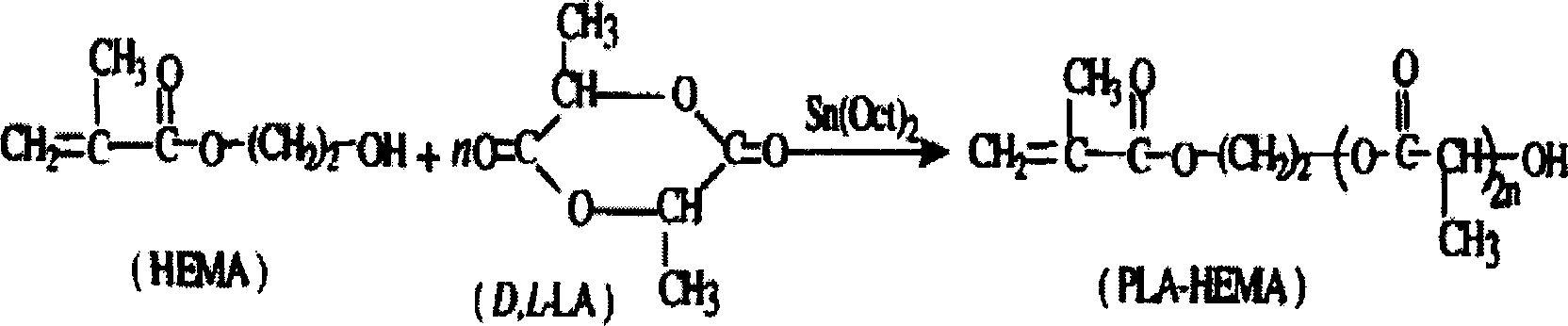

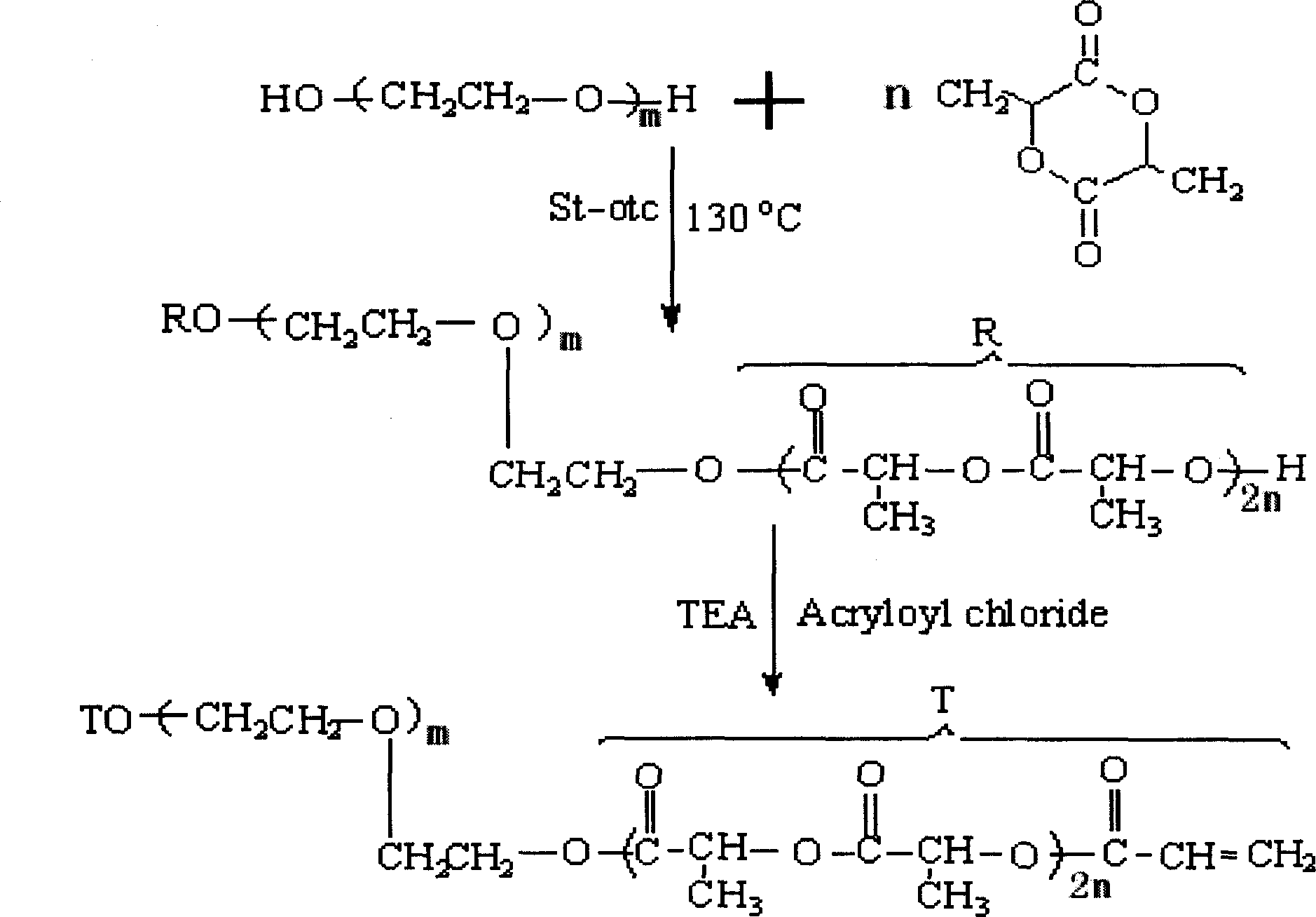

Biodegradable active medical tissue adhesive and its preparation method

InactiveCN100998889AAdjustable mechanical propertiesLow heat of polymerizationImpression capsSurgical adhesives(Hydroxyethyl)methacrylateHard tissue

A biodegradable and bioactive medical tissue adhesive with high bilcompatibility and adjustable mechanical strength and degradating speed for adhering soft tissue and hard tissue is prepared from the liquid phase (hydroxyethyl methylacrylate ring- opening polymerized cycloester type macro-molecular monomer), the alcohol type compound (biodegradable cross-linking agent, vinylpyrrolidone, N,N-dimethyl p- tolueneamine, or hydroquinone), and the solid phase (encapsulated natural powder, pore-forming agent, and benzoly peroxide) through mixing.

Owner:广州暨科拓源生物材料科技开发有限公司

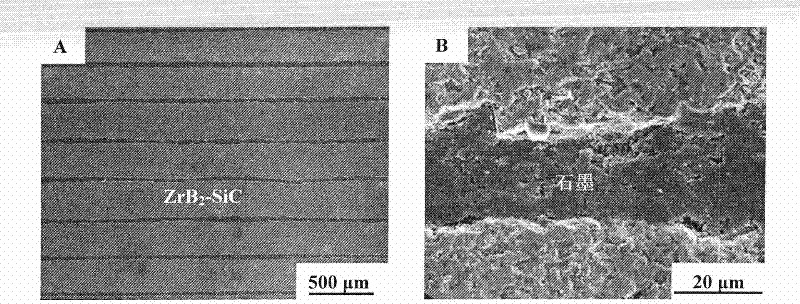

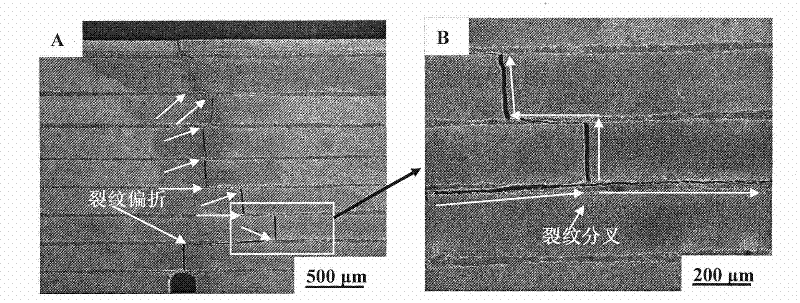

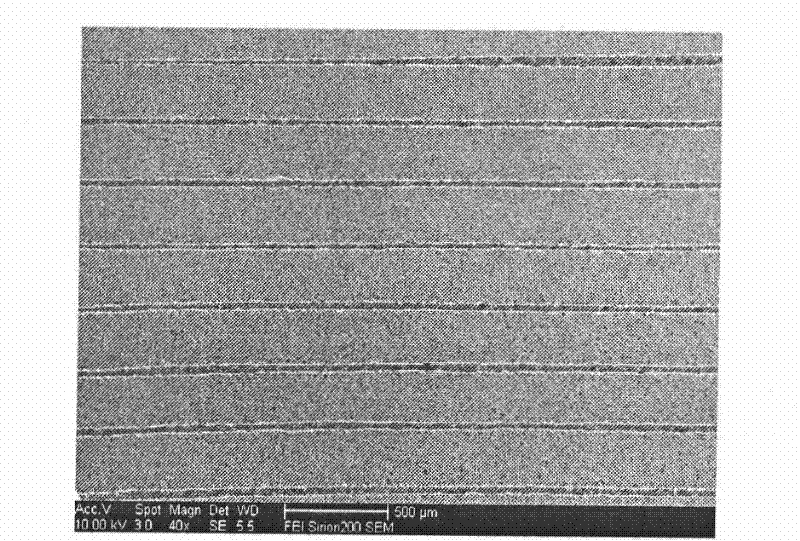

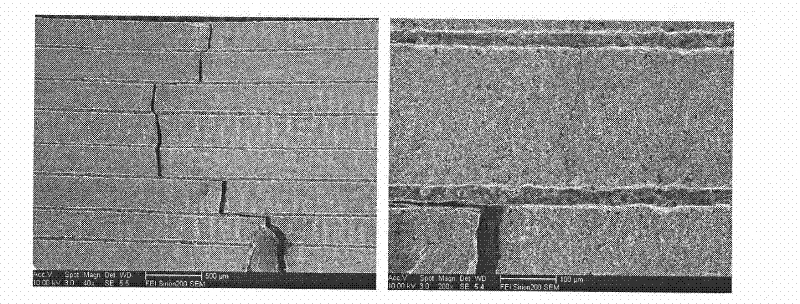

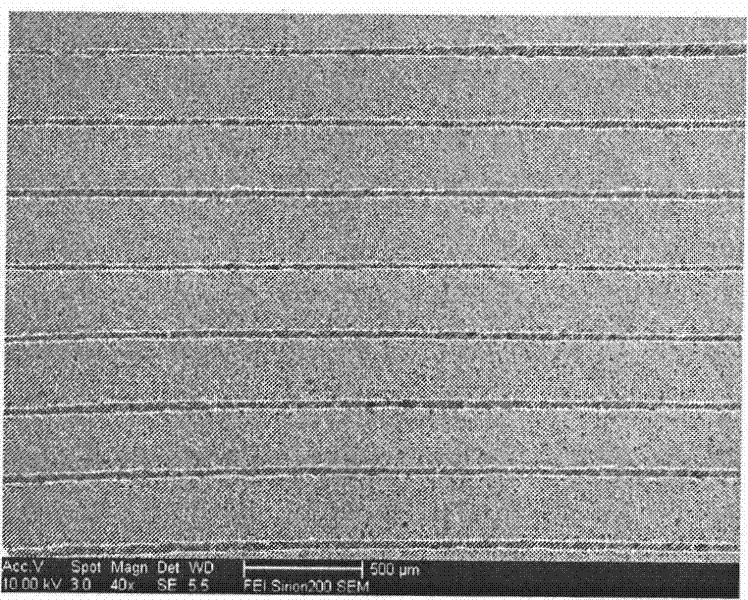

Preparation method of zirconium boride-silicon carbide/graphite layered superhigh temperature ceramic

InactiveCN102173829AAdd extension pathImprove fracture toughnessCeramic layered productsSolventPlasticizer

The invention provides a preparation method of zirconium boride-silicon carbide / graphite layered superhigh temperature ceramic. The preparation method is characterized by comprising the following steps: 1) separately preparing a zirconium boride casting sheet and a zirconium oxide casting sheet by using a casting method, namely, adding a binder and a plasticizer in a solvent and evenly mixing, separately adding a zirconium boride ceramic powder material and a graphite ceramic powder material, and evenly mixing to form a casting material, then carrying out casting forming, and drying at room temperature and demoulding to respectively obtain the zirconium boride casting sheet with the thickness of 200-1000 mu m and the graphite casting sheet with the thickness of 20-100 mu m; 2) respectively slicing the zirconium boride casting sheet and the graphite casting sheet according to the size of a mould; 3) putting the zirconium boride sheet and the graphite sheet in a graphite mould in an alternatively overlapping way for vacuum derosination; and 4) hot pressed sintering in an argon atmosphere to prepare the layered superhigh temperature ceramic. According to the invention, preparation process is simple, cost is low, the machinability of the material is strong, compositions are controllable, and the toughness of the material is up to 11.3MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

Application of porous titanium alloy in medical science as carrier

InactiveCN106390207AEasy to control shapeThe size is easy to controlTissue regenerationProsthesisSpinal columnMicro arc oxidation

The invention relates to an application of porous titanium alloy in medical science as a carrier. The application comprises the following steps: 1, winding and braiding medical titanium alloy wires to prepare porous titanium alloy; and 2, loading a drug to the surface or the porous structure of the porous titanium alloy through laser cladding, micro-arc oxidation, anodization, osmosis, an entrapping method, a solvent volatilization, a melting method or an adsorption balancing method. The porous titanium alloy can be used as an artificial joint, spinal column fusion, bone filling, bone restoration or bone transplantation material in order to realize surface activity increase, osteocyte growth and differentiation promotion, infection prevention, targeted administration and local administration effects. Compared with carriers in the prior art, the porous titanium alloy used as the carrier has the advantages of simplicity and easiness in operation, controllable structure, convenience in drug load, firm drug combination and low cost.

Owner:SHANGHAI JIAO TONG UNIV

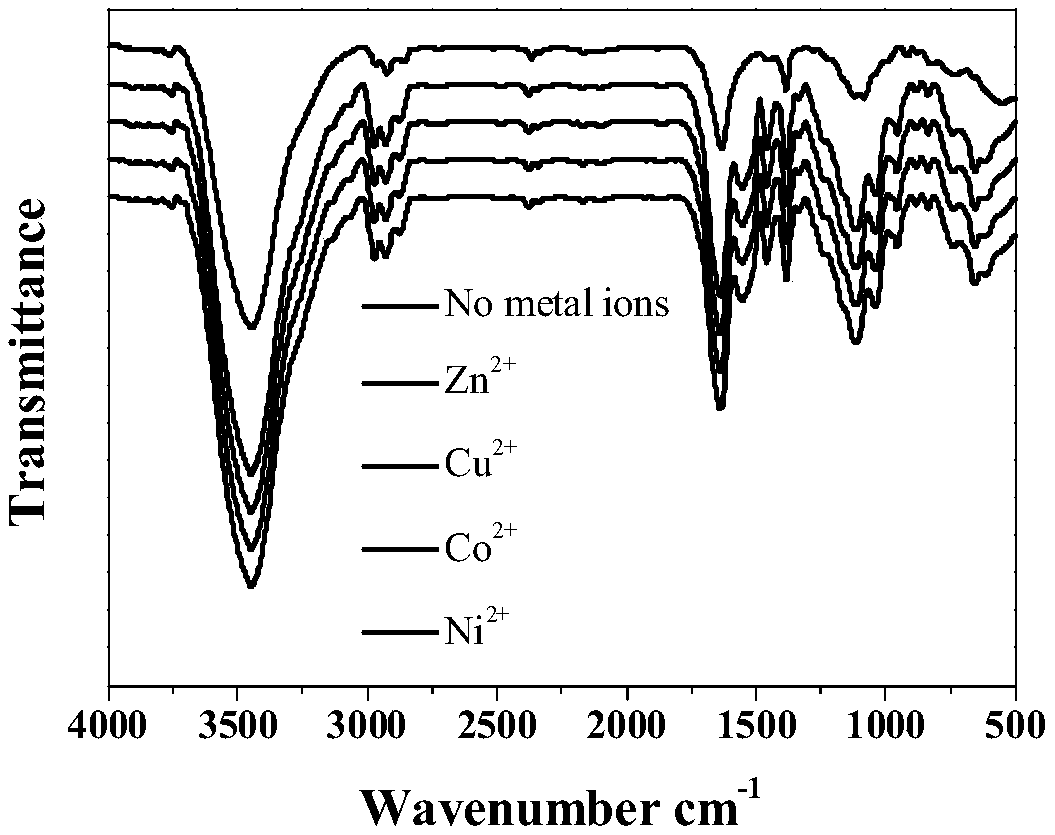

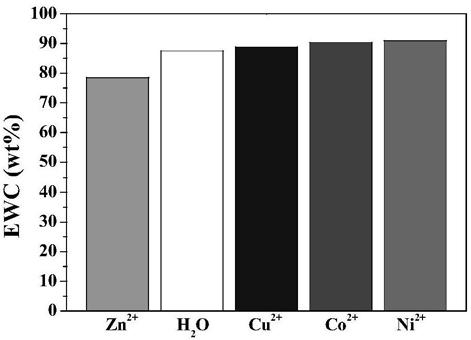

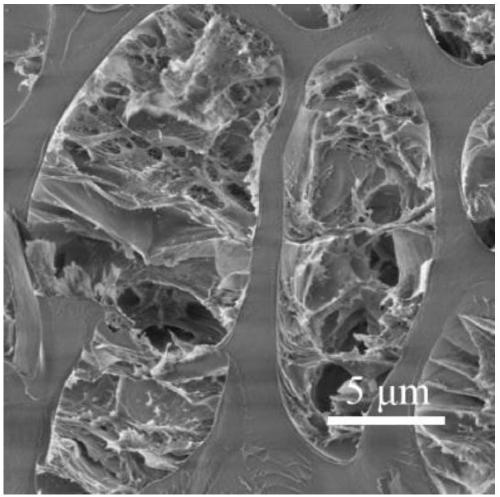

Thermosensitive conducting hydrogel with enhanced metal ion coordination and preparation method thereof

The invention relates to a preparation method of thermosensitive conducting hydrogel with enhanced metal ion coordination, and belongs to the technical field of the thermosensitive conducting hydrogel. The method includes the following steps: (1) dissolving monomeric vinylimidazole and N-isopropylacrylamide in deionized water, adding a crosslinking agent, an initiator and an accelerator, performing prepolymerization after dissolving and uniform mixing, and performing complete reaction to obtain a chemically crosslinked hydrogel precursor; (2) taking out the hydrogel precursor obtained in the step (1), soaking the hydrogel precursor in a solution containing divalent metal zinc, copper, cobalt and nickel ions for coordination, soaking the hydrogel precursor in water to remove redundant uncoordinated ions, and performing swelling equilibrium to obtain the metal-ion-coordinated thermosensitive conducting hydrogel. The preparation method has the advantages that the mechanical strength of the hydrogel is regulated through reversible physical cross-linking between the metal ions and a specific ligand, and the hydrogel has quick thermosensitivity and electrical conductivity.

Owner:SHANDONG UNIV

Biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite

InactiveCN101524558AGood biocompatibilityImprove creep resistanceProsthesisPowder metallurgyBone tissue engineering

The invention relates to a biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite, belonging to the field of biomedical materials. The material of the invention is composed of the composite of magnesium-calcium alloy and hydroxylapatite particles, the components and mass percent thereof are: 0.01-5% of Ca, 0-1% of Zn and Mg as the balance; the mass ratio of the hydroxylapatite to magnesium-calcium alloy is 0.01-50:100. In the invention, powder metallurgic method is adopted. The material matrix of the invention has close bonding with strengthened nano particles which areevenly distributed. The composite of the invention can be biologically degradable and has fine mechanical property and biological activity, and wide application prospect in medical material field such as repairing impairment of scaffold for bone tissue engineering, fixed fasteners within bones and weight-bearing parts of bones.

Owner:CHONGQING UNIV

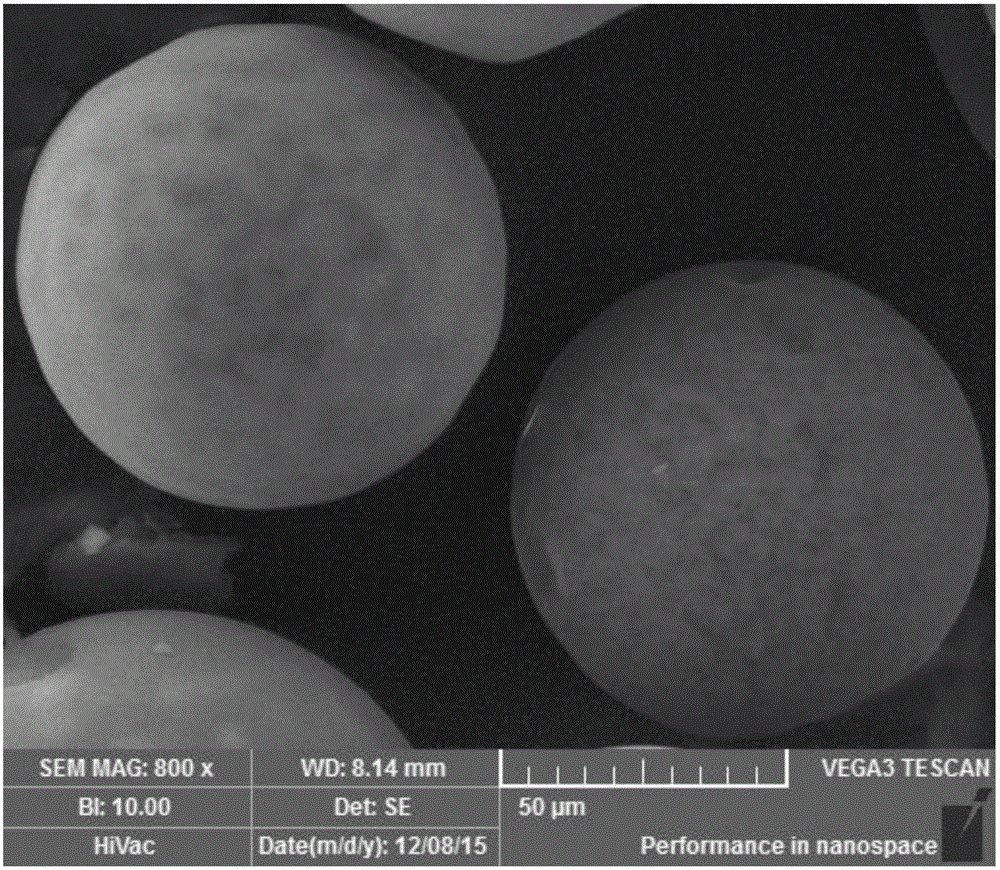

Method for preparing microcapsules through polymer precoating

ActiveCN105854745AEffective dispersionImprove versatilityMicroballoon preparationMicrocapsule preparationOrganic solventPolymer science

The invention discloses a method for preparing microcapsules through polymer precoating. The method includes the following steps that firstly, polymer is added into an organic solvent, stirred and mixed evenly to obtain a polymer solution, and then a core material is added, stirred and evenly mixed to obtain a mixed solution; secondly, colloid protector is added into water, stirred and evenly mixed, the mixed solution in the first step is added during stirring, the temperature is raised so that the organic solvent can completely volatilize, and microcapsules of the polymer precoated core material are obtained; thirdly, a wall material is added, stirred and fully cured, and the microcapsules are obtained. The method is good in universality, simple, quick, economical and capable of being widely used in the field of novel microcapsule preparation. The microcapsules are adjustable in size and structure, surface functional modification can be conducted, performance is excellent, and the microcapsules are economical and practical.

Owner:GUANGZHOU MILLIM VEGETABLE TECH DEV CO LTD

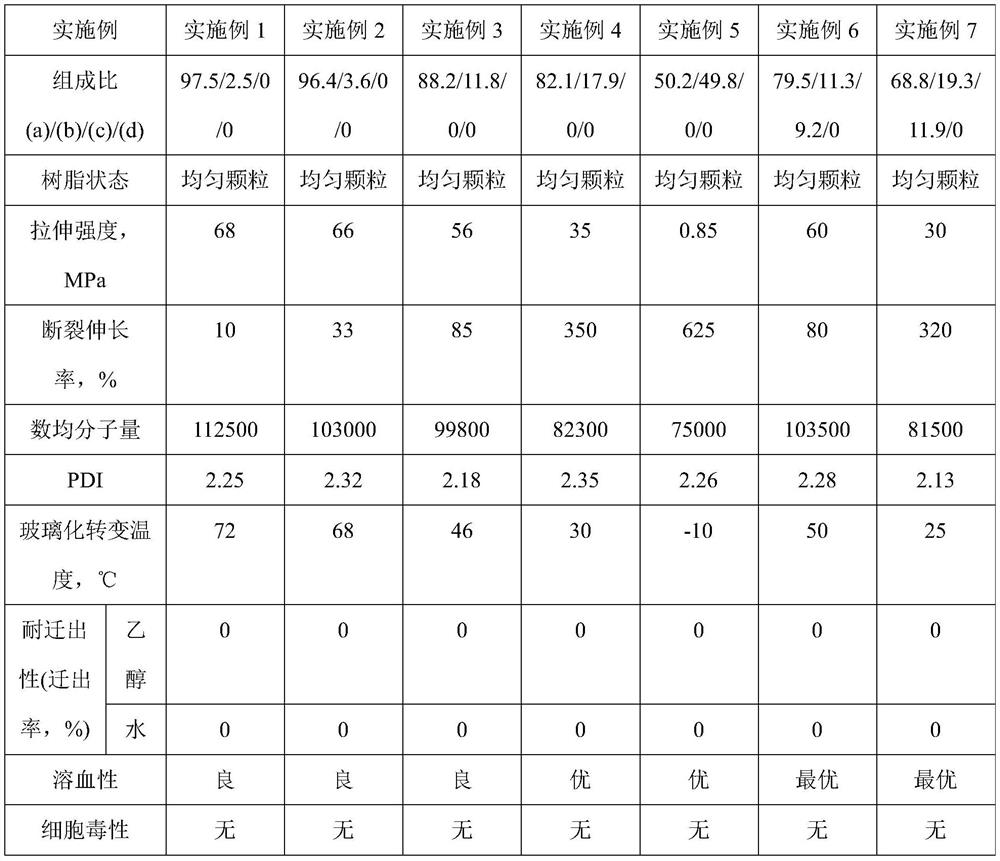

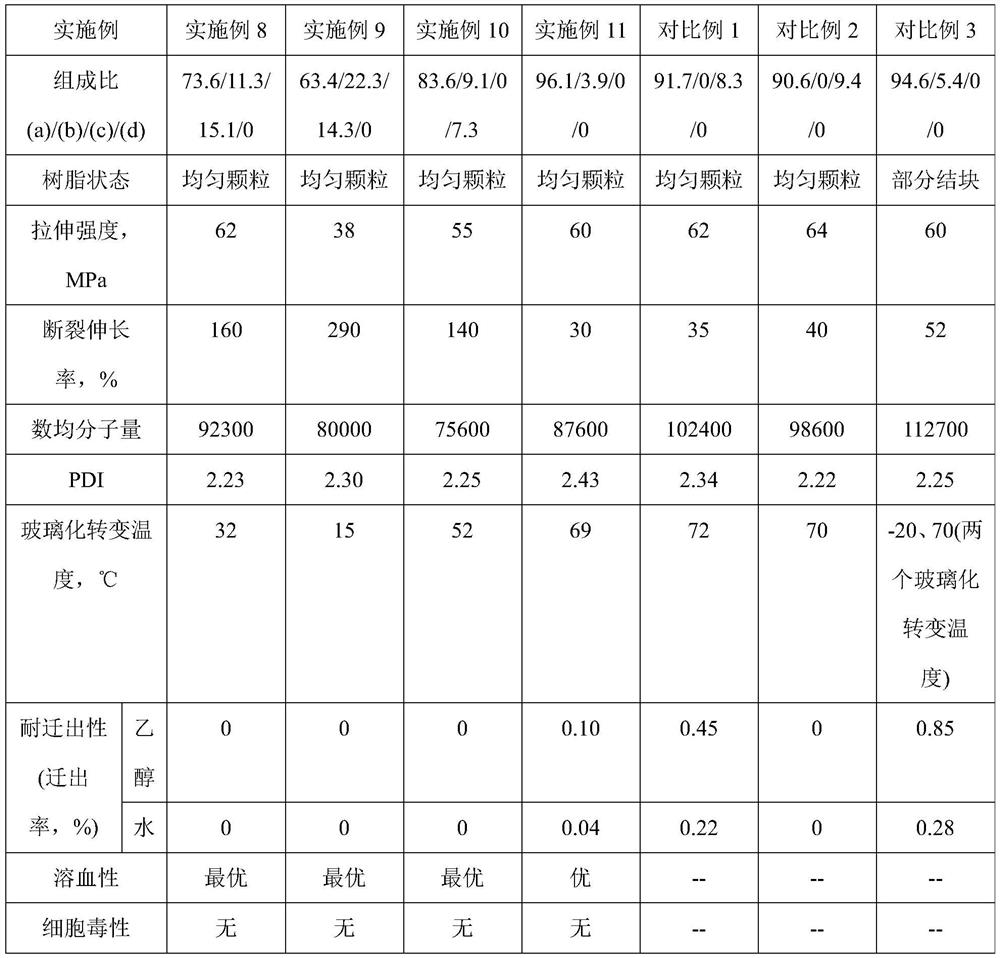

Self-plasticizing vinyl chloride-based copolymer, method for producing same, composition comprising same, and resin product produced from same

The present invention relates to a self-plasticizing vinyl chloride-based copolymer, a method for preparing the self-plasticizing vinyl chloride-based copolymer, a composition comprising the self-plasticizing vinyl chloride-based copolymer, and a resin product made from the composition. The self-plasticizing vinyl chloride-based copolymer has excellent self-plasticizing properties and processability; and products made from the vinyl chloride-based copolymer also have excellent biological properties. The invention provides the self-plasticizing vinyl chloride-based copolymer. The self-plasticizing vinyl chloride-based copolymer comprises a structural unit (a) based on vinyl chloride and a structural unit (b) based on a monomer represented by formula (1): CH2 = CR1COO (R2O) xR3 (1), whereinR1 is at least one selected from the group consisting of hydrogen and a linear or branched alkyl group having 1-6 carbon atoms, and R2 is at least one selected from the group consisting of hydrogen and a branched alkyl group having 1-6 carbon atoms. The number x of repeating units is an integer selected from 2-20, each R2 is selected from a linear or branched alkylene group having 2-10 carbon atoms, and the R2 may be the same or different; and R3 is at least one selected from the group consisting of hydrogen and a linear or branched alkyl group having 1-4 carbon atoms.

Owner:BEIJING UNIV OF CHEM TECH

Medical drug-loaded metal-macromolecular gradient porous composite

InactiveCN106267361AGood mechanical propertiesSimple and efficient operationTissue regenerationProsthesisPorous layerMetal

The invention relates to a medical drug-loaded metal-macromolecular gradient porous composite. A medical polymer material is adopted as a matrix of the metal-macromolecular gradient porous composite, and a porous material woven from medical metal wires in a wound mode is adopted as a wild phase, wherein the volume fraction of the matrix ranges from 10% to 90%; according to the metal-macromolecular gradient porous composite, the matrix is extruded into a hole of the wild phase, then part of wild phase metal is removed through a chemical corrosion method, and the gradient porous material with a porous surface and a solid interior is formed. Compared with the prior art, the material has the excellent mechanical property and good bone transmission and inducing capacity, and the surface layer porous layer thickness, the pore size and porosity can be controlled. Drugs can be loaded into the surface layer porous layer according to needs, and the functions of preventing infection and promoting bone growth and healing are achieved. A preparation method has the advantages of being easy to operate and practicable, low in cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Optical component assembly

InactiveUS7663210B2Easy and cheap and reliableIncrease flexibilityLaser detailsSemiconductor/solid-state device detailsOptical radiationOptical limiting

Optical components are flip chip mounted onto a substrate for improved alignment. Each device is fabricated using “build-up” layers above a substrate. Each has an optical confinement region in which optical radiation travels in use, and a bonding surface. The overall depth of the layers above the optical confinement region is closely controlled during fabrication, for instance by the use a “spacer” layer, so that when the devices are subsequently flip chip mounted adjacent one another on a shared substrate by means of their bonding surfaces, they can be passively positioned so that their optical confinement regions abut and optical radiation can be coupled from one to the next in use.

Owner:OPTITUNE

Method for preparing poly(butylene succinate) through transesterification method

The invention relates to the field of high polymer material synthesis and discloses a method for preparing poly(butylene succinate) through a transesterification method. The method comprises the following steps: carrying out esterification reaction on dimethyl succinate, a dihydric alcohol monomer containing 1,4-butanediol and a composite catalyst in a nitrogen atmosphere, wherein the reaction temperature is 110-150 DEG C and the reaction time is 2-3 hours; carrying out condensation polymerization in a vacuum condition, wherein the vacuum degree is 10-300Pa of absolute pressure, the reaction temperature is 150-240 DEG C and the reaction time is 2-3 hours, thereby preparing the poly(butylene succinate). According to the method, on one hand, the problem of high corrosivity of a polymeric monomer in the prior art can be solved, and on the other hand, the problems of multiple byproduct micromolecules and relatively low yield in the prior art can be solved, so that the production cost of the poly(butylene succinate) can be effectively reduced.

Owner:NINGBO ZHETIE JIANGNING CHEM

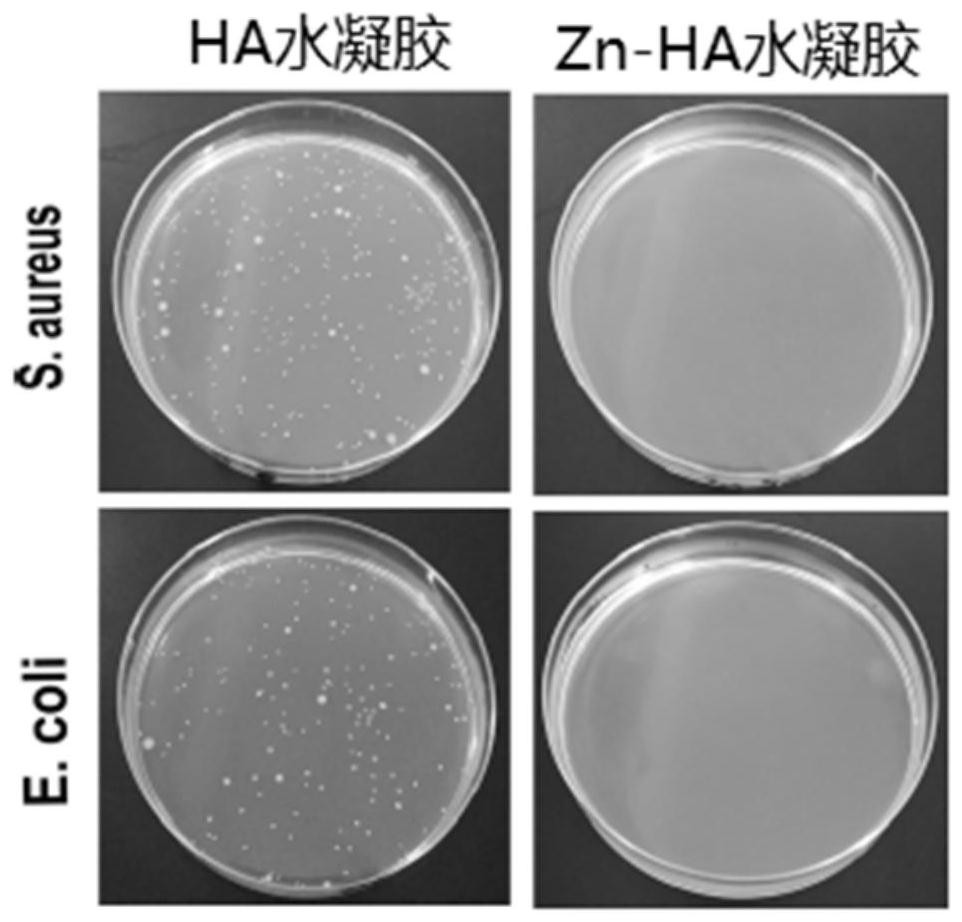

Metal ion cross-linked hydrogel as well as preparation method and application thereof

ActiveCN112426981AMild preparation conditionsSimple processGel preparationColloidal chemistry detailsCross linked hydrogelsHydrazide

The invention discloses metal ion cross-linked hydrogel and a preparation method and application thereof. Hydrazide group modified water-soluble macromolecules are prepared through a carbodiimide method, then a hydrazide polymer aqueous solution and a metal ion solution are mixed to be uniform, and the metal ion cross-linked hydrogel is obtained. The hydrogel disclosed by the invention takes metalions as a cross-linking agent, has the advantages of controllable gelling time, adjustable mechanical properties, self-healing property and the like, and is simple in preparation method, mild in process conditions and wide in applicable metal ion variety. The hydrogel disclosed by the invention has a wide application prospect in the fields of three-dimensional tumor model construction, tumor local treatment, biomedical diagnosis and treatment agents, wound antibacterial dressings, drug delivery, removal of heavy metal ions in sewage and the like.

Owner:XI AN JIAOTONG UNIV

Biodegradable poly-caprolactone artificial breast wall material and preparation method thereof

InactiveCN1593674AAdjustable mechanical propertiesDegradation rate adjustableProsthesisFiberPulp and paper industry

The invention provides a biodegradable poly-caprolactone artificial breast wall material and preparation method thereof, wherein the material comprises 10-70% of chitosan fiber and balancing ploycaprolactone. When short chitosan fiber is employed, the short chitosan fiber is weighed and mixed with ploycaprolactone and stirred in high speed mixing machine, the premix is compounded, squeezed and granulated with a double bolt extrusion machine, or compounded and squashed with a closed-smelting machine, then is subject to compression moulding on vulcanizing press and cut into samples. The invention also provides the preparing method for the situation when long chitosan fiber is employed.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing lamellar zirconium boride ultrahigh-temperature ceramic through casting method

InactiveCN102173831AAdd extension pathImprove fracture toughnessCeramic layered productsBorideArgon atmosphere

The invention provides a method for preparing lamellar zirconium boride ultrahigh-temperature ceramic through a casting method. The method is characterized by comprising the following steps of: (1) respectively preparing two zirconium boride casting sheets with different components and thicknesses by adopting the casting method: firstly adding a binder and a plasticizer to a solvent, uniformly stirring, then respectively adding zirconium boride ceramic powder, uniformly stirring to form two casting materials with different components, then carrying out casting forming, and drying and demoulding at room temperature to respectively obtain a zirconium boride casting sheet A with the thickness of 300-1000 micrometers and a zirconium boride casting sheet with the thickness of 20-100 micrometers; (2) respectively slicing the zirconium boride casting sheet A and the zirconium boride casting sheet B according to the size of a mould; (3) alternately overlapping the sliced zirconium boride casting sheet A and the sliced zirconium boride casting sheet B, placing into a graphite grinding tool, and degreasing in vacuum; and (4) carrying out hot pressed sintering in an argon atmosphere at the sintering temperature of 1900-2000 DEG C under the pressure of 20-40 MPa so as to obtain the lamellar zirconium boride ultrahigh-temperature ceramic. A casting forming technology is adopted in the invention and the method has simple process; and in addition, an obtained material reaches high toughness value at 9.3 MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

A kind of multi-block copolyester and preparation method thereof

The general structural formula of the multi-block copolyester disclosed in the present invention is: in the formula, R represents the hydrocarbon group of diisocyanate, x, a, b are all integers from 2 to 10, and y and c are integers from 0 to 8 , and when x=b, y≠c, when y=c, x≠b, j, k, n are all integers greater than 5, and the intrinsic viscosity of the multi-block copolyester is 0.7~4.7dL / g , the melting point is 70-240°C, the tensile strength is 10-67MPa, and the elongation at break is 20-1100%. The invention also discloses a preparation method of the multi-block copolyester. The multi-block copolyester prepared by the invention has high melting point and molecular weight, good mechanical properties, and better controllability and repeatability than the traditional transesterification method, which can make the multi-block copolyester prepared by it have a wider application range. for extensive.

Owner:SICHUAN UNIV

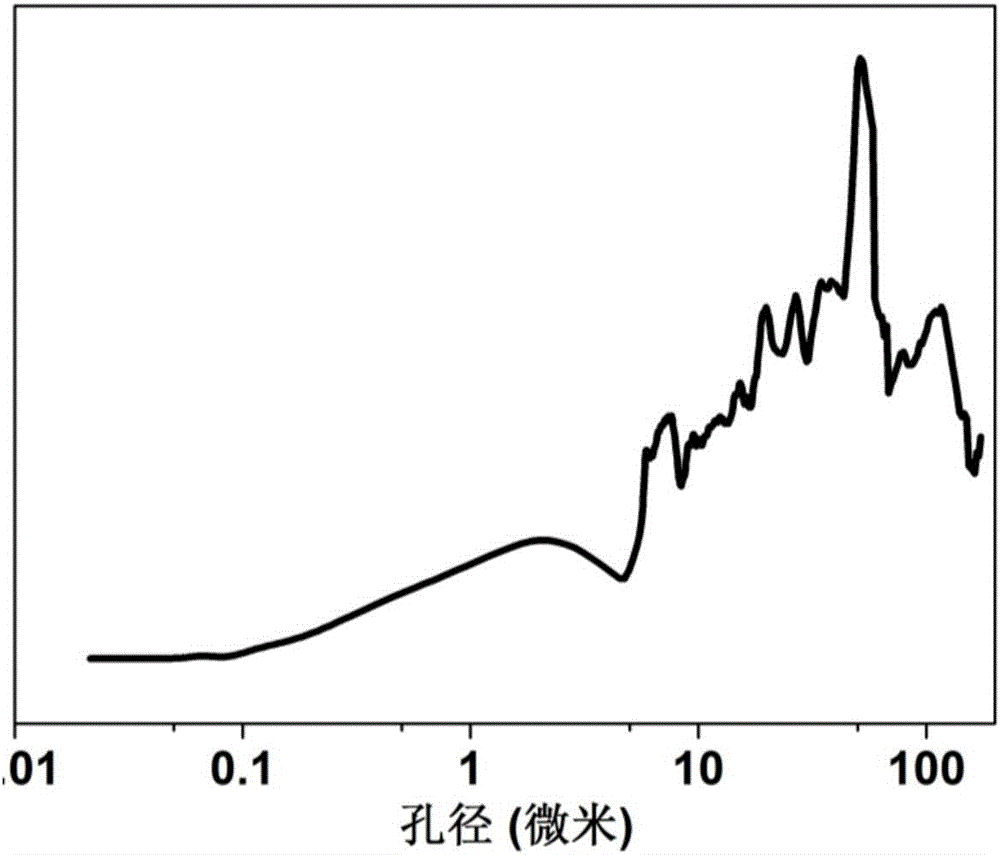

Preparation method of short-peptide/silicon dioxide/hydroxyapatite porous composite material

ActiveCN106668941AAdjustable mechanical propertiesFacilitates adhesion and proliferationTissue regenerationProsthesisAdhesiveFreeze dry

The invention relates to a preparation method of a short-peptide / silicon dioxide / hydroxyapatite porous composite material, belonging to the technical field of preparation of biological composite materials. The short-peptide / silicon dioxide / hydroxyapatite porous composite material can be used as a bone-repairing three-dimensional scaffold material, has good biological activity, mechanical property and degradation characteristic, and is beneficial to improvement of the bone repairing effect. The preparation method comprises the steps of dissolving short-peptide molecules into water for assembly; mixing the assembled short-peptide solution, a silicon precursor and an adhesive, and reacting to form short-peptide / silicon dioxide gel; replacing the gel by using ultra-pure water and then freezing a sample by using a condensation induction method and carrying out freeze-drying to obtain a short-peptide / silicon dioxide porous material; soaking the material by using simulated body fluid, and carrying out freeze-drying to obtain the short-peptide / silicon dioxide / hydroxyapatite porous composite material. The short-peptide / silicon dioxide / hydroxyapatite porous composite material is used for preparing an organic / inorganic porous composite material, has a hierarchical porous structure which is easy to regulate and control, and can be applied to the field of bone repairing as a three-dimensional scaffold of an artificial bone material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

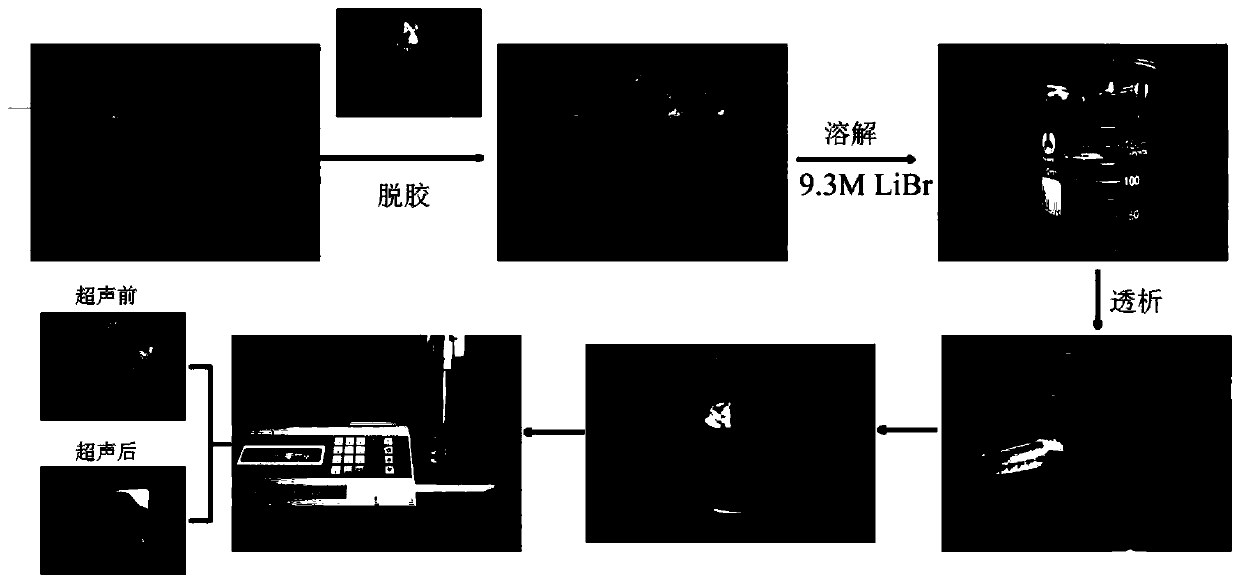

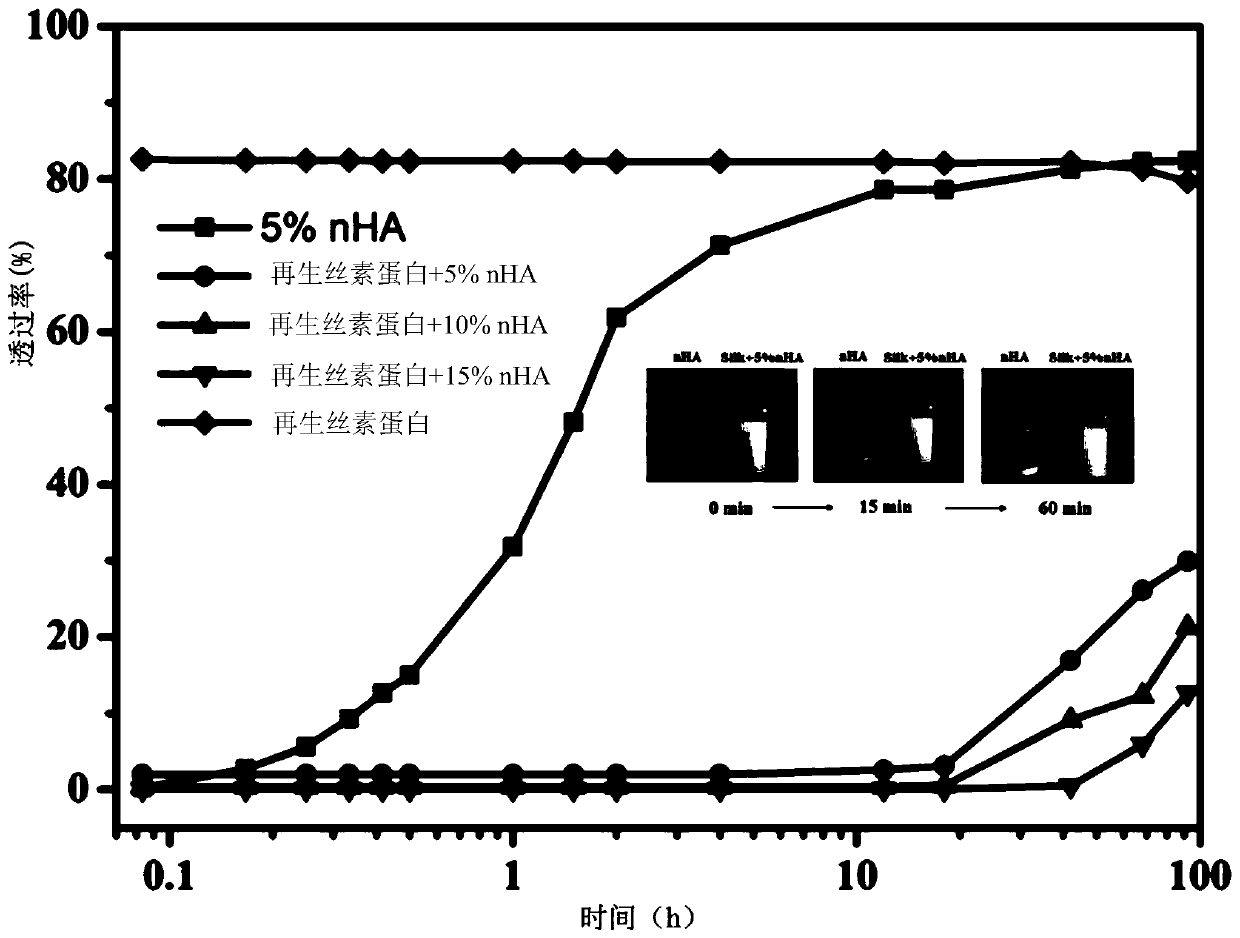

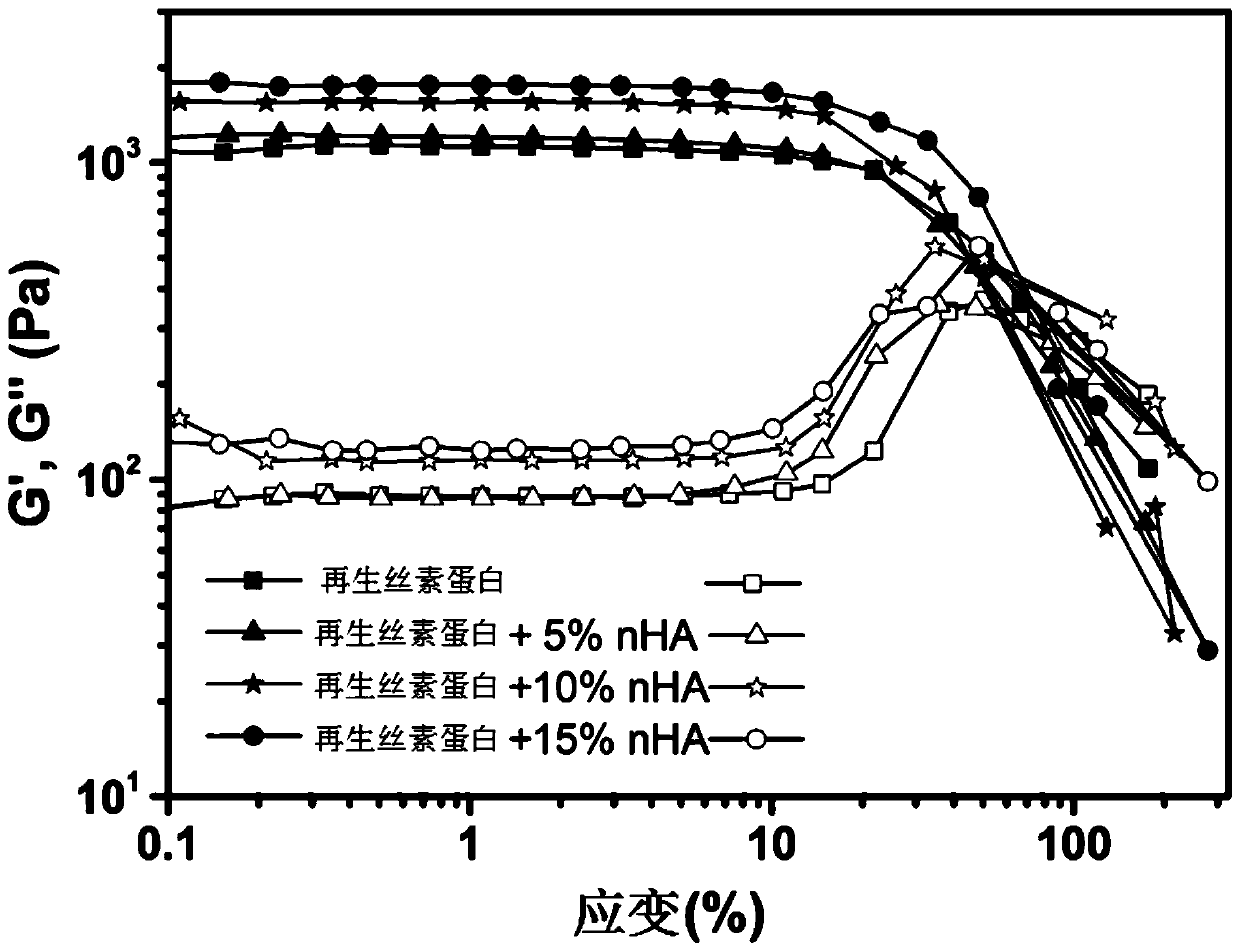

Nano hybrid silk fibroin hydrogel and preparation method and application thereof

ActiveCN110917400ARapid gelationAvoid the use of chemical crosslinkersPharmaceutical delivery mechanismTissue regenerationFibroinStem like cell

The invention discloses a nano hybrid silk fibroin hydrogel and a preparation method and application thereof, and belongs to the technical field of biomedical materials. The nano hybrid silk fibroin hydrogel is prepared by pre-blending a regenerated silk fibroin aqueous solution and nano hydroxyapatite and performing ultrasonic treatment. According to the preparation method of the nano hybrid silkfibroin hydrogel, the ultrasonic condition and the mixing ratio of the two materials are changed, the gelation time is controlled, and rapid gelation is realized, so that use of a potentially toxic chemical crosslinking agent is avoided, and activity of cells or biological factors can be well maintained. The nano hybrid silk fibroin hydrogel provided by the invention has controllable gel performance, controllable mechanical performance, good cell compatibility and good bone induction capability, can load stem cells for repairing bone defect, and is expected to be used for embedding active factors for synergistic treatment.

Owner:SUN YAT SEN UNIV

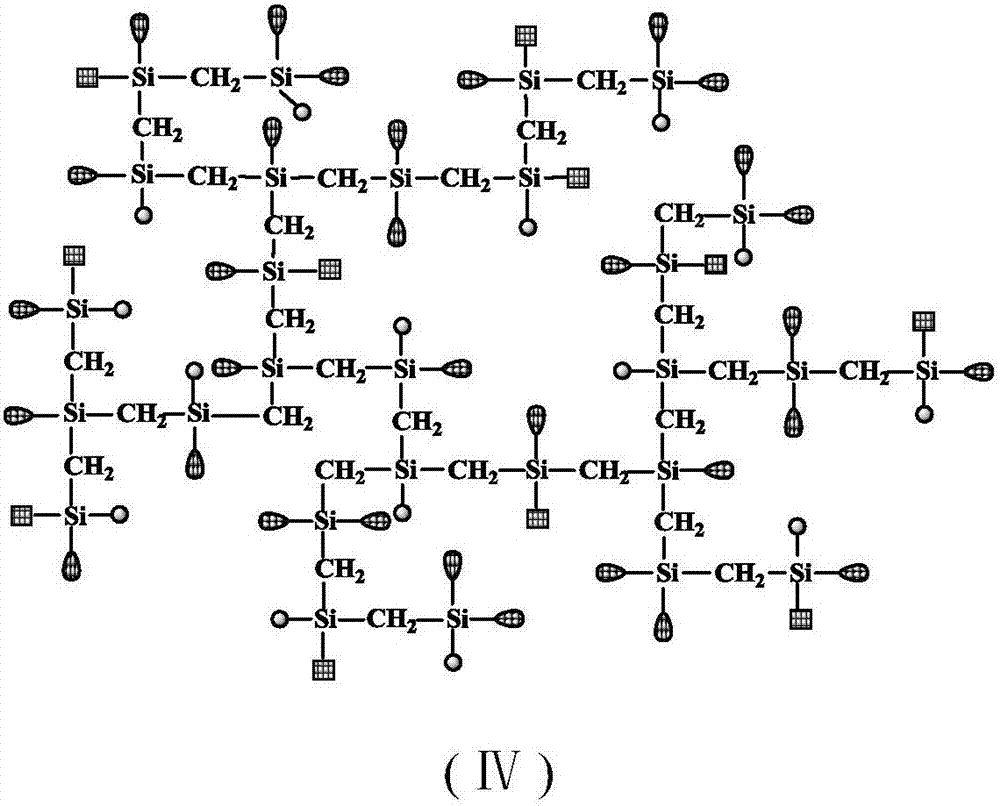

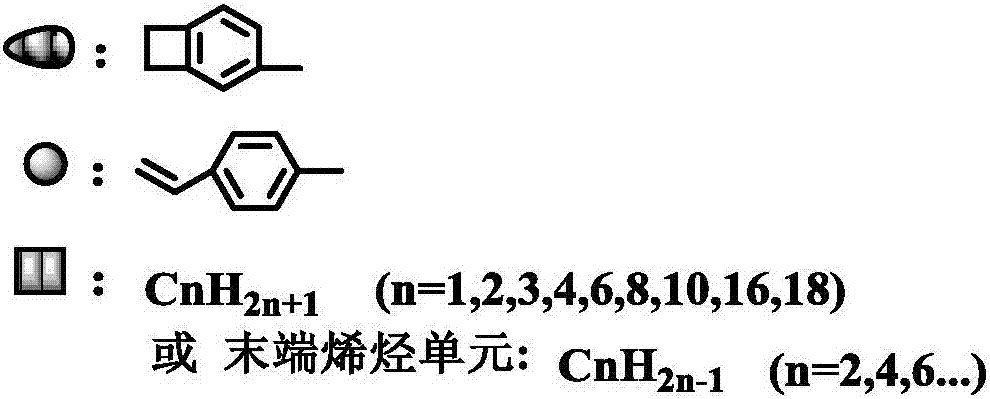

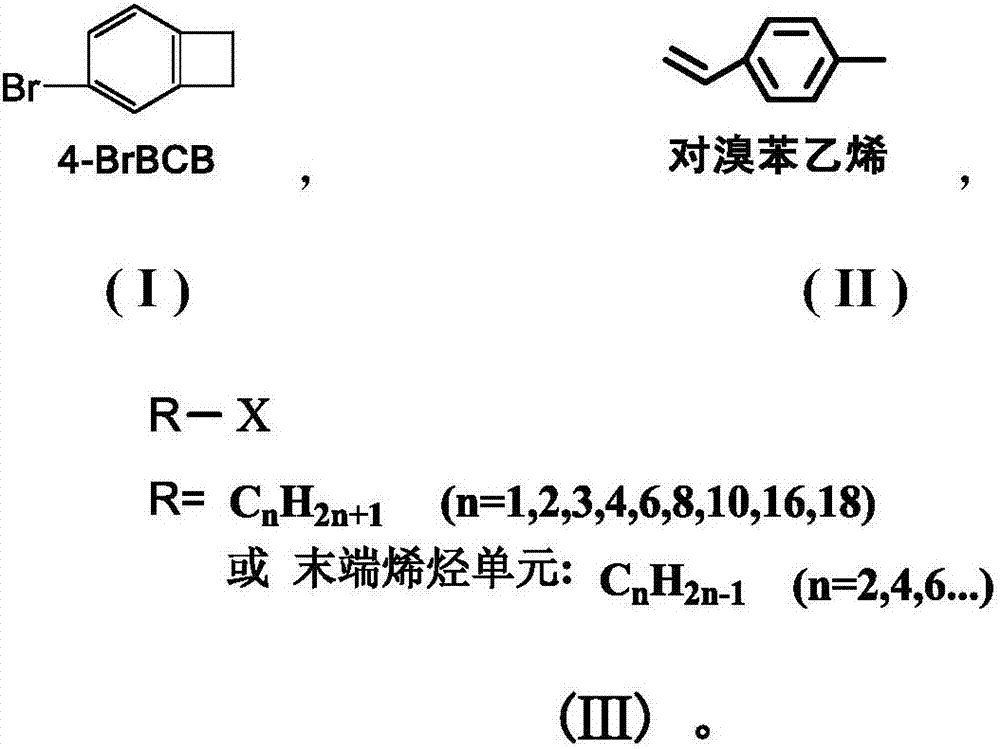

Light/heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin and preparation method thereof

The invention discloses light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin as shown in a formula (IV) and a preparation method thereof. The preparation method of the hyperbranched polycarbosilane benzocyclobutene resin comprises the following steps: generating a Grignard reagent from chloromethyltrichlorosilane under the action of magnesium; then performing a coupling reaction with Si-Cl to further form a hyperbranched Si-Cl bond-containing hyperbranched polycarbosilane polymer; adding 4-bromobenzocyclobutene to react; adding p-bromostyrene to react; then adding alkyl (alkenyl) halide to react; performing cooling; adding distilled water (deionized water) into the system for a quenching reaction; and performing solvent extraction, concentration, and purification steps such as distillation or column chromatography on silica gel to obtain the light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin. The light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin prepared by the method is excellent in thermal, electrical and photosensitive properties and is suitable for being used as a high performance dielectric film material or a packaging material in the field of microelectronics industry, space flight and aviation and national defense and the like. The formula (IV) is as shown in the specification.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of nano-composite hydrogel and application of nano-composite hydrogel in promoting healing of diabetic wounds

PendingCN113956413AHigh selectivityAlleviate oxidative stress microenvironmentPharmaceutical delivery mechanismProsthesisMetal oxide nanoparticlesPolymer solution

The invention provides a preparation method of nano-composite hydrogel and application of the nano-composite hydrogel in promoting healing of diabetic wounds. The method comprises the following steps: preparing a functionally modified natural high-molecular polymer and functional metal oxide nanoparticles, mixing the functionally modified natural high-molecular polymer solution with the functional metal oxide nanoparticles, and finally preparing the nano composite hydrogel by means of enzymatic crosslinking and photo-crosslinking. The hydrogel prepared by the method has multiple functions, and can be used for adjusting the pathological microenvironment of the diabetic wound to promote the healing of the diabetic wound.

Owner:NANJING UNIV OF TECH

TBJ tissue repair film type stent and preparation method thereof

The invention discloses a TBJ tissue repair film type stent and a preparation method thereof. The TBJ tissue repair film type stent comprises three layers of regional structure with gradient changes:a polymer / ceramic composite material area, a polymer area and a polymer / ceramic composite material area. The preparation method comprises the following steps: firstly, obtaining the polymer film and the polymer / ceramic composite film through blending and hot-press molding, splicing the two films, carrying out hot-press fusion, and then performing axial mechanical stretching along the vertical direction of the interface of the connecting line to obtain the film type TBJ stent. The stent material is biomimics TBJ tissue in design, has multiple gradient characteristics of material component, structure and mechanical property changes, further has effects of mechanical enhancement and composite regulation of ion and mechanical signals, which is a tendon-bone repair stent material with high bionic tissue characteristics and excellent mechanical properties, and can be applied to regeneration induction and functional reconstruction of cells and extracellular matrixes in the tendon-bone junction.

Owner:HUNAN UNIV

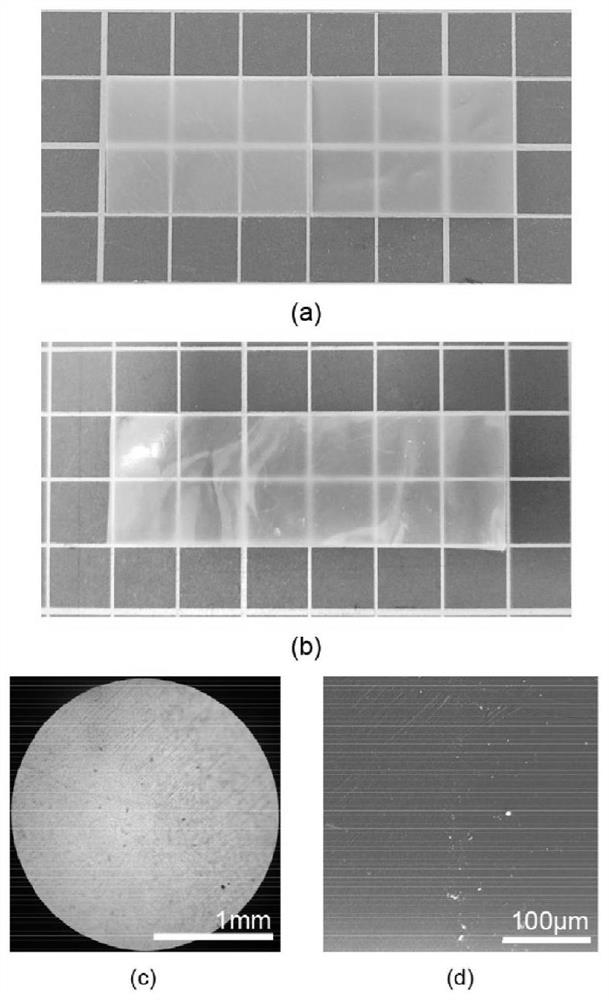

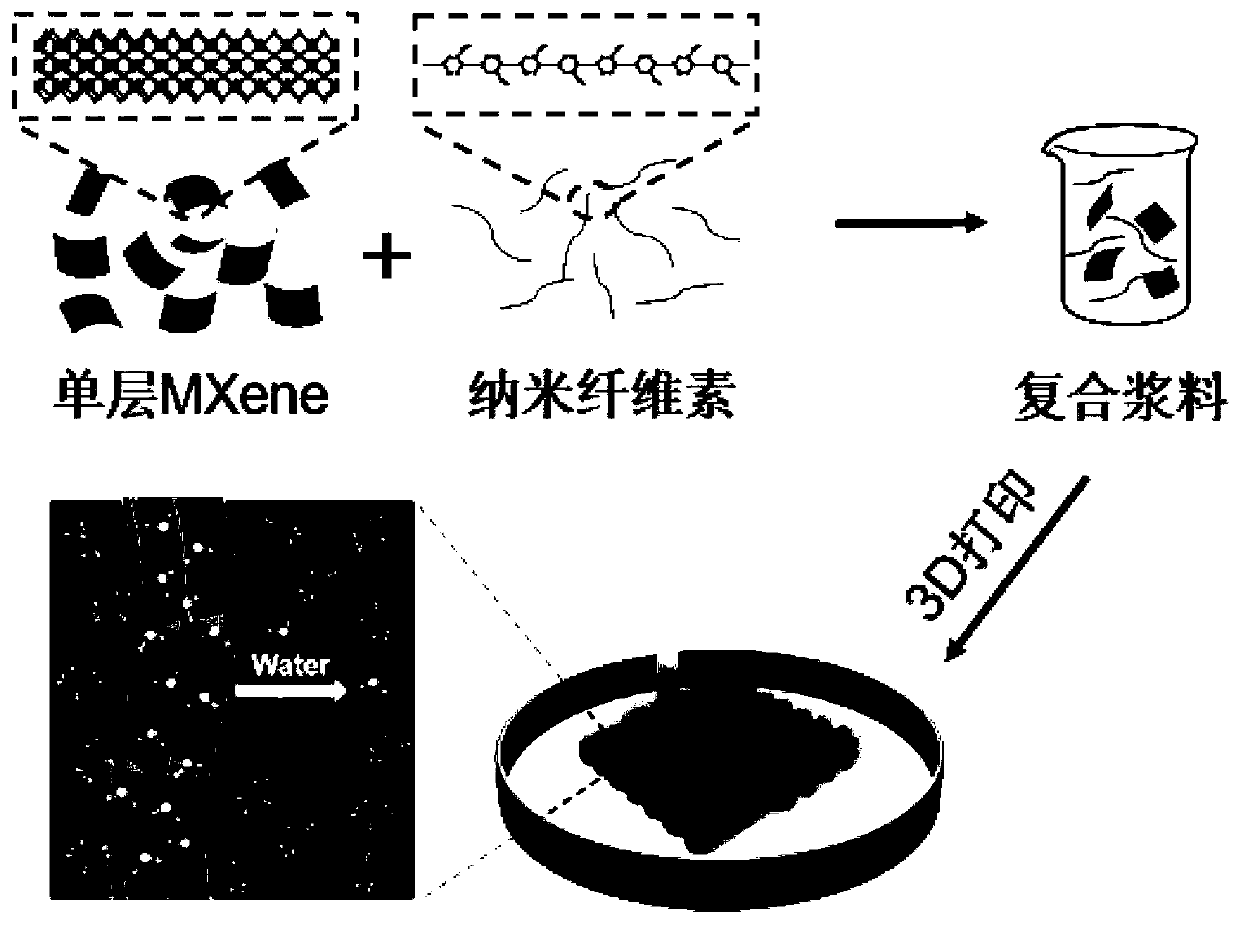

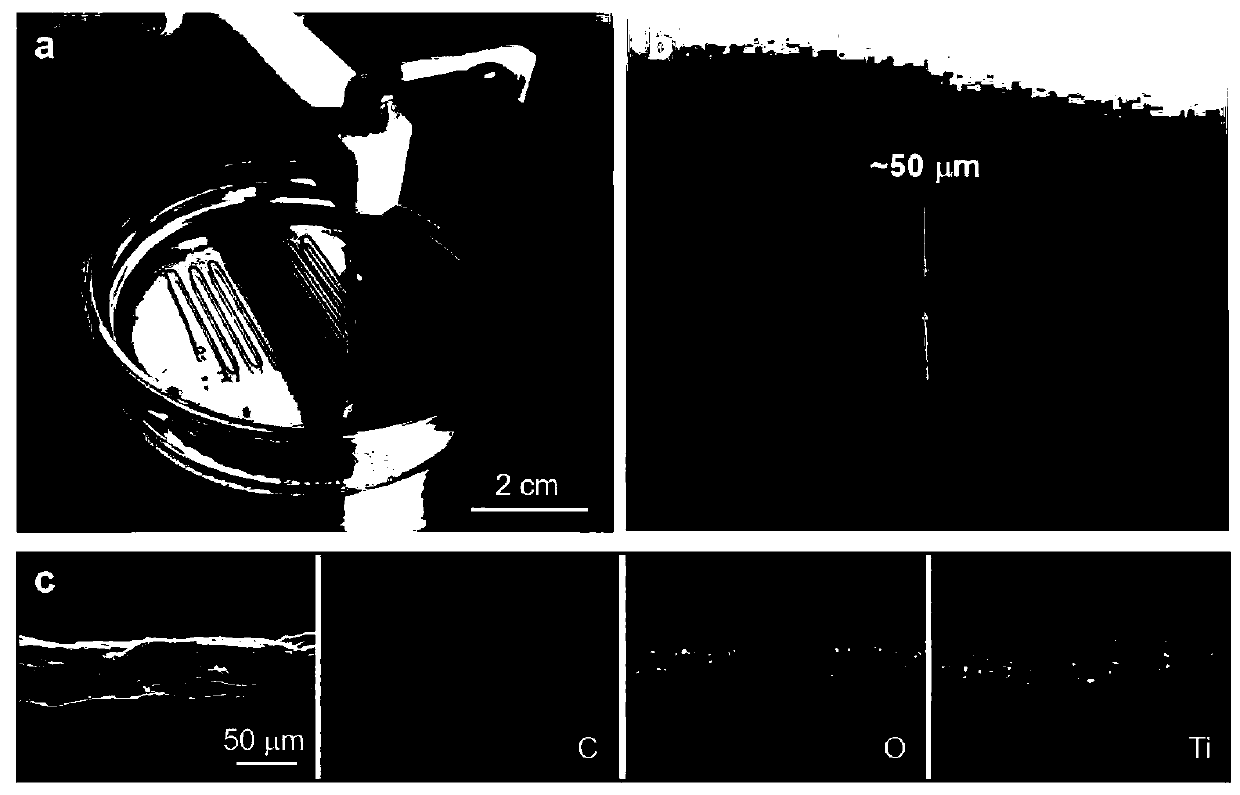

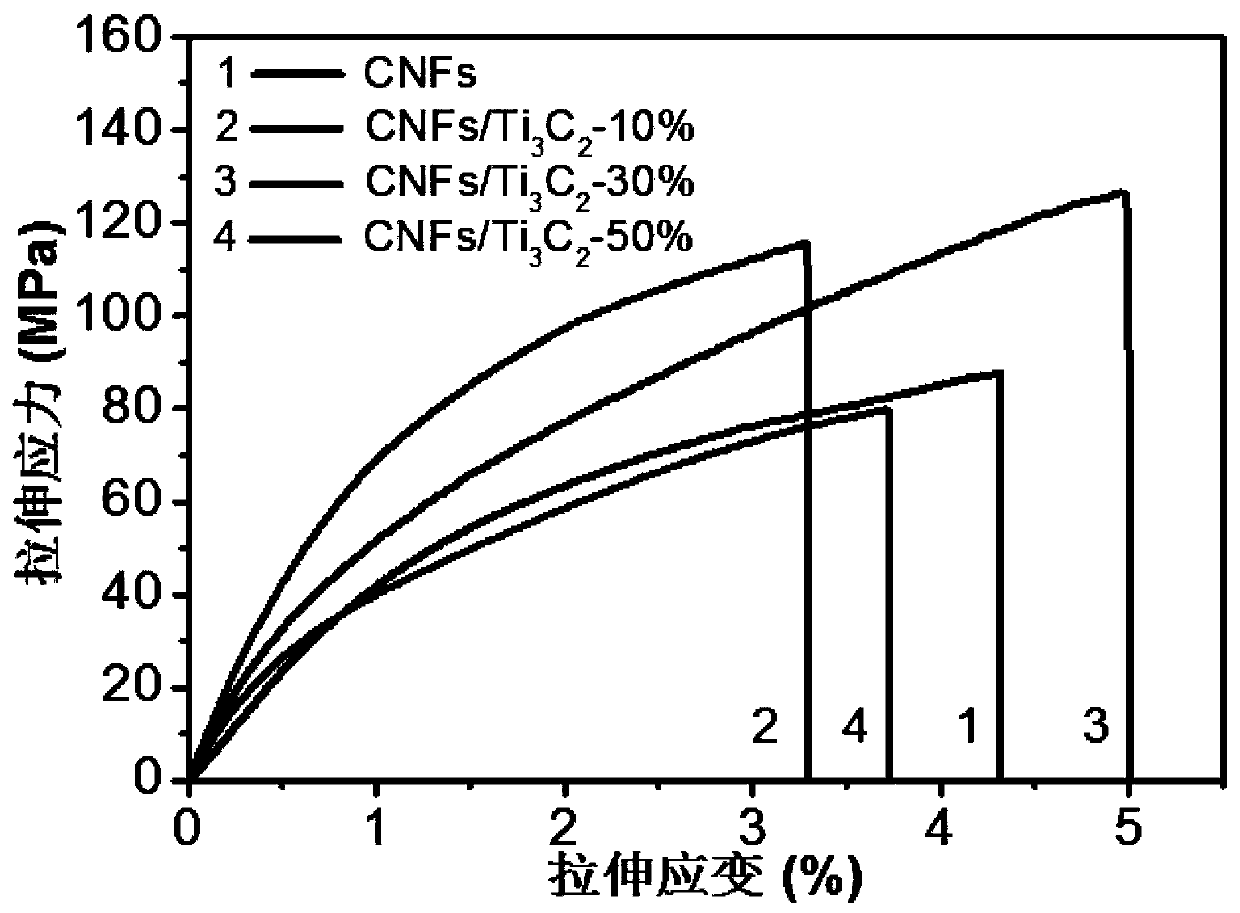

Multifunctional intelligent fiber or fabric

ActiveCN110528101AVersatilityOvercome single functionElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentFiberPolymer science

The invention relates to a multifunctional intelligent fiber or fabric. The multifunctional intelligent fiber or fabric is obtained by directly extruding a mixed sizing agent containing oxidized nanocellulose and a MXene material into a solvent for forming; the weight ratio of the oxidized nanocellulose to the MXene material in the mixed sizing agent is 9:1-3:7, preferably 7:3-1:2, and more preferably 1:1.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

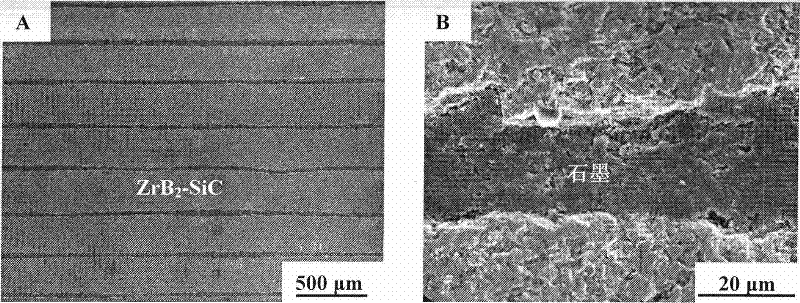

Preparation method of zirconium boride-silicon carbide/boron nitride lamellar ultrahigh-temperature ceramic

InactiveCN102173827AImprove fracture toughnessAdd extension pathCeramic layered productsBorideHigh fracture

The invention provides a preparation method of zirconium boride-silicon carbide / boron nitride lamellar ultrahigh-temperature ceramic. The preparation method of the zirconium boride-silicon carbide / boron nitride lamellar ultrahigh-temperature ceramic is characterized by comprising the following steps of: (1) respectively preparing a zirconium boride casting sheet and a boron nitride casting sheet by adopting a casting method: firstly adding a binder and a plasticizer to a solvent, uniformly stirring, then respectively adding zirconium boride ceramic powder and boron nitride boride ceramic powder, uniformly stirring to form casting materials, then carrying out casting forming, and drying and demoulding at room temperature to respectively obtain the zirconium boride casting sheet with the thickness of 200-1000 micrometers and the boron nitride casting sheet with the thickness of 20-100 micrometers; (2) respectively slicing the zirconium boride casting sheet and the boron nitride casting sheet according to the size of a mould; (3) alternately overlapping the zirconium boride slices and the boron nitride slices, placing into a graphite grinding tool, and degreasing in vacuum; and (4) carrying out hot pressed sintering in an argon atmosphere to prepare the lamellar ultrahigh-temperature ceramic. The invention has simple preparation process, low cost and controllable component; and in addition, an obtained material has higher high-temperature oxidation resistance and reaches high fracture toughness at 18.1 MPa.m<1 / 2>.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com