Method for preparing microcapsules through polymer precoating

A technology of polymers and microcapsules, applied in the field of polymer pre-coating to prepare microcapsules, can solve the problems of limited use range, inability to connect core material and wall material reasonably, inability to achieve effective encapsulation and stable storage, etc. Excellent and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

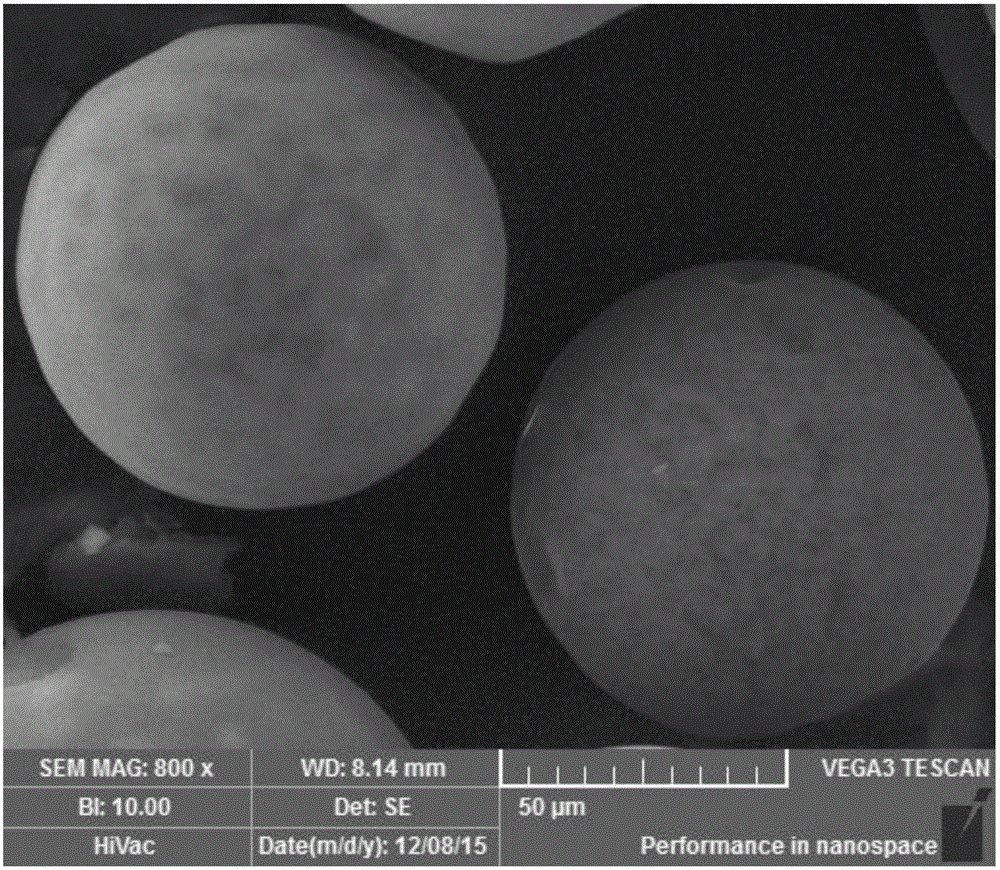

Image

Examples

Embodiment 1

[0047] 1) Add 1.0g polymethyl methacrylate and 20.0g dichloromethane into a beaker, stir and mix evenly to obtain a 5% polymethyl methacrylate dichloromethane solution, add 1.0g rose essential oil, stir and mix Uniformly, a mixed solution is obtained;

[0048] 2) Add 100.0g of distilled water and 0.5g of polyvinyl alcohol (1788) into a reactor equipped with a heating device and a stirrer, heat and stir until the polyvinyl alcohol is completely dissolved, then lower the system temperature to room temperature. Then add the mixed solution in step 1), maintain the stirring speed at 500rpm, and raise the temperature at a rate of 5.0°C / min to slowly volatilize the dichloromethane. When the temperature reaches 50.0°C, stop the heating and keep it warm for 30min to obtain polymethyl methacrylate. Microcapsules coated with rose essential oil;

[0049] 3) Lower the temperature of the reaction system to room temperature, add 0.5 g of gelatin, stir at a speed of 300 rpm, and mature in a ...

Embodiment 2

[0051]1) Add 5.0g polyacrylamide and 50.0g dichloromethane into a beaker, stir and mix evenly to obtain a polyacrylamide dichloromethane solution with a mass percentage of 10%, add 10.0g clove oil, stir and mix evenly to obtain a mixed solution;

[0052] 2) Add 300.0g of distilled water and 4.5g of sodium dodecylsulfonate to the reactor with heating device and stirrer, heat and stir until the sodium dodecylsulfonate is completely dissolved, then lower the temperature of the system to room temperature , then add the mixed solution in step 1), maintain the mixer speed at 1000rpm, and raise the temperature at a rate of 3.0°C / min to slowly volatilize the dichloromethane. When the temperature reaches 50.0°C, stop the temperature rise and keep it warm for 20min to obtain polyacrylamide pre-coating Microcapsules of clove oil;

[0053] 3) Lower the temperature of the reaction system to room temperature, add 10 g of polystyrene, stir at 800 rpm, and mature in a water bath at 60°C for 5...

Embodiment 3

[0055] 1) Add 8.0g polybutylacrylate-acrylic acid and 40.0g chloroform into a beaker, stir and mix evenly to obtain a 20% mass percent polybutylacrylate-acrylic acid chloroform solution, add 24.0g patchouli oil, and stir Mix evenly to obtain a mixed solution;

[0056] 2) Add 500.0g of distilled water and 15.0g of polyvinylpyrrolidone into the reactor with heating device and stirrer, heat and stir until the polyvinylpyrrolidone is completely dissolved, then lower the system temperature to room temperature, and then add step 1) For the mixed solution, maintain the mixer speed at 3000rpm, raise the temperature at a rate of 2.0°C / min to slowly volatilize chloroform, and when the temperature reaches 72.0°C, stop the heating and keep it warm for 40min to obtain polybutylacrylate-acrylic acid pre-coated patchouli oil microcapsules;

[0057] 3) Lower the temperature of the reaction system to room temperature, add 30g of urea-formaldehyde resin, stir at a speed of 1000rpm, and mature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com