Flame retardant cellulose fiber and preparation method thereof

A technology of flame-retardant cellulose and cellulose, which is applied in the field of flame-retardant fibers, can solve the problems that the production process of flame-retardant fibers cannot meet the requirements of energy conservation and environmental protection, reduce the mechanical properties of product fibers, and increase the production cost of products, so as to achieve environmental benefits. The effect of protection, low operation cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention simultaneously designs the preparation method (preparation method for short) of described flame-retardant cellulose fiber, and this preparation method comprises the following processes according to the mass ratio composition of flame-retardant cellulose fiber described in the present invention:

[0022] 1. Prepare flame retardant spinning solution; according to the mass ratio of flame retardant of the present invention to cellulose, first flame retardant is added in the ionic liquid at normal temperature, and the flame retardant is dispersed in the ionic liquid under mechanical stirring uniform, then add cellulose into the ionic liquid to fully dissolve, the dissolution temperature is 70-110°C, and prepare a flame-retardant spinning solution; the mass ratio of the flame retardant to cellulose is 10-25:100; The mass ratio of the cellulose to the ionic liquid is 5-35:95-65.

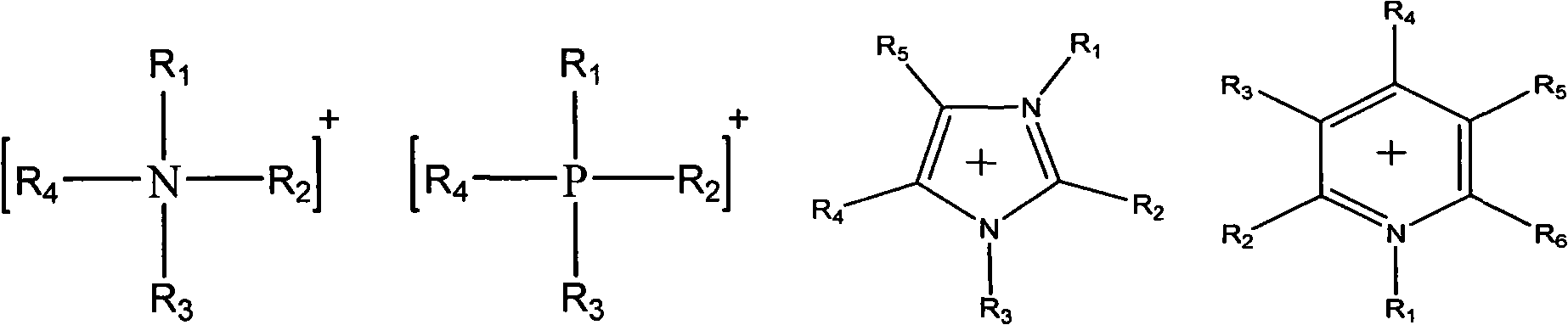

[0023] The ionic liquid is composed of cations and anions; the cations are ...

Embodiment 1

[0033] Add 0.5g of the flame retardant DDPSN that is crushed into an average particle size of less than 1um into 95g of AMIMCI ionic liquid at room temperature, stir evenly, and then add the crushed (opened fibers that are crushed into 1mm×1mm or less) fibers into the ionic liquid Vegetarian wood pulp (polymerization degree DP=592, α-cellulose content 92%) 5g, dissolving temperature is 70 ℃, mechanically stirs until completely dissolving, promptly prepares flame-retardant spinning solution;

[0034] The spinning solution is degassed, filtered, metered, spinned, coagulated (the coagulation bath is water, and the temperature of the coagulation bath is 20°C), drawing, washing, drying and other conventional wet process steps to obtain the fiber.

[0035] After testing, the dry breaking strength of the fiber obtained in this example is 1.97cN / dtex, and the limiting oxygen index (LOI) is 25.

Embodiment 2

[0037] Add 0.5 g of the flame retardant DDPSN crushed into a particle size of less than 1 um into 95 g of AMIMCI ionic liquid at room temperature, stir evenly, then add 5 g of crushed cellulose cotton pulp (DP=800, α-cellulose content 95%), The dissolution temperature is 70°C, mechanically stirred until completely dissolved, and the flame-retardant spinning solution is obtained; the spinning solution is degassed and then spun by dry and wet methods, the spinning air gap is 10cm, and the coagulation bath is 50% ionic liquid aqueous solution. The temperature of the coagulation bath was 20°C. After drawing, washing, drying and other steps, the fiber can be obtained. The rest are the same as embodiment 1.

[0038] After testing, the dry breaking strength of the fiber obtained in this example is 2.35 cN / dtex, and the limiting oxygen index (LOI) is 26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com