Patents

Literature

165results about How to "Strong damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

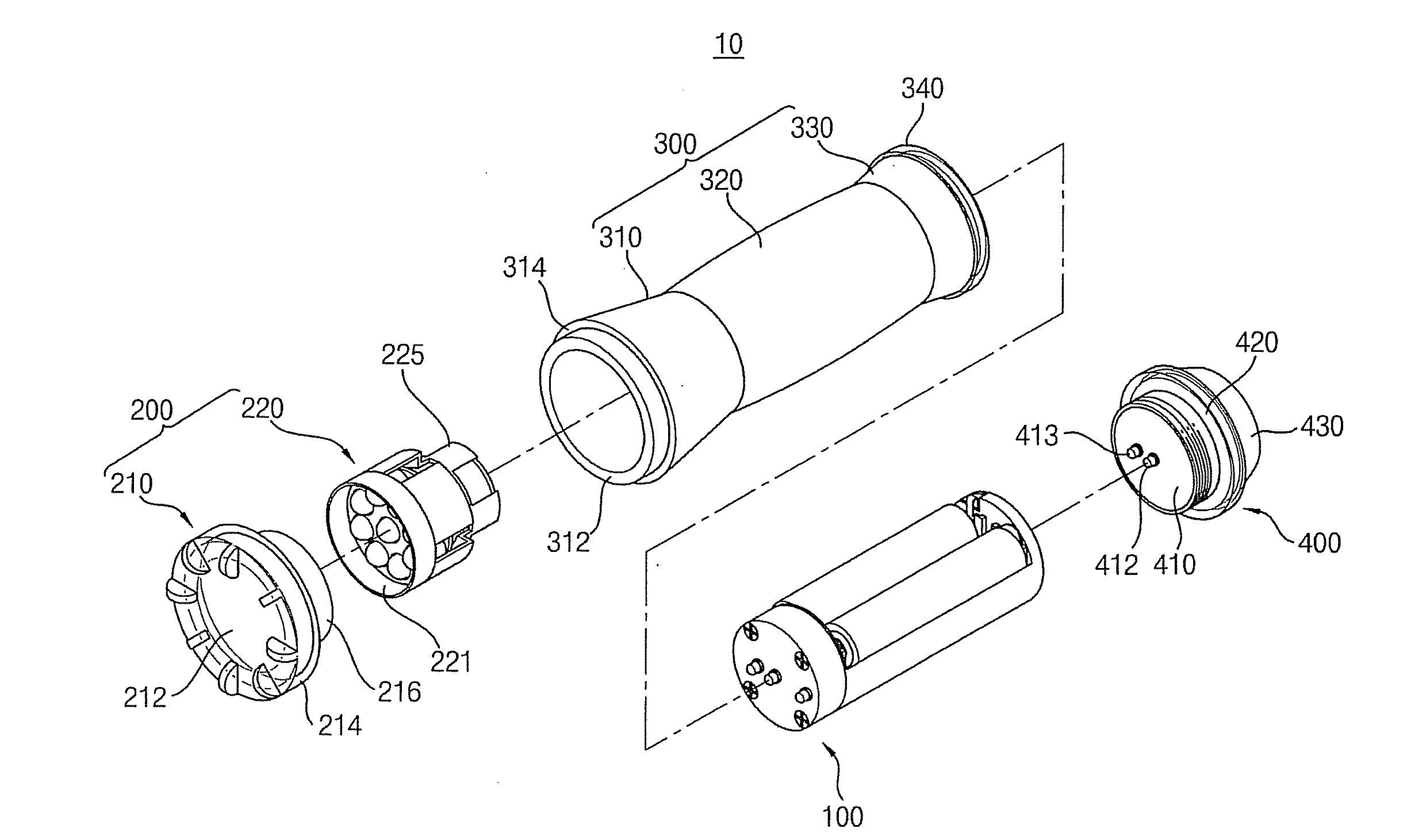

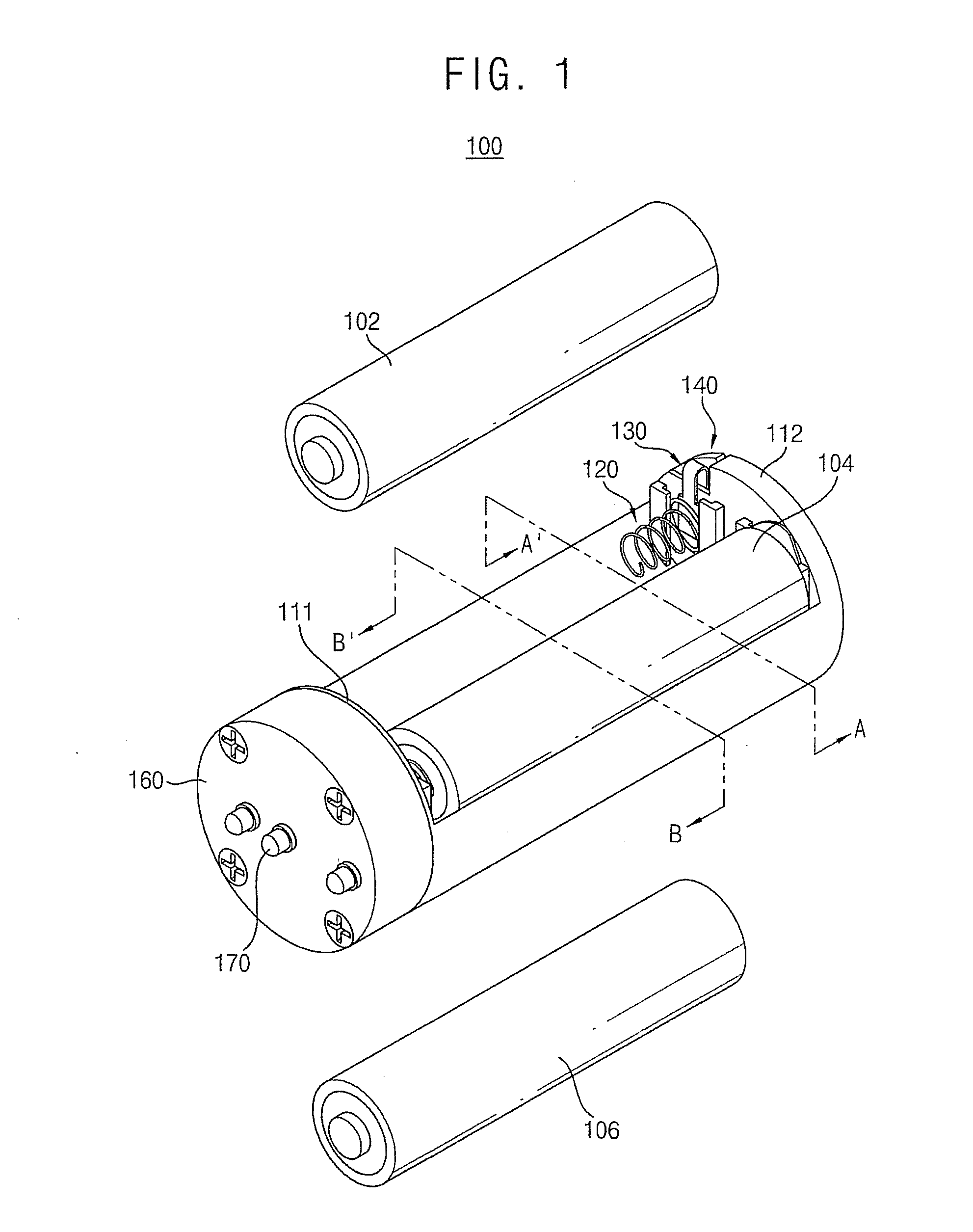

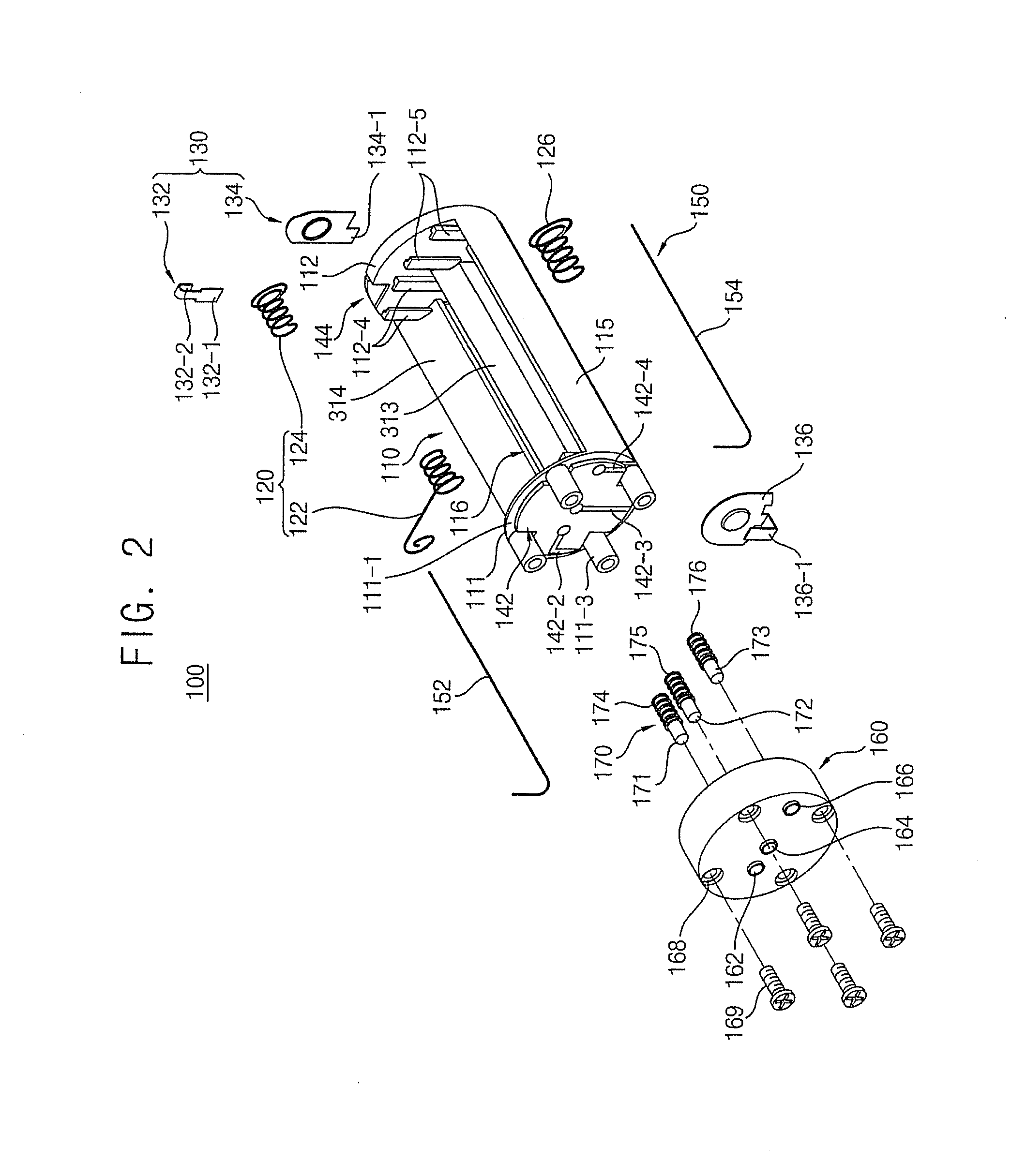

Dry cell holder and flashlight having the same

InactiveUS20100231142A1Strong damageLight weightPoint-like light sourceElectric circuit arrangementsSwitching signalFlashlight

A dry cell holder may include a cylindrical body, an anode terminal, a cathode terminal, a switching signal terminal, a first electrode terminal and a second electrode terminal. The cylindrical body may have a front plate and a rear plate. The anode terminal may be formed on the front plate. The cathode terminal may be formed on the front plate. The switching signal terminal may be formed on the front plate. The first electrode terminal may be formed on the rear plate. The first electrode terminal may be connected to the anode terminal. The first electrode terminal may be connected to the cathode terminal. The second electrode terminal may be formed on the rear plate. The second electrode terminal may be connected to the switching signal terminal.

Owner:AITEC

Flame retardant cellulose fiber and preparation method thereof

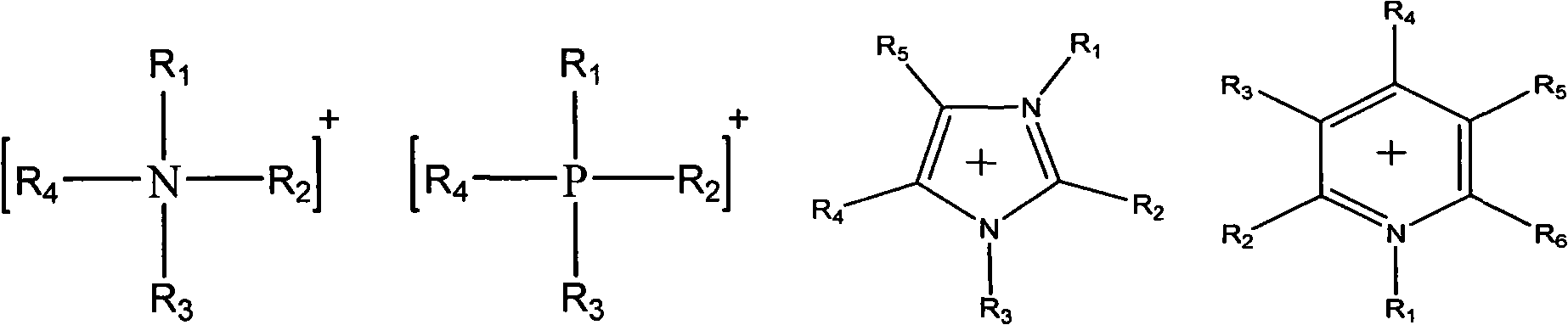

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

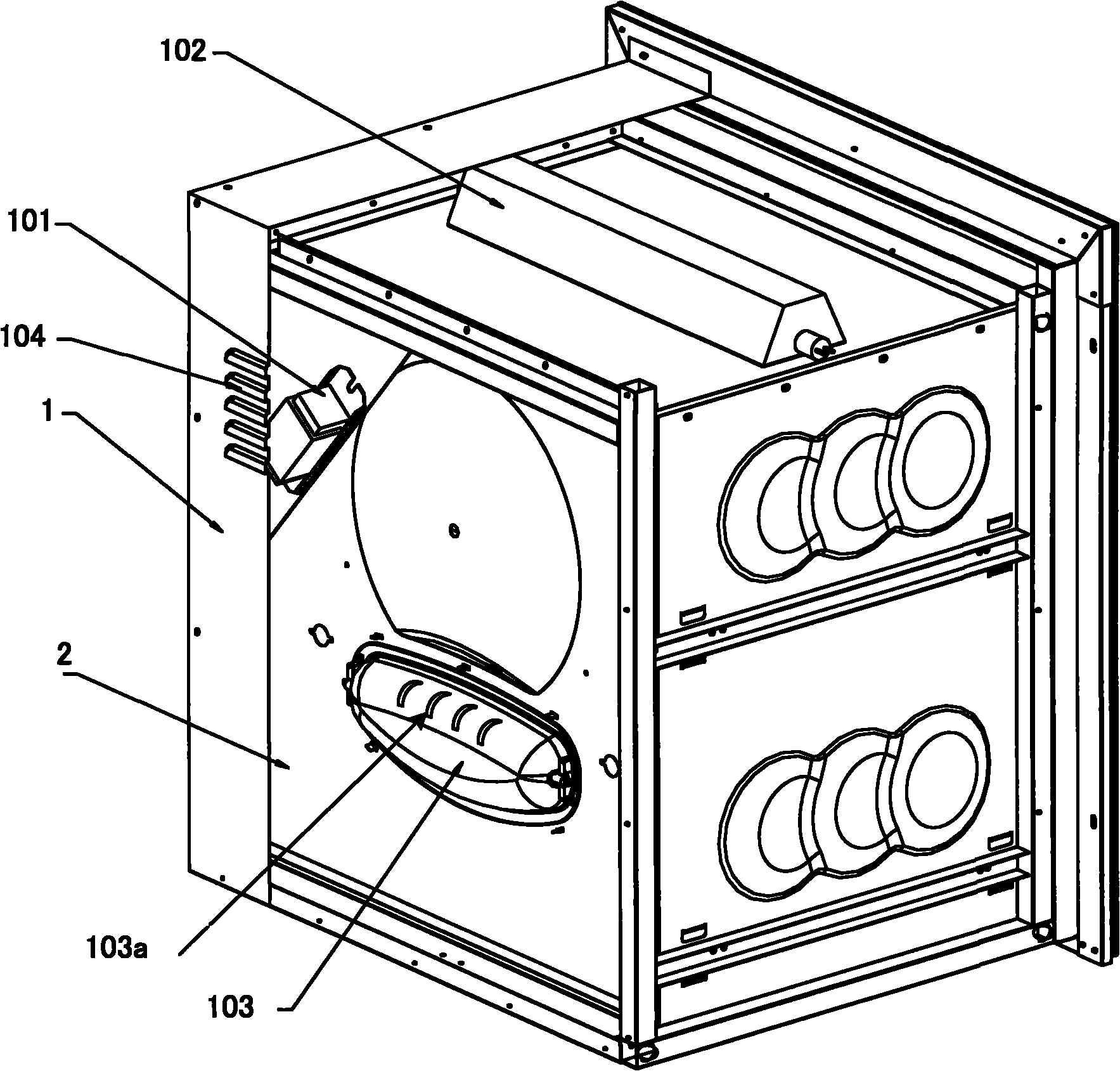

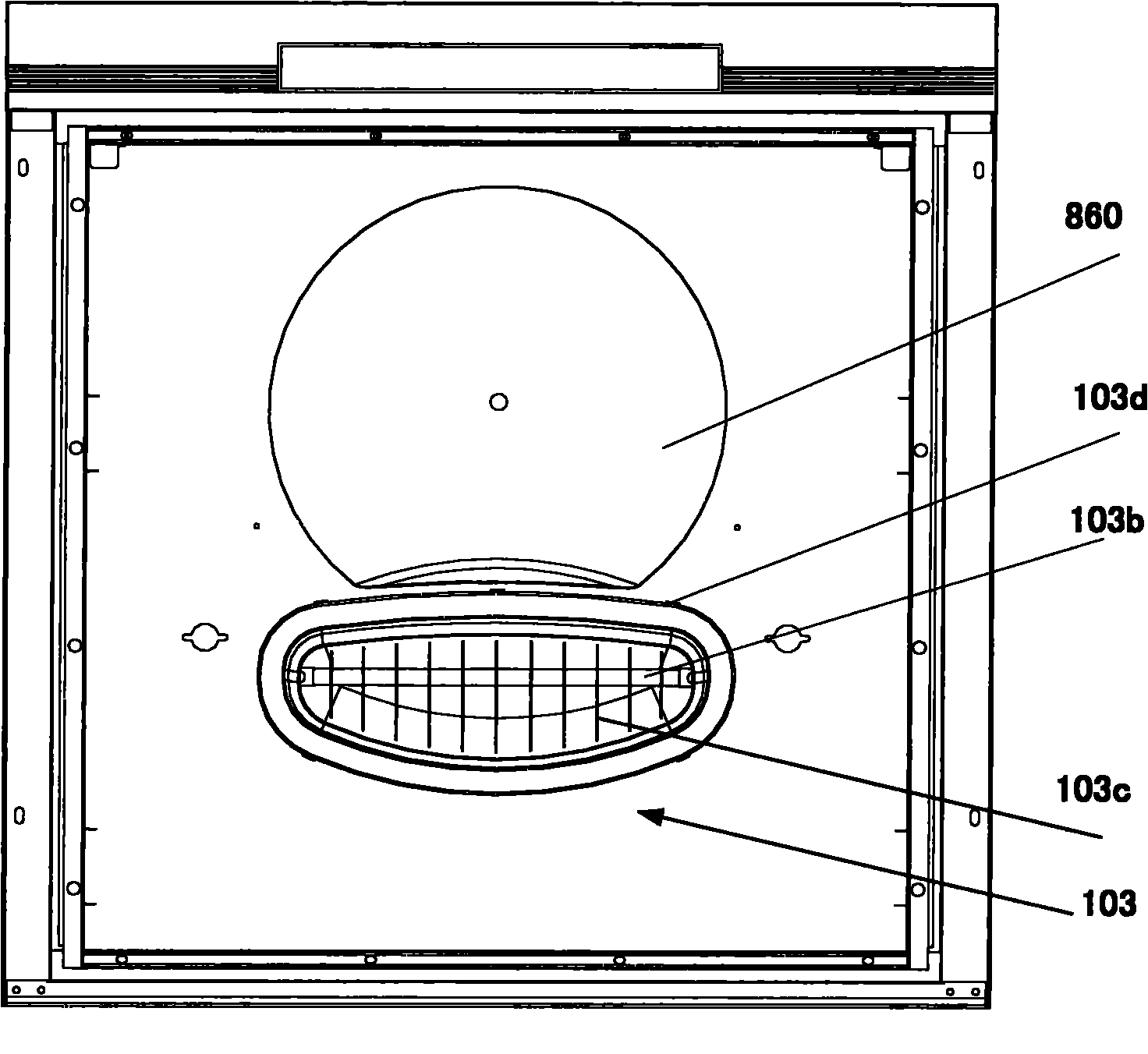

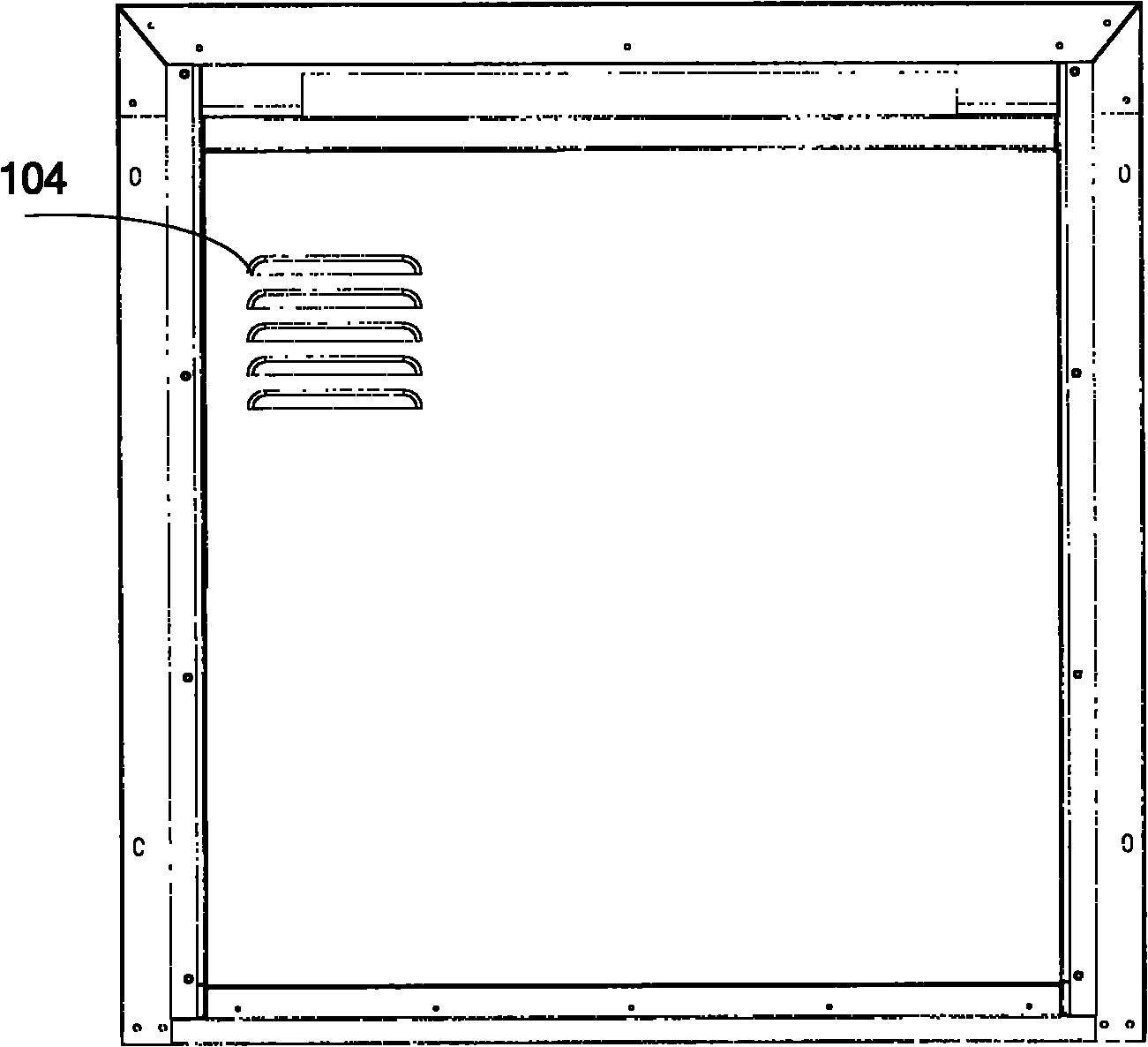

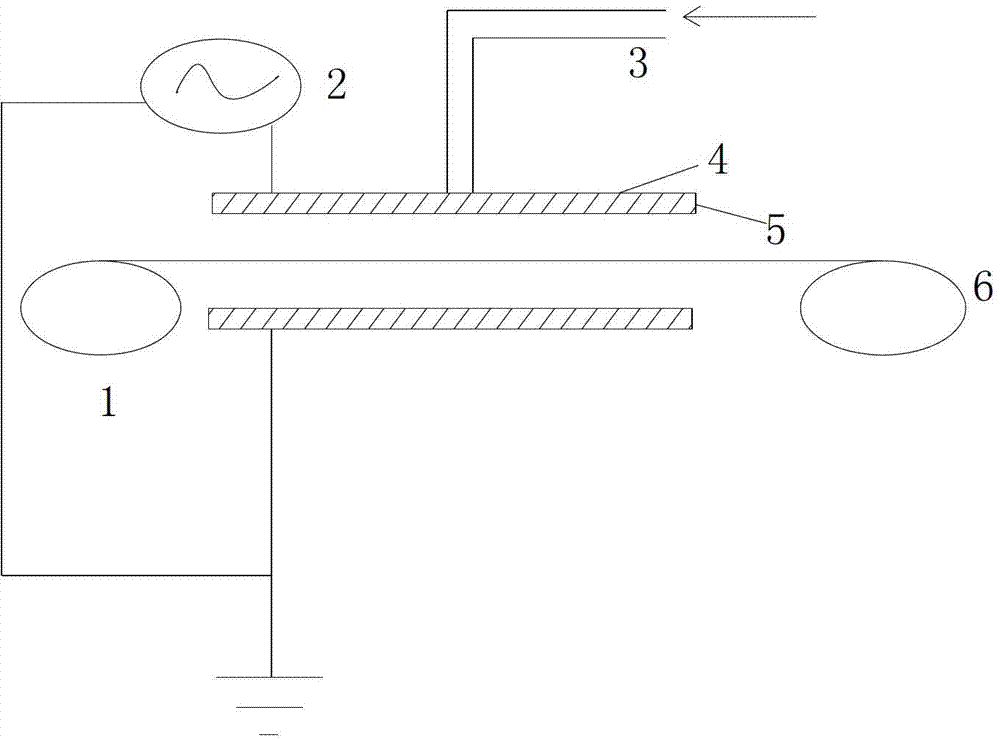

Disinfecting method of disinfection cabinet and disinfection cabinet

ActiveCN101890174AAvoid the problem of easy leakage of ozoneHigh sealing requirementsHeatRadiationThermal energyEngineering

The invention provides a disinfecting method of a disinfection cabinet and the disinfection cabinet. The disinfecting method adopted combined light waves and heat to sterilize and disinfect, wherein the light wave has a wall-broken effect on bacteria. The invention also provides the disinfection cabinet adopting the disinfecting method, which is composed of an outer shell and an inner shell, wherein the outer shell encircles the inner shell to form an interlayer, and the inner shell forms an inner cavity provided with a device for producing light waves having a wall-broken effect on bacteria and a device for producing heat capable of maintaining the disinfection cabinet inner cavity at a certain temperature. By the invention, sterilization and disinfection can be realized by combing light waves and heat, thus greatly shortening the disinfecting time.

Owner:HAIER GRP CORP +1

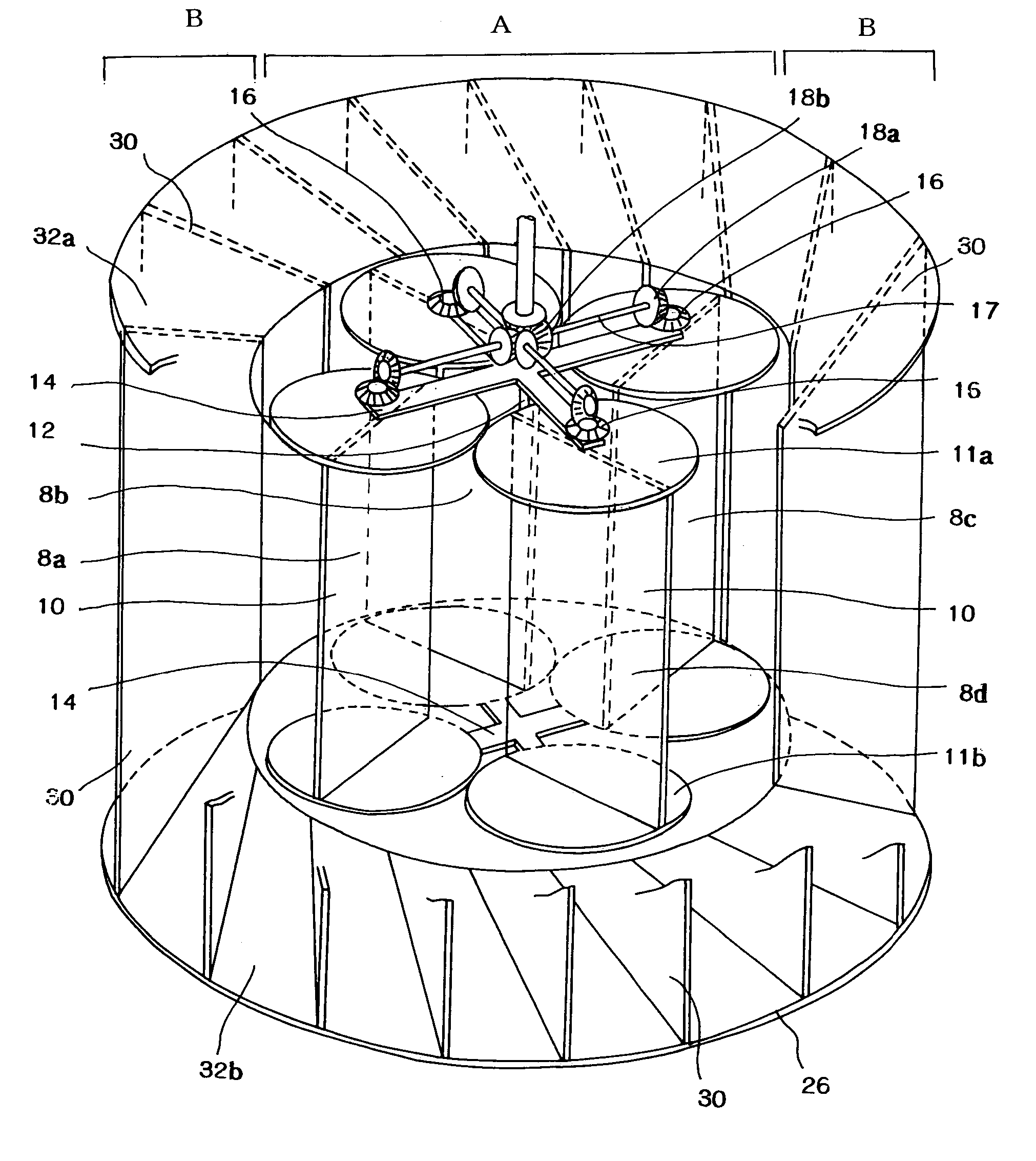

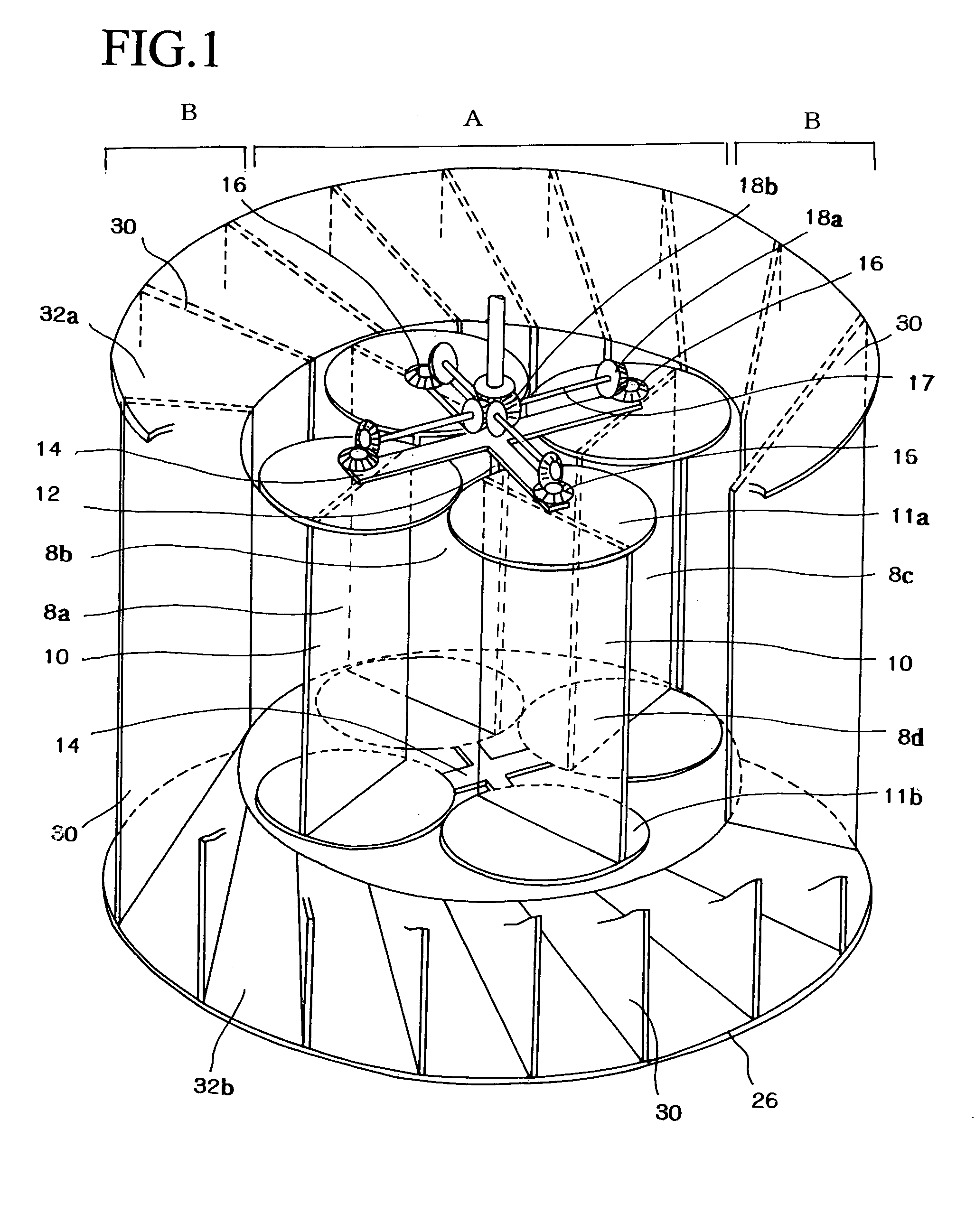

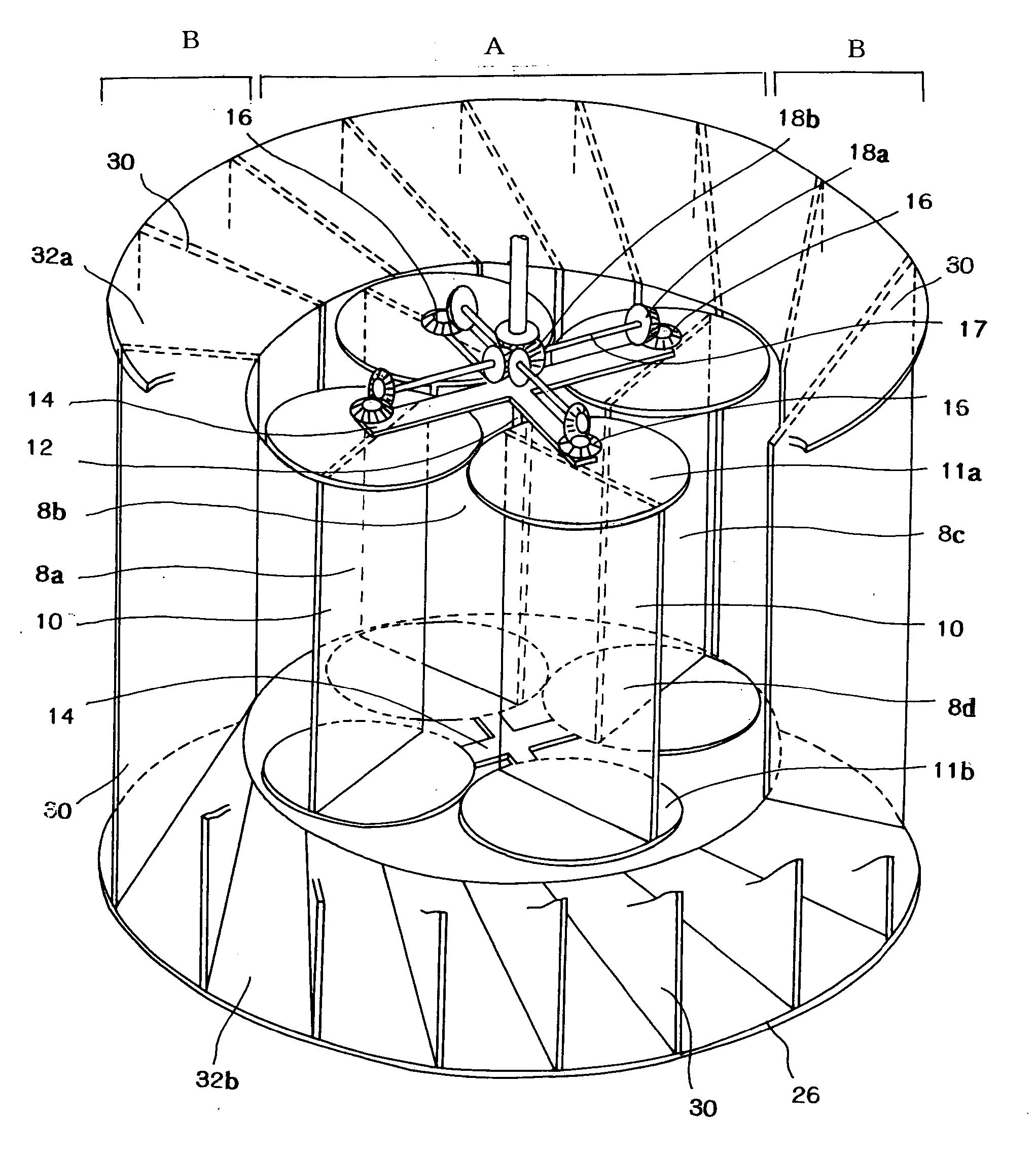

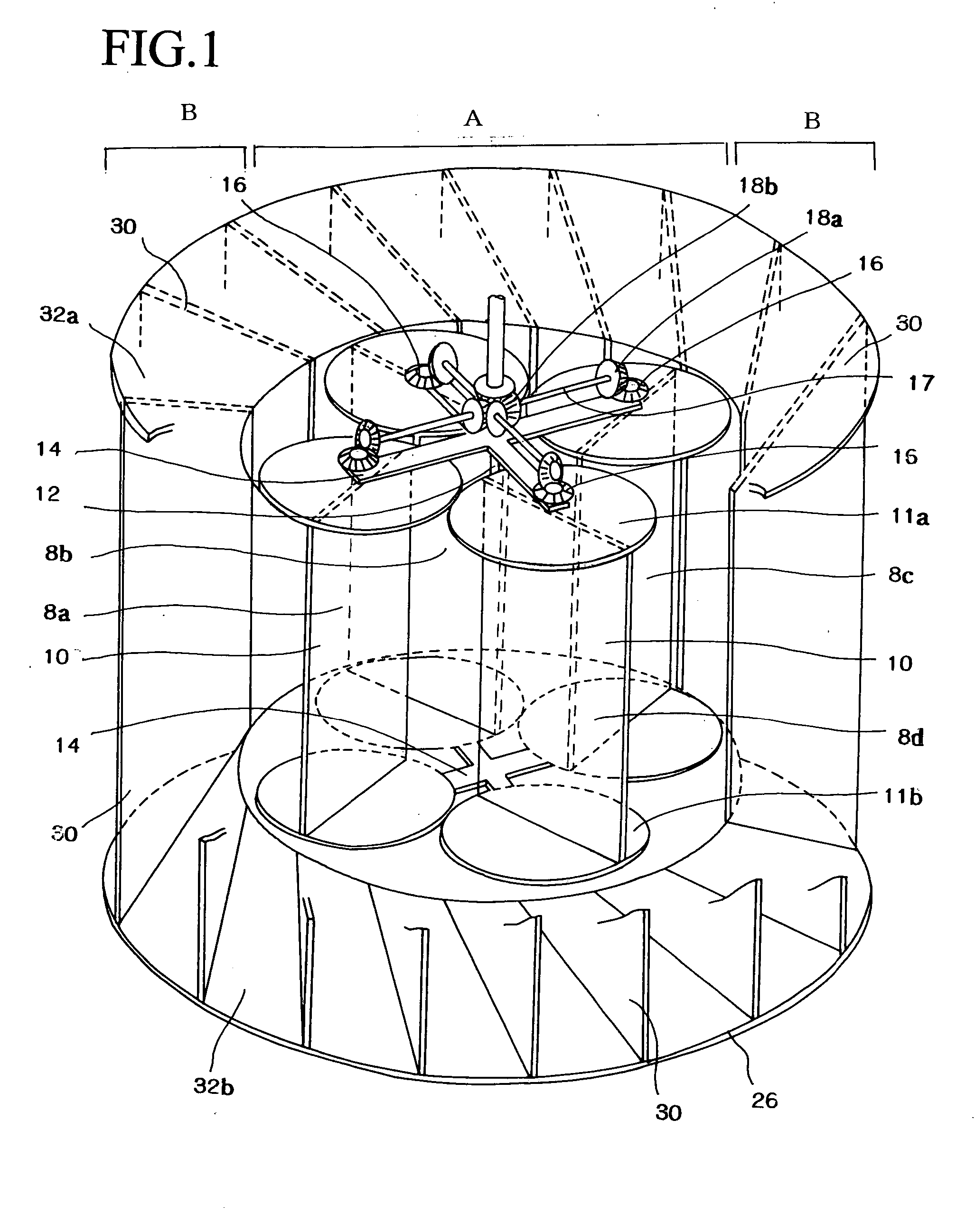

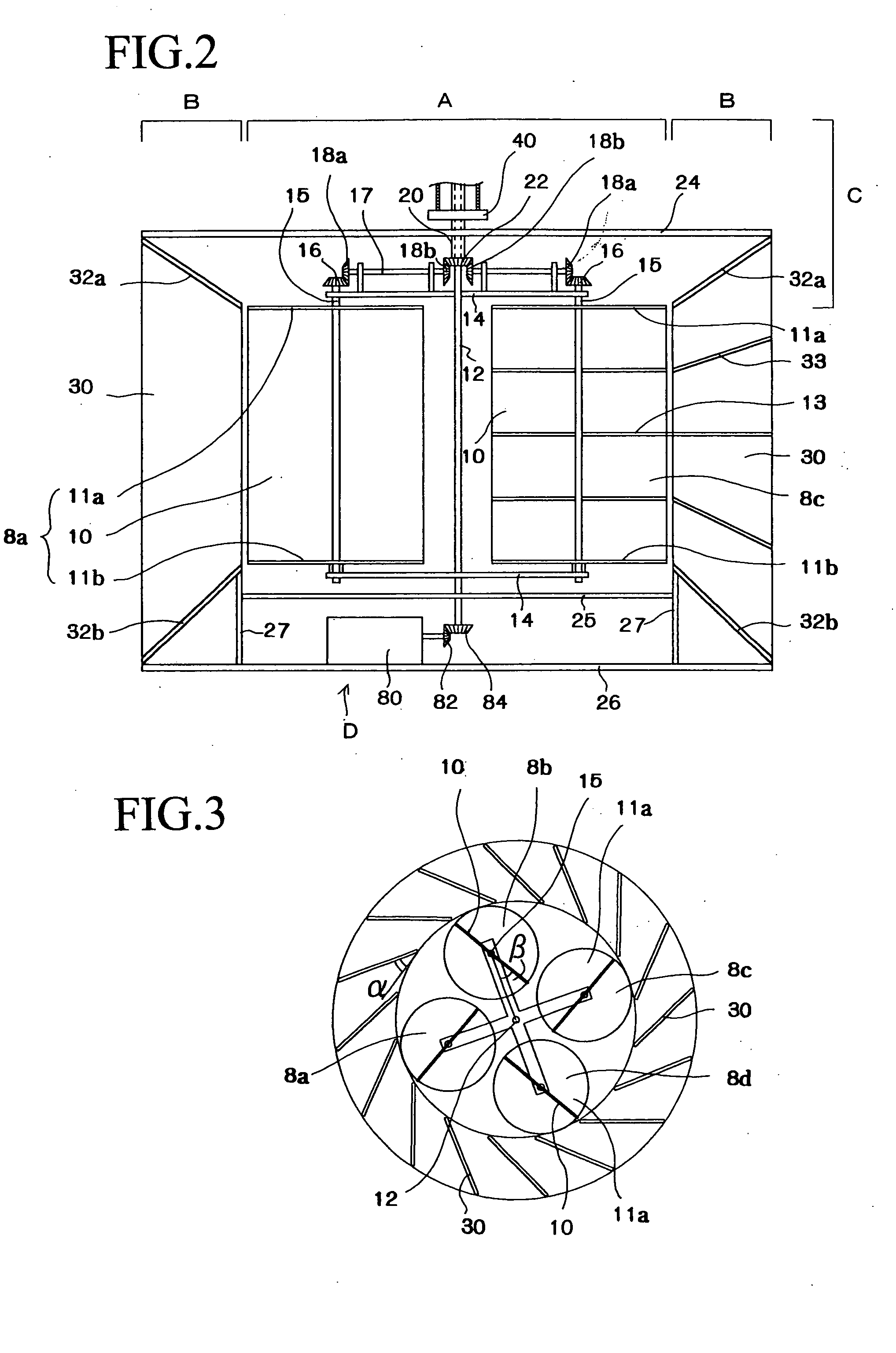

Vertical shaft driving device for vertical wind mills or the like and electric power generator using the same

InactiveUS7094017B2High output powerIncrease wind speedPropellersPump componentsClassical mechanicsWater flow

Owner:LEDERER YURIKO +1

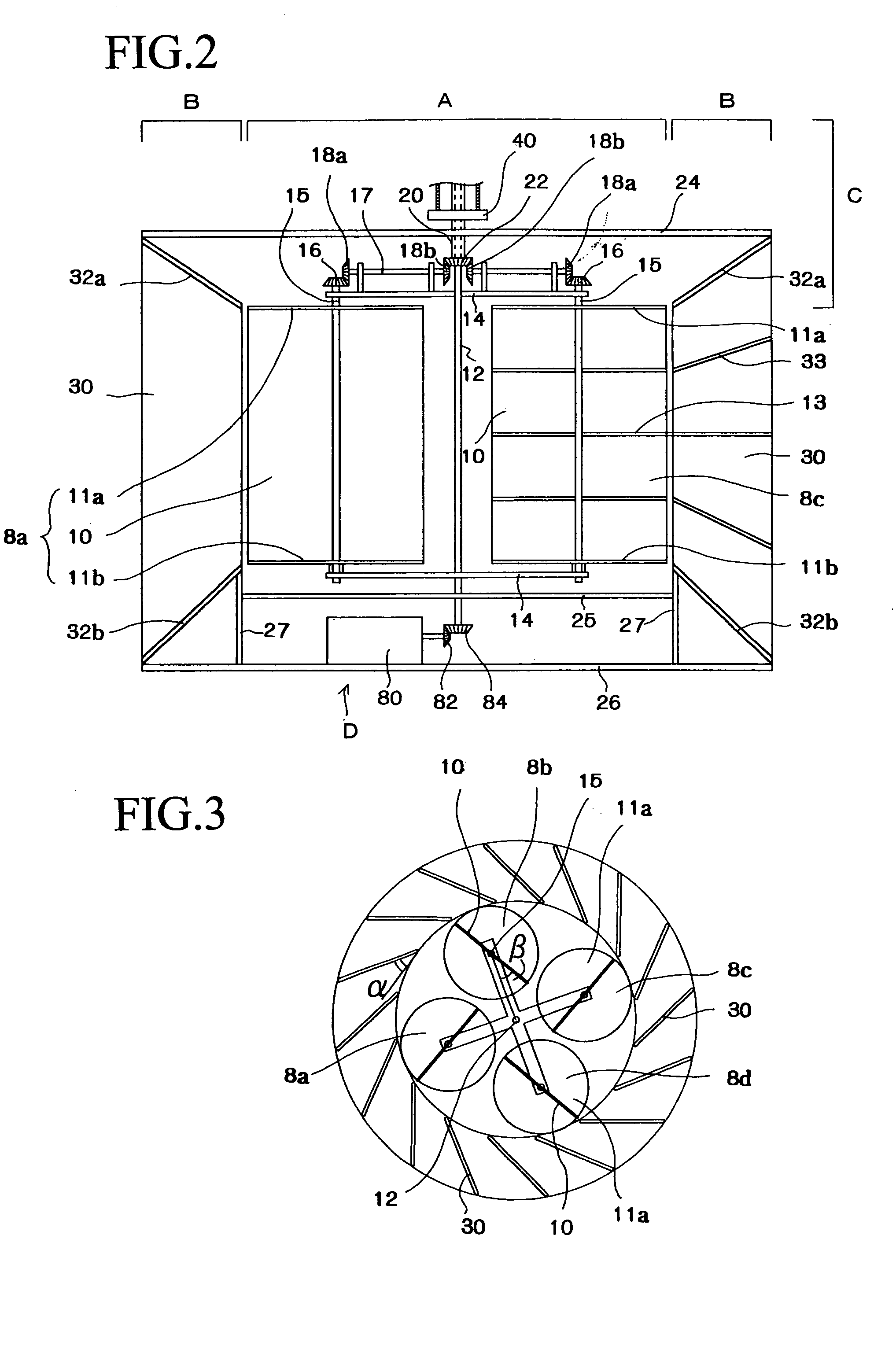

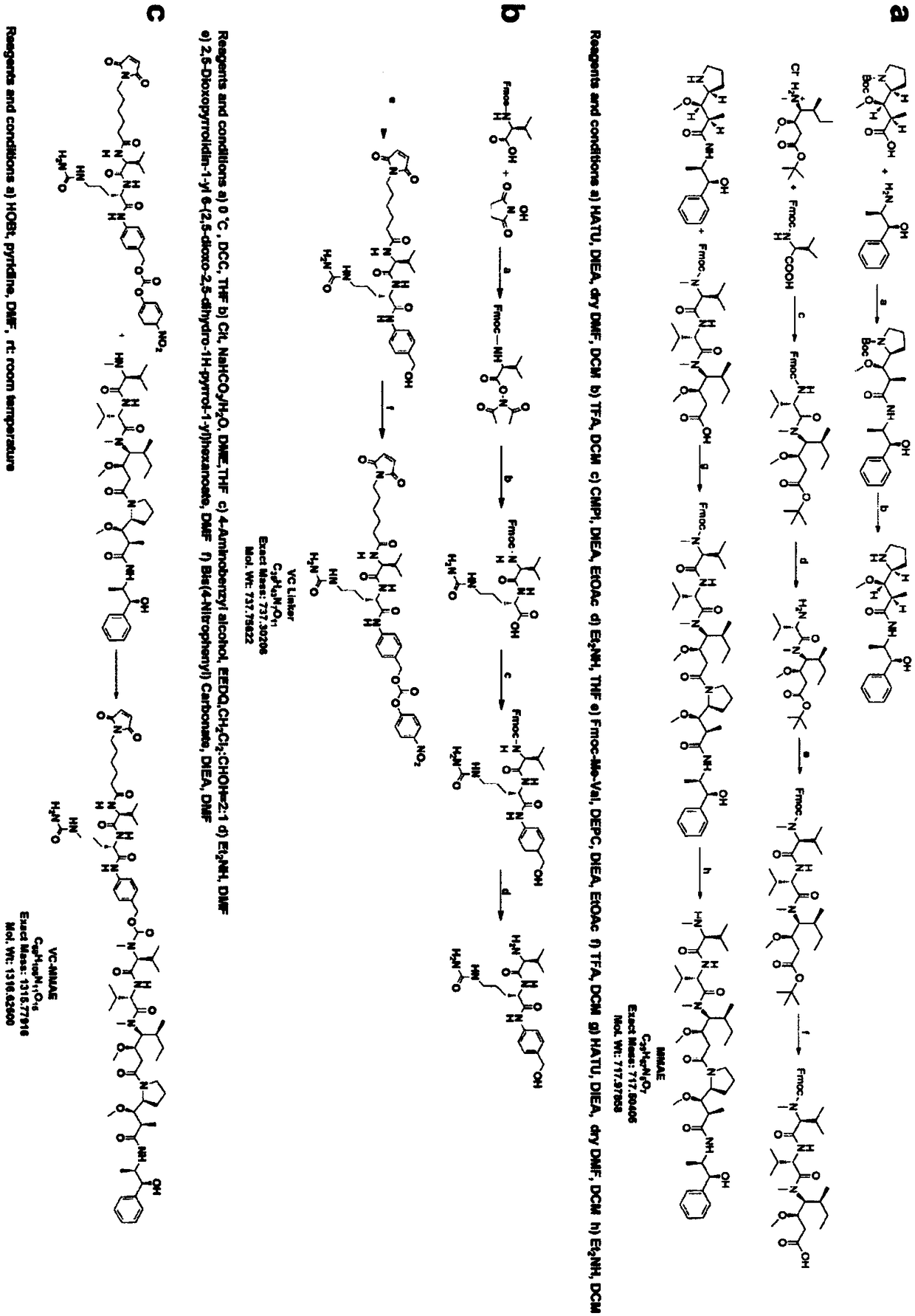

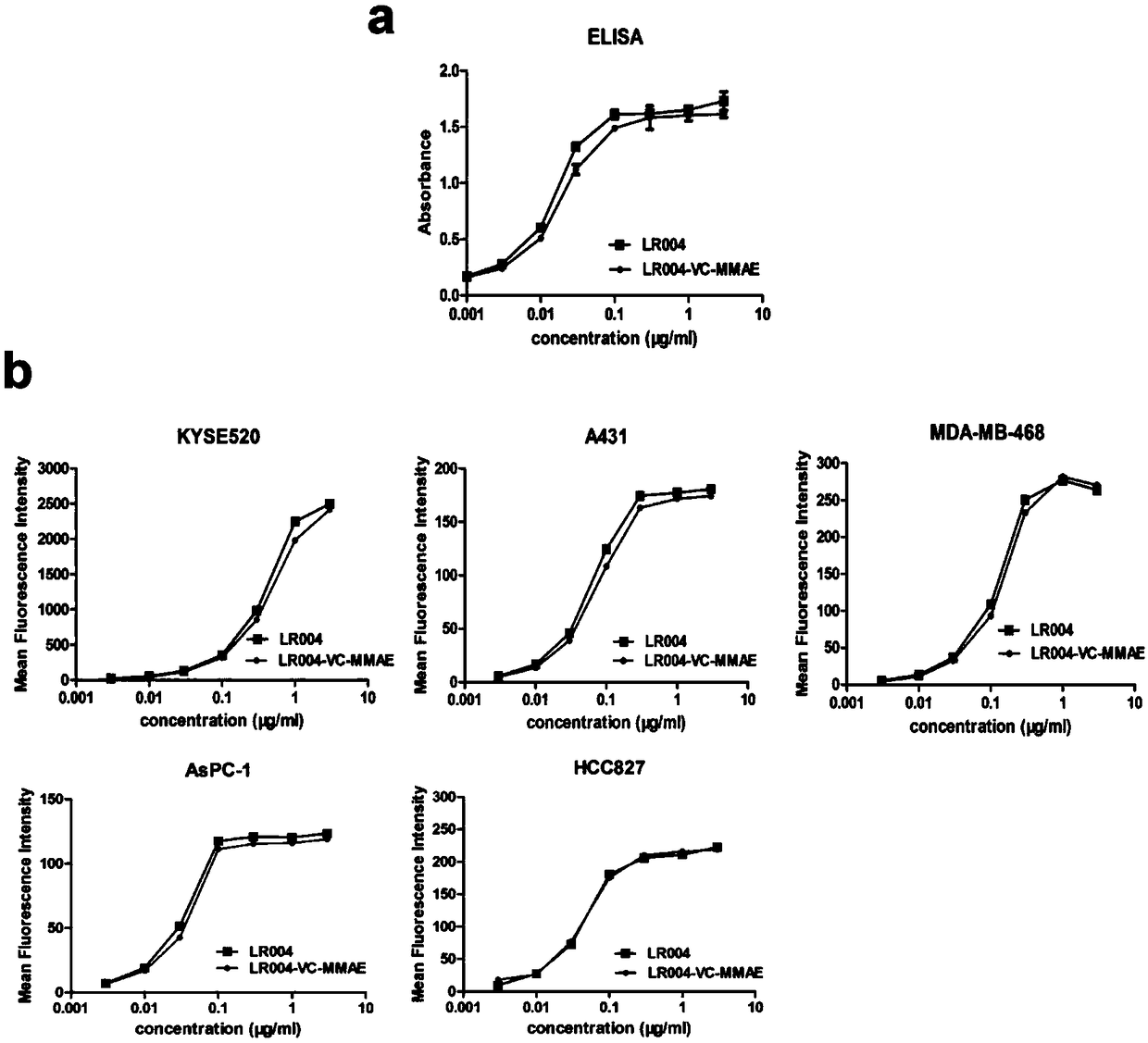

An antibody-coupled drug targeting on EGFR, a preparation method thereof, and uses thereof

ActiveCN109200291ADid not affect stabilityStable and controllable qualityTetrapeptide ingredientsAntibody ingredientsHalf-lifeAntibody conjugate

The invention discloses an antibody coupling drug targeting on EGFR, a preparation method thereof and uses thereof. The antibody-conjugated drug targeting EGFR is named LR004-VC-MMAE consisting of anantibody, a cytotoxic drug and a linker, wherein the antibody drug conjugate has a structure represented by the formula I, wherein mAb is an LR004 monoclonal antibody, n=2-8. The novel antibody-conjugated drug LR004-VC-MMAE can not only target EGFR antigen, but also has strong cytotoxicity to tumor cells. Compared with LR004 itself, it did not affect the affinity, endocytosis and targeting of theantibody, and better retained its biological function. Compared to LR004, the antitumor effect of LR004-VC-MMAE antibody-conjugated drug is significantly improved, and the tumor disappeared. Comparedto LR004, LR004-VC-MMAE antibody-conjugated total antibody showed longer half-life, slower clearance rate, lower concentration of free MMAE in plasma, shorter half-life and faster clearance rate, which is conducive to reduce toxicity.

Owner:MEDICINE & BIOENG INST OF CHINESE ACAD OF MEDICAL SCI

Making method of high temperature-resistant filter material

ActiveCN101584953APerformance impactImprove temperature resistanceFiltration separationGlass fiberFiber

The invention provides a making method of a high temperature-resistant filter material, characterized in specific steps of mixing glass fiber and polyphenylene sulphide between which the weight ratio is 1:1 to 1:5, weaving into a substrate cloth of which the density is 100 to 170g / m, respectively placing a polyphenylene sulphide fiber net of which the density is 150 to 350g / m on upper and lower sides to obtain a three-layer composite material of which the density is 400 to 800g / m; pre-needling the three-layer composite material, spunlacing to pre-wet at high pressure, spunlacing the front and back faces to reinforce for 4 to 8 times, condensation resisting, and finishing to obtain the high temperature-resistant filter material. The high temperature-resistant filter material has good high temperature-resistance, long service life and high filtering performance.

Owner:DONGHUA UNIV

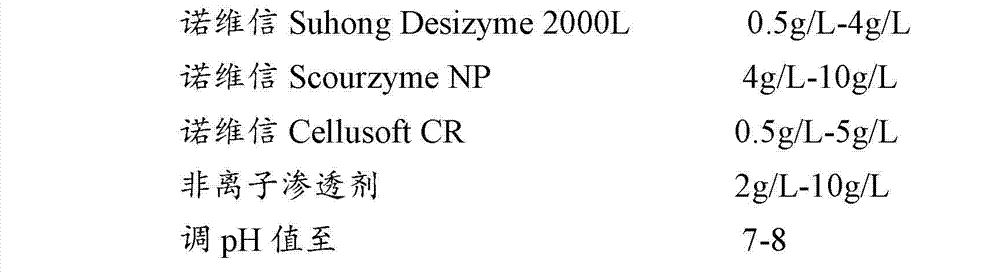

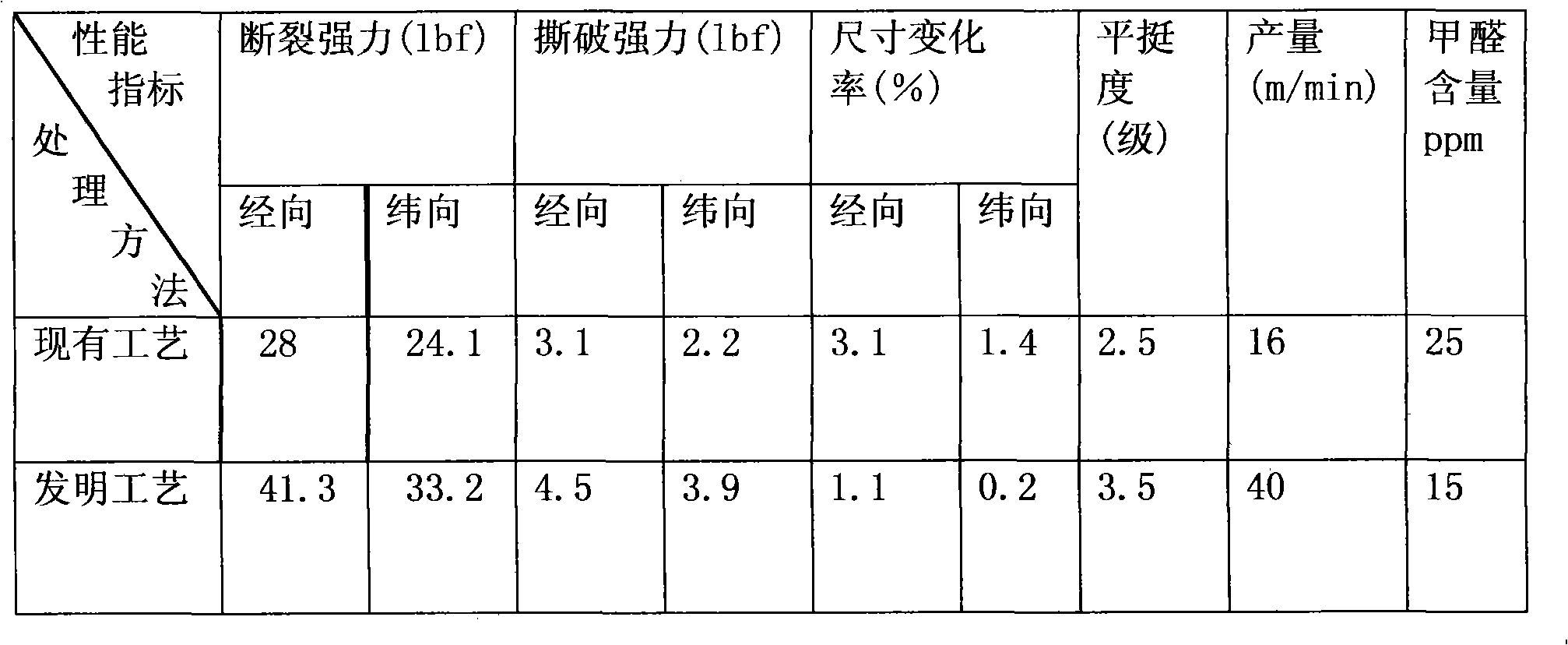

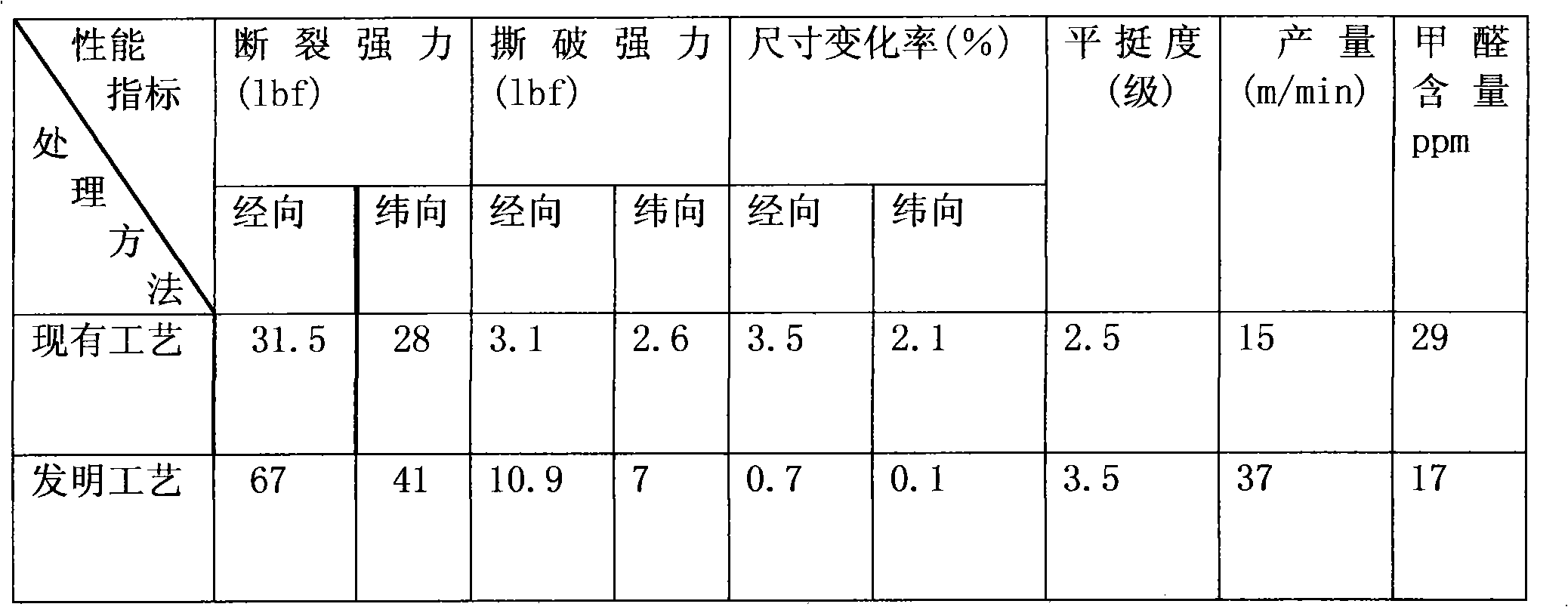

Dyeing and finishing method of real silk/ cotton intertexture

ActiveCN102251403AStrong damageIncrease the rate of first-class productsBiochemical fibre treatmentBleaching apparatusShrinkage rateEngineering

The invention provides a dyeing and finishing method of a real silk / cotton intertexture, and belongs to a dyeing and finishing method of a fabric. The method comprises the following steps of: a, performing sewing and singeing treatment on a gray fabric; b, packaging and de-sizing; c, performing package and oxygen bleaching treatment, and drying; d, packaging and dyeing; e, packaging and softening; and f, performing preshrinking treatment to finish dyeing and finishing, wherein the warp and weft shrinkage rates of the fabric are less than 3 percent after the preshrinking treatment. Because biological de-sizing, scouring and degumming processes are adopted in the dyeing and finishing method, the method has the advantages of high efficiency and mild reaction conditions; particularly, because protease for degumming is adopted, powerful damage to real silk fibers is low, and the degumming effect is good; and by adopting a jig dyeing process, the quality problems of contamination, scratch, pleat and the like easily produced in a long-vehicle pad dyeing process can be effectively avoided.

Owner:YUYUE HOME TEXTILE

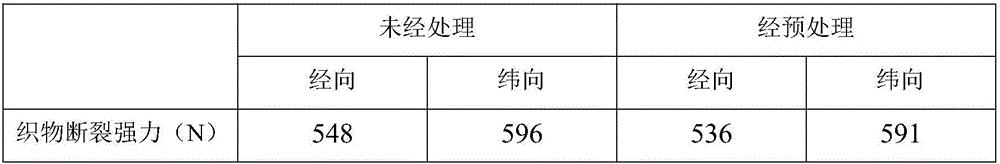

Elastic polyester-cotton fabric dyeing and finishing pretreatment method

InactiveCN103821006AReduce energy consumptionLow processingBiochemical fibre treatmentBleaching apparatusPolyesterTextile printer

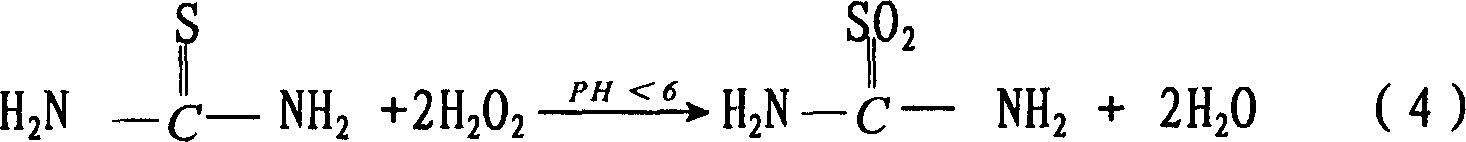

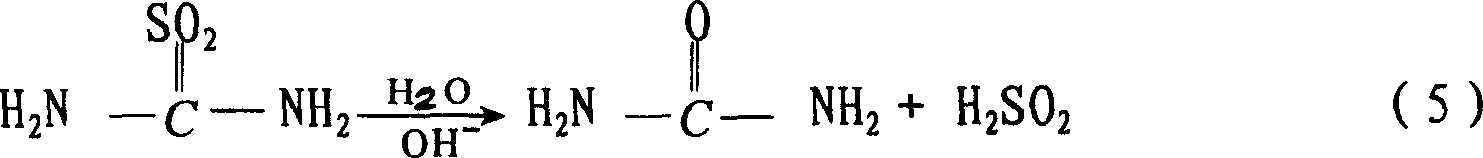

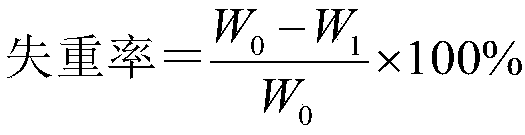

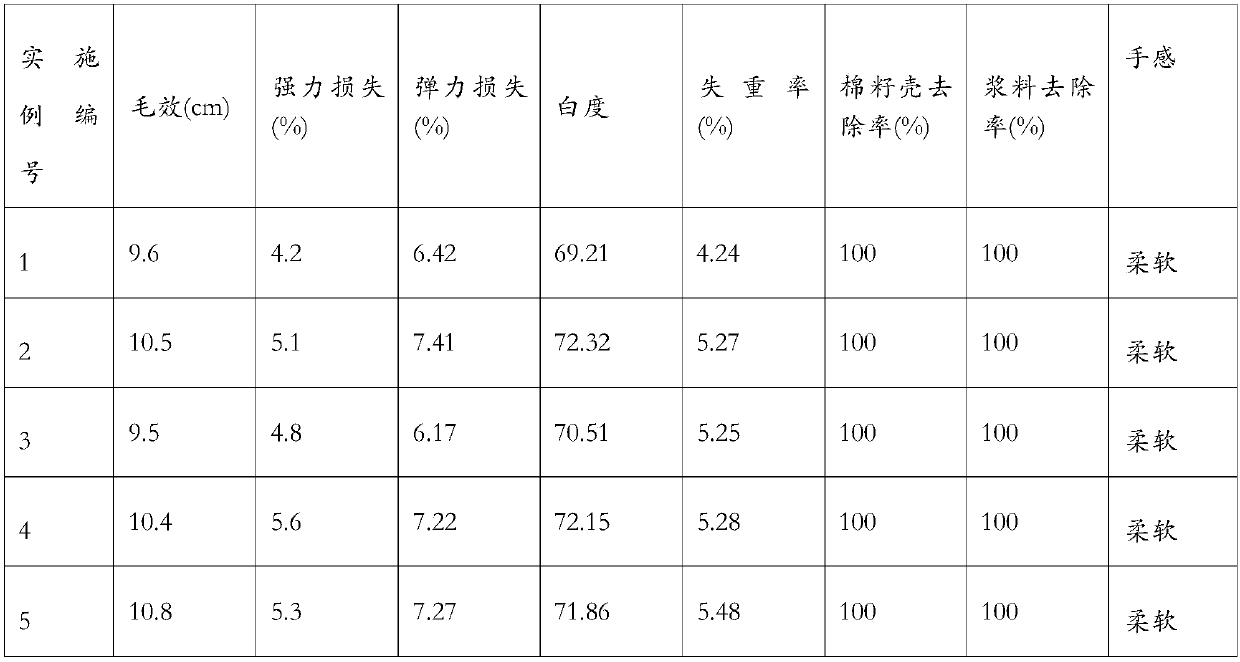

The invention relates to an elastic polyester-cotton fabric dyeing and finishing pretreatment method and belongs to the field of a textile printing and dyeing technology. The invention aims to raise whiteness and water absorbability of a product and minimize reduction of mechanical properties of fabric. Firstly, hot-water preshrinking and pre-setting treatment are carried out on fabric so as to raise external dimension stability of the elastic fabric; then, dyeing and finishing pretreatment is carried out with amylase, pectase and the like so as to remove most non-fibrous symbiont; and finally, hydrogen peroxide bleaching and deoxygenation treatment are combined to remove a few pigment and impurities in the elastic fabric so as to finish dyeing and finishing pretreatment of the fabric. The method comprises the following technological steps: preshrinking and pre-setting; bio-enzyme (amylase, pectase, laccase and cellulose) treatment; hydrogen peroxide bleaching; and catalase deoxygenation. In comparison with a traditional alkali pretreatment process, the method provided by the invention has advantages as follows: production energy consumption is reduced, and quality of the elastic polyester-cotton fabric is raised.

Owner:吴江市桃源海润印染有限公司

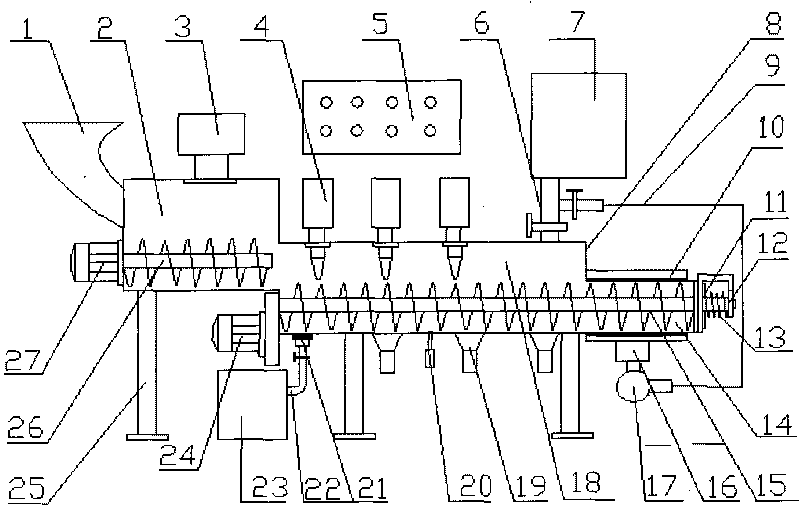

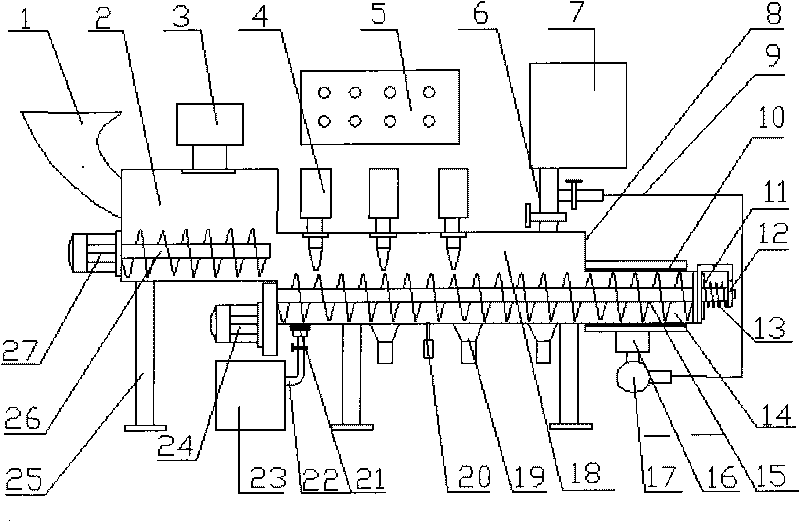

Tea microwave and ultrasonic wave combined dynamic countercurrent extraction method and equipment

The invention discloses tea microwave and ultrasonic wave combined dynamic countercurrent extraction method and equipment. Microwave-ultrasonic wave combination stage-by-stage time-division extraction is adopted to give full play to the characteristics and the advantages of a microwave and ultrasonic wave extraction technology. In the whole extraction process, the flow direction of an extraction solvent is opposite to that of tea, thereby realizing a dynamic countercurrent continuous extraction function, being beneficial to extracting active ingredients of the tea and maximizing the tea extraction function and the efficiency; the rear end of extraction equipment is provided with a solid-liquid separation device, so that tea dregs after extraction can be dehydrated for realizing the comprehensive utilization of the tea dregs on one hand, and on the other hand, the filtered tea liquid can be circulated and utilized, thereby reducing the loss of the active ingredients in the tea liquid;the whole extraction process is completed at lower temperature, thereby being beneficial to preventing the active ingredients in the tea from being damaged by high temperature up to the hilt, saving the usage amount of the extraction solvent, reducing pollution and lowering the cost. The invention can realize industrial large-scale extraction production.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Heavy pure cotton fabric cold padding and stacking pretreatment method

ActiveCN103088645AExcellent desizingExcellent and refinedPhysical treatmentBiochemical fibre treatmentPretreatment methodTherapeutic effect

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after normal pressure plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the normal pressure plasma treatment on the singed heavy pure cotton grey fabric; carrying out refining enzyme liquid padding on the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process; and the process is a clean production process meeting the environmental protection requirement, so that the sewage treatment burdens of enterprises are greatly reduced, the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:浙江肯特科技股份有限公司

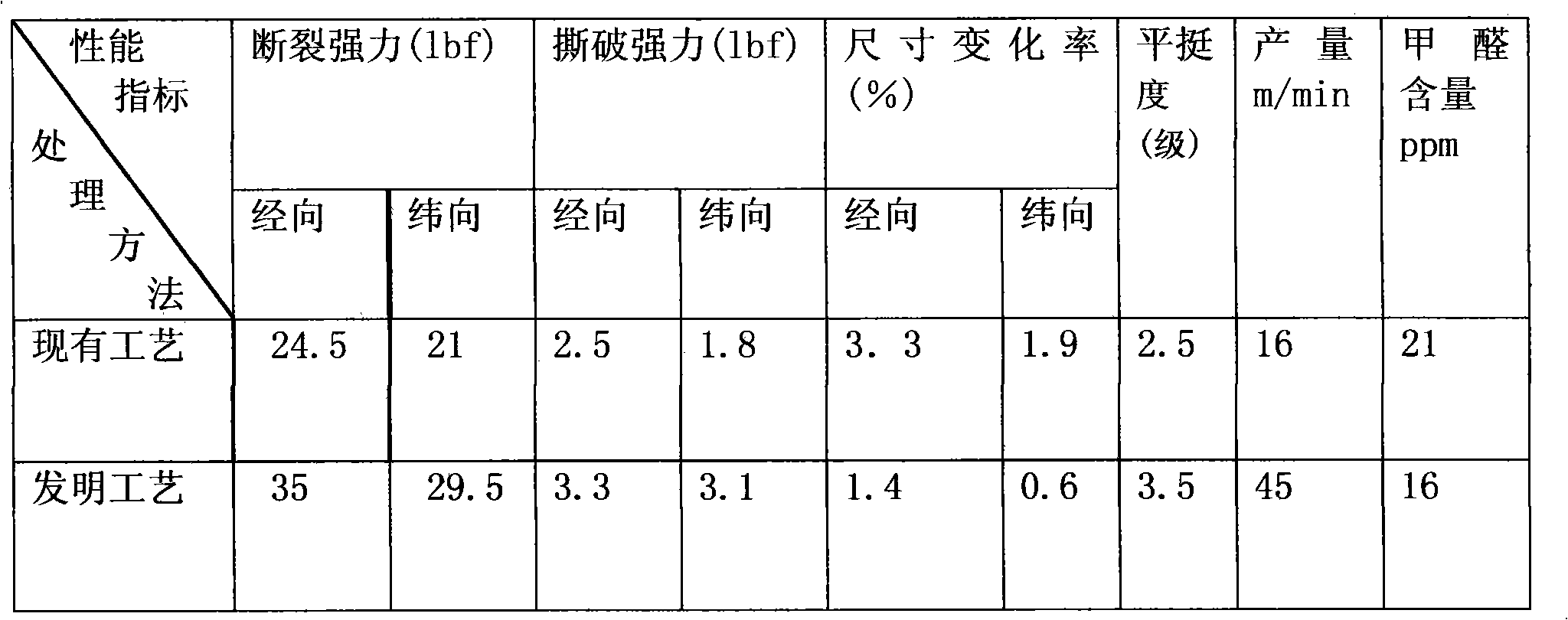

Processing method of natural wash-and-wear purified cotton fabrics

ActiveCN105350286AWith non-iron effectLittle impact on hand feelingBiochemical fibre treatmentDyeing processYarnEnzyme

The invention discloses a processing method of natural wash-and-wear purified cotton fabrics; the whole processing technology comprises yarn choosing, yarn dyeing, slashing, weaving, singeing, desizing, mercerizing, liquid ammonia treatment, bio-enzyme treatment, drying, wash-and-wear resin finishing, and preshrinking. The processing method has the advantages that the purified cotton fabrics obtained by the method enable the wash-and-wear grade to reach 3.0 or more, organosilicon is applied in actual production of the purified cotton wash-and-wear fabrics, and the obtained purified cotton fabrics have a wash-and-wear effect, also do not contain formaldehyde, are environmentally friendly, and are harmless to human bodies; and in addition, strong damage on the fabrics in the processing process is small, the influence on a fabric hand feeling is small, and the hand feeling of the fabrics obtained from processing is quite smooth and soft.

Owner:浙江盛泰服装集团股份有限公司

Method for suppressing and eliminating fluorescence of textile product by fluorescence quenching agent

InactiveCN101187150AStrong damageInhibit or eliminate fluorescent substancesVegetal fibresAnimal fibresFluorescenceQuenching

The invention relates to a method to repress and eliminate the fluorescence of fabric, which comprises chlorine dioxide fluorescence elimination method, chlorine dioxide or sodium chlorite fluorescence elimination method and peroxy-acetic acid fluorescence elimination method, wherein these methods can effectively repress or eliminate the fluorescence on the fabric made of fibrin fiber or protein fiber, the processed fabric has little damage under strong force, the method can eliminate the fluorescence on the fabrics and also can be used in the colorful fabric color-stripping process.

Owner:DONGHUA UNIV

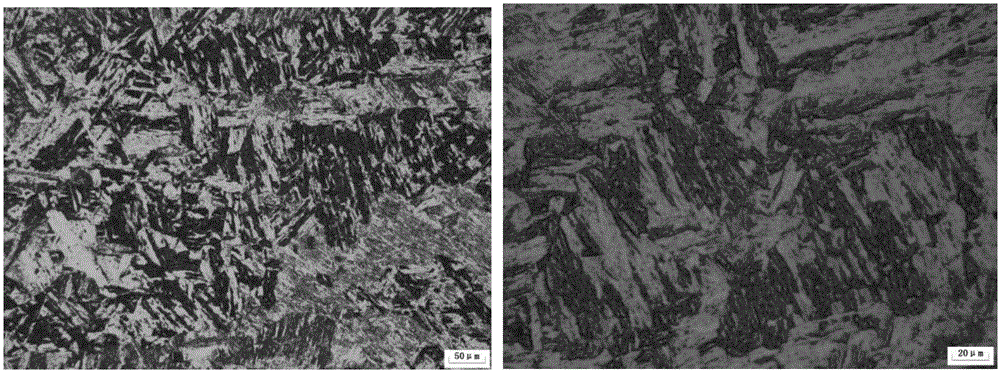

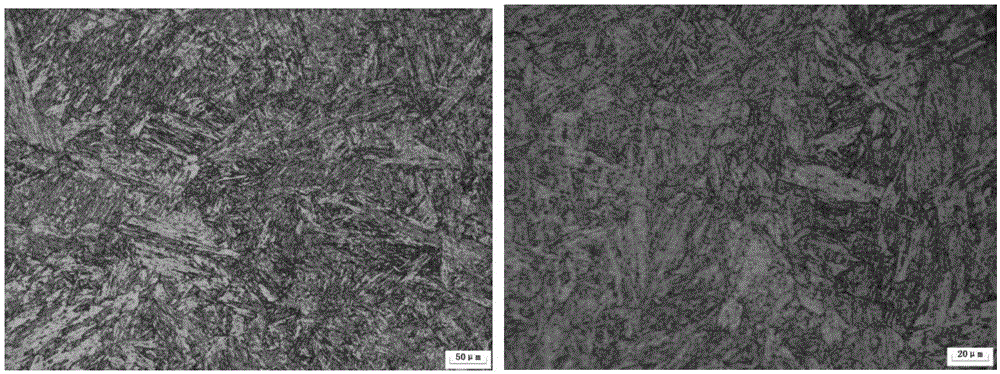

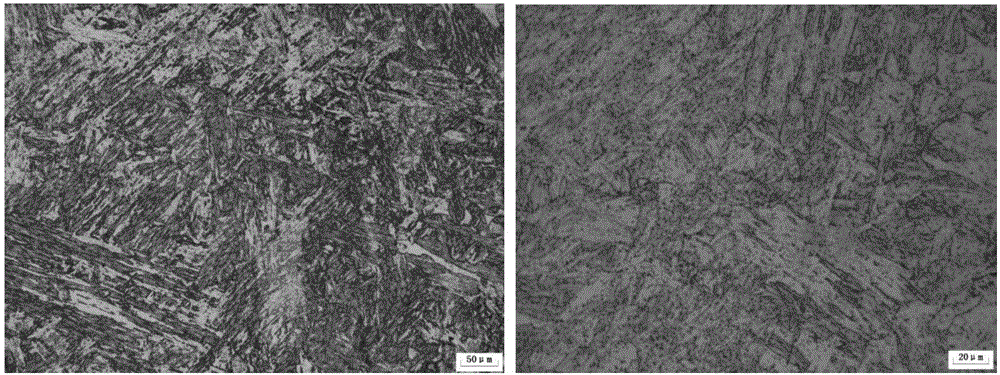

Method for improving structure and performance of T92 steel welding joint and T92 steel welding joint

InactiveCN106624416AGood welding performanceImprove toughnessWelding apparatusMechanical propertyHeat treated

Owner:中国大唐集团科学技术研究总院有限公司

Vertical shaft driving device for vertical wind mills or the like and electric power generator using the same

InactiveUS20050079054A1Reduce resistanceRotation speed is limitedPropellersPump componentsWater flowKnife blades

Owner:LEDERER YURIKO +1

Shrinkproof crease-resistant low strength loss flax fabric dyeing and finishing technique

InactiveCN101565898AImprove production efficiencyIncrease productivityDyeing processVegetal fibresWater solublePulp and paper industry

The invention discloses a shrinkproof crease-resistant low strength loss flax fabric dyeing and finishing technique, which belongs to the technical field of dyeing and finishing. The technical flow comprises the working procedures of: padding the flax fabric after being colored through finishing working liquid, baking at high temperature, rinsing, drying and pre-shrinking. The working procedure of padding through the finishing working liquid comprises the finishing working procedures of two dipping and two rolling; the padding pick-up of the first finishing working liquid is 90-100 percent, the pressure is 1.5-1.7Kg and the vehicle speed is 40-55 meters / minute; the padding pick-up of the second finishing working liquid is 60-70 percent, the pressure is 1.8-2.0Kg and the vehicle speed is 40-55 meters / minute; the prescription of the second padding finishing working liquid comprises 60-100g / L of resin cross linking agent, 15-25g / L of catalyst as well as 30-50g / L of softening agent. The flax fabric processed by the technique solves the contradiction between the processing yield and quality of fabric. The shrinkproof crease-resistant performance of the processed fabric is excellent, the strength loss is small and the processing yield is high. The shrinkproof crease-resistant low strength loss flax fabric dyeing and finishing technique has extremely high popularization and application values in the dyeing and finishing industry.

Owner:ZHEJIANG GUANDONG DYEING & GARMENT

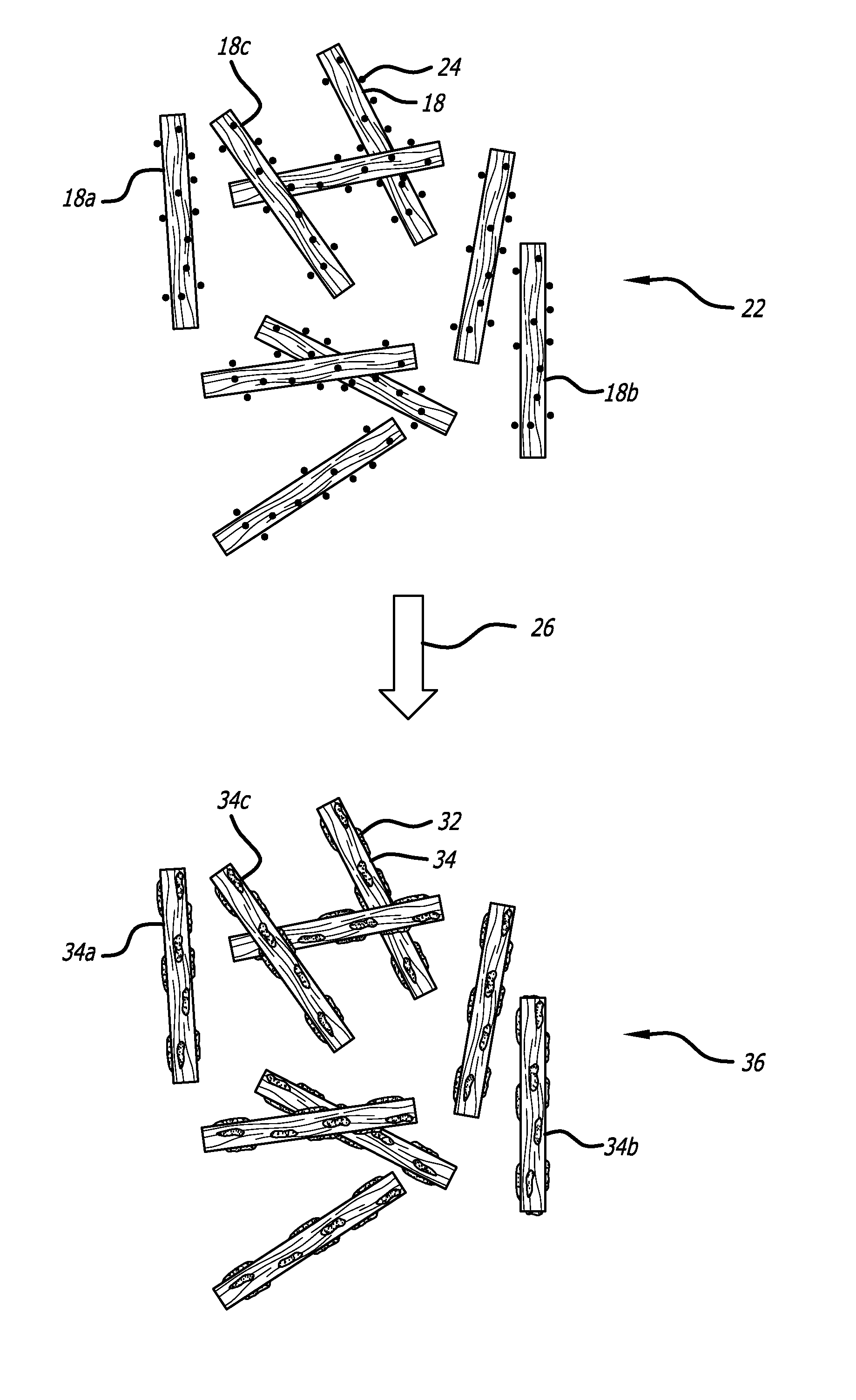

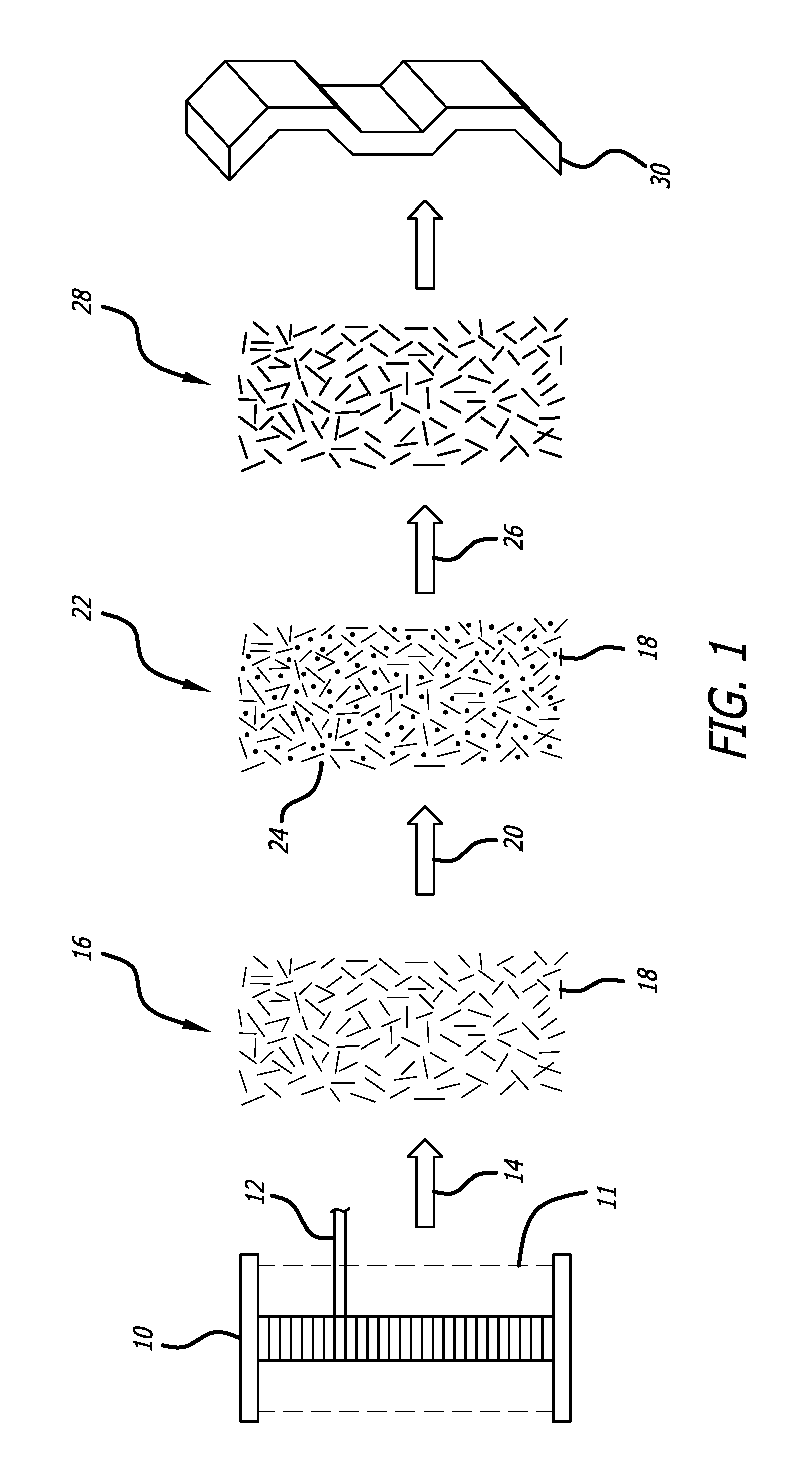

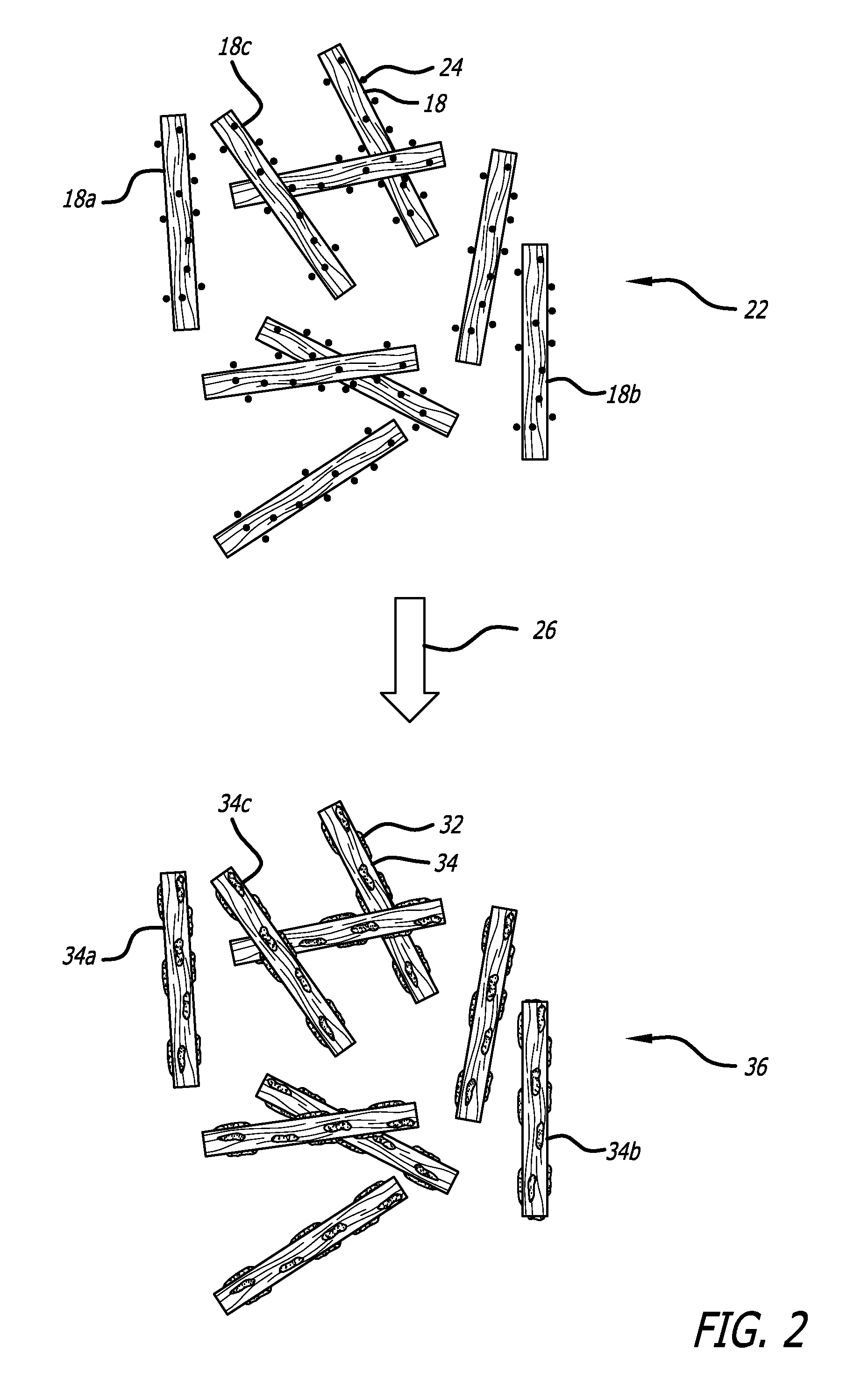

Method for making a discontinuous fiber molding compound

InactiveUS20140377556A1Improve mechanical propertiesSimple and complex partLayered productsSpecial tyresFiberCompound a

A method for making a discontinuous fiber molding compound from carbon fiber tow. The method involves using remnants of carbon fiber tows from spent carbon fiber spools. The remnants are chopped into pieces to form an assembly of chopped carbon fiber tows that are from 1 cm to 10 cm long. The chopped carbon fiber tows are then mixed with a powdered resin to form a blend of chopped carbon fiber tows and powdered resin. The blend is heated to soften / melt the particles of resin and then cooled to form a discontinuous fiber molding compound.

Owner:HEXCEL

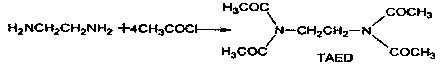

Scouring enzyme, and preparation method, application and application method thereof

InactiveCN102797146ALess fiber damageEasy to cleanBiochemical fibre treatmentBleaching apparatusSodium silicateChemistry

The invention relates to a scouring enzyme which is characterized by comprising the following raw materials in percentage by weight: 30-50% of sodium metasilicate, 3-10% of alkaline pectin compound enzyme, 20-50% of sodium carbonate, 5-10% of non-ionic surface active agent, 3-8% of peroxide oxydol activating agent, and 2-5% of sodium nitrilo triacetate; and the peroxide oxydol activating agent is prepared by compounding tetraacetylethylenediamine (TAED) and sodium percarbonate at a mass ratio of 1:2. The preparation method of the scouring enzyme comprises the following steps: non-ionic surface active agent and sodium carbonate are mixed uniformly and then are added with alkaline pectin compound enzyme to be mixed uniformly; peroxide oxydol activating agent and sodium nitrilo triacetate are added in the mixture in sequence; and sodium metasilicate is added finally, and the mixture is uniformly mixed and stirred for about one hour. The scouring enzyme can be used for boiling and bleaching of cotton yarn, cotton cloth, flax and ordinary cotton fabric or other mixed fabric before dyeing and has the advantages of simple process, low energy consumption, short time and low damage to fiber.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Pretreatment process for combed polyester cotton bleached cloth

InactiveCN103437140AStrong damageHigh whitenessMercerising of indefinite length fabricsBiochemical fibre treatmentPolyesterEthylene diamine

The invention relates to a pretreatment process for combed polyester cotton bleached cloth. The pretreatment process comprises the procedures of singeing, desizing, bleaching, mercerizing and heat-shaping, wherein during desizing, the enzyme-desizing cold-dwelling process that desizing anzyme and a penetrant are added into the desizing procedure is adopted; in the bleaching procedure, the following materials are adopted: 0.2-0.4 part of potassium borate serves as the bleaching liquor, 0.8-1.2 part(s) of diethylenetriaminepenta acid (DTPMP), 0.8-2 part(s) of acrylic acid maleic acid copolymer, 0.5-1 part of 1, 5-anhydrous glucitol, 1-2 part(s) of caprolactam activator, 0.4-0.7 part of tetraacetylethylenediamine (TAED), 3-8 parts of sodium hydroxide, 3-7 parts of hydrogen peroxide and 900-1000 parts of water. When the pretreatment process is used for processing fabrics, prominent damage to the fabrics is small; as enzyme desizing is adopted, the desizing ration is improved; the bleaching liquor adopted in the bleaching procedure can effectively improve the whitenness of the fabrics; meanwhile, the pretreatment cost is lowered.

Owner:如皋市五山漂染有限责任公司

Desizing and decolorizing composite enzyme and nostalgic-style denim fabric washing process thereof

InactiveCN109338706APromote oxidationEven contactDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsEthylenediamineAcetic acid

The invention relates to a desizing and decolorizing composite enzyme and a nostalgic-style denim fabric washing process thereof. The desizing and decolorizing composite enzyme is prepared from the following components in percentage by weight: 30% to 35% of desizing enzyme, 13% to 16% of ligninase; 20 to 26% of neutral cellulase, 26% to 32% of tetrasodium ethylenediaminetetraacetate, 5% to 8% of anonionic surfactant and the balance of deionized water. The nostalgic-style denim fabric washing process comprises the following steps of: desizing and decoloring treatment, potassium permanganate strong decolorizing treatment, demanganization treatment, normal temperature washing, polishing soft treatment, dehydration and drying treatment. According to the process, the desizing and decolorizingare carried out in one bath, so that the water and energy are saved, the abrasion caused by machinery to denim fabrics is decreased, the strong damage is reduced, the discharge of harmful substances is decreased, and the washed denim fabrics are free of pilling and furring and have softer hand feeling.

Owner:青岛奥洛思新材料有限公司

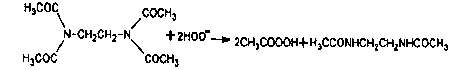

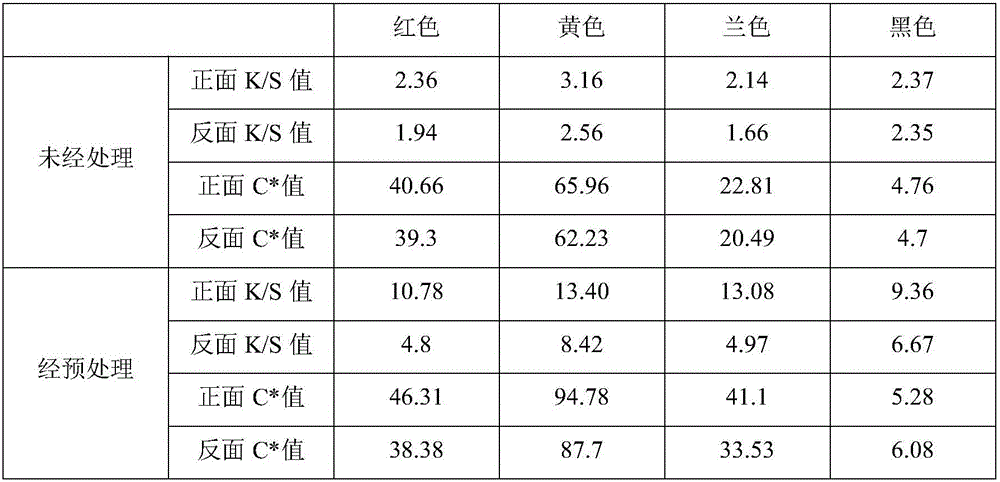

Method for improving permeability and clarity of double-faced penetrated print of real silk fabric

The invention discloses a method for improving the permeability and clarity of double-faced penetrated print of a real silk fabric and belongs to the field of fine chemical engineering. For solving the problem that the double-faced penetrated print of the real silk fabric has poor permeability and low clarity, the method for improving the permeability and clarity of the double-faced penetrated print of the real silk fabric through the combined effect of negative ion dispersed nano-porous oxide and a penetrating agent is provided, and the permeability, clarity, color depth and brilliance of the double-faced penetrated print of the real silk fabric can be obviously improved. The method is simple in process and can meet the requirements for large-scale production and processing, and luster and strength damage of the preprocessed real silk fabric is small.

Owner:JIANGNAN UNIV

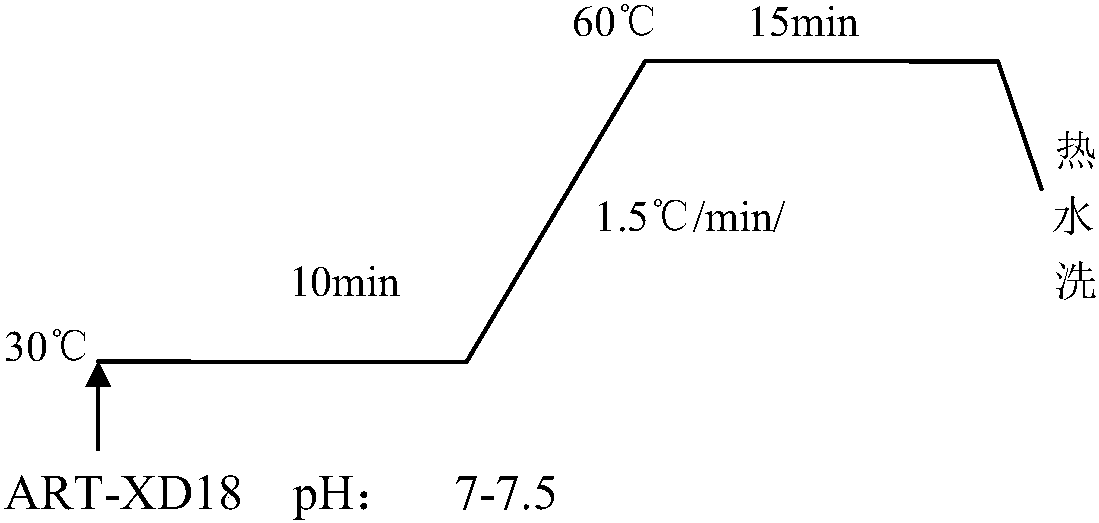

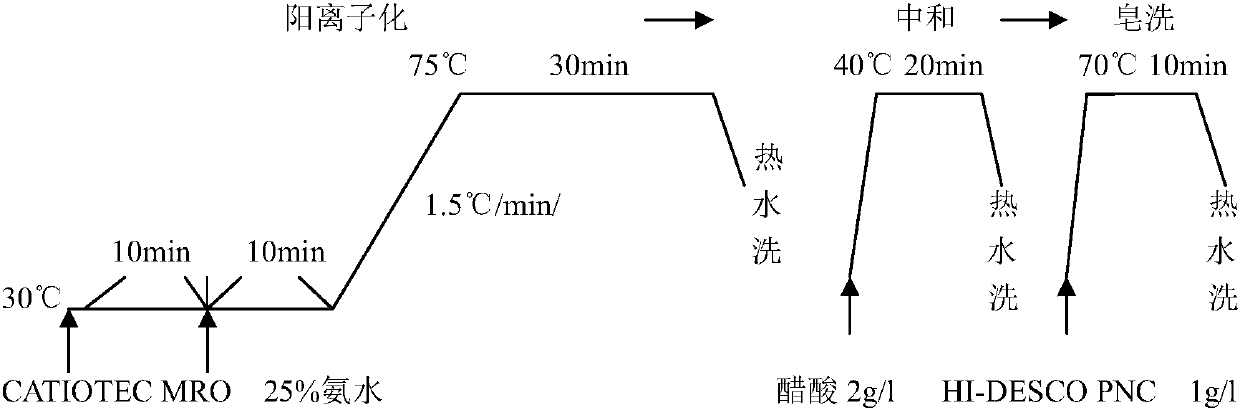

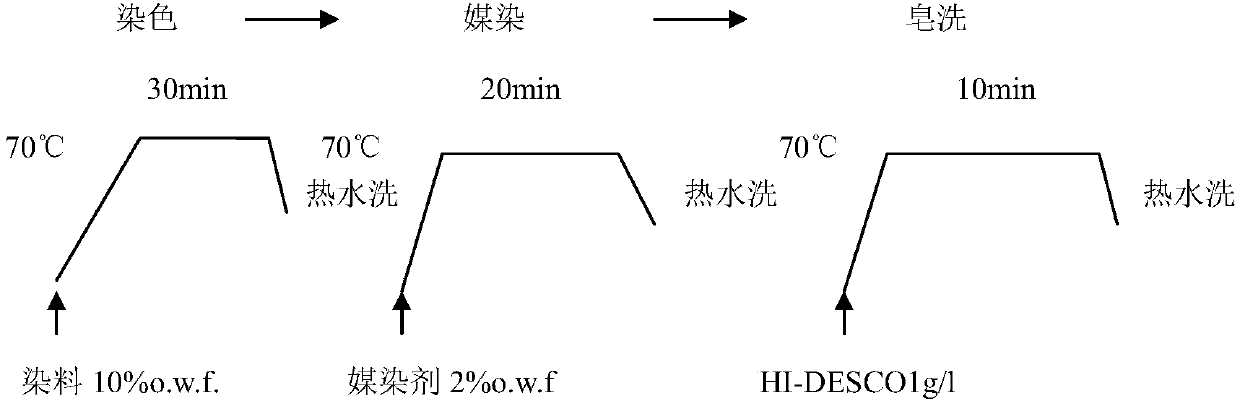

Cashmere dyeing process utilizing natural vegetable dyes and cashmere products

ActiveCN110714341AImprove product added valueSafe and comfortable to wearDry-cleaning apparatus for textilesDyeing processYarnEngineering

The invention discloses a cashmere dyeing process utilizing natural vegetable dyes and cashmere products. The cashmere dyeing process utilizing natural vegetable dyes include the steps of washing of cashmere yarn, cationization of cashmere fiber, neutralization, primary soaping, dyeing, mordanting, secondary soaping, softening, dehydrating, and drying. Cashmere is modified through the special modification technology, and the fiber has cationized charge after being modified by a modifier; high-quality natural vegetable dyes of RAKUTO KASEI INDUSTRIAL CO., LTD. are adopted, are bonded with cationic groups on the cashmere fiber under action of different mordants, and the cashmere fiber is dyed with different colors naturally through deionized fixation. The cashmere products dyed with the natural vegetable dyes have the advantages that natural quality of cashmere is guaranteed, and additional value of products is increased; the textile has health function, is safe and comfortable to wear,is popular to world high-end brand buyers and top dress designers, and has good prospects.

Owner:NINGBO KANGSAINI TEXTILE PROD

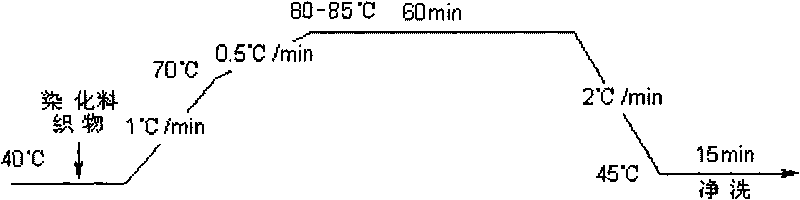

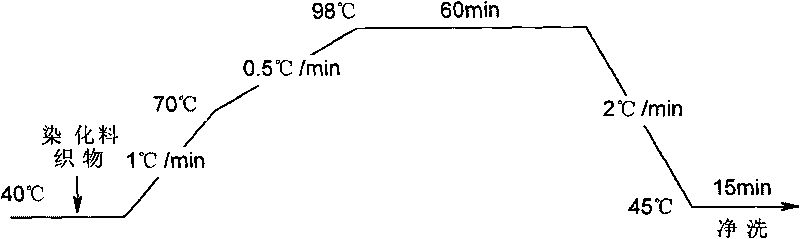

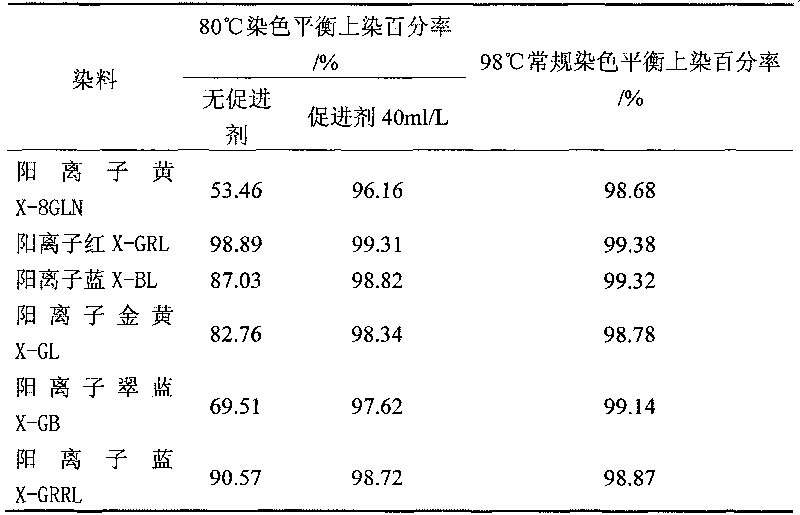

Dyeing promoter of acrylic fiber cationic dye and application thereof

The invention discloses a dyeing promoter of an acrylic fiber cationic dye. The dyeing promoter consists of benzoic alcohol, butyl acetate, a compound emulsifier and water, wherein the volume ratio of the benzoic alcohol to the butyl acetate to the compound emulsifier to the water is 10:10:1-2:78-79. The dyeing promoter of the acrylic fiber cationic dye can improve the dye-uptake of the lower temperature dyeing of the acrylic fibers with the cationic dye, and ensures high color fastness of dyed textile and small strength loss of fibers.

Owner:ZHEJIANG SCI-TECH UNIV

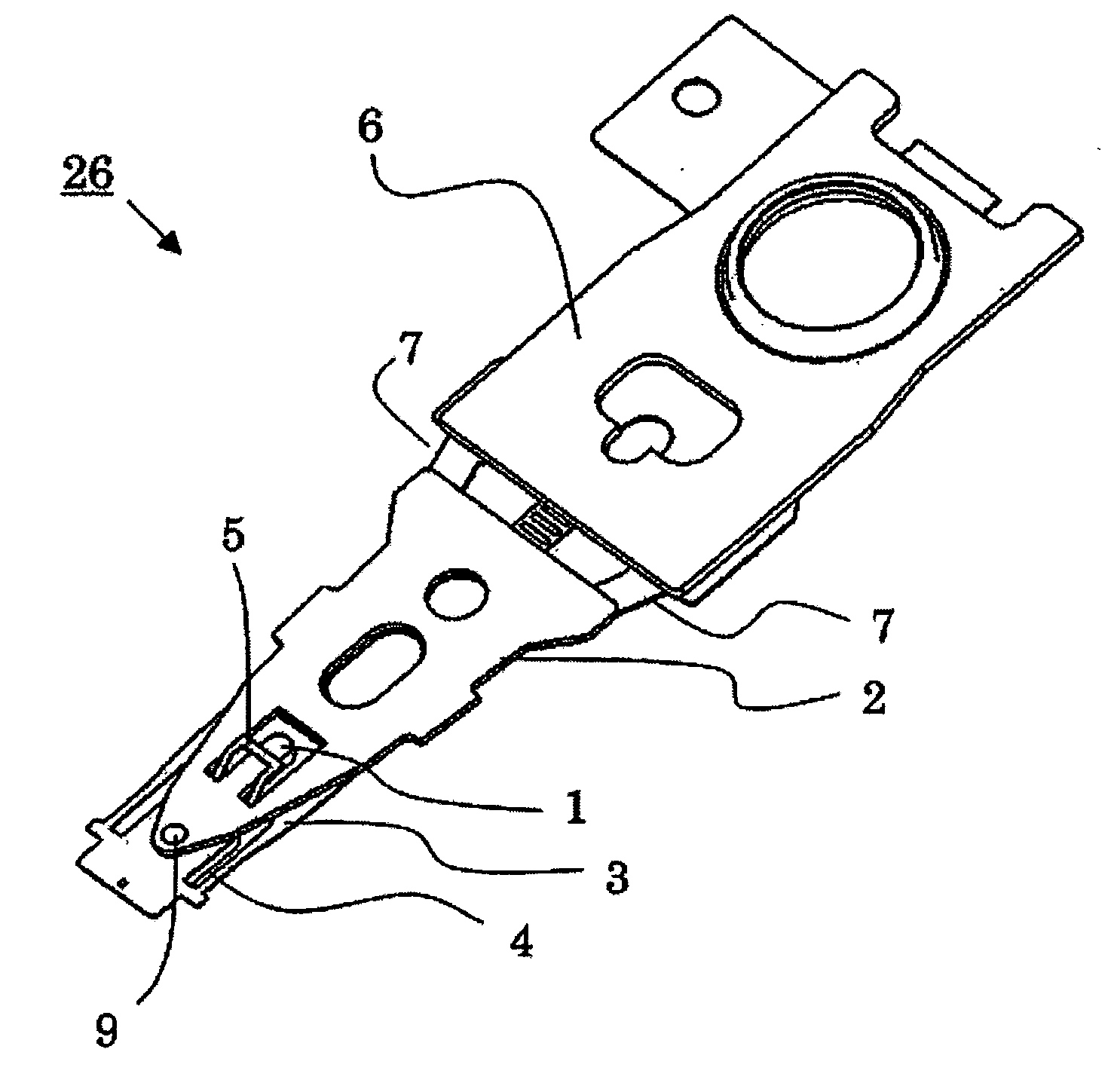

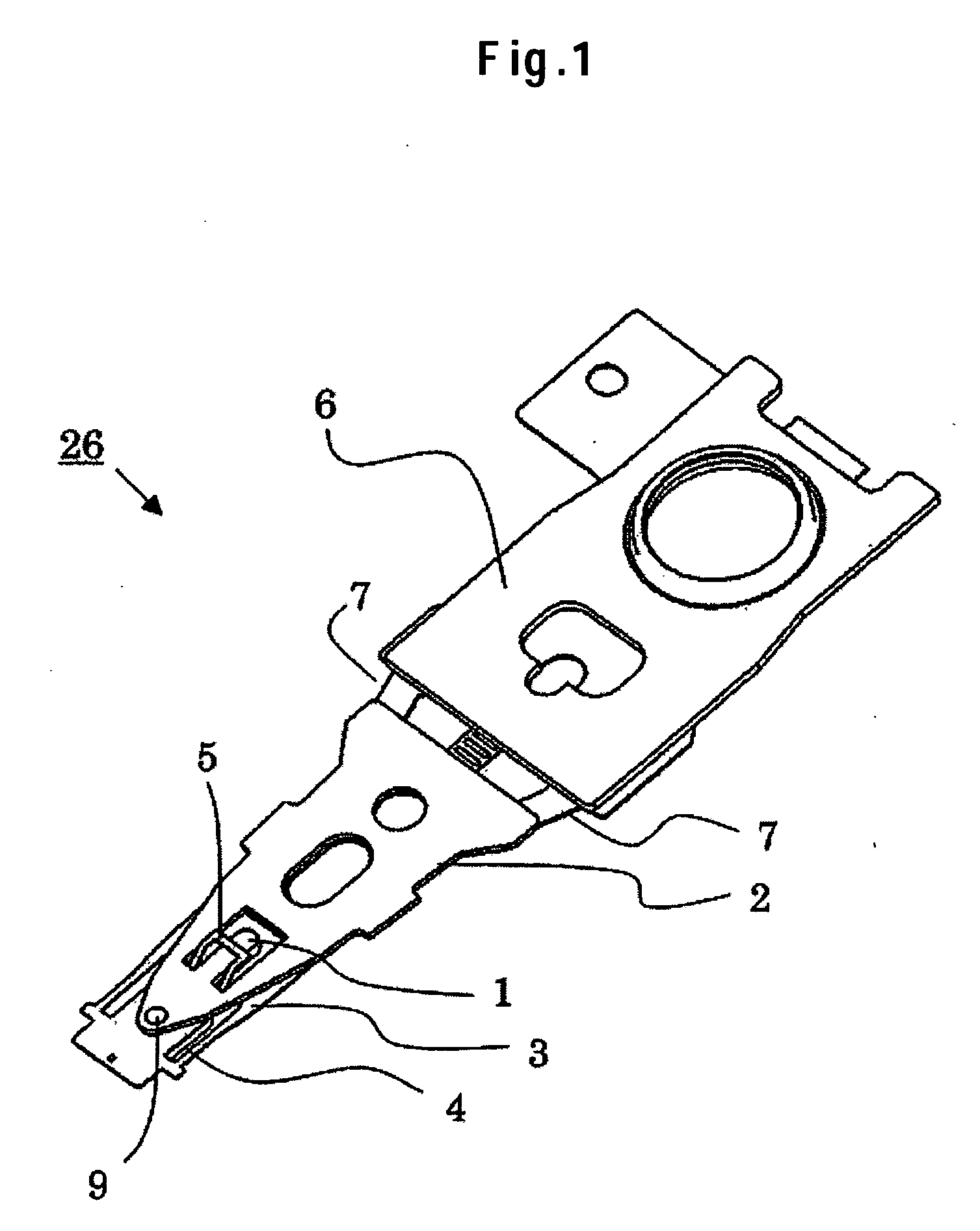

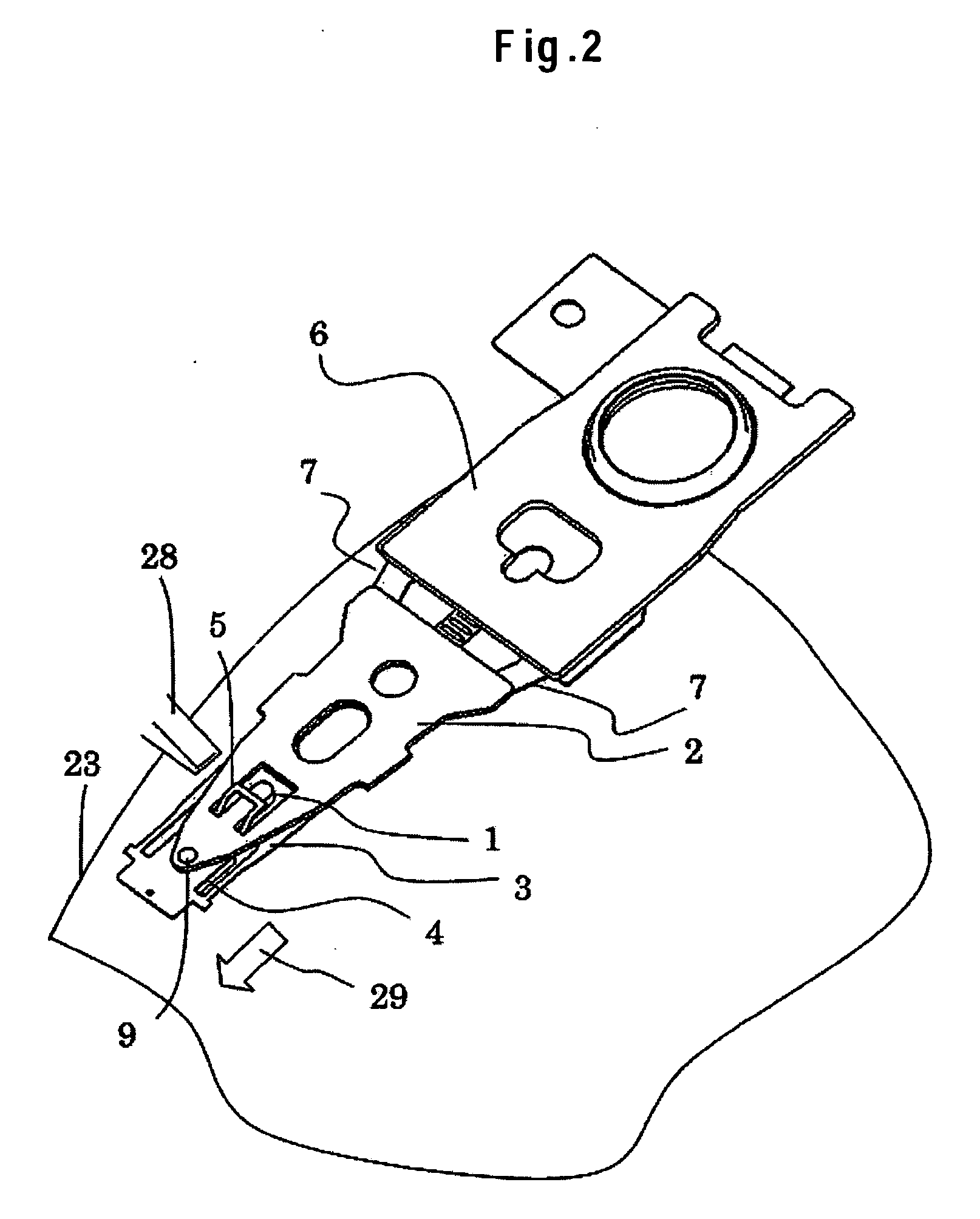

Suspension, magnetic head assembly, and magnetic disk drive

ActiveUS20060034017A1Control fluctuationsIncrease probabilityElectrical connection between head and armRecord information storageMechanical engineeringGimbal

Embodiments of the invention limit a pitch attitude angle of a magnetic head slider during loading without allowing gimbal stiffness of a flexure in an ordinary flying state to be increased. In one embodiment, a limiter formed by part of a flexure is disposed so as to provide a clearance from a lift tab formed by part of a load beam. A limiter clearance, if the clearance between the limiter and the lift tab is so called for convenience sake, must be maintained as a physical clearance when a magnetic head slider is in an ordinary flying state. The lift tab and the limiter are disposed on a side of an air inflow end of the magnetic head slider. The limiter clearance during unloading is thereby made small so as to allow proper and positive unloading operation. In addition, the limiter clearance made small during loading allows the absolute value of a pitch attitude angle of the magnetic head slider to be limited to a small one if the pitch attitude angle tends to become negative due to disturbances or vibration from the loading operation itself.

Owner:WESTERN DIGITAL TECH INC

Process for producing natural elastic yarn-dyed fabrics with mulberry boiled-off silk wefts

The invention discloses a process for producing natural elastic yarn-dyed fabrics with mulberry boiled-off silk wefts, and belongs to the technical field of production of natural elastic yarn-dyed fabrics with mulberry silk. The process includes warp preparation, weft processing, yarn dyeing and after finishing. Warps are made of 23 dtex mulberry raw color silk f1, weft processing sequentially includes steps of doubling, primary twisting, primary type approval, coiling, degumming, dyeing, sizing, heavy twisting and secondary type approval, and doubling includes carrying out zero-twist doublingon every four 4 pieces of 23 dtex mulberry raw silk f1; primary twisting is carried out under the condition of 500 twist / meter in S twist directions; primary type approval is carried out at the temperature of 80 DEG C for 40 min; sizing slurry comprises sodium alginate with the mass concentration of 5 g / L, the bath ratio is 1:15, and heat is preserved at the temperature of 50 DEG C for 20 min; the twist directions of strong twisting are identical to the twist directions of primary twisting, and strong twisting is carried out under the condition of 2600 twists / meter; secondary type approval iscarried out at the temperature of 90 DEG C for 60 min; after finishing includes hot water loose type low-tension type approval, the bath ratio is 1:10, water is heated until the temperature of the water reaches 60 DEG C, heat is preserved at the temperature of 60 DEG C for 30 min, and after finishing is carried out to obtain the natural elastic yarn-dyed fabrics which are finished products. The process has the advantages that the natural elastic yarn-dyed fabrics are easy to weave, the mulberry boiled-off silk wefts for weaving the natural elastic yarn-dyed fabrics are low in type approval temperature and little in strength damage after being twisted, and the natural elastic yarn-dyed fabrics have good hand feeling.

Owner:DALI SILK ZHEJIANG

Dyeing defect positioning and stripping method for real silk fabric

InactiveCN1730800ADecompose thoroughlySevere oxidizingBleaching apparatusDyeing processThioureaDye molecule

The present invention discloses method of locating and eliminating dyeing defect for silk fabric and solves the technological problem of eliminating dyeing defect from silk fabric without obvious damage on the strength of the silk fiber. The method includes the following steps: treating the silk fabric with dyeing defect with catalyst metal salt to make the dye adsorb the catalyst metal salt; rinsing to eliminate the catalyst metal salt adsorbed onto the silk protein while maintaining the catalyst metal salt adsorbed onto the dye molecules; oxidizing and stripping with hydrogen peroxide solution; reducing and eliminating color with thiourea to eliminate dyeing defect; and water washing. Thus treated silk fabric has whiteness over 68 and silk strength maintaining rate over 71 %.

Owner:ZHEJIANG SCI-TECH UNIV +1

Short-flow pre-treatment method for pure cotton heavy fabrics

PendingCN109576975ASimple processWater saving and energy saving production costVegetal fibresChemistryDyeing

The invention discloses a short-flow pre-treatment method for pure cotton heavy fabrics and belongs to the technical field of dyeing and finishing pre-treatment. The short-process pre-treatment methodfor pure cotton heavy fabrics comprises the steps of padding a singed pure cotton heavy gray fabric with scouring and bleaching liquid, then piling up the fabric at room temperature, executing steaming and washing, executing slight rinsing with a dilute aqueous solution of hydrogen peroxide, finally executing low-alkali mercerizing, and then executing full washing to complete the pure cotton heavy fabric pre-treatment process. The process is good in treatment effect, has the advantages of small fabric strength damage, high quality, soft handfeel, high hair effect and good glossiness, also creates the high color yield condition for subsequent dyeing and printing processing and is simple in technological operation and strong in controllability. In addition, the treatment wastewater, chemical agent use amount and energy consumption of the process are far lower than those of a traditional strong alkali scouring process, and the burden of sewage treatment of enterprises is greatly reduced.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

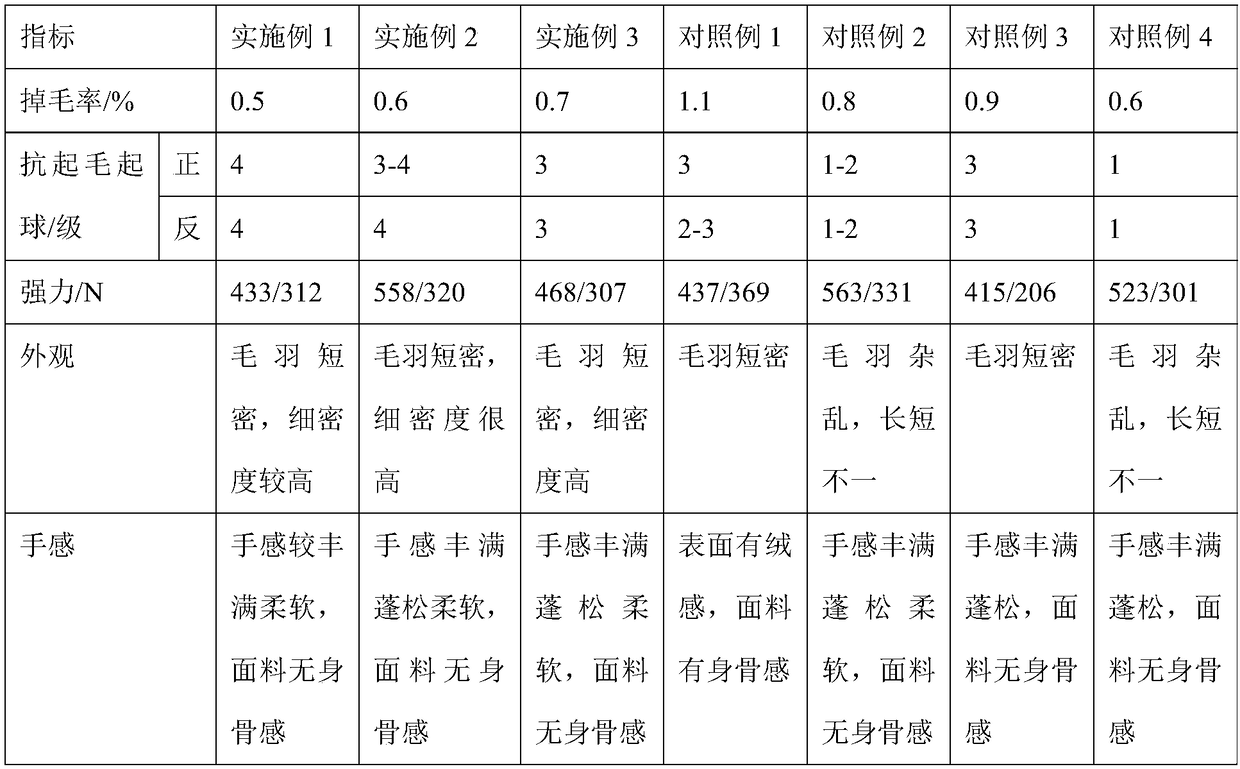

Dyeing and finishing treatment method for all-cotton suede-like broad width fabric

ActiveCN108589155AThick and fluffy feelNot easy to shed hair and good performanceRougheningGallingEngineering

The invention discloses a dyeing and finishing treatment method for all-cotton suede-like broad width fabric. The method comprises the following steps: pre-treatment, galling, cropping, printing / dyeing, and post-treatment in order to obtain the finished product fabric; during a galling process, a front surface and a back surface are subjected to the galling and cropping processes, the galling andcropping processes are alternative carried out, in the galling process of the front surface and the back surface, a right surface of the fabric is a cylinder roller, the back surface of the fabric isa negative-pressure air suction device, during a cropping process, carbon brushes with an even number is added at 10-30 cm before a cloth-holding cutter, and the rotation direction of the adjacent twocarbon brushes is opposite. The fabric has abundant feeling, and each index is qualified.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for breeding, raising seedling by using light catalyzed Nano active water

InactiveCN1957651ANon-toxic and low costImprove permeabilitySeed and root treatmentPlant genotype modificationWater featureMacromolecular Substances

A method for treating seeds and culturing seedlings by use of photocatalytic nano-class active water features that the seeds are immersed in said water for allowing the macromolecular substances (positive H ions and negative OH ions) to penetrate into the cells of seeds, so reaching the mutagenic purpose, and said water can be sprayed onto seedlings for fast culturing the seedlings, resulting in strong growth power and high yield of crops.

Owner:张金龙

Bamboo fiber fabric dyeing and finishing process

InactiveCN105887514AStrong damageGuaranteed strongDry-cleaning apparatus for textilesBleaching apparatusFiberEngineering

The invention discloses a bamboo fiber fabric dyeing and finishing process. The bamboo fiber fabric dyeing and finishing process comprises the following steps of: scouring and bleaching, namely scouring and bleaching a bamboo fiber fabric with a bamboo fiber fabric solution and drying; after drying, pre-shaping; pre-treating, namely desizing a pre-shaped textile; dyeing, namely immersing the fabric with 75wt% ethanol; adding the bamboo fiber fabric solution into an active dyestuff to prepare a dyeing solution; immersing the bamboo fiber fabric with the dyeing solution; putting the dyed bamboo fiber fabric into a reducing washing solution to be subjected to reduction and washing; washing the bamboo fiber fabric with clean water; after-finishing, namely putting the dyed textile into a hydrophilic amino silicon softening agent and padding; after padding, adding bamboo-vinegar liquor to prepare a finishing solution and then carrying out after-finishing; and tentering, namely drying the textile subjected to the after-finishing and tentering and shaping. By improving a scouring and bleaching method and a formula of the scouring and bleaching solution, strength damages of fibers are reduced; the pre-treatment has desizing and scouring effects and the strength of the bamboo fibers does not have relatively large loss; a dyeing process guarantees good dyeing effect and dyeing fastness and the surface of the finally produced textile is flat; the color and luster are uniform and the dyeing fastness of the dyestuff is high.

Owner:NEWSEGA TEXTILE NANTONG CO LTD

Dyeing and finishing process of corn fiber / cotton blended fabric

ActiveCN104131474AStrong damagePromote infectionFabric breaking/softeningBleaching apparatusYarnPolymer science

A dyeing and finishing process of a corn fiber / cotton blended fabric. The fabric is prepared from blended weaving of 50 wt.% of corn fiber and 50 wt.% of cotton fiber. The cotton fiber has main body length range of 30-40 mm; the dyeing and finishing process mainly includes weaving, boiling off, bleaching, dyeing and finishing; and the weaving process mainly includes opening picking, cotton carding, drawing, roving, spun yarn, spooling, beaming, slashing and weaving. After staining, the corn fiber and cotton fiber have good homochromatism, and strength damage of the fabric is reduced.

Owner:宣城凯欧纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com