Foamless detergent and preparation method thereof

A technology of detergent and Sapindus saponin, which is applied in the field of non-foaming detergent and its preparation, can solve the problems of endangering the survival of aquatic animals, and achieve the effects of strong activity, high washing power and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

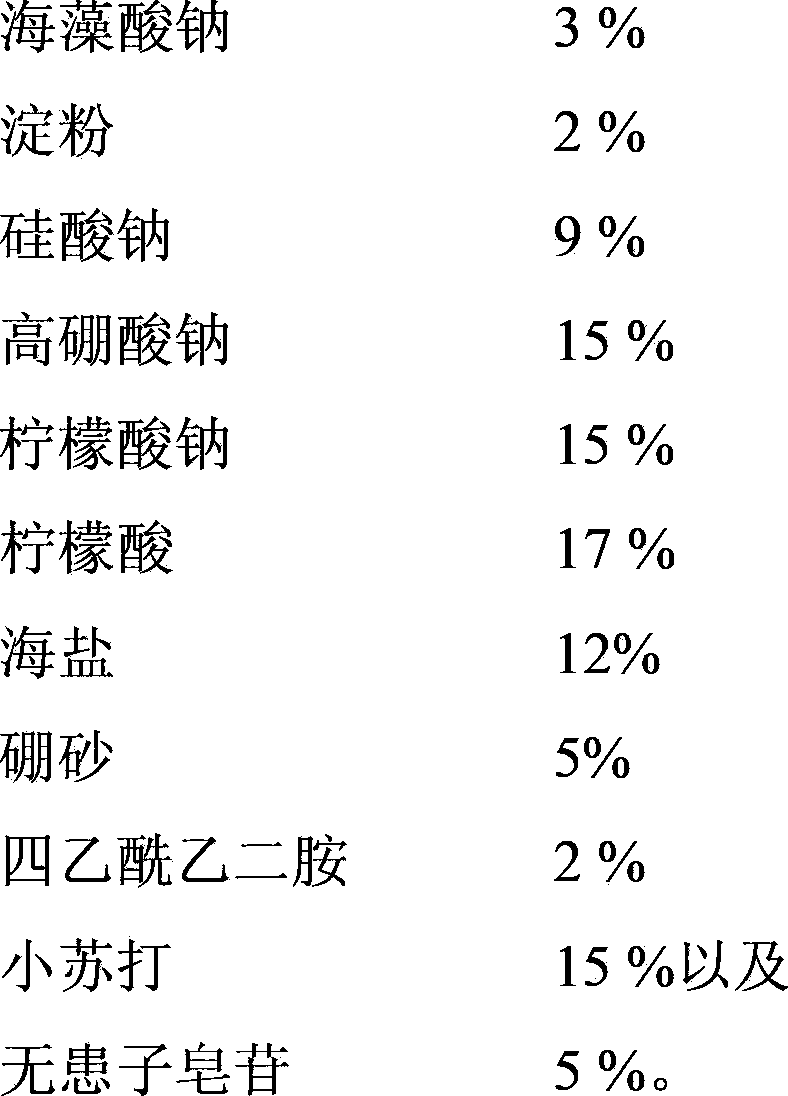

[0021] The non-foaming detergent of embodiment 1 is made up of following weight percent raw material:

[0022]

[0023] The preparation of the non-foaming detergent of embodiment 1 comprises the following steps:

[0024] Step a, first put the weighed sodium silicate and sodium perborate into the stirring tank through a filter screen and stir for 10 minutes; , Tetraacetylethylenediamine and borax are dropped into the stirred tank through a strainer and stirred for 5 minutes; step c, the mixture obtained in step a is added to the mixture obtained by b, after stirring for 5 minutes, citric acid is added, and then stirred for 10 minutes; Step d, after the sampling test and analysis are qualified, the material is discharged and packaged, and the non-foaming detergent product is obtained.

Embodiment 2

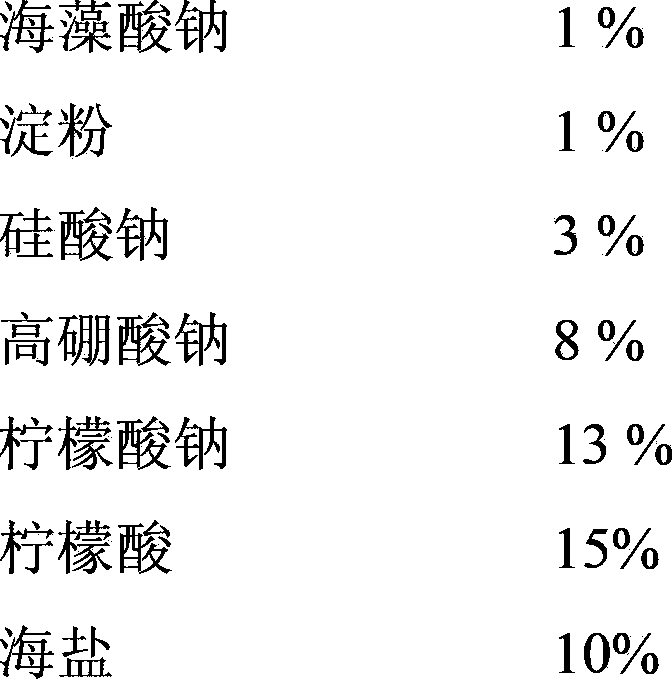

[0026] The non-foaming detergent of embodiment 2 is made up of following weight percent raw material:

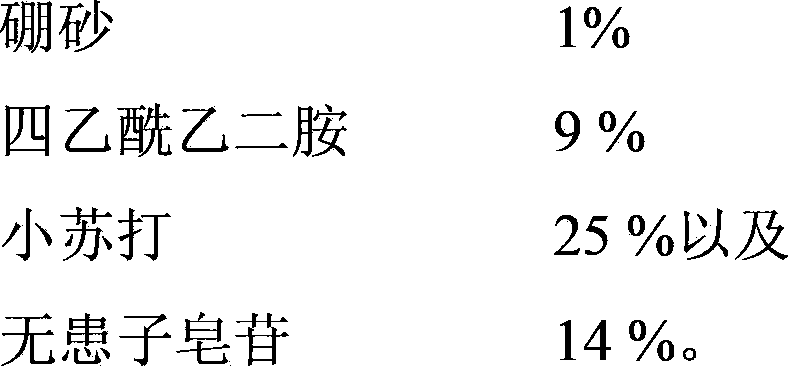

[0027]

[0028]

[0029] The preparation of the non-foaming detergent of embodiment 2 comprises the following steps:

[0030] Step a, first put the weighed sodium silicate and sodium perborate into the stirring tank through a filter screen and stir for 15 minutes; , Tetraacetylethylenediamine and borax are put into the stirred tank through a filter screen and stirred for 7 minutes; step c, the mixture obtained in step a is added to the mixture obtained by b, after stirring for 7 minutes, citric acid is added, and then stirred for 5 minutes; Step d, after the sampling test and analysis are qualified, the material is discharged and packaged, and the non-foaming detergent product is obtained.

Embodiment 3

[0032] The non-foaming detergent of embodiment 3 is made up of following weight percent raw material:

[0033]

[0034] The preparation of the non-foaming detergent of embodiment 3 comprises the following steps:

[0035] Step a, first put the weighed sodium silicate and sodium perborate into the stirring tank through a filter screen and stir for 12 minutes; , Tetraacetylethylenediamine and borax are dropped into the stirred tank through a filter screen and stirred for 10 minutes; step c, adding the mixture obtained in step a into the mixture obtained in b, stirring for 7 minutes, adding citric acid, and stirring for another 7 minutes; Step d, after the sampling test and analysis are qualified, the material is discharged and packaged, and the non-foaming detergent product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com