Patents

Literature

76 results about "Tetraacetylethylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

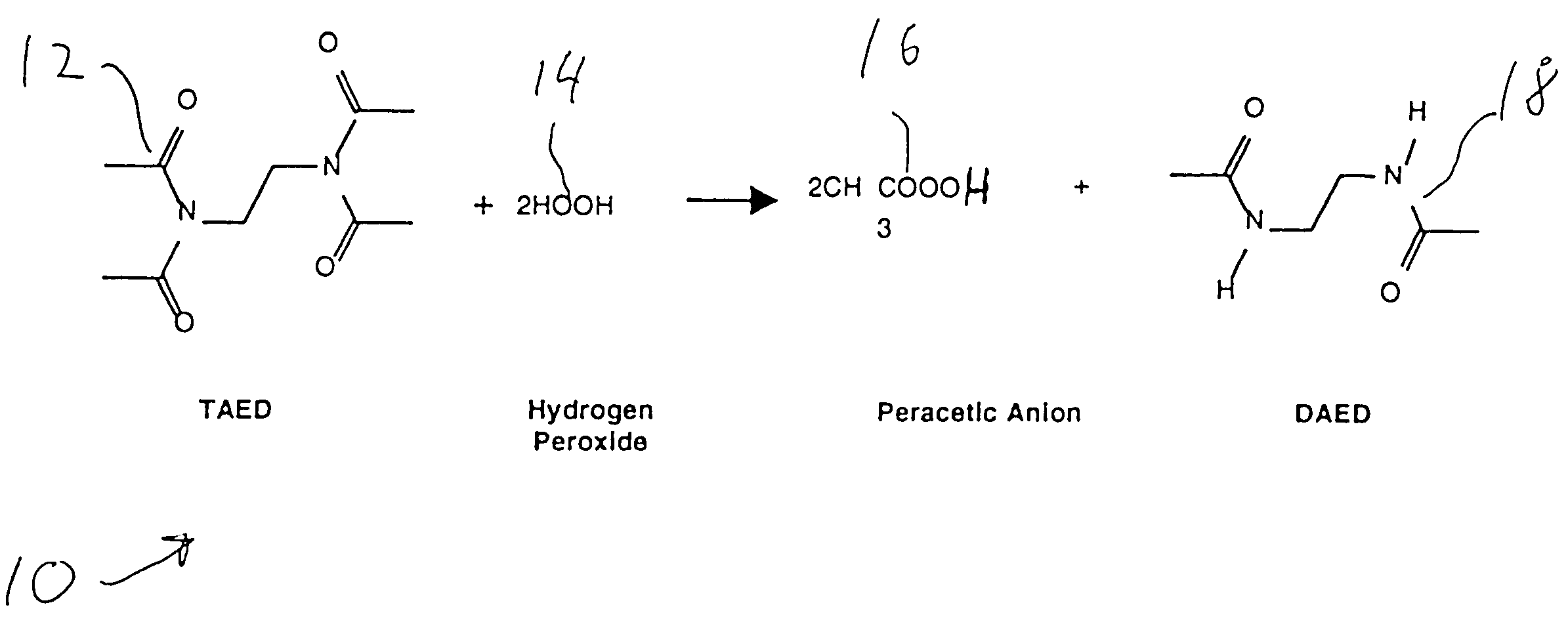

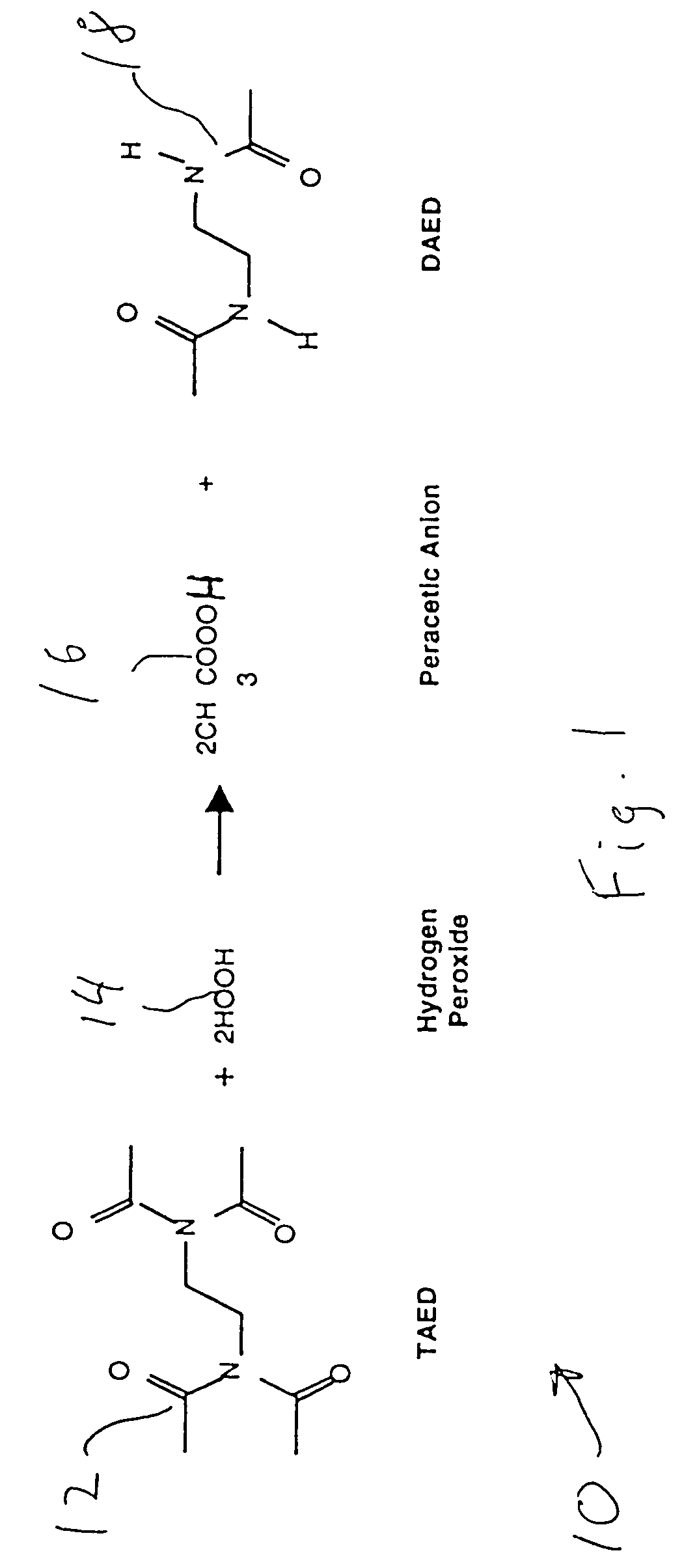

Tetraacetylethylenediamine, commonly abbreviated as TAED, is an organic compound with the formula (CH₃C(O))₂NCH₂CH₂N(C(O)CH₃)₂. This white solid is commonly used as a bleach activator in laundry detergents and for paper pulp. It is produced by acetylation of ethylenediamine.

Virucide composition and sporicide composition

InactiveUS6506416B1Avoid it happening againImprove the immunityBiocidePeroxide active ingredientsAlkaline earth metalTetraacetylethylenediamine

The present invention provides a virucide composition and / or sporicide composition having a high virucidal effect and sporicidal effect and being excellent in safety and workability. That is, the present invention provides a virucide composition and / or sporicide composition comprising (a) an inorganic peroxide, (b) tetraacetylethylenediamine and (c) at least one selected from a salt of an alkaline metal salt with an inorganic acid and a salt of an alkaline earth metal with an inorganic acid in a specific ratio.

Owner:KAO CORP

Peroxyacetic acid generator and preparation method thereof

InactiveCN102964285APromote effectivenessSystem stabilityBiocideOrganic compound preparationTetraacetylethylenediamineSURFACTANT BLEND

The invention provides a peroxyacetic acid generator which consists of acetylsalicylic acid, tetraacetylethylenediamine, sodium percarbonate, a surfactant, a corrosion inhibitor and a pH regulator at a mass ratio of 1:(1.5-2.0):(3.5-5):(0.02-0.05):(0.1-0.3):(3-6). Meanwhile, the invention also discloses a preparation method of the peroxyacetic acid. Through the invention, by adding the pH regulator, the pH value of the mixed solution is stabilized at about 7-8, and then the prepared peroxyacetic acid solution has higher stability and lower corrosivity.

Owner:北京红辉力上科技有限公司

Controlled production and release of oxygen activated biocide into holding tanks for RV's, boats and the like

ActiveUS7291276B1Multiplies numberSpecific water treatment objectivesDetergent materialsControlled releaseEthylene diamine

Waste in a black or gray water holding tank is treated by an oxygen activated biocide by the addition of tetra acetyl ethylene diamine (TAED) and a peroxygen compound. Hydrogen peroxide and / or peracetic acid are released over a period of time and thus maintained in the wastewater solution. Peracetic acid under controlled release conditions dissipates prior to the wastewater being deposited in a wastewater treatment plant.

Owner:ARC PRODS

Decoloration method of colored cashmere loose fiber

InactiveCN103243543AHigh whitenessQuality impactBleaching apparatusAnimal fibresFiberTetraacetylethylenediamine

The invention discloses a decoloration method of colored cashmere loose fiber, which comprises the following steps of: A, degreasing by use of a solution containing 4-5wt% of degreasing agent, 5-7wt% of formaldehyde, 1-5wt% of sodium carbonate and the balance of water; B, performing oxidation bleaching by use of a solution containing 1-2wt% of cashmere caring agent, 1.5-2wt% of tetraacetylethylenediamine, 20-30wt% of hydrogen peroxide, 10-15wt% of sodium chloride and the balance of water; C, flushing with deionized water; D, performing reduction and oxidation by use of a solution containing 0.5-1wt% of fluorescent whitening agent, 1-2wt% of cashmere caring agent, 2-5wt% of sodium hydrosulfite, 1-3wt% of ferrous sulfate, 10-15wt% of ferrous sulfate and the balance of water; E, performing oxygen washing by use of a solution containing 1-2wt% of hydrogen peroxide, 0.5-1wt% of ammonia water and the balance of water; and F, drying. The method disclosed by the invention can improve the whiteness of the bleached cashmere and reduce the yellowing degree of cashmere after longtime use.

Owner:NINGXIA RONGCHANG CASHMERE IND GROUP

Pretreatment process for combed polyester cotton bleached cloth

InactiveCN103437140AStrong damageHigh whitenessMercerising of indefinite length fabricsBiochemical fibre treatmentPolyesterEthylene diamine

The invention relates to a pretreatment process for combed polyester cotton bleached cloth. The pretreatment process comprises the procedures of singeing, desizing, bleaching, mercerizing and heat-shaping, wherein during desizing, the enzyme-desizing cold-dwelling process that desizing anzyme and a penetrant are added into the desizing procedure is adopted; in the bleaching procedure, the following materials are adopted: 0.2-0.4 part of potassium borate serves as the bleaching liquor, 0.8-1.2 part(s) of diethylenetriaminepenta acid (DTPMP), 0.8-2 part(s) of acrylic acid maleic acid copolymer, 0.5-1 part of 1, 5-anhydrous glucitol, 1-2 part(s) of caprolactam activator, 0.4-0.7 part of tetraacetylethylenediamine (TAED), 3-8 parts of sodium hydroxide, 3-7 parts of hydrogen peroxide and 900-1000 parts of water. When the pretreatment process is used for processing fabrics, prominent damage to the fabrics is small; as enzyme desizing is adopted, the desizing ration is improved; the bleaching liquor adopted in the bleaching procedure can effectively improve the whitenness of the fabrics; meanwhile, the pretreatment cost is lowered.

Owner:如皋市五山漂染有限责任公司

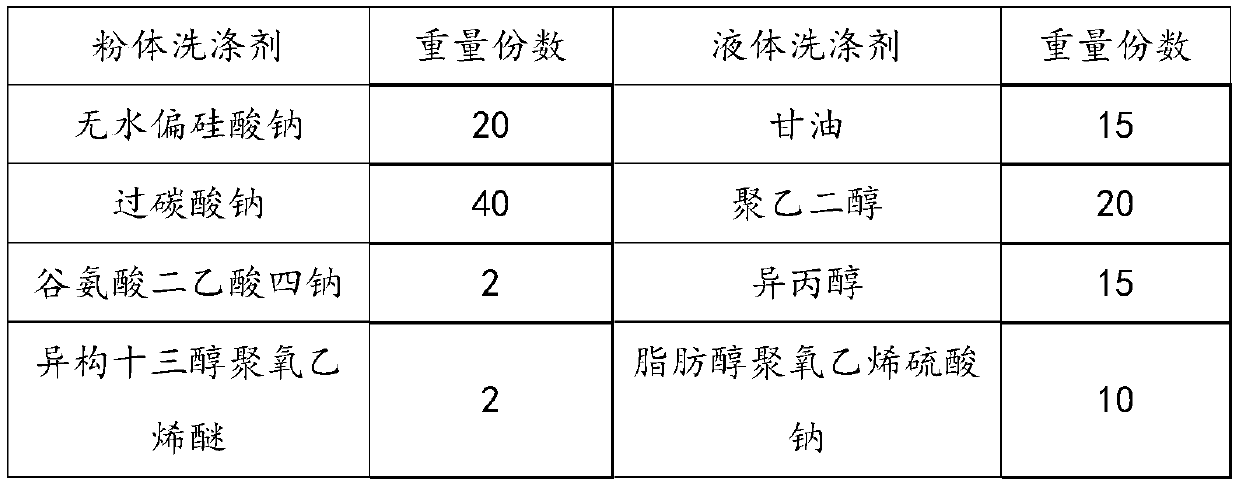

Tableware detergent for dishwashers

InactiveCN110257180ASolve the problem of excessive foam volumeImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsTetraacetylethylenediamineSodium citrate

The invention discloses a tableware detergent for dishwashers, wherein the tableware detergent comprises a powder detergent and a liquid detergent according to a mass ratio of (6-12):1, wherein the powder detergent comprises, by mass, 20-50 parts of an alkaline auxiliary agent, 10-40 parts of sodium percarbonate, 2-8 parts of tetraacetylethylenediamine, 1-4 parts of a nonionic surfactant, 1-3 parts of a biological enzyme preparation, 10-20 parts of sodium citrate, 1-8 parts of a chelating agent, and 2-10 parts of an organosilicon antifoaming agent, and the liquid detergent comprises, by weight, 25-50 parts of a solvent, 40-60 parts of a surfactant, 3-8.5 parts of a neutralizing agent, and 3-10 parts of water. According to the present invention, by adjusting the formula and the ratio of the powder detergent and the liquid detergent and controlling the foam amount during the use, the tableware detergent is suitable for dishwashers, solves the problem of too foam amount of the existing detergent, and has characteristics of strong detergency, strong wettability and good washing effect.

Owner:GUANG DONG YOU KAI TECHNICAL CO LTD

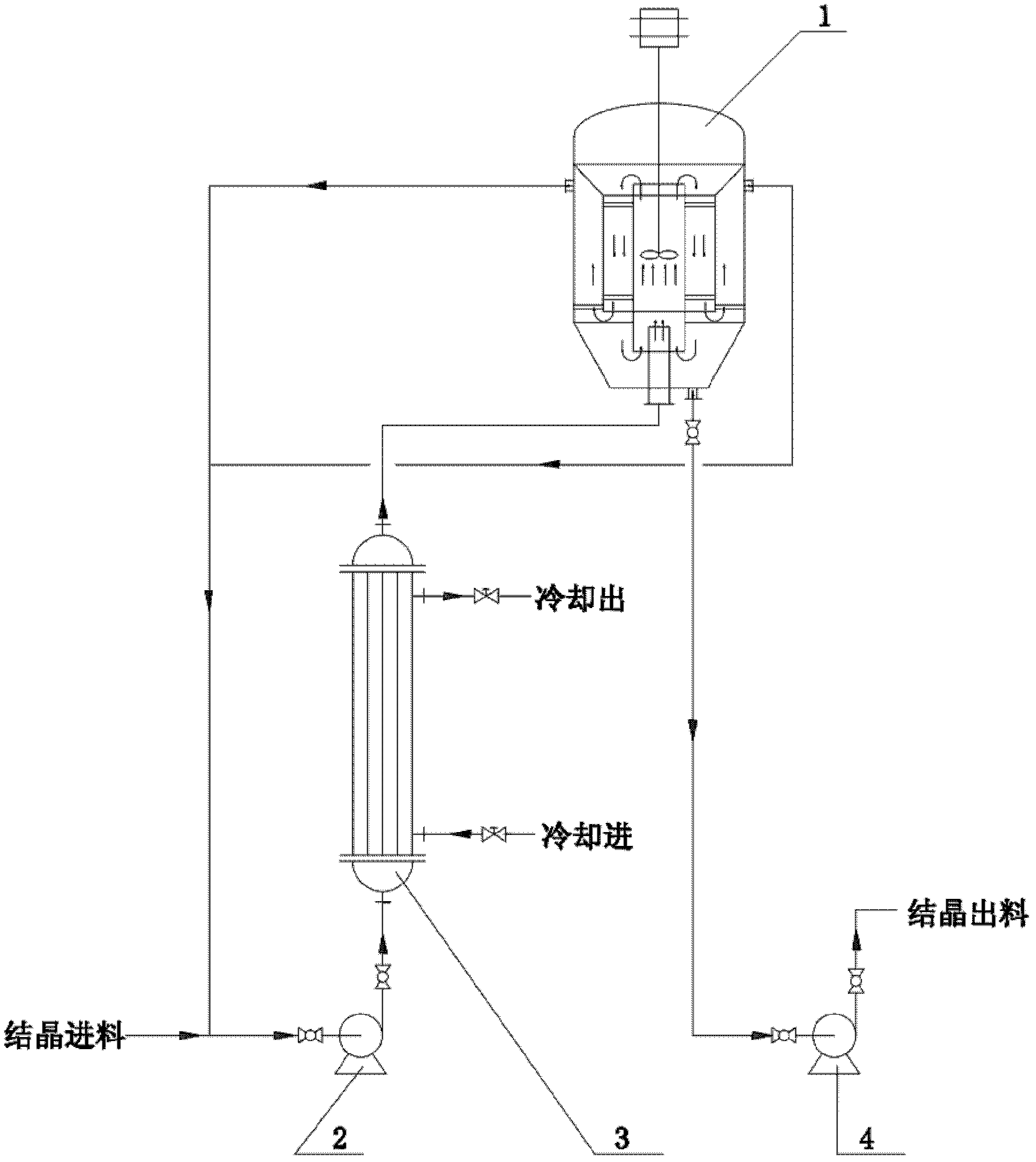

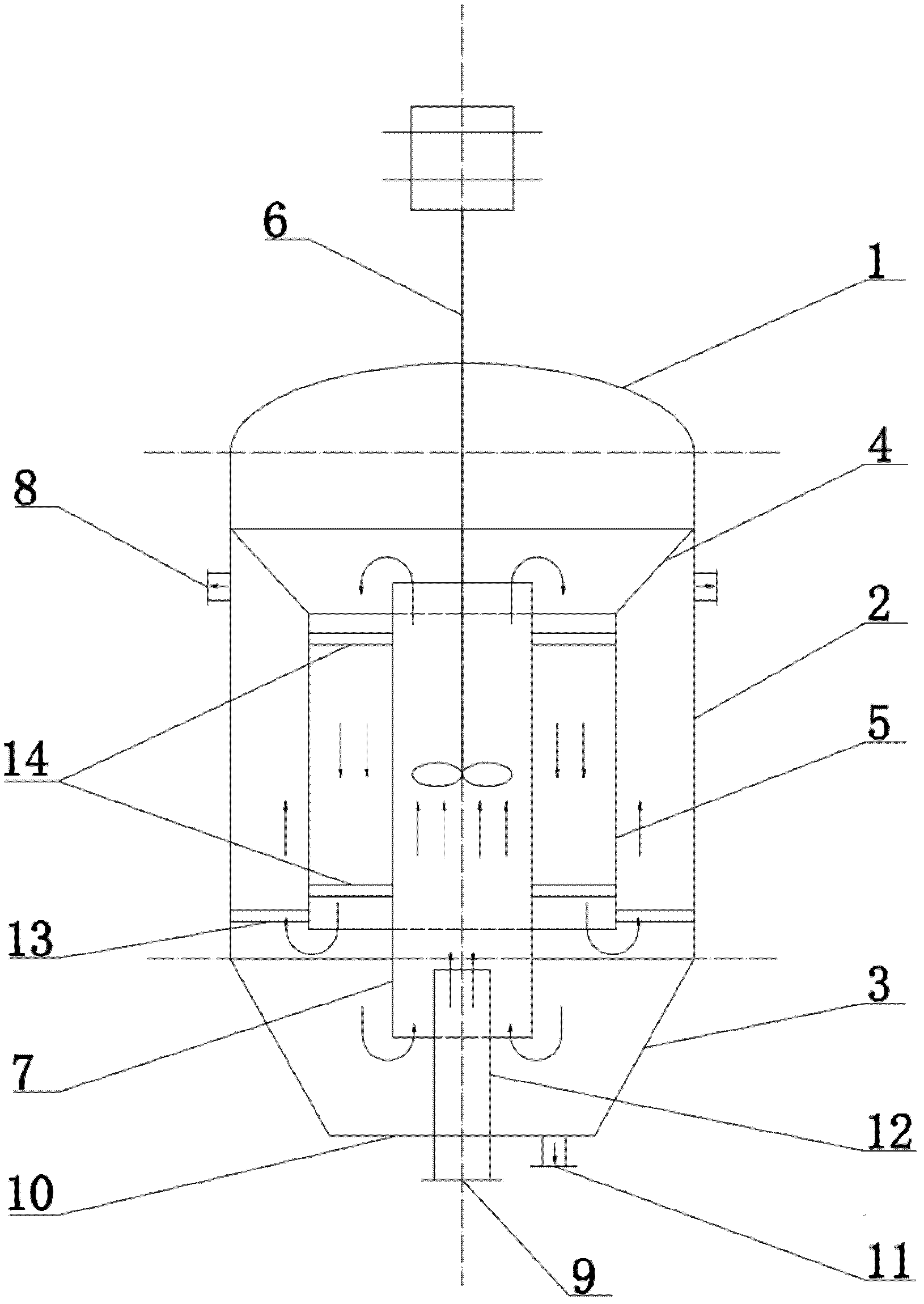

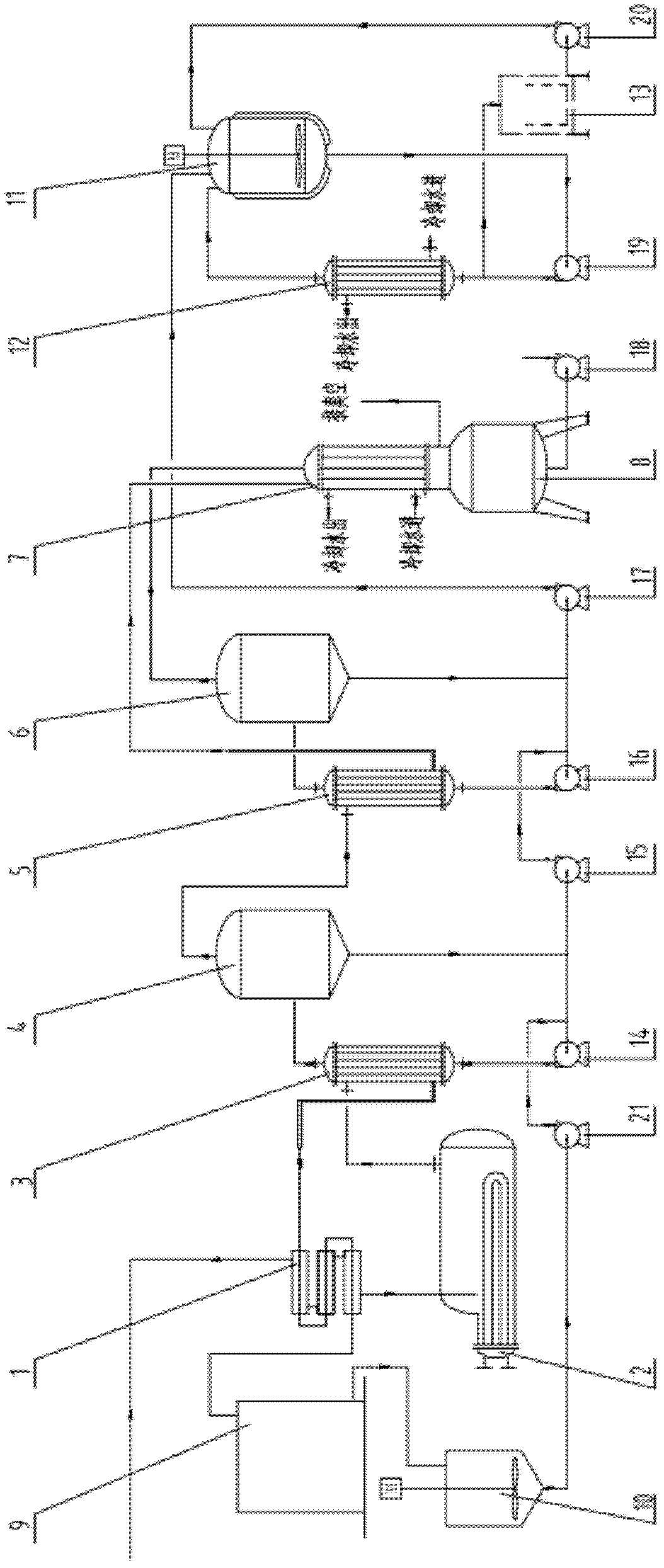

Continuous crystallization method of tetraacetylethylenediamine

ActiveCN102580347AContinuous crystallization achievedIncrease productivitySolution crystallizationCyclic processTetraacetylethylenediamine

The invention discloses a continuous crystallization method of tetraacetylethylenediamine. The method is characterized by comprising the following steps that: (a) after the synthesis reaction of tetraacetylethylenediamine is finished, reaction material enters a crystallization pre-cooling kettle, and the temperature of the material is kept at 100-140 DEGE C; (b) the material in the crystallization pre-cooling kettle is conveyed by a crystallization feed pump, mixed with the outer circulation material of a continuous crystallizer and then conveyed by an outer circulation pump 2 of a crystallizer, and enters a continuous crystallizer 1 through a heat exchanger 3; (c) the material in the crystallizer passes through an outer circulation material outlet 2.8 and the outer circulation pump 2 and the heat exchanger 3 to enter the crystallizer from the an outer circulation material inlet 2.9 to finish the outer circulation process; and (d) the material discharged from the crystallization system is conveyed into a centrifugal separation device by a crystallization discharge pump 4 from a crystal mush outlet 2.11, and the obtained solid is washed and dried to obtain the crystal of tetraacetylethylenediamine. Through the method disclosed by the invention, the high-purity pure white tetraacetylethylenediamine product can be directly obtained, continuous crystallization is realized, and the production efficiency and product quality are obviously improved.

Owner:ZHEJIANG JINKE CHEM

Method for extracting celluloses, hemicelluloses and lignins from pennisetum hydridum

The invention discloses a method for extracting celluloses, hemicelluloses and lignins from pennisetum hydridum. The method includes: (1) adding benzene-alcohol mixed liquid into the pennisetum hydridum to realize dewaxing, adding water into dewaxed pennisetum hydridum, extracting, filtering, and drying to obtain pretreated pennisetum hydridum; (2) sequentially adding NaOH-H2O2 mixed solution and tetraacetylethylenediamine into the pretreated pennisetum hydridum, treating for 1-4h at the temperature of 55-95 DEG C, filtering, and drying filter residues to obtain the celluloses; (3) adjusting a pH value of filtrate with the celluloses extracted to 5.0-5.5, adding ethyl alcohol to realize precipitation of hemicelluloses, and centrifugally separating to obtain the hemicelluloses; (4) recovering the ethyl alcohol in supernatant obtained after centrifugal separation at the step (3), adjusting a pH value of raffinate with ethyl alcohol recovered to 1.5-2.5, and centrifugally separating to obtain the lignins. By adoption of the method, the celluloses, the hemicelluloses and the lignins can be sequentially and effectively extracted in the same process, high extraction rate is realized, and high-value utilization of wood fibers in the pennisetum hydridum is improved.

Owner:QILU UNIV OF TECH

Paper mill cleaner with taed

InactiveUS20060019854A1Easy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphatePhosphate Chelator

A detergent composition adapted to clean paper making equipment without the use of chlorinated compounds includes a phosphate sequesterant system, a non-foaming nonionic surfactant, a polyacrylic acid detergent polymer and, as a bleaching source, a combination of a peroxy compound and tetraacetylethylenediamine. Suitable peroxy compounds include sodium percarbonate, sodium perborate, and sodium persulfate. This composition, when added to water and circulated through paper making equipment effectively cleans the equipment, removing pitch and other stickies as well as dirts, greases, and the like.

Owner:DUBOIS CHEM

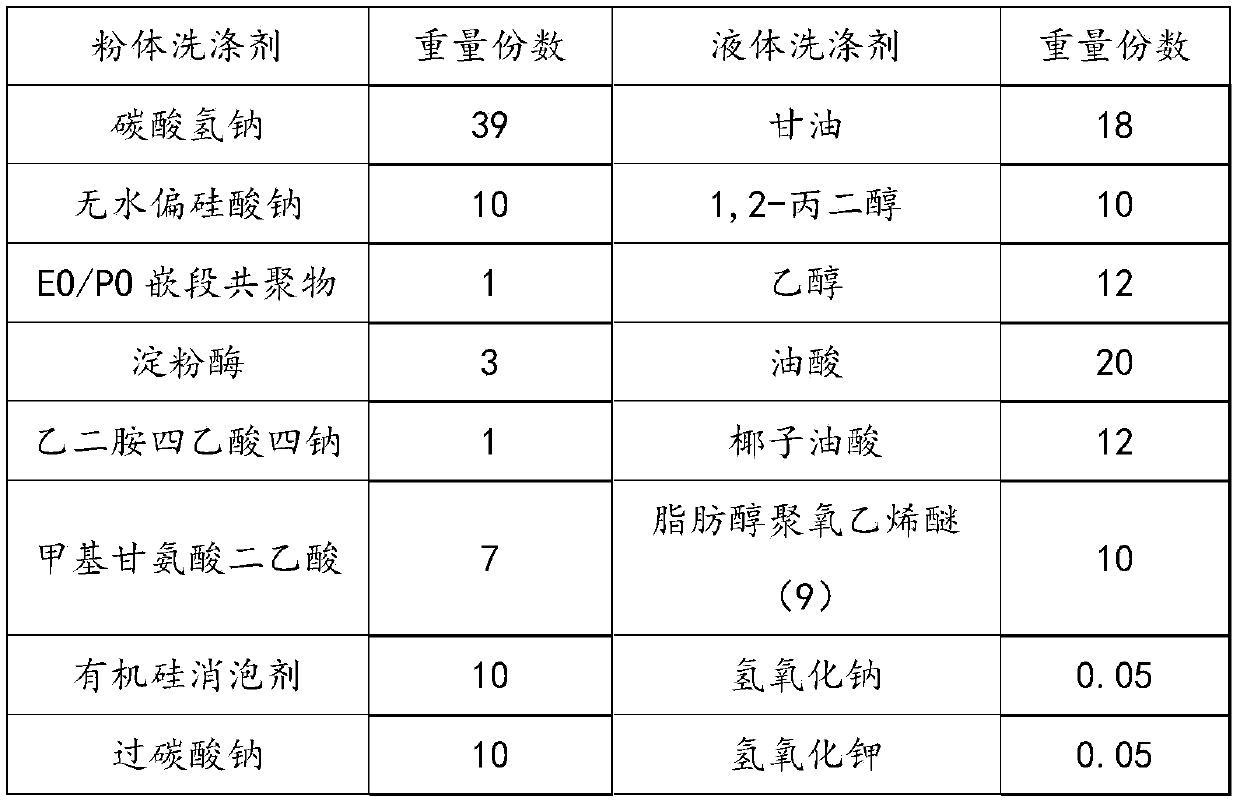

Foamless detergent and preparation method thereof

InactiveCN103805351AImprove solubilityHigh activityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium bicarbonateSolubility

The invention discloses a foamless detergent, which includes: sodium alginate, starch, sodium silicate, citric acid, sodium citrate, sea salt, sodium perborate, tetraacetylethylenediamine and borax, and also includes: sodium bicarbonate and soapnut saponin. The preparation method comprises the steps of: mixing sodium silicate with sodium perborate, mixing sapindus saponin, sodium alginate, starch, citric acid, sodium citrate, sea salt, sodium bicarbonate, tetraacetylethylenediamine and borax, then mixing the two mixtures, adding citric acid and conducting mixing again. The detergent has the characteristics of compatible raw materials, good water solubility, strong activity under a low temperature condition, high detergency, complete stain removal ability, and no foam or odor, and the water discharged after washing can be effectively biodegradable. The washing process has no harm to fabrics and human skin, Staphylococcus aureus, Escherichia coli, Candida albicans and the like can be effectively inhibited, odor can be eliminated, water and power can be saved, the foamless detergent is in line with energy-saving and emission reduction, environmental protection and low carbon.

Owner:陈树锋

Method for scouring and bleaching cotton fabric with composite enzyme preparation in one bath

InactiveUS20100192308A1Increase consumptionHigh high pollutionBleaching apparatusBiochemical treatment with enzymes/microorganismsEthylenediamineCellulose

A method for scouring and bleaching cotton fabric with composite enzyme preparation in one bath is provided. The method relates to the application of composite alkaline enzyme preparation in scouring and bleaching processes of cotton fabric. The enzyme preparation for scouring and bleaching cotton fabric is compounded from cutinase, alkaline pectase, alkaline xylanase, alkaline cellulose, and carbohydrate oxidase. The method includes: scouring the cotton fabric by adding the composite enzyme preparation, glucose, oxidation bleaching stabilizer RB-3, penetrant JFC, and Triton X-100 in a treating bath at 55-70° C. and pH 8-10, and then bleaching the cotton fabric for 30 min by directly adding tetraacetyl ethylenediamine (TAED) in the scouring bath to activate hydrogen peroxide. After being treated by the method of the present invention, the cotton fabric has high impurity removal ratio, favorable wettability, and high whiteness. The present invention has the advantages of low power consumption, short process flow, and being environment friendly, and may be used to replace conventional chemical treatment process under the condition of concentrated alkali and high temperature.

Owner:JIANGNAN UNIV

Combined treatment method for two kinds of waste acid water generated in tetraacetylethylenediamine (TAED) production

ActiveCN102583853AAvoid it happening againSave energyMultistage water/sewage treatmentCarboxylic acid salt preparationThermal energyEthylenediamine

The invention discloses a combined treatment method for two kinds of waste acid water generated in tetraacetylethylenediamine (TAED) production. The combined treatment method is characterized by comprising the following steps of: evaporating dark acid water generated after washing TAED crystals by using live steam; carrying out multi-effect concentration on decolored neutralized liquid by using the acid steam generated by evaporation as a heat source; cooling and crystallizing; and separating solid from liquid to obtain sodium acetate trihydrate which is a by-product, wherein the live steam can be generated by burning residues for recycling after the dark acid water is evaporated, The decolored neutralized liquid is generated by the method that after the acid steam is subjected to heat exchange, the acid steam is condensed into colorless acid water; then the colorless acid water is mixed with light acid water generated by high-temperature dewatering after acetic acid and ethanediaminereact in the production of the TAED; alkali is added to the mixed liquid for neutralization; and then the mixed liquid is decolored by using thiourea dioxide. According to the combined treatment method, the acid steam of the dark acid water is used as a primary heat source for carrying out the multi-effect concentration on the mixed liquid of the mixed acid, therefore, energy can be greatly saved, and environment friendliness is facilitated; and the thiourea dioxide is used as a decoloring agent, the complication of solid and liquid separation and the generation of solid waste residues, whichare brought by decoloring solid adsorptive substances such as activated carbon, are also avoided.

Owner:浙江金科日化新材料股份有限公司

Novel bleaching agent for textile pretreatment

InactiveCN104805678AAvoid damageImprove bleaching effectBleaching apparatusHexamethylenetetramineBleach

The invention discloses a novel bleaching agent for textile pretreatment. The novel bleaching agent is prepared by the following components in parts by weight: 20 to 40 parts of hydrogen peroxide, and 2 to 6 parts of potassium borate; 2 to 5 parts of ethylene diamine tetra sodium; 3 to 5 parts of sodium tripolyphosphate, 10 to 15 parts of acetic acid, 1 to 4 parts of magnesium chloride, 3 to 5 parts of tetraacetylethylenediamine, 2 to 6 parts of sodium silicate, 0.5 to 1.3 parts of sodium hydroxyethyl sulfonate, 10 to 18 parts of sodium percarbonate, 8 to 15 parts of sodium pyrophosphate, 10 to 20 parts of hexamethylenetetramine, and 100 to 120 parts of water. The novel bleaching agent has the advantages that the safety and non-toxic effects are realized, and the bleaching effect is good; at the premise of realizing good bleaching effect, the bleaching temperature is lowered, the damage to a fabric is reduced, the novel bleaching agent is suitable for bleaching the dirt of various fabrics, and the manufacturing cost is low.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

Low-speed wire cut electrical discharge machining solution

InactiveCN102787004AEDM safety is goodHigh surface finishLubricant compositionSodium molybdateLow speed

The invention discloses a low-speed wire cut electrical discharge machining solution. The low-speed wire cut electrical discharge machining solution comprises 15 to 25wt% of white oil, 10 to 20wt% of higher fatty alcohol, 2 to 8wt% of tetraacetylethylenediamine, 0.5 to 1.0wt% of sodium molybdate, 0.05wt% of nano-alumina powder, and the balance 100# machine oil. The low-speed wire cut electrical discharge machining solution has a high flash point, good processability and a long service life, and does not influence a human body and a machine.

Owner:KUNSHAN RUIJIE PRECISION MOLD

Antistatic cleaning agent for carpet

InactiveCN102876477AEasy to useStrong decontaminationSurface-active detergent compositionsDetergent compounding agentsSodium bicarbonateTetraacetylethylenediamine

The invention discloses an antistatic cleaning agent for a carpet. The antistatic cleaning agent is prepared from the following components in part by weight: 15 to 25 parts of cationic water soluble acrylic copolymer, 8 to 10 parts of sodium bicarbonate, 4 to 5 parts of sodium tripolyphosphate, 30 to 40 parts of urea, 10 to 12 parts of sodium benzoate, 4 to 6 parts of tetraacetylethylenediamine, and 30 to 40 parts of cationic water. The antistatic cleaning agent for the carpet is convenient to use and strong in detergency; and after being cleaned by the cleaning agent, the carpet does not generate static electricity, so that dust cannot be adsorbed to the carpet easily.

Owner:NANTONG HUAHAOJU ELECTRONICS TECH

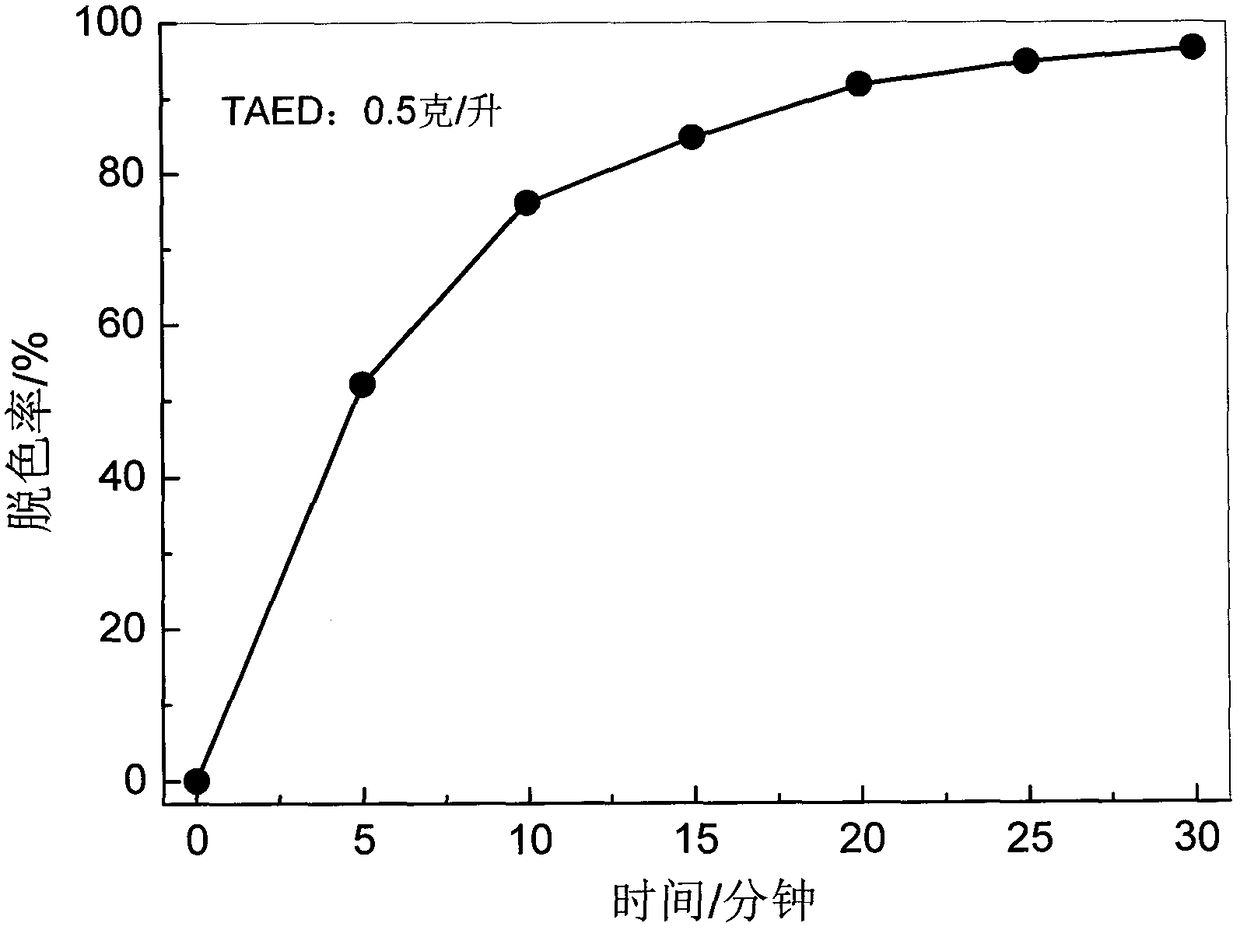

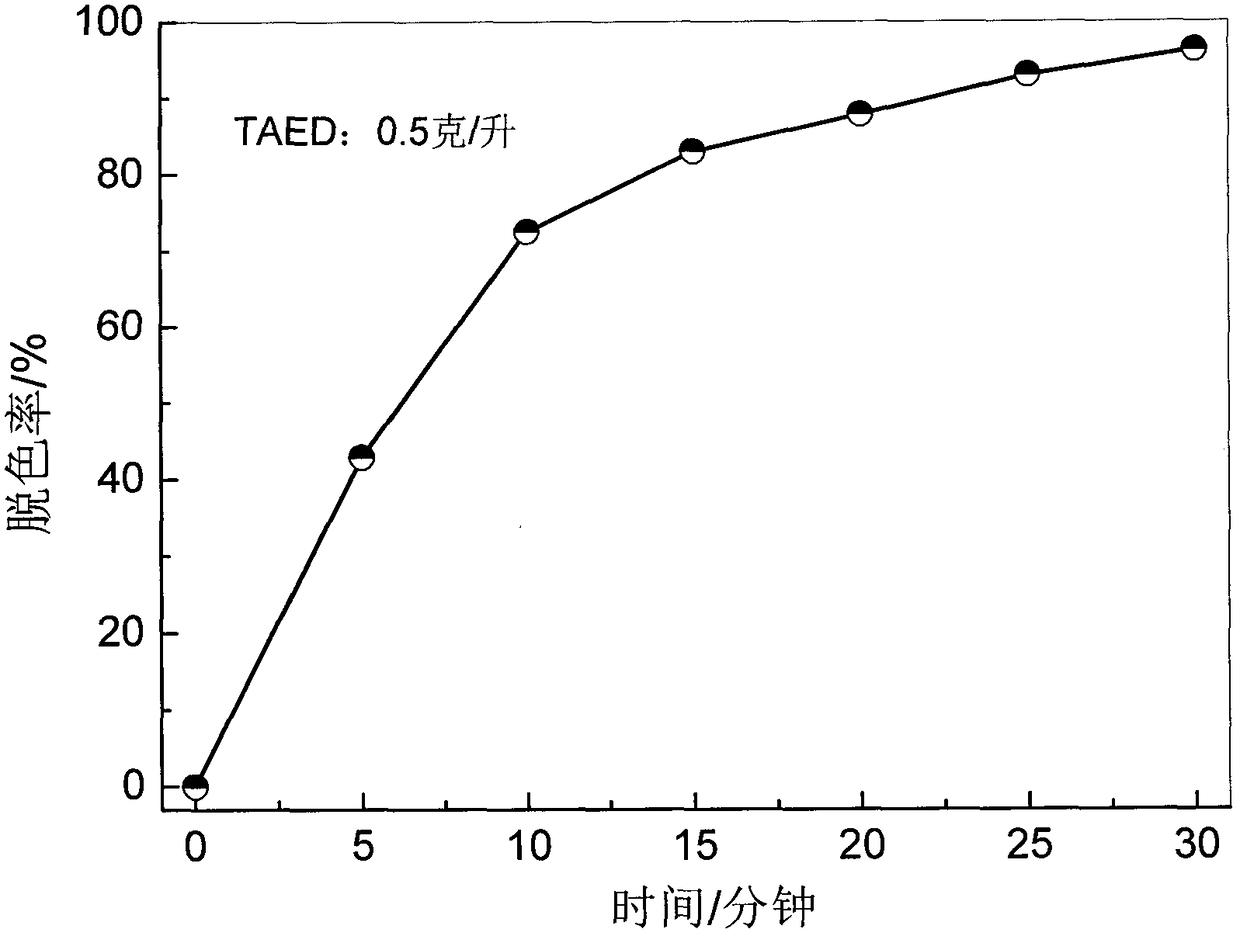

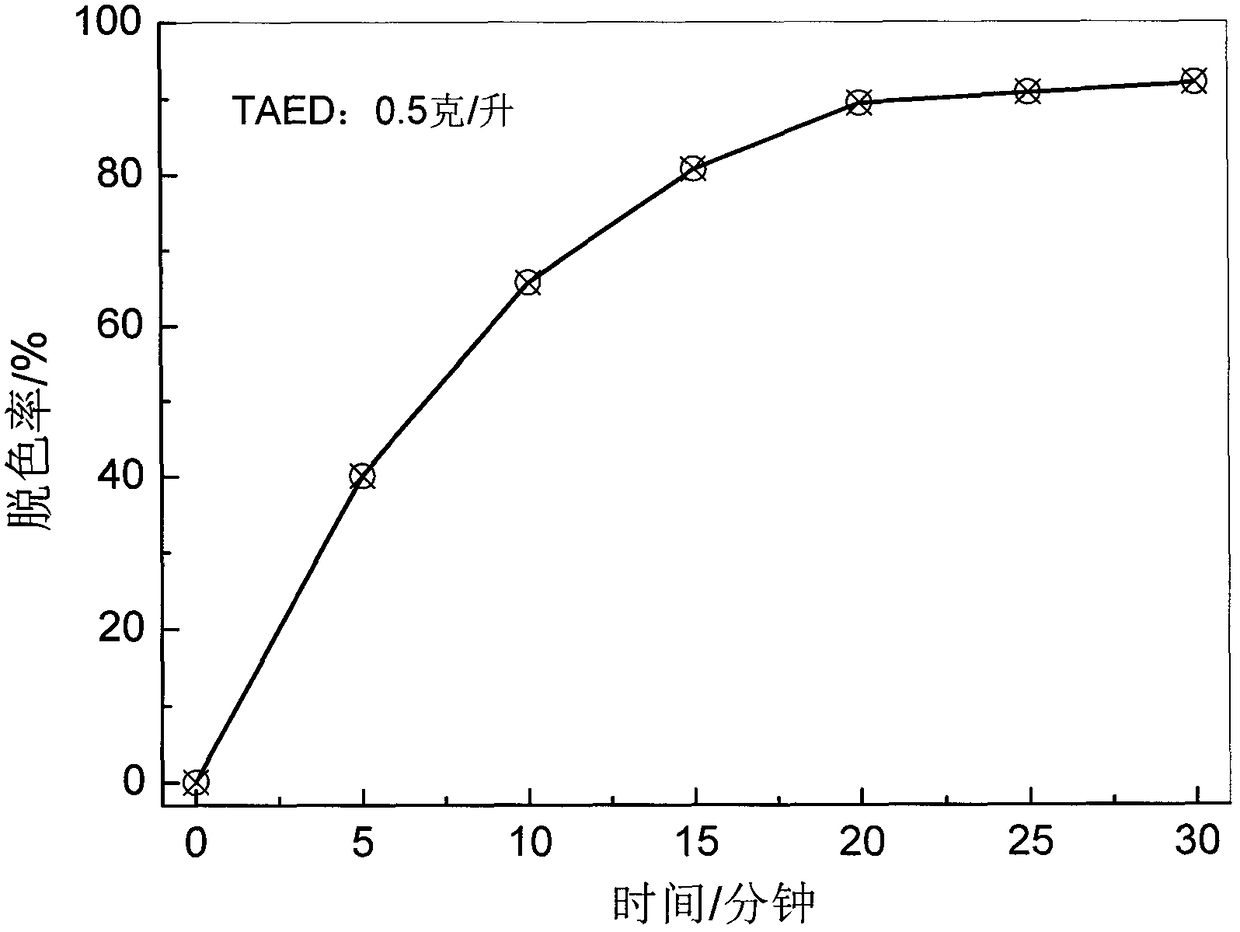

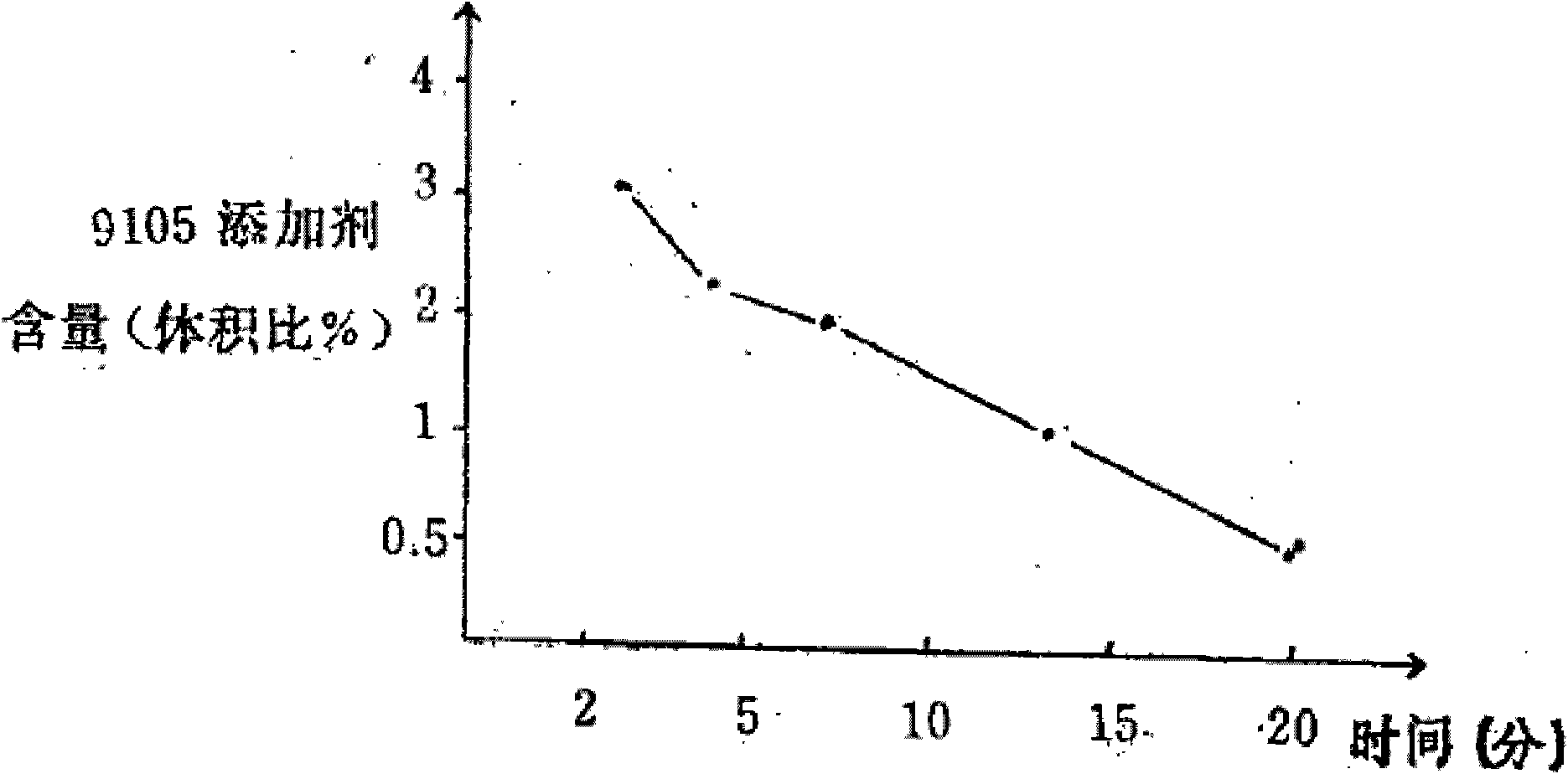

Method for degrading dye wastewater by using tetraacetylethylenediamine (TAED)/solid oxidant (SPS, SPC or SPB) catalytic oxidation system

InactiveCN108191035AAchieve decolorization and degradationLow costOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsInorganic saltsTetraacetylethylenediamine

The present invention provides a method for degrading dye wastewater by using a tetraacetylethylenediamine (TAED) / solid oxidant (SPS, SPC or SPB) catalytic oxidation system. The method comprises: adding a catalyst tetraacetylethylenediamine to dye wastewater to achieve the concentration of 0.5-2 g / L in the wastewater, adding any one oxidant (SPS, SPC or SPB) to achieve the concentration of 0.2-1 g / L in the wastewater, adjusting the pH value of the mixed solution to 9-10 with a sodium hydroxide solution, and carrying out a reaction on the mixed solution for 30 min at a temperature of 30-70 DEGC so as to achieve the decolorization degradation of the dye. According to the present invention, with the application of the TAED / solid oxidant catalytic oxidation system in the dye degradation treatment, the characteristics of high safety, high efficiency and environmental friendliness can be achieved; and the method can promote the degradation of the dye by using the inorganic salts and the surfactants in the wastewater, such that the operation cost is low, and the method is easy to perform.

Owner:TIANJIN POLYTECHNIC UNIV

Detergent additive

ActiveUS20200165545A1Organic detergent compounding agentsNon-surface-active detergent compositionsPolymer scienceTetraacetylethylenediamine

A detergent additive comprising an active, the active comprising one or both of tetraacetylethylenediamine or triacetylethylenediamine; and a copolymer having maleic anhydride-based repeat units and either or both of olefinic or styrenic-based repeat units; and wherein at least a portion of the maleic anhydride-based repeat units are neutralized.

Owner:DOW GLOBAL TECH LLC

Detergent additive

ActiveUS20200148976A1Organic detergent compounding agentsNon-surface-active detergent compositionsPolymer scienceTetraacetylethylenediamine

A detergent additive comprising an active, the active comprising one or both of tetraacetylethylenediamine and triacetylethylenediamine; and polyvinyl butyral. A method of preparing a detergent additive comprising providing a solvent to a reaction mixture; providing polyvinyl butyral to the reaction mixture; providing an active to the reaction mixture, the active comprising one or both of tetraacetylethylenediamine and triacetylethylenediamine; mixing the reaction mixture; and spray-drying the reaction mixture.

Owner:DOW GLOBAL TECH LLC

Marking pen cleaning agent and preparation method thereof, and marking pen mark cleaning method

ActiveCN112481051AImprove permeabilityEffective dissolutionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhenyl EthersLimonene

The invention provides a marking pen cleaning agent, a preparation method thereof and a marking pen mark cleaning method, and relates to the technical field of cleaning agents. The marking pen cleaning agent provided by the invention comprises a component A and a component B. The component A comprises the following components in percentage by mass: 30-50% of a divalent acid ester solvent, 20-40% of n-bromopropane, 10-20% of ethylene glycol phenyl ether, 10-20% of dimethyl carbonate and 0-10% of D-limonene. The component B comprises the following components in percentage by mass: 12-30% of a decolorizing agent, 2-5% of sodium dodecyl benzene sulfonate, 1-3% of tetraacetylethylenediamine, 61-85% of water and 0-1% of a stabilizer. The cleaning agent provided by the invention can be used for thoroughly cleaning marks of a marking pen on the rough surface of a microporous material.

Owner:新安洁智能环境技术服务股份有限公司

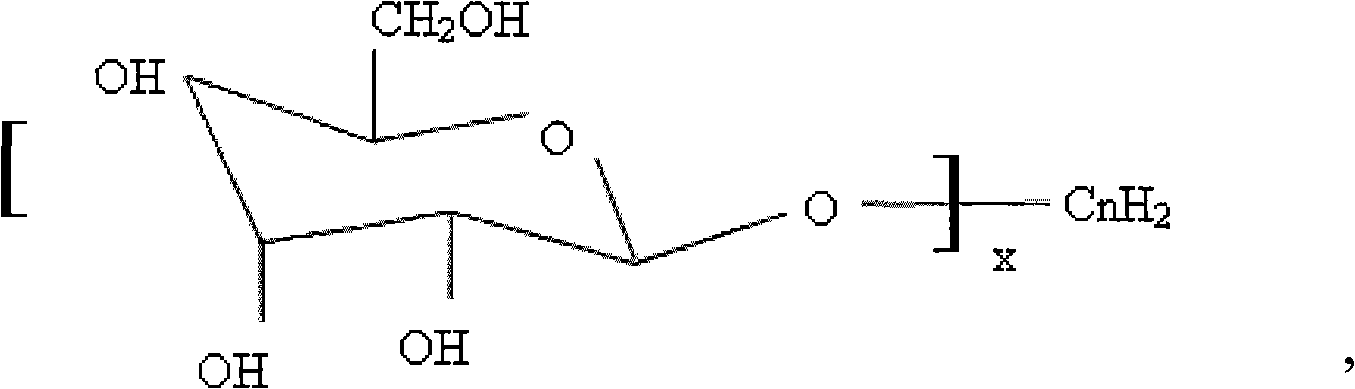

Rust-removing oil-removing wax-removing additive and preparation method thereof

The invention discloses a rust-removing oil-removing wax-removing additive and a preparation method thereof, and aims to solves the environmental pollution problem that the prior hydrochloric acid or sulfuric acid pickle generates a large amount of acid mist when cleaning corrosion and oxide scale on the surface of metal and generates a large amount of phosphor and COD when removing oil and wax. The additive comprises the following raw materials by weight: 10%-20% of modified oleic acid, 3%-13% of alkyl polyglucoside, 3%-13% of coconut oil fatty acid diethanol amide, 1%-10% of 65% ethanol, 2%-7% of tetraacetylethylenediamine and balance of water. The preparation method of the additive includes steps of dissolving the modified oleic acid by the ethanol, and uniformly mixing the ethanol solution, the alkyl polyglucoside, the coconut oil fatty acid diethanol amide, the tetraacetylethylenediamine and water. The additive can be used for removing rust, oil and wax on surface of metal.

Owner:台州长航环保科技有限公司 +1

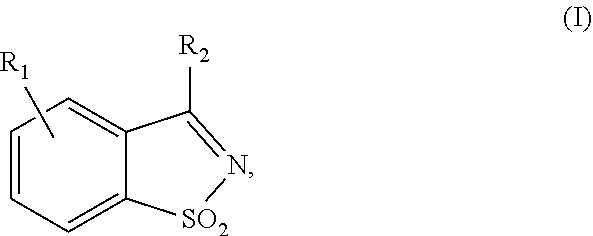

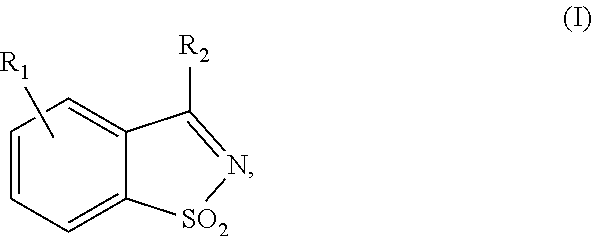

Co-Granules, Detergents and Cleaning Agents and Use Thereof

ActiveUS20210277333A1Improve washabilityReduce in quantityBiocideOrganic detergent compounding agentsCelluloseBenzoic acid

Described are co-granules coated with cellulose ether and containingb1) cyclic sulfonimine,b2) bleach activator selected from the group consisting of tetraacetylethylenediamine, decanoyloxybenzoic acid or mixtures thereof, andb3) cellulose ether as binder.These co-granules can be produced by wet granulation and are very storage-stable.The co-granules can be used in detergents and cleaning agents, which contain(a) bleaching agent selected from the group consisting of perborate, percarbonate or mixtures thereof, and(b) the co-granules coated with cellulose ether.These detergents and cleaning agents contain highly active bleach activators and bleach catalysts and are characterized by high storage stability. The combination of components b1) and b2) and peroxygen compound a) leads to a pronounced disinfection effect even at low temperatures.The detergents and cleaning agents can be used even at low temperatures and show a good washing performance.

Owner:WEYLCHEM PERFORMANCE PROD GMBH

Detergent additive

InactiveUS20200181536A1Organic detergent compounding agentsNon-surface-active detergent compositionsPolymer scienceTetraacetylethylenediamine

A detergent additive comprising an active comprising one or both of tetraacetylethylenediamine, triacetylethylenediamine; and an interpolymer complex, the interpolymer complex comprising both a proton-accepting-(co)polymer and a proton-donating (co)polymer.

Owner:DOW GLOBAL TECH LLC

Detergent additive

ActiveUS20200181534A1Organic detergent compounding agentsNon-surface-active detergent compositionsAcetoacetatesPolymer science

A detergent additive comprising an active, the active comprising one or both of tetraacetylethylenediamine or triacetylethylenediamine; and the reaction product of a compound that functions as a Michael donor and a compound that functions as a Michael acceptor; wherein, the compound that functions as a Michael donor is selected from the group consisting of acetoacetate esters, cyanoacetate esters and malonic acid esters; the compound that functions as a Michael acceptor is a multifunctional acrylate; and the weight percent of the tetraacetylethylenediamine in the detergent additive is 10 to 90 percent.

Owner:DOW GLOBAL TECH LLC

Titanium tube for coil-tube heat exchanger

InactiveCN107620058AAntioxidant is goodExcellent abrasion resistanceMetallic material coating processesHeat exchange apparatusMorpholineHydroxyethyl cellulose

The invention discloses a titanium tube for a coil-tube heat exchanger. The titanium tube comprises a titanium tube body, and the titanium tube body is subject to passivating treatment. The passivating treatment comprises the following steps: (1) sequentially putting 1-2 parts by weight of polyoxyethylene ether, 0.7 part by weight of sodium molybdate, 0.6 part by weight of calcium borate, 1.1 parts by weight of tetraacetylethylenediamine, and 1.7 parts by weight of oleoyl amino acid sodium into 25 parts by weight of deionized water, and stirring uniformly; (2) then, sequentially putting 0.9 part by weight of silicate-calcium powder, 1.3 parts by weight of hydroxyethyl cellulose, 2.1 parts by weight of sulfated castor oil, 1.5 parts by weight of boric acid morpholine and 1.3 parts by weightof benzotriazole, and continuing to stir till all the substances are sufficiently and uniformly mixed, so as to obtain a passivating treatment solution; and (3) putting the titanium tube body in thepassivating treatment solution for 30 seconds' passivating treatment at 50 DEG C, and taking out the treated titanium tube body for drying. As the titanium tube body of the titanium tube disclosed bythe invention is subject to passivating treatment, the properties of the titanium tube body are good and the surface smoothness of the titanium tube body is high.

Owner:CHANGSHU OUDI PIPE IND CO LTD

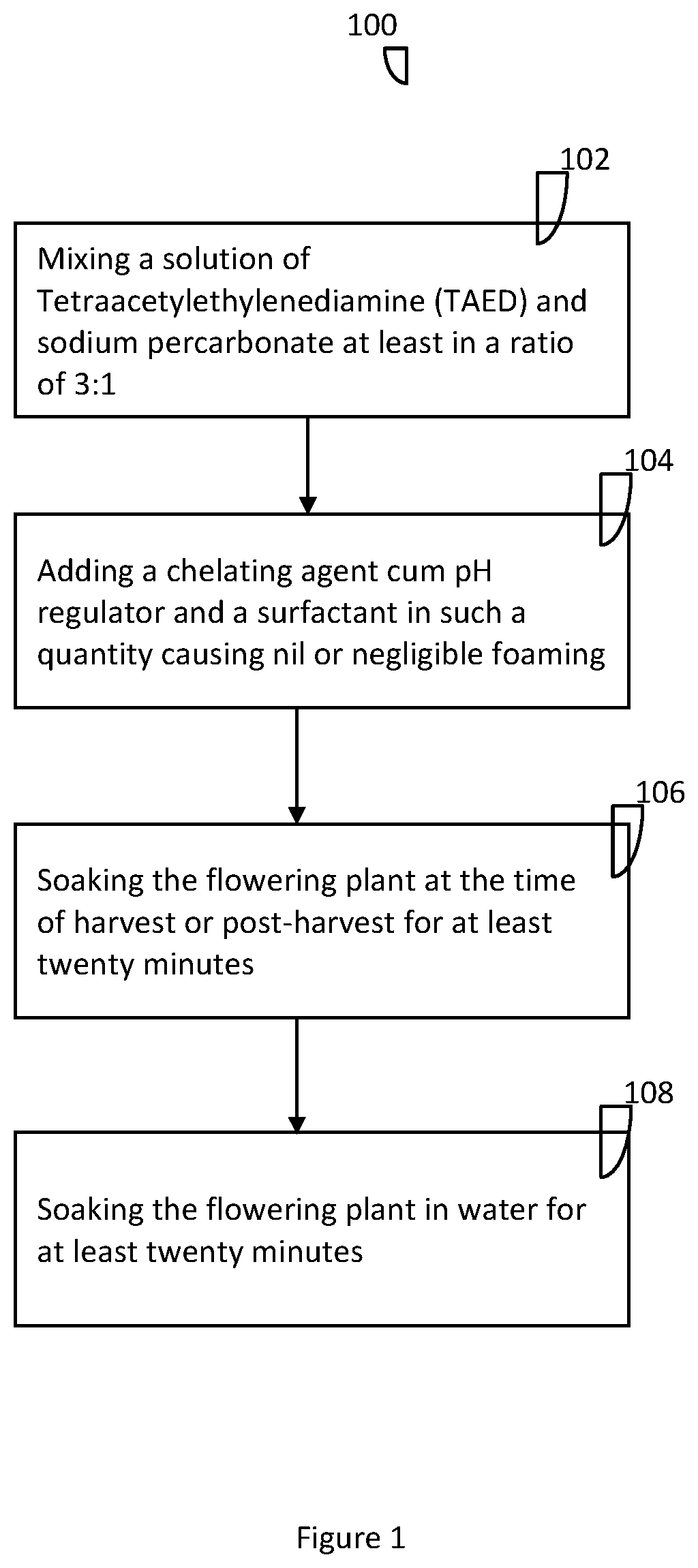

Harvest/post harvest wash composition for flowering plants and a method of using the same

InactiveUS20210047589A1Inorganic/elemental detergent compounding agentsBiocideEthylenediamineTetraacetylethylenediamine

The present invention discloses a harvest / post-harvest composition for washing flowering plants and a method of using the same. The composition includes a solution of Tetraacetylethylenediamine (TAED) and sodium percarbonate in a ration ranging from 1:1 to 3:1, respectively. The composition also includes a chelating agent and a pH regulator, which work to activate the TAED; and a surfactant. The pH regulator and the surfactant are added in quantity as minimal as possible to avoid foaming entirely or to produce negligible foaming.

Owner:PH2O LLC

Ultraviolet-proof automobile windshield washer fluid

InactiveCN111423942AImprove decontamination abilityEfficient removalInorganic/elemental detergent compounding agentsCationic surface-active compoundsEthylenediamineActive agent

The invention discloses ultraviolet-proof automobile windshield washer fluid. The windshield washer fluid is prepared from the following raw materials in percentage by mass: 4.8%-6.2% of SPC (sodium percarbonate), 2.0%-5.0% of TAED (tetraacetylethylenediamine), 7.0%-9.0% of polyvinylpyrrolidone, 1.0%-3.0% of a cationic gemini surface active agent DHGS, 1.0%-5.0% of lauramidopropyl hydroxyl sulphobetaine, 17.0%-21.0% of propylene glycol monomethyl ether, 0.5%-3.0% of a light stabilizer, 1.0%-2.0% of nano titanium dioxide, 0.1%-0.8% of sodium citrate, 3.0%-8.0% of rosin amine polyoxyethylene ether, and the balance being deionized water. The windshield washer fluid provided by the invention has strong decontamination capability, can quickly and effectively remove shellac, greasy dirt, dust and other stains on automobile glass, and has excellent ultraviolet resistance.

Owner:YANCHENG INST OF IND TECH

Detergent additive

ActiveCN110869482AOrganic detergent compounding agentsNon-surface-active detergent compositionsPolymer scienceTetraacetylethylenediamine

Owner:DOW GLOBAL TECH LLC

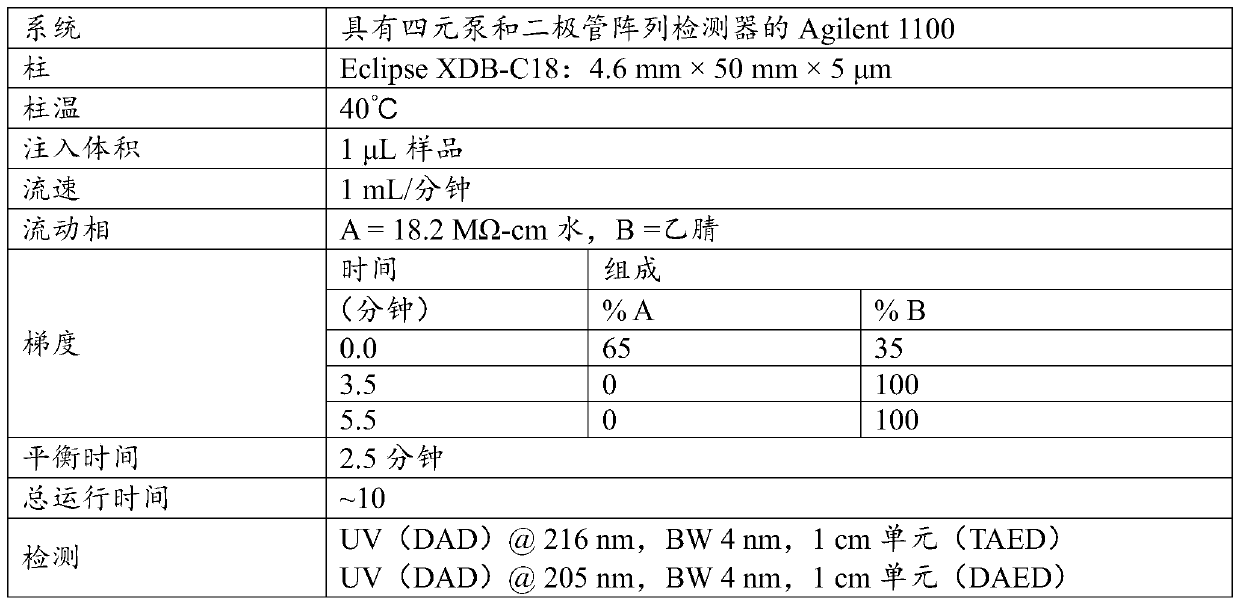

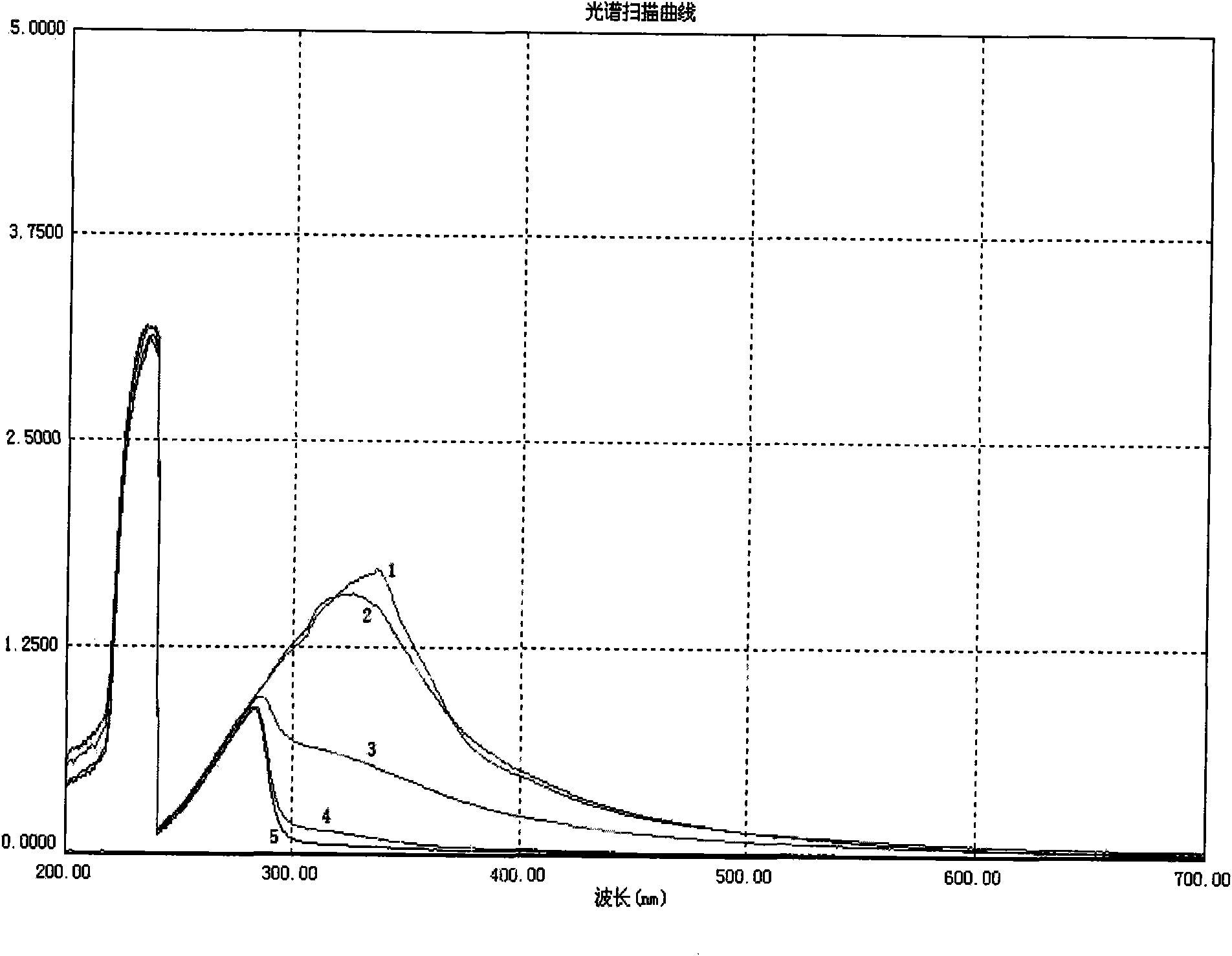

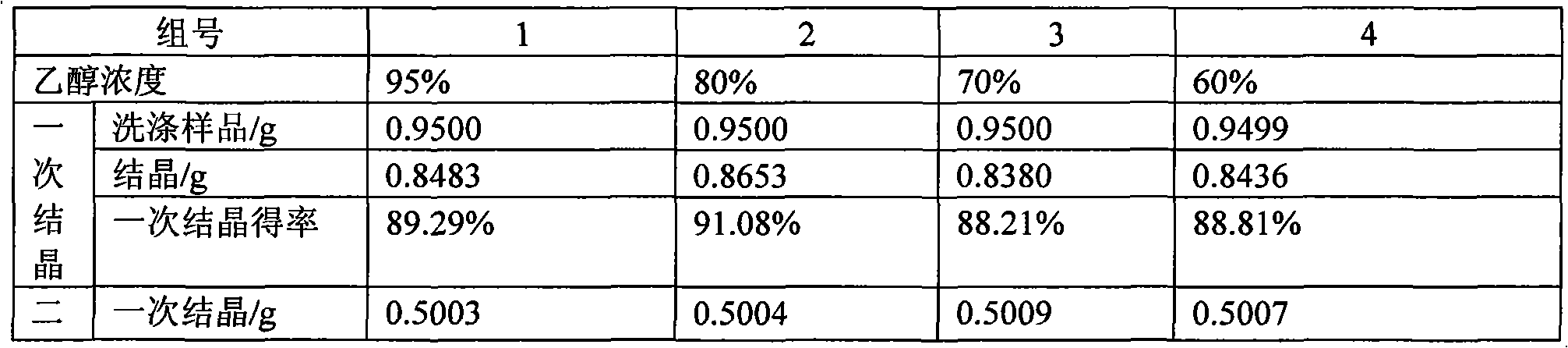

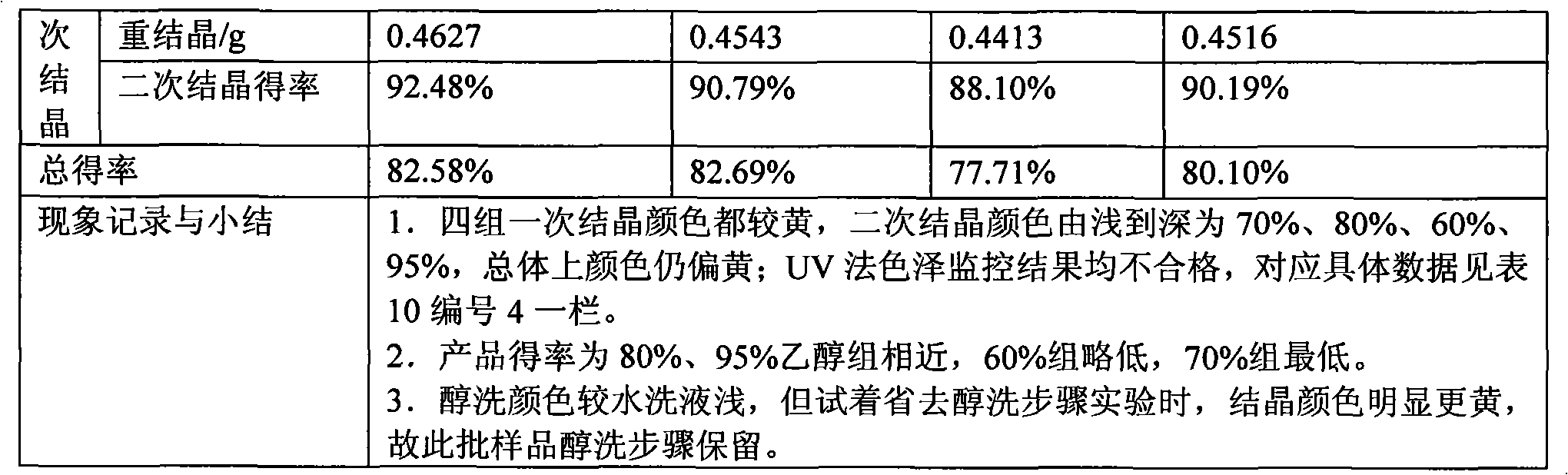

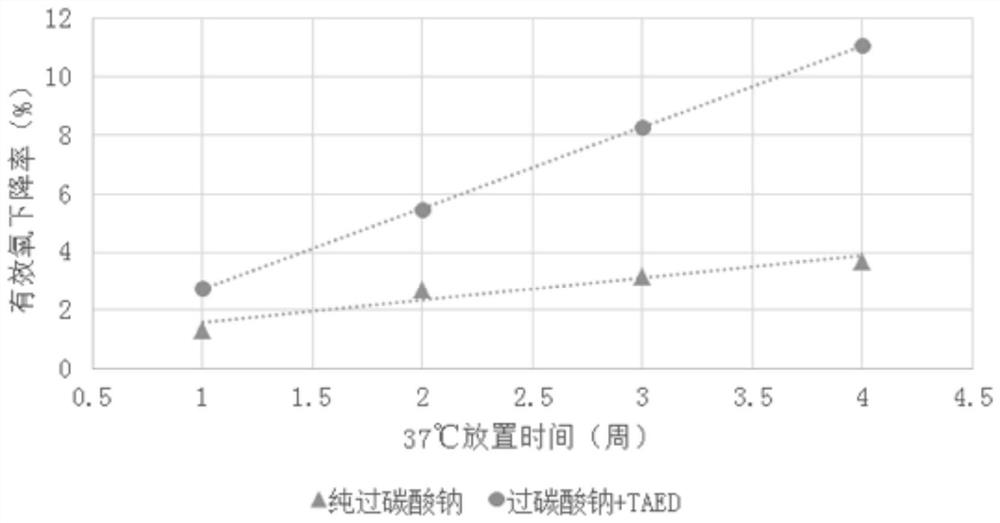

Tetraacetylethylenediamine (TAED) recrystallization method

The invention provides a tetraacetylethylenediamine (TAED) recrystallization method, wherein the effective recrystallization is carried out by adopting a crude TAED product washed with water or water-containing alcohol or other solvents and selecting a mixed solvent of halogenated varsol and water-containing alcohol with different concentrations. The method has the advantages that the mixed solvent has low boiling point, has high solubility and fast solution speed for crude the TAED product mixed with pigments, refluxes directly or under the condition of stirring, and has faster speed and complete effect on cooling crystallization, crystals are good in graininess, crystallized pigments are quantitatively detected and controlled, the solvent is easy for recycling, and the like, and in addition, the requirements for equipment are simple, the investment is low and the cycle is short.

Owner:ZHEJIANG UNIV

Preparation method for cleaning agent for crude oil storage tank

InactiveCN109234057AEasy to cleanInorganic/elemental detergent compounding agentsCationic surface-active compoundsSodium metasilicatePolyethylene glycol

The invention relates to a preparation method for a cleaning agent for a crude oil storage tank, and belongs to the technical field of crude oil equipment cleaning. The preparation method comprises the following steps that oleic acid, lipase, pine needle essential oil, sodium metasilicate pentahydrate, sodium alkylarylsulfonate, tetraacetylethylenediamine, palmitic acid, fulvic acid and glycerol monolaurate are heated and then are uniformly mixed so as to obtain a first mixture; a cationic surfactant and polyethylene glycol are added into the first mixture, and after heating is carried out, uniform mixing is carried out so as to obtain a second mixture; and an anionic surfactant and sodium pyrophosphate are added into the second mixture, and after heating is carried out, mixing is carriedout under a high-speed dispersing condition so as to obtain the cleaning agent.

Owner:邳州市铁富九龙公共服务有限公司

Stable and efficient machine dishwashing agent

ActiveCN114686319AHas alkali resistanceAvoid reciprocal reactionsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateActive agent

The invention relates to a stable and efficient machine dishwashing agent, and relates to the technical field of detergents. According to the stable and efficient machine dishwashing agent, a polyethylene-vinyl alcohol water-soluble film serves as a carrier, and a cavity A, a cavity B and a cavity C are formed in the carrier; the component A in the cavity comprises the following components in percentage by mass: 1%-5% of anhydrous sodium metasilicate, 15%-30% of sodium percarbonate and the balance of sodium carbonate; the component B in the cavity comprises 10%-20% of tetraacetyl ethylenediamine, 5%-10% of ethylenediamine tetraacetic acid, 5%-10% of a dispersing agent and the balance of citric acid; the component C in the cavity comprises 3%-6% of propylene glycol, 1%-3% of water, 2%-5% of an enzyme preparation and the balance of a surfactant; the mass ratio of the component A to the component B to the component C is 10: (2-5): (1-4). According to the stable and efficient machine-used dishwashing agent, the water-soluble film is used as a carrier to coat all the components in a cavity manner, so that forming auxiliaries are reduced; the components are prevented from reacting with one another, the shelf life is prolonged, the washing performance of the product is improved, and good washing and sterilizing effects can be achieved with a small dosage.

Owner:WALCH GUANGZHOU COMMODITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com